Page 1

Installation Instructions for:

EPM for V8 Engines

WARNING:

This installation is not for the tuning novice nor the PC illiterate!

Use this system with EXTREME caution! Misuse of this product

can destroy your engine! If you are not well versed in engine

dynamics and the tuning of management systems or are not PC

,!

This product is legal in California for racing vehicles only and should

literate, please do not attempt the installation. Refer the

installation to a AEM trained tuning shop or call 800-423-0046

for technical assistance. You should also visit the AEM Tech

Forum at http://www.aempower.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

never be used on public highways.

ADVANCED ENGINE MANAGEMENT INC.

2205 126

© 2007 Advanced Engine Management, Inc.

th

Street Unit A Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

Http://www.aempower.com

Instruction Part Number: 10-3252

Page 1 of 2

Page 2

The AEM Engine Position Sensor (EPM) replaces the stock V8 distributor and allows

the use of a coil on plug or wasted spark ignition system and can be used with any

aftermarket engine management system that recognizes the common 24 – 1 input for

crank and cam signal. The EPM provides precise engine position using dual zero

speed optical sensors. This offers the advantage of immediate signal generation when

the engine is cranked.

Read and understand these instructions BEFORE attempting to install this

product.

The EPM is outfitted from AEM with a “steel” distributor gear. If your cam requires the

use of a “bronze” gear please call AEM for further details. If you are not sure which

gear you need please double check with your cam manufacture first to verify the type of

gear needed for your cam.

1) Remove the Stock Distributor and install the AEM EPM. You can rotate the EPM so

that the cable routing is optimized for your application, timing will be set with the

EMS software.

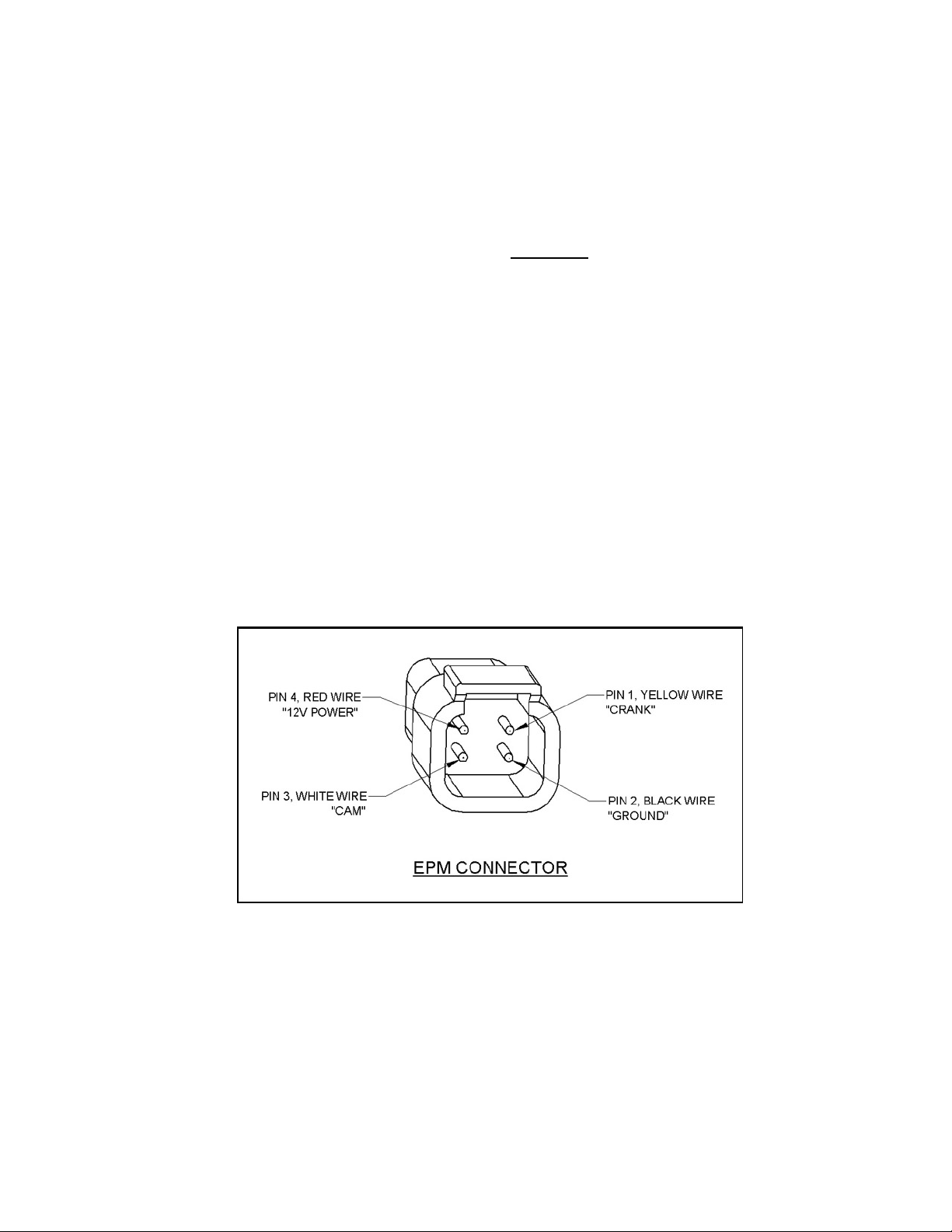

2) EPM Wiring

a) The EPM has a short cable with a 4 pin connector, supplied with the EPM is the

mating connector housing with 5 crimp terminals. The connector pinouts are

shown in figure 1.

Figure 1.

b)

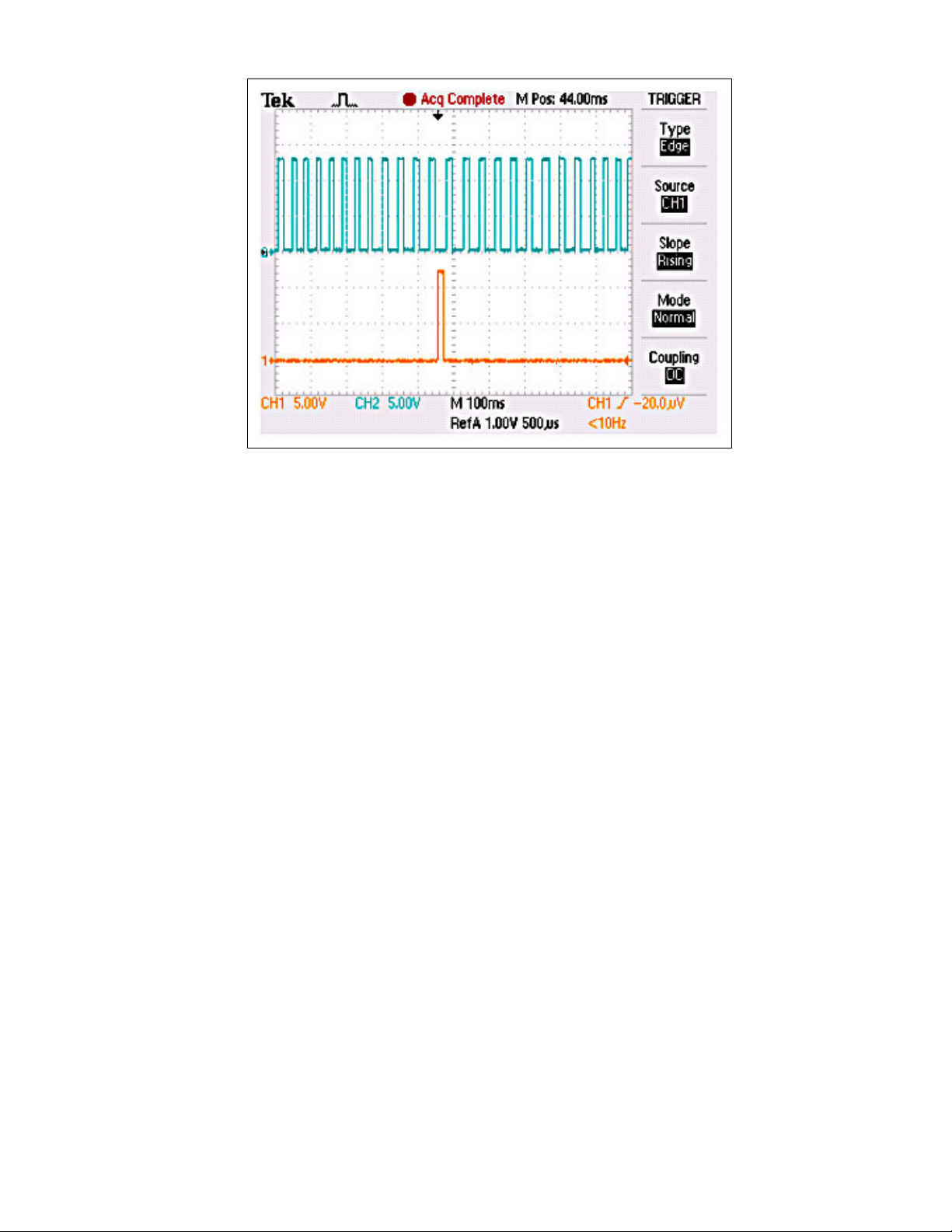

The EPM puts out a 12V square wave, 24 crank signals and 1 short pulse cam

signal every 360 distributor degrees, see figure 2.

Page 2 of 3

Page 3

Figure 2.

Page 3 of 3

Loading...

Loading...