ENGLISH

■

GROUND TESTER

6422

6424

User Manual

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

certifies that this instrument has been calibrated using

standards and instruments traceable to international

standards.

We guarantee that at the time of shipping your

instrument has met its published specifications.

An N.I.S.T. traceable certificate may be requested at

the time of purchase, or obtained by returning the

instrument to our repair and calibration facility, for a

nominal charge.

The recommended calibration interval for this

instrument is 12 months and begins on the date of

receipt by the customer. For recalibration, please use

our calibration services. Refer to our repair and

calibration section at www.aemc.com

.

Serial #:

Catalog #:

Model #: 6422 / 6424

Please fill in the appropriate date as indicated:

Date Received:

Date Calibration Due:

Chauvin Arnoux®, Inc.

d.b.a AEMC

®

Instruments

www.aemc.com

2 Ground Tester Models 6422/6424

CONTENTS

1. INTRODUCTION .................................................................................. 8

1.1. Battery Installation ......................................................................... 8

1.2. Battery Charging (Model 6424) .................................................... 10

1.3. Desktop Stand ............................................................................. 11

1.4. Instrument Interface ..................................................................... 11

1.5. Instrument Functions ................................................................... 13

1.6. Buttons and Keys ......................................................................... 13

1.7. LCD Display ................................................................................. 15

2. OPERATION ............................................................................... 16

2.1. Voltage Measurement .................................................................. 16

2.2. Resistance Measurement (2P) .................................................... 17

2.3. Grounding Resistance Measurement (3P) ................................... 20

2.4. AC Current Measurement (Model 6424) ...................................... 30

3. SPECIFICATIONS ...................................................................... 32

3.1. General Reference Conditions ..................................................... 32

3.2. Electrical Specifications ............................................................... 32

3.3. Influences ..................................................................................... 24

3.4. Uncertainty ................................................................................... 36

3.5. Environmental Conditions ............................................................ 37

3.6. Power Supply ............................................................................... 37

3.7. Mechanical Specifications ............................................................ 38

3.8. International Standards ................................................................ 38

3.9. Electromagnetic Compatibility (CEM) .......................................... 38

4. MAINTENANCE ......................................................................... 39

4.1. Cleaning ....................................................................................... 39

4.2. Replacing the batteries ................................................................ 39

REPAIR AND CALIBRATION .............................................................. 40

TECHNICAL AND SALES ASSISTANCE ............................................. 40

LIMITED WARRANTY ........................................................................ 41

Ground Tester Models 6422/6424 3

Thank you for purchasing the AEMC Ground Tester Model 6422 or 6424. For

best results from your instrument and for your safety, read the enclosed

operating instructions carefully and comply with the precautions for use. These

products must be only used by qualified and trained users.

WARNING, risk of DANGER! The operator must refer to these

instructions whenever this danger symbol appears.

CAUTION! Risk of electric shock. The voltage at the parts marked

with this symbol may be dangerous.

Useful information or tip.

Earth/ground.

Current clamp.

The product is declared recyclable following a life cycle analysis in

accordance with standard ISO 14040.

Battery.

Guarantees conformity with European directives and with

regulations covering EMC.

In the European Union, the product must undergo selective disposal

for the recycling of electric and electronic material, in compliance with

Directive WEEE 2002/96/EC.

4 Ground Tester Models 6422/6424

Precautions

This instrument is compliant with safety standard IEC 61010-2-030 for voltages

up to 600V in category IV. Do not use the instrument for measurements on

circuits that are not in measurement categories II, III, or IV or that might be

connected inadvertently to circuits that are not in measurement categories II, III,

or IV.

The operator and/or the responsible authority must carefully read and

clearly understand the various precautions to be taken in use. Sound

knowledge and a keen awareness of electrical hazards are essential

when using this instrument.

If you use this instrument other than as specified, the protection it

provides may be compromised, thereby endangering you.

Do not use the instrument on networks of which the voltage or category

exceeds those mentioned.

Do not use the instrument if it seems to be damaged, incomplete, or

poorly closed.

Before each use, check the condition of the insulation on the leads,

housing, and accessories. Any item of which the insulation is

deteriorated (even partially) must be set aside for repair or scrapping.

Before using your instrument, check that it is perfectly dry. If it is wet, it

must be thoroughly dried before it can be connected or used.

The use of leads (or accessories) of a lower voltage or category limits the

voltage or category of the combined instrument and leads (or

accessories) to that of the leads (or accessories).

Use personal protection equipment systematically.

When handling the leads, test probes, and alligator clips, keep your

fingers behind the physical guard.

All troubleshooting and metrological checks must be performed by

competent and accredited personnel.

Definition of Measurement Categories (CAT)

CAT IV Measurement category IV corresponds to measurements taken at the

source of low-voltage installations.

Example: power feeders, counters and protection devices.

CAT III Measurement category III corresponds to measurements on building

installations.

Example: distribution panel, circuit-breakers, machines or fixed

industrial devices.

CAT II Measurement category II corresponds to measurements taken

on circuits directly connected to low-voltage installations.

Example: power supply to domestic electrical appliances and

portable tools.

Ground Tester Models 6422/6424 5

Receiving Your Shipment

Upon receiving your shipment, make sure that the contents are consistent with

the packing list. Notify your distributor of any missing items. If the equipment

appears to be damaged, file a claim immediately with the carrier and notify your

distributor at once, giving a detailed description of any damage. Save the

damaged packing container to substantiate your claim.

Ordering Information

Ground Tester Model 6422…………………..…….……............... Cat. #2135.55

Includes 6 AA alkaline batteries, carrying bag and user manual

Ground Tester Model 6422 Kit-150 ft …………………..….......... Cat. #2135.56

Includes ground tester, two 150 ft color-coded leads on spools (red/blue),

one 30 ft lead (green), two T-shaped auxiliary ground electrodes, set of two

5 ft color-coded (red/blue) leads, one 100 ft AEMC® tape measure, 6 AA

batteries, carrying bag and user manual

Ground Tester Model 6424…………………..…….……............... Cat. #2135.57

Includes 6 AA rechargeable NiMH batteries, USB to wall charger, 5V, 2A,

USB charger cable, carrying bag and user manual

Ground Tester Model 6424 Kit-150 ft …………………..….......... Cat. #2135.58

Includes ground tester, two 150 ft color-coded leads on spools (red/blue), one

30 ft lead (green), two T-shaped auxiliary ground electrodes, set of two 5 ft

color-coded (red/blue) leads, one 100 ft AEMC

rechargeable NiMH batteries, USB to wall charger, 5V, 2A, USB charger

cable, carrying bag and user manual

®

tape measure, 6 AA

Ground Tester Model 6424 Kit-300 ft …………………..….......... Cat. #2135.59

Includes ground tester, two 300 ft color-coded leads on spools (red/blue), two

100 ft color-coded leads (hand-tied, green/black), four T-shaped auxiliary

ground electrodes, set of two 5 ft color-coded (red/blue) leads, one 100 ft

®

AEMC

charger, 5V, 2A, USB charger cable, carrying bag and user manual

tape measure, 6 AA rechargeable NiMH batteries, USB to wall

Accessories

Ground Rod – Set of 2, 17” stainless steel T-shaped

auxiliary rods ………………..……………………………….......... Cat. #2135.44

AC Current Probe Model MN72 for use with Model 6424 only... Cat. #2153.06

Calibration checker for ground tester

models 6422/6424…….… Cat. #5000.92

6 Ground Tester Models 6422/6424

Replacement Parts

Bag – Multi-purpose large canvas bag

(replacement for ground kits) …………..………..…….….......... Cat. #2119.82

Case – Replacement carrying case for Models 3620, 3640,

4600, 4610, AN1, 6422, 6424, 6501 & 6503…………….……... Cat. #2126.71

Tape measure – AEMC

Test Kit for 3-Point Testing ………………………………….…..… Cat. #2135.35

Includes two 150 ft color-coded leads on spools (red/blue), one 30 ft lead

(green), two T-shaped auxiliary ground electrodes, set of two 5 ft colorcoded (red/blue) leads, one 100 ft AEMC

Ground Rod – Set of 2, 14.5” T-shaped auxiliary rods …..…..… Cat. #2135.39

Cable – Replacement USB charger cable w/wall plug

for Model 6424 ……………………………………………….…..… Cat. #2135.93

®

100 ft ………………………….……..… Cat. #2130.60

®

tape measure, and carrying bag

Ground Tester Models 6422/6424 7

1. INTRODUCTION

1.1 Battery Installation

1. Open the battery compartment cover.

2. With your fingers on either side of the cover, insert a tool (for example a

screwdriver) in the latching system, and lift up.

3. Remove the battery compartment cover.

8 Ground Tester Models 6422/6424

4. Pull open the rubber seal covering the battery compartment.

5. Insert the batteries, ensuring correct polarities. We recommend

disposable batteries for the Model 6422 (for example alkaline) and

rechargeable batteries for the Model 6424. The Model 6422 comes with

alkaline batteries installed, and the Model 6424 with rechargeable

batteries installed.

6. Press the rubber seal back in place, ensuring it correctly covers the

compartment.

7. Replace the battery compartment cover.

If you insert disposable batteries in the Model 6424, the batteries will

last longer but the battery level indicator will be inaccurate.

If you insert rechargeable batteries in the Model 6422, the battery level

indicator will always display low battery level and the batteries

will not last as long.

Ground Tester Models 6422/6424 9

1.2 Battery Charging (Model 6424)

Before using the Model 6424 for the first time, you should fully charge the

battery. Charging must be done in a location with the temperature between 32

and 104°F (0 and 40°C).

Do not perform the charging procedure if disposable batteries are

installed in the instrument.

1. Connect one end of the provided USB cable to the Model 6424 terminal

block and the other end to a wall outlet using the provided externalpower-to-USB adapter.

2. The instrument displays CHrG. While the battery charges, the battery

level indicator displays progress. Full charging requires approximately 6

hours.

3. When the battery level indicator shows full charge disconnect the

USB cable from the instrument.

10 Ground Tester Models 6422/6424

1.3 Desktop Stand

Terminal block:

Hazardous

Backlit LCD display

TEST button

ON/OFF button

The instrument is equipped with two back supports that enable desktop operation

from an angled position. Pull the supports out to lock them in place, then place

the instrument on a flat surface.

1.4 Instrument Interface

1.4.1 Model 6422

3 measurement

terminals

voltage indicator

Ground Tester Models 6422/6424 11

1.4.2 Model 6424

Terminal block

Battery charger

input

MN72 AC Current Probe

Measurement terminals

Backlit LCD display

ON/OFF button

Function keys

TEST button

Connector for optional

Hazardous voltage indicator

Measurement data storage location

12 Ground Tester Models 6422/6424

1.5 Instrument Functions

terminals to C, P, X (§2.3.2).

The Models 6422 and 6424 are battery-powered portable measuring instruments

with LCD displays.

These instruments check the safety of electrical installations. They can be used

to test a new installation before it is powered up. They can also check an existing

installation (after it has been disconnected) or diagnose a malfunction in an

installation.

Function 6422 6424

Ground resistance measurement (with three rods)

Voltage measurement

Resistance measurement

Average of ground measurements at 52, 62, and 72%

RH over limit detection

RE over limit detection

Stray or foreign voltage on USE detection

AC current measurement with current clamp

(optional)

1.6 Buttons and Keys

Both models:

Buttons Function

Long press (>2 seconds) turns instrument ON.

Second long press turns instrument OFF.

Short press starts ground measurements in automatic mode

(§2.3.3).

Long press starts ground measurements in permanent mode.

TEST

+ TEST

Pressing TEST during a measurement stops the

measurement (§2.3.5).

At the end of the measurement, pressing TEST exits the frozen

measurement display.

Pressing and TEST simultaneously for >5 seconds while

turning ON the instrument changes the names of the H, S, E

Ground Tester Models 6422/6424 13

Model 6424 only:

Ke ys Function

V/A takes voltage measurements (§2.1), or current

V/A

Ω

measurements if a current probe is connected (§2.4).

In the latter case, a second press forces voltage

measurements.

Ω takes resistance measurements (§2.2).

Ω and TEST pressed simultaneously takes ground resistance

measurements (§2.3).

stores the displayed measurement with the S rod at 52%

of the distance (§2.3.4).

52%

0

62%

Pressing and then activates/deactivates lead

compensation.

Pressing and then for >2 seconds compensates the

resistance of the leads for the resistance measurement

(§2.2.2).

stores the displayed measurement with the S rod at 62%

of the distance (§2.3).

Pressing and then turns on backlighting for one

minute, or turns backlighting off.

stores the displayed measurement with the S rod at 72%

72%

CLR

of the distance (§2.3.4).

Pressing and then deactivates the Auto Off feature.

activates the “second” functions of the 52%, 62%, and

72% keys (§2.3).

Pressing for >2 seconds erases the values stored in

memory.

14 Ground Tester Models 6422/6424

1.7 LCD Display

1. Battery level indicator

Auto Off enabled/disabled

lead compensation

2. Input terminals

3. In a 3P ground measurement:

HOLD indicates measurement is frozen

AVG indicates the displayed measurement is the average of 3

measurements

% indicates the range of variation in the averaged measurements

4. Main display

5. Errors in the displayed measurement and (Model 6424) in the ground

measurement stored in memory

6. (Model 6424) additional information about the ground measurement

Ground Tester Models 6422/6424 15

2. OPERATION

2.1 Voltage Measurement (Model 6424)

The Model 6424 measures the RMS (Root Mean Square) voltage up to 600VAC.

1. Turn ON the instrument by pressing for >2 seconds.

2. Press to access the voltage measurement mode. The

symbol V appears on the right side of the LCD.

3. Connect one end of the leads to the V and COM terminals and the other

end to the sample under test.

The measurement appears on the LCD.

If the measurement falls outside the instrument’s measurement range,

the LCD displays >700.0V.

16 Ground Tester Models 6422/6424

2.2 Resistance Measurement (2P)

2.2.1 Model 6422

The sample under test should not be live.

1. Turn ON the instrument by pressing for >2 seconds. The

symbol 2P appears on the right side of the LCD.

2. Connect one end of the leads to the Ω and COM terminals and the other

end to the sample under test.

The measurement appears on the LCD.

Ground Tester Models 6422/6424 17

2.2.2 Model 6424

If the message Err appears, the compensation procedure failed, either

The sample under test should be de-energized.

1. Turn ON the instrument by pressing for >2 seconds. The

symbol 2P appears on the right side of the LCD.

2. If the Model 6424 is already ON but in voltage or current

measurement mode, press to access the resistance

measurement mode.

3. Before making measurements, perform lead compensation. This

subtracts the test lead resistance from the measurement. Connect one

end of the leads to the Ω and COM terminals and touch the other ends

together, creating a short-circuit.

4. Press the button.

5. Press for >2 seconds. The symbol blinks during the

compensation procedure. When finished, the LCD displays

00.00Ω.

because the value to be compensated exceeds 5Ω or because the

leads were disconnected during compensation.

Press to deactivate/reactivate lead compensation.

18 Ground Tester Models 6422/6424

6. Connect one end of the leads to the Ω and COM terminals and the other

end to the sample under test.

The measurement appears on the LCD.

The instrument displays the measured value minus the compensation.

The value displayed may be negative if the leads used for the

measurement are not the ones that were compensated. In this case,

repeat the compensation. Lead compensation is preserved after Auto

Off but not after the instrument is manually turned OFF.

Error messages:

>99.99kΩ: The measured value falls outside the instrument’s

measurement range.

NOISE: A stray or foreign voltage UHE > 3V is detected between the Ω

and COM terminals.

: A stray or foreign voltage U

and COM terminals; in this case measurement is not possible.

Note that 2P mode is useful for ensuring the H electrode connection is intact.

HE > 50V is detected between the Ω

Ground Tester Models 6422/6424 19

2.3 Grounding Resistance (3P)

This function performs a 3-pole (3P) test to measure grounding resistance when

the electrical installation to be tested is de-energized (for example a new

installation). It uses two auxiliary rods, with the third rod being the grounding

electrode to be tested (hence the name 3P or 3-pole). To perform a 3P test, the

instrument:

1. Generates a 128Hz square wave between the H and E terminals, with

an amplitude of 10V peak. If the measurement is unstable, the test

frequency will automatically switch from 128Hz to 256Hz to improve the

measurement.

2. Measures the resulting current IHE along with the voltage between the S

and E terminals USE.

3. Calculates the value of RE = U

The 3P test can also be performed on an existing electrical installation, but the

power must be OFF. Whether testing a new or existing installation, the grounding

electrode system under test must be isolated from other grounding connections

during the measurement.

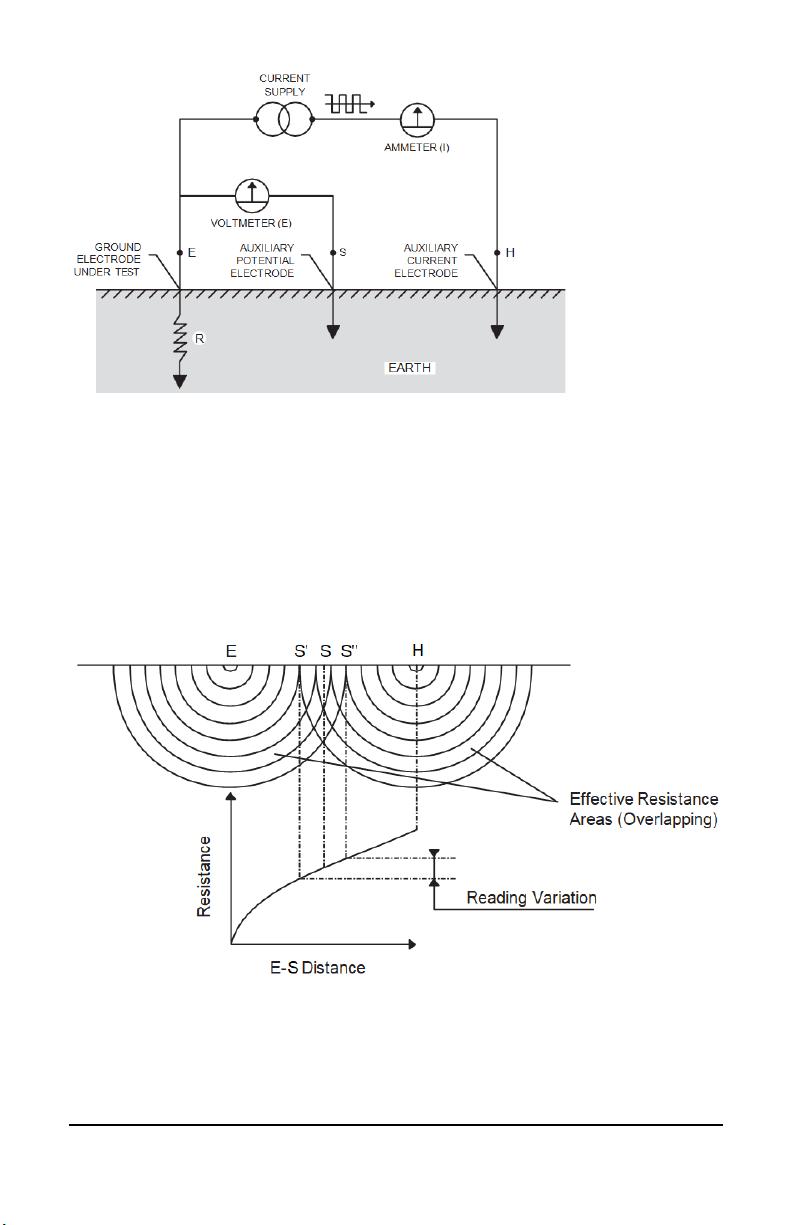

2.3.1 3-Point Test Theory of Operation

3-Point measurement is used to measure resistance to ground of auxiliary

ground electrodes and grids. The potential difference between rods E and S is

measured by a voltmeter, and the current flow between rods E and H is

measured by an ammeter.

By Ohm’s Law E = RI or R = E/I, we may obtain the ground electrode resistance

R.

SE

/ IHE.

If E = 20V and I = 1A, then:

20

E

=

I

= 20 ohms

1

R=

It is not necessary to calculate all the measurements when using a ground tester.

The ground tester will measure directly by generating its own current and

displaying the resistance of the ground electrode.

20 Ground Tester Models 6422/6424

2.3.1.1 Position of the Auxiliary Electrodes in Measurements

The goal in precisely measuring the resistance to ground is to place the auxiliary

current electrode H far enough from the ground electrode under test so that the

auxiliary potential electrode S will be outside of the effective resistance areas of

both the ground electrode and the auxiliary current electrode. The best way to

find out if the auxiliary potential rod S is outside the effective resistance areas is

to move it between E and H and to take a reading at each location. If the auxiliary

potential rod S is in an effective resistance area (or in both if they overlap), by

displacing it, the readings taken will vary noticeably in value. Under these

conditions, no exact value for the resistance to ground may be determined.

On the other hand, if the auxiliary potential rod S is located outside the effective

resistance areas, as S is moved back and forth the reading variation is minimal.

The readings taken should be relatively close to each other, and are the best

values for the resistance to ground of the ground E. The readings should be

plotted to ensure that they lie in a “plateau” region as shown below.

Ground Tester Models 6422/6424 21

2.3.1.2 Measuring Resistance of Ground Electrodes (62% Method)

The 62% method the most accurate method but is limited by the fact that the

ground tested is a single unit. This method applies only when all three electrodes

are in a straight line and the ground is a single electrode, pipe, or plate, etc., as

shown below.

Consider the illustration below, which shows the effective resistance areas

(concentric shells) of the ground electrode E and of the auxiliary current

electrode H. The resistance areas overlap.

22 Ground Tester Models 6422/6424

If readings were taken by moving the auxiliary potential electrode S towards

either E or H, the reading differentials would be great and we could not obtain a

reading within a reasonable band of tolerance. The sensitive areas overlap and

act constantly to increase resistance as S is moved away from E.

Now consider the illustration below, where the E and H electrodes are sufficiently

spaced so that the areas of effective resistance do not overlap. If we plot the

resistance, measured we find that the measurements level off when S is placed

at 62% of the distance from E to H, and that the readings on either side of the

initial Y setting are most likely to be within the established tolerance band. This

tolerance band is defined by the user and expressed as a percent of the initial

reading: ±2%, ±5%, ±10%, etc.

Ground Tester Models 6422/6424 23

2.3.1.3 Auxiliary Electrode Spacing

No definite distance between X and Z can be given, since this distance is relative

to the diameter of the electrode tested, its length, the homogeneity of the soil

tested, and particularly, the effective resistance areas. However, an approximate

distance may be determined from the following chart which is given for a

homogeneous soil and an electrode of 1" in diameter. (For a diameter of 1/2",

reduce the distance by 10%; for a diameter of 2" increase the distance by 10%.)

24 Ground Tester Models 6422/6424

Approximate Distance to Auxiliary Electrodes Using the 62% Method

6 ft

45 ft

72 ft

8 ft

50 ft

80 ft

12 ft

60 ft

96 ft

18 ft

71 ft

115 ft

20 ft

74 ft

120 ft

30 ft

86 ft

140 ft

Depth Driven Distance to Y Distance to Z

10 ft 55 ft 88 ft

2.3.1.4 Multiple Electrode System

A single driven ground electrode is an economical and simple means of making a

good ground system, but sometimes a single rod will not provide sufficient low

resistance, and several ground electrodes will be driven and connected in

parallel by a cable.

Very often when two, three or four ground electrodes are used, they are driven in

a straight line. When four or more are used, a hollow square configuration is

used and the ground electrodes are still connected in parallel and equally spaced

(see below).

Ground Tester Models 6422/6424 25

In multiple electrode systems, the 62% method electrode spacing may no longer

Max Grid Distance

Distance to Y

Distance to Z

6 ft

78 ft

125 ft

8 ft

87 ft

140 ft

10 ft

100 ft

160 ft

12 ft

105 ft

170 ft

14 ft

118 ft

190 ft

16 ft

124 ft

200 ft

18 ft

130 ft

210 ft

20 ft

136 ft

220 ft

30 ft

161 ft

260 ft

40 ft

186 ft

300 ft

50 ft

211 ft

340 ft

60 ft

230 ft

370 ft

80 ft

273 ft

440 ft

100 ft

310 ft

500 ft

120 ft

341 ft

550 ft

140 ft

372 ft

600 ft

160 ft

390 ft

630 ft

180 ft

434 ft

700 ft

200 ft

453 ft

730 ft

be applied directly. The distance of the auxiliary electrodes is now based on the

maximum grid distance (e.g. in a square, the diagonal; in a line, the total length).

A square having a side of 20 ft will have a diagonal of approximately 28 ft.

Multiple Electrode System

2.3.2 Terminals Definitions

By default, the instrument’s terminals are defined as H, S, and E. To change

these to C, P, and X:

While turning ON the instrument, simultaneously press and

hold down the and TEST buttons for >5 seconds. The

terminal assignments will be changed to C, P, and X. These

assignments will be retained even when the instrument is

turned OFF.

26 Ground Tester Models 6422/6424

2.3.3 Grounding Resistance Measurement

For the first grounding resistance test, we recommend starting with the 62%

distance.

1. Place the H and S rods in a line with the grounding electrode under test.

The distance between the S rod and the grounding electrode must be

approximately 62% of the distance (d) between the H rod and the

grounding electrode. (To avoid electromagnetic interference, we

recommend using the full length of the cables, placing them several

inches apart and avoiding loops.)

2. Connect the cables to the H and S terminals.

3. Power down the installation and isolate the ground under test from other

ground systems and connections.

4. Connect the E terminal to the grounding electrode to be tested.

5. Press TEST to take a measurement in automatic mode.

The TEST button blinks red, then the measurement is displayed. It

remains frozen (HOLD) until you press TEST again.

(Model 6424) R

and USE values are displayed.

H

Ground Tester Models 6422/6424 27

2.3.4 Measurement Average (Model 6424)

After completing the measurement made with the S rod at 62% of the distance

between the H rod and the grounding electrode, press to store the value in

memory.

1. Place the S rod at 72% of the distance d and take another measurement.

2. Press to store the measurement.

3. Place the S rod at 52% of d, and take another measurement.

4. Press to store the measurement.

The instrument immediately calculates and displays the average of the

three measurements and the percent difference between the lowest and

highest values. For the measurement to be valid, the difference must not

exceed 5%. If it is, place the H electrode out further and repeat the tests

at the 52%, 62%, and 72% distances.

Press for >2 seconds to erase the stored measurements.

28 Ground Tester Models 6422/6424

2.3.5 Measurement Mode (Model 6424)

1. Place the H and S rods and connect the instrument as explained in

§2.3.2.

2. Press TEST for >2 seconds to start the measurement.

The TEST button blinks red, then the measurement is displayed.

(Model 6424) RH and USE values are displayed.

3. Press TEST to stop the measurement.

2.3.6 Validating the Measurement

1. Place S rod at 72% of d and take a measurement.

2. Move the S rod to 52% of d and take a measurement.

All three measurements must be within 5% of each other for the measurement to

be valid. If not, the S rod is within the zone of influence of the grounding

electrode. If this is the case, place the H electrode further away and repeat the

measurement.

Ground Tester Models 6422/6424 29

2.3.6.1 Auxiliary Rod Positioning

To ensure measurements are not distorted by interference, we recommend

repeating the measurement with the auxiliary rods placed at a different distance

and in another direction (for example rotated 90° from the first alignment).

If the measurements match, they are valid. If they differ significantly, they could

be influenced by factors such as ground currents or a groundwater artery. In this

case, we recommend driving the auxiliary rods deeper into the ground.

If in-line rod configuration is not possible, you can place the rods in an equilateral

triangle. To validate the measurement, move the S rod on either side of the line

HE.

2.3.6.2 Ground Measurement Tips

To avoid “cross-talk” with the measurement current, do not route the

connecting cables of the rods near or parallel to other cables

(transmission or power supply), metal pipes, rails, or fences.

To reduce auxiliary rod resistance, add one or more rods, two meters

apart, in the H (S) circuit of the circuit.

Another way to reduce rod resistance is to drive the rods deeper and

firmly pack the earth around them, or sprinkle water on them.

After completing the measurement, reconnect the grounding strip

before restoring power to the installation.

30 Ground Tester Models 6422/6424

2.3.7 Error Messages

>3.000kΩ

RH ! (blinking)

(Model 6422) Measurement outside range

>60.00kΩ

S (blinking)

P (blinking)

NOISE

(Model 6424) Measurement outside range

S rod resistance >50kΩ

H rod resistance >15kΩ

or UHE voltage amplitude is between 3 and 50V

U

SE

(blinking)

USE or UHE > 50V (no measurement is possible)

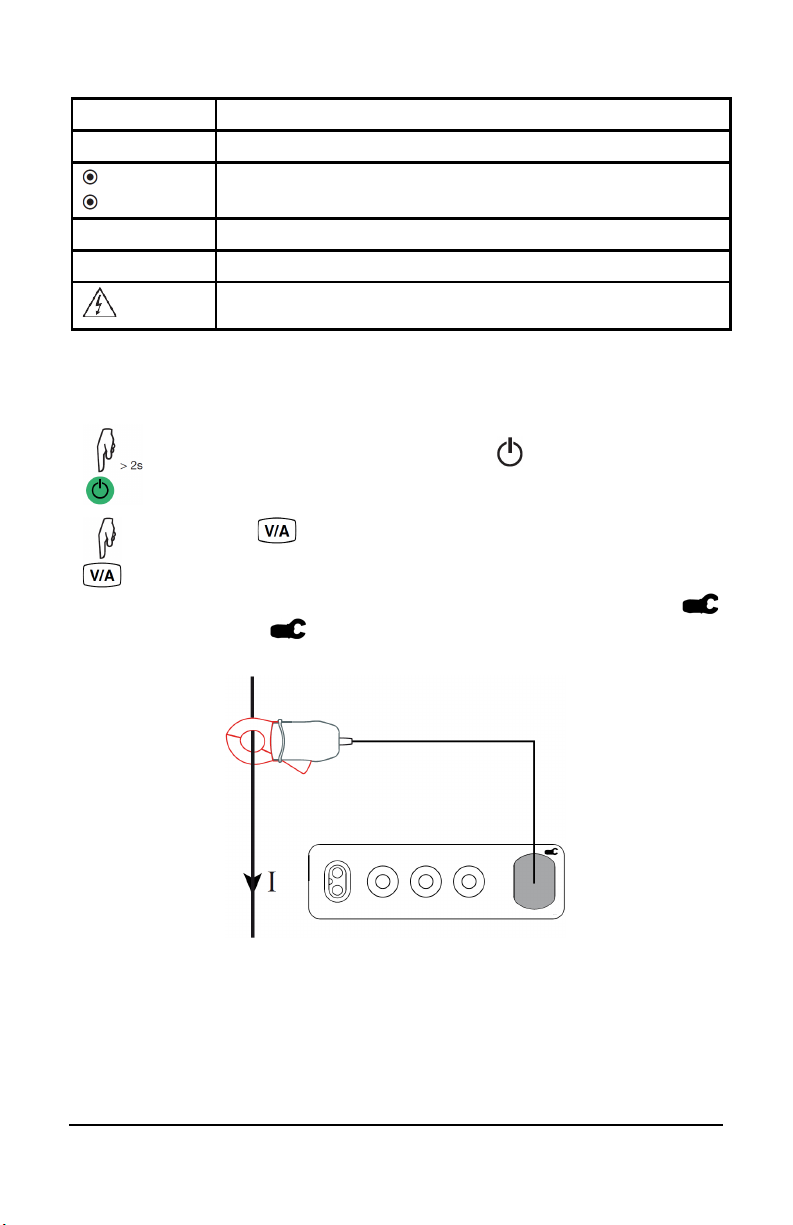

2.4 AC Current Measurement (Model 6424)

AC current measurement requires an optional MN72 current probe.

1. Turn ON the instrument by pressing for >2 seconds.

2. Press .

3. Connect the clamp to the instrument’s current terminal (identified by the

symbol). The A and symbols appear on the LCD.

4. Open the clamp and place it on the conductor under test.

Ground Tester Models 6422/6424 31

The measurement appears on the LCD.

Error messages:

>70.00A: The measured value falls outside the instrument’s

measurement range.

Err: The probe is not completely inserted (the symbol also

blinks).

32 Ground Tester Models 6422/6424

3. SPECIFICATIONS

Quantity of influence

Reference values

Model 6424: 6 ± 0.2 V

Frequency

45 to 65Hz

Electric field

< 0.1V/m

Magnetic field

< 40A/m

Resolution

0.1V

Intrinsic uncertainty

± (1% R + 1 ct)

3.1 General Reference Conditions

Temperature 73 ± 3.6 °F (23 ± 2 °C)

Relative humidity 45 to 75% RH

Supply voltage

Intrinsic uncertainty is the error defined under the reference conditions.

Operating uncertainty includes the intrinsic uncertainty plus the effects of

variation of the quantities of influence (supply voltage, temperature, interference,

etc.) as defined in standard IEC 61557-5.

The uncertainties are expressed in % of the reading (R) and in number of display

counts (ct): ± (a% R + b ct)

The Model 6424 cannot make measurements when the battery

charger is connected.

Model 6422: 8 ± 0.2 V

3.2 Electrical Specifications

3.2.1 Voltage Measurement

Additional reference condition:

Peak factor = √2

UHE Voltage Measurement

Measurement range 0.1 – 600.0V

Ground Tester Models 6422/6424 33

3.2.2 Resistance Measurement (2P)

range

uncertainty

voltage

range

Intrinsic

uncertainty

frequency

±10V

PEAK

Measurement

range

Resolution

0.01Ω

0.1Ω

1Ω

10Ω

uncertainty

Measurement

frequency

voltage

Additional reference conditions:

External voltage between H and E terminals = zero.

Resistance of the leads ≤ 0.1Ω.

Measurement

Resolution

Intrinsic

UHE no-load

0.05 - 99.99Ω 80.0 - 999.9Ω 0.800 - 9.999kΩ 8.00 - 50.00kΩ

0.01Ω 0.1Ω 1Ω 10Ω

± (2% R + 10 ct) ± (2% R + 2 ct) ± (2% R + 1 ct) ± (2% R + 1 ct)

±10V

PEAK

The compensation of the leads of the Model 6424 may result in a negative

reading of up to 5Ω.

3.2.3 Ground Resistance Measurement (3P)

Additional reference conditions:

Resistance of the E lead: ≤ 0.1Ω

R

(rod + lead) ≤ 100Ω

H

(rod + lead) ≤ 1kΩ

R

S

Spurious voltages on U

Model 6422 Ground Measurement

Measurement

Resolution

Measurement

and USE ≤ 0.01V

HE

0.50 - 99.99Ω 80.0 - 999.9Ω 0.800 – 2.000kΩ

0.01Ω 0.1Ω 1Ω

± (1% R + 10 ct) ± (1% R + 2 ct) ± (1% R + 1 ct)

128Hz or 256Hz

No-load voltage

Model 6424 Ground Measurement

Intrinsic

No-load

The measurement current is a square signal of not more than 20mA.

34 Ground Tester Models 6422/6424

0.50 - 99.99Ω 80.0 - 999.9Ω 0.800 - 9.999kΩ 8.00 - 50.00kΩ

± (1% R + 10 ct) ± (1% R + 2 ct) ± (1% R + 1 ct) ± (1% R + 1 ct)

128Hz, or 256Hz if the spurious voltage is at 128Hz

±10V

PEAK

RH Ground Electrode Resistance Measurement (Model 6424)

8.00 – 49.99kΩ

1Ω

10Ω

0.01V

0.1V

range

uncertainty

of use

Variation of the measurement

Typical

Maximum

Frequency

DC to 440Hz

-

-3dB

Peak factor

1.4 to 3 (up to 300V)

-

± 1% R

Measurement range

Resolution

Intrinsic uncertainty

Voltage Measurement (Model 6424)

U

SE

Measurement range

Resolution

Intrinsic uncertainty

The instrument is protected up to 600V between any two of the three input

terminals.

0.050 – 9.999kΩ

± (10% R + 1 ct) ± (10% R + 1 ct)

0.10 - 99.99V

± (2% R + 2 ct) ± (2% R + 2 ct)

80.0 - 600.0V

AC/DC

AC/DC

3.2.4 Current Measurement (Model 6424)

Additional reference condition:

Peak factor = √2

Measurement

0.5 - 999.9mA 0.800 - 9.999A 8.00 - 60.00A

Resolution

Intrinsic

0.1mA 1mA 10mA

± (1% R + 4 ct) ± (1% R + 2 ct) ± (1% R + 2 ct)

3.3 Influences

3.3.1 Voltage Measurement (Model 6424)

Quantities of influence

Temperature

Relative humidity 10 to 90% RH - ± 2% R

DC and 50/60Hz

common mode rejection

Limits of the range

14 to + 122 °F

(-10 to + 50 °C)

0 to 600VAC 65dB 50dB

± 0.2% R ± (0.5% R + 1 ct)

Ground Tester Models 6422/6424 35

3.3.2 Resistance Measurement (2P)

influence

of use

Variation of the measurement

Typical

Maximum

Relative humidity

10 to 90% RH

± 1% R

± 2% R

posed on

influence

of use

Variation of the measurement

Typical

Maximum

Relative humidity

10 to 90% RH

-

± 2% R

Rod resistance

RS

Quantities of

Temperature

Supply voltage

50/60Hz voltage

superim

the test voltage

Limits of the range

14 to + 122 °F

(-10 to + 50 °C)

Model 6422: 6.0 to 9.6V

Model 6424: 6.0 to 7.6V

0 to 3V

3 to 25V

3.3.3 Ground Measurement (3P)

Quantities of

Temperature

Supply voltage

Voltage in series

between S and

E, 50/60Hz

Limits of the range

14 to + 122 °F

(-10 to + 50 °C)

Model 6422: 6.0 to 9.6V

Model 6424: 6.0 to 7.6V

0 to 3V ± (0.5% R + 0.2Ω) ± (1% R + 1Ω)

3 to 25V ± (2% R + 8Ω) ± (4% R + 20Ω)

± (25 ppm R +

10mΩ/°C)

- ± (2% R + 1Ω)

± (0.5% R + 0.5Ω)

± (2% R + 5Ω)

± 1% R ± 2% R

- ± (2% R + 1Ω)

± (200 ppm R +

2 mΩ/°C)

± (2% R + 1Ω)

± (4% R + 10Ω)

Voltage in series

between H and

E, 50/60Hz

Rod resistance

R

H

36 Ground Tester Models 6422/6424

0 to 3V ± (0.5% R + 0.2Ω) ± (1% R + 1Ω)

3 to 25V ± (20% R + 10Ω) ± (30% R + 20Ω)

0 to 50 kΩ - ± (2% R + 1Ω)

< 100 x R

R

H

and RH < 50kΩ

E

± (2% R + 2 ct) ± (10% R + 5 ct)

3.3.4 Current Measurement (Model 6424)

influence

of use

Variation of the measurement

Typical

Maximum

Relative humidity

10 to 90% RH

± 0% R

± 1% R

Quantities of

Temperature

Limits of the range

14 to + 122 °F

(-10 to + 50 °C)

± 250 ppm R ± 500 ppm R

Frequency DC to 440Hz - -3dB

Peak factor 1.4 to 3 (up to 30A) ± 0% R ± 1%

3.4 Uncertainty

The instruments comply with standard IEC-61557 part 5, which requires that the

operating uncertainty (B) be less than 30%.

In ground measurement:

= ±||+ .

+

+

+

+

with

A = intrinsic uncertainty

E1 = influence of the reference position ± 90°

E

= influence of the supply voltage within the limits indicated by the

2

manufacturer

E3 = influence of the temperature between 32 and 95°F (0 and 35°C)

E

= influence of the interference voltage in series mode (3V at 16.6; 50; 60

4

and 400Hz)

E5 = influence of the resistance of the rods from 0 to 100 x RA but ≤ 50kΩ

E

= influence of the network frequency from 99 to 101% of the nominal

7

frequency

E

= influence of the network voltage from 85 to 110% of the nominal voltage

8

The uncertainty of operation of the instrument is ≤ 15% + 1Ω

+

+

Ground Tester Models 6422/6424 37

3.5 Environmental Conditions

Voltage /

Current

> 2500 measurements from 5s to

100Ω

> 2000 measurements from 5s to

100Ω

Ground test

(3P)

> 2000 measurements from

100Ω

Instrument off

> 1 year

> 1 year

1 = Reference range, 70 to 77°F (21 to 25°C)

2 = Operating range, 14 to 122°F (-10 to +50°C)

3 = Storage range (without batteries), -40 to +158°F (-40 to +70°C)

Range for recharging of the rechargeable batteries; 32 to 104°F (0 to 40°C)

Indoor and outdoor use

Altitude < 6500’ (2,000m)

Pollution degree 2

3.6 Power Supply

Model 6422: 6 LR6 or AA disposable batteries.

Model 6424: 6 NiMH type AA rechargeable batteries. The charging time is

approximately 6 hours.

During charging, the instrument cannot make measurements. All front

panel buttons are disabled.

Typical time between battery charges

Function

Resistance

Model 6422

(disposable batteries

> 80h > 50h

> 1500 measurements from 100Ω

Model 6424

(rechargeable batteries)

38 Ground Tester Models 6422/6424

3.7 Mechanical Specifications

Dimensions (L x D x H): 8.78 x 4.96 x 2.75” (223 x 126 x 70mm)

Weight:

Protection class:

Free fall test:

approximately 2.2 lb (1kg)

IP 65 per IEC 60 529 IK 04

per IEC 50102

1 meter per IEC 61010-1

3.8 International Standards

The instrument:

Conforms with IEC 61010-2-030, 600V CAT IV, pollution degree 2.

Assigned characteristics: measurement CAT IV, 600 V with respect to

earth.

Complies with IEC 61557 parts 1 and 5.

Is protected by reinforced insulation.

3.9 Electromagnetic Compatibility (CEM)

The instrument conforms with standard IEC 61326-1.

Ground Tester Models 6422/6424 39

4. MAINTENANCE

Except for the batteries, the instrument contains no parts that can

be replaced by personnel who have not been specially trained and

accredited. Any unauthorized repair or replacement of a part by

an “equivalent” may severely impair safety.

4.1 Cleaning

Disconnect the instrument from all leads, probes, etc. and turn it OFF.

Use a soft cloth, dampened with soapy water. Rinse with a damp cloth and dry

rapidly with a dry cloth or forced air. Do not use alcohol, solvents, or

hydrocarbons.

4.2 Battery Replacement

1. Disconnect the instrument from all leads, probes, etc. and turn it OFF.

2. Open the battery compartment as instructed in §1.1.

3. Remove the old batteries.

4. Insert new batteries as instructed in §1.1.

Spent batteries must not be treated as ordinary household waste.

Take them to the appropriate recycling collection facility.

40 Ground Tester Models 6422/6424

REPAIR AND CALIBRATION

To ensure that your instrument meets factory specifications, we recommend that

it be sent back to our factory Service Center at one-year intervals for

recalibration, or as required by other standards or internal procedures.

For instrument repair and calibration:

You must contact our Service Center for a Customer Service Authorization

Number (CSA#). This will ensure that when your instrument arrives, it will be

tracked and processed promptly. Please write the CSA# on the outside of the

shipping container. If the instrument is returned for calibration, we need to know if

you want a standard calibration; or a calibration traceable to N.I.S.T. (includes

calibration certificate plus recorded calibration data).

Ship To: Chauvin Arnoux

15 Faraday Drive

Dover, NH 03820 USA

Phone: (800) 945-2362 (Ext. 360)

(603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

E-mail: repair@aemc.com

(Or contact your authorized distributor)

Cost for repair, standard calibration, and calibration traceable to N.I.S.T. are

available.

NOTE: You must obtain a CSA# before returning any instrument.

®

, Inc. d.b.a. AEMC® Instruments

TECHNICAL AND SALES ASSISTANCE

If you are experiencing any technical problems, or require any assistance with

the proper operation or application of your instrument, please call, mail, fax or email our technical support team:

Chauvin Arnoux

Phone: (800) 343-1391

(508) 698-2115

Fax: (508) 698-2118

E-mail: techsupport@aemc.com

www.aemc.com

NOTE: Do not ship instruments to our Foxborough, MA address.

®

, Inc. d.b.a. AEMC® Instruments

Ground Tester Models 6422/6424 41

LIMITED WARRANTY

The instrument is warranted to the owner for a period of two years from the date

of original purchase against defects in manufacture. This limited warranty is

given by AEMC

purchased. This warranty is void if the instrument has been tampered with or

abused, or if the defect is related to service not performed by AEMC

Instruments. The warranty does not apply in the following cases:

Inappropriate use of the equipment or use with incompatible equipment.

Modifications made to the equipment without the explicit permission of the

manufacturer’s technical staff.

Work done on the device by a person not approved by the manufacturer.

Adaptation to a particular application not anticipated in the definition of the

equipment or not indicated in this user’s manual.

Damage caused by shocks, falls, or floods.

Full warranty coverage and product registration is available on our website at

www.aemc.com/warranty.html

Information for your records.

What AEMC® Instruments will do: If a malfunction occurs within the warranty

period, you may return the instrument to us for repair, provided we have your

warranty registration information on file or a proof of purchase. AEMC

Instruments will, at its option, repair or replace the faulty material.

®

Instruments, not by the distributor from whom it was

. Please print the online Warranty Coverage

REGISTER ONLINE AT:

www.aemc.com

®

®

Warranty Repairs

What you must do to return an Instrument for Warranty Repair:

First, request a Customer Service Authorization Number (CSA#) by phone or by

fax from our Service Department (see address below), then return the

instrument along with the signed CSA Form. Please write the CSA# on the

outside of the shipping container. Return the instrument, postage or shipment

pre-paid to:

Chauvin Arnoux

15 Faraday Drive • Dover, NH 03820 USA

Phone: (800) 945-2362 (Ext. 360)

(603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

E-mail: repair@aemc.com

Caution: To protect yourself against in-transit loss, we recommend you insure

your returned material.

NOTE: You must obtain a CSA# before returning any instrument.

®

, Inc. d.b.a. AEMC® Instruments

42 Ground Tester Models 6422/6424

Ground Tester Models 6422/6424 43

03/20

99-MAN 100517 v1

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

15 Faraday Drive • Dover, NH 03820 USA

Phone: (603) 749-6434 • Fax: (603) 742-2346

www.aemc.com

Loading...

Loading...