Page 1

WARNING:

!

WARNING:

AEM Performance Electronics

P/N 30-2860 B Series COP

Conversion Kit

Instruction Manual

This product is legal in California for racing vehicles only and should never be

This installation is not for the tuning novice! Use this system

with EXTREME

dynamics and the tuning of engine management systems DO

NOT attempt the installation. Refer the installation to an AEM

trained tuning shop. A list of AEM trained tuning shops is

available at www.aemelectronics.com/dealer_locator.php or by

calling 800-423-0046.

NOTE: All supplied AEM calibrations, Wizards and other tuning

information are offered as potential starting points only. IT IS

THE RESPONSIBILITY OF THE ENGINE TUNER TO

ULTIMATELY CONFIRM THE CALIBRATION IS SAFE FOR ITS

INTENDED USE. AEM holds no responsibility for any engine

damage that results from the misuse or mistuning of this

product!

caution! If you are not well versed in engine

used on public highways.

WARNING: IT IS RECOMMENDED THAT TIMING BE CONFIRMED ON EACH

CYLINDER BEFORE ATTEMPTING TO START THE ENG INE!

2205 126th Street Unit A, Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number: 10-2860 Rev B

2011 AEM Performance Electronics

Page 2

KIT CONTENTS

1 x 35-2840 IGNITER W/ BRACKET

1 x 30-3255 HONDA EPM

4 x 30-2850 COIL

1 x 35-3860 B SERIES COP HARNESS

1 x 35-3861 EPM HARNESS

2 x #6 MOUNTING SCREW

2 x DIELECTRIC GREASE

INSTALLATION TIPS

1. Read through the entire manual and instructions before beginning the

installation.

2. Disconnect the negative battery cable(s) before beginning any work.

3. Maintain a clean and neat work area throughout the installation.

4. When raising or working under a vehicle, use properly rated stands/jacks.

5. Make sure all connectors are fully seated and inserted.

6. Make sure all components and cables are routed and installed away from any

direct heat sources or sharp objects.

TABLE OF CONTENTS

• Installation 2

• EMS/ECU Configuration 8

• Jumper Settings 12

• Syncing The EMS Timing 17

• EMS Pin Locations 18

• Connector Pinouts 19

• Factory Tachometer Setup 20

• Specifications 21

• Recommended Parts 21

• Replacement Parts 21

• Warranty 22

INSTALLATION

Removing the Factory Ignition

Remove the spark plug wires from the distributor and cylinder head. Unplug the

distributor from the factory wiring harness and remove the distributor from the engine.

The distributor is held in place by three mounting bolts. See Figure 1 below.

Page 2 10-2860 B Series COP Instructions RevB 111117

Page 3

Figure 1. Factory Distributor

Figure 2. Factory Distributor

Remove the retaining clip from the drive gear and remove the pin, drive gear, and shim.

Save the parts as they will be reused on the EPM. See Figures 2 and 3 below.

Page 3 10-2860 B Series COP Instructions RevB 111117

Page 4

Figure 3. Retaining Clip, Pin, Drive Gear, and Shim (left to right)

Figure 4. EPM with Shim, Drive Gear, Pin, and Retaining Clip Installed

Removed from Distribut or

AEM Engine Position Module (EPM)

Apply a small amount of clean engine oil to the shaft on the EPM and install the shim,

drive gear, pin, and retaining clip. See Figure 4 below.

Apply a small amount of clean engine oil to the O-ring on the EPM and install the EPM

as shown below in Figure 5. Secure the EPM using one of the stock distributor bolts

and washers.

Page 4 10-2860 B Series COP Instructions RevB 111117

Page 5

Figure 5. EPM Installed on B Series Engine

Figure 6. Coils Installed in Cylinder Head

Coils

With the factory plug wires removed, apply a small a mo unt o f diel ectric grease inside

the boot of the coils and install the coils on the spark plugs. Make sure the coils are

fully seated in the head and on the spark plugs. See Figure 6 below.

Page 5 10-2860 B Series COP Instructions RevB 111117

Page 6

B Series COP Harness

Figure 7. B Series COP Harness Connected to Coils

Figure 8. Igniter Mounted and Connected to B Series COP Harness

Lay the B Series COP harness over the cylinder head and connect the coil connectors

to the coils. See Figure 7 below. Make sure the connectors ar e fully seated and locked

into position.

Route the harness through the engine bay, away from any high heat sources and sharp

objects. The branch labeled “EMS” should be routed towards the ECU. The branch

labeled “Power” should be routed towards the power source.

Igniter

With the harness routed, find a suitable mounting location for the igniter and mount the

igniter. Two #6 screws are supplied for mounting the igniter to the firewall or engine

bay. Connect the two igniter connectors from the harness to the igniter. Make sure the

connectors are fully seated and locked into position. See Figure 8 below.

Page 6 10-2860 B Series COP Instructions RevB 111117

Page 7

EPM Harness

Figure 9. EPM Harness Connected to EPM

Connect the 4-pin connector on the EPM harness to the mating connector on t he EPM .

Make sure the connector is fully seated and locked into position. Route the harness

through the engine bay, away from any high heat sources and sharp objects, towards

the ECU. See Figure 9 below.

Wiring

EPM Harness

RED – EPM Power, Connect to 12 volts

BLACK – EPM Ground, connect to ground

GREEN – Crank Signal, connect to crank input on EMS/ECU

WHITE – Cam Signal, connect to cam input in EMS/ECU

DRAIN WIRE – Connect to power ground/drain in EMS/ECU

Page 7 10-2860 B Series COP Instructions RevB 111117

Page 8

B Series COP Harness

Figure 10. EPM Timing Pattern

RED (IGN) – Connect to switched, fused ( 15 A or greater) 12 volts

BLACK (GND) – Connect to ground

ORANGE (COIL 1) – Connect to Coil 1 Trigger in EMS/ECU

BLUE (COIL 2) – Connect to Coil 2 Trigger in EMS/ECU

PINK (COIL 3) – Connect to Coil 3 Trigger in EMS/ECU

GREY (COIL 4) – Connect to Coil 4 Trigger in EMS/ECU

EMS/ECU CONFIGURATION

Timing Patten

The EPM has a 24 and 1 timing pattern. There are 24 crank signals and one cam

signal for every engine cycle. Both output signals are 12 volt square waves. See

Figure 10 below.

EMS Wizard

The AEM EMS must be configured to accept the timing pattern from the EPM. In

AEMTuner, go to Wizards > Setup Wizard and select the AEM EPM. See Figure 11

below.

Page 8 10-2860 B Series COP Instructions RevB 111117

Page 9

Figure 11. Selecting the AEM EPM

Figure 12. Coil and Injector Tab Showing Coil Settings

Coil Firing

In order for the EMS to fire each coil individually, the coils must be activated and

configured correctly in AEM Tuner. Click on the Coils and Injectors tab labeled Coils/Inj

and activate Coils 1 – 4. See Figure 12 below.

Page 9 10-2860 B Series COP Instructions RevB 111117

Page 10

The Coil Phasing sets the firing order of the coils and must match the Injector phasing.

Voltage

Dwell Time (mS)

16

2.2

15

2.2

14

2.4

13

2.7

12

3.0

11

3.1

10

3.5

9

3.8

8

4.1

7

4.1

6

4.1

Table 1. Series 2 Coil Dwell Settings for Dwell vs Battery V Table

For the example shown above in Figure 12, Coil 1 and Injector 1 both have a value of

12. The corresponding values for Coils and Injectors 2-4 also match. See the

advanced calibration notes on phasing included with the EMS for more information on

Coil and Injector phasing.

NOTE: IT IS RECOMMENDED THAT TIMING BE CONFIRMED ON ALL CYLINDERS

BEFORE ATTEMPTING TO START THE ENGINE!

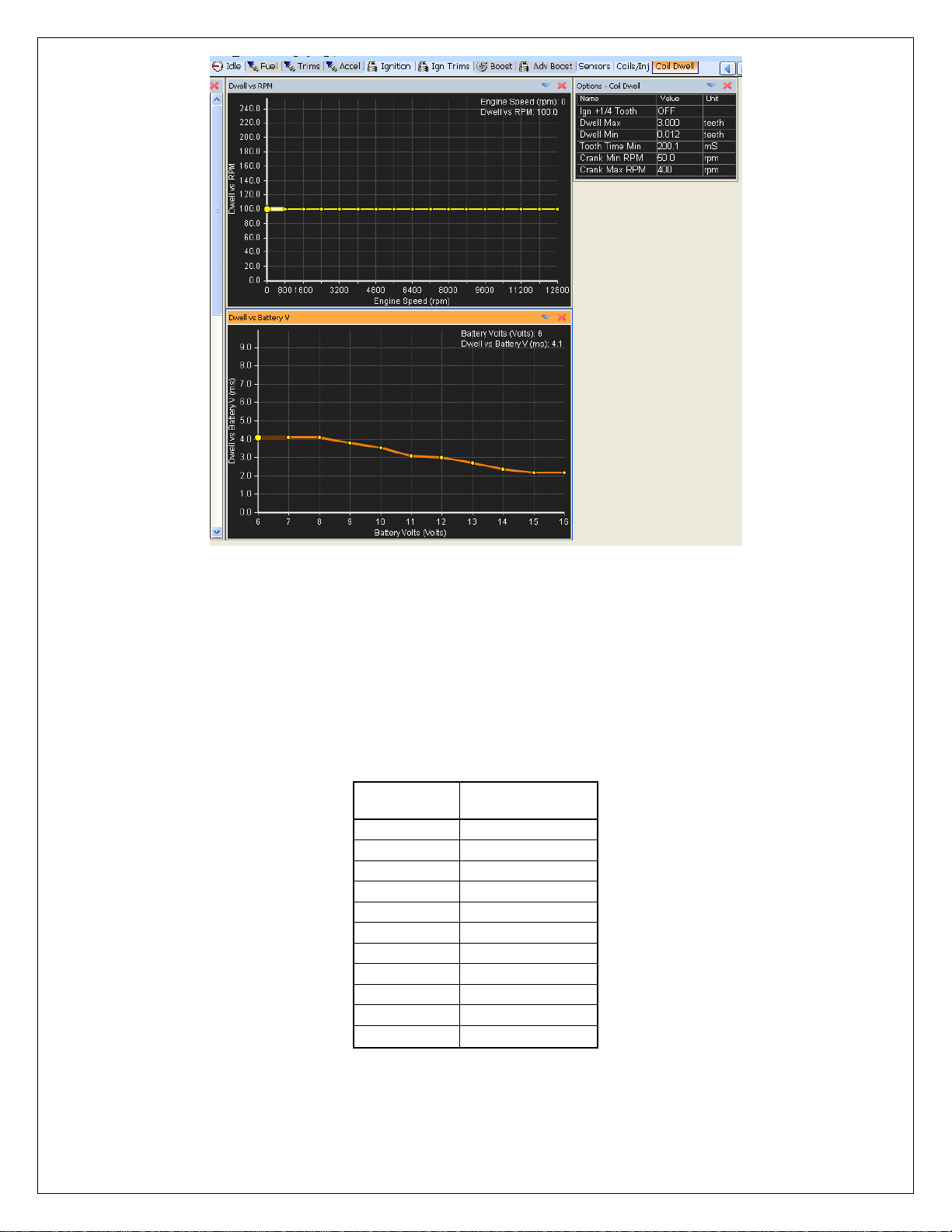

Series 2 EMS Coil Dwell

The coil dwell settings are listed below in Table 1. Dwell times in excess of those listed

in Table 1 will not improve spark performance and may cause the igniter and/or coil to

overheat. Click on the coil dwell tab labeled Coil Dwell in AEM Tuner and adjust the

tables as shown in Figure 13 below. The values in Tabl e 1 sh ould be entered in the

Dwell vs Battery table. The Dwell vs RPM table should remain at 100% for all engine

speeds.

Page 10 10-2860 B Series COP Instructions RevB 111117

Page 11

Voltage

Dwell vs Batt

Volts

16

37

15

37

14

40

13

45

11

52

10

60

9

65

8

70 7 70 6 70

Figure 13. Series 2 Coil Dwell Settings

Table 2. Series 1 Dwell vs Batt Volts Table Values

Series 1 EMS Coil Dwell

Open the coil dwell template in AEM Pro by clicking on the ignition drop down menu and

going to Ignition>advanced ignition>coil dwell setup>coil dwell. Enter the values shown

below in Table 2 into the Dwell vs Batt Volts Table. The Dwell vs RPM Table should

remain constant at a value of 100. Enter a value of 30 into the Coil Dwell Factor option.

See Figure 14 below.

12 50

Page 11 10-2860 B Series COP Instructions RevB 111117

Page 12

Figure 15. Falling Edge Trigger Signal

Figure 14. Series 1 Coil Dwell Settings

ECU Trigger

The Four Channel Coil Driver included in this kit requires a 5V logic level trigger signal

that is configured to fire the coil on its falling edge. See Figure 15 below.

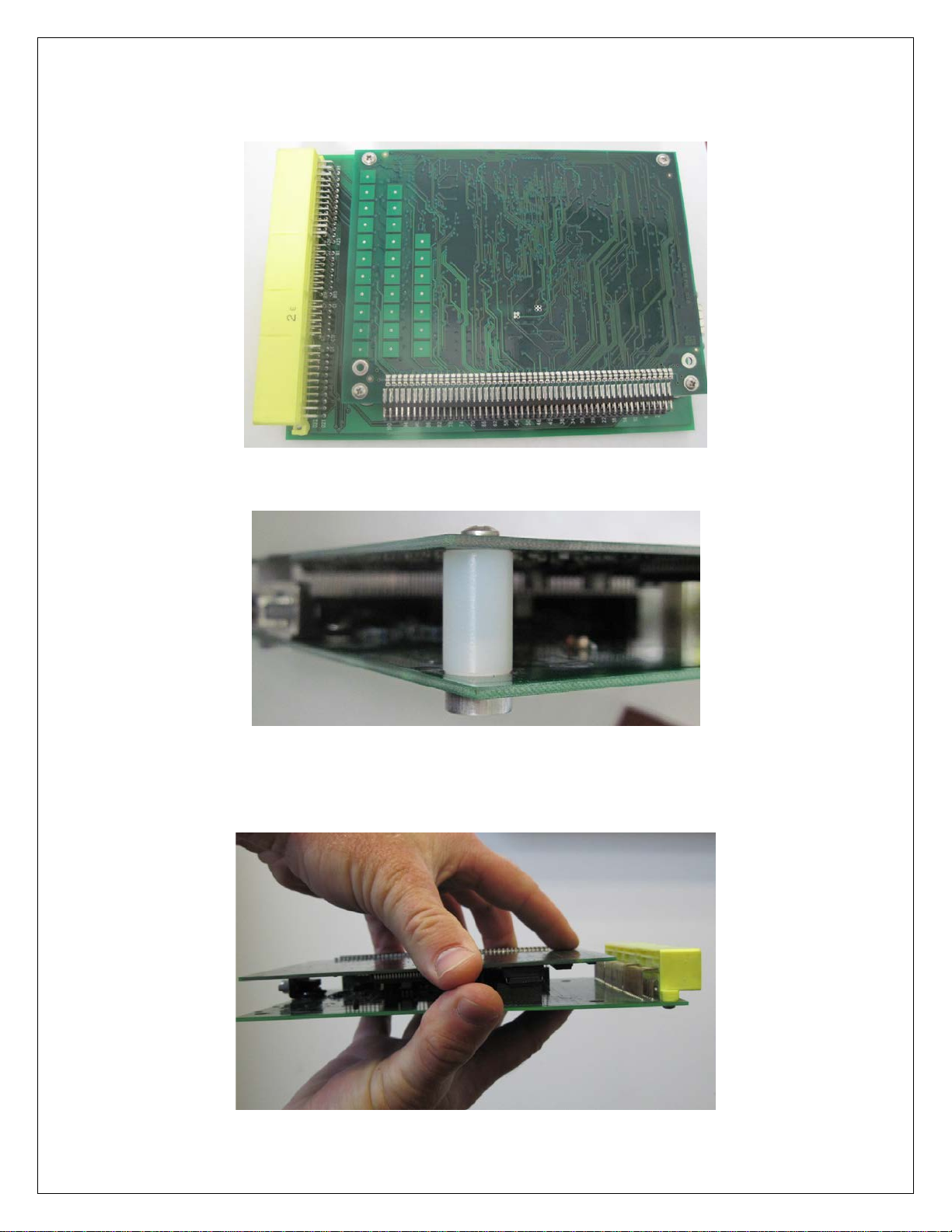

EMS Jumper Settings

The default factory jumper settings on the AEM EMS units will need to be changed in

order to work with the new signal requirements for the EPM and Igniter. The jumpers

are on the EMS circuit boards, making it necessary to remove the circuit boards from

the EMS enclosure. Remove the four screws from the front fac eplate of the EMS

enclosure and remov e the fac e pl ate . See Figure 16 below.

Page 12 10-2860 B Series COP Instructions RevB 111117

Page 13

Figure 16. Front View of EM S Showing Faceplate and Four Scr ews.

Figure 17. Bottom View of EMS Enclosure Showing Four Mounting Screws

Figure 18. Removing the Circuit Boards

Remove the four mounting screws on the bottom of the EMS enclosure. See Figure 17

below.

Slide the circuit boards out of the enclosure as shown below in Figure 18.

Page 13 10-2860 B Series COP Instructions RevB 111117

Page 14

Remove the four screws and spacers that hold the two circuit boards together. The

Figure 19. Top View of Circuit Boards Showing Four Mounting Screws

Figure 20. Circuit Board Screw, Spacer, and Nut

Figure 21. Holding Circuit Boards for Separation

screws are threaded into round nuts on the bottom of the boards. See Figures 19 and

20 below.

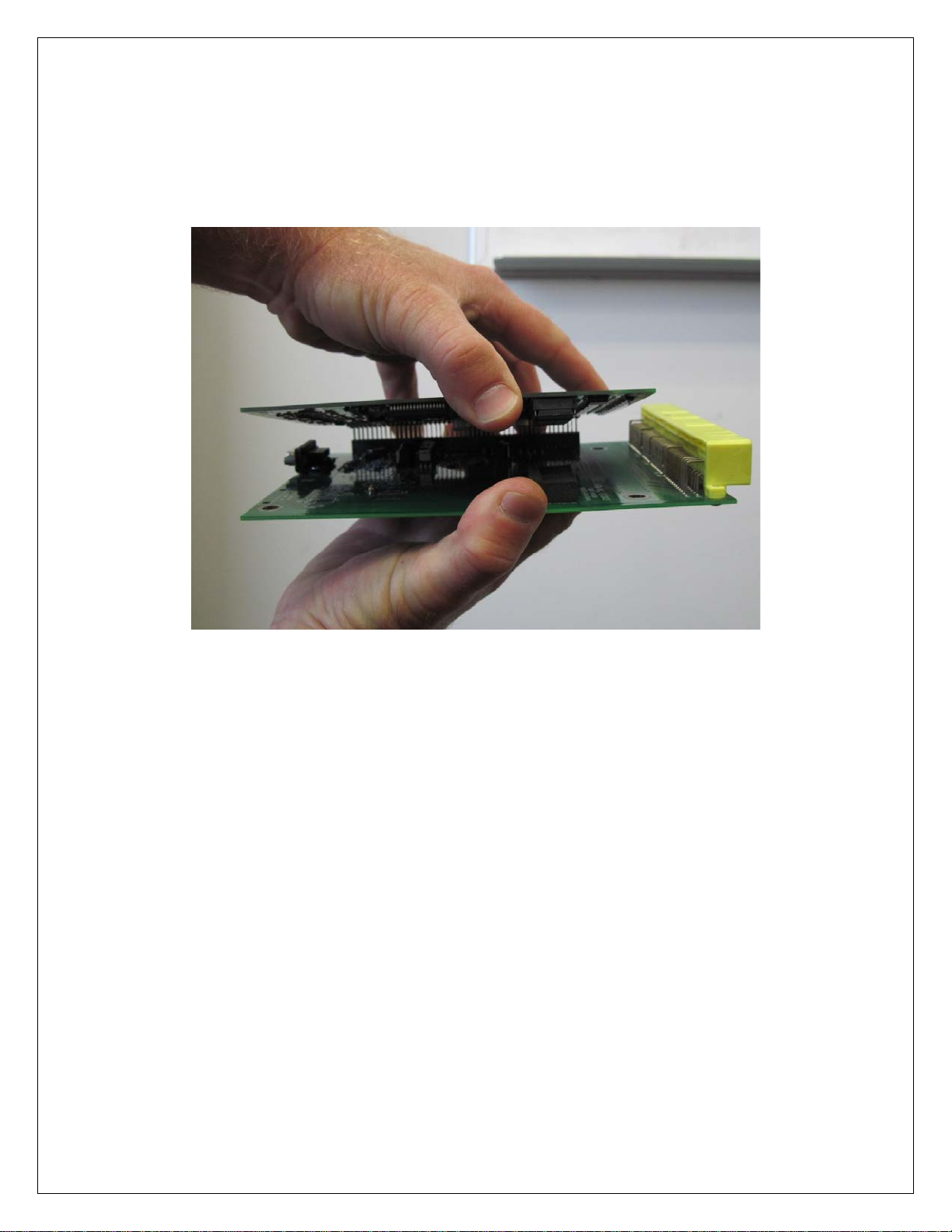

With the four screws and spacers removed, the circuit boards can be separated. Hold

the circuit boards as shown below in Figure 21.

Page 14 10-2860 B Series COP Instructions RevB 111117

Page 15

Figure 22. Separating the Circuit Boards

Separating the circuit boards requires some patience and caution. It works well to think

of the circuit board assembly as a hardcover book, with each circuit board being a

cover. Begin to separate the circuit boards, similar to opening a book. Close the circuit

boards and open again. This may take several tries. The connector between the circuit

boards will loosen up a little each time the circuit boards are opened and closed. See

Figure 22 below.

With the circuit boards separ at ed, locate the JPT and JPC jumpers. The JPT and JPC

jumpers each have three pins. A “jumper” is placed over two of the pins, connecting the

two pins together. The pins are numbered one, two and three. Pin one is designated

by a “1” on the circuit board. See Figures 23 and 24 below for examples of jumper

positions.

Page 15 10-2860 B Series COP Instructions RevB 111117

Page 16

Jumper

EMS 30-1040/30-6040

EMS 30-1050/30-6050

EMS 30-1060/30-6060

JPC1

1-2

1-2

1-2

JPC2

1-2

1-2

1-2

JPC3

1-2

1-2

1-2

JPC5

1-2

1-2

1-2

JPT1

1-2

1-2

1-2

JPT2

1-2

1-2

1-2

Table 3. EMS Jumper Position Settings

Figure 23. JPT1, 2, & 3 Jumpers Shown In 1-2

Figure 24. JPC jumpers Shown In 1-2 Position

position with JPT4 jumper shown in the

2-3 position for reference

Place the jumpers in the positions listed in Table 3. Only the jumpers listed below

should be moved for this installation.

JPC4 1-2 1-2 1-2

The EMS is ready to be reassembled after setting the jumpers. When reconnecting the

circuit boards, be sure all the pins are lined up correctly before fully inserting the

connector. With the pins correctly lined up, hold the EMS as shown below in Figure 25.

Page 16 10-2860 B Series COP Instructions RevB 111117

Page 17

Figure 26. Ignition Timing Sync Wizard

Figure 25. Reassembling the Circuit Boards

Once reassembled, install the EMS and reconnect the battery cables. Model specific

EMS instructions are included with each EMS kit and are available online in the

“Instructions and Manual” section of the AEM Performance Electronics Forum at

http://forum.aempower.com/forum/index.php?board=90.0. NOTE: THE STEPS

OUTLINED IN THE EMS INSTRUCTION MANUAL MUST BE FOLLOWED WHEN

INSTALLING THE EMS.

NOTE: IT IS RECOMMENDED THAT TIMING BE CONFIRMED ON EACH CYLINDER

BEFORE ATTEMPTING TO START THE ENGINE!

Syncing the EMS Timing

NOTE: THE EMS TIMING MUST BE SYNCED BEFORE TUNING

Start the engine and make whatever adjustments may be needed to sustain a safe and

reasonably smooth idle. Verify the ignition timing: Select Wizards>>Ignition Timing

Sync from the pull-down menu. Click the ‘Lock Ignition Timing’ checkbox and set the

timing to a safe and convenient value (for instance, 10 degrees BTDC), see Figure 26

below. Use a timing light and compare the physical timing numbers to the timing value

you selected. Use the Sync Adjustment Increase/Decrease buttons to make the

physical reading match the timing number you selected.

Page 17 10-2860 B Series COP Instructions RevB 111117

Page 18

EMS Pin Locations

PIN

EMS 30-6040

EMS 30-6050

EMS 30-6060

Harness

Harness

Coil 1

A21

C4

A20

NA

Orange

Coil 2

B6

C12

B7

NA

Blue

Coil 3

B3

C13

B9

NA

Pink

Coil 4

B4

C14

B10

NA

Grey

Cam

B11

C29

C4

White

NA

Pwr Gnd

A23 A24 A26 B2

B2 B10 B20 B22

A9 A10 A22 A23

Drain

NA

SW +12

A25 B1 C1

A21 B9

A11 A24 C6

Red

NA

Snsr Gnd

D21 D22

A7 A31 C7 C18 D9

D11 D12 D13

Black

NA

PIN

EMS 30-1040

EMS 30-1050

EMS 30-1060

EPM

Harness

COP Harness

Coil 2

B6

C12

B7

NA

Blue

Coil 3

B3

C13

B9

NA

Pink

Coil 5

B4

A1

B19

NA

Grey

Cam

B11

C29

C4

White

NA

Crank

B15

C8

C2

Green

NA

SW +12

A25 B1 C1

A21 B1 B9

A11 A24 C6

Red

NA

Snsr Gnd

A26 B2 D21 D22

A7 A31 C7 C18 D9

D11 D12 D13

Black

NA

Table 4. Series 2 EM S Pin Locations

Table 5. Series 1 EMS Pin Locations

Relevant pin locations for the 30-6040, 30-6050, and 30-6060 Series 2 EMS units are

shown below in Table 4.

EPM

Crank B15 C8 C2 Green NA

COP

Relevant pin locations for the 30-1040, 30-1050, and 30-1060 Series 1 EMS units are

shown below in Table 5. Take notice that the Series 1 EMS units use the #5 coil driver

on cylinder 4. The Series 2 EMS units use the #4 coil driver on cylinder 4.

Coil 1 A21 B13 A20 NA Orange

Pwr Gnd A23 A24 B2 B10 B20 B22 A9 A10 A22 A23 Drain NA

Page 18 10-2860 B Series COP Instructions RevB 111117

Page 19

CONNECTOR PINOUTS

Pin

Coil 1

Coil 2

Coil 3

Coil 4

1 +12V

Red

Red

Red

Red

2 Trigger

Orange

Blue

Pink

Grey

Pin

Description

Color

1

Coil 1 Negative

2

Coil 2 Negative

Blue

3

Coil 3 Negative

Pink

4

Coil 4 Negative

Grey

Pin

Description

Color

1

Coil 4 Trigger

Grey

2

Coil 3 Trigger

Pink

3

Ground

Black

4

Coil 2 Trigger

Blue

5

Coil 1 Trigger

Orange

Figure 27. Coil Connector Shown Looking at Pins

Figure 28. 4-Pin Igniter Connector Shown Looking at Pins

Figure 29. 5-Pin Igniter Connector Shown Looking at Pins

Pinouts for the EPM and B Series COP harness connectors are shown below.

Coil Connector

4-Pin Igniter Connector

Orange

5-Pin Igniter Connector

Page 19 10-2860 B Series COP Instructions RevB 111117

Page 20

PIN

EMS 30-6040

EMS 30-6050

EMS 30-6060

Tacho Output (LS 7)

C3

A19

C26

Power Source

A25 B1 C1

B1 B9

A11

Name

Value

Tacho Freq In

None

Tacho Freq Out

None

Tacho M

0

Tacho Output

LS7

Pin

Description

Wire Color

1

Crank

Green

2

Ground

Black

3

Cam

White

4

Power

Red

Figure 30. EPM Connector Shown Looking at Pins

Table 7. AEMTuner Tacho

Figure 30. AEMTuner Tacho Table settings

EPM Connector

FACTORY TACHOMETER Setup

Normally the distributor provides the input signal for the tachometer, but with the Honda

COP kit installed your car will no longer be using a distributor. The tachometers signal

wire is now left connected to nothing. There is however a simple fix for this provided by

the Series 2 EMS. The Series 2 EMS provides a signal output for the tachometer.

Connect the signal input from your tachometer to the appropriate pin for the EMS you

are using. Pin locations for the 30-6040, 30-6050, and 30-6060 Series 2 EMS units are

shown below in Table 6. The ground and power wires of your tachometer will still

remain connected as they were before.

Table 6. Series 2 EMS Pin Locations

Ensure that the tacho signal that will be generated by your EMS is set up correctly.

Open the calibration you are using in AEMTuner and view the “Tacho-Speedo” tab.

Make sure the “Tacho Options” table matches the settings shown below in Table 7 and

that the Tacho table looks like Figure 30 below.

Options settings

Page 20 10-2860 B Series COP Instructions RevB 111117

Page 21

SPECIFICATIONS

30-2860 B Series COP

Ignition Type

Inductive with Igniter

Ignition Channels

4

Timing Pattern

24 Crank, 1 Cam

Timing Pattern Signal

12 volt square wave

Ignition Trigger Signal

5 volt logic level falling edge trigger

Boost Level

Up to 15 psi

Max Dwell Time

See Table 1

Operating Voltage (nominal)

12 volts dc

RECOMMENDED PARTS

30-51XX Analog Style Gauges

30-44XX Digital Style Gauges

30-2340 4 Channel UEGO Controller

30-4100 Digital Gauge Style UEGO Con troller

30-5130 Analog Gauge Style UEGO Controller

30-2310 Inline UEGO Controller

30-2500 AQ1 Data Logger

30-2821 4 Channel Twin Fire CDI (Optional upgr ad e for higher boost levels abov e

15 psi, some wiring required)

REPLACEMENT PARTS

30-2840 4 Channel Igniter

30-3255 Honda EPM

30-2850 Coil

35-3860 B Series COP Harness

35-3861 EPM Harness

If further tuning help is needed be sure to visit the video gallery or performance

electronics forum at www.aemelectronics.com for comprehensive instructional videos

and information.

Page 21 10-2860 B Series COP Instructions RevB 111117

Page 22

WARRANTY

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to t he consumer that all A EM High Performance products will be free from defects in

material and workmanship for a period of twelve (12) m onths from date of the original purchas e. Products that fail within this 12month warranty period will be repaired or replaced at A EM’s option, when determ i ned by AEM that the product f ailed due t o def ects

in material or workmanship. This warranty is limited to the repair or replacem ent of the AEM part. In no event shall thi s warranty

exceed the original purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential damages

or cost incurred due to the failure of this product. Warrant y claims to AEM must be transportation prepaid and accompanied with

dated proof of purchase. This warranty applies only to the original purchaser of product and is non-transferable. All implied

warranties shall be limited in duration to the said 12 month warranty period. Improper use or installation, accident, abuse,

unauthorized repairs or alterations voids this warranty. AEM disclaims any liability for consequential damages due to breach of any

written or implied warranty on all products manufactured by AEM. Warranty returns will only be accepted by AEM when

accompanied by a valid Return Goods Authorization (RGA) number. P roduct must be received by AEM within 30 days of the date

the RGA is issued.

Please note that before AEM c an issue an RGA f or any product , it is first necessary for the installer or end user to contact the AEM

Performance Electronics tech line at 1-800-423-0046 to discuss t he problem. Most issues can be resolved over the phone. Under

no circumstances should a system be returned or a RGA requested before the above process transpires.

Need additional help? Contact the AEM Performance Electronics tech department at

1-800-423-0046 or tech@aempower.com, or visit the AEM Performance Electronics

forum at http://forum.aempower.com/forum/

Page 22 10-2860 B Series COP Instructions RevB 111117

Loading...

Loading...