Page 1

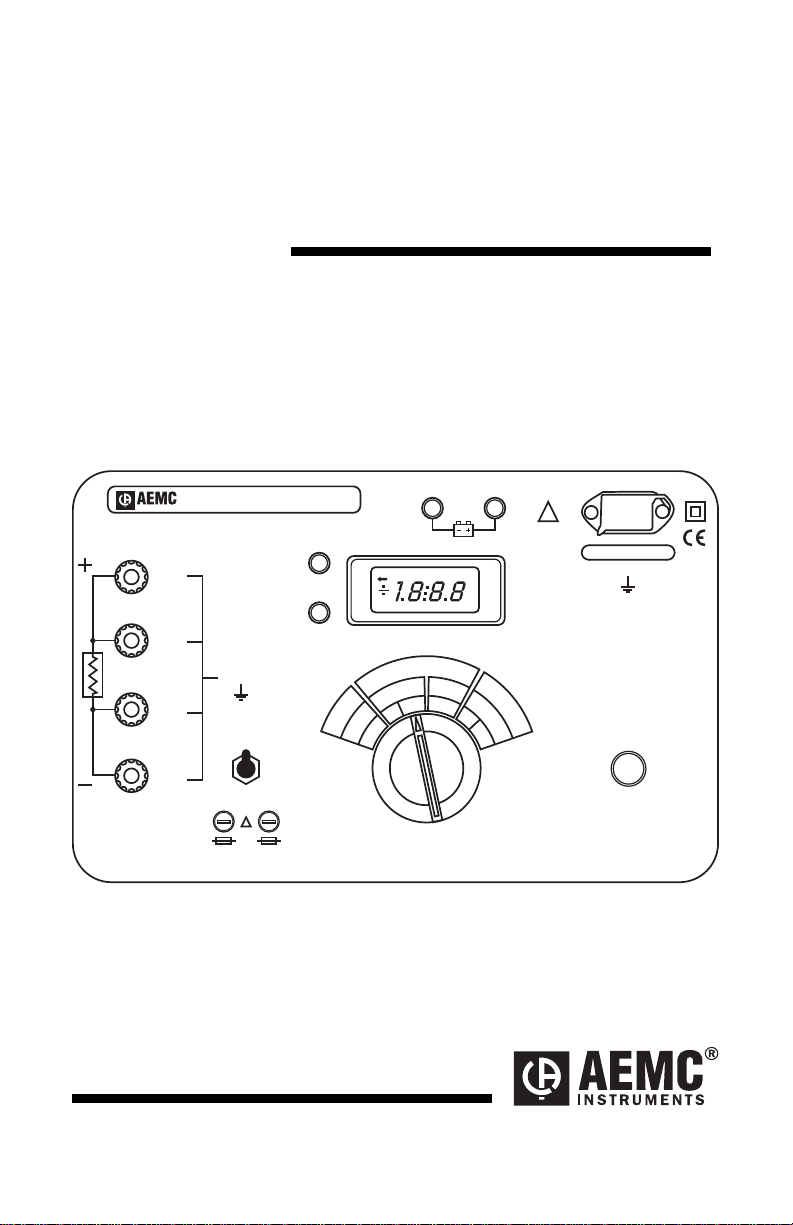

Micro-Ohmmeter

Model 5600

USER MANUAL

®

MICRO-OHMMETER MODEL 5600

INSTRUMENTS

FAULT

C

1

10A

THERMAL

+ I

- I

!

FF

8A 380V

6.3 x 32

200 kA

F2

PROTECTION

Ω

µ

0

1

P

1

Rx

P

C

30V CAT II

2

2

F1

A

0

0

0

2

LOW CHARGING

Ω

m

A

1

2

0

0

2

0

2

!

0

.

1

A

0

Ω

0

0

0

.

0

2

1

0

A

2

0

0

20 VA

50/60/400 Hz_110V

300V, CAT II

ON/OFF

Page 2

Limited Warranty

The Model 5600 is warranted to the owner for a period of 2 years from the

date of original purchase against defects in manufacture. This limited

warranty is given by AEMC

was purchased. This warranty is void if the unit has been tampered with,

abused or if the defect is related to service not performed by AEMC

®

Instruments, not by the distributor from whom it

®

Instruments.

For full and detailed warranty coverage, please read the Warranty

Coverage Information, which is attached to the Warranty Registration

Card (if enclosed) or is available at www.aemc.com. Please keep the

Warranty Coverage Information with your records.

What AEMC

®

Instruments will do:

If a malfunction occurs within the warranty period, you may return the

instrument to us for repair, provided we have your warranty

registration information on file or a proof of purchase. AEMC®

Instruments will, at its option, repair or replace the faulty material.

YOU CAN NOW REGISTER ONLINE AT:

www.aemc.com

Warranty Repairs

What you must do to return an Instrument for Warranty Repair:

First, request a Customer Service Authorization Number (CSA#) by phone or

by fax from our Service Department (see address below), then return the

instrument along with the signed CSA Form. Please write the CSA# on the

outside of the shipping container. Return the instrument, postage or

shipment pre-paid to:

Chauvin Arnoux

15 Faraday Drive • Dover, NH 03820 USA

Tel: (800) 945-2362 (Ext. 360)

(603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

repair@aemc.com

®

, Inc. d.b.a. AEMC® Instruments

Caution: To protect yourself against in-transit loss, we recommend you

insure your returned material.

NOTE: All customers must obtain a CSA# before returning any

instrument.

Page 3

Table of Contents

Warning

International Electrical Symbols................................................................3

Definition of Measurement Categories......................................................3

Receiving Your Shipment..........................................................................4

Packaging..................................................................................................4

Accessories and Replacement Parts........................................................4

Description ................................................................................................4

Electrical Specifications ............................................................................5

Mechanical Specifications.........................................................................6

Safety Specifications.................................................................................6

Control & Connector Identification............................................................7

Disassembly..............................................................................................8

AC Power Selection..................................................................................9

Indicators.................................................................................................10

Operating Procedure...............................................................................12

Application Examples..............................................................................14

Maintenance............................................................................................17

Repair and Calibration ............................................................................18

Technical and Sales Assistance .............................................................18

.....................................................................................................3

Battery Indicators.................................................................................10

Display Indicators................................................................................10

Fault Indicators....................................................................................11

Connections and Reading...................................................................12

Very Low Resistance...........................................................................13

Meter Readings...................................................................................13

Measuring Winding Resistance of Motors and Transformers.............14

Measuring Resistance on Electric Motors...........................................15

Battery Strap Measurements...............................................................16

Warning ...............................................................................................17

Cleaning...............................................................................................17

- 2 -

Page 4

Micro-Ohmmeter Model 5600

Warning

• These safety warnings are provided to ensure the safety of personnel

and proper operation of the instrument.

• Do not attempt to perform any tests with this instrument until you have

read the instruction manual.

• Tests are to be carried out on non-live and de-energized circuits only!

• The micro-ohmmeter should never be used in an explosive

environment (this includes poorly ventilated battery rooms and

enclosures).

• Make sure the internal battery is fully charged prior to testing. If the

instrument has been unused for several months, recharge the battery.

• We recommend recharging the micro-ohmmeter every month to

ensure a full battery charge when used.

• Only install fuses which are direct replacements.

• If the case needs cleaning, do not use any alcohol or oil based

cleaners. Preferably use soapy water with a damp cloth or sponge.

International Electrical Symbols

This symbol signifies that the instrument is protected by double

or reinforced insulation. Use only specified replacement parts

when servicing the instrument.

This symbol signifies CAUTION! and requests that the user refer

to the user manual before using the instrument.

Risk of electric shock. The voltage at the parts marked with this

symbol may be dangerous.

Definition of Measurement Categories

Cat. IV: For measurements performed at the primary electrical supply

(<1000V) such as on primary overcurrent protection devices,

ripple control units, or meters.

Cat. III: For measurements performed in the building installation at the

distribution level such as on hardwired equipment in fixed

installation and circuit breakers.

Cat. II: For measurements performed on circuits directly connected to

the electrical distribution system. Examples are measurements

on household appliances or portable tools.

- 3 -

Page 5

Micro-Ohmmeter Model 5600

Receiving Your Shipment

Upon receiving your shipment, be sure that the contents are consistent

with the packing list. Notify your distributor of any missing items. If the

equipment appears to be damaged, file a claim immediately with the

carrier and notify your distributor with a detailed description of any

damage. Save the damaged packing container to substantiate your claim.

Packaging

The Model 5600 Micro-Ohmmeter (Cat. #1431.01) is supplied with a

power supply lead, hex wrench, and user manual.

Accessories and Replacement Parts

Kelvin probes, set of two, on 10 ft color-coded leads with

banana plug terminations.....................................................Cat. #1017.82

Kelvin clips, 1A, set of two, on 10 ft color-coded leads

with banana plug terminations.............................................Cat. #1017.83

Kelvin clips, 10A, set of two, on 10 ft color-coded leads

with spade lug terminations..................................................Cat. #1017.84

Fuse, set of 10, 8A, 1¼ x 1/4" fast blow...............................Cat. #2970.13

Battery 6V, 7 Ah rechargeable NiCad..................................Cat. #2960.12

Soft carrying bag for accessories.........................................Cat. #2119.83

Kelvin Probes 20 ft spring loaded........................................Cat. #2118.52

Description

The Model 5600 performs reliable low resistance measurements with

test currents to 10A and resolution to one micro-ohm.

The front end of the Model 5600 employs a four-wire Kelvin

configuration, which eliminates test lead resistance for a

measurement accuracy of 0.25%. A reverse polarity switch

compensates for the effect of DC voltage interference on the accuracy

and permits reading averaging. A built-in circuit filters against AC

signals.

- 4 -

Page 6

Micro-Ohmmeter Model 5600

The Micro-Ohmmeter Model 5600 is housed in a sealed field case.

Power is supplied by a long-life NiCad battery with a built-in recharger

(110/220V). The large, easy-to-read LCD is 18mm high; it displays the

value of resistance, and indicates overrange and reversed connection of

measurement leads.

Four LEDs on the front panel indicate measurement faults (open circuit,

blown fuse, etc.); thermal protection; low battery and battery recharging.

For operator safety and instrument protection, the micro-ohmmeter is

fuse protected at the inputs. Two fuses, accessible on the front panel,

protect against stored energy in inductive loads.

Enhanced internal circuitry protects against possible inductive kickback

when the current is shut off. A built-in thermal switch protects the microohmmeter against overheating on the 10A range when in continuous

use.

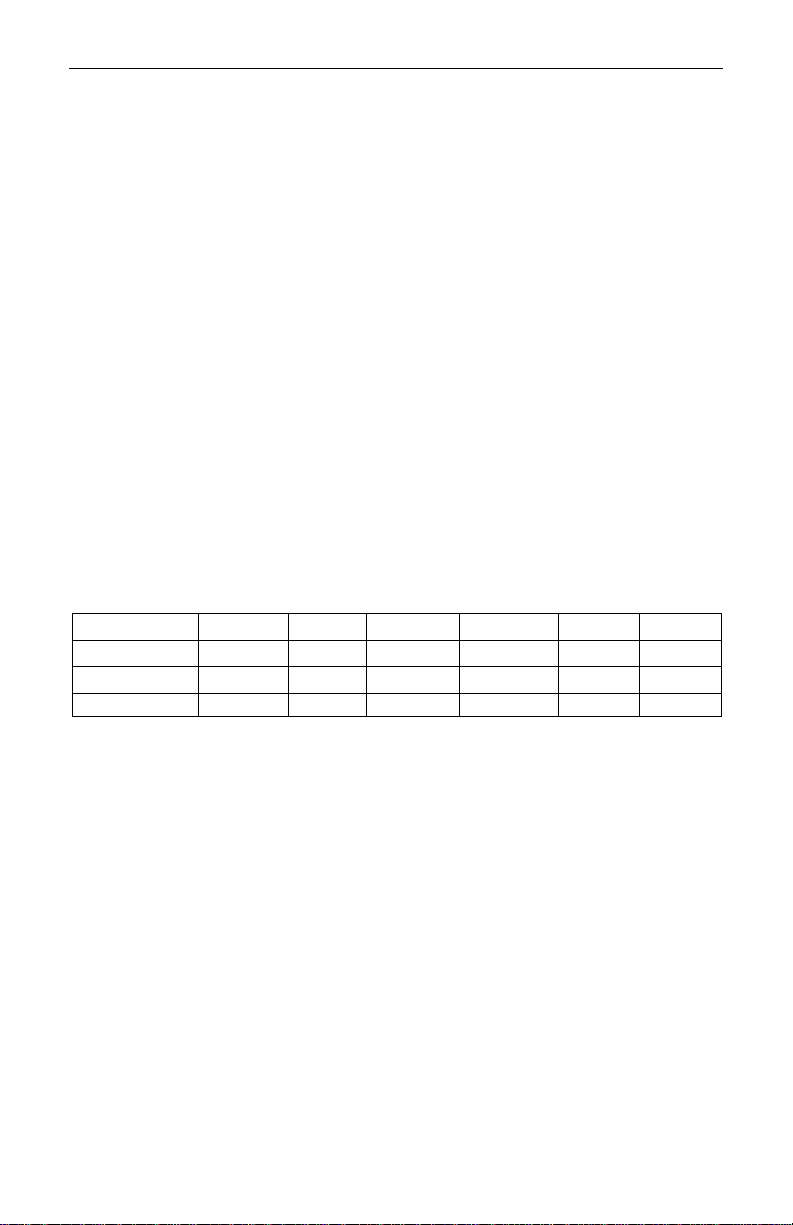

Electrical Specifications

Specifications are given for an ambient temperature of 23°C ± 3°, relative

humidity of 40 to 60% and a supply voltage of 6V ± 0.1V.

Ranges

Display

Resolution

Test Current

2000µΩ 20mΩ 200mΩ 2000mΩ 20Ω 200Ω

1999 19.99 199.9 1999 19.99 199.9

1µΩ 10µΩ 100µΩ 1mΩ 10mΩ 100mΩ

10A 1A 1A 100mA 10mA 10mA

Accuracy:

2000µ

Ω

range:

0.25% of Reading typical, 0.5% max ± 2cts

Ω

20, 200, 2000m

, 20, 200Ω ranges:

0.25% of Reading typical, 0.5% max ± 1ct

Influence of Environment Conditions:

Temperature: 0.1% per 10°C typical, 0.25% max.

Humidity: 0.5% max from 10 to 90%

Battery Voltage: ± 0.1% from 4.5 to 7V

Power Supply:

Rechargeable 6V, 7 Ah NiCad battery;

Built-in 110/220V (47 to 450Hz) charger;

Automatic shutoff after 4 minutes non-use;

Automatic shutoff when battery voltage <4.5V

- 5 -

Page 7

Micro-Ohmmeter Model 5600

Battery Life (Typical):

Ω

2000µ

20-200m

2000m

range: 200 to 300 8-second measurements

Ω

ranges: 900 30-second measurements (approx)

Ω

, 20-200Ω ranges: 5000 30-second measurements (approx)

Operating Voltage: 4.5 to 7V

Recharge Time: 14 hours from full discharge (approx)

DC

Mechanical Specifications

Display: 2000ct, 7 segment LED

Case: Fiberglass-charged polycarbonate, with handle and removable lid,

watertight to IP534 (lid closed), IP520 (lid open).

Color: Safety yellow case with gray faceplate

Operating Temperature: 14° to 131°F (-10° to 55°C)

Storage Temperature: -4° to 131°F (-20°C to 55°C)

Dimensions: 15.35 x 10.24 x 9.84" (390 x 260 x 250mm)

Weight: 17 lbs 10 oz (8kg approx) without leads

Safety Specifications

Safety Standards:

Electrical: EN 61010, 300V, Cat. III

Electromagnetic:

IEC 801-2, Electrostatic discharge

IEC 801-3, Electromagnetic Fields

IEC 801-5, Electrical shocks

Mechanical/environmental:

IEC 529, Protection Index (IP)

IEC 68.2.6, Vibrations

IEC 68.2.27, Shocks

IEC 68.2.29, Shake

IEC 68.2.31, Knock over

IEC 68.2.32, Drop test

Case Material: UL 94

Overload Input Protection: 380Vrms

Fuses: Two high interrupting capacity, 8A, 380V, 1¼ x ¼"

- 6 -

Page 8

Micro-Ohmmeter Model 5600

Control & Connector Identification

1. Lead connection terminal lugs; accepts 4mm diameter banana jack

or 6mm (min) spade lugs.

2. Thermal protection indicator

3. Measurement current fault indicator

4. Liquid crystal display

5. Battery indication lights (low battery & charging)

6. Line cord input socket for battery recharging

7. On/Off power button

8. Six-position rotary switch selects measurement range & output

current

9. Polarity inverter switch

10. Input fuse holders

2

®

MICRO-OHMMETER MODEL 5600

INSTRUMENTS

C

1

P

1

1

Rx

30V CAT II

P

2

+ I

C

2

- I

8A 380V

F1

6.3 x 32

200 kA

10

3 4

FAULT

10A

THERMAL

PROTECTION

Ω

µ

A

0

0

1

0

0

2

!

FF

F2

9

LOW CHARGING

Ω

m

0

A

1

2

0

0

2

0

2

8

5

!

.

1

A

Ω

0

0

0

0

.

0

2

1

0

A

2

0

0

6

20 VA

50/60/400 Hz_110V

300V, CAT II

ON/OFF

7

Figure 1

- 7 -

Page 9

Micro-Ohmmeter Model 5600

Disassembly

Before replacing the internal batteries or changing the power supply

voltage rating, the chassis must first be removed. Use the hex key to

unscrew the six fastening screws from the chassis, which are located on

the bottom of the case.

Pull out the chassis. Do not forget to unplug the two leads that connect

the power supply board in the bottom of the case to the boards, which

are mounted in the chassis. Be sure to note the polarity when

reconnecting the leads.

Detachable Cover

The cover hinges are fitted with spring-loaded clips, which allow the

cover to be removed. To detach the cover from the Model 5600, open

the lid to a horizontal position and apply downward pressure to the hinge

side of the cover while gripping it firmly (see Fig. 2).

To re-attach the cover, position the cover in a horizontal position and fit

the hinges into the respective housing. Apply strong rear-to-front

pressure to the cover until it snaps into place.

Unhinging

F

Figure 2

- 8 -

F

Supporting Point

Page 10

Micro-Ohmmeter Model 5600

AC Power Selection

The Model 5600 may be recharged by 110V or 220VAC (47 to 450Hz).

The instrument includes a 110V supply cord, which provides the

charging voltage for the rechargeable battery. Verify that “110V” appears

on the indicator located below the line cord indicator socket on the front

panel; this will permit recharging with the 110V supply cord.

To change the charging voltage, disassemble the unit as previously

noted. Move the switch on the power supply board to the “220V” position

(see Fig. 3). A 220V supply cord (not supplied) is required for 220V

operation. Be sure to change the indicator on the front panel to the

“220V” position by removing the two screws that secure it and turning the

indicator over.

Power Supply Board

6 V DC

Source Voltage Selection

Switch (110V AC/220V AC)

6 V

10 A

110V

220V

Supply Fuse

Figure 3

CAUTION: Do not change the charging voltage while the Model

5600 is connected to the AC supply.

- 9 -

Page 11

Micro-Ohmmeter Model 5600

Indicators

Battery Indicators

• LOW - When flashing, indicates battery life is sufficient for

measurement

s at 10A and more than 100 measurements for other test

currents. When the flashing stops, the instrument no longer has

sufficient power to perform any further tests. Recharge the batteries.

• CHARGING - The green charging light indicates that the battery is

currently being recharged. This indicating light will remain on as long

as the instrument is connected to AC supply.

10

Display Indicators

• “1” - On the left of the display indicates range overload

“—” - On the left of the display indicates a reversed conne

•

measurement

INSTRUMENTS

Rx

leads (crossing the voltage and current

®

MICRO-OHMMETER MODEL 5600

C

1

P

1

30V CAT II

P

2

+ I

C

2

- I

!

FF

8A 380V

F1

F2

6.3 x 32

200 kA

FAULT

10A

THERMAL

PROTECTION

Ω

µ

1

Ω

m

A

1

0

0

2

0

2

A

0

0

0

0

2

Figure 4

LOW CHARGING

0

.

1

A

2

0

0

0

2

0

!

Ω

0

.

0

1

A

2

0

0

.

leads).

20 VA

50/60/400 Hz_110V

300V, CAT II

ON/OFF

ction of the

- 10 -

Page 12

Micro-Ohmmeter Model 5600

Fault Indicators

• FAULT - The fault light will illuminate in one of two case

1.

If the measured resistance is very high in relation to the rang

Switchin

If the current output is zero, due to an open circuit or blown fuse.

2.

Check the circuit for probe/clip contact on test sample an

con

• THERMAL PROTECTION - On the 2000µΩ range (10A), thermal

protection of the instrument is provided by an internal thermostat

which interrupts the 10A current during prolonged operation.

overhe

indicator light and disables the 10A, 2000µΩ range. The other ran

may still be used during this condition.

: To make a rapid test of the internal fuses, short-circuit terminals

NOTE

C1 and C2. Switch on the instrument using the On/Off button. If the

“Fault” light comes on, at least one of the two fuses is blown.

g to a higher range will extingui

dition of fuses.

ated, the thermal protection circuit turns on its respective

sh the light.

s:

e.

d

When

ges

Warning

When using 20 ft spring loaded Kelvin lead (Cat.# 2118.52) on

the 10A range, the fault light may stay on all the time.

Measured values are good.

- 11 -

Page 13

Micro-Ohmmeter Model 5600

Operating Procedure

Before performing the resistance test, verify that the sample under test is

not energized.

Connections and Reading

Clean all surfaces before connecting test leads. Verify a solid connection

between test leads and the sample. Set the On/Off button to the ON

position and select the range that provides the most stable reading. If the

anticipated resistance is not known, begin with the highest range (200Ω)

and successively lower the range selection until adequate resolution is

achieved. The range selection may be changed while the instrument

remains energized.

Read the displayed resistance value directly. The use of a Kelvin

connection eliminates test lead resistance, as shown in Figure 5.

®

MICRO-OHM

INSTRUMENTS

C

1

P

1

Rx

P

2

2

C

- I

!

F1

UI

Figure 5

- 12 -

Page 14

Micro-Ohmmeter Model 5600

Very Low Resistance

When measuring very low resistive values (2000µΩ range) the presence

of stray DC currents may affect the accuracy of the measurements.

These currents can be present due to a variety of reasons including

chemical or thermal EMF in samples made of dissimilar metals. You can

eliminate the effects of this by reversing the direction of current flow

(inverter switch, see Figure 6) and using the average of forward and

reverse readings. A minus sign will appear in the display when the switch

is in the reverse position. Disregard this sign when calculating the

average values.

The presence of AC interference in the sample under test may cause the

measured value on the display to fluctuate. This interference may

become more noticeable in the presence of strong electric fields. The

effects of this interference may be reduced by twisting the leads

together.

+ I

– I

Figure 6

Meter Readings

When testing resistive samples, the meter reading will stabilize within the

first few seconds. On inductive loads (e.g. transformers), the

measurement reading may take from several seconds to a few minutes

to stabilize and depends greatly on the type of equipment and the

impedance of the equipment under test. On very large samples such as

utility transformers, 10 to 15 minutes charging time may be necessary.

- 13 -

Page 15

Micro-Ohmmeter Model 5600

Application Examples

The Model 5600 performs reliably on a variety of low resistance

situations. Typical applications include:

• Contact resistance of breakers and switches

• Wire to terminal connections

• Winding resistance

• Motors and generators

• Aircraft and rail bonds

• Grounding connections

• Many other very low resistance samples

The proper procedures for using the Model 5600 in some specific

applications are outlined below.

Measuring W

CAUTION: Prior to and after testing a transformer winding, the

inding Resistance of Motors and Transformers

energy stored in the magnetic field must be dissipated by shorting the

transformer terminals. For additional safety, the transformer terminals

should be jumpered together before the instrument is disconnected.

One terminal of the sample should be grounded for safety!

Make connections to the transformer as shown in Figure 7. On larger

transformers, the measurement stabilization time will increase.

®

MICRO-OHM

INSTRUMENTS

C

1

P

1

Rx

P

2

C

2

– I

!

F1

Figure 7

- 14 -

Page 16

Micro-Ohmmeter Model 5600

Measuring Resistance on Electric Motors

For this test, Kelvin probes should be used (Figur e 8). Make co ntact with

each segment on the motor commutator. Allow approximately two

seconds for the display to stabilize.

®

MICRO-OHM

INSTRUMENTS

C

1

P

1

Rx

P

2

C

2

– I

!

F1

Figure 8

- 15 -

Page 17

Micro-Ohmmeter Model 5600

Battery Strap Measurements

Proper battery strap resistance measurements will help ensure proper

voltage output. The resistance on battery strap connections should be

measured using the Kelvin probes (see Figure 9). Measurements must

be made with the system power turned off.

The average resistance of all the intercell connections should be

determined by totaling the individual resistances and dividing by the

number of connectors. Each individual cell resistance should not exceed

the average by more than 10%. See the manufacturer's specifications for

typical resistance values.

®

MICRO-OHM

INSTRUMENTS

C

1

P

1

Rx

P

2

C

2

Battery Battery

– I

!

F1

Figure 9

- 16 -

Page 18

Micro-Ohmmeter Model 5600

Maintenance

Warning:

• For maintenance use only original factory replacement parts.

• To avoid electrical shock, do not attempt to perform any servicing

unless you are qualified to do so.

• Do not perform any service while the micro-ohmmeter is on any circuit.

• To avoid electrical shock and/or damage to the instrument, do not get

water or other foreign agents into the electronic module.

• Make sure the internal battery is fully charged prior to testing. If the

instrument has been left unused for several months, recharge the

battery.

• We recommend recharging the micro-ohmmeter every month to

ensure a full battery charge when used.

• When replacing fuses, install only fuses which are direct

replacements.

Cleaning

• If the case needs cleaning, do not use any alcohol or oil based

cleaners. Preferably use soapy water with a damp cloth or sponge.

• Dry immediately after cleaning. Avoid water penetration into the

electronic module.

• Make sure the micro-ohmmeter and all leads are dry before further

use.

- 17 -

Page 19

Micro-Ohmmeter Model 5600

Repair and Calibration

To ensure that your instrument meets factory specifications, we recommend

that it be submitted to our factory Service Center at one-year intervals for

recalibration, or as required by other standards or internal procedures.

For instrument repair and calibration:

You must contact our Service Center for a Customer Service Authorization

number (CSA#). This will ensure that when your instrument arrives, it will be

tracked and processed promptly. Please write the CSA# on the outside of

the shipping container. If the instrument is returned for calibration, we need

to know if you want a standard calibration, or a calibration traceable to

N.I.S.T. (includes calibration certificate plus recorded calibration data).

Chauvin Arnoux

d.b.a. AEMC

15 Faraday Drive

Dover, NH 03820 USA

Tel: (800) 945-2362 (Ext. 360)

(603) 749-6434 (Ext. 360)

Fax: (603) 742-2346 or (603) 749-6309

repair@aemc.com

(Or contact your authorized distributor)

Costs for repair, standard calibration, and calibration traceable to N.I.S.T. are

available.

NOTE: All customers must obtain a CSA# before returning any

instrument.

®

, Inc.

®

Instruments

Technical and Sales Assistance

If you are experiencing any technical problems, or require any

assistance with the proper operation or application of your instrument,

please call, fax or e-mail our technical support hotline:

Chauvin Arnoux®, Inc.

d.b.a. AEMC® Instruments

Phone: (800) 945-2362 (Ext. 351)

(603) 749-6434 (Ext. 351)

Fax: (603) 742-2346

techsupport@aemc.com

- 18 -

Page 20

Chauvin Arnoux®, Inc. d.b.a AEMC® Instruments

99-MAN 100040 v12 02/18

15 Faraday Drive • Dover, NH 03820 USA

www.aemc.com

Loading...

Loading...