AEM 30-5131M Analog EGT Metric Gauge User Manual

AEM Performance Electronics

2205 126th Street Unit A, Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aempower.com

Instruction Part Number: 10-5131 Rev 04

2009 AEM Performance Electronics

Part Number 30-5131

Analog EGT Gauge

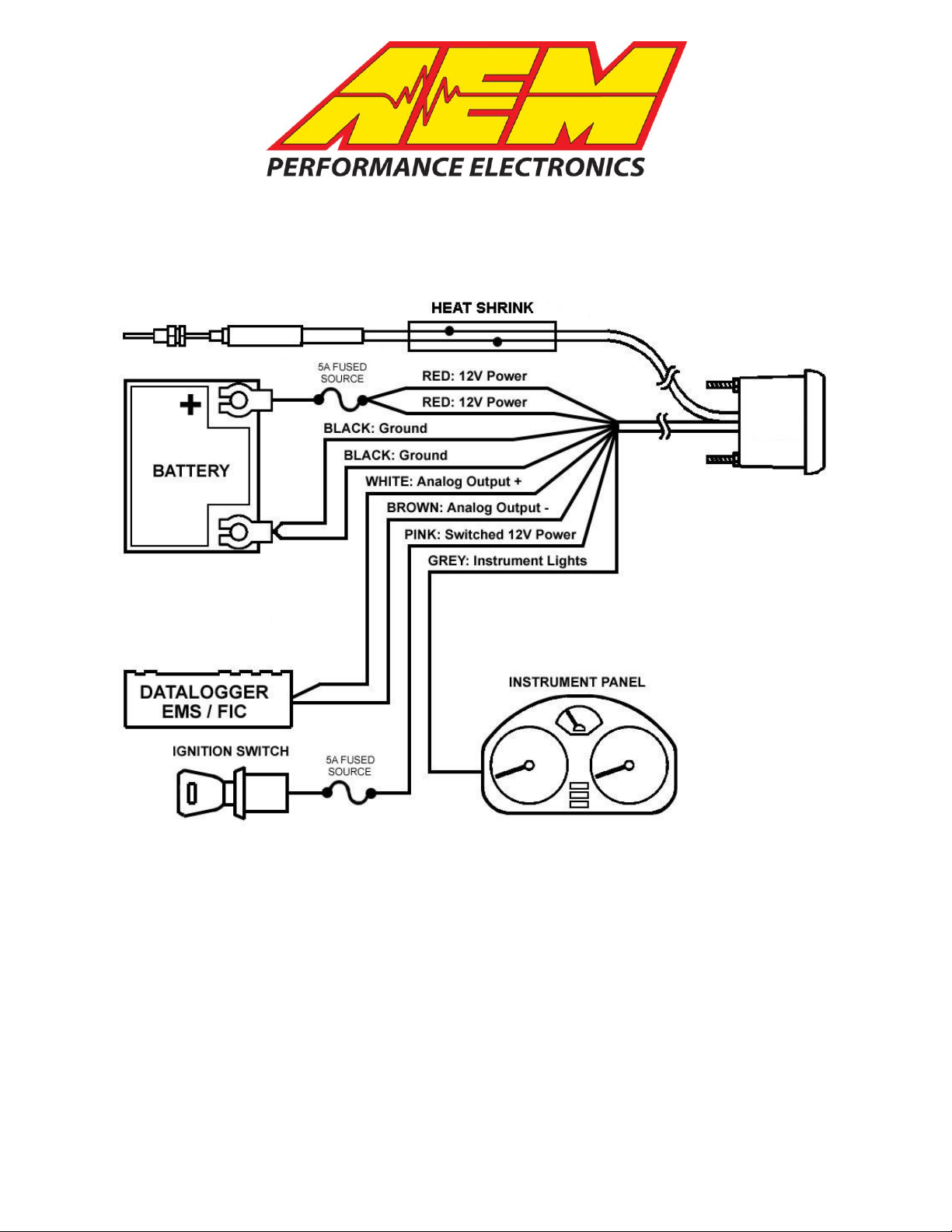

Figure 1. Wiring Schematic

AEM EGT Gauge Parts

1 x 35-5131(B/W) EGT Gauge Assembly

1 x 30-2065 EGT Sensor Thermocouple w/Mount

1 x 35-4302 Install Kit (6 Butt Connectors)

1 x 10-5131 Installation Instructions

1 x 35-3411 8-Pin Power Harness

1 x 35-3414 2-Pin Sensor Harness

1 x 35-8529S Silver Bezel

1 x 6” Heat Shrink

2 x 4-40 Hex Nut

2 x 4-40 Screw

INSTALLATION

1. Disconnect the negative battery cable.

2. Secure the gauge in a 2 1/16th” (52MM) mounting hole with the supplied bracket.

3. Plug the 8-wire power harness into the mating connector on the back of the

gauge and connect the wires as shown in Figure 1. Note: the locating tabs on

the side of the connector should be nearest the center of the gauge.

4. Connect the sensor cable to the gauge. The locating tabs should be closest to

the center of the gauge.

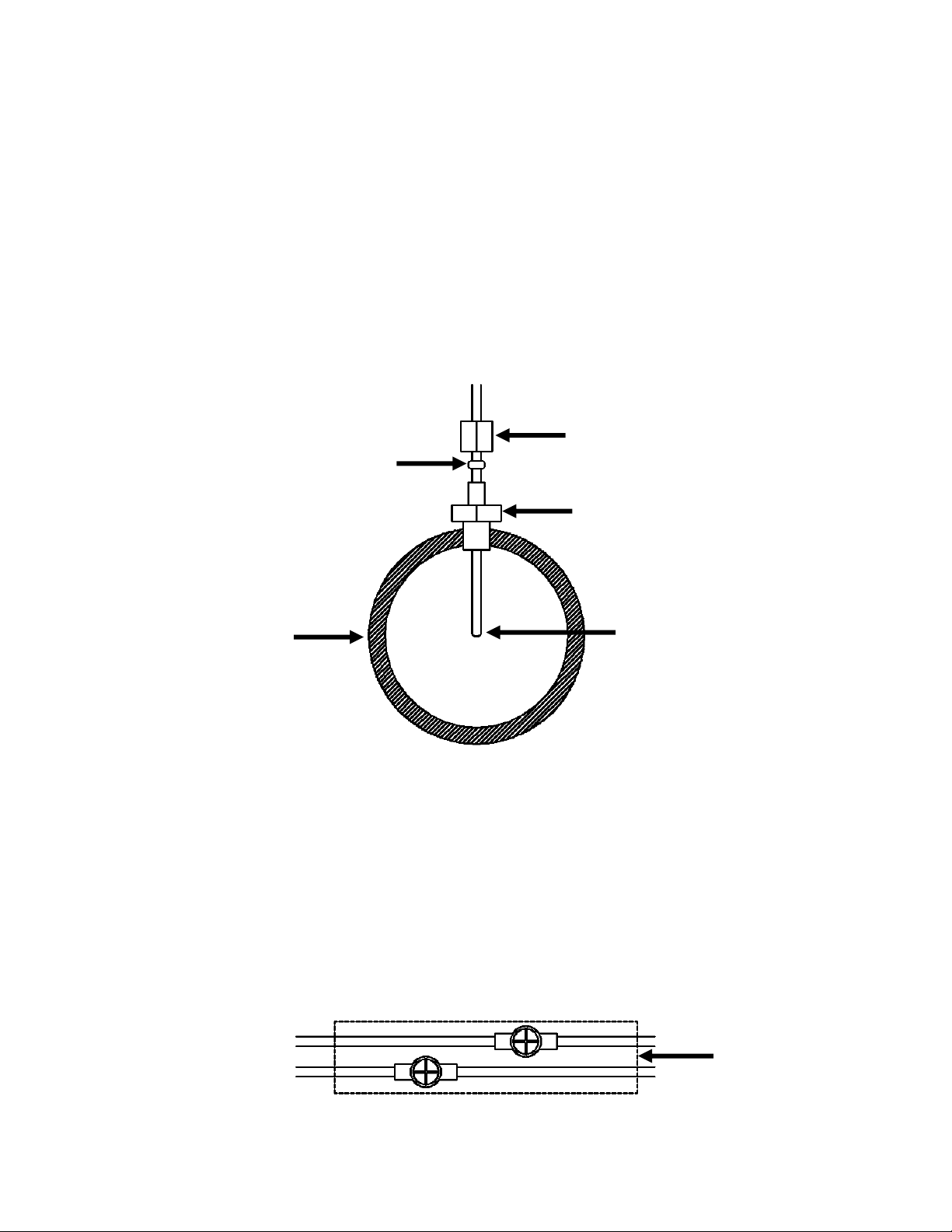

5. Mount the thermocouple as shown in figure 2.

6. Slide the heat shrink tube over the sensor cable and connect the thermocouple to

the cable as shown below in figure 3.

RED - Connect BOTH RED wires to a constant 12 volt power source utilizing a 5A fuse.

BLACK – Connect BOTH BLACK wires to a clean ground.

PINK - Connect to a switched 12 volt power source utilizing a 5A fuse.

GREY - Connect to instrument lighting circuit supply voltage.

*WHITE - Connect to Analog + Input.

*BROWN - Connect to Analog – input. (Must be connected if Analog + is used)

*optional – only needed if using the available differential analog output

Wiring notes:

RED - When wired as shown above, the gauge will park the needle upon

powering down. Alternatively, both RED wires can be connected to a switched, fused

12 volt power source. With both RED wires and the PINK wire connected to switched

power, the needle will remain at its current position upon powering down. For both

power connection methods, the needle will rotate to the parked position before rotating

to the value of the current operating condition upon powering up.

GREY – The GREY wire is used to control the lighting intensity of the gauge.

Maximum lighting intensity is achieved when the GREY wire is connected to 12 volts.

Minimum lighting intensity is achieved when the GREY wire is not connected. The

instrumentation illumination on many vehicles is controlled by varying the supply voltage

to the instrument panel lights. When the GREY wire is connected to the instrument

panel supply voltage, the intensity of the gauge is controlled by the dimmer switch on

the dash.

WHITE – The WHITE wire should be connected to the Analog + input on the

EMS or the analog + input on a similar device.

BROWN – The BROWN wire should be connected to the Analog – input. If the

EMS or similar device does not have a – input, the BROWN wire should be connected

to a sensor ground. If no sensor ground is available, the BROWN wire should be

connected to a power ground. Note: The BROWN wire must be connected in order

to get correct readings from the analog output.

Page 2

Thermocouple Mounting

FERRULE SLEEVE

COMPRESSION NUT

THREADED BODY

PIPE/MANIFOLD

WITH 1/8” NPT

THREADS OR

13/32” HOLE

TIP OF THERMOCOUPLE

NEAR CENTER OF

PIPE/MANIFOLD

HEAT SHRINK

Figure 3. Thermocouple to Cable Connection

Figure 2. Thermocouple Mounting

The thermocouple included in the kit comes with a stainless steel compression style

mounting adapter. The mounting adapter consists of three pieces: compression nut,

ferrule sleeve, threaded body. The threaded body has 1/8” NPT male threads. To

install the sensor, the threaded body can either be threaded into a hole with mating 1/8”

NPT threads, or welded to the pipe/manifold. Remove the compression nut, ferrule

sleeve, and thermocouple from the threaded body. For a welded installation, drill a

13/32” hole and weld the threaded body, being careful not to cause any distortion. .

For a threaded installation, either thread the body into an existing hole with 1/8” NPT

threads or drill a hole using an “R” size drill bit and cut the threads using a 1/8” NPT tap.

With the compression nut and ferrule sleeve on the thermocouple, insert the

thermocouple into the threaded body so the tip of the thermocouple is near the center of

the pipe/manifold and tighten the compression nut to the threaded body.

Connecting the Thermocouple

Slide the supplied heat shrink onto the sensor cable. Connect the RED wire from the

thermocouple to the RED wire on the harness and the YELLOW wire from the

thermocouple to the YELLOW wire on the harness using the supplied 4-40 screws and

hex nuts. Make sure the connections are not touching. Center the heat shrink over the

connections and apply mild heat to the heat shrink until it shrinks over the connections.

Page 3

Loading...

Loading...