Page 1

AEM Performance Electronics

2205 126th Street Unit A, Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number: 10-2320 Rev 01

2009 AEM Performance Electronics

Part Number 30-2320

AEM X-WIFI UEGO/EGT Module

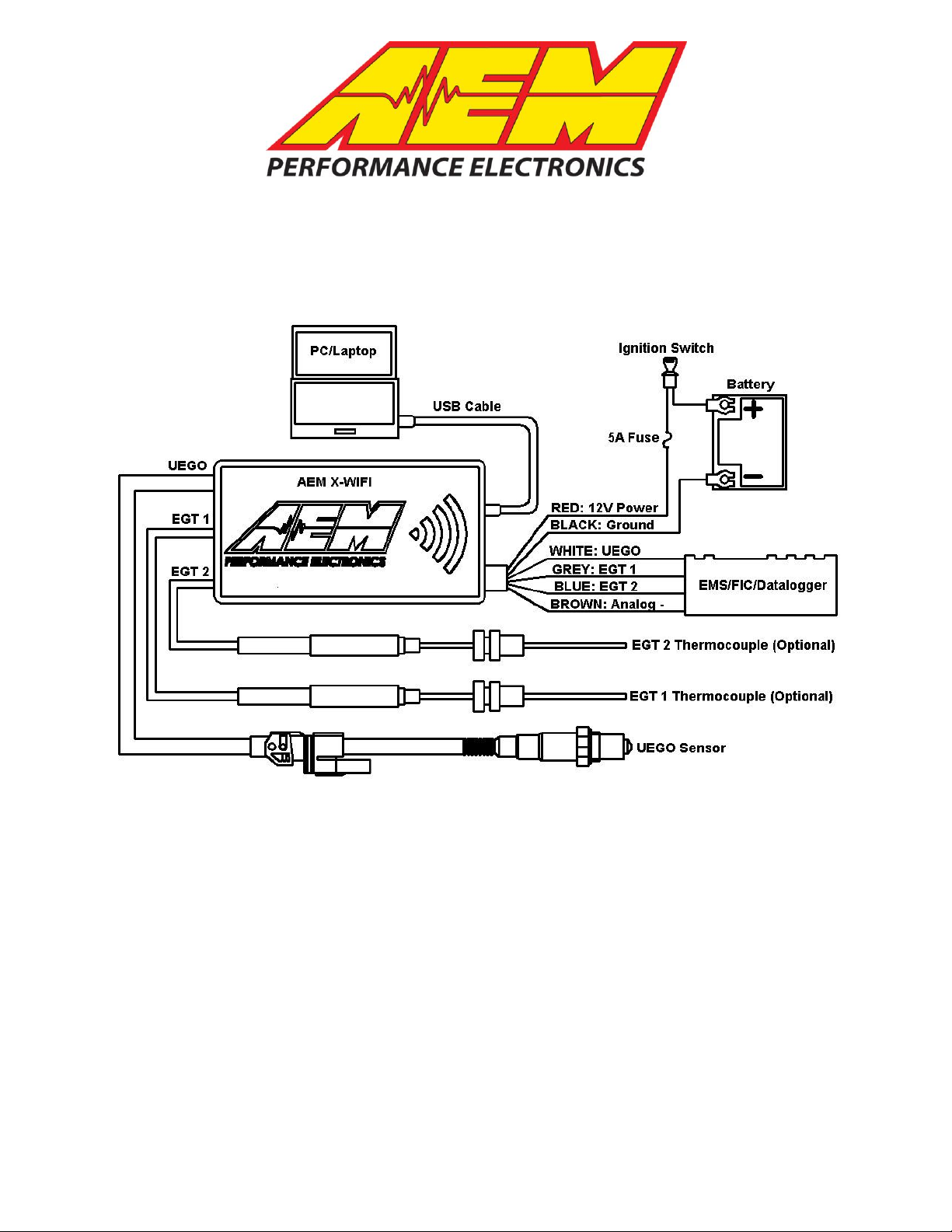

Figure 1. Wiring Schematic

AEM X-WIFI Parts

1 x 30-2320 X-WIFI Module

1 x 30-2001 UEGO Sensor

1 x 35-8535 Install Kit (UEGO Bung and 6 Butt Connectors)

1 x 10-2320 Installation Instructions

1 x 35-3416 8-Pin Power Harness

1 x 35-3400 6-Pin UEGO Sensor Harness

1 x 35-3009 USB Cable

4 x Zip Tie

Page 2

INSTALLATION

1. Disconnect the negative battery cable.

2. Find a suitable, in cab, mounting location and secure the X-WIFI module using

the supplied zip ties. Note: The X-WIFI is not weatherproof and should not be

mounted in the engine bay or exposed to outside elements

3. Plug the 8-pin power harness into the mating connector on the right side of the XWIFI and connect the wires as shown in Figure 1.

4. Mount the UEGO sensor as shown in figure 3.

5. Connect the sensor to the X-WIFI using the 6-wire sensor cable. The connector

with the grey latch connects to the sensor. The single-row connector connects to

the left side of the X-WIFI.

6. Mount the optional EGT sensor(s) as shown in Figure 6.

7. Slide the heat shrink tube over the sensor cable and connect the EGT to the

cable as shown below in Figure 7.

8. Connect the 3-pin EGT sensors cable(s) to the X-WIFI.

RED - Connect to a switched, fused (5A) 12 volt power source.

BLACK – Connect to a clean power ground.

*BLUE - Connect to available 5 volt analog channel for EGT input.

*GREY - Connect to available 5 volt analog channel for EGT input.

*WHITE - Connect to Lambda + Input.

*BROWN - Connect to sensor ground. (Must be connected if the White, Grey, or blue

wire is used)

*optional – only needed if using the available differential analog output

Wiring notes:

GREY – The GREY wire should be connected to an available analog channel on the

EMS or similar device.

BLUE – The BLUE wire should be connected to an available analog channel on the

EMS or similar device.

WHITE – The WHITE wire should be connected to the Lambda + input on the EMS or

the analog + input on a similar device.

BROWN – The BROWN wire should be connected to the Lambda – input or the analog

– input. If the EMS or similar device does not have a – input, the BROWN wire should

be connected to a sensor ground. If no sensor ground is available, the BROWN wire

should be connected to a power ground. Note: The BROWN wire must be connected

in order to get correct readings from the analog outputs.

Page 2

Page 3

Displaying Data with WIFI Enabled Electronic Devices

>10°

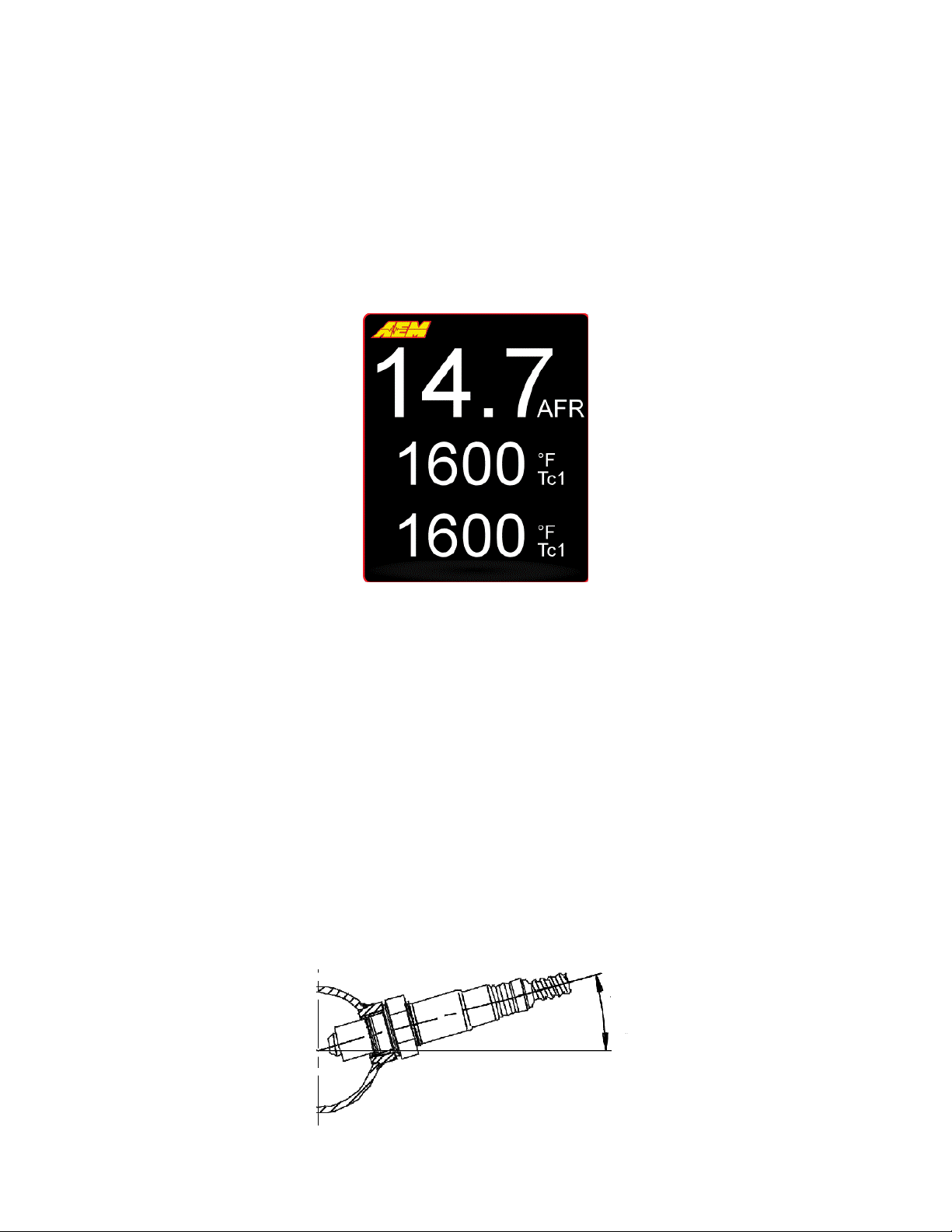

FIGURE 2. Web Page Data

Figure 3. Minimum mounting angle for the UEGO Sensor

Real time AFR and EGT data from the X-WIFI can be viewed on WIFI enabled

electronic devices using a standard web browser. Locate the network “AEM X-WIFI”

and connect. Type the address 192.168.3.88 in the address bar of the browser and

open the web page. A screen showing the AFR and EGT values will appear as shown

below in Figure 2. If a UEGO sensor error is detected, the AFR value will display “Err”

followed by a number. The number corresponds to the number of flashes on the error

status light as described in the Status Lights section below. Visit the video gallery at

www.aemelectronics.com for information on configuring specific WIFI enabled mobile

electronic devices.

UEGO Sensor Mounting

A weld-in M18 X 1.5 UEGO bung is supplied for sensor installation. Mount the UEGO

sensor in the exhaust system at least 18 inches downstream from the exhaust port. If

you anticipate high EGT's (over 800C), run a turbocharger, run at high RPM for

extended periods of time or plan on running leaded race fuel then you must mount the

sensor at least 36 inches or more downstream of the exhaust port as all of these can

cause the sensor to overheat. On turbocharged engines the UEGO sensor must be

installed after the turbo charger, if not, the pressure differential will greatly affect

the accuracy of the unit. For accurate readings, the sensor must be mounted before

catalytic converters and/or auxiliary air pumps. To prevent collection of liquids between

the sensor housing and sensor element during the cold start phase, the installation

angle should be inclined at least 10° from horizontal with the electrical connection

upwards, see Figure 3.

Page 3

Page 4

# of Flashes

Fault

Corrective Action

1-6

Sensor Wiring and/or sensor

Check sensor cable for

broken wires/shorts

7

System voltage below 10 volts dc

Check electrical system

for good connections

and proper function

Table 1. Error Codes

Figure 4. UEGO Status Lights

WARM UP

STATUS LIGHT

UEGO ERROR

STATUS LIGHT

Status Lights

The AEM X-WIFI has two status lights, see Figure 4. The warm up status light on the

left flashes during sensor warm up. Once the sensor reaches operating temperature,

usually within 30 seconds, the light will remain on. During sensor warm up, AFR

readings may not be accurate. The UEGO error status light on the right will flash if a

sensor error is detected. The status light will flash on and off a number of times,

followed by a short pause. The error codes are listed below in Table 1.

UEGO Analog Output

The UEGO analog output from the AEM X-WIFI is a linear dc voltage signal that varies

from 0.5 Vdc at 8.5:1 AFR Gasoline to 4.5Vdc at 18.0:1 AFR Gasoline over the

operating range of the X-WIFI. The signal is used for sending information to a data

logger or an engine management system like the AEM EMS or F/IC. The transfer

function for the output is listed below.

AFR = 2.375(V) + 7.3125

For example, if the output is 2.0 Vdc, the AFR is 12.06:1

2.375 * 2.0 + 7.3125 = 12.06

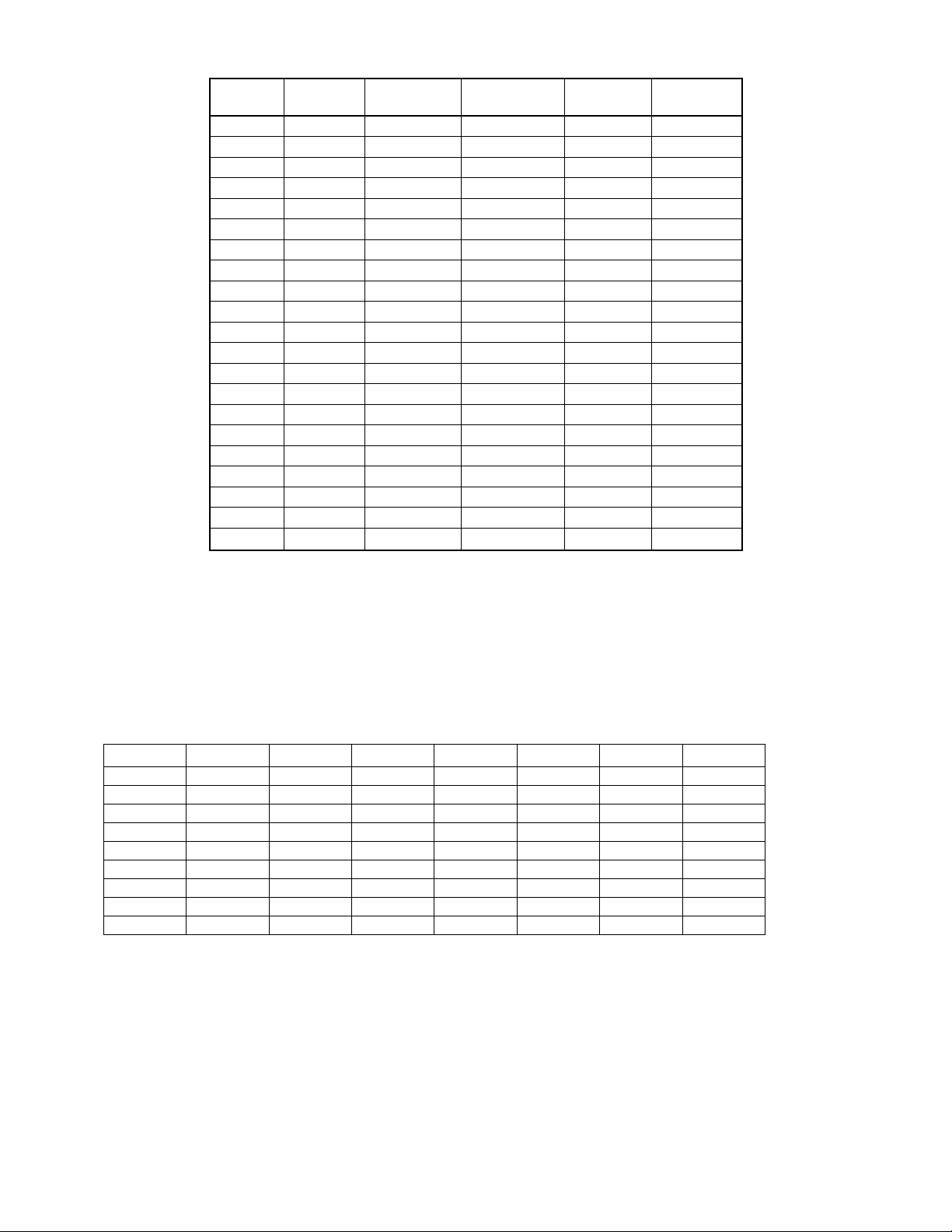

A table showing the analog output voltage and corresponding Air/Fuel ratios for some of

the common fuels is shown below in Table 2.

Page 4

Page 5

VOLTS

LAMBDA

AFR GAS

AFR

METHANOL

AFR E85

AFR

ETHANOL

0.50

0.58

8.5

3.7

5.6

5.2

0.71

0.61

9.0

3.9

5.9

5.5

0.92

0.65

9.5

4.1

6.3

5.8

1.13

0.68

10.0

4.4

6.6

6.1

1.34

0.71

10.5

4.6

6.9

6.4

1.55

0.75

11.0

4.8

7.3

6.7

1.76

0.78

11.5

5.0

7.6

7.0

1.97

0.82

12.0

5.2

7.9

7.3

2.18

0.85

12.5

5.4

8.2

7.7

2.39

0.88

13.0

5.7

8.6

8.0

2.61

0.92

13.5

5.9

8.9

8.3

2.82

0.95

14.0

6.1

9.2

8.6

3.03

0.99

14.5

6.3

9.6

8.9

3.11

1.00

14.7

6.4

9.7

9.0

3.24

1.02

15.0

6.5

9.9

9.2

3.45

1.05

15.5

6.7

10.2

9.5

3.66

1.09

16.0

7.0

10.6

9.8

3.87

1.12

16.5

7.2

10.9

10.1

4.08

1.16

17.0

7.4

11.2

10.4

4.29

1.19

17.5

7.6

11.5

10.7

4.50

1.22

18.0

7.8

11.9

11.0

Voltage

AFR

Voltage

AFR

Voltage

AFR

Voltage

AFR

0.00

8.43

1.40

10.64

2.81

13.99

4.21

17.31

0.16

8.43

1.56

11.02

2.96

14.34

4.37

17.69

0.31

8.43

1.72

11.40

3.12

14.72

4.52

18.05

0.47

8.43

1.87

11.75

3.28

15.10

4.68

18.05

0.62

8.79

2.03

12.13

3.43

15.46

4.84

18.05

0.78

9.17

2.18

12.49

3.59

15.84

4.99

18.05

0.94

9.55

2.34

12.87

3.74

16.20

NA

NA

1.09

9.90

2.50

13.25

3.90

16.58

NA

NA

1.25

10.28

2.65

13.61

4.06

16.96

NA

NA

Table 2. EMS Software Values

Table 2. AFR Values

Configuring the AEM EMS

With an EMS calibration open, go to Setup>Sensors>Oxygen Sensor #1(2)>O2 Sensor

#1(2) Cal Table>Table, and enter the values below into the O2 Sensor #1(2) Cal Table.

Connect the WHITE Analog Output + wire to the EMS Lambda input and the BROWN

Analog Output – wire to the EMS sensor ground. Table 3 below lists the Lambda and

Sensor ground pin locations for the different EMS part numbers.

Page 5

Page 6

AEM EMS P/N

Lambda

#1 Pin

Lambda

#2 Pin

Sensor

GND Pin

30-1000/1001/1002/1040/1042

D14

D16

D21

30-1010/1012/1050/1052

C16

A23

C18

30-1020/1060

D7

D14

D12

30-1030/1031/1070

C13

C14

A16

30-1080

C16

C8

C14

30-1081

C16

B11

C14

30-1100/1101

B47

B48

B65

30-1110

1C

9C

13C

30-1120/1121/1130

B6

B14

B9

30-1220

30

31

60

30-1300

4

66

17

30-1310/1311/1312/1313

76

75

92

30-1320

71

73

34

30-1400

29

43

46

30-1401

44

43

46

30-1510

C2-31

C2-33

C2-32

30-1600/1601/1602/1603

19

NA

21

30-1610/1611/1612

46

52

50

30-1620/1621/1622/1623

29

55

30

30-1710

2N

4J

2C

30-1720

C3

D3

O3

30-1800

C3

A2

D4

30-1810

D19

B17

B19

30-1820/1821

A26

D25

C35

30-6100/30-6101

B47

B48

B65

30-6010/6012/6050/6052

C16

A23

C18

30-6000/6001/6002/6040/6042

D14

D16

D21

30-6060

D7

D14

D12

30-6310/30-6311/30-6313

76

75

92

30-6320

71

73

34

Table 3. EMS Pin Locations

Configuring the AEM F/IC

With an FIC calibration open, go to Setup>Aux Gauge, and complete the Aux gauge

setup window as shown below in Figure 5.

Page 6

Page 7

AEM F/IC P/N

Lambda Pin

Sensor GND Pin

30-1910(X)

Pin 18 of 22-pin connector

Pin 5 of 22-pin connector

30-1930(X)

Pin 18 of 22-pin connector

Pin 20 of 20-pin connector

Pin 5 of 22-pin connector

Figure 5. F/IC Aux Gauge Setup

Table 4. F/IC Pin Locations

Connect the WHITE Analog Output + wire to the Aux Gauge input and the BROWN

Analog Output – wire to the sensor ground. Table 4 below lists the Lambda and Sensor

ground pin locations for the different FIC part numbers.

Thermocouple Mounting

The optional thermocouple comes with a stainless steel compression style mounting

adapter. The mounting adapter consists of three pieces: compression nut, ferrule

sleeve, threaded body. The threaded body has 1/8” NPT male threads. To install the

sensor, the threaded body can either be threaded into a hole with mating 1/8” NPT

threads, or welded to the pipe/manifold. Remove the compression nut, ferrule sleeve,

and thermocouple from the threaded body. For a welded installation, drill a 13/32” hole

and weld the threaded body, being careful not to cause any distortion. . For a threaded

installation, either thread the body into an existing hole with 1/8” NPT threads or drill a

hole using an “R” size drill bit and cut the threads using a 1/8” NPT tap. With the

compression nut and ferrule sleeve on the thermocouple, insert the thermocouple into

the threaded body so the tip of the thermocouple is near the center of the pipe/manifold

and tighten the compression nut to the threaded body. See Figure 6. Table 5 below

lists some of the common EGT measurements and corresponding thermocouple

mounting locations.

Page 7

Page 8

EGT Measurement

Mounting Location

Individual Cylinder EGT

1-2 inches from exhaust port

Turbine Inlet Temperature

2-3 inches from turbine inlet

Cylinder Bank EGT

Header collector

FERRULE SLEEVE

COMPRESSION NUT

THREADED BODY

PIPE/MANIFOLD

WITH 1/8” NPT

THREADS OR

13/32” HOLE

TIP OF THERMOCOUPLE

NEAR CENTER OF

PIPE/MANIFOLD

HEAT SHRINK

Figure 7. Thermocouple to Cable Connection

Figure 6. Thermocouple Mounting

Table 5. Common Thermocouple Mounting Locations

When using both thermocouples for comparison (bank 1 EGT and bank 2 EGT for

example), make sure to mount both thermocouples in a similar fashion (distance from

port, tip depth, tube diameter, etc) so the readings are not influenced by installation

differences.

Connecting the Thermocouple

Slide the supplied heat shrink onto the sensor cable. Connect the RED wire from the

thermocouple to the RED wire on the harness and the YELLOW wire from the

thermocouple to the YELLOW wire on the harness using the supplied 4-40 screws and

hex nuts. Make sure the connections are not touching. Center the heat shrink over the

connections and apply mild heat to the heat shrink until it shrinks over the connections.

See Figure 7.

EGT Analog Outputs

Page 8

Page 9

VOLTAGE

°F

°C

0.50

0

-18

0.75

113

45

1.00

225

107

1.25

338

170

1.50

450

232

1.75

563

295

2.00

675

357

2.25

788

420

2.50

900

482

2.75

1013

545

3.00

1125

607

3.25

1238

670

3.50

1350

732

3.75

1463

795

4.00

1575

857

4.25

1688

920

4.50

1800

982

Table 6. Analog EGT Calibrations

The analog EGT outputs from the AEM X-WIFI are linear dc voltage signals that vary

from 0.5 Vdc at 0 Degrees Fahrenheit (-18 Degrees Celsius) to 4.5Vdc at 1800

Degrees Fahrenheit (982 Degrees Celsius) over the operating range of the X-WIFI.

The signals are used for sending information to a data logger or an engine management

system like the AEM EMS or F/IC. The transfer functions for the analog outputs are

listed below in Degrees Fahrenheit and Degrees Celsius.

Temperature (Degrees Fahrenheit) = 450 * Voltage - 225

For example, if the output is 2.5 Vdc, the temperature is 900 Degrees Fahrenheit.

450 * 2.5 – 225 = 900 Degrees Fahrenheit

Temperature (Degrees Celsius) = 250 * Voltage – 143

For example, if the output is 2.5 Vdc, the temperature is 482 Degrees Celsius.

250 * 2.5 – 143 = 482 Degrees Celsius

A list of output voltages and corresponding temperatures is shown below in Table 6.

Configuration

The AEM X-WIFI has two configuration buttons. Configuration button one is used for

accessing the WIFI setup options. Configuration button two is used for future updates.

See Figure 8.

Page 9

Page 10

Figure 8. Configuration Buttons

CONFIGURATION

BUTTON 1

CONFIGURATION

BUTTON 2

WIFI

AEM X-WIFI is preconfigured for adhoc communications with standard WIFI settings

that are suitable for most applications. The IP address, subnet mask, and SSID are

listed below:

IP address: 192.168.3.88

Subnet Mask: 255.255.0.0

SSID: AEM X-WIFI

The default X-WIFI settings are permanently stored in the module and can be restored

by the following sequence. Plug the USB cable into the pc/laptop. Press and hold

configuration button 1. With configuration button 1 depressed, plug the USB cable into

the X-WIFI and continue to hold configuration button 1 for eight seconds then release.

The AEM X-WIFI is also capable of secure infrastructure WIFI communications. The

communication settings are configurable in the advanced configuration window. The

advanced configuration window can be viewed using a standard hyper terminal

communication. The settings for the hyper terminal communication are shown below in

Figure 9.

Page 10

Page 11

FIGURE 9. HYPER TERMINAL SETTINGS

FIGURE 10. ADVANCED WIFI CONFIGURATION

To view the advanced configuration screen, open the hyper terminal communication,

but do not connect. Plug the USB cable into the pc/laptop. Press and hold

configuration button 1. With configuration button 1 depressed, plug the USB cable into

the X-WIFI and continue to hold configuration button 1 for two seconds, then release.

Click the connect button on the hyper terminal communication. The advanced

configuration screen will appear as shown below in Figure 10.

Consult your router documentation for the necessary network settings.

Page 11

Page 12

Displaying Data with a PC/Laptop

Figure 12. Barrel Style Power Connection

POWER

CONNECTION

Figure 11. PC Data Viewer

Real time AFR and EGT data can also be viewed via a pc/laptop with USB connection.

See figure 11. Download the data viewer program and instructions from the AEM

Performance Electronics forum at www.aemelectronics.com.

Portable Power Connection

The AEM X-WIFI has an on-board barrel connector that can be used to power the

module using a 5 amp 12Vdc power supply when a hard wired power connection is not

desired. The power supply must have a 2.1MM ID X 5.5MM OD plug with the center pin

positive. See Figure 12.

Connector Pinouts

The pinouts for the 6-pin sensor harness, 3-pin sensor harness, and 8-pin power

harness are provided below in Figure 13.

Page 12

Page 13

X-WIFI

Supply Current (nominal, peak)

1.5A, 3A peak

Differential Analog Outputs

3

Measuring Range: UEGO

8.5:1 to 18:1 AFR Gasoline, 0.58-1.22 Lambda

UEGO Sensor Accuracy

0.1 AFR

Measuring Range: EGT

0 – 1800 Degrees Fahrenheit,

-18-982 Degrees Celsius

EGT Sensor Accuracy

0.75% FS

Operating Voltage (nominal)

8.5-15 volts dc

Harness & Connector Temp Limit:

105C

Web Browser Requirements

Javascript, Ajax, and Canvas for graphical web

pages

Figure 13. Harness Pinouts

Specifications

Notes

If further tuning help is needed be sure to visit the video gallery or performance

electronics forum at www.aemelectronics.com for comprehensive instructional videos

and information.

The UEGO sensor contains a ceramic module and should not be subject to mechanical

or thermal shock or it may be damaged. The sensor is not designed for operation on

leaded fuels, doing so will dramatically shorten sensor life. Long term running in the rich

region (Lambda < 0.95) will shorten sensor life. High exhaust temperatures (over 850C)

will shorten sensor life. Engine oil consumption at a rate greater than 1 quart per 1,000

miles will shorten sensor life. With the UEGO Sensor installed, do not run the engine

without power applied to the X-WIFI.

Replacement/Optional X-WIFI Components

30-2001 UEGO Sensor

35-4005 UEGO Sensor Bung

35-3416 8-Pin Power Harness

35-3400 6-Pin UEGO Sensor Harness

30-2065 K-Type Thermocouple with Bung (Optional)

35-2066 3-Pin Thermocouple Harness (Optional)

Page 13

Page 14

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to the consumer that all AEM High Performance products will be free from defects in

material and workmanship for a period of twelve (12) months from date of the original purchase. Products that fail within this 12month warranty period will be repaired or replaced at AEM’s option, when determined by AEM that the product failed due to defects

in material or workmanship. This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty

exceed the original purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential damages

or cost incurred due to the failure of this product. The Bosch LSU 4.2 UEGO sensor has a limited life and is not warranted.

Warranty claims to AEM must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only

to the original purchaser of product and is non-transferable. All implied warranties shall be limited in duration to the said 12 month

warranty period. Improper use or installation, accident, abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims

any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by AEM.

Warranty returns will only be accepted by AEM when accompanied by a valid Return Goods Authorization (RGA) number. Product

must be received by AEM within 30 days of the date the RGA is issued.

Please note that before AEM can issue an RGA for any product, it is first necessary for the installer or end user to contact the AEM

Performance Electronics tech line at 1-800-423-0046 to discuss the problem. Most issues can be resolved over the phone. Under

no circumstances should a system be returned or a RGA requested before the above process transpires.

Need additional help? Contact the AEM Performance Electronics tech department at

1-800-423-0046 or tech@aempower.com, or visit the AEM Performance Electronics

forum at http://forum.aempower.com/forum/

Page 14

Loading...

Loading...