Page 1

QIG-0001_0A • 11/1/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 1 of 7

Max. TDS

< 200 ppm

Chloride

< 150 ppm

Conductivity

< 3000 μS

pH

7.5-9.5

WARNING!

Follow all provisions, warnings, and cautions provided in the AM boiler/water heater Operations and Maintenance (O&M) manuals. Failure to

comply with the O&M can lead to extensive property damage and/or personal injury or death.

Do not store any flammable materials or liquids in the immediate vicinity of the unit.

Provisions for sufficient combustion air and ventilation of the boiler room are required (see O&M for details).

Liquefied petroleum gas-burning appliances shall not be installed in a pit, basement or similar location where heavier-than-air-gas might

collect.

The unit installation and startup must be carried out by trained and qualified professionals.

MASSACHUSETTS INSTALLATIONS: Installer must be licensed within the Commonwealth of Massachusetts. Unit must be installed according to

all local codes. See O&M manual for more information.

In the event of a breakdown and/or malfunction of the unit, turn it off and do not make any attempt to repair it; service must be performed

by a certified service technician using original spare parts.

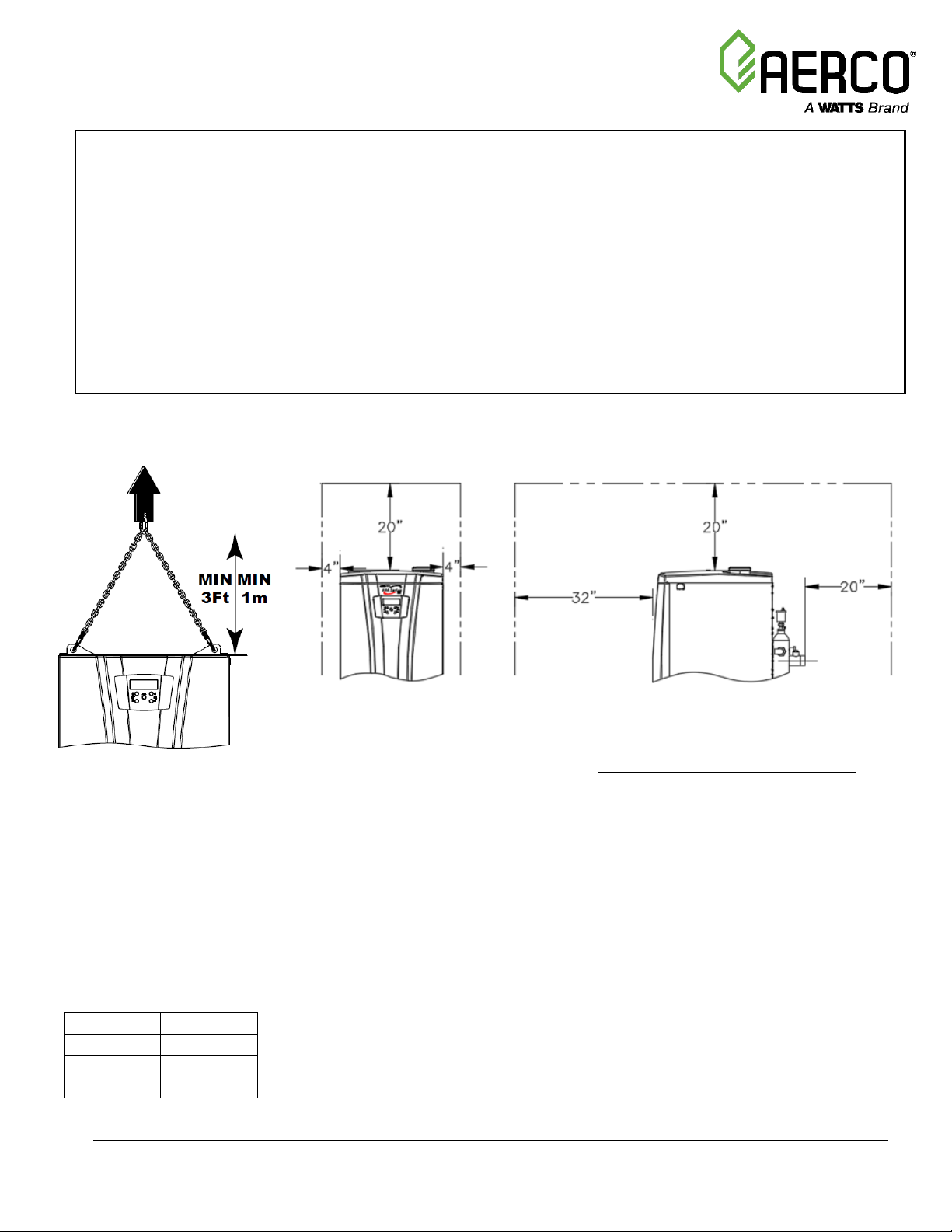

Transport, Installation Requirements

CORRECT WAY TO LIFT UNIT:

INSTALLATION CLEARANCES

Accessories Included (inside

unit):

(1) Gas to LP conversion kit

(1) Remote temperature sensor

(2) Spare vent thermal fuses

(1) Neutralizer media

(4) Adjustable foot

(1) Outdoor sensor-boiler models only

(1) Piping kit for circulation pump—

(AMRI models only; shipped loose)

ALCOVE/CLOSET INSTALLATIONS:

Follow rules on clearances, venting, ventilation openings as per the O&M and the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CAN/CSA B149.1, Natural Gas and Propane Installation Code and local codes. DO NOT use

non-metallic exhaust pipe material into a closet or alcove; the only exhaust pipe material accepted is AL29-4C.

COMBUSTION AIR REQUIREMENTS:

The combustion air must be free of chlorine, halogens or any other chemicals that are detrimental to the operation

of the unit. Sufficient air supply must be provided to support room air combustion - see O&M and Venting

Applications Guide GF-146-V for details.

GAS PRESSURE REQUIREMENTS:

• The inlet supply to the unit must be at least 3” W.C. when firing at maximum input. Maximum allowable gas pressure

is 13”W.C.

• A lock-up style external gas regulator is required when supply pressure is greater than 13” W.C.

• External gas regulator is required for State of Massachusetts, regardless of supply pressure.

• Unit is factory shipped for Natural Gas operation. For Propane operation, see O&M for conversion instructions.

WATER CHEMISTRY:

• Do NOT use artificially softened water

• Consult chemical manufacturer for certification of inhibitor, anti-freeze, etc. used for hydronic systems

• For best results, clean hydronic system before adding inhibitors; isolate boiler from piping during system flushing

Water Chemistry

Allowable Limits:

AM Series Quick Installation Guide

Page 2

Quick Installation Guide

AM Series

QIG-0001_0A • 11/1/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 2 of 7

Equivalent Pipe Lengths

Diam

Sharp 90°

Sweep 90°

45°

AM 199/250

3”

10 ft.

5 ft.

5 ft.

AM 399/500

4”

10 ft.

5 ft.

5 ft.

AM 750/1000

6”

10 ft.

5 ft.

5 ft.

Exh Outlet

Duravent PolyPro

AM 199/250

3”

3PPS-03PVCM-3PPF

AM 399/500

4”

4PPS-04PVCM-4PPF

AM 750/1000

6”

6PPS-06PVCM-6PPF

Centrotherm Innoflue

(PP)

AM 199/250

3”

ISAAL03

AM 399/500

4”

ISAAL04

AM 750/1000

6”

ISAAL06

Security Chimneys (Al29-

4C)

AM 199/250

3”

SS3PVCU

AM 399/500

4”

SS4PVCU

AM 750/1000

6”

SS6PVCU

Security Chimneys DW

(Al29-4C)

AM 199/250

3”

SS3PVCUK

AM 399/500

4”

SS4PVCUK

AM 750/1000

6”

SS6PVCUK

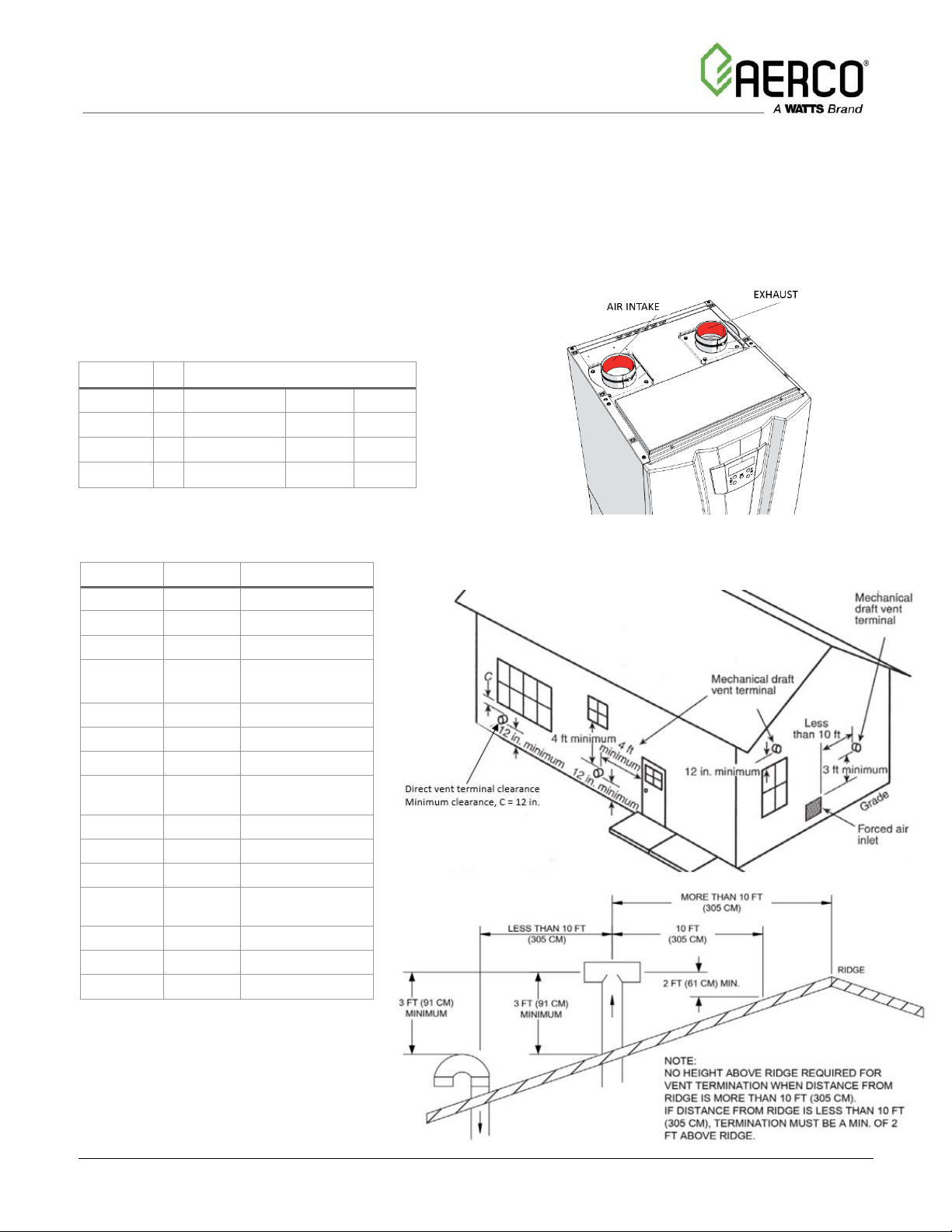

Venting/Air Intake

ACCEPTABLE MATERIALS

• Acceptable vent materials: Al29-4C Stainless Steel, Polypropylene, CPVC, PVC. For Alcove/Closet Installation, use Al29-4C only.

• Do not use PVC exhaust for applications where return water temperature > 145F. See O&M for additional information.

• Polypropylene and Al29-4C exhaust requires additional adapters - contact the vent manufacturer for suitable adapter.

VENT/AIR INTAKE SIZING:

• Maximum length of vent is 60 equivalent ft.

• Maximum length of air intake is 60 equivalent ft.

• For manifolded vents, see O&M manual

Exhaust Adapter supplied with unit accepts

PVC. When using polypropylene or Al29-4C

exhaust, additional adapter required—

example manufacturers:

VENT TERMINATION

Page 3

Quick Installation Guide

AM Series

QIG-0001_0A • 11/1/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 3 of 7

POTABLE APPLICATIONS

MINIMUM FLOW

10 grains/gal max

200ppm TDS max

POTABLE APPLICATIONS

MINIMUM FLOW

18 grains/gal max

200ppm TDS max

AM 199

11 gpm

18 gpm

AM 250

12 gpm

18 gpm

AM 399

22 gpm

37 gpm

AM 500

24 gpm

37 gpm

AM 750

36 gpm

60 gpm

AM 1000

48 gpm

75 gpm

WATER PIPING:

Boiler applications:

• Use primary/secondary piping configuration.

• Common pipe diameter must be sized for less than 4.0 ft/sec; common pipe length must

be 3 to 5 times its diameter.

• Single unit application - relocate supply temperature sensor from boiler header to system

piping.

• Multiple unit application - install Cascade header temperature sensor in the system piping

(see AERCO Cascade Sequencer user manual (GF-146-CS) for installation details).

Water heating applications:

• A storage tank must be used. See below for basic

piping configurations.

• An anti-scald valve must be used and installed in

accordance with local codes.

Ensure that the minimum system flow is met

per chart and table below, otherwise the flow

sensors will automatically stop the burner.

AM SERIES PRESSURE DROP

A: AM 199/250; Min flow (high fire) =11 gpm/ 12 gpm

B: AM 399; Min flow (high fire) =22 gpm

C: AM 500; Min flow (high fire) =24 gpm

D: AM 750; Min flow (high fire) =36 gpm

E: AM 1000; Min flow (high fire) =48 gpm

Page 4

Quick Installation Guide

AM Series

QIG-0001_0A • 11/1/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 4 of 7

BOILER APPLICATIONS

WATER HEATING APPLICATIONS

(with Integrated Tank)

The condensate drain must

slope down and away from

the boiler into a drain; it

must be installed accordingly

in order to avoid the freezing

of the liquid.

WATER HEATING APPLICATIONS

(Separate Tank)

Page 5

Quick Installation Guide

AM Series

QIG-0001_0A • 11/1/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 5 of 7

Install a 15 am fused disconnect or service switch. (15 amp). All electrical conduit and hardware should be installed so that it does not interfere with

the removal of any cover, inhibit service or maintenance, or prevent access between the unit and walls or another unit.

All AM Series pump relays are rated for 3A max. When pumps used exceed 3A, an appropriately sized external relay or starter must be used.

CONNECTING UNITS IN CASCADE:

Up to eight boilers or water heaters may be combined in a cascading

system using the optional Cascade Sequencer. Refer to the AERCO

Cascade Sequencer user manual (GF-146-CS) for installation details.

MODBUS INTERFACE CONNECTIONS:

The AM unit can be controlled from a building management system via MODBUS

interface. This requires a Communication Module on each unit (AM399-1000: factory

installed; AM199/250: optional). Refer to the AM Series MODBUS User Manual (GF146-MB) for wiring and setup details.

Electrical/Controls Wiring - BOILER

To program the settings indicated below, see Page

6 for control panel button functions.

• Main Power supply: Terminals 101/102/PE

• Low Water Cut Off: Terminals 103/104

• Primary Pump (boiler loop): Terminals

113/114

• Constant Setpoint Enable/Disable (if

employed; otherwise jumped): Terminals

10/11

Set Para. 2003=0

• Outdoor Sensor (if employed): Terminals

14/15

Set Para. 2003=1 (Outdoor Reset)

See O&M for additional settings for Outdoor Reset

• 0-10VDC (if employed): Terminals 22/23

Set Para. 2003=4 (0-10V)

Notes on 0-10VDC analog input:

- analog input drives the supply

temperature

- requires a Communication Module on

each unit (AM399-1000: factory

installed; AM199/250: optional).

-

See O&M for additional settings when

controlling via 0-10VDC.

•

Indirect Fired heater sensor (if employed) *:

Terminals 12/13

Set Para. 3012=1

See O&M for additional settings for Indirect

Fired Water Heating

• Indirect Fired heater pump: Terminals

107/108

• Secondary Pump (system loop): Terminals

105/106

BOILER APPLICATION Basic Wiring and Settings:

STARTUP PRECEDURE - BOILER APPLICATION

(Prior to startup, see page 7 for Combustion Calibration)

1. Open the manual gas shutoff valve.

2. Turn power switch ON

3. Change heating setpoint: C/A. Press B to save.

4. If an indirect water heater is connected use R/S to change

domestic hot water temperature. Press B to save.

NOTE: If the burner fails to ignite within 60 seconds, the

boiler will attempt ignition another four times. Consult O&M

manual if the boiler reaches a lockout condition after four

ignition retries.

Page 6

Quick Installation Guide

AM Series

QIG-0001_0A • 11/1/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 6 of 7

Electrical/Controls Wiring - WATER HEATER

Install a 15 am fused disconnect or service switch. (15 amp). All electrical conduit and hardware should be installed so that it does not interfere with

the removal of any cover, inhibit service or maintenance, or prevent access between the unit and walls or another unit.

All AM Series pump relays are rated for 3A max. When pumps used exceed 3A, an appropriately sized external relay or starter must be used.

WATER HEATER APPLICATION

Basic Wiring and Settings:

• Main Power supply: Terminals 101/102/PE

• Low Water Cut Off: Terminals 103/104

• Storage tank pump: Terminals 113/114

• Storage tank sensor: Terminals 8/9

(replace factory installed header sensor)

Set Para. 2003=0

STARTUP PRECEDURE - WATER HEATER APPLICATION

(Prior to startup, see page 7 for Combustion Calibration)

1. Open the manual gas shutoff valve.

2. Turn power switch ON

3. Change storage tank water temperature: C/A. Press B to save.

NOTE: If the burner fails to ignite within 60 seconds, the boiler will

attempt ignition another four times. Consult O&M manual if the

boiler reaches a lockout condition after four ignition retries.

CONNECTING UNITS IN CASCADE:

Up to eight boilers or water heaters may be combined in a cascading system using

the optional Cascade Sequencer. Refer to the AERCO Cascade Sequencer user

manual (GF-146-CS) for installation details.

MODBUS INTERFACE CONNECTIONS:

The AM unit can be controlled from a building management system via MODBUS interface. This requires a Communication Module on each unit

(AM399-1000: factory installed; AM199/250: optional). Refer to the AM Series MODBUS User Manual (GF-146-MB) for wiring and setup details.

Controls Panel Button Functions

To access Installer Menu (Para 2000’s):

Hold B and S (5 seconds) until G appears.

Scroll through parameters: R/S

Select parameter: B (value blinks)

Change parameter value: R/S

Confirm new value: B

Exit Installer Menu: Hold B (>5 seconds) until G disappears.

To access Factory Menu (Para 3000’s):

Turn power switch to OFF.

Hold B and S, turn power switch ON, wait until “init” is displayed.

Release B then release S.

Select parameter: B (value blinks)

Change parameter value: R/S

Confirm new value: B

Exit Installer Menu: Wait min. 10 seconds. Turn power switch to

OFF. Turn power switch ON.

A - Setpoint Button (–): lowers the heating setpoint.

B - Multifunction button: resets any lockouts; accesses user and installer menus.

C - Setpoint Button (+): raises the heating setpoint.

D – Flame icon: indicates that a flame is present .

E - Radiator icon. indicates that a heating service is enabled. Blinks when heating service is active.

H - Unit of measure of the pressure (M).

F - Faucet icon: Indicates that the domestic hot water service is enabled. Blinks when domestic hot water service is active.

L - Burner unit indicators: Lights up when burner is burning; blinks when burner is in lockout or has a block ing error.

M - Pressure gauge and parameter display.

G - Gear icon: indicates access to the installer menu.

N - Supply or indirect water heater temperature gauge and display of parameter values.

0 - Unit of measure of the temperature (N).

P - Sensor icon: indicates that the outdoor sensor is active.

R - Multifunction button (+): raises the domestic hot water temperature;

scrolls through parameters; increases

parameter values.

S - Multifunctional button ( –): lowers the domestic hot water temperature;

scrolls through parameters; decreases

parameter values.

T - On-Off power switch.

Page 7

Quick Installation Guide

AM Series

QIG-0001_0A • 11/1/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 7 of 7

Combustion Calibration

GAS SUPPLY PRESSURE TEST

1. Close the manual gas shutoff valve.

2. Remove the front cover.

3. Turn inlet pressure port D screw three turns CCW.

4. Connect manometer to port D.

5. Open the manual gas shutoff valve.

6. Check gas pressure does not exceed 13” W.C. Adjust upstream

gas regulator as needed.

7. Turn power switch ON.

8. Generate heat demand: press C (boiler/water heater) or R

(indirect water heater) to its maximum setting.

9. Set Para 2200 (AM 399-1000) or 2010 (AM 199/250) to HIGH

10. Check gas pressure is between 3”-13” W.C. Adjust upstream

gas regulator as needed.

11. Return Para. 2200 or 2010 to OFF

COMBUSTION CALIBRATION

1. Follow vent pipe manufacturer’s instruction to install combustion analyzer probe 8” after the flue gas exhaust connection.

2. Start unit per procedure on this page.

3. Set unit to standby: Press A (boiler) or S (water heater) until “OFF” is displayed

4. Set Para 2201 (AM 399-1000) or 2010 (AM 199/250) to HIGH

5. Generate demand: Press C (boiler) or R (water heater) until setpoint is above “OFF” (e.g. 90F)

6. Wait 2-3 min. for CO2 to stabilize.

7. Compare CO2 reading with high fire range in Table below, making sure to use the range for gas type in use. If CO2 reading is outside the range,

use screw E (2.5mm Allen) to adjust: CW to reduce CO2, CCW to increase CO2. Adjust in small increments and wait for CO2 to stabilize in between

readings.

8. Set Para 2201 OR 2010 to LOW.

9. Wait 2-3 min. for CO2 to stabilize.

10. Compare CO2 reading with low fire range in Table below, making sure to use the range for gas type in use. If low fire CO2 reading is outside the

range, STOP the unit and call the Factory service department.

11. Set Para. 2201 or 2010 to OFF.

12. AM 399-1000: repeat steps 3-9 for burners 2, 3 and 4 as applicable, using parameters 2202-2204 to calibrate each burner in turn.

13. Close the combustion analyzer probe.

Loading...

Loading...