Page 1

TRU-TIME

ADJUSTABLE

CAM GEAR

Part Number:

23-800BK & 23-804BK

WARNING:

This installation is not for the mechanically challenged! If you

are not mechanically inclined or do not understand the

procedure please do not attempt the installation. Refer the

installation to a reputable mechanic. It is highly recommended to

,!

Legal in California only for racing vehicles which may never be used upon a

public highway.

purchase the factory service manual to use as a guide along with

these instruction sheets

.

©2011 Advanced Engine Management, Inc.

AEM Performance Electronics

th

2205 W. 126

Phone: (310) 484-2322 Fax: (310) 484-0152

Street, Unit A, Hawthorne, CA 90250

http://www.aemelectronics.com

Instruction Part Number: 10-7030 Rev C

Page 2

You have just purchased the BEST adjustable cam sprockets available. These AEM billet

aluminum adjustable cam gears are CNC machined from billet aluminum and then laser etched

with cam timing marks for adjustment up to ±10° at the cam or ±20° at the crankshaft. Using the

vernier scale on the sprocket hub helps to do the cam timing changes quickly and accurately.

The inner hub is anodized for lasting beauty and resistance to corrosion. The out gear sector is

hard anodized for resistance to wear.

We have found that there are significant power gains to be made by adjusting the cam timing

even with stock cams and compression. Adjustable cam sprockets are usually required in

applications where an aftermarket or reground performance cams are installed or the cylinder

head has been milled 0.005” or more. The use of these cam sprockets allows the extraction of

maximum power from your engine. We have recorded gains of up to 10~15 horsepower due to

cam timing tuning using adjustable cam sprockets.

When an aftermarket or reground cam is installed, the original manufacturer’s cam timing

specifications are no longer accurate. The adjustable cam sprocket allows you to make

necessary adjustments to cam timing to maximize the performance of your engine. This is

accomplished by “degreeing in” the optimum cam timing for a particular engine set up.

The adjustable cam gear is especially effective when used with heads that have been milled.

The adjustability of the gear allows the accommodation of the changes in cam timing due to the

variation of timing belt length from the bottom gear to the top gear when the head is milled. If the

head has been milled 0.005” or greater the relationship between the head and the block is

altered by moving the head closer to the crankshaft resulting in retarded cam timing.

It must be emphasized that the preceding descriptions are generalizations and any adjustments

made must be done with a conservative approach and on a dynamometer or on a racetrack. We

do not condone any illegal activity on the street.

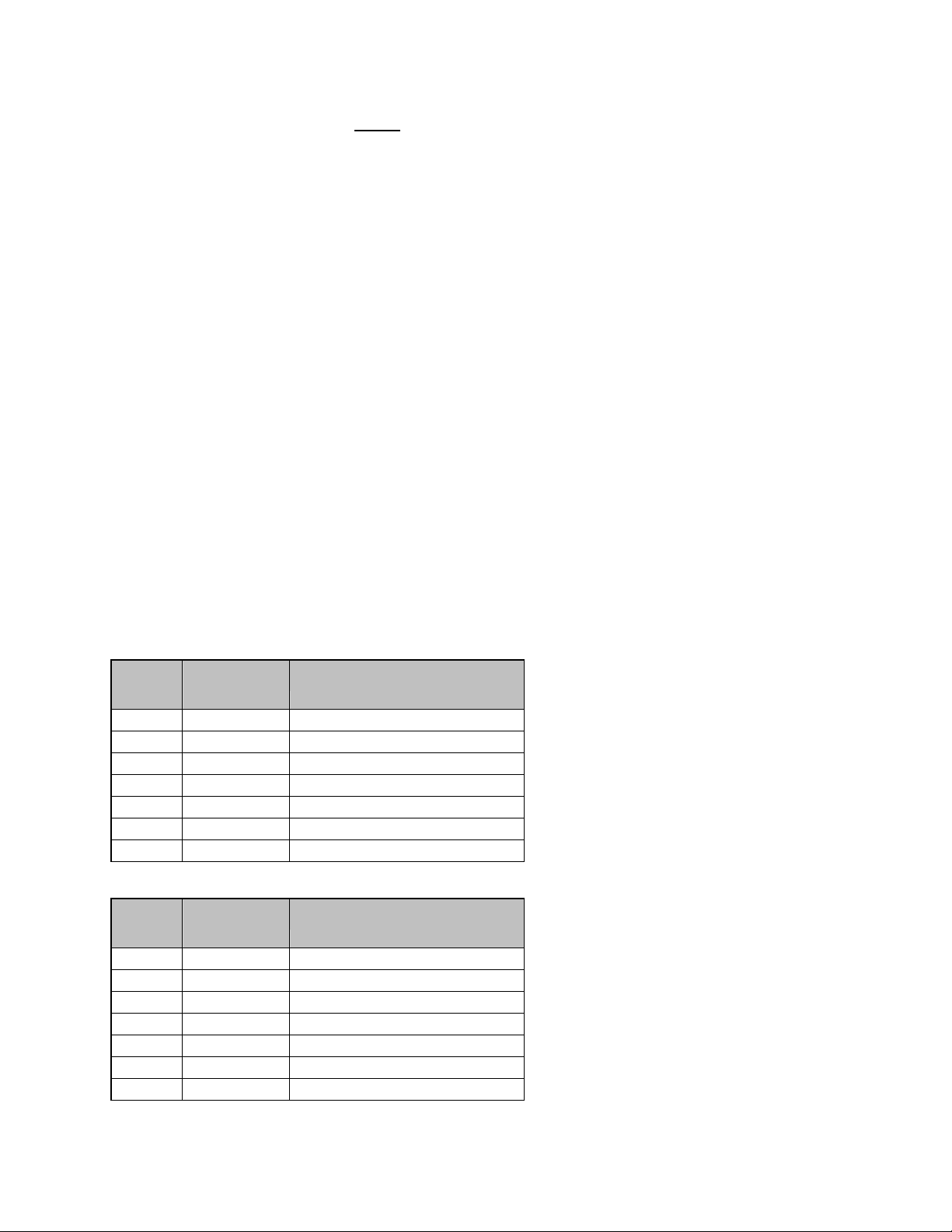

Part Number: 23-800

Quanity Part Number Description

5 1-2037 Bolt, 5/16 x 1/2

5 1-304 Washer, SS 5/16 x .570 x 1/32

1 10-7030 Instructions, 23-600 & 23-604

2 10-922S Decal, AEM Large Silver

1 2-810BK Inner Hub, Honda

1 2-801HA Outer Gear

1 90741-657-000 Key, Honda Cam

Part Number: 23-804

Quanity Part Number Description

5 1-2037 Bolt, 5/16 x 1/2

5 1-304 Washer, SS 5/16 x .570 x 1/32

1 10-7030 Instructions, 23-600 & 23-604

2 10-922S Decal, AEM Large Silver

1 2-804 Inner Hub, Honda

1 2-801HA Outer Gear

1 90741-657-000 Key, Honda Cam

Page 3

Getting started

a) The procedure to change the gears is similar to the timing belt replacement procedure outlined in

the factory service manual.

i) Note: This would be an appropriate time to replace the timing belt if replacement is

due or is close to the replacement interval.

b) Obtain a suitable box or container to hold the hardware that will be removed from the engine

during this installation. This will aid in the prevention of lost nuts and bolts.

c) Disconnect the negative battery terminal before starting these procedures.

d) Raise the front of the vehicle and support on jack stands. To ensure maximum safety use jack

stands that are properly rated for the task.

e) Remove the four nuts securing the driver side wheel and tire. Remove wheel and tire and set

aside.

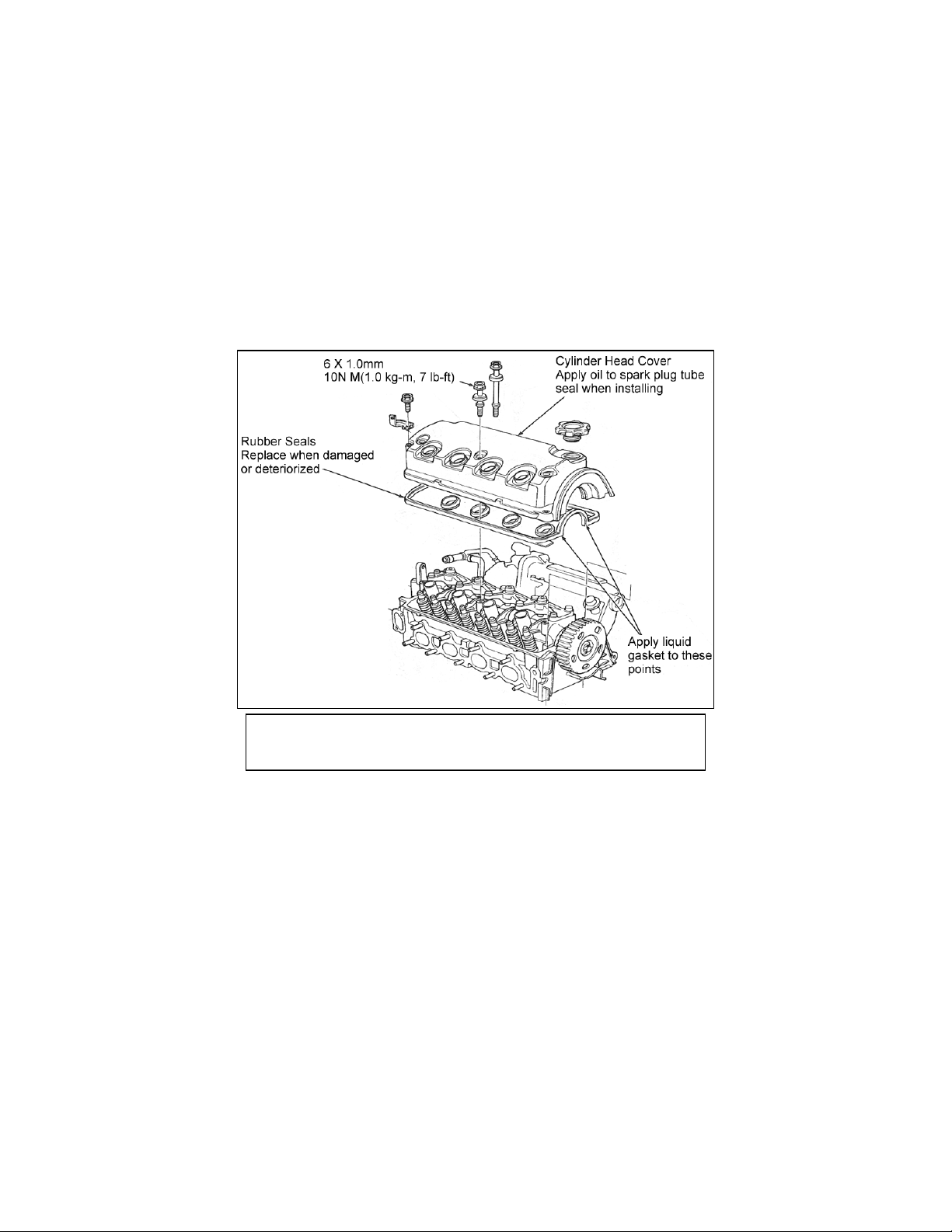

2) Removal of the stock cam Gear

a) Remove the spark plug wires. Remove the bolts securing

the valve cover to the cylinder head. Remove valve cover.

Page 4

b) Remove the bolts securing the upper cover. Remove the upper cover.

Remove the rubber plug to expose the belt tensioner adjustment bolt.

c) Align the motor to TDC. Always rotate motor in a counter-clockwise motion.

Page 5

e) Remove the bolt securing the camshaft pulley.

Remove the Camshaft pulley.

d) Loosen the belt tensioner bolt 180 degrees.

Push the tensioner to release tension from the

belt, and then retighten the adjusting bolt.

Remove the timing belt.

3) Installation of the AEM Cam Gear.

a) Inspect the AEM Tru-Time Adjustable Cam Gear:

i) The laser etched timing marks on inner hub and the outer gear should be clear and easy to

read.

ii) Loosen the cam gear bolts on the AEM cam gear and rotate the hub clockwise and counter

clockwise. It should move freely without any binding. Set the timing mark to 0° and tighten

the five cam gear bolts to 15 lb. ft.

iii) Compare the AEM cam gear to the O.E. cam gear. Make sure the major features of the two

cam gears are identical. This will include the timing belt tooth profile, keyway location and

laser etched TDC marks.

b) If the AEM cam gear does not function as described or look to be dimensionally correct in any

way do not

continue with this installation.

c) Install the AEM cam gear using the instructions for the removal of the O.E. cam gear in the

opposite order.

d) Apply engine oil to the threads of the camshaft bolt and crankshaft bolt. Torque to factory

specifications.

e) Tension Adjustment

Page 6

i) The tensioner is spring-loaded to apply proper tension to the belt automatically after making

the following adjustment.

ii) Always rotate the crankshaft counterclockwise when viewed from the pulley side. Rotating it

clockwise may result in improper adjustment of the belt tension.

iii) Set the engine to TDC.

iv) Loosen the adjusting bolt 180°.

v) Rotate the crankshaft counterclockwise so that the timing belt moves 3-teeth on the camshaft

pulley to create tension on the timing belt.

vi) Make sure the timing belt and camshaft pulley are engaged securely.

vii) Torque the adjusting bolt.

f) Rotate the crankshaft 6 complete revolutions and return it to the TDC mark on the crankshaft

pulley. The TDC marks on the AEM cam gear should align with the diagrams above. Note: If

marks do not line up the timing belt must be removed, the cam gear repositioned and the timing

belt re-installed. Repeat this step until the TDC marks on the AEM cam gear line up properly.

4) Calibration of the Tru-Time Adjustable Cam Gear

Adjustment of an AEM cam gear is best carried out on a dynamometer so that quantifiable results can be

measured.

a) Loosen the cam gear bolts.

b) To change the cam timing, place a wrench on the camshaft bolt. Turn the wrench counter

clockwise to advance the cam timing or clockwise to retard the cam timing.

c) Rotate the cam timing to the desired position and retighten the cam gear bolts to 15 lb. ft. Note: If

the head has been milled, take extreme caution when retarding the cam timing. There must be a

minimum clearance of 0.06” between the piston and the valve.

d) The cam timing directly affects the ignition timing in your vehicle. Once the adjustment of the

cam gear has been made you must reset the ignition timing back to the original location.

e) After changing the cam timing, perform a dyno run. If the results are positive then proceed further

in the direction of the timing change. If the performance decreased, then adjust the cam timing in

the opposite direction. Repeat this step until the optimum setting is found for your vehicle.

f) Apply Locite Red, or other suitable thread-locking compound; to the threads of the cam gear

bolts. Torque the bolts to 15 lb. ft.

The calibration of the AEM Tru-Time Adjustable Cam Gear is now complete.

Important information for the proper use of the Cam Bolts!

• The recommended torque specification is 15 lb. ft.

• Do not over torque. The maximum torque specification is 20 lb. ft.

• Anything less than the recommended torque value will allow the gear to slip.

Page 7

12 Month Limited Warranty

Advanced Engine Management, Inc. warrants to the consumer that all AEM High Performance

products will be free from defects in material and workmanship for a period of twelve (12)

months from date of the original purchase. Products that fail within this 12 month warranty

period will be repaired or replaced at AEM’s option, when determined by AEM that the product

failed due to defects in material or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall this

warranty exceed the original purchase price of the AEM part nor shall AEM be responsible for

special, incidental or consequential damages or cost incurred due to the failure of this product.

Warranty claims to AEM must be transportation prepaid and accompanied with dated proof of

purchase. This warranty applies only to the original purchaser of product and is non-transferable.

All implied warranties shall b e limited in duration to the said 12 month warranty period. Improper

use or installation, accident, abuse, unauthorized repairs or alterations voids this warranty.

An AEM Warranty Claim Form Must Accompany All Warranty Claims. Products returned to AEM

with no Return Goods Authorization and or No Warranty Claim Form may be rejected and

returned to sender.

AEM disclaims any liability for consequential damages due to breach of any written or implied

warranty on all products manufactured by AEM. Warranty returns will only be accepted be AEM

when accompanied by a valid Return Goods Authorization (RGA) number. Credit for defective

products will be issued pending inspection. Product must be received by AEM within 30 days of

the date RGA was issued.

Loading...

Loading...