Page 1

WARNING:

!

This installation is not for the electronic novice or the PC illiterate!

Use this system with EXTREME caution! If you are not well versed

in electronics and vehicle instrumentation or are not PC literate,

please do not attempt the installation. Refer the installation to an

AEM trained tuning shop. A list of AEM trained tuning shops is

available at www.aemelectronics.com/dealer_locator.php or by

calling 800-423-0046. You should also visit the AEM Performance

Electronics Forum at http://www.aemelectronics.com.

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

Instruction Manual

Infinity Layover Harness

GM LS Engines 24x

This product is legal in California for racing vehicles only and should never be used on public highways.

NOTE: All supplied AEM calibrations, Wizards and other tuning information are offered as potential starting points only. IT IS

THE RESPONSIBILITY OF THE ENGINE TUNER TO ULTIMATELY CONFIRM IF THE CALIBRATION IS SAFE FOR ITS

INTENDED USE. AEM holds no responsibility for any engine damage that results from the misuse or mistuning of this

product!

AEM Performance Electronics

2205 126th Street Unit A, Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number: 10-3532

2014 AEM Performance Electronics

Page 2

Introduction

This Infinity Layover Harness was designed for the GM LS Engine 24x (manual transmission). The harness includes all

standard GM (or equivalent) connectors for direct plug-in fitment, and requires minimal wiring to complete the Power

Distribution Center (PDC) connections. The Infinity ECU is sold separately, and includes base configuration files for the

GM LS Engines 24x.

Overview

This Instruction Manual describes the harness layout, and provides instructions for installation of the harness on a vehicle.

All included connectors are listed in detail in the provided pinout. Also included are instructions for adding new circuits into

the Infinity connectors if additional sensors or outputs are desired. Please read the entire Instruction Manual prior to

beginning the installation.

Included Items

Connectors

Infinity C1 and C2

8 injectors

2 coil pack connectors, Bank-1 and Bank-2

Oil Pressure sensor

Crank Position Sensor

Cam Position Sensor

Knock connector (supports 2 sensors)

Alternator, 1-wire

Cable Throttle Body

Idle Air Control Valve, 4-wire stepper

UEGO Wideband 02 sensors, Bank-1 and Bank-2

Mass Air Flow sensor

Intake Air Temperature sensor

Engine Coolant Temperature sensor

Manifold Absolute Pressure sensor

Vehicle Speed Sensor

Reverse Lockout Solenoid

Cylinder head grounds, Bank-1 and Bank-2

AEMnet

Power Distribution Center

Bussmann Relay/Fuse Box with flying leads

Relays/Fuses

Relay, ISO 280 Micro Relay 35A/12V (5 ea)

Fuse, Mini ATM 30A (4 ea)

Fuse, Mini ATM 20A (1 ea)

Fuse, Mini ATM 10A (1 ea)

Fuse, Mini ATM 5A (4 ea)

Rev A, 2013/02/05

Page 3

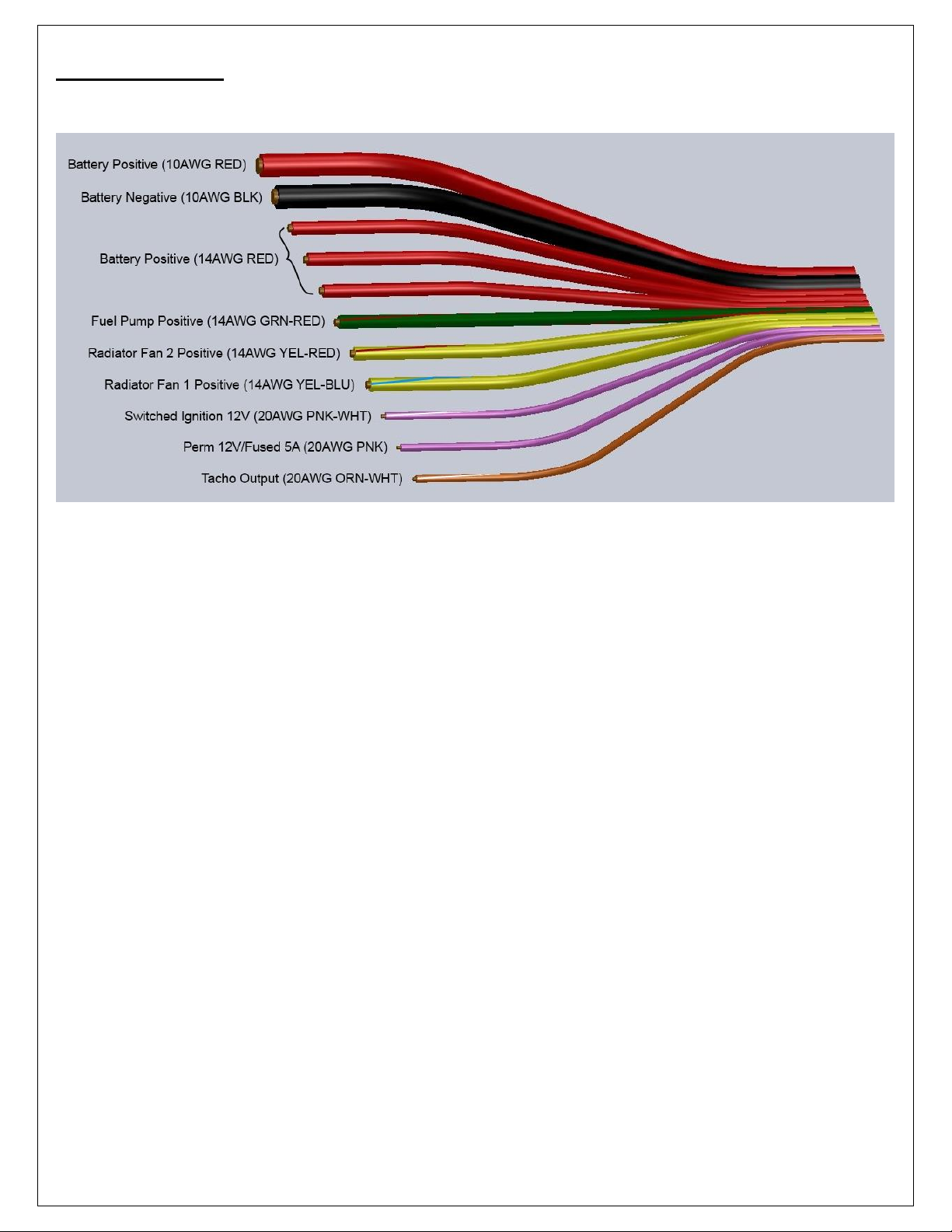

Power Distribution Center

Included in the harness is a Bussmann Power Distribution Center (PDC), pre-populated with the required relays and fuses

for correct operation of the harness. The PDC comes with a bundle of flying leads that need to be properly wired as part of

the installation. Flying leads include switched ignition, battery power and ground, and switched power to Fuel Pump and

Coolant Fans 1 & 2.

Connector Labels

All connectors come labeled to assure proper installation and reduce setup time.

Rev A, 2013/02/05

Page 4

Downloadable Files

The Quickstart Guide and Layover Harness Instruction Manual can be downloaded from www.aemelectronics.com. These

documents are available for download here: www.aemelectronics.com/engine-management-systems-9/infinity-8-10-12-

stand-alone-programmable-ems-90/infinitytuner-software-and-instruction-downloads-92/

Configuration files can be downloaded from www.aeminfinity.com/. An experienced tuner must be available to configure

and manipulate the data before driving can commence

Downloadable files for GM LS Engines 24x

GM_LSX_Supported_Application_v92-20130718RevA.pdf

GM_LSX_24X_Infinity_Layover_Harness_RevA.pdf

7100-XXXX-62 INF-10 Universal v95

7101-XXXX-63 INF-8 Universal v95

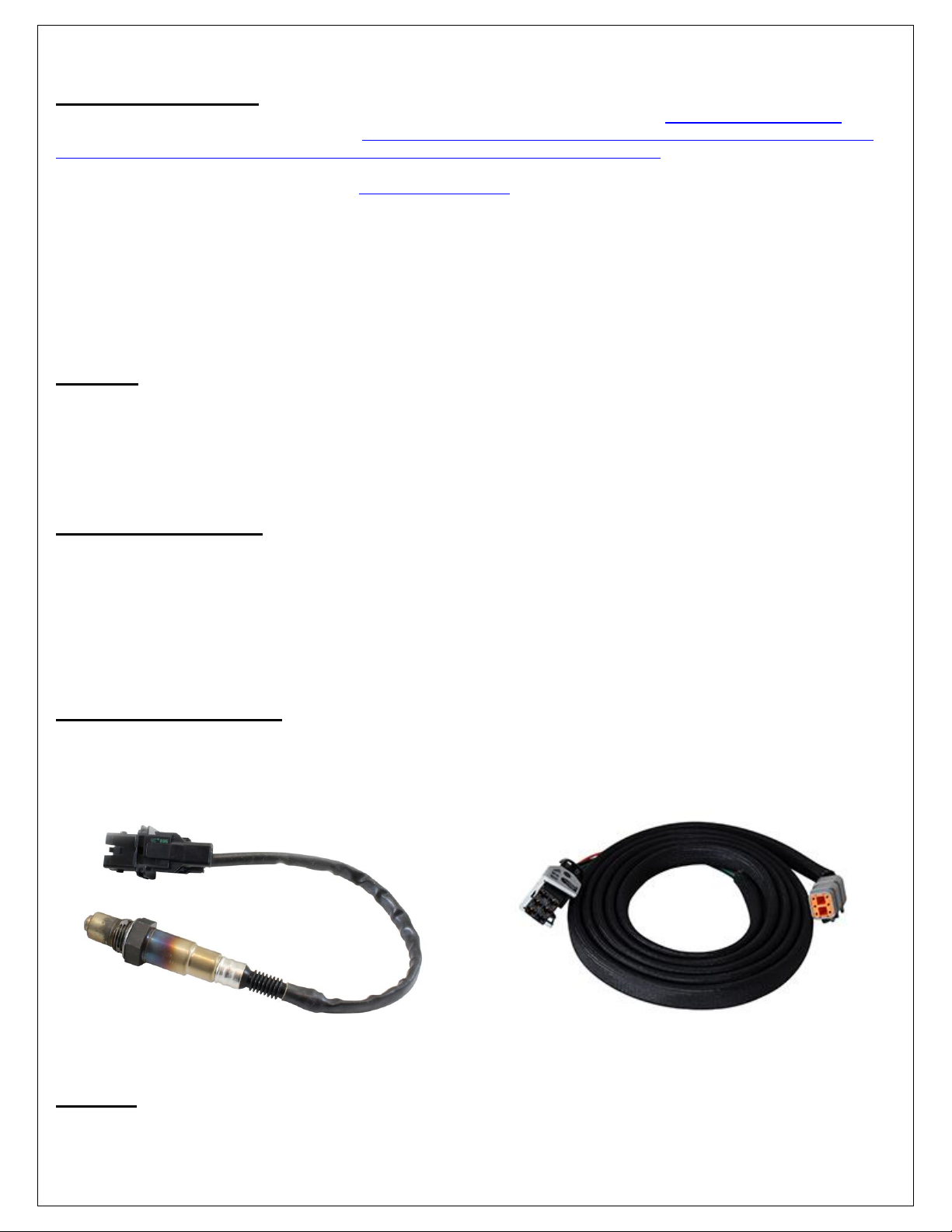

Options

30-2001 UEGO Wideband O2 Sensor

Bosch LSU4.2 Wideband O2 Sensor that connects to AEM 30-3600 UEGO Wideband O2 Sensor Extension Harness

30-3600 UEGO Wideband O2 Sensor Extension Harness

Extension harness to connect AEM UEGO Wideband O2 sensor to 6 pin Deutsch

Cable Throttle Body

The GM LS Engines 24x layover harness is designed for use with a cable throttle body and 4-wire stepper IACV.

However, the Infinity ECU does support up to 2 Drive-By-Wire throttle bodies. Additional wiring can be added into the

Infinity connectors to support Drive-By-Wire throttle bodies if desired. Refer to the included pinout for proper pin numbers.

Drive-By-Wire throttle bodies incorporate idle control into the main throttle body, eliminating the need for a separate Idle

Air Control Valve. If converting to Drive-By-Wire, move the IACV connector branch to a safe location and secure with an

automotive grade tie wrap.

Wideband 02 Sensors

AFR1 (UEGO Sensor Bank 1) and AFR2 (UEGO Sensor Bank 2) plugs are for connecting UEGO wideband Bosch

LSU4.2 sensors (AEM 30-2001) models only. The UEGO extension harness (AEM 30-3600) mates with the layover

harness to the sensor (1 required for each sensor used). Use of any other type of wideband sensor can damage the

sensor and/or the Infinity ECU.

AEMnet

AEMNet is an open architecture based on CAN 2.0 which provides the ability for multiple enabled devices, such as

dashboards, data loggers, etc. to easily communicate with one another through two twisted cables (CAN+/CAN-).

Rev A, 2013/02/05

Page 5

Installation Notes

Wiring Conventions and EMI

The GM LS Engines 24x layover harness comes pre-wired with all connectors, fuses, and relays needed to operate an

engine. However, the PDC does require extension/termination of the flying leads to their appropriate devices, and

additional sensors and other devices can be wired into the harness as needed for the specific application. The following

guidelines should be adhered to while completing the required wiring.

A proper wiring job includes proper termination of the wire at the sensor. The wire terminal end must be moisture tight

where it plugs into the sensor and it must have strong, electrically sound terminals. The preferred method of securing a

wire to a terminal is to use a crimp terminal with NO solder. It is important to use the proper crimping tool for sound

terminal construction. Plastic terminal plugs must have moisture tight seals. Inspect each plug to make sure the seals are

in place. Di-electric grease can be added in the terminal slots to further aid in corrosion resistance.

If a splice into a wire must be made and no solder-less terminals are available, then you must properly solder the splice.

Noise can be a serious problem and can cause intermittent misfiring of the engine. Every precaution should be taken to

prevent interference to the ECU’s operation. Resistive plug leads are REQUIRED. The GM LS Engines 24X Layover

Harness comes with shielded cables for the cam and crank position sensors. These wires have shield grounds that are

grounded at the Infinity ECU plug. They are NOT grounded at the sensor end of the cable. Attempting to ground both

ends of the cable will cause a condition called ground looping and will remove any noise protection the cable has.

To eliminate or reduce the chance of EMI, wires that carry high current must run in twisted pairs. An example of this would

be the power leads from a multiple spark ignition system. These ignition systems can carry up to 100 amps for a couple

milliseconds at the time of discharge, which induces a strong magnetic field in close proximity of the wires.

The routing of the wire loom is critical to EFI system performance and safety. The following safety considerations should

be made when installing the wire loom:

Heat protection: the loom should be placed away from or insulated from sources of heat. The obvious item(s) that

should be avoided are the exhaust manifolds, EGR delivery tubes, and turbochargers. If it is absolutely necessary

to route a wire in close proximity to any of these items, then a suitable insulator must be used.

Noise suppression: do not route wires near the HT leads. For coil-on-plug ignition systems this is not as critical.

Moving component protection: route wires away from moving components such as fans, the blower belt, or the

throttle linkage. Also, make sure the wires are not under any strain when the engine is at full deflection on the

motor mounts.

Never have the wires in exposed bundles throughout the engine compartment.

Determining ECU Location

It is recommended that the ECU be placed in an environment that does not expose it to temperatures above 85°

Celsius (160F).

In cases where the Infinity is to be used in place of the stock ECU, the location that the stock ECU occupied is

suitable.

On applications where the ECU is to be located in a different position than stock, the interior of the vehicle is best.

The Infinity should be located in a place that reduces the length of extension wires from the PDC while

maintaining an environmentally sound location.

The ECU location must permit the PDC to be mounted in a serviceable location.

Power Distribution Center

The PDC contains all of the Relays and Fuses for the entire harness, and should be mounted in a location which permits

serviceability. Ideally the PDC should be located in the passenger compartment, or if necessary within the engine

compartment as far away from heat sources as can be achieved.

The PDC contains the flying lead bundle which must be wired to the battery, fuel pump and radiator fan(s), and switched

ignition. Routing of this flying lead bundle should also be taken into account when determining the mounting location of

the PDC.

Rev A, 2013/02/05

Page 6

Required Wiring

The GM LS Engines 24x Layover Harness comes with a flying lead bundle wired into the PDC. Each of the flying leads

needs to be wired to an appropriate device, or sealed and tied wrapped if not used.

Power and Ground

The Infinity must have an electrically secure ground connection, which means that the battery negative must be

properly grounded to the battery AND the cylinder head grounds muse be properly grounded to the engine. The

ground wires must have perfect electrical conductivity, which means that there must not be any paint or rust under

the wire terminals.

The Battery Negative (10AWG BLK) and Battery Positive (10AWG RED) wires must be extended long enough to

reach the battery without having excess length. A 10AWG or larger gauge wires must be used to make the

extensions.

The 3 Battery Positive (14AWG RED) wires supply power to 3 relays:

1. FPump

2. RadFan1

3. RadFan2

Each 14AWG wire can be extended with a 14AWG or larger gauge wire and connected directly to the battery

positive. Alternatively, the 3 wires can be spliced together with a large enough gauge wire to support the

amperage load of all three devices combined. The amperage load of your Radiator Fans and Fuel Pump is

unique, and the wire gauge selected for your splice must be calculated correctly. Large voltage drops, burned

wire insulation, and fire can occur from using too small of a gauge wire. Reference an American Wire Gauge table

for more details on amperage ratings.

To prevent rust build up, we recommend applying a protective layer of dielectric grease, such as Standard Ignition

SL-4, to the bare metal surface.

Fuel Pump

Run this wire to the fuel pump positive terminal. This wire provides fused/switched power to the fuel pump. A separate

ground wire needs to connect the fuel pump negative terminal to chassis/battery ground.

Radiator Fan 1 Positive

Run this wire to the Radiator Fan 1 positive terminal. This wire provides fused/switched power to the radiator fan. A

separate ground wire needs to connect the radiator fan negative terminal to chassis/battery ground.

Radiator Fan 2 Positive

Run this wire to the Radiator Fan 2 positive terminal. This wire provides fused/switched power to the radiator fan. A

separate ground wire needs to connect the radiator fan negative terminal to chassis/battery ground.

Rev A, 2013/02/05

Page 7

Switched Ignition 12V

The Switched Ignition flying lead (PNK-WHT) must be connected to the output on the ignition switch that supplies 12V

when the switch is in the Start and Run position. The ignition switch output should be isolated, meaning that it is dedicated

to the PNK-WHT wire, and should NOT supply switched ignition power to any other device.

Perm 12V

The Perm 12V/Fused 5A PNK flying lead can be used to power the ignition switch if the switch does not already have a

12V source wired to it.

Tacho Output

The Tacho Output (20AWG ORN-WHT) transmits a 0-12V pulse signal. The Tacho Output can be configured in the

Infinity Tuner Wizard to transmit the desired pulses per engine revolution in order to match the installed tachometer.

INFINITY CONNECTORS

The AEM Infinity EMS uses the MX123 Sealed Connection System from Molex.

Refer to the 10-7100 for EMS 30-7100 Infinity Quick Start Guide for details on

connector assembly and handling.

AEM strongly recommends that users become familiar with the proper tools and

procedures before attempting any modifications. The entire user manual can be

downloaded direct from Molex at:

http://www.molex.com/mx_upload/family//MX123UserManual.pdf

Rev A, 2013/02/05

Page 8

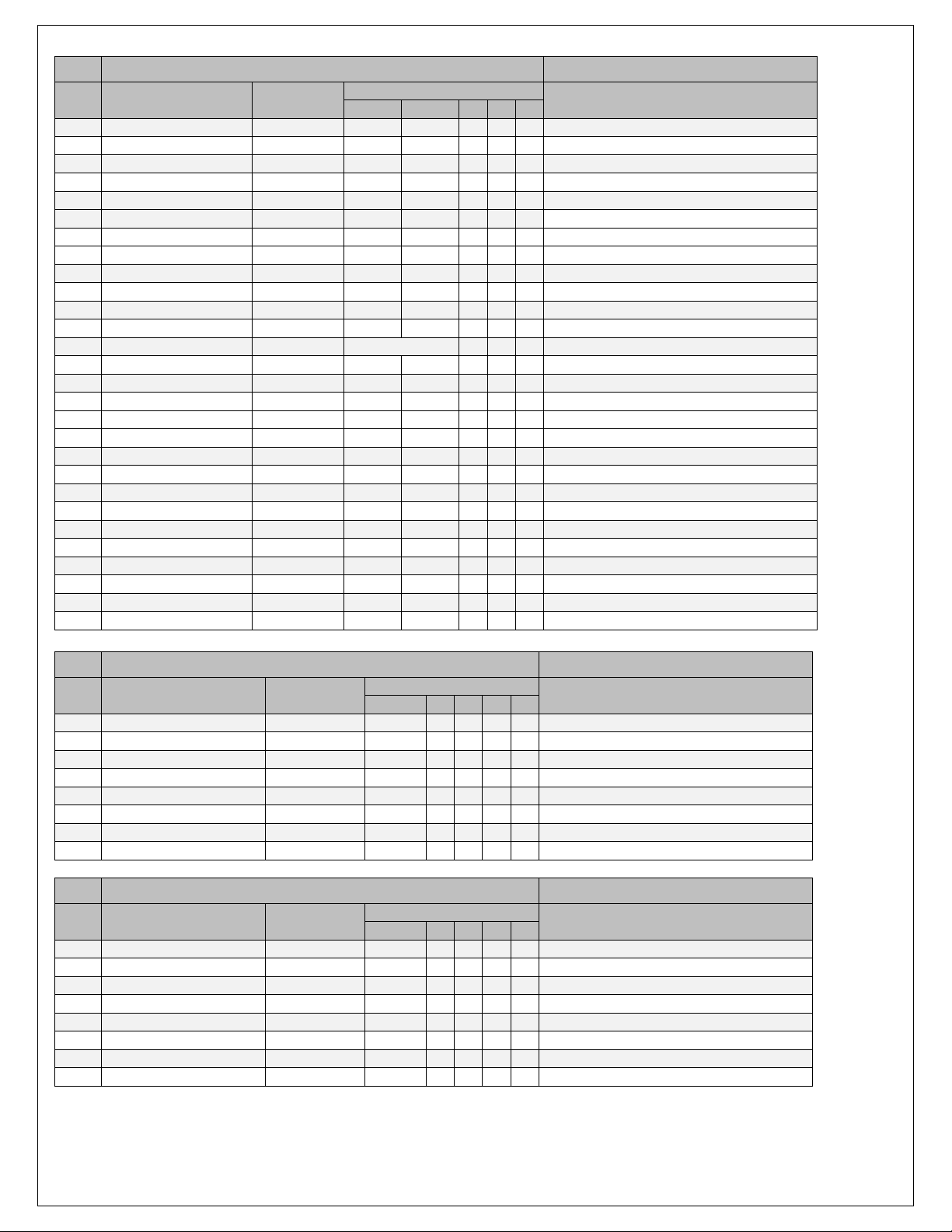

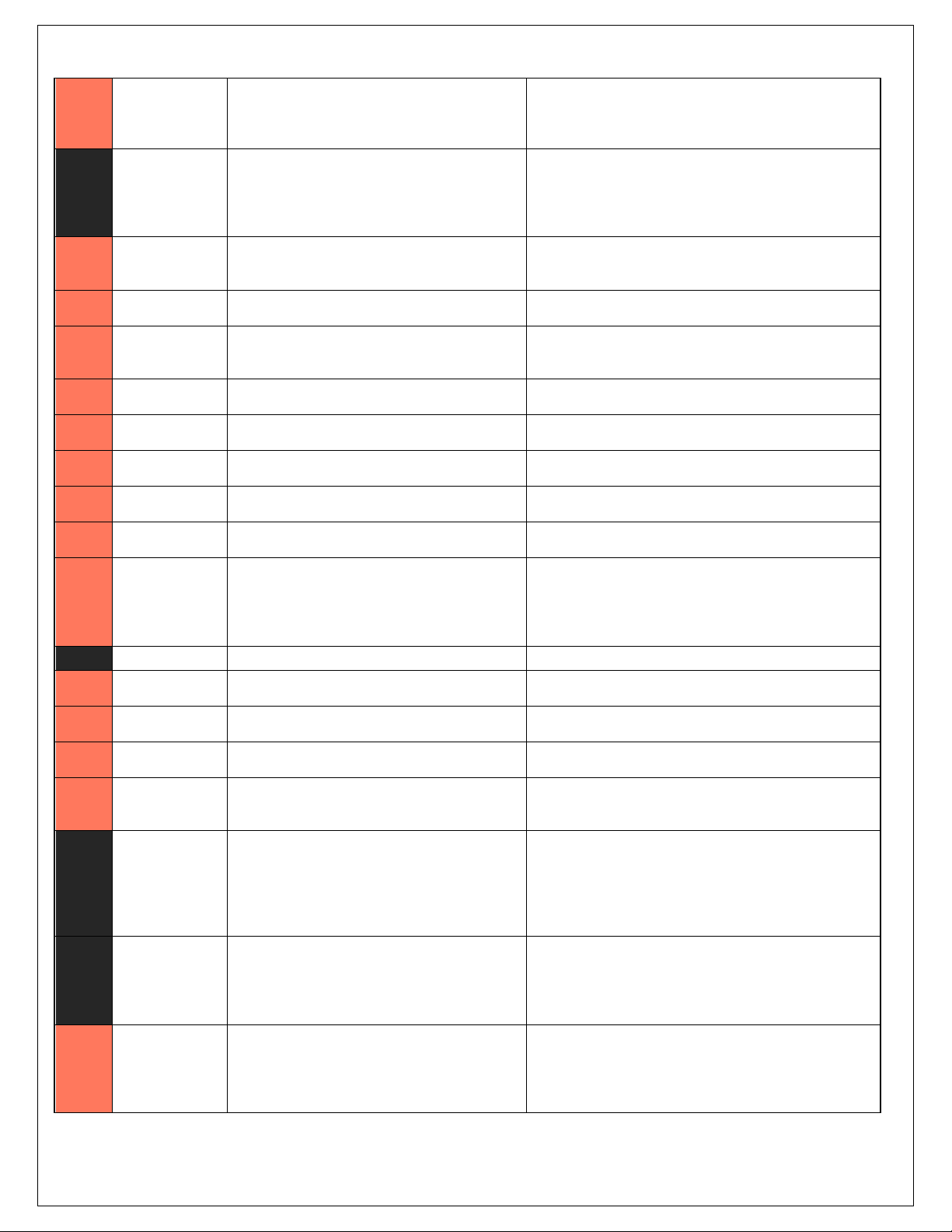

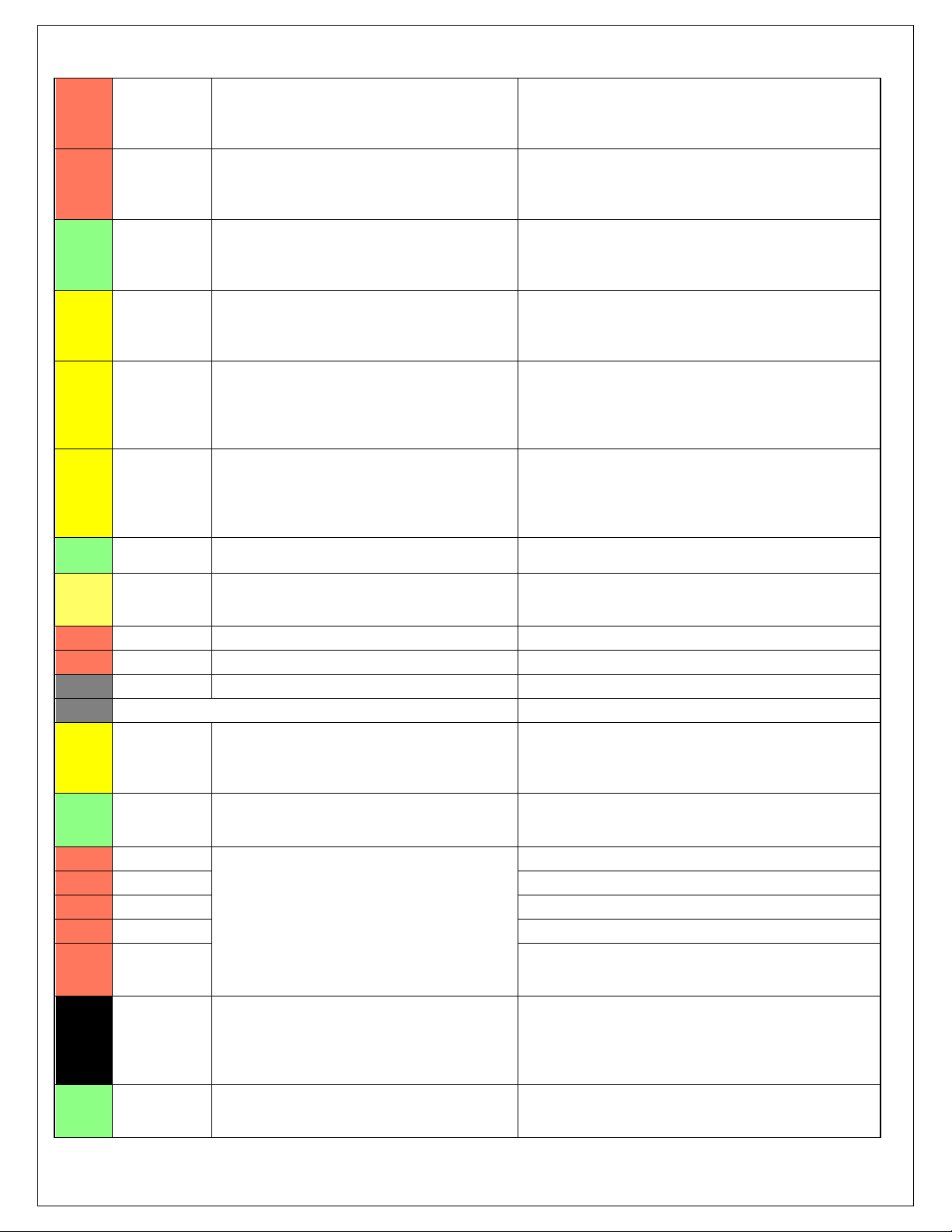

C1

Infinity Connector C1

73 Way F Receptacle 0.64 2.8 Series Sealed (GY)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

C1-2

GRN

20

C23-B

---

---

---

---

Reverse Lockout Lowside Driver

C1-4

WHT

18

C26-4

---

---

---

---

Deutsch DTM04-6P UEGO B1-HEAT

C1-5

GRN

20

C26-2

---

---

---

---

Deutsch DTM04-6P UEGO B1-IA

C1-6

RED

20

C26-6

---

---

---

---

Deutsch DTM04-6P UEGO B1-IP

C1-7

BLK

20

C26-1

---

---

---

---

Deutsch DTM04-6P UEGO B1-UN

C1-8

ORN

20

C26-5

---

---

---

---

Deutsch DTM04-6P UEGO B1-VM

C1-10

PNK/RED

20

P1-7A

---

---

---

---

12V Perm Power

C1-11

DK GRN/WHT

20

C4-C

---

---

---

---

Coil 4

C1-12

LT BLU

20

C3-F

---

---

---

---

Coil 3

C1-13

RED/WHT

20

C4-B

---

---

---

---

Coil 2

C1-14

PPL

20

C3-G

---

---

---

---

Coil 1

C1-15

LT BLU/WHT

20

C4-F

---

---

---

---

Coil 6

C1-16

DK GRN

20

C3-C

---

---

---

---

Coil 5

C1-17

VIO

20

P1-5D

---

---

---

---

Radiator Fan 1 Relay Control Lowside

C1-18

VIO/BLK

20

P1-7D

---

---

---

---

Radiator Fan 2 Relay Control Lowside

C1-19

YEL/BLK

20

C17-B

---

---

---

---

Crank Position Sensor Ground

C1-20

PNK/BLK

20

C18-B

---

---

---

---

Cam Position Sensor Ground

C1-21

DK BLU/BLK

20

C17-A

---

---

---

---

Crank Position Sensor Signal

C1-22

BRN/WHT

20

C18-A

---

---

---

---

Cam Position Sensor Signal

C1-24

YEL

20

C14-A

---

---

---

---

Mass Air Flow Sensor Signal

C1-27

DK BLU

20

C20-A

---

---

---

---

Knock Sensor Signal 1

C1-28

LT BLU

20

C20-B

---

---

---

---

Knock Sensor Signal 2

C1-29

YEL/WHT

20, 20

P1-1D

P1-3D

---

---

---

EFI-1 Relay/EFI-2 Relay Control Lowside

C1-30

BRN

20

C3-E

---

---

---

---

Coil Signal Ground (Bank 1)

C1-31

GRN

22

C28-2

---

---

---

---

CAN Low (twisted pair)

C1-32

WHT

22

C28-1

---

---

---

---

CAN High (twisted pair)

C1-34

VIO/WHT

20

P1-9D

---

---

---

---

Fuel Pump Relay Control Lowside

C1-35

DK BLU

20

C16-C

---

---

---

---

Throttle Position Sensor Signal

C1-36

LT GRN

20

C13-B

---

---

---

---

Manifold Absolute Pressure Signal

C1-41

GRY

20

C17-C

---

---

---

---

Crank Position Sensor +5V Supply

C1-42

GRY

20

C18-C

---

---

---

---

Cam Position Sensor +5V Supply

C1-44

RED

20

C21-B

---

---

---

---

12V High Side Driver -> 470Ω -> Alternator

C1-55

MESH

---

C17-M

C18-M

---

---

---

Ground for Cam/Crank wire shieldings (drains)

C1-56

YEL/BLK

20

C10-B

---

---

---

---

Injector 6 Control Lowside

C1-57

BLK/WHT

20

C9-B

---

---

---

---

Injector 5 Control Lowside

C1-58

LT BLU/BLK

20

C8-B

---

---

---

---

Injector 4 Control Lowside

C1-59

PNK/BLK

20

C7-B

---

---

---

---

Injector 3 Control Lowside

C1-60

BLK

20

C28-4

---

---

---

---

AEMnet Ground

C1-61

PNK/YEL

20

SP-4

---

---

---

---

ECU 12V from EFI-1

C1-62

LT GRN/BLK

20

C6-B

---

---

---

---

Injector 2 Control Lowside

C1-63

BLK

20

C5-B

---

---

---

---

Injector 1 Control Lowside

C1-64

PNK/YEL

20

SP-4

---

---

---

---

ECU 12V from EFI-1

C1-65

PNK/WHT

20

1' flying lead for ign switch

12V Switched Ignition

C1-66

YEL

20

C19-B

---

---

---

---

Engine Coolant Temperature Sensor Signal

C1-67

TAN

20

C24-B

---

---

---

---

Intake Air Temperature Sensor Signal

C1-69

LT GRN/WHT

20

C15-B

---

---

---

---

IAC Stepper Motor Coil B High

C1-70

LT BLU/WHT

20

C15-D

---

---

---

---

IAC Stepper Motor Coil A High

C1-71

LT GRN/BLK

20

C15-A

---

---

---

---

IAC Stepper Motor Coil B Low

C1-72

LT BLU/BLK

20

C15-C

---

---

---

---

IAC Stepper Motor Coil A Low

C1-73

BLK

14

SP-1

---

---

---

---

Battery Ground

GM LS Engines 24x Pinout

Rev A, 2013/02/05

Page 9

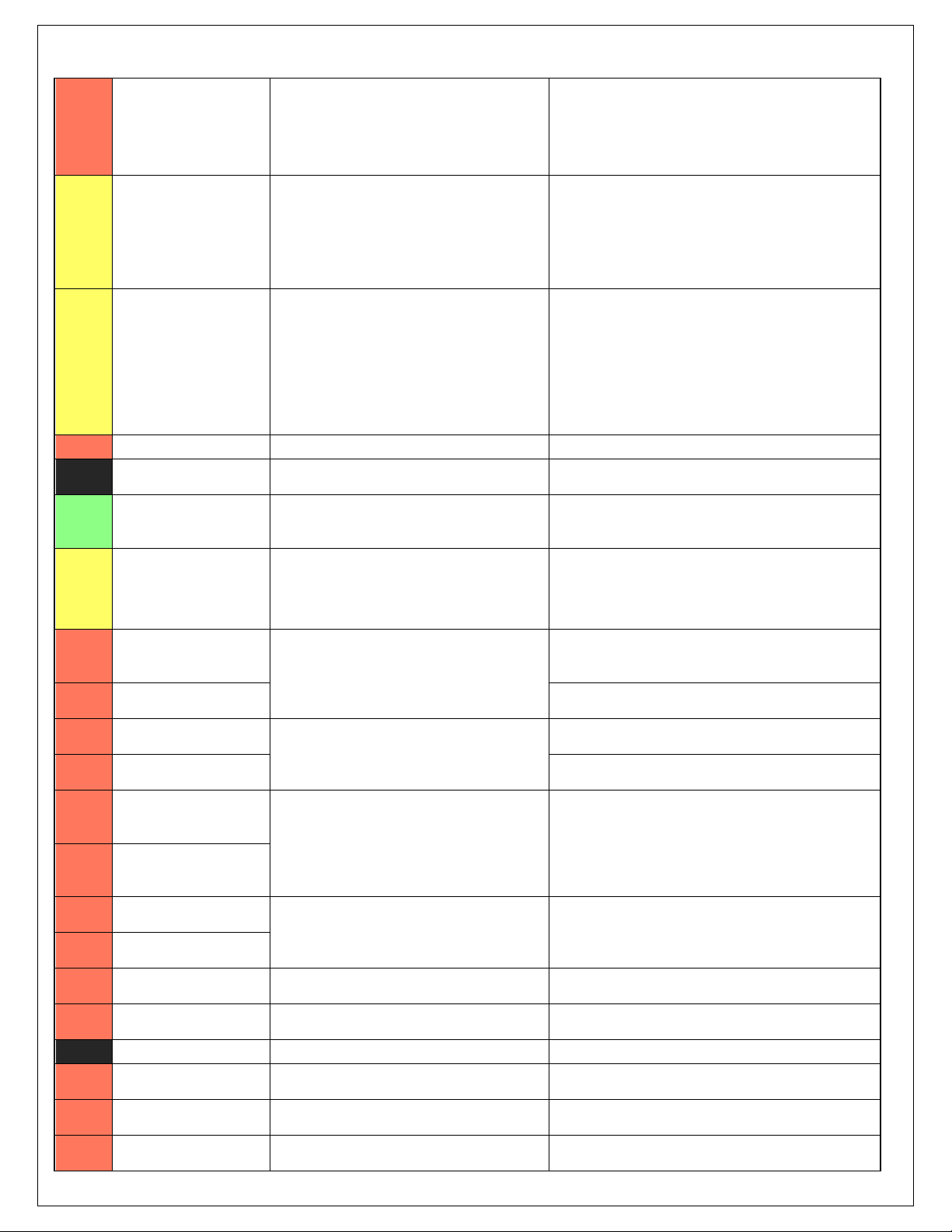

C2

Infinity Connector C2

56 Way F Receptacle 0.64 2.8 Series Sealed (BU)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

C2-3

BLK

18

SP-1

---

---

---

---

Battery Ground

C2-4

RED/BLK

20

C11-B

---

---

---

---

Injector 7 Control Lowside

C2-5

DK BLU/WHT

20

C12-B

---

---

---

---

Injector 8 Control Lowside

C2-8

BRN

20

C4-E

---

---

---

---

Coil Signal Ground (Bank 2)

C2-9

PNK/YEL

20

SP-4

---

---

---

---

ECU 12V from EFI-1

C2-13

---

---

---

---

---

---

---

Optional Drive-by-Wire (AccPedalPosition-2)

C2-14

---

---

---

---

---

---

---

Optional Drive-by-Wire (AccPedalPosition-1)

C2-18

GRN

20

C25-C

---

---

---

---

AEM Oil Pressure Sensor Signal

C2-21

---

---

---

---

---

---

---

Optional Drive-by-Wire (TPS1B)

C2-22

GRY

20

C13-C

---

---

---

---

MAP Sensor 5V Supply

C2-23

GRY

20

C16-A

---

---

---

---

TPS 5V Supply

C2-24

GRY

20

C25-B

---

---

---

---

Oil Pressure Sensor 5V Supply

C2-29

ORN/WHT

20

1' Flying Lead

---

---

---

Tacho Signal Out (1' flying lead)

C2-30

BLK, PPL

20

C25-A

C24-A

---

---

---

Sensor Ground

C2-31

TAN, BLK

20

C19-A

C16-B

---

---

---

Sensor Ground

C2-32

ORN/BLK

20

C13-A

---

---

---

---

MAP Sensor Ground

C2-34

---

---

---

---

---

---

---

Optional Drive-by-Wire (TPS2A)

C2-36

---

---

---

---

---

---

---

Optional Drive-by-Wire (TPS2B)

C2-39

BLK

18

SP-1

---

---

---

---

Battery Ground

C2-40

BLK

18

SP-1

---

---

---

---

Battery Ground

C2-45

ORN

20

C27-5

---

---

---

---

Deutsch DTM04-6P UEGO B2-VM

C2-46

BLK

20

C27-1

---

---

---

---

Deutsch DTM04-6P UEGO B2-UN

C2-47

RED

20

C27-6

---

---

---

---

Deutsch DTM04-6P UEGO B2-IP

C2-48

GRN

20

C27-2

---

---

---

---

Deutsch DTM04-6P UEGO B2-IA

C2-49

WHT

18

C27-4

---

---

---

---

Deutsch DTM04-6P UEGO B2-HEAT

C2-50

PNK/RED

---

P1-7A

---

---

---

---

12V Perm Power

C2-51

RED

20

C3-B

---

---

---

---

Coil 7

C2-52

PPL/WHT

20

C4-G

---

---

---

---

Coil 8

C3

Coil B1

7 Way F Metri-Pack 150 Series Sealed (Cream)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

BLK

16

SP-1

---

---

---

---

Power Ground

B

RED

20

C2-51

---

---

---

---

IC 7 Control

C

DK GRN

20

C1-16

---

---

---

---

IC 5 Control

D

---

---

---

---

---

---

---

Not Used

E

BRN

20

C1-30

---

---

---

---

Signal Ground

F

LT BLU

20

C1-12

---

---

---

---

IC 3 Control

G

PPL

20

C1-14

---

---

---

---

IC 1 Control

H

PNK

16

SP-5

---

---

---

---

Ignition Voltage

C4

Coil B2

7 Way F Metri-Pack 150 Series Sealed (Cream)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

BLK

16

SP-1

---

---

---

---

Power Ground

B

RED/WHT

20

C1-13

---

---

---

---

IC 2 Control

C

DK GRN/WHT

20

C1-11

---

---

---

---

IC 4 Control

D

---

---

---

---

---

---

---

Not Used

E

BRN

20

C2-8

---

---

---

---

Signal Ground

F

LT BLU/WHT

20

C1-15

---

---

---

---

IC 6 Control

G

PPL/WHT

20

C2-52

---

---

---

---

IC 8 Control

H

PNK

16

SP-6

---

---

---

---

Ignition Voltage

Rev A, 2013/02/05

Page 10

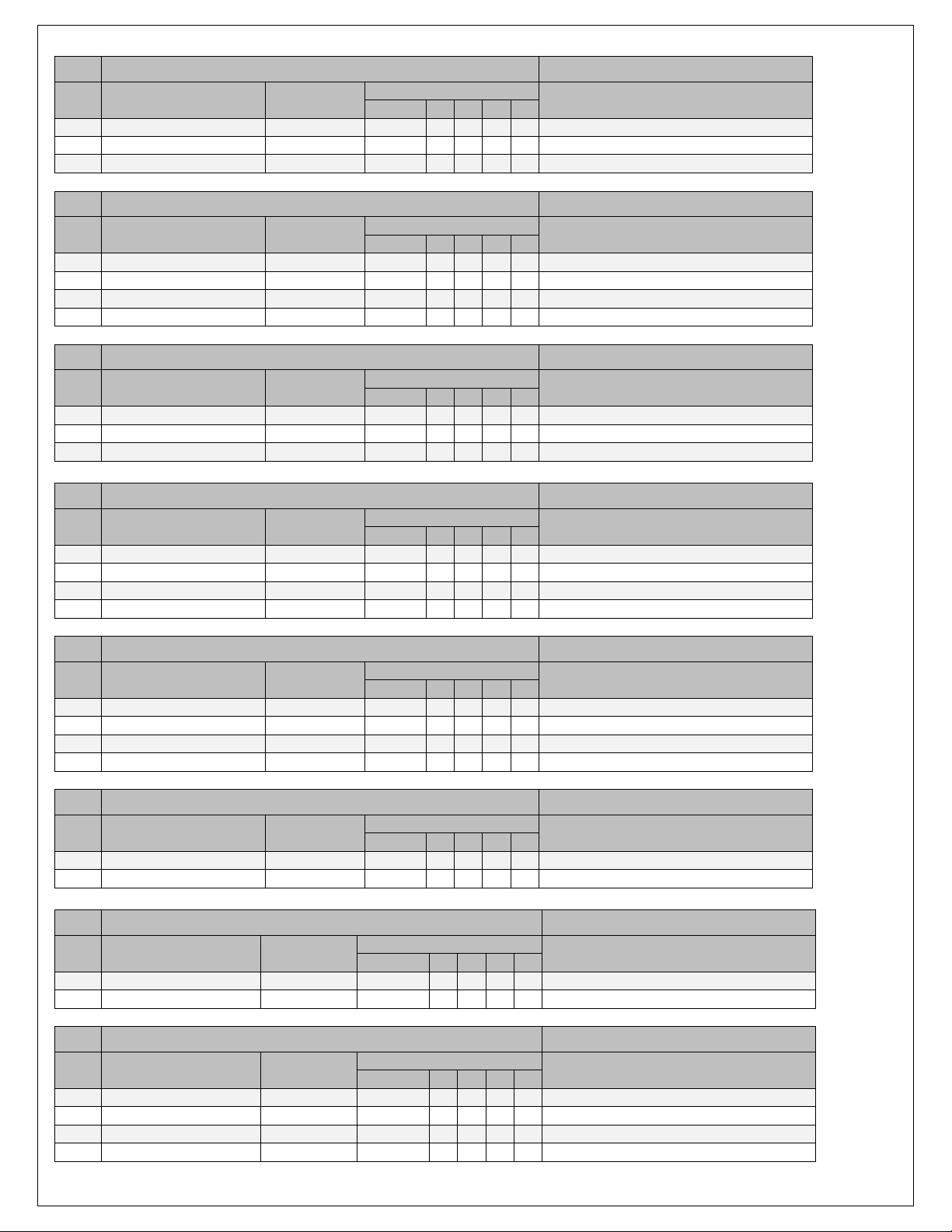

C5

Injector 1

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-2

---

---

---

---

Ignition Voltage

B

BLK

20

C1-63

---

---

---

---

Fuel Injector 1 Control

C6

Injector 2

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-3

---

---

---

---

Ignition Voltage

B

LT GRN/BLK

20

C1-62

---

---

---

---

Fuel Injector 2 Control

C7

Injector 3

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-2

---

---

---

---

Ignition Voltage

B

PNK/BLK

20

C1-59

---

---

---

---

Fuel Injector 3 Control

C8

Injector 4

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-3

---

---

---

---

Ignition Voltage

B

LT BLU/BLK

20

C1-58

---

---

---

---

Fuel Injector 4 Control

C9

Injector 5

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-2

---

---

---

---

Ignition Voltage

B

BLK/WHT

20

C1-57

---

---

---

---

Fuel Injector 5 Control

C10

Injector 6

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-3

---

---

---

---

Ignition Voltage

B

YEL/BLK

20

C1-56

---

---

---

---

Fuel Injector 6 Control

C11

Injector 7

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-2

---

---

---

---

Ignition Voltage

B

RED/BLK

20

C2-4

---

---

---

---

Fuel Injector 7 Control

C12

Injector 8

2 Way F Metri-Pack 280.1 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

PNK

20

SP-3

---

---

---

---

Ignition Voltage

B

DK BLU/WHT

20

C2-5

---

---

---

---

Fuel Injector 8 Control

C13

MAP Sensor

3 Way F Metri-Pack 150 Series (GRY)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

ORN/BLK

20

C2-32

---

---

---

---

Sensor Ground

B

LT GRN

20

C1-36

---

---

---

---

MAP Sensor Signal

C

GRY

20

C2-22

---

---

---

---

5-Volt Reference

Rev A, 2013/02/05

Page 11

C14

MAF Sensor

3 Way F Metri-Pack 150 Series (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

YEL

20

C1-24

---

---

---

---

MAF Sensor Signal

B

BLK

20

SP-3

---

---

---

---

Ground

C

PNK

20

SP-7

---

---

---

---

Ignition Voltage

C15

Idle Air Control Motor

4 Way F Metri-Pack 150.2 Series Pull to Seat

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

LT GRN/BLK

20

C1-71

---

---

---

---

IAC Stepper Motor Coil B LOW

B

LT GRN/WHT

20

C1-69

---

---

---

---

IAC Stepper Motor Coil B HIGH

C

LT BLU/BLK

20

C1-72

---

---

---

---

IAC Stepper Motor Coil A LOW

D

LT BLU/WHT

20

C1-70

---

---

---

---

IAC Stepper Motor Coil A HIGH

C16

Throttle Position Sensor

3 Way F Metri-Pack 150 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

GRY

20

C2-23

---

---

---

---

5-Volt Reference

B

BLK

20

C2-31

---

---

---

---

Sensor Ground

C

DK BLU

20

C1-35

---

---

---

---

TPS Sensor Signal

C17

Crank Position Sensor

3 Way F Metri-Pack 150 Series (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

DK BLU/BLK

20

C1-21

---

---

---

---

CKP Sensor Signal

B

YEL/BLK

20

C1-19

---

---

---

---

Sensor Ground

C

GRY

20

C1-41

---

---

---

---

5-Volt Reference

M

Mesh

---

C1-55

---

---

---

---

Shielding Drain

C18

Cam Position Sensor

3 Way F Metri-Pack 150 Series (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

BRN/WHT

20

C1-22

---

---

---

---

CMP Sensor Signal

B

PNK/BLK

20

C1-20

---

---

---

---

Sensor Ground

C

GRY

20

C1-42

---

---

---

---

5-Volt Reference

M

Mesh

---

C1-55

---

---

---

---

Shielding Drain

C19

Engine Coolant Temp Sensor

2 Way F Metri-Pack 150.2 Series Sealed P2S (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

TAN

20

C2-31

---

---

---

---

Sensor Ground

B

YEL

20

C1-66

---

---

---

---

ECT Sensor Signal

C20

Knock Sensors

2 Way F Metri-Pack 150 Series Sealed (BLK)

Pin

Wire Color

Gauge

Destination

Description

1

2 3 4 5 A

DK BLU

20

C1-27

---

---

---

---

Knock Sensor 1 Signal

B

LT BLU

20

C1-28

---

---

---

---

Knock Sensor 2 Signal

C21

Alternator

4 Way F Metri-Pack 150 Series Sealed (BLK)

Pin

Wire Color

Gauge

Destination

Description

1

2 3 4 5 A

Not Used

---

---

---

---

---

--- B

RED

20

C1-44

---

---

---

---

12V High Side Driver -> 470Ω -> Alternator

C

Not Used

---

---

---

---

---

---

D

Not Used

---

---

---

---

---

---

Rev A, 2013/02/05

Page 12

C22

Vehicle Speed Sensor

2 Way F Metri-Pack 150.2 Series Pull to Seat (BLK)

Pin

Wire Color

Gauge

Destination

Description

1

2 3 4 5 A

GRY/BLK

20

C2-26

---

---

---

---

Vehicle Speed Signal LOW

B

PPL/WHT

20

C2-25

---

---

---

---

Vehicle Speed Signal HIGH

C23

Reverse Lockout Solenoid

2 Way F Metri-Pack 150 Series Sealed (WHT)

Pin

Wire Color

Gauge

Destination

Description

1

2 3 4 5 A

PNK

20

P1-10A

---

---

---

---

Ignition Voltage

B

GRN

20

C1-2

---

---

---

---

Reverse Lockout Signal (lowside driver)

C24

Intake Air Temp Sensor

2 Way F Metri-Pack 150.2 Series Pull to Seat (GRY)

Pin

Wire Color

Gauge

Destination

Description

1

2 3 4 5 A

PPL

20

C2-30

---

---

---

---

Sensor Ground

B

TAN

20

C1-67

---

---

---

---

IAT Sensor Signal

C25

AEM Oil Pressure Sensor

3 Way F Metri-Pack 150 Series (BLK)

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

A

BLK

20

C2-30

---

---

---

---

Sensor Ground

B

GRY

20

C2-24

---

---

---

---

5V Reference

C

GRN

20

C2-18

---

---

---

---

Sensor Signal

C26

UEGO Sensor Bank 1

Deutsch DTM04-6P

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

1

BLK

20

C1-7

---

---

---

---

UEGO UN 1

2

GRN

20

C1-5

---

---

---

---

UEGO IA 1

3

BRN

18

SP-5

---

---

---

---

UEGO +12V 1

4

WHT

18

C1-4

---

---

---

---

UEGO HEAT 1

5

ORN

20

C1-8

---

---

---

---

UEGO VM 1

6

RED

20

C1-6

---

---

---

---

UEGO IP 1

C27

UEGO Sensor Bank 2

Deutsch DTM04-6P

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

1

BLK

20

C2-46

---

---

---

---

UEGO UN 2

2

GRN

20

C2-48

---

---

---

---

UEGO IA 2

3

BRN

18

SP-6

---

---

---

---

UEGO +12V 2

4

WHT

18

C2-49

---

---

---

---

UEGO HEAT 2

5

ORN

20

C2-45

---

---

---

---

UEGO VM 2

6

RED

20

C2-47

---

---

---

---

UEGO IP 2

C28

CAN

Deutsch DTM04-4P

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

1

WHT

20

C1-32

---

---

---

---

CAN_High (twisted pair)

2

GRN

20

C1-31

---

---

---

---

CAN_Low (twisted pair)

3

RED

20

SP-7

---

---

---

---

AEMnet 12V Supply

4

BLK

20

C1-60

---

---

---

---

AEMnet Ground

Rev A, 2013/02/05

Page 13

P1

Power Distribution Center

Bussmann 15303-4-0-4

Pin

Wire Color

Gauge

Destination

Description

1 2 3 4 5

1AA

RED

14

SP-8

---

---

---

---

EFI-1 30A Fuse

1A

RED

14

P1-1B

---

---

---

---

EFI-1 30A Fuse

1B

RED

14, 20

P1-A

P1-2B

---

---

---

EFI-1 Relay Pin 30

1C

---

---

---

---

---

---

---

---

1D

YEL/WHT

20

P1-3D

---

---

---

---

EFI-1 Relay Pin 86

2AA

RED

14

SP-8

---

---

---

---

EFI-2 30A Fuse

2A

RED

14

P1-3B

---

---

---

---

EFI-2 30A Fuse

2B

RED

20

P1-1B

---

---

---

---

EFI-1 Relay Pin 85

2C

---

---

---

---

---

---

---

---

2D

PNK

14,18,20

SP-5

P1-8AA

P1-6B

---

---

EFI-1 Relay Pin 87

3AA

RED

14

1' Flying Lead to Battery Pos (+)

RadFan 1 30A Fuse

3A

RED

14

P1-5B

---

---

---

---

RadFan 1 30A Fuse

3B

RED

14, 20

P1-2A

P1-4B

---

---

---

EFI-2 Relay Pin 30

3C

---

---

---

---

---

---

---

---

3D

YEL/WHT

20, 20

C1-29

P1-1D

---

---

---

EFI-2 Relay Pin 86

4AA

RED

14

1' Flying Lead to Battery Pos (+)

RadFan 2 30A Fuse

4A

RED

14

P1-7B

---

---

---

---

RadFan 2 30A Fuse

4B

RED

20

P1-3B

---

---

---

---

EFI-2 Relay Pin 85

4C

---

---

---

---

---

---

---

---

4D

PNK

14,20,20

SP-6

P1-9AA

P1-10AA

---

---

EFI-2 Relay Pin 87

5AA

RED

14

1' Flying Lead to Battery Pos (+)

Fuel Pump 20A Fuse

5A

RED

14

P1-9B

---

---

---

---

Fuel Pump 20A Fuse

5B

RED

14

P1-3A

---

---

---

---

RadFan 1 Relay Pin 30

5C

---

---

---

---

---

---

---

---

5D

VIO

20

C1-17

---

---

---

---

RadFan 1 Relay Pin 86

6AA

RED

20

SP-8

---

---

---

---

Switched Ignition 5A Fuse

6A

PNK

20

1' Flying Lead to ignition switch

Switched Ignition 5A Fuse

6B

PNK

20, 20

P1-2D

P1-8B

---

---

---

RadFan 1 Relay Pin 85

6C

---

---

---

---

---

---

---

---

6D

YEL/BLU

14

1' Flying Lead

---

---

---

RadFan 1 Relay Pin 87

7AA

RED

20

SP-8

---

---

---

---

Perm Battery Power 5A Fuse

7A

PNK/RED

20, 20

C1-10

C2-50

---

---

---

Perm Battery Power 5A Fuse

7B

RED

14

P1-4A

---

---

---

---

RadFan 2 Relay Pin 30

7C

---

---

---

---

---

---

---

---

7D

VIO/BLK

20

C1-18

---

---

---

---

RadFan 2 Relay Pin 86

8AA

PNK

18

P1-2D

---

---

---

---

ECU 12V Supply 10A Fuse

8A

PNK/YEL

18

SP-4

---

---

---

---

ECU 12V Supply 10A Fuse

8B

PNK

20, 20

P1-6B

P1-10B

---

---

---

RadFan 2 Relay Pin 85

8C

---

---

---

---

---

---

---

---

8D

YEL/RED

14

1' Flying Lead

---

---

---

RadFan 2 Relay Pin 87

9AA

PNK

20

P1-4D

---

---

---

---

MAF / AEMnet 12V Power 5A Fuse

9A

PNK

20

SP-7

---

---

---

---

MAF / AEMnet 12V Power 5A Fuse

9B

RED

14

P1-5A

---

---

---

---

Fuel Pump Relay Pin 30

9C

---

---

---

---

---

---

---

---

9D

VIO/WHT

20

C1-34

---

---

---

---

Fuel Pump Relay Pin 86

10AA

PNK

20

P1-4D

---

---

---

---

Reverse Lockout 5A Fuse

10A

PNK

20

C23-A

---

---

---

---

Reverse Lockout 5A Fuse

10B

PNK

20

P1-8B

---

---

---

---

Fuel Pump Relay Pin 85

10C

---

---

---

---

---

---

---

---

10D

GRN/RED

14

1' Flying Lead

---

---

---

Fuel Pump Relay Pin 87

Rev A, 2013/02/05

Page 14

SP-1

Battery Ground Splice

Wire Color

Gauge

Destination

Description

1

2 3 4

5

1

BLK

10

1' flying lead, route via P1 then to

splice

Battery Neg (-) flying lead

2

BLK

16

C3-A

---

---

---

---

Coil B1 Power Ground

3

BLK

16

C4-A

---

---

---

---

Coil B2 Power Ground

4

BLK

20

C14-B

---

---

---

---

MAF Ground

5

BLK

14

C1-73

---

---

---

---

ECU Ground

6

BLK

18

C2-3

---

---

---

---

ECU Ground

7

BLK

18

C2-39

---

---

---

---

ECU Ground

8

BLK

18

C2-40

---

---

---

---

ECU Ground

9

BLK

12

Head B1

---

---

---

---

Cylinder Head B1 Ground

10

BLK

12

Head B2

---

---

---

---

Cylinder Head B2 Ground

SP-2

Injector B1 +12V Splice

Wire Color

Gauge

Destination

Description

1

2 3 4 5 1

PNK

16

SP-5

---

---

---

---

Splice SP-5

2

PNK

20

C5-A

---

---

---

---

Injector 1 +12V

3

PNK

20

C7-A

---

---

---

---

Injector 3 +12V

4

PNK

20

C9-A

---

---

---

---

Injector 5 +12V

5

PNK

20

C11-A

---

---

---

---

Injector 7 +12V

SP-3

Injector B2 +12V Splice

Wire Color

Gauge

Destination

Description

1

2 3 4 5 1

PNK

16

SP-6

---

---

---

---

Splice SP-6

2

PNK

20

C6-A

---

---

---

---

Injector 2 +12V

3

PNK

20

C8-A

---

---

---

---

Injector 4 +12V

4

PNK

20

C10-A

---

---

---

---

Injector 6 +12V

5

PNK

20

C12-A

---

---

---

---

Injector 8 +12V

SP-4

ECU +12V EFI Splice

Wire Color

Gauge

Destination

Description

1

2 3 4 5 1

PNK/YEL

18

P1-8A

---

---

---

---

ECU 12V Supply 10A Fuse

2

PNK/YEL

20

C1-61

---

---

---

---

ECU 12V from EFI-1

3

PNK/YEL

20

C1-64

---

---

---

---

ECU 12V from EFI-1

4

PNK/YEL

20

C2-9

---

---

---

---

ECU 12V from EFI-1

SP-5

EFI-1 +12V Out Splice

Wire Color

Gauge

Destination

Description

1

2 3 4 5 1

PNK

14

P1-2D

---

---

---

---

EFI-1 Relay Pin 87

2

PNK

16

SP-2

---

---

---

---

Splice SP-2

3

BRN

18

C26-3

---

---

---

---

UEGO Bank 1 +12V

4

PNK

16

C3-H

---

---

---

---

Coil Bank 1 +12V

SP-6

EFI-2 +12V Out Splice

Wire Color

Gauge

Destination

Description

1 2 3 4 5

1

PNK

14

P1-4D

---

---

---

---

EFI-2 Relay Pin 87

2

PNK

16

SP-3

---

---

---

---

Splice SP-3

3

BRN

18

C27-3

---

---

---

---

UEGO Bank 2 +12V

4

PNK

16

C4-H

---

---

---

---

Coil Bank 1 +12V

Rev A, 2013/02/05

Page 15

SP-7

MAF/AEMnet +12V Splice

Wire Color

Gauge

Destination

Description

1 2 3 4 5

1

PNK

20

P1-9A

---

---

---

---

MAF/AEMnet 5A Fuse

2

PNK

20

C14-C

---

---

---

---

MAF +12V

3

RED

20

C28-3

---

---

---

---

AEMnet +12V

SP-8

Battery Power Splice

Wire Color

Gauge

Destination

Description

1 2 3 4 5

1

RED

10

1' flying lead from splice

Battery Pos (+) flying lead

2

RED

14

1AA

---

---

---

---

EFI-1 30A Fuse

3

RED

14

2AA

---

---

---

---

EFI-2 30A Fuse

4

RED

20

6AA

---

---

---

---

Switched Ignition 5A Fuse

5

RED

20

7AA

---

---

---

---

Perm Battery Power 5A Fuse

Rev A, 2013/02/05

Page 16

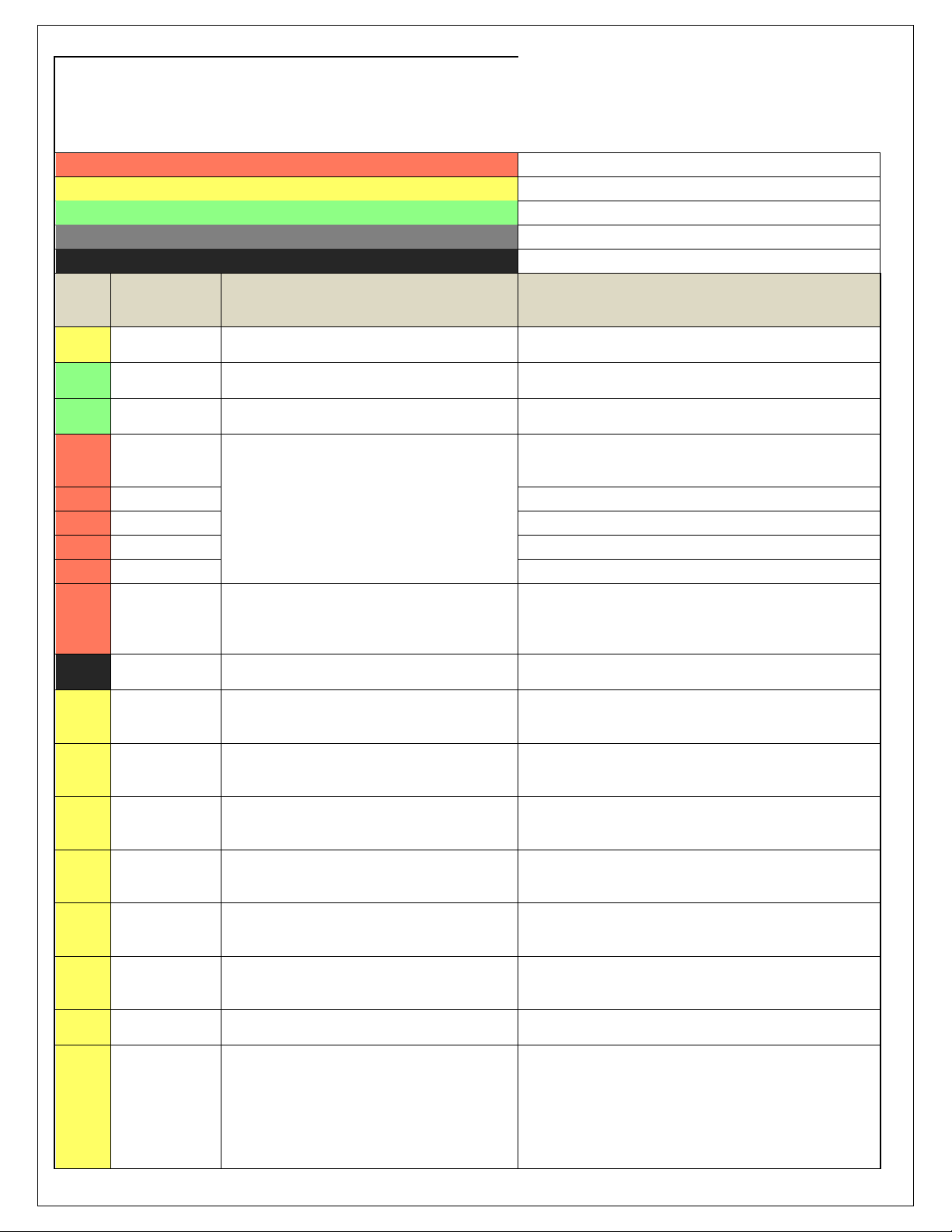

Infinity ECU Pinout

Infinity - 10, P/N 30-7100/01

Dedicated

Dedicated and not reconfigurable

Assigned

Assigned but reconfigurable

Available

Available for user setup

Not Applicable

Not used in this configuration

Required

Required for proper function

Infinity

Pin

Hrdwr Ref.

Hardware Specification

Notes

C1-1

LowsideSwitch_4

Lowside switch, 4A max, NO internal flyback diode.

See Setup Wizard Pages "User GPOs" for activation criteria and

"LowSide Assignment Tables" for output assignment

C1-2

LowsideSwitch_5

Lowside switch, 4A max with internal flyback diode.

Inductive load should NOT have full time power.

See Setup Wizard Page "LowSide Assignment Tables" for output

assignment and 2D table "LS5_Duty [%]" for activation.

C1-3

LowsideSwitch_6

Lowside switch, 4A max with internal flyback diode.

Inductive load should NOT have full time power.

See Setup Wizard Page "LowSide Assignment Tables" for output

assignment and 2D table "LS6_Duty [%]" for activation.

C1-4

UEGO 1 Heat

Bosch UEGO controller

Lowside switch for UEGO heater control. Connect to pin 4 of

Bosch UEGO sensor. NOTE that pin 3 of the Sensor is heater (+)

and must be power by a fused/switched 12V supply.

C1-5

UEGO 1 IA

Trim Current signal. Connect to pin 2 of Bosch UEGO sensor

C1-6

UEGO 1 IP

Pumping Current signal. Connect to pin 6 of Bosch UEGO sensor

C1-7

UEGO 1 UN

Nernst Voltage signal. Connect to pin 1 of Bosch UEGO sensor

C1-8

UEGO 1 VM

Virtual Ground signal. Connect to pin 5 of Bosch UEGO sensor.

C1-9

Flash_Enable

10K pulldown

Not usually needed for automatic firmware updates through

Infinity Tuner. If connection errors occur during update,

connect 12 volts to this pin before proceeding with upgrade.

Disconnect the 12 volts signal after the update.

C1-10

+12V_R8C_CPU

Dedicated power management CPU

Full time battery power. MUST be powered before the ignition

switch input is triggered (See C1-65).

C1-11

Coil 4

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C1-12

Coil 3

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C1-13

Coil 2

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C1-14

Coil 1

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C1-15

Coil 6

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C1-16

Coil 5

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C1-17

LowsideSwitch_2

Lowside switch, 4A max, NO internal flyback diode.

See Setup Wizard Pages "User GPOs" for activation criteria and

"LowSide Assignment Tables" for output assignment

C1-18

LowsideSwitch_3

Lowside switch, 4A max with internal flyback diode.

Inductive load should NOT have full time power.

See Wizard page "LowSide Assignment Tables" for output

assignment.

MIL Activates when any of the following flags are true:

ErrorAirTemp, ErrorBaro, ErrorCoolantTemp, ErrorEBP,

ErrorFuelPressure, UEGO_0_Diag_error, UEGO_1_Diag_error,

ErrorMAFAnalog, ErrorMAFDigital, ErrorMAP, ErrorOilPressure,

ErrorThrottle.

Rev A, 2013/02/05

Page 17

C1-19

AGND_1

Dedicated analog ground

Analog 0-5V sensor ground

C1-20

AGND_1

Dedicated analog ground

Analog 0-5V sensor ground

C1-21

Crankshaft

Position Sensor

Hall

10K pullup to 12V. Will work with ground or

floating switches.

See Setup Wizard page Cam/Crank for options.

C1-22

Camshaft Position

Sensor 1 Hall

10K pullup to 12V. Will work with ground or

floating switches.

See Setup Wizard page Cam/Crank for options.

C1-23

Digital_In_2

10K pullup to 12V. Will work with ground or

floating switches.

See Setup Wizard page Cam/Crank for options.

C1-24

Digital_In_3

10K pullup to 12V. Will work with ground or

floating switches.

See Setup Wizard page Turbo Speed for calibration constant.

TurboSpeed [RPM] = Turbo [Hz] * Turbo Speed Calibration.

C1-25

Digital_In_4

10K pullup to 12V. Will work with ground or

floating switches.

See Setup Wizard page Vehicle Speed for calibration constant.

C1-26

Digital_In_5

10K pullup to 12V. Will work with ground or

floating switches.

See channel FlexDigitalIn [Hz] for raw frequency input data.

C1-27

Knock Sensor 1

Dedicated knock signal processor

See Setup Wizard page Knock Setup for options.

C1-28

Knock Sensor 2

Dedicated knock signal processor

See Setup Wizard page Knock Setup for options.

C1-29

+12V_Relay_Cont

rol

0.7A max ground sink for external relay control

Will activate at key on and at key off according to the

configuration settings.

C1-30

Power Ground

Power Ground

Connect directly to battery ground

C1-31

CANL_Aout

Dedicated High Speed CAN Transceiver

Recommend twisted pair (one twist per 2") with terminating

resistor. Contact AEM for additional information.

C1-32

CANH_Aout

Dedicated High Speed CAN Transceiver

Recommend twisted pair (one twist per 2") with terminating

resistor. Contact AEM for additional information.

C1-33

LowsideSwitch_1

Lowside switch, 4A max with internal flyback diode.

Inductive load should NOT have full time power.

See Setup Wizard page Boost Control for options. Monitor

BoostControl [%] channel for output state.

C1-34

Lowside Fuel

Pump drive

Lowside switch, 4A max, NO internal flyback diode.

Switched ground. Will prime for 2 seconds at key on and

activate if RPM > 0.

C1-35

Analog_In_7

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU. See the Setup Wizard Set Throttle Range page for

automatic min/max calibration. Monitor the Throttle [%]

channel. Also DB1_TPSA [%] for DBW applications.

C1-36

Analog_In_8

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU. See the Setup Wizard Set Manifold Pressure page for

setup and calibration. Monitor the MAP [kPa] channel.

C1-37

Analog_In_9

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU. See the Setup Wizard Fuel Pressure page for setup

and calibration. Monitor the FuelPressure [psig] channel.

Rev A, 2013/02/05

Page 18

C1-38

Analog_In_10

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently

damage the ECU. See the Setup Wizard Barometric

Pressure page for setup and calibration. Monitor the

BaroPress [kPa] channel.

C1-39

Analog_In_11

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently

damage the ECU.

See the 1D lookup table 'ShiftSwitch' for setup. Also

assignable to multiple functions. See Setup Wizard for

details.

C1-40

Analog_In_12

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently

damage the ECU.

See the 1D lookup table 'ModeSwitch' for input state.

A multi-position rotary switch such as AEM P/N 30-2056 is

recommended.

Also assignable to multiple functions. See Setup Wizard

for details.

C1-41

+5V_Out_1

Regulated, fused +5V supply for sensor power

Analog sensor power

C1-42

+5V_Out_1

Regulated, fused +5V supply for sensor power

Analog sensor power

C1-43

HighsideSwitch_1

0.7A max, High Side Solid State Relay

See Setup Wizard page 'HighSide Assigment Tables' for

configuration options. See 2D lookup table 'HS1_Table'

for activation settings.

C1-44

HighsideSwitch_0

0.7A max, High Side Solid State Relay

See Setup Wizard page 'HighSide Assigment Tables' for

configuration options. See 2D lookup table 'HS0_Table'

for activation settings.

See Setup Wizard page 'VTEC' for default activation

criteria.

C1-45

Crankshaft Position

Sensor VR+

Differential Variable Reluctance Zero Cross

Detection

See Setup Wizard page Cam/Crank for options.

C1-46

Crankshaft Position

Sensor VR-

See Setup Wizard page Cam/Crank for options.

C1-47

Camshaft Position Sensor

1 VR-

Differential Variable Reluctance Zero Cross

Detection

See Setup Wizard page Cam/Crank for options.

C1-48

Camshaft Position Sensor

1 VR+

See Setup Wizard page Cam/Crank for options.

C1-49

VR+_In_2

Differential Variable Reluctance Zero Cross

Detection

See Non Driven Wheel Speed Calibration in the Setup

Wizard Vehicle Speed page.

C1-50

VR-_In_2

C1-51

VR-_In_3

Differential Variable Reluctance Zero Cross

Detection

See Driven Wheel Speed Calibration in the Setup Wizard

Vehicle Speed page.

C1-52

VR+_In_3

C1-53

DBW1 Motor -

5.0A max Throttle Control Hbridge Drive

+12V to close

C1-54

DBW1 Motor +

5.0A max Throttle Control Hbridge Drive

+12V to open

C1-55

Power Ground

Power Ground

Connect directly to battery ground

C1-56

Injector 6

Saturated or peak and hold, 3A max continuous

Injector 6

C1-57

Injector 5

Saturated or peak and hold, 3A max continuous

Injector 5

C1-58

Injector 4

Saturated or peak and hold, 3A max continuous

Injector 4

Rev A, 2013/02/05

Page 19

C1-59

Injector 3

Saturated or peak and hold, 3A max continuous

Injector 3

C1-60

Power Ground

Power Ground

Connect directly to battery ground

C1-61

+12V

12 volt power from relay

12 volt power from relay. Relay must be controlled by

+12V Relay Control signal, pin C1-29 above.

C1-62

Injector 2

Saturated or peak and hold, 3A max continuous

Injector 2

C1-63

Injector 1

Saturated or peak and hold, 3A max continuous

Injector 1

C1-64

+12V

12 volt power from relay

12 volt power from relay. Relay must be controlled by

+12V Relay Control signal pin C1-29 above.

C1-65

+12V_SW

10K pulldown

Full time battery power must be available at C1-10 before

this input is triggered.

C1-66

Analog_In_Temp_1

12 bit A/D, 2.49K pullup to 5V

See "Coolant Temperature" Setup Wizard for selection.

C1-67

Analog_In_Temp_2

12 bit A/D, 2.49K pullup to 5V

See "Air Temperature" Setup Wizard for selection.

C1-68

Harness_Analog_In_Temp

_3

12 bit A/D, 2.49K pullup to 5V

See 1D table OilTempCal table for calibration data and

OilTemp [C] for channel data.

C1-69

Stepper_2A

Automotive, Programmable Stepper Driver, up

to 28V and ±1.4A

Be sure that each internal coil of the stepper motor are

properly paired with the 1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-70

Stepper_1A

Automotive, Programmable Stepper Driver, up

to 28V and ±1.4A

Be sure that each internal coil of the stepper motor are

properly paired with the 1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-71

Stepper_2B

Automotive, Programmable Stepper Driver, up

to 28V and ±1.4A

Be sure that each internal coil of the stepper motor are

properly paired with the 1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-72

Stepper_1B

Automotive, Programmable Stepper Driver, up

to 28V and ±1.4A

Be sure that each internal coil of the stepper motor are

properly paired with the 1A/1B and 2A/2B ECU outputs.

Supports Bi-Polar stepper motors only.

C1-73

Power Ground

Power Ground

Connect directly to battery ground

C2-1

DBW2 Motor +

5.0A max Throttle Control Hbridge Drive

+12V to open

C2-2

DBW2 Motor -

5.0A max Throttle Control Hbridge Drive

+12V to close

C2-3

Power Ground

Power Ground

Connect directly to battery ground

C2-4

Injector 7

Saturated or peak and hold, 3A max continuous

Injector 7

C2-5

Injector 8

Saturated or peak and hold, 3A max continuous

Injector 8

C2-6

Injector 9

Saturated or peak and hold, 3A max continuous

Injector 9

C2-7

Injector 10

Saturated or peak and hold, 3A max continuous

Injector 10

C2-8

Power Ground

Power Ground

Connect directly to battery ground

C2-9

+12V

12 volt power from relay

12 volt power from relay. Relay must be controlled by

+12V Relay Control signal, pin C1-29 above.

C2-10

Injector 11

Saturated or peak and hold, 3A max continuous

Not used

C2-11

Injector 12

Saturated or peak and hold, 3A max continuous

Not used

Rev A, 2013/02/05

Page 20

C2-12

Analog_In_17

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU. See Setup Wizard Input Functions page for input

selection. See AC_Request_In 1-axis table for activation logic.

C2-13

Analog_In_18

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU.

C2-14

Analog_In_19

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU.

C2-15

Analog_In_Temp

_4

12 bit A/D, 2.49K pullup to 5V

See ChargeOutTemp [C] table for calibration data and

ChargeOutTemp [C] for channel data.

C2-16

Analog_In_Temp

_5

12 bit A/D, 2.49K pullup to 5V

See AirboxTemp [C] table for calibration data and AirboxTemp

[C] for channel data.

C2-17

Analog_In_Temp

_6

12 bit A/D, 2.49K pullup to 5V

See FuelTemp [C] table for calibration data and FuelTemp [C]

for channel data.

C2-18

Analog_In_13

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU. See Setup Wizard Oil Pressure page for setup

options. See OilPressure [psig] for channel data.

C2-19

Analog_In_14

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU. See the TC_SlipTrgtTrim [MPH] 1-axis table. A multiposition rotary switch such as AEM P/N 30-2056 is

recommended.

C2-20

Analog_In_15

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU. See Setup Wizard Exhaust Pressure page for setup

options. See EBPress [kPa] for channel data.

C2-21

Analog_In_16

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage

the ECU.

C2-22

+5V_Out_2

Regulated, fused +5V supply for sensor power

Analog sensor power

C2-23

+5V_Out_2

Regulated, fused +5V supply for sensor power

Analog sensor power

C2-24

+5V_Out_2

Regulated, fused +5V supply for sensor power

Analog sensor power

C2-25

VR+_In_5

Differential Variable Reluctance Zero Cross

Detection

See Driven Wheel Speed Calibration in the Setup Wizard

Vehicle Speed page.

C2-26

VR-_In_5

C2-27

VR-_In_4

Differential Variable Reluctance Zero Cross

Detection

See Non Driven Wheel Speed Calibration in the Setup Wizard

Vehicle Speed page.

C2-28

V R+_In_4

C2-29

LowsideSwitch_9

Lowside switch, 4A max with internal flyback diode,

2.2K 12V pullup. Inductive load should NOT have full

time power.

See Setup Wizard page Tacho for configuration options.

C2-30

AGND_2

Dedicated analog ground

Analog 0-5V sensor ground

Rev A, 2013/02/05

Page 21

C2-31

AGND_2

Dedicated analog ground

Analog 0-5V sensor ground

C2-32

AGND_2

Dedicated analog ground

Analog 0-5V sensor ground

C2-33

Analog_In_20

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage the

ECU.

C2-34

Analog_In_21

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage the

ECU. See 3StepSwitch 1-axis table for setup.

C2-35

Analog_In_22

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage the

ECU. See USBLoggingRequestIn channel for input state. See

Setup Wizard page USB Logging for configuration options.

C2-36

Analog_In_23

12 bit A/D, 100K pullup to 5V

0-5V analog signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low reference. Do not connect

signals referenced to +12V as this can permanently damage the

ECU. See ChargeOutPress [kPa] channel for input state. See

Setup Wizard page Charge Out Pressure for calibration options.

C2-37

Digital_In_6

No pullup. Will work with TTL signals.

Input can be assigned to different pins. See Setup Wizard page

Input Function Assignments for input mapping options.

C2-38

Digital_In_7

No pullup. Will work with TTL signals.

See ClutchSwitch 1-axis table for setup options. Input can be

assigned to different pins. See Setup Wizard page Input

Function Assignments for input mapping options.

C2-39

Power Ground

Power Ground

Connect directly to battery ground

C2-40

Power Ground

Power Ground

Connect directly to battery ground

C2-41

CanH_Bout

Dedicated High Speed CAN Transceiver

Not used

C2-42

CanL_Bout

Dedicated High Speed CAN Transceiver

Not used

C2-43

LowsideSwitch

_8

Lowside switch, 4A max with internal flyback diode.

Inductive load should NOT have full time power.

Activates if any of the following flags are true:

OilPressProtectOut, LeanProtectOut, CoolantProtect. Output

can be assigned to other functions. See Setup Wizard page

LowSide Assignment Tables for additional options.

C2-44

LowsideSwitch

_7

Lowside switch, 4A max with internal flyback diode.

Inductive load should NOT have full time power.

See Spare GPO1 Basic Setup section of User GPIOs and PWM

Setup Wizard page LowSide Assignment Tables for additional

options.

C2-45

UEGO 2 VM

Bosch UEGO Controller

Virtual Ground signal. Connect to pin 5 of Bosch UEGO sensor.

C2-46

UEGO 2 UN

Nernst Voltage signal. Connect to pin 1 of Bosch UEGO sensor

C2-47

UEGO 2 IP

Pumping Current signal. Connect to pin 6 of Bosch UEGO sensor

C2-48

UEGO 2 IA

Trim Current signal. Connect to pin 2 of Bosch UEGO sensor

C2-49

UEGO 2 HEAT

Lowside switch for UEGO heater control. Connect to pin 4 of

Bosch UEGO sensor. NOTE that pin 3 of the Sensor is heater (+)

and must be power by a fused/switched 12V supply.

C2-50

+12V_R8C_CP

U

Dedicated power management CPU

Optional full time battery power. MUST be powered before the

ignition switch input is triggered (See C1-65).

C2-51

Coil 7

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

Rev A, 2013/02/05

Page 22

C2-52

Coil 8

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C2-53

Coil 9

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C2-54

Coil 10

25 mA max source current

0-5V Falling edge fire. DO NOT connect directly to coil primary.

Must use an ignitor OR CDI that accepts a FALLING edge fire

signal.

C2-55

Highside Fuel

Pump switch

Highside switch, 0.7A max, Solid State Relay, NO

internal flyback diode.

+12V High Side Drive. Will prime for 2 seconds at key on and

activate if RPM > 0.

C2-56

Not used

Not used

Not used

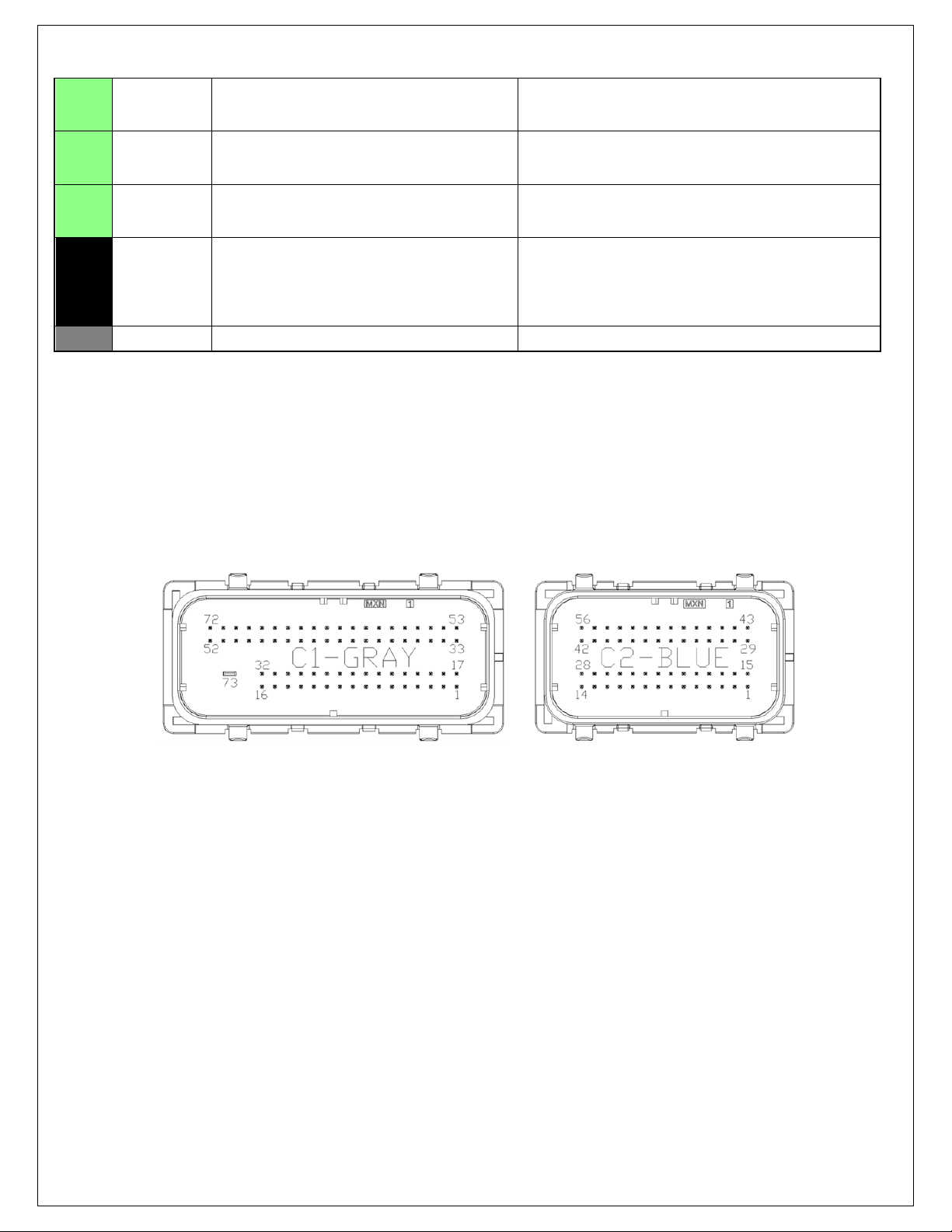

AEM Infinity Connectors Viewed From Wire Side

Rev A, 2013/02/05

Page 23

12 Month Limited Warranty

Advanced Engine Management, Inc. warrants to the consumer that all AEM High Performance products will be free from defects in

material and workmanship for a period of twelve (12) months from date of the original purchase. Products that fail within this 12 month

warranty period will be repaired or replaced at AEM’s option, when determined by AEM that the product failed due to defects in material

or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty exceed the original purchase price

of the AEM part nor shall AEM be responsible for special, incidental or consequential damages or cost incurred due to the failure of this

product.

Warranty claims to AEM must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies

only to the original purchaser of product and is non-transferable. All implied warranties shall be limited in duration to the said 12 month

warranty period. Improper use or installation, accident, abuse, unauthorized repairs or alterations voids this warranty.

An AEM Warranty Claim Form Must Accompany All Warranty Claims. Products returned to AEM with no Return Goods

Authorization and or No Warranty Claim Form may be rejected and returned to sender.

AEM disclaims any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by

AEM. Warranty returns will only be accepted be AEM when accompanied by a valid Return Goods Authorization (RGA) number. Credit

for defective products will be issued pending inspection. Product must be received by AEM within 30 days of the date RGA was issued.

Please note that before we can issue an RGA for any product, it is first necessary for the installer or end user to contact our

EMS tech line at (800) 423-0046 to discuss the problem. Most issues can be solved over the phone. Under no circumstances

should a product be returned or RGA requested before the above process transpires.

AN AEM WARRANTY CLAIM FORM MUST ACCOMPANY ALL ELECTRONICS WARRANTY CLAIMS. AEM ELECTRONIC

Products returned to AEM with no RGA and or No Warranty Claim Form may be rejected and returned to sender.

A copy of the AEM Warranty Claim Form can be e-mailed or faxed by contacting (310) 484-2322 and ask for Warranty/Claims

Department.

Need additional help? Contact the AEM Performance Electronics tech department at 1-800-423-0046 or tech@aempower.com,

or visit the AEM Performance Electronics forum at: http://forum.aempower.com/forum/

Rev A, 2013/02/05

Loading...

Loading...