Page 1

Hoffman Specialty

Installation & Maintenance

Instructions

HS-222(E)

Float and Thermostatic Traps

Series H, C and X

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of steam systems in accordance with all applicable codes

and ordinances.

• To prevent serious burns, wear heat resistant gloves when opening and closing steam

valves, or handling hot equipment.

• To prevent serious burns, the internal pressure of the trap must be 0 psi (0 bar) before

servicing.

• To prevent serious personal injury from steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a drain, or stand at least 100 ft. (30 m) from

the front of the pipe opening.

• To prevent property damage, personal injury, or death, cap off the gate valves if they are

not connected to a drain and when they are not in use for test or pressure relief.

Failure to follow this warning could cause property damage, personal injury or death.

!

WARNING

CAUTION

WARNING

®

Series C

1

1

⁄4 & 11⁄2 NPT

Series C

2 NPT

Series X

2 NPT

Series C

2

1

⁄2 NPT

Series H

Ratings

Maximum Max. Operating

NPT Size - in. Temperature Pressure

°F (°C) psig (bar)

3

⁄4

”, 1” and

11⁄4

” H

406 (208)

175 (12.1)

11⁄4

” C and All

11⁄2

” -

21⁄2

”

377 (192)

Page 2

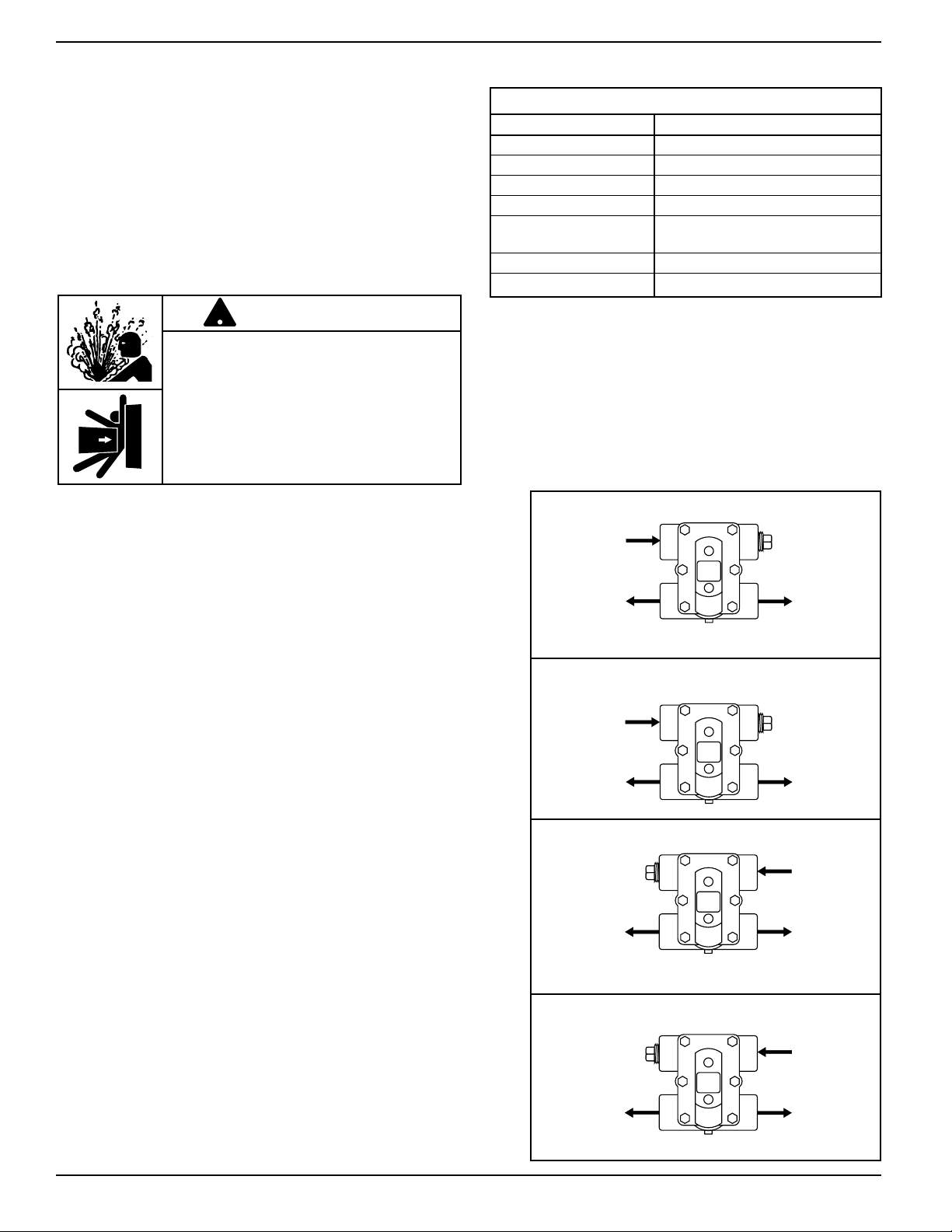

INLET

TEST

INLET

OUTLET

OUTLET

TEST

OUTLET

INLET

TEST

INLET

OUTLET

TEST

2

1. Determine where to install the trap, based on the

following requirements:

• The trap must be located as close as possible to, and

below the equipment to be drained.

• The trap must be in a straight run of horizontal pipe as

shown in the “Typical Piping Diagrams,” and pitched to

allow condensate to flow into trap inlet, and away from

trap outlet.

• Allow for enough space around the trap for servicing,

which may include removal of the body or cover,

depending on the model you are installing.

The Hoffman Series H traps provide an additional opening

where a test valve may be installed. On traps that do not

have an additional opening, the test valve can be installed

in a tee fitting in the discharge line.

OPERATION

Float and thermostatic traps have two basic elements: a

thermostat for venting air from the system during start-up

and a float assembly for draining condensate.

The thermostat is normally open. It allows air to vent until it

is within 10-30°F (4-12°C) of the steam temperature.

The float assembly drains condensate from the system

when buoyancy force lifts the float ball and opens the

valve. The weight of the float ball causes the pin to close

against the trap seat when condensate is not present.

Materials of Construction

Part Specifications

Body and Cover Cast Iron 30,000 psi tensile

Valve Pin and Seat Stainless Steel (Hardened)

Float Stainless Steel

Lever Assembly Stainless Steel

Thermostatic Air Vent Stainless Steel Cage and

Thermal Element

Cover Bolts Grade 5

Baffle Stainless Steel {21/2” units only}

To prevent serious personal injury from steam

pipe blow down, connect a temporary pipe

between the steam pipe opening and a drain,

or stand at least 100 ft. (30m) from the pipe

opening.

Failure to follow this warning could cause

property damage, personal injury, or death.

!

WARNING

INSTALLATION –

Series H, C and X Float and

Thermostatic Steam Traps

STEP 1

Page 3

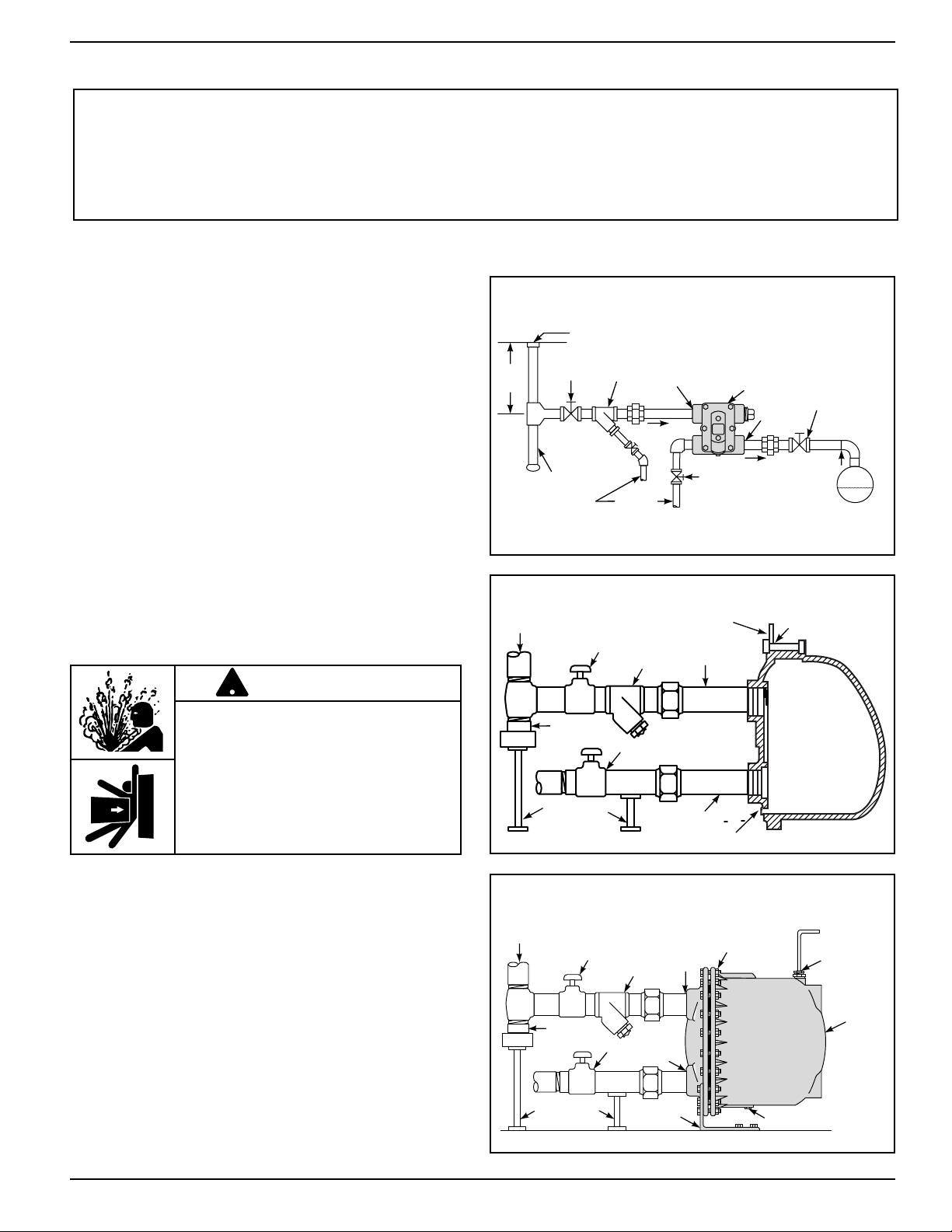

Shut-Off

Valve

"Y" Strainer

To Drain

To Return Line

Trap

Gravity Return to

Vented Receiver

Test Valve

Equipment Drain Point

Static

Head

Dirt Pocket

Inlet

Outlet

Shut-Off

Valve

Dirt

Pocket

Drain Plug

Outlet Valve

Supply

Inlet

Valve

Y Strainer

Cover Bolts

Thermostatic

Vent Pipe to

Gravity Return

Line or Drain

Pipe Supports

Support Foot

Inlet

Outlet

Trap

TYPICAL PIPING DIAGRAMS

Supply

Inlet

Valve

Y Strainer

Cover Bolts

Eye Hook

Dirt

Pocket

Pipe Supports

Drain Plug

Outlet Valve

Inlet

Outlet

Series H Trap Draining to Gravity Return Line

Series C and X Pattern Trap Installations

2

1

⁄2" Series C Pattern Trap Installations

• Install a Hoffman Specialty Y-strainer in the pipe,

ahead of the steam trap. This prevents dirt from

entering the trap.

• Install a blow down valve by connecting it to the

strainer drain plug. This allows the Y-strainer to be

cleaned.

• Install a shut-off valve in the inlet pipe and the outlet

pipe. This allows the trap to be isolated when

servicing.

• Install a test valve in the outlet pipe, and cap it. This

allows the trap to be tested. The cap is used as

safety precaution when the unit is not being tested.

• Blow down the piping using full steam pressure for

(5) five minutes. This cleaning process will remove

debris from the pipe and oil from the system.

Test traps by following the “Troubleshooting” procedure

on page 6.

3

To prevent serious personal injury from

steam pipe blow down, connect a temporary

pipe between the steam pipe opening and a

drain, or stand at least 100 ft. (30m) from

the pipe opening.

Failure to follow this warning could cause

property damage, personal injury, or death.

!

WARNING

STEP 2

IMPORTANT: To prevent system damage from water

hammer or sudden shock, open supply valves slowly.

If you are uncertain about the product’s adaptability

for your application, please call the factory or

authorized representative before using the product.

The trap seat rating (stamped on the nameplate) must

be equal to or greater than the maximum pressure

differential across the trap.

Page 4

4

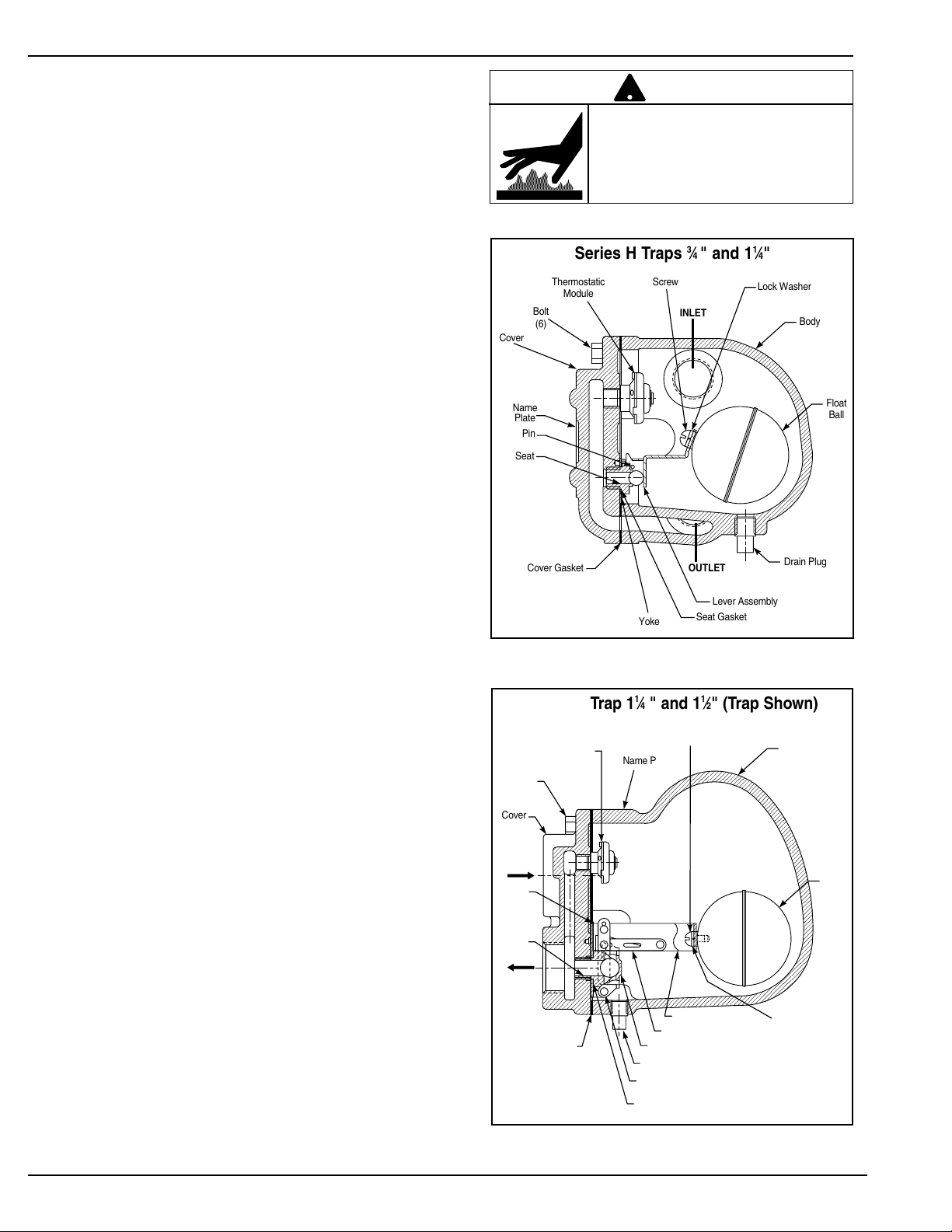

REPAIR PROCEDURES FOR ALL TRAPS

REMOVAL FROM SERVICE

1. Close inlet and outlet supply valves and allow unit to

cool. If a test valve is installed, open this valve to

relieve any pressure.

2. Remove the drain plug to drain condensate from the

trap body.

3. Remove the bolts that attach the cover to the body.

SERIES H TRAPS

REPAIR

4. With cover assembly removed from trap body, remove

pin that holds lever assembly to yoke. Inspect seat

and pin for wear, replace if worn.

5. Inspect thermostatic element by placing it in boiling

water to see if it closes. If it doesn't close, replace it.

6. Check alignment of pin and seat, adjust or replace

parts as necessary.

7. Check float ball for damage, shake the float to make

sure there is no fluid inside the float. Replace if

necessary.

8. Clean gasket surfaces and install new cover gasket.

9. Reassemble the cover to the body. Tighten the bolts in

the indicated sequence shown on page 5. Torque all

bolts evenly to the indicated values.

SERIES C & X TRAPS

REPAIR

4. With body assembly removed from trap cover, remove

pin that holds lever assembly to yoke. Inspect seat

and pin for wear, replace if worn.

5. Inspect thermostatic element by placing it in boiling

water to see if it closes. If it doesn't close, replace it.

6. Check alignment of pin and seat, adjust or replace

parts as necessary.

7. Check float ball for damage, shake the float to make

sure there is no fluid inside the float. Replace if

necessary.

8. Clean gasket surfaces and install new cover gasket.

9. Reassemble the body to the cover. Tighten the bolts in

the indicated sequence shown on page 5. Torque all

bolts evenly to the indicated values.

To prevent serious burns, the internal

pressure of the trap must be 0 psi

(0 bar) before servicing.

Failure to follow this caution will

cause personal injury.

CAUTION

!

Thermostatic

Module

Cover

Bolt

(6)

Pin

Seat

Name

Plate

Cover Gasket

Yoke

Seat Gasket

Lever Assembly

Drain Plug

Float

Ball

Body

Lock Washer

Screw

INLET

OUTLET

Series H Traps 3⁄4 " and 11⁄4"

Cover

Name Plate

Seat Gasket

Pin (4)

Lever Seat Assembly

Lever Linkage (3)

Lever

Lock Washer

Cover Gasket

Seat

Yoke

Screw

Thermostatic

Module

Bolt

(6)

Body

Float

Ball

INLET

OUTLET

Drain Plug

Series C Trap 11⁄4 " and 11⁄2" (Trap Shown)

Page 5

5

RETURN TO SERVICE

10. Insert and securely tighten drain plug.

11. Open supply valve on trap outlet side, slowly open the

supply valve to the trap inlet.

12. Check for leaks and normal operation.

Test traps by following the “Troubleshooting” procedure on

page 6.

Gasket

Thermostat

Lever

Retainer

Clip

Lever

Assembly

“E” Ring

Cover

Yoke

Pin

Seat

Gasket

Float

Ball

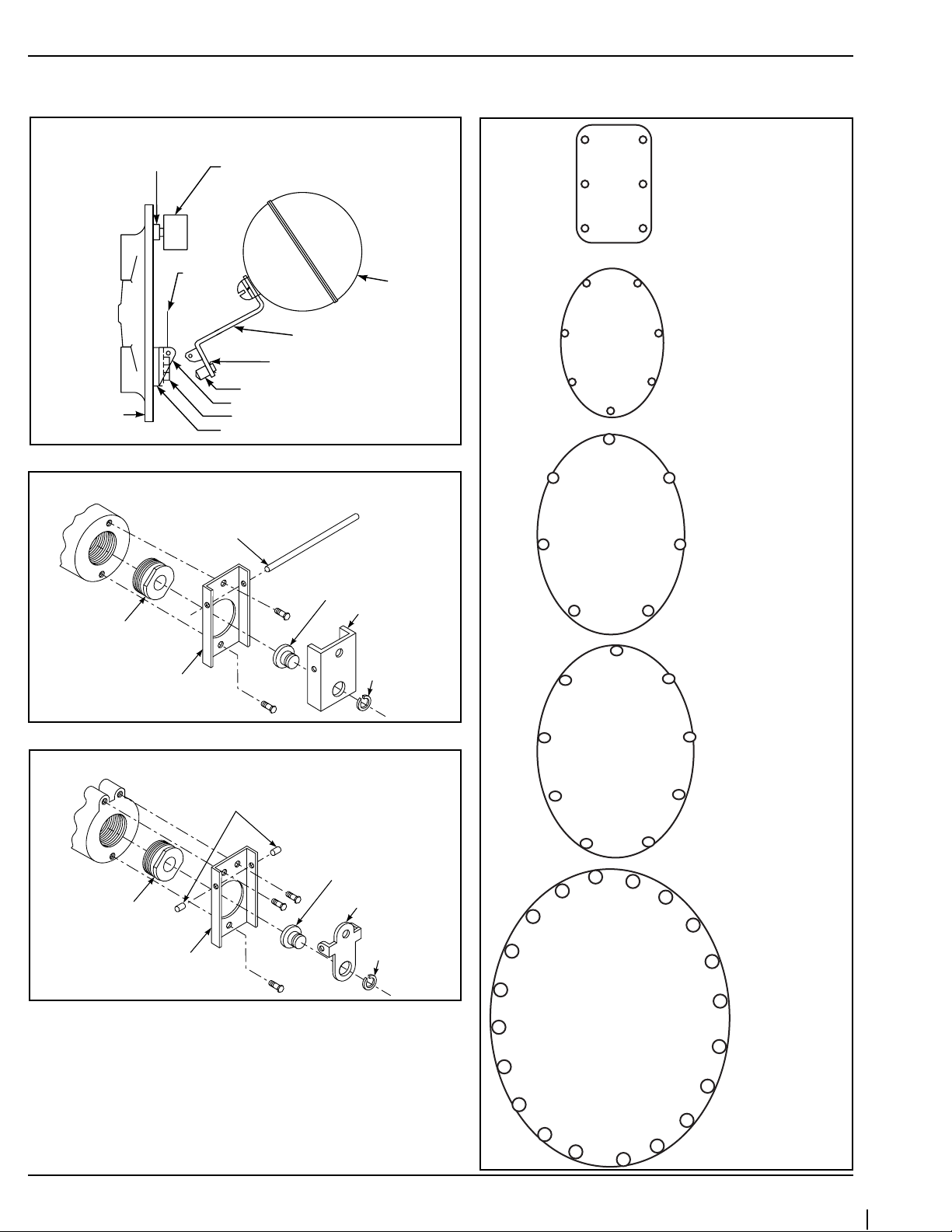

19

18

14

10

6

2

4

8

12

16

20

17

13

9

5

1

3

7

11

15

8

4

2

6

9

7

3

1

5

7

4

2

6

3

1

5

4

7

2

5

3

6

1

5

1

3

4

2

6

Series C Trap Cover 2" Standard Capacity

Pin

Seat

Bracket

“E” Ring

Seat

Yoke

Pins

Seat

Bracket

“E” Ring

Seat

Yoke

Series X Trap Seat and Yoke 2"

Series C Seat and Yoke 2

1

⁄2" Units

Internal Component Detail Illustration

Cover Bolt Pattern Layout

Series H 3⁄4

" to 2" Traps and

Series C

11⁄4"and

11⁄2

" Traps

with six bolt pattern

Tighten Bolts to 28 +/- 3 ft-lbs.

(38 +/- 4 N-m) Torque

Series H

11⁄2

" and 2" Traps

with seven bolt pattern

Tighten Bolts to 28 +/- 3 ftlbs. (38 +/- 4 N-m) Torque

Series C 2" Traps

Tighten Bolts to 75 ft-lbs.

(102 N-m) Torque

Series X 2" Traps

Tighten Bolts to 150 ftlbs. (205 N-m) Torque

Series C

21⁄2" Traps

Tighten Bolts to 75

ft-lbs. (102 N-m)

Torque

Tighten and torque bolts in numerical order, beginning with #1.

Page 6

TROUBLESHOOTING

Problem:

1. Improper heating.

a. Cause: Thermostat failed closed and prevents

air from escaping.

Test: Blow air through the thermostat

when it is at normal room temperature, for a visual check. If air does not

pass through, the thermostat is not

functioning properly.

b. Cause: Float assembly failed closed and

caused condensate to back-up into the

steam space.

Test: Using a stethoscope, listen for a gur-

gling sound. No gurgling indicates that

condensate is not draining.

Using a thermometer, check the trap discharge temperature. If the temperature is

lower than normal, the condensate is not

draining.

c. Cause: Incorrect trap seat pressure selected.

Test: Check seat pressure rating on trap name-

plate. The seat pressure rating must be

equal or higher than the steam supply

pressure.

2. Energy wasted.

a. Cause: Thermostat failed open and allowed live

steam to blow through the trap.

Test: Using a stethoscope, listen for a low pitch

whistle as steam passes through the open

orifice. A whistle indicates the thermostat

failed open.

b. Cause: Float assembly failed open and allowed

live steam to blow through the trap.

Test: Install a test valve in the discharge line

from the trap outlet. Observe the trap

operation for steam leakage. Excessive

steam leakage indicates the float assembly

failed open.

Using a stethoscope, listen for a low pitch

whistle by positioning the stethoscope near

the thermostat or the float assembly. A

whistle indicates the thermostat or float

assembly (depending on where the stethoscope is positioned) failed open.

OR

OR

MAINTENANCE

When checked regularly and properly maintained, the

Series FT Float and Thermostatic traps will

provide optimum performance and long life.

SCHEDULE:

• Initially, every 2 - 3 days after start-up until

system is clean.

• Every 6 months thereafter.

1. Inspect joints for leaks. Stop all leaks by tightening

bolts and replacing gaskets, if necessary.

2. Clean strainers by opening the blow down valve

and allowing full steam pressure to flow out for (2)

two minutes. Then, close the valve.

To prevent serious burns, the internal

pressure of the trap must be 0 psi

(0 bar) before servicing.

Failure to follow this caution will

cause personal injury.

CAUTION

!

To prevent serious personal injury from steam

pipe blow down, connect a temporary pipe

between the steam pipe opening and a

drain, or stand at least 100 ft. (30m) from

the pipe opening.

Failure to follow this warning could cause

property damage, personal injury, or death.

!

WARNING

Hoffman Specialty

ITT

8200 N. Austin Ave.

Morton Grove, IL 60053

tel: 847-966-3700

fax: 847-966-9052

www.hoffmanspecialty.com

©2007 ITT Corporation

Printed in U.S.A. 6-07 510837

Loading...

Loading...