Page 1

Instruction Manual

P/N 30-2906-0 AQ1 Data Logger

Harness Plug and Pin Kit

WARNING:

This installation is not for the electronic novice or the PC

illiterate! Use this system with EXTREME caution! If you are not

well versed in electronics and vehicle instrumentation or are not

PC literate, please do not attempt the installation. Refer the

,!

installation to an AEM trained tuning shop. A list of AEM

trained tuning shops is available at

http://www.aemelectronics.com/dealer_locator.php or by calling

800-423-0046. You should also visit the AEM Tech Forum at

http://www.aemelectronics.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

Note: This harness is only to be used

with the 30-2500 AQ1 Data Logger.

AEM Performance Electronics

th

2205 126

Phone: (310) 484-2322 Fax: (310) 484-0152

Street Unit A, Hawthorne, CA. 90250

http://www.aemelectronics.com

Instruction Part Number: 10-2906-0 Rev A

© 2011 AEM Performance Electronics

Page 2

The 30-2906-0 AQ1 Data Logger Harness Plug and Pin Kit is designed for applications

requiring a custom harness or for applications not using the hard wired analog,

analog/frequency, or switch-to-ground inputs. The plug and pin kit harness comes with

the necessary AEMnet, Power/Ground, RS232, USB, and CAN leads. The pin locations

for the analog, analog/frequency, and switch-to-ground inputs are not populated. A bag

of 20 terminals is included for connecting the analog, analog/frequency, and switch-toground inputs.

KIT CONTENTS

1 x AQ1 Data Logger Harness Plug and Pin Kit

1 x Bag of 20 Terminals

WIRING

Power Connections

RED (PERM PWR)- Connect to a fused (5 Amp) constant 12 volt power source.

RED (SWIGN) – Connect to a fused (5 Amp) switched 12 volt power source.

BLACK (BATT GND) – Connect to a clean power ground. (Do not connect to a sensor

ground)

AEMnet

AEMnet is an open architecture software and hardware interface based on the CAN 2.0

specification, which provides the ability for multiple enabled devices to easily

communicate with each other through a single cable. The hardware connection is made

through a Deutsch 4P DTM connector and contains 12 volt switched power and ground

(2A max) as well as the CAN data lines. Devices connected to the AEMnet transmit

data through this one connection and most of these devices receive power from this

same connection as well.

The following AEM products are currently AEMnet enabled:

Series 2 Engine Management System

EMS-4 Universal Standalone Engine Management System

4-Channel Wideband UEGO Controller

AQ-1 Data Logger

Plug the Deutsch 4-pin DTM connector on the AQ1 Data Logger harness into the

mating connector on other AEMnet compatible devices.

Page 2 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 3

INPUT SIGNALS

Analog 1-4 are 0-5V analog inputs with optional pull-up resistor for RTD/Thermistor-

style sensor. Examples: AEM gauges, MAP/pressure sensors, TPS/APP/shock

travel/load cell sensors, analog MAF sensors, any 2 wire RTD or thermistor style temp

sensor. See “Using the AQ1 Data Logger” for more information on configuring Inputs 1-

4. The corresponding wires in the harness for Analog 1-4 are Yellow and are labeled

INPUT 1, INPUT 2, INPUT 3 and, INPUT 4.

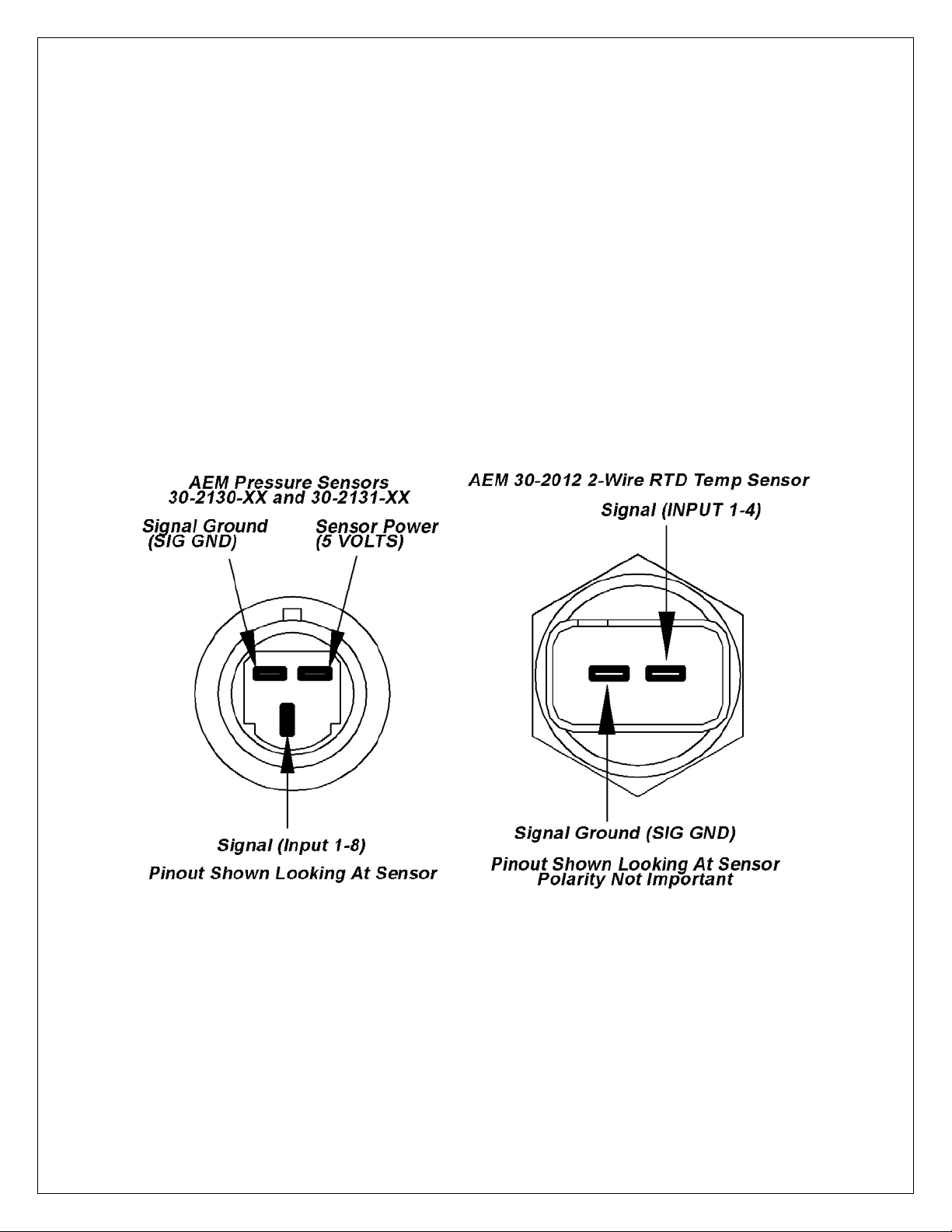

Analog/Frequency 5-8 are analog inputs for that can optionally measure frequency (05 V or 0-16 V) Examples: RPM, vehicle speed, frequency based MAF, injector duty

cycle, boost control solenoid, flow sensor, hall sensor, any 3 wire pressure sensor. See

“Using the AQ1 Data Logger” for more information on configuring Inputs 5-8. The

corresponding wires in the harness for Analog/Frequency 5-8 are Yellow and are

labeled INPUT 5, INPUT 6, INPUT 7, and INPUT 8.

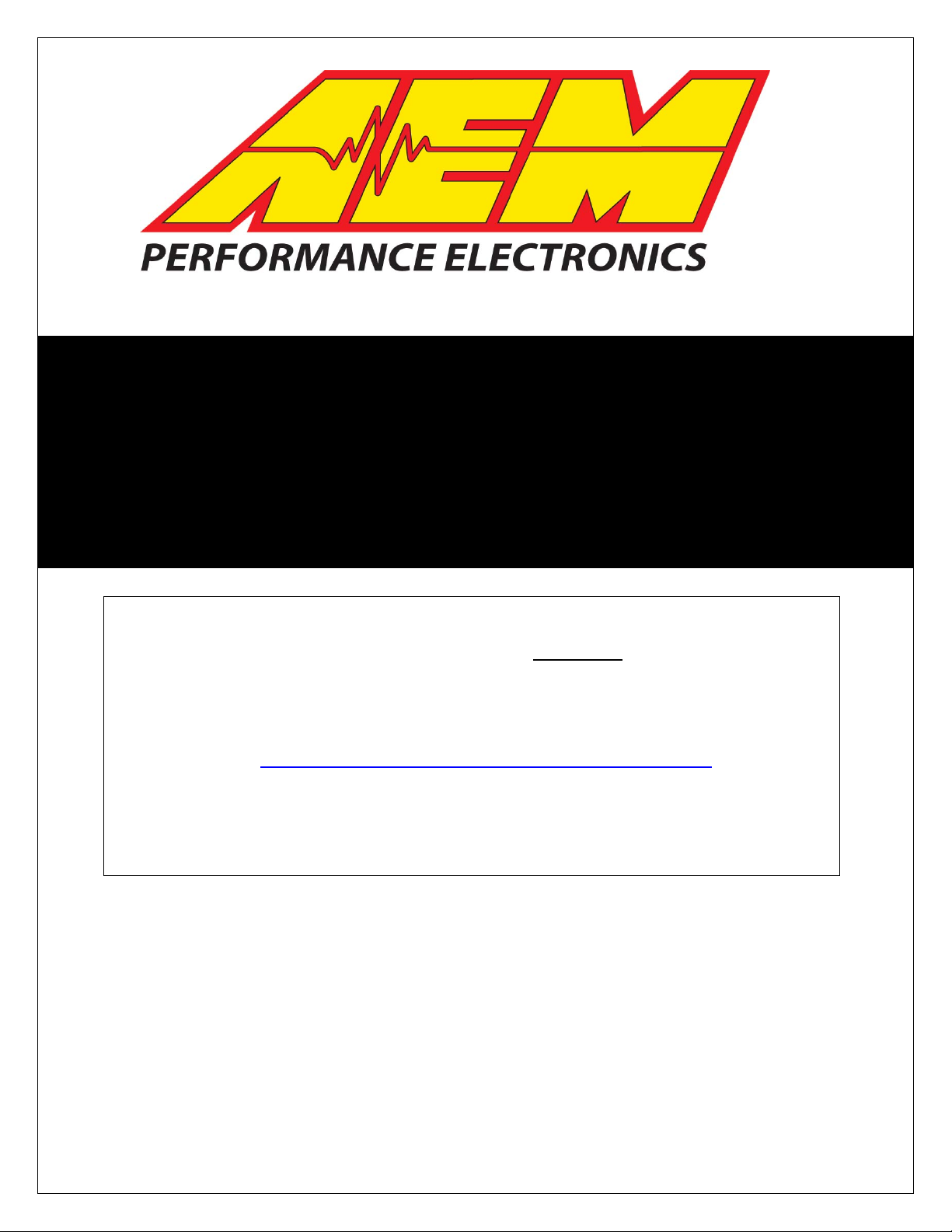

Connection diagrams are shown below for some of the more common sensors/signals

to be used with Inputs 1-4 and Inputs 5-8. See Figure 1.

Figure 1. AEM Pressure Sensors(Left) AEM Temp Sensor (Right)

Figure 2 below shows the connection for an engine speed signal using an AEM Twin

Fire CDI.

Page 3 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 4

Figure 2. Engine RPM Signal From CDI

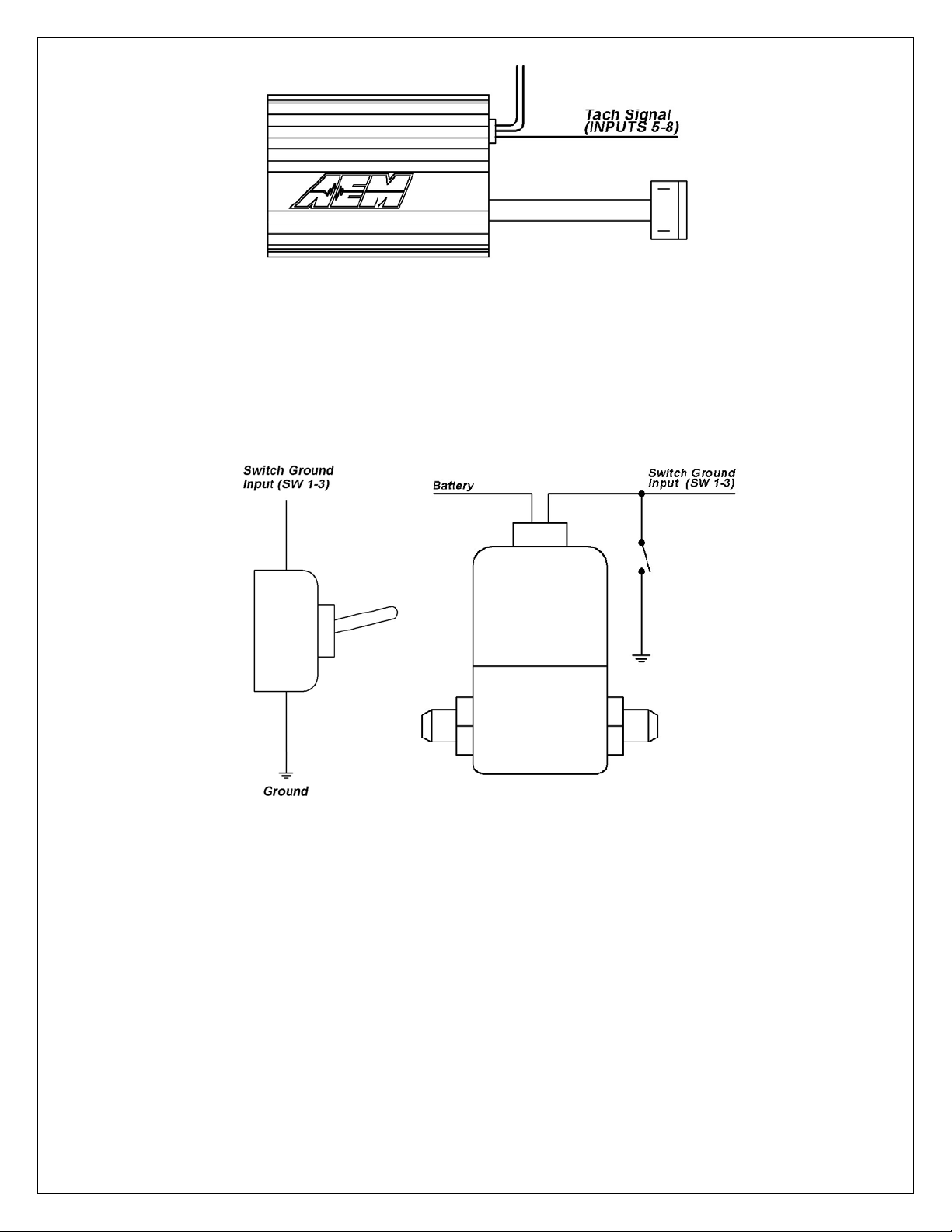

Digital 1-3 are switched to ground digital inputs, 16.5 V MAX tolerance.

Examples: Clutch/brake/cooling fan ground switch, nitrous solenoid ground or ground

switch input to start/stop Logger (Ground activated input). Figure 3 below shows wiring

diagrams for an on/off activation switch and a nitrous solenoid. The corresponding

wires in the harness for Digital 1-3 are Brown and are labeled SW 1, SW 2, and SW 3.

Figure 3. Activation Switch (Left) and Nitrous Solenoid (Right) Connections

SENSOR POWER

The AQ1 Data Logger has an internal low current 5 volt power supply that is used for

powering sensors that require a 5 volt excitation. The corresponding wires in the

harness are Red and are labeled 5 VOLTS.

SENSOR GROUND

The AQ1 Data Logger also has an internal low current sensor ground that is used for

sensors that require a signal ground. The corresponding wires in the harness are Black

and are labeled SIG GND.

Page 4 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 5

RS 232

The RS232 serial input on the AQ1 Data Logger is configurable to read either a

standard NMEA GPS data stream or the data stream from an AEM EMS. See “Using

the AQ1 Data Logger” for more information on configuring the RS232 input. The AQ1

Data Logger harness comes with a male DB9 connector. When connecting to an AEM

EMS, the male DB9 connector plugs directly into the mating connector on the back of

the AEM EMS. The pinout for a GPS connection is shown below in Figure 4. AEM

recommends using one of the Garmin GPS models listed below.

Garmin GPS 18x PC – 1 Hz model with DB9 connector and 12 volt power adapter

Garmin GPS18x 5Hz- 5 Hz OEM model, some wiring required.

Figure 4. Typical GPS Connection

CAN BUS 2

Not used with AQ1 Data Logger PN 30-2500

USB

The AQ1 Data Logger has two USB ports for easy connection and programming. The

AQ1 Data Logger receives low voltage power from the USB port, allowing users to

access the SD card and make configuration changes at all times, 12 volt power is not

necessary. The black remote mount USB port in the harness is designed for easy in

vehicle programming and data downloads. The USB port on the back of the enclosure

allows for easy bench top programming and data downloads when the module is

removed from the vehicle. See Figure 5 below.

Figure 5. AQ1 On-Board (Left) and Harness (Right) USB Ports

Page 5 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 6

30-2906-0 Connector Pinout

Pin Description Wire Stamping

1 Switched 12V SW IGN

2 Switch to Ground Digital Input 1 (16V Max) NOT POPULATED

3 Switch to Ground Digital Input 2 (16V Max) NOT POPULATED

4 Switch to Ground Digital Input 3 (16V Max) NOT POPULATED

5 Shield NOT POPULATED

6 Permanent 12V PERM PWR

7 Sensor Ground NOT POPULATED

8 Analog 1 (5V Max) NOT POPULATED

9 Analog 2 (5V Max) NOT POPULATED

10 Analog 3 (5V Max) NOT POPULATED

11 Analog 4 (5V Max) NOT POPULATED

12 Analog / Frequency 5 (5V / 16V Max) NOT POPULATED

13 Analog / Frequency 6 (5V / 16V Max) NOT POPULATED

14 Analog / Frequency 7 (5V / 16V Max) NOT POPULATED

15 Analog / Frequency 8 (5V / 16V Max) NOT POPULATED

16 RS-232 Tx (Output) N/A

17 RS-232 Rx (Input) N/A

18 RS-232/USB GND N/A

19 Power Ground BATT GND

20 Sensor 5V NOT POPULATED

21 Reserved N/A

22 Reserved N/A

23 Reserved N/A

24 Reserved N/A

25 Reserved N/A

26 Reserved N/A

27 AEMnet+ N/A

28 AEMnet- N/A

29 Reserved N/A

30 AEMnet Negative N/A

31 USB- N/A

32 USB+ N/A

33 CAN H N/A

34 CAN L N/A

35 Shield N/A

36 USB 5V N/A

Page 6 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 7

Figure 6. 36 Pin AQ1 Data Logger Connector, Wire Entry View

Crimping and Installing Terminals

Begin by cutting the strain relief tie wrap holding the

terminal bag as shown.

Page 7 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Using a sharp pick or probe, push in on the

locking tabs holding the outer retainer.

Page 8

Remove the retainer.

Use pick to pry open the retaining tabs

holding the backshell halves together

Open the shell to expose

the cavities.

Page 8 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 9

To remove a terminal, carefully pry up on the retaining

clip. Be careful as the clips can break if bent too far.

To add a new circuit, insert the terminal from the

back as shown until it clicks into place

Showing terminal fully seated.

Page 9 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 10

Delphi Part No: 12070948

Application: Unsealed Micro-Pack 100, Female only

Core and Insulation

Cable Range (mm2): 2.0-0.35

The tool is available in many places. One is shown below. Web

address – http://www.mouser.com AEM recommends using the proper

tool for all ECU terminations.

Image shows a properly crimped terminal. Top View.

Side View. After crimping, be sure to do a pull test

to make sure the terminal is properly installed.

Page 10 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Page 11

RECOMMENDED PARTS

30-51XX Analog Style Gauges

30-44XX Digital Style Gauges

30-2340 4 Channel UEGO Controller

30-4100 Digital Gauge Style UEGO Controller

30-5130 Analog Gauge Style UEGO Controller

30-2310 Inline UEGO Controller

30-2320 X-Wifi

30-2130-XX Stainless Steel Body Pressure Sensor

30-2131-XX Brass Body Pressure Sensor

30-2010 GM Style Inlet Air Temp Sensor

30-2011 GM Style Coolant Temp Sensor

30-2012 Fluid Temp Sensor, 1/8” NPT

If further tuning help is needed be sure to visit the video gallery or performance

electronics forum at www.aemelectronics.com for comprehensive instructional videos

and information.

WARRANTY

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to the consumer that all AEM High Performance products will be free from defects in

material and workmanship for a period of twelve (12) months from date of the original purchase. Products that fail within this 12month warranty period will be repaired or replaced at AEM’s option, when determined by AEM that th e product failed due to defects

in material or workmanship. This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty

exceed the original purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential damages

or cost incurred due to the failure of this product. Warranty claims to AEM must be transportation prepaid and accompanied with

dated proof of purchase. This warranty applies only to the original purchaser of product and is non-transferable. All implied

warranties shall be limited in duration to the said 12 month warranty period. Improper use or installation, accident, abuse,

unauthorized repairs or alterations voids this warranty. AEM disclaims any liability for consequential damages due to breach of any

written or implied warranty on all products manufactured by AEM. Warranty returns will only be accepted by AEM when

accompanied by a valid Return Goods Authorization (RGA) number. Product must be received by AEM within 30 days of the date

the RGA is issued.

Please note that before AEM can issue an RGA for any product, it is first necessary for the installer or end user to contact the AEM

Performance Electronics tech line at 1-800-423-0046 to discuss the problem. Most issues can be resolved over the phone. Under

no circumstances should a system be returned or a RGA requested before the above process transpires.

Need additional help? Contact the AEM Performance Electronics tech department at

1-800-423-0046 or tech@aempower.com, or visit the AEM Performance Electronics

forum at http://forum.aempower.com/forum/

Page 11 10-2906-0 AQ1 Harness Instructions RevA 110707.doc

Loading...

Loading...