Page 1

WARNING:

This installation is not for the electronic novice or the PC illiterate!

Instruction Manual

P/N 30-4900 Wideband Failsafe Gauge

Use this system with EXTREME caution! If you are not well versed

in electronics and vehicle instrumentation or are not PC literate,

please do not attempt the installation. Refer the installation to an

AEM trained tuning shop. A list of AEM trained tuning shops is

available at www.aemelectronics.com/dealer_locator.php or by

!

Wideband Failsafe Gauge Parts List

calling 800-423-0046. You should also visit the AEM Performance

Electronics Forum at http://www.aemelectronics.com.

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

Qty Description Qty Description

1 Wideband Failsafe Gauge 1 Faceplate, Lambda Black

1 UEGO Sensor 1 Faceplate, Vacuum Black

1 UEGO Harness 1 Harness, Input / Output

1 Install Kit w/ Bung 1 Rubber Band

1 Power Harness 1 Wideband Failsafe Instructions

1 USB Cable 1 Gauge Box

1 Faceplate, AFR White 1 Boost Hose Adapter

1 Faceplate, Boost Black 1 Vacuum Hose, 7/64” ID x 36” L

1 Faceplate, Boost White 1 Silver Bezel

This product is legal in California for racing vehicles only and should never be used on public highways.

AEM Performance Electronics

2205 126th Street Unit A, Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number: 10-4900 Rev B

2012 AEM Performance Electronics

Page 2

GETTING STARTED

THIS PRODUCT DOES NOT INCLUDE SOFTWARE IN THE PACKAGING. PLEASE DOWNLOAD

AND INSTALL THE WIDEBAND FAILSAFE CONFIGURATION SOFTWARE FROM THE AEM

WEBSITE AT: www.aemelectronics.com/downloads

Alternatively, register on the AEM Electronics Forums at http://forum.aempower.com/forum/index.php

Click on the All Software & Firmware Downloads forum. Click on the AEM Wideband Failsafe Software

link to reach the download page. The most recent software revision will be posted here as well as the link

above. Note that you can subscribe to this thread to be notified when software updates are released. All

current software releases will include a set of revision notes describing feature changes or additions since

the last update.

Software Installation Instructions

Follow the Installation Instructions as outlined in the forum post described above. After the software

installation is complete, click on the AEM Wideband Failsafe icon (shown below) to launch the

application.

Connect the USB cable to the PC. The Wideband Failsafe will turn ON with ignition key-on power.

Alternatively, the Wideband Failsafe can be bench-programmed outside of the vehicle without powering it

by connecting just the USB cable. However, the UEGO sensor, MAP sensor, analog outputs, and CAN

outputs will not function.

Firmware Updates

To update the firmware, download the firmware file, if available, from

www.aemelectronics.com/downloads. While connected to the gauge with the USB cable, open the

AEM Wideband Failsafe Software. Go to the Tools drop down menu and select Update Firmware and

follow the on-screen instructions.

Page 3

Page 3

Overview

AEM Wideband Failsafe is an advanced safety device that allows the end user to closely monitor the

performance of their engine. As a tuning tool, this device provides the ability to accurately monitor AFR,

while actively protecting the engine by constantly recording AFR curves and activating a user-defined

failsafe strategy if it runs dangerously lean or excessively rich.

The Wideband FAILSAFE Gauge is a UEGO (Universal Exhaust Gas Oxygen) controller with an internal

boost sensor, an internal data logger and a full color Organic Light Emitting Diode (OLED) display. It

includes technology to activate a failsafe strategy in the event AFR falls outside of a user-defined

operating window. If the AFR falls outside of the set operating window, the Wideband FAILSAFE Gauge

triggers a user defined output function that can save an engine from catastrophic damage.

Installation Diagram

Page 4

Page 4

Installation

1. Disconnect the negative battery cable.

2. Temporarily install gauge without bracket into desired mounting location. Gauge mounts into a 2-1/16”

(52MM) hole. The supplied rubber band can be used as a spacer around the gauge if it fits loosely in

mounting hole.

3. Locate a suitable place in the exhaust system to install the included oxygen sensor weld bung. On nonturbocharged engines, mount the oxygen sensor in the exhaust system at least 18 inches downstream

from the exhaust port. On turbocharged engines the oxygen sensor must be installed after the

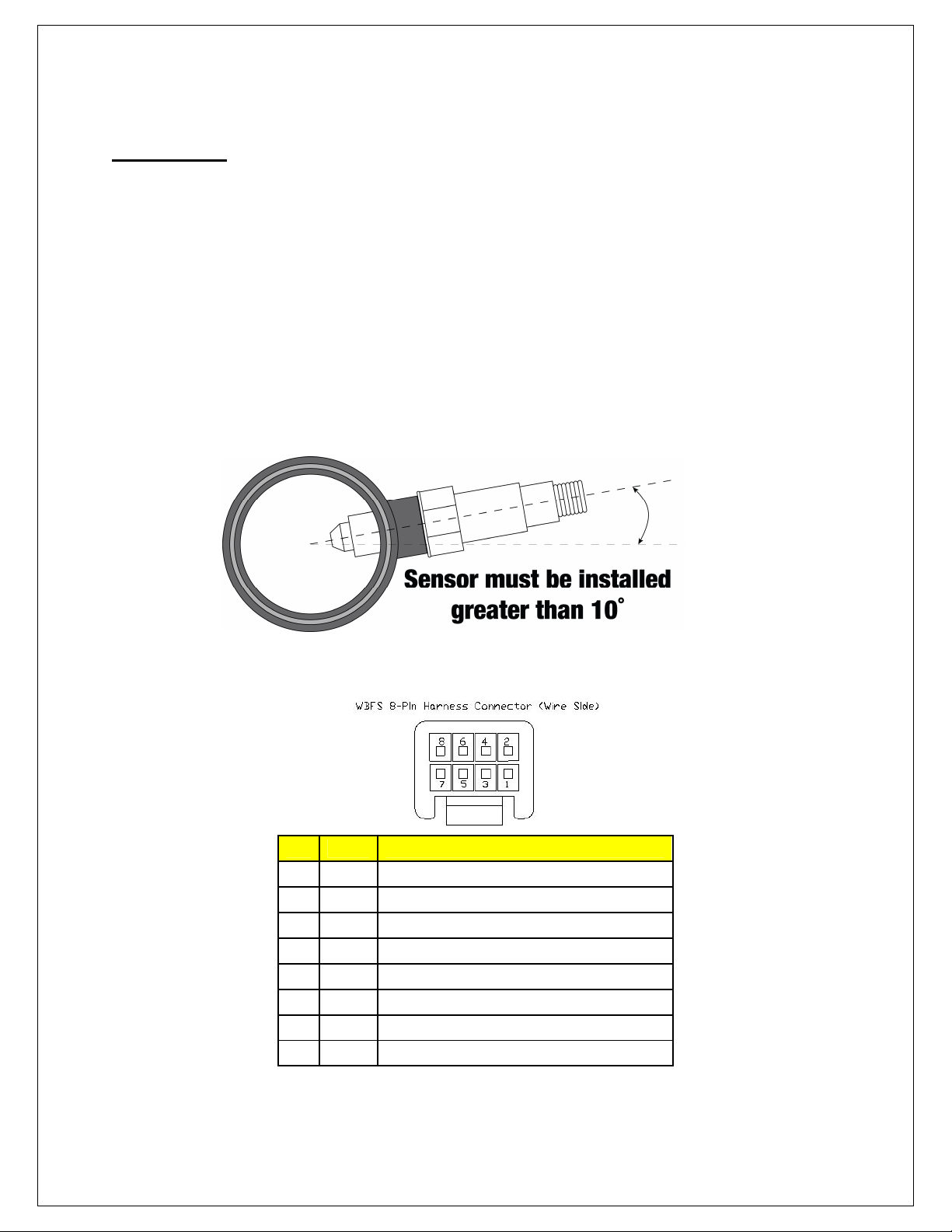

turbocharger, ideally 18” downstream from the turbocharger exhaust housing. NOTE: If the sensor is

mounted before the turbocharger the pressure differential will affect the accuracy of the unit. For

accurate readings, the sensor must be mounted upstream of the catalytic converters and/or auxiliary air

pumps. To prevent collection of liquids between the sensor housing and sensor element during the cold

start phase, the installation angle should be inclined at least 10° from horizontal with the electrical

connection upwards, see image below.

4. Next, the UEGO sensor 8-pin wiring harness should be routed to the oxygen sensor bung.

Pin Color

1 N/C N/C

2 White Heat 3 Orange VM

4 Green IA

5 Red IP

6 Black UN

7 N/C N/C

8 Brown 12V

Description

Page 5

Page 5

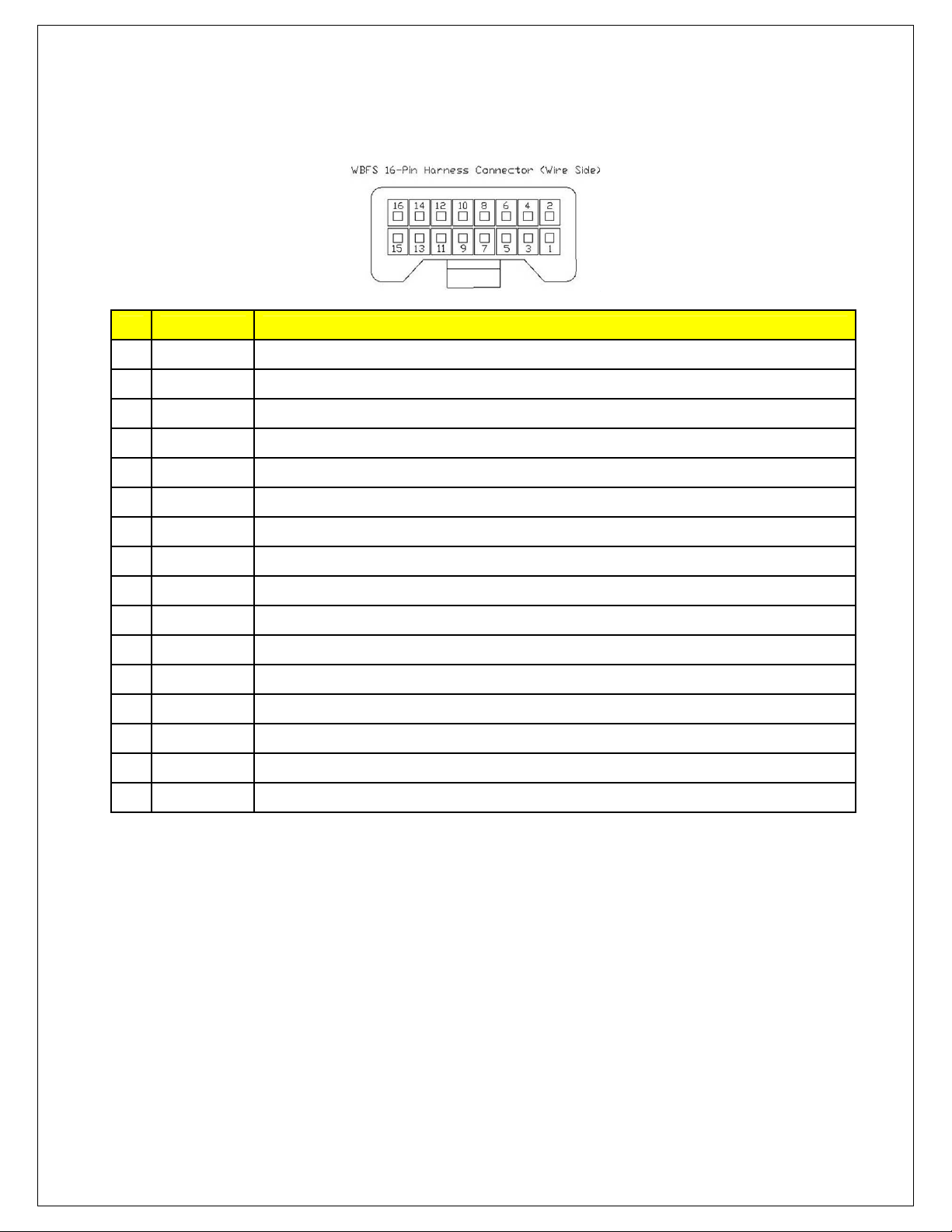

5. Next the main 16-pin connector will be manually wired into the vehicle.

Pin

1 Black Ground; connect to good chassis ground or directly to battery negative (−) terminal

2 Red Ignition power; connect to a fused key on +12V power source

3 Black USB - Dedicated

4 N/C Reserved

5 Red USB - Dedicated

6 Green USB - Dedicated

7 Blue *OPTIONAL* Ground output; connect to an external auxiliary device (1.5A max current)

8 White USB - Dedicated

9 Green *OPTIONAL* Engine Speed Input; connect to a square wave trigger

10 Gray *OPTIONAL* Gauge backlighting; connect to instrument lighting dimmer wire

11 N/C Reserved

12 N/C** *OPTIONAL* AEMnet 13 N/C** *OPTIONAL* AEMnet +

Color Description

14 Brown *OPTIONAL* Analog ground for AFR and MAP; connect to sensor ground of data logger or EMS

15 White *OPTIONAL* 0-5V analog output for AFR; connect to + analog input of data logger or EMS

16 Yellow *OPTIONAL* 0-5V analog output for MAP; connect + analog input of data logger or EMS

NOTES:

• Pins 14/15 are differential analog outputs. The brown wire should be connected to an analog

ground input for best results. If the EMS, logger or similar device does not have an analog ground

input, the brown wire should be connected to a sensor ground. If no sensor ground is available, the

brown wire should be connected to a power ground. The brown wire must be connected in order to

obtain correct AFR and MAP readings from the analog output(s).

• ** Pins 12/13 are un-populated as delivered. Please order the optional 30-3439 wiring harness to

connect the WBFS gauge to other AEMnet products.

• The WBFS gauge is able to receive RPM CAN data input from an AEM ECUs such as the Series-2.

6. Connect all cables and wiring harnesses to gauge. Fully install gauge into hole using mounting bracket

and nuts.

Page 6

Page 6

7. Install USB cable so the PC end of the cable is easily accessible and route the gauge end of cable to

Description

Button

Description

the gauge mounting location. USB cable is meant to be permanently installed to gauge and left in

vehicle. Stow PC end of cable in location such as glove box or center console, etc.

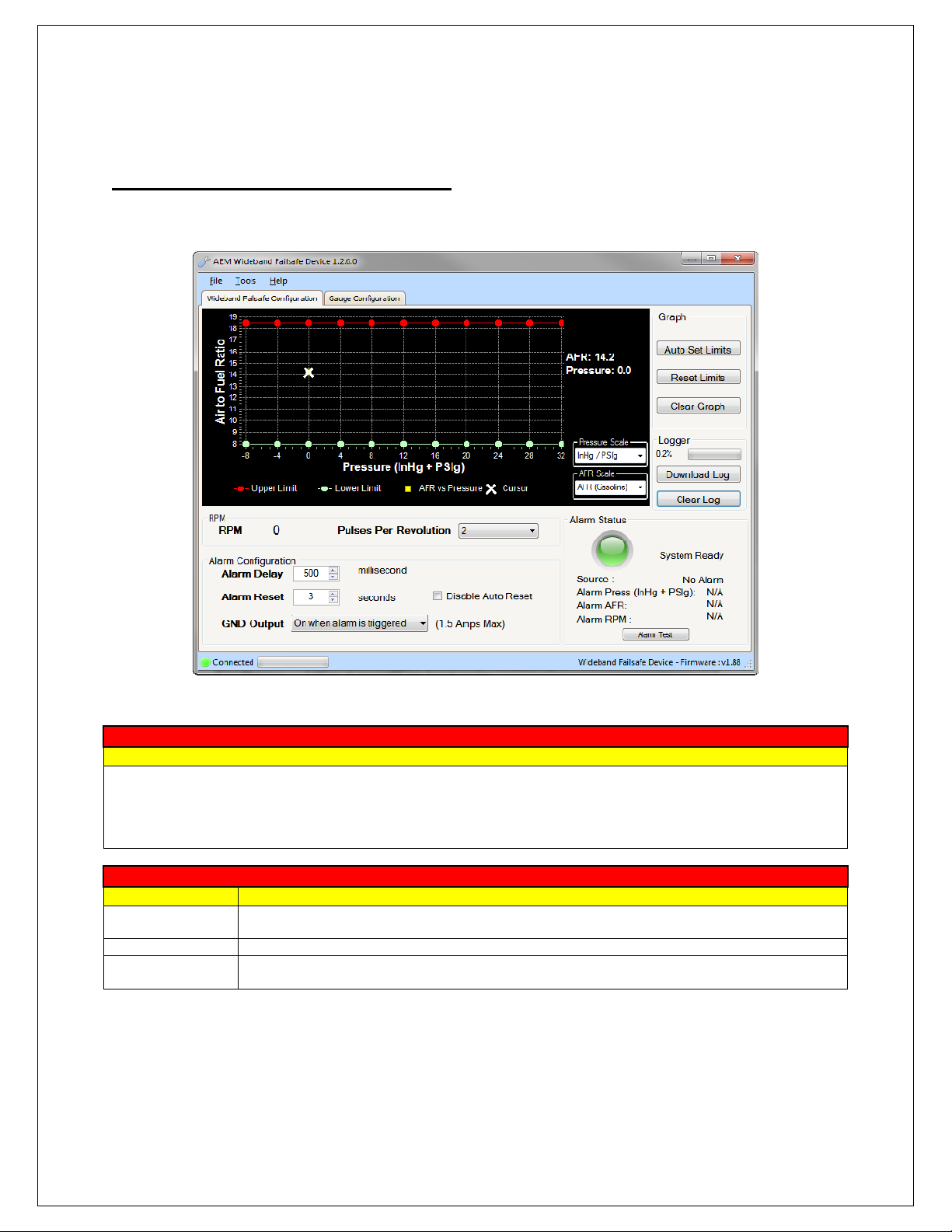

Wideband Failsafe Configuration

In this tab, the AFR monitoring and alarm output functionality of the Wideband Failsafe can be configured.

Air to Fuel Ratio vs. Pressure

Displays AFR vs. Pressure data points. AFR points will be populated live whenever the PC is connected to the

Wideband Failsafe and the UEGO sensor is registering an input. The current AFR and Pressure values are shown

live on the right side of the graph. The graph area is where the high and low AFR limit lines are established.

Configure the pressure scale and AFR scale before setting the boundary lines as they will reset each time a different

scale is selected.

Graph

Auto Set Limits

Reset Limits Resets the upper AFR limit line to maximum and the lower AFR limit line to minimum

Clear Graph

Automatically sets the upper and lower AFR lines based on an average of the collected AFR

data points

Clears all the displayed AFR data points from the graph; does not clear stored AFR data from

logger

Page 7

Page 7

Logger

Button

Description

Parameter

Description

Option

Description

Option

Description

Parameter

Description

Option

Description

Log Percentage Displays current amount of data recorded

Download Log

Clear Log Clears all stored AFR data from the logger

Downloads all the collected AFR data that is stored in the logger; will prompt to save log to disk;

log files saved as .daq for direct viewing in AEMdata program

RPM

RPM Displays the current engine speed dictated by the Pulses Per Revolution option.

Pulses Per

Revolution

Using the RPM parameter, select the number of pulses per revolution to properly calibrate the

engine speed input.

Alarm Configuration

Alarm Delay

Alarm Reset

Disable Auto Reset Select to require power cycle to reset alarm; overrides the automatic alarm reset period.

GND Output

Period of time that measured AFR can be outside the upper and lower AFR limit lines before an

alarm condition is triggered; 100-1000 milliseconds

Period of time AFR must be within the acceptable range before the alarm will automatically

reset and turn OFF; 1-10 seconds

Select to turn the ground output ON or turn the ground output OFF when an alarm is triggered;

1.5 amps max

Alarm Status

Status Indicator Color indicates status; green is system ready, red is alarm triggered

Source

Alarm Press Pressure when alarm was triggered; Units determined by Pressure Scale selection

Alarm AFR AFR when alarm was triggered; Units determined by AFR Scale selection

Alarm Test Simulates the alarm to test output configuration; test duration set by Alarm Delay value

Indicates the source of the alarm condition; possible alarm conditions are high AFR, low AFR,

auxiliary input, and alarm test

Page 8

Page 8

Gauge Configuration

Option

Description

Option

Description

Option

Description

Option

Description

In this tab, the gauge lighting and display features can be configured.

Display Option

Center

Display

Installed

Faceplate

Center display reading configuration; use to select either pressure (InHg / PSIg or Bar) or O2 sensor

(AFR or Lambda)

Faceplate configuration; use to match 24 outer LEDs to faceplate with either Pressure (InHg / PSIg

or Bar) or O2 sensor (AFR or Lambda) [See Appendix II – Changing Faceplate / Bezel]

Alarm Flash

Flash Speed Select speed of flashing while alarm is triggered; flash slow or fast

Dimmer Max Brightness

Dimmer Max

Brightness

Select whether +12V or ground indicates maximum backlighting brightness

Bar-Graph LED Color

RED LED (1) Can be disabled; use slider to configure multiple LEDs. Reference gauge display at bottom right.

ORG LED (2) Can be disabled; use slider to configure multiple LEDs. Reference gauge display at bottom right.

GRN LED (3) Cannot be disabled; use slider to configure multiple LEDs. Reference gauge display at bottom right.

ORG LED (4) Can be disabled; use slider to configure multiple LEDs. Reference gauge display at bottom right.

RED LED (5) Can be disabled; use slider to configure multiple LEDs. Reference gauge display at bottom right.

Page 9

Page 9

Wideband Failsafe Tuning

The following is a basic guideline strategy for configuring the Wideband Failsafe for the first time. The

ideal time to configure the Wideband Failsafe is while the vehicle is being dyno tuned. Ensure your

engine is fully functional mechanically before starting to configure the Wideband Failsafe!

1. In the Wideband Failsafe Configuration tab, click Clear Graph and Reset Limits to zero all settings.

2. If a boosted pressure scale is selected, there will be a pink triangular cursor on the left side of the

graph when the engine is in high vacuum, as shown below. The upper and lower limits for this high

vacuum area will use the lowest pressure (furthest left) breakpoint for alarm triggering.

Page 10

Page 10

3. Run the engine as you would normally drive the vehicle then complete a series of long sweeping high

load 3rd and 4th gear pulls going from low to high RPM each time to populate the graph with AFR data.

Avoid making quick hard pulls as this may skew the AFR data points. Repeat this procedure until a

baseline AFR curve is established. Note: You may notice that a few random AFR data points are

plotted well outside of the normal AFR curve. This is caused by dynamic tip-in wall wetting in transient

pressure situations. This is normal behavior and false triggers can be ignored in the configuration

setup process below.

Page 11

Page 11

4. With a baseline AFR curve now established, click on Auto Set Limits and the software will

produce its best suggested high and low AFR limit lines based on the populated AFR data shown

on the graph. Review and adjust the high and low AFR limit lines as needed to contour the lines

around the baseline AFR curve (shown below). This can be done by clicking on a breakpoint and

either dragging up or down with the mouse or by clicking the up and down arrows on the

keyboard. To move to the next breakpoint, click on it with the mouse or use the right and left

arrows. Pressing the Tab key will toggle back and forth between the high and low limit lines.

5. Test the configuration using your anticipated normal operating conditions with varying engine speed

and engine load situations to account for starting, stopping, accelerating, high boost, low boost, tip in,

fast shifts, slow shifts, etc. If false triggers occur, either adjust the high or low AFR curve up or down

at the pressure breakpoint where the alarm occurred or adjust the Alarm Delay setting.

NOTE: There are two general configuration strategies to follow when using the Wideband Failsafe. The

high and low AFR limit lines can be set very tightly to the baseline AFR curve and a longer Alarm Delay

can be used. Conversely, the high and low AFR limit lines can be set further way from the baseline AFR

curve and a shorter Alarm Delay can be used. Furthermore, many tuners may conclude that a rich AFR

is more acceptable for, safety measures, than a lean AFR. If true, a looser tolerance can be put into the

lower limit line as depicted in the graph above. Only thorough configuration testing will reveal which

strategy is best for your application.

Page 12

Page 12

Data Logger

The Wideband Failsafe has an internal logger that can store approximately 2.5 hours of data. The

system maintains two levels of data logs. First, all AFR data points are stored and downloadable for

viewing on the AFR vs. Pressure Graph in the Wideband Failsafe Configuration tab. Second, all inputs,

outputs, and alarm triggers are logged in special log file format for viewing with the AEMdata software

that comes as part of the Wideband Failsafe download package. Once the logger memory has filled up,

the logger will begin to loop log and the oldest data will be discarded as new data is collected (data points

that were collected will slowly start disappearing). The following is a basic guideline on how to use the

internal data logger. NOTE: The internal data logger is always running when 12V is present.

1. Connect USB cable to PC.

2. In the Wideband Failsafe Configuration tab under Logger, click Download Log. All logged

AFR data points will now be displayed in the AFR vs. Pressure Graph.

3. To download the log to the PC, click YES when prompted to save data to disc and then save

log in desired location.

4. Click YES when prompted to open file in AEMdata.

5. The saved data log will now open as shown below.

Page 13

Page 13

Plot One

Parameter

Description

Parameter

Description

Parameter

Description

AFR Current measured AFR (Gasoline)

AFR Upper Limit Current upper AFR limit value as set from the Wideband Failsafe Configuration tab

AFR Lower Limit Current lower AFR limit value as set from the Wideband Failsafe Configuration tab

Plot Two

Manifold Pressure Current measured Manifold Pressure in PSIg

Engine Speed Current measured RPM, if connected and used

Plot Three

Alarm Source

Alarm Status Indicates state of alarm; 1-alarm triggered, 0-alarm not triggered

Alarm Reset Limit Alarm Reset value

Alarm Reset

Counter

Alarm Delay Limit Alarm Delay value

Alarm Delay

Counter

Indicates what triggered the alarm condition; 3-low AFR condition, 5-high AFR condition, 3auxiliary input, 9-alarm test

Counts up from zero to Alarm Reset value once AFR has returned into the acceptable range

Counts up from zero to Alarm Delay value when AFR occurs outside the high or low AFR

limits; once full Alarm Delay value is reached the alarm will trigger; counter will reset back to

zero if AFR returns back into the acceptable range once count up has began

AEM EMS Series 1 / Series 2 Parameters

Below is the Wideband Failsafe related parameter names found in the AEM EMS Series 1 & 2

programmable ECU software when using the AEMNet daisy-chain. Note the slight difference in

nomenclature used with the AEM Wideband Gauge. Use the descriptions listed above for detailed

information.

AEM Wideband Failsafe Gauge Name AEM EMS Series 1/Series 2 Name

AFR [AFR Gasoline] WBFS AFR

AFR Upper Limit [AFR Gasoline] WBFS Up Limit

AFR Lower Limit [AFR Gasoline] WBFS Low Limit

Manifold Pressure [psi] WBFS Boost

Engine Speed [rpm] WBFS RPM

Alarm Status WBFS Alarm

Alarm Reset Limit [ms] WBFS Alarm Rst Lmt

Alarm Reset Counter [ms] WBFS Alarm Rst Cnt

Alarm Delay Limit [ms] WBFS Alarm Dly Lmt

Alarm Delay Counter [ms] WBFS Alarm Dly Cnt

Alarm Status WBFS Status

Page 14

Page 14

Function

Description

Output Configuration

The Wideband Failsafe has one ground (low side) output that is triggered when an alarm condition exists.

This output can be used in a multitude of ways to reduce boost, retard ignition timing, or otherwise protect

an engine in the event there is a problem with the fuel system. The following is an index of possible

auxiliary devices that can be triggered by the alarm output:

AEM EMS

Nitrous Fuel &

Ignition Maps

Boost Switch Use the ground output to trigger the boost switch; a lower boost value can be targeted

Two-Step Use the ground output to trigger the two-step; a lower engine rev limit can be selected

Use the ground output to trigger the nitrous fuel and ignition maps; ignition timing can be

reduced and fuel can be added

MSD Ignition Products

Product Description

Brown wire: use a relay to apply +12V to trigger ignition interrupt

DIS2 (62112)

DIS4 (62152)

6AL-2 (6421) Blue wire: use a relay to apply +12V to trigger two step

Programmable

6AL-2 (6530)

Digital 6 Plus (6520)

Start/Retard Control (8982) Violet wire: use a relay to apply +12V to trigger timing retard

Timing Controller (8980) Grey wire: ground input to trigger timing retard

Blue wire: use a relay to apply +12V to trigger two step

Pink wire: use a relay to apply +12V to trigger timing retard

Brown wire: use a relay to apply +12V to trigger ignition interrupt

Blue wire: use a relay to apply +12V to trigger two step

Pink wire: use a relay to apply +12V to trigger timing retard

Dark blue wire: use a relay to apply +12V to trigger launch rev limit

Light blue wire: use a relay to apply +12V to trigger burn out rev limit

Pink wire: use a relay to apply +12V to trigger timing retard

Blue wire: use a relay to apply +12V to trigger two step

Pink wire: use a relay to apply +12V to trigger timing retard

Warning Light

The Wideband Failsafe can also be used to directly activate a warning light (Autometer PN 3239 or

similar). Connect the warning light’s white wire to 12V and the low side output to the warning light’s black

(ground) wire to turn the light ON. NOTE: High current lights will require a relay to be installed.

Page 15

Page 15

NC/NO Relay

The following are examples of how a NC/NO relay (Bosch PN 0-332-019-203 or similar) can be

configured for use with the Wideband Failsafe.

Signal Interrupt: The low side (ground) output from the Wideband Failsafe can be used to turn ON a NC

(normally closed) relay and interrupt the output signal from a boost controller to its boost solenoid (shown

below). NOTE: Be sure that pulling power from the boost solenoid will decrease boost down to the

wastegate spring pressure rather than increase boost to the turbochargers max. This will depend on what

type of wastegate is used and how it is plumbed with vacuum hose.

Auxiliary Device: The low side (ground) output from the Wideband Failsafe can be used to turn ON a NO

(normally open) relay and activate or deactivate an auxiliary device that can be used to reduce timing or

boost or control some other function when the current requirement is greater than 1.5 amps.

Page 16

Page 16

Appendix I - Analog Outputs

Voltage

Pressure (psig)

Pressure (Bar)

Pressure (kPA)

Voltage

AFR (Gas)

AFR (Lambda)

There are 2 analog outputs from the Wideband Failsafe; Pressure (MAP) and AFR (O2). These outputs

are both linear DC voltage signals that vary with Pressure or AFR. These signals are used for sending

information to a data logger or an engine management system such as an AEM EMS, AEM F/IC, AEM

Infinity, etc.

Pressure Output Transfer Function

Pressure (psig) = (10 * Volts) – 16

0.5 -11 0.25 25

1.0 -6 0.59 59

1.5 -1 0.94 94

2.0 4 1.28 128

2.5 9 1.63 163

3.0 14 1.97 197

3.5 19 2.32 232

4.0 24 2.66 266

4.5 29 3.01 301

AFR Output Transfer Function

AFR (Gas) = (2.375 * Volts) + 7.3125

0.5 8.50 0.58

1.0 9.69 0.66

1.5 10.88 0.74

2.0 12.06 0.82

2.5 13.25 0.91

3.0 14.44 0.99

3.5 15.63 1.07

4.0 16.81 1.15

4.5 18.00 1.23

Page 17

Page 17

Appendix II - Changing Faceplate / Bezel

The Wideband Failsafe gauge comes with the black bezel and Air/Fuel-Gasoline faceplate installed.

However, a silver bezel and multiple faceplates are also included. To change them, orient the gauge so

you are looking at the faceplate. Rotate the bezel counter-clockwise to unscrew it from the gauge cup.

The bezel, lens, and rubber spacer are all removable. Next, remove the faceplate, but note the two

keyways on each side. When inserting the new faceplate be cognizant of these keyways and line them up

before reassembling.

When reassembling the gauge, it may be necessary to apply a light amount of pressure on the lens and

spacer to keep the faceplate from rotating when reinstalling the bezel. Do not over-tighten the bezel

when reassembling the gauge.

Page 18

Page 18

Appendix III - AEMnet

The following instructions describe the proper installation of the optional AEMnet Harness (30-

3439), which is used to connect the Wideband Failsafe AEMnet communication lines to a second

(or multiple) AEMnet device(s).

1. Disconnect the Wideband Failsafe 16-pin harness connector from the Wideband Failsafe gauge. The

harness connector has a latch on the bottom side that needs to be squeezed as the connector is

lightly freed from the gauge. Refer to Figure 1 below.

Figure 1

2. Locate the green and white pre-crimped terminals on the end of the AEMnet Harness. Figure 2 below

shows the Wideband Failsafe connector and pinout including the green and white leads from the

AEMnet harness.

Figure 2

3. Before inserting the terminals into the connector, refer to Figure 3 to be sure that the locking

mechanism on the terminals is positioned properly in the connector.

Figure 3

Page 19

Page 19

4. Insert the AEMnet+ terminal (white wire) into the available Pin 13 on the Wideband Failsafe

connector. Push the wire in until the locking mechanism on the terminal and connector lock into

place. Pull lightly on the white wire to confirm the locking mechanism has latched. Figure 4 below

shows the correct placement of the AEMnet+ terminal.

Figure 4

5. Insert the AEMnet- terminal (green wire) into the available Pin 12 on the Wideband Failsafe

connector. Push the wire in until the locking mechanism on the terminal and connector lock into

place. Pull lightly on the green wire to confirm the locking mechanism has latched. Figure 5 below

shows the correct placement of the AEMnet- terminal.

Figure 5

6. Connect the Deutsch connector on the opposite end of the AEMnet harness to a mating Deutsch

connector on a second device with AEMnet capabilities. The AEMnet harness includes a male and

female Deutsch connector, allowing AEMnet devices to be daisy-chained together.

Page 20

Page 20

AEMnet Messages

Message

Message

Message

0x00000026 (29-bit)

Rate: 10mS continuous

Byte Label Data Type Scaling Offset Range

0

1

2

3

4

5

6 (bit0)

6 (bit1)

6 (bit2)

6 (bit3)

6 (bit4)

6 (bit5)

6 (bit6)

6 (bit7)

7 (bit0)

7 (bit1)

7 (bit2)

7 (bit3)

7 (bit4) --- --- --- --- --7 (bit5) --- --- --- --- --7 (bit6) --- --- --- --- --7 (bit7) --- --- --- --- ---

AFR Heater Time-Out Error

Lambda 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Pressure 16 bit unsigned .001 PSI/bit -15 -15 to 50.535 PSI

RPM 16 bit unsigned .39063 RPM/bit 0 0 to 25,600 RPM

AFR Ready

AFR Heater Open Error

AFR CJ125 Error

AFR Sensor Heating Up

AFR Low Voltage

AFR Heater Short Error

AFR Overtemp Error

Alarm Status

Alarm Source

Alarm Source

Alarm Source

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

0x00000027 (29-bit)

Rate: 10mS continuous

Byte Label Data Type Scaling Offset Range

0

1

2

3

4

5

6

7

Lambda Upper Limit 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda Lower Limit 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Alarm Delay Limit 16 bit unsigned 1 mS/bit 0 0 to 65,535 mS

Alarm Delay Counter 16 bit unsigned 1 mS/bit 0 0 to 65,535 mS

0x00000028 (29-bit)

Rate: 10mS while in alarm mode, not transmitted otherwise

Byte Label Data Type Scaling Offset Range

0

1

2

3

4

5

6

7

Alarm Lambda 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Alarm Pressure 16 bit unsigned .001 PSI/bit -15 -15 to 50.535 PSI

Alarm Reset Limit 16 bit unsigned 1 mS/bit 0 0 to 65,535 mS

Alarm Reset Counter 16 bit unsigned 1 mS/bit 0 0 to 65,535 mS

Page 21

Page 21

12 Month Limited Warranty

Advanced Engine Management, Inc. warrants to the consumer that all AEM High Performance products will be free

from defects in material and workmanship for a period of twelve (12) months from date of the original purchase.

Products that fail within this 12 month warranty period will be repaired or replaced at AEM’s option, when determined

by AEM that the product failed due to defects in material or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty exceed the

original purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential

damages or cost incurred due to the failure of this product.

Warranty claims to AEM must be transportation prepaid and accompanied with dated proof of purchase. This

warranty applies only to the original purchaser of product and is non-transferable. All implied warranties shall be

limited in duration to the said 12 month warranty period. Improper use or installation, accident, abuse, unauthorized

repairs or alterations voids this warranty.

An AEM Warranty Claim Form Must Accompany All Warranty Claims. Products returned to AEM with no

Return Goods Authorization and or No Warranty Claim Form may be rejected and returned to sender.

AEM disclaims any liability for consequential damages due to breach of any written or implied warranty on all

products manufactured by AEM. Warranty returns will only be accepted be AEM when accompanied by a valid

Return Goods Authorization (RGA) number. Credit for defective products will be issued pending inspection. Product

must be received by AEM within 30 days of the date RGA was issued.

Please note that before we can issue an RGA for any product, it is first necessary for the installer or end user

to contact our EMS tech line at (800) 423-0046 to discuss the problem. Most issues can be solved over the

phone. Under no circumstances should a product be returned or RGA requested before the above process

transpires.

AN AEM WARRANTY CLAIM FORM MUST ACCOMPANY ALL ELECTRONICS WARRANTY CLAIMS. AEM

ELECTRONIC Products returned to AEM with no RGA and or No Warranty Claim Form may be rejected and

returned to sender.

A copy of the AEM Warranty Claim Form can be e-mailed or faxed by contacting (310) 484-2322 and ask for

Warranty/Claims Department.

Need additional help? Contact the AEM Performance Electronics tech

department at 1-800-423-0046 or tech@aempower.com, or visit the AEM

Performance Electronics forum at: http://forum.aempower.com/forum/

Page 22

Loading...

Loading...