Page 1

KC Series Gas-Fired Boiler

USER MANUAL

Applicable to Serial Number G-11-0695 and above

KC Series

Gas Fired

GF-109

OMM-0016_0B

Boiler System

Semi-Instantaneous, Condensing,

Forced Draft,

Natural Gas and Propane Fired,

Hot Water Boiler

1,000,000 BTU/HR Input

Patent No. 4,852,524

REVISED JULY 7, 2011

Page 2

KC Series Gas-Fired Boiler

USER MANUAL

Telephone Support

Direct to AERCO Technical Support

(8 to 5 pm EST, Monday through Friday)

(800) 526-0288

GF-109

OMM-0016_0B

AERCO International, Inc.

100 Oritani Drive

Blauvelt, New York 10913

www.aerco.com

© AERCO International, Inc., 2011

The information contained in this operation and maintenance manual is subject to

change without notice from AERCO International, Inc.

AERCO makes no warranty of any kind with respect to this material, including but not

limited to implied warranties of merchantability and fitness for a particular application.

AERCO International is not liable for errors appearing in this manual. Nor for

incidental or consequential damages occurring in connection with the furnishing,

performance, or use of this material.

Printed in U.S.A.

Page 3

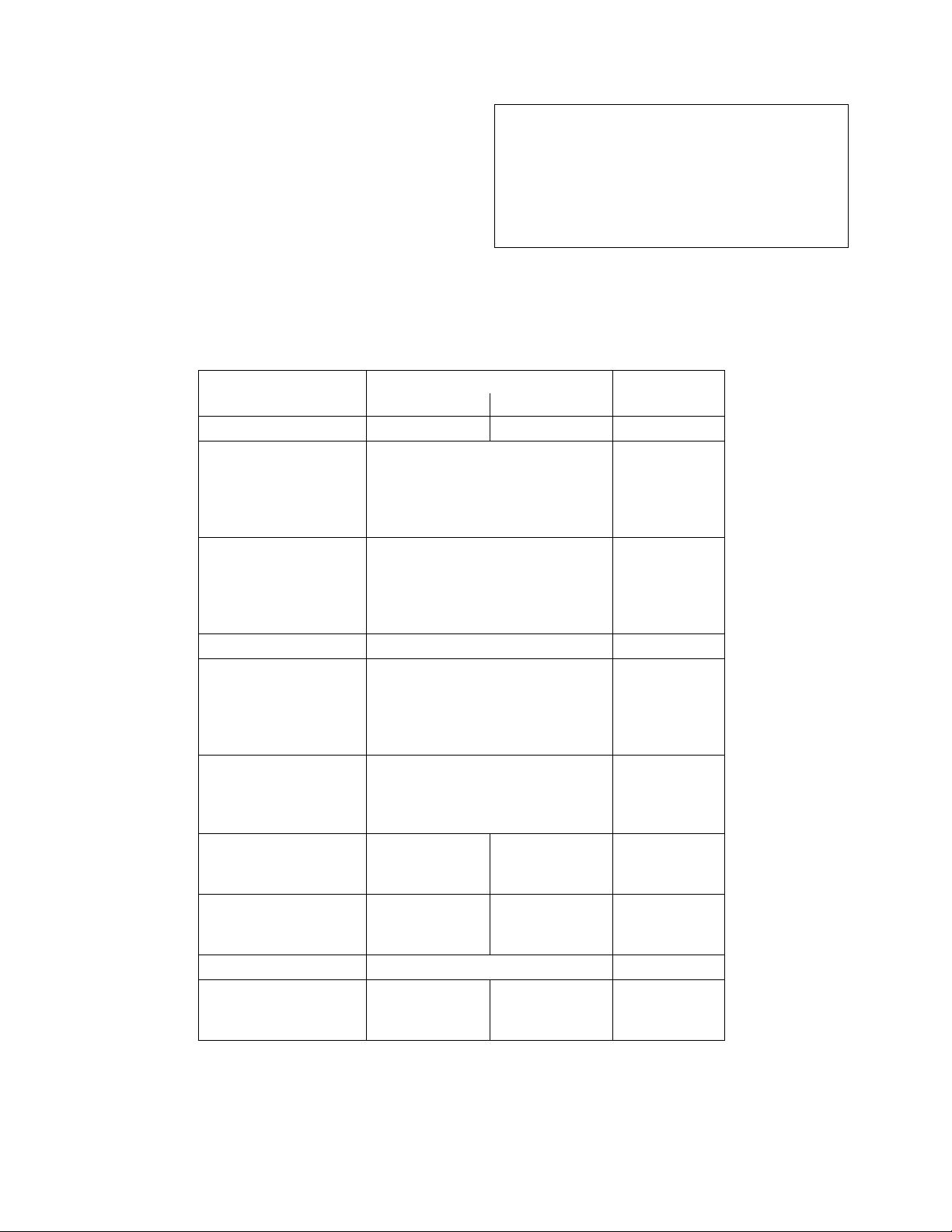

CONTENTS

Para.

Subject

Page

1.1

Warnings & Cautions

1-1

1.2

Emergency Shutdown

1-2

Para.

Subject

Page

1.3

Prolonged Shutdown

1-2

Para.

Subject

Page

2.1

Receiving the Unit

2-1

2.2

Unpacking

2-1

2.3

Installation

2-2

2.4

Gas Supply Piping

2-4

2.5

Electrical Supply

2-5

Control Wiring

Para.

Subject

Page

2.7

I/O Box Connections

2-8

2.8

Auxiliary Relay Contacts

2-10

2.9

Flue Gas Vent Installation

2-10

2.10

Combustion Air

2-10

Para.

Subject

Page

3.1

Introduction

3-1

3.2

Control Panel Description

3-1

3.3

Control Panel Menus

3-3

3.4

Operating Menu

3-4

3.5

Setup Menu

3-4

Para.

Subject

Page

3.6

Configuration Menu

3-5

3.7

Tuning Menu

3-6

3.8

Start Sequence

3-7

3.9

Start/Stop Levels

3-9

Para.

Subject

Page

4.1

Initial Startup Requirements

4-1

4.2

Tools and Instrumentation for

Combustion Calibration

4-1

4.3

Combustion Calibration

4-2

Para.

Subject

Page

4.4

Propane Combustion Calibration

4-5

4.5

Unit Reassembly

4-6

4.6

Over-Temperature Limit Switch

Adjustments

4-6

Para.

Subject

Page

5.1

Introduction

5-1

5.2

Indoor/Outdoor Reset Mode

5-1

5.3

Constant Setpoint Mode

5-2

5.4

Remote Setpoint Modes

5-2

5.5

Direct Drive Modes

5-3

Para.

Subject

Page

(BMS)

(CCS)

GF-109 - THE AERCO KC1000 GAS FIRED BOILER

Operating & Maintenance Instructions

FOREWARD A

SECTION 1 – SAFETY PRECAUTIONS 1-1

SECTION 2 – INSTALLATION PROCEDURES 2-1

2.6 Mode of Operation and Field

2-6

SECTION 3 – CONTROL PANEL OPERATING PROCEDURES 3-1

SECTION 4 – INITIAL START-UP 4-1

Section 5 – MODE OF OPERATION 5-1

5.6 Boiler Management System

5.7

Combination Control System

5-4

5-5

i

Page 4

CONTENTS

Para.

Subject

Page

6.1

Testing of Safety Devices

6-1

6.2

Low Gas Pressure Fault Test

6-1

6.3

High Gas Pressure Fault Test

6-1

6.4

Low Water Level Fault Test

6-2

6.5

Water Temperature Fault Test

6-2

6.6

Interlock Fault Tests

6-3

6.7

Flame Fault Test

6-3

Para.

Subject

Page

6.8

Air Flow Fault Test

6-4

6.9

SSOV Proof of Closure Switch

6-4

6.10

Purge Switch Open During

Purge

6-5

6.11

Ignition Switch Open During

Ignition

6-5

6.12

Safety Pressure Relief Valve

Test

6-6

Para.

Subject

Page

7.1

Maintenance Schedule

7-1

7.2

Spark Ignitor

7-1

7.3

Flame Detector

7-2

7.4

Combustion Calibration

7-2

Para.

Subject

Page

7.5

Safety Device Testing

7-2

7.6

Manifold and Exhaust Tubes

7-2

7.7

Heat Exchanger Water Side

Injection

7-5

7.8

Condensate Drain Assembly

7-6

Para.

Subject

Page

8.1

Introduction

8-1

Para.

Subject

Page

Para.

Subject

Page

9.1

Introduction

9-1

9.2

RS232 Communication Setup

9-1

Para.

Subject

Page

RS232 Communication

9.4

Data Logging

9-2

App

Subject

Page

A

Boiler Menu Item Descriptions

A-1

B

Startup, Status and Fault

Messages

B-1

C

Temperature Sensor Resistance

Chart

C-1

D

Indoor/Outdoor Reset Ratio

Charts

D-1

App

Subject

Page

E

Boiler Default Settings

E-1

F

Dimensional and Part Drawings

F-1

G

Piping Drawings

G-1

H

Wiring Schematics

H-1

I

KC1000 Control Panel Views

I-1

J

Recommended Spare Parts

J-1

SECTION 6 – SAFETY DEVICE TESTING PROCEDURES 6-1

SECTION 7 – MAINTENANCE 7-1

SECTION 8 – TROUBLESHOOTING 8-1

SECTION 9 – RS232 COMMUNICATION 9-1

9.3 Menu Processing Utilizing

9-1

APPENDICES

WARRANTIES W-1

ii

Page 5

FOREWORD

Foreword

The AERCO KC boiler is a true industry advance that meets the needs of today's energy and

environmental concerns. Designed for application in any closed loop hydronic system, the load

tracking capability relates energy input directly to fluctuating system loads through a 20:1

modulating turndown ratio for natural gas units and 14:1 for propane units. The boiler’s

condensing capability offers extremely high efficiencies and makes the KC boiler ideally suited

for modern low temperature, as well as, conventional heating systems.

The KC boiler can be used singular or in modular arrangements for inherent standby with

minimum space requirements. Venting capabilities offer maximum flexibility and allow

installation without normal restrictions. The advanced electronics of each boiler module offer

selectable modes of operation and interface capabilities.

After prolonged shutdown, it is recommended that the startup procedures in Section 4 and test

procedures in Section 6 of this manual be performed, to verify system operating parameters. If

there is an emergency, turn off the electrical power supply to the Aerco boiler or close the

manual gas valve located before the unit. The installer is to identify the emergency shut-off

device. FOR SERVICE OR PARTS, contact your local sales representative or AERCO

INTERNATIONAL.

NAME:

ORGANIZATION:

ADDRESS:

TELEPHONE:

INSTALLATION DATE: _____________________________________________

A

Page 6

Page 7

SAFETY PRECAUTIONS

SECTION 1 -- SAFETY PRECAUTIONS

1.1 WARNINGS & CAUTIONS

Installers and operating personnel MUST, at all

times, observe all safety regulations. The

following warnings and cautions are general and

must be given the same attention as specific

precautions included in these instructions. In

addition to all the requirements included in this

AERCO Instruction Manual, the installation of

units MUST conform with local building codes,

or, in the absence of local codes, ANSI Z223.1

(National Fuel Gas Code Publication No. NFPA-

54) for gas-fired boilers and ANSI/NFPASB for

LP gas-fired boilers. Where applicable, the

equipment shall be installed in accordance with

the current Installation Code for Gas Burning

Appliances and Equipment, CSA B149.1, and

applicable Provincial regulations for the class;

which should be carefully followed in all cases.

Authorities having jurisdiction should be

consulted before installations are made.

See pages 1-2, 1-3 and 1-4 for important

information regarding installation of units

within the Commonwealth of Massachusetts.

IMPORTANT

This Instruction Manual is an integral

part of the product and must be

maintained in legible condition. It must

be given to the user by the installer

and kept in a safe place for future

reference.

WARNINGS

MUST BE OBSERVED TO PREVENT

SERIOUS INJURY.

WARNING

BEFORE ATTEMPTING TO

PERFORM ANY MAINTENANCE ON

THE UNIT, SHUT OFF ALL GAS AND

ELECTRICAL INPUTS TO THE UNIT.

WARNING

DO NOT USE MATCHES, CANDLES,

FLAMES, OR OTHER SOURCES OF

IGNITION TO CHECK FOR GAS

LEAKS.

WARNING

A DOUBLE-POLE SWITCH MUST BE

INSTALLED ON THE ELECTRICAL

SUPPLY LINE OF THE UNIT. THE

SWITCH MUST BE INSTALLED IN

AN EASILY ACCESSIBLE POSITION

TO QUICKLY AND SAFELY DISCONNECT ELECTRICAL SERVICE.

DO NOT AFFIX SWITCH TO UNIT

SHEET METAL ENCLOSURES.

WARNING

THE EXHAUST VENT PIPE OF THE

UNIT OPERATES UNDER A POSITIVE PRESSURE AND THEREFORE MUST BE COMPLETELY

SEALED TO PREVENT LEAKAGE

OF COMBUSTION PRODUCTS INTO

LIVING SPACES.

WARNING

FLUIDS UNDER PRESSURE MAY

CAUSE INJURY TO PERSONNEL

OR DAMAGE TO EQUIPMENT

WHEN RELEASED. BE SURE TO

SHUT OFF ALL INCOMING AND

OUTGOING WATER SHUTOFF

VALVES. CAREFULLY DECREASE

ALL TRAPPED PRESSURES TO

ZERO BEFORE PERFORMING

MAINTENANCE.

WARNING

ELECTRICAL VOLTAGES OF 120

VAC ARE USED IN THIS EQUIPMENT. THEREFORE THE COVER

ON THE UNIT’S POWER BOX

(LOCATED ON THE FRONT RIGHT

SIDE OF THE UNIT UNDER THE

HOOD AND SHEET METAL SIDE

PANEL) MUST BE INSTALLED AT

ALL TIMES, EXCEPT DURING

MAINTENANCE AND SERVICING.

CAUTIONS

Must be observed to prevent equipment damage or loss of operating

effectiveness.

1-1

Page 8

SAFETY PRECAUTIONS

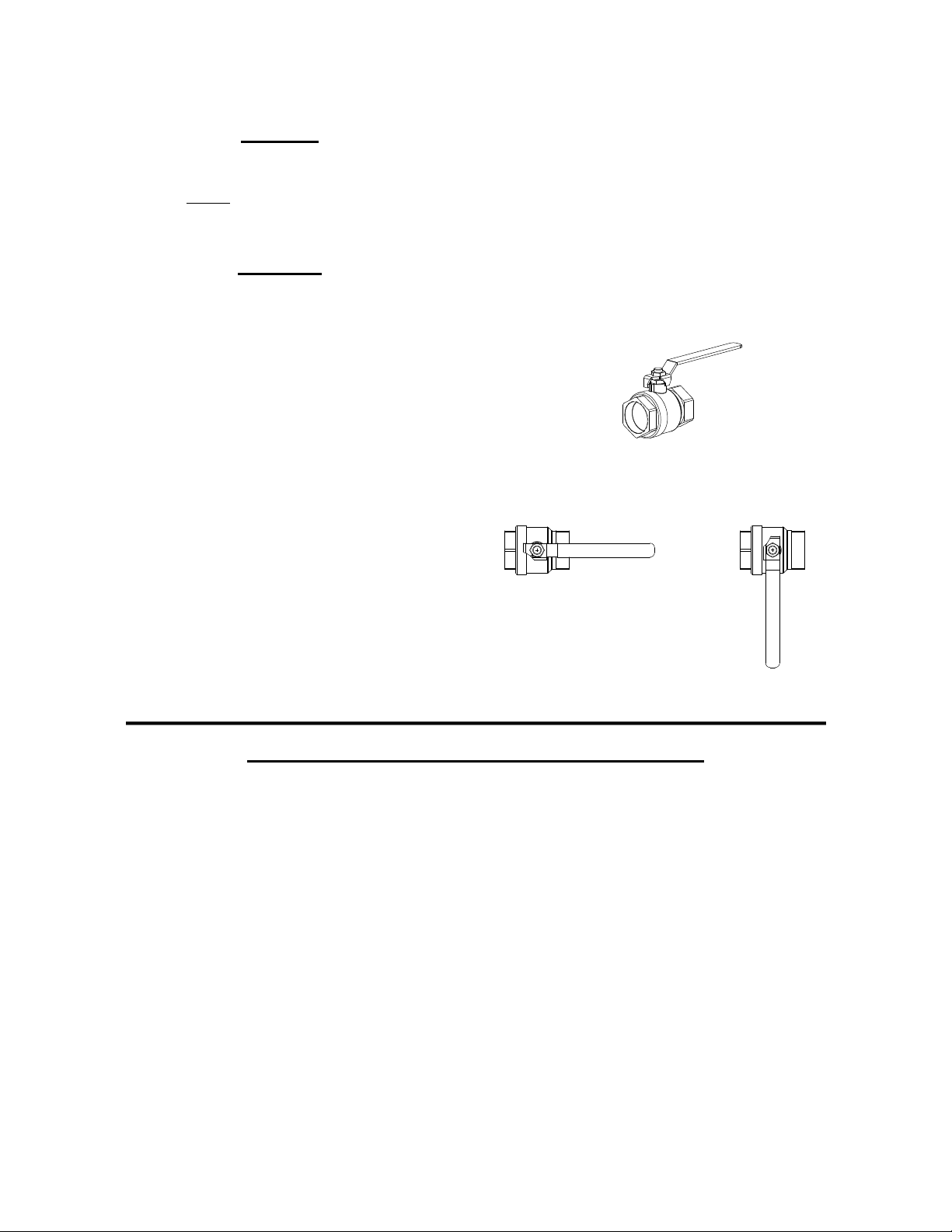

MANUAL GAS SHUTOFF VALVE

VALVE OPEN

VALVE CLOSED

CAUTION

Many soaps used for gas pipe leak

testing are corrosive to metals. The

piping must

be rinsed thoroughly with

clean water after leak checks have

been completed.

CAUTION!

DO NOT use this boiler if any part has

been under water. Call a qualified

service technician to inspect and

replace any part that has been under

water.

1.2 EMERGENCY SHUTDOWN

If overheating occurs or the gas supply fails to

shut off, close the manual gas shutoff valve

(Figure 1-1) located external to the unit.

IMPORTANT

The Installer must identify and indicate

the location of the emergency shutdown

manual gas valve to operating personnel.

1.3 PROLONGED SHUTDOWN

After prolonged shutdown, it is recommended

that the startup procedures in Chapter 4 and the

safety device test procedures in Chapter 5 of

this manual be performed, to verify all systemoperating parameters. If there is an emergency,

turn off the electrical power supply to the

AERCO boiler and close the manual gas valve

located upstream the unit. The installer must

identify the emergency shut-off device.

Boiler Installations within the Commonwealth of Massachusetts must conform to the following

requirements:

• Boiler must be installed by a plumber or a gas fitter who is licensed within the Commonwealth of

• Prior to unit operation, the complete gas train and all connections must be leak tested using a

• If a glycol solution is used as anti-freeze protection, a backflow preventer must be installed

• The vent termination must be located a minimum of 4 feet above grade level.

• If side-wall venting is used, the installation must conform to the following requirements extracted

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or

structure used in whole or in part for residential purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet above

finished grade in the area of the venting, including but not limited to decks and porches, the following

requirements shall be satisfied:

Figure 1-1: Manual Gas Shutoff Valve

IMPORTANT – FOR MASSACHUSETTS INSTALLATIONS

Massachusetts.

non-corrosive soap.

upstream of the Fill/Makeup Valve.

from 248 CMR 5.08 (2):

1-2

Page 9

SAFETY PRECAUTIONS

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the

side wall horizontal vented gas fueled equipment, the installing plumber or gasfitter shall observe

that a hard wired carbon monoxide detector with an alarm and battery back-up is installed on the

floor level where the gas equipment is to be installed. In addition, the installing plumber or

gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with an

alarm is installed on each additional level of the dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to

secure the services of qualified licensed professionals for the installation of hard wired carbon

monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in

a crawl space or an attic, the hard wired carbon monoxide detector with alarm and

battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of

completion of installation, the owner shall have a period of thirty (30) days to comply with

the above requirements; provided, however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as

required in accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior

of the building at a minimum height of eight (8) feet above grade directly in line with the exhaust

vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign

shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled

equipment shall not approve the installation unless, upon inspection, the inspector observes

carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR

5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the

most current edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or

structure separate from the dwelling, building or structure used in whole or in part for residential

purposes.

(c) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When

the manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting

system design or venting system components with the equipment, the instructions provided by the

manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system

components; and

2. A complete parts list for the venting system design or venting system.

1-3

Page 10

SAFETY PRECAUTIONS

(d) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side wall horizontally vented gas fueled equipment does

not provide the parts for venting the flue gases, but identifies "special venting systems", the following

requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or

equipment installation instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions

for that system shall include a parts list and detailed installation instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for venting instructions, and/or all venting design

instructions shall remain with the appliance or equipment at the completion of the installation.

_______________________________ [End of Extracted Information From 248 CMR 5.08 (2)

1-4

Page 11

SECTION 2 - INSTALLATION PROCEDURES

2.1. RECEIVING THE UNIT

Each KC1000 Boiler is shipped as a single

crated unit. The crated unit shipping weight is

approximately 1500 pounds. It must be moved

with the proper rigging equipment for safety and

to avoid unit damages. The unit should be

completely inspected for shipping damage and

completeness at the time of receipt from the

carrier and before the bill of lading is signed.

Each unit has Tip-N-Tell indicator on the outside

of the crate, that indicates if the unit has been

turned on its side. If the Tip-N-Tell indicator is

tripped, do not sign for the shipment. Request a

freight claim and inspection by a claims adjuster

before proceeding or refuse delivery of the

equipment.

2.2. UNPACKING

Carefully unpack the unit. Take care not to

damage the unit jacket when cutting away

packaging materials. An inspection of the unit

should be made to determine if damage during

shipment occurred that was not indicated by the

Tip-N-Tell. The freight carrier should be notified

INSTALLATION

immediately if any damage is detected. The

following accessories come standard with each

unit and are packed separately within the unit’s

packing container

• Spare Spark Ignitor

• Spare Flame Detector

• Manual 1-1/4" Gas Shutoff Valve

• Drain Valve Assembly

• ASME Pressure Relief Valve

• Ignitor Removal Tool (One per Site)

• Temperature/Pressure Gauge and Fittings

• 2 Lifting Lugs

• Stainless Steel Condensate Cup

• Shell Cap

• Wing Nut for Shell Cap

Optional accessories are also separately packed

within the unit’s packing container. Standard and

optional accessories shipped with the unit

should be identified and put in a safe place until

installation or use.

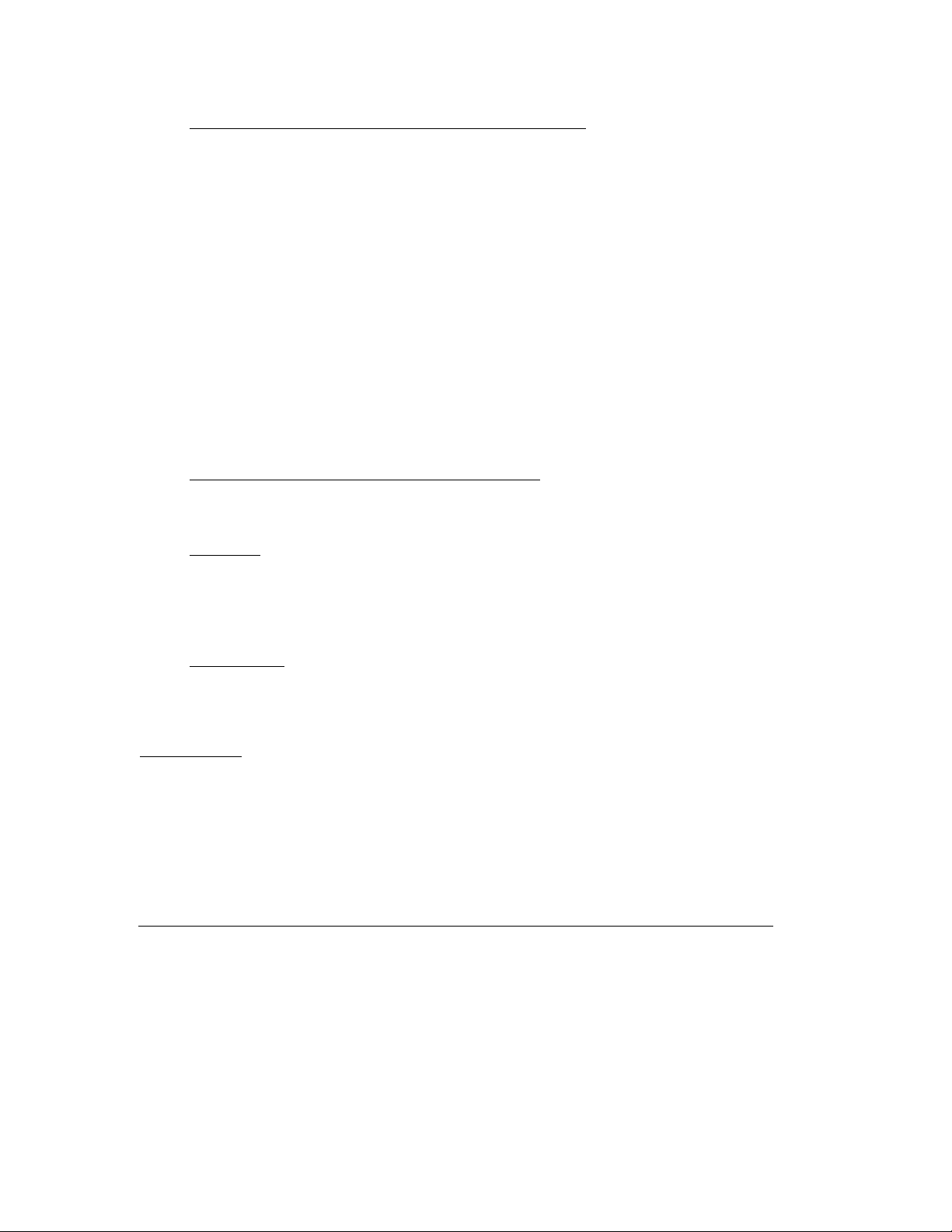

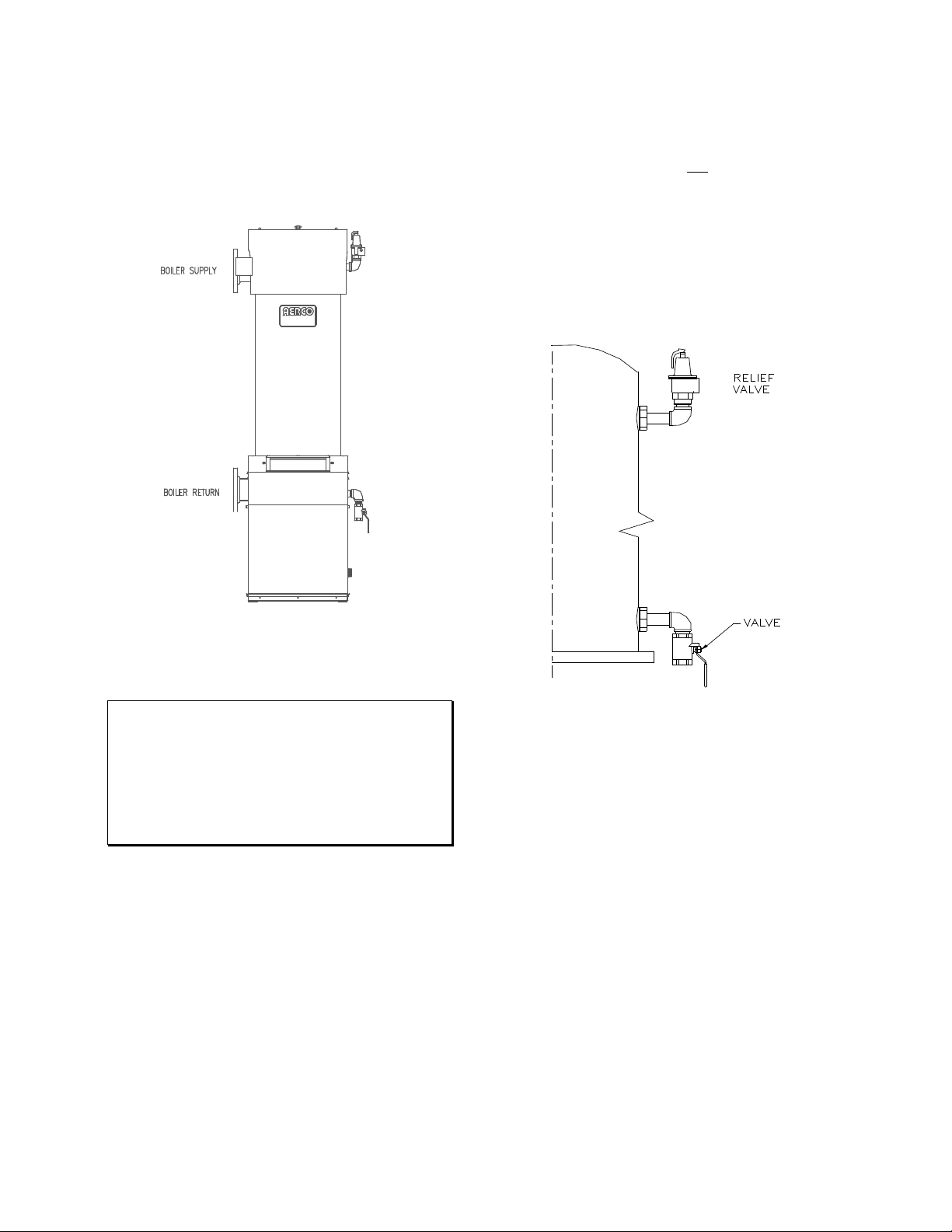

Figure 2.1. Boiler Clearances

2-1

Page 12

INSTALLATION

LIFTING LUGS

2.3 INSTALLATION

The unit must be installed with the prescribed

clearances for service as shown in Figure 2.1.

The minimum

AERCO, are listed below. Local building codes

may require more clearance and take

precedence

Minimum clearances required:

Sides 24"

Front 18"

Rear 18"

Top 18"

All gas piping, water piping, and electrical

conduit or cable must be arranged so that they

do not interfere with the removal of any cover, or

inhibit service or maintenance of the unit.

KEEP UNIT AREA CLEAR AND FREE

FROM COMBUSTIBLE MATERIALS AND

FLAMMABLE VAPORS AND LIQUIDS.

MASSACHUSETTS INSTALLATIONS

For boiler installations within the

Commonwealth of Massachusetts, the

boiler must be installed by a plumber or

gas fitter who is licensed within the

Commonwealth. In addition, the boiler

installation must comply with all

requirements specified in Section 1

(Safety Precautions), pages 1-2 and 1-3.

2.3.1. SETTING THE UNIT

Remove the unit from the wooden skid and

place in position using a block and tackle or

hoist attached to the lifting lugs, (see Figure

2.2). USE ONLY THE LIFTING LUGS TO

MOVE THE UNIT.

The KC-1000 is U/L approved for installation on

combustible flooring. A 4” to 6" high housekeeping concrete pad is recommended and

allows for sufficient drainage of the condensate.

It is suggested that units be secured using the

holes provided in the frame base. Piping must

not be used to secure the unit in place. See

drawing AP-A-568 in Appendix F for the base

frame dimensions.

clearance dimensions, required by

WARNING!

In multiple unit installations, it is important to

plan the position of each unit. Sufficient space

for piping connections and future maintenance

requirements must be given. All piping must

include ample provision for expansion.

If installing a Combination Control (CCP)

system, it is important to identify and place the

Combination Mode units in the proper physical

location.

Figure 2.2

Lifting Lug Location

2.3.2 SUPPLY AND RETURN PIPING

The locations of the 4" flanged system supply,

and return piping connections, to the unit are

shown in Figure 2.3. The return connection is

located on the left side near the base of the

unit’s shell. The supply connection is located on

the left side near the top of the unit’s shell.

Whether installing single or multiple units, install

the piping and accessories as shown in the

appropriate piping diagram located in the

Appendix G. For applications other than standard space heating, consult the AERCO Boiler

Application Guide, GF-1070, or AERCO for the

appropriate piping schematics.

The minimum flow rate through the unit is 25

GPM and the maximum flow rate is 150 GPM.

Each unit is fitted with 4" flanges for high flow

application and the system velocity at the unit

return should not exceed 5 feet per second.

Each unit must have individual valves on the

supply, and return, for maintenance. In multiple

unit installations, the flow through each unit must

be balanced.

2-2

Page 13

INSTALLATION

Every boiler plant must have a source of makeup water to it. As with any closed loop hydronic

system, air elimination and expansion equipment must be provided as part of the overall

installation. All piping MUST include ample

provision for expansion.

The relief piping must be full size without

reduction. No valves, restrictions, or other

blockages should be allowed in the discharge

line. In multiple unit installations the relief valve

discharge lines must not

(connected), together. Each must be individually

run to a suitable discharge location. The drain

valve provided should be installed on the right

hand side of the unit towards the bottom of the

shell. The valve should be pointed in the down

position, (see Figure 2.4).

be manifolded,

Figure 2.3

Supply and Return Location

NOTE:

The maximum working pressure for

installations within the Province of Alberta is

87 psig. Therefore a pressure relief valve

with a setting of 75 psig (or lower) should be

installed for these installations. See Drawing

AP-A-863 in Appendix F.

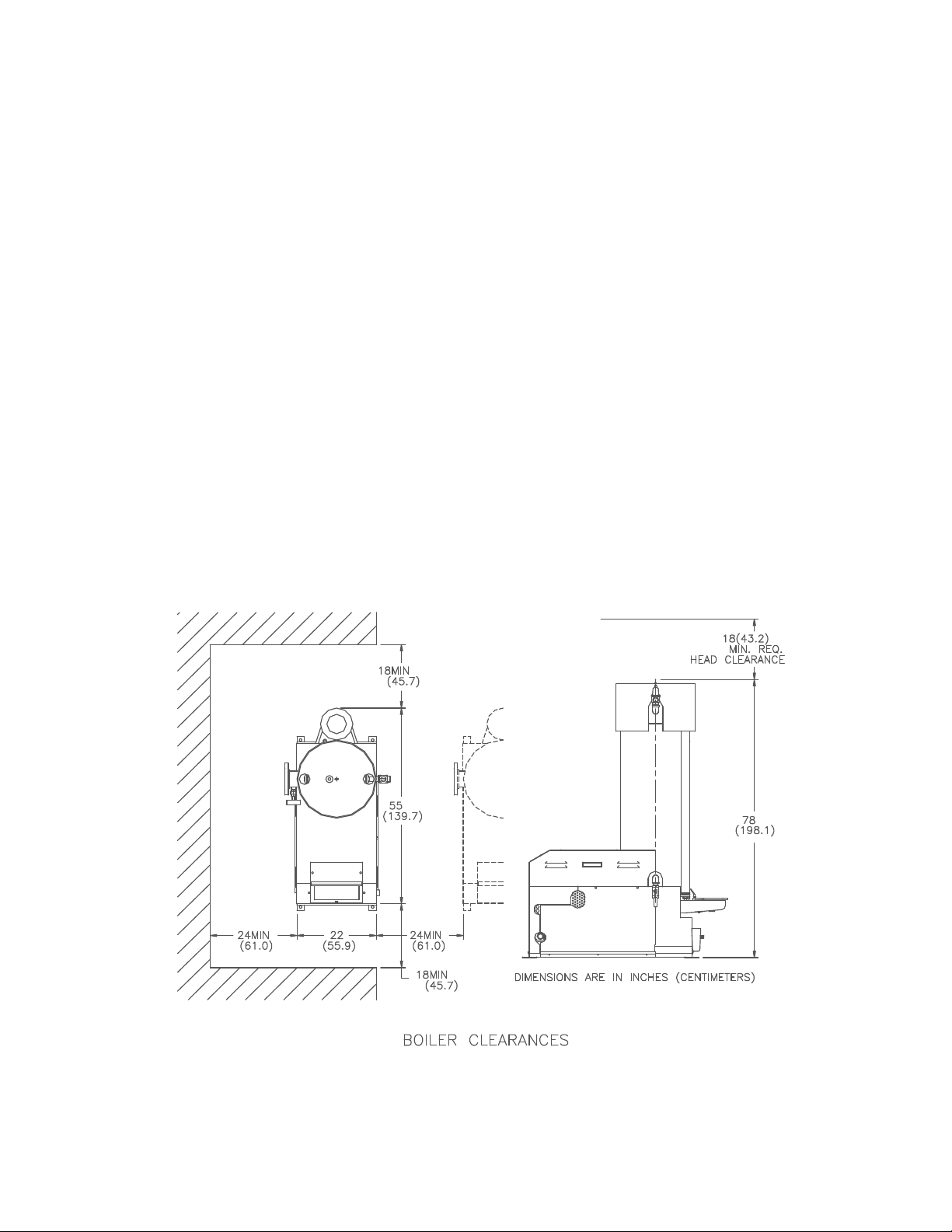

2.3.3 PRESSURE RELIEF AND DRAIN

VALVE INSTALLATION

An ASME rated Relief Valve is supplied with

each unit. The supplied pressure relief valve

setpoint will be 30, 50, 75, 100, or 150

ordered from the factory. Install the pressure

relief valve in the tapping provided opposite the

system supply connection, (see Figure 2.4). The

pressure relief valve should be piped in the

vertical position using the fittings supplied. A

suitable pipe compound should be used on the

threaded connections, and excess should be

wiped off to avoid getting any into the valve

body. The discharge from the relief valve should

be piped to within 12 inches of the floor to

prevent injury in the event of a discharge.

psig as

Figure 2.4

Relief and Drain Valve Location

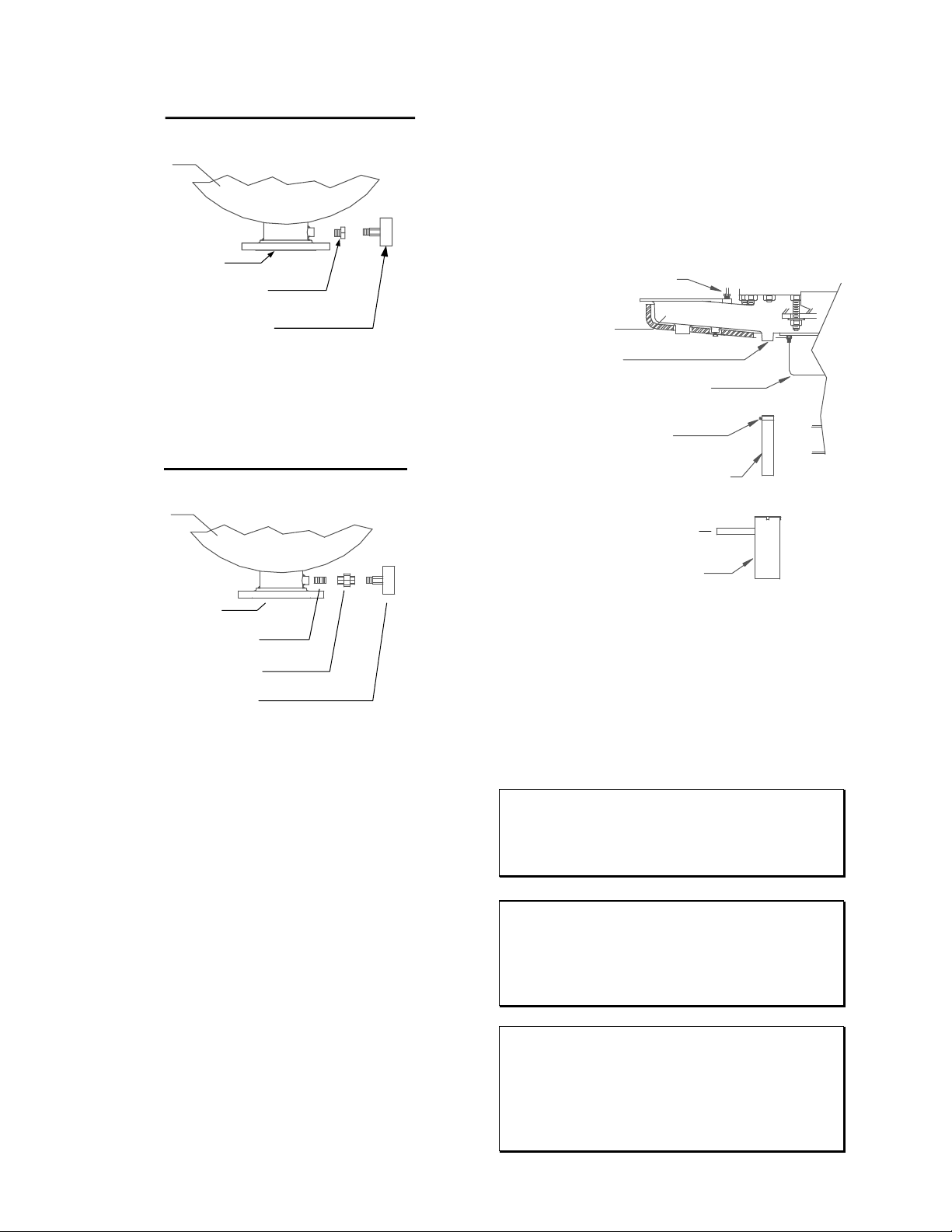

2.3.4 TEMPERATURE/PRESSURE

INDICATOR

The unit is supplied with one of two styles of

Temperature/Pressure Indicators that must be

installed in the tapping on the supply flange of

the unit (see Figures. 2.5a and 2.5b). A suitable

pipe compound should be used sparingly to the

threaded connection.

2-3

Page 14

INSTALLATION

SHELL

CAP

PARTIAL TOP VIEW OF BOILER

FOR INSTALLATION OF PRESS./TEMP. GAUGE

PART NO. 122994-1 (PRESS. RANGE 0 – 75 PSI)

SYSTEM

SUPPLY

1/2" x 1 /4"

REDUCING BUSHING

PRESS./TEMP. GAUGE

SHELL

CAP

PARTIAL TOP VIEW OF BOILER

FOR INSTALLATION OF PRESS./TEMP. GAUGE

PART NO. 122994-2 (PRESS. RANGE 0 – 200 PSI)

PART NO. 122994-3 (PRESS. RANGE 0 – 300 PSI)

SYSTEM

SUPPLY

1/2" NIPPLE

1/2" UNION

PRESS./TEMP. GAUGE

TEMPERATURE SENSOR

EXHAUST

MANIFOLD

CONDENSATE

DRAIN

BURNER

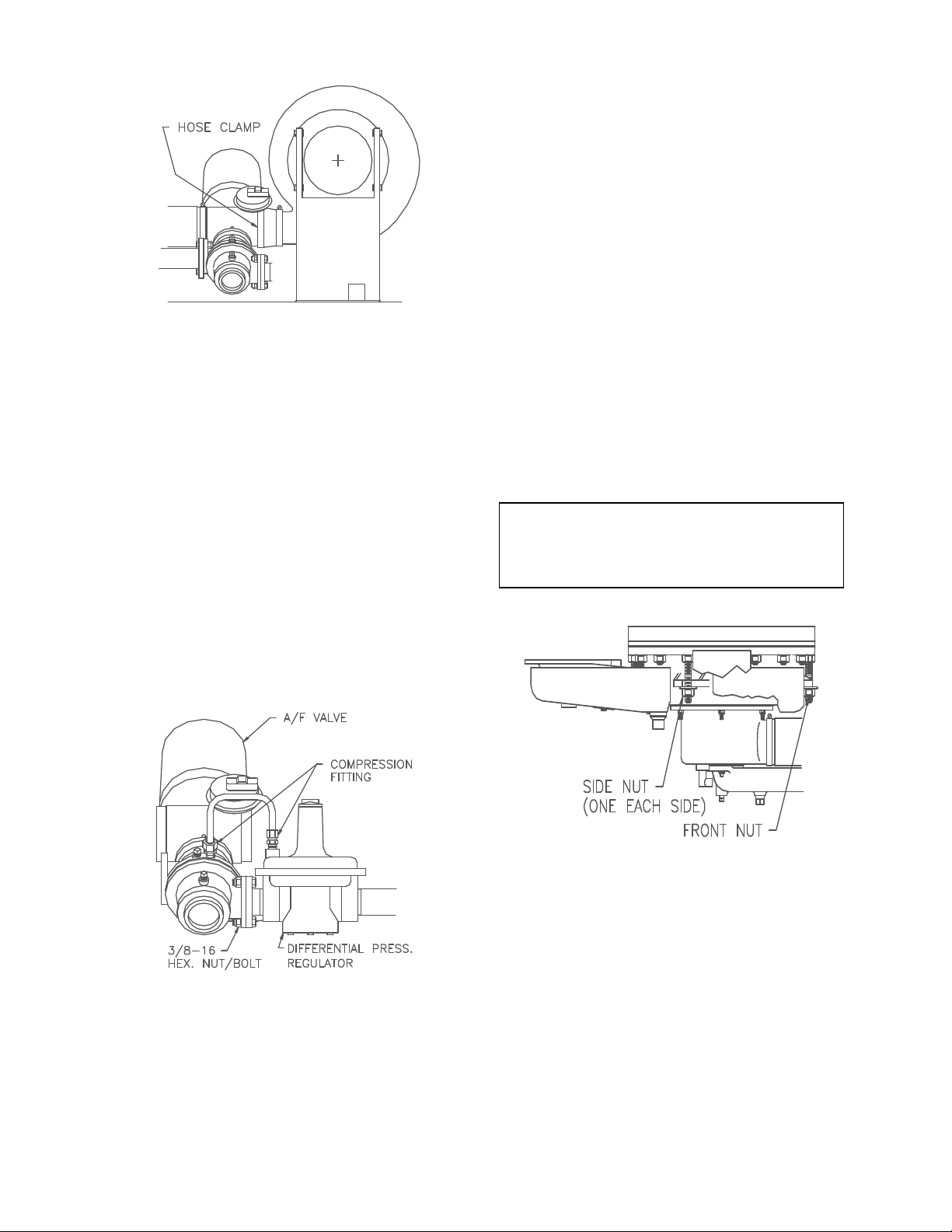

HOSE CLAMP

1-3/4" O.D. x 8-1 /2

“ LG.

SILICONE HOSE

5/8" O.D. TUBE CONN.

CONDENSATE CUP

PLACED ON FLOOR

Figure 2.5a

Pressure /Temperature Gauge Installation

route it to a floor drain. If a floor drain is not

available, a condensate pump can be used to

remove the condensate to drain. The

condensate drain line must be removable for

routine maintenance. Therefore, DO NOT hardpipe.

4. Replace the rear cover and side panel on the

unit.

Pressure/Temperature Gauge Installation

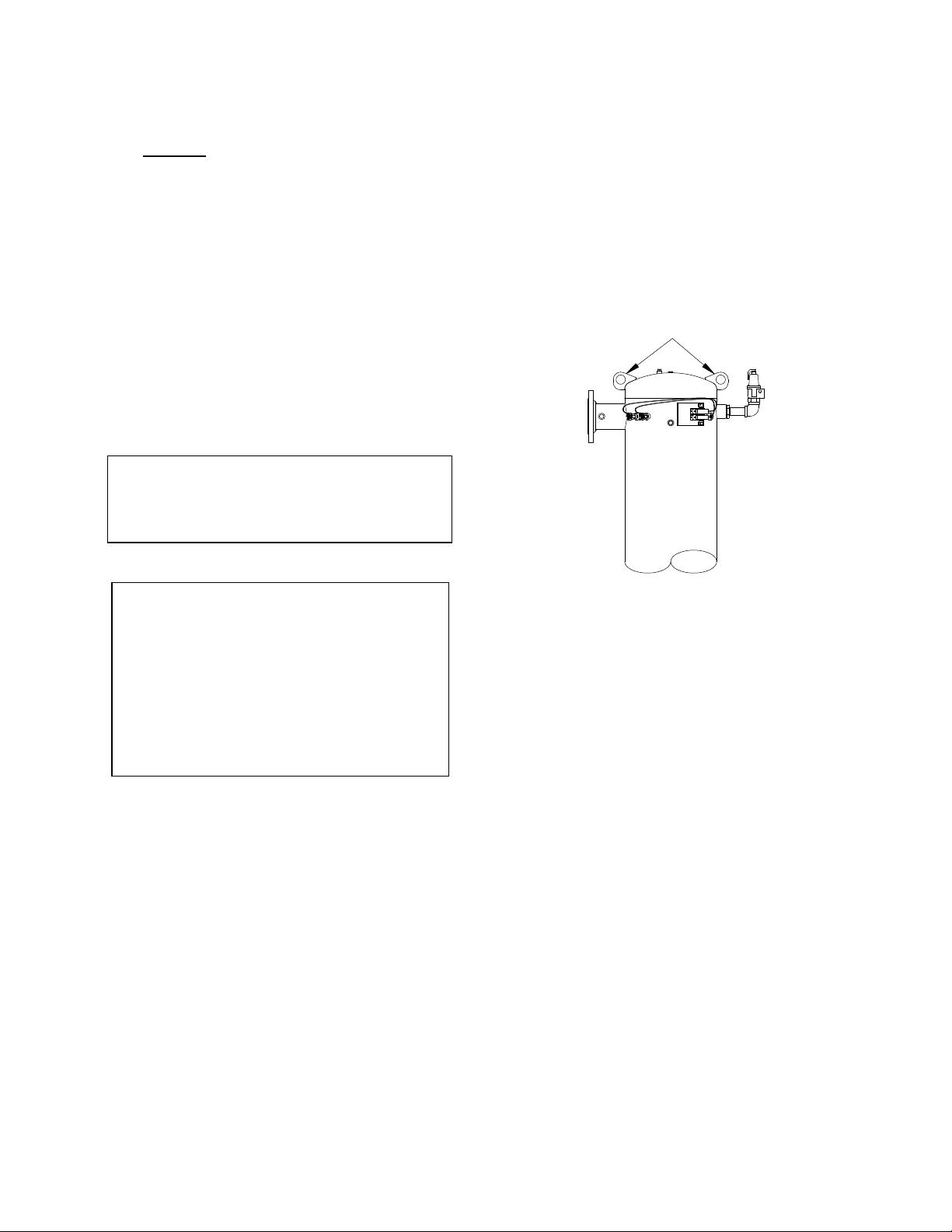

2.3.5 CONDENSATE PIPING

The KC Boiler is designed to condense.

Therefore, the installation site must include

suitable provisions for condensate drainage or

collection. A stainless steel condensate cup is

separately packed within the unit’s shipping

container. To install the condensate cup,

proceed as follows:

1. Remove the left side panel and only the left

half of the rear cover to provide access to the

exhaust manifold and burner (Figure 2.6).

2. Insert the 1-3/4 inch manifold drain hose into

the condensate cup. Allow the cup to rest on

the floor directly beneath the manifold drain

hole (Figure 2.6).

3. Attach a length of 3/4 inch I.D. polypropylene

tubing to the condensate cup drain tube and

2-4

Figure 2.5b

Figure 2.6

Condensate Drain System Location

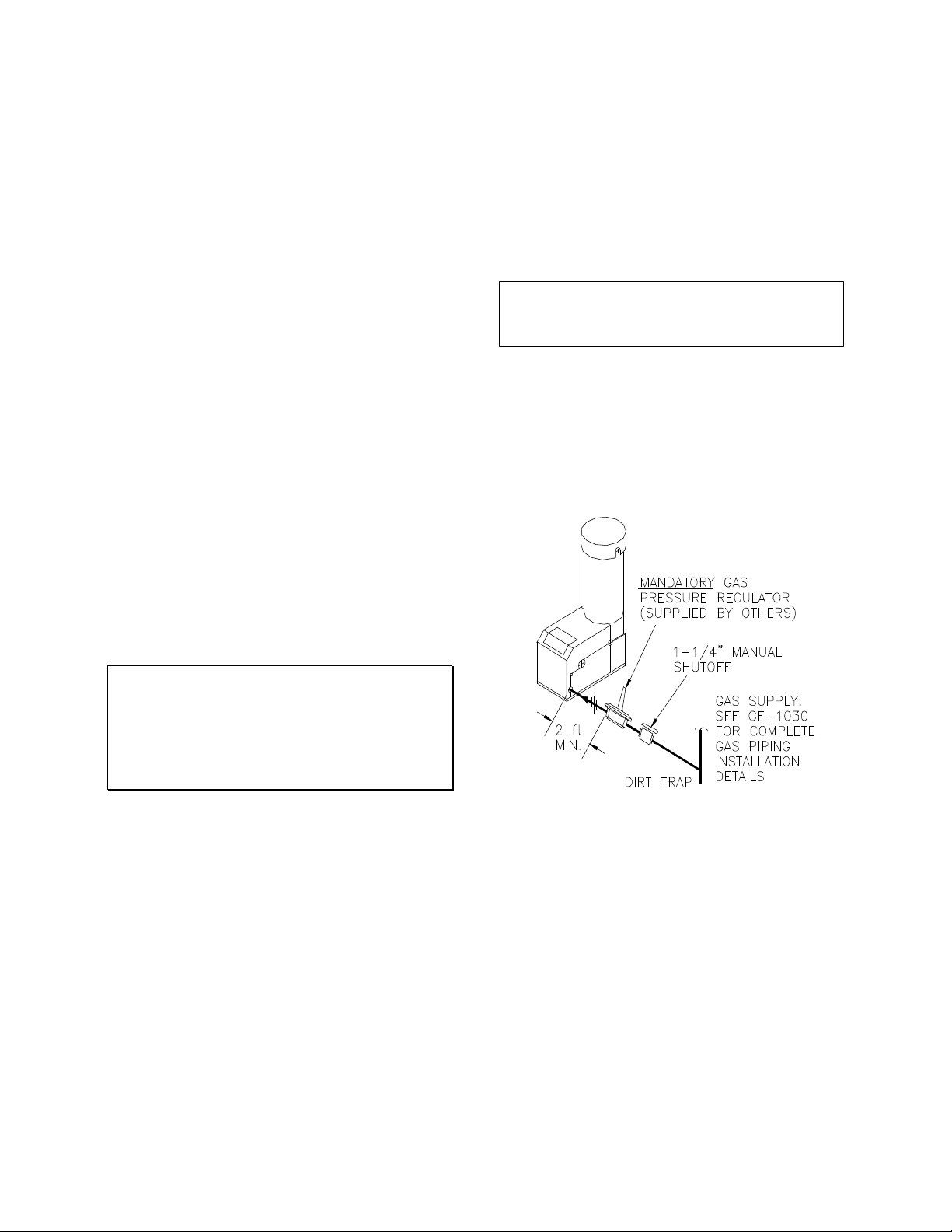

2.4. GAS SUPPLY PIPING

The AERCO Gas Fired Equipment Gas Components and Supply Design Guide (GF-1030) must be

consulted before any gas piping is designed or

started.

WARNING!

DO NOT USE MATCHES, CANDLES,

FLAMES OR OTHER SOURCES OF

IGNITION TO CHECK FOR GAS LEAKS.

CAUTION!

Soaps used for gas pipe leak testing can be

corrosive to metals. Piping must be rinsed

thoroughly with clean water after leak

checks have been completed.

NOTE:

All gas piping must be arranged so that it

does not interfere with removal of any

cover, inhibit service or maintenance, or

prevent access between the Unit and walls,

or another unit.

Page 15

INSTALLATION

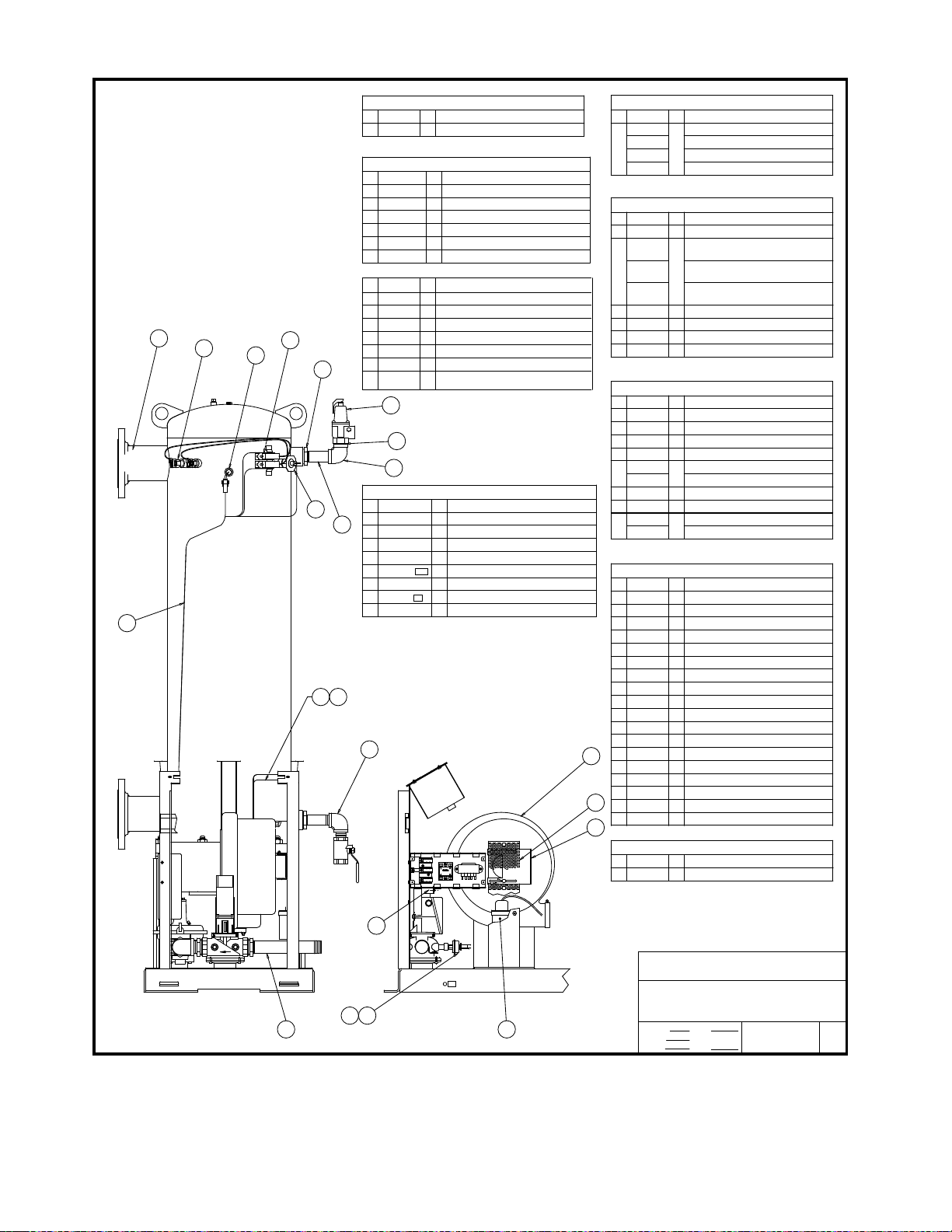

The location of the 1-1/4" inlet gas connection is

on the right side of the unit as shown in Figure

2.7.

All pipe should be de-burred and internally

cleared of any scale or iron chips before

installation. No flexible connectors or nonapproved gas fittings should be installed. Piping

should be supported from floor or walls only and

must not be secured to the unit.

A suitable piping compound, approved for use

with gas, should be used sparingly. Any excess

must be wiped off to prevent clogging of

components.

To avoid damage to the unit, when pressure

testing gas piping, isolate the unit from the

supply gas piping. At no time should there be

more than 14” W.C. the unit. Bubble test all

external piping thoroughly for leaks using a

soap and water solution or suitable equivalent.

The gas piping must meet all applicable codes.

it. When the gas supply pressure will not exceed

14” W.C. a non-lock up or flow through style

regulator may be used. When supply gas

pressure will exceed 14” W.C., a lock up style

regulator must be used. The gas supply

regulator must be propery vented to outdoors.

Consult the local gas utility for exact

requirements concerning venting of supply gas

regulators.

CAUTION!

A lockup style regulator must be used when

gas supply pressure exceeds 14” W.C.

2.4.2 MANUAL GAS SHUTOFF VALVE

A 1-1/4” manual gas shut-off valve is furnished

with each unit. The valve should be positioned

as shown in Figure 2.7. The manual gas shut-of

valve must be installed upstream of the supply

regulator in a readily accessible location.

2.4.1 GAS SUPPLY PRESSURE

REGULATOR

An external, in-line, supply gas regulator

(supplied by others) should be positioned as

shown in Figure 2.7. Union connections should

be placed in the proper locations to allow

maintenance of the regulator if required

NOTE:

An individual gas pressure regulator must

be installed upstream of each KC1000. The

regulator must regulate gas pressure to 8.5”

W.C. at 1,000,000 BTU/H for natural gas

and propane units.

The maximum static inlet pressure to the unit

must be no more than 14” water column.

Minimum gas pressure is 8.5” W.C. for FM gas

trains and 8.9” W.C. for IRI gas trains when the

unit is firing at maximum input. Gas pressure

should not exceed 10.5” W.C. at any time when

firing. Proper sizing of the gas supply regulator

in delivering the correct gas flow and outlet

pressure is mandatory. The gas supply pressure

regulator must maintain the gas pressure at a

regulated 8.5” W.C. minimum for FM gas trains

and 8.9” W.C. for IRI gas trains at maximum

BTU input (1,000,000 BTU/HR) for natural gas

and propane installations. The supply gas

regulator must be of sufficient capacity volume,

(1000 cfh), for the unit and should have no more

than 1" droop from minimum to full fire. The

supply gas regulator must also be rated to

handle the maximum incoming gas pressure to

Gas Supply Regulator and Manual Shut -Off

2.4.3 IRI GAS TRAIN KIT

The IRI gas train is an optional gas train

required in some areas by code or for insurance

purposes. The IRI gas train is factory pre-piped

and wired. (Refer to Appendix F, Drawing No.

SD-A-584).

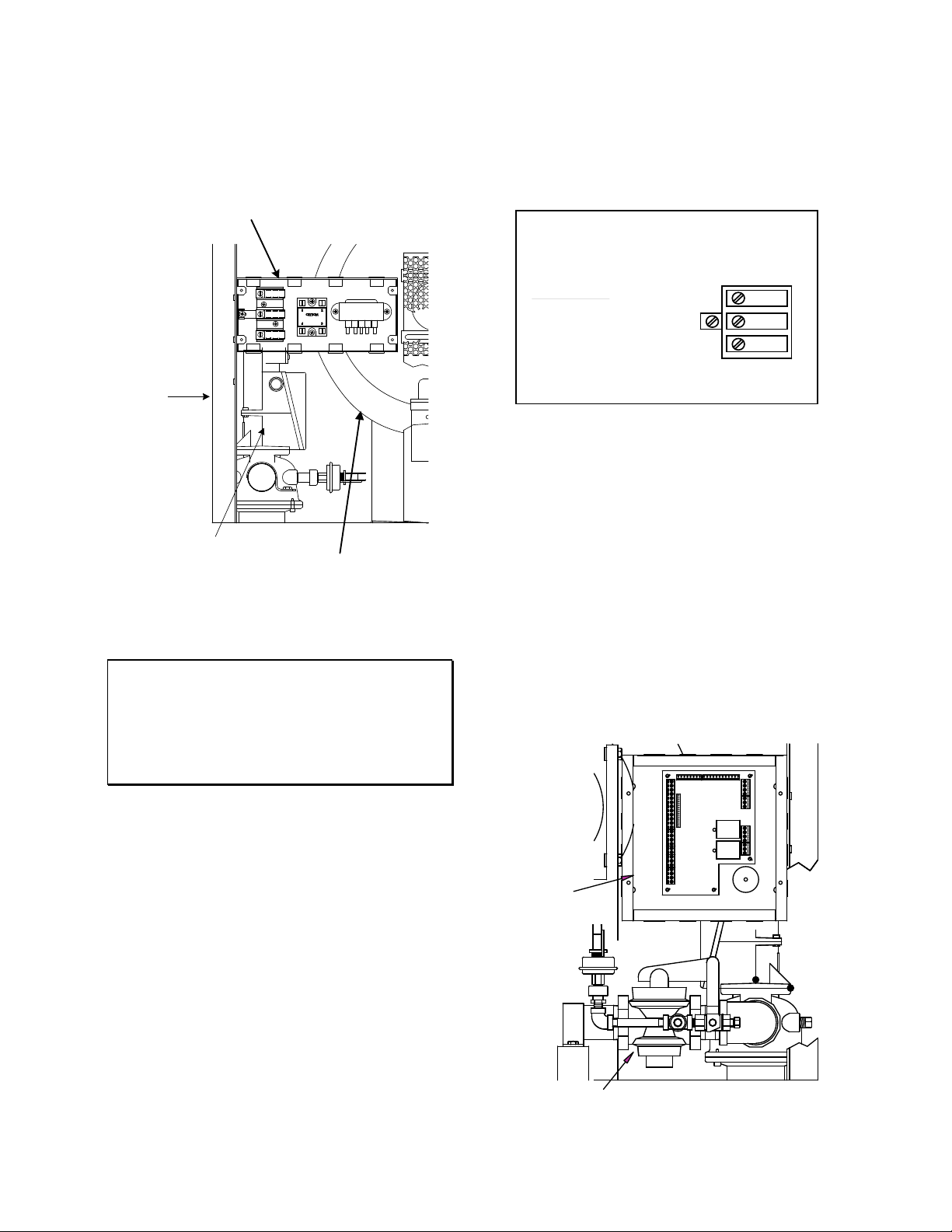

2.5 ELECTRICAL SUPPLY

The AERCO Gas Fired Equipment Electrical

Power Wiring Guide, (GF-1060), must be

consulted in addition to the following material

before wiring to the unit is started. AC power

connection to the unit are made at the Power

Box.This box is located on the front right side of

the unit as shown in Figure 2.8. Conduit should

Figure 2.7

Valve Location

2-5

Page 16

INSTALLATION

POWER BOX

BLOWER

SSOV

ACTUATOR

FRAME

USE COPPER CONDUCTORS ONLY FOR FIELD WIRING

60 HZ

DISCONNECT POWER BEFORE SERVICING

DANGER: HIGH VOLTAGE

20 AMP

120 VAC,

NEUTRAL

GROUND

LINE

POWER BOX

AERCO INTERNATIONAL INC.

INPUT POWER

I/O

BOX

GAS SHUT-OFF VALVE

BLOWER

be run from the knockouts in the side of the box

in such a manner that it does not interfere with

the removal of any sheet metal covers. A flexible

electrical connection may be utilized to allow the

covers to be easily removed.

Figure 2.8

AC Power Box Location

NOTE:

All electrical conduit and hardware should

be installed so that it does not interfere with

the removal of any cover, inhibit service or

maintenance, or prevent access between

the unit and walls or another unit.

2.5.1 ELECTRICAL REQUIREMENTS

Electrical requirements for each unit are 120

VAC, 1 Phase, 60 Hz, 20 Amps from a

dedicated electrical circuit. No other devices

should be on the same electrical circuit as a

KC1000 unit.

A double-pole switch must be installed on the

electrical supply line in an easily accessible

location to quickly and safely disconnect

electrical service. DO NOT attach the switch to

sheet metal enclosures of the unit.

After placing the boiler in service, the ignition

safety shutoff device must be tested. If an

external electrical power source is used, the

installed boiler must be electrically bonded to

ground in accordance with the requirements of

the authority having jurisdiction. In the absence

of such requirements, the installation shall

2-6

conform to National Electrical Code (NEC),

ANSI/NFPA 70 and/or the Canadian Electrical

Code (CEC) Part I, CSA C22.1 Electrical Code.

The AC power wiring diagram is shown in Figure

2.9.

Figure 2.9

AC Power Wiring Diagram

2.6 MODE OF OPERATION and FIELD

CONTROL WIRING

The KC Boiler is available in several different

modes of operation. While each unit is factory

configured and wired for the mode specified on

the equipment order, some field wiring may be

required to complete the installation. This wiring

is typically routed to the Input/Output (I/O) Box

located on the left side of the unit beneath the

removable side panel (see Figure 2.10). Field

wiring for each particular mode of operation is

described in the following paragraphs. For

additional information concerning modes of

operations, refer to Section 5.

Figure 2.10

Input/Output (I/O) Box Location

Page 17

INSTALLATION

mA OUT

RS-485

COMM.

+

-

+

-

ANALOG IN

SENSOR COMMON

OUTDOOR SENSOR IN

REMOTE INTL'K IN

B.M.S. (PWM) IN

SHIELD

+

-

+

-

AUX SENSOR IN

NOT USED

EXHAUST SWITCH IN

DELAYED INTL'K IN

FAULT RELAY

120 VAC, 5A, RES

AUX RELAY

120 VAC, 5A, RES

G

RELAY CONTACTS:

120 VAC, 30 VDC

5 AMPS RESISTIVE

DANGER

120 VAC USED

IN THIS BOX

NOT USED

NOT USED

NC

COM

NO

NC

COM

NO

NOT USED

2.6.1 CONSTANT SETPOINT MODE

The Constant Setpoint Mode is used when it is

desired to have a fixed setpoint that does not

deviate. No wiring connections other than

electrical supply connections are required for

this mode. However, if desired, fault monitoring

or enable/disable interlock wiring can be utilized

(see paragraphs 2.7.9 and 2.7.10).

2.6.2 INDOOR/OUTDOOR RESET MODE

This mode of operation increases supply water

temperature as outdoor temperatures decrease.

An outside air temperature sensor (AERCO PN

122790) is required. The sensor MUST BE

wired to the I/O Box wiring terminals (see Figure

2.11). For more information concerning the

outside air sensor installation, refer to paragraph

2.7.1. For programming and setup instructions

concerning the indoor/outdoor-reset mode of

operation, refer to Section 5, paragraph 5.1.

.

2.6.3 BOILER MANAGEMENT SYSTEM

When using an AERCO Boiler Management

System (BMS), the field wiring is connected

between the BMS Panel and each Boiler’s I/O

Box terminal strip (Figure 2-11). Twisted

shielded pair wire from 18 to 22 AWG must be

utilized for the connections. The BMS Mode can

utilize either pulse width modulation (PWM)

signaling, or RS485 Modbus signaling. For PWM

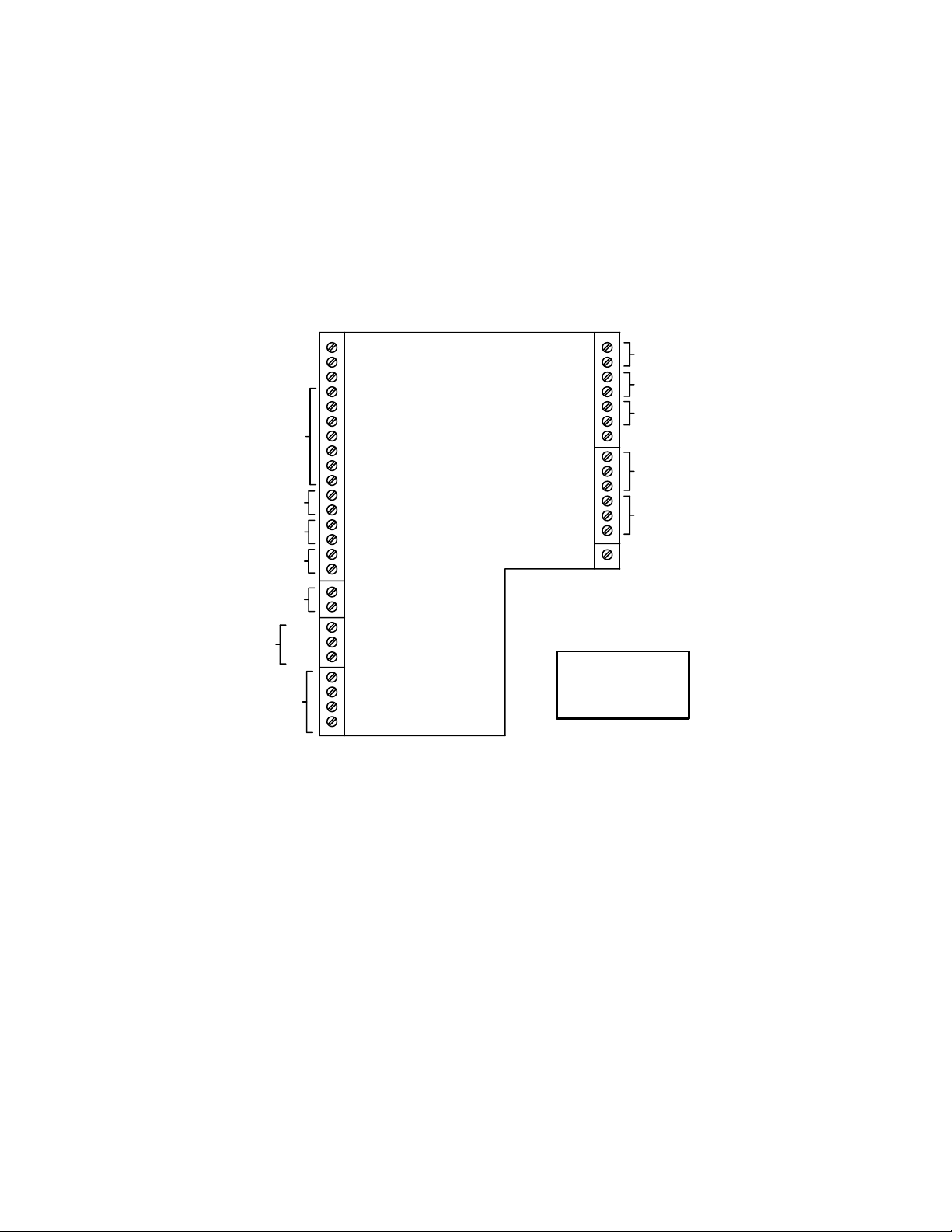

I/O Box Terminal Strip

(BMS) MODE

NOTE

BMS Model 168 can utilize either pulse

width modulation (PWM) or RS485

Modbus signaling to the Boiler. BMS II

Model 5R5-384 can utilize only RS485

signaling to the Boiler.

Figure 2.11

signaling, connections are made from the

AERCO Boiler Management System to the

B.M.S. (PWM) IN terminals on the I/O Box

terminal strip. For RS485 Modbus signaling,

connections are made from the BMS to the

RS485 COMM terminals on the I/O Box terminal

strip. Polarity must be maintained and the shield

must be connected only at the AERCO BMS.

The boiler end of the shield must be left floating.

For additional instructions, refer to Chapter 5,

paragraph 5.6 in this manual. Also, refer to GF108M (BMS Model 168) and GF-124 (BMS II

Model 5R5-384), BMS -Operations Guides.

2-7

Page 18

INSTALLATION

2.6.4 REMOTE SETPOINT and DIRECT

DRIVE MODES

The KC1000 Boiler can accept several types of

signal formats from an Energy Management

System or other source to control either the

setpoint (Remote Setpoint Mode) or valve

position (Direct Drive Mode) of the Boiler. These

formats are:

4 to 20 mA/1 to 5 Vdc

0 to 20 mA/0 to 5 Vdc

PWM – (Pulse Width Modulated signal. See

paragraph 2.7.4)

Network – (RS485 Modbus. See para. 2.7.7)

While it is possible to control one or more boilers

using one of the above modes of operation, it

may not be the method best suited for the

application. Prior to selecting one of the above

modes of operation, it is recommended that you

consult with your local AERCO representative or

the factory for the mode of operation that will

work best with your application. For more

information on wiring the 4 to 20 mA / 1to 5VDC

or the 0 to 20 mA / 0 to 5 VDC, see paragraph

2.7.3.

2.6.5 COMBINATION MODE

NOTE

Only BMS Model 168 can be utilized for

the Combination Mode, not the BMS II

(Model 5R5-384).

With a Combination Mode unit, field wiring is

between the unit’s I/O Box, the CCP

(Combination Control Panel), and the BMS

Model 168 (Boiler Management System). The

wiring must be done using a shielded twisted

pair of 22 AWG wire. Polarity must be

maintained between the unit, the CCP, and the

BMS. For further instructions and wiring

diagrams, refer to the GF-108 Boiler

Management System Operations Guide and the

CCP-1 data sheet.

2.7 I/O BOX CONNECTIONS

The types of input and output/signals and

devices to be connected to the I/O Box terminals

shown in Figure 2.11 are described in the

following paragraphs.

CAUTION!

DO NOT make any connections to the I/O

Box terminals labeled “NOT USED”.

Attempting to do so may cause equipment

damage.

2.7.1 OUTDOOR SENSOR IN

An outdoor air temperature sensor (AERCO Part

No. 122790) will be required mainly for the

Indoor/Outdoor Reset mode of operation. It can

also be used with another mode if it is desired to

use the outdoor sensor enable/disable feature.

This feature allows the boiler to be enabled or

disabled based on the outdoor air temperature.

The factory default for the outdoor sensor is

DISABLED. To enable the sensor and/or select

an enable/disable outdoor temperature, see the

Configuration menu in Section 3.

The outdoor sensor may be wired up to 200 feet

from the boiler and is connected to the

OUTDOOR SENSOR IN and the SENSOR

COMMON terminals in the I/O box (see Figures

2.10 and 2.11). Wire the sensor using a twisted

shielded pair cable of 18-22 AWG wire. There is

no polarity when terminating the wires. The

shield is to be connected only to the terminals

labeled SHEILD in the I/O Box. The sensor end

of the shield must be left free and ungrounded.

When mounting the sensor, it must be located

on the North side of the building where an

average outside air temperature is expected.

The sensor must be shielded form direct sunlight

as well as impingement by the elements. If a

shield is used, it must allow for free air

circulation.

2.7.2 AUX SENSOR IN

The AUX SENSOR IN terminals can be used to

add an additional temperature sensor for

monitoring purposes. This input is always

enabled and is a view only input that can be

seen in the operating menu. The sensor must be

wired to the AUX SENSOR IN and SENSOR

COMMON and must be similar to AERCO

BALCO wire sensor P/N 12449. A resistance

chart for this sensor can be found in Appendix

C.

2-8

Page 19

INSTALLATION

2.7.3 ANALOG IN

The ANALOG IN + and – terminals are used

when an external signal is used to drive the

valve position (Direct Drive Mode) or change the

setpoint (Remote Setpoint Mode) of the Boiler.

Either a 4 to 20 mA / 1 to 5 VDC or a 0 to 20 mA

/ 0 to 5 VDC signal may be used to vary the

setpoint or valve position. The factory default

setting is 4 to 20 mA / 1 to 5 VDC, however this

may be changed to 0 to 20 mA / 0 to 5 VDC

using the Configuration Menu described in

Section 3. If voltage rather than current is

selected as the drive signal, a DIP switch must

be set on the PMC Board located inside the

Control Box. Contact the AERCO factory for

information on setting DIP switches.

All supplied signals must be floating

(ungrounded) signals. Connections between the

source and the Boiler’s I/O Box must be made

using twisted shielded pair of 18 –22 AWG wire

such as Belden 9841(see Figure 2.11). Polarity

must be maintained and the shield must be

connected only at the source end and must be

left floating (not connected) at the Boiler’s I/O

Box.

Whether using voltage or current for the drive

signal, they are linearly mapped to a 40°F to

240°F setpoint or a 0% to 100% valve position.

No scaling for these signals is provided.

2.7.4 B.M.S. (PWM) IN

NOTE

Only BMS Model 168 can utilize Pulse

Width Modulation (PWM), not the BMS II

(Model 5R5-384).

These terminals are used to connect the

AERCO Boiler Management System (BMS)

Model 168 to the unit. The BMS Model 168

utilizes a 12 millisecond, ON/OFF duty cycle.

This duty cycle is Pulse Width Modulated (PWM)

to control valve position. A 0% valve position =

a 5% ON pulse and a 100% valve position = a

95% ON pulse.

2.7.5 SHIELD

The SHIELD terminals are used to terminate any

shields used on sensor wires connected to the

unit. Shields must only be connected to these

terminals.

2.7.6 mA OUT

These terminals provide a 4 to 20 mA output

that can be used to monitor setpoint ( 40°F to

220°F), outlet temperature (30°F to 245°F), or

valve position (0% to 100%). This function is

enabled in the Configuration Menu (Section 3,

Table 3-4).

2.7.7 RS-485 COMM

These terminals are used for RS-485 MODBUS

serial communication between the unit and an

external “Master”, such as a Boiler Management

System or other suitable device.

2.7.8 EXHAUST SWITCH IN

These terminals permit an external exhaust

switch to be connected to the exhaust manifold

of the boiler. The exhaust sensor should be a

normally open type switch (such as AERCO Part

No. 123463) that closes (trips) at 500

o

F.

2.7.9 INTERLOCKS

The unit offers two interlock circuits for

interfacing with Energy Management Systems

and auxiliary equipment such as pumps or

louvers. These interlocks are called the Remote

Interlock and Delayed Interlock (Figure 2.11).

The wiring terminals for these interlocks are

located inside the I/O Box on the left side of the

unit. The I/O Box cover contains a wiring

diagram which shows the terminal strip locations

for these interlocks which are labeled REMOTE

INTL’K IN and DELAYED INTL’K IN. Both

interlocks, described in the following

paragraphs, are factory wired in the closed

position.

NOTE:

Both the Delayed Interlock and Remote

Interlock must be in the closed position to

allow the unit to fire.

2.7.9.1 REMOTE INTERLOCK IN

The remote interlock circuit (REMOTE INTL’K

IN) is provided to remotely start (enable) and

stop (disable) the Boiler if desired. The circuit is

24 VAC and comes factory pre-wired closed

(jumpered).

2-9

Page 20

INSTALLATION

2.7.9.2 DELAYED INTERLOCK IN

The delayed interlock circuit (DELAYED INTL’K

IN) is typically used in conjunction with the

auxiliary relay described in paragraph 2.8. This

interlock circuit is located in the purge section of

the start string. It can be connected to the

proving device (end switch, flow switch etc.) of

an auxiliary piece of equipment started by the

boiler’s auxiliary relay. The delayed interlock

must be closed for the boiler to fire. If the

delayed interlock is connected to a proving

device that requires time to close (make), a time

delay (Aux Start On Dly) that holds the start

sequence of the boiler long enough for for a

proving switch to make can be programmed.

Should the proving switch not prove within the

programmed time frame, the boiler will shut

down. The Aux Start On Dly can be

programmed from 0 to 120 seconds. This option

is locate in the Configuration Menu (Section 3).

2.7.10 FAULT RELAY

The fault relay is a single pole double throw

(SPDT) relay having a normally open and

normally close set of relay contacts that are

rated for 5 amps at 120 VAC and 5 amps at 30

VDC. The relay energizes when any fault

condition occurs and remains energized until the

fault is cleared and the CLEAR button is

depressed. The fault relay connections are

shown in Figure 2.11.

2.8 AUXILIARY RELAY CONTACTS

Each Boiler is equipped with a single pole

double throw (SPDT) relay that is energized

when there is a demand for heat and de-

energized after the demand for heat is satisfied.

The relay is provided for the control of auxiliary

equipment, such as pumps and louvers, or can

be used as a Boiler status indictor (firing or not

firing). Its contacts are rated for 120 VAC @ 5

amps. Refer to Figure 2.11 to locate the AUX

RELAY terminals for wiring connections.

2.9 FLUE GAS VENT INSTALLATION

The AERCO Venting and Combustion Air Guide,

GF-1050, must be consulted before any flue or

inlet air venting is designed or installed.

Suitable, U/L approved, positive pressure,

water-tight vent materials as specified in

AERCO’s GF-1050, must be used for safety and

UL certification. Because the unit is capable of

discharging low temperature exhaust gases, the

flue must be pitched back to the unit a minimum

of 1/4" per foot to avoid any condensate pooling

and to allow for proper drainage.

While there is a positive flue pressure during

operation, the combined pressure drop of vent

and combustion air systems must not exceed

140 equivalent feet of 0.81” W.C.. Fittings as

well as pipe lengths must be calculated as part

of the equivalent length. For a natural draft

installation the draft must not exceed - 0.25”

W.C..These factors must be planned into the

vent installation. If the maximum allowable

equivalent lengths of piping are exceeded, the

unit will not operate properly or reliably.

2.10 COMBUSTION AIR

The AERCO Venting and Combustion Air Guide,

GF-1050, MUST be consulted before any flue or

combustion supply air venting is designed or

started. Combustion air supply is a direct

requirement of ANSI 223.1, NFPA-54, CSA

B149.1 and local codes. These codes should be

consulted before a permanent design is

determined.

The combustion air must be free of chlorine,

halogenated hydrocarbons, or other chemicals

that can become hazardous when used in gasfired equipment. Common sources of these

compounds are swimming pools, degreasing

compounds, plastic processing and refrigerants.

Whenever the environment contains these types

of chemicals, combustion air must be supplied

from a clean area outdoors for the protection

and longevity of the equipment.

The more common methods of combustion air

supply venting are outlined below. For

combustion air supply from ducting, consult the

AERCO GF-1050, Venting and Combustion Air

Guide.

2.10.1 COMBUSTION AIR FROM

OUTSIDE THE BUILDING

Air supplied from outside the building must be

provided through two permanent openings. For

each unit these two openings must have a free

area of not less than one square inch for each

4000 BTUs input of the equipment or 250

square inches of free area. The free area must

take into account restrictions such as louvers

and bird screens. For Canada installations, refer

to the requirements specified in CSA B149.1.10,

8.4.1 and 8.4.3.

2.10.2 COMBUSTION AIR FROM INSIDE

THE BUILDING

When combustion air is provided from within the

building, it must be supplied through two

permanent openings in an interior wall. Each

opening must have a free area of not less than

one square inch per 1000 BTUH of total input or

2-10

Page 21

INSTALLATION

1000 square inches of free area. The free area

must take into account any restrictions such as

louvers.

2.10.3 SEALED COMBUSTION

The KC Boiler is UL approved for 100% sealed

combustion application when installed properly.

When a sealed combustion air application is

installed, the sealed combustion air piping must

be deducted from the maximum allowable

discharge piping amounts. Each unit must have

a minimum 6" diameter connection made to the

special Inlet Air Adapter # GP-18917 available

from AERCO. This adapter bolts directly on to

the air inlet of the unit’s blower. See installation

instructions with adapter. All inlet air ducts must

be sealed air tight.

2-11

Page 22

Page 23

CONTROL PANEL OPERATING PROCEDURES

3

1

2

7

4

6

10

8

9

5

11

12

SECTION 3 - CONTROL PANEL OPERATING PROCEDURES

3.1. INTRODUCTION

The information in this Section provides a guide

to the operation of the KC1000 Boiler using the

Control Panel mounted on the front of the unit.

It is imperative that the initial startup of this unit

be performed by factory trained personnel.

Operation prior to initial startup by factory

trained personnel will void the equipment

warranty. In addition, the following WARNINGS

and CAUTIONS must be observed at all times.

CAUTION:

All initial installation procedures must be

satisfied before attempting to start the unit.

WARNING:

ELECTRICAL VOLTAGES IN THIS

SYSTEM INCLUDE 120 AND 24 VOLTS

AC. IT MUST NOT BE SERVICED OR

ACCESSED BY OTHER THAN FACTORY

CERTIFIED SERVICE TECHNICIANS.

WARNING:

DO NOT ATTEMPT TO DRY FIRE THE

BOILER. STARTING THE UNIT WITHOUT

A FULL WATER LEVEL CAN SERIOUSLY

DAMAGE THE UNIT AND MAY RESULT IN

PERSONNEL INJURY OR PROPERTY

DAMAGE. THIS SITUATION WILL VOID

ANY WARRANTY.

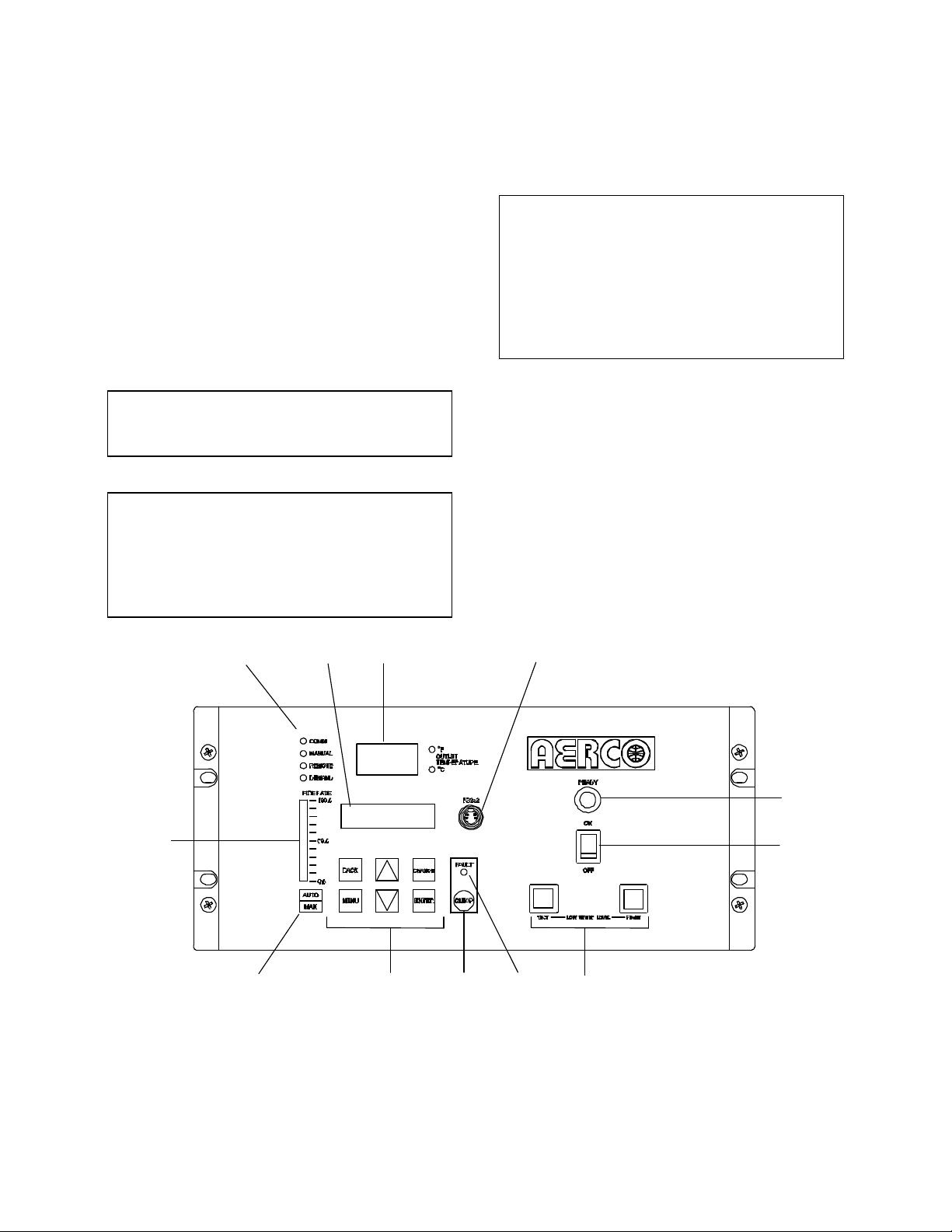

3.2. CONTROL PANEL DESCRIPTION

The KC1000 Control Panel shown in Figure 3-1

contains all of the controls, indicators and

displays necessary to operate, adjust and

troubleshoot the KC1000 Boiler. These operating controls, indicators and displays are listed

and described in Table 3-1. Additional information on these items are provided in the individual

operating procedures provided in this Section.

Figure 3-1. Control Panel Front View

3-1

Page 24

CONTROL PANEL OPERATING PROCEDURES

FUNCTION

follows:

COMM

Lights when RS-232 communication is occurring

keypad.

from an Energy Management System

DEMAND

Lights when there is a demand for heat.

Menu Selection

in degrees Fahrenheit or degrees Celsius.

connected to the boiler Control Panel.

5

READY Indicator

Lights when all Pre-Purge conditions have been satisified.

6

ON/OFF Switch

Enables and disables boiler operation.

Pressing CLEAR resets the display.

condition occurs. An alarm message will appear in the VFD.

alarms

the Control Panel Menus:

The Menu categories wrap around in the order shown.

category.

Table 3-1. Operating Controls, Indicators and Displays

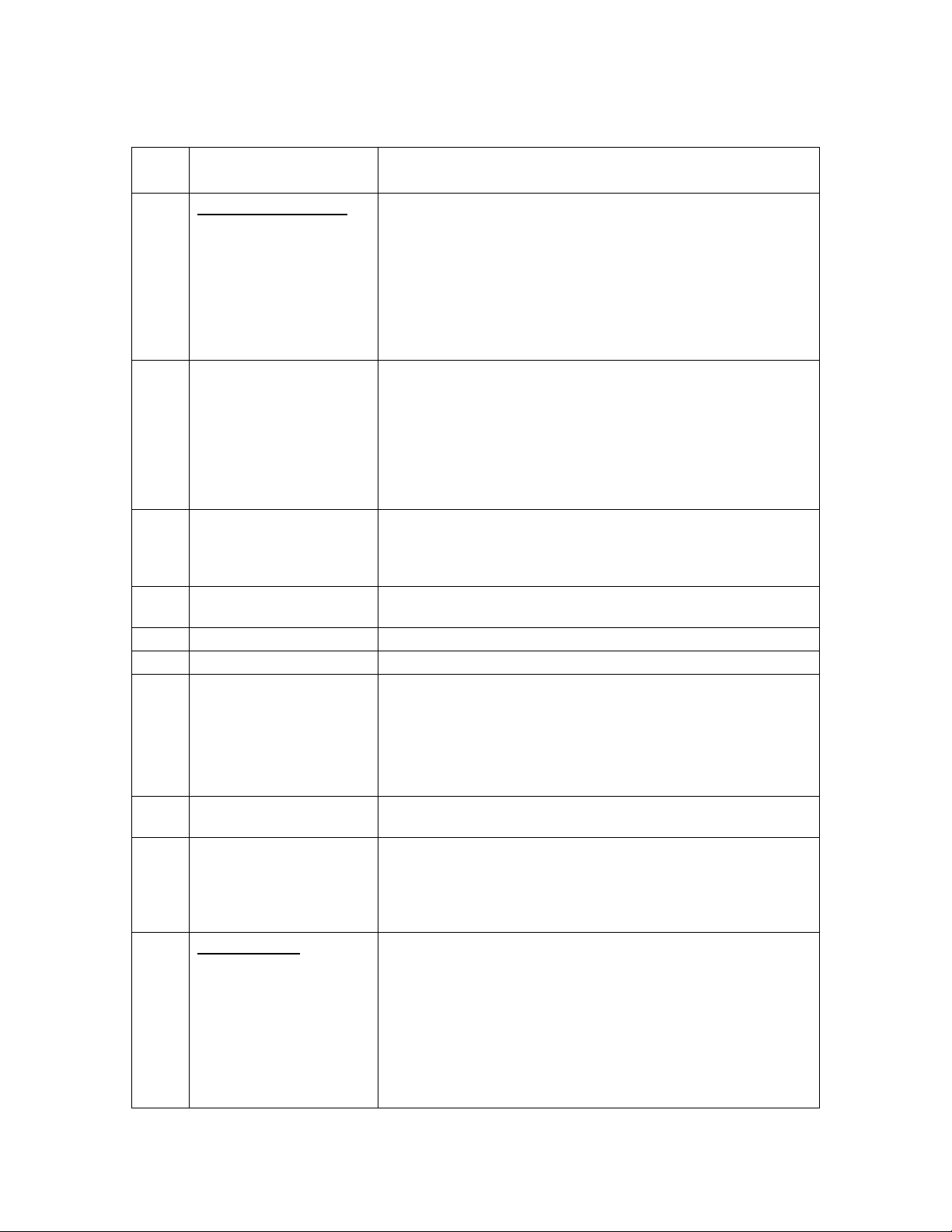

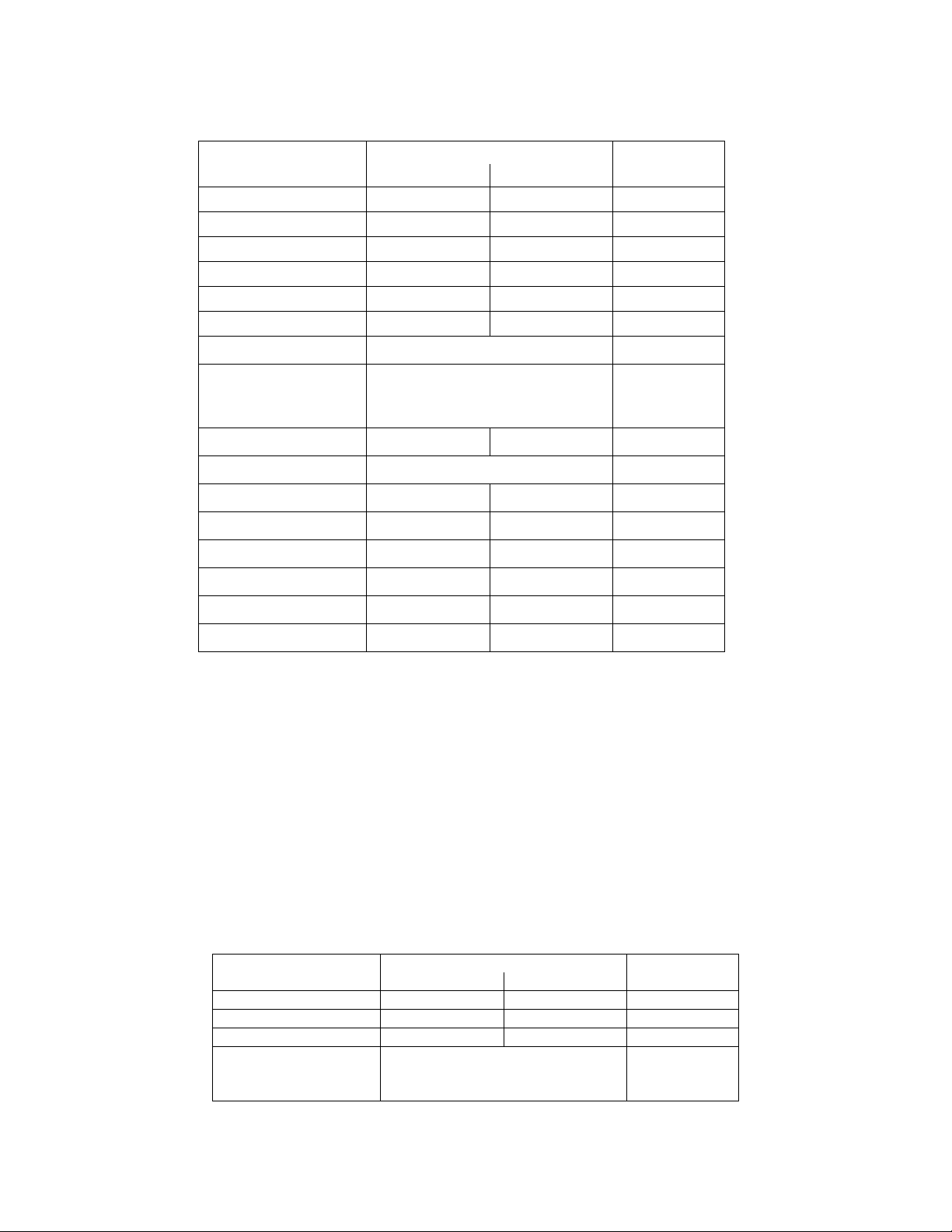

ITEM

NO.

CONTROL, INDICATOR

OR DISPLAY

1 LED Status Indicators Four Status LEDs indicate the current operating status as

MANUAL

REMOTE

2 VFD Display Vacuum Fluorescent Display (VFD) consists of 2 lines, each

3

OUTLET

TEMPERATURE

Display

4 RS-232 Port Port permits a Laptop Computer or External Modem to be

7

LOW WATER LEVEL

TEST/RESET Switches

Lights when the unit is being controlled using the front panel

Lights when the unit is being controlled by an external signal

capable of displaying up to 16 alphanumeric characters. The

information displayed includes:

Startup Messages

Alarm Messages

Operating Status Messages

3–Digit, 7–Segment LED display continuously displays the

outlet water temperature. The °F or °C LED next to the

display lights to indicate whether the displayed temperature is

Allow the operator to test the operation of the water level

monitor.

Pressing TEST opens the water level probe circuit and

simulates a Low Water Level alarm.

Pressing RESET resets the water level monitor circuit.

8 FAULT Indicator Red FAULT LED indicator lights when a boiler alarm

9 CLEAR Key Turns off the FAULT indicator and clears trhe alarm message

if the alarm is no longer valid. Lockout type alarms will be

latched and cannot be cleared by simply pressing this key.

Troubleshooting may be required to clear these types of

10 MENU Keypad Consists of 6 keys which provide the following functions for

MENU

BACK

Steps through the main menu categories shown in Figure 3-2.

Allows you to go back to the previous menu level without

changing any information. Continuously pressing this key will

bring you back to the default status display in the VFD. Also,

this key allows you to go back to the top of a main menu

3-2

Page 25

CONTROL PANEL OPERATING PROCEDURES

FUNCTION

pressing the ▲ arrow key will increment the selected setting.

setting.

flashing will increment or decrement the displayed setting.

display will stop flashing.

100%

Table 3-1. Operating Controls, Indicators and Displays - Continued

ITEM

NO.

CONTROL, INDICATOR

OR DISPLAY

10

(Cont.)

▲ (Up) Arrow When in one of the main menu categories (Figure 3-2),

pressing this key will select the displayed menu category. If

the CHANGE key was pressed and the menu item is flashing,

▼ (Down) Arrow

When in one of the main menu categories (Figure 3-2),

pressing this key will select the displayed menu category. If

the CHANGE key was pressed and the menu item is flashing,

pressing the ▼ (Down) arrow key will increment the selected

Permits a setting to be changed (edited). When the

CHANGE key is pressed, the displayed menu item will begin

to flash. Pressing the ▲ or ▼ arrow key when the item is

Saves the modified menu information in memory. The

CHANGE

ENTER

11 AUTO/MAN Switch This switch toggles the boiler between the Automatic and

Manual modes of operation. When in the Manual (MAN)

mode, the front panel controls are enabled and the MANUAL

status LED lights.

When in the Automatic (AUTO) mode, the MANUAL status

LED will be off and the front panel controls disabled.

12

VALVE POSITION

Bargraph

20 segment red LED bargraph continuously shows the

Air/Fuel Valve Position (% open) in 5% increments from 0 to

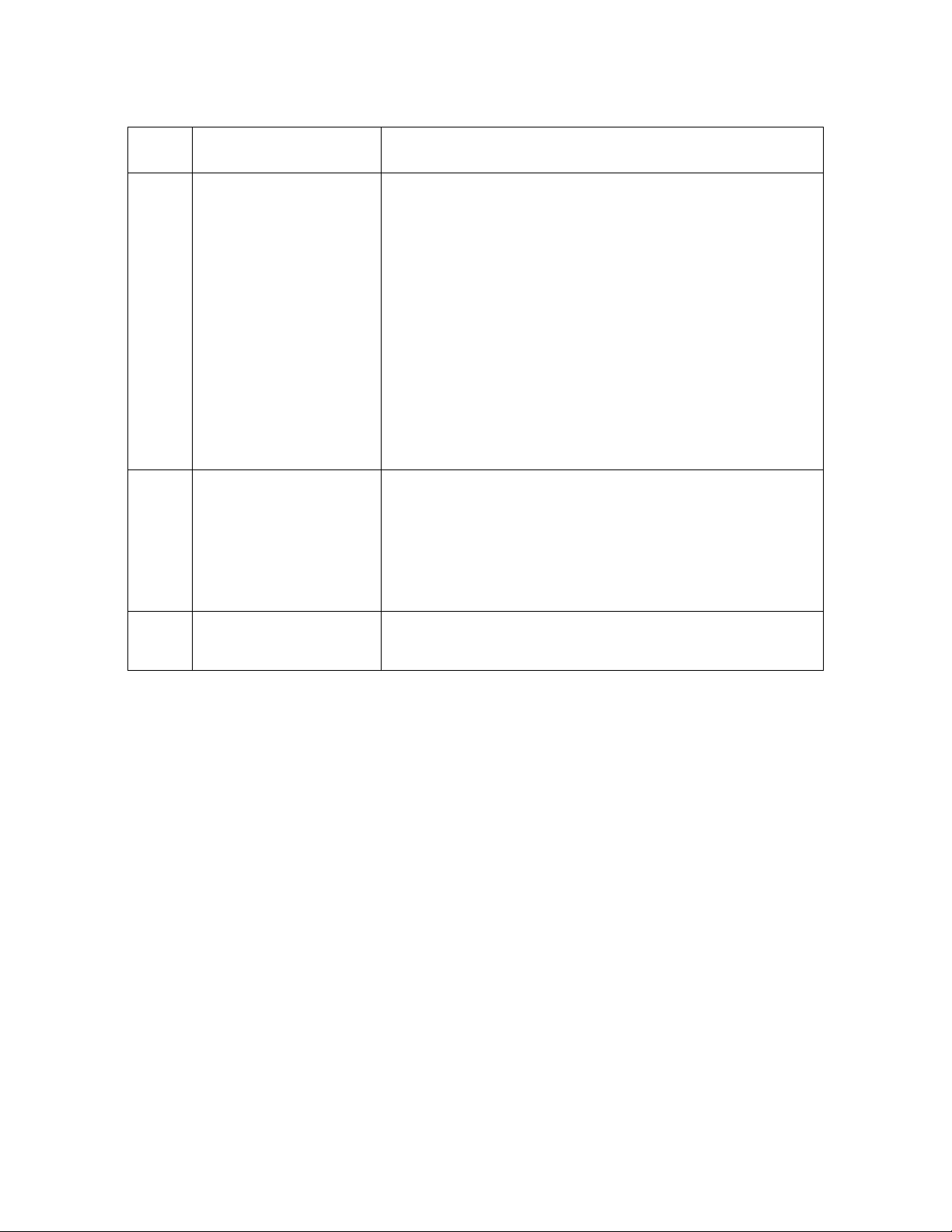

3.3. CONTROL PANEL MENUS

The Control Panel incorporates an extensive

menu structure which permits the operator to set

up, and configure the unit. The menu structure

consists of four major menu categories as

shown in Figure 3-2. Each of the menus shown,

contain options which permit operating

parameters to be viewed or changed. The

menus are protected by a password to prevent

unauthorized use.

Prior to entering the correct password, the

options contained in the Operating, Setup,

Configuration and Tuning Menu categories can

be viewed. However, with the exception of

Internal Setpoint Temperature (Configuration

Menu), none of the viewable menu options can

be changed.

Once the valid password (159) is entered, the

options listed in the Setup, Configuration and

Tuning menus can be viewed and changed, if

desired.

3.3.1. Menu Processing Procedure

Accessing each menu and option is

accomplished using the Menu Keys shown in

Figure 3-1. Therefore, it is imperative that you

be thoroughly familiar with the following basic

steps before attempting to perform specific

menu procedures.

1. The Control Panel will normally be in the

Operating Menu and the VFD will display the

current unit status. Pressing the ▲ or ▼

arrow key will display the other available data

items in the Operating Menu.

2. Press the MENU key. The display will show

the Setup Menu which is the next menu

category shown in Figure 3-2. This menu

contains the Password option which must be

entered if other menu options will be

changed.

3. Continue pressing the MENU key until the

desired menu is displayed.

3-3

Page 26

CONTROL PANEL OPERATING PROCEDURES

OPERATION

SETUP

CONFIGURATION

TUNING

PASSWORD

4. With the desired menu displayed, press the

▲ or ▼ arrow key. The first option in the

selected menu will be displayed.

5. Continue to press the ▲ or ▼ arrow key until

the desired menu option is displayed.

Pressing the ▲arrow key will display the

available menu options in the Top-Down

sequence. Pressing the ▼ arrow key will

display the options in the Bottom-Up

sequence. The menu options will wraparound after the first or last available option

is reached.

6. To change the value or setting of a displayed

menu option, press the CHANGE key. The

displayed option will begin to flash. Continue

to press the ▲ or ▼ arrow key for the option

to be changed. The available menu option

choices will be displayed. The menu option

choices do not wrap around.

7. To select and store a changed menu option,

press the ENTER key.

NOTE:

The following paragraphs provide brief

descriptions of the options contained in each

menu. Refer to Appendix A for detailed

descriptions of each menu option. Refer to

Appendix B for listings and descriptions of

displayed startup, status and error messages.

3.4. OPERATING MENU

The Operating Menu displays a number of key

operating parameters for the unit as listed in

Table 3-2. This menu is “Read-Only” and does

not allow personnel to change or adjust any of

the displayed items. Since this menu is “ReadOnly”, it can be viewed at any time without

entering a password. Press the ▲ arrow key to

display the menu items in the order listed (TopDown). Pressing the ▼ arrow key will display

the menu items in reverse order (Bottom-Up).

3.5. SETUP MENU

The Setup Menu (Table 3-3) permits the

operator to set the unit password which is

required to change any of the menu options. To

prevent unauthorized use, a previously entered

password entry will time-out after 1 hour. Therefore, the password must be reentered when

required. In addition to permitting password

entries, the Setup Menu is also used to enter

date and time, language to be used for display

messages, units of temperature measurements

and entries required for external communication

and control of the unit via the RS-232 port. A

view-only software version display is also

provided to indicate the current Control Box

software version.

Figure 3-2. Menu Structure

3-4

Page 27

CONTROL PANEL OPERATING PROCEDURES

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Menu Item

Display

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

NOTE

The Outdoor Temp display item shown with an asterisk in Table

3-2 will not be displayed unless the Outdoor Sensor function has

been enabled in the Configuration Menu (Table 3-4).

Table 3-2. Operating Menu

Status Message

Active Setpoint 40°F 240°F

AIR Temp -70°F 245°F

Outdoor Temp* -70°F 130°F

Valve Position In 0% 100% Valve

Flame Strength 0% 100%

Run Cycles 0 999,999,999

Position

Run Hours 0 999,999,999

Fault Log 0 19 0

Passsword 0 9999 0

Language English English

Time 12:00 am 11:59 pm

Date 01/01/00 12/31/99

Unit of Temp Fahrenheit or Celsius Fahrenheit

Comm Address 0 127 0

Baud Rate 2400, 4800, 9600, 19.2K 9600

Software Ver 0.00 Ver 9.99

Table 3-3. Setup Menu

3-5

Page 28

CONTROL PANEL OPERATING PROCEDURES

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

3.6. CONFIGURATION MENU

The Configuration Menu shown in Table 3-4

permits adjustment of the Internal Setpoint

(Setpt) temperature regardless of whether the

valid password has been entered. Setpt is

required for operation in the Constant Setpoint

mode. The remaining options in this menu

require the valid password to be entered, prior to

changing existing entries. This menu contains a

number of other configuration settings which

may or may not be displayed, depending on the

current operating mode setting.

Table 3-4. Configuration Menu

Internal Setpt Lo Temp Limit Hi Temp Limit 130°F

Unit Type

Unit Size

Fuel Type Natural Gas, Propane Natural Gas

Boiler Mode

Remote Signal

(If Mode = Remote

Setpoint, Direct Drive

or Combination)

Bldg Ref Temp

(If Mode = Outdoor

Reset)

Reset Ratio

(If Mode = Outdoor

Reset)

Outdoor Sensor Enabled or Disabled Disabled

System Start Tmp

(If Outdoor Sensor =

Enabled)

KC Boiler, KC Boiler LN,

BMK Boiler, BMK Boiler LN,

BMK Boiler Dual, KC Water

Heater, KC Water Heater LN,

Water Heater 2010

0.5 MBTU, 1.0 MBTU

1.5 MBTU, 2.0 MBTU

3.0 MBTU, 3.5 MBTU

4.0 MBTU, 5.0 MBTU

Constant Setpoint,

Remote Setpoint,

Combination

Outdoor Reset

4 – 20 mA/1 – 5V

0 -20 mA/0 – 5V

PWM Input (BMS)

40°F 230°F 70°F

0.1 9.9 1.2

30°F 100°F 60°F

NOTE:

The Configuration Menu settings shown in

Table 3-4 are Factory-Set in accordance

with the requirements specified for each

individual order. Therefore, under normal

operating conditions, no changes will be

required.

KC Boiler

1.0 MBTU

6.0 MBTU

Constant

Setpoint

Direct Drive

4 – 20 mA,

1-5V

Network

3-6

Page 29

CONTROL PANEL OPERATING PROCEDURES

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

Available Choices or Limits

Menu Item Display

Minimum

Maximum

Default

Prop Band

1°F

120°F

70°F

Integral Gain

0.00

2.00

1.00

Derivative Time

0.0 min

2.0 min

0.0 min

Reset Defaults?

Yes

Are You Sure?

No

Table 3-4. Configuration Menu - Continued

Setpt Lo Limit 40°F Setpt Hi Limit 60°F

Setpt Hi Limit Setpt Lo Limit 220°F 195°F

Temp Hi Limit 40°F 240°F 195°F

Max Valve Position 40% 100% 100%

Pump Delay Timer 0 min. 30 min. 0 min.

Aux Start On Dly 0 sec. 120 sec. 0 sec.

Failsafe Mode Shutdown or Constant Setpt Shutdown

*Analog Output

(See CAUTION at

end of Table 3-4 )

Low Fire Timer 2 sec. 600 sec. 2 sec.

Setpt Limiting Enabled or Disabled Disabled

Setpt Limit Band 0°F 10°F 5°F

Network Timeout 5 Sec 999 Sec 30 Sec

HI DB Setpt EN 0% 100% 30%

Demand Offsert 0 25 10

Deadband High 0 25 2

Deadband Low 0 25 2

Off, Setpoint, Outlet Temp,

Valve Position 4-20 mA,

Valve Position 0-10V

*CAUTION:

DO NOT CHANGE the Analog Output Menu Item from its Default setting

(Valve Position 0-10V).

3.7. TUNING MENU

The Tuning Menu items in Table 3-5 are Factory

set for each individual unit.

Table 3-5. Tuning Menu

*Valve

Position

0-10V

Do not change these menu entries unless

specifically requested to do so by FactoryTrained personnel.

No

3-7

Page 30

CONTROL PANEL OPERATING PROCEDURES

STEPPER

MOTOR

DETAIL "A"

DIAL

(DETAIL “A”)

100

BLOWER

BURNER

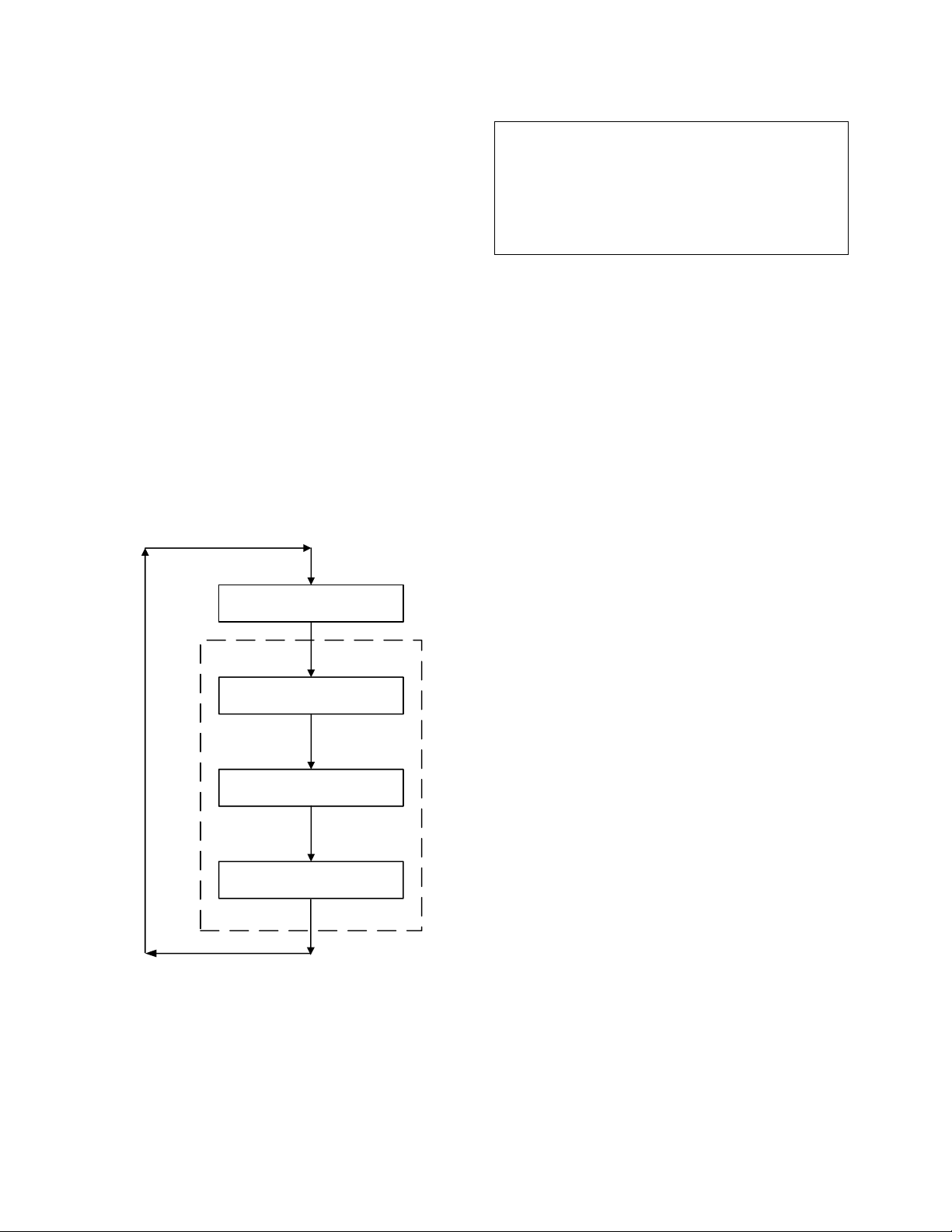

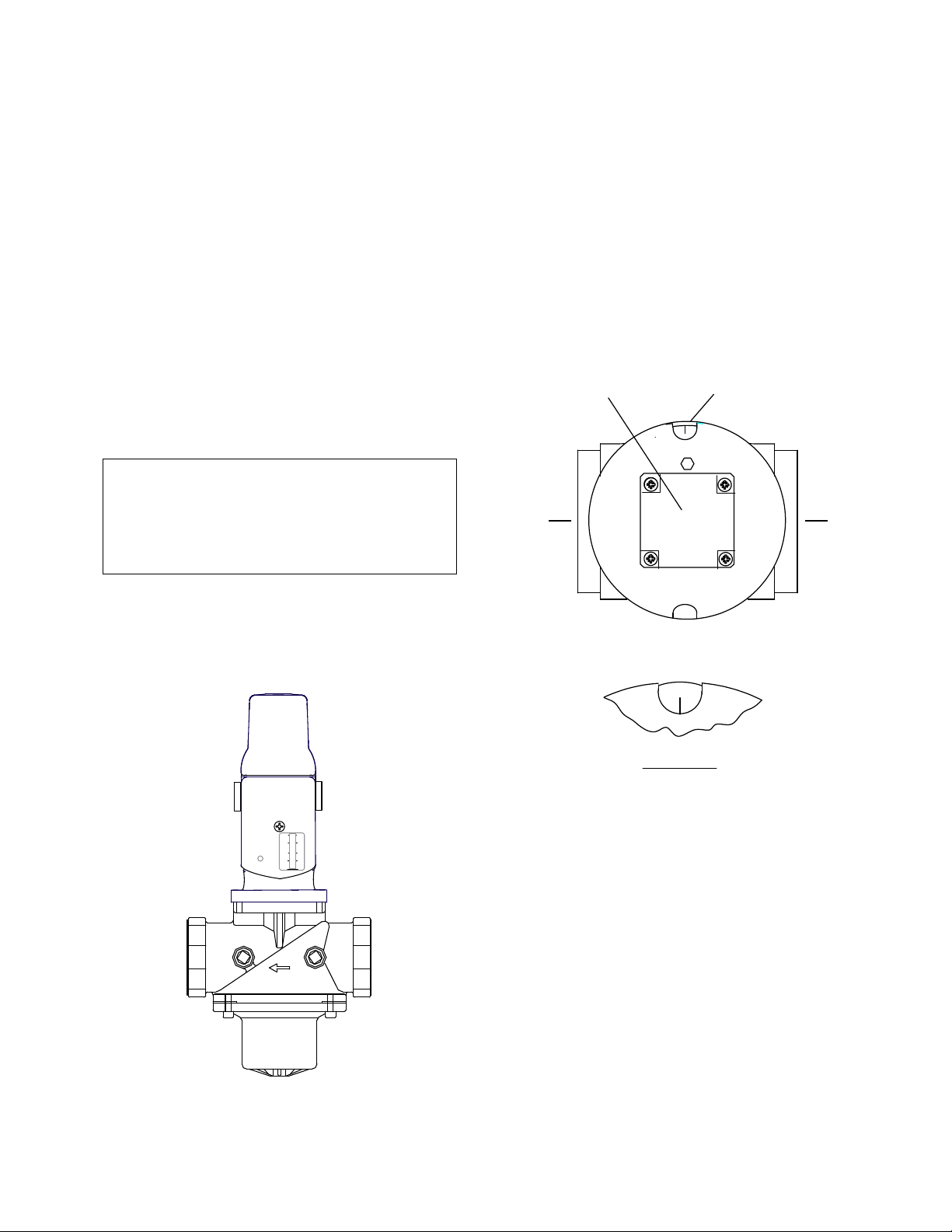

3.8. START SEQUENCE

When the Control Box ON/OFF switch is set to

the ON position, it checks all pre-purge safety

switches to ensure they are closed. These

switches include:

• Safety Shut-Off Valve Proof of Closure

(POC) switch

• Low Water Level switch

• High Water Temperature switch

• High Gas Pressure switch

• Low Gas Pressure switch

If all of the above switches are closed, the

READY light above the ON/OFF switch will light

and the unit will be in the Standby mode.

When there is a demand for heat, the following

events will occur:

NOTE:

If any of the Pre-Purge safety device switches

are open, the appropriate fault message will be

displayed. Also, the appropriate fault messages

will be displayed throughout the start sequence,

if the required conditions are not observed.

3. With all required safety switches closed, a

purge cycle will be initiated and the following

events will occur:

(a) Blower relay energizes and turns on

blower.

(b) Air/Fuel Valve rotates to the full-open

purge position and closes purge position

switch. The dial on the Air/Fuel Valve

(Figure 3-4) will read 100 to indicate that

the valve is full-open (100%).

(c) The VALVE POSITION bargraph will

show 100%.

1. The DEMAND LED status indicator will light.

2. The unit checks to ensure that the proof of

closure switch in the Safety Shut-Off Valve

(SSOV) is closed (Figure 3-3).

Figure 3-4.

Air/Fuel Valve In Purge Position

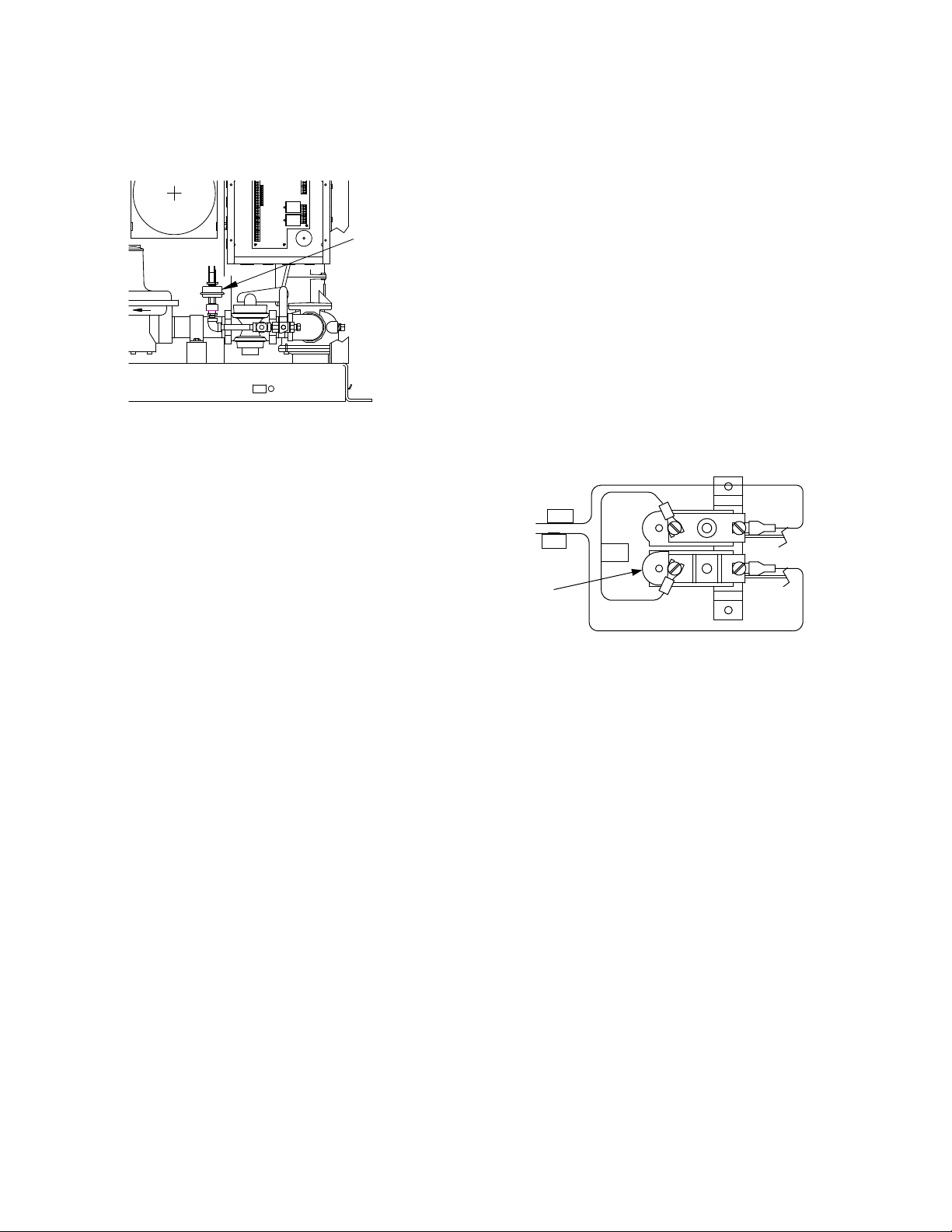

4. Next, the blower proof switch (Figure 3-5)

closes and the display will show Purging and

indicate the elapsed time of the purge cycle

in seconds.

3-8

Figure 3-3.

Safety Shut-Off Valve

Page 31

CONTROL PANEL OPERATING PROCEDURES

154

155

AIR/FUEL VALVE

BLOWER PROOF

SWITCH

TO FRAME

HARNESS

STEPPER

MOTOR

DETAIL "A"

DIAL

(DETAIL “A”)

BLOWER

BURNER

25

Figure 3-5.

Blower Proof Switch

5. Upon completion of the purge cycle, the

Control Box initiates an ignition cycle and the

following events occur:

(a) The Air/Fuel Valve rotates to the low-fire

ignition position and closes the ignition

switch. The dial on the Air/Fuel Valve

(Figure 3-6) will read between 25 and 35

to indicate that the valve is in the lowfire position.

(b) The igniter relay is activated and

provides ignition spark.

Figure 3-6.

Air/Fuel Valve In Ignition Position

9. Once the demand for heat has been

satisfied, the Control Box will turn off the gas

valve. The blower relay will be deactivated

and the Air/Fuel Valve will be closed.

Standby will be displayed.

(c) The gas Safety Shut Off Valve (SSOV)

is energized (opened) allowing gas to

flow into the Air/Fuel Valve.

6. Up to 7 seconds will be allowed for ignition to

be detected. The igniter relay will be turned

off one second after flame is detected.

7. After 2 seconds of continuous flame, Flame

Proven will be displayed and the flame

strength will be indicated. After 5 seconds,

the current date and time will be displayed in

place of the flame strength.

8. With the unit firing properly, it will be

controlled by the temperature controller

circuitry. The VALVE POSITION will be

continuously displayed on the front panel

bargraph.

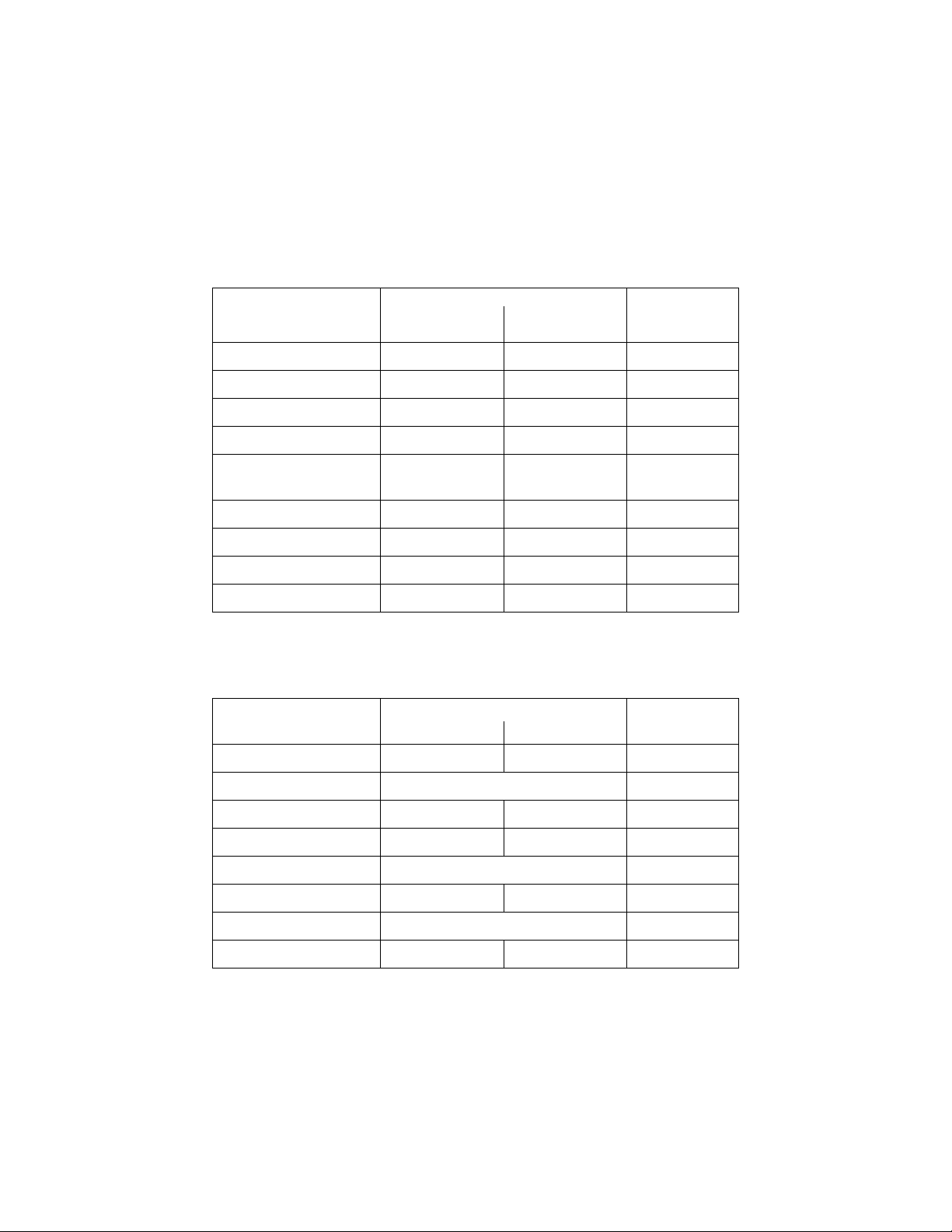

3.9. START/STOP LEVELS

The start and stop levels are the valve position

percentages that start and stop the unit, based

on load. These levels are Factory preset as

follows for natural gas and propane units:

• Start Level: 20% (All units)

• Stop Level: 13% (Natural Gas)

• Stop Level: 16% (Propane)

Normally, these settings should not require

adjustment.

Note that the energy input of the boiler is not

linearly related to the valve position percentage

(Air/Fuel Valve Position). Refer to Table 3-6 for

the relationship between the energy input and

valve position percentage for a unit running on

natural gas.

3-9

Page 32

CONTROL PANEL OPERATING PROCEDURES

Table 3-6.

Relationship Between Air/Fuel Valve Position and Energy Input of a Unit Running on Natural Gas

Valve position,

Air/Fuel Valve

Position

(% Open)

0 0 0

10 0 0

13

(Stop Level)

20 89,000 9%

30 191,000 19%

40 311.000 31%

50 460,000 46%

60 600,000 60%

70 699,000 70%

80 836,000 84%

90 955,000 96%

100 1,000,000 100%

Energy Input

(BTU/Hr)

50,000 5 %

Boiler Energy Input

(% of Full Capacity)

3-10

Page 33

SECTION 4 - INITIAL START- UP

4.1 INITIAL START- UP REQUIREMENTS

The initial start-up of the KC-1000 Boiler is

comprised of the following steps:

• installation completed 100%

• combustion calibration

• proper setting of controls and limits

• mode of operation settings (see Section 5)

• safety device testing (see Section 6)

Installation procedures should be completed

100% before performing initial start-up and initial

the start-up must be complete prior to putting the

unit into service. Starting a unit without the

proper piping, venting, or electrical systems can

be dangerous and void the product’s warranty.

These start-up instructions should be precisely

followed in order for the unit to operate safely, at

a high thermal efficiency, and with low flue gas

emissions.

Initial unit start-up is to be performed ONLY by

AERCO factory trained start-up and service

personnel. After following the steps in this

section, it will be necessary to perform the mode

of operation settings in section 5, and the safety

control test procedures in section 6 to complete

the initial unit start-up.

An AERCO Gas Fired Startup Sheet included

with each KC-1000 must be completed for each

unit for warranty validation and a copy must be

returned promptly to AERCO at:

AERCO International, Inc.

159 Paris Ave.

Northvale, NJ 07647

WARNING!

DO NOT ATTEMPT TO FIRE THE UNIT

WITHOUT FULL WATER LEVEL. THIS

CAN SERIOUSLY DAMAGE THE UNIT

AND MAY RESULT IN PERSONAL

INJURY OR PROPERTY DAMAGE. THIS

IS NOT COVERED BY WARRANTY.

CAUTION!

All installation procedures in Section 2 must

be completed before attempting to start the

unit.

INITIAL START-UP

4.2 TOOLS AND INSTRUMENTATION

FOR COMBUSTION CALIBRATION

To properly perform combustion calibration, the

proper instruments and tools must be used and

correctly installed on the unit. The following

paragraphs outline the necessary tools and

instrumentation as well as their installation.

4.2.1 REQUIRED TOOLS AND

INSTRUMENTATION

The following tools and instrumentation are

necessary to perform combustion calibration of

the unit:

1. A digital combustion analyzer with oxygen

accuracy to 0.4%, and carbon monoxide in

PPM.

2. *A 16" W.C. manometer and plastic tubing.

3. One 1/4” and two 1/8” NPT-to-barbed fittings

for use with manometers.

4. A flat-tip screwdriver for adjusting the

AERCO differential gas pressure regulator.

5. Small and large flat blade screwdrivers.

6. 7/16" open end wrench and small adjustable

wrenches.

7. Tube of silicone adhesive

*For propane fired units: an additional 8" W.C.

manometer and 1/2" NPT to barbed fitting is

needed.

4.2.2 INSTALLING THE SUPPLY GAS

MANOMETER

1. Close the main manual gas supply valve up

stream of the unit.

2. Remove the 1/4" NPT pipe plug from the

port on the inlet side of the safety shut off

valve (see Figure 4.1).

3. Install a barbed fitting into the pipe plug

tapping.

4. Attach one end of a length of plastic tubing

to the barbed fitting and one end to the 16"

W.C. manometer.

4-1

Page 34

SSOV

1/8" NPT PLUG

(INSTALL

MANOMETER

HERE)

3/8" - 1/2"

HOLE FOR

COMBUSTION

ANALYZER

PROBE

EXHAUST

MANIFOLD

12" - 18"

INITIAL START-UP

Figure 4.1

1/8” Gas Plug Location

4.2.3 PREPARING THE FLUE VENT PROBE HOLE

1. If the unit has been installed using the

recommended AL29-4C vent, there will be a

3/8” hole, 18” to 24” above the exhaust

manifold. The outer vent section, that covers

vent section connections must be loosened

and moved to uncover the hole (see

Fig. 4.2).

2. If equipped with one, adjust the stop on the

combustion analyzer probe so that it

extends into the flue gas flow without hitting

the opposite wall of the flue. Do not insert

the probe at this time.

4-2

Figure 4.2

Analyzer Probe Hole Location

IMPORTANT

The unit is shipped from the factory set up for

either natural gas or propane, as specified by

the Style No. on the Sales Order.

For propane units, refer to paragraph 4.4 for

some additional setup procedures unique to

propane units. The oxygen and carbon

monoxide levels in Tables 1, 2 and 3 apply to

both natural gas and propane. However, it

should be noted that in Table 2 the oxygen and

carbon monoxide levels are measured at 13%

for natural gas and 16% for propane.