Page 1

Power & Energy Logger

Model PEL 105

User Manual

ENGLISH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Copyright © Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments. All rights reserved.

No part of this documentation may be reproduced in any form or by any means (including electronic storage and retrieval or translation into any other

language) without prior agreement and written consent from Chauvin Arnoux

This documentation is provided “as is,” without warranty of any kind, express, implied, or otherwise. Chauvin Arnoux®, Inc. has made every reasonable

effort to ensure that this documentation is accurate; but does not warrant the accuracy or completeness of the text, graphics, or other information contained in this documentation. Chauvin Arnoux

not limited to) physical, emotional or monetary damages due to lost revenues or lost profits that may result from the use of this documentation, whether

or not the user of the documentation has been advised of the possibility of such damages.

Chauvin Arnoux®, Inc, AEMC®, DataView®, AmpFlex®, and MiniFlex® are registered trademarks of AEMC® Instruments.

®

, Inc. shall not be liable for any damages, special, indirect, incidental, or inconsequential; including (but

®

, Inc., as governed by United States and International copyright laws.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Thank you for purchasing a Power Energy Logger Model PEL 105.

For best results from your instrument and for your safety, read the enclosed operating instructions carefully and comply

with the precautions for use. These products must be only used by qualified and trained users.

WARNING, risk of DANGER! The operator must refer to

these instructions whenever this danger symbol appears.

Useful information or hint to read. Main power supply input.

Equipment is protected by double insulation. Ground/Earth.

USB socket.

SD Card.

The product has been declared recyclable after analysis of its life cycle in accordance with the ISO14040 standard.

The CE marking guarantees conformity with European directives and with regulations covering EMC.

The trash can with a line through it means that in the European Union, the product must undergo selective disposal for the

recycling of electric and electronic material, in compliance with Directive WEEE 2002/96/EC.

Ethernet socket (RJ45).

Definition of Measurement Categories (CAT)

■ CAT II Measurement category II corresponds to measurements taken on circuits directly connected to low-voltage installations.

Example: power supply to domestic electrical appliances and portable tools.

■ CAT III Measurement category III corresponds to measurements on building installations.

Example: distribution panel, circuit-breakers, machines or fixed industrial devices.

■ CAT IV Measurement category IV corresponds to measurements taken at the source of low-voltage installations.

Example: power feeders, counters and protection devices.

PRECAUTIONS FOR USE

These warnings are provided to ensure the safety of personnel. Please read and comply with these precautions.

■ This instrument complies with safety standard IEC 61010-2-030, the leads comply with IEC 61010-031 for voltages of 1000V

in measurement category III or 600V in measurement category IV, and the current sensors comply with IEC 61010-2-032.

■ Carefully read and understand all required precautions when using this instrument. Failure to comply with these safety

instructions can create a risk of electric shock, fire, and explosion; resulting in destruction of the instrument, injury to the user,

and damage to the facility. If the instrument is used other than as specified in this manual, the protection provided by the

instrument may be impaired.

■ Do not use the instrument in an explosive atmosphere or in the presence of flammable gas or smoke.

■ Do not use the instrument on electrical networks with a rated voltage or category higher than those listed for the instrument.

■ Respect the maximum rated voltages and currents between terminals and in relation to ground/earth.

■ Do not use the instrument if it seems to be damaged, incomplete, or poorly closed.

■ Before each use, check the condition of the insulation of the leads, the instrument, and all accessories. Any insulation that

appears damaged (even partially) must be taken out of service for repair or disposal.

■ Use leads and accessories for voltage according to IEC 61010-031 and measurement categories at least equal to those of

the instrument. An accessory with a lower category reduces the category of the combined instrument/accessory combination

to that of the accessory.

■ Respect the environmental conditions of use listed in this manual.

■ Do not modify the instrument or replace components using substitute parts. Repairs and adjustments must be performed by

AEMC Instruments.

■ Use personal protection equipment when conditions require it.

■ Keep hands and fingers away from unused terminals.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

TABLE OF CONTENTS

Precautions for Use ........................................................................................................... iii

1. INTRODUCTION .............................................................................................................. 6

1.1 Receiving Your Shipment ........................................................................................................................................6

1.2 Ordering Information ...............................................................................................................................................6

1.2.1 Accessories .................................................................................................................................................. 7

1.2.2 Replacement Parts.......................................................................................................................................7

2. FEATURES ....................................................................................................................... 8

2.1 Description ..............................................................................................................................................................8

2.2 Front Panel .............................................................................................................................................................. 9

2.3 Input Terminals ......................................................................................................................................................10

2.4 Button Functions ................................................................................................................................................... 11

2.5 LCD Screens ......................................................................................................................................................... 12

2.6 LED Status Indicators ...........................................................................................................................................13

2.7 Installing the SD Card ...........................................................................................................................................14

3. SET UP & CONFIGURATION .......................................................................................... 15

3.1 Powering the Instrument ....................................................................................................................................... 15

3.1.1 Phase Voltage Power .................................................................................................................................15

3.2 Charging the Battery .............................................................................................................................................16

3.3 Turning the Instrument ON/OFF ............................................................................................................................16

3.3.1 Turning the Instrument ON .........................................................................................................................16

3.3.2 Turning the Instrument OFF .......................................................................................................................16

3.4 Bluetooth Enabling and Disabling ......................................................................................................................... 17

3.5 Wi-Fi Enabling and Disabling ................................................................................................................................17

3.6 Configuring the PEL 105 .......................................................................................................................................17

3.6.1 Configuration Mode ...................................................................................................................................18

3.6.2 Selecting the Hookup ................................................................................................................................19

3.6.3 Selecting Nominal Current and Voltage .....................................................................................................20

3.6.4 Setting the Aggregation Period for a Recording ........................................................................................ 22

3.7 Viewing Instrument Information .............................................................................................................................22

4. OPERATION ................................................................................................................... 23

4.1 Hooking Up to the Distribution System .................................................................................................................23

4.1.1 Single-Phase 2-Wire (1P-2W) ....................................................................................................................24

4.1.2 Single-Phase 3-Wire (1P-3W) ....................................................................................................................25

4.1.3 3-Phase 3-Wire ∆ (2 current probes) (3P-3W∆2) .......................................................................................25

4.1.4 3-Phase 3-Wire ∆ (3 current probes) (3P-3W∆3) .......................................................................................25

4.1.5 3-Phase 3-Wire Open ∆ (2 current probes) (3P-3WO2) .............................................................................26

4.1.6 3-Phase 3-Wire Open ∆ (3 current probes) (3P-3WO3) .............................................................................26

4.1.7 3-Phase 3-Wire Y (2 current probes) (3P-3WY2) .......................................................................................26

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 5

4.1.8 3-Phase 3-Wire Y (3 current probes) (3P-3WY3) .......................................................................................27

4.1.9 3-Phase 3-Wire ∆ Balanced (1 current probe) (3P3W∆b) ..........................................................................27

4.1.10 3-Phase 4-Wire Y (3 current probes) (3P-4WY) .......................................................................................27

4.1.11 3-Phase 4-Wire Y Balanced (3P-4WYb) ..................................................................................................28

4.1.12 3-Phase 4-Wire Y 2½ Element (3P-4WY2) ...............................................................................................28

4.1.13 3-Phase 4-Wire ∆ (3P-4W∆) ..................................................................................................................... 28

4.1.14 3-Phase 4-Wire Open ∆ (3P-4WO)...........................................................................................................29

4.1.15 DC 2-Wire (dC-2W) ..................................................................................................................................29

4.1.16 DC 3-Wire (dC-3W) ..................................................................................................................................29

4.1.17 DC 4-Wire (dC-4W) ..................................................................................................................................30

4.2 Viewing Data .........................................................................................................................................................30

4.2.1 Measurement Mode ................................................................................................................................... 31

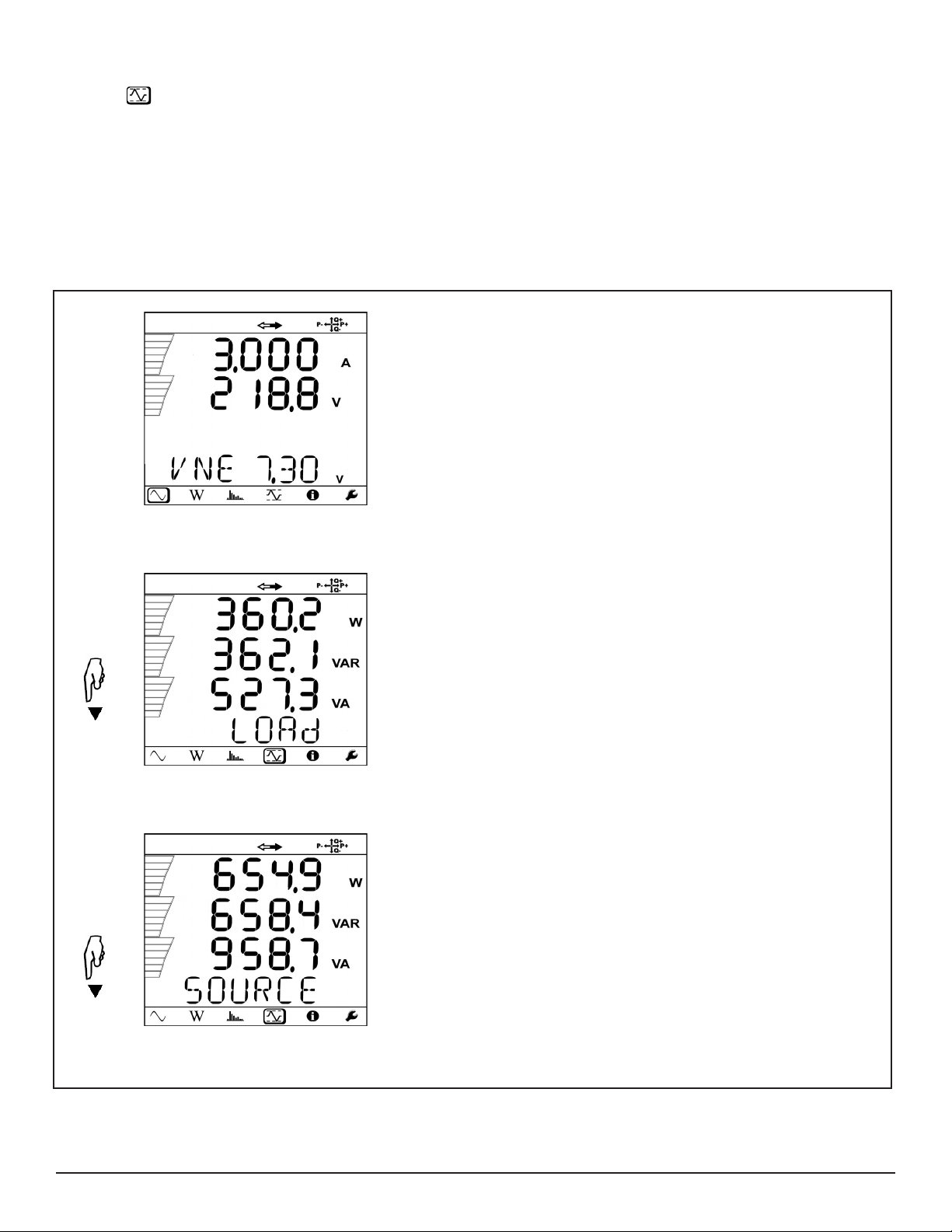

4.2.1.1 1-Phase 2-Wire (1P-2W) ....................................................................................................................31

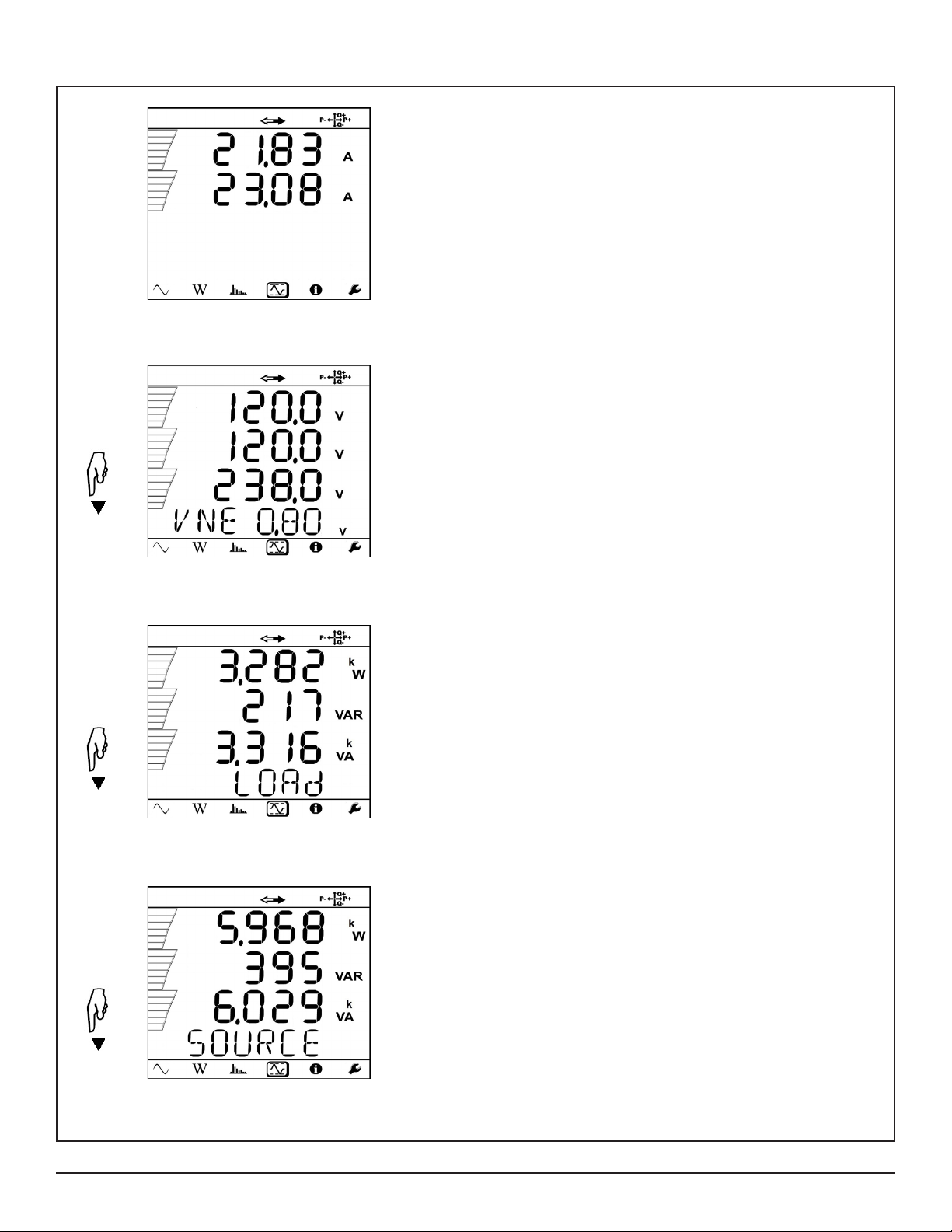

4.2.1.2 1-Phase 3-Wire (1P-3W) ....................................................................................................................32

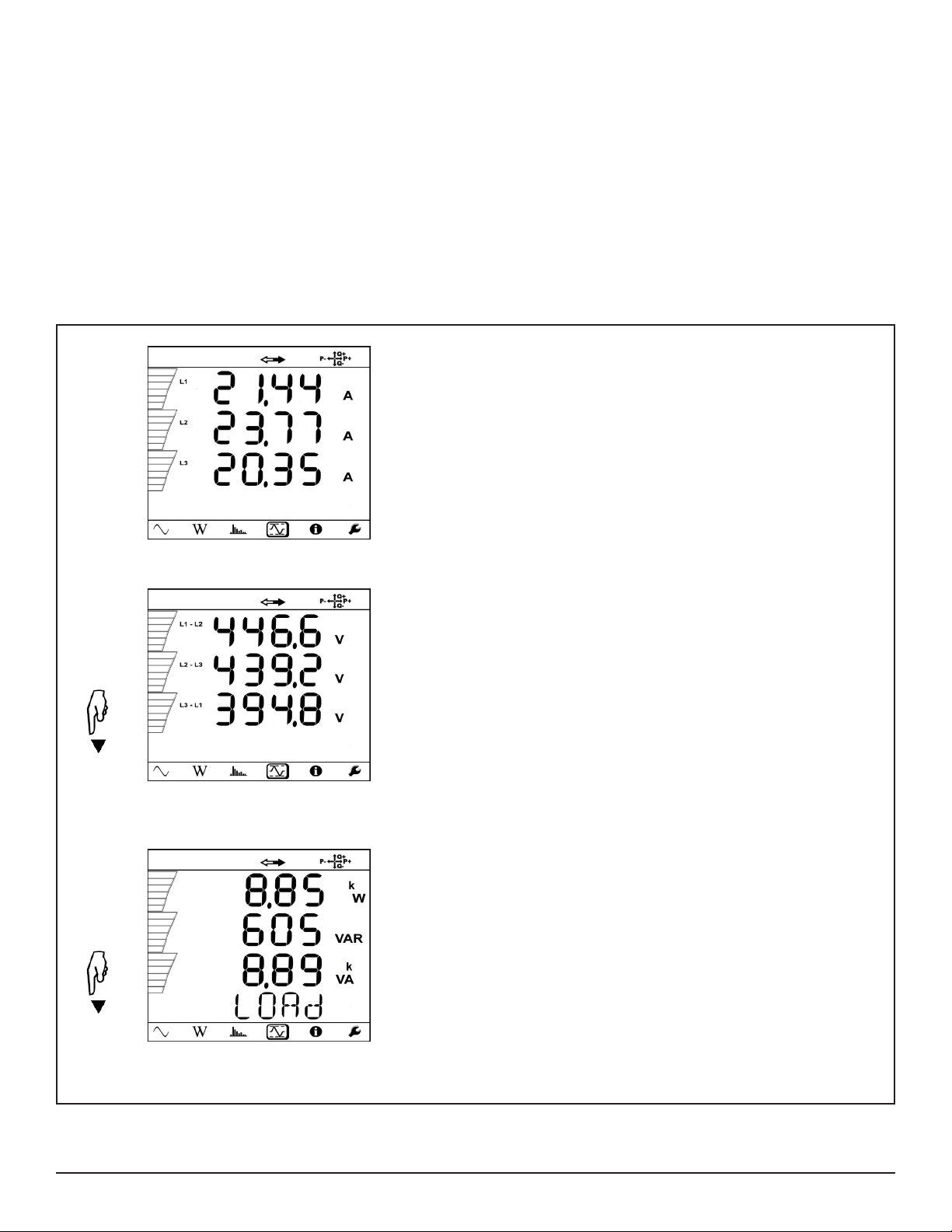

4.2.1.3 3-Phase 3-Wire Unbalanced .............................................................................................................. 33

4.2.1.4 3-Phase 3-Wire ∆ Balanced (3P-3W∆b) .............................................................................................35

4.2.1.5 3-Phase 4-Wire Unbalanced .............................................................................................................. 36

4.2.1.6 3-Phase 4-Wire Y Balanced (3P-4WYb) ............................................................................................38

4.2.1.7 DC 2-Wire (dC-2W) ............................................................................................................................39

4.2.1.8 DC 3-Wire (dC-3W) ............................................................................................................................40

4.2.1.9 DC 4-Wire (dC-4W) ............................................................................................................................41

4.2.2 Energy Mode .............................................................................................................................................. 42

4.2.2.1 AC Energy Screens ............................................................................................................................42

4.2.2.2 DC Energy Screens ............................................................................................................................45

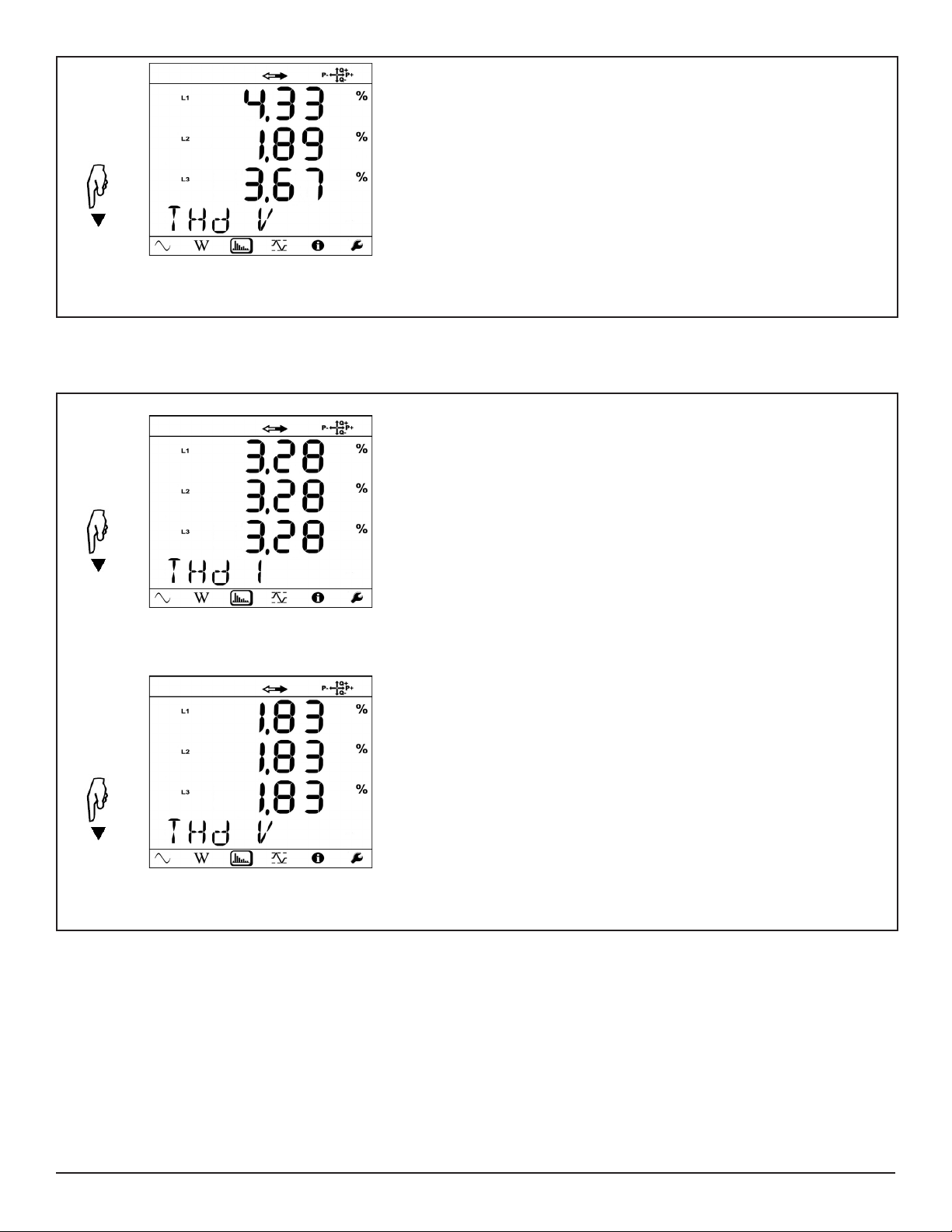

4.2.3 Harmonics Mode........................................................................................................................................46

4.2.3.1 1-Phase 2-Wire (1P-2W) ....................................................................................................................46

4.2.3.2 1-Phase 3-Wire (1P-3W) ....................................................................................................................46

4.2.3.3 3-Phase 3-Wire Unbalanced .............................................................................................................. 47

4.2.3.4 3-Phase 3-Wire ∆ Balanced (3P-3W∆b) .............................................................................................48

4.2.3.5 3-Phase 4-Wire Unbalanced .............................................................................................................. 48

4.2.3.6 3-Phase 4-Wire Balanced (3P-4WYb) ................................................................................................ 49

4.2.4 Maximum Mode ......................................................................................................................................... 50

4.2.4.1 1-Phase 2-Wire (1P-2W) ....................................................................................................................50

4.2.4.2 1-Phase 3-Wire (1P-3W) ....................................................................................................................51

4.2.4.3 3-Phase 3-Wire ..................................................................................................................................52

4.2.4.4 3-Phase 4-Wire .................................................................................................................................53

5. RECORDING DATA ........................................................................................................ 55

5.1 Recording Session Overview ................................................................................................................................55

5.2 Starting and Stopping a Recording ....................................................................................................................... 56

6. DATAVIEW® & PEL CONTROL PANEL ............................................................................. 57

6.1 Installing DataView ................................................................................................................................................58

6.2 The PEL Control Panel ..........................................................................................................................................61

6.3 Connecting to the Computer .................................................................................................................................61

6.3.1 USB ............................................................................................................................................................ 62

6.3.2 Bluetooth .................................................................................................................................................... 62

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

3

Page 6

6.3.3 Wi-Fi Direct Connection ............................................................................................................................. 63

6.3.4 Point-to-Point Ethernet Cable .................................................................................................................... 63

6.3.5 Ethernet Network via LAN or Wi-Fi ............................................................................................................ 63

6.3.6 Network via IRD Server .............................................................................................................................. 64

6.4 Setting Date and Time ...........................................................................................................................................64

7. SPECIFICATIONS .......................................................................................................... 65

7.1 Reference Conditions ............................................................................................................................................ 65

7.2 Electrical Specifications ........................................................................................................................................65

7.2.1 Voltage Inputs ............................................................................................................................................65

7.2.2 Current Inputs ............................................................................................................................................65

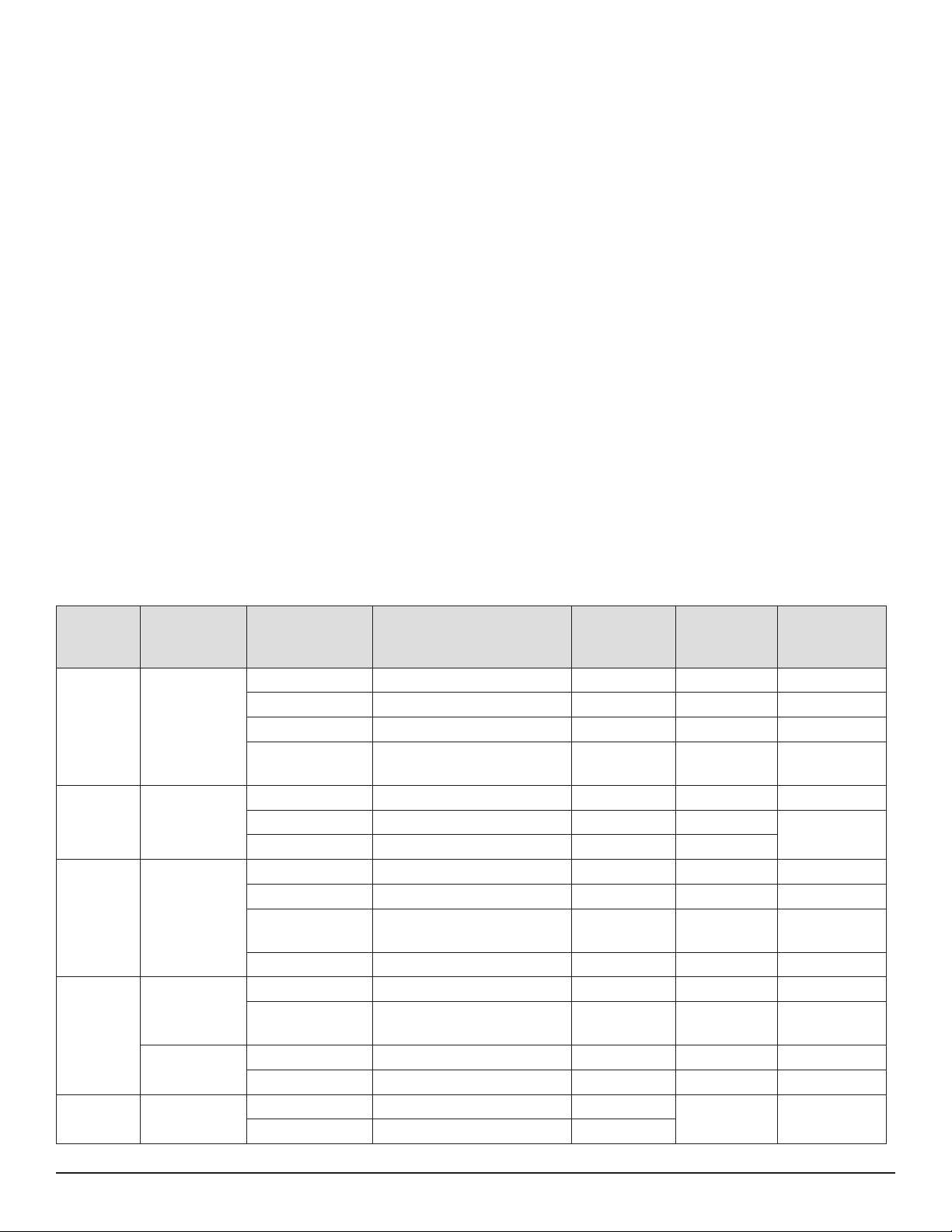

7.2.3 Measurement Ranges ................................................................................................................................ 66

7.2.3.1 Measurement Specifications at 50/60Hz .......................................................................................... 66

7.2.3.2 Measurement Specifications at 400Hz .............................................................................................67

7.2.3.3 Measurement Specifications for DC ................................................................................................. 68

7.2.3.4 Temperature .......................................................................................................................................69

7.2.3.5 Common Mode Rejection .................................................................................................................. 69

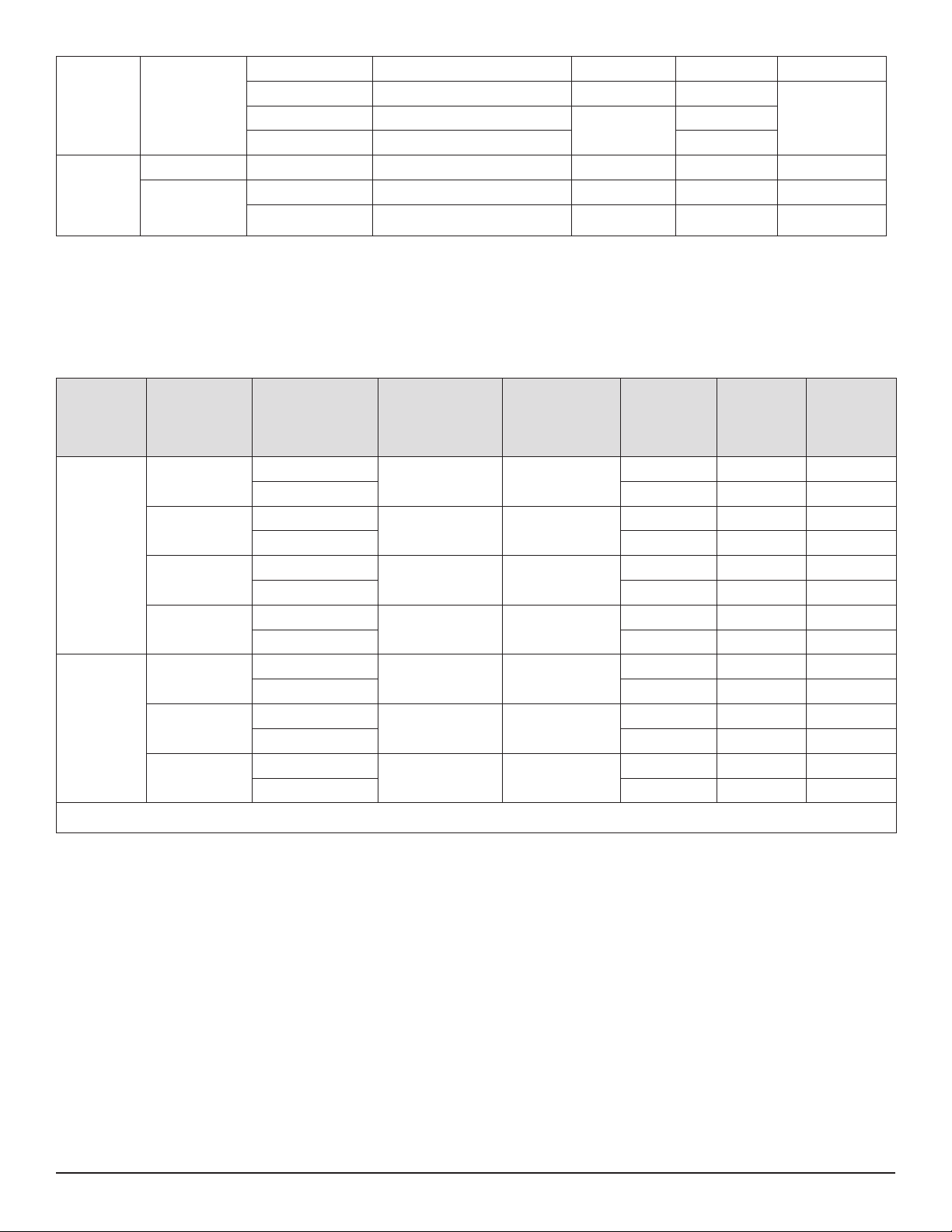

7.2.4 Current Probe Specifications ..................................................................................................................... 69

7.2.4.1 Current Probes with 1V Output .......................................................................................................... 69

7.2.4.2 AmpFlex®/MiniFlex® ........................................................................................................................... 70

7.3 Communication ..................................................................................................................................................... 70

7.4 Power Consumption ..............................................................................................................................................71

7.5 Physical .................................................................................................................................................................71

7.6 Environmental ........................................................................................................................................................72

7.7 Electrical Safety .....................................................................................................................................................72

7.8 Electromagnetic Compatibility ..............................................................................................................................72

7.9 Memory Card ........................................................................................................................................................72

7.10 Current Probes and Sensors ............................................................................................................................... 72

7.10.1 AmpFlex® Model A196-24-BK .................................................................................................................73

7.10.2 MiniFlex® Model MA193 ........................................................................................................................... 73

7.10.3 Model J93 ................................................................................................................................................74

7.10.4 Model MR193-BK ....................................................................................................................................74

7.10.5 Model MN93-BK ...................................................................................................................................... 75

7.10.6 Model SR193-BK ..................................................................................................................................... 75

7.10.7 Model MN193-BK .................................................................................................................................... 76

7.10.8 Model SL261 ............................................................................................................................................ 76

7.11 Voltage Test Leads ..............................................................................................................................................77

8. MAINTENANCE & TROUBLESHOOTING ........................................................................ 78

8.1 Maintenance .......................................................................................................................................................... 78

8.1.1 Erasing and Upgrading Memory ................................................................................................................ 78

8.1.2 Upgrading Firmware ..................................................................................................................................78

8.1.3 Battery Maintenance .................................................................................................................................. 80

8.1.4 Cleaning the Instrument ............................................................................................................................. 80

8.2 Troubleshooting ..................................................................................................................................................... 80

8.2.1 Instrument Does Not Turn ON....................................................................................................................80

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 7

8.2.2 Instrument Turns ON but Does Not Function ............................................................................................81

8.2.3 Cannot Configure the Instrument ...............................................................................................................81

8.2.4 Recording Sessions Do Not Start .............................................................................................................. 81

8.2.5 Recording Sessions End Prematurely ........................................................................................................81

8.2.6 Cannot Connect to a Computer .................................................................................................................81

8.2.7 Cannot Turn OFF the Instrument ...............................................................................................................82

APPENDIX A: THEORY OF OPERATION ............................................................................. 83

A.1 Sampling ............................................................................................................................................................... 83

A.1.1 Locking the Sampling Frequency .............................................................................................................. 84

A.1.2 AC/DC ........................................................................................................................................................ 84

A.1.3 Neutral Current Measurement ...................................................................................................................84

A.1.4 “200ms” Quantities ....................................................................................................................................84

A.1.5 “1s” Quantities (one second) .................................................................................................................... 84

A.1.6 Aggregation ...............................................................................................................................................84

A.1.7 Minimum and Maximum ........................................................................................................................... 84

A.1.8 Energy Calculations .................................................................................................................................. 85

A.2 Phase Sequence ................................................................................................................................................... 85

A.2.1 Current Phase Sequence .......................................................................................................................... 85

A.2.2 Voltage Phase Sequence ..........................................................................................................................86

A.2.3 Current vs Voltage Phase Sequence ........................................................................................................87

APPENDIX B: MEASUREMENT QUANTITIES ..................................................................... 88

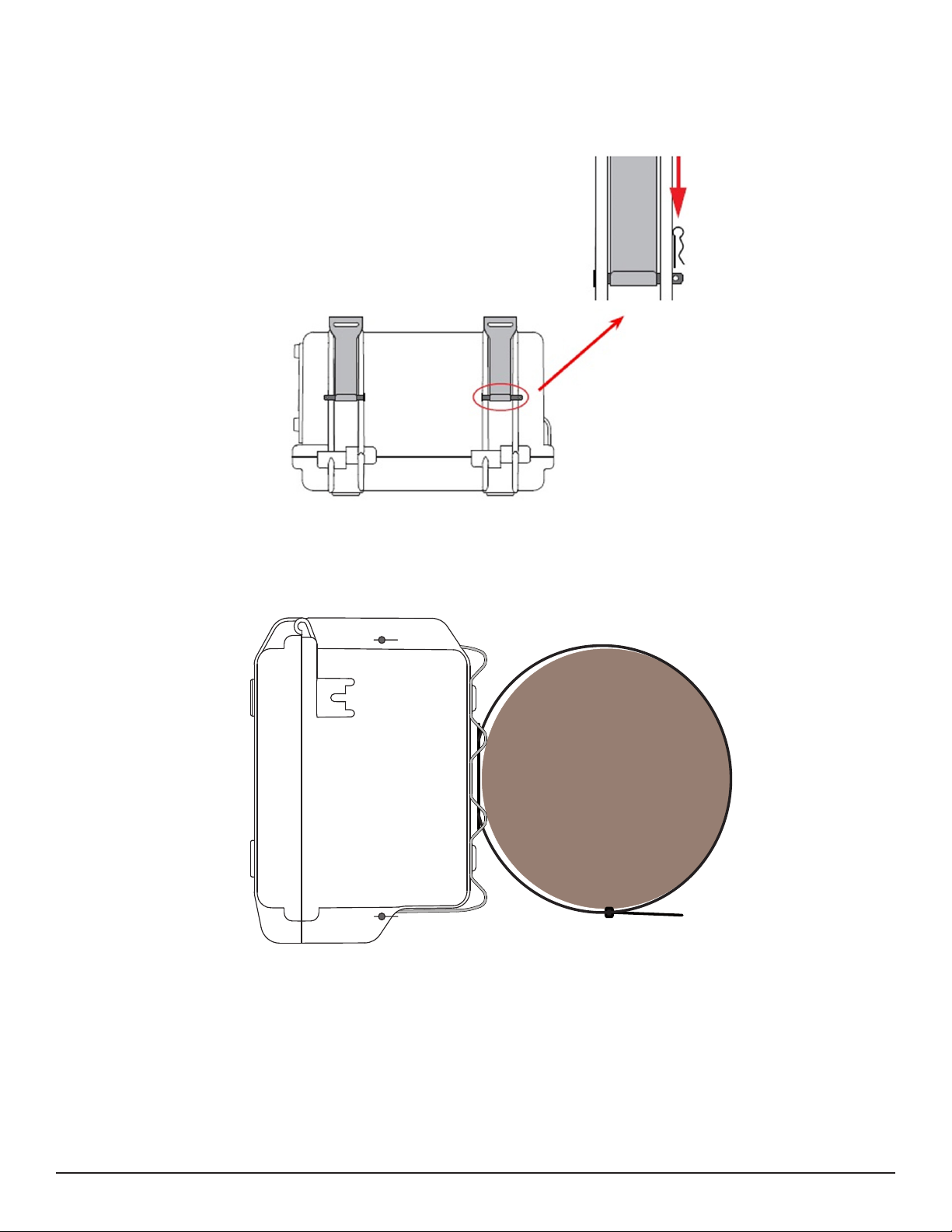

APPENDIX C: POLE MOUNTING ........................................................................................ 96

GLOSSARY ........................................................................................................................ 98

Limited Warranty ............................................................................................................101

Warranty Repairs ............................................................................................................101

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

5

Page 8

1. INTRODUCTION

1.1 Receiving Your Shipment

Upon receiving your PEL 105 product package, ensure the contents are consistent with the packing list. Notify your

distributor of any missing items. If the equipment appears to be damaged, file a claim immediately with the carrier and notify

your distributor at once, providing a detailed description. Save the damaged packing container to substantiate your claim.

1.2 Ordering Information

Power & Energy Logger Model PEL 105 (no sensors) ..................................................................................... Cat. #2137.57

Power & Energy Logger Model PEL 105 (with four A196-24-BK sensors) ...................................................... Cat. #2137.59

Shipping Contents:

(1) Power & Energy Logger

Model PEL 105

Cat. #2137.57 or Cat. #2137.59

(5) Black Test Leads and Alligator Clips

Cat. #2140.73*

(*Replacement comes in Qty of 1)

®

(4) 24" AmpFlex

(Only Shipped with PEL 105 Cat. #2137.59)

Also Includes:

• 4 GB USB Stick (DataView/User Manual)

• 9.6V NiMh Battery - installed

• 8 GB SD-Card - installed

• High Voltage Warning/Caution Card

Model A196-24-BK

Cat. #2140.75

(1) Power Adapter 110/240V

w/ Power Cord

Cat. #5000.19

(12) Color-coded

ID Markers

Cat. #2140.45

(1) Large Classic Tool Bag

Cat. #2133.73

Accessory Pouch

Cat. #2137.80

(1) USB SD-Card Adapter

Cat. #5000.45

(1) 5 ft USB Cable

Cat. #2140.46

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 9

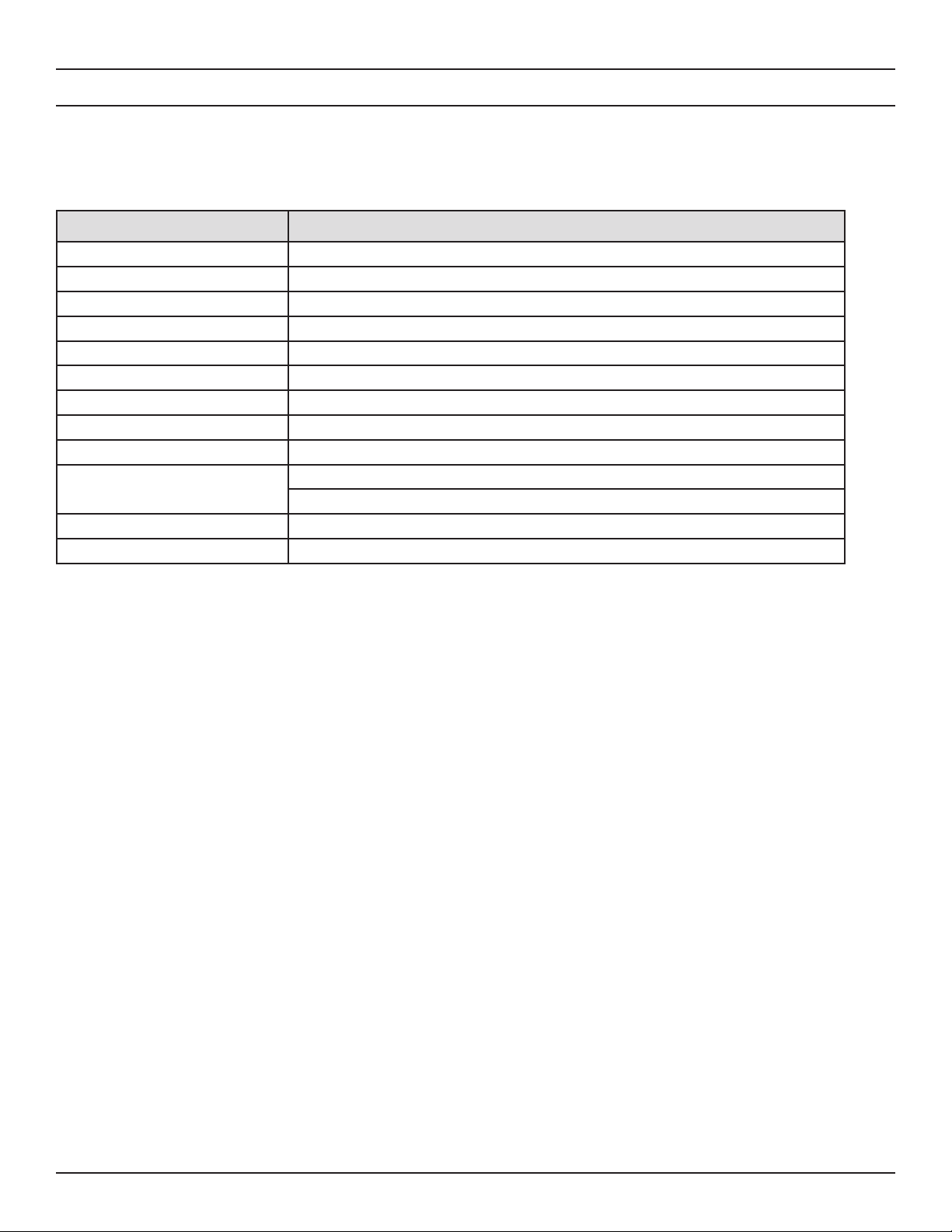

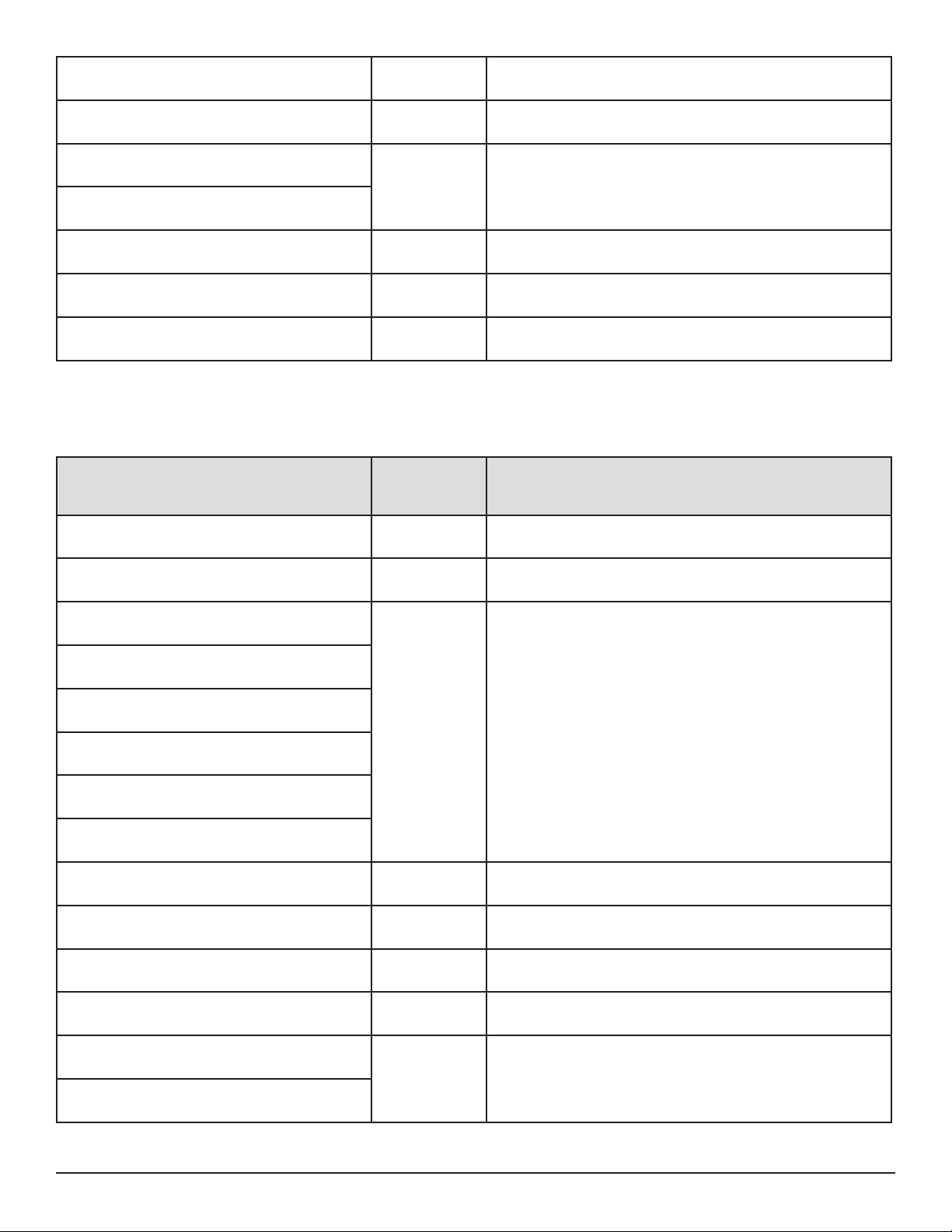

1.2.1 Accessories

USB cable, A/B 10 ft (3m) ................................................................................................................................Cat. #2136.80

Pole Mounting Kit .............................................................................................................................................Cat. #2137.81

AC/DC Current Probe Model J93 .....................................................................................................................Cat. #2140.49

AC/DC Current Probe Model MR193-BK .........................................................................................................Cat. #2140.28

AC Current Probe Model MN93-BK .................................................................................................................Cat. #2140.32

AC Current Probe Model SR193-BK ................................................................................................................Cat. #2140.33

AmpFlex® Sensor Model A196-24-BK (Waterproof) .........................................................................................Cat. #2140.75

AmpFlex® Sensor 36” Model 193-36-BK ........................................................................................................Cat. #2140.35

AC Current Probe Model MN193-BK ...............................................................................................................Cat. #2140.36

MiniFlex® Current Sensor 10” Model MA193-10-BK .......................................................................................Cat. #2140.48

AC/DC Current Probe Model SL261* ...............................................................................................................Cat. #1201.51

*BNC Adapter for Current Probe Model SL261..........................................................................................Cat. #2140.40

1.2.2 Replacement Parts

Large Classic Tool Bag .....................................................................................................................................Cat. #2133.73

Accessory Pouch .............................................................................................................................................Cat. #2137.80

Set of 12 Color-coded Input ID Markers ..........................................................................................................Cat. #2140.45

USB Cable A/B, 5 ft (1.5m) ...............................................................................................................................Cat. #2140.46

Lead – One 10 ft (3m) Black Lead (Waterproof cap) {Rated 1000V CAT IV} &

One Black Alligator Clip {Rated 1000V CAT IV, 15A, UL} .................................................................................Cat. #2140.73

AmpFlex® Sensor Model A196-24-BK (Waterproof) .........................................................................................Cat. #2140.75

Adapter – Replacement Power Adapter 110V/230V with US Power Cord ......................................................Cat. #5000.19

USB SD-card Adapter ......................................................................................................................................Cat. #5000.45

DataView® Software and Instrument Firmware Updates

Available at www.aemc.com

PEL Android App Available on the Google Play Store at

https://play.google.com/store/apps/details?id=com.aemc.pel&hl=en

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

7

Page 10

2. FEATURES

2.1 Description

The Power & Energy Logger Model PEL 105 provides all the necessary functions and features for recording power/energy

data for most 50Hz, 60Hz, 400Hz, and DC distribution systems worldwide. The instrument is designed for full outdoor or

indoor use, resistant to both water (IP67) and sunlight (UL746C f1).

The instrument measures phase-to-phase (U12, U23, U31), phase-to-neutral (V1, V2, V3) and neutral-to-ground/earth (VNE)

voltage up to 1000V in measurement Category IV, with pollution degree 4 (IEC 61010-1 Ed3). The instrument also measures

phase (I1, I2, I3) and neutral (IN) current, using a variety of external current probes/sensors.

A total of 17 types of electrical hookups are supported, including single-phase, split-phase, 3-phase 3-wire, 3-phase

4-wire, open, and DC 2-, 3- and 4-wire.

This measurement data is then used to calculate:

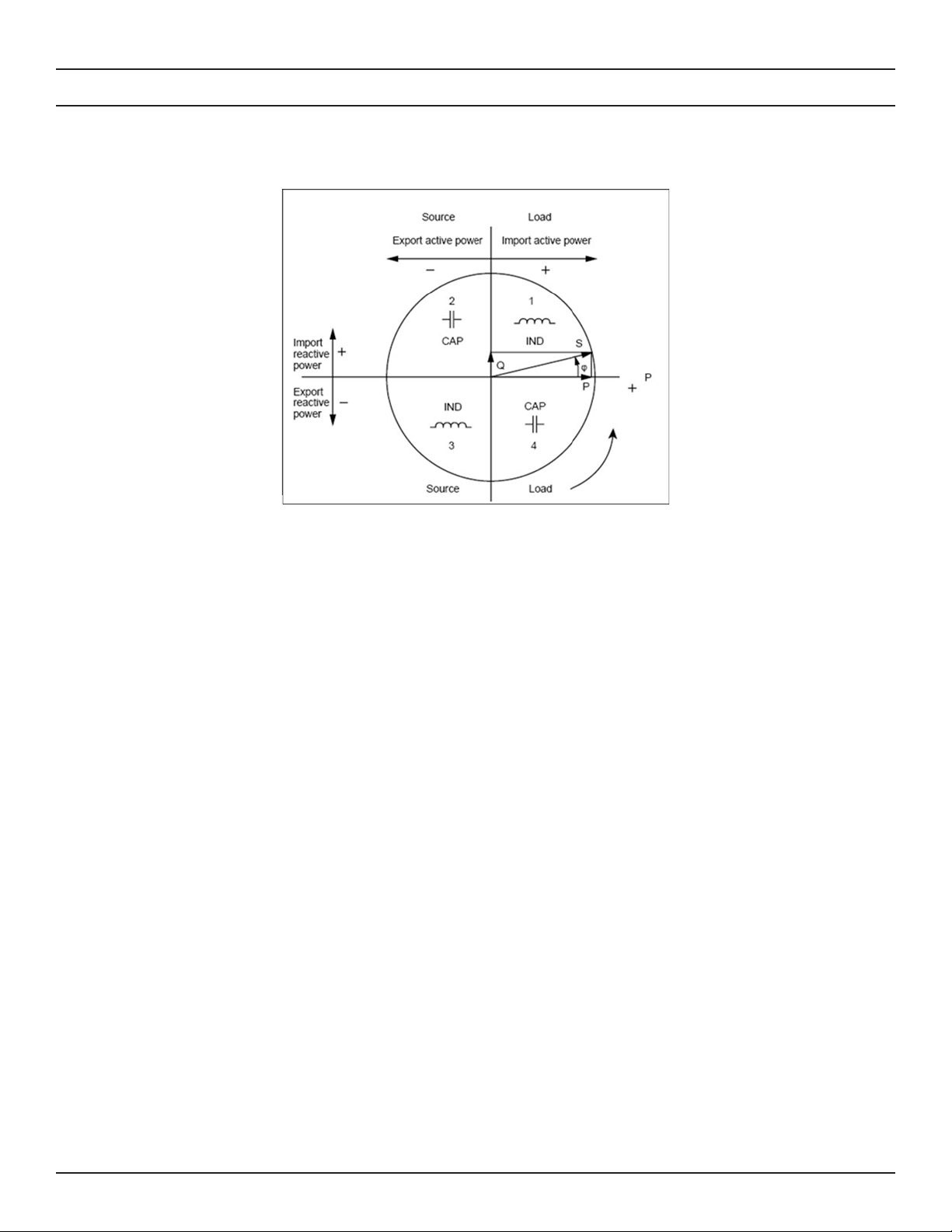

■ Power (VA, W, and var )

■ Energy (VAh, Wh (source and load), and VArh (4 quadrants)

■ Power Factor (PF), Cos ϕ, and Tan ϕ

■ Crest Factor

■ Total Harmonic Distortion (THD) for voltages and currents

■ Harmonics from the fundamental signal up to the 50th order for 50/60Hz voltages and currents

■ Frequency measurements

■ RMS and DC measurements @ 128 samples/cycle (each phase simultaneously)

The instrument can be connected to a computer running DataView data analysis software via Wi-Fi, Bluetooth©, network,

USB, or point-to-point Ethernet cable. The DataView PEL Control Panel on the computer can view real-time data, start and

stop a recording session, download previously recorded sessions stored on the instrument for further analysis and report

generation, and set configuration variables.

Other features include:

■ Measurements are sampled every 200ms and 1s, and can be aggregated from 200ms to 1 hour and stored in

a removable SD card or SDHC card (up to 32GB). This provides high data resolution and detail, especially for

detecting short-term electrical phenomena. For 50 and 60Hz systems, 200ms aggregation is calculated every 10

or 12 cycles, respectively. For 400Hz systems, aggregation is performed every 80 cycles.

■ Aggregated harmonics represent the minimum and maximum values of aggregated quantities for a given

duration. These values can be displayed on the LCD front panel display, or on the computer via the DataView

PEL Control Panel

■ The instrument can be powered from line voltage terminals or an AC/DC power adapter.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 11

2.2 Front Panel

14

The instrument front panel interface includes LED status indicators, screens that appear on the LCD, and buttons to

navigate these screens, select options, and enter data.

1

2

MODEL PEL 105

3

10

11

12

13

4

5

6

7

8

9

15

16

17

18

Figure 1

1. USB Port 10. Bluetooth LED

2. Ethernet Port 11. Recording LED

3. Power Input 12. Control Button

4. External Power LED 13. Power Button

5. Battery LED 14. Input Terminals

6. Phase Sequence LED 15. SD Card Slot

7. Overload LED 16. LCD Screen

8. SD Card LED 17. Directional Buttons (Up, Down, Left, Right)

9. Wi-Fi LED 18. Enter button

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

9

Page 12

2.3 Input Terminals

The instrument provides four current and five voltage input terminals for connecting to the electrical network under test.

These terminals are threaded to provide IP67 water-tight connections.

The instrument ships with five female “banana” voltage terminals that can be screwed onto the threaded voltage terminals.

IN I3 I2 I1

1

2

3

VN V3 V2 V1

Figure 2

1. Holes for color-coding clips (see below)

2. Current terminals

3. Voltage terminals

The number and configuration of probes and voltage leads depend on the hookup type. To help organize these connections,

12 sets of color-coded rings and inserts are supplied with your instrument. Use these ID markers to identify the leads and

terminals.

■ Detach the appropriate inserts and place them in the holes provided over the terminals (larger inserts for current

terminals, smaller inserts for voltage terminals).

■ Clip the rings of the same color to the ends of the lead you will connect to the terminal.

VE/GND

Figure 3

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 13

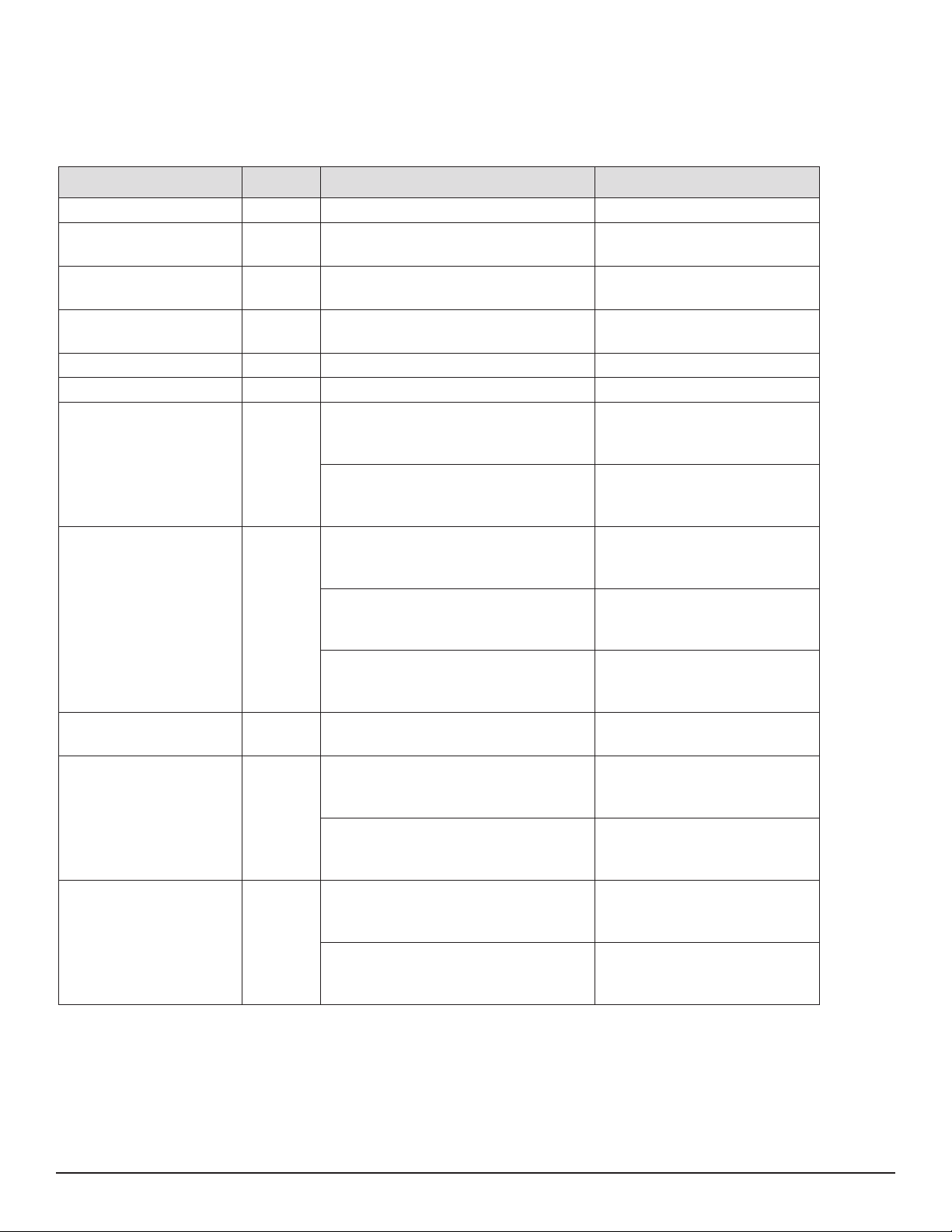

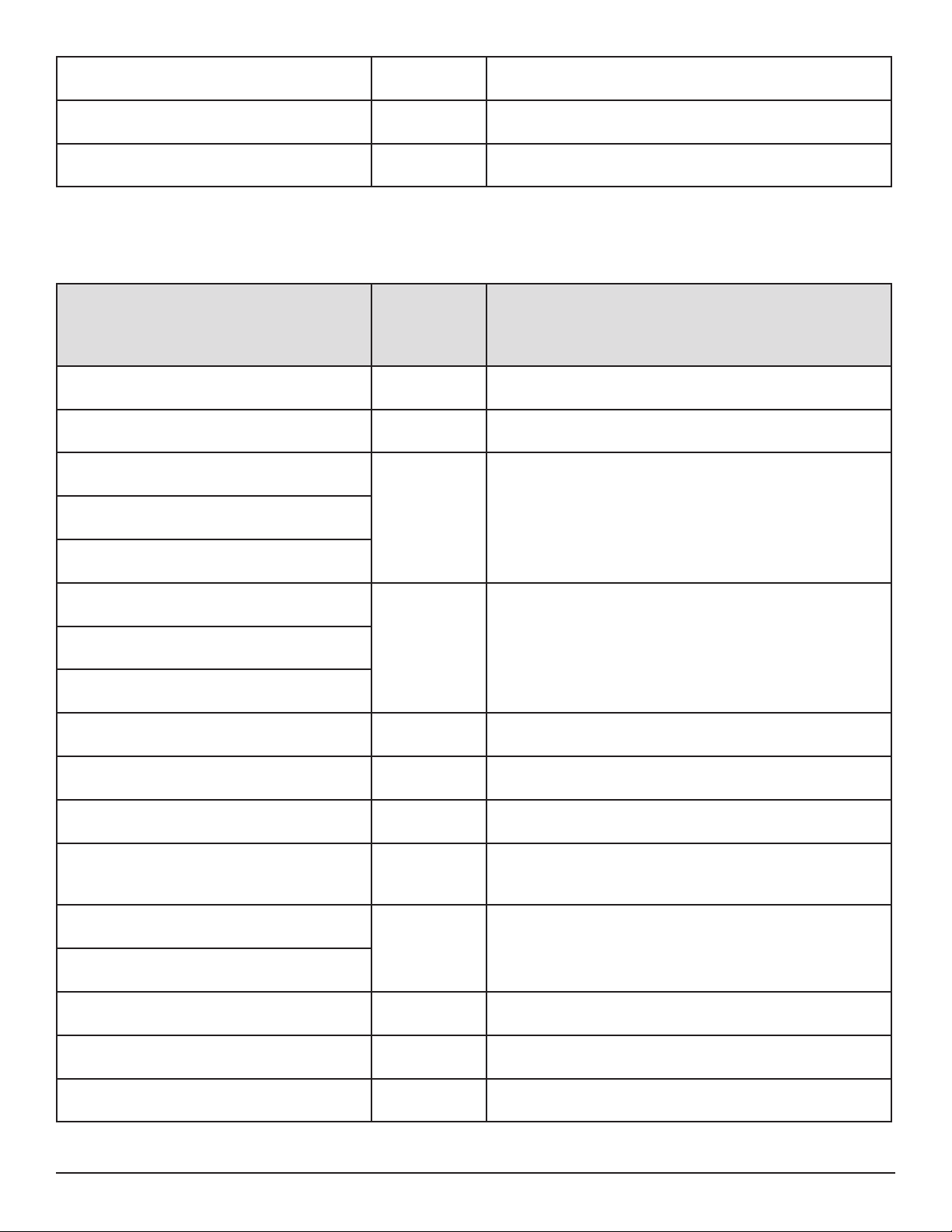

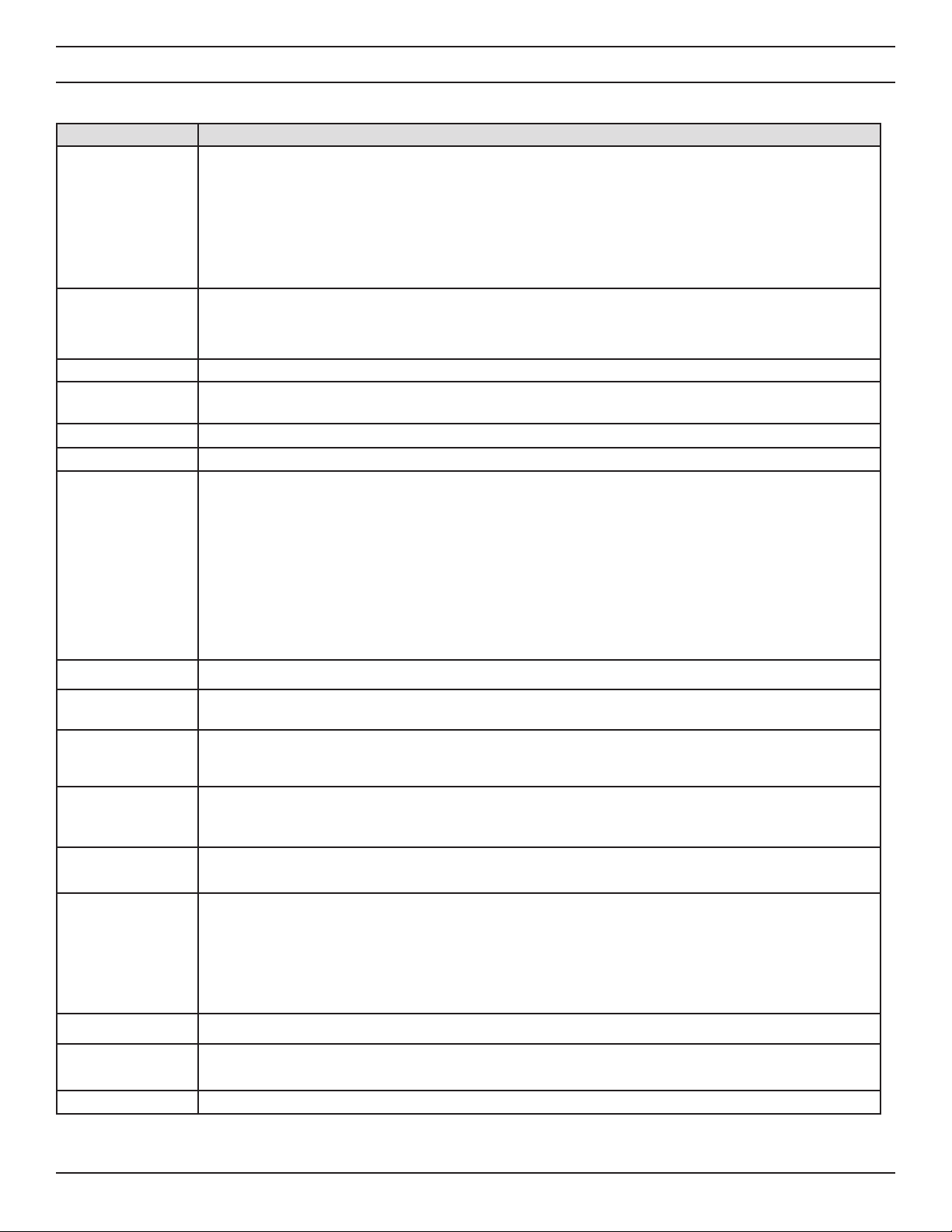

2.4 Button Functions

BUTTON

DESCRIPTION

Power

- Turns the instrument ON or OFF when running on battery power. The instrument cannot be turned

OFF via the Power button while it is running on external AC or line input power.

- Glows green when the instrument is running on power supplied by the line voltage terminal input

(see § 3.3.1).

- When not glowing, indicates the line power feature is enabled but the instrument is running on

external AC or battery power.

- Blinks red when the line power is disabled.

Control (Start/Stop)

- Starts or stops a data recording session.

- Enables or disables Bluetooth.

- Enables or disables Wi-Fi.

- When pressed and held down simultaneously with the Power button for 2 seconds,

enables/disables the line power feature.

Enter

- In Configuration mode, selects a parameter for editing. This initiates the edit mode

(the selected parameter blinks). Pressing this button again saves the modification.

- In Measurement mode, displays additional information for some measurement screens.

- In Energy mode, displays partial energy data.

- In all other modes, this button is inactive.

Left and Right

- Changes modes. Note that this functionality is “circular” – pressing the Right button ► while in

Configuration mode navigates to the top-level Measurement screen; pressing the Left button ◄ while

in Measurement mode goes to the top-level Configuration screen.

- In edit mode, these buttons select editable parameters.

Up and Down

- When editing parameters in Configuration mode, these buttons cycle through the available options for

the selected setting.

- In all other modes, these buttons navigate through the individual screens.

NOTE: In this manual, the symbol indicates when you need to press a button to perform a task.

For example,

represents “press the Control button.

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

11

Page 14

2.5 LCD Screens

1

2 4

3

Figure 4

1. Status icons.

2. Bargraphs. These indicate the percentage (0% to 100%) of full range or full load as defined through the

DataView PEL Control Panel.

3. Mode icons that control the data and information displayed (see the table below).

4. Units of measure.

The Status & Mode icons on the top and bottom of the display indicate the following information:

ICON DESCRIPTION

Indicates (1) the phase sequence may be incorrect, or (2) there is a missing phase. This icon only

appears in Measurement mode.

Indicates measurement data is available for recording. The absence of this icon may indicate an internal

issue with the instrument.

Indicates the current power quadrant.

Real-time Measurement Mode: Displays the measurement values for voltage, current, power, frequency, power factor, and tangent angle.

Power and Energy Mode: Displays the energy values for reactive energy, apparent energy, and kilowatt

hour.

Harmonics Mode: Displays harmonics for current and voltage.

Max Mode: Displays the maximum values for the measurement and energy values.

Information Mode: Displays electrical hookup and other instrument-related information (these screens

are read-only).

Configuration Mode: Displays screens containing user-selectable configuration settings and options.

NOTE: As a screen saver feature, when the instrument is ON and there is no activity on the user interface for

approximately three minutes, the LCD automatically enters Backlight Standby mode. In this mode, measurements

and recordings stay active but the LCD backlight turns OFF. To restore the backlight, press any navigation button.

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 15

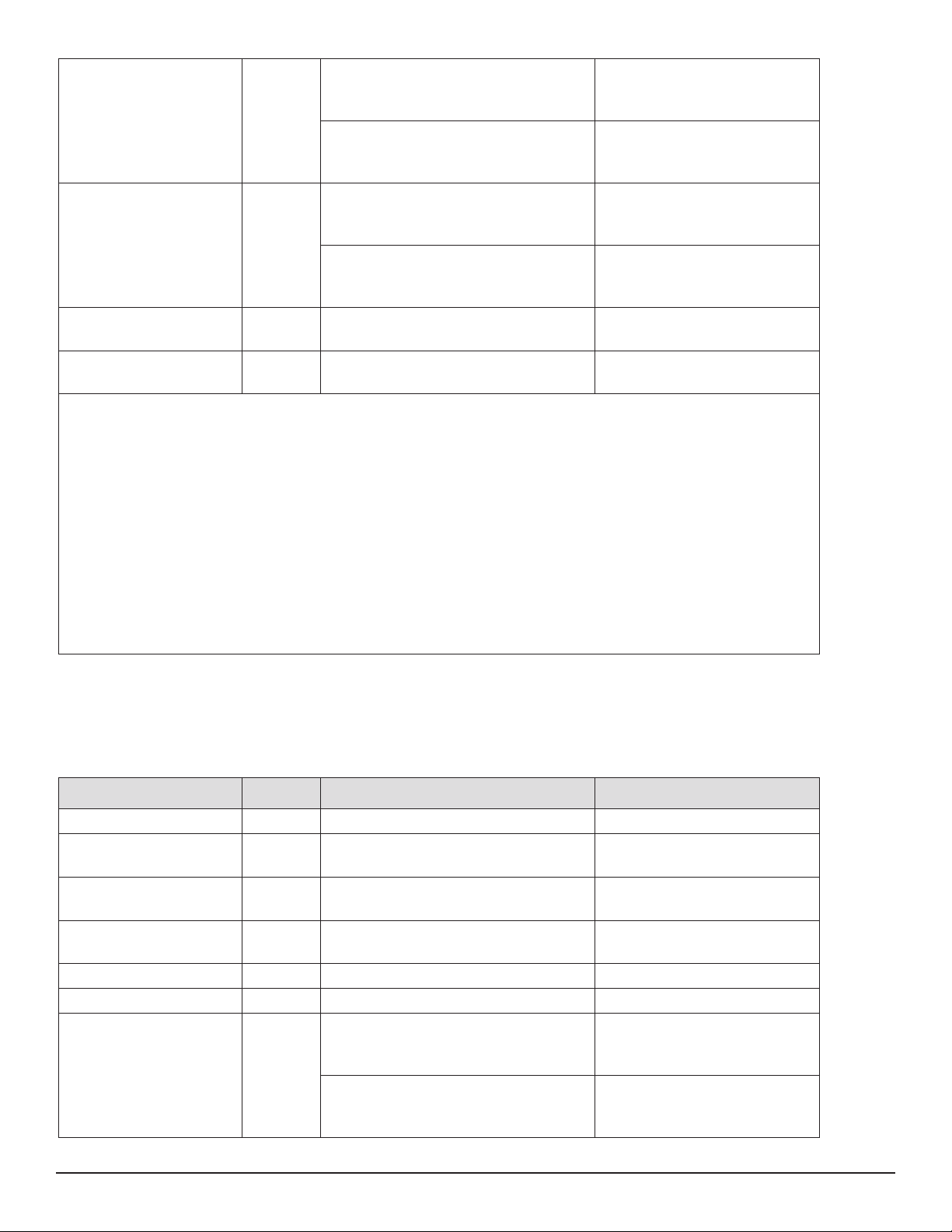

2.6 LED Status Indicators

On the left side of the front panel is a vertical row of LEDs (see Figure 1) which provide the following information:

LED STATUS

External Power (Green)

ON: Instrument is currently running on external AC power.

OFF: Instrument is running on battery or phase power.

Battery (Yellow/Red)

ON: - Steady yellow: Battery is actively charging.

- Blinking yellow (once per second): Battery is recovering from a full discharge.

- Blinking red (twice per second): Battery is low and there is no external AC power connected.

OFF: Battery is fully charged.

Phase Sequence (Red)

ON: Blinks once per second to indicate one of the following:

- The phase difference between current phases is greater than 30° relative to the expected differ-

ence (120° for three-phase and 180° for two-phase).

- The phase difference between the voltage phases is greater than 10° relative to the expected

difference.

- The phase difference between the current phase and voltage phase for each phase is greater

than 60°.

OFF: Phase rotation order is correct.

REC

Overload (Red)

ON: At least one input is overloaded, or current inputs are mismatched.

OFF: No input overload.

SD-Card (Red/Green/Orange)

ON: - Steady red: SD card is locked, unrecognized, or not present.

- Blinking red: SD card is initializing.

- Blinking orange: SD card is full.

- Steady green: SD card is present, recognized, and unlocked.

- Blinking green: SD card will be full before the end of the in-progress or pending recording.

Wi-Fi (Green)

ON: - Steady: Wi-Fi is enabled but not currently transmitting

- Blinking: Wi-Fi is enabled and transmitting.

OFF: Wi-Fi is disabled.

Bluetooth (Blue)

ON: - Steady: Bluetooth is enabled but not currently transmitting.

- Blinking: Bluetooth is enabled and transmitting.

OFF: Bluetooth is disabled.

Recording (Green)

ON: - Blinks twice every 5 seconds when recording.

- Blinks once every 5 seconds when not recording.

In addition, the Power button (described in § 2.4) glows green when the instrument is running on phase voltage power,

and blinks red once per second when phase voltage power is disabled. (See also § 3.1.1.)

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

13

Page 16

2.7 Installing the SD Card

Data recording sessions are stored in the included 8GB SD card, which also accepts FAT32 SDHC cards up to 32GB

capacity. If the SD card is unformatted, you will need to format it before use. Formatting can be done through a Microsoft

Windows command, or through the DataView PEL Control Panel.

To install the SD card:

1. Locate the card slot on the front panel (see Item 15 in Figure 1).

2. Ensure that the write-protect sliding tab on the card is in the “unlock” position

(towards the metal contacts).

LOCK

3. Insert the SD card into the slot, with the metal contacts facing up

(towards the top of the instrument).

4. Press the SD card into the slot until it clicks in place.

5. Press the attached cap into the card slot to ensure waterproofing.

6. If the SD Card is not formatted, the

LED glows red. To format the

installed card, open the PEL Control Panel (see § 6). Click Instrument in the

menu bar and select Configure. Then click Format SD-Card in the General tab

of the Configure Instrument dialog box, and click Yes to confirm.

When the card is installed and ready for use, the LED glows steady green. To remove a card, press down on it until

the card unclicks. It will pop up, allowing you to pull it from the slot.

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 17

3. SET UP & CONFIGURATION

Before using the instrument for the first time, ensure the battery is fully charged (see § 3.2) and that the instrument is ready

for operation. You must also configure the instrument for the hookup type appropriate for the electrical distribution system

under test.

NOTE: Before changing any setup or configuration setting, ensure that no recording is active or pending on the

instrument.

3.1 Powering the Instrument

The instrument can operate on three different sources of power:

■ External power provided by plugging into an AC outlet with the AC adapter. When you connect the instrument to

an AC outlet, it automatically turns ON. The instrument will always run on external AC power when plugged in,

even if phase power and/or battery power are also available.

■ Phase power provided through line voltage at the terminals. If AC wall power is disconnected, the instrument

runs on phase voltage power if it is available and enabled.

■ Battery backup power. If neither external AC power nor phase voltage is available, the instrument runs on battery

power.

3.1.1 Phase Voltage Power

Powering the instrument through phase voltage power requires no special preparation or equipment; simply connect two

voltage leads to an AC power line, connect the leads to the instrument using any available voltage terminals (see § 3), and

unplug the external AC adapter if connected. By default, the instrument will immediately begin drawing phase power from

the line.

The Power button glows green when the instrument is running on phase power. In this situation, the instrument cannot

be turned OFF via the button.

Note that you cannot power the instrument from a DC network. Also note that if the AC adapter is plugged in, the instrument will use this source instead of phase power.

You can disable the phase power feature by pressing and simultaneously for two seconds. When you do this,

blinks red once every two seconds, indicating the instrument cannot run on phase power. Pressing and simulta-

neously for two seconds re-enables this feature. You can also disable and enable this feature through the DataView PEL

Control Panel (see § 6).

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

15

Page 18

3.2 Charging the Battery

120V ± 10%, 60Hz

The PEL 105 is equipped with a NiMH battery, which provides power in the event of a disruption in the phase power or

external AC power. Before the first use, start by fully charging the battery.

230V ± 10%, 50Hz

Figure 5

3.3 Turning the Instrument ON/OFF

■ Connect the supplied power cord to the instrument

and AC power. The device will automatically turn ON.

■ The LED lights; it will go out only when the

battery is fully

charged.

■ A low battery charging takes approximately 5 hours.

Fully charging the battery may take up to 5 hours if the

battery is at or near complete discharge. If after 5 hours

the LED does not turn OFF, operate the instrument on

battery power until the battery runs low, and then repeat the

charging procedure.

In normal operation, a fully charged battery will provide

power for up to one hour before requiring another charging

session (although this period may be shorter if the instrument is actively using Bluetooth or Wi-Fi to communicate).

The LED glows red when the battery is low and in need

of charging.

3.3.1 Turning the Instrument ON

3.3.2 Turning the Instrument OFF

The procedure for turning OFF the instrument depends upon the power source. First check to see whether or not a recording is scheduled or in progress (the LED blinks twice every five seconds when a recording is active). If so, either stop

the recording, or wait until it is finished. Then do one of the following:

In addition, the instrument includes a feature that automatically turns it OFF after a period of inactivity when running on

battery power. This period, which is defined through the PEL Control Panel, can be set to 3, 10, or 15 minutes. It can also

be disabled.

■ On AC power or phase voltage power, the instrument automatically turns ON when you connect it.

■ On battery power, you must press for two seconds to turn ON the instrument.

■ AC power (indicated when the LED is lit): Unplug the AC power adapter, and then press for two

seconds. When all LEDs light up simultaneously, release .

■ Phase voltage power (indicated when glows green): Disconnect the voltage terminal leads from the

instrument, then press for two seconds and release it when all LEDs light up simultaneously.

■ Battery power: Press for two seconds and release it when all LEDs light up simultaneously.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 19

3.4 Bluetooth Enabling and Disabling

To communicate via a Bluetooth connection, check the Bluetooth LED on the instrument. If this is OFF, Bluetooth is

disabled. To enable Bluetooth:

1. Press and hold down . After a few moments the Recording LED lights up; continue to press the button

until the LED lights up.

2. Release ; when you do the LED lights and remains lit, indicating Bluetooth is now enabled.

3. To disable Bluetooth, press until the LED lights up; then release the button. The LED will turn OFF.

In addition to enabling and disabling Bluetooth, the PEL Control Panel allows you to change the instrument’s Bluetooth

name, enable Bluetooth password-protection, and select whether or not the instrument is visible to other Bluetooth devices.

3.5 Wi-Fi Enabling and Disabling

The procedure for enabling Wi-Fi is similar to the process for enabling Bluetooth:

1. Check the Wi-Fi LED. If this is OFF, press and hold down until the LED lights up.

2. To disable Wi-Fi, press until the LED lights up; then release the button.

You can also enable and disable Wi-Fi through the PEL Control Panel. In addition, you can change the SSID (Service Set

Identifier) name, and define a Wi-Fi password via the PEL Control Panel. (Note that the default Wi-Fi password is printed

on a label placed inside the instrument’s cover.)

3.6 Configuring the PEL 105

Before you can use the instrument for the first time, you must set a number of configuration variables. Full setup and configuration is performed through a computer running the DataView PEL Control Panel (see § 6). This includes setting the

instrument’s time and date (§ 6.4).

In addition, a subset of configuration settings can be performed directly on the instrument via its LCD interface, including:

■ Select the hookup for the electrical distribution system under test

■ Set voltage and current ratios appropriate for the connected probes or sensors

■ Set the aggregation period for a recording session

■ Review instrument settings, such as date and time

Before you can perform any configuration on the instrument, the Control button must be enabled. This button is

enabled and disabled through the PEL Control Panel. When this button is disabled, Configuration mode displays the

word LOCK, and no configuration screens are available. (Note that LOCK also appears if the PEL Control Panel is actively

configuring the instrument.) If is disabled, enable it as follows:

1. Open the PEL Control Panel.

2. Ensure that the instrument is connected by checking its status in the PEL Network frame. If not, reconnect it by

highlighting the instrument, selecting Instrument in the menu bar, and clicking Reconnect Instrument.

3. Select the instrument, and click Instrument in the menu bar.

4. Select Configure. This displays the Configure Instrument dialog box.

5. De-select the checkbox “Lock out the Control button on the instrument front panel.”

6. Click OK to save the change.

Consult the PEL Control Panel Help system for assistance in completing the preceding steps.

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

17

Page 20

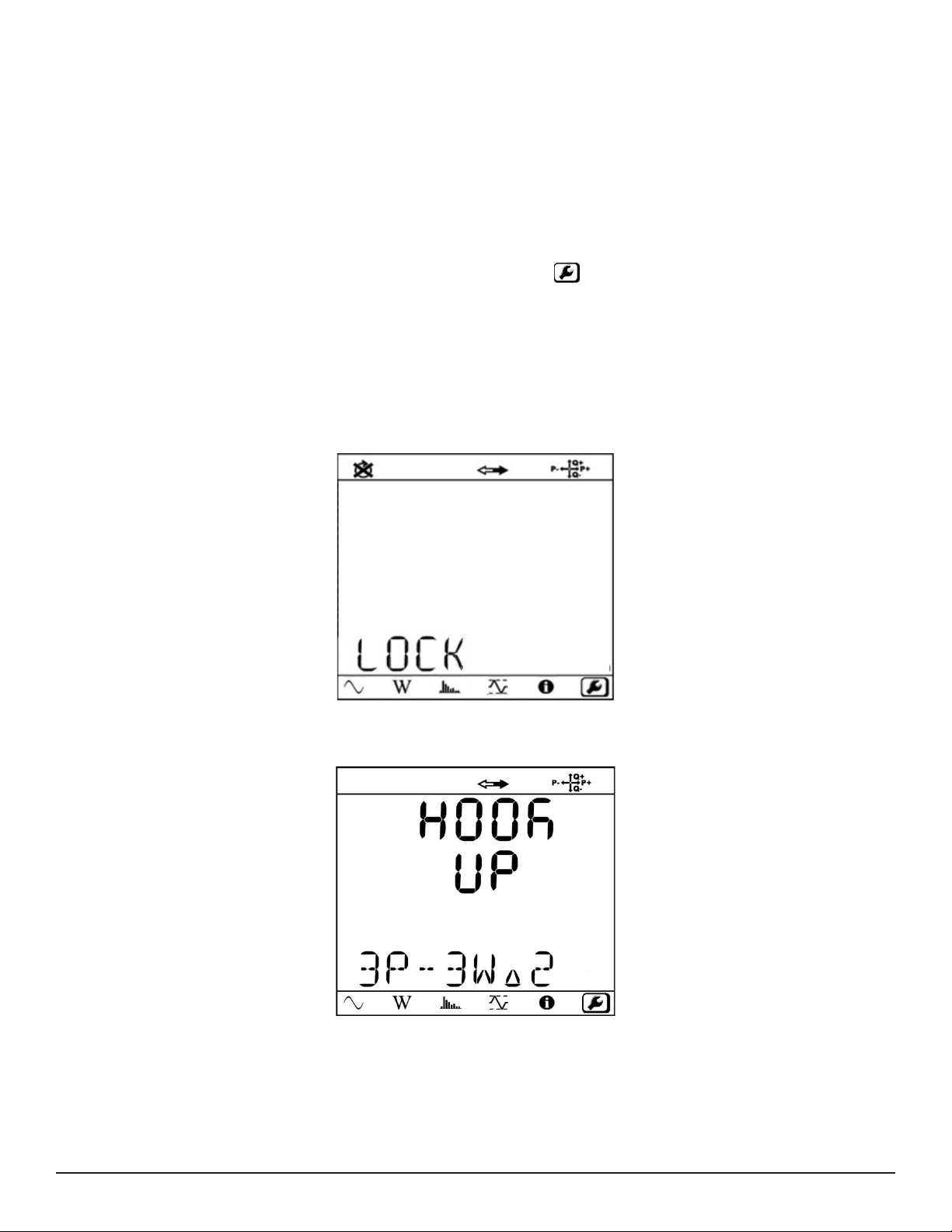

3.6.1 Configuration Mode

Configuration mode enables you to change several settings, including:

■ Hookup type

■ Primary and secondary nominal voltage

■ Primary nominal current

■ Primary nominal neutral current

■ Aggregation period

To enter Configuration mode, press either ◄ or ► until the Configuration icon is highlighted. Note that there are several

situations that prevent you from making changes in Configuration mode:

■ The instrument is currently being configured by the PEL Control Panel.

■ Local configuration is locked (disabled) through an option in the PEL Control Panel. This prevents configuration

even when the instrument is disconnected from the Control Panel.

■ A recording session is in progress.

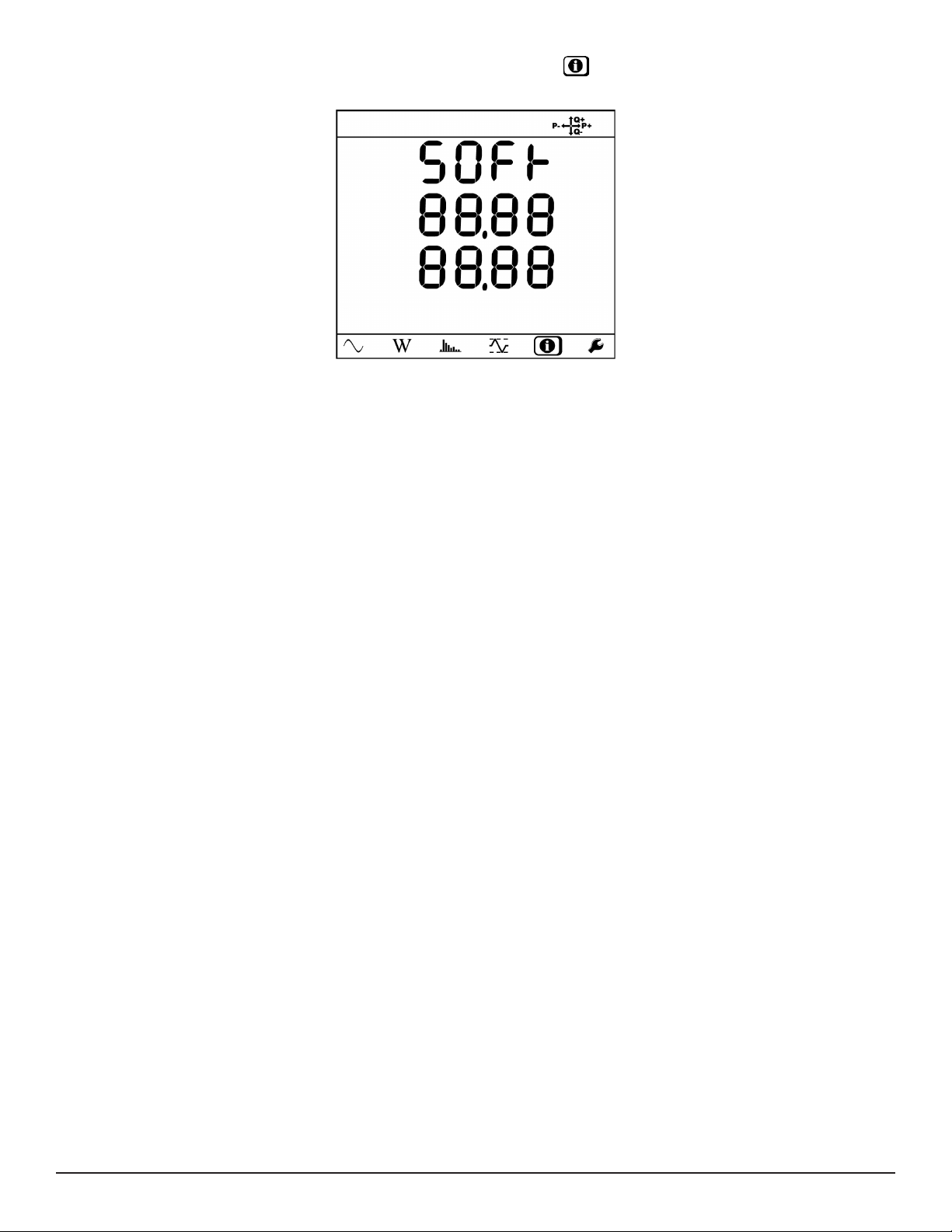

If any of these situations is in effect, the word LOCK appears on the screen:

Figure 6

Otherwise, the Hookup configuration screen appears:

Figure 7

This is the top-level screen in Configuration mode, and serves as the starting point for all configuration tasks.

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 21

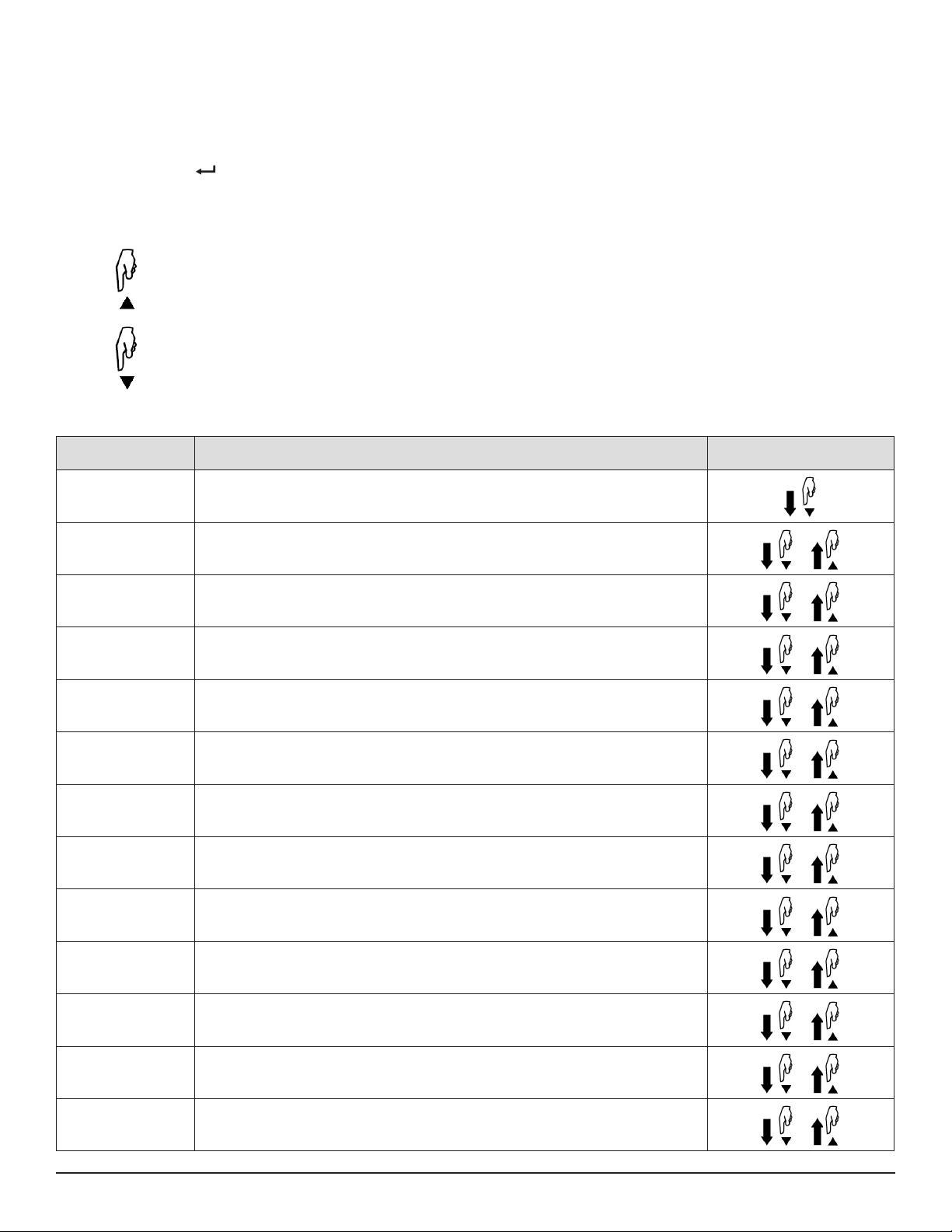

3.6.2 Selecting the Hookup

The Hookup configuration screen lets you select the type of hookup for the electrical distribution system under measurement. This must be the same physical hookup as the probes/sensors (see § 4).

To select the hookup:

1. Press Enter . The displayed hookup type blinks, indicating you are now in edit mode.

2. Press ▲ or ▼ to navigate through the available hookup types.

For example, in the following table:

■ displays the preceding (next higher) hookup.

■ displays the following (next lower) hookup.

Options are:

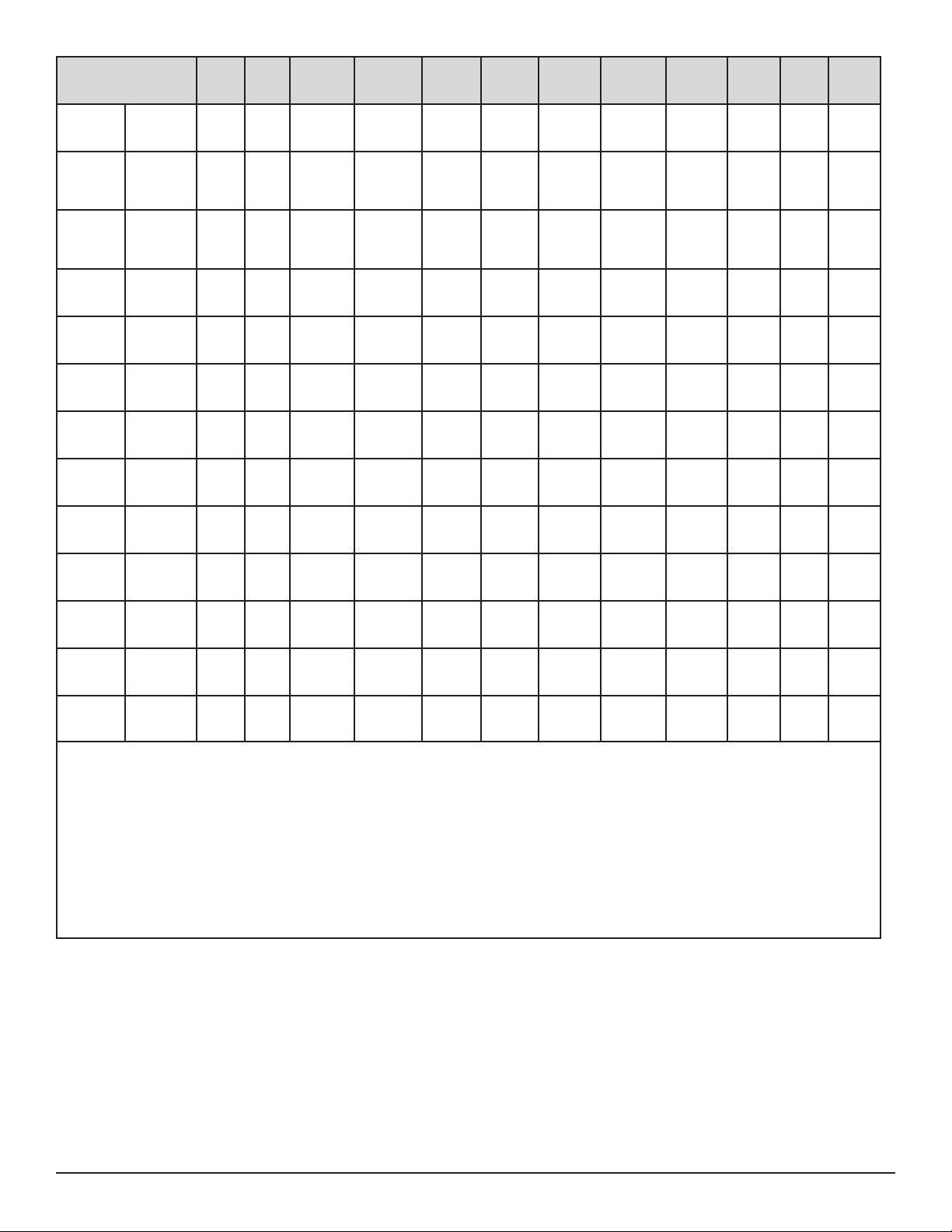

OPTION HOOKUP TYPE TO CHANGE, PRESS:

dC-4W DC 4-wire

dC-3W DC 3-wire

dC-2W DC 2-wire

3P-4WO 3-phase 4-wire Open ∆

3P-3WO3 3-phase 3-wire Open ∆ (3 current probes)

3P-3WO2 3-phase 3-wire Open ∆ (2 current probes)

3P-3WY3 3-phase 3-wire Y (3 current probes)

3P-3WY2 3-phase 3-wire Y (2 current probes).

3P-4W∆ 3-phase 4-wire ∆

3P-4WY2 3-phase 4-wire Y 2½

3P-4WYb 3-phase 4-wire Y balanced (fixed, voltage measurement)

3P-4WY 3-phase 4-wire Y

3P-3W∆b 3-phase 3-wire ∆ balanced

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

19

Page 22

3P-3W∆3 3-phase 3-wire ∆ (3 current probes)

3P-3W∆2 3-phase 3-wire ∆ (2 current probes)

1P-3W 1-phase 3-wire (split phase)

1P-2W 1-phase 2-wire

Note that this list is not cyclical; pressing ▼ while 1P-2W is displayed (or pressing ▲ while dC-4W is displayed) has no

effect.

When the desired hookup type appears, press to save it. The hookup type stops blinking, indicating you have exited

edit mode.

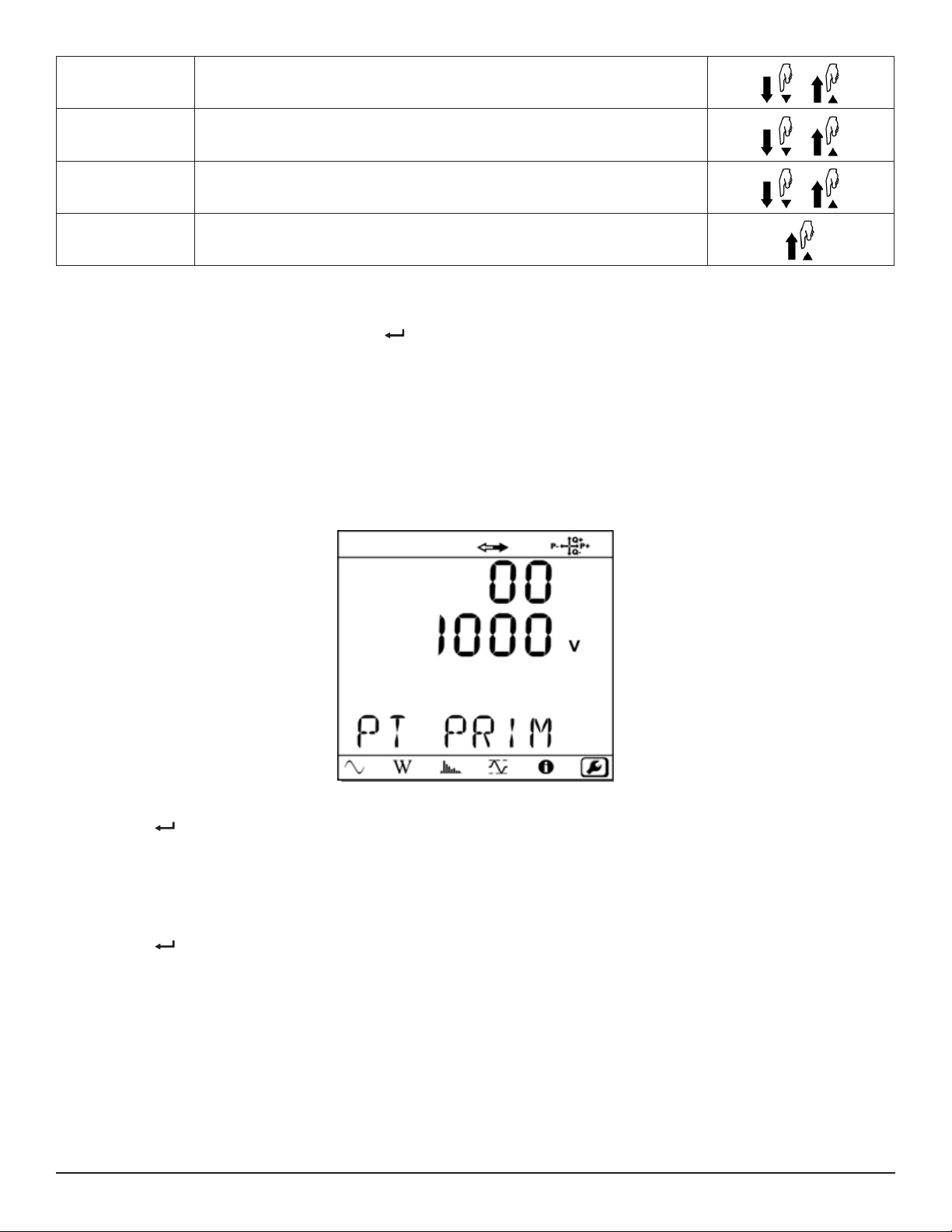

3.6.3 Selecting Nominal Current and Voltage

Configuration mode lets you set a voltage ratio for the transformer being measured (if necessary). This involves setting a

primary nominal voltage and secondary nominal voltage for the transformer. To do this, display the Hookup configuration

screen and proceed as follows:

1. Press ▼ to display the Primary Nominal Voltage (PT PRIM) configuration screen.

Figure 8

2. Press . The first digit of the primary nominal voltage value blinks. (Note that although this value is displayed on

two separate lines, it is a single number.)

3. Press ◄ or ► to navigate through the displayed digits.

4. When the desired digit is selected, press ▲ or ▼ to change its value. The primary nominal voltage can range

from 50 volts to 650000 volts.

5. Press when the displayed voltage is correct.

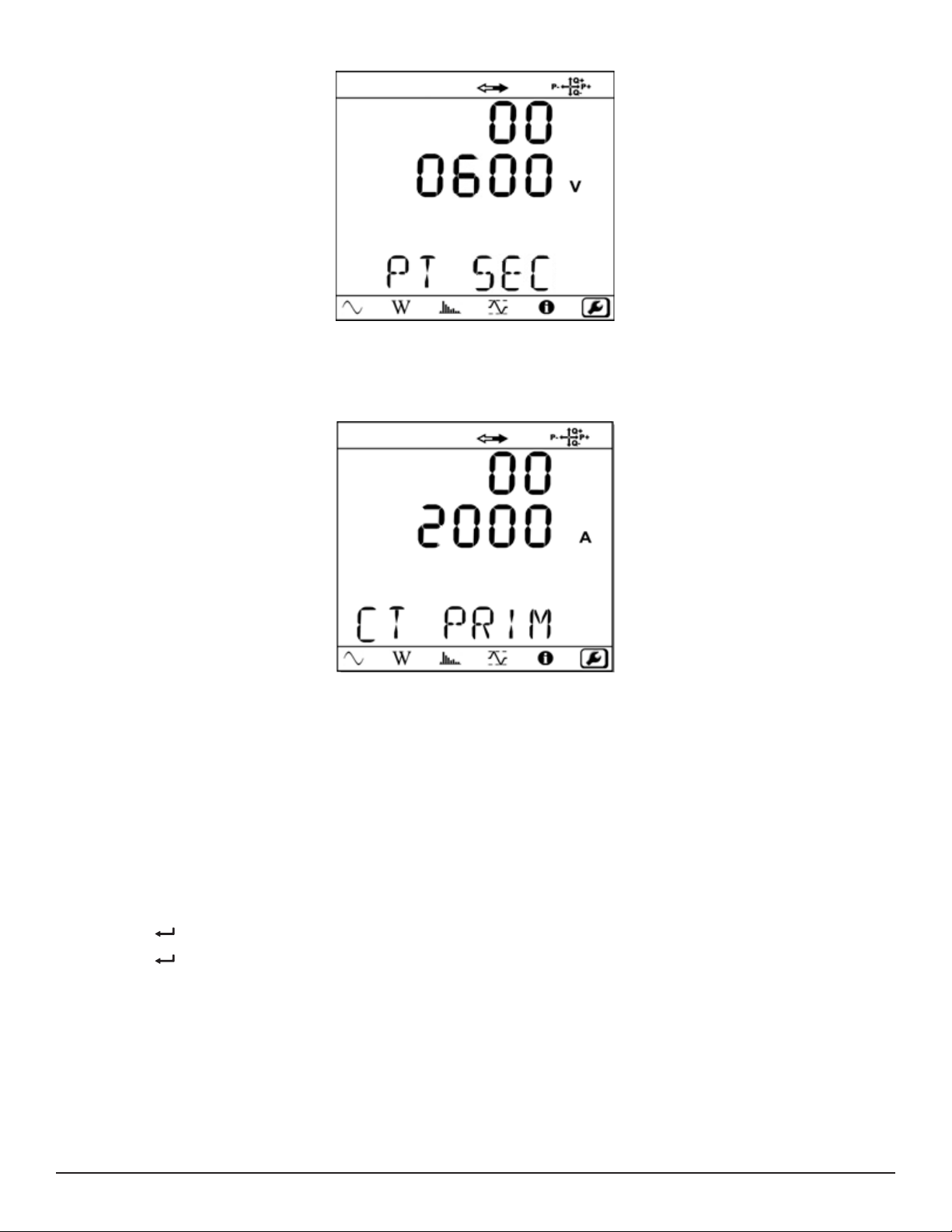

6. Press ▼ to display the Secondary Nominal Voltage (PT SEC) configuration screen. This functions similarly to the

Primary Nominal Voltage screen. Allowable secondary nominal voltage values range from 50 to 1000V.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 23

Figure 9

7. If a probe or sensor is connected, and the type of probe/sensor supports setting a transformer ratio, you can

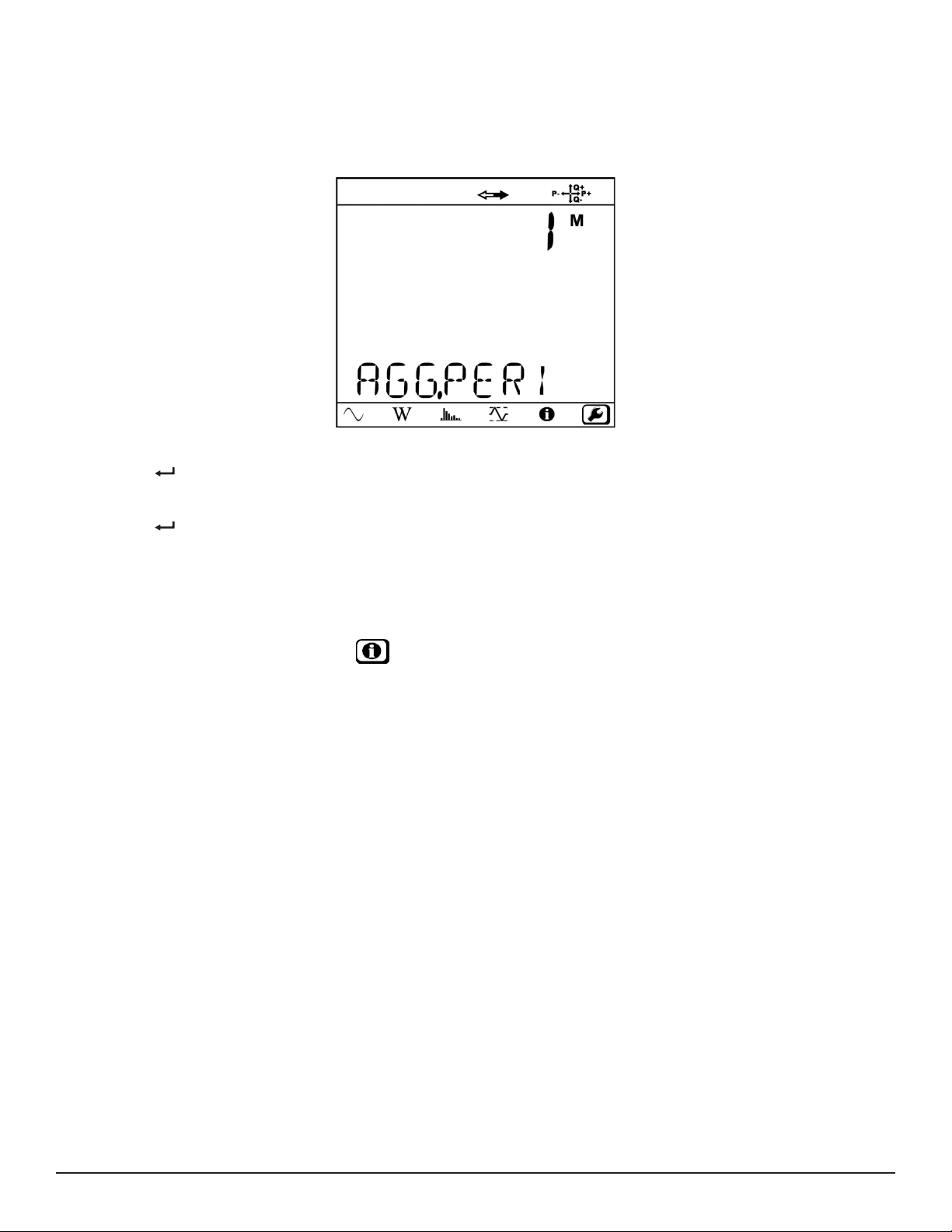

configure the primary nominal current appropriate for the probe. To do this, press ▼ at the Secondary Nominal

Voltage configuration screen. This displays the Primary Nominal Current (CT PRIM) configuration screen.

Figure 10

The primary nominal current depends on the type of probe/sensor or adapter:

- AmpFlex/MiniFlex: 100, 400, 2000, or 10000A

- MN93: automatic 200A

- MN193 5A range: 5 to 25000A

- MN193 100A range: automatic 100A

- S93: automatic 3500A

- SL261: 10 or 1000A

- SR193 and MR193: automatic 1000A

- 5A Adapter Box: 5 to 25000A

- BNC Adapter: 1 to 25000A

8. Press and use the directional buttons to select the appropriate value.

9. Press to save your changes.

10. If a probe or sensor is connected to the instrument’s neutral input terminal, pressing ▼ at the Primary Nominal

Current configuration screen displays the Primary Neutral Current screen. This screen functions similarly to the

Primary Nominal Current screen. Allowable values are:

- AmpFlex/MiniFlex: 100, 400, 2000, or 10000A

- BNC Adapter: 1 to 25000A

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

21

Page 24

3.6.4 Setting the Aggregation Period for a Recording

When recording data (see § 5), the instrument performs measurement aggregation. This involves determining the average

value for a measured parameter over a user-specified time interval. This interval is called the aggregation period, and can

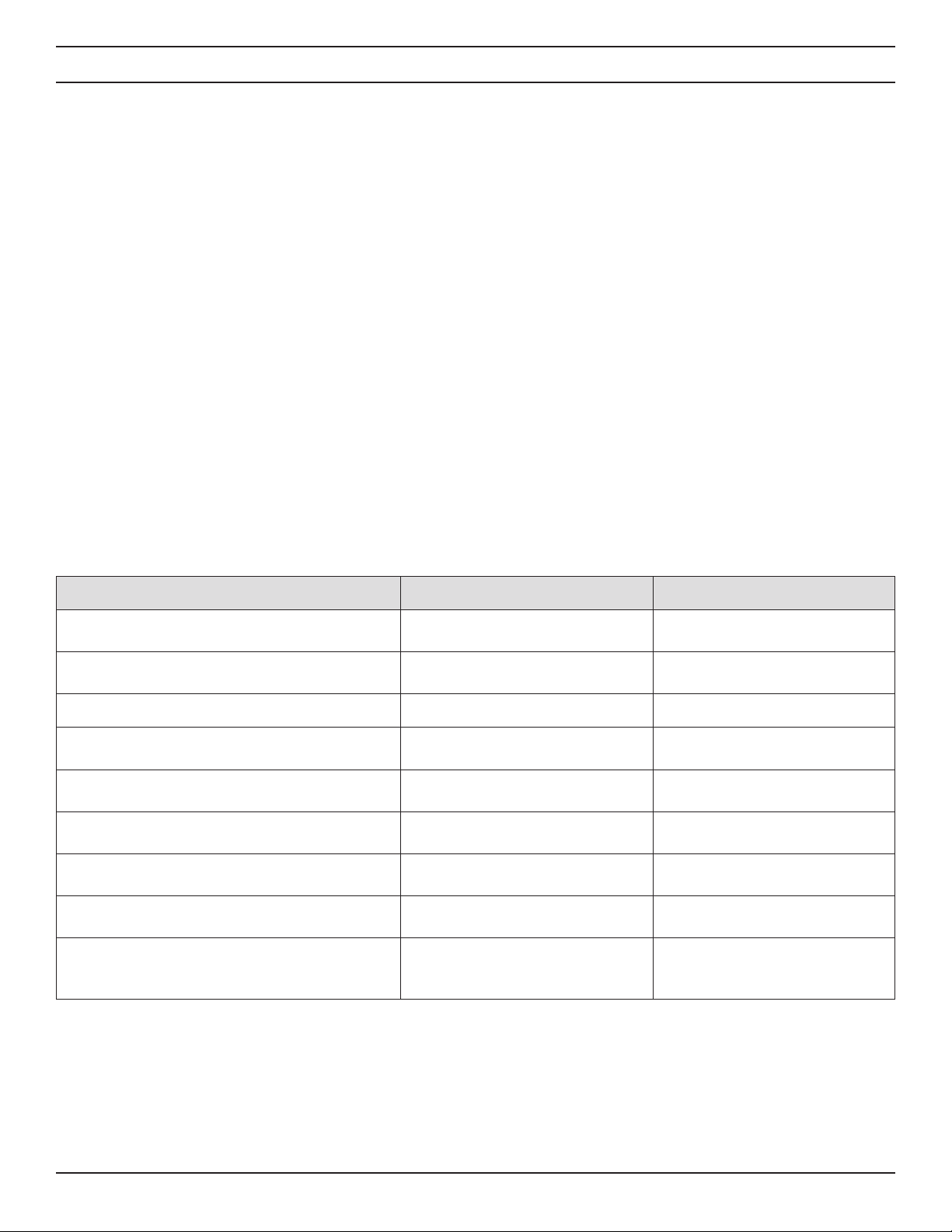

be set in Configuration mode. To do this:

1. From the Hookup configuration screen, press ▲ to display the Aggregation Period screen.

Figure 11

2. Press to select the aggregation period value.

3. Press ▲ or ▼ to make changes. Available options in minutes are 1 through 6, 10, 12, 15, 20, 30, and 60.

4. Press to save your changes.

3.7 Viewing Instrument Information

Information mode enables you to review instrument information and settings. To enter Information mode:

1. Press ◄ or ► until the Information icon is selected.

2. Press ▲ or ▼ to cycle through a series of read-only screens.

These screens display settings for the following:

■ Hookup

■ Primary nominal voltage

■ Secondary nominal voltage

■ Primary nominal current

■ Primary nominal neutral current (when available)

■ Aggregation period

■ Date and time

■ LAN IP address

■ WiFi IP address

■ Firmware revision number

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 25

4. OPERATION

4.1 Hooking Up to the Distribution System

The Model PEL 105 works with a variety of current probes and sensors. Choosing which type to use depends on the current to be measured and the diameter of the electrical cables. Each probe and sensor comes with its own documentation,

which you should consult before connecting to the instrument.

The instrument may be supplied with four water-tight AmpFlex® Model A196-24-BK current probes. This 24” flexible probe

measures the current in a cable without opening the circuit. The probe also comes in a 36” length (A193-36-BK). Their

performance specifications are otherwise identical; although the A193-36-BK is not water-tight.

To connect the probe to the electrical network under measurement, do the following:

1. Connect the probe lead onto the appropriate current terminal. Which terminal to use depends on the hookup

type, as explained later in this section. Note: When using AmpFlex A196-24-BK probe, be sure to screw the lead

onto the threaded terminal to ensure water-tight (IP67) operation.

2. Open the probe by pressing the release levers on the side of the coupling and pulling out the end.

3. Wrap the probe around the electrical cable to be measured.

4. Close the probe by inserting the end back into the coupling.

This is the basic connection procedure for flexible loop probes. Clamp-on probes require a similar connection process.

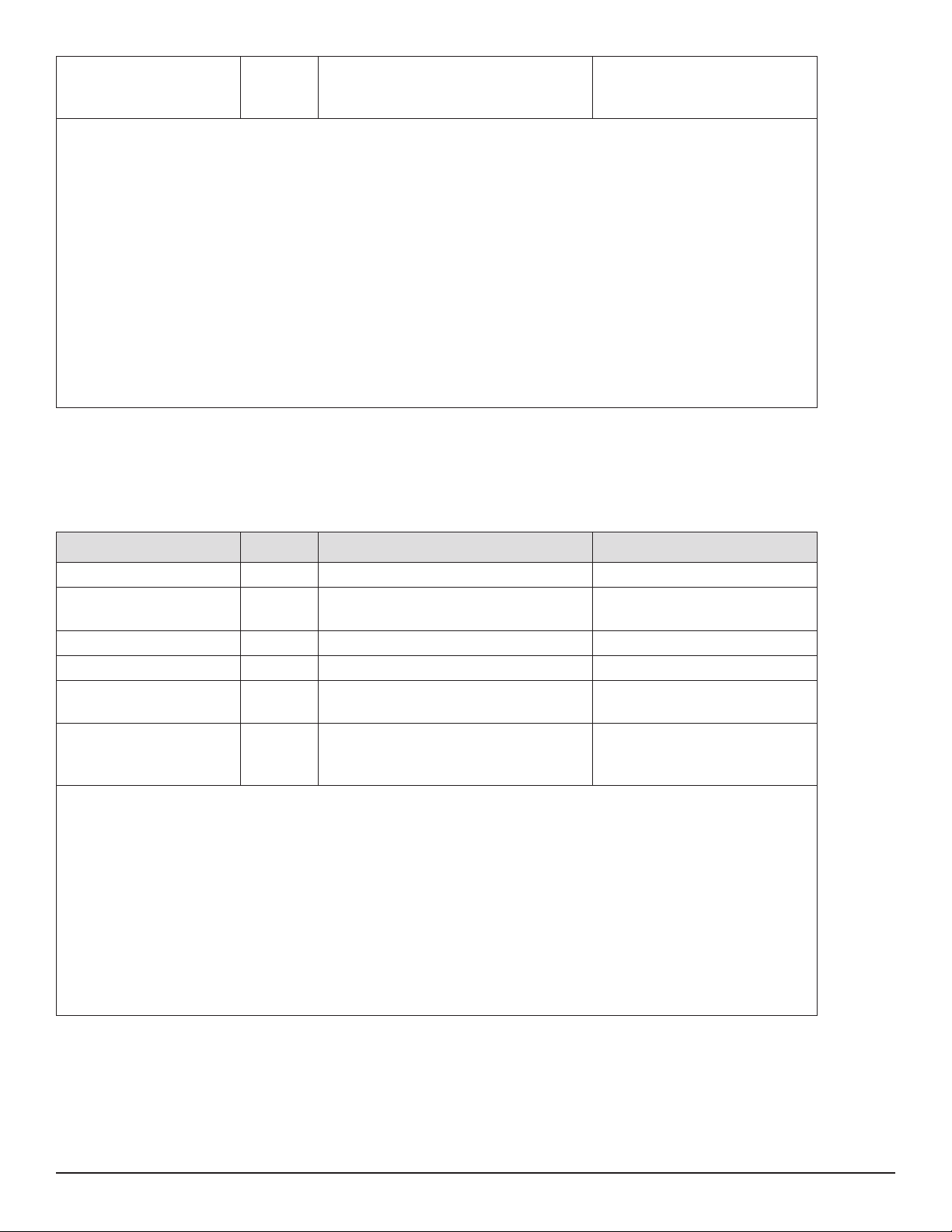

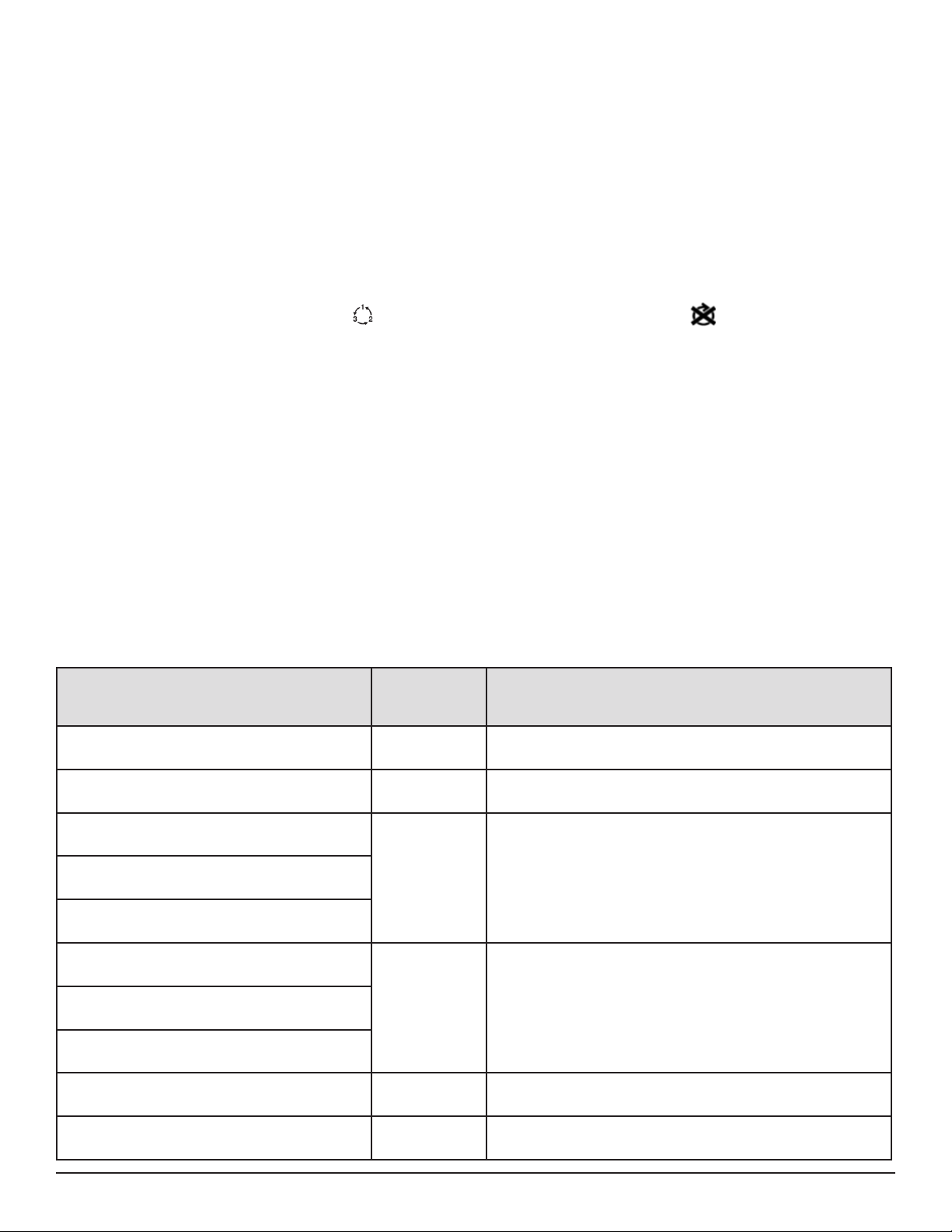

The following table provides measurement specifications for supported probes and sensors. For detailed probe/sensor

specifications, see § 7.9.

Model Nominal Range Measurement Range

Flexible Current Probe AmpFlex®

Model A196-24-BK (waterproof – IP67)

Flexible Current Probe AmpFlex®

Model 196-36-BK

Flexible Current Probe MiniFlex® MA193 100/400/2000/10000A

AC/DC Current Probe J93

Clamp-On AC/DC Current Probe Model

MR193-BK

Clamp-On AC Current Probe Model MN93-BK 200AAC for F ≤1kHz

Clamp-On AC Current Probe Model SR193-BK 1000AAC for F ≤1 kHz

Clamp-On Current Probe Model MN193-36-BK 5A and 100A

AC/DC Current Probe Model SL261

(requires a BNC Adapter, catalog #2140.40,

for use with the PEL 105)

100/400/2000/10000A

100/400/2000/10000A

3500A

AC

5000A

DC

1000AAC, 1400ADC max

AC

10A and 100A

AC/DC

AC

AC

AC

200mA to 12000A

50mA to 12000A

200mA to 3000A

50 to 3500A

50 to 5000A

AC

DC

AC

AC

AC

1 to 1000AAC, 1 to 1300A peak

AC+DC

0.5 to 240AAC max (I >200A not

permanent)

1 to 1200AAC max (I >1000A not

continuously)

5A: 0.005 to 6AAC max

100A: 0.2 to 120AAC max

100mV/A: 50mA to 10A peak

10mV/A: 0.5 to 100A peak

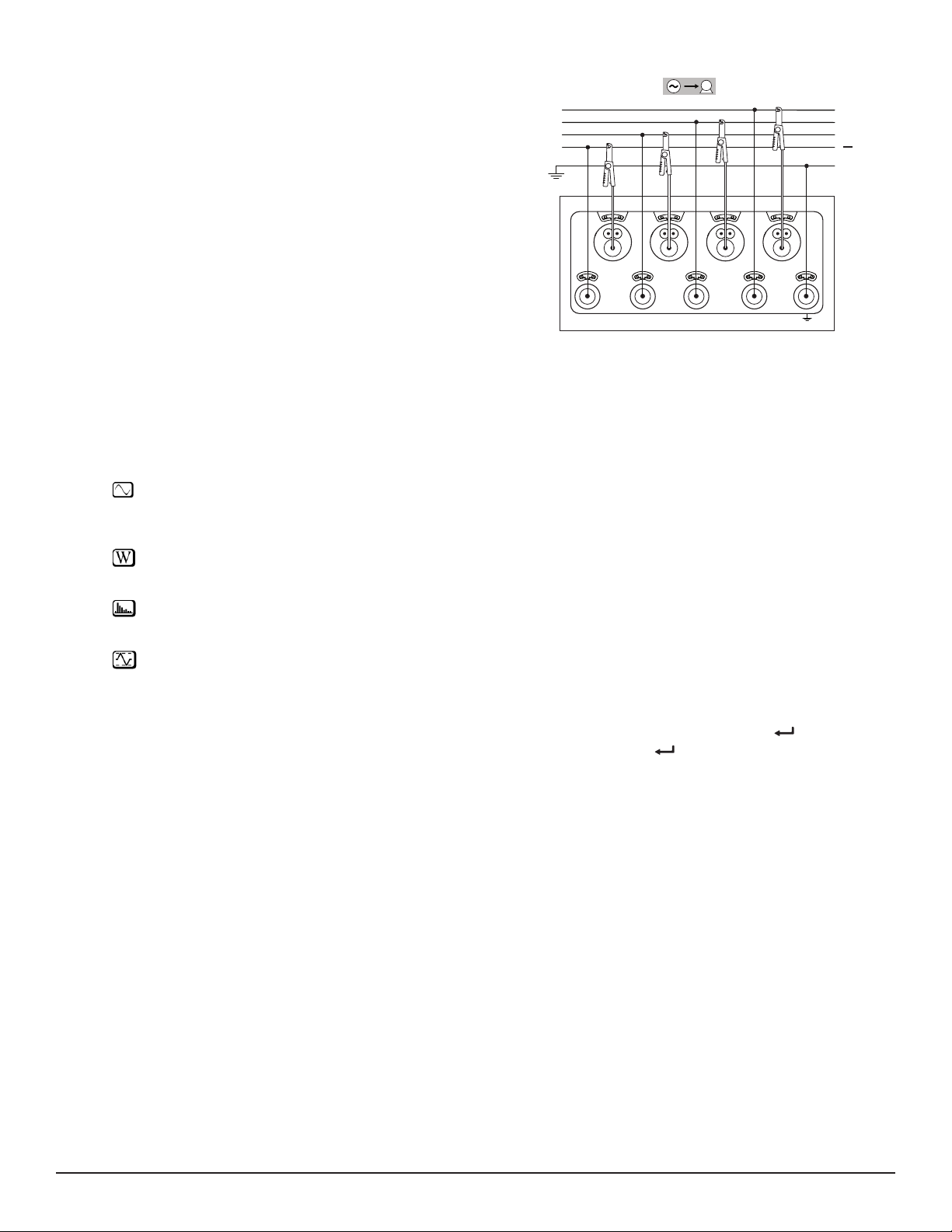

The PEL 105 supports 17 hookup types. For each, the following sections provide:

■ A connection diagram. This includes a depiction of the instrument’s current terminals I1, I2, I3, and IN (neutral);

and voltage terminals V1, V2, V3, VN, and VE/GND (ground/earth). The diagram also includes an illustration of

how the current probes and voltage leads are connected to electrical lines, neutral, and ground.

■ An icon showing the direction towards the load.

■ Instructions for how to connect the probes and leads.

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

23

Page 26

In each diagram, the top row of terminals connect current probes/sensors, the bottom row connect voltage test leads. The

VN V3 V2 V1

VE/GND

IN I3 I2 I1

L1

N

Source

Load

labels identify the input terminals functions. For example, I1 connects a current probe/sensor to line 1; I2 connects to line

2, and so on.

The following instructions assume you will use the neutral current terminal and the ground/earth voltage terminal. Use of

these terminals is not strictly required; however they provide a higher level of accuracy when used.

For all hookups, ensure that the arrow on the probe is directed towards the load (for example, see Figure 13). This provides

proper phase angle for power measurements and other phase-sensitive measurements.

Figure 12

NOTE: When connecting to the electrical network, be sure to observe all safety precautions as stated in the documentation that accompanies the probes and sensors.

4.1.1 Single-Phase 2-Wire (1P-2W)

Connect:

■ VN test lead to neutral (N).

■ VE/GND test lead to ground (optional, normally not used in

this hookup).

■ V1 test lead to L1.

■ IN probe to neutral (optional, normally not used in this

hookup).

■ I1 probe to L1.

Figure 13

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 27

4.1.2 Single-Phase 3-Wire (1P-3W)

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

N

L2

L2 L1

N

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

L2 L1

L3

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

L2 L1

L3

Split phase from a center tap transformer.

Connect:

■ VN test lead to neutral (N).

■ VE/GND test lead to ground (optional, normally not used in

this hookup).

■ V1 test lead to L1.

■ V2 test lead to L2.

■ IN probe to neutral (optional, normally not used in this

hookup).

■ I1 probe to L1.

■ I2 probe to L2.

4.1.3 3-Phase 3-Wire ∆ (2 current probes) (3P-3W∆2)

Connect:

■ VE/GND test lead to ground.

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ I1 probe to L1.

■ I3 probe to L3.

4.1.4 3-Phase 3-Wire ∆ (3 current probes) (3P-3W∆3)

Figure 14

Figure 15

Connect:

■ VE/GND test lead to ground.

■ V1 test lead to L1.

■ V2 test lead to L2.

Find Quality Products Online at: sales@GlobalTestSupply.com

■ V3 test lead to L3.

■ I1 probe to L1.

■ I2 probe to L2.

■ I3 probe to L3.

Power & Energy Logger Model PEL 105

www.GlobalTestSupply.com

Figure 16

25

Page 28

4.1.5 3-Phase 3-Wire Open ∆ (2 current probes) (3P-3WO2)

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

L2 L1

L3

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

L2 L1

L3

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

L2

L3

L1

N

Connect:

■ VE/GND test lead to ground.

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ I1 probe to L1.

■ I3 probe to L3.

4.1.6 3-Phase 3-Wire Open ∆ (3 current probes) (3P-3WO3)

Connect:

■ VE/GND test lead to ground.

Figure 17

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ I1 probe to L1.

■ I2 probe to L2.

■ I3 probe to L3.

4.1.7 3-Phase 3-Wire Y (2 current probes) (3P-3WY2)

Connect:

■ VE/GND test lead to ground.

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ I1 probe to L1.

■ I3 probe to L3.

Figure 18

Figure 19

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 29

4.1.8 3-Phase 3-Wire Y (3 current probes) (3P-3WY3)

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

L2

L3

L1

N

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

L2 L1

L3

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

N

L2

L3

L1

N

Connect:

■ VE/GND test lead to ground.

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ I1 probe to L1.

■ I2 probe to L2.

■ I3 probe to L3.

4.1.9 3-Phase 3-Wire ∆ Balanced (1 current probe) (3P3W∆b)

Connect:

■ VE/GND test lead to ground.

Figure 20

■ V1 test lead to L1.

■ V2 test lead to L2.

■ I3 probe to L3.

4.1.10 3-Phase 4-Wire Y (3 current probes) (3P-4WY)

Connect:

■ VE/GND test lead to ground.

■ VN test lead to neutral (N).

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ IN probe to neutral.

■ I1 probe to L1.

■ I2 probe to L2.

■ I3 probe to L3.

Figure 21

Figure 22

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

27

Page 30

4.1.11 3-Phase 4-Wire Y Balanced (3P-4WYb)

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

N

L2

L3

L1

N

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

N

L2

L3

L1

N

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

N

L1L2L3

N

Connect:

■ VE/GND test lead to ground.

■ VN test lead to neutral (N).

■ V1 test lead to L1.

■ IN probe to neutral.

■ I1 probe to L1.

4.1.12 3-Phase 4-Wire Y 2½ Element (3P-4WY2)

Connect:

■ VE/GND test lead to ground.

Figure 23

■ VN test lead to neutral (N).

■ V1 test lead to L1.

■ V3 test lead to L3.

■ IN probe to neutral.

■ I1 probe to L1.

■ I2 probe to L2.

■ I3 probe to L3.

4.1.13 3-Phase 4-Wire ∆ (3P-4W∆)

Connect:

■ VE/GND test lead to ground.

■ VN test lead to neutral (N).

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ IN probe to neutral.

■ I1 probe to L1.

■ I2 probe to L2.

■ I3 probe to L3.

Figure 24

Figure 25

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 31

4.1.14 3-Phase 4-Wire Open ∆ (3P-4WO)

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

L1

L2

L3

N

L1L2L3

N

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

+1

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

+1

+2

Connect:

■ VE/GND test lead to ground.

■ VN test lead to neutral (N).

■ V1 test lead to L1.

■ V2 test lead to L2.

■ V3 test lead to L3.

■ IN probe to neutral.

■ I1 probe to L1.

■ I2 probe to L2.

■ I3 probe to L3.

4.1.15 DC 2-Wire (dC-2W)

Connect:

■ VE/GND test lead to ground.

■ VN test lead to the common conductor.

■ V1 test lead to conductor +1.

■ IN probe to the common conductor.

■ I1 probe to conductor +1.

Figure 26

Figure 27

4.1.16 DC 3-Wire (dC-3W)

Connect:

■ VE/GND test lead to ground.

■ VN test lead to the common conductor.

■ V1 test lead to conductor +1.

■ V2 test lead to conductor +2.

■ IN probe to the common conductor.

■ I1 probe to conductor +1.

■ I2 probe to conductor +2.

Power & Energy Logger Model PEL 105

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Figure 28

29

Page 32

4.1.17 DC 4-Wire (dC-4W)

VN V3

Source Load

V2 V1

VE/GND

IN I3 I2 I1

+1

+2

+3

Connect:

■ VE/GND test lead to ground.

■ VN test lead to the common conductor.

■ V1 test lead to conductor +1.

■ V2 test lead to conductor +2.

■ V3 test lead to conductor +3.

■ IN probe to the common conductor.

■ I1 probe to conductor +1.

■ I2 probe to conductor +2.

■ I3 probe to conductor +3.

Figure 29

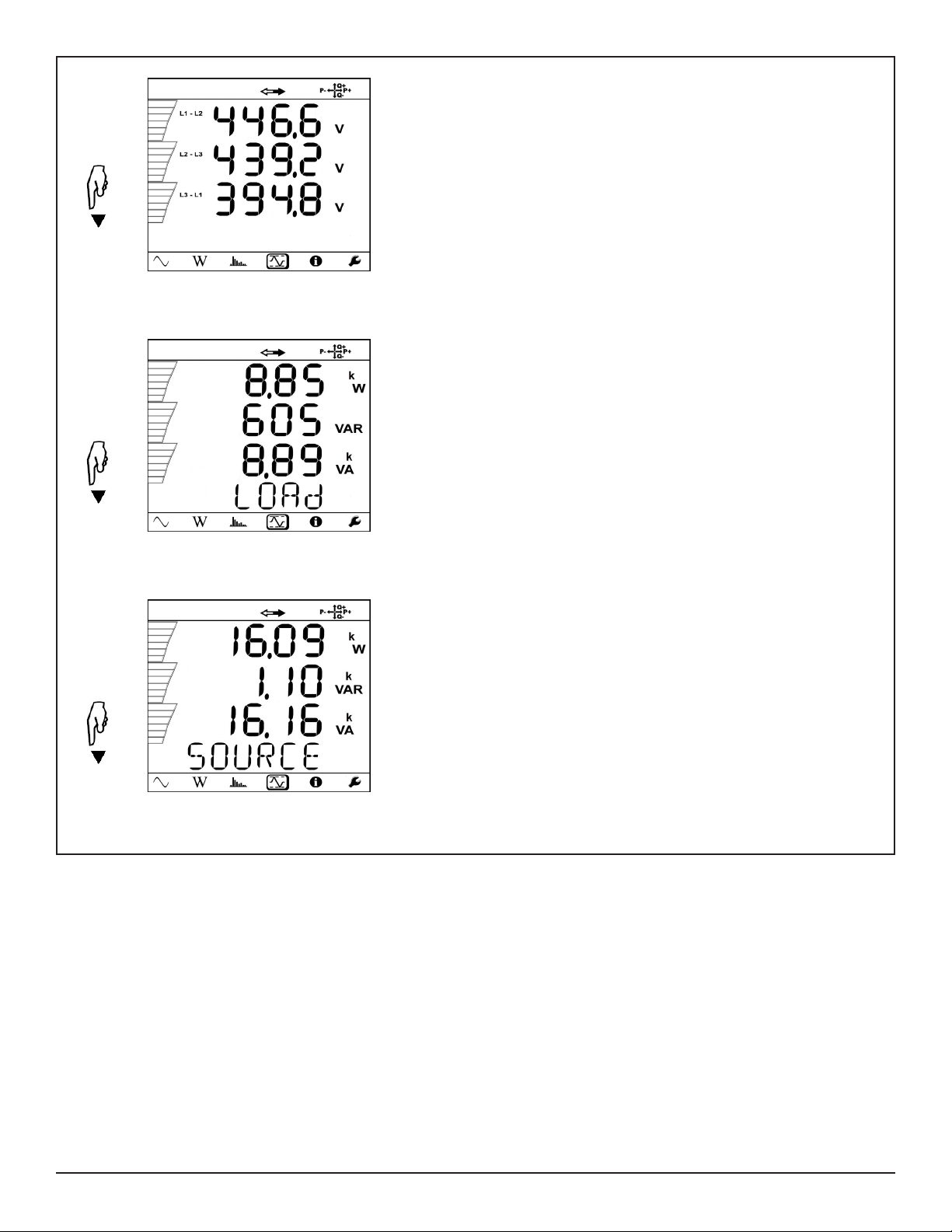

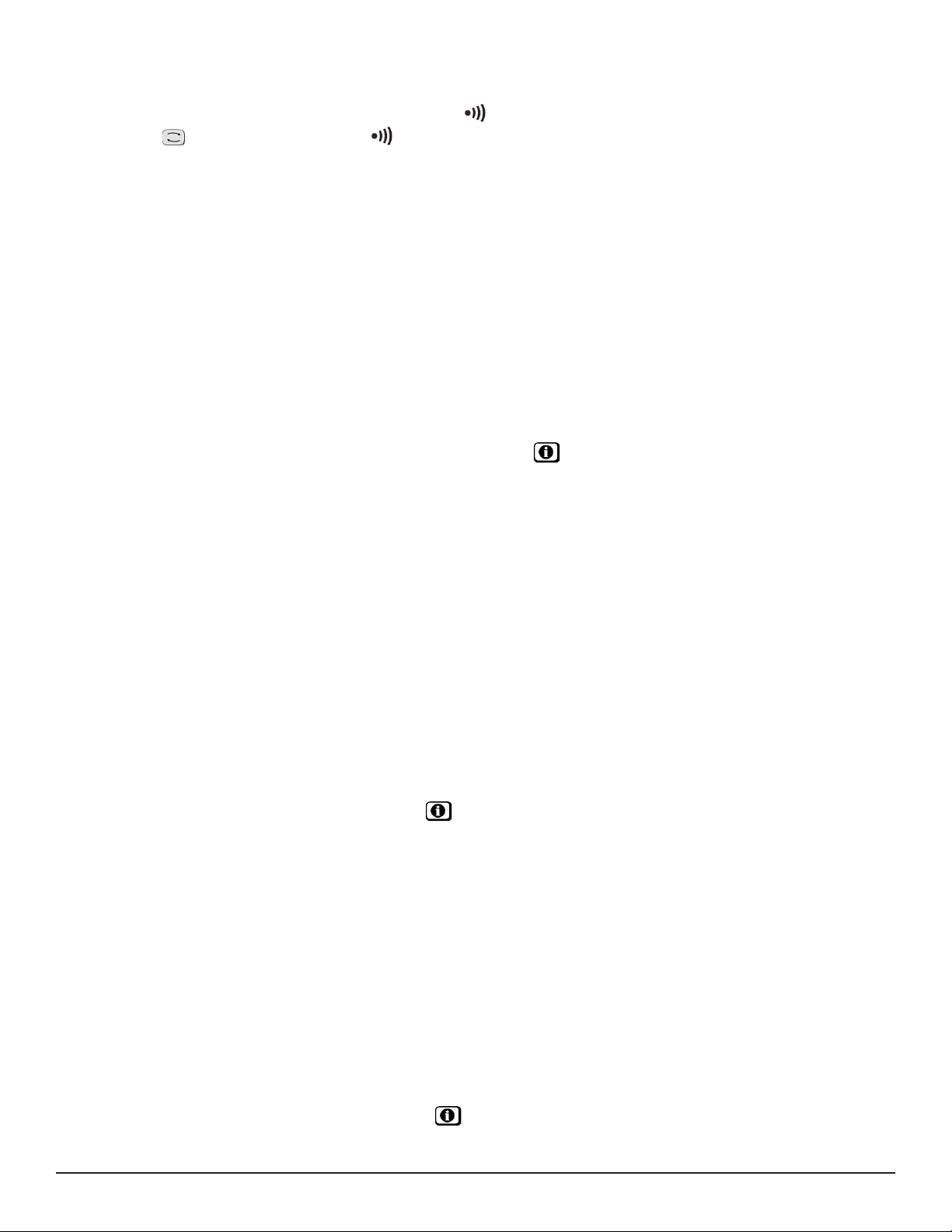

4.2 Viewing Data

The PEL 105 provides four data viewing modes:

■ Measurement mode displays real-time data currently being measured by the probes/sensors. This includes

voltage, current, power, frequency, power factor, and tangent angle.

■ Energy mode displays energy use, including reactive energy, apparent energy, and kilowatt hour.

■ Harmonics mode displays harmonics for currents and voltages.

■ Maximum mode displays the maximum values for measurement and energy values.

Press ◄ or ► to navigate to the desired mode. When a mode is selected, a box appears around its icon at the bottom of

the display screen (Figure 5). Each mode provides a set of screens for viewing data. Press ▲ or ▼ to navigate through

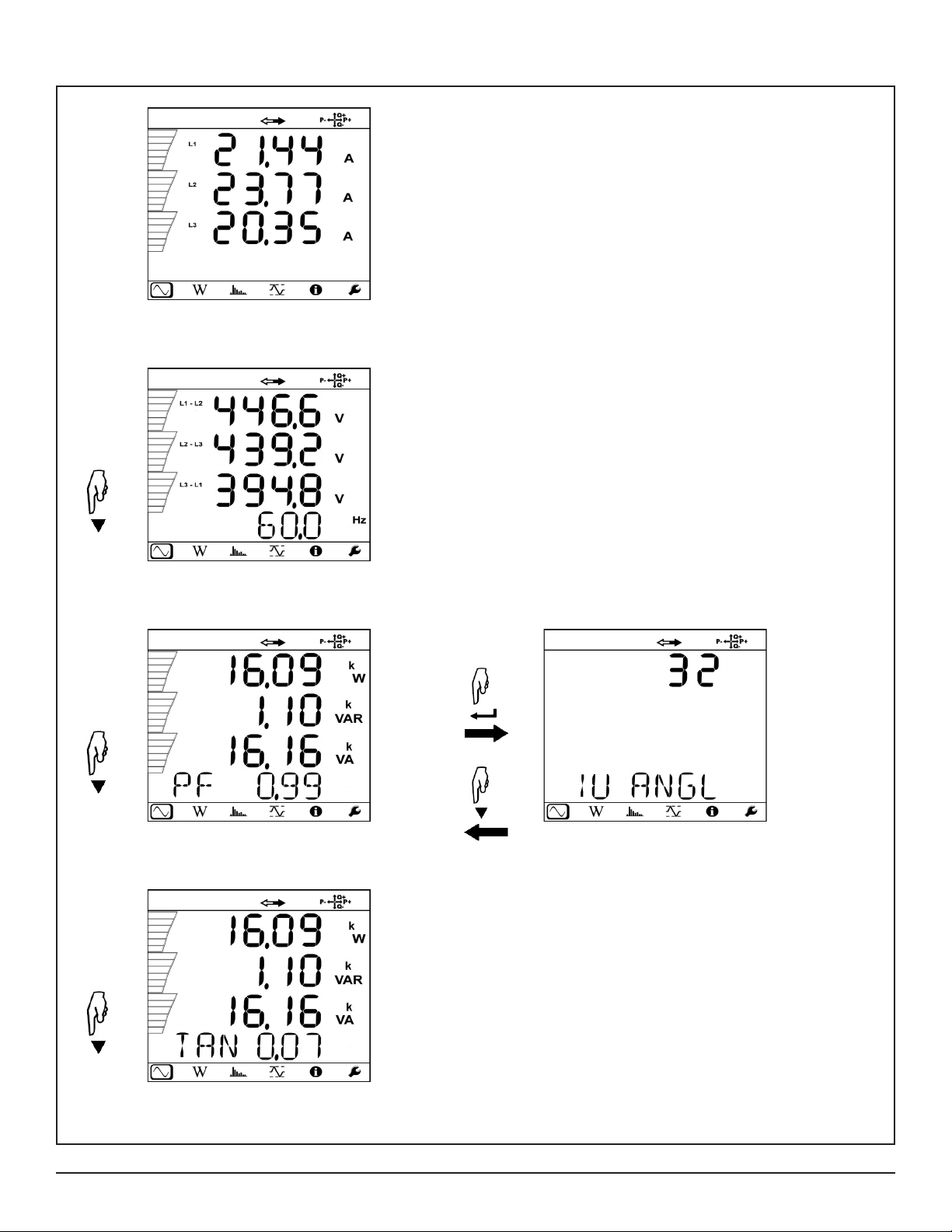

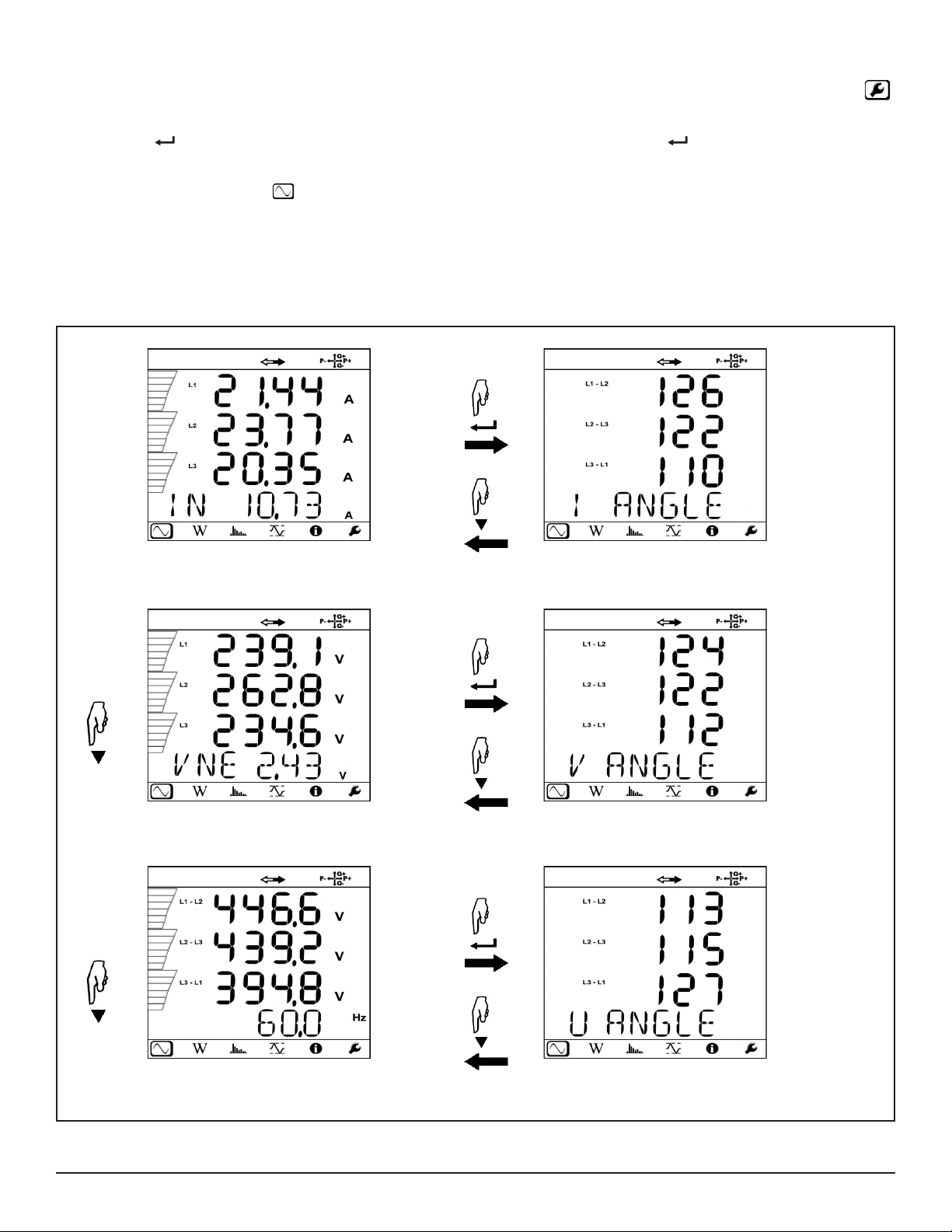

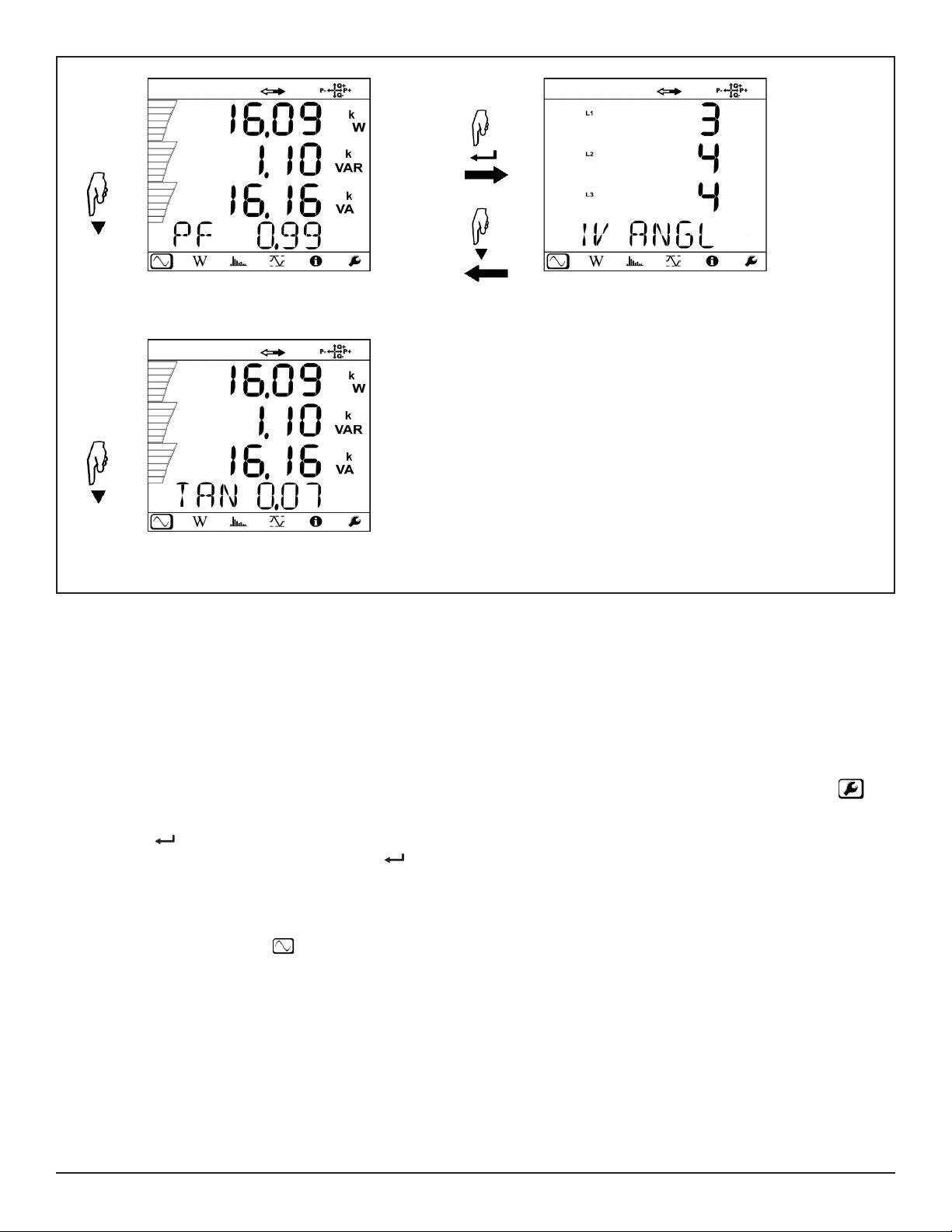

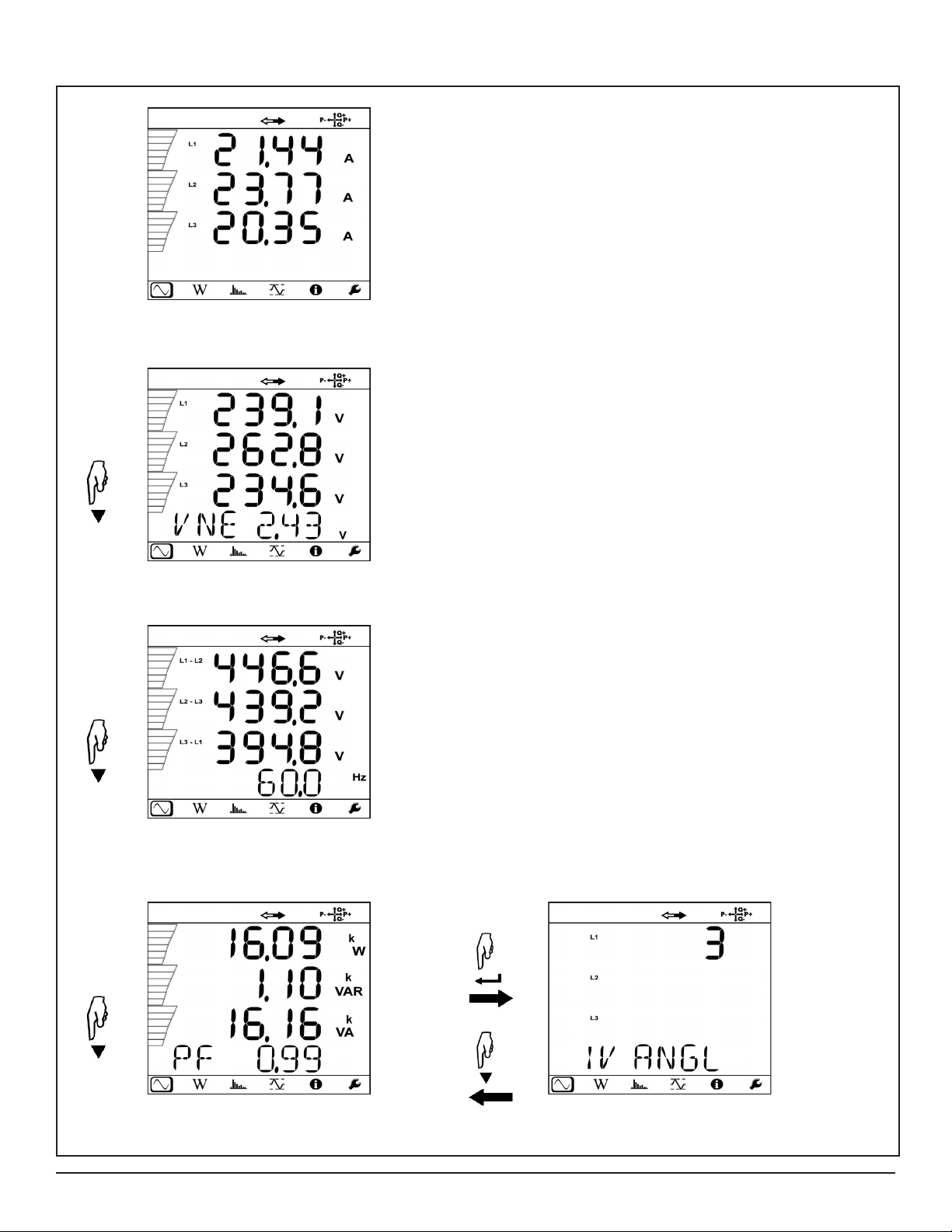

these screens. Some of these screens include additional information which you can view by pressing . For example,

several Measurement mode screens display phase angle information when you press . Pressing ▲ or▼ while viewing

an additional information screen returns to the previous screen.

The sequence of screens, and the information each one shows, is dependent on the electrical hookup setting.

The following tables list the screens available in Measurement, Energy, Harmonics, and Maximum modes. For each screen,

the following information is displayed:

■ Image of the screen.

■ Title of screen, summarizing the information it displays.

■ Button to push to view the screen, shown to the left of the screen shot.

■ A list of the variables displayed on the screen, shown to the right of the screen image. These variables are

defined in the Glossary.

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Power & Energy Logger Model PEL 105

Page 33

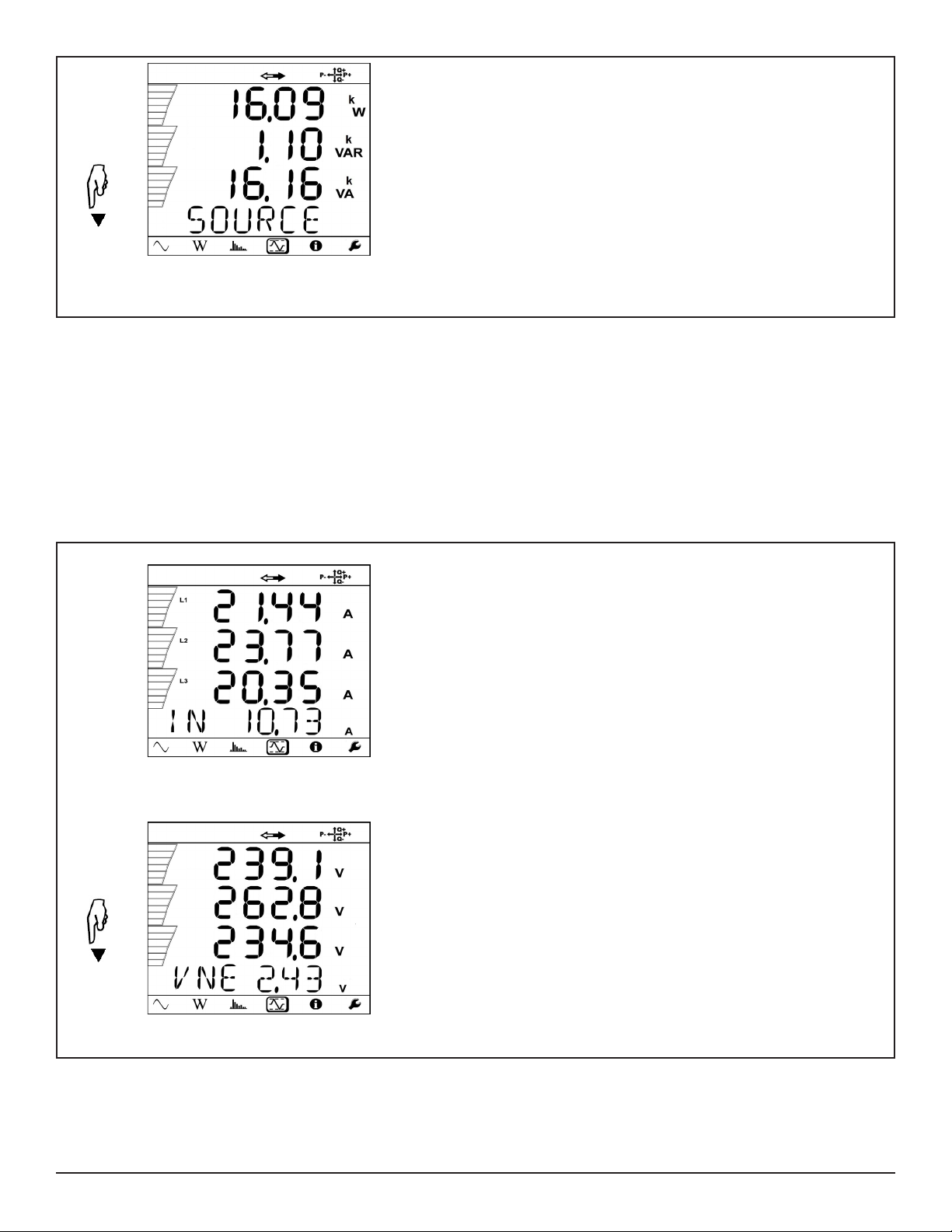

4.2.1 Measurement Mode

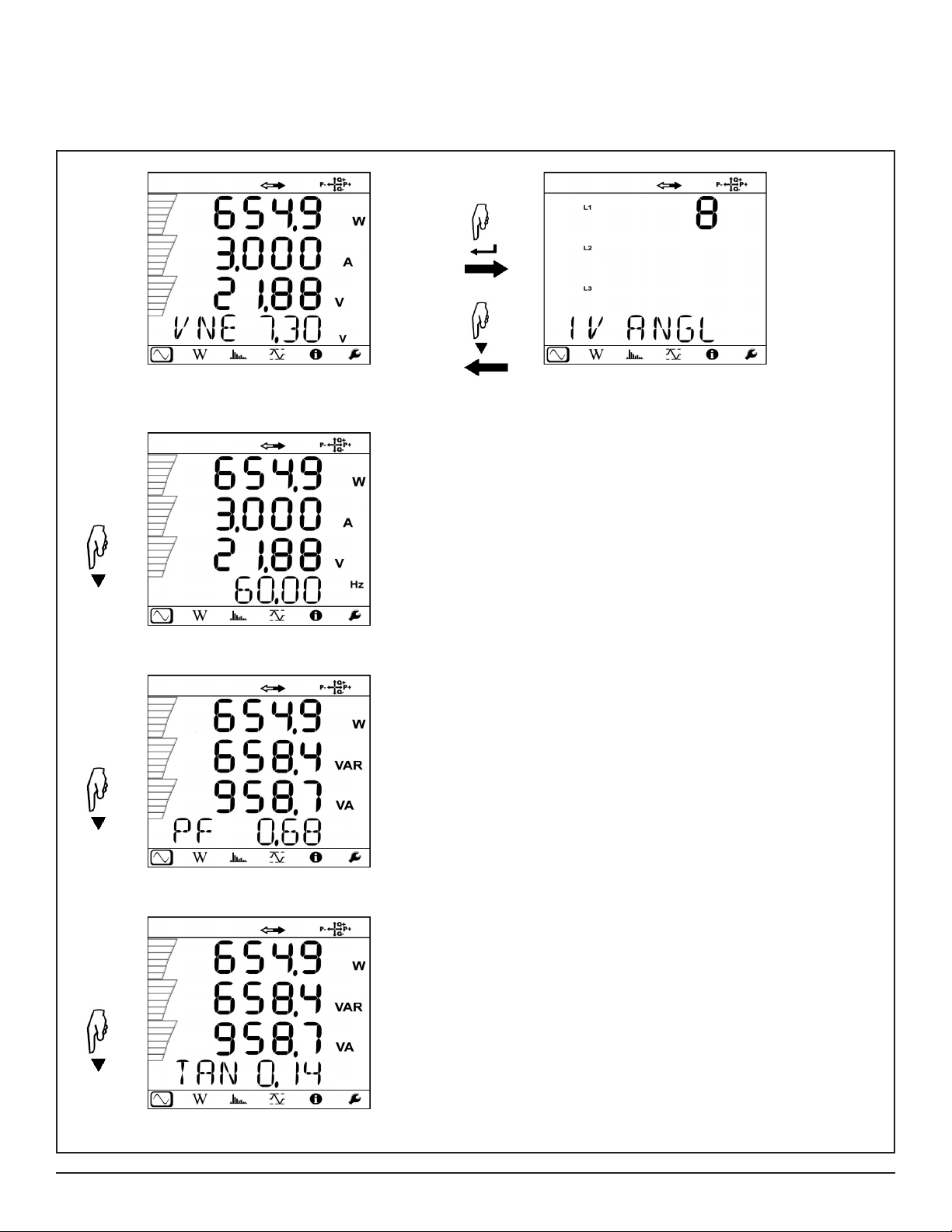

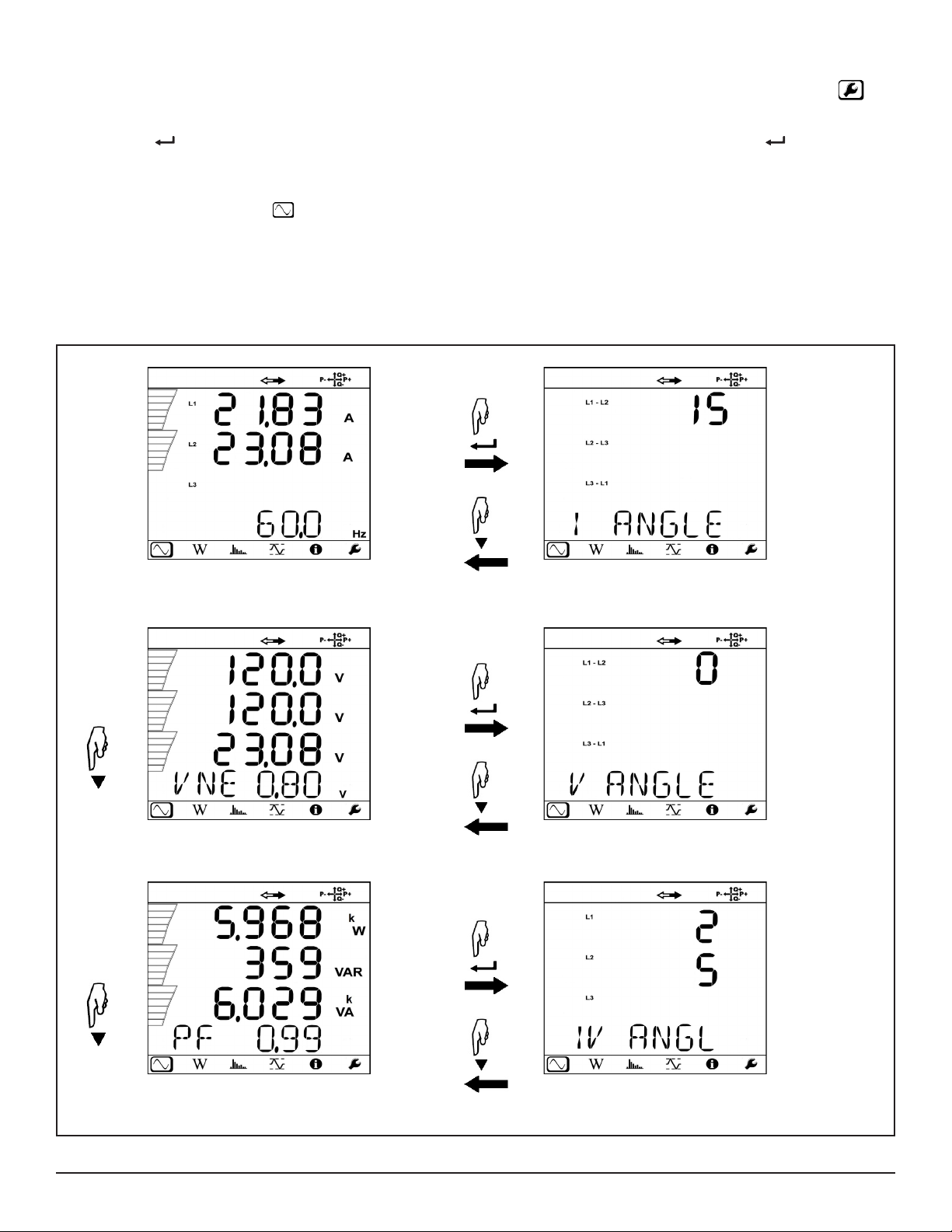

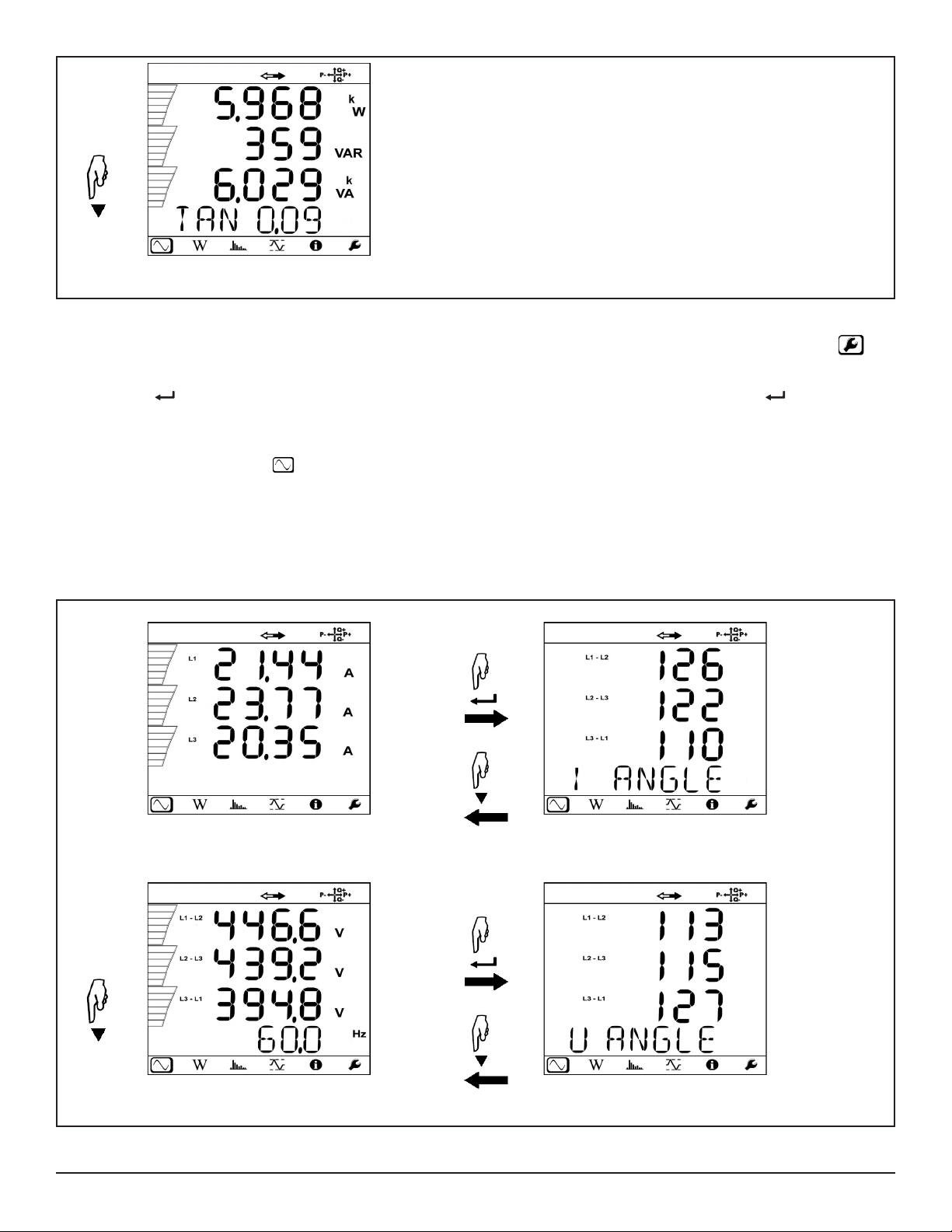

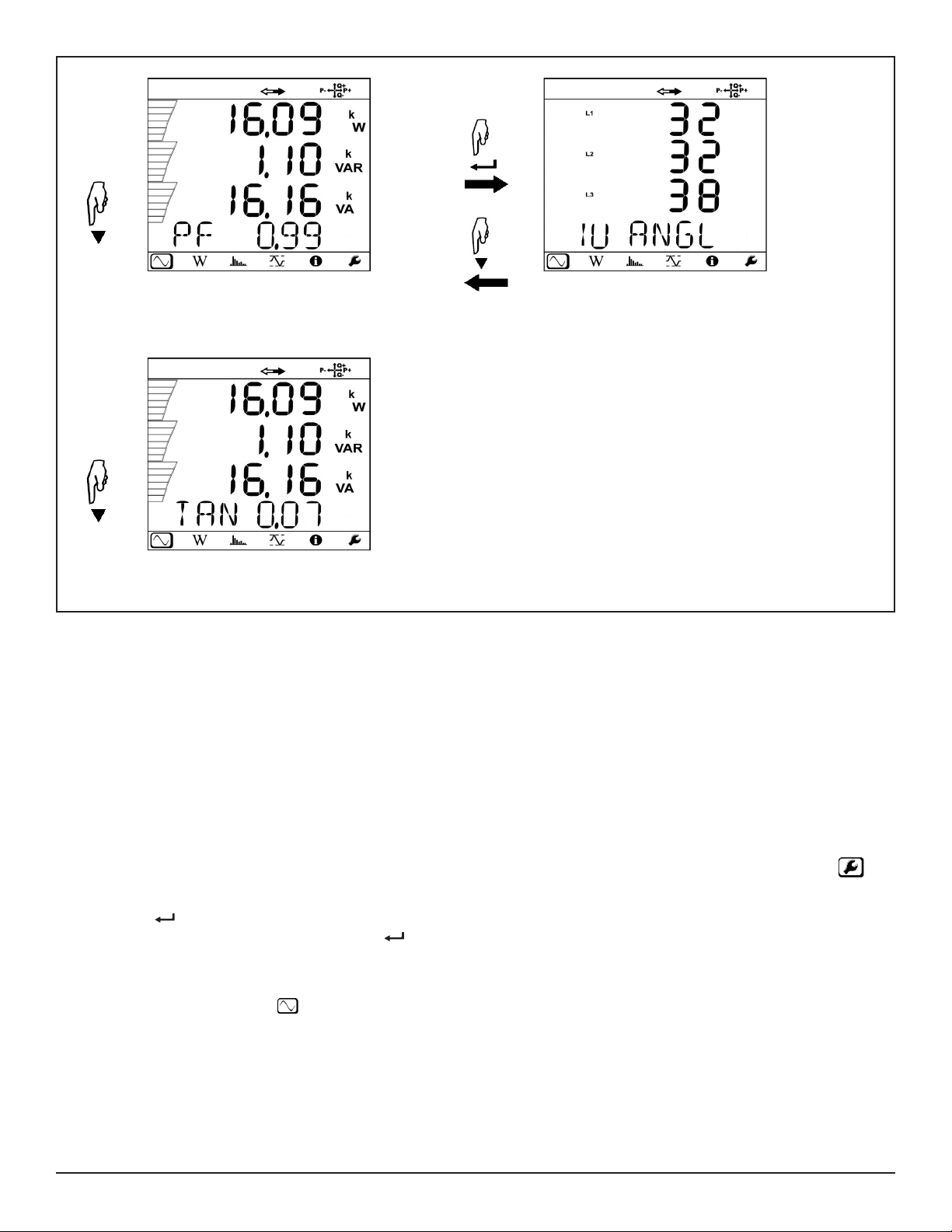

4.2.1.1 1-Phase 2-Wire (1P-2W)

ϕ (I1, V1)

P

I

V

V

N

Active power/current/voltage

(1-phase 2-wire)