Page 1

OMM-0087_0E

GF-143

MODULE X EXT

PENDING

Natural Ga s Modulating &

Condensing Modular Hot

Water Boiler

Covering Models:

• EXT 321

• EXT 481

• EXT 641

• EXT 802

• EXT 962

• EXT 1123

USER MANUAL

Inst all at i on , Op erati on an d M ai ntenance

Modular Condensing Boilers

Light Commercial Series

Latest Update: 12/01/2014

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

Page 2

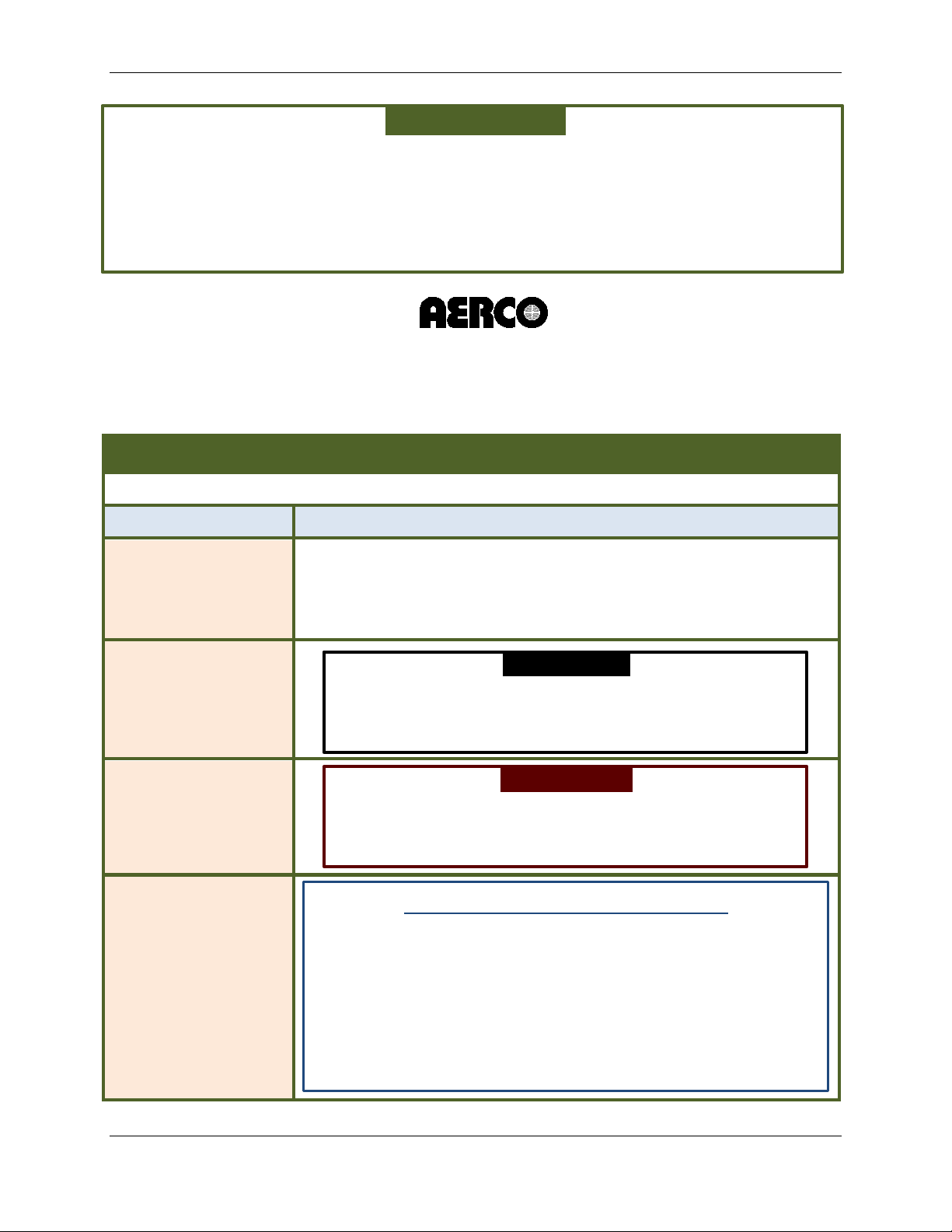

AERCO Document Conventions

NOTE

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

DISCLAIMER

The information contained in this manual is subject to change without notice from AERCO

Inter nat ion al, Inc. AERCO makes no warr ant y of an y kind w i th r espec t to this mater ial, including,

bu t not limit ed t o, imp lied w arrant ies of merc hant abil ity and fit ness for a par tic ul ar appli cat ion.

AERCO International is not liable for errors appearing in this manual, nor for incidental or

consequential damages occurring in connection with the furnishing, performance, or use of

these materials.

AERCO Technical Support:

(Mon–Fri, 8am-5pm EST)

1 (800) 526-0288

In this document, some types of information are presented as shown in the following examples:

Message Type Example and Description

Notes

Cautions

Warnings

NOTE messages indicate specific information related to the

surrounding contextual information, and highlighted for special

attention.

CAUTION!

CAUTION messages inform of potential problems relating to the

functioning of equipment, safety to persons, harm to the

environment, and/or damage to property or equipment.

WARNING!

WARNING messages warn of potential dangerous situations that

may result in serious injury and/or death to persons or animals.

Text is red within a red box.

How Instructions are Presented

1. Instructions are shown in a blue box with an underlined title.

2. All text, excepting in accompanying illustrations, is colored blue.

Instructions

Page 2 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

3. All procedures are listed in steps starting with “1.” and using

letters [a), b), c), etc.] indicating sub=steps.

4. Steps that are continued on the next page have a “- Continued”

appended to the instruction title.

Page 3

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

TABLE OF CONTENTS

CHAPTER 1: GENERAL INFORMATION ............................................................................................ 7

1.1 Correct Use Of The Appliance .............................................................................................................................. 7

1.2 Water Treatment ................................................................................................................................................. 7

1.3 Information To Be Made Available To The User .................................................................................................. 7

1.4 Safety Warnings ................................................................................................................................................... 8

1.5 Modifications To Parts Connected To The Appliance .......................................................................................... 8

1.6 For Appliances Operating With Propane Gas ...................................................................................................... 9

1.7 Data Plate .......................................................................................................................................................... 10

1.8 Operational Requirements ................................................................................................................................ 11

1.8.1 General Requirements ............................................................................................................................ 11

1.8.2 Regulatory Requirements ....................................................................................................................... 11

1.8.3 Water Quality Requirements .................................................................................................................. 12

1.9 Tools, Materials, And Additional Equipment ..................................................................................................... 13

1.10 Disposal............................................................................................................................................................ 13

1.11 General Warnings ............................................................................................................................................ 13

1.11.1 Using the Operation and Maintenance Manual ................................................................................... 13

1.11.2 Installation and Servicing Personnel ..................................................................................................... 13

1.11.3 Installation Materials ............................................................................................................................ 13

1.11.4 Preparing Boiler for Servicing ............................................................................................................... 14

1.11.5 Returning a Boiler to Service ................................................................................................................ 14

1.11.6 Change in Ownership ............................................................................................................................ 14

1.12 Operational Limits of the Boiler....................................................................................................................... 14

CHAPTER 2: T ECHNICAL FEATURES AND DIMENSIONS ............................................................. 15

2.1 Modulex EXT Technical Features ....................................................................................................................... 15

2.1.1 Temperature Control Devices: ................................................................................................................ 15

2.1.2 Control Panel (E8) Includes: .................................................................................................................... 15

2.1.3 Other Features Include: .......................................................................................................................... 15

2.2 General Boiler Operation ................................................................................................................................... 16

2.3 Dimensional Drawings ....................................................................................................................................... 17

2.4 Performance Data ............................................................................................................................................. 21

CHAPTER 3: INSTALLATION INSTRUCTIONS ................................................................................ 23

3.1 General Warnings .............................................................................................................................................. 23

3.1.1 Appropriate Use of the Boiler ................................................................................................................. 23

3.1.2 Prerequisite System Flushing .................................................................................................................. 23

3.1.3 Installation Personnel Qualifications ...................................................................................................... 23

3.1.4 Carbon Monoxide Detector Installation ................................................................................................. 23

3.2 Code and Standards Approvals .......................................................................................................................... 24

3.3 Packaging ........................................................................................................................................................... 24

3.4 Transporting and Securing the Boiler Safely ...................................................................................................... 27

3.5 Removal From Boiler Bed And Installation Of Boiler Feet ................................................................................. 28

3.6 Boiler Location Inside A Boiler Room................................................................................................................. 29

3.6.1 Boiler Room Safety Concerns.................................................................................................................. 30

3.6.2 Products to Avoid in the Boiler Room ..................................................................................................... 30

3.7 Minimum Clearances For Servicing ................................................................................................................... 31

3.8 Boiler Connections ............................................................................................................................................. 32

3.8.1 Changing Exhaust Outlet Location .......................................................................................................... 32

3.8.2 Reversing Gas Manifold Connections ..................................................................................................... 33

3.8.3 Reversing Cold/Hot Water Flow & Return Connections ......................................................................... 34

3.8.3.1 Reversing Cold/Hot Water Flow & Return Piping Connectors ............................................................. 34

3.8.3.2 Reversing Flow & Return Temperature Sensors .................................................................................. 35

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 3 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 4

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

3.8.3.3 Reversing Boiler Sensor Kf And Automatic Air Vent ............................................................................ 35

3.9 Gas Connection General Information ................................................................................................................ 36

3.9.1 Natural Gas Connections ........................................................................................................................ 37

3.9.1.1 Natural Gas Piping Sizes ....................................................................................................................... 37

3.9.1.2 Natural Gas Piping Connections........................................................................................................... 37

3.9.1.3 Natural Gas Supply Pressure Requirements ........................................................................................ 37

3.9.2 Propane Gas Connections ....................................................................................................................... 37

3.9.2.1 Propane Gas Piping Sizes ..................................................................................................................... 37

3.9.2.2 Propane Gas Piping Connections ......................................................................................................... 37

3.9.2.3 Propane Gas Supply Pressure Requirements ....................................................................................... 38

3.10 Flow And Return Pipe Connections ................................................................................................................. 38

3.11 Pressure Relief Valve ....................................................................................................................................... 38

3.12 CSD-1 Manifold Assembly (Supplied) .............................................................................................................. 39

3.13 Determination of Primary Boiler Pump Or Boiler System Pump ..................................................................... 40

3.14 Condensate Piping and Drain .......................................................................................................................... 42

3.15 Water Treatment ............................................................................................................................................. 43

3.16 Important Installation Warnings...................................................................................................................... 44

3.16.1 Oxygen Levels in the System Water Warning ....................................................................................... 44

3.16.2 Antifreeze Compatibility Warning ........................................................................................................ 44

3.16.3 Lime Scale and Corrosive Water Damage Warning .............................................................................. 44

3.16.4 Connection to Refrigeration System Warning ...................................................................................... 44

3.17 Air Intake Connection ...................................................................................................................................... 44

3.18 Flue Manifold Connection ............................................................................................................................... 44

3.19 Flue Exhaust Piping to Vent ............................................................................................................................. 46

3.20 Vent Starter Pieces .......................................................................................................................................... 46

3.21 Combustion Air and Ventilation Openings ...................................................................................................... 48

3.21.1 Insufficient Ventilations and Combustion Air ....................................................................................... 48

3.21.2 Room Air Combustion ........................................................................................................................... 49

3.21.3 Sealed Combustion ............................................................................................................................... 49

3.22 Installation of the Exhaust and Air Intake System ........................................................................................... 49

3.22.1 Important Factors for Terminal Orientation and Location ................................................................... 50

3.22.2 Minimum and Maximum Wall Thickness .............................................................................................. 51

3.23 Vent Pipe Sizing ............................................................................................................................................... 51

3.24 Electrical Connections...................................................................................................................................... 53

3.24.1 Regulations in Force.............................................................................................................................. 53

3.24.2 Mains Electrical Supply Connection (120 V – 60 Hz)............................................................................. 53

3.24.3 Service Relay Requirement ................................................................................................................... 54

3.24.4 Electrical Requirements ........................................................................................................................ 54

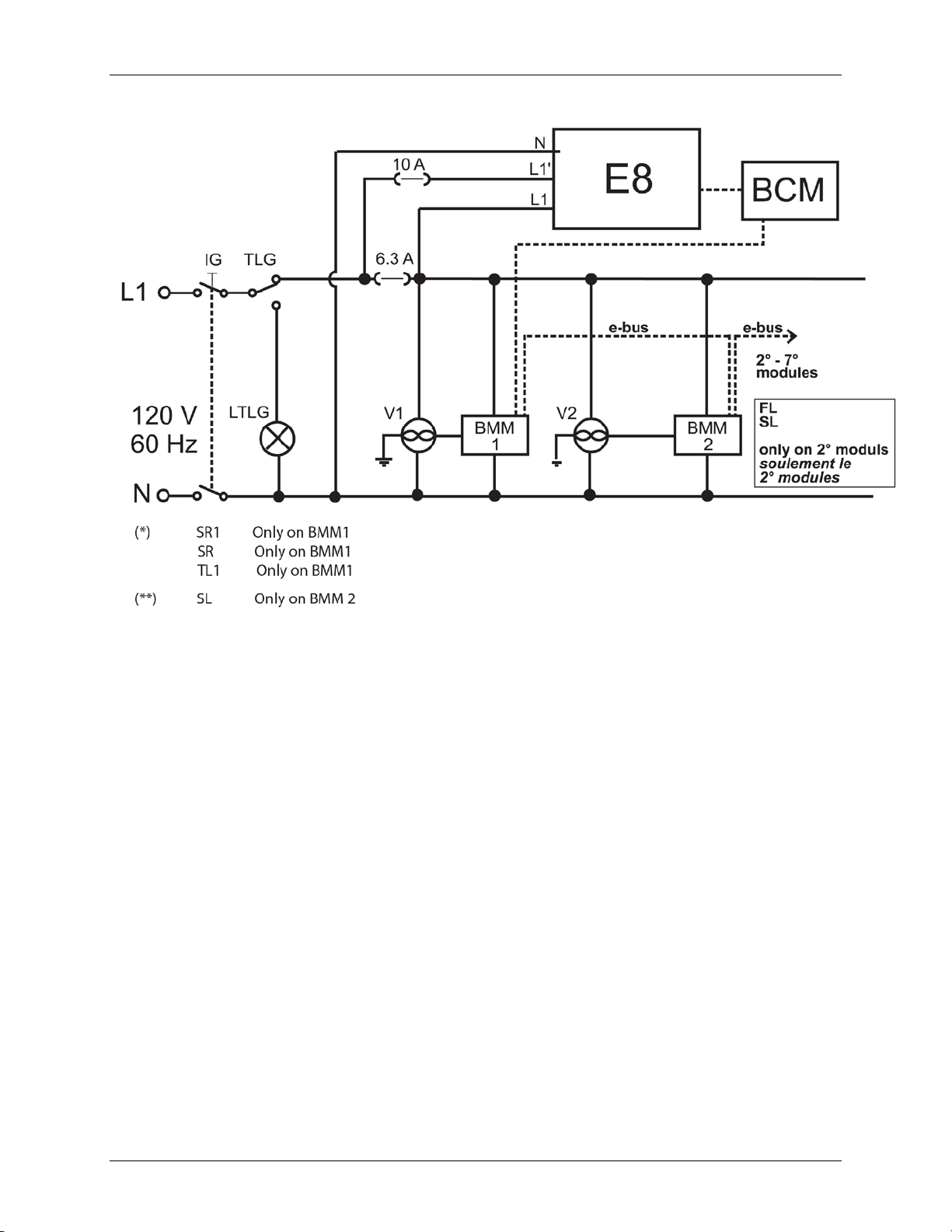

3.25 Functional Wiring Diagram .............................................................................................................................. 57

3.26 Ladder Diagrams .............................................................................................................................................. 59

3.27 General Ladder Diagram .................................................................................................................................. 60

3.28 E8 Controller and BCM Terminal Assignments ................................................................................................ 60

3.29 Installation Examples ....................................................................................................................................... 63

3.30 Starting Up: Filling and Deaerating the Boiler ................................................................................................. 65

3.30.1 Necessary Precautions for Safety ......................................................................................................... 65

3.30.2 Supply Voltage, Gas Pressure, and Water pressure .............................................................................. 65

3.31 Filling the System ............................................................................................................................................. 65

3.31.1 Necessary Precautions While Filling the System .................................................................................. 65

3.31.2 Filling Locations and Preparation.......................................................................................................... 66

3.32 Testing The Ignition Safety Shut Off Device..................................................................................................... 68

3.33 Burner Calibration ........................................................................................................................................... 69

3.33.1 Installing the Gas Analyzer Probe ......................................................................................................... 69

3.33.2 Maximum Output Calibration ............................................................................................................... 70

3.33.3 Minimum Output Calibration................................................................................................................ 71

3.33.4 Final Check and Ignition Failure Adjustment Procedure....................................................................... 71

Page 4 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 5

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

3.34 Sweeper Mode (Manual Control) .................................................................................................................... 74

3.35 High Altitude Adjustment ................................................................................................................................ 75

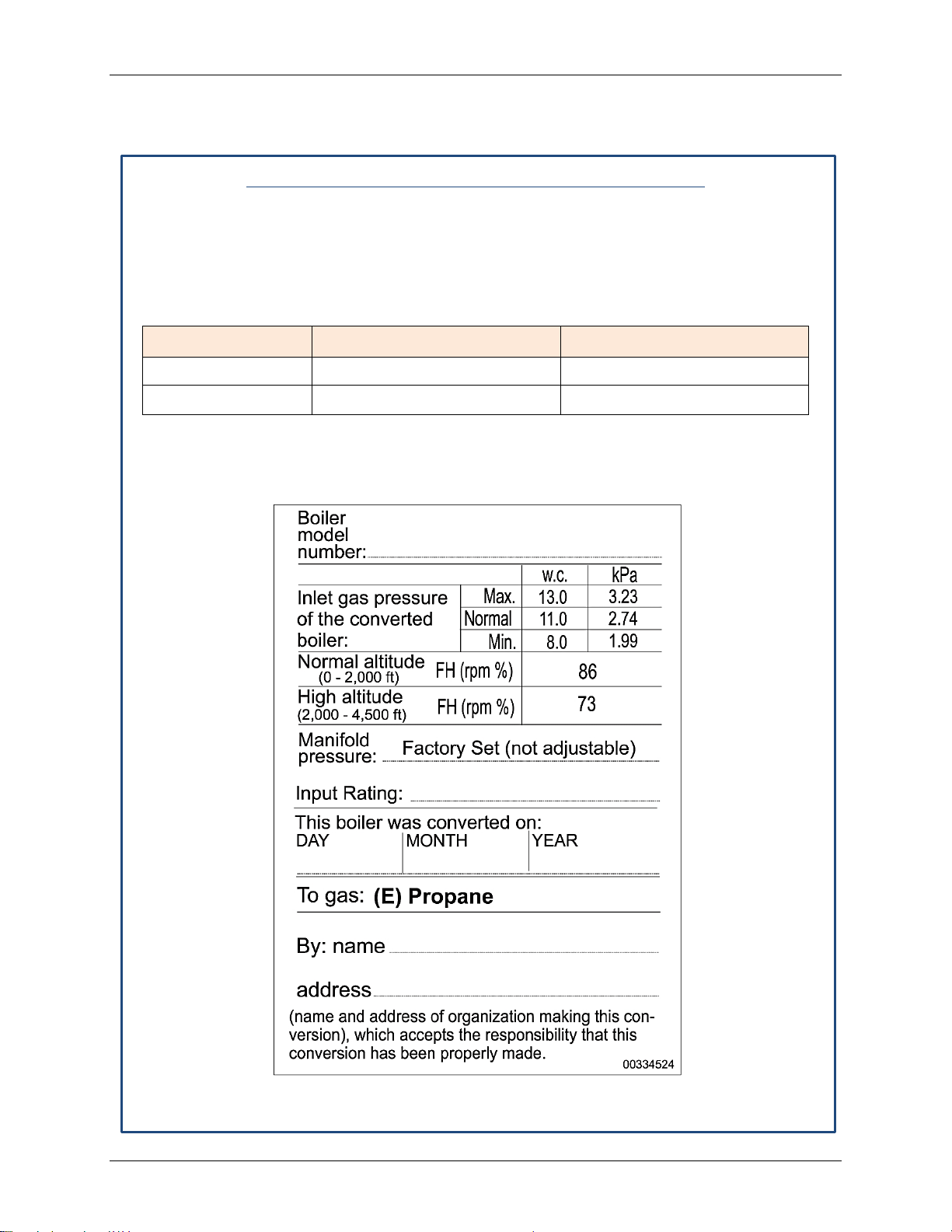

3.36 High Altitude Conversion Label........................................................................................................................ 76

3.37 Conversion From Natural Gas To Propane Gas................................................................................................ 77

3.38 Controls And Emergency Functions ................................................................................................................. 78

3.39 Initial Boiler Ignition......................................................................................................................................... 79

3.39.1 Preliminary Checks................................................................................................................................ 79

CHAPTER 4: E8 CONTROLLER AND BCM MODULES ................................................................... 81

4.1 E8 Controller ...................................................................................................................................................... 81

4.1.1 E8 Controller Features and Functions ..................................................................................................... 81

4.1.2 E8 Display Functions ............................................................................................................................... 82

4.1.3 E8 HEATING Mode Selection................................................................................................................... 83

4.1.4 E8 MENU Mode Operation (Door Open) ................................................................................................ 84

4.1.5 E8 MENU Navigation and Parameter Settings ........................................................................................ 85

4.1.6 E8 Parameter Navigation, Selection, and Setting ................................................................................... 86

4.2 BCM (Boiler Communication Module) ............................................................................................................... 87

4.2.1 BCM Features and Functions .................................................................................................................. 87

4.2.2 BCM Description ..................................................................................................................................... 87

CHAPTER 5: OPERATION ................................................................................................................ 91

5.1 Installation Menu: Initializing the E8 Controller ................................................................................................ 92

5.2 Quick Start Instructions ..................................................................................................................................... 93

5.2.1 Setting Maximum and Minimum Flow Temperature ............................................................................. 93

5.2.2 Setting Room Temperature and Outdoor Compensation....................................................................... 93

5.2.3 Setting Heating Programs and Pumps .................................................................................................... 94

5.3 Menu And Sub-Menu Descriptions .................................................................................................................... 95

5.3.1 Menus (Top Level): ................................................................................................................................. 96

5.3.2 Sub-Menus: ............................................................................................................................................. 96

5.4 General Menu .................................................................................................................................................... 97

5.5 Service Menu ..................................................................................................................................................... 99

5.6 Display Menu ................................................................................................................................................... 101

5.7 User Menu ....................................................................................................................................................... 103

5.8 Time Program Menu ........................................................................................................................................ 105

5.9 Expert Menu .................................................................................................................................................... 106

5.10 Other Possible Settings .................................................................................................................................. 110

5.10.1 Settings for Heating Circuit 1/2........................................................................................................... 110

5.10.1.1 Heating Adjustment With Constant Flow Temp .............................................................................. 110

5.10.1.2 Temperature Settings For Heating Circuits ...................................................................................... 110

5.10.1.3 A Second DHW Storage Tank ........................................................................................................... 111

5.10.1.4 Temperature Setting For Second DHW Storage Tank ...................................................................... 111

5.10.1.5 Swimming Pool ................................................................................................................................ 111

5.10.1.6 Swimming Pool Temperature Setting .............................................................................................. 111

5.10.1.7 Screed Dry Program (For Floor Heating Installation) ....................................................................... 111

5.10.1.8 Temperature Setting For Screed Program ....................................................................................... 111

5.10.1.9 Signal 0 – 10 V ................................................................................................................................. 111

5.10.1.10 Slope And Temperature Setting with 0 – 10 V Signal ................................................................... 111

5.10.2 Setting of DHW Circuit ........................................................................................................................ 112

5.10.2.1 Operation of Pumps In Parallel ........................................................................................................ 112

5.10.2.2 Use of a DHW Storage Tank Thermostat (On/Off) ........................................................................... 112

5.10.2.3 Antilegion ......................................................................................................................................... 112

5.10.2.4 Setting for Solar Panel Use .............................................................................................................. 112

5.11 ACCESS CODE SETTING .................................................................................................................................. 112

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 5 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 6

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

CHAPTER 6: TROUBLESHOOTING ............................................................................................... 113

6.1 E8 Controller Error Codes ................................................................................................................................ 113

6.1.1 E8 Controller Fault Codes ..................................................................................................................... 114

6.1.2 BCM (Boiler Communications Module) Fault Codes ............................................................................. 117

6.1.3 BMM (Burner Management Module) Fault Codes ............................................................................... 118

CHAPTER 7: INSPECTION AND MAINTENANCE SCHEDULE ...................................................... 121

7.1 Instructions for Inspection And Maintenance ................................................................................................. 122

7.2 Periodic Examination Of Venting System ........................................................................................................ 122

7.3 Proper Procedure For Cleaning Exhaust Flue .................................................................................................. 122

7.3.1 Cleaning the Condensate Drain Line ..................................................................................................... 123

7.4 Checking CSD-1 Manifold Flow Switch ............................................................................................................ 123

7.5 Visual Inspection Of The Flame ....................................................................................................................... 124

7.6 Proper Reassembly and Resealing of the Vent-Air Intake System................................................................... 124

7.7 Pressure Switch Hoses And Connections ......................................................................................................... 125

7.8 Burner / Heat Exchanger Cleaning Procedure ................................................................................................. 126

7.9 Heat and Return Sensor Resistance Values ..................................................................................................... 126

7.10 Unit Disassembly ........................................................................................................................................... 126

7.11 Cleaning the Burner Module and Combustion Chamber............................................................................... 134

7.12 Reassembly of the Burner Modules............................................................................................................... 136

7.13 Final Procedures After Maintenance ............................................................................................................. 136

7.14 Maintenance Kit Part Number ....................................................................................................................... 137

7.15 Accessory Kit Part Numbers........................................................................................................................... 138

CHAPTER 8: SPARE PARTS DRAWI NG AND LISTS .................................................................... 139

AERCO/MODULEX STANDARD WARRANTY ................................................................................... 147

Page 6 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 7

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

CHAPTER 1: GENERAL INFORMATION

1.1 Correct Use of the Appliance

The MODULEX EXT boiler has been designed utilizing the latest heating technologies and in

compliance w i th the curren t s af ety regulations. However, if not used or operated properly, the uni t

may cause inju ry or d eath to persons , or serious d amag e to th e equipment or s urrounding objects.

The MODULEX EXT boiler i s des i g ned t o be u s ed i n pum p ed h ot w ater c ent r al h eat i ng sy st em s.

Any other use of this appliance shall be considered improper, and AERCO declines any

resp ons ib ili t y for d am ages or i nj uri es c aus ed b y t he im p roper use of th is equi pm ent. In order to

use the equipm ent appropriately and safely according to its design, it is essent ial to carefull y

follow the instructions in this manual.

1.2 Water Treatment

•

It i s vi t al t o m ai nt ai n t h e pH of b oi l er w at er b etw een 6 .5 an d 8 . Fai l ur e t o d o so cou l d res u lt i n

severe damage t o the b oiler.

• The hardness of the main water supply influences the frequency with which the heat

exchanger must be cleaned.

• I n hard w ater areas wher e the m ain wat er can exceed 1 5°f total hard ness , a scal e redu cin g

device is recommended. The choice of this device has to be made taking into consideration the

characteri stics of t he water.

• In or der to improve the resistance to lime scale i t is r ecommen ded th at the domestic hot wat er

temp erat ure be as near as pos s ib le to t he temperatu re required for end us e.

• AERCO recommends inspecting the state of cleanliness of the domestic hot water heat

exchanger at t he end of the first year and subsequently, on the basis of the lime scale found,

this period can be extended to two year s after th e ini tial insp ection.

1.3 Information to Be Made Available To The User

Go through the information in this manual with the owner/operator and make sure that he or she is

famili ar wit h all necessary operat in g inst ructi ons, in particul ar:

• These instructions sh all b e made av ail abl e t o th e end user, tog eth er wi th an y ot her l iter atu re

reg ardi ng thi s ap pl ianc e. It is highly recommended that th e us er ke ep t hes e doc um ent s i n a

safe and convenie nt pl ac e i n order t o al way s hav e t hem at hand f or future ref erence.

• It is i mp erat ive that a proper ven ting and exhau st s ystem b e i mpl emen ted with t hi s unit . R efer

to the AERCO Venting Application Guide (GF-115-V).

• It is absolutely forbidden to make any alterations to the boiler not in keeping with the

manuf acturers r ecommen dations and instructi ons.

• It is critical to check the system’s water pressure and ensure it is at the correc t pressu re.

• For optimal operation of time and temperature controls, therm ostats, heating controls and

radiators, refer t o separat e E8 Controller Us er M anual (GF-115-C).

• It i s obl ig atory to c arr y out com preh ens ive maintenance services annually with a combustion

analysis every t wo years (in compliance with national and local laws).

• If th e ap pl i ance i s sol d or tr ans fer r ed to an ot h er own er , or i f t h e pr es ent u s er m ov es from th e

installation site and leaves the appliance installed, ensure that the manual stays with the boiler

so that it can be consulted by the new owner and/or installer.

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 7 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 8

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

Failure to follow the instructions indicated in this manual, which is supplied with the boiler,

could cause injury to persons, animals or damage to property. The m anufacturer shall not

be held l i ab l e for any such i n jury and /or d amage.

1.4 Safety Warning s

WARNING!

• Children m ust be supervised so they do not play on , arou n d , or

wi th th e applian ce.

• The installation, adjustment, and servicing of this appliance

must be carried out by a competent person and installed in

accor d anc e wi t h th e cu r ren t st an d ard s an d r egu l ati on s . Fai lu r e

to c or r ect l y i nst al l thi s appliance could cause injury to persons,

anim al s or dam age t o p rop ert y. Th e man ufac tu rer shal l not be

held liab le for any i nju ry and/or dam age.

• Servicing or repairs of the appliance must be carried out by

AERCO authorized servic e technicians; AERCO recommends

drawing up a service contract. Incomplete, inappropriate, or

ir regul ar ser vici ng c ould compr om ise t he saf e oper ati on of t he

appliance, and could cause injury to persons, animals or

damage to property for which AERCO shall not be held liable.

1.5 Modifications To Parts Connected To The Appliance

Do not c arry out any modi f ications to the fol lowi ng parts:

• The boiler

• To the g as, air , water s upply pipes and electrical power

• To the f lue pi pe, safety reli ef val ve and it s drainage pipe

• To the con s tructive c omp onents whic h influence the applianc e’s safe operati on

WARNING!

W hen ti ghten i ng or l oos eni n g th e scr ew pip e c on n ect i on s, us e onl y

properly sized wrenches. The improper use of inadequate

equ ipment can cau se damage (for example, water or gas leak ages)

to the equipment.

Page 8 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 9

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

WARNING!

WHAT TO DO IF YOU SMELL GAS:

Instal lati on, Operation & Maintenan ce Manual

1.6 For Appliances Operating With Propane Gas

Bef ore inst all in g t he appl iance, en sure that th e gas tan k has been purged. For cor rect

instructions on purging the tank, con tact the liquid gas s upplier or a compet ent person who is

legall y authoriz ed to provide such information. If the tank has not been correctly purged,

problems may occur during ignition. If this happens cont act the liquid gas tank’s supplier.

Do not store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

•

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in the building.

•

Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

•

If you cannot contact your gas supplier, call the fire

department.

The boiler must be installed in such way as to avoid, under the

foreseen operation conditions, the freezing of the water and to

prevent the c ontrol devic es from being expos ed to t emper atures

lower than 5°F (15°C) or higher than 104°F (40°C). The boiler must

be p rot ect ed against en vironmental var iati ons wit h:

• The insulation of the hydraulic pipelines and the condensate

drain.

• The adoption of specific antifreeze products in the Cold/Hot

water installation.

WARNING!

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 9 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 10

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

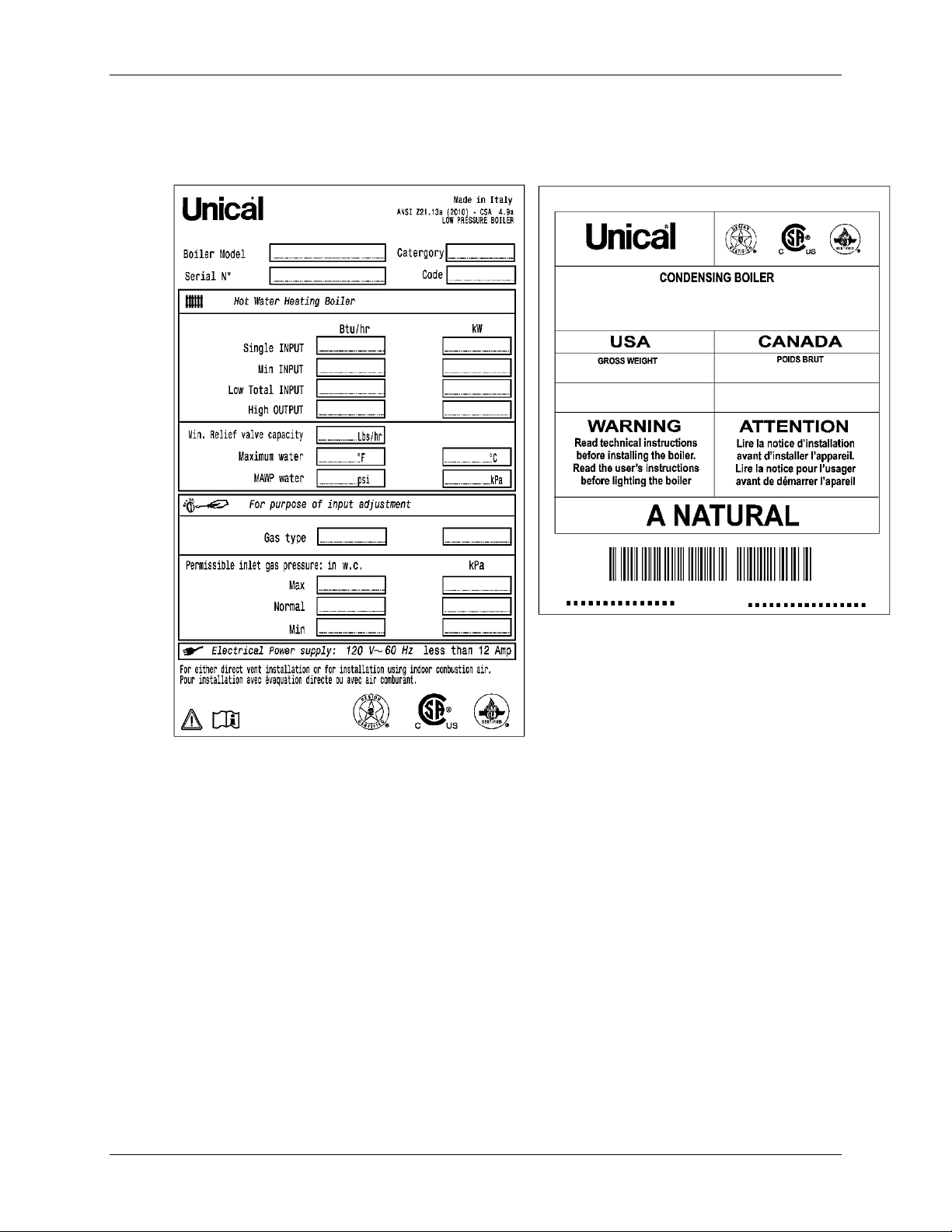

1.7 Data Plate

A sample Data Plate for a MODULEX EXT boiler is shown in the left figure below. A sample of the

Data Packagi ng l abel i s s hown in the right image below.

Figure 1-1: MODULEX EXT Data Plate (L) and Data Packing Label (R)

Eac h unit is fit ted wi th a d ata pl ate, w hich m ay be con sult ed for th e det ails on gas t ype, power

source and vent i ng class ificat ion .

Page 10 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 11

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

1.8 Operational Requirements

General Requirements 1.8.1

The followi ng instr uc tions MUST be f ol lowed :

• The boi ler mu st only be u sed for its designated purpose as described in these Installation

Instructions.

• Each unit is fitted with a data plate. Consult the details on this plate to verify whether t he boil er

is compliant with its intended location, e.g.: gas type, power source and venting classification.

• On ly use the b oil er with th e ac ces sories and sp are part s l isted.

• Oth er combin ations of accessories and products must only be used i f they are speci fically

designed for the intended application and do not affect the system performance or t h e saf ety

requirements.

• Maintenan ce and repairs must only be performed by trained professionals.

• Installation of a condensing gas boiler must b e approv ed per all fed eral and local gover nment

codes, regulations, and laws.

• Operation of a condensing gas boiler must use a vent system that has been specifically

desig ned and approv ed for this type of b oil er.

• Note that local p ermi ssion and approval f or t he vent s ystem an d condensate water connection

to a pub l ic sewag e system may be required.

Regulatory Requirements 1.8.2

You must also conform to any rules, regulations, or laws concerning the following:

• Local building codes regarding the instal lati on.

• Local building codes concerning the air i ntake and outlet systems and the vent connection.

• Regulations for t he power s upply connec tion.

• Tech nical rules laid down by the gas utility com pany conc erning the c onnecti on of th e gas

connect ion to t he l oc al g as mai ns.

• Instructions and standards concerning the safety equipment for the water/space heating

system.

• Installation instructi ons for building heati ng sy stems.

• The boiler must be located in an area where leakage of the boiler or connections will not result

in damag e to t he are a adj acen t t o the b oiler or to l ower fl oors of th e str uctu re. W hen suc h

loc at ion s c ann ot b e avoi ded, i t i s r ecomm en ded that a su it ab le d rain pan b e in st all ed u nder

the boi ler.

• Do not res tr i ct or seal any air in take or out let openin gs.

• If you find any defects, you must in form t he own er, i n writ ing, of th e syst em def ect and th e

associat ed haz ard.

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 11 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 12

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

WARNING!

Should overheatin g occ ur, or th e gas sup ply fail to s hut off, do n ot

turn off or disconnect the electrical supply to the pump. Instead,

shut of f the g as sup ply at a locati on ext ernal to th e boil er.

Water Quality Requirements 1.8.3

NOTE

For addi tion al i nform ati on conc ern ing w ater quality and treatment,

ref er t o AER CO tec h nical doc um ents Gl yc ol Di rect i ve and AERCO

Piping Application Guide (GF-136-P).

Unsuitable heating system water can cause the formation of scale or sludge, which affects system

efficiency. It can also cause corrosion and reduc e l ife of th e heat exchanger.

• You must follow guidelines for boiler water quality.

• Thoroughly flush the system prior to filling .

• Follow the cleaning instructions.

• Never use water to fill the heating system that has been treated by reverse osmosis,

deionization, or di stilled wat er in or der to soften the water.

• Do not us e i nhi bitors or oth er additives unless approved by AERCO for that purpose.

• When frost protection of the heating system is desired, only use AERCO-approved

antifreezes. The allow ed m aximum concent ration is 50% .

• When using oxygen-permeable pipes, e. g. for under floor heating systems, you must

separate the system fr om the boiler using plate heat exchangers.

• Cl ose t h e v al ves of t h e boiler while flushing the sy st em , do n ot i nt r oduce any sys tem c lean er

into t he boil er loop. Fl ush s ystem t horoughly to remove all system cleaner bef ore f illi ng boiler.

Approve d antif reeze (maxi m u m concentration of 50%):

• Rh omar RhoGard Mutli-Metal (AL safe)

• Noble Noburst AL

Approved system clea ne rs:

• Nob le Noburst Hydr onic Sy stem Cleaner

• Fer nox F3 Cl eaner

• Rhomar Hydro-Solv 9100

Th e sy stem c l eaner s f rom NoB u rst, R hom ar , an d F ern ox ar e NOT t o be u s ed i n t h e b oi l er itself.

Th e b oi ler mu st b e c l os ed of f (v al v es c l os ed) from t h e res t o f t h e sy st em or not c on n ec t ed whi l e

the cleaners are in the system. The system shoul d then be drai ned and then thoroughly flushed

with clean water to remove all the system cleaner.

Approved inhibitors:

• Rhomar Pro-tek 922

• Noble Noburst AL inhibitor

• AERCO/Sentinel products. See list in GF-136-P, section 2.3 - System Flushing,

Treatment, and Cleans ing.

Page 12 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 13

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

•

•

•

•

•

•

•

•

•

Instal lati on, Operation & Maintenan ce Manual

1.9 Tools, Materials, And Additional Equipment

For the installation and maintenance of the boiler you will need:

Standard tools for space heati ng, g as and w ater fitting

Manometer that i s capab le of reading both pos i tive an d negative pr essu res

Combustion an alyzer

Digital multimeter

pH digital meter

Metric Allen wrenches

Metric socket wrenches

1.10 Disposal

Dispose of the boiler packaging in an environmentally sound manner.

Disp ose of comp onent s of t he heating sys tem ( e.g. boiler or c ont rol d ev ice), that mu st b e

rep laced in an env iron mentally responsib le man ner.

1.11 General Warnings

Using the Operation and Maintenance Manual 1.11.1

This instruction manual is an integral and indispensable part of the product and must be

retained by the pers on i n c harge of the applian ce. Please read the instruct ions contained in this

manual carefully as they provide im portant information regarding the s afe installation, use and

servic ing of this appli ance. Keep thi s manual in a s af e pl ace for fu tu re ref erenc e.

Installation and Servi cin g P ers onn el 1.11.2

Installation and servicing must be carried out in accordance with the regulations in force

acc ord ing to t he m anuf act urer ’s i ns tru ct ions and b y l egal ly c omp eten t au thor iz ed pe rs ons. By

defi n i t i on , a comp et en t p e rson i s a p er s on wh o h as a speci f i c t ec h n i c al q ual i f i c at i on i n t h e fiel d

of component s fo r c ent ral heating systems f or domest ic use, domest ic hot w ater producti on, and

servicing. This person must have the qualifications legitimized by the current laws and

reg ulations in for ce.

Inappropriate, incomplete, or irregular servicing could compromise the safe operation of the

app lian ce, an d cou ld cau se inju ry to pers ons, ani mals or damage t o property. The manufacturer

shall not be held li abl e for any su ch in ju ry an d/ or damage.

Any repairs must be carried out by AERCO authorized technicians and using only original spare

par t s. N on -obs erv an c e o f t h e above r eq u i r em ent m ay j eop ard i z e th e s af ety of t h e app l i ance an d

void any warranties.

In the event of failure and/or faulty functioning of the appliance, switch off the boiler. Do not

attempt to make any repairs, but instead contac t qual ified tech ni cians.

To guar ant ee the efficiency and corr ect f unct ion ing of t he appliance it is required th at the b oiler be

serviced annually by a qualifi ed person.

Installation Materials 1.11.3

The installations for the domestic hot water production MUST be built, in their entirety, with

mat erials (t aps, p ipes, fitti ngs , et c.) approv ed f or dri nk able water.

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 13 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 14

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

Preparing Boiler for Servicing 1.11.4

Before carrying out any cleaning or servicing t urn off the electrical supply to the boiler by means

of the ON/OFF switch and/or by means of the appropriate shutdown devices.

Returning a Boiler to Service 1.11.5

Bef ore pu t ti ng a b oil er, w hich has been unused for a length of time, bac k in t o ser vi ce, ri nse t h e

entire d om est ic hot w ater system, allowing the w ater to flow an approp riate amount of tim e in

order to circulate throughout the entire system.

Change in Ow nership 1.11.6

If the ap pliance i s sold or transferred t o another owner, or if t he p resent user mov es from the

installation site and leaves the appliance installed, ensure that the manual stays with the

app li ance so that it c an be c onsulted by the new own er and/or installer.

1.12 Operational Limits of the Boiler

Max. boi ler temperat ure: 180° F

•

Max Al lowable Working Tem peratu re ASME: 2 00 °F

•

• Ma x. Allowable Working Pressure ASME: 92 psi

Page 14 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 15

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

•

Instal lati on, Operation & Maintenan ce Manual

CHAPTER 2: TECHNICAL FEATURES AND DIMENSIONS

2.1 Modulex EX T Technical Features

Com pact, gas fired, L ow N Ox, condensing boiler.

•

Comprised of one sectional boiler bod y, suit abl e as a single boi ler or in a cascaded group.

•

May be instal led i n ei th er an in s ide or outside location.

•

Low inter nal water volume.

•

Fas t r espon se to load variations.

•

Flue exhaust outlet positi onable on three sides.

•

Manifold delivery and return (reversible).

•

Made up of two or more heating elements ( 2 to 7 ), cast alumin um / sil icon / mag nesium.

•

Full range of modulation by variable speed blowers and premix burners.

•

Eac h heat in g el em ent m oni tor s i ts own wat er temperature, and will individually shutdown

•

if f low i s inter rupt ed, w ithout affecting th e oth er burner s ecti ons.

One gas supply line (reversible).

•

• Individual modules capable of between 46 and 160.5 kBTU/hr.

These b oil ers ar e designed f or use with category IV venting.

The boiler is supplied c omplete with all the safety and control devices in accordance with all

current regulations, and its technical and functional features comply with the regulations

prescribed by: ANSI Z21.13 / CSA 4.9 - Gas-fired low pressure steam and hot water boilers.

Temperature Control Devices: 2.1.1

• Local NTC sensor (each heating

element)

• Limit thermostat room (each heating

element)

• Return NTC s ens or (General)

• Safety therm ostat approved (manual

reset)

• Flow sens or B CM

• Flow NTC sensor (General)

Control Panel (E8) Includes: 2.1.2

• ON-OFF switch

• Temperature control / Boiler operation

• Fuses

• Air pressure fans

• Conden sat e level sensor

• Air pr essu re sw i tc h (ant i-obstruction)

• High limit sensors

Other Features Includ e: 2.1.3

• NTC heat sensors for global temperature control on the flow and return.

• 0-10V output to control variable speed pri mary pum p.

• Integral insulation with hypoallergenic synthetic wool.

Premix fiber m esh modulating burner (premixes into the fan with autom atic diaphragm

backflow separation from the co mbust io n chamber).

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 15 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 16

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Instal lati on, Operation & Maintenan ce Manual

Less th an 49 dBA of noise at maximum power.

Heati ng operati on: instantaneous power microprocessor control, with preset parameters for

com par is on b etw een tem per atu re ( or c alc ulat ed fr om t he e xter nal t em per atur e regu lat i on)

and gl obal temperat ure f low .

Operation modes:

o A bilit y to c ontrol power to the in dividu al heating elements for any calibration with or

without confidential code access.

o Pr oducti on of A.C.S. (Active Cooling System) by NTC sensor of priorities for control by

boiler feed pum p or by three-way divert er valve c ontr oller.

E8 electronic controller included.

BCM ( Boil er Commun i cation M anager) included.

Ability to control power of the individual heating elements.

Con tr ol of heat d eman d: c onstant or rem ote s et poi nt.

Monitoring of oper ating s tat us and temperatu re.

Rep ort in g of alarms .

Setting of parameters.

Em er g enc y oper at i on preven t s t h e boiler from shutting dow n as a r esu l t of th e i nter ruption

of comm unicat ion with a control system or any r emote control un i t .

Alarm management.

Alarm reset input.

Warnin g alarm relay.

Stainless steel condensate collector tank with siphon , drain trap, and smoke chamber.

Easil y r emovabl e st ainl ess steel panels pai nted for outd oor inst al lation.

Built-in air v ent

2.2 General Boiler Operation

The boi ler m ay b e oper at ed fr om t he E8 controller or al ter nat iv ely from a B CM (Boi ler Casc ade

Manager).

The boiler management logi c prov ides t he maximum numb er of simultaneou sly operati ng heating

elements in order to maximize h eat p roduct ion and over all efficiency. Burner efficiency and a high

heat exchange between surfaces con tribute to th e reliab le and eff icient output power. The various

components are designed t o w ork together so that op erati ng ti me is shared equally among the

components, thus reducing maintenance and labor costs.

Th e hot w ater moved by t he pum p is pushed to the return of the p rim ary fl ow of the h ydrau li c

separat or . F r om h er e a sec on d pum p will distribute the hot water to the various destinations. The

cooled return water is drawn by the pump through t he hy draul ic s eparator to r esume the cycle via

the boiler.

WARNING!

If in stalli ng t o an outd oor locat ion wher e fre ezing temperat ures may

occ ur , it is nec essar y t o in st all d evic es an d/ or m ater ial s t o pr even t

any freezing in the condensate drain and the Flow and Return

manifolds. Failure to do so may cause serious damage to the

equipment.

Page 16 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 17

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

On Modulex EXT models 321,

Instal lati on, Operation & Maintenan ce Manual

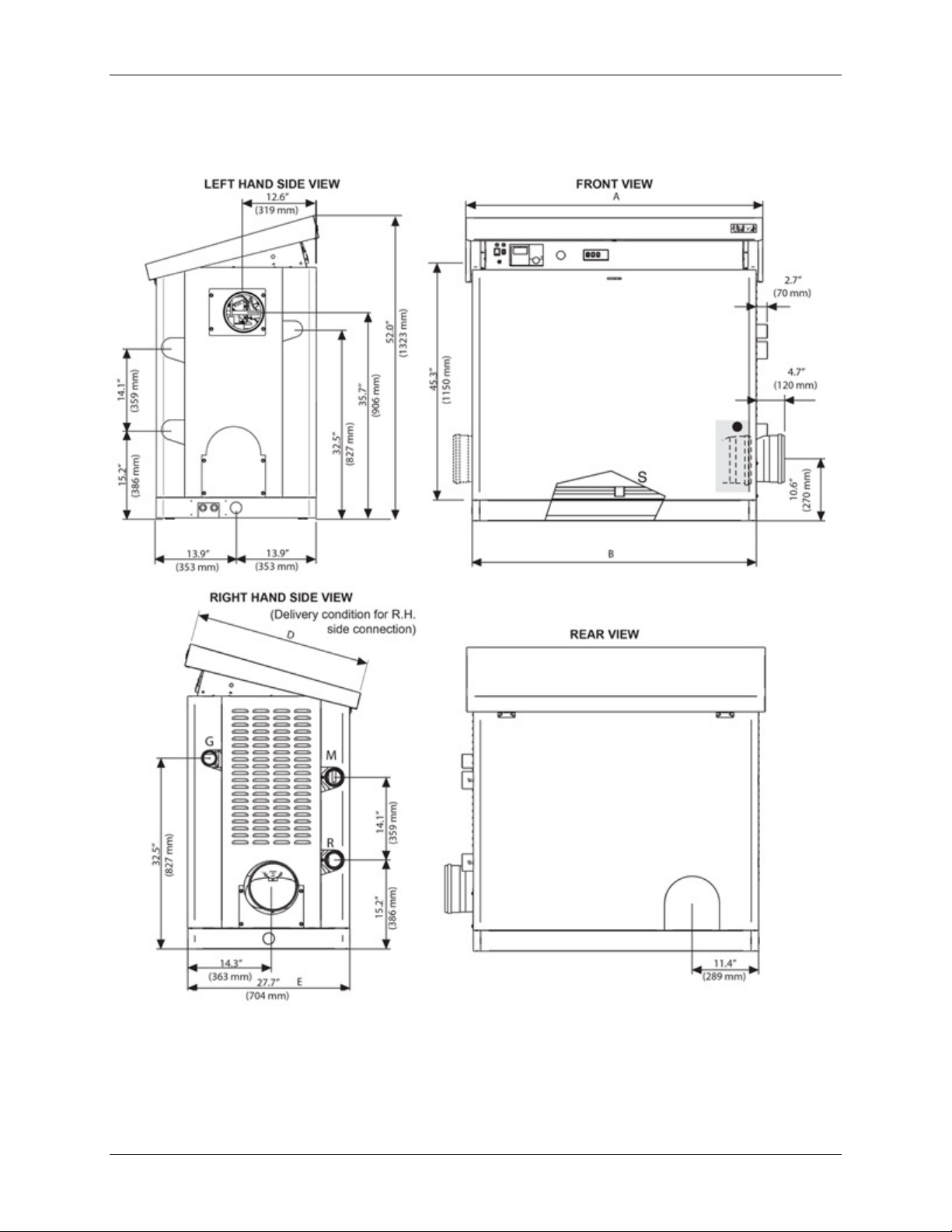

2.3 Dimensional Drawings

642 and 962 the flue terminal

ends inside the casing

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 17 of 148

GF-143 Phone: 800-526-0288 12/01/14

Figure 2-1: MODULEX EXT Dimensional Drawings (Si de V iews)

Page 18

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Model

321

481

641

802

962

1123

Dimensions:

No. of Modules

2 3 4 5 6

7

30.0‘‘

30.0‘‘

40.6‘‘

40.6‘‘

51.2‘‘

51.2‘‘

2½‘‘

2½‘‘

2½‘‘

2½‘‘

2½‘‘

2½‘‘

Instal lati on, Operation & Maintenan ce Manual

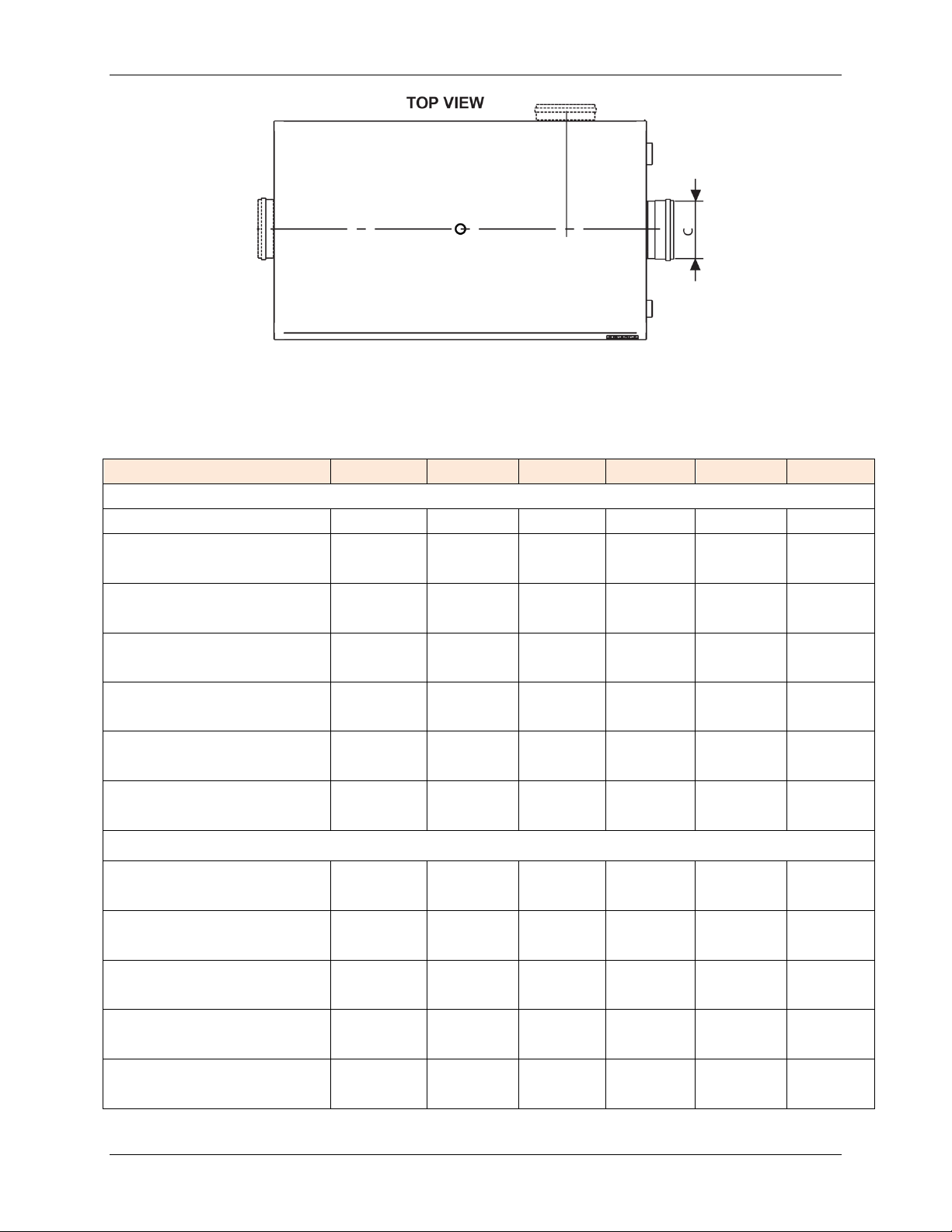

Figure 2-2: MODULEX EXT Dimensional Drawings (Top View)

Table 2-1: MODULEX EX T Dim ens ion s and Size s

Height (Open) - inches/mm

Height (Closed) - inches/mm

Width ‘’A’’ - inches/mm

Width ‘’B’’ - inches/mm

Dep th ‘’D’’ - inches/mm

Dept h ‘’E’’ - inches/mm

Connections:

Gas - inches/mm

M C/H System Flow

- inches/mm

R C/H System Return

- inches/mm

52.1‘‘

1323

45.3‘‘

1150

764

27.8‘‘

707

30.3‘‘

770

27.7‘‘

704

2‘‘

60.3

76.1

2½‘‘

76.1

52.1‘‘

1323

45.3‘‘

1150

764

27.8‘‘

707

30.3‘‘

770

27.7‘‘

704

2‘‘

60.3

76.1

2½‘‘

76.1

52.1‘‘

1323

45.3‘‘

1150

1032

38.4‘‘

975

30.3‘‘

770

27.7‘‘

704

2‘‘

60.3

76.1

2½‘‘

76.1

52.1‘‘

1323

45.3‘‘

1150

1032

38.4‘‘

975

30.3‘‘

770

27.7‘‘

704

2‘‘

60.3

76.1

2½‘‘

76.1

52.1‘‘

1323

45.3‘‘

1150

1300

48.9‘‘

1243

30.3‘‘

770

27.7‘‘

704

2‘‘

60.3

76.1

2½‘‘

76.1

52.1‘‘

1323

45.3‘‘

1150

1300

48.9‘‘

1243

30.3‘‘

770

27.7‘‘

704

2‘‘

60.3

76.1

2½‘‘

76.1

Vent Conne c t ion ‘’C’’

- inches/mm

Con dens ate d rai n diameter

- inches/mm

Page 18 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

5.9‘‘

150

1.57‘‘

40

5.9‘‘

150

1.57‘‘

40

5.9‘‘

150

1.57‘‘

40

5.9‘‘

150

1.57‘‘

40

7.8‘‘

200

1.57‘‘

40

7.8‘‘

200

1.57‘‘

40

Page 19

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

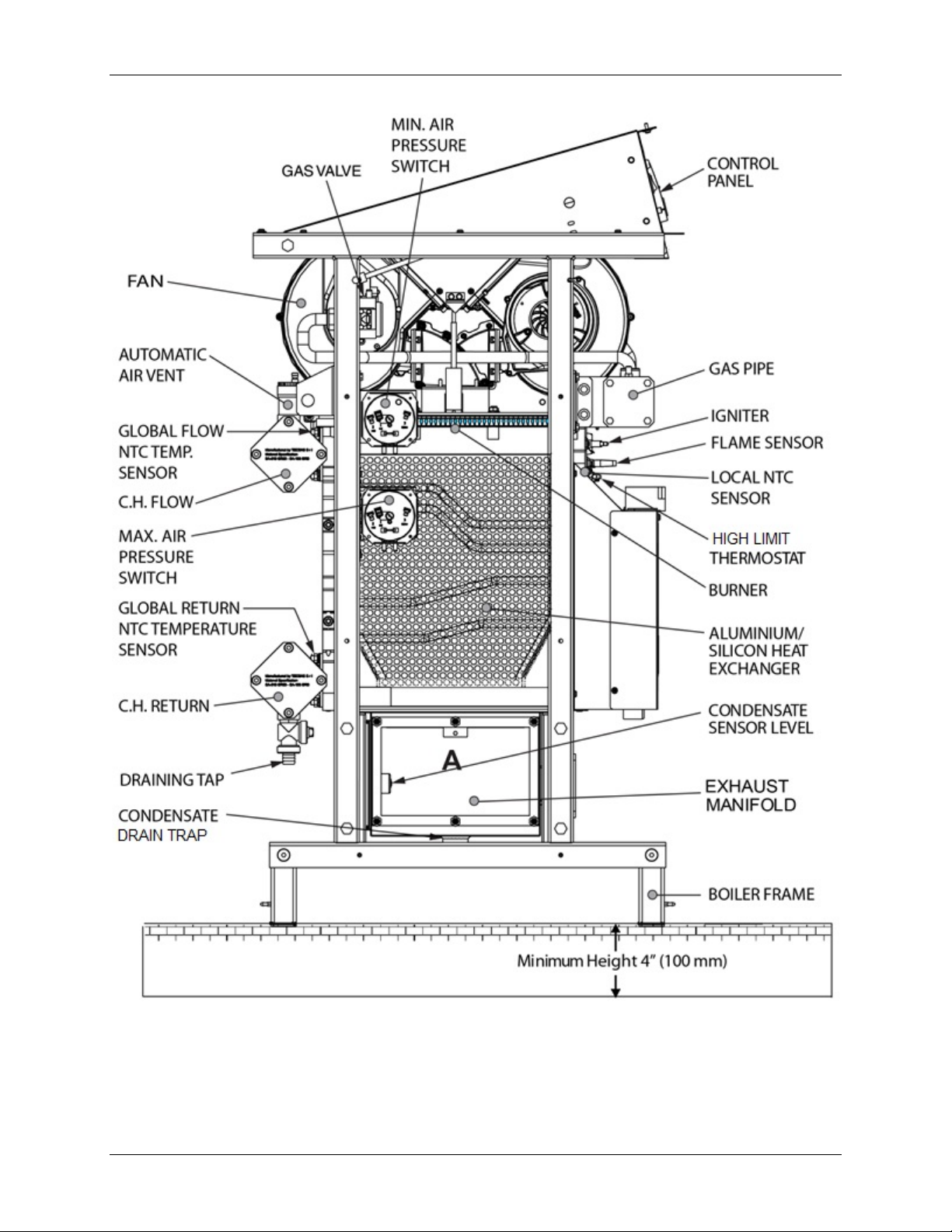

Figure 2-3a: MODULEX EXT Main Components (Left Side Vie w)

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 19 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 20

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

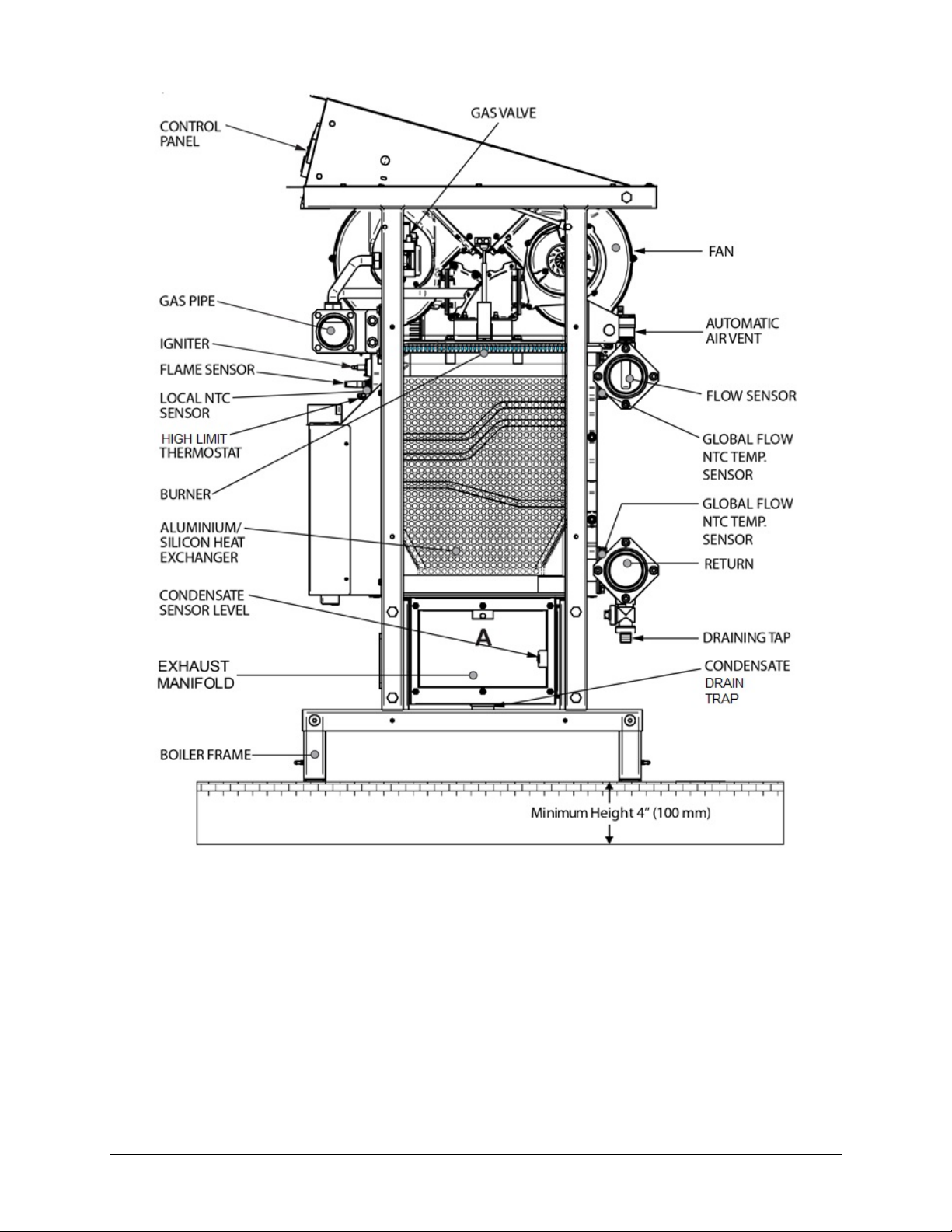

Figure 2-3b: MODULEX EXT Main Components (Right Side View)

• Exhaust and condensate evacuation connections: are on the RIGHT

HAND side (supply condition), but may be moved to the RIGHT HAND or

REAR positions.

• Air intake connect io n : located on th e LE F T HAND side.

• Cold/Hot flow connection: on the RIGHT HAND side (suppl y condition), but

may be moved to the LEFT HAND position.

• Cold /H ot retu rn conn ect ion: on t he RIGHT HAND si de (supply c ondition) ,

but may be moved to the LEFT HAND position.

• Gas connection: on t he R I GHT HA ND s id e (supply condition) , but may be

moved to the LEFT HAND position.

Page 20 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 21

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

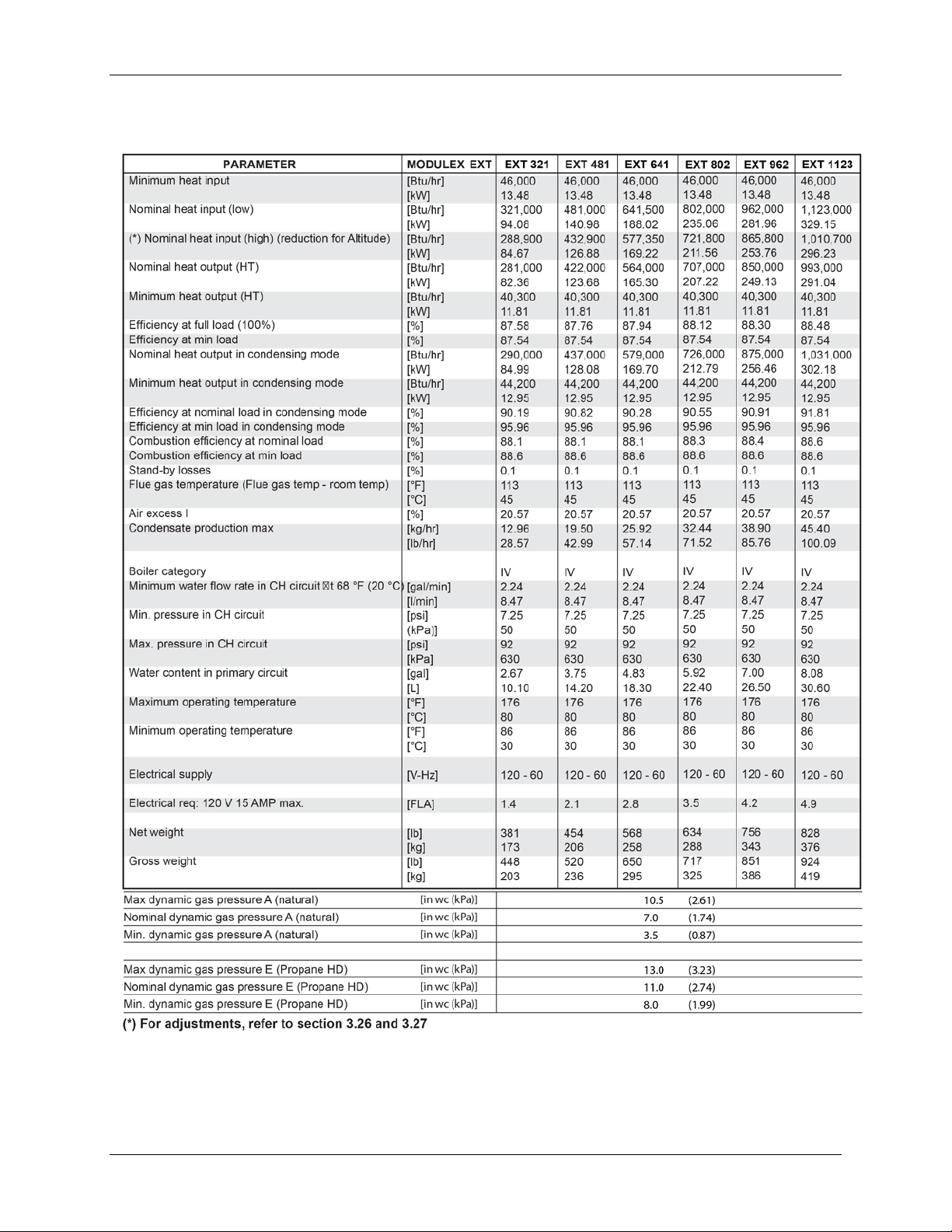

2.4 Per for ma nce Data

Table 2-2: MODULEX EXT Perfor manc e Data

NOTE

The Tec hnical d ata plat e is pl aced u nder the c as in g.

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 21 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 22

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

(This page intentionally blank)

Page 22 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 23

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.1 General Warnings

Appropriate Use of t he Boil er 3.1.1

This boiler MUST be us ed for the use for which it has been exp ressively designed. Any other

use shall b e con sidered impr oper and ther efore dan gerous.

This boiler i s des igned to he at water at a temperature below t he boiling point at atmospheric

pressure.

Prerequisite System Flushing 3.1.2

Before ins tallin g t he boil er th e followin g actions MUST be carried out b y a competent engine er

or tec hnici an:

a) The whole system should be thoroughly flushed in order to remove any

resid ual dirt or grime which could compromise correct boiler operation.

b) Check that the boiler has been preset for operating with the gas type

available. This is verifiable via the indication on the packaging and on the

data badge;

c) Check that the flue pipe has an adequate draft, does not have any

con stri cti ons or ob str uct ions, and t hat no oth er ap pli anc e’s fl ue out let s have

been fitted, unless the flue pipe is serving more t han one heating appliance,

according to the specific standards and regulations in forc e. The connection

between t h e boi l er an d fl u e ou t l et c an be m ad e on l y af t er t hi s ver i f ic at i on has

been car ri ed out .

Installation Personnel Qualifications 3.1.3

The appliance must be installed by a qualifi ed engineer or t ech ni cian, who complies with the

technical requirements, who, under his own respon sibi lity, guarante es the compliance of th e

st an d ar ds ac c ording to t he lates t r egulations.

The app lianc e must be positioned so that at l east the mi nim um op erational and s ervicing

clearances are p rov ided .

The boiler must be connected to a heating system which is compatible to it s performance and

output.

FOR MASSACHUSETTS INSTALLATIONS: The b oil er MUST be i nst all ed by a pl umb er or g as

fitter licensed within the Commonwealth of Massachusetts.

Carbon Monoxide Detector Installation 3.1.4

The instal lati on MUST conf orm to th e requirements of th e aut hori ty having j urisdicti on or, in t he

absence of suc h requiremen ts, to on e of the following:

• United States: Installation must conform to the requirements of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• Canada: Installation must conform to the requirements of CAN/CSA-

B149.1 - Natural Gas and P ropane Inst al lation Code

• Where required by the authority having jurisdiction, the installation must

conform to the Standard ASME CSD-1 Controls and Safety Devices for

Automatically Fired Boile rs.

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 23 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 24

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

3.2 Code and Standards Approvals

The MODULEX EXT boil er has b een reviewed for compli ance w i th the applic abl e sections of

the following North A meri can Standards:

• ANSI Z21.13/CSA 4.9: Gas-fired low press ure s te am and hot wat er boiler s

• ASME SECTION IV: A SME B oil er and P res sur e Ves sel Cod e wi th ad den da, S ect ion IV :

Ru les for Con st ructi on of He ating Boilers

• BTS – 2000: Testing standard method to determine efficiency of commercial space

heating boilers.

• SCAQMD RULE 1146.2: Emissions of oxid es of nitrog en from large wat er he aters and

small boi lers and process h eater s.

• CSD-1: Cont rol s an d saf ety devices for automatic all y gas-fired boiler s.

3.3 Packaging

The MODULEX EXT boiler is delivered assembled and protected by a plastic bag inside a

strong cardboard box and fixed on a p all et. T hi s allows the boi ler to b e handled by a forklift.

CAUTION!

Remove both straps and the cardboard box from above, making

sur e the pr oduct i s intact. The pac king el ements (cardb oard box,

strap s, plastic bag s, et c…) should be kept away from children, as

these present suffocation and choking hazards.

AERCO r ef uses all liability for inju ry to persons , an i mals or damage

to property derived from not respecting the above mentioned

recommendations.

In the packaging, in addition to t he b oiler, you will also find the f ollowing contents (see Fi gures

3-1 and 3-2):

ON THE BOILER FRONT:

• The flue exhaust ter min al scr ewed t o th e fron t of the f rame

• The sealing gasket for flue outlet mounted in the flue assembly.

• A cardboard box containing:

o The sealing gasket for connection between condensate tray and terminal

o 4 elbows + 1 T ee pi ece + 1 plastic plug, Ø 1.6” (40 m m) for condensate drai n.

o the screws necessary for installing the flue exhaust terminal

• External sensors: Remote Temperatur e, D. H.W. storage t ank & O utdoor temperature

Nipple/cap for fl ue exhau st gas sampling tests

•

Resistor kit for emer gency operation

•

Cab le gl ands for electrical supply

•

Pins for mounting soc ket s

•

Kit sheet for output cables 120 / 24 V

•

Page 24 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 25

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

A cardboard box containing:

•

o

Four (4) frame support feet

o

3 hole covers for swit ching flue exh aust l ocation

o

3 insulation gask ets (f or installat ion out side).

A cardboard box containing:

•

o

CSD-1 header

o

Rel ief valve

ON THE BOILER RIGHT SIDE:

One 39. 3 inch (1 met er) pipe for the con d en s at e evac u at ion system. -

•

Left and right side covers.

•

ON THE BACK OF TH E BOILER

Socket, front and rear.

•

ON THE BOILER T OP :

a plastic bag containing:

•

o

This installation manual for the i nstal ler.

o

User manual for th e user.

o

E8 controller instruction manual.

Pins to hold t he fan assemb ly in a r aised posit ion .

•

IN A SEPARATE BOX

• PVC vent ing starter piece and pipe clamps

• Temperature & Pressure gauge

• Flow S wit ch

• Pi pe adaptor (r ubber )

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 25 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 26

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

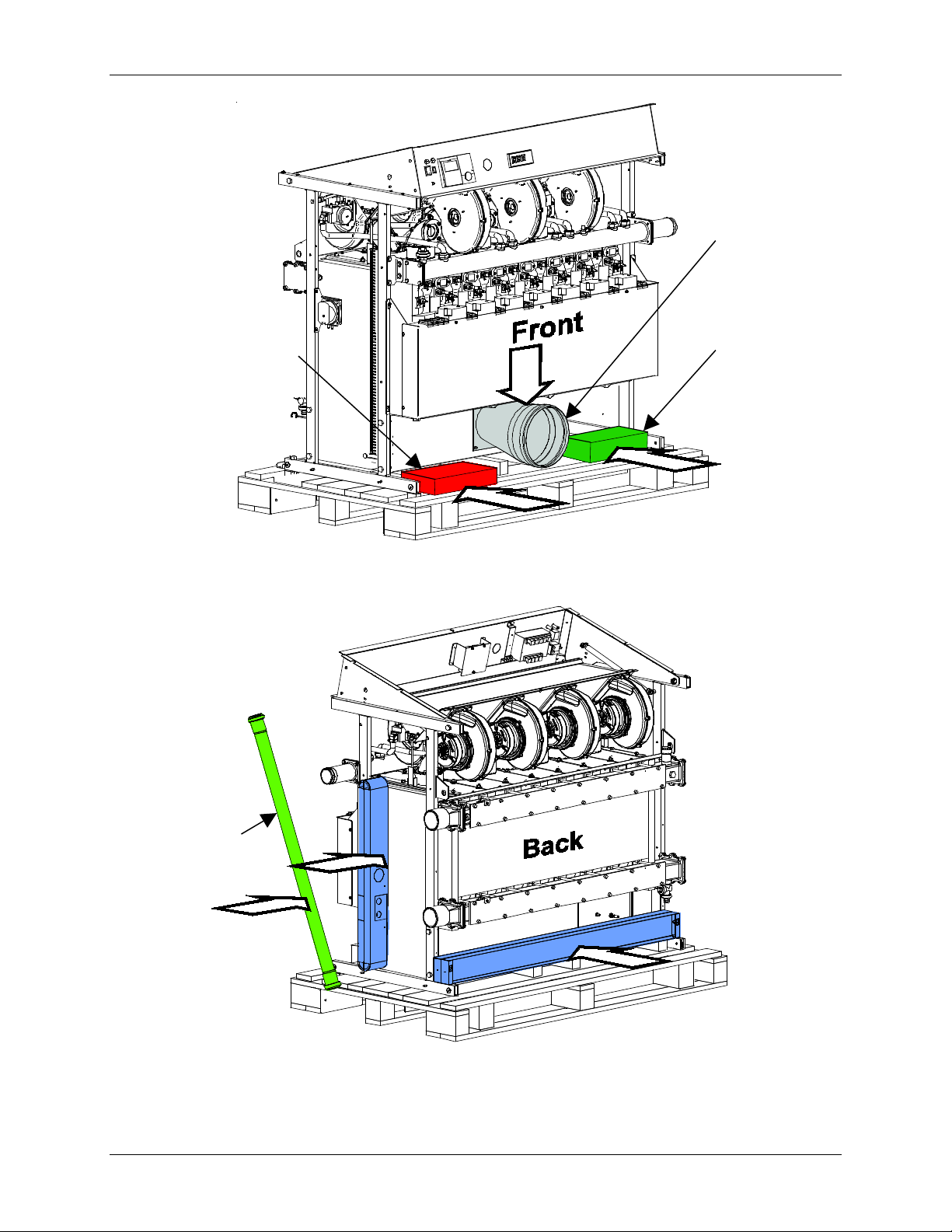

Cardboard Box

with Parts

Cardboard Box

with Parts

Flue Assembly

And Gasket

Condensate

Drain Pipe

Instal lati on, Operation & Maintenan ce Manual

Figure 3-1: MODULEX EXT Unpacking (Front View)

Page 26 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Figure 3-2: MODULEX EXT Unpacking (Rear View)

Page 27

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

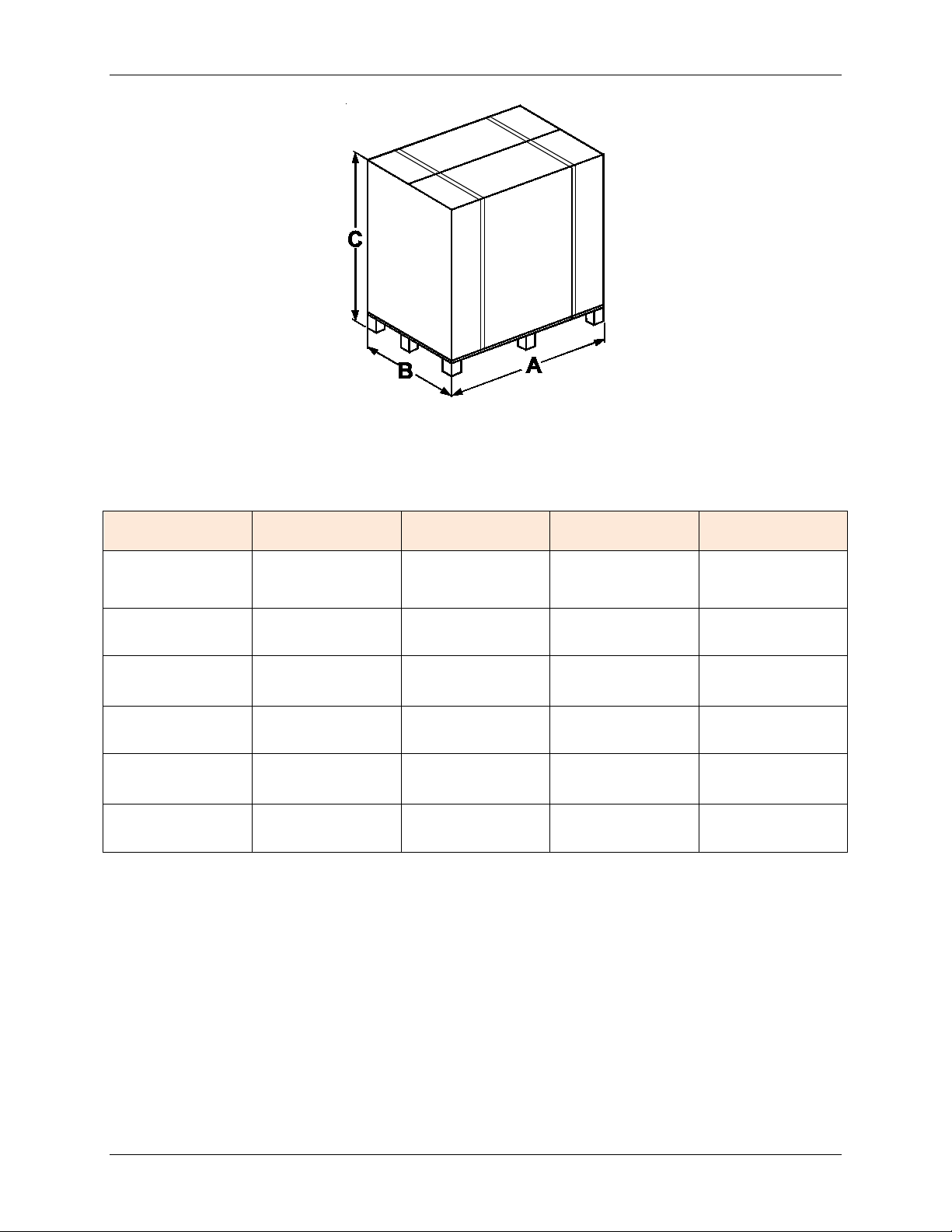

Figure 3-3: MODULEX EXT Shipping Package

Table 3-1: MODULEX EX T Ship pin g P acka ge Dim en sio ns

Model A B C Gross W ei gh t

321

481

641

802

962

1123

43.7‘‘

1110 mm

43.7‘‘

1110 mm

43.7‘‘

1110 mm

43.7‘‘

1110 mm

54.1‘‘

1375 mm

54.1‘‘

1375 mm

35.0‘‘

890 mm

35.0‘‘

890 mm

35.0‘‘

890 mm

35.0‘‘

890 mm

35.0‘‘

890 mm

35.0‘‘

890 mm

49.2‘‘

1250 mm

49.2‘‘

1250 mm

49.2‘‘

1250 mm

49.2‘‘

1250 mm

49.2‘‘

1250 mm

49.2‘‘

1250 mm

448 lb.

203 kg

520 lb.

236 kg

650 lb.

295 kg

716 lb.

325 kg

851 lb.

386 kg

924 lb.

419 kg

3.4 Transporting and Securing the Boiler Safely

The boiler is sus ceptib le to se ri ous damage wh en not s ecu red properly.

• Follow the transportation instructions on the packaging.

• On ly tran sport the boil er us in g appropr iate t ranspor tat ion equipment , such as a hand-truck

wi th a fasten in g belt or sp ecial eq uipment for tran sporti ng heavy eq ui pment.

• When moving t h e b oi l er, it must b e sec u r ed on t h e t r an sp ortat i on eq ui pment t o pr ev ent i t

from fall i ng off.

• Protect all parts against impacts, during transportation.

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 27 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 28

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

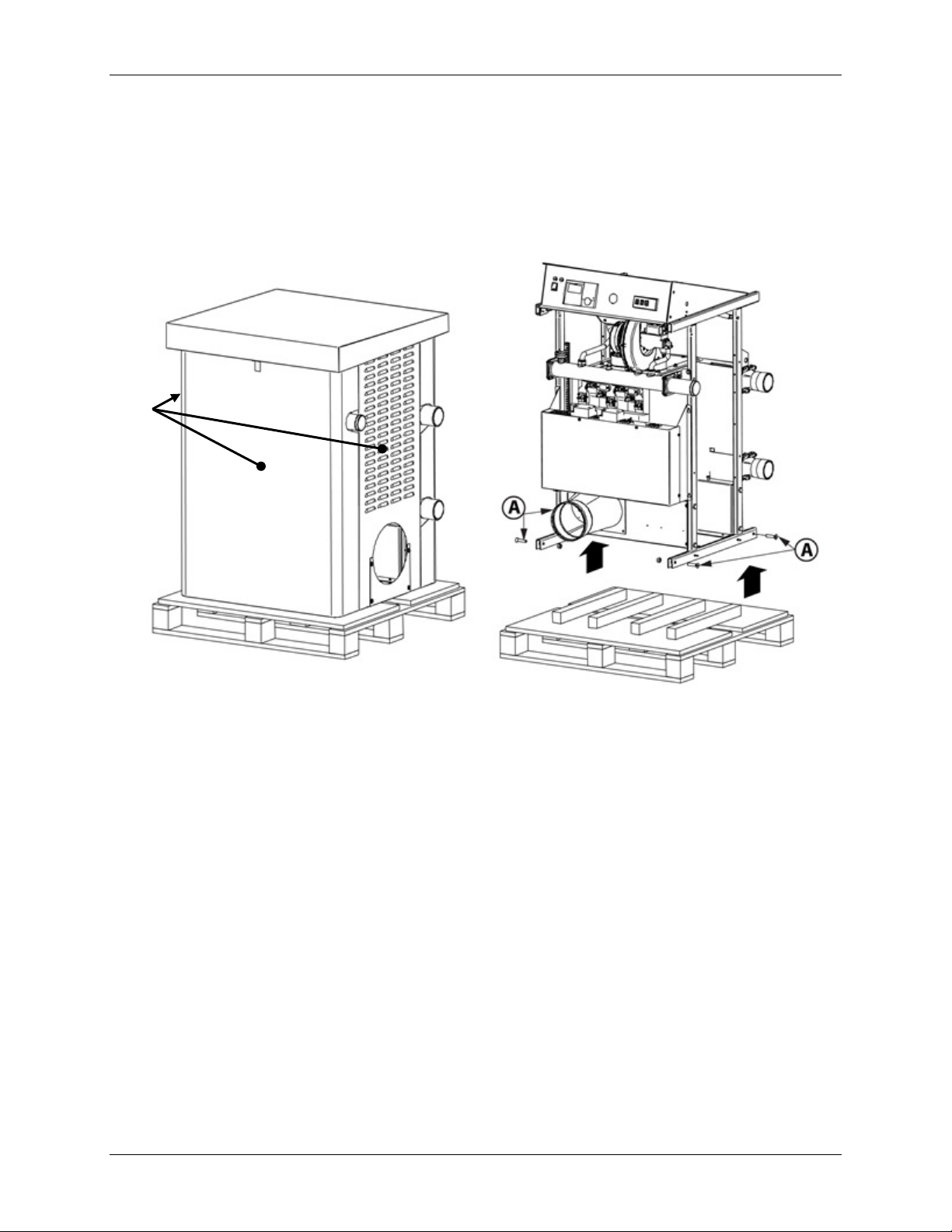

3.5 Removal From Boiler Bed And Insta llation Of Boiler Feet

Foll ow the di rec tions below to prepare t he boiler for installation:

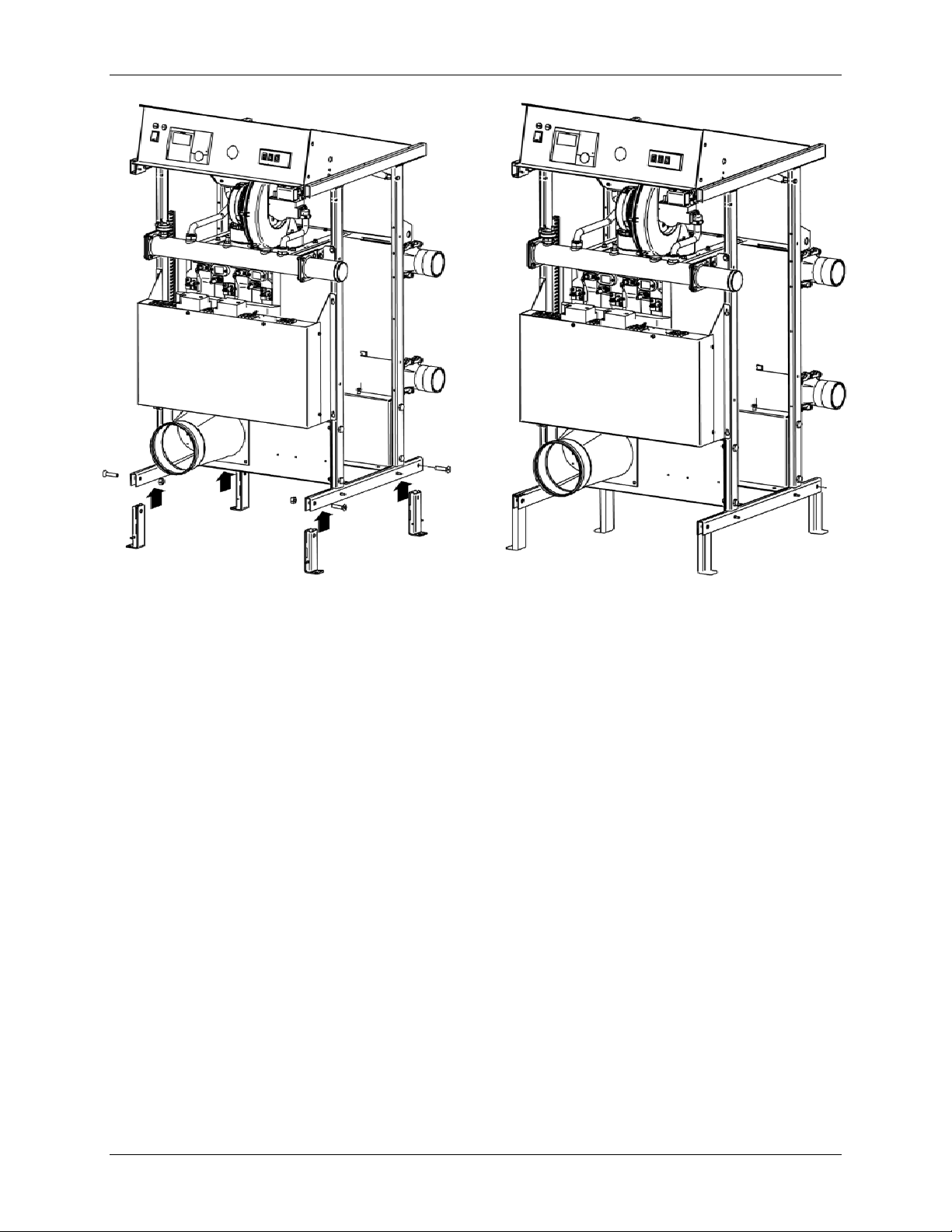

1) Remove th e covers of the boiler (Fi gure 3-4).

2) Lift the boiler with a hoist or for klift b ands (F i gure 3-4).

3) Remove th e 4 screws ’’A’’ (Figure 3-4).

Covers

(Remove)

Figure 3-4: EXT Unpacking (Left = With Covers, Right = Lifted Without Covers)

4) Retrieve the four (4) support feet from on e of t he cardboard boxes packaged wi th the

boiler.

5) A tt ach the four (4 ) support feet to t he c hassis using the four ’’A’’ screws removed i n Step

3 (Figure 3-5).

6) P lace the b oiler on concrete slab and re-mount the cover(s) over t he boi ler.

Page 28 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 29

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

Figure 3-5: MEXT Unpacking (Left = Attach Feet, Right = Ready for Cover)

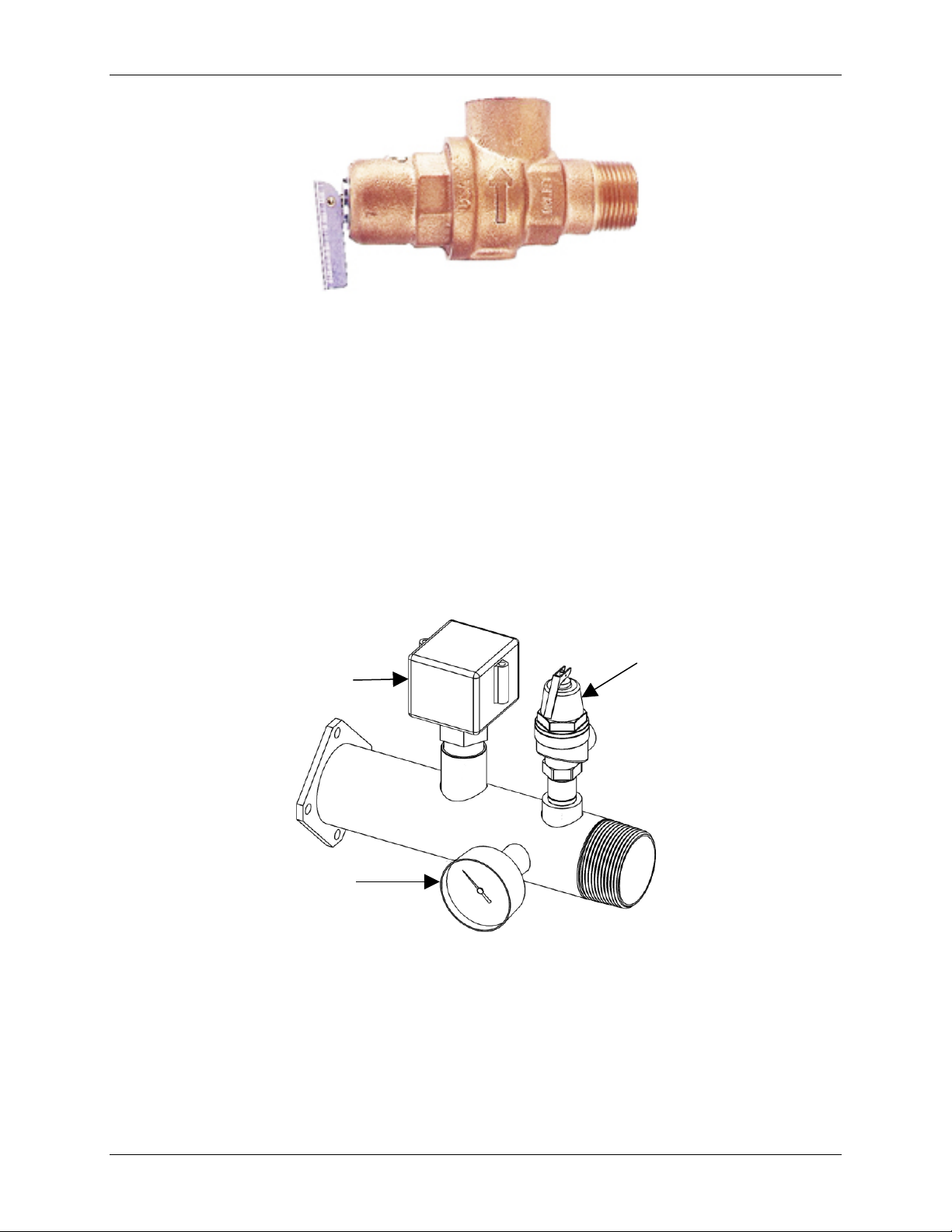

3.6 Boiler Location Inside A Boiler Room

Sp ec ial att ent i on sh all be p ai d t o l ocal r egu l ati ons and l aw s ab out b oil er enclosures and boiler

rooms, particularly to the m inimum clearances around the boil er. The installation shall be in

compliance with all the latest regulations and laws about boiler enclosures, boiler rooms,

in stal l at i ons of he at i n g and hot -wat er s ys tems , v ent i l ati on , vents c apable of exhausting the flue

gases of condensing boilers, and any other applicable requirements.

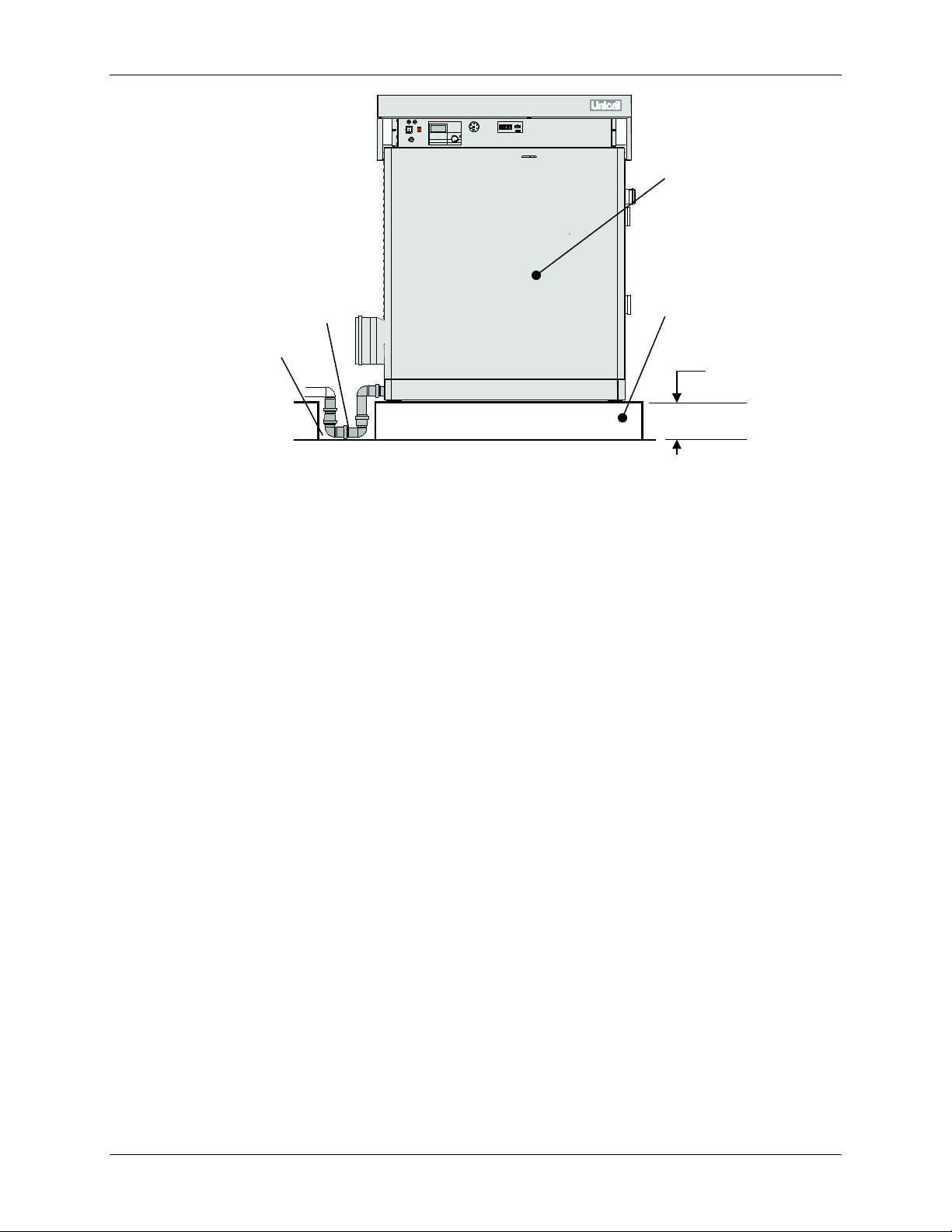

Th e boi ler can be p ut on a flat and suf fic ien tly str ong bas e wi th the same dim ensions as the

boi l er an d at l east 3.93’’ (100 mm) high (see Figure 3-6), in order to assemble the condensate

trap. An alternative to this base m ay be a 100mm deep well or trench next to the boiler to

acc om m odat e t he c ond en s ate “ U” d r ain pi pe (see Figure 3-6). Af ter in st all at ion t he b oil er sh all

be p erfect ly horizontal and stable, to reduce any pos sible vib rations or noises .

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 29 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 30

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Condensate

Drain Pipe

Boiler Housekeeping

Pad (Support Base)

At Least

3.93” (100mm)

MODUL EX EX T

Boiler Front

Instal lati on, Operation & Maintenan ce Manual

Well or Trench

for Condensate

Drain Pipe

Figure 3-6: Boiler (Front View) on Housekeeping Pad with Condensate Drain Pipe

Boiler Room Safety Concerns 3.6.1

When selecting the position for t he inst allat ion of t he b oiler pleas e com ply with the f ollow ing

safety requirements:

• Ensure easy access to the component s of th e boiler to f acil itat e maint enance.

• The ro om where t he boi ler will be placed mus t always be frost free.

Do n ot s tore or use g as ol i n e o r ot h er f l am mabl e v ap or s an d l i q u i d s i n t h e vicinity of this

•

or an y ot h er app l i an c e.

Never use or store any chlorinated detergents or halogenated hydrocarbons (e.g. in

•

spraycans, solvents and detergents, paints, adhesives) in proximit y to the boiler .

For outd oor in stallati on see Warning for Outdoor installation on page 16.

•

Products to Avoid in the Boiler Room 3.6.2

Do NO T st ore the fol low ing p roducts in the b oiler room and/or around com busti on air int ake

vents.

• Spray cans containing chlorocarbons/ fluorocarbons

• Am moni um an d/ or am moni um sol ut ion s

• Permanent wave sol ut ion s

• Chlor inated wa xes and/or cleaners

• Chlorinated swimmi ng pool chemi cals

• Cal cium chl oride used f or t hawing

• Sodium chloride used for water sof tening

• Refrigerant leaks

• Paint or varnish remover s

Page 30 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 31

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Instal lati on, Operation & Maintenan ce Manual

• Hydroch lori c acid/ muri atic aci d

• Cements and glues

• Antistatic fabric sof ten ers u sed in cloth es dr yers

• Chlorine-type ble aches, detergents , an d cleani ng solv ent s

• Adhesives used to fasten building products

• other damaging or flammable products

3.7 Recommended Clearances for Servicing

Recommended c l ear ances ar ound the boiler are listed below (see Figure 3-7):

TOP of the boi l er : 24‘‘ ( 600 mm)

FRONT of the boiler: 24’’ (600 mm)

RIGHT side: 24’’ ( 600 mm)

LEFT side: 24’’ (600 mm)

FLOOR/GROUND: 4’’ (100 mm)

BACK of the boiler: 24’’ (600 mm)

Figure 3-7: EXT Boiler Clearances

It is recommended to provide the boiler with the clearances as shown in the drawing in order to be

able t o perform normal ser vice and cleaning operat ions. M inimum required clearances depend on

the piping and venting configuration. For further details, contact your loal manufacturer’s

representative.

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 31 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 32

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

3-9.

Instal lati on, Operation & Maintenan ce Manual

3.8 Boiler Connections

At del i very , the MODULEX EXT boiler is setup with al l c on nec t ion s, (i.e. c ol d/ hot w ater f low &

return, gas, and exhaust outlet) on it s RIGHT HAND side.

Changing Exhaust Outlet Location 3.8.1

To move the flue exhaust outlet terminal from the RIGHT HAND side (standard delivery

posi ti on ) to th e REAR posit ion, it is necessary to request t he Rear Exhaust kit (P/N 00364937),

which includ es a cover for closing off the RIGHT HAND side panel exhaust opening (see Figure

3-9).

Rear flue

manifold ki t

includes the

cover for the

right-hand

exhaust h ole.

See Figure

Figure 3-8: Rear Exhaust Kit (P/N 00364937) for Changing Exhaust Outlet from RIGHT

HAND side to REAR on

EXT 802, 962, 1123 (only)

Page 32 of 148 AERCO Int ernational, Inc. • 100 O ritani Dr. • Blauvelt, NY 1091 3 OMM-0087_0E

12/01/14 Phone: 800-526-0288 GF-143

Page 33

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Opening Cover

Sup ply Gas to

Connector

NOTE

Tor que al l bolts to 8 .8 5 ft-lbs (12 N/m)

Instal lati on, Operation & Maintenan ce Manual

Exhaust

Figure 3-9: Rear Exhaust Kit (P/N 00364937) for Changing Exhaust Outlet from RIGHT

HAND side to REAR

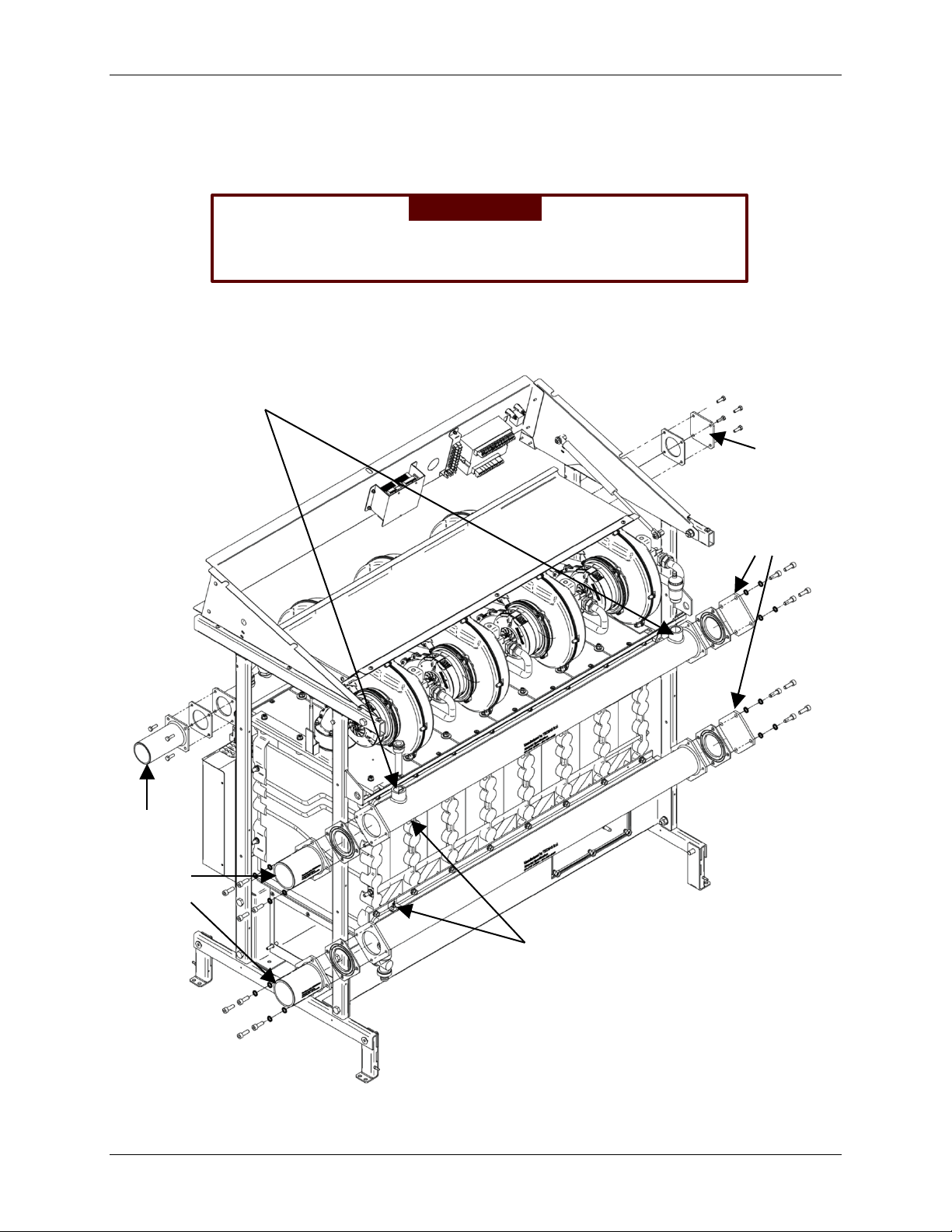

Reversing Gas Manifold Connections 3.8.2

To move th e gas connect ion from the RIGHT HAND side (standard d eli very posit ion ) to the LEFT

HAND side, swap the end plate and the gas supply connector screwed onto the gas manifold

ends as shown in Figure 3-10. Ensure t hat the gaskets for ALL con nec tion s ar e rev ers ed alon g

with the connectors themselves.

Gas Manifold

Gasket

Gas Manifold

Gasket

Gas Manifold

End Plate

Gas Manifold

Figure 3-10: Reversing Gas Connections from RIGHT HAND to LEFT HAND

OMM-0087_0E AERCO International, Inc. • 100 Or itani Dr. • Blau velt, NY 10913 Page 33 of 148

GF-143 Phone: 800-526-0288 12/01/14

Page 34

MODULEX EXT 321, 481, 641, 802, 962, 1123 BOILERS

Reverse positions

NOTE

Torque all bolts to 8.85 ft-lbs (12 N/m)

Instal lati on, Operation & Maintenan ce Manual

Reversing Cold/Hot Water Flow & Return Connections 3.8.3

Change of Water Flow and Return connections from RIGHT hand to LEFT hand requires

reversing connectors, moving the Flow and Return Temperture Sensors to other end, and

exchanging posit ion s of th e Boiler Sensor KF an d A utomatic Air Vent.

WARNING!

En sure that the gaskets for AL L connection s are rev ersed along

with the connectors themselves.

3.8.3.1 Reversing Cold/Hot Water Flow & Return Piping Connectors

Re fer to Figure 3-11 and reverse the connectors and end caps on Supply, Flow, and Return

pipes . Ensur e that all gas kets are also reversed.

of Boiler Sensor

KF and Automatic

Air Vent. See

Figure 3-13.

Move

end caps (and

gaskets) to other

end of

Flow/Return