Page 1

Installation, Operation & Maintenance Manual (IOMM)

GF-135

OMM-0089_0A

USER MANUAL

Installation, Oper atio n and M ainte nan ce

GAS FIRED B OILE R

Natural Gas or Propane Gas

Modulating & Condensing Hot

Water Boiler:

06/19/2014

Page 1 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 2

AERCO Document Conventions

NOTE

GF-135 Esteem 399 Low NOx Boiler

OMM-0089_0A Installation, Operation & Maintenance Manual

DISCLAIMER

The information contained in this manual is subject to change without notice from AERCO

International, Inc. AERCO makes no warranty of any kind with respect to this material, including,

but not limited to, implied warranties of m erchantability and fitness for a particular application.

AERCO International is not liable for errors appearing in this manual, nor for incidental or

consequential damages occurring in connection with the furnishing, performance, or use of

these materials.

AERCO Technical Support:

(Mon–Fri, 8am-5pm EST)

1 (800) 526-0288

In this document, some types of information are presented as shown in the following examples:

Message Type Example and Description

NOTES

CAUTIONS

WARNINGS

NOTE messages indicate specific information related to the

surrounding contextual information, and highlighted for special

attention.

CAUTION!

CAUTION messages inform of pot ential probl em s rel ating to

the functioning of equipment, safety to persons, harm to the

environm ent, and/or damage to property or equipm ent.

WARNING!

WARNING messages warn of potential dangerous situations

that may result in serious injury and/or death to persons or

animals. Text is red within a red box.

How Instructions are Presented

1. Instructions are shown in a blue box with an underlined title.

2. All text, excepting in accompanying illustrations, is colored

INSTRUCTIONS

blue.

3. All procedures are listed in steps starting with “1.”, and using

letters [a), b), c), etc.] to indicate sub-steps.

4. Steps that are continued on the next page have a “(Cont.)”

append ed to the instruction title.

Page 2 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 3

GF-135 Esteem 399 Low NOx Boiler

OMM-0089_0A Installation, Operation & Maintenance Manual

TABLE OF CONTENTS

CHAPTER 1: SAFETY PRECAUTIONS .............................................................................................. 9

1.1 WARNINGS & CAUTIONS ..................................................................................................................................... 9

1.2 EMERGENCY SHUTDOWN .................................................................................................................................. 10

1.3 PROLONGED SHUTDOWN .................................................................................................................................. 11

CHAPTER 2: INSTALLATION .......................................................................................................... 15

2.1 CODE COMPLIANCE ........................................................................................................................................... 15

2.2 DETERMINING PRODUCT LOCATION ................................................................................................................. 15

2.3 BOILER REPLACEMENT ....................................................................................................................................... 16

2.4 RECOMMENDED CLEARANCES .......................................................................................................................... 16

2.5 RESIDENTIAL GARAGE INSTALLATIONS .............................................................................................................. 17

2.6 BOILER FREEZE PROTECTION FEATURE.............................................................................................................. 17

CHAPTER 3: COMBUSTION AIR AND VENTING ............................................................................ 19

3.1 COMBUSTION AIR CONTAMINATION ................................................................................................................ 19

3.2 POTENTIAL CONTAMINATING PRODUCTS ......................................................................................................... 19

3.2.1 Areas Likely to Contain Contaminating Products ....................................................................................... 20

3.3 VENTILATION AND COMBUSTION AIR REQUIREMENTS - DIRECT VENT ............................................................ 20

3.4 VENTILATION AND COMBUSTION AIR REQUIREMENTS - CATEGORY IV ........................................................... 21

3.5 METHODS OF SUPPLYING COMBUSTION AIR TO A CONFINED SPACE - CATEGORY IV ...................................... 21

3.5.1 INDOOR COMBUSTION AIR......................................................................................................................... 22

3.5.2 OUTDOOR COMBUSTION AIR ..................................................................................................................... 23

3.5.2.1 Option 1: One Permanent Opening to Outside ................................................................................... 23

3.5.2.2 Option 2: Two Permanent Openings to Outside.................................................................................. 24

3.6 COMBINATION OF INDOOR AND OUTDOOR COMBUSTION AIR ....................................................................... 25

3.6.1 Outdoor Opening(s) Location ..................................................................................................................... 25

3.6.2 Outdoor Opening(s) Size ............................................................................................................................. 25

3.7 COMBUSTION AIR AND VENT PIPING ................................................................................................................ 25

3.8 REMOVAL OF AN EXISTING BOILER FROM A COMMON VENT SYSTEM .............................................................. 26

CHAPTER 4: UNIT PREPARATION.................................................................................................. 29

4.1 HANDLING INSTRUCTIONS................................................................................................................................. 29

4.2 WALL MOUNTING INSTALLATION...................................................................................................................... 29

4.3 WALL MOUNTING GUIDELINES.......................................................................................................................... 29

4.4 STUD WALL INSTALLATION ................................................................................................................................ 30

4.5 BOILER MOUNTING............................................................................................................................................ 30

CHAPTER 5: BOILER PIPING .......................................................................................................... 31

5.1 GENERAL PIPING REQUIREMENTS ..................................................................................................................... 31

5.2 PRESSURE RELIEF VALVE .................................................................................................................................... 31

5.3 BOILER AIR VENT................................................................................................................................................ 32

5.4 LOW WATER CUTOFF DEVICE ............................................................................................................................ 32

5.5 ADDITIONAL LIMIT CONTROL ............................................................................................................................ 33

5.6 BACKFLOW PREVENTER ..................................................................................................................................... 33

5.7 BOILER SYSTEM PIPING APPLICATIONS ............................................................................................................. 33

5.8 EXPANSION TANK AND MAKEUP WATER .......................................................................................................... 33

5.8.1 Diaphragm Expansion Tank ........................................................................................................................ 34

5.8.2 Closed-Type Expansion Tank ...................................................................................................................... 34

5.9 CIRCULATOR ...................................................................................................................................................... 34

5.10 SIZING PRIMARY PIPING .................................................................................................................................. 34

5.11 DOMESTIC HOT WATER SYSTEM PIPING ........................................................................................................ 34

Page 3 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 4

GF-135 Esteem 399 Low NOx Boiler

OMM-0089_0A Installation, Operation & Maintenance Manual

5.12 SYSTEM PIPING - ZONE CIRCULATORS ............................................................................................................. 34

5.13 SYSTEM PIPING - ZONE VALVES ....................................................................................................................... 35

5.14 SYSTEM PIPING - THROUGH BOILER ................................................................................................................ 35

5.15 SYSTEM PIPING - RADIANT HEATING ............................................................................................................... 35

5.16 SYSTEM PIPING—SPECIAL APPLICATIONS ....................................................................................................... 36

5.17 SYSTEM PIPING—MULTIPLE UNITS INSTALLATION ......................................................................................... 36

CHAPTER 6: INSTALLING VENT, AIR INTAKES, AND DRAIN ....................................................... 43

6.1 INSTALLING VENT AND COMBUSTION AIR INTAKE............................................................................................ 43

6.2 INSTALLING CONDENSATE DRAIN ASSEMBLY .................................................................................................... 43

CHAPTER 7: GAS PIPING ................................................................................................................ 45

7.1 GAS SUPPLY PIPING CONNECTION .................................................................................................................... 45

7.2 NATURAL GAS .................................................................................................................................................... 46

7.2.1 Pipe Sizing - Natural Gas ............................................................................................................................. 46

7.2.2 Natural Gas Supply Pressure Requirements ............................................................................................... 47

7.3 PROPANE GAS .................................................................................................................................................... 47

7.3.1 Pipe Sizing – Propane Gas ........................................................................................................................... 47

7.3.2 Propane Gas Supply Pressure Requirements.............................................................................................. 48

CHAPTER 8: INTE RNAL WIRING..................................................................................................... 51

8.1 GENERAL REQUIREMENTS ................................................................................................................................. 51

8.2 FUSE LOCATIONS ............................................................................................................................................... 51

8.2.1 EZ-SETUP Controller Module Fuses Location.............................................................................................. 51

8.2.2 Line Voltage Fuses Location ........................................................................................................................ 52

CHAPTER 9: EXTERNAL WIRING ................................................................................................... 55

9.1 INSTALLATION COMPLIANCE ............................................................................................................................. 55

9.2 LINE VOLTAGE CONNECTIONS ........................................................................................................................... 55

9.3 CIRCULATOR WIRING ......................................................................................................................................... 56

9.4 ALARM WIRING.................................................................................................................................................. 57

9.5 LOW VOLTAGE CONNECTIONS .......................................................................................................................... 57

9.6 THERMOSTAT WIRING ....................................................................................................................................... 57

9.7 OUTDOOR SENSOR WIRING ............................................................................................................................... 58

9.8 DOMESTIC HOT WATER WIRING ....................................................................................................................... 58

9.9 ADDITIONAL BOILER LIMITS ............................................................................................................................... 58

9.10 EXTERNAL MODULATION CONTROL ................................................................................................................ 58

9.11 SYSTEM SENSOR WIRING ................................................................................................................................. 58

9.12 CASCADE WIRING ............................................................................................................................................ 59

9.13 MODBUS WIRING ............................................................................................................................................ 59

CHAPTER 10: BASIC EZ-SET CONTROLLER OPERATION ........................................................... 65

10.1 EZ-SET CONTROLLER INTRODUCTION.............................................................................................................. 65

10.2 EZ-SET CONTROLLER FEATURES AND FUNCTIONS........................................................................................... 65

10.3 CONTROLLER NAVIGATION .............................................................................................................................. 66

10.4 HOME SCREEN ................................................................................................................................................. 68

10.5 MAIN MENU .................................................................................................................................................... 70

10.6 EZ SETUP ................................................................................................................................................... 71

10.7 HEATING EZ SETUP ............................................................................................................................... 71

10.7.1 Select CH Demand (Default: Switch & Outdoor Reset) ............................................................................ 71

10.7.2 CH1 Setpoint (Default: 180°F [82°C]) ........................................................................................................ 72

Page 4 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 5

GF-135 Esteem 399 Low NOx Boiler

OMM-0089_0A Installation, Operation & Maintenance Manual

10.7.3 CH2 Setpoint (Default: 140°F [60°C]) ........................................................................................................ 72

10.7.4 Select CH1 Reset Curve (Default: Finned Tube Baseboard) ...................................................................... 72

10.7.5 Select CH2 Reset Curve (Default: Low Mass Radiant) .............................................................................. 72

10.7.6 Set Warm Weather Shutdown Temperature (Default: OFF) .................................................................... 73

10.8 DOMESTIC HOT WATER EZ SETUP ....................................................................................................... 74

10.8.1 Select DHW Demand (Default: Switch) ..................................................................................................... 74

10.8.2 Boiler DHW Setpoint (Default: 186°F [86°C])............................................................................................ 74

10.8.3 DHW Storage Setpoint (Default: 140°F [60°C]) ......................................................................................... 75

10.8.4 DHW Priority Timeout (Default: Off) ........................................................................................................ 75

10.9 EZ SETUP RESET .................................................................................................................................... 76

10.10 DISPLAY EZ SETUP ............................................................................................................................. 76

10.11 CH/DHW OPERATION ........................................................................................................................ 77

10.12 BOILER INFORMATION ............................................................................................................................. 77

10.12.1 Boiler Information Logging ..................................................................................................................... 79

10.13 LOCKOUT HISTORY......................................................................................................................................... 80

10.13.1 Lockout Details ....................................................................................................................................... 80

CHAPTER 11: START-UP PREP ARATION ...................................................................................... 85

11.1 CHECK BOILER SYSTEM WATER CHEMISTRY .................................................................................................... 85

11.1.1 Water pH Level 6.0 to 8.0 ......................................................................................................................... 85

11.1.2 Water Hardness Less Than 7 Grains ......................................................................................................... 85

11.1.3 Chlorinated Water .................................................................................................................................... 85

11.1.4 Flush Boiler to Remove Sediment ............................................................................................................. 85

11.1.5 Check and Test Antifreeze ........................................................................................................................ 86

11.1.6 Use of Antifreeze in the Boiler System ..................................................................................................... 86

11.2 BOILER CLEANING ............................................................................................................................................ 86

11.2.1 Cleaning an Old Boiler and System ........................................................................................................... 86

11.2.2 Cleaning of New Boiler/System: ............................................................................................................... 87

11.2.3 Filling the Boiler System ........................................................................................................................... 87

11.3 CHECK LOW WATER CUT-OFF DEVICE ............................................................................................................. 87

11.4 CHECK FOR GAS LEAKS ..................................................................................................................................... 88

11.5 CHECK THERMOSTAT CIRCUIT ......................................................................................................................... 88

11.6 INSPECTION OF CONDENSATE DRAIN ASSEMBLY ............................................................................................ 89

CHAPTER 12: START-UP PROCEDURES ....................................................................................... 91

12.1 FINAL CHECKS BEFORE START-UP .................................................................................................................... 91

12.2 ESTEEM START-UP ........................................................................................................................................... 91

12.3 OPERATING INSTRUCTIONS (READ BEFORE OPERATING BOILER) .................................................................. 91

12.3.1 Troubleshooting Start-Up Problems ......................................................................................................... 93

12.4 INSPECTION OF THE ESTEEM BOILER AND SYSTEM......................................................................................... 93

12.4.1 Boiler Piping inspection ............................................................................................................................ 93

12.4.2 Vent Piping and Combustion Air Piping inspection .................................................................................. 93

Page 5 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 6

GF-135 Esteem 399 Low NOx Boiler

OMM-0089_0A Installation, Operation & Maintenance Manual

12.4.3 Gas Piping Inspection................................................................................................................................ 94

12.4.4 Flame Pattern and Combustion Verification ............................................................................................ 94

12.4.5 Measure and Verify Input Rating - Natural Gas Only................................................................................ 96

12.4.6 High Temperature Limit Testing ............................................................................................................... 97

CHAPTER 13: OUTDOOR RESET CONTROL .................................................................................. 99

13.1 OUTDOOR TEMPERATURE SENSOR INSTALLATION ....................................................................................... 100

13.2 OUTDOOR TEMPERATURE SENSOR WIRING ................................................................................................. 101

CHAPTER 14: EXTERNAL MODULATING CONTROL ................................................................... 103

14.1 WIRING THE EXTERNAL MODULATING CONTROLLER ................................................................................... 103

14.2 EZ-SETUP CONTROLLER PROGRAMMING FOR EXTERNAL 0-10V SIGNAL ...................................................... 103

14.3 EXTERNAL PROGRAMMING OF 0-10V MODULATING CONTROL ................................................................... 103

CHAPTER 15: CHECK-OUT PROCEDURES .................................................................................. 105

CHAPTER 16: MAINTENANCE SCHEDULE .................................................................................. 107

16.1 SERVICE TECHNICIAN MAINTENANCE ........................................................................................................... 107

16.1.1 General Maintenance ............................................................................................................................. 107

16.1.2 Poor Performance Maintenance ............................................................................................................ 107

16.1.3 Owner Maintenance ............................................................................................................................... 107

CHAPTER 17: MAINTENANCE PROCEDURES ............................................................................. 109

17.1 REPORTED PROBLEMS ................................................................................................................................... 109

17.2 SURROUNDING AREA INSPECTION ................................................................................................................ 109

17.3 BURNER AREA INSPECTION ........................................................................................................................... 109

17.4 SYSTEM PIPING INSPECTION .......................................................................................................................... 110

17.5 CLEAN CONDENSATE DRAIN ASSEMBLY ........................................................................................................ 110

17.6 VENTILATION AIR OPENINGS INSPECTION .................................................................................................... 110

17.7 VENT AND COMBUSTION AIR PIPING INSPECTION........................................................................................ 110

17.8 BOILER SYSTEM INSPECTION ......................................................................................................................... 111

17.9 EXPANSION TANK INSPECTION ...................................................................................................................... 111

17.10 BOILER RELIEF VALVE INSPECTION .............................................................................................................. 111

17.11 IGNITION ELECTRODE INSPECTION .............................................................................................................. 112

17.12 IGNITION WIRING AND GROUND WIRING INSPECTION .............................................................................. 112

17.13 CONTROL WIRING INSPECTION ................................................................................................................... 112

17.14 CONTROL SETTINGS INSPECTION ................................................................................................................ 112

17.15 PERFORM START-UP AND CHECKOUT PROCEDURES .................................................................................. 112

17.16 BURNER FLAME INSPECTION AND TROUBLESHOOTING ............................................................................. 113

17.17 FLAME SIGNAL INSPECTION ......................................................................................................................... 114

17.18 COMBUSTION LEVELS INSPECTION.............................................................................................................. 114

17.19 FLUE GAS TEMPERATURE CHECK ................................................................................................................ 114

17.20 HEAT EXCHANGER CLEANING...................................................................................................................... 115

17.21 REVIEWING MAINTENANCE REQUIREMENTS WITH OWNER ...................................................................... 115

17.22 Handling Previously Fired Combustion Chamber Insulation ....................................................................... 116

CHAPTER 18: EZ-SETUP CONTROLLER OPERATION AND SETTINGS ..................................... 117

18.1 ENTERING THE INSTALLER ACCESS CODE ...................................................................................................... 117

18.2 USING THE INSTALLER MENU ........................................................................................................................ 118

18.3 CH and DHW SETTINGS MENU ................................................................................................................ 121

18.3.1 Heating Operation (Default: Enabled) .................................................................................................... 121

18.3.2 Demand Type (Default: Switch & Outdoor Reset) .................................................................................. 122

Page 6 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 7

GF-135 Esteem 399 Low NOx Boiler

OMM-0089_0A Installation, Operation & Maintenance Manual

18.3.3 Absolute Max CH Setpoint (Default: 188°F [87°C]) ................................................................................. 123

18.3.4 CH1 Maximum Setpoint (Default: 180°F [82°C])..................................................................................... 123

18.3.5 CH1 Minimum Setpoint (Default: 120°F [49°C]) ..................................................................................... 124

18.3.6 Reset Curve Coldest Day (Default: 0°F [-18°C])....................................................................................... 124

18.3.7 Reset Curve Warmest Day (Default: 64°F [18°C]) ................................................................................... 124

18.3.8 CH2 Circuit (Default: Enabled) ................................................................................................................ 125

18.3.9 CH2 Maximum Setpoint (Default: 140°F [60°C])..................................................................................... 125

18.3.10 CH2 Minimum Setpoint (Default: 80°F [27°C]) ..................................................................................... 125

18.3.11 Warm Weather Shutdown (Default: Off).............................................................................................. 126

18.3.12 Pump Constant Circulation (Default: Disabled) .................................................................................... 126

18.3.13 CH Post Pump Time (Default: 1 Minute)............................................................................................... 127

18.3.14 Freeze Protection (Default: Enabled) ................................................................................................... 128

18.3.15 Frost Protection Setpoint (Default: -22°F [-30°C]) ................................................................................ 129

18.3.16 Parallel Shift Value (Default: 0°F [0°C]) ................................................................................................. 129

18.3.17 CH Call Blocking (Default: 1 Minute)..................................................................................................... 130

18.3.18 System Pump (Default: CH1/CH2) ........................................................................................................ 130

18.4 DHW SETTINGS MENU ....................................................................................................................... 135

18.4.1 DHW Operation (Default: Enabled) ........................................................................................................ 136

18.4.2 Demand Type (Default: Switch) .............................................................................................................. 137

18.4.3 Boiler DHW Setpoint (Default: 186°F [86°C]).......................................................................................... 137

18.4.4 DHW Storage Setpoint (Default: 140°F [60°C]) ....................................................................................... 137

18.4.5 DHW on Differential (Default: 6°F [3°C])............................................................................................... 138

18.4.6 DHW Storage Adder (Default: 46°F [25°C])............................................................................................ 139

18.4.7 DHW Post Pump Time (Default: 1 Minute) ............................................................................................ 139

18.4.8 DHW Priority Timeout (Default: OFF) .................................................................................................... 140

18.4.9 DHW Priority (Default: ENABLED) ......................................................................................................... 140

18.4.10 DHW Call Blocking (Default: 0 Minutes) ............................................................................................. 141

18.4.11 DHW to CH Call Blocking (Default: 1 Minute) ..................................................................................... 141

18.4.12 Antilegionella Function (Default: DISABLED) ...................................................................................... 142

18.5 BOILER SETTINGS MENU ...................................................................................................................... 143

18.5.1 Lockout Temp (Default: 210°F [99°C]) .................................................................................................... 143

18.5.2 Modbus Address (Default: 0=BCST) ........................................................................................................ 144

18.6 RESET ALL SETTINGS MENU ............................................................................................................... 144

18.7 CASCADE MENU AND OPERATING INFORMATION ........................................................................................ 146

18.7.1 Cascade Installation – System Piping ...................................................................................................... 148

18.7.2 Cascade Installation – System Sensor Installation .................................................................................. 148

18.7.3 Cascade Installation – Cascade Communication Cable........................................................................... 149

18.7.4 Cascade Installation – Low Voltage Wiring Connections ........................................................................ 149

18.7.5 Cascade Installation – Line Voltage Wiring Connections ........................................................................ 150

18.8 CASCADE AUTODETECTION MENU ...................................................................................................... 151

18.8.1 Cascade Operation – Lockouts ............................................................................................................... 151

Page 7 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 8

GF-135 Esteem 399 Low NOx Boiler

OMM-0089_0A Installation, Operation & Maintenance Manual

18.9 CASCADE INFORMATION MENU ......................................................................................................... 158

18.9.1 System Temperature Logging ................................................................................................................. 158

18.9.2 Cascade Settings Menu ................................................................................................................... 159

18.9.3 Stage Delay (Default: 60 Seconds) .......................................................................................................... 160

18.9.4 Minimum firing Rate (Default: 30%) ....................................................................................................... 160

18.9.5 Boiler Enabling Algorithm ....................................................................................................................... 161

18.9.6 Boiler Disabling Algorithm ...................................................................................................................... 161

18.9.7 Maximum Firing Rate (Default: 398 MBH).............................................................................................. 161

18.9.8 CH or DHW Boilers (Default: 0) ............................................................................................................... 162

18.9.9 Automatic Rotation (Default: Enabled) ................................................................................................. 163

18.9.10 CH Proportional Gain (Default: 7) ......................................................................................................... 164

18.9.11 CH Integral Gain (Default: 245) ............................................................................................................. 165

18.9.12 DHW Proportional Gain (Default: 7) ..................................................................................................... 166

18.9.13 DHW Integral Gain (Default: 245) ......................................................................................................... 167

18.9.14 Modbus Address (Default: 0 = BcST) .................................................................................................... 168

18.9.15 Modbus Interface ................................................................................................................................. 169

18.10 MANUAL OPERATION .................................................................................................................................. 171

18.10.1 Fan Parameter .............................................................................................................................. 171

18.10.2 CH CH1 Parameter ........................................................................................................................ 172

18.10.3 DHW Parameter............................................................................................................................ 172

18.10.4 SYS CH2 Parameter ....................................................................................................................... 173

APENNDIX A: PART AND DIMENSIONAL DRAWINGS.................................................................... 175

APENNDIX B: CIRCULATOR PRESSURE LOSS CHARTS .............................................................. 183

Page 8 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 9

GF-135 Esteem 399 Low NOx Boiler Chapter 1

OMM-0089_0A Installation, Operation & Maintenance Manual Safety Precauti ons

CHAPTER 1: SAFETY PRECAUTIONS

1.1 WARNINGS & CAUTIONS

The following general warnings and cautions m ust be given the same attention as specific

precautions included in these instructions. In addition to the requirements included in this

Manual, the installation MUST conform with local building codes, or, in the absence of loc al

codes, ANSI Z223.1 (National Fuel Gas Code Publication No. NFPA-54). Where ASME CSD-1

is required by local jurisdiction, the installation must conform to CSD-1.

Where applicable, the equipment must be installed in accordance with the current Installati on

Code for Gas Burning Appliances and Equipment, CGA B149, and applicable Provincial

regulations for the class. Authorities having jurisdiction should be consulted before installations

are made.

See the last two pages of this chapter for important information regarding installation of units

within the Commonwealth of Massachusetts.

IMPORTANT!

• This Instruction Manual is an integral part of the product and

must be maintained in legible condition. It must be given to the

user by the installer and kept in a safe place for future

reference.

• Installation and service m ust be performed by a qualified

installer, service agency or the gas supplier.

WARNING!

• Do not use matches, candles, fl am es, or other sources of

ignition to check for gas leaks.

• Prior to installing this product read all instructions included in

this manual and all accompanying manuals/documents. Perform

all installation steps required in these manuals in the proper

order given. F ailure t o adhere t o the guid elines within these

manuals can result in severe personal injury, death or

substantial property dam age.

• Fluids under pressure m ay cause injury to personnel or damage

to equipm ent when rel eased. Be sure to shut off all incoming

and outgoing water shutoff valves. Carefully decrease all

trapped pressures to zero before perform ing maintenance.

• Before attempting to perform any m ainten ance on the unit, shut

off all gas and electrical inputs to the unit.

• The exhaust vent pipe of the unit operates under a positive

pressure and therefore must be completely sealed to prevent

leakage of combustion products into living spaces.

• High electrical voltages are used in this equipment, therefore

the cover on the unit’s power box m ust be installed at all times,

except during maintenance and servicing.

Page 9 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 10

GF-135 Esteem 399 Low NOx Boiler Chapter 1

OMM-0089_0A Installation, Operation & Maintenance Manual Safety Precautions

WARNING!

A double-pole switch must be installed on the electrical supply line

of the unit. The switch must be installed in an easily accessible

position to quickly and safely disconnect electrical servic e. Do n ot

affix switch to unit sheet metal enclosures.

CAUTION!

• Many of the soaps used for gas pipe leak testing are corrosive

to m etals. The piping must be rinsed thoroughly with clean

water after l eak checks have been completed.

• DO NOT use this boiler if any part has been under water. Call a

qualified service technician to inspect and replace any part that

has been under water.

WARNING!

Should overheating occur or the gas supply fails to shut off, turn

OFF the manual gas control valve external to the appli ance.

DO NOT add cold make up water when the boiler is hot. Thermal

shock can cause pot ential cracks in the heat exchanger.

WARNING!

IF YOU SMELL GAS:

• Do Not try to light any appliance

• Do Not touch any electrical switch

• Do Not use any phone or cell phone in your building.

• Immediately call your gas supplier from a different location.

• Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Please have the unit’s model num ber and the serial num ber from the rating label, on the

backside of the control panel when inquiring about service or troubleshooting.

AERCO International accepts no liability for any damage resulting from incorrect installation or

from the use of components or fittings not specified by AERCO International.

1.2 EMERGENCY SHUTDOWN

Turn the service sw itch on the Esteem 399 Low NOx control panel to “OFF”

Page 10 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 11

GF-135 Esteem 399 Low NOx Boiler Chapter 1

OMM-0089_0A Installation, Operation & Maintenance Manual Safety Precautions

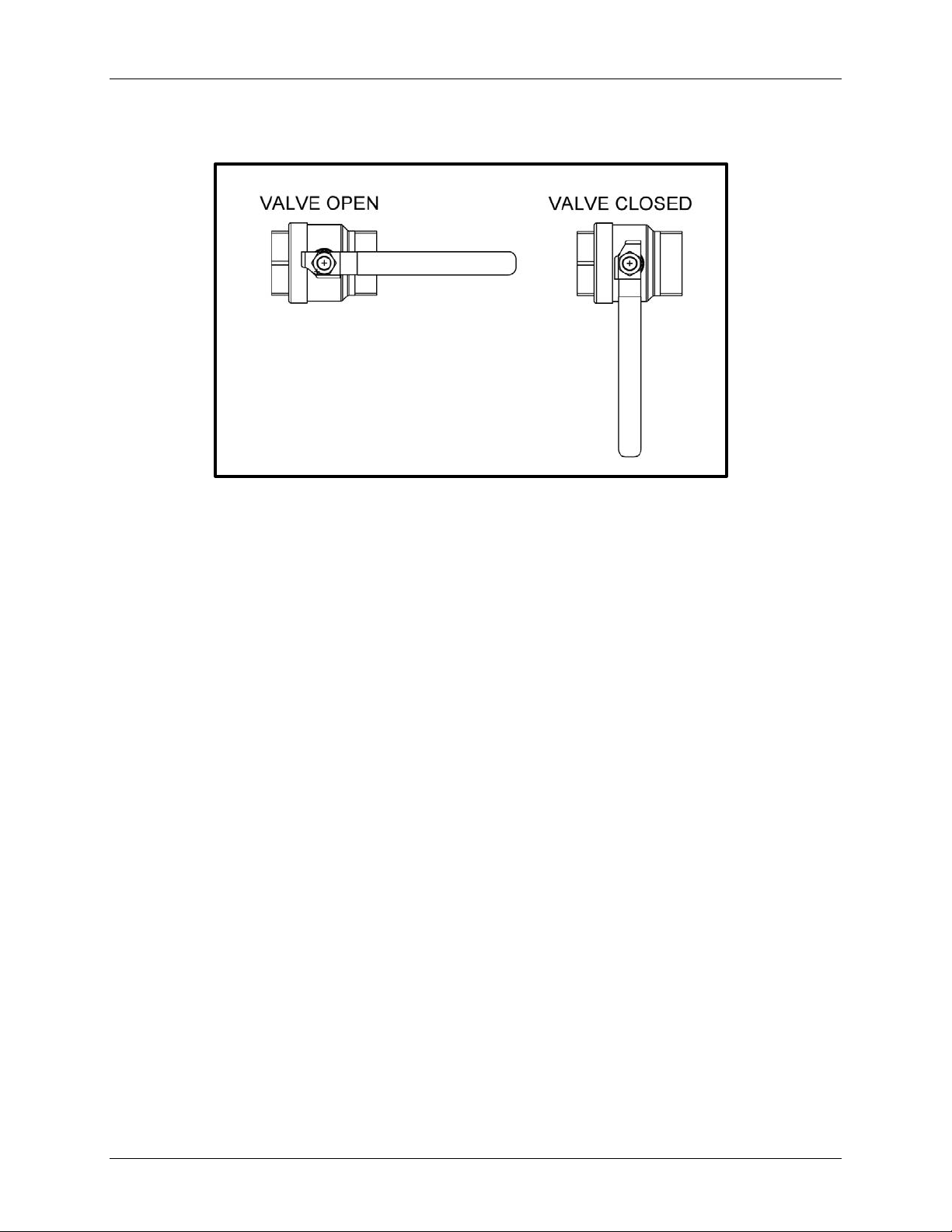

If overheating occurs or the gas supply fails to shut off, close the manual gas shutoff valve

(Figure 1-1) located external to the unit.

NOTE

The Installer must identify and indicate the

location of the emergency shutdown

manual gas valve to operating personnel.

Figure 1-1: Typical Manual Gas Shutoff Valve

1.3 PROLONGED SHUTDOWN

After prolonged shutdown, it is recommended that the startup procedures and the safety device

test procedures in Ch apter 12 of this manual be performed, to verify all system-operating

parameters.

If there is an em ergency, turn off the electrical power supply to the AERCO boiler and close the

manual gas valve located upstream from the unit.

The installer must identify the emergency shut-off device to those responsible for oper ation of

the boiler.

Page 11 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 12

GF-135 Esteem 399 Low NOx Boiler Chapter 1

OMM-0089_0A Installation, Operation & Maintenance Manual Safety Precautions

IMPORTANT – FOR MASSACHUSETTS INSTALLATIONS

Boiler Installations within the Comm onwealth of Massachusetts must

conform to the foll owing requirements:

• Boiler m ust be installed by a plumber or a gas fitter who is licensed

within the Commonwealth of Massachusetts.

• Prior to unit op eration, the complete g as train and all connections must

be leak tested using a non-corr osive soap.

• The vent t ermination must be located a minimum of 4 feet above grade

level. If side-wall venting is used, the installation must conform to the

following requirem ents extracted from 248 CMR 5.08 (2):

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling,

building or structure used in whole or in part for residential purposes, including those owned or

operat ed by the Commonwealth and where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the venting, including but not limited to decks

and porches, the following requirements shall be satisfied:

• INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of

the side wall horizontal vent ed gas fueled equipment, the installing plumber or gasfitter

shall observe that a hard wired carbon monoxide detector with an alarm and battery

back-up is inst alled on the fl oor l evel where the g as equipment is to be inst alled. In

addition, the installing plumber or gasfitter shall observe that a battery operated or hard

wired carbon m onoxide d etector with an al arm is installed on each additional l evel of the

dwelling, building or structure served by the side wall horizontal vented gas fueled

equipment. It shall be the responsibility of the property owner to secure the services of

qualified licensed professionals for the inst allation of hard wired carbon monoxide

detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a

crawl space or an attic, the hard wired carbon m onoxide detector w ith alarm and battery

back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision cannot be met at the time of

com pletion of inst allation, the owner shall have a period of thirty (30) days to comply with

the above requirements; provided, however, that during said thirty (30) day period, a

battery operat ed carbon m onoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as

required in accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior

of the building at a minimum height of eight (8) feet above grade directly in line with the exhaust

vent terminal for the horizontally vented g as fu el ed heating appliance or equipment. The sign

shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state or l ocal gas inspector of the side wall horizontally vented gas fuel ed

equipment shall not approve the install ation unless, upon inspection, the inspector observes

carbon monoxide detectors and signage inst alled in accordance with the provisions of 248 CMR

5.08(2)(a)1 through 4.

Page 12 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 13

GF-135 Esteem 399 Low NOx Boiler Chapter 1

OMM-0089_0A Installation, Operation & Maintenance Manual Safety Precautions

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in

the most current edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room

or structure separate from the dwelling, building or structure used in whole or in part for

residential purposes.

(c) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM

PROVIDED. W hen the manufacturer of Product Approved side wall horizontally vented gas

equipment provides a venting system design or venting system components with the equipment,

the instructions provided by the manufacturer for installation of the equipment and the venting

system shall include:

1. Detailed instructions for the installation of the venting system design or the venting

system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT

PROVIDED. When the manufacturer of a Product Approved side wall horizontally vented gas

fueled equipment does not provide the parts for venting the flue gases, but identifies "special

venting systems", the following requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance

or equipment installation instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the

instructions for that system shall include a parts list and detailed installation instructions.

(e) A copy of all install ation instructions for all Product Approved sid e wall horizontally vented

gas fueled equipment, all venting instructions, all parts lists for venting instructions, and/or all

venting design instructions shall remain with the appliance or equipment at the completion of the

installation.

[End of Extracted Information From 248 CMR 5.08 (2)]

Page 13 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 14

GF-135 Esteem 399 Low NOx Boiler Chapter 1

OMM-0089_0A Installation, Operation & Maintenance Manual Safety Precautions

(This page left intentionally blank)

Page 14 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 15

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Installation

CHAPTER 2: INSTALLATION

2.1 CODE COMPLIANCE

This product must be installed in accordance to the following:

All applicable local, state, national and provincial codes, ordinances, regulations and

•

laws.

For installations in Massachusetts, code requires the boil er to be inst alled by a licensed

•

plumber or gas fitter, and if antifreeze is utilized, the installation of a reduced pressure

backflow prevent er device is required in the boiler’s cold water fill or make up wat er

supply line.

For installation in Massachusetts all direct vent ed appliances m ust comply with the

•

guidelines as outlined in section 1.3 of Chapter 1.

The National Fuel Gas Code NFPA54/ ANSI Z 223.1—Latest edition.

•

National Electric Code ANSI/NFPA 70.

•

For installations in Canada -“Installation Code for Gas Burning Equipment” CGA/B149.1

•

or B149.2 Canadian Electrical Code Part 1 CSA C22.1.

Standards for Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME

•

CSD-1, when required.

NOTE

The Esteem 399 Low NOx boiler gas manifold and gas controls

meet the safe lighting and other p erform ance requirem ents as

specified in ANSI Z21.13 latest edition.

2.2 DETERMINING PRODUCT LOCATION

Before locating the Esteem 399 Low NOx check for convenient locations to:

Heating system piping

•

Venting

•

Gas supply piping

•

Electrical service

•

Ensure the boiler location allows the combustion air/vent piping to be routed directly through the

building and terminate properly outside with a minimum amount of length and bends.

Ensure the area chosen for the installation of the Esteem 399 is free of any combustible

materials, gasoline and other flamm able liquids.

The Esteem boiler is certified for indoor conditioned space only.

WARNING!

Failure to remove or maintain the area free of combustible

materials, gasoline and other flamm able liquids or vap ors can

result in severe personal injury, death or substantial property

damage.

Ensure the Esteem 399 and its controls are protected from dripping or spraying water during

normal operation or service.

Page 15 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 16

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Installation

The Esteem 399 Low NOx should be installed in a location so that any water leaking from the

boiler or piping connections or r elief valve will not cause damage to the ar ea surrounding the

unit or any lower floors in the structure.

2.3 BOILER REPLACEMENT

If the Esteem 399 is replacing an existing boiler, the following items should be checked and

corrected prior to installation:

Boiler piping leaks and corrosion.

•

Improper location and sizing of the expansion tank on the boiler heating loop.

•

If applicable, level and qu ality of freeze prot ection within the boiler system.

•

See the warning in section 17.22 Handling Previously Fired Combustion Chamber

•

Insulation.

2.4 RECOMMENDED CLEARANCES

The Esteem 399 Low NOx is approved for zero clearance to combustibles, excluding vent and

boiler piping.

Boiler Piping - 1/4 inch from combustible materials.

•

See Vent System Installation Supplement GF-125V for vent clearance requirements.

•

To provide service access to the unit it is recommended that the following clearances be

maintained:

Surface Dimension

Top Jacket 24 inches [610 mm].

Front 24 inches [610 mm].

Rear 0 inches

Sides 6 inches [153 mm]

Bottom Pi ping 24 inches [610 mm].

WARNING!

If the clearances listed above cann ot be m aintained or the

enclosure in which the boiler is installed is less than 85 cubic feet,

the space m ust be ventilated. See chapter 3 for requirem ents.

NOTE

When maintaining zero clearance or less than recommended

clearances, some pr oduct labeling may become hidden and

unreadable.

Page 16 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 17

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Installation

WARNING!

When installing the Esteem boiler in a confined space, sufficient

air must be provided for proper combustion and venting and to

all ow, under normal oper ating conditions, proper air fl ow around

the product to maintain am bient temperatures within safe limits to

com ply with the National Fuel Gas Code NFPA 54…Latest

Edition.

2.5 RESIDENTIAL GARAGE INSTALLATIONS

When installing the Esteem boiler in a residential garage, the foll owing special precautions

per NFPA 54/ANSI Z223.1 must be taken:

Mount the unit a minimum 18 inches [458 mm] above the floor level of the garage.

•

Ensure the burner and ignition devices / controls are no less than 18 inches [458

•

mm] above the floor level.

Locate or protect the unit in a manner so it cannot be damaged by a moving vehicle.

•

2.6 BOILER FREEZE PROTECTION FEATURE

The boiler control has a freeze protection feature built in. This feature monitors the boiler

temperature and responds as follows when no call for heat is present:

46ºF [8ºC] CH (1) & Auxiliary Boiler Pumps ON

•

42ºF [6ºC] CH (1), Auxiliary Boil er & System Pumps ON, Burner operates at low fire

•

60ºF [15ºC] Freeze protection ends. Burner & all pumps OFF after completing CH

•

Post Pump Tim e.

CAUTION!

The boiler freeze protection feature is disabled during a hard

lockout, however the space heating circulator will operate.

CAUTION!

The boiler freeze protection feature is designed to protect the

boiler. The boiler should be installed in a primary/secondary piping

arrangem ent if it is installed in an unheated space or exposed to

water tem peratures of 46ºF or less. See “Chapt er 5 B oiler Piping”

for primary/secondary piping examples. See Section 11.1.6 for

antifreeze guidelines.

Page 17 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 18

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Installation

(This page left intentionally blank)

Page 18 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 19

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

CHAPTER 3: COMBUSTI ON AIR AN D VENTING

3.1 COMBUSTION AIR CONTAMINATION

WARNING!

If the Esteem boiler combustion air inlet is located in any area

likely t o cause or contain contamination, or if products, which

would contaminate the air c annot be removed, the combustion air

must be re-piped and term inated to another l ocation.

Contaminated combustion air will damage the unit and its burner

system , resulting in possible severe p ersonal injury, death or

substantial property dam age.

WARNING!

Do not operate the Esteem boiler if its combustion air inlet is

located near a laundry room or pool facility. These areas will

always contain hazardous contaminants.

Pool and laundry products and common household and hobby products often contain fluorine or

chlorine compounds. When these chemicals pass through the burner and vent system, they can

form strong acids. These acids can create corrosi on of the heat exchanger, burner components

and vent system, causing serious damage and presenting a possible threat of flue gas spillage

or water leakage into the surrounding area.

Please read the inform ation listed below. If contaminating chemicals are located near the area

of the combustion air inlet, the installer should pipe the combustion air inlet to an outside area

free of these chemicals per Chapt er 5 of this installation manual.

3.2 POTENTIAL CONTAMINATING PRODUCTS

Spray cans containing chloro/fluorocarbons

•

Permanent W ave Solutions

•

Chlorinated wax

•

Chlorine—based swimming pool chemicals / cleaners

•

Calcium Chloride for melting ice

•

Sodium Chloride for water soft ening

•

Refrigerant leaks

•

Paint or varnish removers

•

Hydrochl oric acid / muriatic acid

•

Cements and glues

•

Antistatic fabric soft en ers used in clothes dryers

•

Chlorine-type bleaches, detergents, and cleaning solvents found in household laundry

•

rooms

Adhesives used to fasten building products and other similar products

•

Page 19 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 20

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

3.2.1 Areas Likely to Contain Contaminating Products

Areas likely to contain potential contaminants are as follows:

• Dry cleaning / laundry areas and establishments

• Beauty sal ons

• Metal fabrication shops

• Swimming pools and health spas

• Refrigeration Repair shops

• Photo processing plants

• Auto body shops

• Plastic manufacturing plants

• Furniture refinishing areas and establishments

• New building construction - Remodeling areas

• Garages with workshop s

3.3 VENTILATION AND COMBUSTION AIR REQUIREMENTS - DIRECT VENT

A Direct Vent appliance uses uncontaminated outdoor air (piped directly to the appliance) for

combustion.

For Direct Vent installations, involving only the Esteem boiler, in which the minimum service

clearances are maintained (see Rec omm ended Cl earances, section 2.4), no ventilation

openings are required.

For Direct Vent, zero clearance install ations involving only the Esteem boiler, the space /

enclosure must have two openings for ventilation. The op enings must be sized to provide 1

square inch of free area per 1,000 BTUH of boiler input. The openings must be placed 12

inches from the top of the space and 12 inches from the floor of the space.

For installations where the Esteem 399 Low NOx shares the sp ace with air movers (exhaust

fan, clothes dryers, fireplaces, etc.) and other combustion equipment (gas or oil) the space m ust

be provided with adequate air openings t o provide ventilation and combustion air to all the

equipment. Sizing of the ventilation / combustion air openings must comply with the National

Fuel Gas Code NFPA 54, ANSI Z223.1 for installations in the U.S. or CSA B149.1 and B149.2

for installations in Canada.

Page 20 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 21

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

WARNING!

The space must be provid ed with ventilation com bustion air

openings properly sized for all make-up air requirements (exhaust

fans, clothes dryers, etc.), which includes the tot al input of all

appliances located in the same space as the Esteem unit(s) using

indirect vent ed air. Esteem units installed with direct vent air

inputs are excluded from such consideration because they receive

com bustion air directly from the outside, and so additional free

area for the openings is not required. Failure to provide properly

sized openings could result in severe p ersonal inju ry, death

or property dam age.

3.4 VENTILATION AND COMBUSTION AIR REQUIREMENTS CATEGORY IV

A Category IV appliance uses uncontaminated indoor or outdoor air (surrounding the appliance)

for combustion.

Piping uncontaminated combustion air directly from the outdoors to the appliance is

recommended. This reduces the risks associated with indoor contaminates, fl ammable vapors

and tight housing construction. This practice also promotes higher system efficiency.

In installations where the Esteem boil er shares the space with air movers (exhaust fan, clothes

dryers, fireplaces, etc.) and other combustion equipment (gas or oil), the spac e m ust be

provid ed with adequate air openings t o provide ventilation and combustion air t o all the

equipment. Sizing of the ventilation / combustion air openings must comply with the National

Fuel Gas Code NFPA 54, ANSI Z223.1 for installations in the U.S. or CSA B149.1 and B149.2

for inst allati ons in Can ada, as referenced in this chapter of the manu al and titled Methods of

Supplying Combustion Air to a Space.

3.5 METHODS OF SUPPLYING COMBUSTION AIR TO A CONFINED SPACE - CATEGORY IV

NOTE

The methods listed in this section for accessing Indoor

Combustion Air assume that the infiltration rate is ad equate and

not less than .40 ACH. For infiltration rates less than .40 ACH,

reference the NFPA 54 National Fuel Gas Code for additional

guidance.

Page 21 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 22

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

3.5.1 INDOOR COMBUSTION AIR

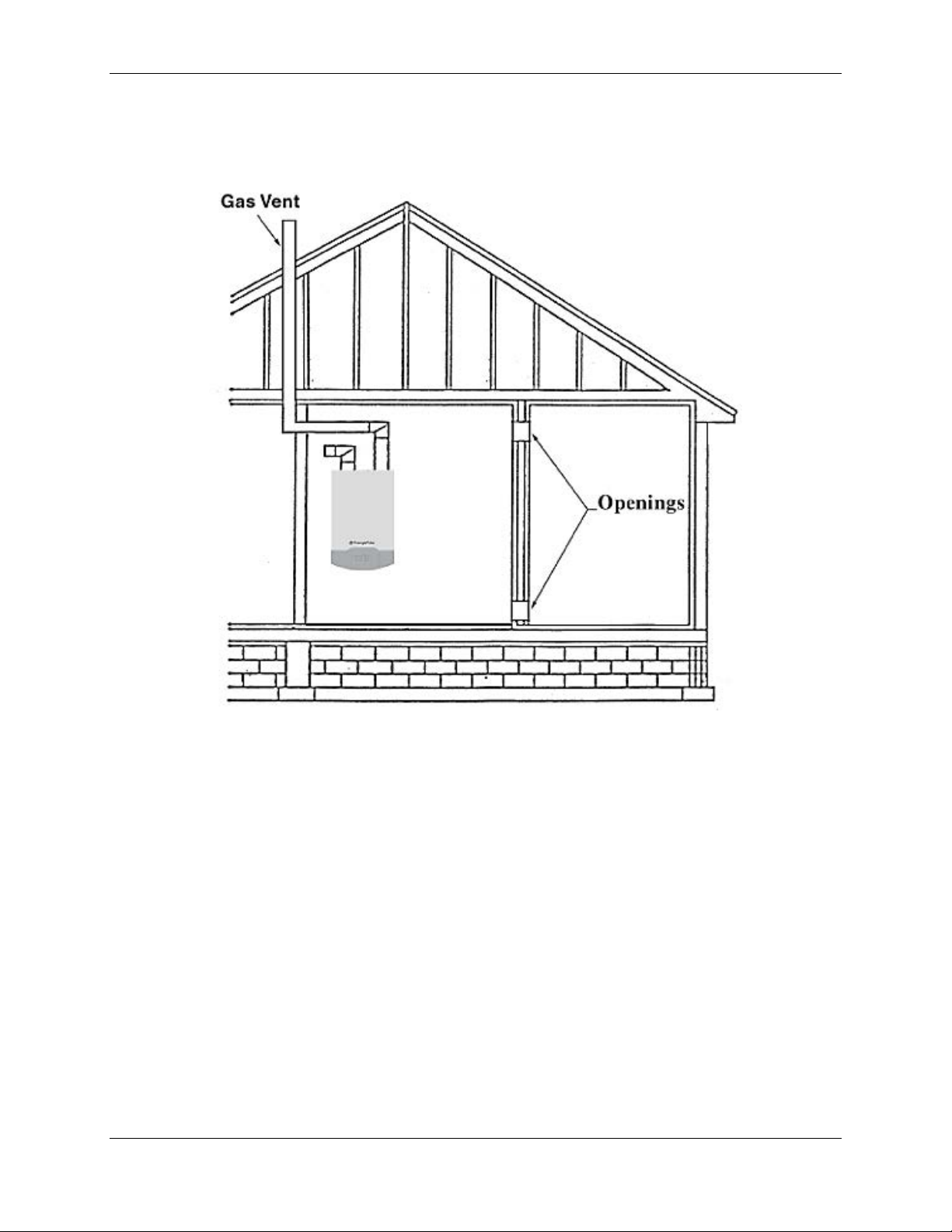

Openings used to connect indoor spaces shall be sized and located in accordance with

Figure 3-1.

Figure 3-1: All Combustion Air from Adjacent Indoor Spaces Through Indoor

Combustion Openings

Each opening shall have a minimum free area of 1 sq. in./1000 Btu/hr. of the total input rating of

all gas utilization equipment in the space, but not less than 100 sq. inches. One opening shall

commence within 12 inches of the top, and one opening shall commence within 12 inches of the

bottom of the enclosure. The minimum dim ension of air openings shall be not l ess than 3

inches.

Combining spaces in different stories. The volumes of spaces in different stories shall be

considered as communicating spaces where such spaces are connected by one or m ore

openings in doors or floors having a total minimum free area of 2 sq. in./1000 Btu/hr. of total

input rating of all gas utilization equipment.

Page 22 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 23

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

3.5.2 OUTDOOR COMBUSTION AIR

The minimum dimension of air openings for outdoor combustion air venting shall be not

less than 3 inches.

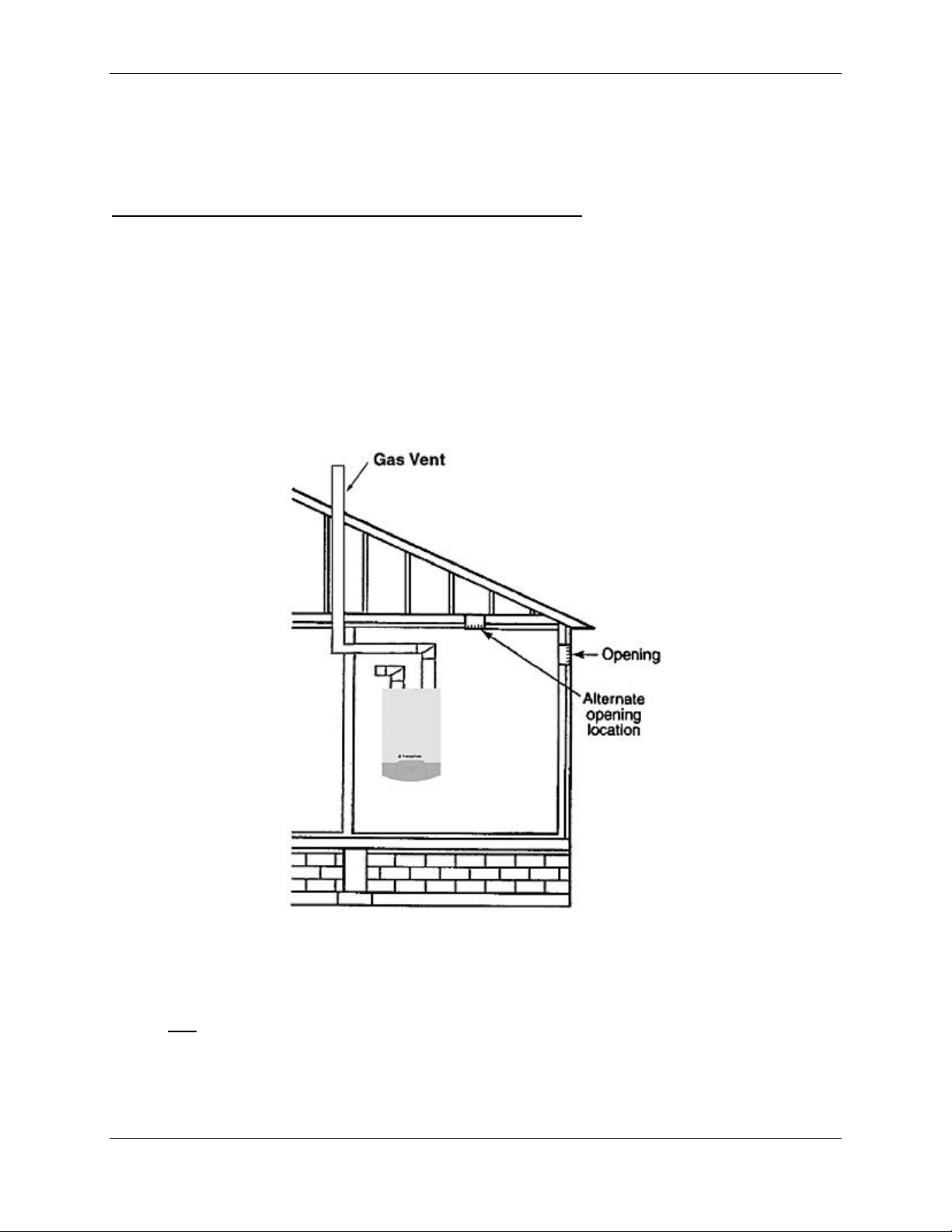

3.5.2.1 Option 1: One Permanent Opening to Outside

Openings used to supply combustion and ventilation air shall be sized and located in

accordance with the following:

One Permanent Opening Method. See Figure 3-2.

•

One permanent opening, commencing within 12 inches of the top of the enclosure,

•

shall be provided. The equipment shall have clearances of at least 1 inch from the

sides and 6 inches from the front of the appliance. The opening shall directly

communicate with the outdoors or shall communicate through a vertical or horizontal

duct to the outdoors or spaces that freely communicate with the outdoors and shall

have a minimum free area of the following:

Figure 3-2: All Combustion Air from Outdoors Through One Permanent Air Opening

• 1 sq. in./3000 Btu/hr. of the total input rating of all equipment located in the enclosures,

and

• Not less than the sum of the areas of all vent connectors in the spac e.

Page 23 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 24

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

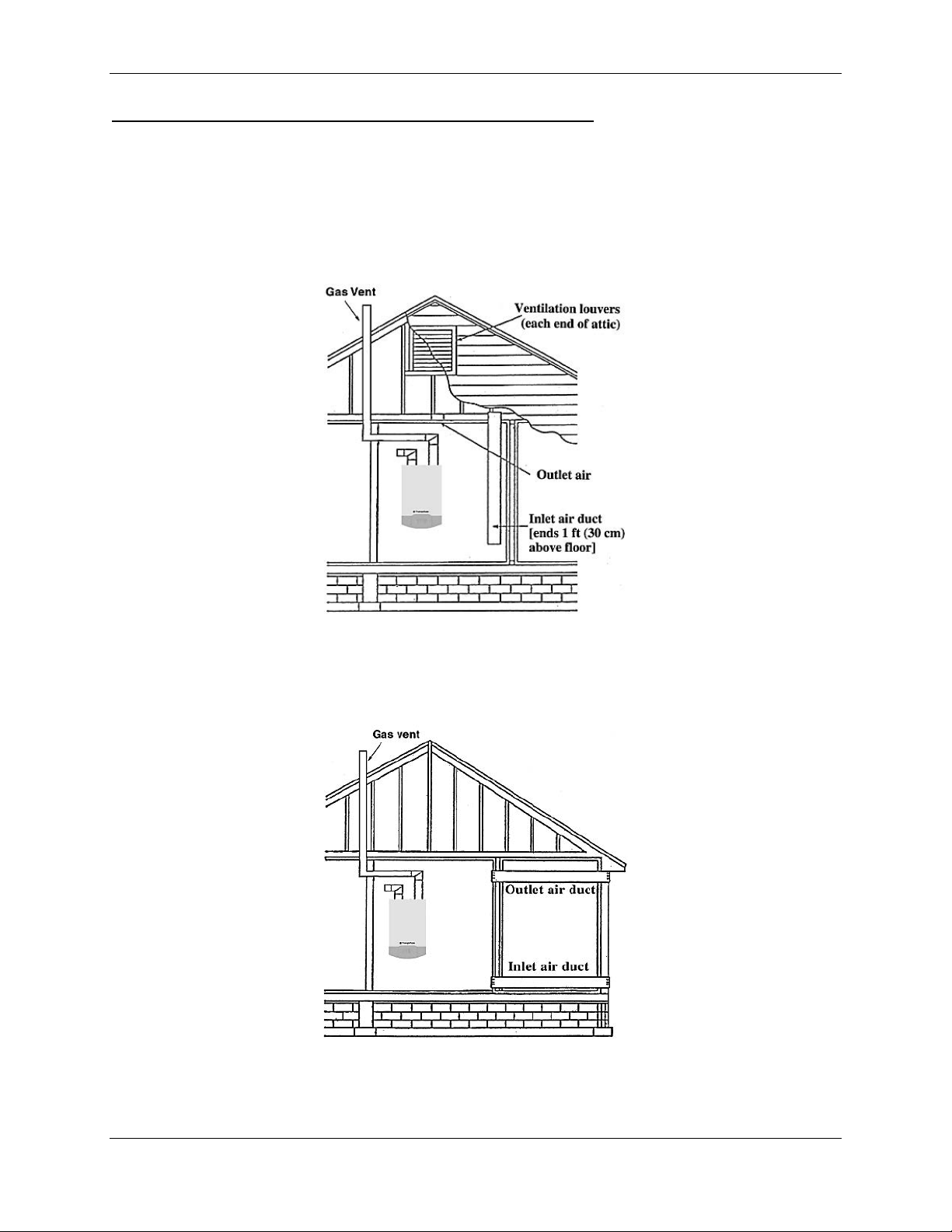

3.5.2.2 Option 2: Two Permanent Openings to Outside

Two permanent openings, one comm encing within 12 inches of the top and one commencing

within 12 inches of the bottom of the enclosure, shall be provided. The openings shall

communicate directly, or by ducts, with the outdoor s or spaces that freely comm unicate with the

outdoors, as foll ows:

• W here directly communicating with the outdoors or where communication to the outdoors

is through vertical ducts, each opening shall have a minimum free area of 1 sq. in./4000

Btu/hr. of total input rating for all equipment in the enclosure. See Figure 3-3.

Figure 3-3: All Combustion Air from Outdoors Through Ventilated Attic

• Where communicating with the outdoors is through horizontal ducts, each opening shall

have a minimum free area of not less than 1 sq. in./2000 Btu/hr. of total input rating of all

equipment in the enclosure. See Figure 3-4.

Figure 3-4: All Combustion Air from Outdoors Through Horizontal Ducts

Page 24 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 25

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

3.6 COMBINATION OF INDOOR AND OUTDOOR COMBUSTION AIR

Indoor Openings: Where used, openings connecting the interior spaces shall comply with the

Indoor Combustion Air section 3.5.

3.6.1 Outdoor Opening(s) Location

Outdoor opening(s) shall be loc ated in accordanc e with the Outdoor Combustion Air section.

3.6.2 Outdoor Opening(s) Size

Outdoor opening(s) shall be calculated in accordance with the following:

The r atio of the interior spaces shall be the availabl e volume of all communicating spaces

•

divided by the required volume.

The outdoor size reduction factor shall be 1 minus the ratio of interior spaces.

•

The minim um size of outdoor opening(s) calculated in accordance with the above outdoor

•

air section multiplied by the reduction factor. The minimum dimension of air openings

shall not be less than 3 in.

WARNING!

Do not install the Esteem boiler into a common vent with other gas

or oil appliances. This may cause flue gas spill age or appliance

malfunction, resulting personal injury, death, and/or property

damage.

3.7 COMBUSTION AIR AND VENT PIPING

WARNING!

Combustion air and vent piping must be sealed gas tight and meet

all provided instructions and applicabl e codes, failure t o comply

will result in severe personal injury or death.

The Esteem boiler requir es a Category IV venting system, which is designed for pressurized

venting and condensate.

The Esteem boiler is certified per ANSI Z21.13 as a Category IV or Direct Vent (sealed

combustion) appliance. A Category IV appliance uses uncontaminated indoor or outd oor air

(surrounding the appliance) for combustion. A Direct Vent appliance uses uncontaminated

outdoor air (piped directly to the appliance) for combustion.

Piping uncontaminated combustion air directly from the outdoors to the appliance is

recommended. This reduces the risks associated with indoor contaminates, fl ammable vapors

and tight housing construction. This practice also promotes higher system efficiency.

NOTE

Install combustion air and vent pipe as detailed in the Esteem

boiler Vent Supplement included in the boiler installation

envelope. Refer to optional vent kit instructions for addition vent

installation instructions.

Page 25 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 26

GF-135 Esteem 399 Low NOx Boiler Chapt er 2

OMM-0089_0A Installation, Operation & Maintenance Manual Combustion Air/Venting

3.8 REMOVAL OF AN EXISTING BOILER FROM A COMMON VENT SYST EM

WARNING!

Do not install the esteem unit into a common vent with other gas

or oil appliances. This may cause flue gas spill age or appliance

malfunction, resulting in possible severe personal injury, death or

substantial property dam age.

NOTE

When an existing boil er is removed from a common venting

system , the common venting system is likely to be too large for

proper venting of the remaining appliances.

At the time of rem oval of an existing boiler, the following steps shall be followed with each

appliance r em aining connected to the common venting system placed in operation, while the

other appliances remaining connected to the common venting system are not in operation.

• Seal any unused openings in the common venting system.

• Visually inspect the venting system for proper size and horizontal pitch and determine

there is no blockage or restriction, leakage, corrosi on and other deficiencies which could

cause an unsafe condition.

• Insofar as is practical, close all building doors and windows and all doors between the

space in which the appliances remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes dryers and any appliance not

connected to the common venting system. Turn on any exhaust fans, such as range

hoods and b athroom exhausts, so they will op erate at maxim um speed. Do not op erate a

summer exhaust fan. Close fireplace dam pers.

• Operate the appliance being inspected. Follow the lighting instructions. Adjust thermostat

so appliance will operate continuously.

• Test for spillage at the draft hood reli ef opening after 5 minutes of m ain burner operation.

Use the flame of a match or candle, or sm oke fr om a cigarette, cigar or pipe.

• After it has been determined that each appliance remaining connected to the common

venting system properly vents when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers, and any other gas-burning appliance to their previous

condition of use.

• Any improper operation of the comm on venting system should be corrected so the

installation conforms with the Nation al Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

CAN/CGA B149, Installation c odes. When re-sizing any portion of the common venting

system , the common venting system should be re-sized to approach the appropriate

tables in Part II of the National Fuel Gas Code ANSI Z223.1/NFPA 54 and/or CAN/CGA

B149, Installation codes.

Page 26 of 188 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 OMM-0089_0A

MC1 06/19/14 Ph.: 800-526-0288

Page 27

GF-135 Esteem 399 Low NOx Boiler Chapt er 3

OMM-0089_0A Installation, Operation & Maintenance Manual Comb. Air & Venting

Commonwealth of Massachusetts Installations Only

For direct-vent appliances, mechanical-vent heating appliances or domestic hot water

equipment, where the bottom of the vent terminal and the air intake is installed below four feet

above grade the following requirements must be satisfied:

1. If there is not one already present, on each floor l evel where there are bed-room(s), a

carbon m onoxide detector and alarm shall be placed in the living area outside the

bedroom(s). The car-bon monoxide detector shall comply with NFPA 720 (2005 Edition).

2. A carbon monoxide det ector shall also be located in the room that houses the appliance or

equipment and shall:

a) Be powered by the same electrical circuit as the appliance or equipm ent such that only

one service switch services b oth the appliance and the carbon monoxid e detector.

b) Have battery back-up power.

c) Meet ANSI/UL 2034 Standards and comply with NFPA 720 (2005 Edition).

d) Have been approved and listed by the Nation ally Recognized Testing Laboratory as

recognized under 527 CMR.

3. A Product-approved vent terminal must be used, and if applicable, a Product-approved air

intake must be used. Install ation shall be in strict compliance with the m anufacturer’s

instructions. A copy of the installation instructions shall remain with the appliance or

equipment at the completion of the installati on.

4. A metal or plastic identification plate shall be m ounted at the exterior of the building, four

feet directly ab ove the locati on of vent terminal. The plate shall be of sufficient size to be