Page 1

362

I

n

n

1

2

A

B

)

D

-

g

.

D

T

g

s

3

.

g

s

.

O

s

.

s

.

T

p

.

t

I

M

.

T

able of Content

s

g

ear

2

6

...............................................................

........................................................

279

..............................................

j

g

(

)

PAGE

General Mountin

Standard

Reversible Clamp ...............................................

Lin

................................................................. 272

Rotary ................................................................. 273

Retrofit Brackets

Operation

Electrical

Mechanical ......................................................... 277

Wiring

General

Accessories

Startup and Checkout

270

271

75

27

278

282

nstallation and Operatio

Non-Spring Retur

General Information

Preliminary Steps

. Belimo actuators with NEMA 1 or NEMA 2 ratings should be mounted indoors in

a dry, relatively clean environment free from corrosive fumes. If the actuator is

mounted outdoors, a protective enclosure must be used to shield the actuator.

. For new construction work, order dampers with extended shafts. Instruct the

installing contractor to allow space for mounting the Belimo actuator on the shaft.

For replacement of existing gear train actuators, there are two options:

. From a performance standpoint, it is best to mount the actuator directly onto the

damper shaft.

. If the damper shaft is not accessible, mount the non-spring return actuator with

a ZG-NMA or ZG-GMA crank arm kit, and a mounting bracket (ZG-100, ZG-101,

ZG-103, ZG-104

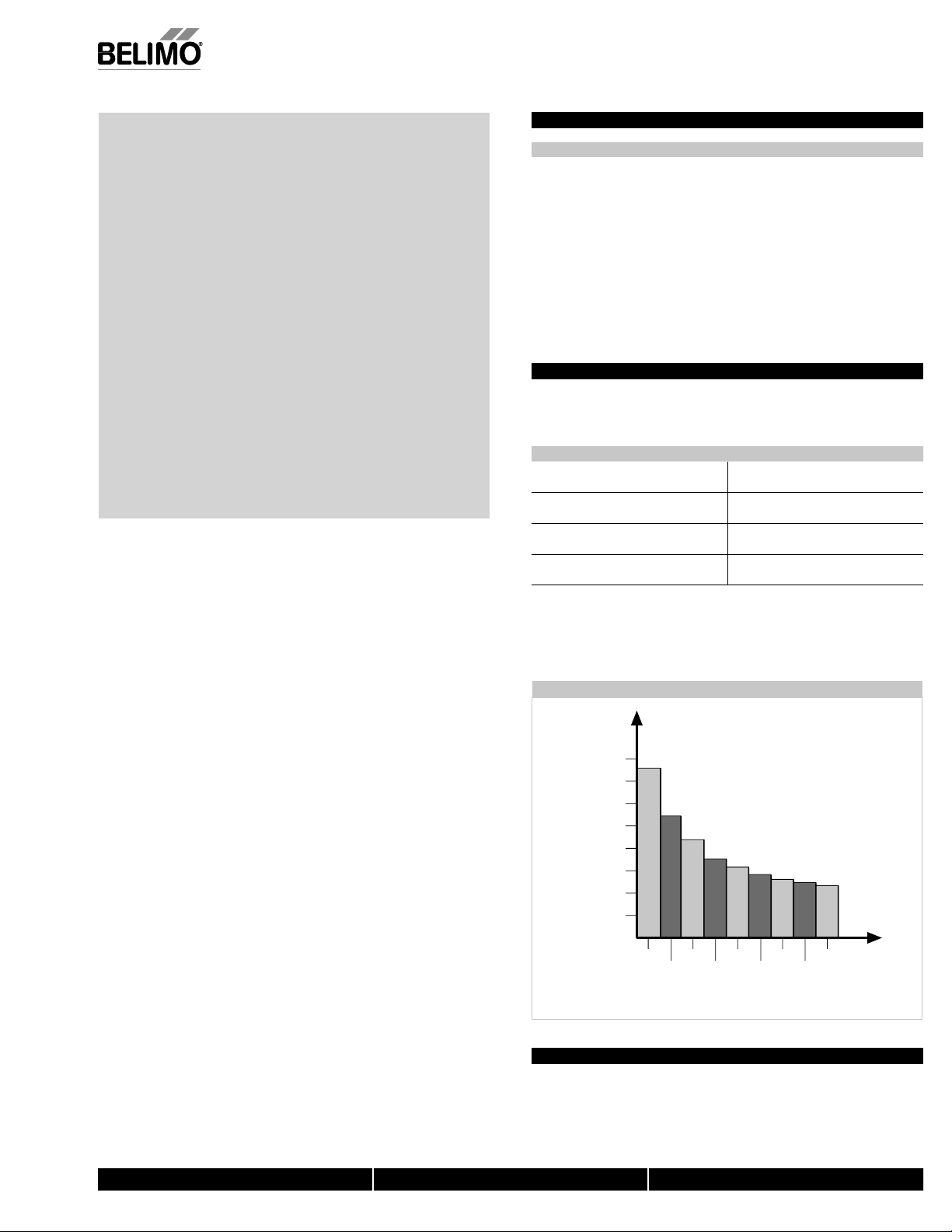

Determining Torque Loading and Actuator Sizing

amper torque loadings, used in selecting the correct size actuator, should be pro

vided by the damper manufacturer. If this information is not available, the following

eneral selection guidelines can be used

amper Type

Opposed blade, without edge seals, for

ht close-off application

non-ti

Parallel blade, without edge seals, for

non-ti

ht close-off application

pposed blade, with edge seals, for tight

close-off application

Parallel blade, with edge seals, for tight

close-off application

he above torque loadings will work for most applications under 2 in. w.g. static

ressure or 1000 FPM face velocity. For applications between this criteria and 3 in.

w.g. or 2500 FPM, the torque loading should be increased by a multiplier of 1.5. If

the application calls for higher criteria up to 4 in. w.g. or 3000 FPM, use a multiplier

of 2.0

orque Loading

in-lb/sq. ft

4 in-lb/sq. ft

5 in-lb/sq. ft

7 in-lb/sq. ft

Torque Loading Char

, Inc.

USA

140

120

100

e. © Belimo Aircontrols

80

60

40

ect to chan

20

Damper Area (sq. ft.)

0

2

M40024 - 05/10 - Sub

Torque Loading (in-lb/ sq. ft.)

46810

3

579

Multiple Actuator Mounting

f more torque is required than one GM can provide, GM24B, GMB24-SR or GMX24-

FT may be installed on the same shaft

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 2

363

S

S.

A*

B

C

D

5/8”

5/16

5”

b

B

”

b

05”

3/8

5”

6 to

b

QB

b

05”

3/8

6 to

b

B

”

b

GMB1/

05”

5”

6 to

b

p

s

.

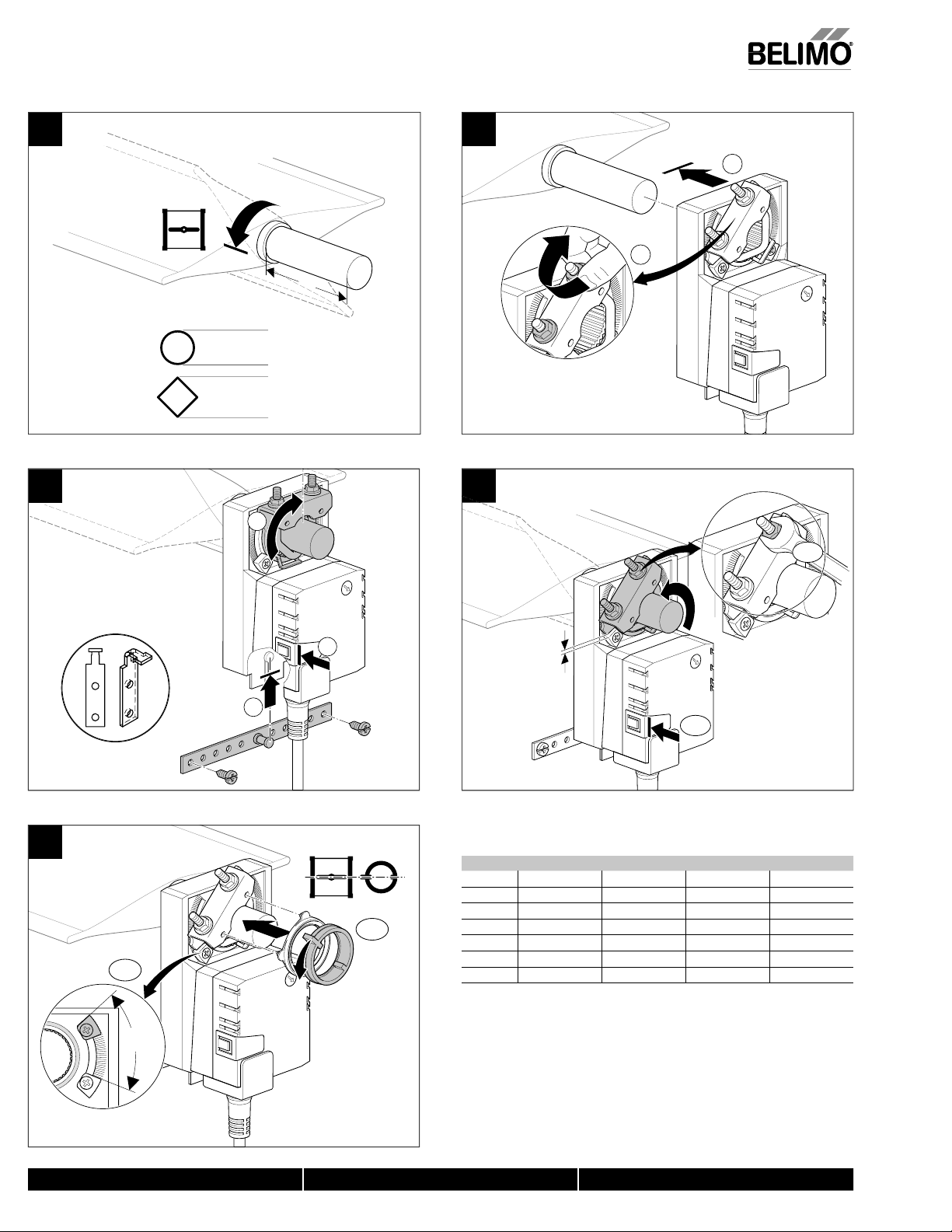

Installation Instructions

Q

uick-Mount Visual Instructions for Mechanical Installatio

n

1

65°

1

3

A

B

2

1

2

C

4

1

D

2

10

LM Universal

Mounting Bracket

5

1

5°

2

1

EE NEXT PAGE FOR STANDARD MOUNTING INSTRUCTION

LM

LMQ

1

2

NM

AM

AMQ

* LMB standard clamp has max 5/8” diameter. Accessory clamp K-LM20 can be

** Shorter with reversible clamp for NMB, AMB, and GMB.

1/4” to

1/2” to 1.05”3/8” to 11/16”1.5

1/2” to 1.

1/2” to 1.05”3/8” to 11/16”1.5” 6 to 7 ft-l

1/2” to 1.

1/2” to 1.05”7/16” to 11/16”1.5

2” to 1.

mounted for sizes u

elf-centers on the following diameter shafts: 1/2” (default), 3/4” and 1.05”. GM

clamps have an insert that self-centers on 3/4” diameter

to 3/4” diameter. NM and AM clamps have an insert that

” to 9/16”1.

” to 11/16”1.

” to 11/16”1.5”

7/16” to 11/16”1.

**

4 to 5 ft-l

6 to 7 ft-l

7 ft-l

7 ft-l

6 to 7 ft-l

7 ft-l

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 3

364

M

n

R

)

.

➀

he d

ibl

desired

.

➁

➀

➁

-

.

➀

b

b

➁

.

➀

.

➁

.

T

p

T

-

c

r

1

.

2

Standard Mounting

j

g

(

)

ounting Installatio

eversible Clamp Quick Mount (NM, AM, GM

1

Turn the damper shaft until the blades are fully closed

2

Slip the actuator’s universal clamp over the damper shaft. Make sure that

uct and the controls on the cover are access

t

mounting position

Hand tighten the two nuts on the actuators universal clamp.

3

Disengage the actuator gear train by pressing the manual override button

and rotate the clamp until centered.

Slide the anti-rotation strap up under the actuator so it engages the

actuator at the center cutout. Bend the bracket as needed to support the rear

of the actuator. Secure to ductwork with self-tapping screws (No. 8 recom

mended)

4

Loosen the nuts on the universal clamp. Press the manual override

utton and rotate the clamp to about 5° from the closed position (1/16 to 1/8”

etween stop and clamp).

Tighten the two nuts on the universal clamp with a 10 mm wrench (see

table for required torque)

5

Snap on the refl ective position indicator

Adjust end-stops, if required

6

Mount actuators indoors. If mounted outdoors, use approved protective enclosure.

e. Place the actuator in the

he damper is now fully closed but the actuator is 5° from fully closed. This is called

“pre-loading” the actuator. When the actuator is powered and sent to the closed

osition: it will put its full torque on the shaft compressing the edge and blade seals.

his ensures that the damper will meet its leakage rating. The actuator is electroni

ally protected from overload and will not be damaged.

Testing the Installation Without Powe

. Disengage the gear train with the manual override button and move the shaft

from closed to open to closed. Ensure that there is no binding and that the

damper goes fully open and closes with 5° of actuator stroke left

. Correct any problems and retest.

, Inc.

USA

e. © Belimo Aircontrols

ect to chan

M40024 - 05/10 - Sub

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 4

365

M

ounting Installatio

n

)

Linear Quick Mount (LH, AH

1

2

3

Ø max. 0.3" [8]

0.8" [20]

0.8" [20]

0.08" [2]

A

Z-DS1

M8

B

Z-DS1

C

°

10

±

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 5

366

M

n

)

K-LU Shaft Clam

p

ZDB-LU Angle of Rotation Limiter

ZDB-LU Angl

j

g

(

)

min.

1/2"

5/16"…1/2"

ounting Installatio

Rotary Quick Mount (LU

[13]

[8...12]

K-LU

e of Rotation Limiter

ZDB-LU Angle of Rotation Limiter

, Inc.

USA

+

330

0

e. © Belimo Aircontrols

300

270

1

240

210

30

60

9

0

12

0

0

18

150

ect to chan

+

M40024 - 05/10 - Sub

0

330

300

0

27

30

60

90

0

0

240

210

180

12

150

240

30

330

0

30

0

27

210

0

0

30

60

18

90

120

150

240

330

120

0

90

30

15

0

60

270

30

0

0

21

0

0

0

180

30

210

60

24

90

0

18

33

270

120

0

0

15

30

0°...120°

300

330

2

0

60

70

24

0

210

90

180

150

120

330

300

240

330

270

270

210

0

300

30

0

60

0

90

3

240

180

21

15

0

0

180

1

2

0

150

90

60

120

0°...270°

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 6

367

M

ounting Installatio

n

3

Quick Mount, Direct Coupled CMB24-3(-T) / CMB120-

1

4

2 3

A

!

M40024 - 05/10 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 7

368

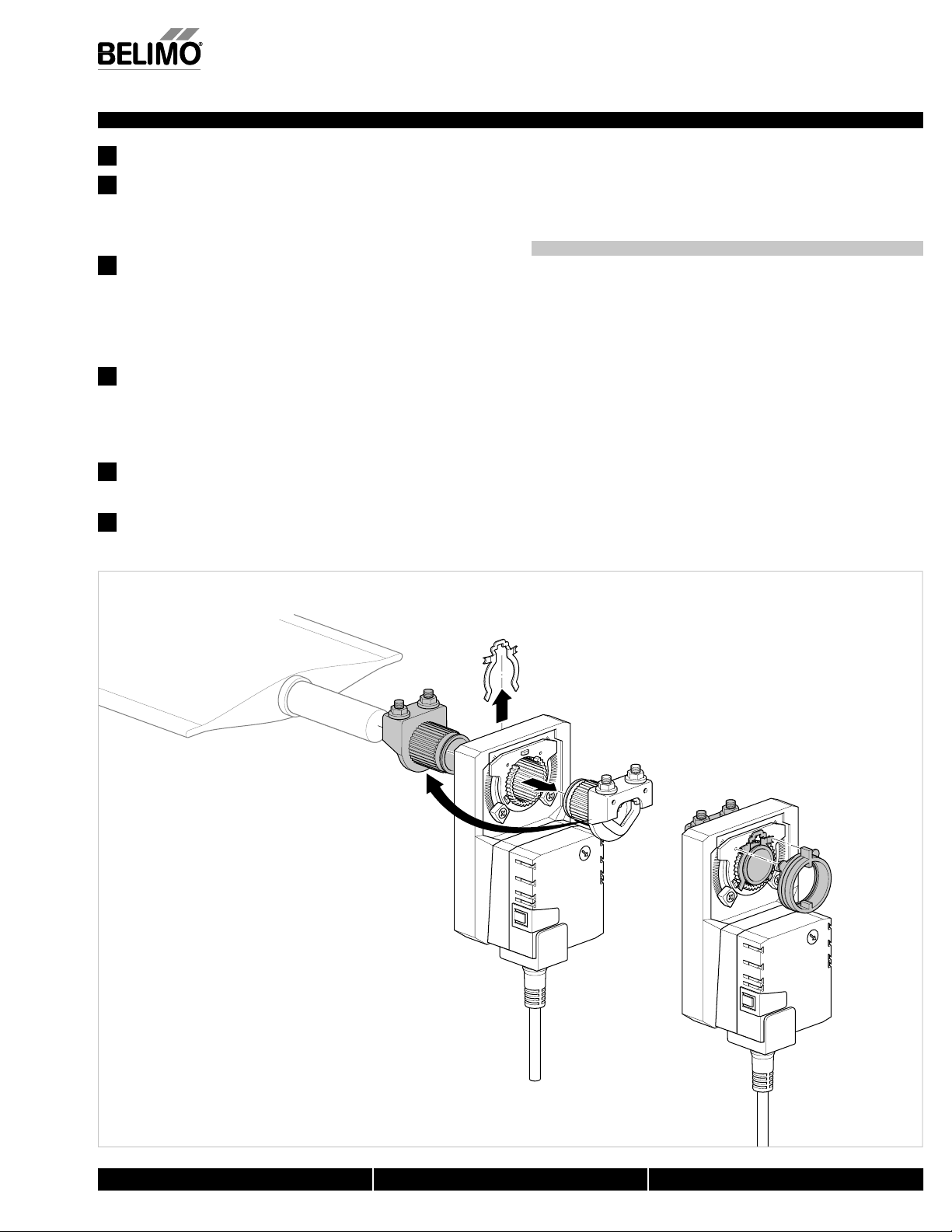

Replacing Discontinued Belimo Actuators

Wh

-

p

b

rep

.

-

r

.

M

s

)

s

A

s

j

g

(

)

en replacing an actuator, whether Belimo or other, be sure to consider the ap

lication parameters before selecting the replacement. The new product may not

e the best fi t for the application. Example would be a Belimo AM24 US mounted

to a valve linkage. The direct replacement of the actuator is AMB24-3. However,

the AM24 US and the AMB24-3 are different lengths, the linkage would need to be

laced as well

Instead of replacing the linkage the retrofi t bracket Z-SMA and Z-GMA can be used

to extend the location of the anti-rotation bracket to match the location of the anti

otation bracket of discontinued Belimo actuators

NOTE: LM and LMB are the same size.

ounting Instruction

Retrofi t Brackets (Z-SMA and Z-GMA

Z-SM

for replacing AM and SM actuator

1

, Inc.

USA

A

2x

Z-GMA

for replacing GM actuators

-

for replacing NM actuator

1x

2 x

NM

GM

e. © Belimo Aircontrols

ect to chan

M40024 - 05/10 - Sub

B

AM

SM

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

3 Nm

2

Page 8

369

O

peratio

n

ica

es

G

B

t

c

the actuator.

on

B

e

t

ion

B

H

H

.

d

f

.

All Beli

g

B

-

s

c

d

1

a

c

bili

Electr

l Featur

Electrical Operation

eneral

elimo non-spring return actuators utilize Halomo sensorless Brushless DC motor

echnology developed by Belimo. The non-spring return actuators use this motor in

onjunction with an Application Specific Integrated Circuit (ASIC). The Halomo ASIC

provides the intelligence to provide a constant rotation rate to prevent damage to

Initializati

When a power source is applied the motor carries out an initialization of the

actuator. The purpose of this initialization is to determine the mechanical angle of

rotation and to adapt the running time to the angle of rotation. When power is

applied, the internal microprocessor recognizes that the actuator is at its full-safe

position and uses this position as the base for all of its calculations.

Brushless DC Motor Operation

elimo’s Halomo sensorless brushless DC motor spins by reversing the poles of

stationary electromagnets housed inside rotation permanent magnets. The

lectromagnetic poles are switched by a special ASIC developed by Belimo. Unlike

he conventional DC motor, there are no brushes to wear or commutators to foul.

Motor Position Detect

elimo's Halomo motor technology is a sensorless, brushless DC motor. The

alomo technology eliminates the need for potentiometers for positioning. The

alomo ASIC detects the spinning rotor by monitoring the back EMF of the motor

poles. The ASIC counts these pulses and calculates position within 1/3 of a motor

revolution

Overload Protection

The Belimo non-spring return actuators are electronically protected from overload at

all angles of rotation by digital technology in the ASIC. The ASIC circuitry constantly

monitors the rotation of the brushless DC motor inside the actuator and stops the

pulsing to the motor when it senses an overload. The motor remains energized an

produces full rated torque when in overload.

The overload filtration helps increase the actuators installed life expectancy by

iltering out unnecessary control signal changes or end-stop pulsing while in

overload. This helps ensure that dampers are fully closed and that edge and blade

seals are always properly compressed

Control Accuracy and Stability

mo actuators have built-in

brushless DC motors which provide

better accuracy and lon

elimo non-spring return actuators are designed with a unique non

ymmetrical deadband. The actuator follows an increasing or decreasing

ontrol signal with a 75 mV resolution. If the signal changes in the opposite

irection, the actuator will not respond until the control signal changes by

75 mV. This allows these actuators to track even the slightest deviation very

ccurately, yet allowing the actuator to “wait” for a much larger change in

ontrol signal due to control signal insta

Actuator responds to a 75 mV signal when

not changing direction from stop position.

Control Position

Actuator responds to a 175 mV signal when

reversing direction from stop position.

Minimum Reversed

Control Deadband

Prior to Normal Control

er service life.

ty.

Satisfied

75 mV

Minimum

Control Resolution

175 m

V

Control Position

Satisfied

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 9

370

Op

n

es

Manual Override

The Beli

t

i

i

c

p

c

.

p

.

g

c

p

.

igh

j

g

(

)

mo non-spring return actuators have a black, “manual override button”

located on the top of the housing. Press this button and the gear train is

disengaged so the damper shaft can be moved manually. Release the button and

he gear train is re-engaged.

Use the manual override to test the installation without power. For tight shut-off the

damper should close with 5° of actuator stroke left.

Direction of Rotation Switch

eratio

Mechanical Featur

Manual Override Button

Non-spring return actuators have a reversing switch on the cover. Switch position

ndicates start point. For the non-spring return, with the switch in position 1, the

actuator rotates clockwise with an decrease in voltage or current. With the switch

n position 0, the actuator rotates counterclockwise with an decrease in voltage or

urrent.

The non-spring return rotates clockwise when the switch is in the 1 position and

ower is applied to wire #2. When power is applied to wire #3 the actuator rotates

ounter clockwise. Rotating the switch to 0 reverses the control logic

During checkout, the switch position can be temporarily reversed and the actuator

will reverse its direction. This allows the technician a fast and easy way to check

the actuator operation without having to switch wires or change settings on the

thermostat. When the check-out is com

to its original position

, Inc.

USA

lete, make sure the switch is placed back

10 VDC 10 VDC

Direction of Rotation Switch

2 VDC

Mechanical Angle of Rotation Limiting

e. © Belimo Aircontrols

The adjustable stops are needed when there is no damper stop or if you want the

damper to stop rotatin

an be indefinitely stalled in any position without harm.

ect to chan

1. Loosen the two end stops with a No. 2 Phillips head screwdriver being careful

not to unscrew the ca

2. Move the stops (in 2.5° steps) to the desired position and re-t

M40024 - 05/10 - Sub

before it reaches its stops. The non-spring return actuators

65°

tive nut under the slot

ten the screws.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Loading...

Loading...