Page 1

Aeon7400A Service Manual

Contents

Contents.........................................................................................................................................................i

1 Introduction.............................................................................................................................................1

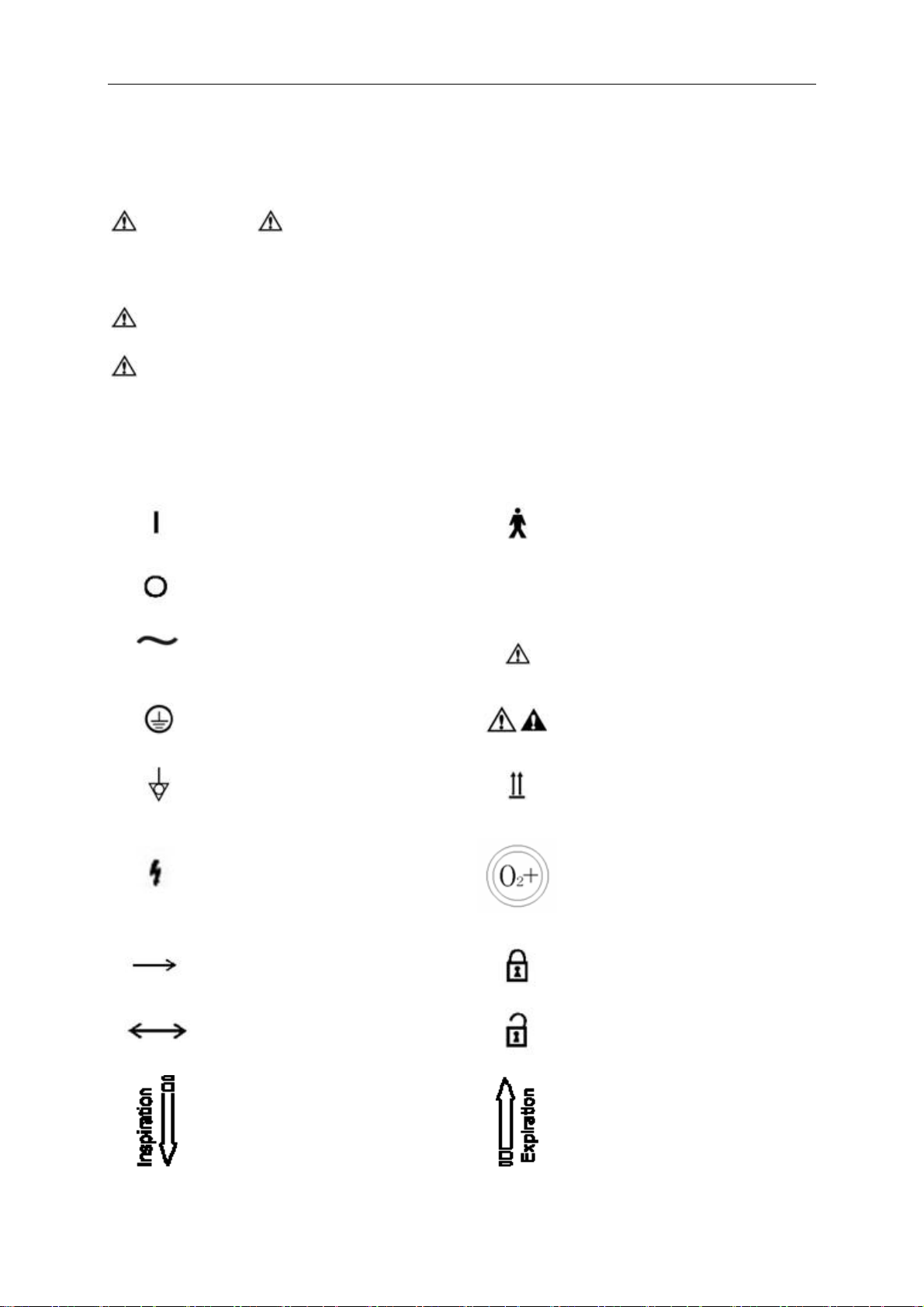

1.1 Symbols.......................................................................................................................................2

1.2 Warranty considerations..............................................................................................................3

2 Description..............................................................................................................................................4

2.1 General description......................................................................................................................4

2.2 Features of Aeon7400A...............................................................................................................4

2.3 Specification................................................................................................................................5

3 Checking .................................................................................................................................................6

3.1 Preoperative Checkout procedures..............................................................................................6

3.2 Testing the gas supply pipeline and the gas cylinder...................................................................8

3.3 Monitoring Flow Control ..........................................................................................................10

3.4 Installing and testing of vaporizer.............................................................................................14

3.5 Testing alarm.............................................................................................................................15

3.6 Testing the Breathing System....................................................................................................16

3.7 Testing Ventilator.......................................................................................................................17

4 Theory and Diagram..............................................................................................................................19

5 User Maintenance..................................................................................................................................21

5.1 Repair Policy.............................................................................................................................22

5.2 Maintaining Outline and Schedule............................................................................................23

5.3 Replacing fuses .........................................................................................................................24

i

Page 2

Page 3

Aeon7400A Service Manual

1 Introduction

This service manual provides procedures for testing and maintaining the Aeonmed model

anesthetic machine. It is not intended to be a complete maintenance document; therefore, it

contains no disassembly or reassembly instructions.

Refer any repairs or adjustments that exceed the scope of this manual to the Service Center of

Beijing Aeonmed Co., Ltd by calling

800-810-8333 or 86-10-88799987-333

This manual contains proprietary information. It is intended for use only by individuals qualified in

the installation and maintenance of the Aeonmed anesthetic machine. Receipt, purchase, or

possession of this document in no way confers or transfers any other rights for the use of this

information. Disclosure or reproduction of the enclosed, without the written permission of Beijing

Aeonmed Co., Ltd is prohibited.

This manual is intended for use only by technicians who have successfully completed Beijing

Aeonmed Co., Ltd training on this product.

Beijing Aeonmed Co., Ltd believes the information herein is accurate but accepts no responsibility

for errors, omissions, or misrepresentation.

1

Page 4

Aeon7400A Service Manual

1.1 Symbols

Warnings and Cautions indicate all the possible dangers in case of violation of the

stipulations in this manual. Refer to and follow them.

WARNING: indicates potential hazards to operators or patients

CAUTION: indicates potential damage to equipment

Instead of illustrations, other symbols may also be utilized. Not all of them may necessarily appear

in the equipment and manual. The symbols include:

ON(Power)

OFF(Power)

Alternating Current

Protectively earth

Equipotential

Dangerous Voltage

Movement in one direction

SN

Type B equipment

Serial Number

Warning or Caution, ISO

7000-0434

NOTE: refer to the manual,

IEC601-1

This way up

Oxygen flush Button

Lock

Movement in two directions

Inspiration flow

2

Unlock

Expiration flow

Page 5

Aeon7400A Service Manual

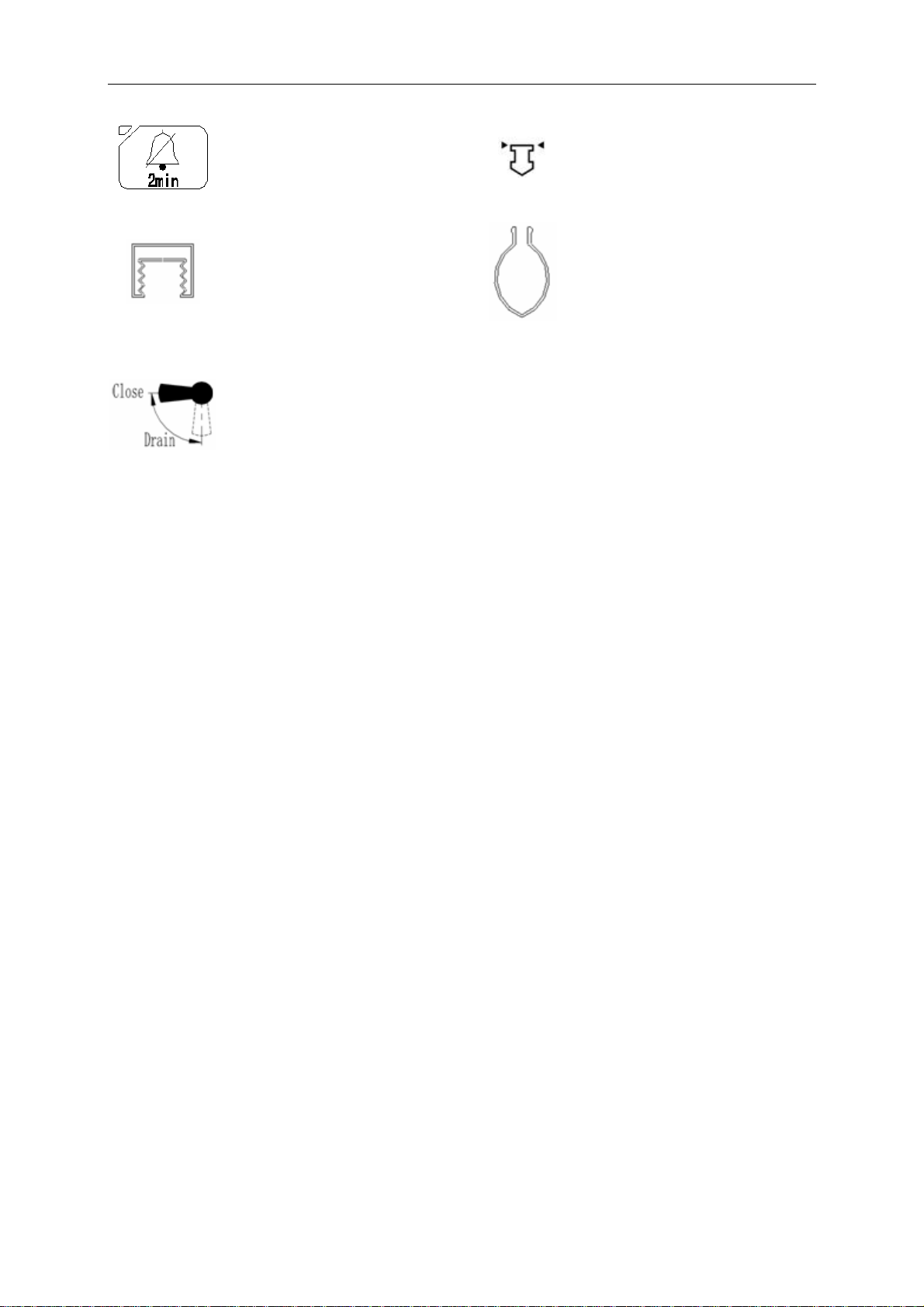

Alarm Silence

Ventilator operate

Directions of Drain Valve

1.2 Warranty considerations

View the reading on the top of

float

Bag operate

Do not make any service repairs on this equipment during the states warranty period. Any

unauthorized work immediately voids the warranty. Aeonmed will not be liable for any repairs

attempted by the owner. Any such attempted repairs other than specified no warranty repairs void

the warranty.

3

Page 6

Aeon7400A Service Manual

2 Description

This chapter describes the systems, features, controls, and labels on the Aeonmed

anesthetic machine. Also included is a description of the table of technical specifications.

2.1 General description

The Aeon7400A range of continuous flow inhalation anesthetic machines are intended for use

with human patients, in conjunction with anesthetic vaporizers, breathing hoses and patient

connection fittings which comply with the relevant ISO standard or equivalent.

Depending upon the patient circuit selected, the machines can be used in semi closed or closed

circuit configurations.

Aeon7400A is applicable for patient of over 300mL with standard set and for child of over 80mL

with bellows assembly and circles of child.

Aeon7400A equipped with MV200 microprocessor ventilator is pneumatic, electronic-controlled,

pressure-limit and time-cycled ventilator with perfect IPPV ventilating mode and monitoring

system.

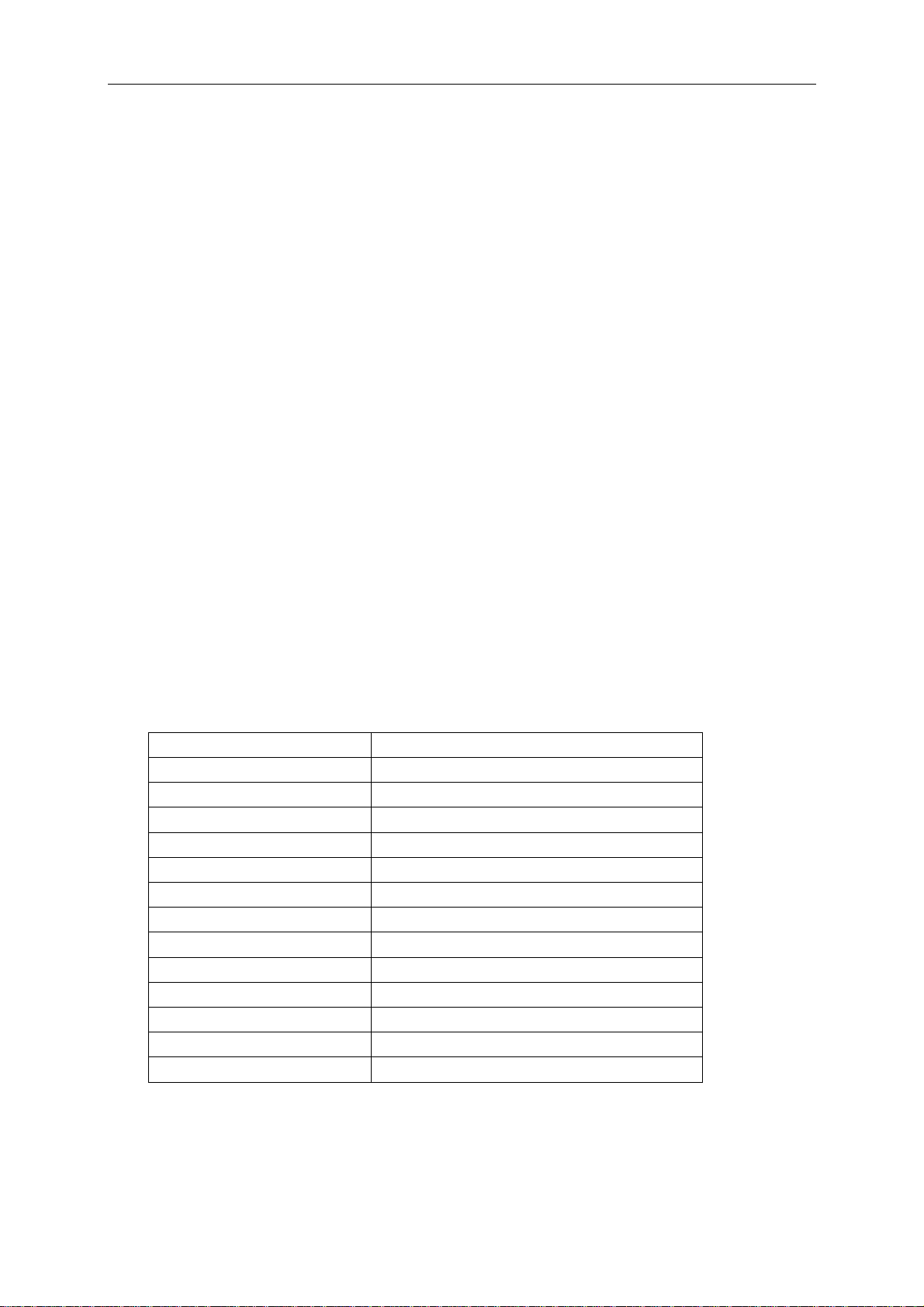

2.2 Features of Aeon7400A

Feature Aeon7400A

Model of ventilator MV200

Mode of ventilation IPPV/Manual

I:E ratio 2:1 to 1:4

Respiration frequency 6 to 60bpm

Tidal volume 0 to 1200ml

Power failure alarm Yes

High pressure 20 to 60cmH2O

Low pressure 5 to 20cmH2O

Alarm silence Not more than 120senconds

vaporizer VP200

Circle absorber Yes

Bellows Adult/pediatric

Flowmeter Four tubes, O2/N2O(cascade/continuous)

4

Page 7

Aeon7400A Service Manual

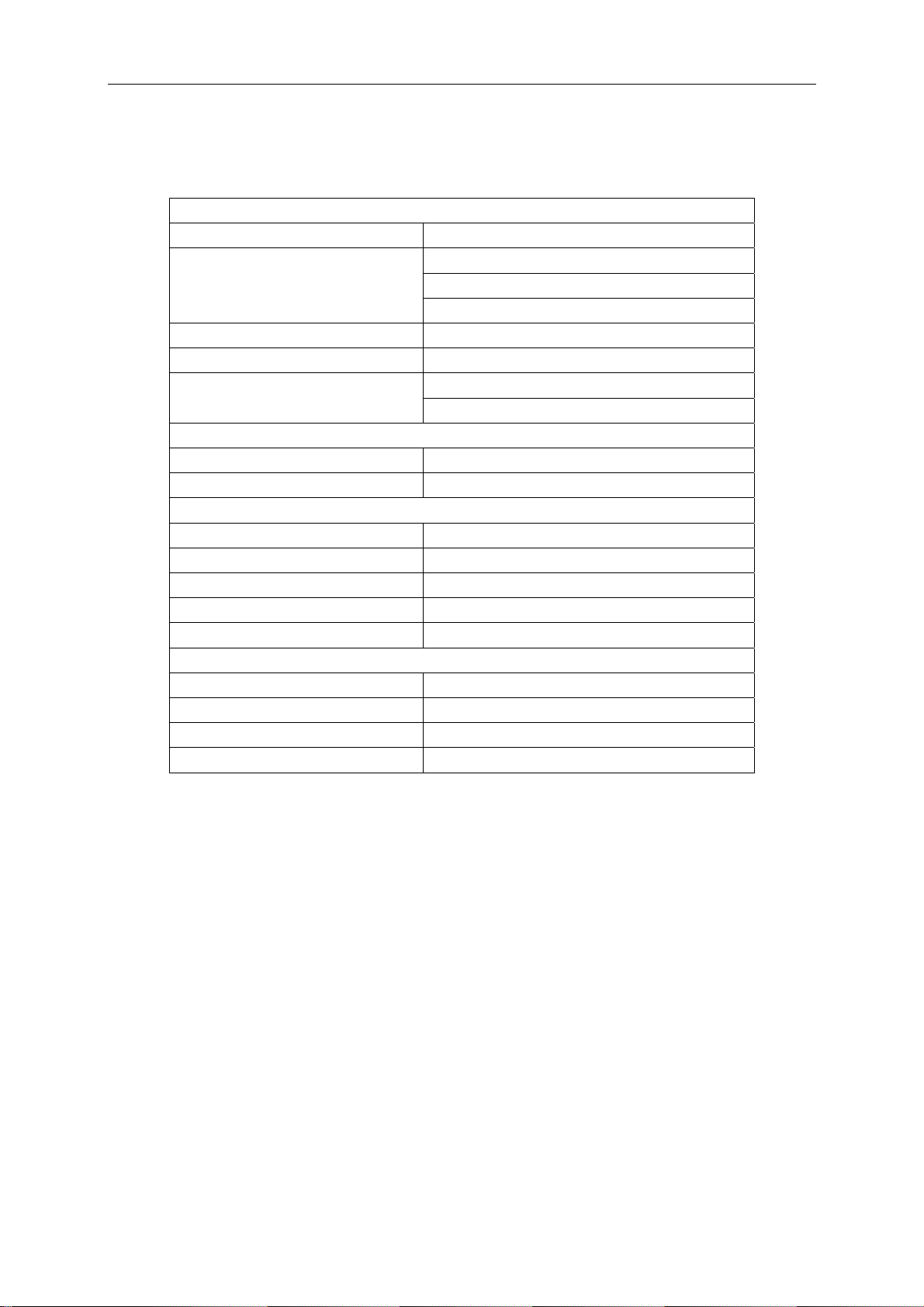

2.3 Specification

Power

Power line

Fuses

Power usage <=50W

Type Positive pressure volume

shock

Gas input

Gas type O2/N2O

Gas pressure 0.3-0.5Mpa

Environment

Ambient temperature

Relative humidity Not more than 80%

Atmospheric pressure 96kPa to104kPa

Noise of whole set <65dB(A)

Warming up no less than 5min

Miscellaneous

Dimensions 1350(H)×620(D)×650(W)mm

Work surface height 840mm

Writing tablet 540×300mm

Weight 120kg (265lb)

220V±22V, 50Hz±1Hz

φ5×20, 0.5A(F)

φ5×20, 5A(F)

φ5×20, 2A(F)

Type of protection: class I Protection against electrical

Degree of protection: Type BF

+5 °C to +40°C

5

Page 8

Aeon7400A Service Manual

3 Checking

3.1 Preoperative Checkout procedures

Test interval Preoperative Checkout should be done in the following situation:

Before the first patient’s use everyday.

Before every patient’s use.

Perform the programs according to requirements after repair or maintenance.

Test schedule is given in the table below:

Before use of the first patient each day Before use of each patient

System check:

Power failure alarm test:

Gas pipeline and gas cylinder test:

Flow control test:

Vaporizer installation and test

Alarm test:

Breathing system test:

Ventilator test:

WARNING: Do not use this system before the operation and maintenance manual

are read and understood.

• Whole system connection

• All warnings and cautions

• Using guide of each system module

Breathing system test:

Ventilator test:

• Testing method of each system module

Before using this system:

• Complete all tests of this section

• Test all the rest of system modules

If test failure, do not use this system. Please contact service representative.

6

Page 9

Aeon7400A Service Manual

3.1.1 System Checkout

WARNING: make sure the breathing circuit is connected correctly and in good

condition.

Make sure:

1 Equipment is in good condition.

2 All the components are correctly connected.

3 Breathing circuit is correctly connected and in good condition; there is sufficient

absorbent in the breathing system.

4 Vaporizer is in lock position and is filled with sufficient anesthetic.

5 The connection and pressure of pipeline gas supply system are correct.

6 The connected cylinder valve should be closed if there are backup cylinders.

WARNING: Do not leave the cylinder valves open during pipeline gas supply

period; otherwise, cylinder gas supply will be used up and lead to

insufficient supply in case of pipeline malfunction.

7. The required emergency device is ready and in good condition.

8. The device for airway maintenance, organ cannula are ready and in good condition.

9. The applicable anesthetic and emergency medicine are ready.

10. Make sure the truckles are tight and locked and free of motion.

11. Connect the power cord to the AC power outlet. The power indicator light will light up

when power is connected.

If failure, that means no electric power supplying. Exchange other sockets, close breaker,

or replace power cord.

3.1.2 Mains failure alarm test

1 Turn power switch to “I”, stand-by interface appears after self-test.

2 After operating 5 minutes, pull out power cord.

3 Make sure that power off failure alarm occurs, it has the following characteristics:

• Alarm sound;

4 Connect power cord again.

5 Make sure the alarm eliminate.

7

Page 10

Aeon7400A Service Manual

3.2 Testing the gas supply pipeline and the gas cylinder

CAUTION: A user must confirm that gas supply is connected correctly; there is

no any disconnection, leakage, faulty connection in gas circuits and

pressure indicates correctly. Stop using and check gas connections if

abnormal.

CAUTION: To prevent from damage:

Open cylinder valve slowly.

Never control the flow with excessive force.

Skip step 2 if the system is not using cylinder gas supply.

1 Disconnect all pipeline gas supply and close all the cylinder valves.

• If the readings of the pipeline pressure gauge and cylinder pressure gauge are not

zero.

• Switch on O

supply.

2

• Adjust flow control to middle range.

• Make sure all the pressure gauges are reset to zero except the O

• Switch off O

• Make sure the O

supply.

2

pressure gauge is reset to zero. The low O2 supply alarm should

2

pressure gauge.

2

be on when pressure drops.

2 Make sure cylinders are fully filled:

• Open each cylinder valve.

• Make sure the pressure of each cylinder is high enough. In case the pressure is

insufficient, close the corresponding cylinder valve and install a fully filled cylinder.

3 Test cylinder high pressure leak one by one.

4 Close flowmeters.

5 Open the cylinders.

6 Record the cylinder pressures.

7 Close the cylinder valves.

8

Page 11

Aeon7400A Service Manual

8 Begin to record the pressures after one minute. If O

pressure drops to 5000 kPa, it

2

means there is a leakage:

• If leakage exists, according to direction of section 5.5, replace a new sheet gasket,

and then tighten T handle.

• Perform this step again. If leakage exists all the same, do not use this system.

9 Step 5 ~ 7 should be repeated for all the cylinders. N

O pressure drop in one minute

2

should not exceed 700 kPa.

10 Close all the cylinder valves.

CAUTION: Do not leave the cylinder valves open during pipeline gas supply

period; otherwise, cylinder gas supply will be used up and lead to

insufficient supply in case of pipeline malfunction.

11 Connect pipeline gas supply.

12 Check pipeline pressure according to the table below:

ANSI (U.S. and International), Australia, Canada,

345 kPa (50 psig)

France and Japan

ISO, Italy, Scandinavia, South Africa, Spain and Switzerland 414 kPa (60 psig)

Austria and Germany 500 kPa (75 psig)

9

Page 12

Aeon7400A Service Manual

3.3 Monitoring Flow Control

WARNING: Refer to Step 1 to 13 of monitoring without oxygen for monitoring

without oxygen.

Refer to Step 1 to 13 of monitoring with oxygen for monitoring with

oxygen.

3.3.1 Monitoring without oxygen

WARNING: The monitoring system cannot be replaced by link system. The fresh

gas containing enough oxygen may not avoid the existence of low

oxygen mixture in the breathing circuit.

If N

O exists, it will pass through the system during the test, which

2

should be securely collected and removed.

Patients may be injured by improper gas mixture. The link system

should not be used if a proper ratio of O

and N2O is not possible.

2

The following procedures can test whether the link system has

serious malfunction; however, it cannot determine whether the

calibration is correct.

CAUTION: The gas flow switch should be adjusted slowly. Do not turn it hard

when the reading of the flowmeter goes beyond the maximum or

minimum flow rate; otherwise, the control valve can be damaged and

the control will not work.

Follow the steps to test the flow control:

1. Connect the pipeline gas supply or open the cylinder valves slowly.

2. Turn clockwise all the flow control till the end (minimum flow).

3. Turn on mains switch.

4. Make sure:

• The oxygen flow is between 25 mL/min and 75 mL/min.

• No gas flowing in any other flow tube.

• Step 5 and step 6 are only applicable for the N

10

O system test.

2

Page 13

Aeon7400A Service Manual

WARNING: During Step 5 to Step 6, keep link systems working state.

Only adjust testing of control (N

Adjust flow according to order (N

If adjustable range exceeds, please adjust flow control to the nearest

place and perform this step again.

5. To test the flow increase of the link system:

• Turn clockwise the N

• Turn counterclockwise the N

• Set N

O flow control to the rate described in the following table. The O2 flow must be

2

O and O2 flow control till the end (minimum flow).

2

O flow control slowly.

2

higher than the minimum flow limit.

Set N

O flow to

2

O2 flow must be higher than the minimum flow

(liters per minute):

0.6 0.2

1.5 0.5

3 1.0

7.5 2.5

O in step 5 and O2 in step 6).

2

O firstly O2 secondly).

2

(liters per minute):

6. This step tests the function of the Link System when flow is reduced, you should:

Set N

(liters per minute):

O flow to

2

O2 flow must be higher than the minimum flow

(liters per minute):

6.0 2.0

3.0 1.0

0.6 0.2

7. Adjust full flow of all the gas to ensure that the flowmeter float must move smoothly.

8. Shut off the oxygen supply either by closing the oxygen cylinder valve, or by disconnecting

the oxygen pipeline supply.

9. Make sure:

• As pressure decreases, the oxygen-supply failure alarm must continuously sound.

• Disconnect the flow of nitrous oxide and oxygen to be sure that the oxygen flow will be

the last to stop.

• If the oxygen is the driving gas of the ventilator, the oxygen-supply failure alarm must

continuously sound.

10. Turn all of the flow control valve knobs completely clockwise to the minimum flow.

11. Reconnect oxygen pipeline supplies or slowly open the oxygen cylinder valve.

12. Turn off mains supply.

11

Page 14

Aeon7400A Service Manual

3.3.2 Monitoring with Oxygen

WARNING: The monitoring system cannot be replaced by link system. The fresh

gas containing enough oxygen may not avoid the existence of low

oxygen mixture in the breathing circuit.

O exists, it will pass through the system during the test, which

If N

2

should be securely collected and removed according to safe and

eligible methods.

Patients may be injured by improper gas mixture. The link system

should not be used if a proper ratio of O

CAUTION: Before continuous testing, perform test of the O2 monitoring device

according to step 8 in section 3.6.

and N2O is not possible.

2

Follow the steps to test the flow control:

1. Connect the pipeline gas supplies, or slowly open the cylinder valve.

2. Turn all of the flow control valve knobs completely clockwise to the minimum flow.

3. Turn on mains switch.

4. Make sure:

• The oxygen flow is between 25 mL/min and 75 mL/min.

• No gas flowing in any other flow tube.

• Step 5 and step 6 are only applicable for the N

O system test.

2

WARNING: During Step 5 to Step 6, keep link systems working state.

Only adjust testing of control (N

Adjust flow according to order (N

O in step 5 and O2 in step 6).

2

O firstly O2 secondly).

2

The oxygen sensor being used must be calibrated correctly.

12

Page 15

Aeon7400A Service Manual

5 To test the flow increase of the link system:

• Turn clockwise the N

• Turn counterclockwise the N

O and O2 flow control till the end (minimum flow).

2

O flow control slowly.

2

• Make sure that the oxygen flow is increasing. The concentration of the oxygen tested

must ≥ 21% during the complete process.

6 To test the flow increase of the link system:

• Set the nitrous oxide flow to 9.0 L/min.

• Set the oxygen flow to 3/min or higher.

• Turn the flow control valve knob of the oxygen clockwise slowly.

• Be sure that the oxygen flow is getting reduced. The concentration of the oxygen tested

must ≥ 21% during the complete process.

7 Adjust all of the gas full flow to ensure that the flowmeter floats must move smoothly.

8 Shut off the oxygen supply either by closing the oxygen cylinder valve, or by disconnecting

the oxygen pipeline supply.

9 Make sure:

• As pressure decreases, the oxygen-supply failure alarm must continuously sound.

• Disconnect the flow of nitrous oxide and oxygen to be sure that the oxygen flow will be

the last to stop.

• If oxygen is the driving gas of the ventilator, the oxygen-supply failure alarm must

continuously sound.

10 Turn all of the flow control valve knobs completely clockwise to the minimum flow.

11 Reconnect oxygen pipeline supplies or open the oxygen cylinder valve slowly.

12 Turn off mains supply.

13

Page 16

Aeon7400A Service Manual

3.4 Installing and testing of vaporizer

3.4.1 Installation

WARNING: Do not take the vaporizer away from the bypass valve with its locking

lever locked.

Do not use more than one vaporizer at the same time in this system.

Install vaporizers in accordance with the following steps:

1. The vaporizer must be disassembled and reinstalled if its top is not horizontal.

2. Set the locking lever of the vaporizer so that it is locked.

3. Try to lift the vaporizer directly upwards so as to separate itself from the bypass valve, but do

not pull the vaporizer forwards. Be careful not to rotate it on the bypass valve.

4. As the vaporizer is taken away from the bypass valve, reinstall the vaporizer and then follow

step 1 to step 3. Do not use this system if you cannot put return the vaporizer to a horizontal

position on the bypass valve.

5. Try on opening two vaporizers at the same time.

• Testing any possible instance of each combination.

• If more than one vaporizer can be opened at the same time, disassemble and reinstall

them, then perform step 1 to step 5.

3.4.2 Testing Vaporizer Back Pressure

CAUTION: About performance testing of vaporizer refer to relevant instruction

for use.

14

Page 17

Aeon7400A Service Manual

3.5 Testing alarm

1 Connect reservoir bag to patient end.

2 Set bag/ventilator switch to ventilator control.

3 Turn on mains switch.

4 Set control options:

Ventilation mode: IPPV mode

Ventilator: VT: 700ml

Anesthetic machine: O2 flow: minimum flow (25-75mL/min)

f: 20bpm

I:E: 1:2

All other gas: close

Press O

flush button to inflate bellows.

2

5 Set bag/ventilator switch to bag control, and then set to ventilator control again. Make sure:

• Auto ventilation start.

• Display right data on the screen.

• Bellow assembly up and down during auto ventilation.

6 Adjust O

flow to 5L/min.

2

7 Make sure:

• Pressure at the end of expiration is 0 cmH

O approximately.

2

• Right data displayed on the screen.

• Bellow assembly up and down during auto ventilation.

8 Test high airway pressure alarm:

• View airway pressure on the screen.

• Adjust lower limit of Paw to above High Pressure, and conform the alarm occurs.

• Adjust lower limit of Paw to below High Pressure, and conform the alarm eliminates.

9 Test low airway pressure alarm:

• Remove reservoir bag form the absorber cycle.

• Other alarm occurs, such as “Minute volume low”.

• Make sure that “Paw low” alarm occurs.

10 Turn off mains supply.

15

Page 18

Aeon7400A Service Manual

3.6 Testing the Breathing System

Refer to the operating manual and:

Verify the non-return valve in the Breathing circuit module works normally:

The non-return exhalation valve will ascend during the exhalation period while it will descend

during the inhalation period.

WARNING: Objects in the breathing system can interrupt or disrupt the delivery

of breathing system gas, resulting in possible patient death or injury:

Do not use any testing plug small enough to slip completely into the

breathing system.

3.6.1 Checking Oxygen flush Switch

Press the oxygen flush button (the sound of gas should be heard from the fresh gas outlet) then

release. The button must immediately drop back to its position and stop delivering the gas.

3.6.2 Testing Breathing System

Turn the switch of the anesthesia machine to Manual Bag. Pressure gauge is zeroed. APL Valve

knob should be fully clockwise to the maximum. Connect the wye connector to the test lung.

Occlude the manual reservoir bag on the port below the switch. Press the oxygen flush button or

open the flowmeter to make the indication of the pressure gauge achieve 3KPa, then release the

button and close the flowmeter. After 20 seconds observation, the pressure indicated by the

pressure gauge must not exceed 0.3KPa.

3.6.3 Testing APL Valve

Adjust the positions of every switch and knob according to the method of testing Breathing

System Leak. Open the oxygen flow to 5 liters per minute. Adjust the APL valve to position the

pressure of the pressure gauge in different places respectively. The common gas outlet must

overflow some gas as the pressure is stable.

WARNING: Be sure that there is no any testing plug or foreign objects in the

Breathing

System.

16

Page 19

Aeon7400A Service Manual

3.7 Testing Ventilator

1 Connect the test lung to the patient circuit port.

2 Set the Reservoir bag / Ventilator switch to the Reservoir bag position.

3 Turn on mains switch.

4 Set control options:

Ventilation mode: IPPV mode

Ventilator: VT: 700ml

f: 20bpm

I:E: 1:2

Anesthetic machine: O2 flow: less than 200mL

All other gas: close

Press O

flush to charge bellows.

2

5 Set the bag / Ventilator switch to ventilator control.

6 Press the Oxygen flush button to inflate the bellows.

7 Ensure:

• Auto ventilation start.

• No low pressure alarm.

• Ventilator displays the correct data.

• The bellows ascend and descend during the period of auto ventilation

8 Set the O

flow control to 5L/min.

2

9 Ensure:

• Ending expiratory pressure is about 0 cmH

2

O.

• Ventilator displays the correct data.

• The bellows inflate and scavenge during the period of auto ventilation.

10 Set the ventilator control and alarm limits to the proper clinical level.

11 Turn off mains supply and close all valves of gas cylinders if not to use the system.

17

Page 20

Aeon7400A Service Manual

12 Ensure that the things in the following table should be prepared completely.

Apparatus: Airway maintenance

Manual ventilation

Organ cannula

anesthesia and emergent drugs applicably

13 System preparation:

• Close all vaporizers.

• Open the APL valve.

• Set the bag / ventilator switch to bag control.

• Set all the flow controls to the minimum.

• Be sure that the breathing system connects correctly

WARNING: Be sure that the breathing system connects correctly.

WARNING: Flush the anesthesia machine for at least one minute by using O2 with

5L/min flow speed to remove unnecessary mixed gas and objects in

the system before connecting the equipment to the patient end.

WARNING: Anesthesia equipment must be connected to the waste gas

scavenging system to outlet the waste gas to prevent the staff

working in the operating rooms from injury.

This requirement must be followed in the testing and clinical

application.

18

Page 21

Aeon7400A Service Manual

4 Theory and Diagram

19

Page 22

Aeon7400A Service Manual

1 N

2 N

3 O

4 O

5 Pressure Gauge 28 O

6 at most two cylinders 29 Micro-checkvalve

7 Cylinder gas supply: input=2.5MPa to

10MPa; Output=350KPa.

pipeline gas supply: input=280KPa to

600KPa

8 Reducer (400kPa) 31 CGO

9 O2 reservoir 32 Absorber

10 Hooter 33 Airway pressure gauge

11 N

12 Reducer (250kPa) 35 Inspiratory valve

13 Magnetic valve 36 Turbo flow sensor

14 Silencer 37 Pressure sensor

15 Atmosphere 38 Patient

16 Venturi 39 Outdoor atmosphere

17 Flow control valve 40 Power cord

18 Reducer 41 AC inlet with fuse and filter

19 Safety valve (6kPa) 42 Power switch

20 Spill-over valve (0.1 to 0.3kPa) 43 Ventilator Panel

21 Expiratory valve 44 Display Panel

22 Bellows 45 Keyboard

23 Bag/Ventilator switch valve 46 Buzzer

O cylinder 24 Manual reservoir bag

2

O Pipeline 25 APL valve (0.19 to 0.6kPa)

2

cylinder 26 Flowmeters

2

pipeline 27 Vaporizer

2

flush

2

30 Pressure relief valve

O cut-off (20 to 200kPa) 34 Expiratory valve

2

20

Page 23

Aeon7400A Service Manual

5 User Maintenance

WARNING: To avoid fire:

z Use the lubricant approved for anesthesia or O

z Never oil or grease any anesthesia or O

2

equipments’ use.

2

equipment. In general,

oils and greases oxidize readily, and – the presence of O

highly flammable.

WARNING: Follow sterilizing control and security stipulations because used

equipment may contain blood and body fluids.

WARNING: Movable components and detachable parts can cause injury. Use

caution when system components and parts are being moved or

replaced.

WARNING: No shock and strong vibration should happen during transportation

because the glass cover of flowmeter is fragile.

WARNING: Disposal of waste or invalidated apparatus must be in accordance

with the relevant policies in local government.

– are

2

21

Page 24

Aeon7400A Service Manual

5.1 Repair Policy

Do not use malfunctioning equipment. Make all necessary repairs, or have the equipment

serviced by an authorized Aeonmed Service Representative. After repair, test the equipment to

ensure that it is functioning properly, in accordance with the manufacturer’s published

specifications.

To ensure full reliability, have all repairs and service done by an authorized Aeonmed

Representative. If this is not possible, replacement and maintenance of parts in this manual

should be performed by a competent, trained individual with experience in Anesthesia Systems

repair, and appropriate testing and calibration equipment.

CAUTION: No repair should ever be undertaken or attempted by anyone without

proper qualifications and equipment.

It is recommended that you replace damaged parts with components manufactured or sold by

Aeonmed. After any repair work, test the unit to ensure it complies with the manufacturer’s

published specifications.

Contact the nearest Aeonmed Service Center for service assistance. In all cases, other than

where Aeonmed’s warranty is applicable, repairs will be made at Aeonmed’s current list price for

the replacement part(s) plus a reasonable labor charge.

22

Page 25

Aeon7400A Service Manual

5.2 Maintaining Outline and Schedule

The following schedule is a recommended minimum standard based upon normal usage and

environmental conditions. Frequency of maintenance for the equipment should be higher if your

actual schedule is more than the minimum standard.

5.2.1 User maintenance

Minimum maintaining

Standard

Daily Clean the outer surface.

weekly Ventilate the system, open flowmeter, and make sure that

monthly Test leakage of bellows assembly. (refer to User Manual)

When cleaning and installing Check if any components are broken, and replace or

As required Replace new gasket of cylinder gas supply.

Planned maintaining Standard

the float move up and down smoothly. It can prevent

blocking and clinging.

repair them if necessary.

Perform flow sensor calibration when flow waveform is

unusual.

Open the drain valve and replace absorbent in the

absorber.

5.2.2 Permissive Repairing

Minimum maintaining

Standard

6 months Test electric current leakage.

6 months Test mechanical safety valve.

12 months Perform the maintenance, checking, testing, calibrating

Planned maintaining Standard

and replacing of the components stipulated in this manual

by qualified individuals.

Notes: This is the recommended minimum maintaining

level. Perform the local policies if they are equal to or

higher than those in this manual.

23

Page 26

Aeon7400A Service Manual

5.3 Replacing fuses

WARNING: Disconnect from power supply before replacing fuses, otherwise that

can injure operator even death.

WARNING: Replace fuses with only those of the specified type and current rating,

otherwise that can damage the equipment.

CAUTION: The fuse is fragile, so replacement should be carefully. Do not use

excessive force.

Replacing steps:

1 Plug the screwdriver to groove on the end of fuse box.

2 Turn counterclockwise 3 to 5 circles then pull out fuse tubes lightly.

3 Take off fuse tubes.

4 Enclose the new ones.

5 Push fuse tubes to original place gently.

6 Turn clockwise 3 to 5 circles with screwdriver to tighten.

7 Connect mains supply.

24

Loading...

Loading...