Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

U S

s

s

C

1150-00001.

F6/F7...HD/HD

Butterfl y Valve

erie

Page 2

2

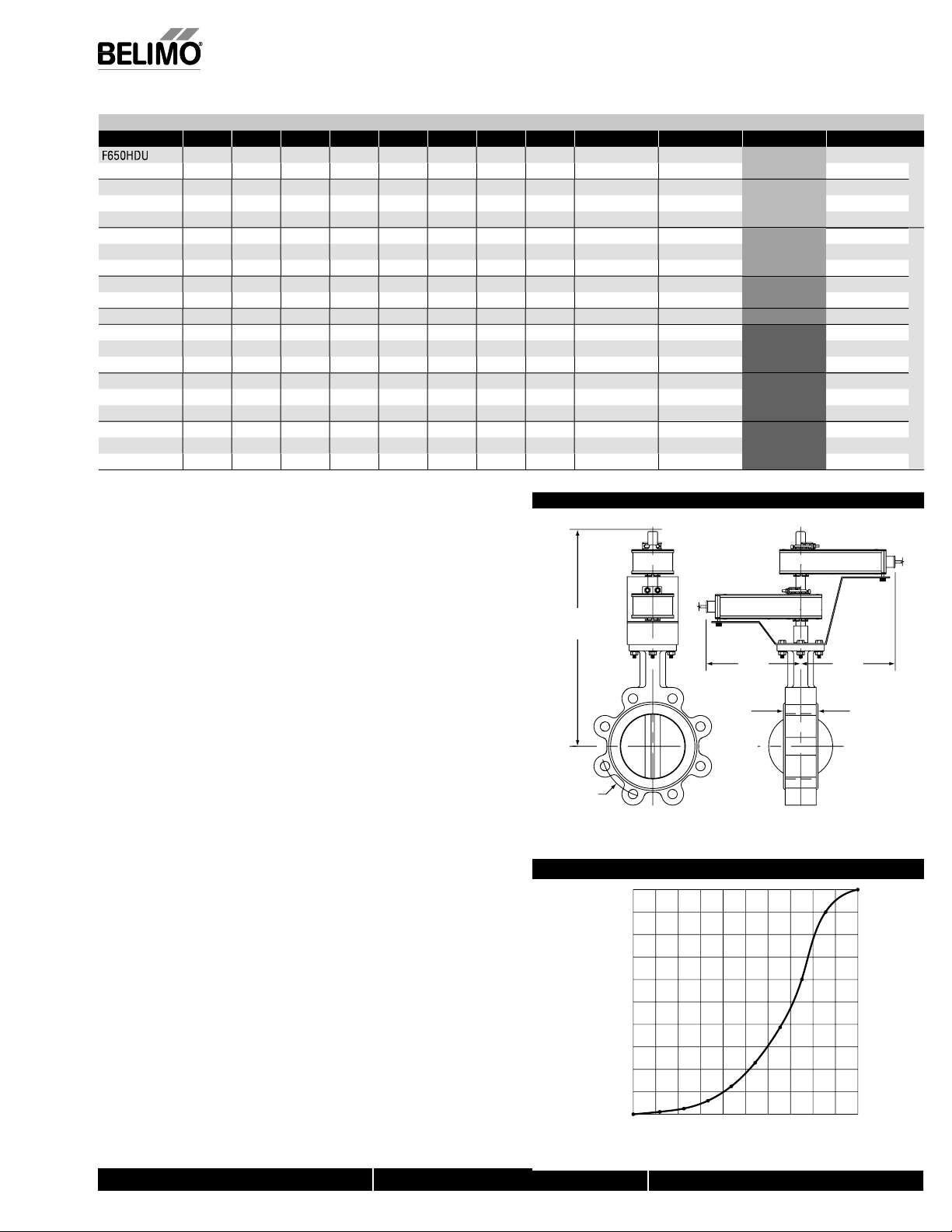

F6…HDU Butterfl y Valves 2”–12” Ductile Iron Lug Body

,

c

S

e

hilled, h

60% gl

l

c

m

Action

90°

S

s

2”

12”

Ty

g

M

ls

Body

h

sc

Seat

S

O

U

g

S

s

l

EPDM

416 stainless s

l

EPDM

g

30°F

°F)

i

y

y

S

g

y

n

hill

.

e

.

0

0HDU

HDU

U

U

U

9

U

U

U

50

U

U

5.06

0515

HDU

10

8.207075

U

6

HDU

”.50

U

”

6

7

”

U

7

9

U

4

1

7

Resilient Seat

304 Stainless Dis

• 50 psi bubble tight shut-off

• Lon

stem design allows for 2” insulation

• Valve face-to-face dimensions compl

• Completely assembled and tested, ready for installation

pplicatio

These valves are designed to meet the needs of HVAC and commercial

applications requiring bubble tight shut-off for liquids. Typical applications

nclude c

air handler coil control, bypass and process control applications. The large

values provide for an economical control valve solution for larger fl ow

applications. Designed for use in Victaulic piping systems when mated to

ictaulic 41 series fl ange nipples

Jobsite Not

alves should be stored in a weather protected area prior to construction.

omplete installation recommendations can be found in Belimo’s Installation

and Maintenance Instructions for F6/F7…HD/HDU Butterfl y Valves

with API 609 & MSS-SP-67

er isolation, cooling tower isolation, change-over systems, large

Technical Data

ervic

Flow characteristi

ize

pe of end fi ttin

ateria

Body fi nis

Di

haft

-ring

pper bushin

Middle bushings

Lower bushing

edia temperature range

peration ambient

emperature range

ody pressure ratin

lose-off pressure 50 ps

Rangeabilit

aximum velocit

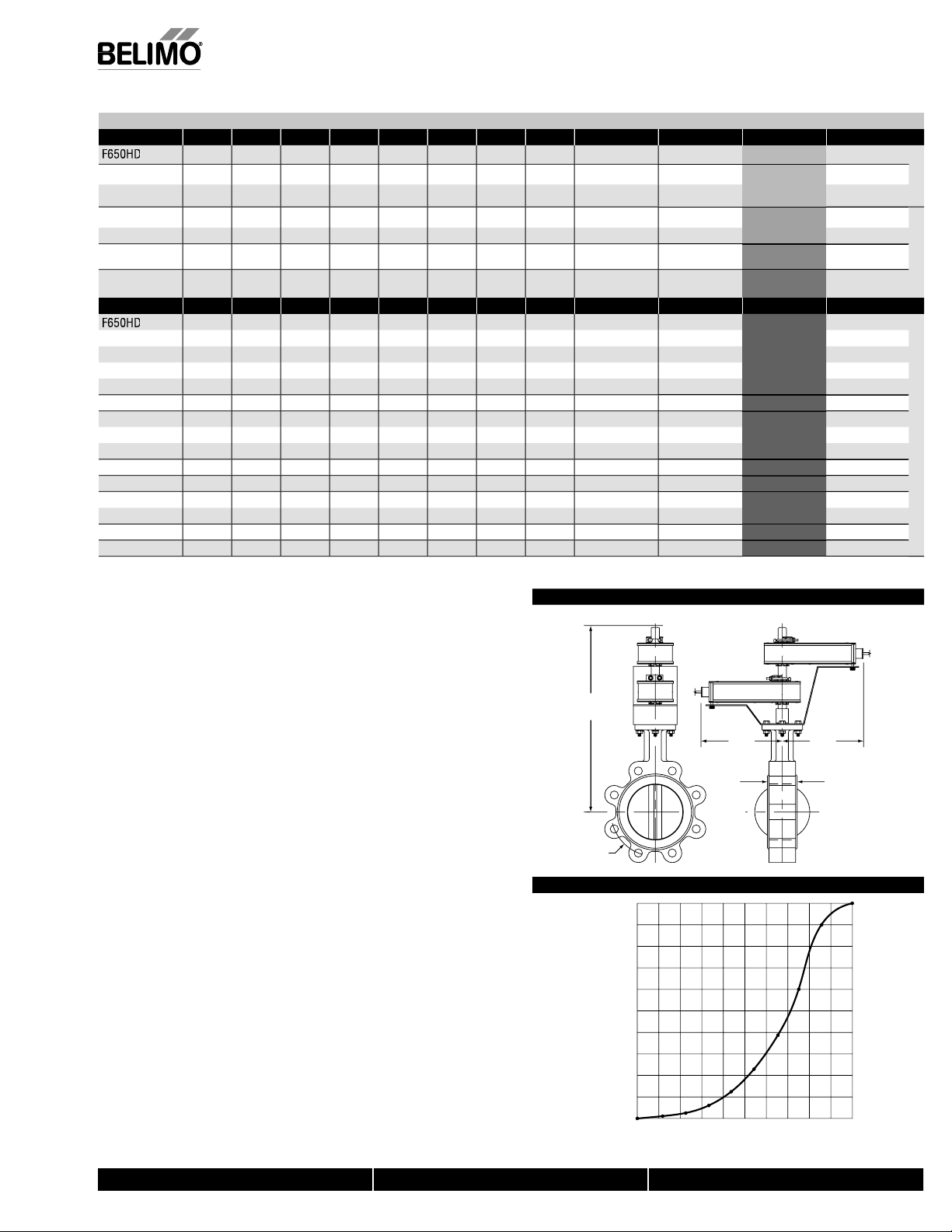

Valve Size

F650HD

5

2

c

for use with ANSI Class 125/150 fl anges

ductile iron A

epoxy powder coated

304

RPTFE

RPTFE

10:1 (for 30° to 70° range)

12 FP

ot water,

odifi ed equal percentage

rotation

to

TM A536

tainless stee

tee

22°F to 250°F [-30°C to 120°C]

22°F to 122°F [-30°C to 50°C]

SME/ANSI Class 125/150

psi at -

11

.

yco

to 275

°

alve

ominal Size

Cv

C

v

90°

60°

5

02 116

00

30

022

92 5” 125 F6125HD

7

136

202

4047 10”

2

°

° 40° 50°

7

2 12”

5

DN

IN

[mm]

5

” 80F680HD

” 100 F6100HD

” 150F6150HD

”

00 F6200HD

27 44

5

pe Suitable Actuators

2-way

F6250HD

F6300HD

MOD

Spring

5

5

° 70°

AF

AM

Series

Non-Spring

Series

GM

GM

1

7

SY Series

N/OFF

°

F6100HD

5

F6150HD

F6200HDU 8

F6250HD

F6300HD

600 .30

5

6

10”

12” 8250 4

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

1579 .80 45

3136 2 89

340 3 151

3

6

5

88 408 727 1202 1903 2854

20

95

8139230 364 54

7

05 36

94 123

072 191

605 958 143

2047

3062 5005 750

240 485

600

579

136

5340

250

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

Page 3

F6…HDU Butterfl y Valves 2”–12” Ductile Iron Lug Body

S

c

)

00.00.50

C

0

S

e

0

0

05.00.001.00.50

00.002.00.50

0

N

S

C

0

0

0

HDU

”

00.00

0.50

0

C

0

5

65.25.25.50.75

0

0

0

HDU

”

00.00.50.50

C

0

0

00.00.2

0

0HDU

340

8.00.00

0.2

C

0

C

0

.

.

.

.

.

0

0

0100

00

O

O

G

(

)

.

Resilient

Maximum Dimensions (Inches

Valve Size Cv 90° Cv 60° A B C D(Max) BHC No. of Holes Lug Bolt Actuator Close-Off (PSI)

F665HDU 2½”

F680HDU

F6100HDU 4”

F6125HDU

F650HDU 2”

F665HDU 2½”

F680HDU

F6100HDU 4”

5

5

F6150HDU

F650HDU 2”

F665HDU

F680HDU

F6100HDU 4”

5

5

F6150HDU

5

F6300HDU 12”

5

96

”

02

16 1.78

” 1022

15 44 1.65 7.00

96

”

02

00

” 1579

1

”

96 75 1.76

”

02

00

” 1579

16 1.78 7.00

30 2.05 8.00 8.00

05 2.19 8.00 8.00

44 1.

16 1.78

30 2.05 8.00 13.00

05 2.19 8.00 13.00

5

250 3062 3.01 8.00 13.00

.65

1.76

2.

2 2.14

1.76 7.00

.

.

.37

7

.5

.

.00

.00

.

.

.25

.25

.

.

.00

.00

.00

.00

.00

.25

.25

.75

0.00 5.50

0.50

5.00

.00

.75

5.50 5.50

6.00

7.00

.00

.50 8 5/8-11UNC

7.5

2.50

.50 8

6.00 5.50

6.25

2.00

3.00

.00

.50 8 5/8-11UNC

.50 8

5

5.5

7.25

7.00 12

.75

5

eat, 304 Stainless Dis

5/8-11UN

5/8-11UNC 5

5/8-11UNC

5/8-11UNC

4-10UNC

5/8-11UNC

5/8-11UN

5/8-11UNC 5

/4-10UNC 5

/4-10UN

5/8-11UNC

5/8-11UNC 5

5/8-11UNC 5

/4-10UN

/4-10UNC 5

/4-10UNC

/8-9UN

/8-9UN

A

*AF

MB(X)

MB(X)

MB(X)

SY1...

Y2...

Y3...

5

5

5

5

5

5

5

5

5

5

5

Fail

af

on-Fail

afe

Dimension “A” is compressed, add .125” for relaxed state.

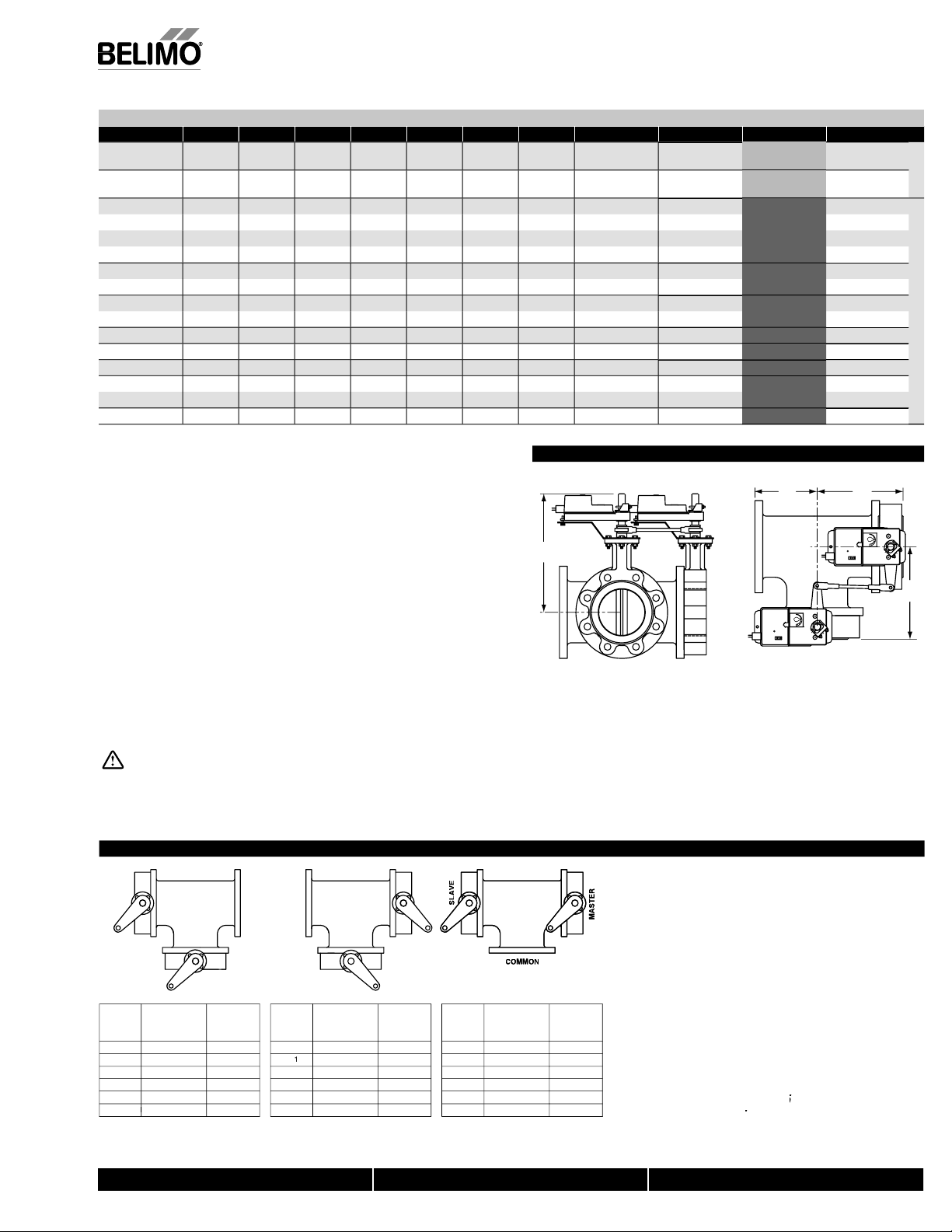

Dimensions

AF, AM and GM maximum actuator ambient temperature is 122°F.

Y maximum actuator ambient temperature is 150°F.

odel SY1… does not have handwheel - override is via 8mm wrench on

bottom side of actuator.

Application Notes

1. Valves are rated at 50 psi differential pressure in the closed position

. Valves are furnished with lugs tapped for use with ANSI Class 125/150

anges. Installation fl anges and hardware are not included

C

3. 2-way assemblies are furnished assembled and tested, ready for installation

4. Dimension “D” allows for actuator removal without the need to remove the

valve from the pipe.

, Inc

5. Weather shields are available, dimensional data upon request

USA

6. Dual actuated valves have actuators mounted on a common valve shaft

. Belimo SY Series actuators are NEMA 4X rated.

Flow Pattern

0

W

7/10 - Subject to change. © Belimo Aircontrols

7

50

F MAXIMUM FL

%

2

4

% OF VALVE OPENIN

1

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 4

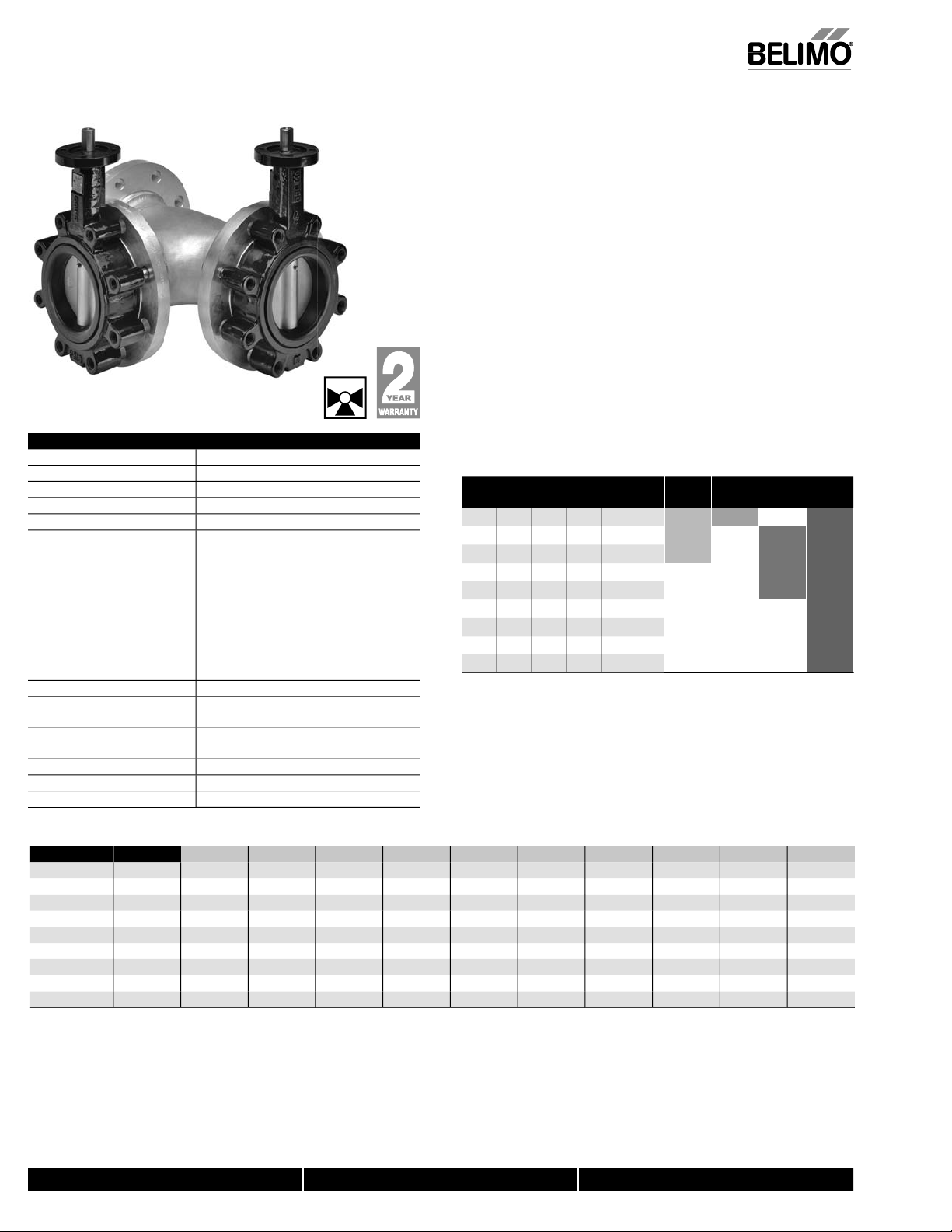

F7…HDU Butterfl y Valves 2”–12” Ductile Iron Lug Body

,

c

e

l

ic

r

n

12”

ls

y

h

t

t

g

g

g

l

less steel

30°F

°F)

e

i

y

)

y

S

g

y

n

s

n

y

e

0HDU

HDU

80HDU

100HDU

”

HDU

9

0HDU

U

U

U

0HDU

06

0

HDU

10

8

80HDU

2070

100HDU

30546

U

5029

0

U

7

200HDU

4

0HDU

1

95340

300HDU

0

2500

0750

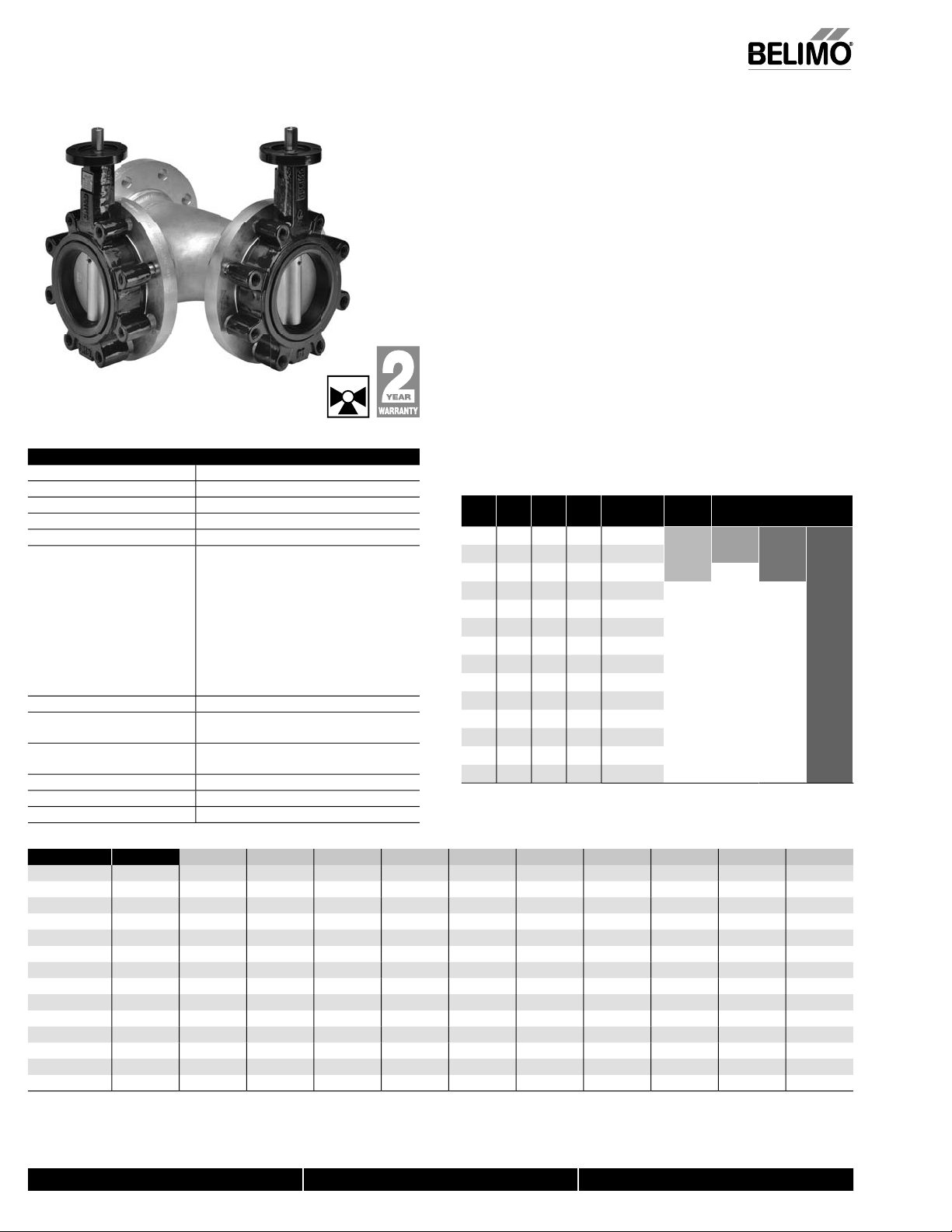

Resilient Seat

304 Stainless Dis

• 50 psi bubble tight shut-off

• Lon

stem design allows for 2” insulation

• Valve face-to-face dimensions compl

• Completely assembled and tested, ready for installatio

• Tees comply with ASME/ANSI B16.1 Class 125 fl ange

Applicatio

These valves are designed to meet the needs of HVAC and commercial

applications requiring bubble tight shut off for liquids. T

include chiller isolation, cooling tower isolation, change-over systems, large

air handler coil control, bypass and process control applications. The large

values provide for an economical control valve solution for larger fl ow

applications. Designed for use in Victaulic piping systems when mated to

ictaulic 41 series fl ange nipples.

obsite Not

alves should be stored in a weather protected area prior to construction.

omplete installation recommendations can be found in Belimo’s Installation

and Maintenance Instructions for F6/F7…HD/HDU Butterfl y Valves.

with API 609 & MSS-SP-67

pical applications

Technical Data

ervic

ow characterist

ctio

izes

Type of end fi tting for use with ANSI 125/150 fl anges

ateria

Bod

Body fi nis

ea

haf

O-rin

Upper bushin

Middle bushings

ower bushin

Media temperature range -22°F to 250°F [-30°C to 120°C]

eration ambient

temperature range -22°F to 122°F [-30°C to 50°C]

ody pressure rating ASME/ANSI Class 125/150

lose-off pressur

Rangeabilit

aximum velocit

Valve Size

75

765

7

7

F7125HD

F7150HD

7

725

7

” 1022 .

6” 1579 .80 45

chilled, hot water, 60% glyco

modifi ed linea

rotation

to

ductile iron ASTM A536

epoxy powder fi nish

stainless stee

standard

stain

RPTFE

RPTFE

psi at 50 ps

10:1 (for 30° to 70° range

12 FP

5 .

5

to 275

10°

.

.

.

0°

5

alve

ominal Size

Cv

C

v

90°

60°

5

7

136

202 8”200

5340

047 10” 250

250

062 12”

0°

1

5

5

0° 50°

5

5

05 366 605 958 143

7

IN

5

237

7

DN

[mm]

5075

00

7

7

pe

3-way

765

7

7

5

7125

715

7200HD

7250HD

7300HD

MOD

0° 70° 80° 90°

2

Spring

7

AF

Series

7

2

5 75

uitable Actuators

Non-Spring

AM

5

7

75

5

5

GM Series

SY Series

N/OFF

5

22

579

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 5

F7…HDU Butterfl y Valves 2”–12” Ductile Iron Lug Body

,

c

)

0HDU

0.1

0

C

0

F

U

00.76.76.00.50

U

0

U

0

U

0

U

50

8.281.00.00

100HDU

0

0

C

0

C

0

0

0

U

01.00.58.58.00

5

U

0

.

3

.

S

0

S

S

G

(

)

.

Resilient Seat

aximum Dimensions (Inches

Valve Size Cv 90° A B C D(Max) BHC No. of Holes Lug Bolt Actuator Close-Off (PSI)

75

765HD

780HD

750HD

765HD

2½”

780HD

7

7125HDU 5”

7150HDU

7200HDU

7250HD

7300HD

10”

12”

”

” 302 5.50 7.28

”

”

”

”

5

.5

.

15 4.50 6.15

96 5.00 6.76

2

.

.5

7.2

.55

022 7.50 9.64

579

136 9.00

.00

0.19

1.37

4

250

2.00

5.01

5

.15

.28

.15

.76

.55

.64

0.19

1.37

5.5

6.25

5.50

6.00 5.50

.75 7.5

2.25 8.50 8

2.75

4.25 11.75 8

5.01 32.00 17.00 12

.75

.00

.75

.50 8

14.2

5/8-11UN

5/8-11UNC

5/8-11UNC 5

5/8-11UNC

5/8-11UNC 5

5/8-11UNC

5/8-11UN

/4-10UN

/4-10UNC 5

/4-10UNC

12

/8-9UNC

/8-9UNC 5

304 Stainless Dis

5

*AF

Y1…

Y2…

Y3…

Y4…

5

5

5

5

ail Safe

Non-Fail Safe

F maximum actuator ambient temperature is 122°F.

SY... maximum actuator ambient temperature is 150°F.

Model SY1… does not have hand wheel-override is via 8mm wrench on bottom

ide of actuator.

cation Notes

1. Valves are rated at 50 psi differential pressure in the closed position.

2. Valves are furnished with lugs tapped for use with ANSI Class 125/150

fl a nges. Installation fl anges and hardware are not included

. 3-way assemblies are furnished assembled and tested, ready for installation.

-way assemblies require the customer to specify the 3-way

All

onfi guration prior to order entry to guarantee correct placement of valves

nd actuators on the assembly.

. Dimension “D” allows for actuator removal without the need to remove the

alve from the pipe.

. Weather shields are available, dimensional data upon request

. Dual actuated valves have single actuators mounted on each valve shaft.

7. Bolts supplied are for shipping purposes only. Upon installation replace with

an appropriate

AE grade 5 or better hardware.

8. Belimo SY Series actuators are NEMA 4X rated.

, Inc

USA

Dimensions

P15

DW

H

7/10 - Subject to change. © Belimo Aircontrols

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 6

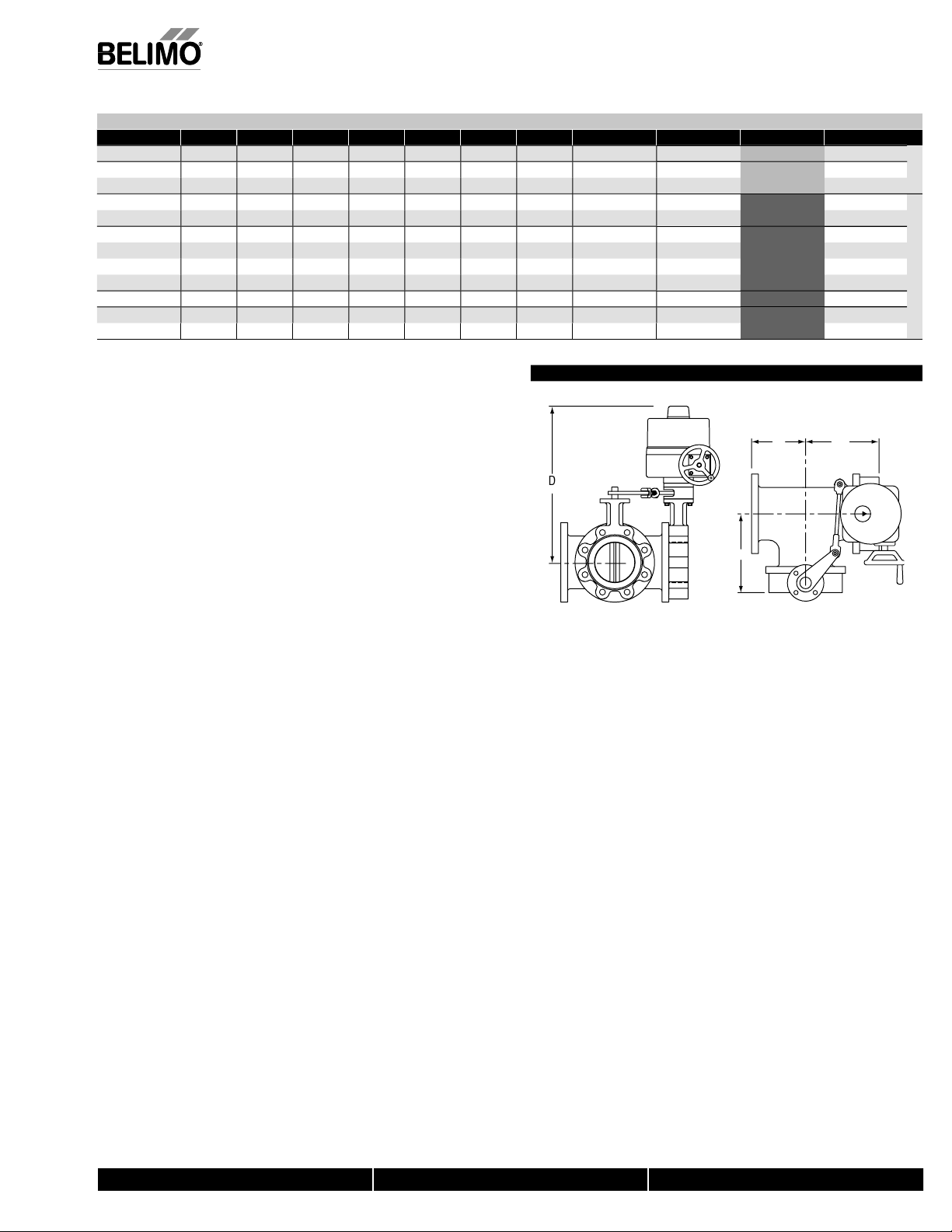

F6…HD Butterfl y Valves 2”–30” Ductile Iron Lug Body

,

c

e

ic

n

s

30”

g

s

yody

sc

t

t

g

g

S

ess steel

less steel

t

g

30°F

°F)

e

(2”-12”), 150

(14”-30”)

y

)

S

f

y

n

n

hill

.

.

e

050HD

”

HD579

050HD

340

050HD50

685050HD

050HD

908500500HD

28

0750HD

/

0HD

06

HD

1/2”

10

8

D

070116275

6

HD

”.5050HD579.80

8579

27

4

4

1

7

1

”

4

7

”

5

8

”

6

9

6

6208

05451701128146445451873426

Resilient Seat

Technical Data

ervic

ow characterist

ctio

Size

Type of end fi ttin

aterial

od

fi nish

i

ea

haf

O-rin

pper bushin

iddle bushings

ower bushing

edia temperature range -22°F to 250°F [-30°C to 120°C]

peration ambien

emperature range -22°F to 122°F [-30°C to 50°C]

ody pressure ratin

lose-off pressur

Rangeabilit

aximum velocity 12 FP

304 Stainless Dis

chilled, hot water, 60% glycol

modifi ed equal percentage

rotation

to

for use with ANSI 125/150 fl anges

ductile iron A

epoxy powder coated

4 stainl

EPDM standard

stain

ASME/ANSI Class 125/150

psi at -

psi

10:1 (for 30° to 70° range

TM A536

to 275

psi

• 200 psi (2” to 12”) and 150 psi (14”-30”) bubble tight shut-of

• Long stem design allows for 2” insulation

• Valve face-to-face dimensions compl

• Completely assembled and tested, ready for installatio

pplicatio

These valves are designed to meet the needs of HVAC and commercial

pplications requiring bubble tight shut-off for liquids. Typical applications

nclude c

ir handler coil control, bypass and process control applications. The large

values provide for an economical control valve solution for larger fl ow

pplications. Designed for use in Victaulic piping systems when mated to

ictaulic 41 series fl ange nipples

Jobsite Note

alves should be stored in a weather protected area prior to construction.

omplete installation recommendations can be found in Belimo’s Installation

nd Maintenance Instructions for F6/F7…HD/HDU Butterfl y Valves

C

v

90°

5

96

5

7

705

7

with API 609 & MSS-SP-67

er isolation, cooling tower isolation, change-over systems, large

lv

Nominal Size

C

v

IN

60°

½” 65 F665HD

5

5

7

5

5

DN

[mm]

5

75

ype Suitable Actuators

2-way

5

5

5

5

Spring

5

AF Series

Non-Spring

AM

GM

SY Series

Valve Size

5

5

H

6100HD 4

5

6300HD

6350HD

6400HD

6450HD

6500HD 20

6600HD 24

750HD

MODON

v

5 .

2 .2

600 .30 1

5

8250

4

6

8

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

11917 6

16388 8 46

21705 1

27908 14

43116 22 1222 2587 5605

7342

0°

.

0°

3

38 715

1

91

1

0°

95

83

302

674

4

0° 50°

5

5

8139230

5

072 191

549 276

130

822 502

628

7

7

79

465 10698 16931 2539

98

0°

5

7

3062 5005 750

4568

6282 9942 14913

8320 13168 19752 21705

16528 26157 3923

0° 80° 90°

64 54

5

230 10844

OFF

5

7

5

5

2

600

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

250

1917

6388

27908

43116

Page 7

F6…HD Butterfl y Valves 2”–30” Ductile Iron Lug Body

c

)

65.00.00.50.75

C

S

e

5

6.00.00.00.50

C

)

S

)

05.00.001.00.50

)

00.00.2

C

S

e

C

05.0013.00

5.50

00

9

9.0013.00

5.50

00.3

005.00.00

C

0.01.005.00.007.00

C

0HD

68.02.005.00.00

C

0

39

0015.004.50

516

C

†

5050HD70

13.00.00.2

C

†

0

C

285.94.00.0053.2

0

†

0

6.5

002.007.50.00

C

†

50

y.

n

.

.

p

.

.

U

070

O

U

O

G

Resilient Seat, 304 Stainless Dis

Maximum Dimensions (Inches

Valve Size Cv 90° Cv 60° A B C D(Max) BHC No. of Holes Lug Bolt Actuator Close-Off (PSI)

.

HD 2½”

680HD

650HD

665HD 2½”

680HD

100HD 4”

Valve Size Cv 90° Cv 60° A(Max) B (Max) C (Max) D(Max) BHC No. of Holes Lug Bolt Actuator Close-Off (PSI)

665HD 2½”

680HD

100HD 4”

6125HD 5” 1022

150HD

6250HD 10” 5340 2047 2.58 12.00 15.00

5

400HD 16”

6500HD 20” 27908

750HD

”

”

”

”

”157

” 734262814

7

1.7

02

15

96 75 1.76 7.00

02

96 75 1.76 8.00 13.00

02

16 1.78

1.65 7.00

16 1.78 8.00 8.00

2.

5

16 1.78 8.00 13.00

92 2.14 8.00 13.00

5

7

5

282

5

0698 5.00 14.00

5

.65

2.

2.1

7

.

.

7 14.

12.

.00

.

.

.00

.00

.00

1.00

0.50

5.00

5.50 5.50

6.00

0.75 5.50

1.00

1.7

2.25

2.7

0.00

1.50

5

4.25 12

1.2

5

5.00

5

.00

.75

.00

.75

.00

.50 8

.75

.75

.75

.5

5/8-11UN

5/8-11UNC

5/8-11UN

5/8-11UNC

5/8-11UNC

5/8-11UNC

5/8-11UNC

5/8-11UN

5/8-11UN

5/8-11UNC 200

5/8-11UNC 2

/4-10UNC 200

/4-10UNC

/4-10UN

/8-9UNC 200

/8-9UN

1-8UN

1-8UN

1 1/8-7UN

1 1/8-7UN

1 1/4-7UNC

1 1/4-7UN

*AF

MB(X

MB(X

*GMB(X

Y2…

Y3…

Y4…

Y5…

SY6…

Y8…

Y11…

Y12…

200

2

1

150

1

00

00

00

00

5

5

5

Fail

af

Non-Fail

afe

Non-Fail

af

imension “A” is compressed, add .125” for relaxed state.

SY6 and larger available in 110/220 VAC versions onl

AF, AM and GM maximum actuator ambient temperature is 122°F.

Y... maximum actuator ambient temperature is 150°F.

lication Notes

1. Valves are rated at 200 psi differential pressure in the closed positio

SY... 150 psi 14”+).

2. Valves are furnished with lugs tapped for use with ANSI Class 125/150

fl anges. Installation fl anges and hardware are not included

3. 2-way assemblies are furnished assembled and tested, ready for installation

. Dimension “D” allows for actuator removal without the need to remove the

valve from the pipe.

5. Weather shields are available, dimensional data u

6. Dual actuated valves have actuators mounted on a common valve shaft

7. Belimo SY Series actuators are NEMA 4X rated.

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

on request

Dimensions

Flow Pattern

W

M FL

5

F MAXIM

DIM

BF2W

A

OF VALVE OPENIN

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 8

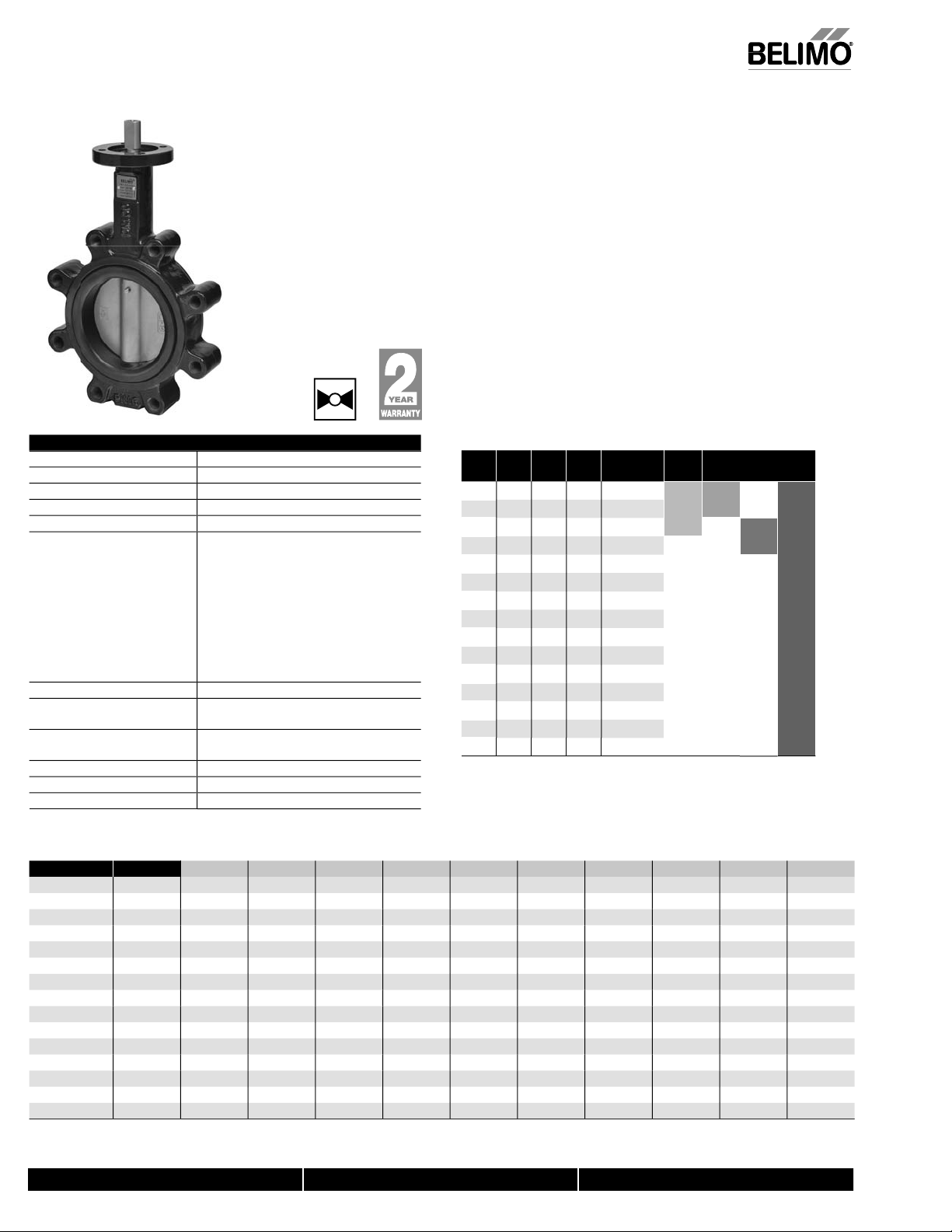

F7…HD Butterfl y Valves 2”–24” Ductile Iron Lug Body

,

c

e

ic

r

on

s

24”

g

s:

y

h

t

g

g

S

d

l

d

l

t

ge

g

)

e

(2”-12”), 150

(14”-24”)

bility

y

S

f

y

s

n

.

e

s

0750HD

HD

50

300

350HD

287600HD

0HD

0670

HD

1078780HD

2070757100HD

30546

5029237

010

0HD579.80

8579

200HD

4

015

0

0485940

1

7

1

4

”

7

50

05

5130

820131681975

05

”

Resilient Seat

Technical Data

ervic

ow characterist

Action

ize

Type of end fi ttin

Material

od

Body fi nis

eat

haf

O-rin

Upper bushin

e bushings

ower bushing

Media temperature range -22°F to 250°F [-30°C to 120°C]

peration ambien

temperature ran

ody pressure ratin

lose-off pressur

angea

Maximum Velocit

Valve Size

75

765

F7125HD

715

7

F7250HD

F7300HD

F7350HD

F7400HD

HD

F74

F7500HD 20

F7600HD 24

304 Stainless Dis

chilled, hot water, 60% glycol

modifi ed linea

° rotati

to

for use with ANSI 125/150 fl anges

ductile iron A

epoxy powder coate

stainless stee

416 stainless stee

PDM

RPTFE

-22°F to 122°F [-30°C to 50°C]

ME/ANSI Class 125/150

200 psi at -30°F to 275°F

psi

0:1 (for 30° to 70° range)

2 FP

5 .

1022 .

4

2

4

6

8250

11917

16388

217

27908 14 791 1674

3116 22 1222 2587 5605 9989 16528 26157 39236 43116

TM A536

standar

10°

.

.

.

11

psi

234

338 715

464

• 200 psi (2” to 12”) and 150 psi (14”-30”) bubble tight shut-of

• Long stem design allows for 2” insulation

• Valve face-to-face dimensions compl

• Completely assembled and tested, ready for installation

• Tees comply with ASME/ANSI B16.1 Class 125 fl ange

Applicatio

These valves are designed to meet the needs of HVAC and commercial

pplications requiring bubble tight shut off for liquids. Typical applications

nclude chiller isolation, cooling tower isolation, change-over systems, large

ir handler coil control, bypass and process control applications. The large

values provide for an economical control valve solution for larger fl ow

pplications. Designed for use in Victaulic piping systems when mated to

ictaulic 41 series fl ange nipples. Fail safe operation is possible with NSV-SY

eries battery backup systems

Jobsite Not

alves should be stored in a weather protected area prior to construction.

omplete installation recommendations can be found in Belimo’s Installation

nd Maintenance Instructions for F6/F7…HD/HDU Butterfl y Valves.

Cv

90°

5

02 116

00

22

579 605

3136 1202

4047

2

7

6388 6282

1705 8320

7908

°

5

1

1

°

2

95

83

2

°

5

412372047

072 191

549 276

130 379

22

628 6465 10698 16931 25396

alve

Nominal Size

C

v

IN

60°

5

”

30

” 100 F7100HD

2

”125F7125HD

” 150 F7150HD

” 200 F7200HD

” 250F7250HD

2

2”

6” 400 F7400HD

8” 450 F7450HD

0698

0” 500 F7500HD

5

7

2

with API 609 & MSS-SP-67

ype

DN

[mm]

2-way

5

5

765

F780HD

F7

7

MOD

°

2

5

3062 5005 750

4568 7230 1084

6282 9942 14913 16388

Spring

HD

uitable Actuator

AM

AF Series

°

2

5

5

24

Non-Spring

GM Series

2

SY Series

N/OFF

°

5

22

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

8250

11917

17

7908

8

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 9

F7…HD Butterfl y Valves 2”–24” Ductile Iron Lug Body

S

c

)

F

e

80HD

07.28.28.00.00

C

50.6

5.50

00

579.00.19.19

5.50

007200HD

00.3

00

C

C

0HD

007.027.02.00

C

†

0

00.39.39.50

516

50

05.5020.63.63.50

516

†

50

00HD

908.00.00.00.505.00

C

0

600HD.007.97.953.2

0

C

†

0

63

G

L

S

G

G

S

C

C

S

OD@

C

S

3X3

3

y

S

R

O

S

E

O

S

R

E

.

).

.

.

ON

.

y.

.

fi

eed to remove

.

0

0

D

AB

C

G

(

)

.

Resilient

Maximum Dimensions (Inches

Valve Size Cv 90° A B C D(Max) BHC No. of Holes Lug Bolt Actuator Close-Off (PSI)

F750HD 2”

15 4.50 6.15

.15

0.25

.75

eat, 304 Stainless Dis

5/8-11UNC

00

ail Saf

F765HD 2½”

F750HD 2”

F765HD 2½”

7

F7100HD 4”

F7125HD

F7150HD

F7250HD

F7300HD

0” 5340

2”

735

F7400HD

F7450HD

75

” 1022 7.

”1

”

” 217

96 5.00 6.76

15 4.50 6.15

96 5.00 6.76

5.5

00 6.50

.

1.00

250

2.00

7

.

.

7

.55

4

7

3.58

5.01

7

AF maximum actuator ambient temperature is 122°F.

Y... maximum actuator ambient temperature is 150°F.

†SY6 and larger available in 110/220 VAC versions onl

Application Notes

1. Valves are rated at 200 psi differential pressure in the closed position.

. Valves are furnished with lugs tapped for use with ANSI Class 125/150

fl a nges. Installation fl anges and hardware are not included

3. 3-way assemblies are furnished assembled and tested, ready for installation.

ll 3-way assemblies require the customer to specify the 3-way

con

guration prior to order entry to guarantee correct placement of valves

and actuators on the assembly.

4. Dimension “D” allows for actuator removal without the n

valve from the pipe.

5. Belimo SY Series actuators are NEMA 4X rated.

5. Weather shields are available, dimensional data upon request

6. Dual actuated valves have single actuators mounted on each valve shaft.

. Bolts supplied are for shipping purposes only. Upon installation replace with

, Inc

USA

n appropriate SAE grade 5 or better hardware.

ote: For tee confi guration, please refer to page 4

.76

.15

.76

.55

.64

0.75 5.50

0.25

.75

0.75 5.50

1.75

.50 8 5/8-11UNC 200

2.2

2.7

.37

.

.75

3.58 30.00 14.25 12

5.01 32.00 17.00 12

.75

1.2

2.7

5

.5

Dimensions

the

5/8-11UNC

5/8-11UNC

5/8-11UNC 200

5/8-11UN

4-10UNC

4-10UNC 2

/4-10UN

/8-9UN

/8-9UNC

1-8UN

1-8UNC

1 1/8-7UNC

1 1/8-7UN

1 1/4-7UN

*AF

Y2…

Y3…

Y4…

Y5…

SY6…

SY7…†

Y9…

Y12…

200

2

200

200

1

1

10

00

Non-Fail Safe

5

5

5

11

DW

10

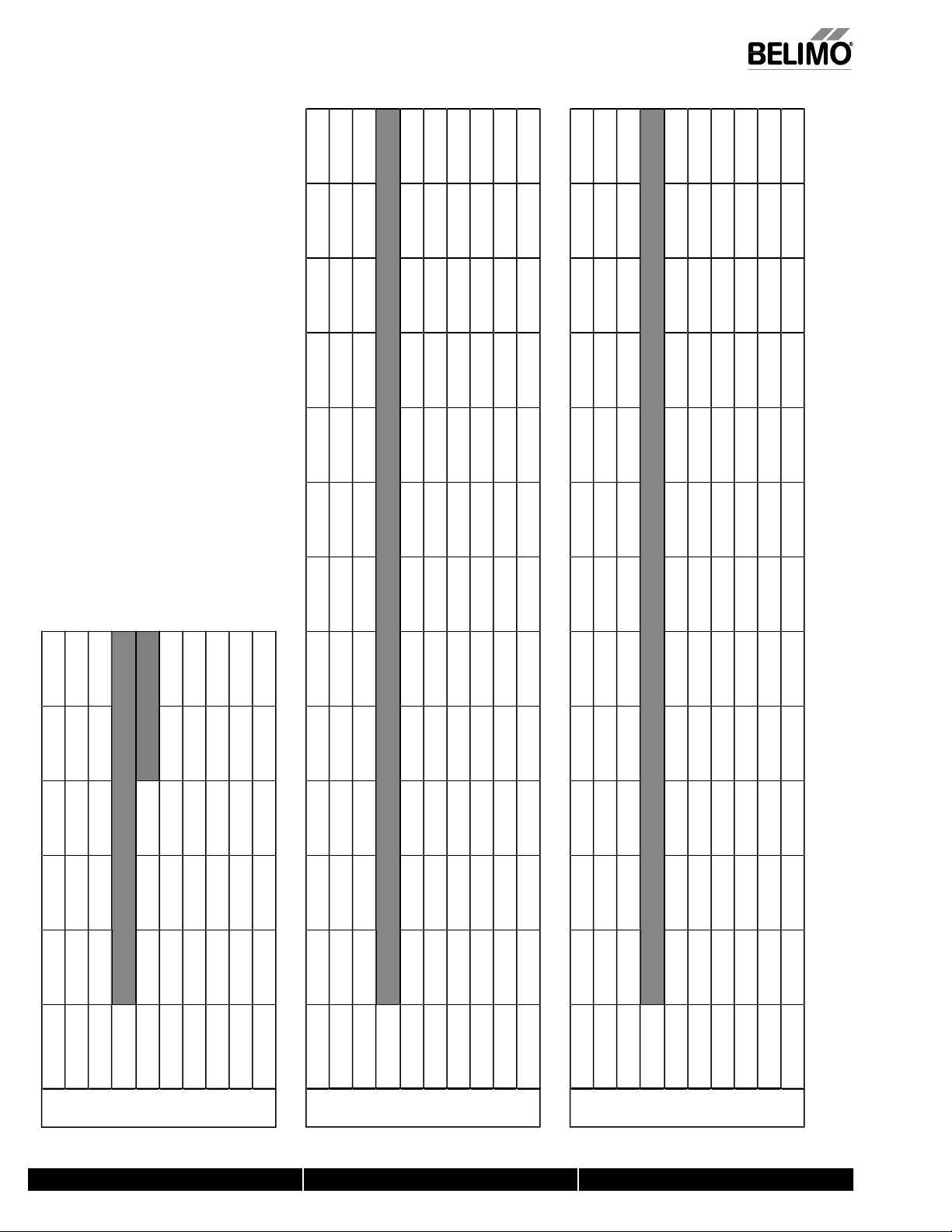

3-Way Confi guration Codes

D1

TE

A

N

MM

N

MM

T

LAV

MA

TE

MA

NOTES

1. Slave Valve operates inversely of the Master Valve.

. The Master Valve is always located on the run

3. The Slave Valve may also have an actuator if

equired (Direct Coupled

7/10 - Subject to change. © Belimo Aircontrols

MOD@2VD

NFI

DE

11

X Specifies Bi-Directional Flow Capabilit

N/OFF OR

ASTER

VALVE I

PEN

PEN

PEN

CLOSED

LOSED

LOSED

LAVE

ASTER

VALVE

FAI

N-FAIL

PEN

LOSED

ON-FAIL

PEN

LOSED

NFI

DE

X

X

X

X

X

LAVE

N/OFF OR

D@2VD

MASTER

ALVE I

PEN

PEN

PEN

LOSED

LOSED

LOSED

ASTER

VALVE

FAIL

N-FAIL

PEN

LOSED

ON-FAIL

PEN

LOSED

X

X

X33

X3

X3

MMON

N/OFF OR

2VD

M

NFI

ASTER

DE

VALVE I

PEN

PEN

1

PEN

LOSED

LOSED

LOSED

MA

VALVE

FAIL

N-FAIL

PEN

LOSED

ON-FAIL

PEN

LOSED

TER

4. On/Off actuator normal position is a function of

fi eld logic

5. Proportional actuator normal position is a function

f the CCW/CW switch.

6. All 3-way assemblies are designed for 90 degree

ctuator rotation

RDERING INFORMATI

Please note that HD series BF valves over 18” and

ALL sizes 3-way tee assemblies ordered with

are special order/custom

built and are

returnable.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

9

Page 10

0

Wire Size vs. Length of Run for SY Series Actuators

g

A

ps

A

ps

A

ps

A

ps

A

ps

i

g

ge

8

5

6

4

0

0

2

4

0

0

4

8

3

3

1

C

A

s

A

s

A

s

A

s

A

s

A

s

A

s

A

s

A

s

A

s

A

s

A

s

i

g

ge

3

5

8

2

2

8

8

8

83

05

89

89

3

89

6

90

90

6

94

2

2

6

923

9

068

8

8

2

634

9

35

9

35

35

0

000

000

6

8

63

2

0

63

0

2

0

925

63

63

5

6

866

88

866

1

C

A

ps

A

ps

A

ps

A

ps

A

ps

A

ps

A

ps

A

ps

A

ps

A

ps

A

ps

A

ps

g

ge

3

5

5

6

7

8

6

6

6

2

8

0

5

5

4

8

8

9

6

937

62

62

0

6

88

90

88

90

88

082

1

2

5

8

4

8

2

8

5

4

3

6

1

4

0

666

286

00

0

000

0

000

0

9

51

8

6

322

63

63

84

2

C

Y11 SY12

Y10

Y9

Y8

Y7

Y6

mp

mp

mp

mp

mp

mp

mp

1

1

7

5

41 4

4

.

.

1.

1

71

14

7

1

71

1

7

1

1

1

5

7

7

1

7

1

1

71

4

5

5

5

1

1

15

77

14

Y12

Y11

Y10

Y9

Y8

Y7

Y6

m

2.

m

1.

m

m

1.

m

m

1.

.

m

947 68

947 75

47 75

189

1

4

1

4

11

14

7

923 2404 174

1923 2404

240

80

676 267

676 2941

294

367

7

5

5

74

5

5

74

5

5

ed to 120 VAC models.

Y5

Y4

Y3

Y2

Y1

.

m

m

m

m

.

m

7

7

40 7

14 1

1

33 14

57

64 182 16

06 36

7

4

4

Y5

Y4

Y3

Y2

Y1

mp

mp

mp

mp

mp

1.

5

MAX Distance between Actuator and Supply (feet)

1.

.5

5

75

75

7

1

47

1

1

111

4

11

41

41

7

4

5741

5

74

5

74

4

Y5

Y4

Y3

Y2

Y1

.

m

.

m

.

m

.

m

.

m

MAX Distance between Actuator and Supply (feet)

au

re

w

181

1

1

1

24 VA

au

re

w

1

1

1

1

au

wire

10 VA

1

16

4

49

MAX Distance between Actuator and Supply (feet)

52

030

5051 303

1

7

47

7

1

410

7692

769

282

8403 735

80

176

1765

960

1

4

1

7

7

4

1

1

7

4

1

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

20 VA

he same conduit. Generally, 24 VAC actuators over 100 VA should be chan

The NEC mandates that 24 VAC over 100 VA power requires CLASS 1 wiring conduit. Local codes may vary. Do NOT mix CLASS 1 & CLASS 2 circuits in

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

1

Page 11

il

V

+

-

n

V

+

-

Adaption

A

V

Actuators: SYx-MFT

pply

n

(

)

.

INSTALLATION NOTES

CAUTION

nterface Wiring Deta

Yx-MFT, 24V, 120/230

tes:

1. Motor CAMS have been factory calibrated and should not be moved.

. An adaption must be performed if any limit switch is adjusted. This will

calibrate the beginning and end stopping points. Press the adaption

utton for 3 seconds and release.

, Inc

USA

Control Signal

Control Signal

FDBK +

FDBK -

Adaptio

PC Tool Service Jack Connection

rection of Rotation

Power Supply Hot +

4

- Power Su

- Power Supply Hot

Commo

Power Supply Com -

7/10 - Subject to change. © Belimo Aircontrols

Control Signal

Control Signal

FDBK +

-

PC Tool Service Jack

rection of Rotation

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

120/230

1

Page 12

2

SYx-P Interface Wiring Detail

C

A

UT-5VDC

C

A

OSS

S

SE

T

OSS

D

)

OSS

N

)

OSS

N

OSS

D

g)

N

N

N

N

/

.

L

i

o

-

INSTALLATION NOTES

CAUTION

FF

N

FF

N

FF

N

FF

N

FF

N

INP

:

pplicable to the SY1 and legacy SY2-12 actuators

.

-10D

5

4-20m

TPUT=

TPUT=

-20m

-10VD

2

FF

RESPONSE = DIREC

O

FF

RESPONSE = REVER

O

L

F

FF

L

O

2

L

1

FF

L

2

1

FF

L

O

IGNALLOSE

F

IGNALPE

R

rse Acting

F

IGNALPE

DirectActing)

F

IGNALLOSE

F

IGNAL =

DirectActing

verse Actin

WARNING

t

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

F

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

1

Page 13

s

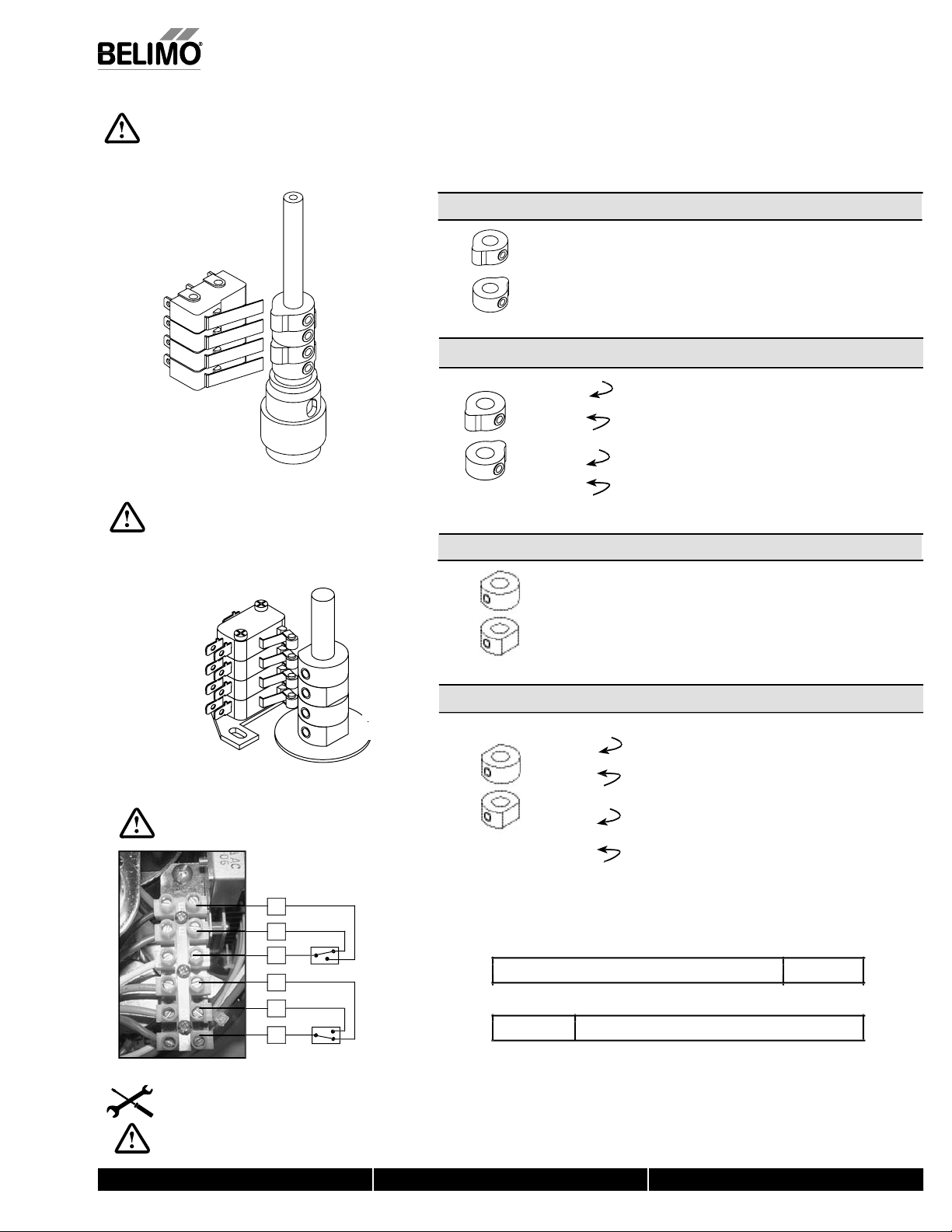

Counter-clockwise Increase Closed Angle

Counter-clockwise Decrease Opening Angle

S

5

85

90°

°

°

3

S4

S1LS2

S3

n

n

Counter-clockwise Increase Closed Angle

Counter-clockwise Decrease Opening Angle

d

WARNING

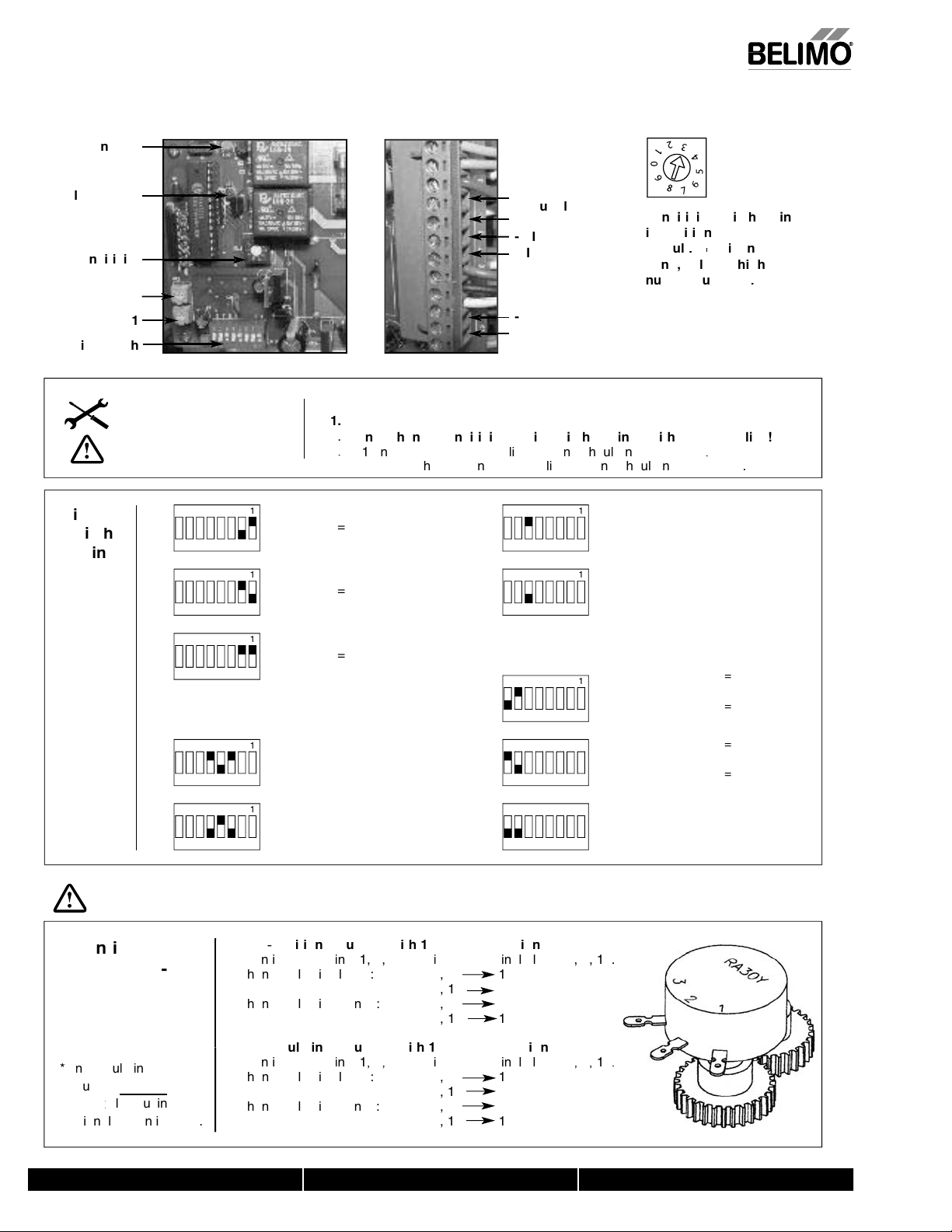

Electrical Travel Adjustment (Factory Pre-set

)

1

CAUTION

CAUTION

g

g

CAUTION

INSTALLATION NOTES

(

)

.

SY-

actory pre-set see chart below. Field adjustable if required

Factory pre-set and calibrated. Do not adjust - warranty voided

SY… Series Non-Spring Actuator

S4

uxiliary Switch for Closed Indicatio

uxiliary Switch for Opened Indicatio

LOSE”

PEN”

Electrical Travel Adjustment

Y-2-12

LS4

L

, Inc

USA

7/10 - Subject to change. © Belimo Aircontrols

L

LS

L

actory pre-set see chart below. Field adjustable if required

LS4

uxiliary Switch for Closed Indication

L

3

uxiliary Switch for Opened Indication

Factory pre-set and calibrated. Do not adjust - warranty voide

“CLOSE”

“OPEN”

witches at left are shown with actuator fully open.

0°

0° 5

°

85° 90

°

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

tes:

. An adaption must be performed when the limit switches are adjusted. For

the SYx-MFT actuators. This will calibrate the be

oints. Press the adaption button for 3 seconds and release.

inning and end stoppin

3

Page 14

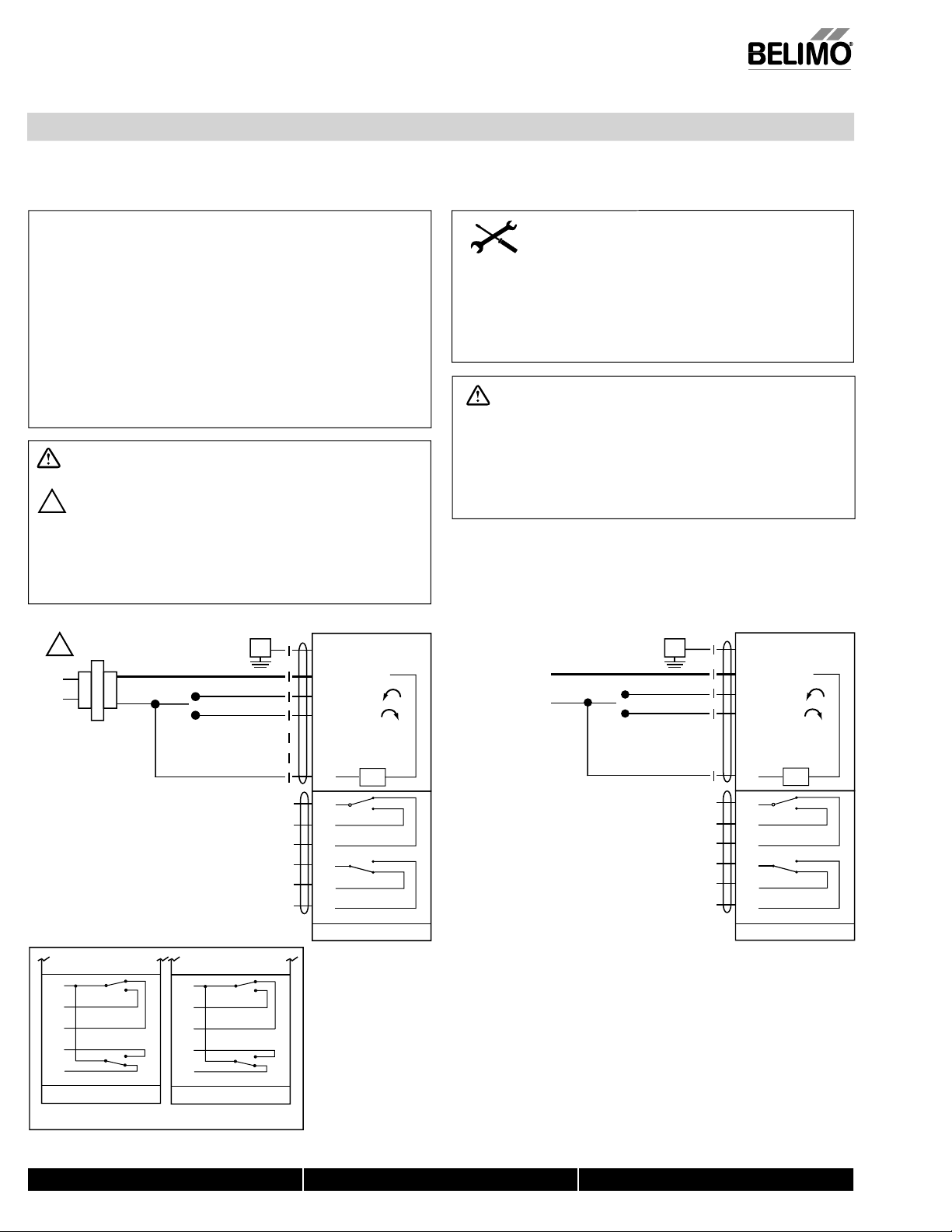

W

iring for Damper Actuators and Control Valves

,

On/Off

Actuators: SY1-24 SY1-110 SY2...12-110 SY2...12-220

24V, 120/230V

546

Hazard Identification

Warnings and Cautions appear at appropriate sections throughout

this manual. Read these carefully.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

Indicates an action or condition that may cause irreversible

damage to the actuator(s) or associated equipment.

Equipment damage!

Power consumption and input impedance must be observed.

NOTES SY1…5-24

Each actuator should be powered by a single, isolated

33

control transformer.

s)SOLATIONRELAYSMUSTBEUSEDINPARALLELCONNECTIONOFMULTIPLEACTUATORS

using a common control signal input.

s(CANNOTBECONNECTEDTOTERMINALANDSIMULTANEOUSLY

sRequired: 4ERMINALNEEDSTOBEFIELDWIREDTOENABLEHEATERCIRCUIT

G

G Ground

1 Common

3 Open

4 Closed

Connect to #1 for fully

5

open indication

Connect to #1 for fully

6

closed indication

7

HTR

Line

Volts

24 VAC Transformer

33

Open

Close

INSTALLATION NOTES

Observe class 1 and class 2 wiring restrictions.

Transformer sizing = SY actuator draw X 1.25 (safety margin)

(Ex. SY2-24 requires 3.0A x 1.25 = 3.75A,

3.75A X 24 VAC = 90VA Transformer).

NOTES SY1…12-110 (220)

sCaution: Power Supply Voltage

s)SOLATIONRELAYSMUSTBEUSEDINPARALLELCONNECTIONOFMULTIPLEACTUATORS

using a common control signal input.

s(,CANNOTBECONNECTEDTOTERMINALANDSIMULTANEOUSLY

sRequired: 4ERMINALNEEDSTOBEFIELDWIREDTOENABLEHEATERCIRCUIT

120 and 230 VAC

N L1

H L2

G

Open

Close

G Ground

1 Common

3 Open

4 Closed

Connect to #1 for fully

5

open indication

Connect to #1 for fully

6

closed indication

HTR

7

A

LS3

B

A-B (Open Indication)

C

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

E

F

LS4

A-E (Closed Indication)

SY1-24

SY1 Contact Arrangements

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

14

A

B

A-B (Open Indication)

C

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

E

F

A-E (Closed Indication)

SY1-110 (220)

A

LS3

B

(Open Indication)

A-C

C

D

LS4

E

(Closed Indication)

D-F

F

Contact Rating: 5A 250 VAC Max.

SY2…5-24

A

LS3

B

A-C

(Open Indication)

C

D

LS4

E

D-F

(Closed Indication)

F

Contact Rating: 5A 250 VAC Max.

SY2…12-110 (220)

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

LS3

LS4

Page 15

p

V

Actuators: SY1-24P SY1-110P SY1-220P

(

)

.

547

Hazard Identification

7ARNINGSAND#AUTIONSAPPEARATAPPROPRIATESECTIONSTHROUGHOUT

this manual. Read these carefully.

CAUTION

)NDICATESAPOTENTIALLYHAZARDOUSSITUATIONWHICHIFNOTAVOIDED

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

Indicates an action or condition that may cause irreversible

damage to the actuator(s) or associated equipment.

%QUIPMENTDAMAGE

0OWERCONSUMPTIONANDINPUTIMPEDANCEMUSTBEOBSERVED

Wiring for Damper Actuators and Control Valves

Pro

ortional, 24V, 120/230

INSTALLATION NOTES

/BSERVE#LASSAND#LASSWIRINGRESTRICTIONS

4RANSFORMERSIZING39ACTUATORDRAW8SAFETYMARGIN

%X39REQUIRES!X!!86!#6!4RANSFORMER

APPLICATION NOTES

Ground shielded wire at control panel chassis.

34

Tape back ground at actuator.

36

Use of feedback is optional.

, Inc

USA

NOTES SY1…24P

Each actuator should be powered by a single, isolated

33

control transformer.

s0OWERSUPPLY#OM.EUTRALAND#ONTROL3IGNAL "–" wiring to a common is

prohibited. Terminals 4 and 6 need to be wired separately.

s$ONOTCHANGESENSITIVITYORDIPSWITCHSETTINGSWITHPOWERAPPLIED

24 VAC Transformer

33

Line

Volts

Control signal

Feedback

G

G Ground

4 Power Supply Com

5 Power Supply Hot

6 Control Signal (-)

7 Control Signal (+)

34

8 Internal Use Only

9 Internal Use Only

10 Internal Use Only

11 Feedback (-)

12 Feedback (+)

36

A

B

!"/PEN)NDICATION

C

#ONTACT2ATING !6!#-AX

!6!#-AX

E

F

!%#LOSED)NDICATION

SY1-24P

NOTES SY1…110P (220P)

sCaution:0OWERSUPPLYVOLTAGE

s0OWERSUPPLY#OM.EUTRALAND#ONTROL3IGNAL "–" wiring to a common is

prohibited. Terminals 4 and 6 need to be wired separately.

s$ONOTCHANGESENSITIVITYORDIPSWITCHSETTINGSWITHPOWERAPPLIED

120 and 230 VAC

G

N L1

H L2

Control signal

34

Feedback

36

LS3

LS4

G Ground

4 Power Supply Com

5 Power Supply Hot

6 Control Signal (-)

7 Control Signal (+)

8 Internal Use Only

9 Internal Use Only

10 Internal Use Only

11 Feedback (-)

12 Feedback (+)

A

LS3

B

!"/PEN)NDICATION

C

#ONTACT2ATING !6!#-AX

!6!#-AX

E

F

LS4

!%#LOSED)NDICATION

SY1 -110P (220P)

7/10 - Subject to change. © Belimo Aircontrols

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

5

Page 16

W

iring for Damper Actuators and

C

s

2

ŏ

ŏ

ŏ

ŏ

ŏ

L

ontrol Valve

Proportional, 24V, 120/230V

Actuators: SY2...5-24MFT SY2...12-120MFT SY2...12-230MFT

Hazard Identification

7ARNINGSAND#AUTIONSAPPEARATAPPROPRIATESECTIONSTHROUGHOUT

this manual. Read these carefully.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

Indicates an action or condition that may cause irreversible

damage to the actuator(s) or associated equipment.

%QUIPMENTDAMAGE

0OWERCONSUMPTIONANDINPUTIMPEDANCEMUSTBEOBSERVED

NOTES SY2...5-24MFT

Each actuator should be powered by a single, isolated

33

control transformer.

s0OWERSUPPLY#OM.EUTRALAND#ONTROL3IGNAL "–" wiring to a common is

prohibited.

Control Signal

Feedback

36

34

Control Signal (+)

Control Signal (-)

Feedback Signal (+)

Feedback Signal (-)

Not Used -

Not Used -

INSTALLATION NOTES

W547-

/BSERVE#LASSAND#LASSWIRINGRESTRICTIONS

4RANSFORMERSIZING39ACTUATORDRAW8SAFETYMARGIN

%X39REQUIRES!X!!86!#6!4RANSFORMER

APPLICATION NOTES

Ground shielded wire at control panel chassis.

34

Tape back ground at actuator.

36

Use of feedback is optional.

NOTES SY2...12-120MFT (230MFT)

sCaution:0OWERSUPPLYVOLTAGE

A

Internal Use Only

B

PC Tool

Service Jack

Y

1

U5

2

C1

C2

Address

Adaption

Y1Y2

SYx-24MFT

1

2

3

/-

~/+

8

9

10

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Power Supply Com

Power Supply Hot

Internal Use Only

Internal Use Only

Internal Use Only

24VAC

33

Control Signal

A

B

C

E

F

SY2...5-24MFT

SY2...12-120MFT

16

G

PE

Power Supply Com – 120v (N) / 230v (L1)

Power Supply Hot – 120v (H) / 230v (L2)

A

B

1

2

3

8

9

10

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Feedback

36

LS3

!"/PEN)NDICATION

#ONTACT2ATING !6!#-AX

!6!#-AX

LS4

!%#LOSED)NDICATION

N

PC Tool

Service Jack

Control Signal (+)

Control Signal (-)

Feedback Signal (+)

Feedback Signal (-)

34

G

Not Used -

Not Used -

PE

Y

1

U5

2

C1

C2

SYx-120MFT

SYx-230MFT

Address Adaption

Y1

Y2

(230MFT)

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

Page 17

Wiring for Damper Actuators and Control Valves

/Off,

V

(

)

.

Actuators: SY1...5-24 SY1...12-110 SY1...12-220

n

24V, 110/120/230

, Inc

USA

Hazard Identification

Warnings and Cautions appear at appropriate sections throughout this

manual. Read these carefully.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

Indicates an action or condition that may cause irreversible damage to the

actuator(s) or associated equipment.

Equipment damage!

Power consumption and input impedance must be observed.

24 VAC Transformer

Line

Vol ts

Open

K1

Close

K1-B

K1-A

G

G

G Ground

1 Common

3 Open

4 Closed

5

6

7

HTR

A

LS3

B

A-C

(Open Indication)

C

D

LS4

E

D-F

(Closed Indication)

F

Contact Rating: 5A 250 VAC Max.

SY2…5-24

G Ground

1 Common

3 Open

4 Closed

5

6

7

HTR

Actuator B

Actuator A

INSTALLATION NOTES

Observe class 1 and class 2 wiring restrictions.

Transformer sizing = SY actuator draw X 1.25 (safety margin)

(Ex. SY2-24 requires 3.0A x 1.25 = 3.75A,

3.75A X 24 VAC = 90VA Transformer).

NOTES

• Caution: Power Supply Voltage.

• Isolation relays must be used in parallel connection of multiple actuators

using a common control signal input.

• "H" (L2) cannot be connected to terminal #3 and #4 simultaneously.

• Required: Terminal #7 needs to be field wired to enable heater circuit.

120 and 230 VAC

N L1

H L2

Open

Close

K1

K1-B

K1-A

G

G

G Ground

1 Common

3 Open

4 Closed

5

6

7

A

B

C

D

E

F

SY2…12-110 (220)

G Ground

1 Common

3 Open

4 Closed

5

6

7

Actuator B

HTR

LS3

A-C

(Open Indication)

LS4

D-F

(Closed Indication)

Contact Rating: 5A 250 VAC Max.

Actuator A

HTR

7/10 - Subject to change. © Belimo Aircontrols

A

B

C

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

E

F

A-E (Closed Indication)

SY1 -24

LS3

A-B (Open Indication)

LS4

A

B

C

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

E

F

A-E (Closed Indication)

SY1-110 (220)

LS3

A-B (Open Indication)

LS4

SY1 Contact Arrangements

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

A

LS3

B

A-C

(Open Indication)

C

D

LS4

E

D-F

(Closed Indication)

F

Contact Rating: 5A 250 VAC Max.

SY2…5-24

A

LS3

B

A-C

(Open Indication)

C

D

LS4

E

D-F

(Closed Indication)

F

Contact Rating: 5A 250 VAC Max.

SY2…12-110 (220)

Page 18

8

W

iring for Control Valves

p

V

Pro

ortional, 24

Actuators: SY1-24P

W550

Hazard Identification

Warnings and Cautions appear at appropriate

sections throughout this manual. Read these carefully.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Indicates an action or condition that may cause

irreversible damage to the actuator(s) or

associated equipment.

Equipment damage!

Power consumption and input impedance

must be observed.

INSTALLATION NOTES

Observe class 1 and class 2 wiring restrictions.

Transformer sizing = SY actuator draw X 1.25 (safety margin)

(Ex. SY2-24 requires 3.0A x 1.25 = 3.75A,

3.75A X 24 VAC = 90VA Transformer).

33

24 VAC Transformer

Line

Volts

33

24 VAC Transformer

35

Feedback (B)

G

36

G

G Ground

4 Power Supply Com

5 Power Supply Hot

6 Control Signal (-)

7 Control Signal (+)

8 Internal Use Only

9 Internal Use Only

10 Internal Use Only

11 Feedback (-)

12 Feedback (+)

A

B

C

E

F

G Ground

Actuator B

LS3

A-B (Open Indication)

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

LS4

A-E (Closed Indication)

SY1 -24P

Actuator A

NOTES SY1-24P

Each actuator should be powered by a single, isolated

33

control transformer.

sSY1-24P notes: Power supply Com/Neutral and Control Signal

"–" wiring to a common is prohibited. Terminals 4 and 6 need to

be wired separately otherwise irreversible damage will occur.

s$ONOTCHANGESENSITIVITYORDIPSWITCHSETTINGSWITH

power applied.

APPLICATION NOTES

Recommended twisted shielded pair for control wiring.

35

Ground shielded wire at control panel chassis.

Tape back ground at actuator.

Use of feedback is optional.

36

Line

Volts

Control Signal

35

Feedback (A)

4 Power Supply Com

5 Power Supply Hot

6 Control Signal (-)

7 Control Signal (+)

8 Internal Use Only

9 Internal Use Only

10 Internal Use Only

11 Feedback (-)

12 Feedback (+)

36

A

B

C

E

F

LS3

A-B (Open Indication)

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

LS4

A-E (Closed Indication)

SY1 -24P

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

1

Page 19

┴

A

┴

/

┴

┴

A

┴

/

Actuators: SY2...5-24MFT

V

(

)

.

Wiring for Control Valves

roportional, Multiple Wiring, 24

W550-2

, Inc

USA

Hazard Identification

Warnings and Cautions appear at appropriate

sections throughout this manual. Read these carefully.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Indicates an action or condition that may cause

irreversible damage to the actuator(s) or

associated equipment.

Equipment damage!

Power consumption and input impedance

must be observed.

Control Signal (+)

Control Signal (-)

Feedback

36

Feedback Signal (+)

Feedback Signal (-)

35

G

Not Used -

Not Used -

INSTALLATION NOTES

Observe class 1 and class 2 wiring restrictions.

Transformer sizing = SY actuator draw X 1.25 (safety margin)

(Ex. SY2-24 requires 3.0A x 1.25 = 3.75A,

3.75A X 24 VAC = 90VA Transformer).

NOTES SY2...5-24MFT

Each actuator should be powered by a single, isolated

33

control transformer.

APPLICATION NOTES

Recommended twisted shielded pair for control wiring.

35

Ground shielded wire at control panel chassis.

Tape back ground at actuator.

36

Use of feedback is optional.

Actuator A

PC Tool

Service Jack

Y

1

U5

┴

C1

C2

PE

Address

2

Adaption

Y1 Y2

SYx-24MFT

B

1

2

3

-

~/+

8

9

10

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Power Supply Com

Power Supply Hot

Internal Use Only

Internal Use Only

Internal Use Only

24VAC

33

Actuator B

PC Tool

Service Jack

Control Signal

Feedback

7/10 - Subject to change. © Belimo Aircontrols

A

LS3

B

A-C

(Open Indication)

C

D

LS4

E

(Closed Indication)

D-F

F

Contact Rating: 5A 250 VAC Max.

36

35

G

Control Signal (+)

Control Signal (-)

Feedback Signal (+)

Feedback Signal (-)

Not Used -

Not Used -

Y

1

U5

C1

C2

PE

Address

2

Adaption

Y1 Y2

SYx-24MFT

B

1

2

3

-

~/+

8

9

10

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Power Supply Com

Power Supply Hot

Internal Use Only

Internal Use Only

Internal Use Only

24VAC

33

SY2…5-24MFT

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

9

Page 20

1

W

iring for Control Valves

p

V

Pro

ortional, 110/220V, 120/230

Actuators: SY1-110P SY1-220P

W552-

Hazard Identification

Warnings and Cautions appear at appropriate

sections throughout this manual. Read these carefully.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Indicates an action or condition that may cause

irreversible damage to the actuator(s) or

associated equipment.

Equipment damage!

Power consumption and input impedance

must be observed.

INSTALLATION NOTES

Observe class 1 and class 2 wiring restrictions.

APPLICATION NOTES

Recommended twisted shielded pair for control wiring.

35

Ground shielded wire at control panel chassis.

Tape back ground at actuator.

Use of feedback is optional.

36

NOTES SY1-110P (220P)

sCaution: Power supply voltage.

s$ONOTCHANGESENSITIVITYORDIPSWITCHSETTINGSWITH

power applied.

Control Signal

120 and 230 VAC

N L1

H L2

35

Feedback (B)

35

Feedback (A)

G

36

G

36

G Ground

4 Power Supply Com

5 Power Supply Hot

6 Control Signal (-)

7 Control Signal (+)

8 Internal Use Only

9 Internal Use Only

10 Internal Use Only

11 Feedback (-)

12 Feedback (+)

A

B

C

E

F

SY1 -110P (220P)

G Ground

4 Power Supply Com

5 Power Supply Hot

6 Control Signal (-)

7 Control Signal (+)

8 Internal Use Only

9 Internal Use Only

10 Internal Use Only

11 Feedback (-)

12 Feedback (+)

A

B

C

E

F

SY1 -110P (220P)

Actuator B

LS3

A-B (Open Indication)

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

LS4

A-E (Closed Indication)

Actuator A

LS3

A-B (Open Indication)

Contact Rating: 5A 125 VAC Max.

3A 250 VAC Max.

LS4

A-E (Closed Indication)

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 21

2

2

ŏ

A

L

ŏ

ŏ

A

L

A

A

A

Actuators: SY2...12-120MFT SY2...12-230MFT

g

V

(

)

.

-

55

Wiring for Control Valves

Proportional, Multiple Wirin

, 120/230

, Inc

USA

Hazard Identification

Warnings and Cautions appear at appropriate

sections throughout this manual. Read these carefully.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Indicates an action or condition that may cause

irreversible damage to the actuator(s) or

associated equipment.

Equipment damage!

Power consumption and input impedance

must be observed.

Control Signal (+)

Control Signal (-)

Feedback

36

G

Feedback Signal (+)

Feedback Signal (-)

35

Not Used -

Not Used -

INSTALLATION NOTES

Observe class 1 and class 2 wiring restrictions.

APPLICATION NOTES

Recommended twisted shielded pair for control wiring.

35

Ground shielded wire at control panel chassis.

Tape back ground at actuator.

Use of feedback is optional.

36

NOTES SY2...12-120MFT (230MFT)

sCaution: Power supply voltage.

PC Tool

Y

1

U5

2

ŏ

C1

C2

PE

ctuator

Service Jack

SYx-120MFT

SYx-230MFT

Power Supply Com – 120V (N) / 230V (L1)

Power Supply Hot – 120V (H) / 230V (L2)

N

Address Adaption

Y1

Y2

B

1

2

3

8

9

10

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Power Supply Com – 120V (N) / 230V (L1)

Power Supply Hot – 120V (H) / 230V (L2)

B

1

2

3

8

9

10

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

Internal Use Only

SYx-120MFT

SYx-230MFT

N

Address Adaption

Y1

Y2

PC Tool

Control Signal

Feedback

7/10 - Subject to change. © Belimo Aircontrols

A

LS3

B

A-C

(Open Indication)

C

D

LS4

E

(Closed Indication)

D-F

F

Contact Rating: 5A 250 VAC Max.

36

G

Control Signal (+)

Control Signal (-)

Feedback Signal (+)

Feedback Signal (-)

35

Not Used -

Not Used -

Y

1

U5

2

C1

C2

PE

ctuator B

Service Jack

SY2...12-120MFT

SY2...12-230MFT

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

1

Page 22

s

(-S) US

ldi

W

lding

W

g

r

n

)

n

d

n

f

°

n

r

ual override

k

ing

.

s

l

)

US

iliary

s

fi

(

)

A

F Actuators, On

/Off

)

)

C

0HDU

00.00.50

0

HD.76.00.00.00.50

U

00.0020.00.50

0.78.00.00.50.0050

U

00.00

50

HDU

14

00.00.00.5050

00.00.50

0

0

92.00.00.50.0050

00.00

50150

0

88.00.00.00.8850

92.00.00.50.6350

P

13.00.00.007.88

Dimensions with 2-Way Valve

F2WUDIM_A

HC

Models

AF24 US

AF24-S US w/built-in Aux. Switche

AF120 US

AF120-S US w/built-in Aux. Switches

Technical Data

ontrol on/off

ower consumption

AF24

AF120(-S) US running W

Transformer sizin

Electrical connectio

ectrical protectio

verload protectio

rotation

Angle o

osition indicatio

n

Running time control

mbient temperature

Housing

gency listing

oise leve

running5 W

o

ng

.5

o

.3

VA, class 2 powe

3 ft, 18 GA appliance cables

-S model has 2 cables

conduit connector

V actuators double insulate

electronic throughout 0° to 95° rotation

5

visual indicato

x cran

50 sec. independent of load

< 20 sec

spr

22° F to 122° F [-30° C to 50° C]

EMA 2 / IP54

UL 873, CSA C22.2 No. 24 certifi ed, CE

ax. 45 dB(A

Dimensions (Inches

alve

650HD 2” 1.65 9.00 9.00 19.50

5

5

665HD

680HD

6100HD

5

650-150SHP

665-150SHP 2½” 1.88 9.00 9.00 20.00

680-150SHP

6100-150SHP

650-300SHP 2” 1.75 9.00 9.00 19.50

665-300SHP

680-300SHP

6100-300SH

ize

.65

.

2½” 1.76.

” 1.78 9.00 9.00 20.50 6.00 20

”2.05.

5”.

” 2.13.

.75

.

.

.

.

.

.

D(Max)BH

21.007.

21.007.

Fail Safe (psi

.75

00

.75 5

.75

.50 15

.00 15

*AF

5

AF...-S

ux

switche

2 x SPDT, 7A (2.5A) @ 250 VAC, UL listed,

one switch is

25° to 85°

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

xed at +5°, one is adjustable

double insulated

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

Page 23

!

.

.

C

85°

!

y

h

dli

y

A

F Actuators, On/Of

f

1 Common

2 + Hot

2

24 VAC Transformer

AF24 US

Line

Volts

3

pjy

94

U

s

10

10

D

AB

C

)

e

0HD.50.1

0765HD5.00.76.76.00

0

0

80HDU

287.28.2

0050

G

(

)

.

Dimensions with 3-Way Valve

alv

75

F750HDU

Dimensions (Inches)

Size

5

.15

(Max) BHC

5.50.75

” 4.50 6.15 6.15 15.50 4.75 5

ail Safe (psi

2*AF

5.5

F765HDU2½” 5.00 6.76 6.76 16.00 5.50 5

7

5.507.

5

.

Wiring Diagrams

1

P11

DW

n/Off Wiring

X

W195-A

uxiliary Switche

AUTION Equipment damage

Actuators may be connected in parallel

ower consumption must be observed.

Actuators may also be powered by 24 VDC

For end position indication, interlock control, fan startup, etc., AF24-S

US incorporates two built-in auxiliary switches: 2 x SPDT, 7A (2.5A)

, UL listed, one switch is fi xed at +5°, one is adjustable 25°

.

, Inc

USA

@ 250 VA

to

Meets cULus or UL and CSA requirements without the

need of an electrical ground connection.

ARNINGive Electrical Components

During installation, testing, servicing and troubleshooting of this product, it may

be necessar

or ot

perform these tasks. Failure to follow all electrical safet

lectrical components could result in death or serious injury.

7/10 - Subject to change. © Belimo Aircontrols

to work with live electrical components. Have a qualifi ed licensed electrician

er individual who has been properly trained in han

ng live electrical components

precautions when exposed to live

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

3

Page 24

C

A

F Actuators, Multi-Function Technolo

gy

s

)

)

C

0HD.6

00.00.50

U

65.00.0019.50.75

HD.76.00.00.00.50

U

00.0020.00.50

00.00.50.00500.78.00.00.50.0050

U

0

HDU

14

00.00.00.50

0

88.00.00.00.5050

92.00.00.50.0050

0

00.00.50.0050

88.00.0020.00.88150

92.00.00.50.6350

00.00

88150

10

10

D

AB

C

)

)

C

0

00.76.76.00.50

0

G

ly

z

%

r

W

n

W

g

)

n

.

ector

3

f

tors

n

g

*

)

)

f

x

)

*

*

)

[

]

)

Ang

n

)

*

id. positi

%

on

°

)

ual override

Allen)

d

y

g

A

e

)

e

)

2

l

el

t

Ag

C

C

900

ee

t

h

s

1

Auxili

s

d

°

Models

-

AFX24-MFT-S-X1 w/built-in Aux. Switche

Technical Data

ower supp

Powe

consumptio

ransformer sizin

Electrical connectio

Overload protectio

Operatin

nput impedance 100 k for 2 to 10 VDC (0.1 mA)

Feedback output U* 2 to 10 VDC, 0.5 mA ma

Torque minimum 180 in-lb (20 Nm

Direction of spring reversible with cw/ccw mounting

rotation

Mechanical

ngle of rotation

Running time spring <20 sec @ -4°F to 122°F [-20° C to 50° C];

verride control

Position indicati

Humidit

mbient temperatur

Storage temperatur

Housing NEMA 2, IP54, Enclosure Type

ousing materia

uality standard ISO

ervicing maintenance fr

Weigh

* Variable when configured with MFT option

AFX24-MFT-S-X

4

-

24 VAC, +/- 20%, 50/60 H

24 VDC, +20% / -10

running

.5

olding

10 VA (Class 2 power source

AFX..

3 ft [1m] default, 10 ft [3m] or 16 ft [5m] 18 GA

appliance or plenum cables, with or without 1/2” conduit

nn

-S models: two

t [1m] default, 10 ft [3m] or

16 ft [5m] appliance cables with or without 1/2" conduit

connec

electronic throughout 0 to 95° rotation

range Y

2 to 10 VDC, 4 to 20 mA (default

ariable (VDC, PWM, floating point, on/off

or 4 to 20 mA

1500

for PWM, floating point and on/off control

motorreversible with built-in switch

95° (adjustable with mechanical end stop, 35° to 95°

<60 sec @ -22°F

-30° C

motor*150 seconds (default), variable (70 to 220 seconds

le of Rotation

off (default

aptatio

min position = 0%

m

on = 50%

max. position = 100

visual indicator, 0° to 95

0° is spring return position

n

mm hex crank (₁₆

, supplie

max. 95% RH, non-condensin

-22 to 122° F (-30 to 50° C

-40 to 176° F (-40 to 80° C

zinc coated metal and plastic casing

lev

40dB(A) motor @ 150 seconds, run time dependen

62dB(A) spring return

ency listings

cULus acc. to UL60730-1A/-2-14, CAN/CSA E60730-

E acc. to 2004/108/EC & 2006/95/E

1:02,

1

4.6 lbs. (1.9 kg), 4.9 lbs. (2 kg) with switc

Rated Impulse Voltage 800V, Type of action 1.AA (1.AA.B for -S version), Control Pollution Degree 3.

Programmed for 70 sec motor run time. At 150 sec motor run time, transformer sizing

ary switche

2 x SPDT 3A (0.5A) @ 250 VAC, UL approve

one set at +10°, one adjustable 10° to 90

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Dimensions with 2-Way Valve

H

alve

5

650HD

ize

2” 1.

Dimensions (Inches

5

.

D(Max)BH

Fail Safe (psi

*AF

.75

5

665HD

2½” 1.76.

.78.

6100HD

5

650-150SHP 2” 1.75 9.00 9.00 19.50

665-150SHP

680-150SHP

6100-150SHP

650-300SHP

” 2.05 9.00 9.00 21.00 7.50 5

.

.

.75 15

.

.

” 2.13 9.00 9.00 21.00 7.50 15

.75

.

665-300SHP 2½” 1.

680-300SHP

6100-300SHP” 2.13.

.

21.007.

Dimensions with 3-Way Valve

P11

DW

7/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

Valve

750HD 2

750HDU2

765HD

765HDU½”

ize A B

.50

.50

½” 5.00

.

780HDU3”5.50 7.28

Dimensions (Inches

D(Max)H

.15 6.15

.15 6.15

.76 6.76

.28

5.50 4.75 200

5.50 4.75 5

6.00 5.50

6.25 6.00 5

Fail Safe (psi

*AF

00

Page 25

.

!

y

AF Actuators, Multi-Function Technolog

y

f

A

f

f

y

f

y

l

1

AFB

AFX

1

_S

e

(

)

.

Wiring Diagrams

Actuators may also be powered by 24 VDC.

IN4004 or IN4007 diode (IN4007 supplied, Belimo part number

40155).

Triac A and B can also be contact closures.

ontrol signal may be pulsed from either the Hot (Source) or

ommon (Sink) 24 VAC line

osition feedback cannot be used with Triac sink controller.

The actuators internal common reference is not compatible.

The ZG-R01 500 Ω resistor converts the 4 to 20 mA control signal to

to 10 VDC, up to 2 actuators may be connected in parallel.

eets cULus or UL and CSA requirements without the

need of an electrical ground connection.

ARNINGLive Electrical Components

During installation, testing, servicing and troubleshooting of this product, it may

be necessar

r other individual who has been properly trained in handling live electrical components

erform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

Control Signal

2 to 10 VDC

, Inc

USA

to work with live electrical components. Have a qualifi ed licensed electrician

24 VAC Transformer

Line

Volts

3

Master

Blk (1) Common

Red (2) + Hot

(–)

(+)

Wht (3) Y

Org (5) U Output 2 to 10 V

CCW CW

5

Input, 2 to 10 V

lave

Master

ly

W399_Butter

VDC/4-20 m

ly

W399_Butter

l

399_Butter

l

399_Butter

7/10 - Subject to change. © Belimo Aircontrols

Master/Slav

Slave

5

Blk (1) Common

Red (2) + Hot

Wht (3) Y