Page 1

WARNING:

The installation of this Fuel Rail Kit requires the removal and installation of fuel system

components. Improper assembly/installation may result in bodily injury or property

damage. If you are not qualified to perform this installation, please refer the installation

to a professional. Read and understand these instructions before attempting to install

this product.

FUEL

RAIL

AN ADAPTER KIT

Installation Instructions for part number:

25-391

1989-1999 Mitsubishi Eclipse Turbo 4G63

Fuel Rail AN Adapter Kit

ADVANCED ENGINE MANAGEMENT INC.

2205 126TH Street, Unit A Hawthorne, CA. 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

Http://www.aempower.com

Part Number: 10-381

2002 Advanced Engine Management, Inc.

Page 2

! WARNING

Read and understand these instructions BEFORE attempting to install this product.

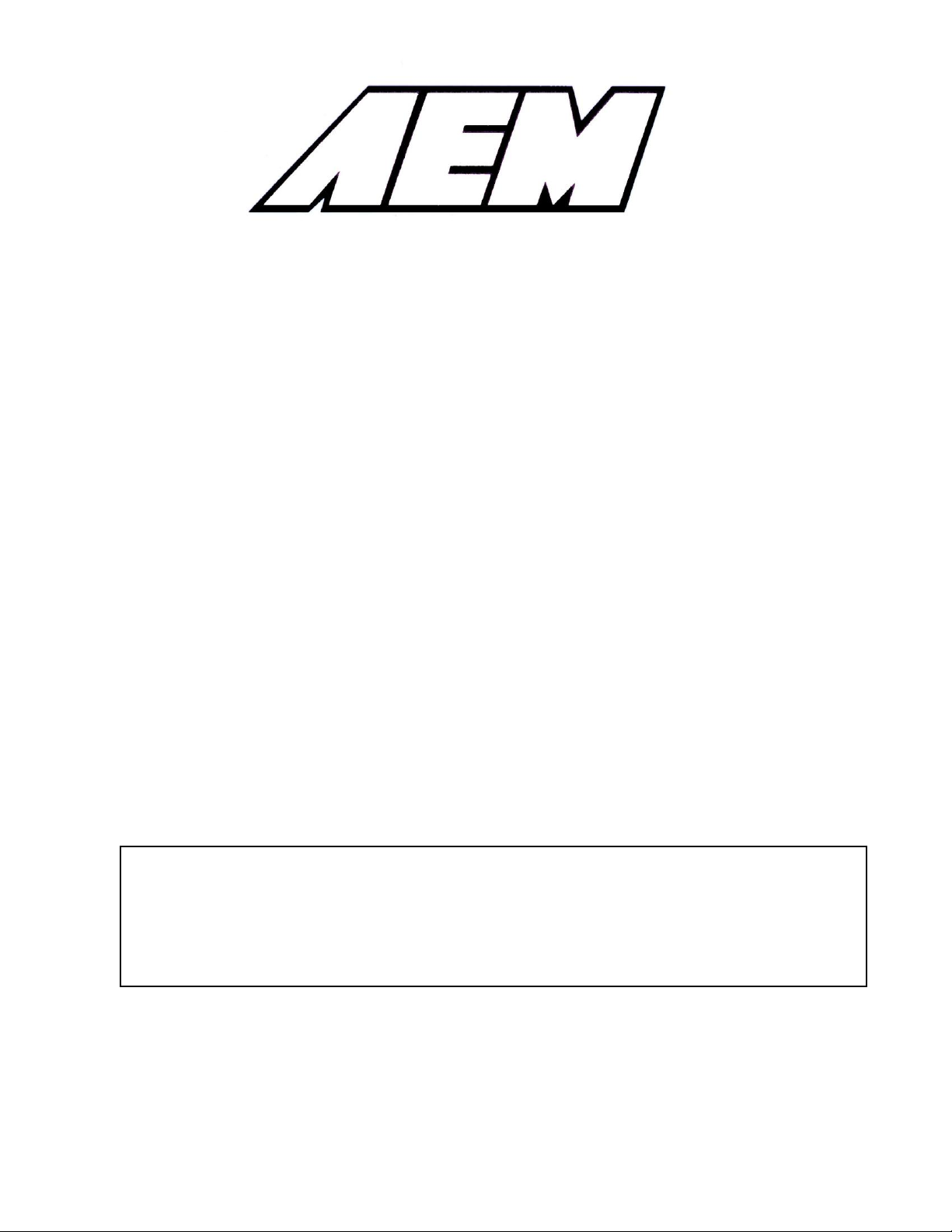

Dowel

pins

a) Remove the two flathead screws from the

bottom of the fuel rail.

b) Remove the dowel pins from the holes

exposed by the removal of the screws. It may

be necessary to push them through from the

access holes in the top of the rail using a paper

clip.

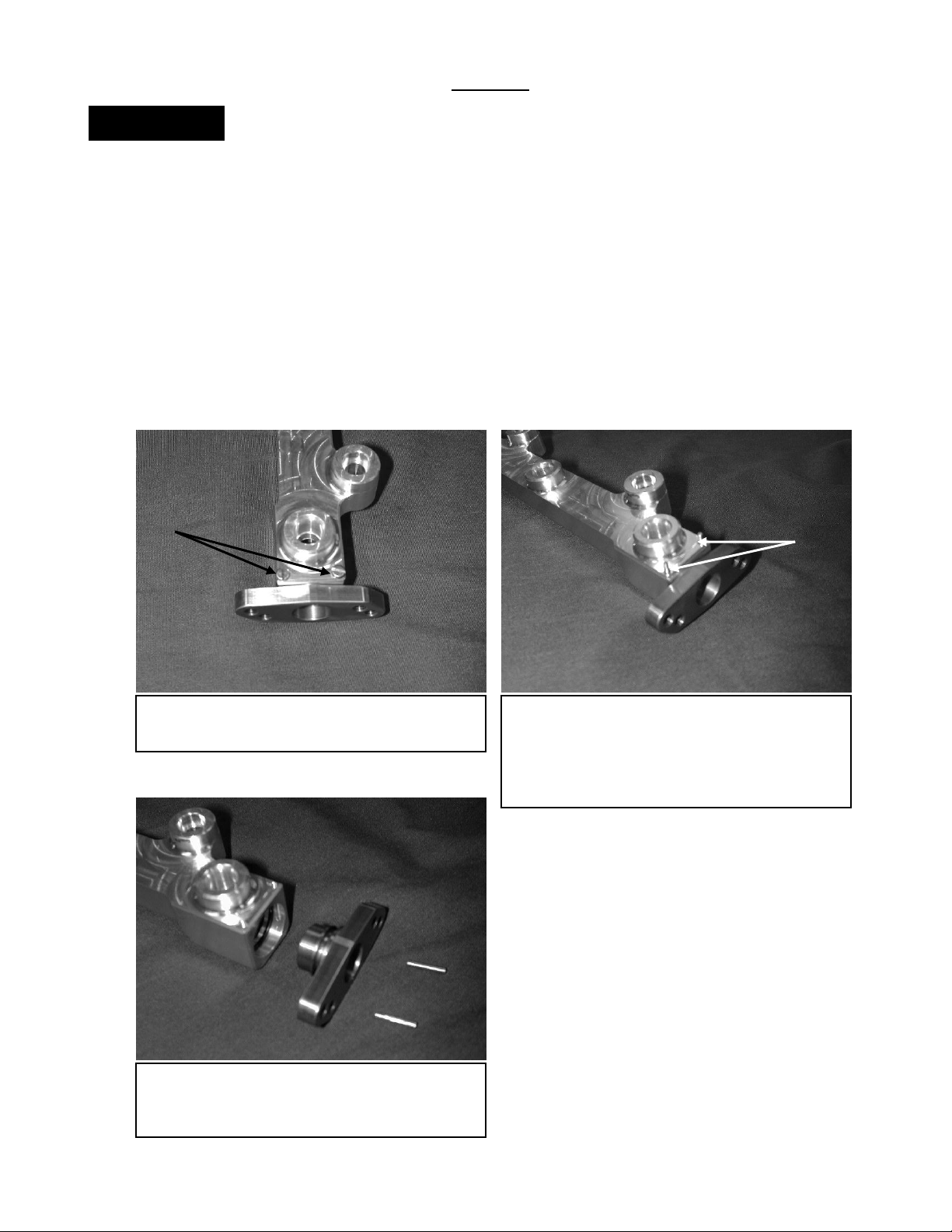

c) Pull the end adapter out of the fuel rail.

Remove the old o-rings and thoroughly clean

all surfaces.

Remove

Do not smoke while working on the fuel system.

Keep open flames or sparks away from your work area.

Be sure to relieve fuel pressure before working on fuel system.

1) Getting started

a) Make sure vehicle is parked on a level surface.

b) Set parking brake.

c) If engine has run within the past two hours let it cool down.

d) Clean area around the fuel rail so that dirt cannot get into the engine.

Note it is recommended to:

Replace all cushion rings, seal rings and fuel injector insulators when fuel rail is disassembled.

2) Disassembly of the AEM Fuel Rail

Page 3

3) Assembly of the AEM Fuel Rail

a) Make sure both ends of the fuel rail are

clean and free of debris and burrs.

b) Insert one 1-3024 o-ring into the inner

groove. Make sure the o-ring is evenly seated

in the groove.

c) Insert another 1-3024 o-ring up against the

first shoulder. Make sure the o-ring is seated

evenly against the shoulder and is past the

slots for the dowel pins.

Make sure o-ring is

past these slots.

d) Refer to this cut-away view for proper o-

ring installation. Warning: The o-rings MUST

be properly seated as shown in this

diagram. Improper installation may

damage the o-rings and cause leakage.

First o-ring goes

in this groove

Second o-ring goes

against this

O-rings MUST be past

the dowel pin slot

Warning: Improper assembly of the AEM fuel rail may result in leakage. Be sure to pressure test the

fuel rail on the vehicle before starting the engine or test-driving. If there is any sign of leakage, the

problem must be corrected before proceeding.

Page 4

f) Gently insert the end adaptor into the fuel

rail. Make sure the o-rings stay in place and

are not torn. Insert two 1-2061 dowel pins into

the dowel pin holes.

g) Insert and tighten two 1-2062 screws into

the dowel pin holes. Repeat steps b-g for the

other side of the fuel rail.

e) Lightly lubricate the tip of the end adapter

and the o-rings in the end of the fuel rail. Clean

engine oil works well.

AEM –AN

Adapter

Supplied –6

Crush Washer or

Earl’s Stat-O-Seal

(P/N 178009ERL)

Earl’s –6 to 9/16-18

Adapter (P/N 985006ERL)

Earl’s –6 90 Degree

Auto-Fit Hose End

This configuration works well on the inlet side of the fuel rail only. A line needs to be made from the

fuel filter to the fuel rail. Because this configuration extends off of the fuel rail so far, it is not

suitable for the return side of the fuel rail. The hose end will come into contact with the timing belt

cover if this configuration is used on the return side of the fuel rail.

Lubricate

Dowell Pins

4) Plumbing the AEM Fuel Rail

The AEM AN Adapter Kit is intended for use in custom fuel system applications. The AEM Universal

Fuel Pressure Regulator (P/N 25-302) may be mounted in a remote location and plumbed into the

fuel system using this kit. Shown below are suggested methods for attaching AN style lines to the

AEM Fuel Rail. Final fuel system configuration and plumbing is up to the end user.

Page 5

Qty.

Part Number

Description

2

2-645

Mitsubishi AN Adapter

4

1-3024

O-Ring (BUNA 70)

2

1-3007

Crush Washer, -6

1

10-381

Instructions

For Technical Inquiries

Please E-Mail us at

tech@aempower.com

This configuration works well on either the inlet or return side of the fuel rail. A line needs to be

constructed from the filter to the rail on the inlet side of the fuel rail. On the return side of the fuel rail,

a line needs to be made from the rail to the remote mounted regulator (AEM P/N 25-302), and from

the regulator’s outlet port to the vehicle’s fuel return line.

AEM –AN

Adapter

Supplied –6

Crush Washer or

Earl’s Stat-O-Seal

(P/N 178009ERL)

Earl’s –6 Swivel Seal Hose

End (P/N 849006ERL)

5) Finishing Touches

a) Connect the negative battery terminal.

b) Turn the ignition switch to the on position for approximately two seconds. Do not operate the starter.

Then turn the ignition switch to the off position.

c) Repeat this procedure three times, and then check all components that were removed during installation

for any signs of fuel leakage.

i. Be sure to check the area around the fuel inlet fitting, the injectors, the regulator,

and the 1/8” NPT plug. If these items were not installed correctly, they may be

prone to leakage.

d) If there are signs of leakage you MUST correct the leak before proceeding.

e) If there are no signs of leakage, then start engine and again check for leaks. If there is any sign of

leaking you MUST repair the leak before driving the vehicle.

Bill of Materials for Kit # 25-391

Loading...

Loading...