Page 1

Instruction

STOP!

THIS PRODUCT HAS LEGAL RESTRICTIONS.

READ THIS BEFORE INSTALLING/USING!

THIS PRODUCT MAY BE USED SOLELY ON VEHICLES USED IN SANCTIONED COMPETITION WHICH MAY

NEVER BE USED UPON A PUBLIC ROAD OR HIGHWAY, UNLESS PERMITTED BY SPECIFIC REGULATORY

EXEMPTION. (VISIT THE “EMISSIONS” PAGE AT HTTP://WWW.SEMASAN.COM/EMISSIONS FOR STATE BY

STATE DETAILS.)

IT IS THE RESPONSIBILITY OF THE INSTALLER AND/OR USER OF THIS PRODUCT TO ENSURE THAT IT IS

USED IN COMPLIANCE WITH ALL APPLICABLE LAWS AND REGULATIONS. IF YOU HAVE PURCHASED

THIS PRODUCT IN ERROR, DO NOT INSTALL AND/OR USE IT. PLEASE CONTACT THE RETAILER FROM

WHOM YOU PURCHASED THE PRODUCT TO ARRANGE A RETURN FOR A FULL REFUND OR VISIT

AEMELECTRONICS.COM/PRODUCT-LEGAL-RESTRICTIONS FOR FURTHER INSTRUCTIONS.

Manual

P/N 30-3510

2001–2006 BMW E46 M3

Manual Transmission

Plug & Play Adapter Harness

WARNING: This installation is not for the tuning novice! Use this system with EXTREME caution! The AEM

Infinity Programmable EMS allows for total flexibility in engine tuning. Misuse or improper tuning of this

product can destroy your engine! If you are not well versed in engine dynamics and the tuning of engine

management systems DO NOT attempt the installation. Refer the installation to an AEM-trained tuning

shop or call 800-423-0046 for technical assistance.

NOTE: All supplied AEM calibrations, Wizards and other tuning information are offered as potential

starting points only. IT IS THE RESPONSIBILITY OF THE ENGINE TUNER TO ULTIMATELY CONFIRM IF THE

CALIBRATION IS SAFE FOR ITS INTENDED USE. AEM holds no responsibility for any engine damage that

results from the misuse or mistuning of this product!

AEM Performance Electronics, 2205 126th Street Unit A, Hawthorne, CA 90250

AEM Performance Electronics

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number: 10-3510

Document Build 9/11/2014

Page 2

2

P/N 30-3510

OVERVIEW

The 30-3510 AEM Infinity Adapter Kit was designed for the 2001–2006 BMW E46 M3 with manual

transmission. This is a true standalone system that eliminates the use of the factory BMW DME (ECU).

The use of this adapter makes the kit “plug and play” so no cutting or splicing wires is necessary. The

base configuration files available for the Infinity EMS are starting points only and will need to be modified

for every specific application. Included in these instructions are descriptions of important differences

between using the factory BMW DME and using the AEM Infinity ECU.

The available AEM Infinity EMS part numbers for this adapter kit are:

NOTE: The Infinity-10 EMS has 2 extra ignition coil and injector outputs for a total of 10 each. These are

sold separately from this adapter kit.

INFORMATION ON INFINITY ECUS USED ON 2005–06 BMW E46 M3’S EQUIPPED WITH FACTORY

COMPETITION PACKAGE:

When the Infinity is used on 2005–06 model year E46 M3s, the DSC lamp will remain illuminated when

the key is in the “on” position. Certain CAN bus features of the Infinity are not available via the steering

wheel cruise control buttons, as these vehicles did not come with factory cruise control buttons. (The

features integrated through CAN bus can be added using an ancillary trim position switch.)

30-7109 INFINITY-8

30-7105 INFINITY-10

GETTING STARTED

Refer to the 10-7100 for EMS 30-7100 Infinity Quick Start Guide for additional information on getting

the engine started with the Infinity EMS. E46 BMW M3 base session is located in C:\Documents\AEM

\Infinity Tuner\Sessions\Base Sessions

DOWNLOADABLE FILES

Files can be downloaded from www.aeminfinity.com. An experienced tuner must be available to configure

and manipulate the data before driving can commence. The Quick Start Guide and Full Manual describe

the steps for logging in and registering at www.aeminfinity.com. These documents are available for

download in the Support section of the AEM Electronics website: http://www.aemelectronics.com/

products/support/instructions

Downloadable files for 2001–2006 BMW E46 M3

7105-XXXX-64 Infinity-10 BMW E46 (XXXX = serial number)

7109-XXXX-65 Infinity-8 BMW E46 (XXXX = serial number)

NOTE: The Flash Enable connector (described in the following pages) MUST be “jumped” in

order to connect to the Infinity and load the initial firmware file. Subsequent firmware

upgrades will not require this step.

Ignition key OFF

Insert zip-tied jumper shunt connector into Flash Enable connector

Ignition key ON (RUN position)

Infinity Tuner | Target | Upgrade Firmware… | Upload downloaded .pakgrp file

Disconnect Flash Enable jumper connector

Infinity Tuner | File | Import Calibration Data | Select appropriate base session file

© 2014 AEM Performance Electronics

Page 3

OPTIONS

30-2001 UEGO Wideband O2 Sensor

Bosch LSU4.2 Wideband O2 Sensor that connects to AEM 30-3600 UEGO Wideband O2 Sensor

Extension Harness

30-3600 UEGO Wideband O2 Sensor Extension Harness

Extension harness to connect AEM UEGO Wideband O2 sensor to 6-pin Deutsch

30-3602 IP67 Logging Cable

USB A-to-A extension cable: 39” long with right angled connector and bayonet style lock

INFINITY CONNECTORS

The AEM Infinity EMS uses the MX123 Sealed Connection

System from Molex. AEM strongly recommends that users

become familiar with the proper tools and procedures for

working with these high density connectors before

attempting any modifications. The entire Molex MX123

User Manual can be downloaded direct from Molex at:

2001–2006 BMW E46 M3

3

http://www.molex.com/mx_upload/family//

MX123UserManual.pdf

© 2014 AEM Performance Electronics

Page 4

4

P/N 30-3510

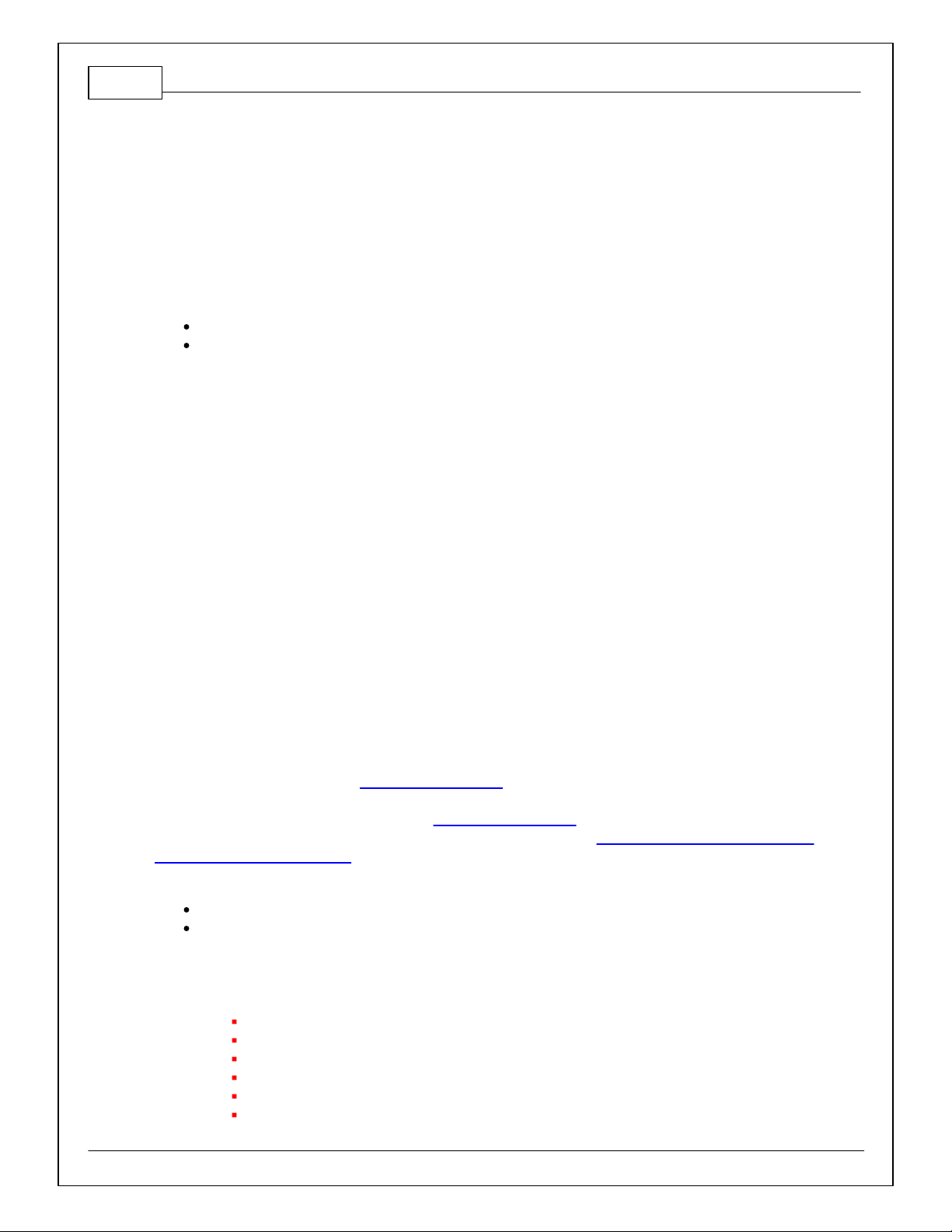

INFINITY ADAPTER HARNESS

Included with the BMW E46 M3 kit is an adapter harness. This is used to make the connection between

the AEM Infinity EMS and the BMW wiring harness plug and play. This is depicted below with the 73-pin

and 56-pin connectors and the BMW M3 header. There are also a few other integrated connectors within

this harness described below.

The gray Deutsch 6P DTM “Lambda #1” and “Lambda #2” plugs are for connecting UEGO wideband

Bosch LSU4.2 sensors (AEM 30-2001). The UEGO extension harness (AEM 30-3600) mates the

adapter harness to the sensor (1 required for each sensor used). Note: Even though the BMW S54

engine architecture is inline, the stock exhaust system pairs the cylinders (1,2,3 and 4,5,6) into 2

separate banks. For this case, 2 sensors are recommended. If a single turbocharger is used, 1 sensor is

sufficient.

The gray Deutsch 4P DTM connector is used for “AEMNet”. AEMNet is an open architecture based on

CAN 2.0 which provides the ability for multiple enabled devices, such as dashboards, data loggers, etc.,

to easily communicate with one another through two twisted cables (CAN+/CAN-).

The black Delphi 2-pin “Flash Enable” connector is used for secondary hardware flashing. The included

shunt connector jumps the 2 wires together. Once initially flashed, the EMS is normally upgraded in the

software, not using this connector.

© 2014 AEM Performance Electronics

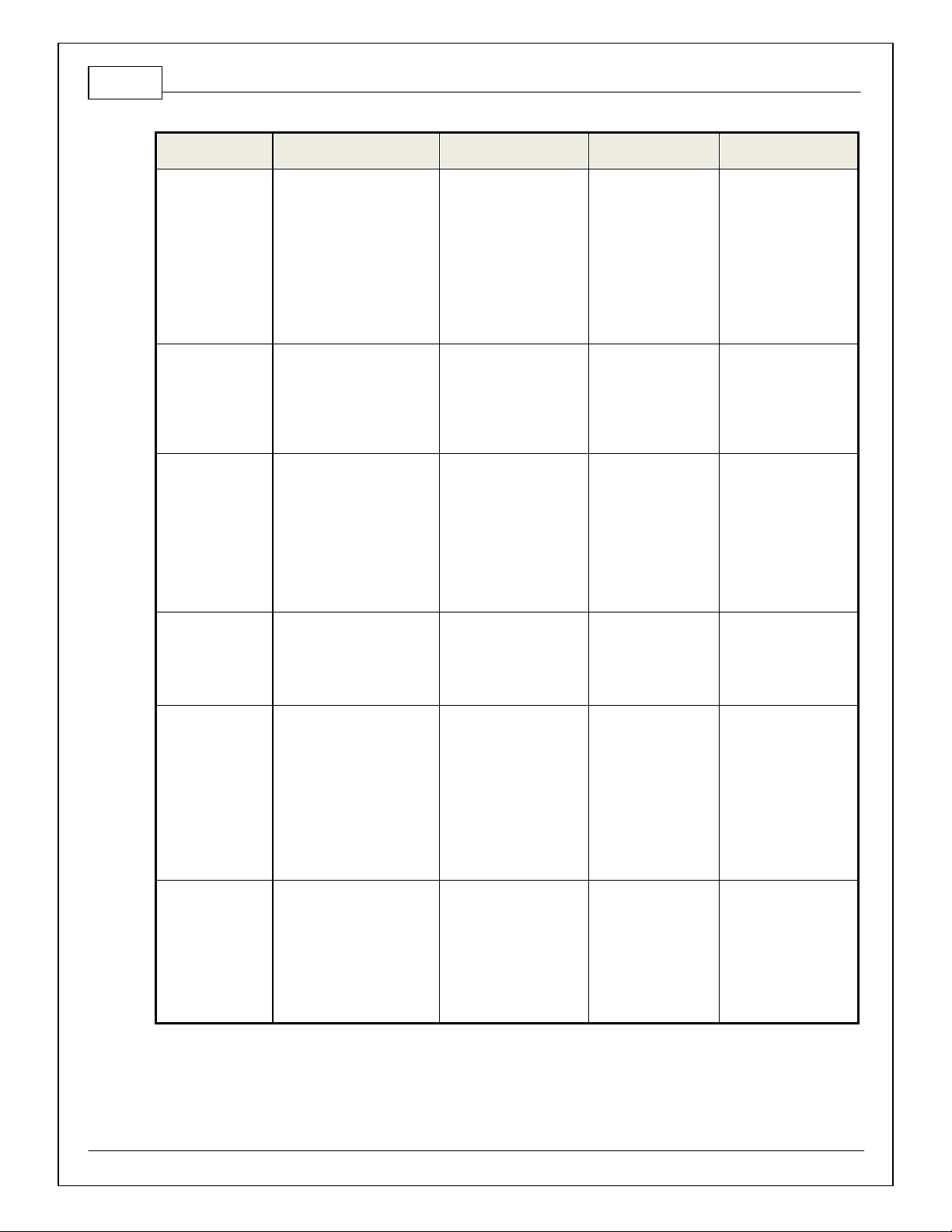

Page 5

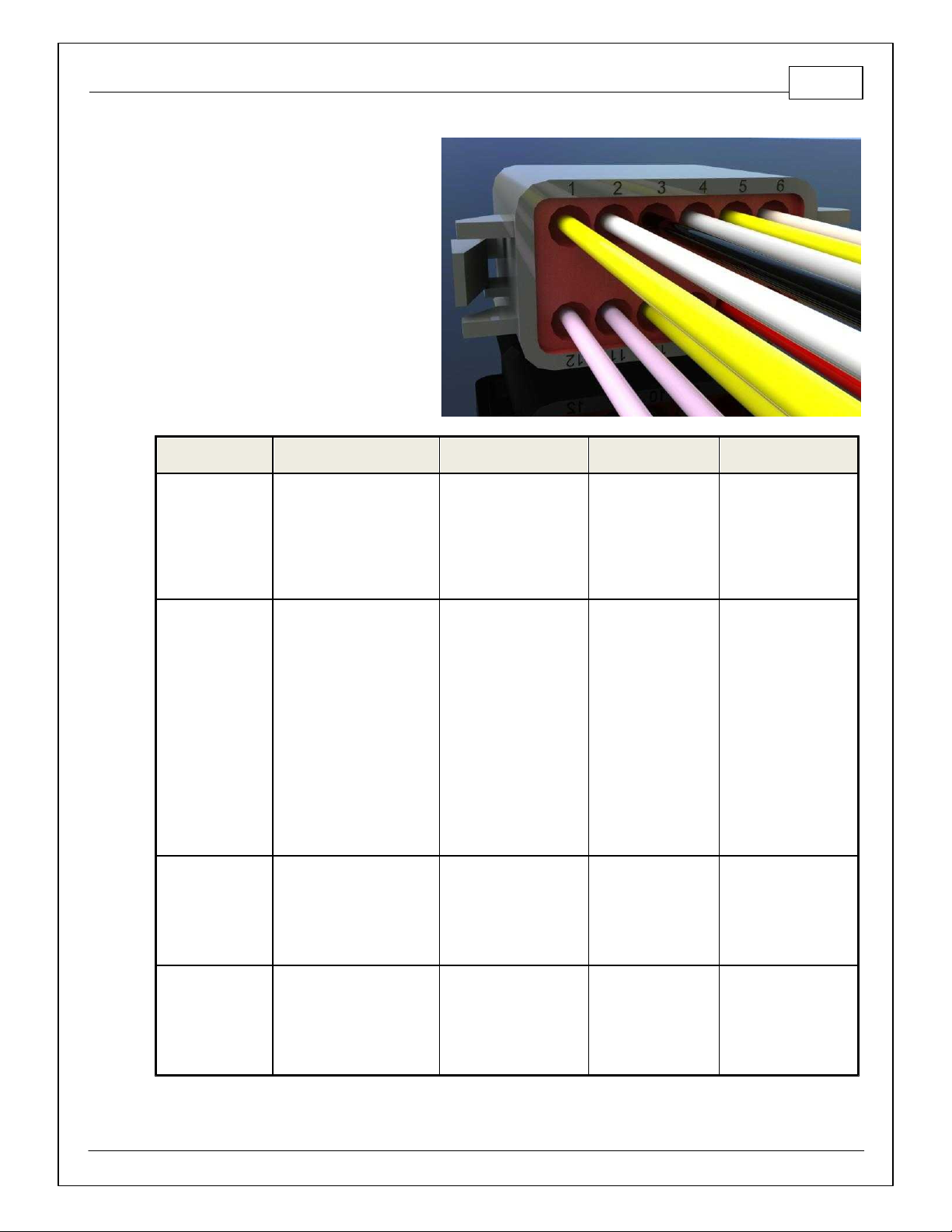

The gray Deutsch 12P DTM “Auxiliary”

Available I/O

Typical Use

Notes

Component

Wiring

Fuel Press

This is used for monitoring

fuel pressure input to the

Infinity. It can also be used

to increase or decrease

injector fuel pulse to

compensate for a failing

fuel pump.

Typical electronic fuel

injection fuel pressure

varies 30–100psi.

AEM carries 0–5V

fuel pressure

sensors (sold

separately).

This w ire goes

directly to the signal

wire of the pressure

sensor.

Air Temp

Air temperature is typically

used for fuel and ignition

timing correction.

The S54 comes

standard with a MAF

sensor which has an

integrated intake air

temperature sensor.

This w ire is run in

parallel with the stock

sensor. This means if

an aftermarket sensor

is to be wired using this

pin, the factory MAF

sensor must be

disconnected or else

the signal will be

skewed drastically.

AEM carries air

temperature sensors

(sold separately).

How ever, the Infinity

can accept any

thermistor sensor

and can be

calibrated in the

Infinity Tuner

software.

Intake air temp

sensors have two

wires with no polarity.

Sensor Ground

Isolated ground for inputs.

This is not the same as

a power ground or

chassis ground.

This is shared for

the Fuel Press, Air

Temp, MAP

(Manifold Press),

Ethanol Sensor,

etc.

This should be wired

to the ground pin of

the following: Fuel

Press, Air Temp,

MAP, and Ethanol

Sensor.

5V Reference

5 volt supply for the

following aux inputs.

When measured with a

voltmeter, it is normal to

not measure exactly

5V.

This is shared for

the Fuel Press,

MAP (Manifold

Press), and

Ethanol Sensor

inputs.

This should be wired

to the voltage

reference pin of the

following: Fuel

Press, MAP, and

Ethanol Sensor.

connector (shown below) is used to

adapt many common ancillary inputs and

outputs easily. Included in the kit are a

DTM 12P mating connector, 12 DTM

terminals, and a DTM 12P wedgelock. If

used, these components will need to be

terminated by the installer or end user

with 16–22awg wire (not included). Note:

the pin numbering is molded into the

connector, as shown.

Below is a description of each of the

available input/output found in the BMW

specific “Auxiliary” connector.

2001–2006 BMW E46 M3

5

© 2014 AEM Performance Electronics

Page 6

6

Available I/O

Typical Use

Notes

Component

Wiring

MAP (Manifold

Press)

Manifold pressure is used

for speed density fuel

calculation, ignition timing

correction, 02 feedback,

boost control, variable

valve control, ancillary

outputs, etc.

Electronic fuel injection

is calculated in absolute

pressure not gauge

pressure.

AEM carries MAP

sensors (sold

separately).

How ever, the Infinity

can accept any 0–

5V pressure sensor

and can be

calibrated in the

Infinity Tuner

software.

This should be wired

directly to the MAP

sensor's signal pin.

Ethanol Sensor

This is used for customers

who are converting their

vehicle to utilize ethanol

fuels such as E85 or E98.

This digital input can be

used for other functions

as w ell.

The GM Fuel

Composition Sensor

(FCS) is the most

commonly used for

converting a vehicle

to flex fuel.

This pin needs to be

wired directly to the

signal pin of the fuel

composition sensor.

Boost Control

Solenoid

This is used to operate a

12V PWM solenoid.

Boost control solenoids

can be normally open

(NO) or normally closed

(NC). This w ill change

the duty cycle strategy

but is also depends

upon how the

wastegate is plumbed

with hoses.

AEM carries boost

control solenoids

(sold separately).

How ever, the Infinity

can control most

factory boost control

solenoids.

Solenoids have two

wires and have no

polarity.

Power from

Relay

Can be used for many

things, however, this 12V

source was implemented

to be paired with the

Boost Control Solenoid.

This 12V is coming

through the vehicle's

main relay.

Because of using

shared power, this

should only be used

for low current

electronics.

N/A

High Side

Output

Can be used to activate the

12V side of a solenoid

If attempting to drive a

component over 4amps,

a relay must be used.

The Infinity can

directly drive an

electronic

component up to

4amps max, such as

a boost solenoid.

For a relay, this

should be wired to

terminal 86 (or 85).

Supply chassis

ground to the opposite

terminal 85 (or 86). If

directly driving a low

current component,

wire this to the 12V

terminal.

Boost Target

Trim Selector

Input

Can be used for to trigger

multiple boost targets.

This analog input can be

used for other functions

as w ell.

AEM 12 Position

Universal Trim Pot

(or typical

potentiometer). Can

also be used with

any simple ON/OFF

sw itch.

This w ire should be

routed to the signal

output of the

component. If used

with a simple ON/OFF

sw itch, route the

opposite terminal to an

Infinity sensor ground.

P/N 30-3510

© 2014 AEM Performance Electronics

Page 7

2001–2006 BMW E46 M3

Available I/O

Typical Use

Notes

Component

Wiring

Radiator Fan 1

Can be used to operate an

auxiliary fan for a radiator,

intercooler, etc.

This low side (ground)

output can be used for

other functions as well.

If attempting to drive a

component over 4amps,

a relay must be used.

The Infinity can

directly drive an

electronic

component up to

4amps max.

For a relay, this

should be wired to

terminal 85 (or 86).

Supply 12V to the

opposite terminal 86

(or 85). If directly

driving a low current

component, wire this

to the ground terminal.

No Lift Shift

Trigger

Cutting fuel and/or cutting

spark and/or retarding

ignition timing when shifting

gears w ithout releasing the

throttle pedal.

Cut time is typically 200300mS. Ignition retard is

typically 20degree with

a 50mS ramp-in time

after the fuel cut.

Ignition cut is not

commonly used.

AEM 12 Position

Universal Trim Pot

(or typical

potentiometer). Can

also be used with

any simple ON/OFF

sw itch.

This w ire should be

routed to the signal

output of the

component. If used

with a simple ON/OFF

sw itch, route the

opposite terminal to an

Infinity sensor ground.

7

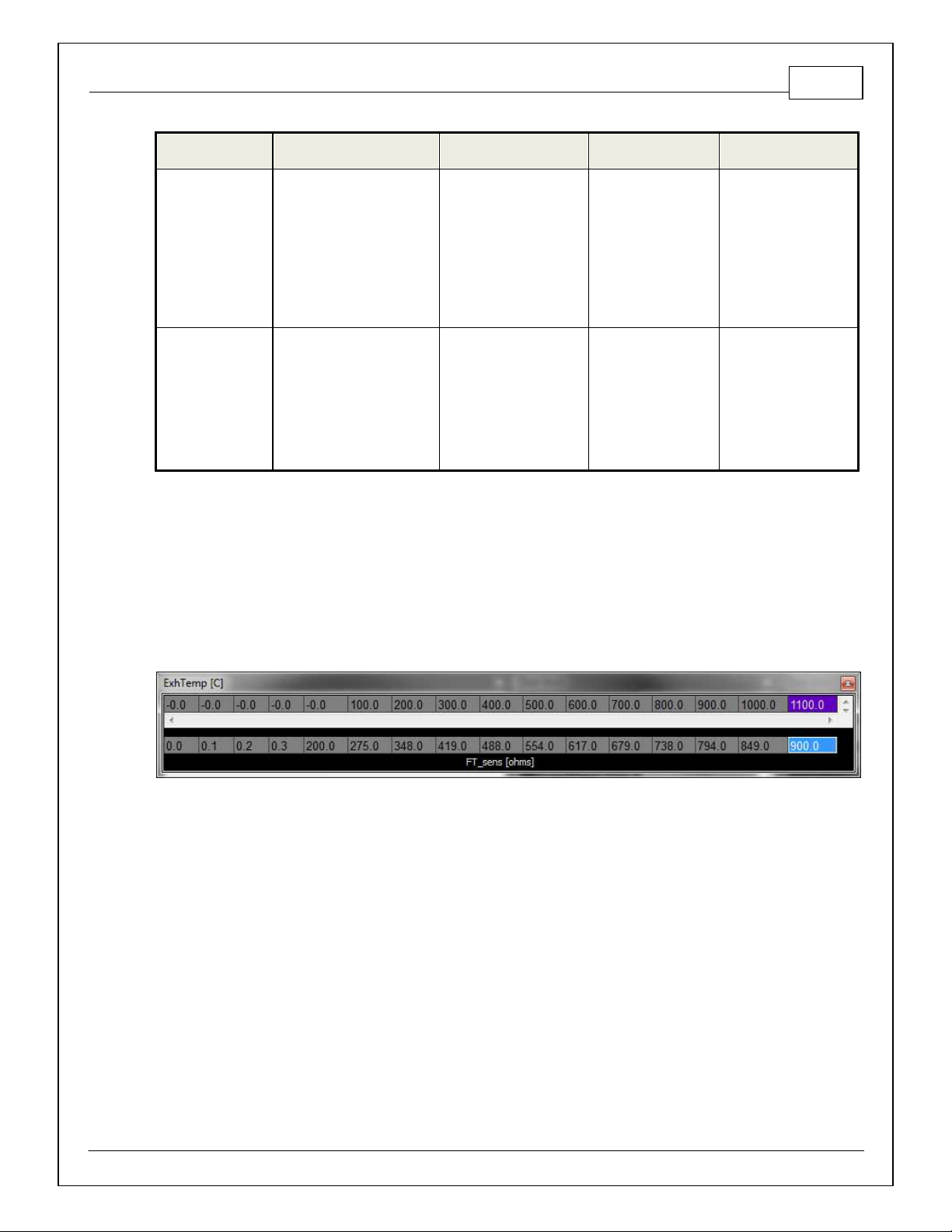

EXHAUST GAS TEMPERATURE SENSOR

The BMW M3 S54 engine uses an exhaust gas temperature sensor (EGT). This is a 0–5V resistive

temperature device (RTD) that is input to the Infinity EMS. AEM has already done the work by calibrating

and entering the EGT data (shown below) into the base session files. There is currently no fuel control,

but this channel can be data logged for tuning purposes.

© 2014 AEM Performance Electronics

Page 8

8

P/N 30-3510

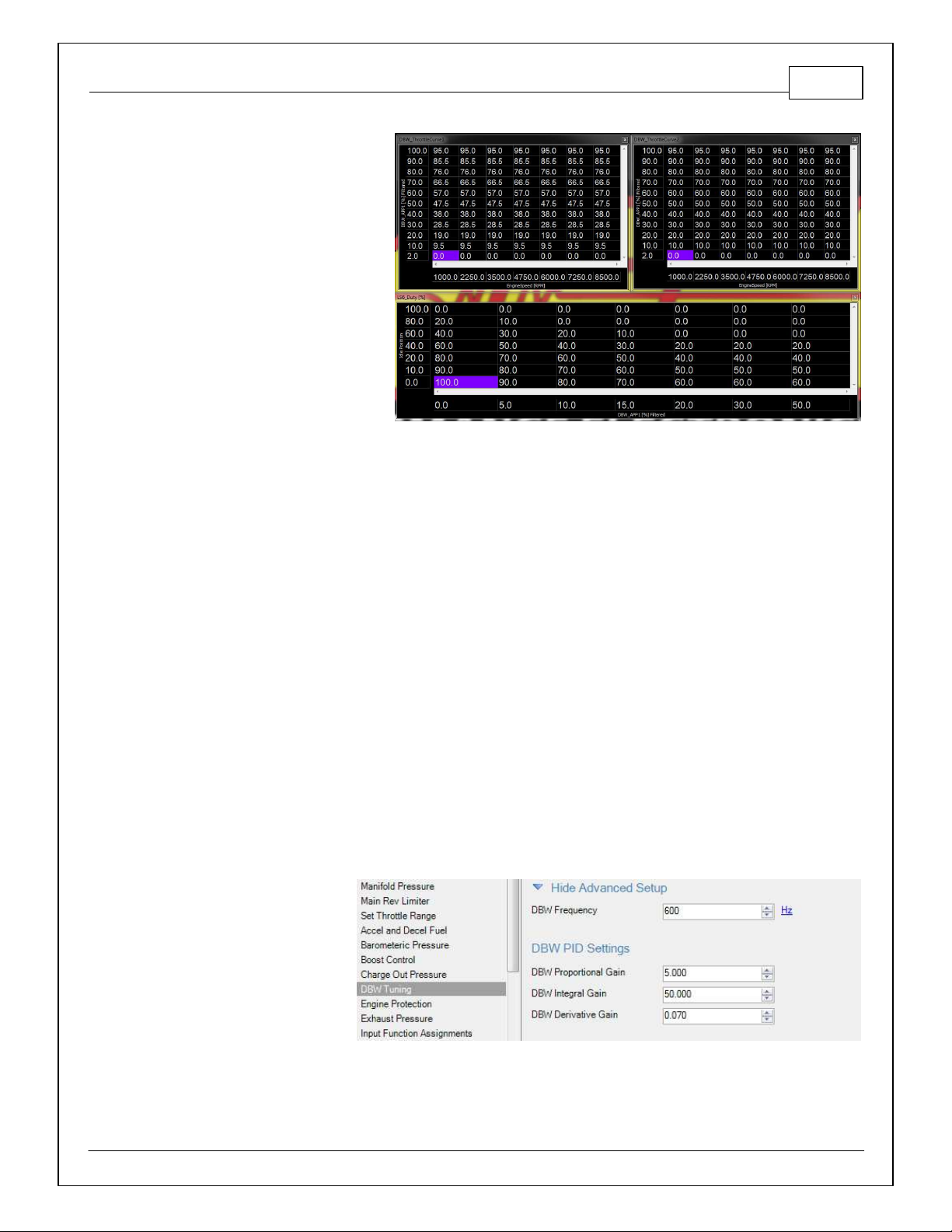

DRIVE-BY-WIRE THROTTLE CONTROL

The BMW M3 S54 engine uses 6 individual throttle

bodies controlled via drive-by-wire (DBW). It is important

to note that throttle control is a critical system which

needs to be correct, and the BMW E46 throttle and

intake system is a unique implementation with several

details that require careful attention. The basic terms of

drive-by-wire are as follows: the ‘gas pedal’ inside the

passenger cabin is called the Accelerator Pedal

(DBW_APP1%), while the electronically controlled

throttles in the engine bay are referenced as ‘Throttle’ (Throttle%, DBW1_TPSA%). Based on the

measured Accelerator Pedal position, the ECU determines a desired DBW_Target position and moves

the Throttle to that position.

under some circumstances, it is absolutely necessary to run the Drive By Wire Wizard before running

the engine for the first time. The wizard should be repeated if any components in the throttle control

system are removed or replaced such as the throttle bodies, TPS sensors, throttle linkage, electronic

throttle control motor, or accelerator pedal.

As shown, there is a

Drive By Wire Wizard

which must be used to

calibrate accelerator

pedal and throttle

position sensors.

Although sensor

calibration values from

one vehicle may be

close enough to work

for another vehicle

Please ensure the vehicle’s battery is fully charged (at least 12.5 Volts) before running the Drive By Wire

Wizard, as low battery voltage can result in abnormal sensor measurements. If a battery charger is

available, it is preferable to connect the battery charger in 5A, 10A, or 20A mode and perform the Drive

By Wire Wizard while the battery voltage is near 13.5–14.0 Volts. When connected to the Infinity EMS

with the engine OFF, go to Plug-in | Wizards | Drive By Wire Wizard. On the first page, be sure to check

the ‘Calibrate Sensor Data Only’ checkbox before selecting ‘Start’. Follow the step-by-step instructions

for each page.

The BMW E46 M3 SPORT button located in the center

console (shown) still serves as a switch input to the

ECU. Contrary to some misinformed beliefs, this button

never changed the maximum power output of the

engine. This switch changes the accelerator-pedal to

throttle-target relationship in the stock BMW DME.

These curves are configurable in the Infinity Tuner

software using the DBW_ThrottleCurve1 /

DBW_ThrottleCurve2 tables, which allow the tuner to define the DBW throttle target based on

Accelerator Pedal Position and Engine Speed.

© 2014 AEM Performance Electronics

Page 9

2001–2006 BMW E46 M3

When accelerator pedal is pressed, idle valve sends more airflow into

engine. Airflow increases w hen LS5_Duty is set to low values.

9

The ModeSelect_DBW table is

preconfigured to switch between

the two different

DBW_ThrottleCurve tables,

depending on the status of the

CAN_SPORTBUTTON signal. The

CAN_SPORTBUTTON toggles

between 0 and 1 (2 and 3 are not

used) when depressing the

SPORT button. States 0 and 1 are

mapped to the

DBW_ThrottleCurve1 and

DBW_ThrottleCurve2 tables

respectively. Both 2D tables use

accelerator pedal position for the

y-axis and RPM for the x-axis.

The values that are entered in the

table are throttle position targets.

Between 0-10% accelerator pedal position, the idle valve supplies all airflow to the engine while the

individual throttles remain fully closed. This behavior can be observed in the LS6_Duty table (which

increases airflow through the idle valve when the accelerator pedal is pressed) and the

DBW_ThrottleCurve tables. If tuners desire to adjust the DBW_ThrottleCurve tables, the lower two rows

must remain set to 0. Great care must be taken when adjusting the ThrottleCurve tables, poor choices

here can result in undesirable engine response or drive-by-wire tracking errors.

If it is desired to mimic the OEM BMW throttle control strategy, set the target to 75% throttle below 5500

RPM when the Accel Pedal is 100% open and 90% throttle above 5500 RPM. NOTE: Do not enter

values above 95% in the throttle curve tables; this will force the throttles against the

mechanical ‘full open’ stop which is not desirable and could cause failsafe actions to occur.

Tuning Tool Tip: Because the AEM base session files use TPS as the VE table y-axis, the throttle target

tables can be used as a tuning aid. Simply set the DBW_APP1 100% row to Throttle target values that

correspond to values which need attention in the VE tables. This enables each cell to be accessed

easily by the tuner on a dynamometer for example.

The factory BMW traction control and rev limiter is controlled using the DBW, whereas many other

applications use a fuel cut or, in some rare cases, an ignition cut or ignition retard. With the AEM

Infinity, these can be controlled by any or all of the aforementioned methods.

Note that there is also a

DBW Tuning section in the

Plug-in | Wizards | Setup

Wizard… However, most of

these channels will already

be set up properly in the

AEM base session file and

should not be changed.

© 2014 AEM Performance Electronics

Page 10

10

P/N 30-3510

There are a few integrated DBW fail safes incorporated into the Infinity system. The ECU constantly

monitors the accelerator pedal sensor voltage and throttle position sensor voltages to ensure the signals

are not excessively high or low due to damaged sensors, short circuits, or broken wires. The ECU also

performs self-diagnostics to ensure the electronic throttle is following desired DBW_Target properly, that

the DBW throttle control motor is not using excessive energy to move the throttle, and watching to see

that all the redundant sensors are working together as expected. If any of these conditions are

determined to be abnormal or unsafe, the ECU can shut the engine down to prevent unintended engine

acceleration. When the ECU shuts the engine off due to problems detected in the DBW system, the

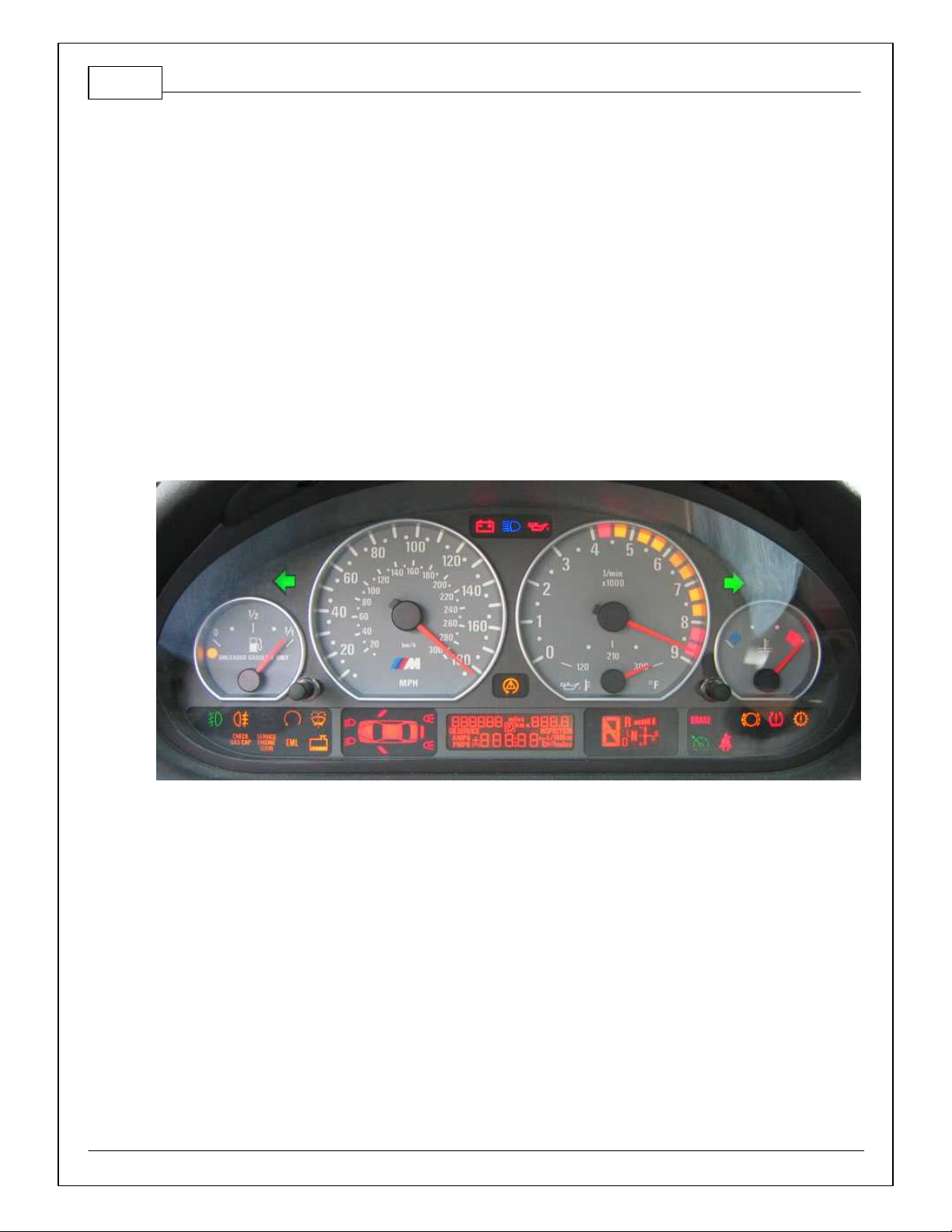

AEM Infinity notifies the driver by illuminating the Engine Malfunction Lamp (EML) on the dashboard. This

error will reset when the ignition key is cycled or if the problem is fixed.

CAN BUS

The AEM Infinity EMS for the BMW E46 M3 supports the majority of the OEM features including:

Tachometer, Oil Temperature Gauge, Coolant Temperature Gauge, A/C Request Button, and Fuel

Consumption (MPG).

When the EMS is connected to a PC and changes are being committed either through table

values or the wizard, the CAN transmission may occasionally pause and the gauges will drop

out one at a time until they all stop working. This does not happen during normal operation.

Cycling the ignition switch will reset everything back.

NOTE: If the vehicle is used on rollers such as a dynamometer where the front wheels and rear wheels

are operating at completely different speeds, the DSC light, the TPMS (tire pressure monitoring system),

and the BRAKE light will illuminate as usual. When the vehicle is driven conservatively on a road, these 3

lights will be OFF like normal. However, if the tires experience any slippage, these 3 lights will flash ON/

OFF, warning the driver of traction issues. If the tires are excessively spun, these 3 lights may stay ON

replicating a dynamometer speed test. If this happens, a simple cycle of the ignition key will reset these

lights back to OFF.

© 2014 AEM Performance Electronics

Page 11

2001–2006 BMW E46 M3

11

Rather than OBD2 diagnostics, the SES-Service Engine Soon light is now dedicated to the AEM

“MILOutput” feature. The AEM MILOutput activates if any 1 of the following inputs are in an error state: air

temp, baro pressure, coolant temp, exhaust back pressure, fuel pressure, UEGO #1, UEGO #2, MAF

analog, MAF digital, MAP, oil pressure, or throttle position. If any of these sensors are not used, they

should be turned OFF in the Wizard to avoid any false readings. To activate the MILOutput feature, go to

the Wizard and check “Enable MIL Output” in Diagnostics.

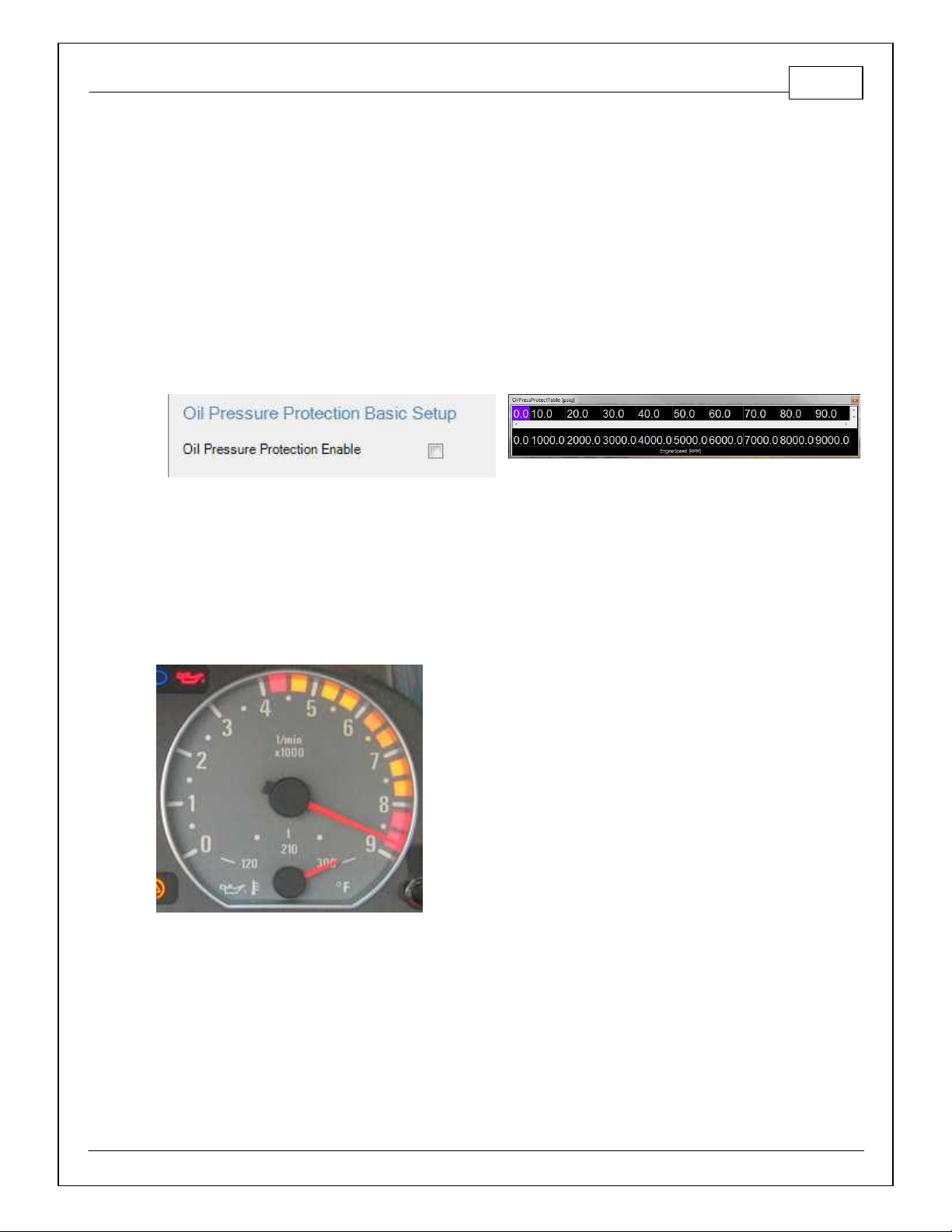

The red oil can light still illuminates if there is low engine oil pressure. However, it will no longer change

to yellow when the engine oil level is low. But, if an aftermarket oil pressure sensor is installed, the oil

can will illuminate yellow and beep if the AEM failsafe “OilPressProtectOut” is triggered. This feature

needs to be activated in the Engine Protection section of the Wizard, as shown below left. Also, there is

a corresponding RPM dependent “OilPressProtect” 1D Table that needs to be set up as well. When the

oil pressure falls below this set value, the Oil Press Protect feature will be activated.

Rather than OBD2 diagnostics, the EML-Engine Malfunction Lamp on the dash warns the driver if the

“DBW_Error_Fatal” has been activated. If this happens, the engine will be shut down for safety and the

error will reset when the ignition key is cycled and the condition that caused the error is no longer

present.

The coolant temperature gauge’s red warning LED, located in the BMW gauge cluster, is programmable.

When the coolant exceeds the value entered in the channel “CoolantHighLEDLimit” the LED will

illuminate (default = 100C).

The 4000–9000RPM red and yellow tachometer LEDs (shown)

will now always match the current RPM limiter. For example, if

the 2-step rev limiter is active and targeting 5000RPM, the

tachometer LEDs will move the displayed “redline” to 5000RPM.

This happens even if the engine is idling and not actively

banging against the 2-step limiter. If the 2-step rev limiter is

OFF, but the main rev limiter is set to 7000RPM, the LEDs will

show the displayed “redline” at 7000RPM. If the 3-step rev

limiter turns ON and changes the target rev limiter to 6500RPM,

the LEDs will show the displayed “redline” at 6500RPM.

The main rev limiter is configurable in the setup wizard. The 2step and 3-step rev limiters are configurable in the setup wizard

and in corresponding tables. Keep in mind, there are fuel cuts,

spark cuts, ignition retards, and cut start windows. The tachometer LEDs are driven by the lower value

between the fuel and spark cuts and ignores the ignition retard and cut start window RPMs.

The following channels on the BMW CAN bus are available for logging. The AEM traction control utilizes

the CAN wheel speed sensors: CAN_FLWS [MPH], CAN_FRWS [MPH], CAN_RLWS [MPH],

CAN_RRWS [MPH]. The following steering channels are only for data logging: CAN_STEERANGLE

[deg].

© 2014 AEM Performance Electronics

Page 12

12

P/N 30-3510

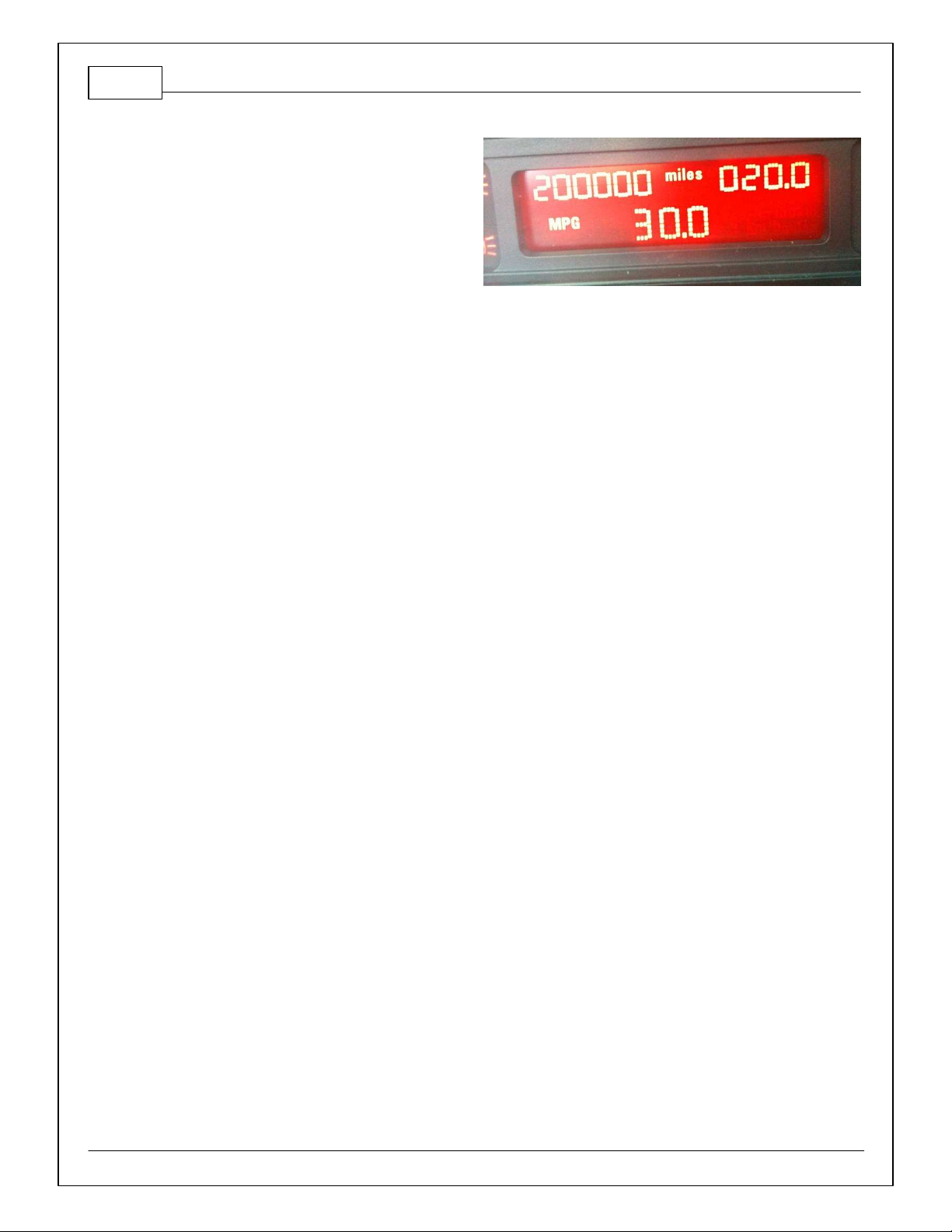

The rate of fuel consumption (MPG) is

calculated based on injector duty cycle,

injector size, engine speed, etc. The output

display will be close, but keep in mind there are

many factors and variables. To customize and

make completely accurate, there is a trim

channel named “CAN_FUELFLOWSCALER”.

The default value is 9.6.

© 2014 AEM Performance Electronics

Page 13

CRUISE CONTROL

Currently, a cruise control feature is not

supported with the AEM Infinity. However,

the multi-functional steering wheel buttons

are run over the BMW MFL bus and are

available for miscellaneous purposes

described below. There are 4 buttons:

Enable, Resume Set, Accelerate+, and

Decelerate- (as shown).

engine’s corresponding RPM. Once the car is launched and the EMS begins to register vehicle speed,

the RPM limit can then be tailored to prevent wheel spin using these tables.

2001–2006 BMW E46 M3

The Enable button now engages the 3-step rev

limiter channel “CAN_CCEnable”. A 3-step rev

limiter is a simplified traction control based

system that uses engine and vehicle speed or

launch timer inputs to limit the RPM of the

engine. To operate, first be sure the

3StepSwitch table is set to recognize the

“momentary” Enable button, as shown. Set

the 3StepTargetFuel and/or the

3StepTargetSpark table’s first (0 MPH) cell to

the desired launch RPM. When the Enable

button is held down, the EMS will limit the

13

The Resume Set button is used as an

AEM traction control switch. Note:

The DSC button is not available as

it is a direct link to the VDC. The

BMW VDC system is disabled

when using the AEM Infinity. Instead, the latching Resume Set button changes the TC_SlipTargetTrim

1-axis lookup table (shown). Simultaneously, the Cruise Control icon on the dash is illuminated to inform

the driver the status of the programmable AEM traction control. Normally this table is used with a

multiple position switch. However, because the BMW Resume Set button is either OFF (0) or ON (1),

only the first two cells of the table are used. Two possible traction scenarios, for example, could be ON/

OFF or aggressive/nonaggressive. To use this feature, it must be enabled in Infinity Tuner: Plug-Ins |

Wizard | Setup wizard | Traction Control | Traction Control Enable.

© 2014 AEM Performance Electronics

Page 14

14

P/N 30-3510

be mistakenly bumped.

The steering wheel’s Accelerate+ and Deceleratemomentary buttons increment and decrement the map

switching function “CAN_MapValueNV”. This feature is

extremely flexible as it can be used to switch VE

tables, ignition maps, lambda targets, and boost

levels.

When the Accelerate+ or Decelerate- button is

depressed (or when KeyOn occurs) the tachometer

displays 1k, 2K, 3K, 4K, 5K, 6K, 7K, or 8K

momentarily representing the currently selected value

of ModeSwitch. Because of the BMW E46 M3

tachometer range, 1–8 are the only valid values (9–12

are not used for this application).

For safety precautions, the AEM base session files

come standard with the VE tables, ignition maps,

lambda targets, and boost tables all set the same

because the Accelerate+ or Decelerate- button could

In order to use this feature, care must be taken into account when setting up the tables and tuning. Enter

the number of the table into the corresponding mode selection table for each feature (VE tables, ignition

maps, lambda targets, and boost levels).

© 2014 AEM Performance Electronics

Page 15

INFINITY EMS INSTALLATION

Open the trunk and disconnect the

battery.

Open the hood and locate the E-Box on

the left side near the firewall. This is

where the factory ECU (Digital Motor

Electronics or DME) resides.

Remove the four screws using a T25

Torx wrench (late models) or 5mm Allen

wrench (early models). Simultaneously

pull up and rotate the E-Box cover to

release it from the vehicle. This will be

reused.

There are 5 DME connectors. These

must be removed in a sequence from the

left to the right (as pictured) or connector

5-4-3-2-1.

First remove connector 5 using your

thumb by squeezing the release tab.

Hold down and pull upwards.

Step 1

2001–2006 BMW E46 M3

15

Step 2

© 2014 AEM Performance Electronics

Page 16

16

Connectors 4, 3 and 2 all have a

swinging latch. First press the “button”

and then rotate the swing latch

downwards towards the DME.

Note: When reinserting connectors into

the header, the swing latch must be

open for initial engagement.

The connector will automatically push

itself away from the DME connector’s

header.

After removing connectors 4, 3, and 2,

remove connector 1 the same way as

connector 5 using your thumb.

Step 3

Step 4

P/N 30-3510

© 2014 AEM Performance Electronics

Page 17

Step 5

To remove the DME (stock ECU) from

the internal plastic “skeleton”, push the

two tabs away from the bottom side of

the DME, as shown.

Simultaneously unlock the plastic tabs

and pull the DME up and out of the

engine bay.

The stock DME will NOT be reused.

Step 6

2001–2006 BMW E46 M3

17

© 2014 AEM Performance Electronics

Page 18

18

Next, there will need to be room made

for the AEM Infinity EMS and jumper

box to fit within the E-Box

compartment.

Note: Some of the instructions below

may slightly differ from vehicle to

vehicle.

Unplug the 2 white connectors (shown)

by squeezing each connector’s locking

tabs.

Note: These two connections will be

reconnected later.

Using a flat blade, such as a

screwdriver, unlock the black fuse

block’s tab, as shown, and lift upwards.

Step 7

Step 8

P/N 30-3510

© 2014 AEM Performance Electronics

Page 19

Step 9

Using a flat blade, such as a

screwdriver, unlock the blue relay’s tab,

as shown, and lift upwards.

Using a flat blade, such as a

screwdriver, unlock the lime green

relay’s tab, as shown, and lift upwards.

Step 10

2001–2006 BMW E46 M3

19

© 2014 AEM Performance Electronics

Page 20

20

Carefully pull the internal plastic mount

upwards a few inches to unlock it from

the base.

Cut the factory cable zip-ties to release

the BMW wiring harness from the

internal plastic mount using a pair of

long-reach dikes.

Cut the zip-tie shown.

Step 11

Step 12

P/N 30-3510

© 2014 AEM Performance Electronics

Page 21

Step 13

There should be 2 cable ties to cut in

the area shown.

Pull the internal plastic mount further

away from the vehicle and cut the zip-tie

shown.

Step 14

2001–2006 BMW E46 M3

21

© 2014 AEM Performance Electronics

Page 22

22

As shown, use a pick to unlock this tab.

Pull the connector downwards to release

it from the inner plastic “skeleton”.

The internal plastic “skeleton” should

now be able to be removed.

To allow space for the AEM EMS kit,

the top portion (that the DME was

secured to) will have to be cut into 2

pieces.

Using a band saw (or similar) cut the

“skeleton” along the dotted line as

pictured.

Step 15

Step 16

P/N 30-3510

© 2014 AEM Performance Electronics

Page 23

Step 17

The pictured piece can be discarded.

Reinstall the other part of the plastic

“skeleton”. Reconnect the relays and

white plastic connector from the previous

steps.

Connect the AEM jumper box and the

90-degree locking comms cable to the

AEM Infinity EMS.

Insert the Infinity in a vertical position

where the DME was mounted previously.

The 2 large Infinity connector cables

should be facing upwards. Note: Infinity

blue connector towards front and gray

connector towards rear of vehicle.

Connect the AEM jumper box to the 5

factory BMW DME connectors in

reverse order (1-2-3-4-5). Place the

jumper box on top of the AEM Infinity

EMS, as shown.

Connect the UEGO extension

harness(s) to the “Lambda1” (and/or

“Lambda2”) 6-pin DTM connector(s). If

using any AEMNet components, such

as an AEM AQ-1 Datalogger, use the 4pin Deutsch DTM “AEMNET” connector.

Evaluate which ancillary sensors, inputs,

and/or outputs will be required to run the

vehicle. Using the aux pin-out

information, wire the components into

the included 12P connector. Plug this

into the adapter harness connector

labeled “AUX”.

2001–2006 BMW E46 M3

23

Step 18

© 2014 AEM Performance Electronics

Page 24

24

Before reinstalling the E-Box cover, cut

half-circle slot(s) along the edge, shown

in yellow. This will allow the comms and

miscellaneous cables to exit the E-Box.

This kit requires a MAP sensor. Use the

aux connector pinout to wire in a sensor

and route the wires through the E-Box

cover.

Using a 7/8” wrench, install the optional

AEM UEGO sensor(s) in the exhaust at

least 36” from the turbo (if applicable).

Connect the UEGO extension

harness(s) to the sensor(s).

Position everything being cautious not to

pinch any of the cables. Secure the EBox cover with the factory fasteners.

This will be a very tight fit.

To remove the cowl, disengage the 3

quarter-turn fasteners and remove the

interior ventilation filter cover and micro

filter element.

Unclip the 4 tabs for the cable duct in

front of the cowl and separate the two

long pieces. Make sure the engine is

cool and pull the large cables out of the

plastic retaining seats and gently lay

them down on the engine.

Unscrew the four T30 Torx bolts and

remove the lower section of the micro

filter housing by pulling towards the front

of the vehicle.

Step 19

P/N 30-3510

Step 20

© 2014 AEM Performance Electronics

Page 25

Step 21

Towards the back of the vacuum rail

there is a barbed nipple (shown). There

is a short 90-degree rubber hose (not

shown) and corresponding hard plastic

tube (shown) that connects the vacuum

rail to the fuel pressure regulator under

the vehicle.

Pull the short rubber hose off the

vacuum rail. Be careful not to lose the

hard plastic tube which will be zip-tied in

place by BMW.

Using the barbed TEE and rubber

vacuum hose included with the kit,

install the MAP sensor’s vacuum

source, as shown.

Find a location to remotely mount the

MAP sensor. Be sure to keep the

vacuum hose and electrical cables away

from hot exhaust gas areas or moving

parts.

Connect the MAP sensor to the auxiliary

connector.

The electrical and mechanical

installation of the BMW E46 M3 Infinity

EMS PnP kit is now complete.

Step 22

2001–2006 BMW E46 M3

25

© 2014 AEM Performance Electronics

Page 26

26

Dedicated

Dedicated and not reconfigurable

Assigned

Assigned but reconfigurable

Available

Available for user setup

Not Applicable

Not used in this configuration

Required

Required for proper function

BMW

Pin

01–06 E46 M3

00–02 M Coupe

00–02 M

Roadster

EMS

Pin

Hardware

Reference

Function

Hardware

Specification

Notes

X

6

0

0

0

1

1

Fuel Injector RelayTerminal 15

C1-61

+12V

+12V

12 volt power from relay

12 volt power from relay. Relay must be

controlled by +12V Relay Control signal

pin C1-29.

2

Voltage Supply-EDK

Actuator with

Potentiometer

C1-54

Harness_HBridge0_1

HBridge0_1

5.0A max Throttle Control Hbridge

Drive

+12V to open

3

Diagnosis Signal TXD

SMG2 Control Module

(SMG Only)

NC

4

Ground Point

C1-30

GND

PGND

Power Ground

Connect directly to battery ground.

5

Ground Connector

C1-55

GND

PGND

Power Ground

Connect directly to battery ground.

6

Ground Connector

C1-60

GND

PGND

Power Ground

Connect directly to battery ground.

7

Fuse F102-Terminal 30

C1-10

+12V_R8C_CPU

+12V (Perm

Power)

Dedicated power management CPU

Full time battery power. MUST be

powered before the ignition switch input

is triggered.

8

Voltage Supply-Engine

Electronics Fuse Carrier

C1-61

+12V

+12V

12 volt power from relay

Relay must be controlled by +12V Relay

Control signal pin C1-29.

9

Negative Activation-EDK

Actuator with

Potentiometer

C1-53

Harness_HBridge0_0

HBridge0_0

5.0A max Throttle Control Hbridge

Drive

+12V to close

X

6

0

0

0

2

1

Heater Ground-Oxygen

Sensor I Before Catalytic

Converter

NC

2

Not Used

NC

3

Not Used

NC

4

Not Used

NC

5

Negative ActivationOxygen Sensor Grounds

NC

6

Not Used

NC

7

Heater Ground-Oxygen

Sensor I Behind Catalytic

Converter

NC

8

Not Used

NC

9

Not Used

NC

10

Signal-Exhaust

Temperature Sensor

C2-17

Harness_Analog_In_T

emp_6

Exhaust Temp

12 bit A/D, 2.49K pullup to 5V

See ExhTemp [C] table for calibration

data and ExhTemp [C] for channel data.

11

Signal-Fuel Pump Relay

C1-34

Harness_LowsideSwit

Fuel Pump

Lowside switch, 4A max, NO internal

Switched ground. Will prime for 2

P/N 30-3510

PINOUTS

BMW Pinouts

© 2014 AEM Performance Electronics

Page 27

2001–2006 BMW E46 M3

BMW

Pin

01–06 E46 M3

00–02 M Coupe

00–02 M

Roadster

EMS

Pin

Hardware

Reference

Function

Hardware

Specification

Notes

1 (USA Models Only)

ch_0

flyback diode.

seconds at key on and activate if RPM >

0.

12

Signal-E-Box Fan

Temperature

GND

13

Heater Ground-Oxygen

Sensor II Before Catalytic

Converter

NC

14

Signal-Heated Oxygen

Sensor I Before Catalytic

Converter

NC

15

Signal-Heated Oxygen

Sensor II Before Catalytic

Converter

NC

16

Signal-Heated Oxygen

Sensor I Behind Catalytic

Converter

NC

17

Not Used

NC

18

Signal-Heated Oxygen

Sensor II Behind Catalytic

Converter

NC

19

Heater Ground-Oxygen

Sensor II Behind Catalytic

Converter

NC

20

Signal-Gear Recognition

Clutch Switch

C2-38

Harness_Digital_In_7

Clutch Switch

10K pullup to 12V. Will work with

ground or floating switches.

See ClutchSwitch 1-axis table for setup

options. Open unless clutch out and

gear in = 12V

21

Signal-CAN Bus Low

SMG2 Control Module

(SMG Only)

NC

22

Signal-CAN Bus High

SMG2 Control Module

(SMG Only)

NC

23

Signal-Main Relay

Activation-DME Relay

C1-29

Harness_

+12V_Relay_Control

Main Relay

0.7A max ground sink for external

relay control

Will activate at key on and at key off

according to the configuration settings.

24

Not Used

NC

X

6

0

0

0

3

1

Signal-Hot-Film Mass

Air Flow Sensor

C2-33

Harness_Analog_In_2

0

MAF Analog

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals referenced to +12V as

this can permanently damage the ECU.

2

Signal-Exhaust Camshaft

Position Sensor I

C1-22

Harness_Digital_In_1

Cam1

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for

options.

3

Not Used

NC

4

Activation VANOS Inlet

Valve Advance

C2-44

Harness_LowsideSwit

ch_7

VANOS

Lowside switch, 4A max with internal

flyback diode. Inductive load should

NOT have full time power.

BMW VANOS Control

5

Signal-Inlet Camshaft

Position Sensor I

C1-23

Harness_Digital_In_2

Cam2

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Cam/Crank for

options.

6

Signal-Exhaust Camshaft

Position Sensor II

NC

7

Voltage Supply-Hot-Film

Mass Air Flow Sensor

EDK Actuator

C2-24

+5V_OUT_2

Sensor +5V

Regulated, fused +5V supply for

sensor power

Analog sensor power

8

Signal-Crankshaft

Position Sensor

C1-45

Harness_VR+_In_0

Crank +

Differential Variable Reluctance

Zero Cross Detection

See Setup Wizard page Cam/Crank for

options.

9

Not Used

NC

10

Signal-EDK Actuator with

C2-21

Harness_Analog_In_1

Throttle2

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

27

© 2014 AEM Performance Electronics

Page 28

28

BMW

Pin

01–06 E46 M3

00–02 M Coupe

00–02 M

Roadster

EMS

Pin

Hardware

Reference

Function

Hardware

Specification

Notes

Potentiometer

6

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals referenced to +12V as

this can permanently damage the ECU.

11

Not Used

NC

12

Not Used

NC

13

Signal-Generator

Terminal 61

N/A

14

Voltage Supply-Throttle

Position Sensor

C1-42

+5V_OUT_1

Sensor +5V

Regulated, fused +5V supply for

sensor power

Analog sensor power

15

Not Used

NC

16

Not Used

NC

17

Ground-Hot-Film Mass

Air Flow Sensor

C2-32

AGND_2

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

18

Not Used

NC

19

Tire Pressure Warning

Pushbutton

NC

20

Ground-EDK Actuator

with Throttle Position

Sensor

C2-32

AGND_2

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

21

Ground-Crankshaft

Position Sensor

C1-46

Harness_VR-_In_0

Crank -

Differential Variable Reluctance

Zero Cross Detection

See Setup Wizard page Cam/Crank for

options.

22

Signal-Intake Air

Temperature

C1-67

Harness_Analog_In_T

emp_2

Intake Air Temp

12 bit A/D, 2.49K pullup to 5V

See "Air Temperature" Setup Wizard for

selection.

23

Signal-Throttle Position

Sensor

C1-35

Harness_Analog_In_7

Throttle Position

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals referenced to +12V as

this can permanently damage the ECU.

See the Setup Wizard Set Throttle

Range page for automatic min/max

calibration. Monitor the Throttle [%]

channel. Also DB1_TPSA [%] for DBW

applications.

24

Signal-Engine Coolant

Temperature Sensor

C1-66

Harness_Analog_In_T

emp_1

Coolant Temp

12 bit A/D, 2.49K pullup to 5V

See "Coolant Temperature" Setup

Wizard for selection.

25

Ground-Engine Coolant

Temperature and Knock

Sensors

C1-19

AGND_1

Sensor Ground

Dedicated analog ground

Analog 0-5V sensor ground

26

Signal-Oil Pressure

Switch

N/A

27

Not Used

NC

28

Not Used

NC

29

Signal-Knock Sensor (Cyl

1-2)

C1-27

Knock1

Knock1

Dedicated knock signal processor

See Setup Wizard page Knock Setup for

options.

30

Signal-Knock Sensor (Cyl

3-4)

NC

31

Signal-Knock Sensor (Cyl

5-6)

C1-28

Knock2

Knock2

Dedicated knock signal processor

See Setup Wizard page Knock Setup for

options.

32

Not Used

NC

33

Signal-Cylinder 1 Fuel

Injection Valve

C1-63

Injector 1

Injector 1

Saturated or peak and hold, 3A max

continuous

Injector 1

34

Signal-Cylinder 2 Fuel

Injection Valve

C1-62

Injector 2

Injector 2

Saturated or peak and hold, 3A max

continuous

Injector 2

35

Signal-Cylinder 3 Fuel

Injection Valve

C1-59

Injector 3

Injector 3

Saturated or peak and hold, 3A max

continuous

Injector 3

36

Signal-Cylinder 4 Fuel

C1-58

Injector 4

Injector 4

Saturated or peak and hold, 3A max

Injector 4

P/N 30-3510

© 2014 AEM Performance Electronics

Page 29

2001–2006 BMW E46 M3

BMW

Pin

01–06 E46 M3

00–02 M Coupe

00–02 M

Roadster

EMS

Pin

Hardware

Reference

Function

Hardware

Specification

Notes

Injection Valve

continuous

37

Signal-Cylinder 5 Fuel

Injection Valve

C1-57

Injector 5

Injector 5

Saturated or peak and hold, 3A max

continuous

Injector 5

38

Signal-Cylinder 6 Fuel

Injection Valve

C1-56

Injector 6

Injector 6

Saturated or peak and hold, 3A max

continuous

Injector 6

39

Signal-Oil Level Sensor

C1-24

Harness_Digital_In_3

Digital 3

10K pullup to 12V. Will work with

ground or floating switches.

Used for BMW Oil Temperature Gauge

40

Not Used

NC

41

Not Used

NC

42

Signal-Evaporative

Emission Valve

C1-18

Harness_LowsideSwit

ch_3

LS3

Lowside switch, 4A max, NO internal

flyback diode.

Lowside switch, 4A max with internal

flyback diode. Inductive load should NOT

have full time power.

43

Signal-VANOS Exhaust

Valve Retard

C1-02

Harness_LowsideSwit

ch_5

VANOS

Lowside switch, 4A max with internal

flyback diode. Inductive load should

NOT have full time power.

BMW VANOS Control

44

Signal-VANOS Exhaust

Valve Advance

C1-02

Harness_LowsideSwit

ch_5

VANOS

Lowside switch, 4A max with internal

flyback diode. Inductive load should

NOT have full time power.

BMW VANOS Control

45

Tire Pressure Warning

Lamp (Except M3)

NC

46

Signal-Close Idle Speed

Control Valve

C1-03

Harness_LowsideSwit

ch_6

Idle Air Control

Lowside switch, 4A max with internal

flyback diode. Inductive load should

NOT have full time power.

BMW Idle Air Control

47

Signal-Open Idle Speed

Control Valve

C1-03

Harness_LowsideSwit

ch_6

Idle Air Control

Lowside switch, 4A max with internal

flyback diode. Inductive load should

NOT have full time power.

BMW Idle Air Control

48

Not Used

NC

49

Not Used

NC

50

Signal-VANOS Inlet

Valve Retard

C2-44

Harness_LowsideSwit

ch_7

VANOS

Lowside switch, 4A max with internal

flyback diode. Inductive load should

NOT have full time power.

BMW VANOS Control

51

Signal-Sucking Jet Pump

Valve

NC

52

Crankcase Breather Valve

(2005-2006 Models)

NC

X

6

0

0

0

4

1

Signal-Battery Charge

Indicator

N/A

2

Signal-Engine Start

Feedback (M3 Only)

NC

3

Signal-Secondary Air

Injection Pump Relay

NC

4

Signal-Electric Fan

C2-43

Harness_LowsideSwit

ch_8

A/C Fan

Lowside switch, 4A max with internal

flyback diode and 12V pullup

resistor. Inductive load should NOT

have full time power.

Lowside switch, 4A max with internal

flyback diode and 12V pullup resistor.

Inductive load should NOT have full time

power.5Ground Point (M3 Only)

C2-03

GND

PGND

Power Ground

Connect directly to battery ground.

6

Signal-Ignition Lock

Control Module for

Instrument Cluster

Terminal 50

NC

7

Ground-Pedal-Position

Sensor

C1-20

AGND_1

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

8

Signal-Pedal-Position

Sensor

C2-13

Harness_Analog_In_1

8

APP1

12 bit A/D, 100K pullup to 5V

12 bit A/D, 100K pullup to 5V

9

Voltage Supply-Pedal-

C2-22

+5V_OUT_2

Sensor +5V

Regulated, fused +5V supply for

Analog sensor power

29

© 2014 AEM Performance Electronics

Page 30

30

BMW

Pin

01–06 E46 M3

00–02 M Coupe

00–02 M

Roadster

EMS

Pin

Hardware

Reference

Function

Hardware

Specification

Notes

Position Sensor

sensor power

10

Signal Fuel Pump Relay 1

(Not USA Models)

C1-34

Harness_LowsideSwit

ch_0

Fuel Pump

Lowside switch, 4A max, NO internal

flyback diode.

Lowside switch, 4A max, NO internal

flyback diode.

11

Signal-Oil Pressure

Control Module for

Instrument Cluster

N/A

12

Ground-Pedal-Position

Sensor

C2-30

AGND_2

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

13

Signal-Pedal-Position

Sensor

C2-14

Harness_Analog_In_1

9

APP2

12 bit A/D, 100K pullup to 5V

0–5V analog signal. Use +5V Out pins

as power supply and Sensor Ground

pins as the low reference. Do not

connect signals referenced to +12V as

this can permanently damage the ECU.

14

Voltage Supply-PedalPosition Sensor

C2-23

+5V_OUT_2

Sensor +5V

Regulated, fused +5V supply for

sensor power

Analog sensor power

15

Signal-Driving Dynamics

Switching Center (M3

Only)

N/A

16

Driving Dynamics Active

LED-Switching Center

(M3 Only)

N/A

17

Engine Speed Signal TDData Link Connector

NC

18

Activation HeatingDiagnostic Fuel Tank

Leakage (USA M3 Only)

NC

19

Reversing Light Switch

(M Roadster Only)

NC

20

Fuel Leakage Valve (Sept

01-up USA M3)/Thermal

Oil Level Switch (M

Roadster)

NC

21

Signal-Oil Level Control

Module for Instrument

Cluster (Except M

Roadster)

C1-24

Harness_Digital_In_3

Digital 3

10K pullup to 12V. Will work with

ground or floating switches.

Used for BMW Oil Temperature Gauge

22

Signal-Processed Wheel

Speed Rear Right-ABS/

ASC Unit ABS/DSC Unit

C1-25

Harness_Digital_In_4

VSS (Hz)

10K pullup to 12V. Will work with

ground or floating switches.

See Setup Wizard page Vehicle Speed

for calibration constant.

23

Not Used

NC

24

Signal-Brake Light

Switching Center Control

Unit

C2-37

Harness_Digital_In_6

Brake Switch

10K pullup to 12V. Will work with

ground or floating switches.

Input can be assigned to different pins.

See Setup Wizard page Input Function

Assignments for input mapping options.

25

Not Used

NC

26

Fuse F29-Terminal 15

C1-65

Harness_+12V_SW

IGN Switch

10K pulldown

Full time battery power must be available

at C1-10 before this input is triggered.

27

Volute Spring-Data Link

MFL

N/A

28

Signal-Fuel Leakage

Pump Module (Sept 01

and Earlier Models Only)

NC

29

Signal-Relay A/C

Compressor

C1-01

Harness_LowsideSwit

ch_4

AC Compressor

Lowside switch, 4A max, NO internal

flyback diode.

See Setup Wizard Pages "User GPOs"

for activation criteria and "LowSide

Assignment Tables" for output

assignment

30

Signal-Leakage

Diagnosis Pump

NC

31

Not Used

NC

32

Signal-Data Link TXD-

NC

P/N 30-3510

© 2014 AEM Performance Electronics

Page 31

2001–2006 BMW E46 M3

BMW

Pin

01–06 E46 M3

00–02 M Coupe

00–02 M

Roadster

EMS

Pin

Hardware

Reference

Function

Hardware

Specification

Notes

Data Link Connector

33

Electronic Vehicle

Immobilizer Control Unit

NC

34

Signal-Brake Light Switch

NC

35

Cruise Control Ground

(Except M3)

NC

36

Signal-Connector CAN

Bus High

C2-41

Harness_CanH_Bout

CAN B +

Dedicated High Speed CAN

Transceiver

BMW CAN bus communication

37

Signal-Connector CAN

Bus Low

C2-42

Harness_CanL_Bout

CAN B -

Dedicated High Speed CAN

Transceiver

BMW CAN bus communication

38

Ground-Coolant Outlet

Temperature Sensor (M3

Only)

C2-31

AGND_2

Sensor Ground

Dedicated analog ground

Analog 0–5V sensor ground

39

Signal-Coolant Outlet

Temperature Sensor (M3

Only)

C2-15

Harness_Analog_In_T

emp_4

ChargeOutTemp

12 bit A/D, 2.49K pullup to 5V

See ChargeOutTemp [C] table for

calibration data and ChargeOutTemp

[C] for channel data.

40

Not Used

NC

X

6

0

0

0

5

1

Signal-Ignition Coil 1

C1-14

Ignition 1

Ignition 1

25 mA max source current

0–5V Falling edge fire. DO NOT

connect directly to coil primary. Must

use an ignitor OR CDI that accepts a

FALLING edge fire signal.

2

Signal-Ignition Coil 2

C1-13

Ignition 2

Ignition 2

25 mA max source current

0–5V Falling edge fire. DO NOT

connect directly to coil primary. Must

use an ignitor OR CDI that accepts a

FALLING edge fire signal.

3

Signal-Ignition Coil 3

C1-12

Ignition 3

Ignition 3

25 mA max source current

0–5V Falling edge fire. DO NOT

connect directly to coil primary. Must

use an ignitor OR CDI that accepts a

FALLING edge fire signal.

4

Not UsedNC

5

Ground Connector

C1-73

GND

PGND

Power Ground

Connect directly to battery ground.

6

Signal-Ignition Coil 5

C1-16

Ignition 5

Ignition 5

25 mA max source current

0–5V Falling edge fire. DO NOT

connect directly to coil primary. Must

use an ignitor OR CDI that accepts a

FALLING edge fire signal.

7

Signal-Ignition Coil 6

C1-15

Ignition 6

Ignition 6

25 mA max source current

0–5V Falling edge fire. DO NOT

connect directly to coil primary. Must

use an ignitor OR CDI that accepts a

FALLING edge fire signal.

8

Not UsedNC

9

Signal-Ignition Coil 4

C1-11

Ignition 4

Ignition 4

25 mA max source current

0–5V Falling edge fire. DO NOT

connect directly to coil primary. Must

use an ignitor OR CDI that accepts a

FALLING edge fire signal.

31

© 2014 AEM Performance Electronics

Page 32

32

Dedicated

Dedicated and not reconfigurable

Assigned

Assigned but reconfigurable

Available

Available for user setup

Not Applicable

Not used in this configuration

Required

Required for proper function

Infinity

Pin

Hardware

Reference

AEM / M3

Function

BMW M3

Pin

Hardware Specification

Notes

C1-1

LowsideSwitch_4

A/C

Compressor

Clutch Relay

4-29

Lowside switch, 4A max,

NO internal f lyback diode.

See Setup Wizard Page "LowSide Assignment

Tables" for output assignment, Honda VTEC

for VANOS triggering and 2D table "LS3_Duty

[%]" for on/off activation.

C1-2

LowsideSwitch_5

Vanos-

Exhaust Cam

3-43, 3-44

Lowside switch, 4A max

with internal fly back diode.

Inductive load should NOT

have f ull time power.

The Vanos drivers are located in the AEM

Jumper Box. BMW Vanos cannot be wired

directly to the Inf inity.

C1-3

LowsideSwitch_6

Idle Air

Control

3-46, 3-47

Lowside switch, 4A max

with internal fly back diode.

Inductive load should NOT

have f ull time power.

The S54 engine uses both an IACV and drive

by wire throttles. Idle speed and low APP

request is controlled using the IACV.

C1-4

UEGO 1 Heat

UEGO 1 Heat

Use 30-3600

Inf inity O2

Sensor

Extension

Harness

Bosch UEGO controller

Lowside switch f or UEGO heater control.

Connect to pin 4 of Bosch UEGO sensor.

NOTE that pin 3 of the Sensor is heater (+)

and must be power by a f used/switched 12V

supply .

C1-5

UEGO 1 IA

UEGO 1 IA

Trim Current signal. Connect to pin 2 of Bosch

UEGO sensor.

C1-6

UEGO 1 IP

UEGO 1 IP

Pumping Current signal. Connect to pin 6 of

Bosch UEGO sensor.

C1-7

UEGO 1 UN

UEGO 1 UN

Nernst Voltage signal. Connect to pin 1 of

Bosch UEGO sensor.

C1-8

UEGO 1 VM

UEGO 1 VM

Virtual Ground signal. Connect to pin 5 of

Bosch UEGO sensor.

C1-9

Flash_Enable

Flash Enable

10K pulldown

Not usually needed f or automatic firmware

updates through Inf inity Tuner. If connection

errors occur during update, jump the 12V

Flash Connector before proceeding with

upgrade. Disconnect the 12V Flash Connector

after the update.

C1-10

+12V_R8C_CPU

Battery Perm

12V Power

1-7

Dedicated power

management CPU

Full time battery power. MUST be powered

before the ignition switch input is triggered.

(See C1-65.)

C1-11

Coil 4

Coil 4

5-9

25 mA max source current

The ignitors are f ound in the AEM Jumper Box.

The BMW Coils cannot be wired directly to the

Inf inity.

C1-12

Coil 3

Coil 3

5-3

25 mA max source current

The ignitors are f ound in the AEM Jumper Box.

The BMW Coils cannot be wired directly to the

Inf inity.

C1-13

Coil 2

Coil 2

5-2

25 mA max source current

The ignitors are f ound in the AEM Jumper Box.

The BMW Coils cannot be wired directly to the

Inf inity.

P/N 30-3510

Infinity Pinouts

© 2014 AEM Performance Electronics

Page 33

2001–2006 BMW E46 M3

Infinity

Pin

Hardware

Reference

AEM / M3

Function

BMW M3

Pin

Hardware Specification

Notes

C1-14

Coil 1

Coil 1

5-1

25 mA max source current

The ignitors are f ound in the AEM Jumper Box.

The BMW Coils cannot be wired directly to the

Inf inity.

C1-15

Coil 6

Coil 6

5-7

25 mA max source current

The ignitors are f ound in the AEM Jumper Box.

The BMW Coils cannot be wired directly to the

Inf inity.

C1-16

Coil 5

Coil 5

5-6

25 mA max source current

The ignitors are f ound in the AEM Jumper Box.

The BMW Coils cannot be wired directly to the

Inf inity.

C1-17

LowsideSwitch_2

LS2

Lowside switch, 4A max,

NO internal f lyback diode.

Found on Aux Connector. See Wizard page

"LowSide Assignment Tables" for output

assignment and 2D table "LS2_Duty [%]" f or

activation.

C1-18

LowsideSwitch_3

Evap

Emission

Valve

3-42

Lowside switch, 4A max

with internal fly back diode.

Inductive load should NOT

have f ull time power.

See Wizard page "LowSide Assignment Tables"

for output assignment and 2D table

"LS3_Duty [%]" for activ ation. MIL Activates

when any of the following flags are true:

ErrorAirTemp, ErrorBaro, ErrorCoolantTemp,

ErrorEBP, ErrorFuelPressure,

UEGO_0_Diag_error, UEGO_1_Diag_error,

ErrorMAFAnalog, ErrorMAFDigital, ErrorMAP,

ErrorOilPressure, ErrorThrottle.

C1-19

AGND_1

Coolant and

Knock Ground

3-25

Dedicated analog ground

Analog 0–5V sensor ground

C1-20

AGND_1

Pedal Sensor

Ground

4-7

Dedicated analog ground

Analog 0–5V sensor ground

C1-21

Crank Position

Sensor Hall

Crank

Position

Sensor Hall

10K pullup to 12V. Will

work with ground or

floating switches.

The BMW S54 uses a VR Crank Sensor, not a

Hall Effect Crank Sensor. See Setup Wizard

page Cam/Crank for options.

C1-22

Cam Position

Sensor 1 Hall

Exhaust Cam

Sensor 1

3-2

10K pullup to 12V. Will

work with ground or

floating switches.

See Setup Wizard page Cam/Crank f or

options.

C1-23

Digital_In_2

Camshaft

Position

Sensor 2 Hall

3-5

10K pullup to 12V. Will

work with ground or

floating switches.

See Setup Wizard page Cam/Crank f or

options.

C1-24

Digital_In_3

Oil Lev el

Sensor

3-39

10K pullup to 12V. Will

work with ground or

floating switches.

Input used to drive the Oil Temperature Gauge

on dash via CAN bus.

C1-25

Digital_In_4

Vehicle Speed

Sensor

4-22

10K pullup to 12V. Will

work with ground or

floating switches.

See Setup Wizard page Vehicle Speed for

calibration constant.

C1-26

Digital_In_5

Flex Fuel

10K pullup to 12V. Will

work with ground or

floating switches.

Found on Aux Connector. See channel

FlexDigitalIn [Hz] f or raw frequency input

data.

C1-27

Knock Sensor 1

Knock Sensor

1

3-29

Dedicated knock signal

processor

See Setup Wizard page Knock Setup for

options.

C1-28

Knock Sensor 2

Knock Sensor

2

3-31

Dedicated knock signal

processor

See Setup Wizard page Knock Setup for

options.

C1-29

+12V_Relay_

Control

Main Relay

2-23

0.7A max ground sink f or

external relay control

Will activ ate at key on and at key off

according to the configuration settings.

C1-30

Power Ground

Ground

1-4

Power Ground

Connect directly to ground.

C1-31

CANL_Aout

AEMNet

CANL

Dedicated High Speed

CAN Transceiv er

4P DTM Connector found in AEM adapter

harness. Contact AEM f or additional

information.

33

© 2014 AEM Performance Electronics

Page 34

34

Infinity

Pin

Hardware

Reference

AEM / M3

Function

BMW M3

Pin

Hardware Specification

Notes

C1-32

CANH_Aout

AEMNet

CANH

Dedicated High Speed

CAN Transceiv er

4P DTM Connector found in AEM adapter

harness. Contact AEM f or additional

information.

C1-33

LowsideSwitch_1

Boost Control

Lowside switch, 4A max

with internal fly back diode.

Inductive load should NOT

have f ull time power.

Found in Aux Connector. See Setup Wizard

page Boost Control for options. Monitor

BoostControl [%] channel for output state.

C1-34

LowsideSwitch_0

Fuel Pump

2-11, 4-10

Lowside switch, 4A max,

NO internal f lyback diode.

Pin is located in 2 diff erent locations

depending on E46 M3. Switched ground. Will

prime for 2 seconds at key on and activate if

RPM > 0.

C1-35

Analog_In_7

Throttle

Position

Sensor

3-23

12 bit A/D, 100K pullup to

5V

0–5V analog signal f rom the TPS located on

the ITB unit.

C1-36

Analog_In_8

MAP Sensor

12 bit A/D, 100K pullup to

5V

Found on the Aux Connector. 0–5V analog

signal. See the Setup Wizard Set Manifold

Pressure page f or setup and calibration.

Monitor the MAP [kPa] channel.

C1-37

Analog_In_9

Fuel Pressure

12 bit A/D, 100K pullup to

5V

Found on the Aux Connector. 0–5V analog

signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low ref erence. See

the Setup Wizard Fuel Pressure page f or

setup and calibration. Monitor the

FuelPressure [psig] channel.

C1-38

Analog_In_10

Baro Sensor

12 bit A/D, 100K pullup to

5V

0–5V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as the

low reference. Do not connect signals

referenced to +12V as this can permanently

damage the ECU. See the Setup Wizard

Barometric Pressure page for setup and

calibration. Monitor the BaroPress [kPa]

channel.

C1-39

Analog_In_11

Shift Switch

Input

12 bit A/D, 100K pullup to

5V

Found on the Aux Connector. 0–5V analog

signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low ref erence. See

the 1D lookup table 'Shif tSwitch' for setup.

Also assignable to multiple functions. See

Setup Wizard for details.

C1-40

Analog_In_12

Mode Switch

12 bit A/D, 100K pullup to

5V

Found on the Aux Connector. 0–5V analog

signal. Use +5V Out pins as power supply and

Sensor Ground pins as the low ref erence. See

the 1D lookup table 'ModeSwitch' for input

state. A multi-position rotary switch such as

AEM P/N 30-2056 is recommended. See Setup

Wizard f or details.

C1-41

+5V_Out_1

+5V Out

Regulated, f used +5V

supply for sensor power

Found on the Aux Connector. Analog sensor

power

C1-42

+5V_Out_1

+5V Out

3-14

Regulated, f used +5V

supply for sensor power

Analog sensor power f or the throttle position

sensor

C1-43

HighsideSwitch_1

HS1

(switched

12V)

0.7A max, High Side Solid

State Relay

See Setup Wizard page 'HighSide Assigment

Tables' f or conf iguration options. See 2D

lookup table 'HS1_Table' f or activation

settings.

C1-44

HighsideSwitch_0

HS0

(switched

12V)

0.7A max, High Side Solid

State Relay

Found on the Aux Connector. See Setup

Wizard page 'HighSide Assigment Tables' f or

conf iguration options. See 2D lookup table

'HS0_Table' for activ ation settings.

P/N 30-3510

© 2014 AEM Performance Electronics

Page 35

2001–2006 BMW E46 M3

Infinity

Pin

Hardware

Reference

AEM / M3

Function

BMW M3

Pin

Hardware Specification

Notes

C1-45

Crank Position

Sensor VR+

Crank

Position

Sensor VR+

3-8

Dif f erential Variable

Reluctance Zero Cross

Detection

See Setup Wizard page Cam/Crank f or

options.

C1-46

Crank Position

Sensor VR-

Crank

Position

Sensor VR-

3-21

C1-47

Cam Position

Sensor 1 VR-

Cam Position

Sensor 1 VR-

Dif f erential Variable

Reluctance Zero Cross

Detection

See Setup Wizard page Cam/Crank f or

options.

C1-48

Cam Position

Sensor 1 VR+

Cam Position

Sensor 1 VR+

C1-49

VR+_In_2

Non Driven

Left Wheel

Speed Sensor

+

Dif f erential Variable

Reluctance Zero Cross

Detection

See Non Driv en Wheel Speed Calibration in

the Setup Wizard Vehicle Speed page.

C1-50

VR-_In_2

Non Driven

Left Wheel

Speed Sensor

-

C1-51

VR-_In_3

Driv en Left

Wheel Speed

Sensor -

Dif f erential Variable

Reluctance Zero Cross

Detection

See Driven Wheel Speed Calibration in the

Setup Wizard Vehicle Speed page.

C1-52

VR+_In_3

Driv en Left

Wheel Speed

Sensor +

C1-53

DBW1 Motor -

DBW Motor

Control Close

1-9

5.0A max Throttle Control

Hbridge Drive

+12V to close

C1-54

DBW1 Motor +

DBW Motor

Control Open

1-2

5.0A max Throttle Control

Hbridge Drive

+12V to open

C1-55

Power Ground

Ground

1-5

Power Ground

Connect directly to ground.

C1-56

Injector 6

Injector 6

3-38

Saturated or peak and

hold, 3A max continuous

Injector 6

C1-57

Injector 5

Injector 5

3-37

Saturated or peak and

hold, 3A max continuous

Injector 5

C1-58

Injector 4

Injector 4

3-36

Saturated or peak and

hold, 3A max continuous

Injector 4

C1-59

Injector 3

Injector 3

3-35

Saturated or peak and

hold, 3A max continuous

Injector 3

C1-60

Power Ground

Ground

1-6

Power Ground

Connect directly to battery ground.

C1-61

+12V

+12V In

1-8

12 v olt power f rom relay

12 v olt power f rom relay . See pin C1-29

above.

C1-62

Injector 2

Injector 2

3-34

Saturated or peak and

hold, 3A max continuous

Injector 2

C1-63

Injector 1

Injector 1

3-33

Saturated or peak and

hold, 3A max continuous

Injector 1

C1-64

+12V

+12V In

12 v olt power f rom relay

Not Connected

C1-65

+12V_SW

Ignition

Switch

4-26

10K pulldown

Full time battery power must be av ailable at

C1-10 before this input is triggered.

C1-66

Analog_In_Temp_

1

Coolant Temp

Sensor

3-24

12 bit A/D, 2.49K pullup to

5V

See "Coolant Temperature" Setup Wizard f or

selection.

C1-67

Analog_In_Temp_

2

Intake Air

Temperature

3-22

12 bit A/D, 2.49K pullup to

5V

See "Air Temperature" Setup Wizard f or

selection.

35

© 2014 AEM Performance Electronics

Page 36

36

Infinity

Pin

Hardware

Reference

AEM / M3

Function

BMW M3

Pin

Hardware Specification

Notes

C1-68

Harness_Analog_I

n_Temp_3

Oil

Temperature

Sensor

12 bit A/D, 2.49K pullup to

5V

See 1D table OilTempCal table f or calibration

data and OilTemp [C] for channel data.

C1-69

Stepper_2A

Stepper 2A

Automotive,

Programmable Stepper

Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the stepper

motor is properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar

stepper motors only.

C1-70

Stepper_1A

Stepper 1A

Automotive,

Programmable Stepper

Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the stepper

motor is properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar stepper

motors only .

C1-71

Stepper_2B

Stepper 2B

Automotive,

Programmable Stepper

Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the stepper

motor is properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar stepper

motors only .

C1-72

Stepper_1B

Stepper 1B

Automotive,

Programmable Stepper

Driv er, up to 28V and

±1.4A

Be sure that each internal coil of the stepper

motor is properly paired with the 1A/1B and

2A/2B ECU outputs. Supports Bi-Polar stepper

motors only .

C1-73

Power Ground

Ground

5-5

Power Ground

Connect directly to ground.

C2-1