Page 1

WARNING:

This installation is not for the

electronic novice

or the PC

AEM Performance Electronics

UEGO CONTROLLER

Instruction Manual

P/N 30-2340 4-CH WIDEBAND

!

illiterate! Use this system with EXTREME caution! If you are not

well versed in electronics and vehicle instrumentation or are not

PC literate, please do not attempt the installation. Refer the

installation to an AEM trained tuning shop. A list of AEM

trained tuning shops is available at

http://www.aemelectronics.com/dealer_locator.php or by calling

800-423-0046. You should also visit the AEM Tech Forum at

http://www.aemelectronics.com

NOTE: AEM holds no responsibility for any engine damage that

results from the misuse of this product!

2205 126th Street Unit A, Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number: 10-2340 Rev 05

2012 AEM Performance Electronics

Page 2

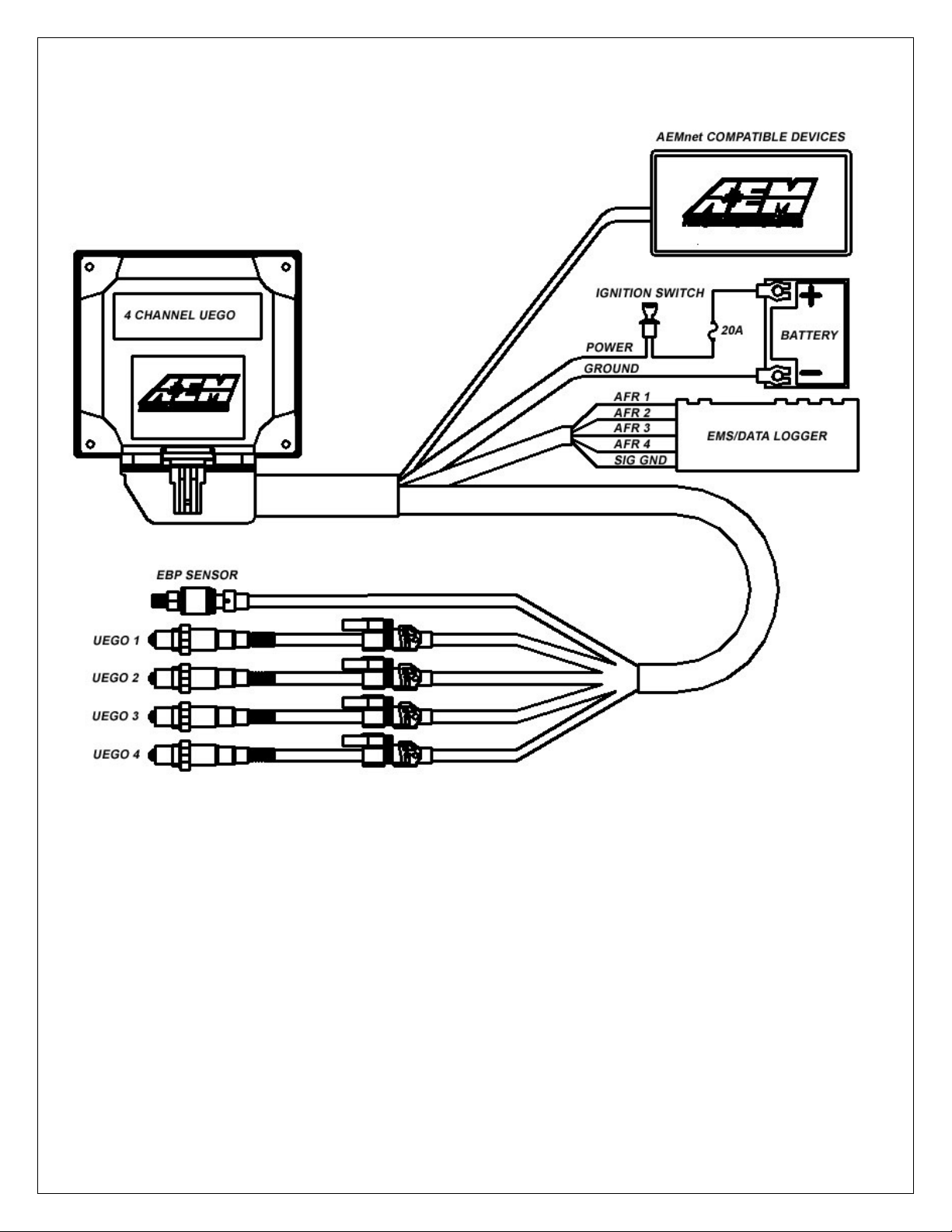

FIGURE 1. Wiring Diagram

Page 2 10-2340 Rev 05 121012

Page 3

KIT CONTENTS

1 x 35-2340 4 CH UEGO Module

1 x 35-2908 Wiring Harness

1 x 35-4008 UEGO Stainless Steel Bung

1 x 30-2001 UEGO Sensor

4 x 1-2059 6-32 Stainless Steel Hex Nut

4 x 1-2047 6-32 x 1 ¼ screw

1 x 10-2340 Installation Instructions

INSTALLATION TIPS

1. Read through the entire manual and instructions before beginning the

installation.

2. Disconnect the negative battery cable(s) before beginning any work.

3. Maintain a clean and neat work area through out the installation.

4. When raising or working under a vehicle, use properly rated stands/jacks.

5. Make sure all connectors are fully seated and inserted.

6. Make sure all components and cables are routed and installed away from any

direct heat sources or sharp objects.

TABLE OF CONTENTS

• Sensor Mounting…………………………………………..4

• Controller Mounting…………………………………….....4

• Power Connections…………………………………….....5

• AEMnet Connections…………………………....………...6

o AEMnet products………………………………..…6

o Series 2 EMS……………………………………....7

o Non AEM Products………………………………...8

• Cylinder Numbering and Mode Selection…………….....9

• Analog Outputs…………………………………………...11

o EMS………………………………………………...12

• Exhaust Back Pressure Compensation………………..14

• Indicator Lights……………………………………………14

• Series 2 EMS AEM Tuner Configuration………………15

• UEGO Connector Pinout………………………………...17

• Specifications……………………………………………..18

• Notes……………………………………………………….18

• Replacement/Optional Parts…………………………….18

• AEMnet message Structure……………………………..18

• Appendix A………………………………………………..19

• Warranty …………………………………………………..30

Page 3 10-2340 Rev 05 121012

Page 4

Sensor Mounting

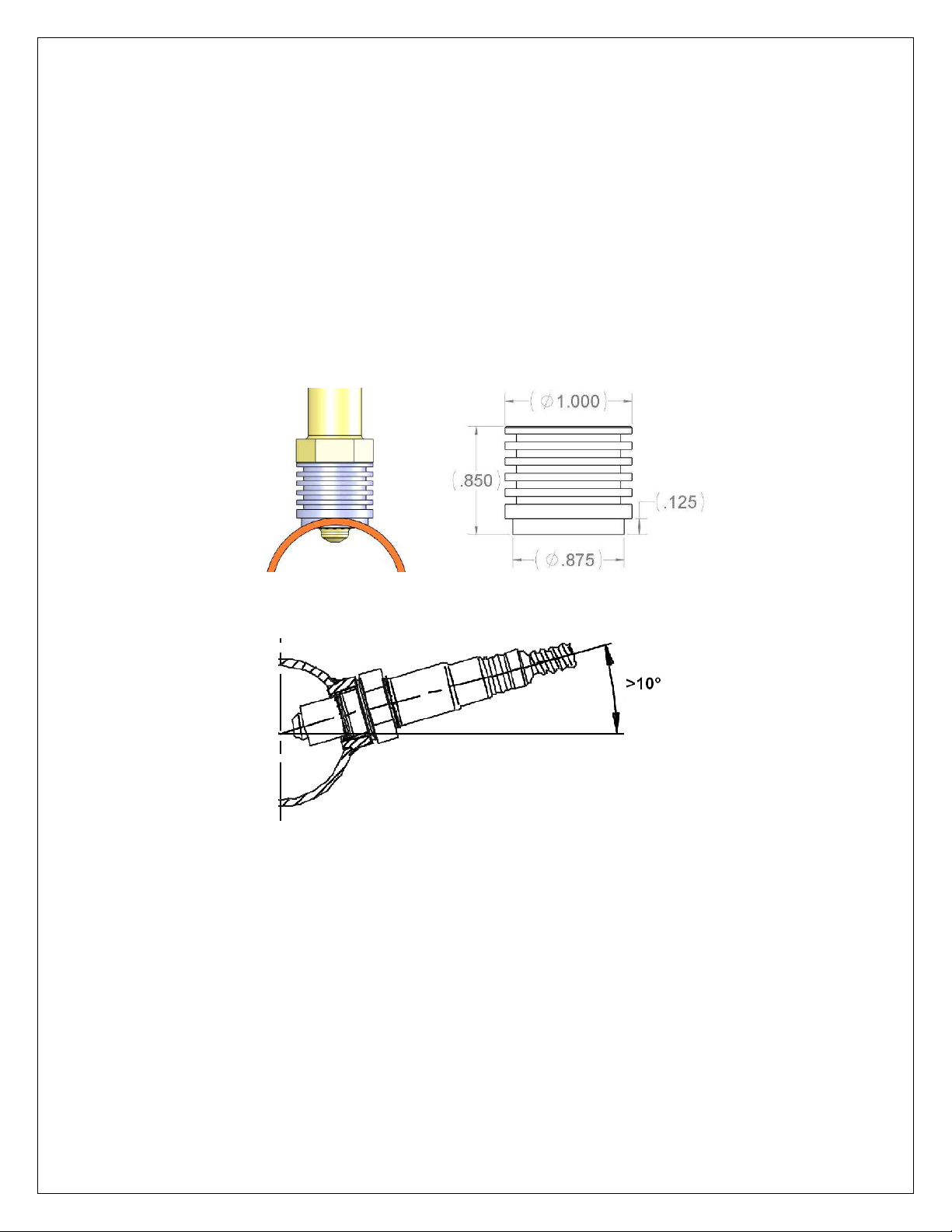

FIGURE

2. Sensor Bung and Sensor Mounting

A high flow stainless steel weld-in sensor bung is supplied for sensor installation

(additional sensors & bungs are available 30-2063). The bung is specifically designed

so the sensor can provide accurate AFR readings with minimal flow intrusion and

survive extreme exhaust gas temperatures. Pick a mounting location(s) that allows for

easy access to the sensor(s). The sensor tip must be exposed to exhaust gas in order

to give accurate AFR readings. For thin wall tubing, drill a 15/16” hole and weld in the

bung. For thick wall tubing/ castings, drill a 1 1/16” hole and weld in the bung. The

sensor must be mounted at an angle of at least 10 degrees from horizontal in order to

prevent liquids from collecting in the sensor housing. See Figure 2 below. NOTE:

THE OPTIONAL AEM EBP (EXHAUST BACK PRESSURE) KIT (PART # 30-2064)

MUST BE USED IF SENSORS ARE MOUNTED PRE-TURBO.

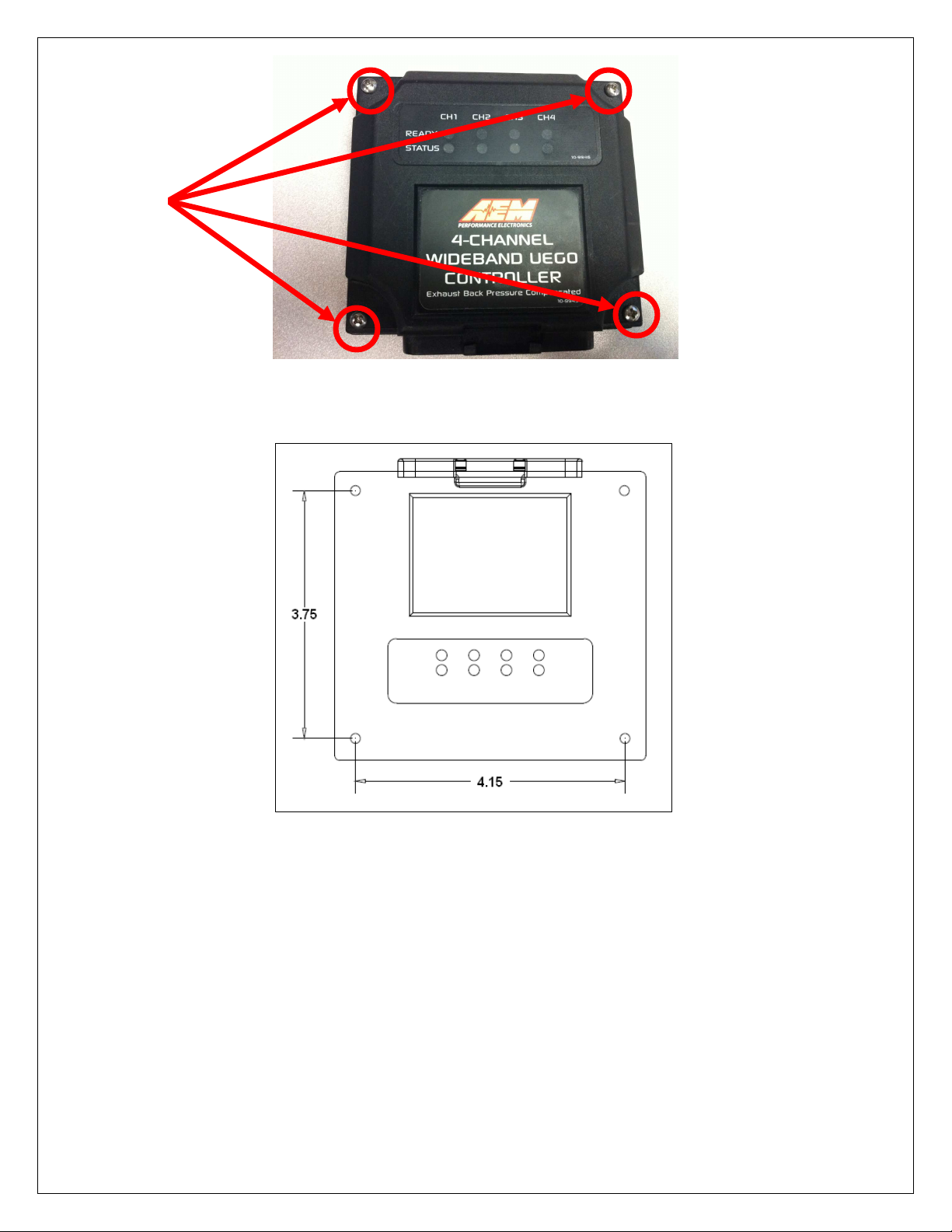

Controller Mounting

Mount the controller using the supplied 6-32 x 1 ¼ stainless steel screws and nuts. See

Figure 3 and Figure 4 for mounting holes and footprint size.

Page 4 10-2340 Rev 05 121012

Page 5

Mounting

Screws

FIGURE 3. Mounting Holes

FIGURE 4. Dimensions

POWER CONNECTIONS

RED – Connect to a switched, fused (20A) 12-volt power source that is on only

when the engine is running.

BLACK – Connect to a clean power ground.

Page 5 10-2340 Rev 05 121012

Page 6

AEMnet CONNECTIONS

AEMnet

AEMnet is an open architecture software and hardware interface based on the CAN 2.0

specification, which provides the ability for multiple enabled devices to easily

communicate with each other through a single cable. The hardware connection is made

through a Deutsch 4P DTM connector and contains 12 volt switched power and ground

(2A max) as well as the CAN data lines. Devices connected to the AEMnet transmit

data through this one connection and most of these devices receive power from this

same connection as well.

Connection via AEMnet/CAN is recommended as it is the easiest connection (only

needs one connection) and it eliminates the possibility of any analog voltage

losses/offsets commonly associated with analog inputs/outputs.

AEMnet PRODUCTS

The following AEM products are currently AEMnet enabled:

Series 2 Engine Management System

EMS-4 Universal Standalone Engine Management System

4-Channel Wideband UEGO Controller

AQ-1 Data Logger

Wideband Failsafe

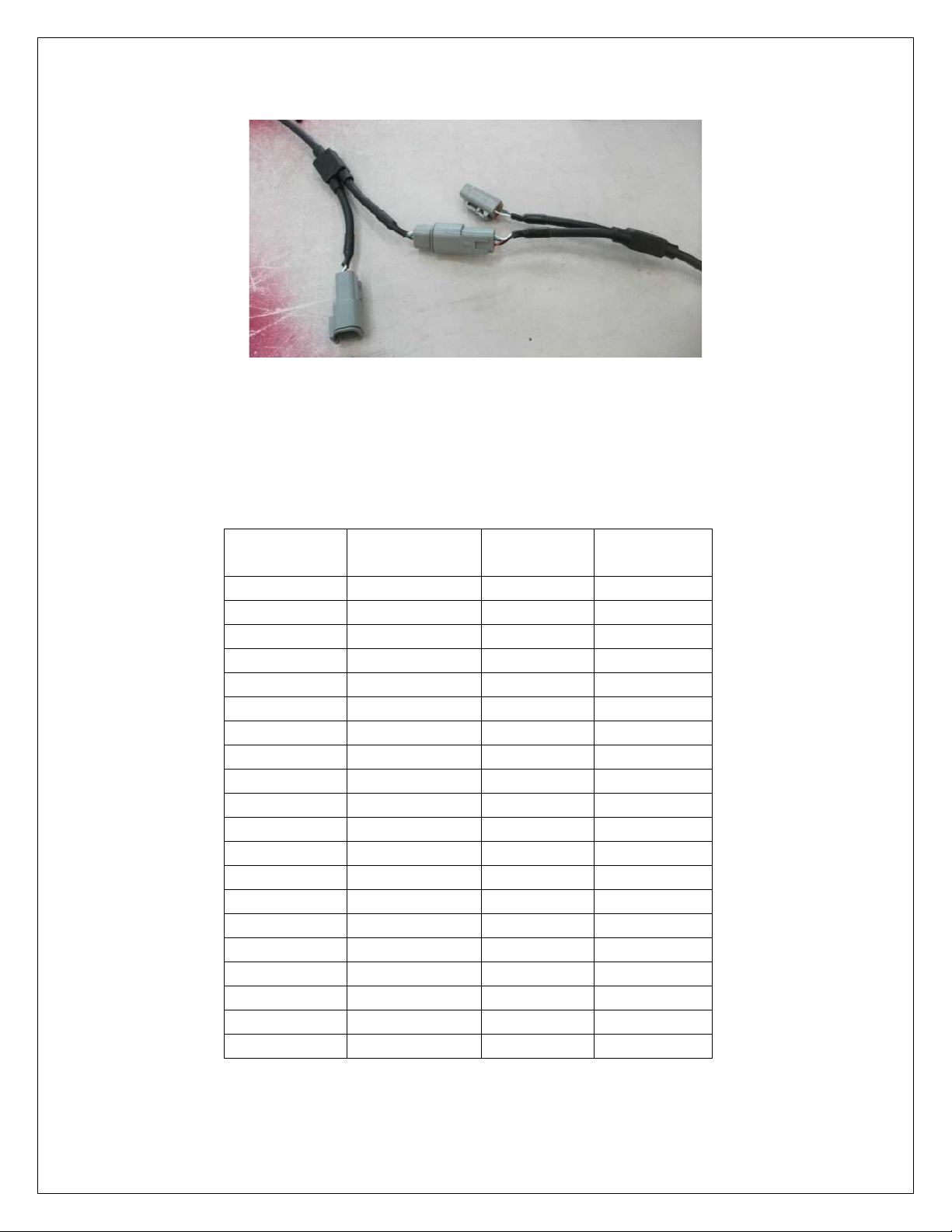

Each 4 CH UEGO controller wiring harness has 2 connectors for accessing the AEMnet

(Refer to figure 5), one for accessing the network and the other for an expansion to

other devices.

FIGURE 5. AEMnet Connector

Page 6 10-2340 Rev 05 121012

Page 7

To join the AEM network, connect the Deutsch male connector to the female connector

of another AEM devices in the network (Figure 6).

FIGURE 6. AEMnet Cable Connection

SERIES 2 EMS

When connecting to a Series 2 EMS, an AEMnet branch will have to be added to the

factory harness. AEM has several AEMnet to Series 2 EMS adapters available. See

Table 1 below for a list of the part numbers and corresponding Series 2 EMS units.

AEM Series 2 AEMnet CAN1L CAN1H

EMS Adapter P/N Pin Location Pin Location

30-6030 30-3430 C22 C21

30-6040 30-3431 A22 C2

30-6050 30-3432 D14 D10

30-6051 30-3432 D14 D10

30-6052 30-3432 D14 D10

30-6053 30-3432 D14 D10

30-6060 30-3432 C28 C29

30-6100 30-3433 11A 12A

30-6101 30-3433 11A 12A

30-6300 30-3434 75 13

30-6310 30-3431 77 87

30-6311 30-3431 57/77 67/87

30-6320 30-3435 33 13

30-6600 30-3436 42 12

30-6601 30-3436 42 12

30-6610 30-3437 12 69

30-6611 30-3437 12 69

30-6620 30-3437 57 40

30-6820 30-3438 B29 B28

30-6821 30-3438 B29 B28

TABLE 1. EMS Adapter P/N & Pin Locations

Page 7 10-2340 Rev 05 121012

Page 8

NOTE: THE SERIES 2 EMS DOES NOT USE INFORMATION TRANSMITTED ON

AEMnet FOR 02 FEEDBACK. THE SERIES 2 EMS USES THE ANALOG INPUTS

FOR 02 FEEDBACK. SEE THE SECTION ON ANALOG INPUTS FOR INFORMATION

ON CONNECTING THE ANALOG INPUTS.

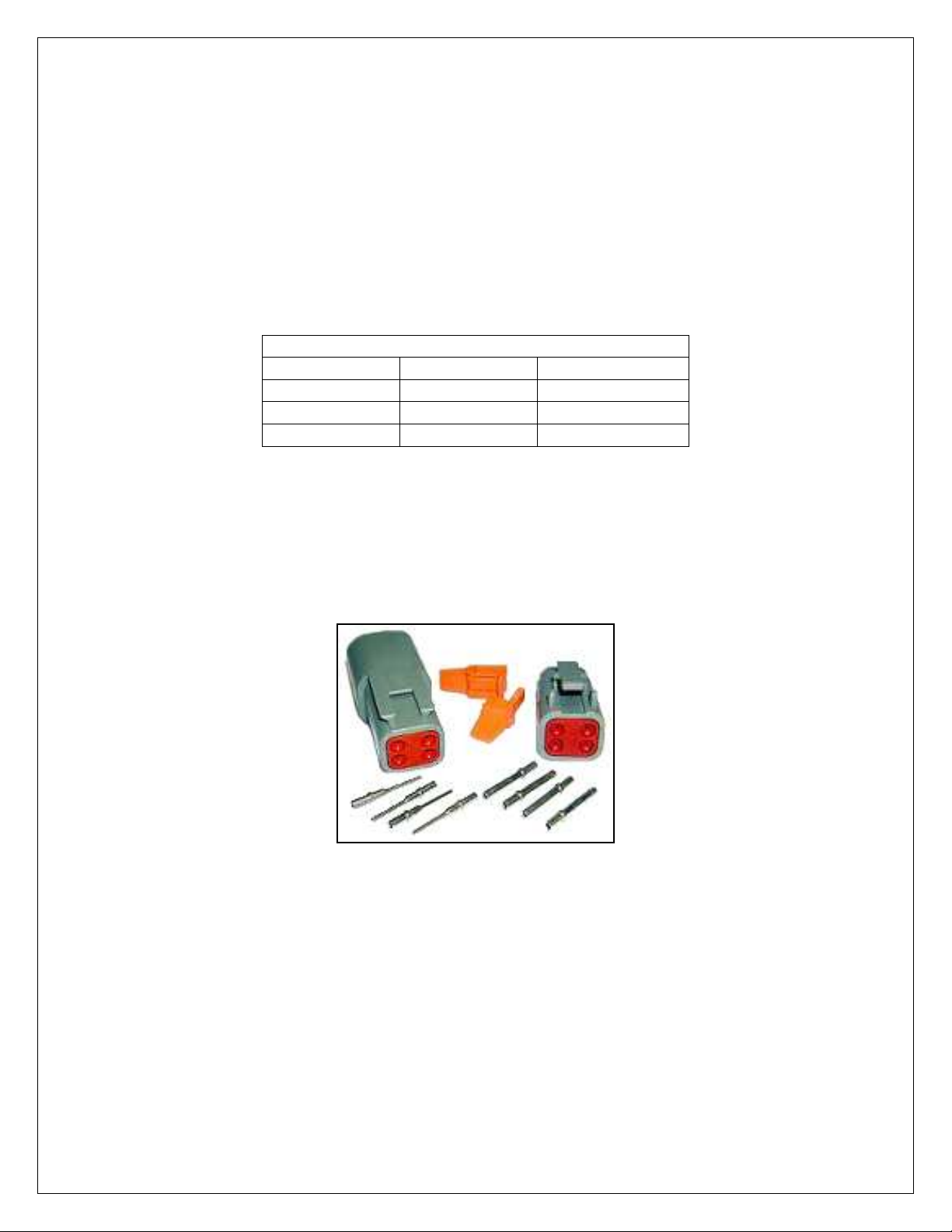

NON-AEM PRODUCTS

Each AEMnet connector has 4 pins. The AEMnet pinout is listed below in Table 2.

NOTE: Pin numbers are located at the back of the connector. Non-AEM devices can

connect to the AEMnet by connecting their CAN +/- wires to the CAN+/- wires on the

AEM network. The connectors are shown in Figure 7.

AEMnet Connector

Pin 1 White CAN +

Pin 2 Green CAN Pin 3 Red 12 Volts

Pin 4 Black Ground

Table 2. AEMnet Pinout

• Deutsch DTM04-4P (Receptacle connector)

• Deutsch 1060-20-0222 (Pins)

• Deutsch DTM06-4S (Plug connector)

• Deutsch 1062-20-0222 (Pins)

Figure 7. Connector Assembly

NOTE: the 4 CH UEGO controller has one terminating resistor. If an additional

terminating resistor is needed, one must be installed on the other device.

Page 8 10-2340 Rev 05 121012

Page 9

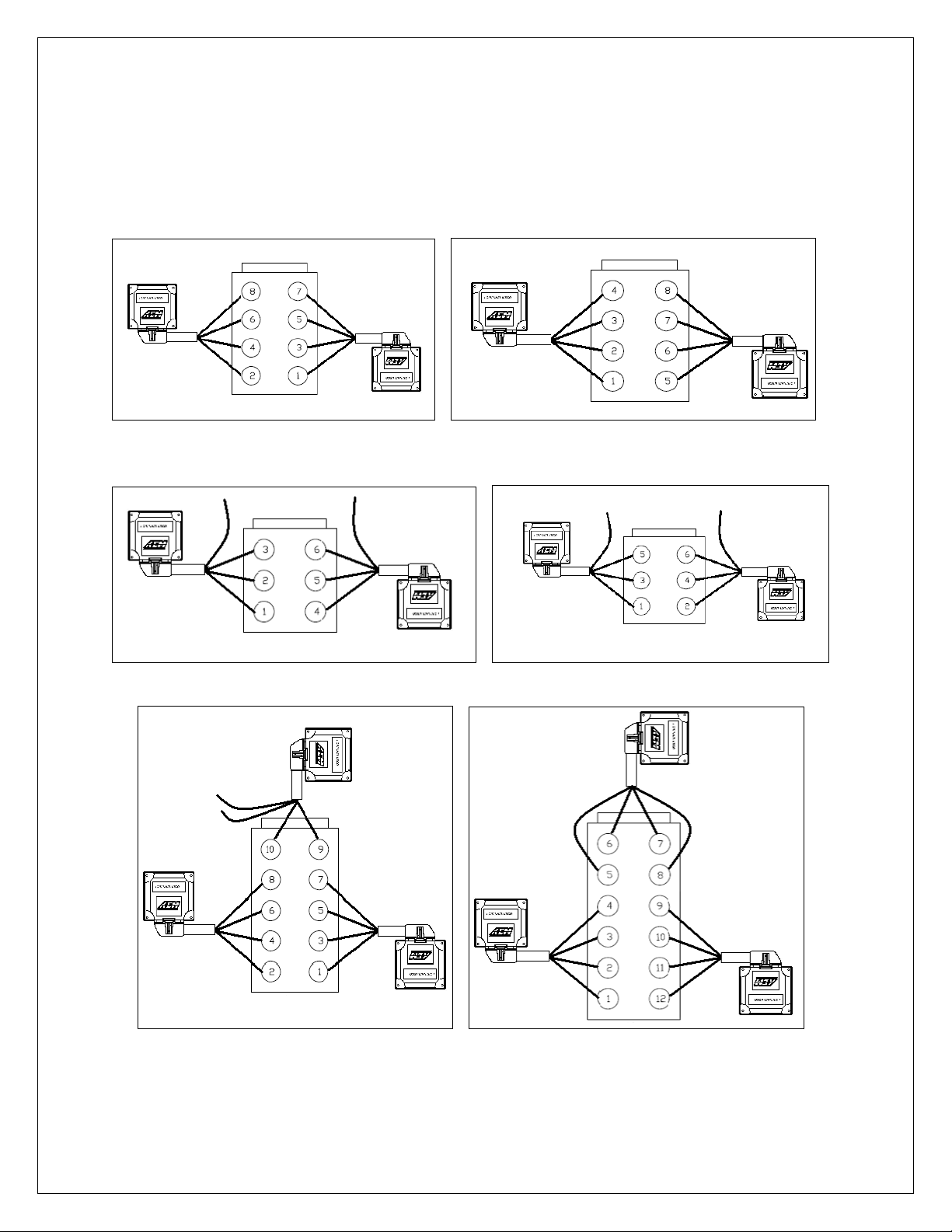

CYLINDER NUMBERING AND MODE SELECTION

MODE

3

MODE 4

MODE 2

MODE 4

MODE

3

MODE

5

MODE 1

MODE 1

MODE

5

MODE 2

MODE

3

MODE 4

MODE 7

MODE 6

There are 7 different cylinder numbering combinations available on AEMnet. The

different combinations allow for easy installation and data analysis, and allow users to

connect up to three 4 Channel UEGO modules on AEMnet. See Table 3 and the

figures below for recommended connections on some of the more common engine

configurations.

CHEVROLET/ DODGE/ TOYOTA FORD

HONDA / ACURA NISSAN / TOYOTA

VIPER V12

Page 9 10-2340 Rev 05 121012

Page 10

MODE 1

MODE

7

MODE 6

4 CYLINDER 6 CYLINDER

FIGURE 8. 4 CH UEGO Controller Cylinder Numbering and Configuration Mode

MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7

UEGO 1 Cylinder1 Cylinder 5 Cylinder 1 Cylinder 2 Cylinder 9 Cylinder 1 Cylinder 4

UEGO 2 Cylinder 2 Cylinder 6 Cylinder 3 Cylinder 4 Cylinder 10 Cylinder 2 Cylinder 5

UEGO 3 Cylinder 3 Cylinder 7 Cylinder 5 Cylinder 6 Cylinder 11 Cylinder 3 Cylinder 6

UEGO 4 Cylinder 4 Cylinder 8 Cylinder 7 Cylinder 8 Cylinder 12

--- ---

TABLE 3. UEGO Sensor Cylinder Numbering

For example, Chevrolet big block engines require two 4 CH UEGO controllers. The first

unit connects to cylinders 2, 4, 6 and 8 using MODE 4 (see Table 2). UEGO 1 connects

to cylinder 2, UEGO 2 to cylinder 4, UEGO 3 to cylinder 6, and UEGO 4 to cylinder 8.

The second unit connects to cylinders 1, 3, 5 and 7 using MODE 3. UEGO 1 connects

to cylinder 1, UEGO 2 to cylinder 3, and so on.

Honda / Acura V6 engines also require two 4 CH UEGO controllers. As shown in

Figure 8, Mode 6 and 7 from Table 2 are used. UEGO 1, 2, and 3 of the first 4 CH

UEGO controller connects to cylinders 1, 2 and 3. UEGO 1, 2, 3 of the second unit go

to cylinder 4, 5 and 6. Unused channels can be left unconnected.

Cylinder Numbering Configuration Mode

NOTE: Only applicable when using AEMnet.

Configuration mode is selected during the power up sequence. By factory default the 4

CH UEGO controller is in MODE 1. There are three wires, CONFIG 1 (pink), CONFIG 2

(purple) and GROUND (yellow) under the sleeve on the wiring harness (Figure 9). To

change the mode, first make sure the 4 CH UEGO controller is powered off. Connect

CONFIG 1 to GROUND and power the 4 CH UEGO controller on. Tap CONFIG 2 to

the GROUND wire. The 4 Channel UEGO controller will jump to the next mode every

time the CONFIG 2 wire is tapped to the GROUND wire. The LEDs will illuminate to

Page 10 10-2340 Rev 05 121012

Page 11

show the selected mode. The number of Status/Error LED’s illuminated corresponds to

the mode selected. When a desired mode is selected, disconnect both CONFIG wires

from the GROUND wire. The mode will be saved in the controller and the LEDs of the

corresponding mode will blink three times. When more than one 4 CH UEGO

controller is connected to the net, the controllers must be in different modes.

Make sure that each controller is set into the correct mode. Upon powering up, the

number of LEDs corresponding to the mode will blink three times to indicate the mode.

For example, if in mode 7, 7 LED’s will blink 3 times.

FIGURE 9. Mode Configuration Wires

ANALOG OUTPUT

The analog output from the 4 CH UEGO controller is a linear dc voltage signal that

varies from 0.5 Vdc at 8.5:1 AFR Gasoline (0.58 Lambda) to 4.5Vdc at 18.0:1 AFR

Gasoline (1.22 Lambda). The signal is used for sending information to a data logger or

an engine management system such as the AEM EMS or F/IC. The transfer function

for the output is listed below.

AFR Gasoline = 2.375(V) + 7.3125

For example, if the output is 2.0 Vdc, the AFR is 12.06:1

2.375 * 2.0 + 7.3125 = 12.06

A table showing the analog output voltage and corresponding Air/Fuel ratios for some of

the common fuels is shown below in Table 3

.

AFR

VOLTS LAMBDA AFR GAS

0.50 0.58 8.5 3.7 5.6 5.2

0.71 0.61 9.0 3.9 5.9 5.5

0.92 0.65 9.5 4.1 6.3 5.8

1.13 0.68 10.0 4.4 6.6 6.1

METHANOL AFR E85

Page 11 10-2340 Rev 05 121012

AFR

ETHANOL

Page 12

1.34 0.71 10.5 4.6 6.9 6.4

1.55 0.75 11.0 4.8 7.3 6.7

1.76 0.78 11.5 5.0 7.6 7.0

1.97 0.82 12.0 5.2 7.9 7.3

2.18 0.85 12.5 5.4 8.2 7.7

2.39 0.88 13.0 5.7 8.6 8.0

2.61 0.92 13.5 5.9 8.9 8.3

2.82 0.95 14.0 6.1 9.2 8.6

3.03 0.99 14.5 6.3 9.6 8.9

3.11 1.00 14.7 6.4 9.7 9.0

3.24 1.02 15.0 6.5 9.9 9.2

3.45 1.05 15.5 6.7 10.2 9.5

3.66 1.09 16.0 7.0 10.6 9.8

3.87 1.12 16.5 7.2 10.9 10.1

4.08 1.16 17.0 7.4 11.2 10.4

4.29 1.19 17.5 7.6 11.5 10.7

4.50 1.22 18.0 7.8 11.9 11.0

TABLE 3. AFR Values

Outputs

The harness for the 4 Channel UEGO controller contains a bundle of 5 output wires.

The four white wires are labeled AFR 1, AFR 2, AFR 3, and AFR 4. The black wire is

labeled SIG GND. Connect the wires as listed below.

WHITE – Connect to Lambda + Input.

BLACK – Connect to sensor ground. Connect to power ground if sensor ground is not

available.

EMS Setup

Connect two WHITE AFR output + wires to O2 #1 and O2 #2 EMS analog input pins.

Connect the BLACK Analog Output – wire to the EMS sensor ground.

NOTE: The current version of EMS has only two input pins dedicated to O2 analog

inputs. To view the analog outputs from all four channels use spare analog inputs, i.e.,

EGT1 ~ 4.

Tuner Setup (Must use 01v22 firmware or newer)

With an EMS calibration open in the AEMTuner software, go to Wizards -> Setup

Wizard and choose Sensor: 02 #1 (AFR) and Sensor 02 #2 (AFR). Under Configuration

Name, choose AEM (4-Channel UEGO PN 30-2340) and click Apply. When the

configuration is set, as shown in figure 10, close the wizard.

Page 12 10-2340 Rev 05 121012

Page 13

FIGURE 10. Series 2 EMS / EMS – 4 Setup Wizard

Viewing Live Data

Open a new Channels Display in AEMTuner and add O2 #1 and O2 #2 channels. The

Channel Display, as shown in figure 11, will show the values in air-to-fuel ratio.

FIGURE 11. O2 #1 and O2 #2

When using spare analog inputs, the values will show in Volts. Use the following

equation to convert to air-to fuel ratio.

AFR Gasoline = 2.375 x voltage + 7.3125

Page 13 10-2340 Rev 05 121012

Page 14

EXHAUST BACK PRESSURE COMPENSATION

(OPTIONAL): MUST BE USED WHEN MOUNTING

UEGO SENSORS PRE-TURBO

UEGO sensors are extremely sensitive to pressure. Without an EBP kit (30-2064),

UEGO sensors mounted before the turbocharger will give inaccurate AFR readings due

to back pressure. When the EBP kit is installed correctly, the 4 CH UEGO controller will

output accurate AFR readings. UNDER NO CIRCUMSTANCES SHOULD UEGO

SENSORS BE MOUNTED PRE-TURBO WITHOUT USING THE EBP KIT.

When using multiple 4 Channel UEGO controllers on twin turbo or dual bank engines, it

is recommended that an EBP kit is used for each controller as back pressure levels can

vary per bank. When using multiple 4 Channel UEGO controllers on single turbo

engines, such as an inline 6, it is possible to share a single EBP source. To share a

single EBP source between multiple controllers, the green and black EBP wires for each

controller must be tied together as shown in Figures 12 and 13. Use extreme caution

when modifying the harness as improper connections may result in inaccurate AFR

readings. Be sure to cover all connections with moisture resistant heat shrink or

equivalent covering.

Figure 12. EBP Sensor Connector Figure 13. Cut & Spliced Wires

INDICATOR LIGHTS

The AEM 4 CH UEGO controller has eight indicator LEDs, one Status and one Ready

LED for each channel (Figure 14). Both Ready and Status LEDs flash during sensor

warm up. Once the UEGO sensor reaches operating temperature, usually within 30

seconds, the Status LED will turn off and the Ready LED will remain on solid. If a

UEGO sensor error is detected, analog output will switch to approximately +5V and both

LEDs will flash. The Status LED will flash on and off a number of times, followed by a

short pause, signifying an error code. The error codes are listed below in Table 4.

Page 14 10-2340 Rev 05 121012

Page 15

# of Flashes Fault Corrective Action

1 UEGO sensor heater open

2 Virtual Ground (VM) Error

3 Nernst Cell (UN) Error

4 Pump current (IP) Error

Check sensor cable for

broken wires/shorts

5 UEGO sensor heater time out

6 UEGO sensor heater short

Check electrical system

7 System voltage below 10 volts dc

for good connections

and proper function

TABLE 4. Error Codes

When there is no UEGO sensor connected to a particular channel, the Status LED of

that channel will remain on solid and the Ready LED will turn off after a few minutes.

The remaining channels with UEGO sensors connected will function properly.

When the exhaust back pressure kit (30-2064) is used, the 4 CH UEGO controller will

monitor exhaust back pressure. (NOTE: The 4 CH UEGO controller is designed to

work with a specific AEM pressure sensor. Do not use any sensor other than the

one included in the Exhaust Back Pressure Kit.) If a pressure sensor error is

detected, the 4 CH UEGO controller turns off all Ready LEDs and flashes Status LEDs,

starting with CH1 and ending with CH4. The analog output voltage level for all 4

channels switches to approximately +5V to signify an error.

Status Indicator

LED

FIGURE 14. Indicator Lights

Ready Indicator

LED

SERIES 2 EMS AEM TUNER CONFIGURATION FOR

AEMnet

Tuner Setup (Must use 01v22 firmware or newer)

In the AEMTuner EMS software, go to Wizards -> Setup Wizard. Under Wizard types,

click on Setup: CAN Receive. Choose a configuration and click Apply. There are

currently 4 configuration types available: MODE 1 + EBP Sensor, MODE 1 + MODE 2,

Page 15 10-2340 Rev 05 121012

Page 16

MODE 4 + MODE 5, and MODE 6 + MODE 7. Once this configuration is completed

Configuration Mode

Channels To Be Added

correctly, the word “Matched” will appear next to the configuration chosen, as shown in

Figure 15. Read the notes under Configuration Notes and close the window.

FIGURE 15. Series 2 EMS / EMS – 4 Setup Wizard

Viewing Live Data

Right-click in a blank space in the AEMTuner software and choose Add Channel

Display. From the list of available channels, select all the ones associated with the

selected configuration mode, as listed in Table 5. Figure 16 shows the Channel display

for “Mode 1 + EBP Sensor.”

Mode 1 + EBP Sensor

UEGO M1 Cyl 1 UEGO M1 Cyl 2

UEGO M1 Cyl 3 UEGO M1 Cyl 4

UEGO M1 EBP Sensor

Mode 1 + Mode 2

UEGO M1 Cyl 1 UEGO M2 Cyl 1

UEGO M1 Cyl 2 UEGO M2 Cyl 2

UEGO M1 Cyl 3 UEGO M2 Cyl 3

UEGO M1 Cyl 4 UEGO M2 Cyl 4

Mode 4 + Mode 5

UEGO M4 Cyl 1 UEGO M5 Cyl 1

UEGO M4 Cyl 2 UEGO M5 Cyl 2

UEGO M4 Cyl 3 UEGO M5 Cyl 3

UEGO M4 Cyl 4 UEGO M5 Cyl 4

Page 16 10-2340 Rev 05 121012

Page 17

Mode 6 + Mode 7

UEGO M6 Cyl 1 UEGO M7 Cyl 1

UEGO M6 Cyl 2 UEGO M7 Cyl 2

UEGO M6 Cyl 3 UEGO M7 Cyl 3

UEGO M6 Cyl 4 UEGO M7 Cyl 4

TABLE 5. Channel Selection

FIGURE 16. Mode 1 + EBP Sensor

UEGO CONNECTOR PIN-OUTS

The pin-out for the UEGO sensor connector is shown below in Figure 17.

FIGRE 17. UEGO Connector Pin-out

Page 17 10-2340 Rev 05 121012

Page 18

SPECIFICATIONS

4 CH UEGO Controller

Supply Current (nominal, peak) 3.2A, 10.5A peak

Differential Analog Outputs 4

Measuring Range: UEGO 8.5:1 to 18:1 AFR Gasoline, 0.58-1.22 Lambda

UEGO Sensor Accuracy 0.1 AFR

Operating Voltage (nominal) 8.5-15 volts dc

Harness & Connector Temp Limit: 105C

NOTES

If further tuning help is needed be sure to visit the video gallery or performance

electronics forum at www.aemelectronics.com for comprehensive instructional videos

and information.

The UEGO sensor contains a ceramic module and should not be subject to mechanical

or thermal shock or it may be damaged. The sensor is not designed for operation on

leaded fuels; doing so will dramatically shorten sensor life. Long term running in the rich

region (Lambda < 0.95) will shorten sensor life. High exhaust temperatures (over 850C)

will shorten sensor life. Engine oil consumption at a rate greater than 1 quart per 1,000

miles will shorten sensor life. With the UEGO Sensor installed, do not run the engine

without power applied to 4 CH UEGO controller.

REPLACEMENT/OPTIONAL UEGO CONTROLLER

COMPONENTS

30-2001 UEGO Sensor

35-4008 Stainless Steel UEGO Sensor Bung

30-2063 Sensor Kit with Stainless Bung

30-2064 Exhaust Back Pressure (EBP) Kit

30-343X AEMnet Adapter

AEMnet MESSAGE STRUCTURE

The 4 CH UEGO controller transmits two messages through the CAN network. The first

message contains Lambda values of all four channels and is transmitted every 10 ms.

The second message, transmitted every 40 ms, includes error flags, cylinder

configuration mode, EBP sensor readings and status. Messages are transmitted in 500

Kbps and use extended format message ID (29 bits). Appendix A shows entire

message protocols, including message IDs, number of bytes, data field, etc.

Page 18 10-2340 Rev 05 121012

Page 19

Lambda values are scaled up by 10,000 to retain decimal points. For example, if a

value of 9,876 is received as a lambda value from a 4 CH UEGO controller, the actual

lambda value is 0.9876. Use the following equation to derive the actual lambda value:

Actual Lambda value = Lambda from a message / 10,000

The back pressure value is scaled up by 100. Use the following equation to derive the

actual back pressure value.

Actual back pressure value (PSIg) = pressure from a message / 100

APPENDIX A

CAN MESSAGE PROTOCOL

CAN 2.0b, 29 bit, 500 kBit/sec

8 data bytes/message

All multi-byte data packed big endian unless specified (most significant byte transmitted first)

All bits numbered with the LSB = bit0, MSB = bit7

Message ID: 0x0000001F

Source: AEM 4 Channel UEGO set on MODE 1

Rate: 10ms continuous

Byte Label Data Type Scaling Offset Range

0

1

2

3

4

5

6

7

Message ID: 0x00000020

Source: AEM 4 Channel UEGO set on MODE 2

Rate: 10ms continuous

Byte Label Data Type Scaling Offset Range

0

1

2

3

4

5

6

7

Message ID: 0x00000021

Lambda 1 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 2 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 3 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 4 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 5 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 6 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 7 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 8 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Page 19 10-2340 Rev 05 121012

Page 20

Source: AEM 4 Channel UEGO set on MODE 3

Rate: 10ms continuous

Byte Label Data Type Scaling Offset Range

0

Lambda 1 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

1

2

Lambda 3 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

3

4

Lambda 5 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

5

6

Lambda 7 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

7

Message ID: 0x00000022

Source: AEM 4 Channel UEGO set on MODE 4

Rate: 10ms continuous

Byte Label Data Type Scaling Offset Range

0

Lambda 2 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

1

2

Lambda 4 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

3

4

Lambda 6 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

5

6

Lambda 8 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

7

Message ID: 0x00000023

Source: AEM 4 Channel UEGO set on MODE 5

Rate: 10ms continuous

Byte Label Data Type Scaling Offset Range

0

Lambda 9 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

1

2

Lambda 10 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

3

4

Lambda 11 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

5

6

Lambda 12 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

7

Message ID: 0x00000024

Source: AEM 4 Channel UEGO set on MODE 6

Rate: 10ms continuous

Byte Label Data Type Scaling Offset Range

0

Lambda 1 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

1

2

Lambda 2 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

3

Page 20 10-2340 Rev 05 121012

Page 21

4

5

6 --- --- --- --- --7 --- --- --- --- ---

Message ID: 0x00000025

Source: AEM 4 Channel UEGO set on MODE 7

Rate: 10ms continuous

Byte Label Data Type Scaling Offset Range

0

1

2

3

4

5

6 --- --- --- --- --7 --- --- --- --- ---

Message ID: 0x000001AF

Source: AEM 4 Channel UEGO set on MODE 1

Rate: 40ms continuous

Byte Label Data Type Scaling Offset Range

0 (bit0)

0 (bit1)

0 (bit2)

0 (bit3)

0 (bit4)

0 (bit5)

0 (bit6)

0 (bit7)

1 (bit0)

1 (bit1)

1 (bit2)

1 (bit3)

1 (bit4)

1 (bit5)

1 (bit6)

1 (bit7)

2 (bit0)

2 (bit1)

2 (bit2)

2 (bit3)

2 (bit4)

2 (bit5)

2 (bit6)

2 (bit7)

AFR 1 Heater Time-Out Error

AFR 2 Heater Time-Out Error

AFR 3 Heater Time-Out Error

Lambda 3 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 4 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 5 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

Lambda 6 16 bit unsigned .0001 Lambda/bit 0 0 to 6.5535 Lambda

AFR 1 Ready

AFR 1 Heater Open Error

AFR 1 VM Error

AFR 1 UN Error

AFR 1 IP Error

AFR 1 Heater Short Error

AFR 1 Overtemp Error

AFR 2 Ready

AFR 2 Heater Open Error

AFR 2 VM Error

AFR 2 UN Error

AFR 2 IP Error

AFR 2 Heater Short Error

AFR 2 Overtemp Error

AFR 3 Ready

AFR 3 Heater Open Error

AFR 3 VM Error

AFR 3 UN Error

AFR 3 IP Error

AFR 3 Heater Short Error

AFR 3 Overtemp Error

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 21 10-2340 Rev 05 121012

Page 22

3 (bit0)

3 (bit1)

3 (bit2)

3 (bit3)

3 (bit4)

3 (bit5)

3 (bit6)

3 (bit7)

4 (bit0)

4 (bit1)

4 (bit2)

4 (bit3)

4 (bit4)

4 (bit5)

4 (bit6)

4 (bit7)

5 (bit0)

5 (bit1)

5 (bit2)

5 (bit3)

5 (bit4)

5 (bit5)

5 (bit6)

5 (bit7)

6

7

Message ID: 0x000001B0

Source: AEM 4 Channel UEGO set on MODE 2

Rate: 40ms continuous

Byte Label Data Type Scaling Offset Range

0 (bit0)

0 (bit1)

0 (bit2)

0 (bit3)

0 (bit4)

0 (bit5)

0 (bit6)

0 (bit7)

1 (bit0)

1 (bit1)

1 (bit2)

1 (bit3)

1 (bit4)

1 (bit5)

1 (bit6)

AFR 4 Ready

AFR 4 Heater Open Error

AFR 4 VM Error

AFR 4 UN Error

AFR 4 IP Error

AFR 4 Heater Time-Out Error

AFR 4 Heater Short Error

AFR 4 Overtemp Error

UEGO Low Voltage Error

EBP sensor ready

EBP sensor Error Low Volt

EBP sensor detected

CAN Config Mode

CAN Config Mode

CAN Config Mode

CAN Config Mode

Reserved

Reserved

Reserved

Reserved

Sensor 4 Heating up

Sensor 3 Heating up

Sensor 2 Heating up

Sensor 1 Heating up

Exhaust Pressure 1 16 bit unsigned .001 psig/bit 0 0 to 655.35 psig

AFR 5 Ready

AFR 5 Heater Open Error

AFR 5 VM Error

AFR 5 UN Error

AFR 5 IP Error

AFR 5 Heater Time-Out Error

AFR 5 Heater Short Error

AFR 5 Overtemp Error

AFR 6 Ready

AFR 6 Heater Open Error

AFR 6 VM Error

AFR 6 UN Error

AFR 6 IP Error

AFR 6 Heater Time-Out Error

AFR 6 Heater Short Error

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 22 10-2340 Rev 05 121012

Page 23

1 (bit7)

2 (bit0)

2 (bit1)

2 (bit2)

2 (bit3)

2 (bit4)

2 (bit5)

2 (bit6)

2 (bit7)

3 (bit0)

3 (bit1)

3 (bit2)

3 (bit3)

3 (bit4)

3 (bit5)

3 (bit6)

3 (bit7)

4 (bit0)

4 (bit1)

4 (bit2)

4 (bit3)

4 (bit4)

4 (bit5)

4 (bit6)

4 (bit7)

5 (bit0)

5 (bit1)

5 (bit2)

5 (bit3)

5 (bit4)

5 (bit5)

5 (bit6)

5 (bit7)

6

7

Message ID: 0x000001B1

Source: AEM 4 Channel UEGO set on MODE 3

Rate: 40ms continuous

Byte Label Data Type Scaling Offset Range

0 (bit0)

0 (bit1)

0 (bit2)

0 (bit3)

0 (bit4)

0 (bit5)

AFR 6 Overtemp Error

AFR 7 Ready

AFR 7 Heater Open Error

AFR 7 VM Error

AFR 7 UN Error

AFR 7 IP Error

AFR 7 Heater Time-Out Error

AFR 7 Heater Short Error

AFR 7 Overtemp Error

AFR 8 Ready

AFR 8 Heater Open Error

AFR 8 VM Error

AFR 8 UN Error

AFR 8 IP Error

AFR 8 Heater Time-Out Error

AFR 8 Heater Short Error

AFR 8 Overtemp Error

UEGO Low Voltage Error

EBP sensor ready

EBP sensor Error Low Volt

EBP sensor detected

CAN Config Mode

CAN Config Mode

CAN Config Mode

CAN Config Mode

Reserved

Reserved

Reserved

Reserved

Sensor 8 Heating up

Sensor 7 Heating up

Sensor 6 Heating up

Sensor 5 Heating up

Exhaust Pressure 2 16 bit unsigned .001 psig/bit 0 0 to 655.35 psig

AFR 1 Ready

AFR 1 Heater Open Error

AFR 1 VM Error

AFR 1 UN Error

AFR 1 IP Error

AFR 1 Heater Time-Out Error

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 23 10-2340 Rev 05 121012

Page 24

0 (bit6)

0 (bit7)

1 (bit0)

1 (bit1)

1 (bit2)

1 (bit3)

1 (bit4)

1 (bit5)

1 (bit6)

1 (bit7)

2 (bit0)

2 (bit1)

2 (bit2)

2 (bit3)

2 (bit4)

2 (bit5)

2 (bit6)

2 (bit7)

3 (bit0)

3 (bit1)

3 (bit2)

3 (bit3)

3 (bit4)

3 (bit5)

3 (bit6)

3 (bit7)

4 (bit0)

4 (bit1)

4 (bit2)

4 (bit3)

4 (bit4)

4 (bit5)

4 (bit6)

4 (bit7)

5 (bit0)

5 (bit1)

5 (bit2)

5 (bit3)

5 (bit4)

5 (bit5)

5 (bit6)

5 (bit7)

6

7

Message ID: 0x000001B2

AFR 1 Heater Short Error

AFR 1 Overtemp Error

AFR 3 Ready

AFR 3 Heater Open Error

AFR 3 VM Error

AFR 3 UN Error

AFR 3 IP Error

AFR 3 Heater Time-Out Error

AFR 3 Heater Short Error

AFR 3 Overtemp Error

AFR 5 Ready

AFR 5 Heater Open Error

AFR 5 VM Error

AFR 5 UN Error

AFR 5 IP Error

AFR 5 Heater Time-Out Error

AFR 5 Heater Short Error

AFR 5 Overtemp Error

AFR 7 Ready

AFR 7 Heater Open Error

AFR 7 VM Error

AFR 7 UN Error

AFR 7 IP Error

AFR 7 Heater Time-Out Error

AFR 7 Heater Short Error

AFR 7 Overtemp Error

UEGO Low Voltage Error

EBP sensor ready

EBP sensor Error Low Volt

EBP sensor detected

CAN Config Mode

CAN Config Mode

CAN Config Mode

CAN Config Mode

Reserved

Reserved

Reserved

Reserved

Sensor 7 Heating up

Sensor 5 Heating up

Sensor 3 Heating up

Sensor 1 Heating up

Exhaust Pressure 1 16 bit unsigned .001 psig/bit 0 0 to 655.35 psig

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 24 10-2340 Rev 05 121012

Page 25

Source: AEM 4 Channel UEGO set on MODE 4

Rate: 40ms continuous

Byte Label Data Type Scaling Offset Range

0 (bit0)

0 (bit1)

0 (bit2)

0 (bit3)

0 (bit4)

0 (bit5)

0 (bit6)

0 (bit7)

1 (bit0)

1 (bit1)

1 (bit2)

1 (bit3)

1 (bit4)

1 (bit5)

1 (bit6)

1 (bit7)

2 (bit0)

2 (bit1)

2 (bit2)

2 (bit3)

2 (bit4)

2 (bit5)

2 (bit6)

2 (bit7)

3 (bit0)

3 (bit1)

3 (bit2)

3 (bit3)

3 (bit4)

3 (bit5)

3 (bit6)

3 (bit7)

4 (bit0)

4 (bit1)

4 (bit2)

4 (bit3)

4 (bit4)

4 (bit5)

4 (bit6)

4 (bit7)

5 (bit0) --- --- --- --- --5 (bit1) --- --- --- --- --5 (bit2) --- --- --- --- ---

AFR 2 Ready

AFR 2 Heater Open Error

AFR 2 VM Error

AFR 2 UN Error

AFR 2 IP Error

AFR 2 Heater Time-Out Error

AFR 2 Heater Short Error

AFR 2 Overtemp Error

AFR 4 Ready

AFR 4 Heater Open Error

AFR 4 VM Error

AFR 4 UN Error

AFR 4 IP Error

AFR 4 Heater Time-Out Error

AFR 4 Heater Short Error

AFR 4 Overtemp Error

AFR 6 Ready

AFR 6 Heater Open Error

AFR 6 VM Error

AFR 6 UN Error

AFR 6 IP Error

AFR 6 Heater Time-Out Error

AFR 6 Heater Short Error

AFR 6 Overtemp Error

AFR 8 Ready

AFR 8 Heater Open Error

AFR 8 VM Error

AFR 8 UN Error

AFR 8 IP Error

AFR 8 Heater Time-Out Error

AFR 8 Heater Short Error

AFR 8 Overtemp Error

UEGO Low Voltage Error

EBP sensor ready

EBP sensor Error Low Volt

EBP sensor detected

CAN Config Mode

CAN Config Mode

CAN Config Mode

CAN Config Mode

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 25 10-2340 Rev 05 121012

Page 26

5 (bit3) --- --- --- --- --5 (bit4)

5 (bit5)

5 (bit6)

5 (bit7)

6

7

Message ID: 0x000001B3

Source: AEM 4 Channel UEGO set on MODE 5

Rate: 40ms continuous

Byte Label Data Type Scaling Offset Range

0 (bit0)

0 (bit1)

0 (bit2)

0 (bit3)

0 (bit4)

0 (bit5)

0 (bit6)

0 (bit7)

1 (bit0)

1 (bit1)

1 (bit2)

1 (bit3)

1 (bit4)

1 (bit5)

1 (bit6)

1 (bit7)

2 (bit0)

2 (bit1)

2 (bit2)

2 (bit3)

2 (bit4)

2 (bit5)

2 (bit6)

2 (bit7)

3 (bit0)

3 (bit1)

3 (bit2)

3 (bit3)

3 (bit4)

3 (bit5)

3 (bit6)

3 (bit7)

4 (bit0)

4 (bit1)

Sensor 8 Heating up

Sensor 6 Heating up

Sensor 4 Heating up

Sensor 2 Heating up

Exhaust Pressure 2 16 bit unsigned .001 psig/bit 0 0 to 655.35 psig

AFR 9 Ready

AFR 9 Heater Open Error

AFR 9 VM Error

AFR 9 UN Error

AFR 9 IP Error

AFR 9 Heater Time-Out Error

AFR 9 Heater Short Error

AFR 9 Overtemp Error

AFR 10 Ready

AFR 10 Heater Open Error

AFR 10 VM Error

AFR 10 UN Error

AFR 10 IP Error

AFR 10 Heater Time-Out Error

AFR 10 Heater Short Error

AFR 10 Overtemp Error

AFR 11 Ready

AFR 11 Heater Open Error

AFR 11 VM Error

AFR 11 UN Error

AFR 11 IP Error

AFR 11 Heater Time-Out Error

AFR 11 Heater Short Error

AFR 11 Overtemp Error

AFR 12 Ready

AFR 12 Heater Open Error

AFR 12 VM Error

AFR 12 UN Error

AFR 12 IP Error

AFR 12 Heater Time-Out Error

AFR 12 Heater Short Error

AFR 12 Overtemp Error

UEGO Low Voltage Error

EBP sensor ready

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 26 10-2340 Rev 05 121012

Page 27

4 (bit2)

4 (bit3)

4 (bit4)

4 (bit5)

4 (bit6)

4 (bit7)

5 (bit0) --- --- --- --- --5 (bit1) --- --- --- --- --5 (bit2) --- --- --- --- --5 (bit3) --- --- --- --- --5 (bit4)

5 (bit5)

5 (bit6)

5 (bit7)

6

7

Message ID: 0x000001B4

Source: AEM 4 Channel UEGO set on MODE 6

Rate: 40ms continuous

Byte Label Data Type Scaling Offset Range

0 (bit0)

0 (bit1)

0 (bit2)

0 (bit3)

0 (bit4)

0 (bit5)

0 (bit6)

0 (bit7)

1 (bit0)

1 (bit1)

1 (bit2)

1 (bit3)

1 (bit4)

1 (bit5)

1 (bit6)

1 (bit7)

2 (bit0)

2 (bit1)

2 (bit2)

2 (bit3)

2 (bit4)

2 (bit5)

2 (bit6)

2 (bit7)

3 --- --- --- --- ---

EBP sensor Error Low Volt

EBP sensor detected

CAN Config Mode

CAN Config Mode

CAN Config Mode

CAN Config Mode

Sensor 12 Heating up

Sensor 11 Heating up

Sensor 10 Heating up

Sensor 9 Heating up

Exhaust Pressure 2 16 bit unsigned .001 psig/bit 0 0 to 655.35 psig

AFR 1 Ready

AFR 1 Heater Open Error

AFR 1 VM Error

AFR 1 UN Error

AFR 1 IP Error

AFR 1 Heater Time-Out Error

AFR 1 Heater Short Error

AFR 1 Overtemp Error

AFR 2 Ready

AFR 2 Heater Open Error

AFR 2 VM Error

AFR 2 UN Error

AFR 2 IP Error

AFR 2 Heater Time-Out Error

AFR 2 Heater Short Error

AFR 2 Overtemp Error

AFR 3 Ready

AFR 3 Heater Open Error

AFR 3 VM Error

AFR 3 UN Error

AFR 3 IP Error

AFR 3 Heater Time-Out Error

AFR 3 Heater Short Error

AFR 3 Overtemp Error

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 27 10-2340 Rev 05 121012

Page 28

4 (bit0)

4 (bit1)

4 (bit2)

4 (bit3)

4 (bit4)

4 (bit5)

4 (bit6)

4 (bit7)

5 (bit0) --- --- --- --- --5 (bit1) --- --- --- --- --5 (bit2) --- --- --- --- --5 (bit3) --- --- --- --- --5 (bit4) --- --- --- --- --5 (bit5)

5 (bit6)

5 (bit7)

6

7

Message ID: 0x000001B5

Source: AEM 4 Channel UEGO set on MODE 7

Rate: 40ms continuous

Byte Label Data Type Scaling Offset Range

0 (bit0)

0 (bit1)

0 (bit2)

0 (bit3)

0 (bit4)

0 (bit5)

0 (bit6)

0 (bit7)

1 (bit0)

1 (bit1)

1 (bit2)

1 (bit3)

1 (bit4)

1 (bit5)

1 (bit6)

1 (bit7)

2 (bit0)

2 (bit1)

2 (bit2)

2 (bit3)

2 (bit4)

2 (bit5)

2 (bit6)

UEGO Low Voltage Error

EBP sensor ready

EBP sensor Error Low Volt

EBP sensor detected

CAN Config Mode

CAN Config Mode

CAN Config Mode

CAN Config Mode

Sensor 3 Heating up

Sensor 2 Heating up

Sensor 1 Heating up

Exhaust Pressure 1 16 bit unsigned .001 psig/bit 0 0 to 655.35 psig

AFR 4 Ready

AFR 4 Heater Open Error

AFR 4 VM Error

AFR 4 UN Error

AFR 4 IP Error

AFR 4 Heater Time-Out Error

AFR 4 Heater Short Error

AFR 4 Overtemp Error

AFR 5 Ready

AFR 5 Heater Open Error

AFR 5 VM Error

AFR 5 UN Error

AFR 5 IP Error

AFR 5 Heater Time-Out Error

AFR 5 Heater Short Error

AFR 5 Overtemp Error

AFR 6 Ready

AFR 6 Heater Open Error

AFR 6 VM Error

AFR 6 UN Error

AFR 6 IP Error

AFR 6 Heater Time-Out Error

AFR 6 Heater Short Error

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 28 10-2340 Rev 05 121012

Page 29

2 (bit7)

3 --- --- --- --- --4 (bit0)

4 (bit1)

4 (bit2)

4 (bit3)

4 (bit4)

4 (bit5)

4 (bit6)

4 (bit7)

5 (bit0) --- --- --- --- --5 (bit1) --- --- --- --- --5 (bit2) --- --- --- --- --5 (bit3) --- --- --- --- --5 (bit4) --- --- --- --- --5 (bit5)

5 (bit6)

5 (bit7)

6

7

AFR 6 Overtemp Error

UEGO Low Voltage Error

EBP sensor ready

EBP sensor Error Low Volt

EBP sensor detected

CAN Config Mode

CAN Config Mode

CAN Config Mode

CAN Config Mode

Sensor 6 Heating up

Sensor 5 Heating up

Sensor 4 Heating up

Exhaust Pressure 2 16 bit unsigned .001 psig/bit 0 0 to 655.35 psig

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Boolean 0 = false, 1 = true 0 0/1

Page 29 10-2340 Rev 05 121012

Page 30

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to the consumer that all AEM High Performance products will be free from defects in

material and workmanship for a period of twelve (12) months from date of the original purchase. Products that fail within this 12month warranty period will be repaired or replaced at AEM’s option, when determined by AEM that the product failed due to defects

in material or workmanship. This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty

exceed the original purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential damages

or cost incurred due to the failure of this product. The Bosch LSU 4.2 UEGO sensor has a limited life and is not warranted.

Warranty claims to AEM must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only

to the original purchaser of product and is non-transferable. All implied warranties shall be limited in duration to the said 12 month

warranty period. Improper use or installation, accident, abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims

any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by AEM.

Warranty returns will only be accepted by AEM when accompanied by a valid Return Goods Authorization (RGA) number. Product

must be received by AEM within 30 days of the date the RGA is issued.

Please note that before AEM can issue an RGA for any product, it is first necessary for the installer or end user to contact the AEM

Performance Electronics tech line at 1-800-423-0046 to discuss the problem. Most issues can be resolved over the phone. Under

no circumstances should a system be returned or a RGA requested before the above process transpires.

Need additional help? Contact the AEM Performance Electronics tech department at

1-800-423-0046 or tech@aempower.com, or visit the AEM Performance Electronics

forum at http://forum.aempower.com/forum/

Loading...

Loading...