Page 1

GF-114

OMM-0035_0C

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Modbus® is a registered

Released: 05/18/2012

MODBUS

USER MANUAL

Installation, Operation, and Maintenance

MODBUS Communication For:

• C-More Boiler Controllers

• Boiler Management System

(BMS/BMS II)

• AERCO Control System

(ACS)

Communication

®

trademark of AEG Modicon

Page 2

GF-114

Technical Support:

www.aerco.com

OMM-0035_0B USER MANUAL

MODBUS

(Mon–Fri, 8am-5pm EST)

Communication

1-800-526-0288

Disclaimer

The information contained in this manual is subject to change

without notice from AERCO International, Inc. AERCO makes no

warranty of any kind with respect to this material, including but not

limited to implied warranties of merchantability and fitness for a

particular application. AERCO International is not liable for errors

appearing in this manual. Nor for incidental or consequential

damages occurring in connection with the furnishing,

performance, or use of this material.

Page 2 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 3

Contents USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

TABLE OF CONTENTS

TABLE OF CONTENTS ............................................................................................................... 3

CHAPTER 1: INTRODUCTION AND GENERAL DESCRIPTION ....................... 7

1.1 INTRODUCTION................................................................................................................... 7

1.2 AERCO BMS AND C-MORE CONTROLLER MODELS COVERED ................................... 7

1.3 MIMIMUM MODBUS SUPPORT REQUIREMENTS ............................................................ 8

1.3.1 Communication Medium ................................................................................................ 9

1.3.2 Address Support............................................................................................................ 9

1.3.3 Modbus Transmission Modes ....................................................................................... 9

1.3.4 Timing Specifications .................................................................................................... 9

1.4 MODBUS FUNCTION SET SUPPORT .............................................................................. 10

1.5 EXCEPTION RESPONSES ................................................................................................ 11

1.6 PHRASES, ABBREVIATIONS & ACRONYMS ................................................................. 11

CHAPTER 2: STANDARD REGISTER ASSIGMENTS .................................... 13

2.1 INTRODUCTION................................................................................................................. 13

2.1.1 Input Registers ............................................................................................................ 13

2.1.2 Holding Registers ........................................................................................................ 13

2.2 C-MORE BOILER CONTROLLER STANDARD REGISTER ASSIGNMENTS ................. 14

2.2.1 C-More Boiler Controller Standard Input Register Assignments ................................. 14

2.2.2 C-More Boiler Controller Standard Holding Register Assignments ............................. 17

2.3 BMS/BMS II CONTROLLER STANDARD REGISTER ASSIGNMENTS .......................... 21

2.3.1 BMS/BMS II Controller Standard Input Register Assignments .................................... 21

2.3.2 BMS/BMS II Controller Standard Holding Register Assignments ............................... 28

2.4 ACS CONTROLLER (ONLY) STANDARD REGISTER ASSIGNMENTS ......................... 36

2.4.1 ACS Controller Standard Input Register Assignments ................................................ 36

2.4.2 ACS Controller Standard Holding Register Assignments ............................................ 43

CHAPTER 3: STANDARD APPLICATION OPERATIONS ............................... 53

3.1 INTRODUCTION................................................................................................................. 53

3.2 C-MORE CONTROLLER STANDARD APPLICATION OPERATIONS ............................ 53

3.2.1 Password Protection for Input and Holding Register Access ...................................... 53

3.2.2 Simultaneous RS232 & RS485 Access to C-More Controller Variables ..................... 54

3.2.3 Direct Drive Control ..................................................................................................... 54

3.2.4 Remote Setpoint Control ............................................................................................. 54

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 3 of 200

Page 4

GF-114

OMM-0035_0C USER MANUAL Contents

3.2.5 Combination Control (BMS/ACS Only) ........................................................................ 55

3.2.6 Physical Slave Address Zero ...................................................................................... 55

3.3 BMS/BMS II/ACS STANDARD APPLICATION OPERATIONS ........................................ 55

3.3.1 Password Protection for BMS/BMS II/ACS Input and Holding Register Access ......... 55

3.3.2 Remote Setpoint Control of BMS/BMS II/ACS Slave By EMS Master ........................ 55

3.3.3 BMS/BMS II/ACS Master Control of C-More Slaves Via Network ............................... 56

3.3.4 BMS Combination Mode Boiler Control of C-More Slaves (BMS and ACS Only) ....... 56

CHAPTER 4: MODBUS NETWORK HARDWARE SETUP & INSTALLATION . 57

4.1 INTRODUCTION................................................................................................................. 57

4.2 PHYSICAL MODBUS RS485 NETWORK WIRING CONNECTIONS ............................... 57

4.2.1 BMS Slave To EMS Master Wiring Connections ........................................................ 57

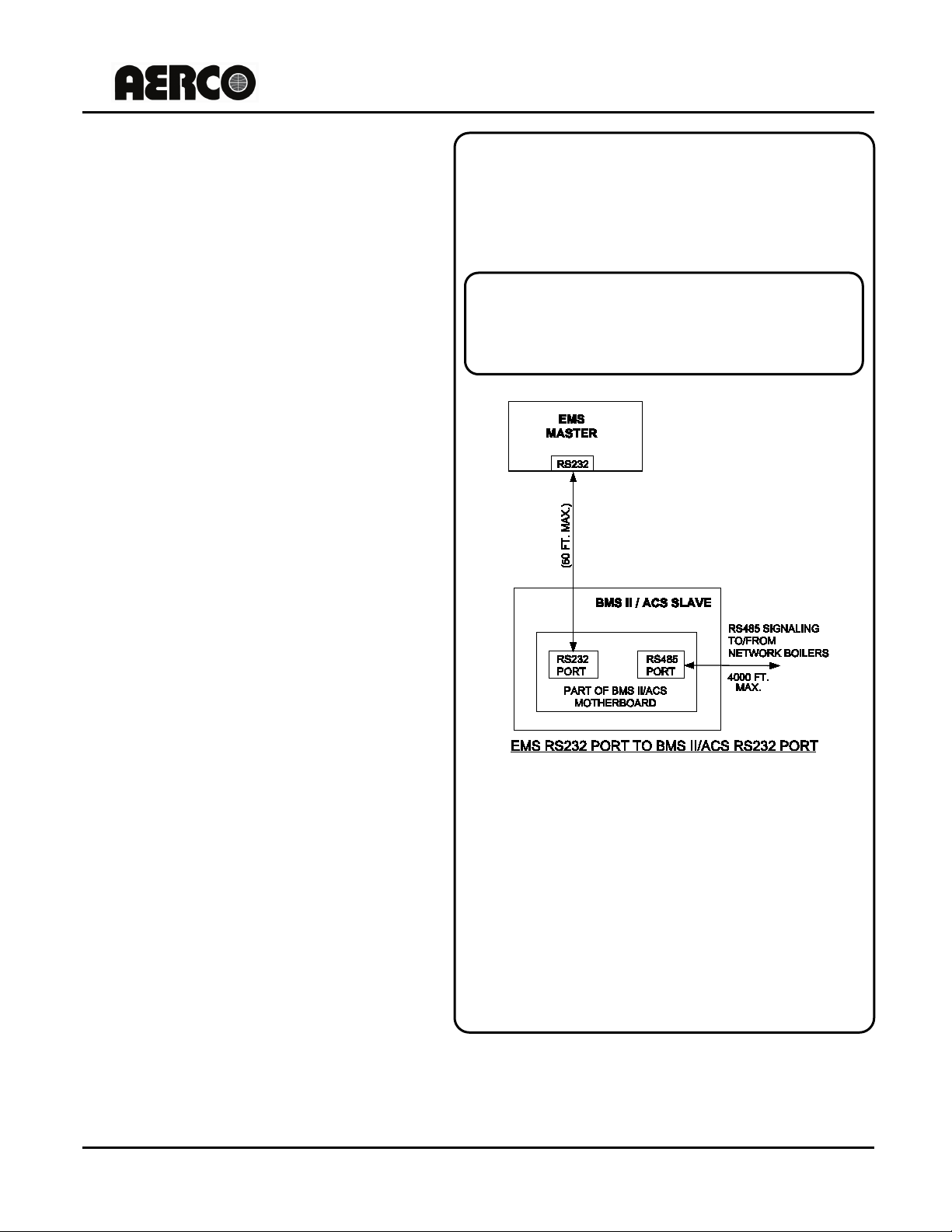

4.2.2 BMS II/ACS Slave To EMS Master Wiring Connections ............................................. 61

4.2.3 BMS/BMS II/ACS Master To C-More Boiler Controller Slaves .................................... 64

MODBUS

Communication

4.2.4 C-More Slaves To BMS/BMS II/ACS or EMS Master ................................................. 66

4.3 RS485 LOOP TERMINATING RESISTORS AND BIAS .................................................... 66

4.3.1 BMS Terminating Resistor .......................................................................................... 66

4.3.2 C-More Boiler Controller Terminating Resistor and Bias ............................................ 66

4.4 MODBUS NETWORK WIRING DIAGRAMS ...................................................................... 70

4.4.1 Wiring Diagrams for Master EMS Controlling BMS Slaves With Legacy (PWM) Boilers

70

4.4.2 Wiring Diagram for Master BMS/BMS II/ACS Controlling Networked C-More Slaves 70

4.4.3 Wiring Diagram For EMS Master Controlling C-More Controller Slaves ..................... 70

CHAPTER 5: MODBUS SOFTWARE SETUP: C-MORE & BMS ...................... 75

5.1 INTRODUCTION................................................................................................................. 75

5.2 C-MORE BOILER CONTROLLER SETUP FOR MODBUS OPERATION ........................ 75

5.2.1 Monitoring and Configuration Control .......................................................................... 76

5.2.2 Modbus Direct Drive Control and Monitoring .............................................................. 76

5.2.3 Modbus Remote Setpoint Control ............................................................................... 76

5.3 BMS SETUP FOR OPERATION AS A SLAVE TO AN EMS MASTER ............................ 77

5.3.1 BMS Monitoring and Configuration By An EMS Master .............................................. 77

5.3.2 BMS Modbus Remote Setpoint Control By An EMS Master ....................................... 77

5.4 BMS SETUP AS MASTER TO C-MORE BOILER CONTROLLERS ................................ 78

Page 4 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 5

Contents USER MANUAL

CHAPTER 6: MODBUS SOFTWARE SETUP: C-MORE & BMS II/ACS ........... 81

6.1 INTRODUCTION................................................................................................................. 81

6.2 C-MORE BOILER CONTROLLER SETUP FOR MODBUS OPERATION ........................ 81

6.2.1 Monitoring and Configuration Control .......................................................................... 81

6.2.2 Modbus Direct Drive Control and Monitoring .............................................................. 82

6.2.3 Modbus Remote Setpoint Control ............................................................................... 82

6.3 BMS II/ACS SETUP FOR OPERATION AS A SLAVE TO AN EMS MASTER ................. 83

6.3.1 BMS II/ACS Monitoring and Configuration By An EMS Master ................................... 83

6.3.2 BMS II/ACS Modbus Remote Setpoint Control By An EMS Master ............................ 83

6.4 BMS II/ACS SETUP AS MASTER TO C-MORE BOILER CONTROLLERS ..................... 84

APPENDIX A: C-MORE BOILER CONTROLLER STATUS & FAULT MESSAGES,

CONVERSION EQUATIONS, BCM FAULT CODES, BMM FAULT CODES, AND I/O

STATUS

TABLES……………………………………………………………………………………………….87

MODBUS

Communication GF-114

OMM-0035_0C

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 5 of 200

Page 6

GF-114

OMM-0035_0C USER MANUAL Contents

MODBUS

(This page intentionally blank)

Communication

Page 6 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 7

Chapter 1

Introduction & Description USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

CHAPTER 1. INTRODUCTION AND GENERAL

DESCRIPTION

1.1 INTRODUCTION

The information contained in this manual provides general guidelines for implementing a

Modbus® communications network utilizing AERCO’s Boiler Management System (BMS) Model

168, Boiler Management System II (BMS II) Model 5R5-384, or AERCO Control System (ACS)

and C-More Boiler Controllers.

Throughout this document, the following terminology shall be used when referring to BMS

Model 168 and BMS II Model 5R5-384:

• BMS: Applies to BMS Model 168 Only

• BMS II: Applies to BMS II Model 5R5-384 Only

• BMS/BMS II: Applies to Both Models (BMS and BMS II)

• BMS II/ACS: Applies to Both Models (BMS II and ACS)

• ACS: Applies to ACS Only

All Modbus networks are implemented utilizing a Master-Slave technique where only one

device, the Master, can initiate a communication sequence. AERCO C-More Controllers can

only function as Slave devices in a Modbus network. However, the AERCO BMS can function

both as a Master controlling C-More Slaves, or as a Slave controlled by an Energy Management

System (EMS) or Building Automation System (BAS) developed by other manufacturers.

1.2 AERCO BMS AND C-MORE CONTROLLER MODELS COVERED

To easily determine if your AERCO BMS or C-More Boiler Controller is equipped with Modbus

capabilities, check the current software version as follows:

For BMS:

• Apply power to the BMS

• The BMS will display: INITIALIZING followed by EPROM REV K

• If REV K or higher is displayed, the BMS Controller can support Modbus

• If the REV level is lower than K, the BMS Controller cannot support Modbus

For BMS II/ACS:

• All BMS II Controllers support Modbus

For C-More:

• Apply external power to the C-More Controller

• Scroll through the Setup Menu and observe the displayed Software Version

• If 2.00 or higher is displayed, the C-More Controller can support Modbus

• If a Software Version lower than 2.00 is displayed, the C-More Controller cannot support

Modbus

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 7 of 200

Page 8

GF-114

Communication Medium:

Allowable Cable Lengths:

PWM:

1,000 Feet, Maximum

Address Support From Master:

1 to 127 (From Master BMS/BMS II/ACS or

0 is Reserved for Broadcast

Messages

Transmission Mode Support

RTU (Remote Terminal Unit)

Timing Specifications:

last character of

Seconds

OMM-0035_0C USER MANUAL Introduction & Description

MODBUS

Communication Chapter 1

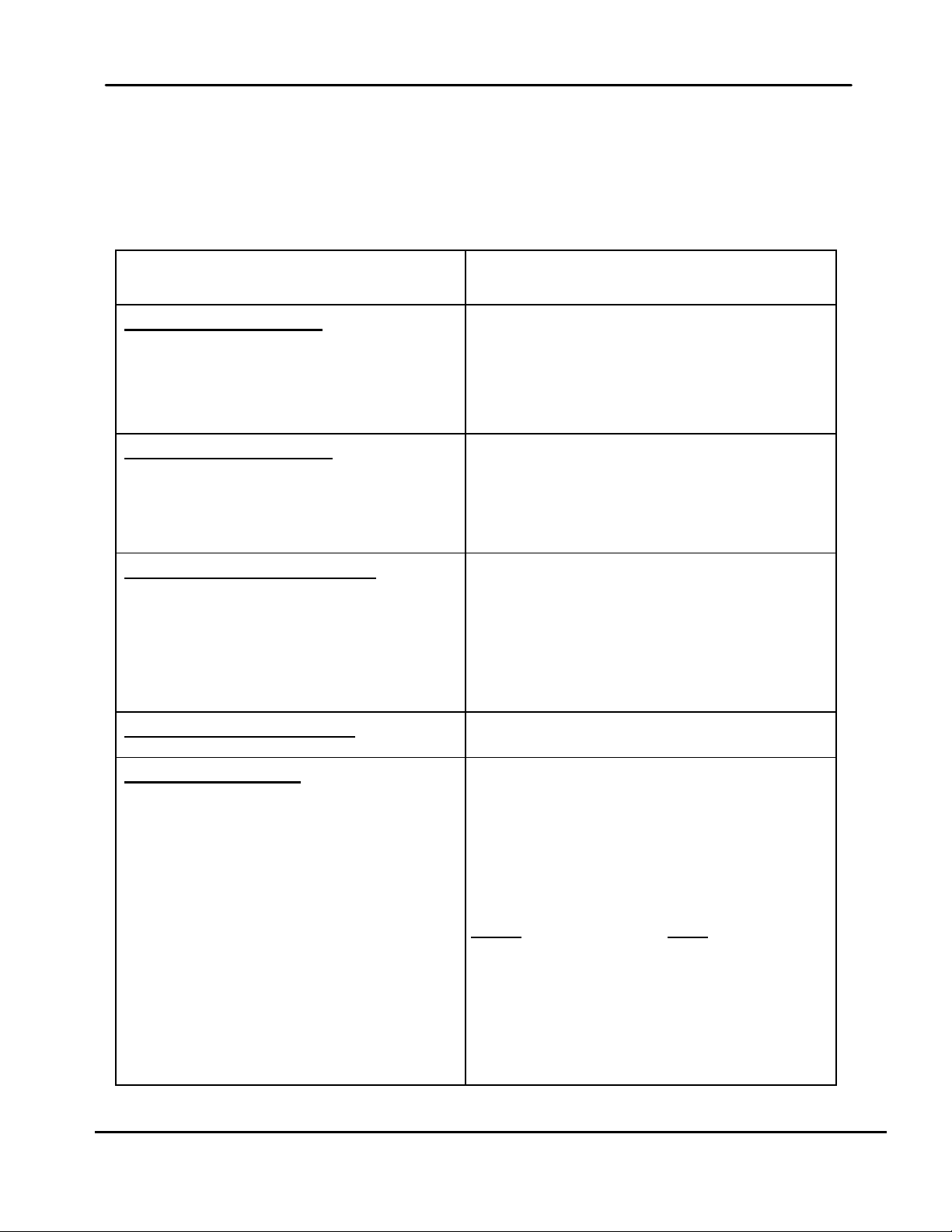

1.3 MIMIMUM MODBUS SUPPORT REQUIREMENTS

Implementation of a Modbus communication network utilizing the AERCO C-More Controller

and BMS/BMS II will be limited to the minimum support requirements listed in Table 1-1 which

follows. The remaining paragraphs in this Section provide more detailed descriptions for each

of the items listed.

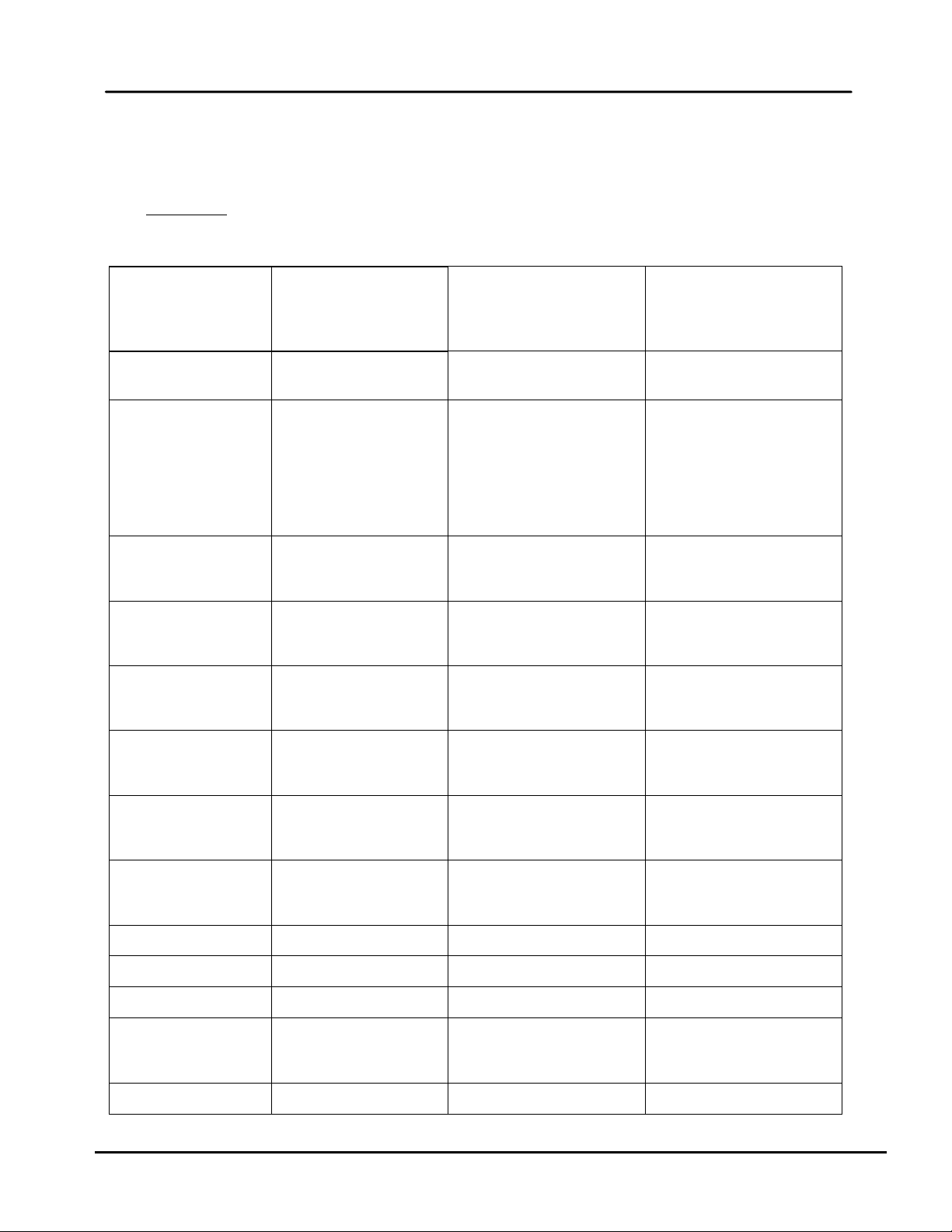

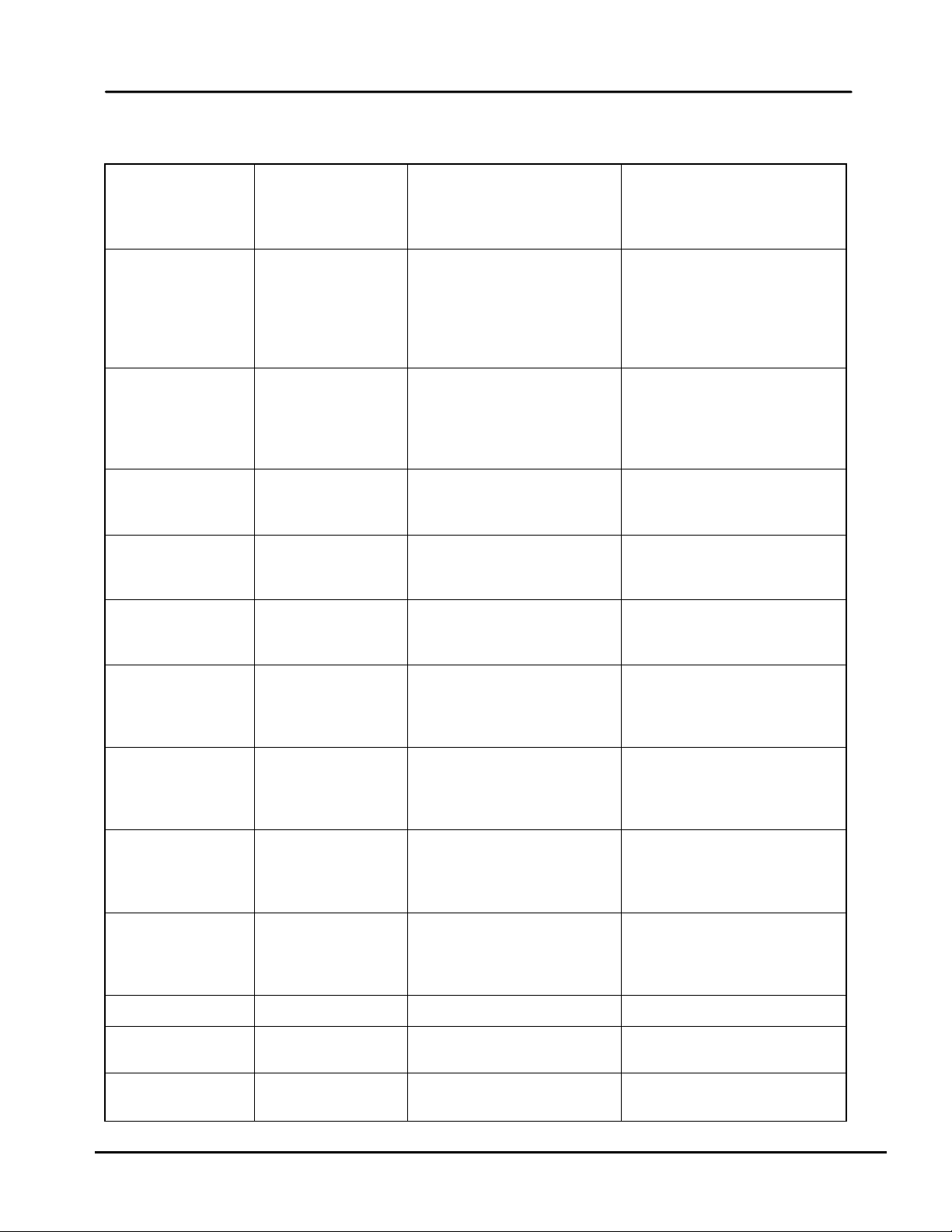

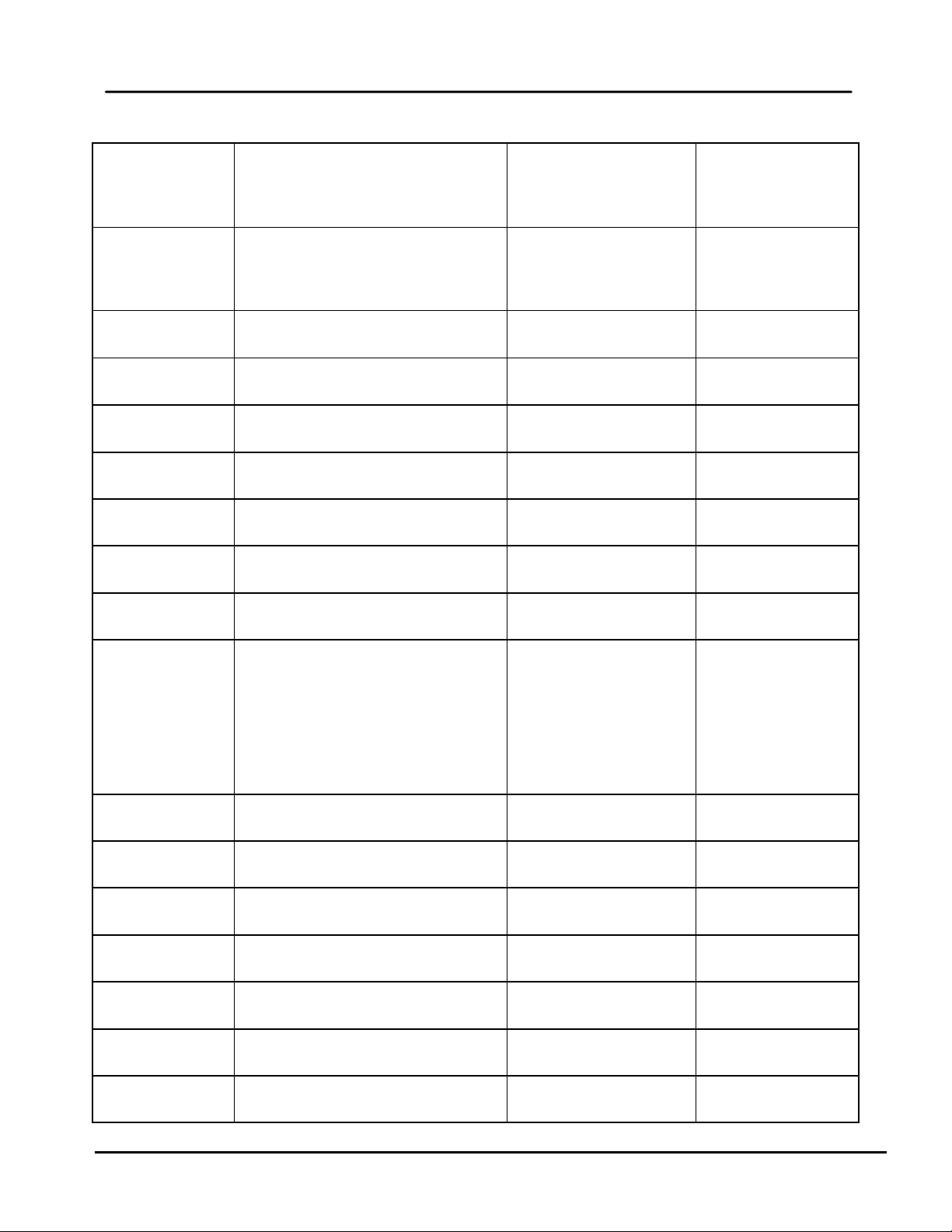

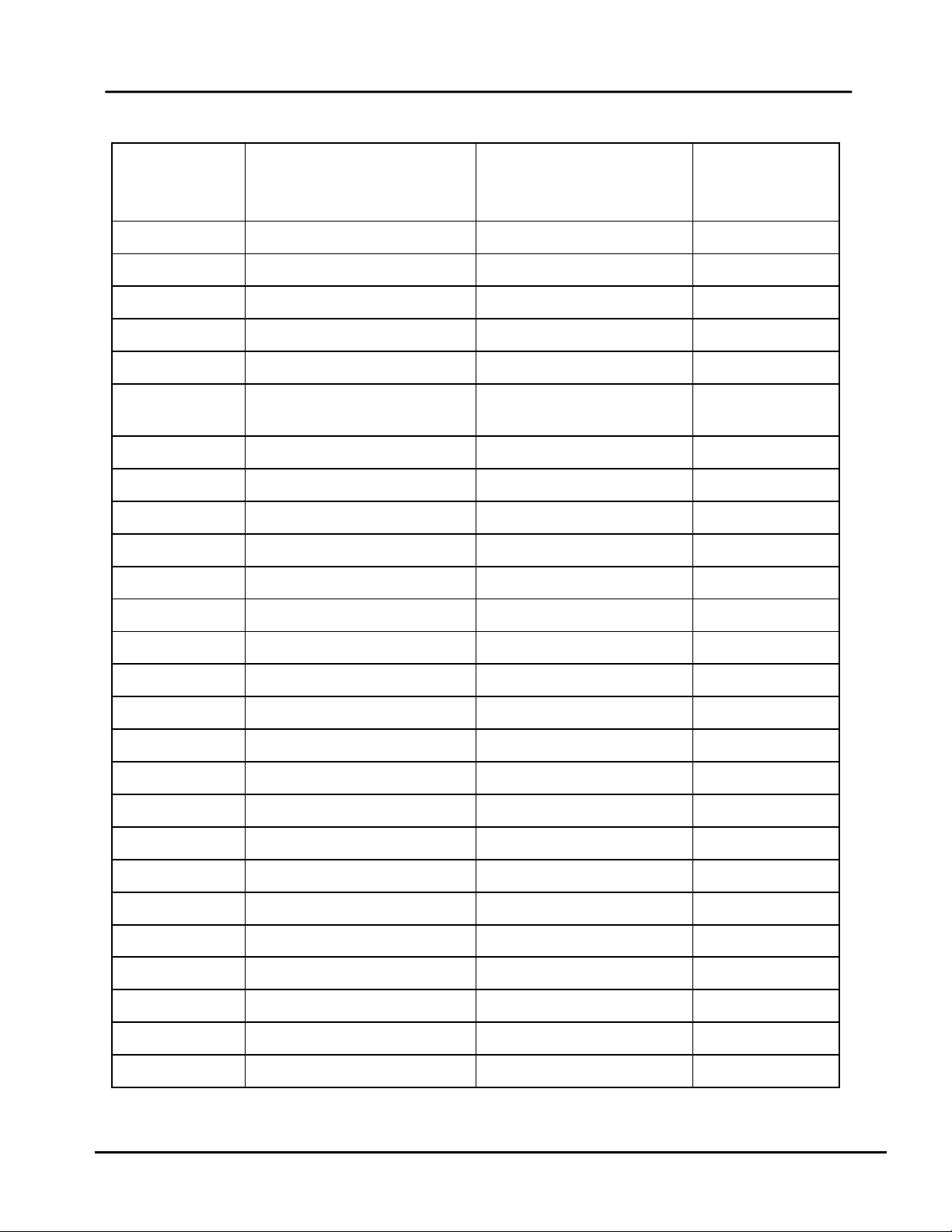

Table 1-1: Modbus Communication and Support Requirements

CHARACTERISTIC REQUIREMENT

EMS Master-To-BMS/BMS II/ACS Slave:

BMS/BMS II/ACS Master-To-C-More Slave:

EMS Master-To- C-More Slave:

RS232:

RS485:

BMS/BMS II/ACS:

C-More Controller (Slave):

Broadcast Messages:

Baud Rate:

Message Framing:

Character Framing:

Heartbeat Timeout:

RS232 (or RS485 With Optional Converter)

RS485, 2-Wire Differential Bus With Shield

RS485, 2-Wire Differential Bus With Shield

50 Feet, Maximum

4,000 Feet, Maximum

128 to 247 (From a Master EMS)

EMS)

Address

Fixed at 9600 For C-More

Adjustable For BMS/BMS II/ACS: 2400, 4800,

9600, 14.4k, 19.2k

Default = 9600

Silent period of at least 3.5 character times

Before first character and After

message

No more than 1.5 character times of silence

between received and transmitted characters

Page 8 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Fixed at 10 seconds For C-More

Adjustable For BMS/BMS II/ACS: 5 to 240

Page 9

Chapter 1

Introduction & Description USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

1.3.1 Communication Medium

The communication medium for each of the possible Modbus network configurations may vary

depending on the Master/Slave scenario being implemented. Detailed installation procedures

and wiring diagrams for the configurations described in the following paragraphs are provided in

Section 4 of this manual.

1.3.1.1 EMS Master To BMS/BMS II/ACS Slave

The Modbus network connections between the EMS and BMS/BMS II/ACS will depend on the

type of port provide on the EMS Master. If the EMS contains a RS232 port, a direct connection

can be made directly to the BMS/BMS II/ACS RS232 port. For optimum results the wire length

between the EMS and BMS/BMS II/ACS RS232 connection should not exceed 50 feet. If the

EMS Master contains a RS485 port, a RS485-to-RS232 converter will be required to implement

the Modbus network.

1.3.1.2 BMS/BMS II/ACS Master To C-More Boiler Controller Slaves

Up to a total of 32 C-More Boiler Controllers can be connected to a BMS/BMS II/ACS Master on

the Modbus Network. Multi-point drop network connections are made using shielded, twistedpair wire. In addition to the Modbus Network Boilers, up to 8 additional Legacy Boilers can be

connected to the BMS Pulse Width Modulation (PWM) wiring connection. The BMS II and ACS

do not support PWM. It should be noted that the BMS, BMS II, and ACS include a Modbus

Pass-Thru feature which, when enabled, permits an EMS to monitor and configure (but not

directly control) the boilers.

1.3.1.3 EMS Master To C-More Boiler Controller Slaves

The number of C-More Boiler Controllers which can be connected to a Modbus Network which

utilizes a third party EMS Master will depend on the EMS’s limitations. Theoretically, the

maximum number of Slave devices is limited to 127. If the EMS contains a RS232 port, a

RS232-to-RS485 converter will be required to provide the necessary RS485 interfaces and

signal levels for the C-More Boiler Controllers. Multi-drop network connections are made using

shielded, twisted-pair wire.

1.3.2 Address Support

Address support is assigned as follows:

• BMS/BMS II/ACS Address Support From EMS Master: 128 – 247 (80 – F7 hex)

• C-More Address Support From BMS/BMS II/ACS or EMS Master: 1 – 127 (01 – 7F hex)

• Broadcast Messages: Address 0 is reserved for all Broadcast messages

1.3.3 Modbus Transmission Modes

Many Modbus Controllers can be set up to transmit using either the ASCII (American Standard

Code for Information Interchange) transmission mode, or the RTU (Remote Terminal Unit)

transmission mode. However, since RTU messages can be formatted using far fewer binary

bits than the corresponding ASCII message, it is far more efficient. Therefore, all Modbus

messages for the AERCO BMS/BMS II/ACS and C-More Boiler Controllers use RTU

transmission ONLY. If a third-party EMS Master is being used in the Modbus network, ensure

that it is set for RTU transmission.

1.3.4 Timing Specifications

As Table 1-1 shows, Baud Rate and Heartbeat Timeout will vary depending on the

Configurations of the AERCO BMS/BMS II/ACS and C-More Boiler Controllers being used in the

Modbus Network. Ensure that the Baud Rate used by the controlling Master (BMS/BMS II/ACS

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 9 of 200

Page 10

GF-114

Function Code

Function Name

Read Holding Register (Read Multiple

Registers)

04

Read Input Registers

06

Preset (Write) Single Register

Diagnostics

Codes)

17

Report Slave ID

Sub-

Code

00

Return Query Data

Loop-Back

01

Restart Communications Options

Resets the Slave. Cancels Listen Only Mode.

02

Return Diagnostic Register

Not Used

04

Force Listen Only Mode

Reset by Restart Communications Option

Also cleared at power up. Clears only the

counters

12

Return Bus Communication Error Count

Slave CRC errors only.

13

Return Bus Exception Error Count

Slave Exception Response count.

Number of messages addressed to the slave

broadcast messages.

Number of messages addressed to the slave

for which no response was returned.

18

Return Bus Character Overrun Count

Number of overrun and framing errors.

OMM-0035_0C USER MANUAL Introduction & Description

MODBUS

Communication Chapter 1

or EMS) matches the appropriate Baud Rate supported by the Network Slaves (BMS/BMS

II/ACS or C-More Controllers). Also, ensure that the Modbus Master can refresh the control

information to all C-More Slaves before the Heartbeat Timeout period expires.

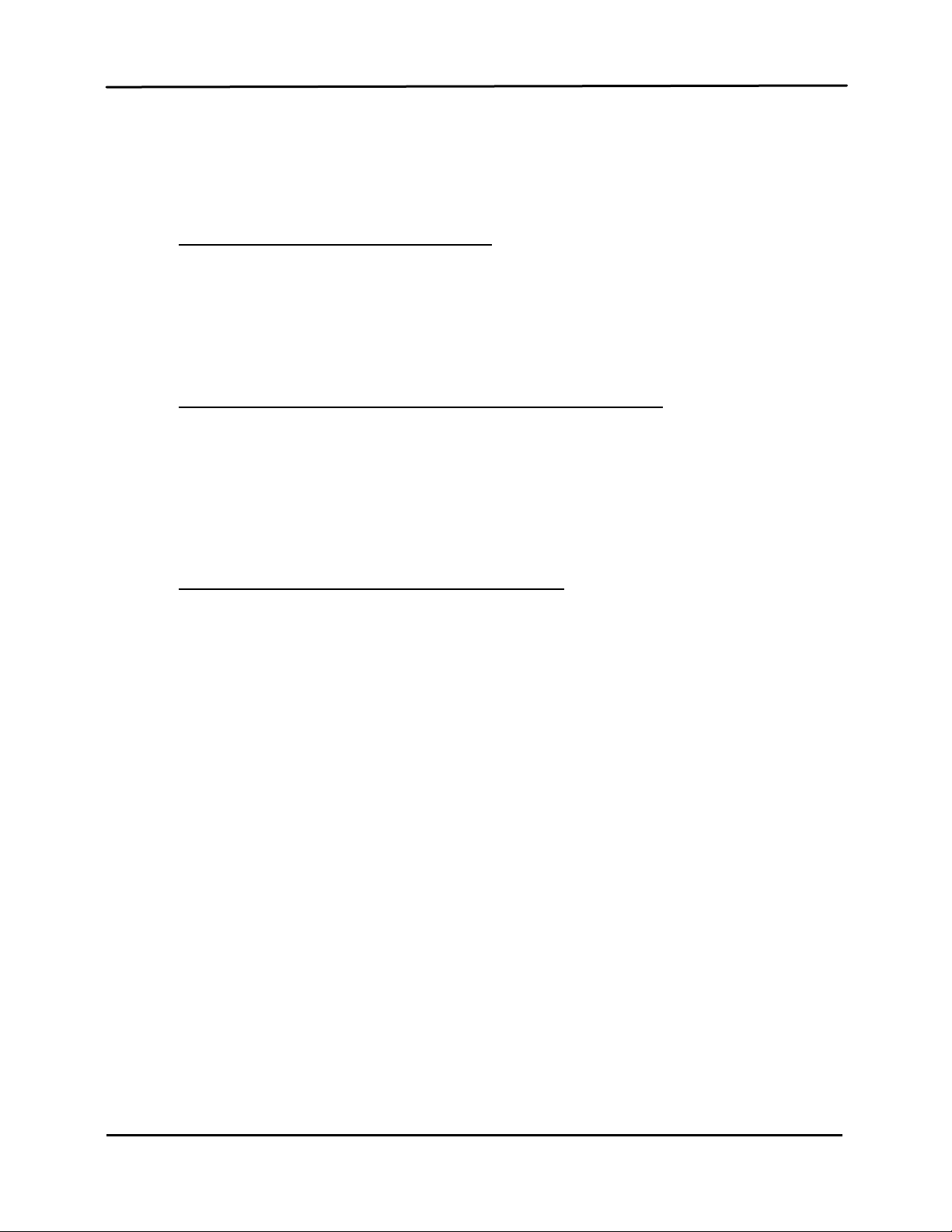

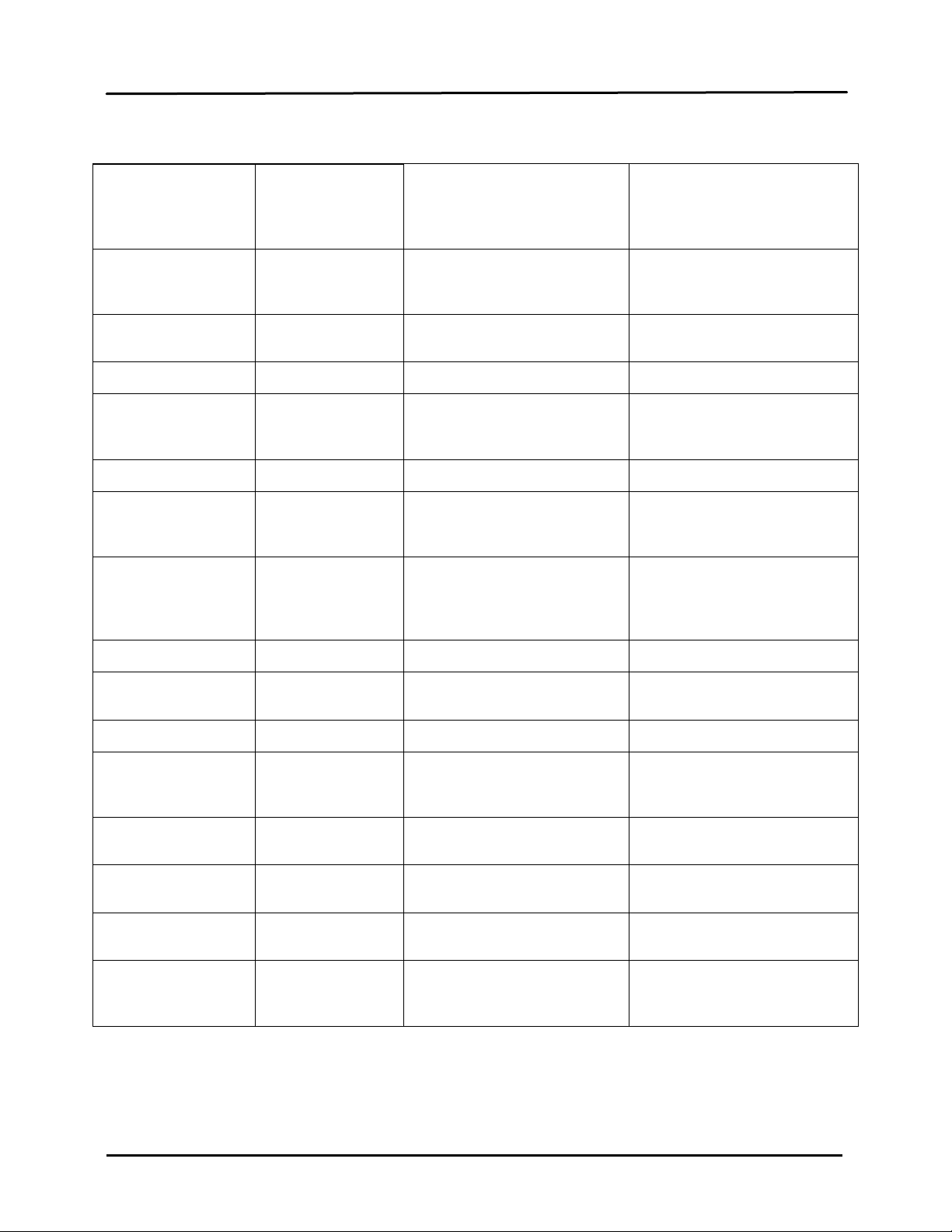

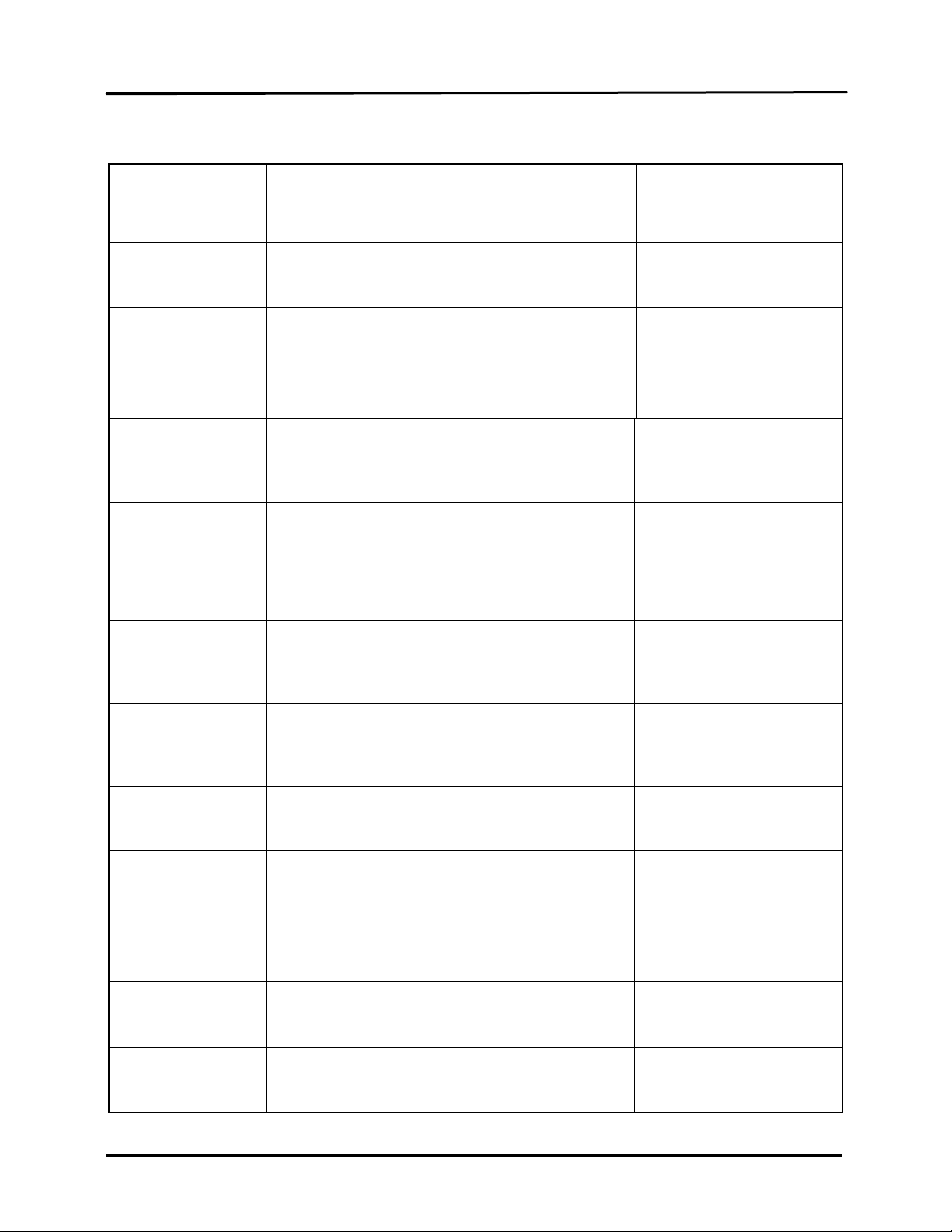

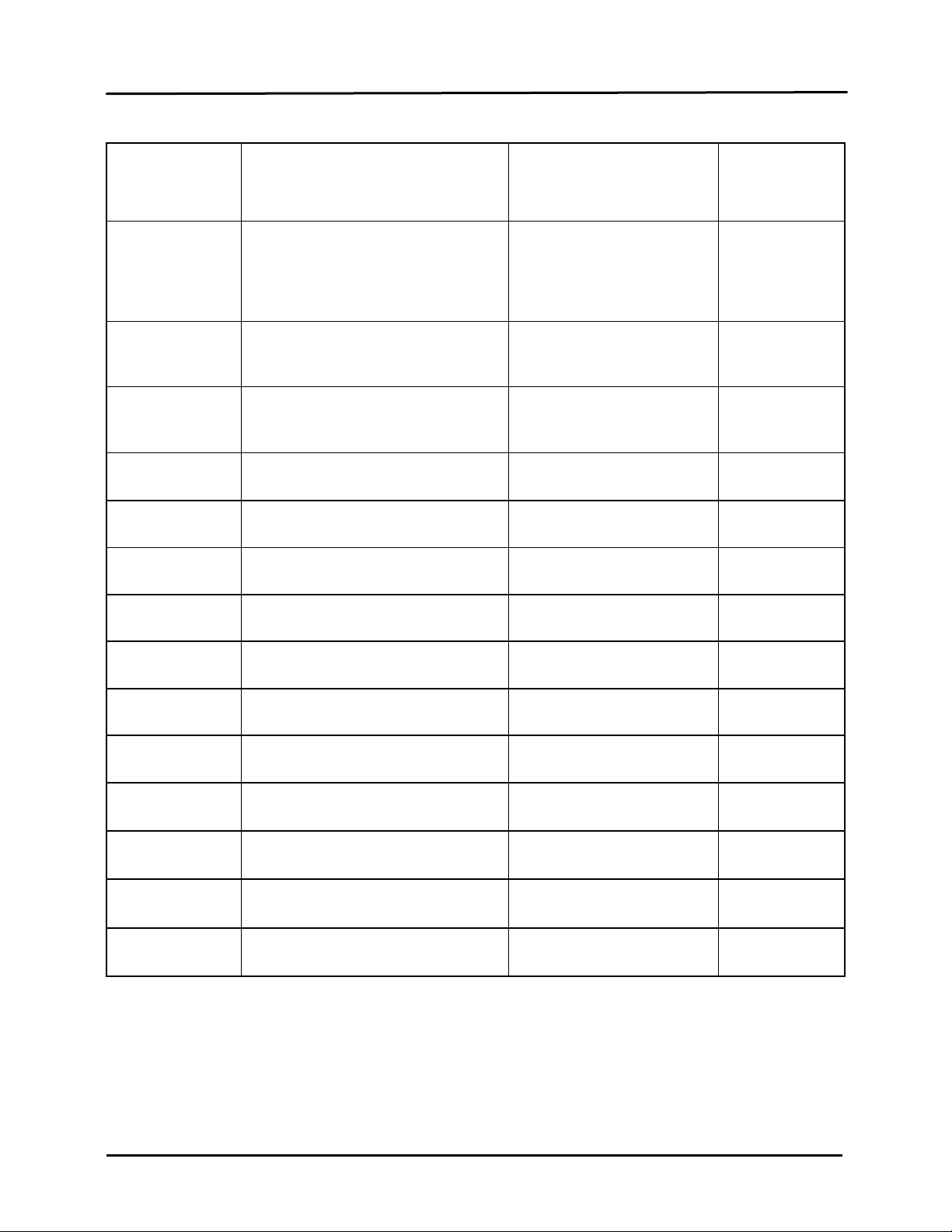

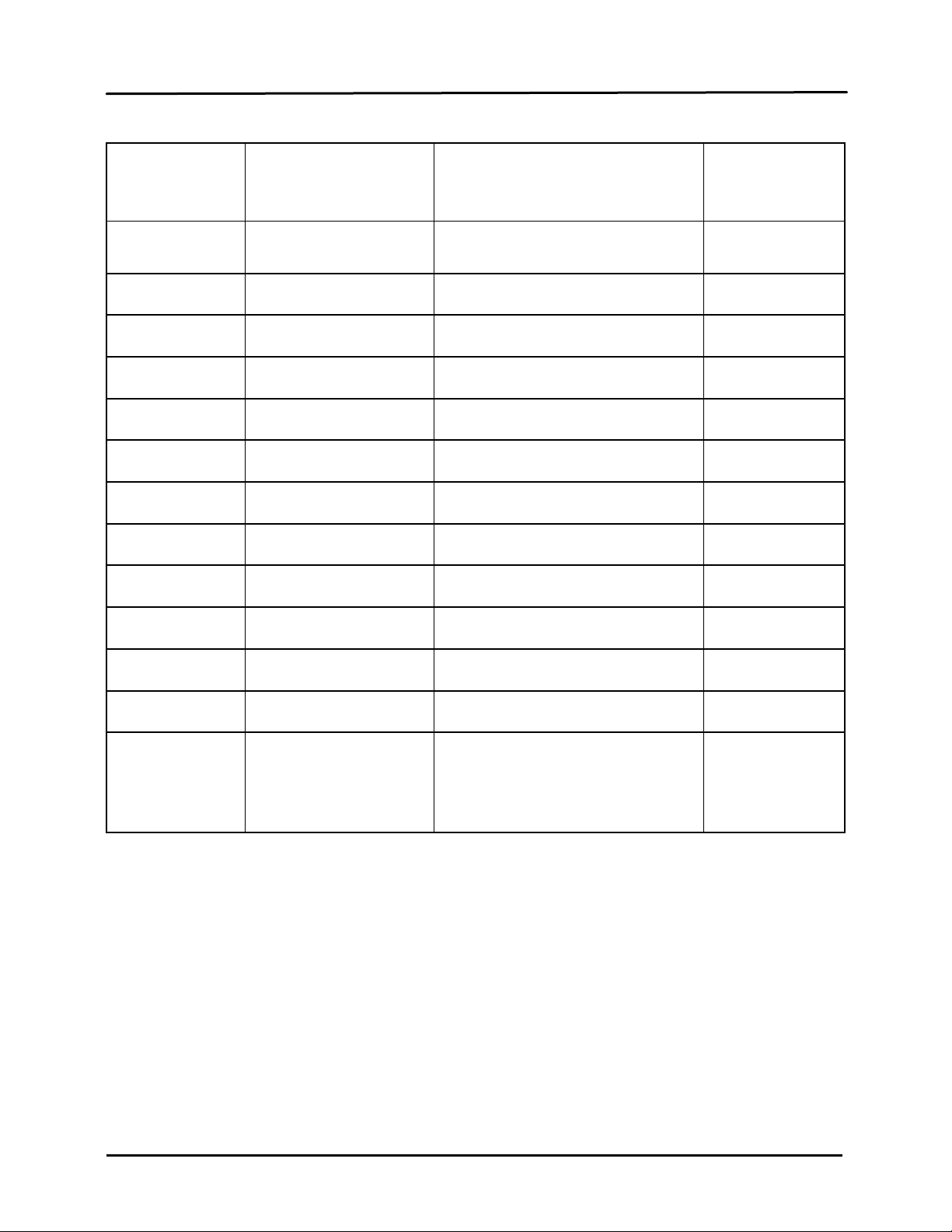

1.4 MODBUS FUNCTION SET SUPPORT

The complete Modbus protocol includes a total of 24 Function Codes. However, for AERCO

BMS/BMS II/ACS and C-More Boiler Controllers, only the Codes listed in Table 1-2 are

supported. The supported Diagnostic Sub-Function Codes associated with Diagnostic Function

Code 08 are listed in Table 1-3.

Table 1-2: Required Function Code Set

03

08

(See Table 1-3 for supported Sub-Function

Table 1-3: Minimum Diagnostic (Function Code 08) Sub-Function Set

Function

10 Clear Counters and Diagnostic Register

Sub-Function Name Comments

14 Return Slave Message Count

15 Return Slave No Response Count

Page 10 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

and successfully processed. Includes

Page 11

Chapter 1

Exception Code

Description

Comments

The function code received is not valid or

is not supported.

The data address received is invalid or is

not accessible due to security setting.

03

Illegal Data Value

The data value received is not valid

Phrase, Abbreviation

or Acronym

ACS

AERCO Control System

ASCII

American Standard Code for Information Interchange

BAS

Building Automation System

Baud

Bits per Second (bps)

BMS (BMS II)

Boiler Management System (Boiler Management System II)

(or Control Box)

used in all Benchmark and KC Series product lines

EMS

Energy Management System

FDX

Full-Duplex

HDX

Half-Duplex

Hex

Hexadecimal Number (0 - 9, A - F)

Input/Output (I/O) Box currently used on all Benchmark and KC

Series products

LSB

Least Significant Byte

A serial, half-duplex data transmission protocol developed by AEG

Modicon

MSB

Most Significant Byte

A standard for serial, full-duplex (FDX) transmission of data based

on the RS232 Standard

A standard for serial, full-duplex (FDX) transmission of data based

on the RS422 Standard

based on the RS485 Standard

RTU

Remote Terminal Unit

Introduction & Description USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

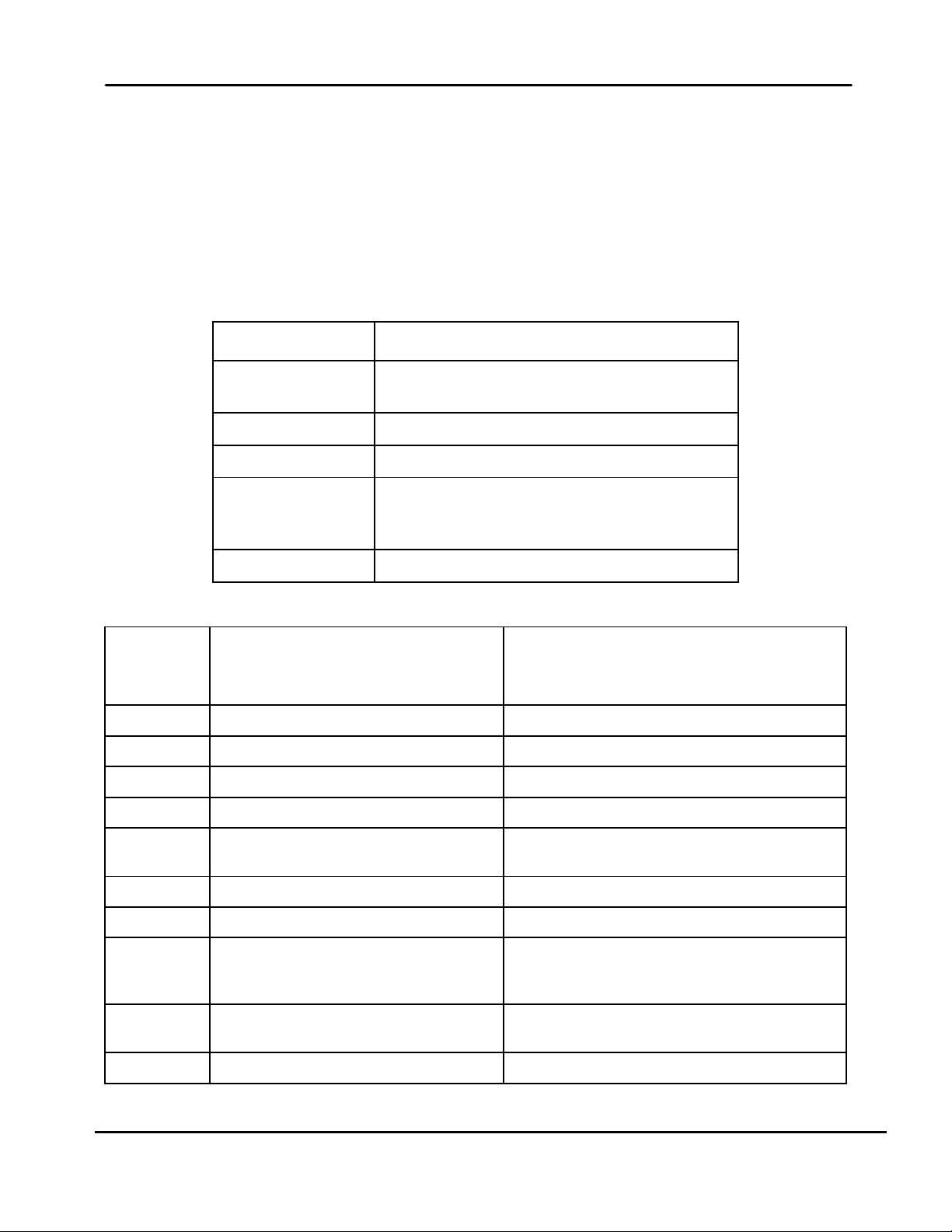

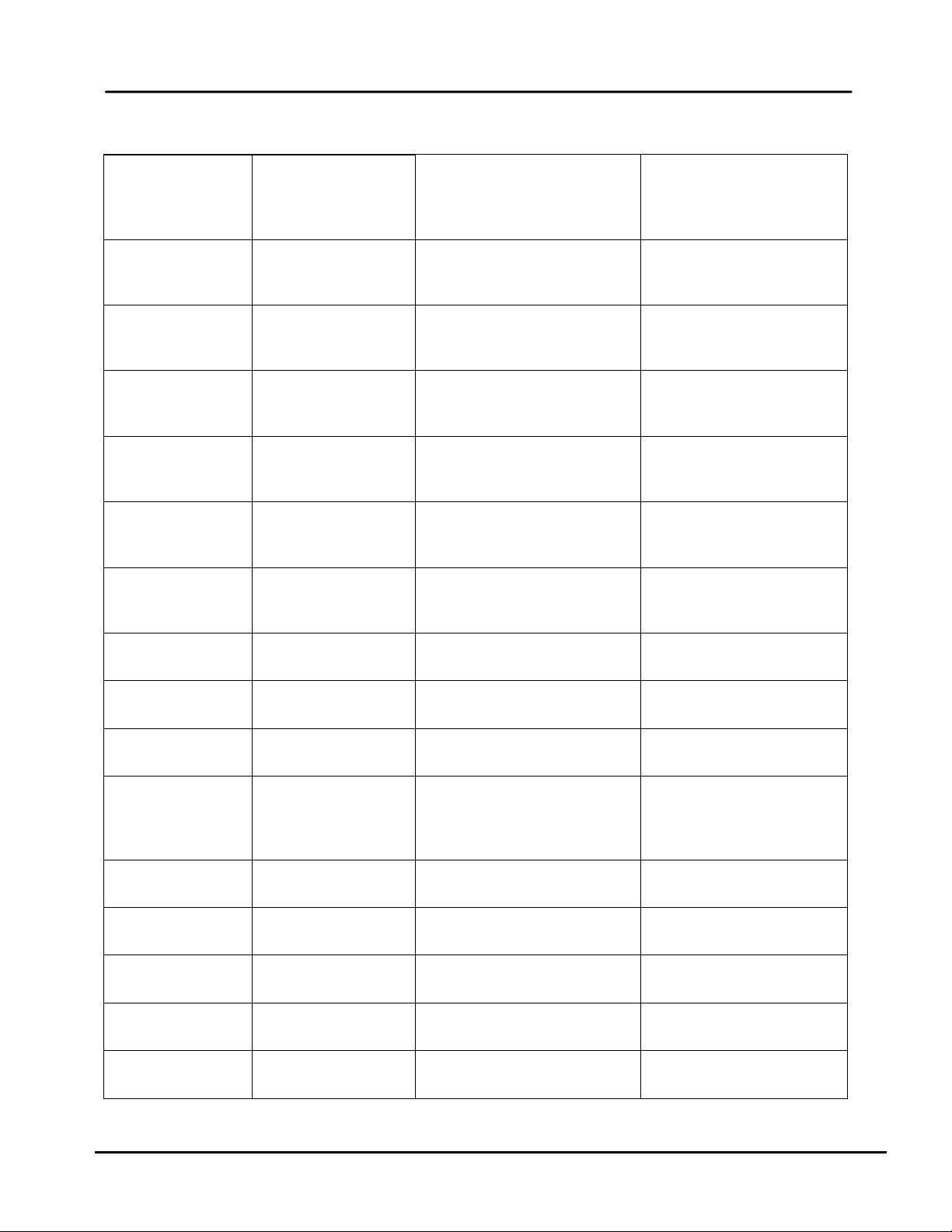

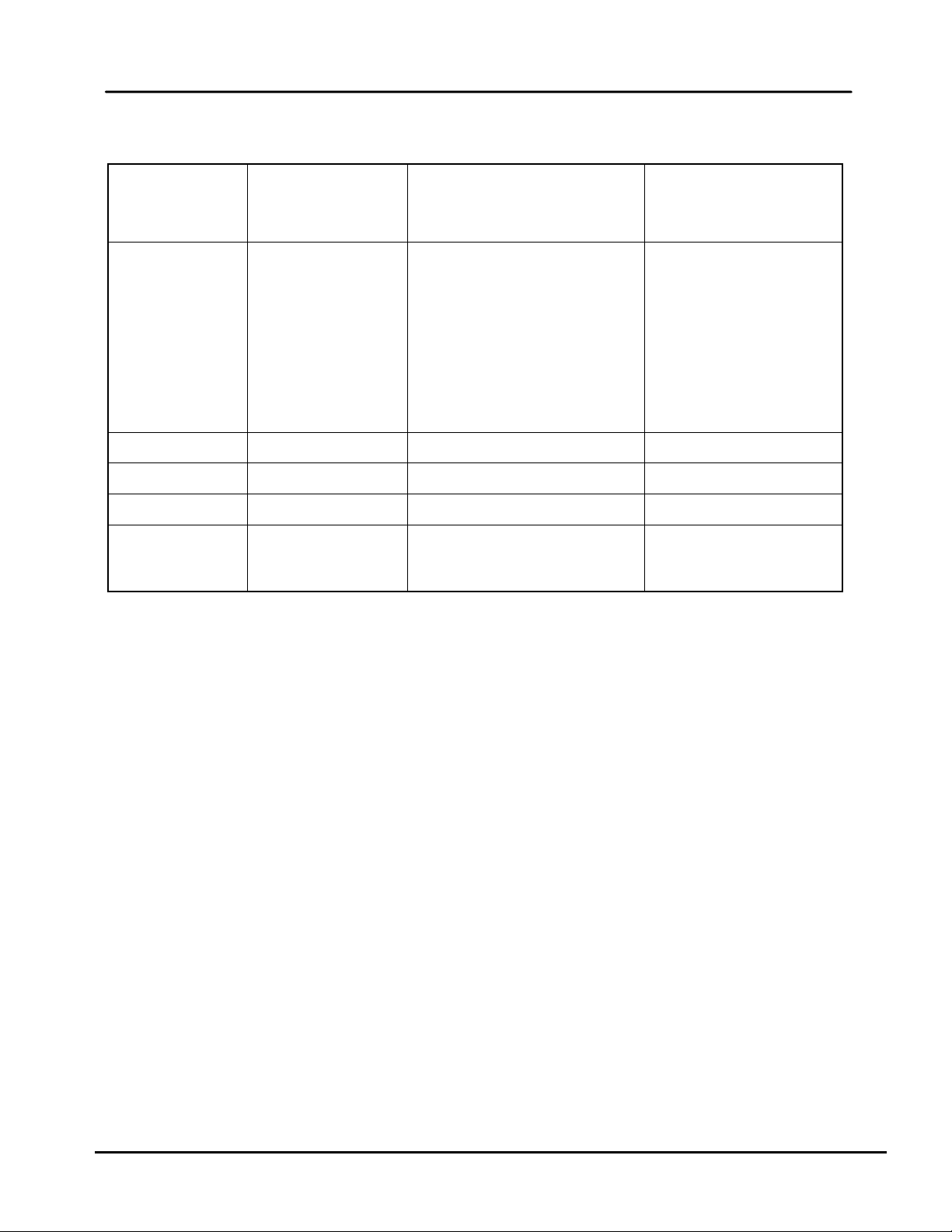

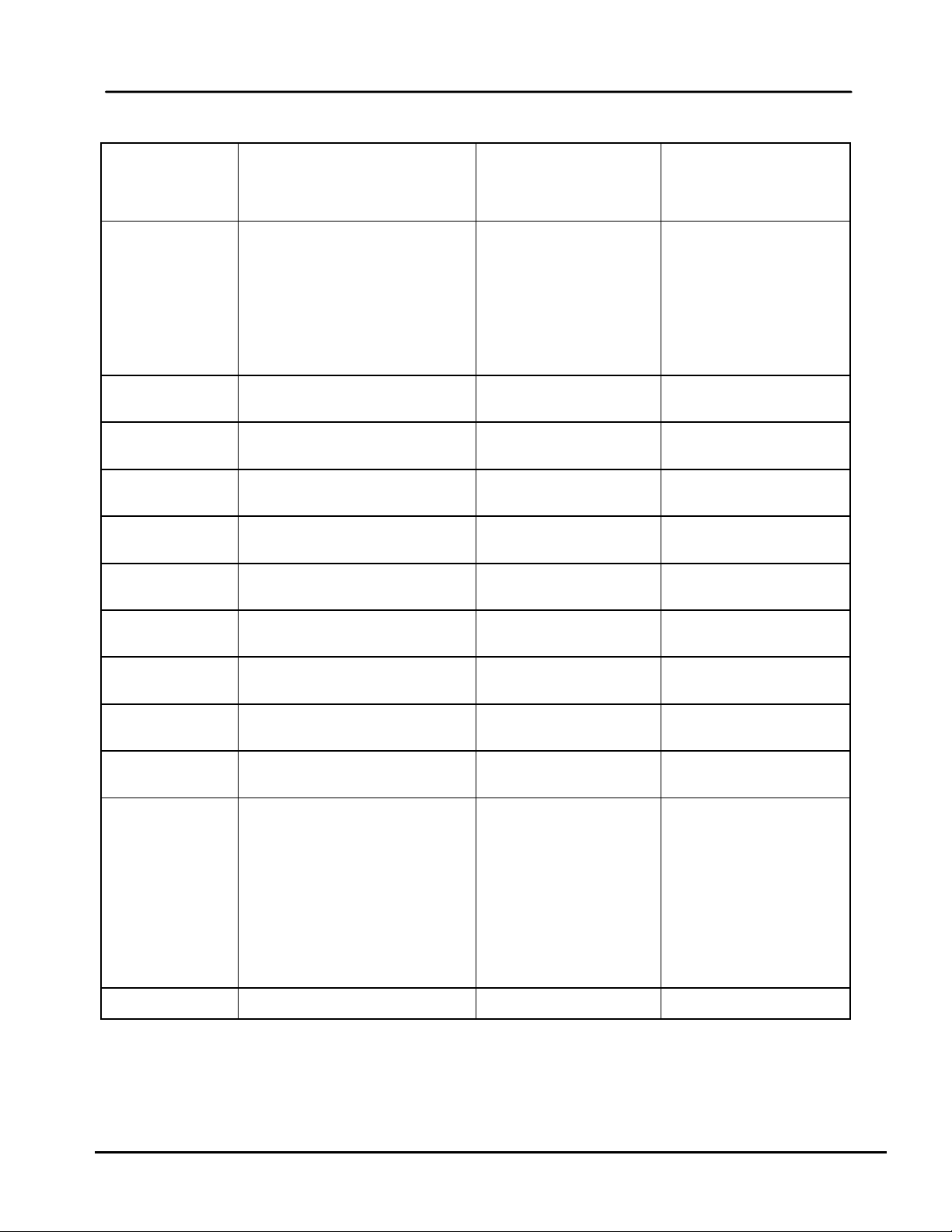

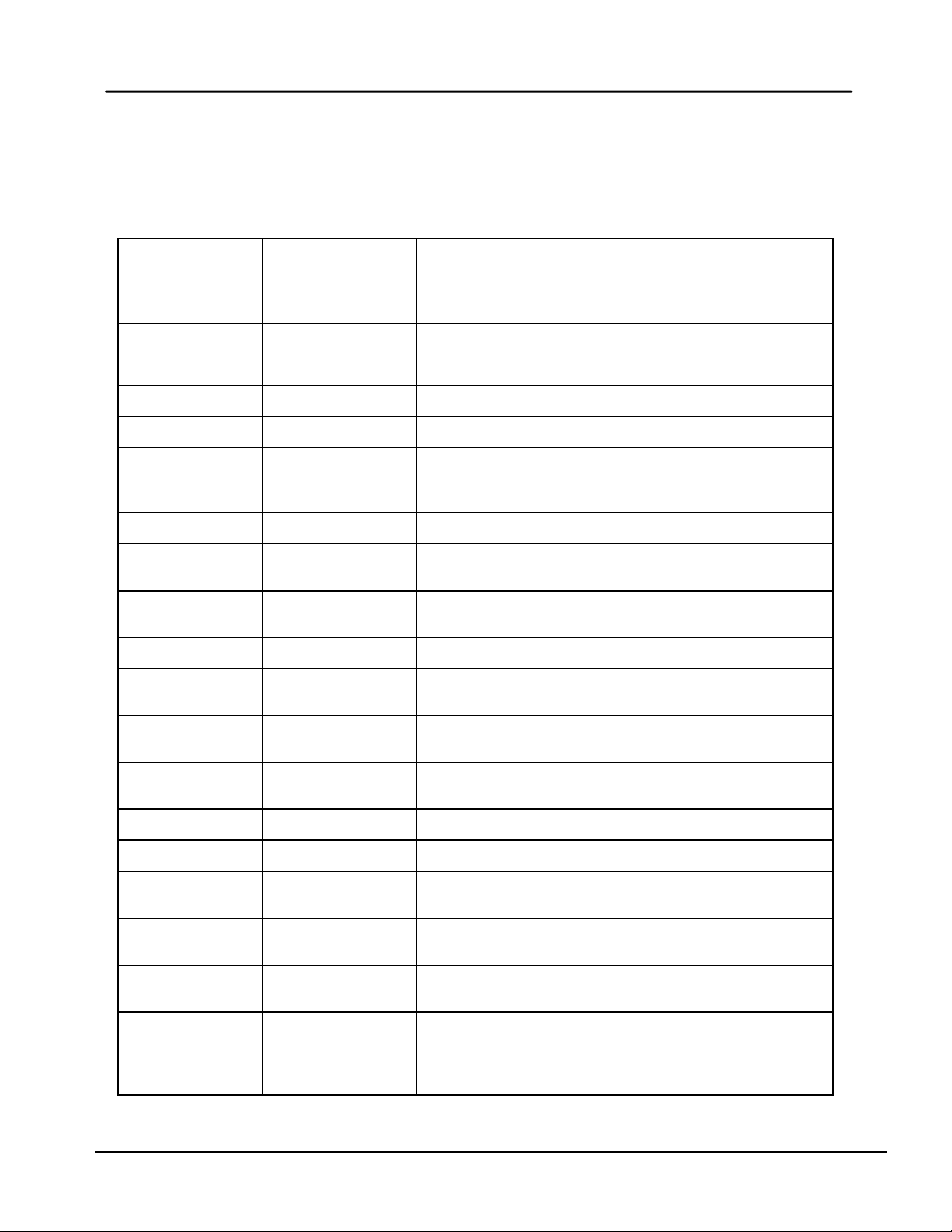

1.5 EXCEPTION RESPONSES

With the exception of Broadcast Messages, queries transmitted by the Master expect a normal

response from the addressed Slave on the network. However, if the addressed Slave cannot

process or interpret the message, it will respond with one of the Exception Codes listed in Table

1-4.

Table 1-4: Minimum Exception Code Set

01 Illegal Function

02 Illegal Data Address

1.6 PHRASES, ABBREVIATIONS & ACRONYMS

The phrases, abbreviations and acronyms used in this manual are listed in Table 1-5.

Table 1-5: Phrases, Abbreviations and Acronyms

C-More Controller

I/O Box

Modbus®

RS232

Meaning

A control system developed by AERCO International and currently

RS422

RS485

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 11 of 200

A standard for serial, half-duplex (HDX) transmission of data

Page 12

GF-114

OMM-0035_0C USER MANUAL Introduction & Description

MODBUS

(This page intentionbally blank)

Communication Chapter 1

Page 12 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 13

Chapter 2

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

CHAPTER 2. STANDARD REGISTER ASSIGMENTS

2.1 INTRODUCTION

This Section provides the standard data register addresses assigned to the AERCO and CMore Boiler Controllers, the AERCO Boiler Management System (BMS/BMS II), and AERCO

Control System (ACS). These data registers consist of Input Registers and Holding Registers.

All register addresses provided throughout this manual are expressed as hexadecimal numbers.

2.1.1 Input Registers

The Input Registers for the AERCO C-More Boiler Controllers and AERCO BMS/BMS II/ACS

are intended for information and functions that cannot or should not be controlled remotely.

Therefore, unless otherwise specified, ALL Input Register data are READ ONLY.

IMPORTANT

All Modbus addresses specified in this manual are written

generically in decimal/hexadecimal format. However, many

Building Automation Systems utilize another form of addressing

where:

40001 is added to the generic address for a Holding Register

address.

And

30001 is added to the generic address for an Input Register

address. Be sure to check the addressing scheme being used by

the BAS that is being interfaced to the XPC Gateway.

2.1.2 Holding Registers

The Holding Registers for the AERCO C-More Boiler Controllers and AERCO BMS/BMS II/ACS

are intended for information and functions that can be read or written (R/W). Therefore unless

otherwise specified, all Holding Register data are R/W.

CAUTION

DO NOT write in any Register Addresses marked as “Reserved” in

the Input Register and Holding Register Tables which follow.

Failure to observe this precaution may result in unstable

operation.

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 13 of 200

Page 14

GF-114

Modbus Data

Decimal (Hex)

Default Message

Display Code

See Appendix A,

Table A-1 for listing

Enum (0, 1, 2, 3, 4, 5)

5 = Unit Status Fault

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

8 (0x0008)

Fire Rate Out

% (0 to 100)

9 (0x0009)

O2 Level

% (0 to 25)

10 (0x000A)

CO Level

PPM (0 to 500)

The actual range for run

0 to 999,999

12 (0x000C)

Run Cycles High (MSB)

Int (0 to 15)

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

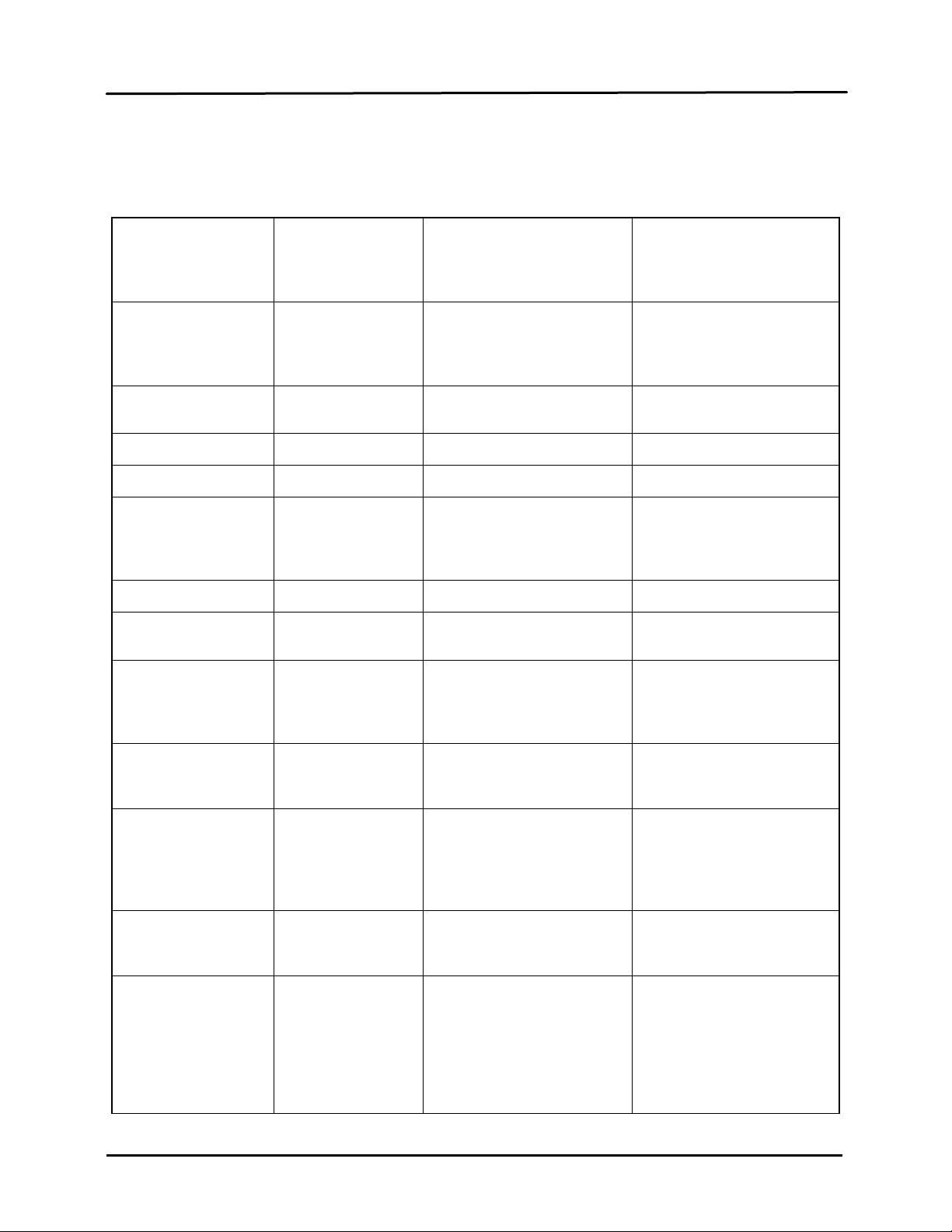

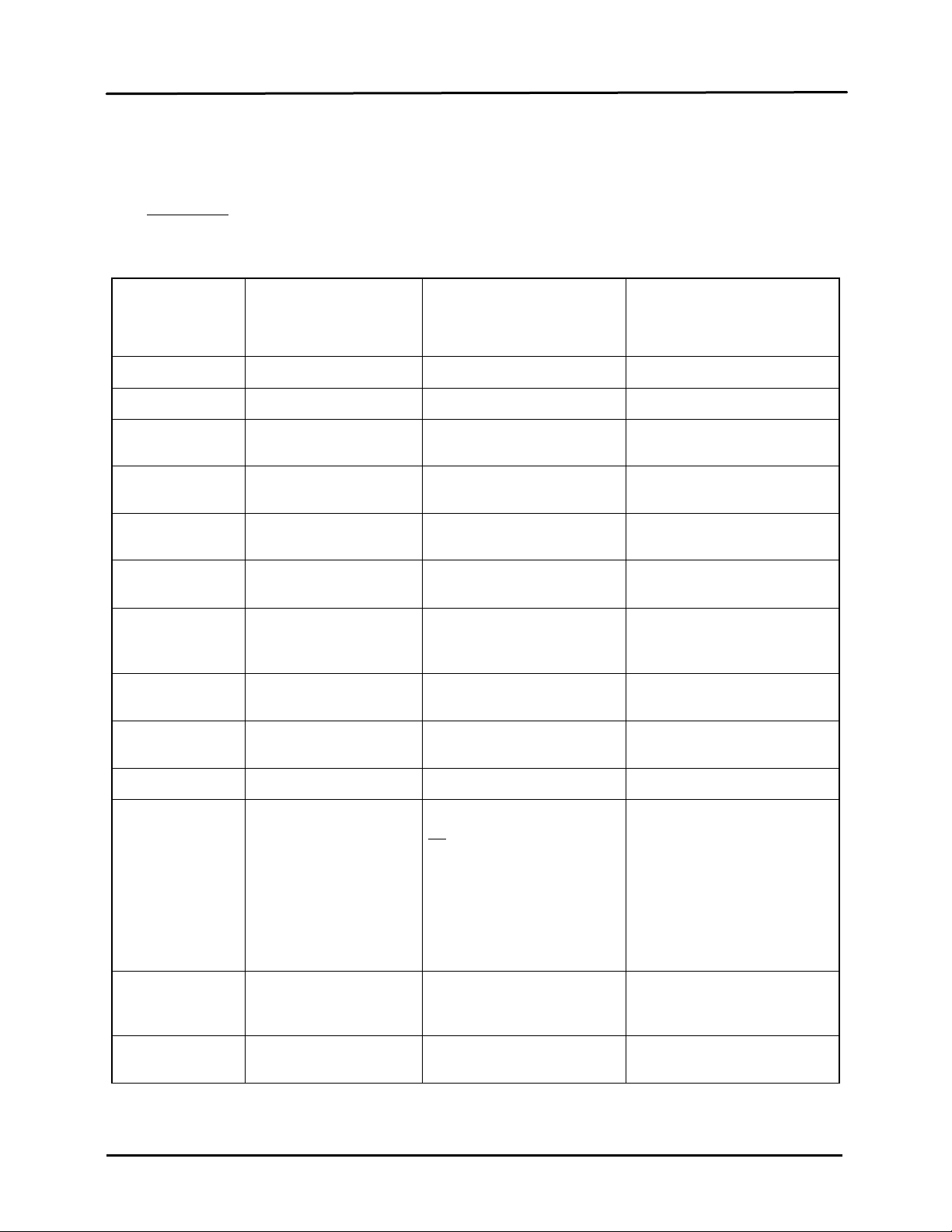

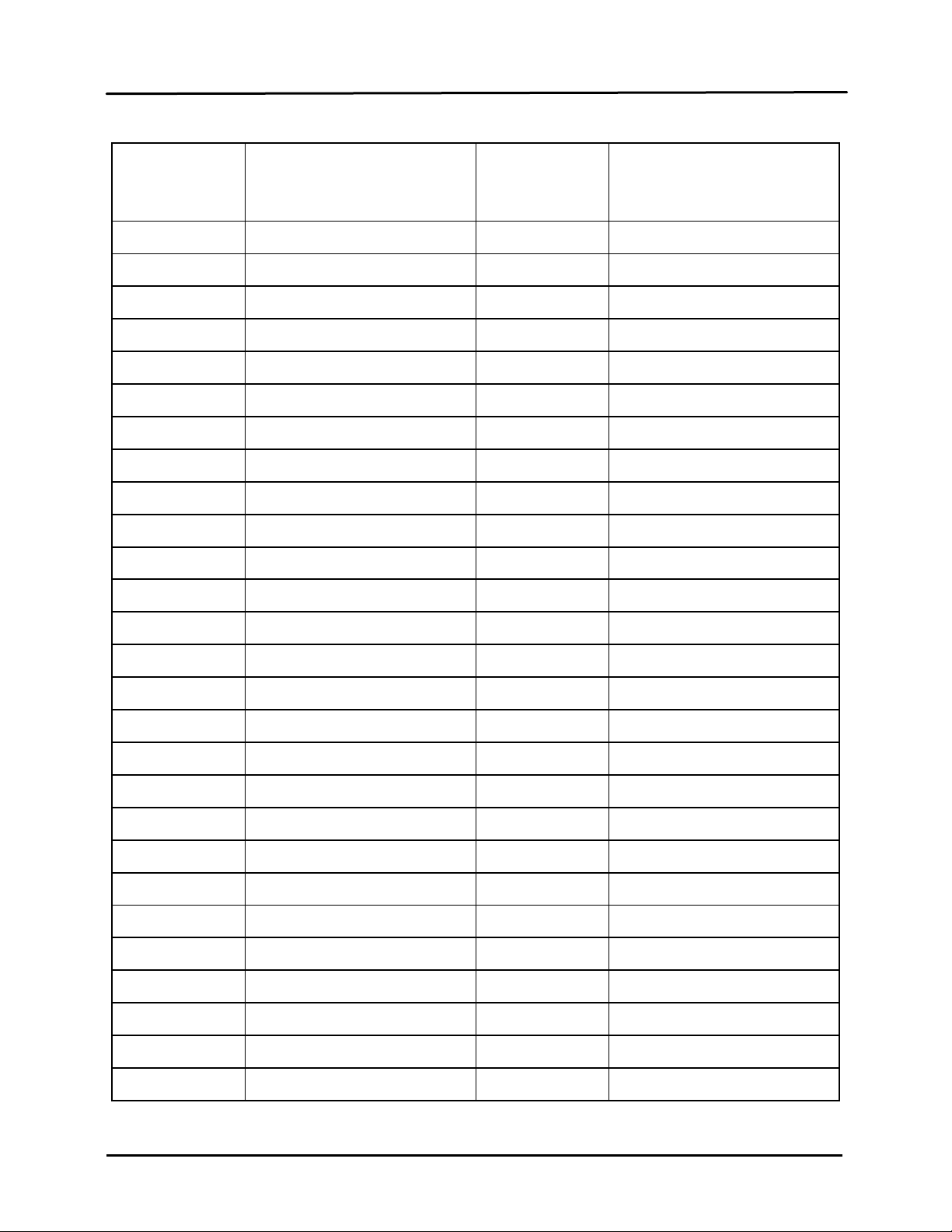

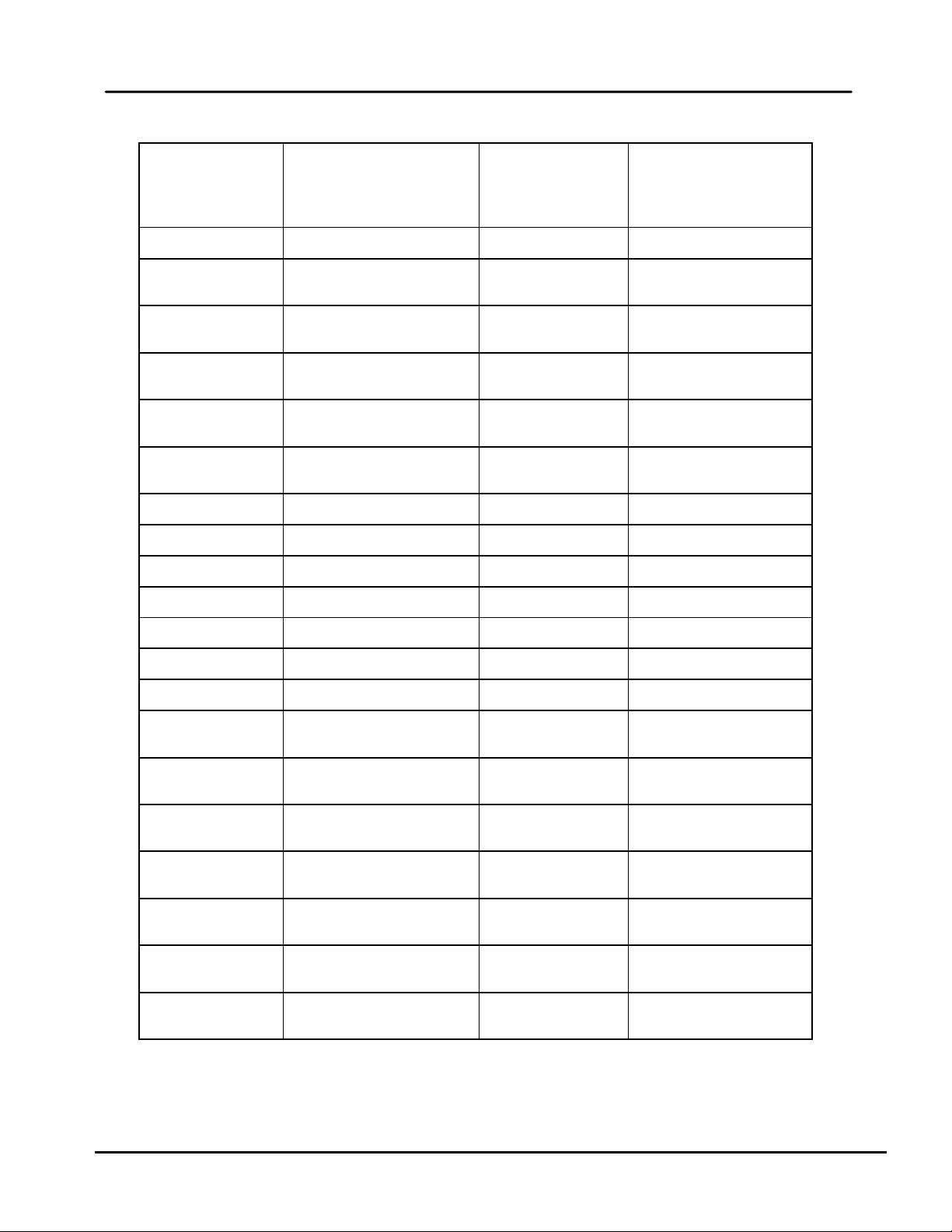

2.2 C-MORE BOILER CONTROLLER STANDARD REGISTER ASSIGNMENTS

2.2.1 C-More Boiler Controller Standard Input Register Assignments

The Read Only Input Register addresses are listed in Table 2-1 which follows:

Table 2-1: C-More Boiler Controller Standard Input Register Address Mapping

Address

0 (0x0000)

1 (0x0001) Unit Status

2 (0x0002) Outlet Temp

3 (0x0003) Inlet Temp DEGREES_1 (0 to 1000)

4 (0x0004) Aux Temp

Menu Item Units and Range

Enum (1 to 64)

0 = Unit Status Disabled

1 = Unit Status Standby

2 = Unit Status Manual

3 = Unit Status Remote

4 = Unit Status Auto

DEGREES_1 (0 to 1000)

DEGREES_1 (0 to 1000)

Default/

Comments

Tables A-2 and A-3 for

Tables A-2 and A-3 for

Tables A-2 and A-3 for

5 (0x0005) Outdoor Temp DEGREES_2 (0 to 1000)

6(0x0006) Exhaust Temp DEGREES_2 (0 to 1000)

7 (0x0007) FFWD Temp DEGREES_1 (0 to 1000)

11 (0x000B) Run Cycles Low (LSB) int (0 to 65535)

Page 14 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Tables A-2 and A-3 for

Tables A-2 and A-3 for

Tables A-2 and A-3 for

cycles is from

Page 15

Chapter 2

Modbus Data

Decimal (Hex)

The actual range for run hours

0 to 999,999

Run Hours

High (MSB)

15 (0x000F)

Flame Strength

% (0 to 100)

See Appendix A,

Conversions

17 (0x0011)

Fire Rate In

% (0 to 100)

Only applicable when in the

the front panel interface

Default = 0

communications

20 (0x0014)

Software Version

int (0 to 65535)

21 (0x0015)

22 (0x0016)

23 (0x0017)

Fault Log Code

Fault Log

The internal variable type for

and the range is 0 to 999999

Fault Log

Cycle (HIGH)

Fault Log

Date

Int (1 to 65535)

1 count/day

Fault Log

Time

Int (0 to 1439)

1 count/min.

See Appendix A,

Conversions

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

Table 2-1: C-More Boiler Controller Standard Input Register Address Mapping

(Continued)

Address

13 (0x000D)

14 (0x000E)

16 (0x0010) Active Set point DEGREES_1 (0 to 1000)

18 (0x0012) Manual Fire Rate % (0 to 100)

19 (0x0013)

Menu Item Units and Range

Run Hours

Low (LSB)

Comm Address

int (0 to 65535)

int (0 to 15)

Int (0 to 127)

Default/

Comments

is from

Tables A-2 and A-3 for

Manual Mode and controlled by

Comm Address 0 disables the

Controller’s Modbus

24 (0x0018)

25 (0x0019)

26 (0x001A)

27 (0x001B)

28 (0x001C)

(Reserved)

Fault Log

Cycle (LOW)

Sensor Log

Active Setpoint

int (0 to 65535)

Int (0 to 15)

DEGREES_1 (0 to 1000)

fault log display cycle is long

Tables A-2 and A-3 for

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 15 of 200

Page 16

GF-114

Modbus Data

Decimal (Hex)

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

See Appendix A,

Conversions

Sensor Log

CO xmitter

Sensor Log

O2 xmitter

Sensor Log

Flow Meter

73 (“I”) = Ignition

82 (“R”) = Run

Time Log

Fire Rate

Time Log

Flame Strength

Time Log

Run Length

Time Log

Date

Int (0 to 65535)

1 count/day

Time Log

Time

Int (0 to 1439)

1 count/min.

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-1: C-More Boiler Controller Standard Input Register Address Mapping

(Continued)

Address

29 (0x001D)

30 (0x001E)

31 (0x001F)

32 (0x0020)

33 (0x0021)

34 (0x0022)

Menu Item Units and Range

Sensor Log

Outlet Temp

Sensor Log

Inlet Temp

Sensor Log

FFWD Temp

Sensor Log

Exhaust Temp

Sensor Log

Outdoor Temp

Sensor Log

Aux Temp

DEGREES_1 (0 to 1000)

DEGREES_1 (0 to 1000)

DEGREES_1 (0 to 1000)

DEGREES_3 (0 to 1000)

DEGREES_2 (0 to 1000)

DEGREES_1 (0 to 1000)

Default/

Comments

Tables A-2 and A-3 for

Tables A-2 and A-3 for

Tables A-2 and A-3 for

Tables A-2 and A-3 for

Tables A-2 and A-3 for

Tables A-2 and A-3 for

35 (0x0023)

36 (0x0024)

37 (0x0025)

38 (0x0026)

39 (0x0027)

40 (0x0028)

41 (0x0029)

42 (0x002A)

43 (0x002B)

Time Log

Status

PPM_UNITS

% (0 to 100)

GPM_UNITS

74 (“O”) = Off

80 (“P”) = Power Up

% (0 to 100)

% (0 to 100)

Int (0 to 65535)

Page 16 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 17

Chapter 2

Modbus Data

Decimal (Hex)

See Appendix A,

Remote Set Point Mode

Normally Read Only. R/W

ONLY in Direct Drive Mode.

2 (0x0002)

Modbus Password

int (0 to 65535)

Default = 0

3 (0x0003)

Password

int (0 to 65535)

Default = 0

See Appendix A,

Default = 130°F

5 (0x0005)

(Reserved)

Int (0 to 1439)

1count/min

Date count starts with Jan.

counts

bool (0, 1)

1=Degrees Celsius (°C)

enum (0, 1, 2, 3, 4)

3 = 19.2k

bool (0, 1)

1 = Water Heater

enum (0, 1, 2, 3, 4, 5)

5 = 3 MBTU

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

2.2.2 C-More Boiler Controller Standard Holding Register Assignments

The Read/Write Input Register address assignments are listed in Table 2-2 which follows.

Unless otherwise specified, all Holding Register menu items are Read/Write (R/W)

Table 2-2: C-More Controller Standard Holding Register Address Mapping

Address

0 (0x0000)

1 (0x0001) Net Direct Drive % (0 to 100)

4 (0x0004) Internal Set Point DEGREES_1 (0 to 1000)

6 (0x0006) Time

7 (0x0007) Date

Menu Item Units and Range Comments

Net Remote Set

Point

DEGREES_1 (0 to 1000)

int (0 to 65535)

1count/day

Tables A-2 and A-3 for

Conversions. R/W ONLY in

Tables A-2 and A-3 for

Conversions

1, 2000. For Example: Jan.

1 2001 would equal 365

8 (0x0008) Unit of Temp

9 (0x0009) Baud Rate

10 (0x000A) Unit Type

11 (0x000B) Unit Size

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 17 of 200

0= Degrees Fahrenheit (°F)

0 = 2.4k

1 = 4.8k

2 = 9.6k

0 = Boiler

0 = 0.5 MBTU

1 = 1 MBTU

2 = 1.5 MBTU

3 = 2 MBTU

4 = 2.5 MBTU

Default = °F

For C-More RS232 port

ONLY

Default = 2 (9.6k)

Default = Boiler

Default = 1 (1 MBTU)

Page 18

GF-114

Modbus Data

Decimal (Hex)

enum (0, 1, 2, 3, 4):

4 = Outdoor Reset

enum (0, 1, 2, 3):

3 = Network

See Appendix A,

Conversions

Int (1 to 99 counts)

(Counts = Actual x 10)

Actual Default = 1.2

1.2 x 10 = 12 counts

bool (0,1)

1 = True

See Appendix A,

Default = 60°F

See Appendix A,

Default = 60°F

See Appendix A,

Default = 200°F

See Appendix A,

Default = 210°F

21 (0x0015)

Max Fire Rate

% (40 - 100)

Default = 100%

MIN_UNITS (0 to 30)

1count/min

SEC_UNITS (0 to 120)

1count/sec

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-2: C-More Controller Standard Holding Register Address Mapping

(Continued)

Address

12 (0x000C) Boiler Mode

13 (0x000D) Remote Signal

14 (0x000E) Bldg Ref Temp DEGREES_1 (0 to 1000)

15 (0x000F) Reset Ratio

16 (0x0010)

Menu Item Units and Range Comments

0 = Constant Setpt

1 = Remote Setpt

2 = Direct Drive

3 = Combo Unit

0 = 4 - 20 mA /1 - 5V

1 = 0 -20mA/0 - 5V

2 = PWM Input

Actual Range = 0.1 to 9.9

Outdoor Sensor

Enable

0 = False

Default = 0

(Constant Setpt)

Default = 0

(4 - 20 mA/1 - 5V)

Tables A-2 and A-3 for

Therefore:

Default = 0 (False)

17 (0x0011) System Start Temp

18 (0x0012) Set Point Lo Limit DEGREES_1 (0 to 1000)

19 (0x0013) Set Point Hi Limit DEGREES_1 (0 to 1000)

20 (0x0014) Temp Hi Limit

22 (0x0016) Pump Delay Timer

23 (0x0017) Aux Start On Delay

Page 18 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

DEGREES_2 (0 to 1000)

DEGREES_1 (0 to 1000)

Tables A-2 and A-3 for

Conversions

Tables A-2 and A-3 for

Conversions

Tables A-2 and A-3 for

Conversions

Tables A-2 and A-3 for

Conversions

Default = 0 min.

Default = 0 sec.

Page 19

Chapter 2

Modbus Data

Decimal (Hex)

enum (0, 1)

1=Constant Setpoint

SEC_UNITS (2 to 60)

1count/sec

See Appendix A,

Conversions

27 (0x001B)

0.00 to 2.00

Actual x 100 Counts

Heater:1.60 (160 counts)

28 (0x001C)

Actual x 100 Counts

(10 counts)

29

Water Heater ONLY

Conversions

30 (0x001E)

Water Heater ONLY

Conversions

31 (0x001F)

bool (0, 1)

1 = On

32 (0x0020)

Thru

59 (0x003B)

60 (0x003C)

bool (0, 1)

1 = Enabled

61 (0x003D)

See Appendix A,

Conversions

62 (0x003E)

Thru

66 (0x0042)

MODBUS

Communication GF-114

Standard Register Assignments USER MANUAL

Table 2-2: C-More Controller Standard Holding Register Address Mapping

(Continued)

OMM-0035_0C

Address

24 (0x0018) Failsafe Mode

25 (0x0019) Low Fire Timer

26 (0x001A) Prop Band

Integral Gain

(0x001D) Min Load Adjust

Menu Item Units and Range Comments

Derivative Time

0=Shutdown

ABS_DEG_1 (0 to 1000)

(0.01 increments)

MIN_UNITS (0.00 to 2.00)

(0.01 min. increments)

1count/0.01min

ABS_DEG_1 (0 to 1000)

Default = 0 (Shutdown)

Default = 2 sec.

Tables A-2 and A-3 for

Defaults:

Boiler: 0.10 (10 counts),

Defaults:

Boiler: 0.00 min.

(0 counts)

Heater: 0.10 min

See Appendix A,

Tables A-2 and A-3 for

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 19 of 200

Max Load Adjust

Outlet Feedback

(Reserved)

Set Point Limit Band

Set Point Limiting

(Reserved)

ABS_DEG_1 (0 to 1000)

0 = Off

0 = Disabled

ABS_DEG_1 (0 to 1000)

See Appendix A,

Tables A-2 and A-3 for

Default = 1 (On)

Water Heater ONLY

Default = 0 (Disabled)

Tables A-2 and A-3 for

Page 20

GF-114

Modbus Data

Decimal (Hex)

67 (0x0043)

Enum (0 to 8)

8 = 24 Hrs.

68 (0x0044)

Fault Log Pointer

int 0 - 9

69 (0x0045)

Sensor Log Pointer

int 0 - 1199

70 (0x0046)

Time Log Pointer

int 0 - 10239

71 (0x0047)

65535 (0xFFFF)

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-2: C-More Controller Standard Holding Register Address Mapping

(Continued)

Thru

Address

Sensor Log Interval

Menu Item Units and Range Comments

0 = Off

1 = 1 Min.

2 = 5 Min.

3 = 15 Min.

4 = 30 Min.

5 = 1 Hr.

6 = 6 Hrs

7 = 12 Hrs.

(Reserved)

Default = 4 (30 min)

Available for future

expansion.

Page 20 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 21

Chapter 2

Modbus Data

Decimal (Hex)

0 (0x0000)

(Reserved)

1 (0x0001)

Header Temperature

40 to 220°F

Outside Air

Temperature

Indoor Air/Return

Temperature

Indoor Air Temp = BMS

Return Temp = BMS II

0 to 100%

(out to boilers)

Header Set

Temperature

Default = 128

is Off-Line as a Slave)

0 to 40 (for BMS)

0 to 32 (for BMS II)

0 to 40 (for BMS)

0 to 32 (for BMS II)

9 (0x0009)

(Reserved)

0 to 65535

5 = 4-20mA Input Error

11 (0x000B)

15 (0x000F)

1 to 40 (for BMS)

1 to 32 (for BMS II)

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

2.3 BMS/BMS II CONTROLLER STANDARD REGISTER ASSIGNMENTS

2.3.1 BMS/BMS II Controller Standard Input Register Assignments

The Read Only Input Register address assignments for the BMS/BMS II are listed in Table 2-3

which follows:

Table 2-3: BMS/BMS II Standard Input Register Address Mapping

Address

2 0x0002)

3 (0x0003)

4 (0x0004) Fire Rate Out

5 (0x0005)

6 (0x0006) Network Address

7 (0x0007) Total Boilers Fired

8 (0x0008) Total Boilers On Line

Menu Item Units and Range

-60 to 120°F

40 to 220°F

40 to 220°F

128 to 247

Default/

Comments

(If Address = 0, BMS/ BMS II

10 (0x000A)

thru

16 (0x0010) Lead Boiler Number

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 21 of 200

Bit:

0 = Outside Air Sensor

Fault/Message Code

(Reserved)

1 = Header Sensor Error

2 = Interlock 1 Error

3 = Interlock 2 Error

4 = Indoor Air Sensor Error/

Return Sensor Error

Interpret Bit 4 as follows:

Indoor Air Sensor Error

applies to BMS.

Return Sensor Error applies

to BMS II.

Page 22

GF-114

Dec. (Hex)

119 = Not On-Line

1–40 = Fired & Sequence

Boilers 1 - 8 are

referred to as the

Legacy (PWM)

Boilers.(BMS Only)

Boiler 2 Status

(PWM Boiler 2)

(Same As Above)

(BMS Only)

Boiler 3 Status

(PWM Boiler 3)

(Same As Above)

(BMS Only)

Boiler 4 Status

(PWM Boiler 4)

(Same As Above)

(BMS Only)

Boiler 5 Status

(PWM Boiler 5)

(Same As Above)

(BMS Only)

Boiler 6 Status

(PWM Boiler 6)

(Same As Above)

(BMS Only)

Boiler 7 Status

(PWM Boiler 7)

(Same As Above)

(BMS Only)

Boiler 8 Status

(PWM Boiler 8)

(Same As Above)

(BMS Only)

119 = Not On-Line

Faulted

Boiler 10 Status (BMS) (Net Boiler 2)

Boiler 2 Status (BMS II)

Boiler 11 Status (BMS) (Net Boiler 3)

Boiler 3 Status (BMS II)

Boiler 12 Status (BMS) (Net Boiler 4)

Boiler 4 Status (BMS II)

Boiler 13 Status (BMS) (Net Boiler 5)

Boiler 5 Status (BMS II)

Boiler 14 Status (BMS) (Net Boiler 6)

Boiler 6 Status (BMS II)

Boiler 15 Status (BMS) (Net Boiler 7)

Boiler 7 Status (BMS II)

Boiler 16 Status (BMS) (Net Boiler 8)

Boiler 8 Status (BMS II)

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-3: BMS/BMS II Standard Input Register Address Mapping (Continued)

Modbus Data

Address

Menu Item Units and Range Comments

17 (0x0011)

18 (0x0012)

19 (0x0013)

20 (0x0014)

21 (0x0015)

22 (0x0016)

23 (0x0017)

24 (0x0018)

25 (0x0019)

Boiler 1 Status

(PWM Boiler 1)

Boiler 9 Status (BMS)

(Net Boiler 1)

Boiler 1 Status (BMS II)

120 = On-Line But Not

Fired

(Same As Above)

(Same As Above)

(Same As Above)

(Same As Above)

(Same As Above)

(Same As Above)

(Same As Above)

120 = On-Line But Not

Fired

1–40 = Fired & Sequence

121 = On-Line But

Disabled

122 = On-Line But

Boilers 9 - 32 are the

Network Boilers.

BMS II has only

Network Boilers,

therefore Net Boiler 1

= Boiler 1, etc.

26 (0x001A)

27 (0x001B)

28 (0x001C)

29 (0x001D)

30 (0x001E)

31 (0x001F)

32 (0x0020)

Page 22 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Page 23

Chapter 2

Decimal (Hex)

(Net Boiler 9)

119 = Not On-Line

122 = On-Line But Faulted

Boiler 18 Status (BMS) (Net Boiler

Boiler 10 Status (BMS II)

Boiler 19 Status (BMS) (Net Boiler

Boiler 11 Status (BMS II)

Boiler 20 Status (Net Boiler 12)

Boiler 12 Status (BMS II)

Boiler 21 Status (Net Boiler 13)

Boiler 13 Status (BMS II)

Boiler 22 Status (Net Boiler 14)

Boiler 14 Status (BMS II)

Boiler 23 Status (Net Boiler 15)

Boiler 15 Status (BMS II)

Boiler 24 Status (Net Boiler 16)

Boiler 16 Status (BMS II)

Boiler 25 Status (Net Boiler 17)

Boiler 17 Status (BMS II)

Boiler 26 Status Net Boiler 18)

Boiler 18 Status (BMS II)

Boiler 27 Status (Net Boiler 19)

Boiler 19 Status (BMS II)

Boiler 28 Status (Net Boiler 20)

Boiler 20 Status (BMS II)

Boiler 29 Status (Net Boiler 21)

Boiler 21 Status (BMS II)

Boiler 30 Status (Net Boiler 22)

Boiler 22 Status (BMS II)

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

Table 2-3: BMS/BMS II Standard Input Register Address Mapping (Continued)

Modbus Data

Address

Menu Item Units and Range Comments

33 (0x0021)

34 (0x0022)

35 (0x0023)

36 (0x0024)

37 (0x0025)

38 (0x0026)

39 (0x0027)

40 (0x0028)

Boiler 17 Status (BMS)

Boiler 9 Status (BMS II)

10)

11)

120 = On-Line But Not Fired

1–40 = Fired & Sequence

121 = On-Line But Disabled

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

41 (0x0029)

42 (0x002A)

43 (0x002B)

44 (0x002C)

45 (0x002D)

46 (0x002E)

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 23 of 200

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Page 24

GF-114

Decimal (Hex)

119 = Not On-Line

Faulted

Boiler 32 Status (Net Boiler 24)

Boiler 24 Status (BMS II)

Boiler 33 Status (Net Boiler 25)

Boiler 25 Status (BMS II)

Boiler 34 Status (Net Boiler 26)

Boiler 26 Status (BMS II)

Boiler 35 Status (Net Boiler 27)

Boiler 27 Status (BMS II)

Boiler 36 Status (Net Boiler 28)

Boiler 28 Status (BMS II)

Boiler 37 Status (Net Boiler 29)

Boiler 29 Status (BMS II)

Boiler 38 Status (Net Boiler 30)

Boiler 30 Status (BMS II)

Boiler 39 Status (Net Boiler 31)

Boiler 31 Status (BMS II)

Boiler 40 Status (Net Boiler 32)

Boiler 32 Status (BMS II)

Bit map of Input/Output

Bit 7 = Empty

58 (0x003A)

Return Sensor Temp

40 °F to 220°F

BMS II Only

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-3: BMS/BMS II Standard Input Register Address Mapping (Continued)

Modbus Data

Address

47 (0x002F)

Boiler 31 Status (Net Boiler 23)

Boiler 23 Status (BMS II)

Menu Item Units and Range Comments

120 = On-Line But Not

Fired

1–40 = Fired & Sequence

121 = On-Line But

Disabled

122 = On-Line But

48 (0x0030)

49 (0x0031)

50 (0x0032)

51 (0x0033)

52 (0x0034)

53 (0x0035)

54 (0x0036)

55 (0x0037)

56 (0x0038)

57 (0x0039) I/O Status 0 to 255

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

status (BMS II Only)

Bit 0 = AUX Relay

Bit 1 = Fault Relay

Bit 2 = Sys Start Relay

Bit 3 = Empty

Bit 4 = Setback

Bit 5 = Interlock 2

Bit 6 = Interlock 1

Page 24 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 25

Chapter 2

Decimal (Hex)

59 (0x003B)

Net Blr 1 Outlet Temp

40°F to 220°F

When Blr Cntl Type = 1 or 2

60 (0x003C)

Net Blr 2 Outlet Temp

40°F to 220°F

61 (0x003D)

Net Blr 3 Outlet Temp

40°F to 220°F

62 (0x003E)

Net Blr 4 Outlet Temp

40°F to 220°F

63 (0x003F)

Net Blr 5 Outlet Temp

40°F to 220°F

64 (0x0040)

Net Blr 6 Outlet Temp

40°F to 220°F

65 (0x0041)

Net Blr 7 Outlet Temp

40°F to 220°F

66 (0x0042)

Net Blr 8 Outlet Temp

40°F to 220°F

67 (0x0043)

Net Blr 9 Outlet Temp

40°F to 220°F

68 (0x0044)

Net Blr 10 Outlet Temp

40°F to 220°F

69 (0x0045)

Net Blr 11 Outlet Temp

40°F to 220°F

70 (0x0046)

Net Blr 12 Outlet Temp

40°F to 220°F

71 (0x0047)

Net Blr 13 Outlet Temp

40°F to 220°F

72 (0x0048)

Net Blr 14 Outlet Temp

40°F to 220°F

73 (0x0049)

Net Blr 15 Outlet Temp

40°F to 220°F

74 (0x004A)

Net Blr 16 Outlet Temp

40°F to 220°F

75 (0x004B)

Net Blr 17 Outlet Temp

40°F to 220°F

76 (0x004C)

Net Blr 18 Outlet Temp

40°F to 220°F

77 (0x004D)

Net Blr 19 Outlet Temp

40°F to 220°F

78 (0x004E)

Net Blr 20 Outlet Temp

40°F to 220°F

79 (0x004F)

Net Blr 21 Outlet Temp

40°F to 220°F

80 (0x0050)

Net Blr 22 Outlet Temp

40°F to 220°F

81 (0x0051)

Net Blr 23 Outlet Temp

40°F to 220°F

82 (0x0052)

Net Blr 24 Outlet Temp

40°F to 220°F

83 (0x0053)

Net Blr 25 Outlet Temp

40°F to 220°F

84 (0x0054)

Net Blr 26 Outlet Temp

40°F to 220°F

85 (0x0055)

Net Blr 27 Outlet Temp

40°F to 220°F

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

Table 2-3: BMS/BMS II Standard Input Register Address Mapping (Continued)

Modbus Data

Address

Menu Item

Units and

Comments

Range

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 25 of 200

Page 26

GF-114

Decimal (Hex)

86 (0x0056)

Net Blr 28 Outlet Temp

40°F to 220°F

87 (0x0057)

Net Blr 29 Outlet Temp

40°F to 220°F

88 (0x0058)

Net Blr 30 Outlet Temp

40°F to 220°F

89 (0x0059)

Net Blr 31 Outlet Temp

40°F to 220°F

90 (0x005A)

Net Blr 32 Outlet Temp

40°F to 220°F

0 to 64 for Cmore;

0 to 65535 for MLX (BCM)

93 (0x005D)

Net Blr 2 Code

Same as Above

94 (0x005E)

Net Blr 3 Code

Same as Above

95 (0x005F)

Net Blr 4 Code

Same as Above

96 (0x0060)

Net Blr 5 Code

Same as Above

97 (0x0061)

Net Blr 6 Code

Same as Above

98 (0x0062)

Net Blr 7 Code

Same as Above

99 (0x0063)

Net Blr 8 Code

Same as Above

100 (0x0064)

Net Blr 9 Code

Same as Above

101 (0x0065)

Net Blr 10 Code

Same as Above

102 (0x0066)

Net Blr 11 Code

Same as Above

103 (0x0067)

Net Blr 12 Code

Same as Above

104 (0x0068)

Net Blr 13 Code

Same as Above

105 (0x0069)

Net Blr 14 Code

Same as Above

106 (0x006A)

Net Blr 15 Code

Same as Above

107 (0x006B)

Net Blr 16 Code

Same as Above

108 (0x006C)

Net Blr 17 Code

Same as Above

109 (0x006D)

Net Blr 18 Code

Same as Above

110 (0x006E)

Net Blr 19 Code

Same as Above

111 (0x006F)

Net Blr 20 Code

Same as Above

112 (0x0070)

Net Blr 21 Code

Same as Above

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-3: BMS/BMS II Standard Input Register Address Mapping (Continued)

Modbus Data

Address

92 (0x005C) Net Blr 1 Code

Menu Item

Units and

Comments

Range

Page 26 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 27

Chapter 2

Decimal (Hex)

0 to 64 for Cmore;

0 to 65535 for MLX (BCM)

113 (0x0071)

Net Blr 22 Code

Same as Above

114 (0x0072)

Net Blr 23 Code

Same as Above

115 (0x0073)

Net Blr 24 Code

Same as Above

116 (0x0074)

Net Blr 25 Code

Same as Above

117 (0x0075)

Net Blr 26 Code

Same as Above

118 (0x0076)

Net Blr 27 Code

Same as Above

119 (0x0077)

Net Blr 28 Code

Same as Above

120 (0x0078)

Net Blr 29 Code

Same as Above

121 (0x0079)

Net Blr 30 Code

Same as Above

122 (0x007A)

Net Blr 31 Code

Same as Above

123 (0x007B)

Net Blr 32 Code

Same as Above

124 (0x007C)

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

OMM-0035_0C

Table 2-3: BMS/BMS II Standard Input Register Address Mapping (Continued)

Modbus Data

Address

Menu Item Units and Range Comments

112 (0x0070) Net Blr 21 Code

Thru

65535 (0xFFFF)

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 27 of 200

(Reserved for future

expansion)

Page 28

GF-114

Modbus Data

Decimal (Hex)

0 (0x0000)

(Reserved)

1 (0x0001)

(Reserved)

2 (0x0002)

(Reserved)

3 (0x0003)

(Reserved)

Valid when Header Set Mode =

Signal = Network

5 (0x0005)

System Start Temp

32 to 120°F

Default = 70°F

0 or 1, 0 = Temp Only,

1 = Temp and Load

Manual Hdr Set

Temp/Internal Setpt

8 (0x0008)

Bldg Ref Temp

40 to 220°F

Default = 70°F

0.0 to 20.0°F/°F

(0.5°F/°F increments)

Default = 00.0°F/°F

(Value x 10) (BMS Only)

Indoor Setpoint

Temp

Default = 70°F

(BMS Only)

0.3 to 3.0

(0.1 increments),

Default = 1.2

(Value x 10)

12 (0x000C)

Max Header Temp

40 to 220°F

Default = 220°F

13 (0x000D)

Min Header Temp

40 to 220°F

Default = 40°F

Default = 45% (BMS)

Default = 20% (BMS II)

Default = 18% (BMS)

Default = 16% (BMS II)

0.00 to 9.99 Rep/Min

(in 0.01 increments

Default = 0.15 Rep/Min

(Value x 100)

0, 1, or 2

2 = Remote Setpt

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

2.3.2 BMS/BMS II Controller Standard Holding Register Assignments

The Holding Register address assignments for the BMS/BMS II/ACS are listed in Table 2-4

which follows. Unless otherwise specified, all Holding Register Menu items are Read/Write

(R/W).

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping

Address

4 (0x0004)

6 (0x0006) System Start Option

7 (0x0007)

9 (0x0009) Indoor Prop Band

Menu Item Units and Range

Net Header Set

Temp

Default/

Comments

40 to 220°F

40 to 220°F Default = 160°F

Remote Setpt and Remote

Default = 0

10 (0x000A)

11 (0x000B) Reset Ratio

14 (0x000E) Start Percent 25 to 100%

15 (0x000F) Stop Percent 10 to 45%

16 (0x0010) Integral Gain

17 (0x0011) Header Set Mode

Page 28 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

50 to 150°F

0 = Constant Setpt

1 = In/Outdoor Reset

Default = 0

(Constant Setpt))

Page 29

Chapter 2

Decimal (Hex)

-2.00 to 2.00

19 0x0013)

Header Temp Bandwidth

5 to 120°F

Default = 70°F

20 (0x0014)

Aux Relay Open

0 to 99%

Default = 45%

0 or 1

1 = 100% Fire Rate and Off

0 or 1

Setpt

0, 1, 2, 3

3 = Interlock 2

0 or 1

1 = Manual

0, 1 or 2

2 = Combination

Default = 0 (BMS Only)

assign Combo Boilers)

27 (0x001B)

(Reserved)

28 (0x001C)

(Reserved)

29 (0x001D)

(Reserved)

Max Power Input

Default = 100%

(Fire Rate)

Interlock 1 Method

(BMS II)

0 or 1

1 = Start Enabled

MODBUS

Communication GF-114

Standard Register Assignments USER MANUAL

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping (Cont.)

OMM-0035_0C

Modbus Data

Address

18 (0x0012) Derivative Gain

21 (0x0015) Aux Relay Mode

22 (0x0016)

23 (0x0017)

Menu Item Units and Range

Temp Sensor Fail

Mode/Failsafe Mode

Fault Alarm Relay Mode

(0.00 increments)

0 = 100% Fire Rate

0 = Shutdown

1 = Switch Inputs/Constant

0 = All Faults,

1 = No Interlock

2 = Interlock 1

Default/

Comments

Default = 0.15

(Value x 100)

Default = 1

(100% Fire Rate & Off)

Default = 0

(Shutdown)

Default = 0

(All Faults)

24 (0x0018) Fault Alarm Clear Method

25 (0x0019) Boiler Operation Mode

Number Of

26 (0x001A)

30 (0x001E)

31 (0x001F)

Combination Mode

Boilers

(BMS)/Sys Intlk Config

0 = Automatic

0 = Parallel

1 = Sequential

0 to 4

50 to 100%

0 = Always Enabled

Default = 0

(Automatic)

Default = 1

(Sequential)

(Start at Boiler 8 and

work back to Boiler 5 to

Default = 1

(Start Enabled)

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 29 of 200

Page 30

GF-114

Decimal (Hex)

32 (0x0020)

Real Time Clock Minutes

00 to 59 Minutes

Present Time

Real Time Clock

Hours

Real Time Clock

Day of Week

Real Time Clock

Year

Real Time Clock

Day of Month

Real Time Clock

Month

38 (0x0026)

Offset Temp Day 1

-50 to 50°F

Default = 0°F

39 (0x0027)

Offset Temp Day 2

-50 to 50°F

Default = 0°F

40 (0x0028)

Offset Temp Day 3

-50 to 50°F

Default = 0°F

41 (0x0029)

Offset Temp Day 4

-50 to 50°F

Default = 0°F

42 (0x002A)

Offset Temp Day 5

-50 to 50°F

Default = 0°F

43 (0x002B)

Offset Temp Day 6

-50 to 50°F

Default = 0°F

44 (0x002C)

Offset Temp Day 7

-50 to 50°F

Default = 0°F

Offset On Time

Day 1 – Minutes

Offset On Time

Day 2 – Minutes

Offset On Time

Day 3 – Minutes

Offset On Time

Day 4 – Minutes

Offset On Time

Day 5 – Minutes

Offset On Time

Day 6 – Minutes

Offset On Time

Day 7 – Minutes

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping (Cont.)

Modbus Data

Address

33 (0x0021)

34 (0x0022)

35 (0x0023)

36 (0x0024)

37 (0x0025)

Menu Item

Units and

Range

00 to 23 Hours Present Time

1 to 7 Present Day

00 to 99 Present Year

01 to 31 Present Day of Month

01 to 12 Present Month

Default/

Comments

45 (0x002D)

46 (0x002E)

47 (0x002F)

48 (0x0030)

49 (0x0031)

50 (0x0032)

51 (0x0033)

00 to 59 Minutes Default = 0

00 to 59 Minutes Default = 0

00 to 59 Minutes Default = 0

00 to 59 Minutes Default = 0

00 to 59 Minutes Default = 0

00 to 59 Minutes Default = 0

00 to 59 Minutes Default = 0

Page 30 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 31

Chapter 2

Decimal (Hex)

52 (0x0034)

Offset On Time

Day 1 – Hours

00 to 23 Hours

Default = 0

53 (0x0035)

Offset On Time

Day 2 – Hours

00 to 23 Hours

Default = 0

54 (0x0036)

Offset On Time

Day 3 – Hours

00 to 23 Hours

Default = 0

55 (0x0037)

Offset On Time

Day 4 – Hours

00 to 23 Hours

Default = 0

56 (0x0038)

Offset On Time

Day 5 – Hours

00 to 23 Hours

Default = 0

57 (0x0039)

Offset On Time

Day 6 – Hours

00 to 23 Hours

Default = 0

58 (0x003A)

Offset On Time

Day 7 – Hours

00 to 23 Hours

Default = 0

59 (0x003B)

Offset Enable

0 or 1

1 = Enabled

Default = 0

60 (0x003C)

Header Offset

0 to 5°F

Default = 0°F

61 (0x003D)

System Start Interlock

1, 2 or 3

Opens Start

3 = Intlk 2 Open Start Relay

Default = 2

62 (0x003E)

69 (0x0045)

(Reserved)

70 (0x0046)

Offset Off Time

Day 1 – Minutes

0 to 59 Minutes

Default = 0

71 (0x0047)

Offset Off Time

Day 2 – Minutes

0 to 59 Minutes

Default = 0

72 (0x0048)

Offset Off Time

Day 3– Minutes

0 to 59 Minutes

Default = 0

73 (0x0049)

Offset Off Time

Day 4– Minutes

0 to 59 Minutes

Default = 0

74 (0x004A)

Offset Off Time

Day 5 – Minutes

0 to 59 Minutes

Default = 0

75 (0x004B)

Offset Off Time

Day 6 – Minutes

0 to 59 Minutes

Default = 0

MODBUS

Communication GF-114

Standard Register Assignments USER MANUAL

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping (Cont.)

OMM-0035_0C

Modbus Data

Address

Menu Item Units and Range

0 = Disabled

Default/

Comments

(Disabled)

Thru

1 = Either Intlk

Relay

2 = Intlk1 Opens Start Relay

(Intlk 1)

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 31 of 200

Page 32

GF-114

Decimal (Hex)

Offset Off Time

Day 7 – Minutes

Offset Off Time

Day 1 – Hours

Offset Off Time

Day 2 – Hours

Offset Off Time

Day 3 – Hours

Offset Off Time

Day 4 – Hours

Offset Off Time

Day 5 – Hours

Offset Off Time

Day 6 – Hours

Offset Off Time

Day 7 – Hours

84 (0x0054)

(Reserved)

0 or 1

1 = Thermistor

Default = 1

BMS Only

0 or 1

1 = Network

0 or 1

1 = Modbus

2400, 4800, 9600, 14.4k,

19.2k

Number Of

Network Boilers

Default = 0 (for BMS)

Default = 2 (for BMS II)

90 (0x005A)

Min Slave Address

0 to 127

Default = 0

Max Slave

Address

Net Boiler 1

Address

Address for Network Boiler

1

Default = 0 (for BMS)

Default = 1 (for BMS II)

Net Boiler 2

Address

Address for Network Boiler

2

Default = 0 (for BMS)

Default = 2 (for BMS II)

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping (Cont.)

Modbus Data

Address

76 (0x004C)

77 (0x004D)

78 (0x004E)

79 (0x004F)

80 (0x0050)

81 (0x0051)

82 (0x0052)

83 (0x0053)

Menu Item Units and Range

Default/

Comments

0 to 59 Minutes Default = 0

0 to 23 Hours Default = 0

0 to 23 Hours Default = 0

0 to 23 Hours Default = 0

0 to 23 Hours Default = 0

0 to 23 Hours Default = 0

0 to 23 Hours Default = 0

0 to 23 Hours Default = 0

85 (0x0055)

86 (0x0056) Remote Signal

87 (0x0057) RS232 Mode

88 (0x0058) RS232 Baud Rate

89 (0x0059)

91 (0x005B)

92 (0x005C)

93 (0x005D)

Indoor Air Input

0 = 4 – 20 Ma

0 = 4 – 20 Ma

0 = Normal

0 to 32

0 to 127, Default = 0

(Thermistor)

Default = 0

(4 – 20 Ma)

Default = 0

(Normal)

Default = 9600

Page 32 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 33

Chapter 2

Decimal (Hex)

Address for Network Boiler 9

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping (Cont.)

OMM-0035_0C

Modbus Data

Address

Menu Item Units and Range

Default/

Comments

94 (0x005E) Net Boiler 3 Address Address for Network Boiler 3 Default = 0

95 (0x005F) Net Boiler 4 Address Address for Network Boiler 4 Default = 0

96 (0x0060) Net Boiler 5 Address Address for Network Boiler 5 Default = 0

97 (0x0061) Net Boiler 6 Address Address for Network Boiler 6 Default = 0

98 (0x0062) Net Boiler 7 Address Address for Network Boiler 7 Default = 0

99 (0x0063) Net Boiler 8 Address Address for Network Boiler 8 Default = 0

100 (0x0064) Net Boiler 9 Address

101 (0x0065) Net Boiler 10 Address Address for Network Boiler 10 Default = 0

102 (0x0066) Net Boiler 11address Address for Network Boiler 11 Default = 0

103 (0x0067) Net Boiler 12 Address Address for Network Boiler 12 Default = 0

Default = 0

104 (0x0068) Net Boiler 13 Address Address for Network Boiler 13 Default = 0

105 (0x0069) Net Boiler 14 Address Address for Network Boiler 14 Default = 0

106 (0x006A) Net Boiler 15 Address Address for Network Boiler 15 Default = 0

107 (0x006B) Net Boiler 16 Address Address for Network Boiler 16 Default = 0

108 (0x006C) Net Boiler 17 Address Address for Network Boiler 17 Default = 0

109 (0x006D) Net Boiler 18 Address Address for Network Boiler 18 Default = 0

110 (0x006E) Net Boiler 19 Address Address for Network Boiler 19 Default = 0

111 (0x006F) Net Boiler 20 Address Address for Network Boiler 20 Default = 0

112 (0x0070) Net Boiler 21 Address Address for Network Boiler 21 Default = 0

113 (0x0071) Net Boiler 22 Address Address for Network Boiler 22 Default = 0

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 33 of 200

Page 34

GF-114

Decimal (Hex)

114 (0x0072)

Net Boiler 23 Address

Address for Network Boiler

23

Default = 0

115 (0x0073)

Net Boiler 24 Address

Address for Network Boiler

24

Default = 0

116 (0x0074)

Net Boiler 25 Address

Address for Network Boiler

25

Default = 0

117 (0x0075)

Net Boiler 26 Address

Address for Network Boiler

26

Default = 0

118 (0x0076)

Net Boiler 27 Address

Address for Network Boiler

27

Default = 0

(119 0x0077)

Net Boiler 28 Address

Address for Network Boiler

28

Default = 0

120 (0x0078)

Net Boiler 29 Address

Address for Network Boiler

29

Default = 0

121 (0x0079)

Net Boiler 30 Address

Address for Network Boiler

30

Default = 0

122 (0x007A)

Net Boiler 31 Address

Address for Network Boiler

31

Default = 0

123 (0x007B)

Net Boiler 32 Address

Address for Network Boiler

32

Default = 0

124 (0x007C)

Network Baud

0=2400, 1=4800, 2=9600,

3=14.4k, 4=19.2k

Default = 2 (9600)

125 (0x007D)

Network Timeout

5 to 240 sec

Default = 60 sec.

126 (0x007E)

Password Lo

0 to 255 (73)

Default = 0

127 (0x007F)

Password Hi

0 to 255 (79)

Default = 0

0 = Round-Robin

1 = Broadcast

Default = 0

(Round Robin)

0 = Disabled

1 = Enabled

Default – 5°F (BMS II

Only)

Outside Temp Sensor

Offset

Default = 20 (BMS II

Only)

Default = 200 (BMS II

Only)

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping (Cont.)

Modbus Data

Address

Menu Item Units and Range

Default/

Comments

128 (0x0080) Modbus Control Type

129 (0x0081) Modbus Pass-Thru

130 (0x0082) Header Dead Band 1 to 15°F

131 (0x0083)

132 (0x0084) Ramp Up %/MIN 0 to 300

133 (0x0085) Ramp Down %/MIN 0 to 300

Page 34 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Default = 0 (Disabled)

-10°F to 10°F

Page 35

Chapter 2

Decimal (Hex)

0 = No Blr Faults,

1 = All Blr Faults

4 to 20 mA Current

Offset

Default = 0

(BMS II Only)

Default = 0

(BMS II Only)

137 (0x0089)

Load Start Pct

1 to Blr Start Level

Default =1 (BMS II Only)

138 (0x008A)

Load Stop Pct

0 to Load Start -1

Default =0 (BMS II Only)

139 (0x008B)

65535 (0xFFFF)

0 = None,

2 = MLX (BCM)

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

Table 2-4: BMS/BMS II Standard Holding Register Address Mapping (Cont.)

OMM-0035_0C

Modbus Data

Address

134 (0x0086) Fault Alarm Boilers

135 (0x0087)

136 (0x0088) Return Sensor Offset -10.0 to 10.0

thru

0x00A1 Boiler control select

Menu Item Units and Range

-1.00 to 1.00 mA

(Reserved For Future

Expansion)

Undefined

1 = C-More

Default/

Comments

Default = 0

Default = 0

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 35 of 200

Page 36

GF-114

Modbus Data

Decimal (Hex)

0 (0x0000)

(Reserved)

1 (0x0001)

Header Temperature

40 to 220°F

2 (0x0002)

Outside Air Temperature

-60 to 120°F

3 (0x0003)

Indoor Air/Return Temperature

40 to 220°F

4 (0x0004)

Fire Rate Out

0 to 100% (out to boilers)

5 (0x0005)

Header Set Temperature

40 to 220°F

6 (0x0006)

Network Address

128 to 247

Default = 128

7 (0x0007)

Total Boilers Fired

0 to 32 (for ACS)

8 (0x0008)

Total Boilers On Line

0 to 32

9 (0x0009)

(Reserved)

0 to 65535

5 = 4-20mA Input Error

11 (0x000B)

15 (0x000F)

16 (0x0010)

Lead Boiler Number

1 to 32

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

2.4 ACS CONTROLLER (ONLY) STANDARD REGISTER ASSIGNMENTS

IMPORTANT!

All Modbus addresses specified in the following tables are written

generically in hexadecimal format. However, many Building

Automation Systems utilize another form of addressing where: 40001

is added to the generic address for a Holding Register address.

And

30001 is added to the generic address for an Input Register address.

Be sure to check the addressing scheme being used by the BAS that

is being interfaced to the ACS.

2.4.1 ACS Controller Standard Input Register Assignments

The Read Only Input Register assignments for the ACS are listed in Table 2-4 which follows:

Table 2-4: ACS Standard Input Register Address Mapping

Address

10 (0x000A)

Menu Item Units and Range

Fault/Message Code

Bit:

0 = Outside Air Sensor

1 = Header Sensor Error

2 = Interlock 1 Error

3 = Interlock 2 Error

4 = Indoor Air Sensor Error/

Return Sensor Error

Default/

Comments

thru

Page 36 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

(Reserved)

Page 37

Chapter 2

Decimal (Hex)

17 (0x0011)

24 (0x0018)

Used for 8 ACS

Boilers Only

119 = Not On-Line

122 = On-Line But Faulted

ACS has only

Boiler 2 Status

(Net Boiler 2)

Boiler 3 Status

(Net Boiler 3)

Boiler 4 Status

(Net Boiler 4)

Boiler 5 Status

(Net Boiler 5)

Boiler 6 Status

(Net Boiler 6)

Boiler 7 Status

(Net Boiler 7)

Boiler 8 Status

(Net Boiler 8)

Boiler 9 Status

(Net Boiler 9)

Boiler 10 Status

(Net Boiler 10)

Boiler 11 Status

(Net Boiler 11)

Boiler 12 Status

(Net Boiler 12)

Boiler 13 Status

(Net Boiler 13)

Boiler 14 Status

(Net Boiler 14)

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

Table 2-4: ACS Standard Input Register Address Mapping (Cont.)

OMM-0035_0C

Modbus Data

Address

Thru

25 (0x0019)

26 (0x001A)

27 (0x001B)

28 (0x001C)

29 (0x001D)

Menu Item Units and Range

Not Applicable

Boiler 1 Status

(Net Boiler 1)

120 = On-Line But Not Fired

1–40 = Fired & Sequence

121 = On-Line But Disabled

Same As Above

Same As Above

Same As Above

Same As Above

Default/

Comments

Legacy (PWM)

Network Boilers

so Net Boiler 1

= Boiler 1, etc.

30 (0x001E)

31 (0x001F)

32 (0x0020)

33 (0x0021)

34 (0x0022)

35 (0x0023)

36 (0x0024)

37 (0x0025)

38 (0x0026)

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 37 of 200

Page 38

GF-114

Decimal (Hex)

119 = Not On-Line

122 = On-Line But Faulted

Boiler 16 Status

(Net Boiler 16)

Boiler 17 Status

(Net Boiler 17)

Boiler 18 Status

(Net Boiler 18)

Boiler 19 Status

(Net Boiler 19)

Boiler 20 Status

(Net Boiler 20)

Boiler 21 Status

(Net Boiler 21)

Boiler 22 Status

(Net Boiler 22)

Boiler 23 Status

(Net Boiler 23)

Boiler 24 Status

(Net Boiler 24)

Boiler 25 Status

(Net Boiler 25)

Boiler 26 Status

(Net Boiler 26)

Boiler 27 Status

(Net Boiler 27)

Boiler 28 Status

(Net Boiler 28)

Boiler 29 Status

(Net Boiler 29)

Boiler 30 Status

(Net Boiler 30)

OMM-0035_0C USER MANUAL Standard Register Assignments

MODBUS

Communication Chapter 2

Table 2-4: ACS Standard Input Register Address Mapping (Cont.)

Modbus Data

Address

39 (0x0027)

40 (0x0028)

41 (0x0029)

42 (0x002A)

43 (0x002B)

44 (0x002C)

45 (0x002D)

Menu Item Units and Range

Boiler 15 Status

(Net Boiler 15)

120 = On-Line But Not Fired

1–40 = Fired & Sequence

121 = On-Line But Disabled

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Default/

Comments

46 (0x002E)

47 (0x002F)

48 (0x0030)

49 (0x0031)

50 (0x0032)

51 (0x0033)

52 (0x0034)

53 (0x0035)

54 (0x0036)

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Same As Above

Page 38 of 200 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph.: 800-526-0288 05/18/12

Page 39

Chapter 2

Decimal (Hex)

119 = Not On-Line

Faulted

Boiler 32 Status

(Net Boiler 32)

Bit map of Input/Output

Bit 7 = Empty

When Ret Sensor Mode

= Normal

When Blr Cntl Type = 1

or 2

60 (0x003C)

Net Blr 2 Outlet Temp

40°F to 220°F

61 (0x003D)

Net Blr 3 Outlet Temp

40°F to 220°F

62 (0x003E)

Net Blr 4 Outlet Temp

40°F to 220°F

63 (0x003F)

Net Blr 5 Outlet Temp

40°F to 220°F

64 (0x0040)

Net Blr 6 Outlet Temp

40°F to 220°F

65 (0x0041)

Net Blr 7 Outlet Temp

40°F to 220°F

66 (0x0042)

Net Blr 8 Outlet Temp

40°F to 220°F

67 (0x0043)

Net Blr 9 Outlet Temp

40°F to 220°F

68 (0x0044)

Net Blr 10 Outlet Temp

40°F to 220°F

Standard Register Assignments USER MANUAL

MODBUS

Communication GF-114

Table 2-4: ACS Standard Input Register Address Mapping (Cont.)

OMM-0035_0C

Modbus Data

Address

55 (0x0037)

56 (0x0038)

57 (0x0039) I/O Status 00 to 255

Menu Item Units and Range

120 = On-Line But Not

Fired

Boiler 31 Status

(Net Boiler 31)

1–40 = Fired &

Sequence

121 = On-Line But

Disabled

122 = On-Line But

Same As Above

Default/

Comments

Status:

Bit 0 = AUX Relay

Bit 1 = Fault Relay

Bit 2 = Sys Start Relay

Bit 3 = Empty

Bit 4 = Setback

Bt 5 = Interlock 2

Bit 6 = Interlock 1

58 (0x003A) Return Sensor Temp 40°F to 220°F

59 (0x003B) Net Blr 1 Outlet Temp 40°F to 220°F

05/18/12 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288 Page 39 of 200

Page 40

GF-114

Decimal (Hex)

69 (0x0045)

Net Blr 11 Outlet Temp

40°F to 220°F