Page 1

MICRO-OHMMETER

6250

ENGLISH

User Manual

Page 2

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

certifies that this instrument has been calibrated

using standards and instruments traceable to

international standards.

We guarantee that at the time of shipping your

instrument has met its published specifications.

An NIST traceable certificate may be

requested at the time of purchase, or obtained

by returning the instrument to our repair and

calibration facility, for a nominal charge.

The recommended calibration interval for this

instrument is 12 months and begins on the date of

receipt by the customer. For recalibration, please

use our calibration services. Refer to our repair

and calibration section at www.aemc.com.

Serial #: ________________________________

Catalog #: 2129.81

Model #: 6250

Please fill in the appropriate date as indicated:

Date Received: _________________________________

Date Calibration Due: _______________________

Chauvin Arnoux®, Inc.

d.b.a AEMC® Instruments

www.aemc.com

Page 3

READ CAREFULLY BEFORE

USING FOR THE FIRST TIME

Your instrument is equipped with a NiMH battery. This technology oers several

advantages:

• Long battery charge life for a limited volume and weight.

• Possibility of quickly recharging your battery.

• Signicantly reduced memory eect: you can recharge your

battery even if it is not fully discharged.

• Respect for the environment: no pollutant materials such as lead

or cadmium, in compliance with the applicable regulations.

After prolonged storage, the battery may be completely discharged. If so, it must

be completely recharged.

Your instrument may not function during part of this recharging operation.

Full recharging of a completely discharged battery may take several hours.

NOTE: In this case, at least 5 charge/discharge cycles will be necessary

for your battery to recover 95% of its capacity.

To make the best possible use of your battery and extend its eective service life:

• Only use the charger supplied with your instrument. Use of

another charger may be dangerous.

• Only charge your instrument at temperatures between 0° and 40°C.

• Comply with the conditions of use dened in the operating manual.

• Comply with the storage conditions specied in the operating

manual.

NiMH technology allows a limited number of charge/discharge cycles depending

signicantly on:

• The conditions of use.

• The charging conditions.

Please refer to § 9 for correct replacement of the battery.

Do not dispose of the battery pack with other solid waste. Used batteries

must be entrusted to a qualied recycling company or to a company

specialized in processing hazardous materials.

Page 4

Table of Contents

1. INTRODUCTION ................................................................................. 5

1.1 International Electrical Symbols ................................................6

1.2 Denition of Measurement Categories .....................................6

1.3 Receiving Your Shipment ..........................................................6

1.4 Ordering Information .................................................................7

1.4.1 Accessories and Replacement Parts ............................7

2. PRODUCT FEATURES ......................................................................... 8

2.1 Description ................................................................................8

2.2 Applications ..............................................................................9

2.3 Key Features ............................................................................9

2.4 Control Features .....................................................................10

2.5 Button Functions ..................................................................... 11

2.6 Display Symbols .....................................................................12

3. SPECIFICATIONS ............................................................................. 14

3.1 Electrical .................................................................................14

3.2 Mechanical ..............................................................................15

3.3 Display ....................................................................................15

3.4 Environmental .........................................................................16

3.5 Safety ......................................................................................16

4. OPERATION ..................................................................................... 17

4.1 Quick Summary ......................................................................17

4.2 Instrument Conguration (SET-UP Mode) .............................. 19

4.2.1 Program Menu Tree ....................................................19

4.2.2 Programming the 9-Pin Interface Port (rS) ................20

4.2.3 Setting the Buzzer Level (bUZZ) ................................21

4.2.4 Reading the Internal Serial Number (EdSn) ...............21

4.2.5 Reading the Internal Software Version (EdPP) ........... 21

4.2.6 Setting Language for Printing Reports (LAnG) ...........22

2

Micro-Ohmmeter Model 6250

Page 5

4.2.7 Setting the Value for Reference Temperature .............22

4.2.8 Selecting the Method/Value for Ambient Temp ...........23

4.2.9 Selecting the Metal Type (nEtA) .................................24

4.2.10 Programming the Alpha Value (ALPH) ........................24

4.2.11 Selecting Temperature Units (dEg) ............................. 24

4.2.12 Setting Alarm Set Point/Direction/Buzzer Level ..........25

4.2.13 Setting the Display Timeout (LlgH) .............................26

4.2.14 Clearing the Memory (nEn) .........................................26

4.3 Operating Procedure ..............................................................28

4.3.1 Connections and Readings .........................................28

4.3.2 Test Lead Connection ................................................. 29

4.3.3 Very Low Resistance ..................................................29

4.3.4 Meter Readings ..........................................................29

4.3.5 Stand-by (ST BY) State .............................................. 30

4.4 Selecting the Test Range ........................................................ 30

4.5 Measurement Modes ..............................................................31

4.5.1 Measurement Safety Warnings ...................................31

4.5.2 Inductive Resistance Measurement Mode ..................31

4.5.3 Resistance Measurement Mode .................................33

4.5.4 Low Inductive Resistance Measurement Mode ..........34

4.6 Ambient Temperature Compensation .....................................35

4.6.1 Activating the Compensation Function ......................38

4.7 Activating Alarms ....................................................................39

5. MEMORY / PRINTING ...................................................................... 40

5.1 Managing and Printing the Data in Memory .........................40

5.2

Displaying and Printing Stored Measurements ...............................41

5.3 Cables and Printers Used with the Interface Port ...................43

6. DATAVIEW® SOFTWARE ................................................................... 45

6.1 Installing DataView® ................................................................45

6.2 Connecting the Instrument to your Computer .........................49

6.3 Establishing Communication to the Instrument ......................49

6.4 Conguring the Instrument .....................................................50

6.5 Downloading Stored Tests ......................................................52

Micro-Ohmmeter Model 6250

3

Page 6

6.6 Creating a DataView® Report .................................................52

6.7 Exporting the Report to a Spreadsheet or PDF File ..............53

7. TROUBLESHOOTING ........................................................................ 54

7.1 Fault Indicators .......................................................................54

8. APPLICATION EXAMPLES ................................................................ 55

8.1 Measuring Winding Resistance of Motors

and Transformers ....................................................................55

8.2 Measuring Resistance on Electric Motors ..............................56

8.3 Battery Strap Measurements ..................................................56

9. MAINTENANCE ................................................................................ 57

9.1 Warning...................................................................................57

9.2 Cleaning ..................................................................................57

9.3 Charging/Recharging the Battery ...........................................58

9.4 Battery and Fuse Replacement ..............................................59

Repair and Calibration ....................................................................60

Technical and Sales Assistance ......................................................60

Limited Warranty .............................................................................61

Warranty Repairs ............................................................................61

4

Micro-Ohmmeter Model 6250

Page 7

CHAPTER 1

INTRODUCTION

WARNING

These safety warnings are provided to ensure the safety of personnel and proper operation of the instrument.

• Do not attempt to perform any tests with this instrument until you

have read the user manual.

• Tests are to be carried out on de-energized circuits only! Never

connect the unit to a live circuit.

• When the unit is measuring resistance showing a high inductive

component (transformers, motors, etc.) after ending the measurement, the unit then discharges the inductive sample and the

warning icon

the connection wires before this icon disappears.

• The micro-ohmmeter should never be used in an explosive

environment (this includes poorly ventilated battery rooms and

enclosures).

appears for the entire duration. Never disconnect

• Make sure the internal battery is fully charged prior to testing. If the

instrument has been left unused for several months, recharge the

battery.

• We recommend recharging the micro-ohmmeter every month to

ensure a full battery charge when used.

• When replacing fuses, install only fuses which are direct replacements.

• If the case needs cleaning, do not use any alcohol or oil based

cleaners. Preferably use soapy water with a damp cloth or

sponge.

• The test leads and measuring wires must be in good condition and

should be changed if there is any evidence of deterioration (insulation split, burnt, etc.).

• Never exceed the safety values indicated in the specications.

Micro-Ohmmeter Model 6250

5

Page 8

1.1 International Electrical Symbols

This symbol signifies that the instrument is protected by double or reinforced insulation.

CAUTION - Risk of Danger! Indicates a WARNING and that the operator must

refer to the user manual for instructions before operating the instrument in all

cases where this symbol is marked.

Important instructions to read and understand completely.

Important information to acknowledge.

Risk of electric shock. The voltage at the parts marked with this symbol may

be dangerous.

Compliance with the Low Voltage & Electromagnetic Compatibility European

directives (73/23/CEE & 89/336/CEE)

In the European Union, this product is subject to a separate collection system

for recycling electrical and electronic components In accordance with directive

WEEE 2002/96/EC

1.2 Definition of Measurement Categories

CAT II: For measurements performed on circuits directly connected to

the electrical distribution system. Examples are measurements

on household appliances or portable tools.

CAT III: For measurements performed in the building installation at

the distribution level such as on hardwired equipment in xed

installation and circuit breakers.

CAT IV: For measurements performed at the primary electrical supply

(<1000V) such as on primary overcurrent protection devices,

ripple control units, or meters.

1.3 Receiving Your Shipment

Upon receiving your shipment, make sure that the contents are consistent

with the packing list. Notify your distributor of any missing items. If the equip-

ment appears to be damaged, le a claim immediately with the carrier and

notify your distributor at once, giving a detailed description of any damage.

Save the damaged packing container to substantiate your claim.

6

Micro-Ohmmeter Model 6250

Page 9

1.4 Ordering Information

Micro-ohmmeter Model 6250 ............................................ Cat. #2129.81

Includes extra large tool bag, set of two 10ft Kelvin clips (10A - Hippo), one RS-232 DB9 F/F

6 ft null modem cable, RS-232 to USB adapter, US 115V power cord, quick reference guide,

one pad of measurement

supplied with product user manual and DataView® software.

1.4.1 Accessories and Replacement Parts

Kelvin clips (10A Hippo), 10 ft color-coded leads ................Cat. #1017.84

Kelvin clips (10A Hippo), 20 ft color-coded leads ................ Cat. #2118.70

Kelvin probes (1A), spring loaded, 10 ft color-coded leads

with banana plug terminations ............................................. Cat. #2118.73

Kelvin probes (1A), spring loaded, 20 ft color-coded leads

with banana plug terminations ............................................. Cat. #2118.74

Kelvin Probes Pistol Grip 10 ft (10A) Spring Loaded........... Cat. #2118.75

Kelvin Probes Pistol Grip 20 ft (10A) Spring Loaded........... Cat. #2118.76

Kelvin Probes 10 ft (10A) Spring Loaded ........................... Cat. #2118.77

Kelvin Probes 20 ft (10A) Spring Loaded ........................... Cat. #2118.78

Kelvin Clips 10 ft (1-10A) ..................................................... Cat. #2118.79

Kelvin Clips 20 ft (1-10A) ..................................................... Cat. #2118.80

Cable, PC RS-232, DB9 F/F 6 ft Null Modem Cable ........... Cat. #2119.45

Replacement Battery 6V, 8.5 Ah rechargeable NiMH

result forms, NiMH rechargeable 6V battery pack, and USB stick

.......... Cat. #2129.91

RTD temperature probe ....................................................... Cat. #2129.95

RTD temperature probe with 7 ft (2m) extension cable ....... Cat. #2129.96

Fuse, set of 3, 16A/250V, 1 1/4 x 1/4" (6.3x32mm)

fast blow ....................................................................................... Cat. #2129.98

Fuse, set of 10, 2A/250V, 3/4 x 3/16" (5x20mm) fast blow .. Cat. #2129.99

Extra large classic tool bag..................................................Cat. #2133.73

Inverter – 12VDC to 120VAC 200 Watt for vehicle use ......... Cat. #2135.43

115V Power Cord ................................................................Cat. #5000.14

Adapter – RS-232 to USB 2.0 .............................................Cat. #5000.60

Order Accessories and Replacement Parts Directly Online

Check our Storefront at www.aemc.com/store for availability

Micro-Ohmmeter Model 6250

7

Page 10

CHAPTER 2

PRODUCT FEATURES

2.1 Description

The Model 6250 Micro-ohmmeter is used to perform low resistance

measurements from 1μΩ to 2500Ω. There are seven ranges with test

currents from 1mA to 10A.

The front end of the micro-ohmmeter employs a four-wire Kelvin conguration, which eliminates test lead resistance for a measurement accuracy

of 0.05%. A built-in circuit lters out AC signals.

The Model 6250 Micro-ohmmeter is packaged in a sealed eld case well

suited for shop and eld use. Power is supplied by a long-life NiMH battery

pack with a built-in recharger (110/220V).

The large, easy-to-read liquid crystal display is 2.25 x 4.00". It displays

the value of resistance, metal type, reference and ambient temperatures

(if selected), alarm conditions (if selected), test current and range and test

mode (Resistive, Inductive or Auto).

For operator safety and instrument protection, the micro-ohmmeter is

fuse protected at the inputs. Two fuses, accessible behind the front panel,

protect against stored energy in inductive loads.

Enhanced internal circuitry protects against possible inductive kickback

when the current is shut o.

A built-in thermal switch protects the micro-ohmmeter against overheating

on the 10A range when in continuous use.

8

Micro-Ohmmeter Model 6250

Page 11

2.2 Applications

Some of the more popular and most frequent uses of the micro-ohmmeter

are in applications for:

•

Checking metallic coating resistance, especially in aeronautics

• Ground connections and continuity measurement

• Resistance measurements on motors and transformers

• Contact resistance measurements on breakers and switches

• Component measurement

• Electrical cable resistance measurement

• Mechanical bond tests

• Wire to terminal connections

• Aircraft and rail bonds

• Many other very low resistance samples

2.3 Key Features

• Measures from 1µΩ to 2500Ω

• Test current selection from 1mA to 10A

• RTD temperature measurement (optional)

• Automatic or manual temperature compensation

• Two programmable alarms with high or low triggering

• Stores up to 1500 test results

• Selectable Inductive or Resistive test modes

• Operator safety by automatic discharge of residual charge on the

equipment under test

• Instantaneous, continuous or multiple test operation

• Selectable metal type (Copper, Aluminum or other) for

temperature compensation

• Internal, rechargeable batteries conduct up to 5000, 10A tests

• A built-in battery pack recharger recharges the batteries by

connecting to the AC line (90V/264V, 45Hz/420Hz) using a

standard line cord

• 4-Wire measurement with automatic compensation of

undesirable voltages and lead resistance

• Large multi-function backlit display

• Direct display of the measurement with its units, range, measure-

ment mode and, if activated, temperature compensation.

• Measurement can be initiated from the front panel or remotely

through the 9-pin communication port

• Rugged, sealed case

Micro-Ohmmeter Model 6250

9

Page 12

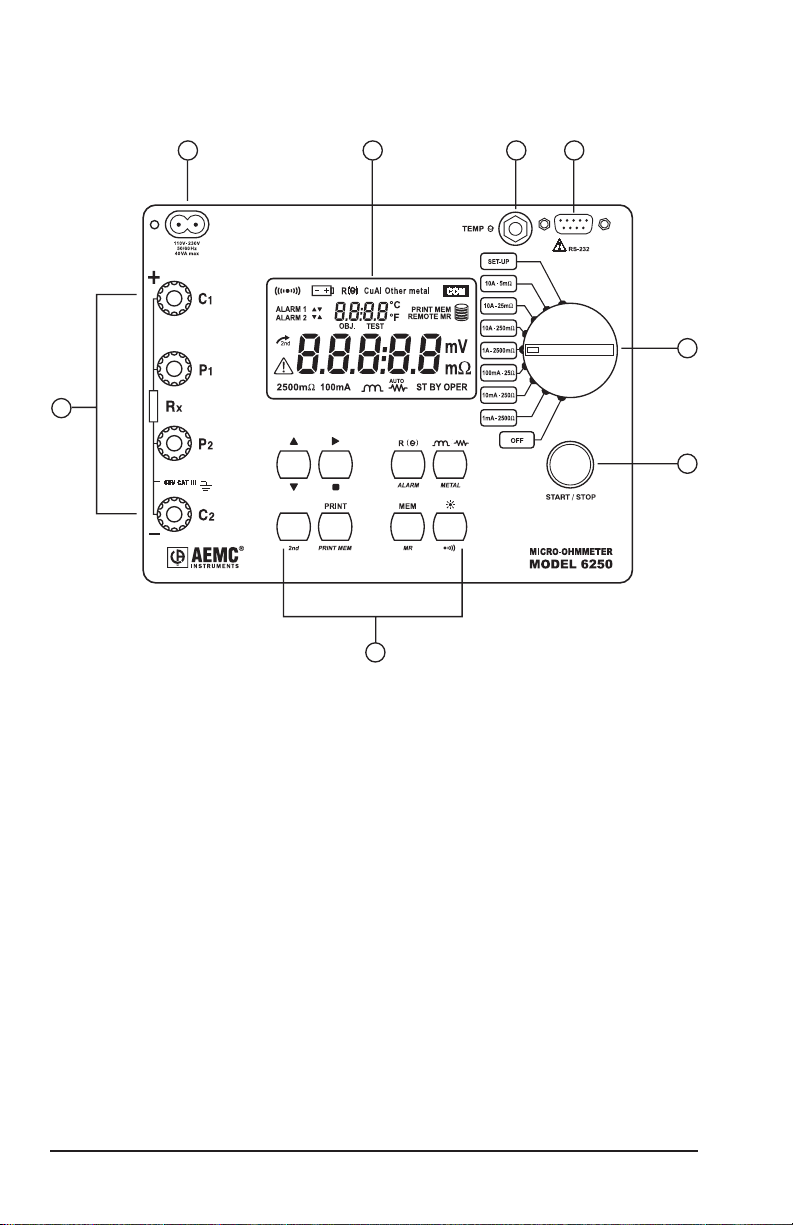

2.4 Control Features

32

1

8

Figure 2-1

54

6

7

1. Kelvin input terminals

2. AC line recharging receptacle

3. Large multi-line backlit liquid crystal display

4. RTD temperature input

5. Communication / remote operation port

6. Range selection switch

7. Test, Start/Stop button

8. Eight program / function buttons

10

Micro-Ohmmeter Model 6250

Page 13

2.5 Button Functions

PRINT

PRINT

MEM

ALARM

METAL

MEM

MR

In SET-UP mode, selects a function or increments a flashing parameter.

In SET-UP mode, selects a function or decrements a flashing parameter

In SET-UP mode, accesses the function to be modified.

In Wrap-Around mode, selects the parameter to be modified (from left to

right)

In SET-UP mode, shifts the decimal point and selects the unit.

Activates the secondary function of a button. The symbol appears on

the left side of the display.

Immediate printing of the measurement to a serial printer. If the temperature

compensation function has been activated, the calculated result and the

temperatures involved are also printed.

Retrieves stored data for printing (this function is independent of the setting

of the switch) except in the OFF and SET-UP positions.

Activates or deactivates the temperature compensation function to calculate the resistance measured at a temperature other than ambient measurement temperature.

Activates or deactivates the alarms. High or low triggering values are

adjusted in SET-UP.

Selects the desired measurement mode prior to starting one of the following measurements: Inductive mode (continuous test), non-inductive mode

(instantaneous test) or non-inductive mode with automatic triggering (multiple tests).

Selects the metal type for the temperature compensation calculation: Cu,

Al, or Other metal.

Stores the measurement at an address identified by an object number

(OBJ) and a test number (TEST).

Two presses on this button are required, one to select the location (use

the ▲ and ► buttons to change the location) and another to store the

measurement.

Retrieves stored data (this function is independent of the selector setting

of the switch) except for the OFF and SET-UP positions. Data is viewed

using the ▲ and ► buttons. The , and ALARM buttons can

be used.

Turns the display backlight ON or OFF.

Activates or deactivates the buzzer and adjusts the sound level.

Micro-Ohmmeter Model 6250

11

Page 14

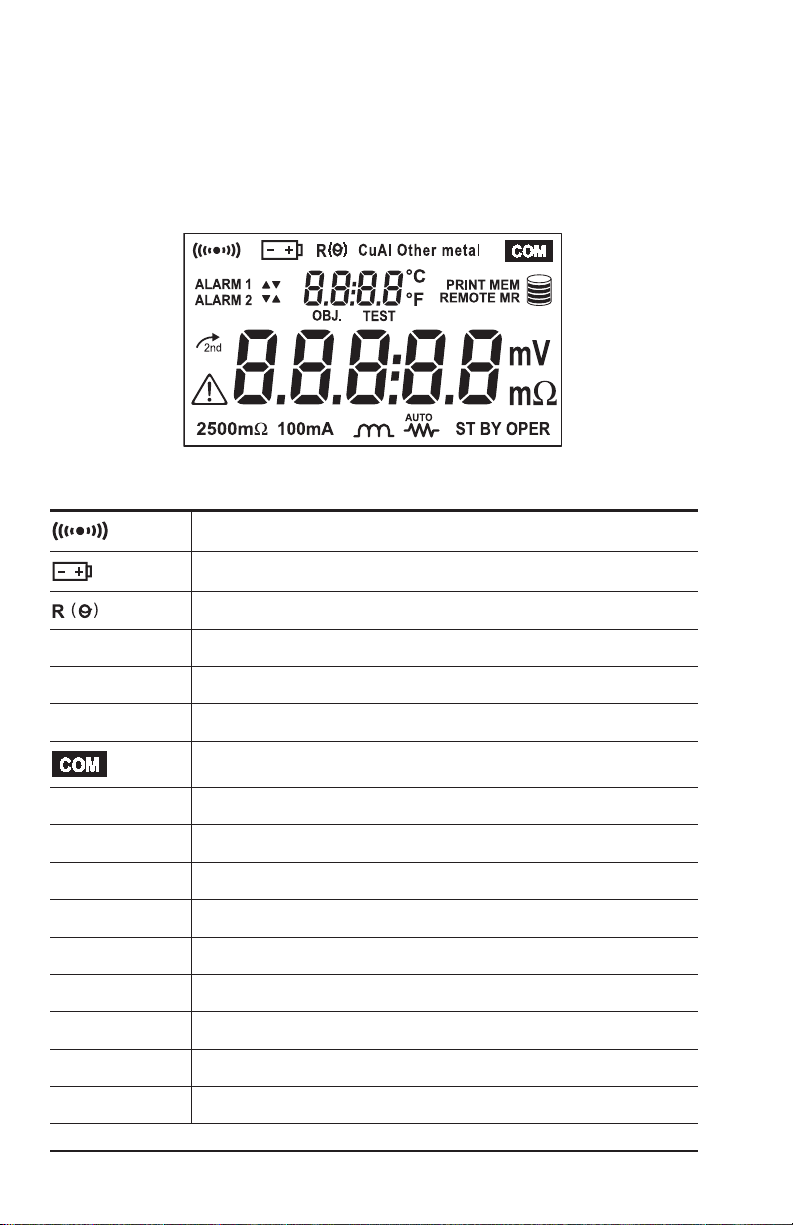

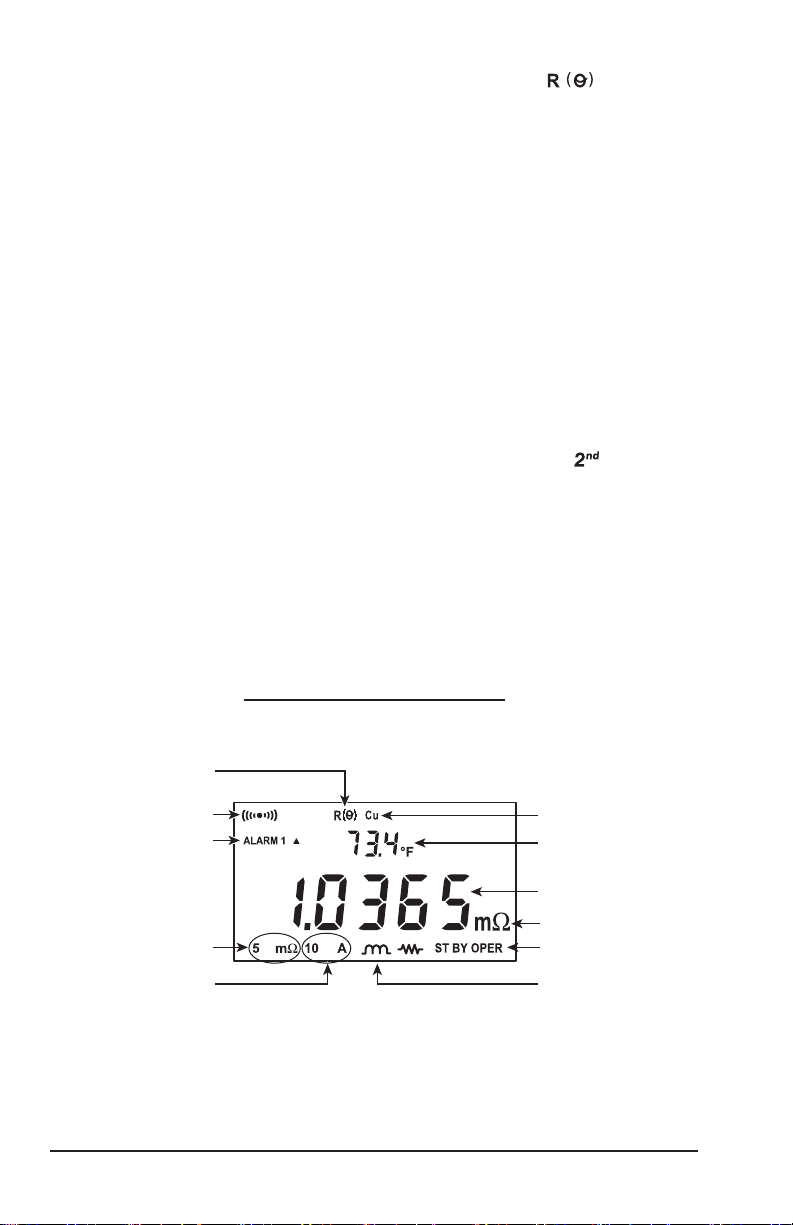

2.6 Display Symbols

The display incorporates two lines of characters to display test results, as

well as a library of symbols to assist the operator in determining conditions

at a glance. The symbols that can appear are shown in Figure 2-2 and are

detailed here.

Figure 2-2

Buzzer ON

Battery condition

Temperature compensation ON

Cu

Al

Other metal

ALARM 1 ▲

ALARM 1 ▼

ALARM 2 ▲

ALARM 2 ▼

OBJ.

TEST

°C / °F

PRINT

MEM

12

Micro-Ohmmeter Model 6250

Copper metal type selected

Aluminium metal type selected

User defined metal type selected

Communication port active

Alarm 1 active with high set point

Alarm 1 active with low set point

Alarm 2 active with high set point

Alarm 2 active with low set point

First position locator for data stored in memory

Second position locator for data stored in memory

Temperature displayed in either degrees Centigrade or Fahrenheit

Printing current test result or tests stored in memory

Displayed measurement about to be stored in memory

Page 15

REMOTE

Instrument under computer control

MR

mV mΩ

AUTO

ST BY

OPER

2500Ω 1mA

250Ω 10mA

25Ω 100mA

2500mΩ 1A

Memory recall

Memory utilization indicator

Units of measure

Resistive material test mode selected

Inductive material test mode selected

Repetitive test mode selected

System idle ready to start a test

Test in process

Second function of a button activated

CAUTION! Refer to the user manual before using the instrument.

2500 ohm, 1 milliamp test range selected

250 ohm, 10 milliamp test range selected

25 ohm, 100 milliamp test range selected

2500 milliohm, 1 Amp test range selected

250mΩ 10A

25mΩ 10A

5mΩ 10A

Micro-Ohmmeter Model 6250

250 milliohm, 10 Amp test range selected

25 milliohm, 10 Amp test range selected

5 milliohm, 10 Amp test range selected

13

Page 16

CHAPTER 3

SPECIFICATIONS

3.1 Electrical

Specications are given for an ambient temperature of 23°C ± 5°, relative humidity

of 45 to 75% and a supply voltage of 6V ± 0.1V.

Measurement Method:

4-Wire Kelvin resistance measurement with compensation for stray/residual voltages

Measurement Ranges:

Range Resolution

5mΩ 0.1µΩ 0.15% ± 1.0µΩ 10A 50mV

25mΩ 1µΩ 0.05% ± 3µΩ 10A 250mV

250mΩ 10µΩ 0.05% ± 30µΩ 10A 2500mV

2500mΩ 0.1mΩ 0.05% ± 0.3mΩ 1A 2500mV

25Ω 1mΩ 0.05% ± 3mΩ 100mA 2500mV

250Ω 10mΩ 0.05% ± 30mΩ 10mA 2500mV

2500Ω 100mΩ 0.05% ± 300mΩ 1mA 2500mV

Accuracy over 1 year

23°C ± 5°C

Measurement

Current

Temperature Measurement: 3-wire 100Ω Platinum RTD

Accuracy: ± 0.5°C

Resolution: 0.1°C

Inuence From Environment Conditions:

Temperature: 0.1% per 10°C typical, 0.25% max

Humidity: 0.5% max from 10 to 90%

Battery Voltage: ± 0.1% from 4.5 to 7.5V

Open Circuit Voltage: 7VDC max

Voltage

Drop

14

Micro-Ohmmeter Model 6250

Page 17

Operating Voltage: 5 to 6VDC

Power Source:

Rechargeable 6V, 8.5 Ah NiMH battery pack

Built-in 90 to 256V (45 to 420Hz) charger

Battery Life: 5000, 10A tests (typical)

Battery Charging: 120/240VAC ± 20% (45 to 400Hz) line voltage

Auto-Power O: when battery voltage <5.0V

Low Battery Indication: The

needs to be recharged

Overload Input Protection: 250Vrms

Fuses:

F1 - 1 1/4 x 1/4" (6.3x32mm), fast acting, 16A/250V current source

protection

F2 - 3/4 x 3/16" (5x20mm), fast acting, 2A/250V charging circuit

protection

symbol is displayed when the battery

3.2 Mechanical

Dimensions: 10.63 x 9.84 x 7.09" (270 x 250 x 180mm)

Weight: 8.1 lbs (3.69kg approx) without leads

Case Protection: ABS plastic polycarbonate: watertight to IP64 (cover

closed), water resistant to IP53 (cover open).

Color: Safety yellow case with gray faceplate

3.3 Display

Blue Electroluminescent backlit Liquid Crystal Display (LCD), 2.25 x 4.00"

with icons and two numeric elds for data presentation.

One numeric eld contains 4 digits for displaying ambient and reference

temperature levels on the top line in “temperature compensation” mode.

The other contains 5 digits and is used to display the measured values on

the bottom line. Error messages are also listed on the bottom line.

Micro-Ohmmeter Model 6250

15

Page 18

3.4 Environmental

Operating Temperature:

14° to 132°F (-10° to 55°C), 10 to 80% (non-condensing)

Storage Temperature: -40° to 140°F (-40° to 60°C)

3.5 Safety

EN 61010-1, 50V, CAT III, Pollution Degree 2

Conducted and radiated emission:

EN 55022, class B

EN 61000-3-2

EN 61000-3-3

Immunity:

EN 61000-4-2 electrostatic discharges

EN 61000-4-3 radiated elds

EN 61000-4-5 shock

EN 61000-4-6 conducted disturbances

EN 61000-4-11 voltage drops

EN 61000-4-4 bursts

*Specications are subject to change without notice

16

Micro-Ohmmeter Model 6250

Page 19

CHAPTER 4

OPERATION

NOTE: Charge the instrument fully before use.

4.1 Quick Summary

The following is a summary instruction set that will assist the operator in

performing measurements. For complete details on each function and test

method refer to the operating procedure section (§ 4.3) and instrument

conguration section (§ 4.2) in this manual.

WARNING: Read and follow all safety warnings on page 4 before operating this instrument.

1. Turn the instrument on and select a test range by turning the rotary

switch to the desired position. If the resistance of the device under test

is unknown, start with the highest range (2500Ω) and work down to

increase resolution as necessary.

2. Select the test method best suited for the measurement by press-

ing the button to select inductive (continuous test), resistive

(instantaneous test) or AUTO (multiple testing).

3. Activate the backlight, if necessary, by pressing the button.

4. Activate the buzzer, if desired, by pressing yellow button followed

by the button.

5.

Activate alarms, if desired, by pressing the yellow button followed

by the ALARM button. Successive presses of this two-button sequence

will select Alarm 1, Alarm 2 or both.

6. Select the metal type for the device under test by pressing the yellow

button followed by the METAL button. Successive presses of this

two-button sequence will select Copper (Cu), Aluminum (Al) or Other

metal. This will be needed for temperature compensation.

Micro-Ohmmeter Model 6250

17

Page 20

7. Activate temperature compensation by pressing the button.

Temperature

A

Test current

Resistance measurement

Inductive test mode

The reference temperature will appear followed by the ambient

temperature on the top line of the display.

8. Start the test by pressing the START/STOP button. The resistance

reading will appear on the lower line of the display. The symbol

OPER will appear on the lower left to indicate that a test is in

process. The Stand-by symbol STBY will appear when the test is

completed. Resistive element tests will stop automatically. Inductive

and AUTO testing will stop when the operator pushes the START/

STOP button a second time.

9. Store the test result in memory by pressing the MEM button at the

conclusion of a test. The next available location will be presented on

the top line of the display. To use this location, press the MEM button

a second time.

10.

Recall readings from memory by pressing the yellow button followed by the MEM button. The last measurement stored in location

OBJ: X TEST: X will be displayed. Use the ▲, ▼ and ► buttons to

select the object and test memory location to review. All information

from the measurement is available for review including metal type,

ambient and reference temperatures, resistance at ambient and reference temperatures, test range and test current.

Typical Operational Display

compensation active

Buzzer active

larm 1 hi set point active

Measurement range

Figure 4-1

18

Micro-Ohmmeter Model 6250

Metal type (Copper)

Reference temperature

Measurement units

Test in process

Page 21

4.2 Instrument Configuration (SET-UP Mode)

4.2.1 Program Menu Tree

The menu tree below shows the order in which functions appear in the

Menu and sub-menus of the set up mode.

Set

r5 – OFF – Trig – PC – uT100 – Print

buzz – off – low high

EdSn – displays internal serial number

EdPP – displays firmware number

Lang – Lg Gb – Lg F

trEF – value

tAnb – Prb – nPrb

nEtA – Copper alpha – Aluminum alpha, Other Metal

ALPH – value

dEg – dEgF – dEgC

ALAr – Alarm 1 – Alarm 2

LlgH – t=OFF – t=1 – t=5 – t=10

nEn – dEL – dEL O – Y – n

The cursor buttons ▲, ▼ and ► have the following functions in the

SET-UP menu:

• The up Arrow ▲ button selects the next function to be programmed

in the top level menu and increments the value of the ashing

variable in the sub-menus.

• The down Arrow ▼ button selects the previous function to be programmed in the top level menu and decrements the value of the

ashing variable in the sub-menus.

•

The right arrow ► button selects the function displayed in the top

level menu and moves the cursor one place to the right or validates

the programming in the sub-menus. See Cables and Printer Used

with the Interface Port (§5.3) for proper connections.

Micro-Ohmmeter Model 6250

19

Page 22

4.2.2 Programming the 9-Pin Interface Port (rS)

The 9-pin interface port on the top right side of the front panel can be pro-

grammed to any of ve communication methods. These consist of:

1.

O: Disable input and output functions of the interface port. This

choice saves battery power.

2. Trigger: Enables the remote measurement function.

3. PC: Activates an RS-232 link between a computer and the unit for

conguring the Model 6250 and for conducting tests and storing

results. When activated, the

4. VT100: Activates an RS-232 link between a display terminal and

the Model 6250. When activated, the

display.

5. Print: Activates the RS-232 link between a printer and the Model

6250 for direct printing of test results. When activated, the

will appear on the display.

The RS-232 modes also allow programming of transmission speed. The

baud rate choices are: 4800, 9600, 19200 and 31250.

The required data conguration settings are: 8 bits, no parity, 1 stop bit,

hardware control (CTS).

icon will appear on the display.

icon will appear on the

icon

• Turn the rotary switch to the SET-UP position.

• Press the

display.

• Press the ►

• Press the ► button to accept this setting or press the

to scroll through the other choices of trigger (trlG), PC, Terminal

(ut100) and Print.

• The choices of PC, terminal and print also require a baud rate

selection.

• After selecting PC, ut100 or Print, pressing the ► button will enter

the baud rate selection menu.

• Press the

and 31250. When the desired baud rate is in the display, validate

it by pressing the ► button to return to the top level rS menu. The

icon will appear in the display.

• Proceed to the next programming variable by pressing the

button

20

Micro-Ohmmeter Model 6250

.

▲ button

button

▲ button

until “rS” appears on the top line of the

, OFF will appear in the display.

▲ button

to toggle the choices for 4800, 9600, 19200

▲

Page 23

4.2.3 Setting the Buzzer Level (bUZZ)

• Turn the rotary switch to the SET-UP position.

• Press the ▲ button until “bUZZ” appears on the top line of the

display.

• Press the ► button to scroll through the choices of OFF (no icon

displayed), LOW (small buzzer icon displayed) or HIGH (large

buzzer icon

sponding icon in the top left corner of the display along with the

associated audible sound.

• When the desired sound level is displayed, press the ► button to

accept it and return to the top level of buzzer set-up.

•

To proceed to the next programming variable, press the ▲ button.

displayed). Each choice will display the corre-

4.2.4 Reading the Internal Serial Number (EdSn)

• Turn the rotary switch to the SET-UP position.

• Press the ▲ button until “EdSn” appears on the top line of the

display.

• Press the ► button to scroll through the serial number. There are

10 digits in the serial number. The rst press will display the rst

ve digits. The second press will display the second ve digits.

EXAMPLE: First press displays: t0302

Second press displays: 044-0

Third press displays: 0001 A

• Press the ► button again to return to the top level of the Serial

Number set-up menu.

•

To proceed to the next programming variable, press the ▲ button.

4.2.5 Reading the Internal Software Version (EdPP)

• Turn the rotary switch to the SET-UP position.

• Press the ▲ button until “EdPP” appears on the top line of the

display.

• Press the ► button to display the rmware version.

• Press the ► button again to return to the top level of the Software

Version set-up menu.

•

To proceed to the next programming variable, press the ▲ button.

Micro-Ohmmeter Model 6250

21

Page 24

4.2.6 Setting the Language used for Printing Reports (LAnG)

• Turn the rotary switch to the SET-UP position.

• Press the ▲ button until “LAnG” appears on the top line of the

display.

• Press the ► button to enter the language selection sub-menu.

• Next, press the ▲ button to toggle between English (Lg Gb) or

French (Lg F).

• Press the ► button to validate the selection and return to the top

level of the Language set-up menu.

•

To proceed to the next programming variable, press the ▲ button.

4.2.7 Setting the Value for the Reference Temperature (trEF)

• Turn the rotary switch to the SET-UP position.

•

Press the ▲ button until “trEF” appears on the top line of the display.

• Press the ► button to enter the reference temperature sub-menu.

The current reference temperature will be displayed with the lead-

ing digit ashing.

• Use the ▲ button to change the leading digit. The minus (-) symbol

can also be programmed in this location.

• When the desired value is reached, press the ► button to move

the next digit to the right.

• Use the ▲ button to change this digit, then press the ► button to

again move to the next digit to the right.

• Repeat this process for each of the 5 digit locations.

•

After the 5th digit is programmed, press the ► button again to return

to the top level of the Reference Temperature set-up menu.

•

To proceed to the next programming variable, press the ▲ button.

NOTE: The program limits for the reference temperature are 32.0 to

130.0°F and -10.0 to 130.0°C. Attempting to set values outside these

limits will cause error message “Err23” (Entry Out of Range) to appear in

the display.

22

Micro-Ohmmeter Model 6250

Page 25

4.2.8 Selecting the Method and Value for Ambient

Temperature (tAnb)

• Turn the rotary switch to the SET-UP position.

• Press the

play.

• Press the ► button to enter the ambient temperature sub-menu.

• The rst choice here is to decide if ambient temperature will be

measured using the RTD temperature probe accessory or if it will

be programmed using the same method as described for refer-

ence temperature. “Prb” (measure the ambient temperature using

the RTD probe accessory) or “nPrb” (no probe, manually enter

the ambient temperature) will be displayed, press the

toggle between the two choices.

• If measuring the ambient temperature is desired, press the ►

button when “Prb” is in the display. The lower display will momentarily show dashes “-----” and then return to the top level ambient

temperature menu.

• If manually entering the ambient temperature is desired, press the

► button when “nPrb” is in the display. The ambient temperature

may now be manually entered.

• The current programmed ambient temperature will be displayed

with the leading digit ashing.

• Use the

can also be programmed in this location.

• When the desired value is reached, press the ► button to move

the next digit to the right.

• Use the

again move to the next digit to the right.

• Repeat this process for each of the 5 digit locations.

• After the 5th digit is programmed, press the ► button again to

return to the top level of the ambient temperature set-up menu.

•

To proceed to the next programming variable, press the ▲ button.

▲ button

▲ button

▲ button

until “tAnb” appears on the top line of the dis-

▲ button

to change the leading digit. The minus (-) symbol

to change this digit then press the ► button to

to

NOTE: The program limits for the reference temperature are 32.0 to

130.0°F and -10.0 to 130.0°C. Attempting to set values outside these

limits will cause error message “Err23” (Entry Out of Range) to appear in

the display.

Micro-Ohmmeter Model 6250

23

Page 26

4.2.9 Selecting the Metal Type (nEtA)

• Turn the rotary switch to the SET-UP position.

• Press the

display.

• Press the ► button to toggle through the choices of Copper (Cu),

Aluminum (Al) or Other Metal. With each press of the right arrow

button, the metal type icon appears at the top of the display.

“nEtA” appears on the small display and the ve digit alpha value

appears on the large display and then automatically returns to the

top level of the metal set-up menu.

• To proceed to the next programming variable, press the ▲

button.

▲ button

until “nEtA” appears on the top line of the

4.2.10 Programming the Alpha Value (ALPH)

• Turn the rotary switch to the SET-UP position.

• Press the

display.

• Press the ► button to begin programming the alpha value. See

Table 2 in §4.6 for common alpha values.

• The current alpha value will be displayed with the leading digit

ashing.

• Use the

value is reached, press the ► button to move the next digit to the

right.

• Use the

again move to the next digit to the right.

• Repeat this process for each of the 5 digit locations.

• After the 5th digit is programmed, press the ► button again to

return to the top level of the alpha set up menu

• To proceed to the next programming variable, press the ▲

button.

▲ button

▲ button

▲ button

until “ALPH” appears on the top line of the

to change the leading digit. When the desired

to change this digit, then press the ► button to

4.2.11 Selecting Temperature Units (dEg)

• Turn the rotary switch to the SET-UP position.

• Press the ▲ button until “dEg” appears on the top line of the display.

24

Micro-Ohmmeter Model 6250

Page 27

• Press the ► button to enter the degree units sub-menu.

• Use the

▲ button

to toggle through the choices of Fahrenheit

(dEgF) or Centigrade (dEgC).

• Press the ► button to validate the selection and return to the top

level of the Temperature units set-up menu.

•

To proceed to the next programming variable, press the ▲ button.

4.2.12 Setting Alarm Set Point, Direction and Buzzer Level (ALAr)

• Turn the rotary switch to the SET-UP position.

• Press the

display.

• Press the ► button, Alarm 1 and its set point, direction and buzzer

level will appear with ALARM 1 ashing.

• To modify the settings of Alarm 1, press the ► button. The direction arrow will now be ashing. To modify Alarm 2 press the

button

• When the direction arrow is ashing, it may be changed by pressing the

point) and LOW (▼ activates below set point).

• Next, press the ► button to adjust the buzzer level for this alarm.

The buzzer icon will be ashing. The choices are OFF (no

icon displayed), LOW (small buzzer icon displayed ) or HIGH

(large buzzer icon

pressing the

• Next, program the set point value used to trigger the alarm (ignoring the decimal point) by pressing the ► button. The leading digit

will be ashing. Adjust the digit value using the

press the ► button to move to the next digit to the right.

• Repeat the process for each of the ve digits.

• Press the ► button when the numeric value is set to the desired

number. The decimal point and units (mΩ or Ω) will be ashing.

• Set the desired resolution and units by pressing the

Each press will move the decimal point one place to the right.

Cycling through milliohms and then through ohms.

• To accept the alarm settings once the decimal point and units

are at the desired values, press the ► button. This will bring you

to Alarm 2. Repeat the process as necessary to set Alarm 2’s

conditions.

▲ button

until “ALAr” appears on the top line of the

, ALARM 2 will then be ashing.

▲ button

to toggle between HIGH (▲ activates above set

displayed). The selection is made by

▲ button

while the icon is ashing.

▲ button

▲ button

then

▲

.

Micro-Ohmmeter Model 6250

25

Page 28

• When Alarm 2 is set press the ► button to return to the top level

of the alarm programming menu. “ALAr” will again appear on the

top line and the bottom line will be blank.

•

To proceed to the next programming variable, press the ▲ button.

4.2.13 Setting the Display Timeout (LlgH)

This setting determines the length of time that the backlight will stay on after

the last button press. The choices are OFF (function disabled, backlight

stays on continuously when activated), 1, 5 or 10 minutes.

• Turn the rotary switch to the SET-UP position.

• Press the ▲ button until “LlgH” appears on the top line of the

display.

• Press the ► button, the last programmed value will appear in the

display.

• Press the ▲ button to toggle through the choices of OFF, t=1, t=5

and t=10.

• When the desired length of time is in the display, press the ►

button to validate the selection.

•

To proceed to the next programming variable, press the ▲ button.

4.2.14 Clearing the Memory (nEn)

You can choose to clear the entire memory or the contents of a specic

object.

• Turn the rotary switch to the SET-UP position.

• Press the ▲ button until “nEn” appears on the top line of the

display.

• Press the ► button, “dEL” will appear on the lower line of the

display.

• Toggle between clearing the entire memory (dEL) or a specic

object (dEL O) using the ▲ button.

• To clear a specic object, press the ► button when “dEL. O” is in

the display, the top line will display Obj 01 with the “0” ashing.

Use the arrow buttons to select the object to be deleted.

• The lower display will show “dEL.02” for example if object number

2 is selected for deletion. As you press the ▲ button, the selected

object will increment accordingly.

26

Micro-Ohmmeter Model 6250

Page 29

• Delete the selected object by rst pressing the ► button and

toggling between Yes “dEL. Y” or No “dEL. n”

• Pressing the ► button while “dEL. Y” is in the display will delete

the contents of the selected object. The display will momentarily

display dashes “-----” and then return to display the next highest

object location.

• Pressing the ► button while “dEL. n” is in the display will cancel

the request.

• Repeat this process for each object to be deleted.

• To clear the entire memory contents, turn the rotary switch to the

SET-UP position.

• Press the ▲ button until “nEn” appears on the top line of the

display.

• Press the ► button, “dEL” will appear on the lower line of the

display.

• Delete all data from memory by rst pressing the ► button, then

toggling between Yes “dEL. Y” or No “dEL. n”

• Pressing the ► button while “dEL. Y” is in the display will clear all

memory of stored measurements.

• Pressing the ► button while “dEL. n” is in the display will cancel

the request.

NOTE: Only objects with data stored in them can be accessed.

To return to the beginning of the SET-UP menu, press the ▲ button when

“nEn” is on the top line of the display

Micro-Ohmmeter Model 6250

27

Page 30

4.3 Operating Procedure

C1

Rc

Rx

Rc

WARNING: Before performing the resistance test, verify that the sample

under test is not energized.

4.3.1 Connections and Readings

Clean all surfaces before connecting test leads. Verify a solid connection

between test leads and the sample. Set the range selector switch to the

desired range for the test. If the anticipated resistance is not known, begin

with the highest range (2500Ω) and successively lower the range selection

until adequate resolution is achieved. The START/STOP button will need

to be pressed each time you change ranges. The range selection may be

changed while the instrument is on.

A diagram of the measurement system is shown in Figure 4-2. The

Model 6250 generates a current (I) from the internal voltage source (V).

A voltmeter measures the voltage drop Vx at the Kelvin probe contact

points to the resistance to be measured (Rx) and displays the resistance

measurement (Rx) directly using the formula Rx = Vx / I.

The result is not aected by the other resistances encountered in the current loop (Ri, Rf, Rc), as long as the total voltage drop induced across Rx

remains below the voltage supplied by the source which is between 5 to

6V. The maximum admissible lead resistance level is Rf ≈ (V- Vx) / I. The

use of Kelvin probes helps, as they eliminate the eect of the lead resistance (Rf).

Ri Rf

P2

I

V

x

P2

+

V

C2

Rf

Rf

Rf

Ri = Unit internal resistance Rc = Contact resistance

Figure 4-2

Rf = Lead resistance Rx = Resistance to be measured

28

Micro-Ohmmeter Model 6250

Page 31

4.3.2 Test Lead Connection

The measurement leads are connected using the four binding posts on the

left side of the front panel as shown in Figure 4-3.

Connect the two red leads to terminals C1 and P1. Connect the two black

leads to terminals C2 and P2.

Any drop in the voltage on the load terminals is measured between the two

“voltage” (V) leads, P1 and P2. The current leads (C1 and C2) can deliver

current from 1mA to 10A.

UI

Figure 4-3

4.3.3 Very Low Resistance

When measuring very low resistive values in the µΩ range, the presence

of stray DC currents may aect the accuracy of the measurements. These

currents can be present due to a variety of reasons including chemical or

thermal EMF in samples made of dissimilar metals. These EMFs are automatically compensated for during the measurement process.

The presence of AC interference in the sample under test may cause the

measured value on the display to uctuate. This interference may become

more noticeable in the presence of strong electric elds. The eects of this

interference may be reduced by twisting the leads around each other.

4.3.4 Meter Readings

When testing resistive samples, the meter reading will stabilize within the

rst few hundred milliseconds. On inductive loads (e.g. transformers), the

measurement reading may take from several seconds to a few minutes

to stabilize and depends greatly on the type of equipment and the imped-

ance of the equipment under test. On very large samples such as utility

transformers, 10 to 15 minutes charging time may be necessary.

Micro-Ohmmeter Model 6250

29

Page 32

4.3.5 Stand-by (ST BY) State

This is the position that the Model 6250 returns to at the end of a measure-

ment cycle after:

• the operator presses the START/STOP button during a test

• any changes to the position of the rotary switch

• every low inductive mode measurement

• an error is detected

4.4 Selecting the Test Range

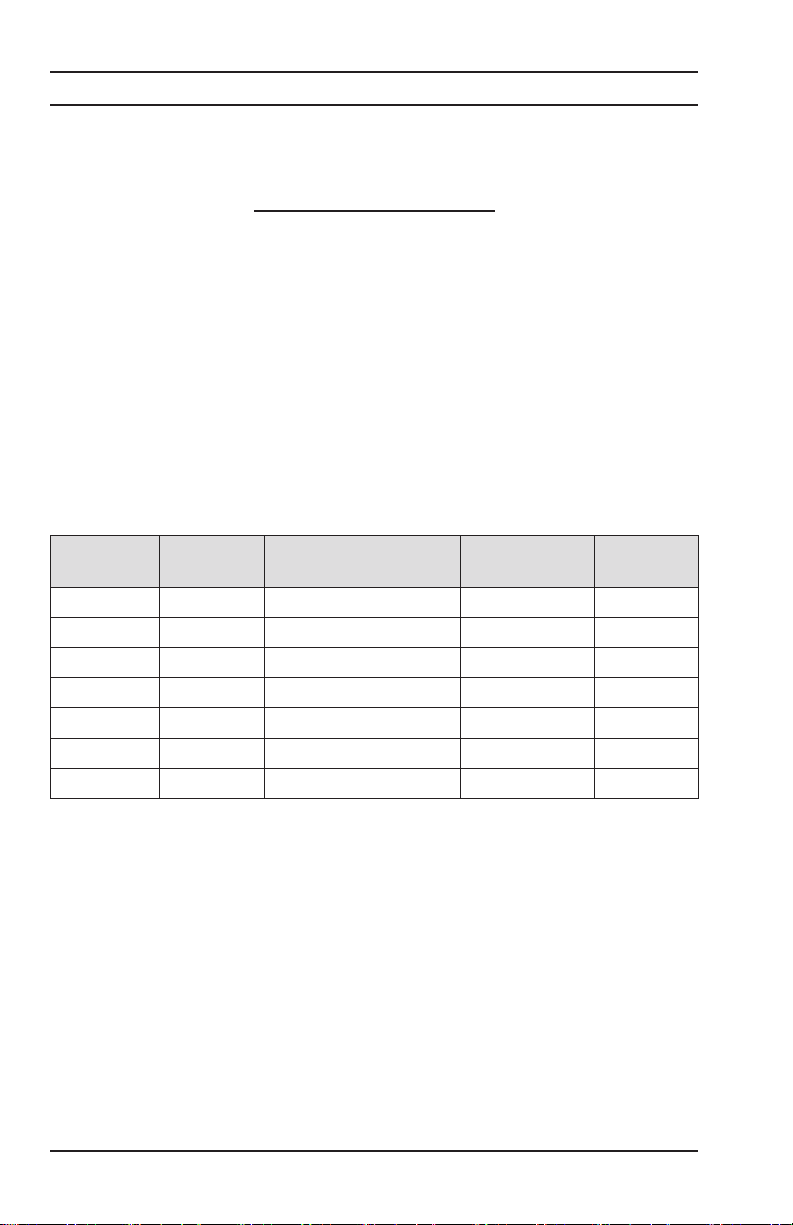

The Model 6250 has seven test ranges to choose from. Table 1 lists the

maximum resistance, test current and resolution for each range.

Resistance Range Test Current Resolution

2500Ω 1mA 100mΩ

250Ω 10mA 10mΩ

25Ω 100mA 1mΩ

2500mΩ 1A 0.1mΩ

250mΩ 10A 10µΩ

25mΩ 10A 1µΩ

5mΩ 10A 0.1µΩ

Table 1

Turn the rotary switch to the desired range, the range and test current

will appear on the lower left side of the display.

Figure 4-4

The Model 6250 is now ready to start a test.

30

Micro-Ohmmeter Model 6250

Page 33

4.5 Measurement Modes

NOTE: For descriptions of all Fault Indicator (Error) codes, refer to

Chapter 7 - “Troubleshooting” in this manual.

4.5.1 Measurement Safety Warnings

WARNING:

• Never use test leads or measuring wires if there is any evidence

of deterioration (insulation split, burnt, etc).

• Never exceed the safety values indicated in the specications.

• Never connect the unit to a live circuit.

• When the unit is measuring resistance showing a high induc-

tive component (transformers, motors, etc.) after ending the

measurement (with the measurement current cut-o), the unit

then discharges this inductance and displays the icon for this

entire duration.

• Never disconnect the connection wires before the icon dis-

appears.

4.5.2 Inductive Resistance Measurement Mode ( )

This mode is intended for performing measurements on inductive devices.

Press the button until the icon shows on the display.

From the Stand-by state, start a test by performing the following:

• Connect the Kelvin probes to the test specimen.

• Press the START/STOP button.

• If the Kelvin probes are incorrectly connected, the display will show

error message “Err 11” (current leads incorrectly connected), or

“Err 12” (voltage leads incorrectly connected). The unit will then

return to the Stand-by state. When the error is corrected, the test

automatically begins again.

Micro-Ohmmeter Model 6250

31

Page 34

• With the current switched o, the residual voltage (V0) across the

100ms

resistor terminals is measured and displayed. If this voltage level

is too high, “Err 13” will be displayed.

• The current (I) is switched on at the start of a measurement and

remains on continuously until the unit is manually returned to the

Stand-by state by pressing the START/STOP button.

• The voltage across the resistor terminals (V1) is measured and

the measurement R = (V1 - V0) / I is displayed.

• All subsequent measurements comprise only a Vn measurement

as V0 remains in memory. The timing sequence for measurement

is shown in Figure 4-5.

NOTE: After ending the measurement, with the current turned off, the 6250

will discharge the device under test as long as the test leads are connected

to the device.

OPER

STBY

I

C

MES

0

1

3

2

n

640ms

1200ms

Figure 4-5

C = connection check

0 = residual voltage measurement (stored)

1,2,3…n = successive voltage measurements across the resistor terminals

• The test is stopped by pressing the START/STOP button.

• Store the measurement by rst pressing the MEM button, then

select the object and test location to store the measurement using

the arrow buttons. When the desired location has been selected,

press the MEM button a second time to complete the data storage

process.

32

Micro-Ohmmeter Model 6250

120ms

Page 35

4.5.3 Resistance Measurement Mode ( )

This mode is intended for measuring contact and metal plating resistance

levels, and as a general rule, any resistance level on material with a time

constant that is less than a few milliseconds.

In this mode, only one measurement is performed per cycle. When the

START/STOP button is pressed, the test current is applied for approximately

400 milliseconds. Residual voltage is measured, a resistance measurement

is taken and the test stops automatically.

The advantages of the resistance mode include:

• Reduced power consumption as the test current is o between

measurements.

• Less heating of the measured resistance.

• Improved compensation of stray voltages as these are measured

and compensated before each resistance measurement.

Press the button until the icon shows on the display.

From the Stand-by state, start a test by performing the following:

• Connect the Kelvin probes to the test specimen.

• Press the START/STOP button.

•

If the Kelvin probes are incorrectly connected, the display will

show error message “Err 11” (current leads incorrectly connected),

or “Err 12” (voltage leads incorrectly connected). The unit will then

return to the Stand-by state. When the error is corrected, the test

can begin again by pressing the START/STOP button.

• With the current switched o, the residual voltage (V0) across the

resistor terminals is measured. If this voltage level is too high,

the unit displays “Err 13” and returns to Stand-by position. (See

Chapter 7 - “Troubleshooting” for all error message descriptions.)

• The current (I) is switched on when the START/STOP button is

pressed.

• The voltage across the resistor terminals (V1) is measured and

then the current is removed.

• The measurement resistance result R = (V1 - V0) / I is displayed

or error message “Err 07” is displayed, if an over range condition

occurs.

Micro-Ohmmeter Model 6250

33

Page 36

The Model 6250 then returns to the Stand-by state at the end of the measurement. The unit is ready to perform another measurement.

OPER

STBY

C

I

MES

100ms

C = connection check

0 = residual voltage measurement

M = measurement of the voltage across the resistor terminals.

O

240ms

360ms

M

Figure 4-6

C

100ms

O

240ms

360ms

M

• Store the measurement by rst pressing the MEM button, then

select the object and test location to store the measurement using

the arrow buttons. When the desired location has been selected,

press the MEM button a second time to complete the data storage

process.

4.5.4 Low Inductive Resistance Automatic Triggering Measurement Mode

This mode is intended only for measuring resistance on material without a

time constant (non-inductive). The use of the spring loaded Kelvin probes

(Cat. #2118.77 or Cat. #2118.78) listed in the accessories section are rec-

ommended for this mode.

From the Stand-by state, start a test by performing the following:

•

Press the button until the AUTO icon shows on the display.

• Press the START/STOP button.

• Connect the probes to the specimen. The unit waits until it detects

that the current and voltage leads are connected correctly.

34

Micro-Ohmmeter Model 6250

Page 37

• Residual voltage (V0) measurement across the resistor terminals

is measured.

• The measurement current (I) is established, the voltage across

the resistor terminals (V1) is measured and the measurement

resistance result R = (V1 - V0) / I is displayed.

• To start a new measurement cycle, Release at least one

probe, and then reconnect it to the next point or specimen.

NOTE: If the range is exceeded, the unit displays “Err 07”. Changing the

range switch position will stop the test cycle and the unit returns to the

Stand-by state. Each measurement taken during the test cycle can be

temperature compensated and stored while the test cycle is running.

• Store the measurement of each specimen or point by rst pressing

the MEM button, then select the object and test location to store

the measurement using the arrow buttons. When the desired location has been selected, press the MEM button a second time to

complete the data storage process.

• The test is stopped by pressing the START/STOP button.

4.6 Ambient Temperature Compensation

Principle

The metals used in the windings of certain devices (for example, the copper

wire used in transformer or motor windings) have high temperature coefcients in the order of 0.4%/°C (for copper or aluminum). This results in

resistance measurements that are highly dependent on the temperature of

the device. Activating temperature compensation will correct for this condition.

The “Temperature Compensation” function can be accessed by pressing

the button before the start of a test in Resistance and Inductive resis-

tance measurement mode. It can also be activated at anytime during Auto

measurement mode.

Its purpose is to compensate the measured or resistance value at the

ambient temperature (whether measured or programmed), to the resistance value that it should have at a reference temperature.

Micro-Ohmmeter Model 6250

35

Page 38

The compensated resistance level is expressed as follows:

R(T

) = R(T

ref

1 + (alpha * T

) * (1 + alpha * T

amb

amb

)

ref

)

Where:

R(T

T

) = the resistance value measured at ambient temperature

amb

= the temperature measured by a Pt100 probe or programmed

amb

by the operator

Alpha = the temperature coecient of the chosen metal (Aluminum,

Copper, “Other metal”)

T

= the programmed reference temperature to which the

ref

measurement is compensated to

The Temperature Coecient of Copper (near room temperature) is +0.393

percent per degree C. This means if the temperature increases 1°C the

resistance will increase 0.393%.

Example: You have 100 feet of 20 gage wire and its resistance is 1.015Ω at

20°C (room temp). If the temperature of the wire goes up 10°C the resistance

will change by 0.0399Ω (10° * 0.00393 / ° * 1.015Ω = 0.0399Ω).

The wire resistance will now be 1.015Ω + 0.0399Ω = 1.0549Ω.

The table below provides the temperature coecients of the more common

metals and alloys.

The Alpha values for Copper and Aluminum are pre-programmed into the

Model 6250. Others may be programmed by selecting Other Metals and

then programming in the alpha constant from the table or other sources.

Material Element/Alloy

Aluminum Element 4.030

Copper Element 3.930

Nickel Element 5.866

Iron Element 5.671

Molybdenum Element 4.579

Tungsten Element 4.403

Silver Element 3.819

Platinum Element 3.729

Gold Element 3.715

Zinc Element 0.847

Steel Alloy 3.000

Nichrome Alloy 0.170

Nichrome V Alloy 0.130

Table 2

36

Micro-Ohmmeter Model 6250

“alpha” per °C

X10

-3

Page 39

A 100Ω platinum RTD can be connected to the front panel of the Model

Pt100 connector

6250 to perform compensated measurements. The temperature sensor

and extension cable assembly, listed in the Accessories section, are recommended. The three pin temperature compensation port is located to the

left of the interface port and is congured as shown in Figure 4-7.

Figure 4-7

To measure the ambient air temperature at the Model 6250, plug the

optional temperature sensor directly into the temperature port on the front

panel as shown in Figure 4-8.

To measure the ambient temperature at the specimen, plug the optional

temperature sensor onto the extension cable and plug the extension cable

into the temperature port on the front panel as shown in Figure 4-9.

Place the temperature sensor in contact with the specimen or in close

proximity to it. Allow 2 minutes for the sensor to normalize to the specimen

temperature before starting a temperature compensated measurement.

Micro-Ohmmeter Model 6250

Figure 4-8

37

Page 40

Figure 4-9

4.6.1 Activating the Compensation Function

Check to ensure that all desired programming and connections are made

correctly. See Setting the Value for Reference Temperature (§4.2.7) and

Selecting the Method for Ambient Temperature (§4.2.8).

• Select the range and the measurement mode.

• Press the button.

The following information will be displayed on-screen:

1.

2. Metal type selected (Cu, Al or Other Metal)

3. Temperature levels T

followed by T

ref

amb

• Press the START/STOP button.

• The unit performs a measurement cycle and directly displays the

compensated resistance value and, depending on set-up, displays

one of the following:

1. The programmed ambient temperature level

2. The temperature level measured by the temperature

sensor

38

Micro-Ohmmeter Model 6250

Page 41

3. “- - - -” if the temperature sensor is activated but is

incorrectly connected or not connected at all

4. The measured temperature is out of range (-10° to 55°C)

If the temperature is out of range or if the sensor leads are disconnected,

the Model 6250 displays “Err 10”.

Temperature compensation can be toggled ON or OFF after the mea-

surement is completed, in resistive and inductive modes or at any time in

AUTO mode.

4.7 Activating Alarms

The alarm programming menu oers the option of choosing one or two

alarm thresholds. An alarm comprises a value, an activation direction

(above ▲ or below ▼ the setpoint) and a sound level setting for the buzzer,

should the alarm become active.

NOTE: Alarms are activated by successively pressing the button fol-

lowed by the ALARM button.

The display will indicate one of the following after each set of button

presses:

• Alarm 1 and the activation direction, ▲ or ▼

• Alarm 2 and the activation direction, ▲ or ▼

• Alarm 1 and Alarm 2 and activation directions, ▲ or ▼ for each

These values and direction parameters are programmable. See Setting

an Alarm Set Point, Direction and Buzzer Levels (§4.2.12). The buzzer will

sound when Alarm 1 and/or Alarm 2 threshold values are reached.

Micro-Ohmmeter Model 6250

39

Page 42

CHAPTER 5

MEMORY / PRINTING

5.1 Managing and Printing the Data in Memory

The memory is organized into locations called Objects and Tests.

There are 99 objects, each containing a maximum of 99 tests (measurements). The maximum number of measurements that can be stored is

approximately 1500.

After taking a measurement, it may be stored in memory by pressing the

MEM button. The MEM icon blinks and the rst available Object and Test

location for storing this measurement is displayed with the last digit of the

test number blinking.

Example: Object 1 and Test 4 are displayed and the 4 will be blinking.

01:04.

OBJ : TEST

The object and test location can be changed using the arrow buttons.

• FREE is displayed when the location is empty

• OCC is displayed when the location has data stored in it

After choosing the measurement’s memory location, pressing the MEM

button a second time validates memory storage in a FREE location.

If an occupied location is selected, the OCC message blinks to warn

that this memory location is already taken. Storage action in this location

requires pressing the MEM button again. The previous measurement in

this location will be replaced by the new measurement.

40

Micro-Ohmmeter Model 6250

Page 43

5.2

Displaying and Printing Stored Measurements

NOTE: To display or print a measurement result stored in memory, press

the yellow button followed by the MR button.

The measurement value for the last object and test saved is displayed.

Example: Object 1 and Test 3 are displayed.

01:03.

OBJ : TEST

The test unit number will be blinking. In this example the 3 will be blinking.

Change the object and test numbers using the arrow buttons. As you

change memory locations, the stored measurement value will be displayed. The following measurement components are also accessible if

stored.

The selected memory location will display:

• The number of the object and test that correspond to the memory

location

• The active range and current level during the measurement

• The measurement value with any compensation used

• The alarm icon for any active alarms that occurred during the

measurement

The parameters set for the alarm threshold, reference temperature,

ambient temperature and metal correction coecient are not directly

accessible. They are accessible by pressing the following:

• Press the button to display ambient temperature at the time

of the stored measurement.

• Press the button a second time to display the reference tem-

perature that the measurement was compensated to.

• Press the button to display the type of metal and alpha

value used for compensation at the time of the measurement.

• Press the PRINT button to print the measurement results stored at

the current memory location. An optional serial printer is required

for this feature.

Micro-Ohmmeter Model 6250

41

Page 44

NOTE: Only memory locations with stored measurements are accessible.

Measurement data stored in memory can be accessed directly from any

switch position except OFF and SET-UP for printing.

Press the yellow button followed by the PRINT MEM button

to access measurement results stored in memory for printing. An

optional serial printer is required for this feature. Use the arrow

buttons to select the object and test to be printed.

A typical printed report using the optional DPU-414-30B portable battery

operated printer (Cat. #2140.21) is shown below.

CHAUVIN ARNOUX - CA6250

NUMBER : ...................................

OBJECT: TEST:

DESCRIPTION: ...............................

............................................

............................................

Meas. Date : ___/___/___

Meas. Type : LOW INDUCTIVE

Metal Type : Cu

Coeff. Metal : 3.93

Measurement Temperature : 23.2 C

Reference Temperature : 20.0 C

Resistance Value (T

Resistance Value (T

amb

) : 1294.6 Ohm

ref

) : 1287.2 Ohm

COMMENTS : ...............................

............................................

............................................

Next test date : ___/___/___

Figure 5-1

Enclosed with this manual is a pad containing 50 forms to record the measurement

results manually. They may be photocopied as needed or downloaded from our

website at www.aemc.com/techinfo/index.asp located in the Micro-ohmmeter

section.

42

Micro-Ohmmeter Model 6250

Page 45

5.3 Cables and Printers Used with the Interface Port

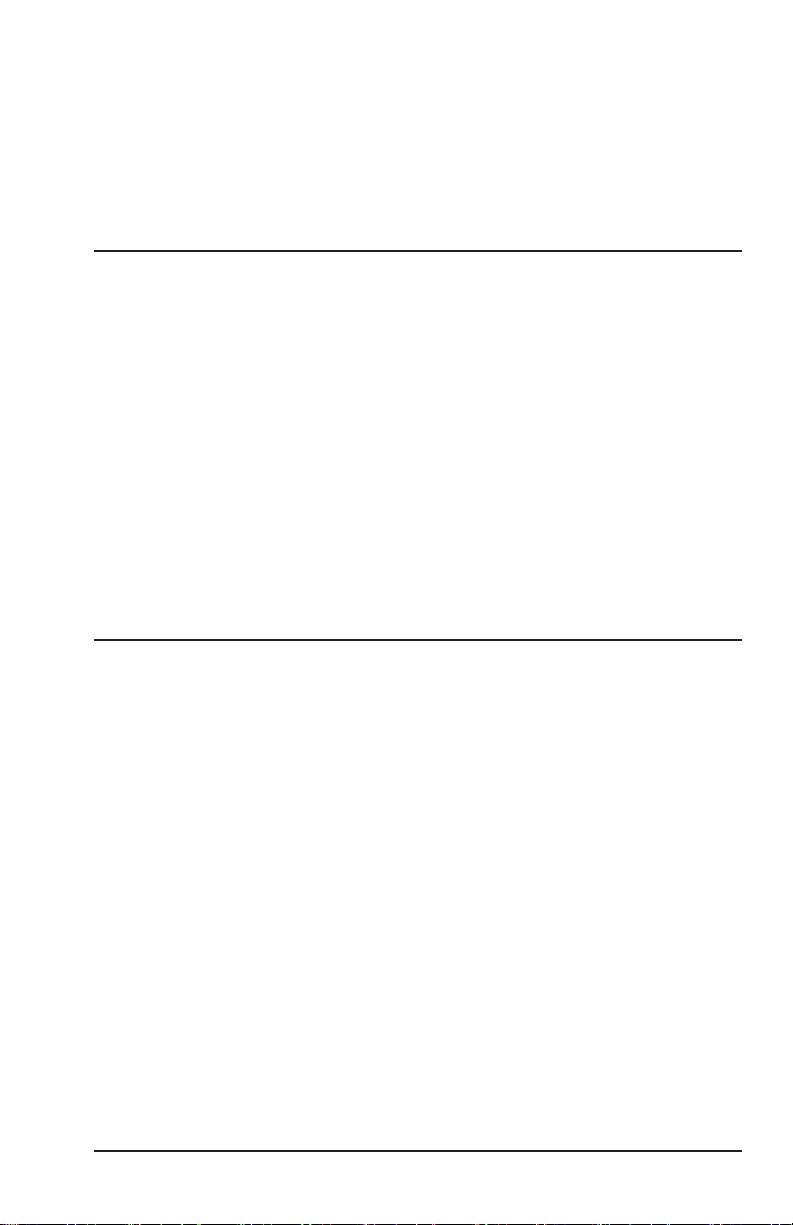

The DB9 interface port can be used to trigger remote measurements

(“TRIG”). Wiring for remote triggering of a test is detailed in Figure 5-2.

The “READY” LED indicates that a measurement can be made.

Figure 5-2

The DB9 interface port can be used for RS-232 communication with a PC,

terminal or a printer. The main connection pins used are detailed in Figures

5-3 and 5-4 respectively.

Connection to a PC or Terminal:

2

3

5

Male Connector Female Connector

Printer end Printer end

Micro-Ohmmeter Model 6250

Figure 5-3

Pin 6250 end

R

x

T

x

2 3 T

3 2 R

Gnd 5 5 Gnd

2

3

5

x

x

43

Page 46

For a Direct Printer Connection:

2

3

8

5

Figure 5-4

Male Connector Female Connector

Printer end Printer end

Pin Pin

R

x

T

x

2 3 T

3 2 R

Gnd 5 5 Gnd

CTS 8 8 CTS

2

3

8

5

x

x

44

Micro-Ohmmeter Model 6250

Page 47

CHAPTER 6

DATAVIEW® SOFTWARE

6.1 Installing DataView

®

DO NOT CONNECT THE INSTRUMENT TO THE PC BEFORE INSTALLING

THE SOFTWARE AND DRIVERS.

NOTE: When installing, the user must have Administrative access

rights during the installation. The users access rights can be changed

after the installation is complete.

DataView® must be reinstalled for each user in a multi-user system.

USB Flash Drive Install

1. Insert the USB stick into an available USB port (wait for driver to be

installed).

2. If Autorun is enabled then an AutoPlay window should appear as

shown.

Micro-Ohmmeter Model 6250

45

Page 48

NOTE: If Autorun is disabled, it will be necessary to open Windows

Explorer, then locate and open the USB stick drive labeled “DataView” to

view the files on the drive.

3. In the AutoPlay window, select Open Folder to view Files.

Double-click on Setup.exe from the opened folder view to launch the

4.

DataView setup program.

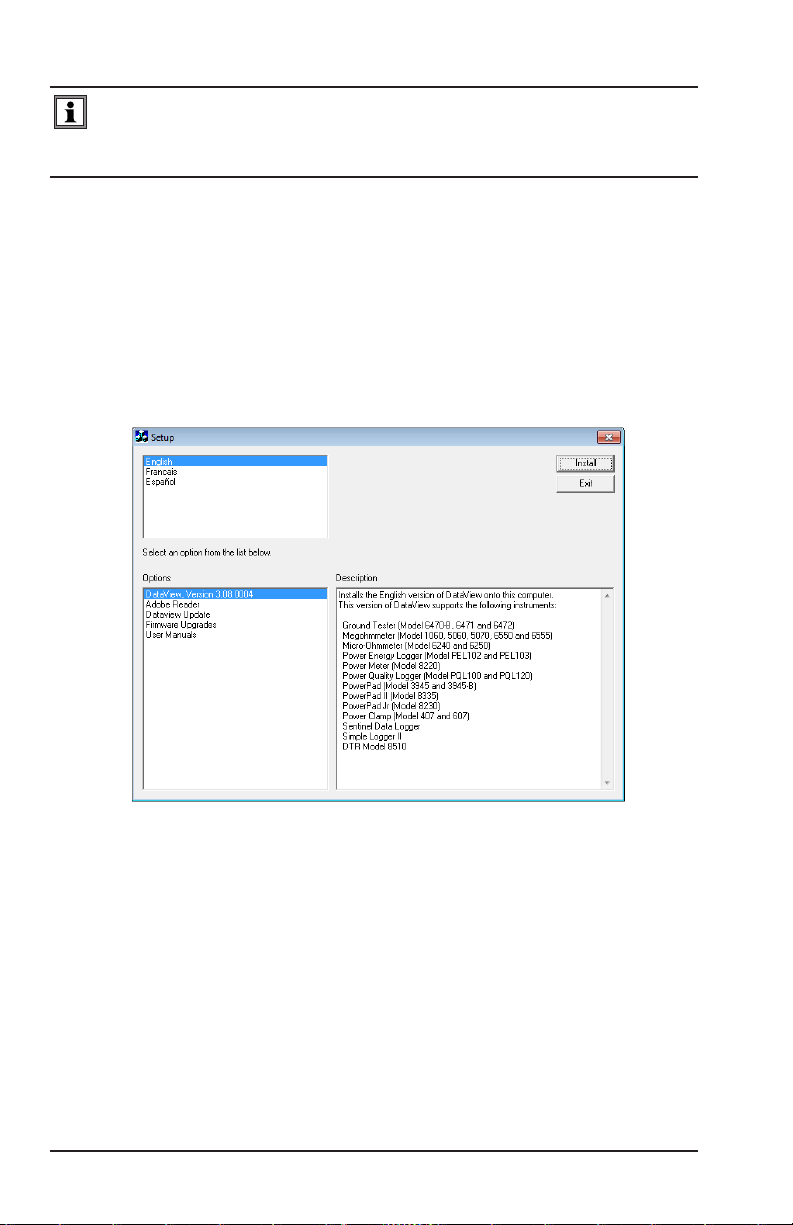

5. A Set-up window, similar to the one below, will appear.

Figure 6-1

There are several dierent options to choose from. Some options(*) require

an internet connection.

46

Micro-Ohmmeter Model 6250

Page 49

• DataView, Version x.xx.xxxx - Installs DataView® onto the PC.

• *Adobe Reader - Links to the Adobe® website to download the

most recent version of Adobe® Reader to the computer. Adobe®

Reader is required for viewing PDF documents supplied with

DataView®.

• *DataView Updates - Links to the online DataView® software

updates to check for new software version releases.

• *Firmware Upgrades - Links to the online rmware updates to

check for new rmware version releases.

• Documents - Shows a list of instrument related documents

that you can view. Adobe® Reader is required for viewing PDF

documents supplied with DataView®.

6. DataView, Version x.xx.xxxx option should be selected by default.

Select the desired language and then click on Install.

7. The Installation Wizard window will appear. Click Next.

8.

To proceed, accept the terms of the license agreement and click Next.

9. In the Customer Information window, enter a Name and Company,

then click Next.

10.

In the Setup Type window that appears, select the “Complete” radio

button option, then click Next.

11. In the Select Features window that appears, select the instrument’s

control panel that you want to install, then click Next.

NOTE: The PDF-XChange option must be selected to be able to generate

PDF reports from within DataView®.

Micro-Ohmmeter Model 6250

47

Page 50

Figure 6-2

12. In the Ready to Install the Program window, click on Install.

13. If the instrument selected for installation requires the use of a USB

port, a warning box will appear, similar to Figure 6-3. Click OK.

Figure 6-3

NOTE: The installation of the drivers may take a few moments. Windows

may even indicate that it is not responding, however it is running. Please

wait for it to finish.

14. When the drivers are nished installing, the Installation Successful

dialog box will appear. Click on OK.

15. Next, the Installation Wizard Complete window will appear. Click on

Finish.

16. A Question dialog box appears next. Click Yes to read the procedure

for connecting the instrument to the USB port on the computer.

48

Micro-Ohmmeter Model 6250

Page 51

NOTE: The Set-up window remains open. You may now select another

option to download (e.g. Adobe® Reader), or close the window.

17. Restart your computer, then connect the instrument to the USB port

on the computer.

18. Once connected, the Found New Hardware dialog box will appear.

Windows will complete the driver installation process automatically.

The DataView folder containing shortcuts for DataView® and each control

panel selected during installation has

been added to your desktop.

NOTE: If you connected your instrument to the computer before installing

the software and drivers, you may need to use the Add/Remove Hard-

ware utility to remove the instrument driver before repeating the process.

6.2 Connecting the Instrument to your Computer

The Model 6250 is supplied with a serial cable (Cat. #2119.45) necessary

for connecting the instrument to the computer.

To connect the instrument to your computer, connect one end of the serial

cable to the communications port on the Model 6250 and the other end to

the port on the computer.

6.3 Establishing Communication to the Instrument

1.

Double-click the Micro-ohmmeter Icon in the DataView folder

that was created during software installation, located on the

desktop. This opens the Micro-ohmmeter Control Panel.

2. From the main menu, go to Instrument > Connect to open the

Connection dialog box.

Figure 6-4

Micro-Ohmmeter Model 6250

49

Page 52

3. Make sure the Communication port and rate match the port that the

serial cable is plugged into and the baud rate the instrument is congured to (see §4.2.2).

4. From the Instrument model drop-down menu, select the correct model,

if necessary.

5. Once the proper parameters have been specied, click OK.

6.4 Configuring the Instrument