Page 1

LAVATHERM 57810

Condensation dryer

User Information

Page 2

Dear customer,

Please read this User Information carefully and keep it to refer to at a

later date.

Pass it on to any subsequent owner of the appliance.

The following symbols are used in the text:

1 Safety instructions

Warning! Notes that concern your personal safety.

Important! Notes that show how to avoid damage to the appliance.

3 Useful tips and hints

2 Environmental information

2

Page 3

Contents

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Environmental tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Description of machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before the first drying cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sorting and preparing laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview of programmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Switching machine on / switching light on . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Opening loading door / filling laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Selecting the programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Selecting additional functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

INTENSITY (RESTVOCHT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AUDIBLE SIGNAL (ZOEMER). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SPECIAL CARE (LAGE TEMP.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SENSITIVE (BEHOEDZAAM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting time delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Starting the programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Changing programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Putting in extra items or taking items out before end of programme . . . . 15

Drying cycle complete / removing laundry. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning fluff filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning the door seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Emptying the condensate tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning the drum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Clean operating screen and housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

What to do if … . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting by yourself . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Changing bulb for inside light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3

Page 4

Programming options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Consumption values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installation and connection instructions. . . . . . . . . . . . . . . . . 25

Installation safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Removing transport safety equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Changing door stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Special accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Guarantee conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Customer services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4

Page 5

Operating Instructions

1 Safety

Before first starting up

• Note the ”Installation and connection instructions”

• Before first starting up, check the machine for any damage incurred

during transport. Never connect up a damaged machine. If parts are

damaged, contact your supplier.

Intended use

• The dryer is intended for drying standard laundry in domestic applications.

• Conversions or modifications to the dryer are not permitted.

• The laundry must not contain flammable solvents (benzene,

alcohol, stain remover, etc.) . Risk of fire and/or explosion! Laundry

which has come into contact with such substances must be rinsed

thoroughly by hand before drying.

• When using dry-cleaning sets: Only use those products which are declared as suitable for the dryer by the manufacturer.

• Do not place items of laundry in the dryer which contain foam rubber

or materials similar to rubber. Risk of fire!

• Do not place heavily worn laundry items in the dryer. Risk of fire!

• Do not place laundry items with loose fillings (e.g. cushions) in the

dryer. Risk of fire!

• Parts with rigid components (e.g. door mats) may cover the air slots.

Risk of fire! Do not place such items in the dryer.

• Do not overfill the dryer. Risk of fire! Observe max. loading volume of

6 kg.

• Ensure that explosive objects (e.g. cigarette lighters, spray cans, etc.)

do not enter the dryer with the laundry. Risk of fire and/or explosion!

• Clean the micro-fine filter and fine strainer after each drying cycle.

• Do not use the machine if there are no lint filters or if these are dam-

aged. Risk of fire!

• Clean the heat exchanger regularly.

• With stacked washer and dryer: Do not place objects on the dryer.

These may fall off during operation.

5

Page 6

• The covering bonnet of the bulb for the drum light must be screwed

down tightly.

Child safety

• Keep packaging away from children. Risk of suffocation!

• Children can often not see the dangers associated with electric ma-

chines. Never leave unsupervised children near the dryer.

• Ensure that children and small animals cannot climb into the dryer’s

drum. Risk of death! Keep the dryer door shut whenever it is not being used.

General safety

• Only specialists may undertake repairs on the dryer.

• Never start up the dryer if the mains cable is damaged or if the oper-

ating screen, operating plate or base area are damaged so that the inside of the machine is open and accessible.

• Switch off the dryer before all cleaning, care or maintenance work.

Also disconnect the mains plug from the socket or – with permanent

connections – switch off the LS switch in the fuse box and/or fully

unscrew the screwed-in fuse.

• Disconnect the machine from the power supply during long pauses in

operations.

• When removing from the socket, never pull the mains plug by the cable, instead take a hold of the plug.

• Manifold plugs, couplings and extension cables must not be used.

Risk of fire from overheating!

• Do not spray down the dryer with jets of water. Risk of electric shock!

• Do not lean on the open door. The machine may tip over.

• Once the drying cycle has been interrupted, the laundry and drum

may be hot. Risk of burns! Take care when removing the laundry.

Disposal

Packaging material

2

The packaging materials are environmentally friendly and can be recycled. The plastic components are identified by markings, e.g. >PE<,

>PS<, etc. Please dispose of the packaging materials in the appropriate

container at the community waste disposal facilities.

6

Page 7

2 Old appliance

The symbol

W on the product or on its packaging indicates that this

product may not be treated as household waste. Instead it shall be

handed over to the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of

correctly, you will help prevent potential negative consequences for the

environment and human health, which could otherwise be caused by

inappropriate waste handling of this product. For more detailed information about recycling of this product, please contact your local city

office, your household waste disposal service or the shop where you

purchased the product.

1 Warning! Remove mains plug from socket when you have no further

use for the machine. Cut off mains cable and dispose of together with

plug.

Destroy loading door lock. Children cannot then lock themselves in the

machine and put their lives at risk.

2 Environmental tips

• In the dryer, laundry becomes fluffy and soft. Fabric softeners are not

therefore needed when washing.

• Your dryer will function most economically if you:

– always keep the ventilation slots on the base of the dryer unob-

structed;

– use the loading volumes specified in the programme overview;

– ensure you have good ventilation in the installation room;

– clean the micro-fine filter and fine strainer after each drying cycle;

– spin the laundry well before drying. Example: Consumption data –

depending on spinning speed – for 6kg of laundry, dried using the

COTTONS STORAGE DRY (KATOEN KASTDROOG) programme.

Pre-draining Drying cycle

Revolutions

per minute

800 4.2 70 3,84 0,58

1200 3.2 53 3,10 0,47

1400 3.0 50 3,00 0,45

1800 2.5 42 2,60 0,39

1) Tariff: 0.15 Euro/kWh

Residual dampness Energy

in litres as a %

in kWh

Costs

in euros

1)

7

Page 8

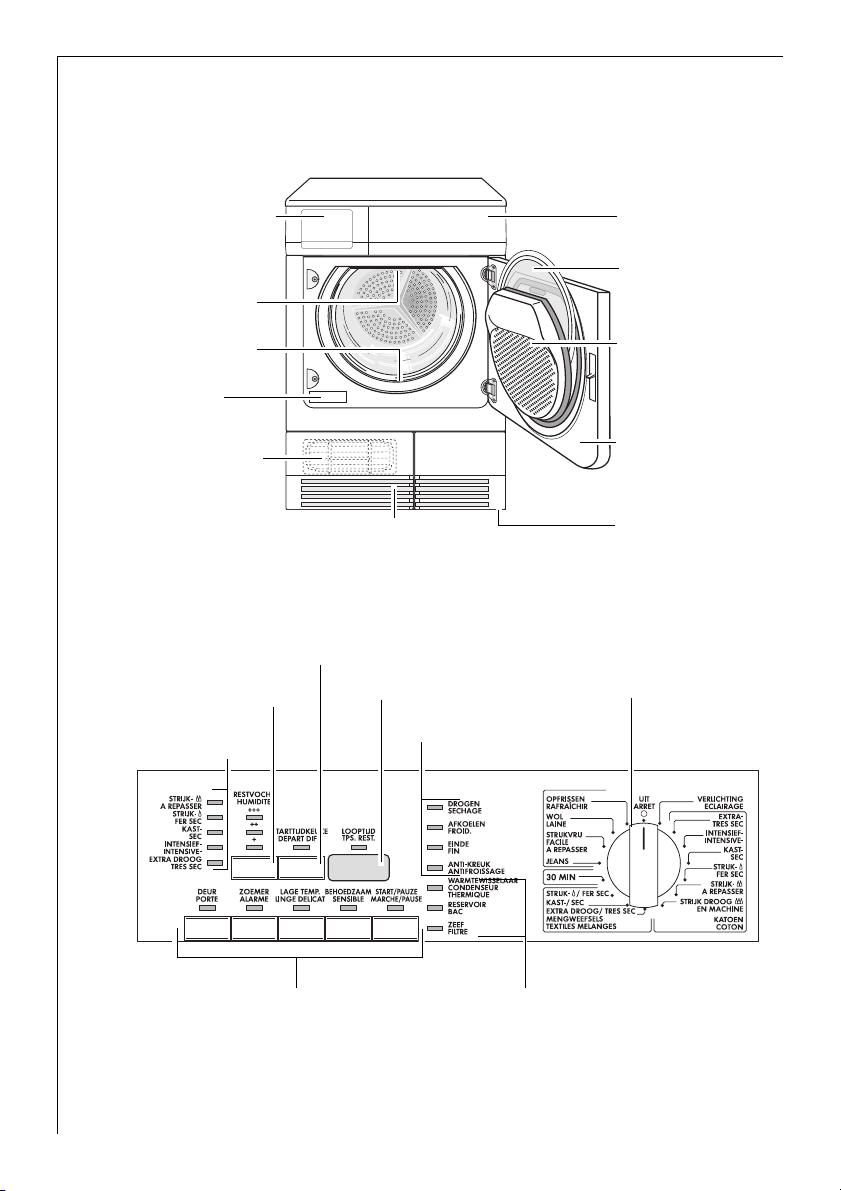

Description of machine

Drawer containing

condensate tank

Lamp for inside

light

Micro-fine filter

lint filter)

Type plate

Base door

upstream of heat

exchanger

Operating screen

DELAY TIMER (STARTTIJDKEUZE) button

INTENSITY (REST-

VOCHT) button

Display showing

level of dryness

Air slots

Multi-display

Programme progress display

Operating screen

Fine strainer

(lint filter)

Large mesh filter

(lint filter)

Loading door

(interchangeable

stop)

Screwed feet

(with height

adjustment)

Programme selector

Block of buttons

and displays

Maintenance displays

– HEAT EXCHANGER (WARMTEWISSELAAR) (clean!)

– EMPTY WATER (RESERVOIR) (empty!)

– CLEAN FILTER (ZEEF) (clean lint filter!)

8

Page 9

Before the first drying cycle

In order to remove any residue which may have been produced during

production, wipe the dryer drum with a damp cloth or undertake a

brief drying cycle (30 MIN) with damp cloths.

Sorting and preparing laundry

Sorting laundry

• Sort by fabric type:

– Cotton/linen for programmes in COTTONS (KATOEN) programme

group.

– Mixtures and synthetics for programmes in EASY CARES (MENG-

WEEFSELS) programme group.

• Sorting by care label. The care labels mean:

n m l k

Basic drying

in tumble dryer

possible

Drying at

normal

temperature

• Do not dry new, coloured textiles together with light-coloured laundry items. Textile colours may bleed.

• Do not dry tricot or knitted items with the EXTRA DRY (EXTRA

DROOG) programme. Items may become stuck!

• Do not dry wool in the dryer. May become entangled! After air-drying, wool may be dried with the WOOL CARE (WOL) programme.

Drying at

reduced temperature

(press SPECIAL CARE

(LAGE TEMP.) button!)

Drying

in tumble dryer

not possible

Preparing laundry

• To avoid laundry becoming tangled: Close zips, button up coverings

and tie loose bands or ribbons (e.g. of aprons).

• Empty pockets. Remove metallic items (paperclips, safety pins etc).

• Turn items with double-layered fabrics inside out (e.g. with cotton-

lined anoraks, the cotton layer should be outermost). These fabrics

will then dry better.

9

Page 10

Overview of programmes

Additional functions

Programme

max. loading volume

(weight when dry)

EXTRA DRY

(EXTRADROOG)

INTENSIVE

DRY

(INTENSIEFDROOG)

STORAGE

DRY

(KASTDROOG)

DAMP

STRIJK-

COTTONS (KATOEN)

DROOG ¢)

HAND IRON

(STRIJKDROOG £)

MACHINE

IRON

(STRIJKDROOG ¤)

EXTRA DRY

(EXTRADROOG)

STORAGE

DRY

(KASTDROOG)

DAMP

(STRIJKDROOG ¢)

EASY CARES (MENGWEEFSELS)

1) SPECIAL CARE (LAGE TEMP.) and SENSITIVE (BEHOEDZAAM) cannot both be selected at the

same time.

2) Press the SPECIAL CARE (LAGE TEMP.) button!

6kg • • • •

6kg • • • •

6kg • • • •

6kg • • • •

6kg • • • •

6kg • • • •

3kg • • • •

3kg • • • •

3kg • • • •

1)

AUDIBLE SIGNAL

(ZOEMER)

SPECIAL CARE

(LAGE TEMP)

SENSITIVE

Application/properties

(BEHOEDZAAM)1)INTENSITY

(RESTVOCHT)

Drying thick or multi-layered

textiles, e.g. terry towelling

items, bathing costumes.

Drying thick textiles, e.g. terry

towelling items, towels.

Drying textiles of even thicknesses, e.g. terry towelling

items, knitted items, towels.

For thin textiles which are still

to be ironed, e.g. knitted

items, cotton shirts.

For normal thickness cotton

or linen laundry, e.g. bedding,

table linen.

For cotton or linen laundry

which are still to be put

through a machine, e.g. bedding, table linen.

Drying thick or multi-layered

textiles, e.g. pullovers, bedding, table linen.

For thin textiles which are not

ironed, e.g. easy care shirts,

table linen, baby’s clothes,

socks, corsetry.

For thin textiles which are still

to be ironed, e.g. knitted

items, cotton shirts.

Care

symbols

m n

m n

m n

m n

m n

m n

m l2)

n

m l

n

m l

n

2)

2)

10

Page 11

Additional functions

Programme

max. loading volume

(weight when dry)

30 MIN 1kg • • - -

LEISURE

(JEANS)

EASY IRON

(STRIJKVRIJ)

WOOL CARE

(WOL)

REFRESH

(OPFRISSEN)

1) SPECIAL CARE (LAGE TEMP.) and SENSITIVE (BEHOEDZAAM) cannot both be selected at the

same time.

2) Press the SPECIAL CARE (LAGE TEMP.) button!

6kg • • • •

1kg • • - -

1kg • • - -

1kg • • - -

1)

AUDIBLE SIGNAL

(ZOEMER)

SPECIAL CARE

(LAGE TEMP)

SENSITIVE

Application/properties

(BEHOEDZAAM)1)INTENSITY

(RESTVOCHT)

For drying individual items of laundry or for small volumes of less than

1kg.

Special programme for leisure clothing, such as jeans, sweat-shirts, etc.,

of different material thicknesses

(e.g. at the cuffs and seams).

Special programme with anti-crease

mechanism for easy care textiles

such shirts and blouses; for minimum ironing effort. The result depends on the type and quality of

textiles. (The loading volume corresponds to approx. 5 to 7 shirts.)

Recommendation: Place textiles in

the dryer straight after spinning.

Once dried, immediately remove textiles and place on clothes hanger.

Special programme for briefly treating woollens with warm air after

they have been dried naturally, worn

or stored for long periods. Wool fibres are aligned and the wool becomes soft and snugly.

Recommendation: Remove textiles

immediately after drying.

Special programme, lasting around

35 minutes, for refreshing or gently

cleaning textiles with commercially

available dry cleaning sets.

(Only use those products which are

declared as suitable for the drier by

the manufacturer; please observe

the manufacturer’s instructions for

use.)

Care

symbol

m l

n

m n

m l2)

n

2)

11

Page 12

Drying

Switching machine on / switching light on

Turn the programme selector to any programme or turn it to LIGHT

(VERLICHTING). The machine has been switched on. When the loading

door is opened, the drum is illuminated.

Opening loading door / filling laundry

1. Open loading door:

– Either use force to push against the loading door (push point )

– or if the machine is switched on: Press the DOOR (DEUR) button.

2. Load your laundry (do not force it in).

1 Caution! Do not jam laundry in between the loading door and rubber

seal.

3. Close loading door securely. Lock must audibly lock.

Selecting the programme

Use the programme selector to set

the programme you require.

The probable programme run time

is displayed (in minutes) on the

multi-display.

12

Page 13

Selecting additional functions

INTENSITY (RESTVOCHT)

Precise setting of humidity content

of laundry. Laundry becomes dryer

from + to +++.

1. Press the INTENSITY (RESTVOCHT)

button as many times as necessary

until the small light at the level of

residual dampness required is illuminated.

If required, press the AUDIBLE SIGNAL (ZOEMER), SPECIAL CARE (LAGE TEMP.) or SENSITIVE

(BEHOEDZAAM) buttons.

AUDIBLE SIGNAL (ZOEMER)

When the drying cycle has finished, an intermittent audible signal will

sound.

SPECIAL CARE (LAGE TEMP.)

For especially gentle drying of sensitive fabrics with the l care label

and for temperature-sensitive textiles (e.g. acrylic, viscose). Programme

is executed with reduced heat.

SPECIAL CARE (LAGE TEMP.) is only suitable for use with loads of up to

3kg!

SENSITIVE (BEHOEDZAAM)

For gentle drying of frequently-worn textiles. Programme starts on full

heat setting, which is then reduced towards the end of the programme

to ensure gentle care of laundry.

3 SPECIAL CARE (LAGE TEMP.) and SENSITIVE (BEHOEDZAAM) cannot be

selected together.

13

Page 14

Setting time delay

3 With the DELAY TIMER (STARTTIJDKEUZE) button, you can delay the

start of a programme by between 30 minutes (30' and a maximum of

23 hours (23h).

1. Select the programme

2. Press the DELAY TIMER (STARTTIJDKEUZE) button as many times as nec-

essary until the required start delay appears on the multi display, e.g.

12h if the programme is to be started in 12 hours. The DELAY TIMER

(STARTTIJDKEUZE) display is illuminated.

3 If 23h is displayed and you press the button again, the time delay will

be cancelled. The display will show 0' and then the duration of the selected programme.

3. To activate the delay timer, press the START/PAUSE (START/PAUZE) button. The amount of time remaining until the programme is set to start

is continuously displayed (e.g. 12h, 11h, 10h, … 30

' etc).

3 Until the start of the programme the drum is moved at longish intervals

to loosen the laundry.

Starting the programme

Press the START/PAUSE (START/PAUZE) button. The programme is started.

The programme progress display and the display showing the level of

dryness show drying progress.

Changing programme

To change a programme which has been selected by mistake once the

programme has started, first turn the programme selector to OFF (UIT)

and then reset the programme.

3 The programme can no longer be changed directly once the programme

has started. If nevertheless there is an attempt to change the programme on the programme knob, the programme progress display and

the maintenance indicators flash. If an option button (excluding the

SIGNAL (ZOEMER) button) is pressed, Err appears in the multidisplay.

The drying programme is not however affected by this (laundry protection).

14

Page 15

Putting in extra items or taking items out before end of

programme

1. Open loading door

1 Warning! Laundry and drum can become hot. Risk of burns!

2. Load or remove laundry items.

3. Close loading securely. Lock must audibly lock.

4. Press the START/PAUSE (START/PAUZE) button to continue the drying

cycle.

Drying cycle complete / removing laundry

Once the drying cycle is complete, the END (EINDE) and CREASE GUARD

(ANTI-KREUK) displays light up. If the AUDIBLE SIGNAL (ZOEMER) button has been pressed, an audible signal sounds intermittently.

3 The drying cycle is automatically followed by a crease guard phase

which lasts around 30 minutes. The drum rotates in intervals during

this phase. The laundry thereby remains relaxed and free of creases. The

laundry can be removed at any time during the crease guard phase.

(The laundry should be taken out towards the end of the crease guard

phase at the latest to prevent creases from forming.)

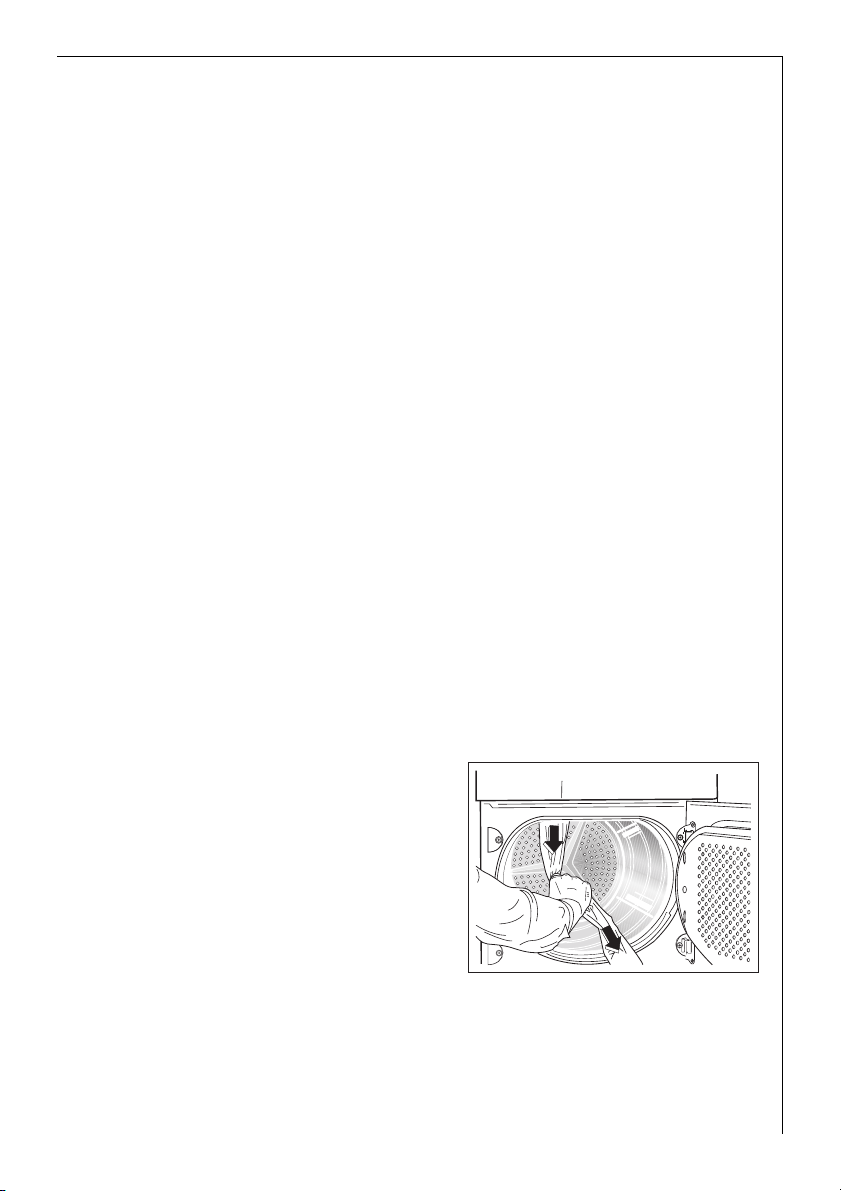

1. Open loading door

2. Before removing the laundry, remove lint from the micro-fine filer. It is

best to use a damp hand for this purpose (refer to “Cleaning and maintenance” section).

3. Remove laundry.

4. Turn the programme selector to OFF (UIT).

Important! After each drying cycle

– clean the micro-fine filter and fine strainer,

– drain the condensate tank

(refer to the “Cleaning and maintenance” section).

5. Close loading door.

15

Page 16

Cleaning and maintenance

Cleaning fluff filter

To ensure that the dryer works perfectly, the fluff filters (micro-fine filter and fine strainer) must be cleaned after every drying cycle.

1 Caution! Never operate the dryer without fluff filters or with damaged

or blocked fluff filters.

1. Open loading door

2. Use a damp hand to clean the mi-

cro-fine filter, which is built into

the lower part of the loading aperture.

3. Push down unlock button on large

mesh filter.

Large mesh filter jumps up.

4. Take out fine strainer.

5. Remove fluff from fine strainer. It

is best to use a damp hand for this

purpose.

16

Page 17

Clean the entire filter area

3 The strainer area does not have to be cleaned after every drying cycle,

but should be checked regularly and cleaned of fluff if necessary.

6. To do this, grip the top of the large

mesh filter and pull it forwards until it comes loose from the two

brackets.

7. Remove fluff from the entire filter

area. It is best to use a vacuum

cleaner for this purpose.

8. Press both journals of the large

mesh filter into the brackets on the

loading door until they snap into

place.

9. Re-insert fine strainer.

10. Press against the large mesh filter

until it locks into the interlock.

3 If the fine strainer is not fitted, the

large mesh filter will not snap into

place and the loading door cannot

be closed.

Cleaning the door seal

Wipe the door seal with a damp cloth immediately after the drying cycle has finished.

17

Page 18

Emptying the condensate tank

Empty condensate tank after every drying cycle.

If the condensate tank is full, an active programme will break off auto-

matically and the EMPTY WATER (RESERVOIR) display will light up. In

order to continue the programme, the condensate tank must first be

emptied.

1 Warning! The condensate is not suitable for drinking or for preparing

foodstuffs.

1. Take out drawer containing condensed water container

completely (1) and pull up the condensed water container’s drainage

pipe as far as it will go (2).

2. Pour condensed water out into a

basin or similar receptacle.

3. Slide outlet connections in and refit condensate tank.

If the programme has been interrupted as a result of the condensate tank being full:

Press the START/PAUSE (START/

PAUZE) button to continue the

drying cycle.

3 The condensate tank has a volume of approx. 4 litres. This is sufficient

for around 6kg of laundry which has previously been spun at 800 revolutions/minute.

3 The condensate can be used as distilled water, e.g. for steam ironing.

However first filter the condensate (e.g. with a coffee filter) to remove

any residue and small pieces of fluff.

Cleaning heat exchanger

If the HEAT EXCHANGER (WARMTEWISSELAAR) display is illuminated,

the heat exchanger needs to be cleaned.

1 Caution! Operating when the heat exchanger is clogged with lint can

damage the dryer. This also increases energy consumption.

18

Page 19

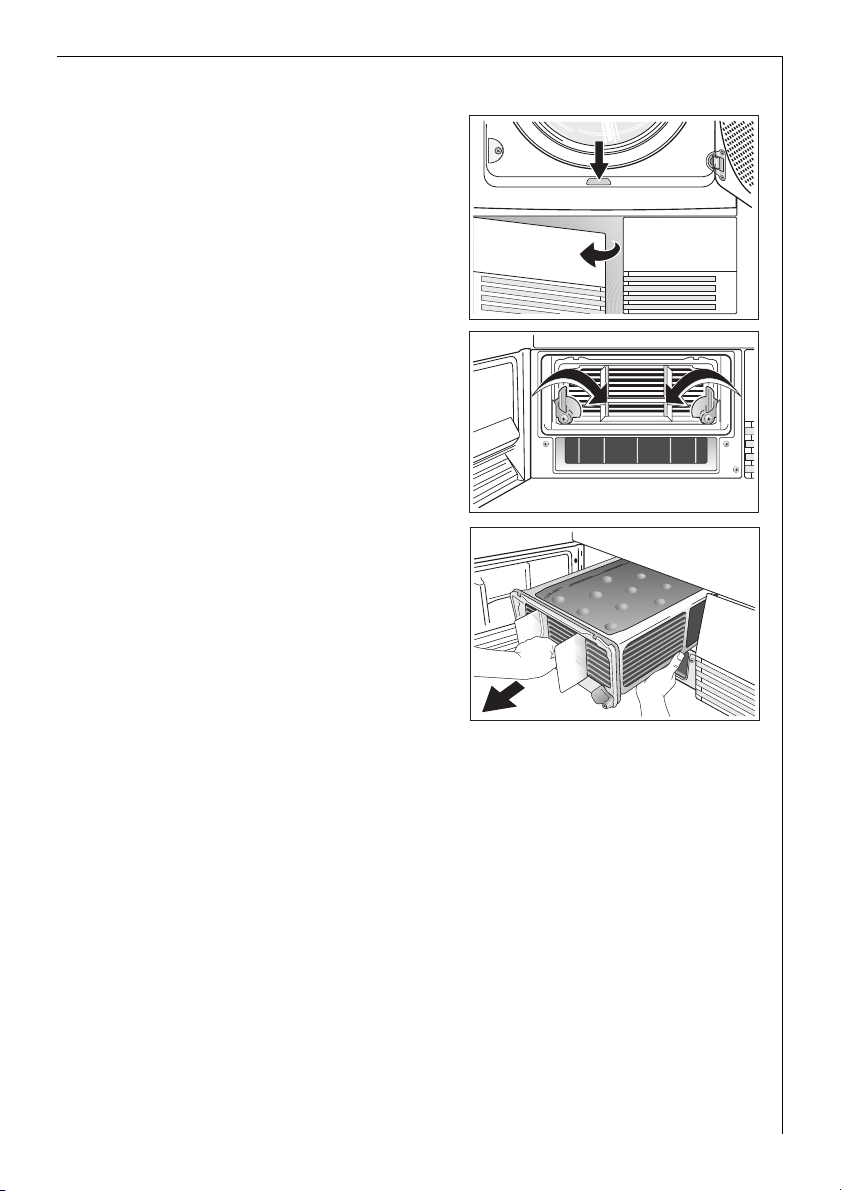

1. Open loading door

2. Open base door. To do this, press

the release button on the bottom

of the loading opening and open

the door to the left.

3. Remove lint from the inside of the

door and the heat exchange chamber. Wipe the door seal with a

damp cloth.

4. Turn both lock washers inwards.

5. Use the handle to pull the heat ex-

changer out of the base and carry

it horizontally to prevent any remaining water from spilling.

6. To empty the heat exchanger, hold

vertically over a washing-up bowl.

1 Caution! Do not use sharp objects

to clean. The heat exchanger could

develop leaks.

7. Clean heat exchanger.

It is best to use a brush or to rinse thoroughly with a shower head.

8. Replace heat exchanger and lock into place (turn both lock washers

outwards until they snap into place).

9. Close base door.

3 The dryer will not operate if the HEAT EXCHANGER (WARMTEWISSE-

LAAR) indicator is still lit.

1 Caution! Never operate the dryer without the heat exchanger.

19

Page 20

Cleaning the drum

1 Caution! Do not use abrasives or steel wool to clean the drum.

3 Lime in the water or cleaning agents may form a barely visible lining on

the inside of the drum. The degree to which the laundry has been dried

is then no longer detected reliably. The laundry is damper than expected when removed from the dryer.

Use a standard domestic cleaner (e.g. vinegar-based cleaner) to wipe

down the inside of the drum and drum ribs.

Clean operating screen and housing

1 Caution! Do not use furniture cleaners or aggressive cleaning agents to

clean the machine.

Use a damp cloth to wipe down the operating screen and housing.

What to do if …

Troubleshooting by yourself

If, during operation, the error code (E plus number or letter) appears on

the multi-display: Switch the machine off and on again. Reset programme. Press the START/PAUSE (START/PAUZE) button

If the error is still displayed, please inform our after-sales service and

quote the error code.

20

Problem Possible cause Remedy

Dryer does not work.

Mains plug is not plugged in

or fuse is not working correctly.

Loading door is open. Close loading door.

Have you pressed the START/

PAUSE (START/PAUZE) button?

Plug in at mains socket. Check

fuse in fuse box (domestic installation).

Press the START/PAUSE (START/

PAUZE) button again.

Page 21

Problem Possible cause Remedy

Select a different programme

the next time you dry (see

“Overview of programmes”

section).

Clean heat exchanger.

Observe recommended loading volumes.

Uncover ventilation slots in

base area.

Clean inside surface of drum

and drum ribs.

Adapt with the INTENSITY

(RESTVOCHT) function (See

“Selecting additional functions” section).

Set programme. Loading door

can be opened at any time by

exerting pressure on the door.

Install fine strainer and/or

snap large mesh filter into

place.

Turn the programme knob to

OFF (UIT). Set the programme

again.

Turn programme selector to

LIGHT (VERLICHTING) or to any

programme.

Replace light bulb (see next

section).

Automatic process; this is not

a machine fault.

Drying results unsatisfactory.

Loading door does not

open with DOOR

(DEUR) button.

Loading door does not

close.

When a button is

pressed, Err appears

in the multi-display.

Drum light does not

work.

PROGRAMME TIME

(LOOPTIJD) display

changes erratically or

stays unchanged for a

long time.

Wrong programme selected.

Lint filter clogged. Clean lint filter.

Heat exchanger clogged

with lint.

Incorrect volume of laundry.

Ventilation slots in base area

covered up.

Residue on inside surface of

drum or drum ribs.

Mains plug disconnected. Plug in at mains socket.

Programme selector in OFF

(UIT) position.

Fine strainer not in place

and/or large mesh filter not

locked in place.

Washing protection. After

the start of the programme,

the option can no longer be

set.

Programme selector in OFF

(UIT) position.

Defective light bulb.

Programme time is corrected automatically depending

on type and volume of

laundry and level of dampness.

21

Page 22

Problem Possible cause Remedy

Programme inactive,

EMPTY WATER (RESERVOIR) display illuminated.

Drying cycle ends

shortly after programme starts. END

(EINDE) display illuminated.

Drying cycle lasts an

unusually long time.

Note:

After around 5 hours

the drying cycle ends

automatically (see

„Drying cycle complete“).

Condensate tank is full.

Not enough washing loaded or washing loaded is too

dry for selected programme.

Lint filter clogged. Clean lint filter.

Heat exchanger clogged

with lint.

SPECIAL CARE (LAGE TEMP.)

button pressed and load

volume too big.

Load volume too big. Reduce load volume.

Laundry insufficiently predrained.

Empty condensate tank, then

start programme with START/

PAUSE (START/PAUZE) button.

Select time programme or

higher drying level (e.g. INTENSIVE DRY - INTENSIEF-DROOG

instead of STORAGE DRY KAST-DROOG).

Clean heat exchanger.

SPECIAL CARE (LAGE TEMP.) is

only suitable for use with

loads of up to 3kg!

Laundry must be adequately

pre-drained.

Changing bulb for inside light

Only use a special bulb which is designed specially for dryers. The special bulb is available from the after-sales service,

ET-Nr. 112 552 000-5.

1 Warning! Do not use standard bulbs! These develop too much heat and

may damage the machine!

1 Warning! Before replacing the bulb, disconnect the mains plug; with a

permanent connection: fully unscrew or deactivate the fuse.

1. Unscrew covering bonnet from above bulb (this can be found directly

behind the loading aperture, at the top; refer to “Description of machine” section.)

2. Replace defective bulb.

3. Screw covering bonnet back down.

1 Warning! For reasons associated with safety, the covering bonnet must

be screwed down tightly. If this is not done, the dryer must not be operated.

22

Page 23

Programming options

Objective Implementation

1. Turn the programme selector to any programme.

Permanently program in

the audible signal which

reminds you that the

programme is complete.

Adjust detection of degree of drying:

If the laundry is slightly

drier or slightly damper

at the end of the programme than with the

standard setting.

If the EMPTY WATER

(RESERVOIR) display is to

remain permanently deactivated when using an

external condensate

drain.

2. Press the AUDIBLE SIGNAL (ZOEMER) button and hold

down for approx. 5 seconds.

A brief signal sounds several times. The AUDIBLE SIGNAL

(ZOEMER) display flashes several times.

The setting is permanently programmed.

The setting is cancelled as described under 1 and 2.

1. Turn the programme selector to any programme.

2. Press the AUDIBLE SIGNAL (ZOEMER) and SENSITIVE

(BEHOEDZAAM) buttons at the same time and hold

down for approx. 5 seconds.

The current setting appears on the multi-display:

– C0: Setting for drier laundry

– C1: Standard setting

– C2: Setting for damper laundry

3. Press the START/PAUSE (START/PAUZE) button until the

setting required appears on the multi-display.

4. Turn the programme selector to OFF (UIT).

The setting is permanently programmed.

1. Turn the programme selector to any programme.

2. Press the DOOR (DEUR) and SPECIAL CARE (LAGE TEMP.)

buttons at the same time and hold down for approx. 5

seconds. The multi-display briefly displays ”0”

The EMPTY WATER (RESERVOIR) display is permanently

deactivated.

The setting is cancelled as described under 1 and 2; the

multi-display however briefly displays ”1” (rather than

”0”).

23

Page 24

Technical data

This appliance conforms with the following EU Directives:

5

– 73/23/EEC dated 19.02.1973 Low Voltage Directive

– 89/336/EEC dated 03.05.1989 EMC Directive inclusive of Amending

Directive 92/31/EEC

– 93/68/EEC dated 22.07.1993 CE Marking Directive

Height x width x depth 85 x 60 x 60 cm

Depth with loading door open 109 cm

Height can be adjusted by 1.5 cm

Weight when empty approx. 42kg

Loading volume (depends on programme)

Energy consumption in accordance with IEC 1121 s. e.

(6kg of cotton, pre-drained at 800 rpm,

COTTONS STORAGE DRY (KATOEN KASTDROOG)

programme)

Scope Domestic

permissible ambient temperature + 5°C to + 35°C

1) Different loading volume data may be needed in some countries as a result of different measuring methods.

1)

max. 6kg

3,84 kWh

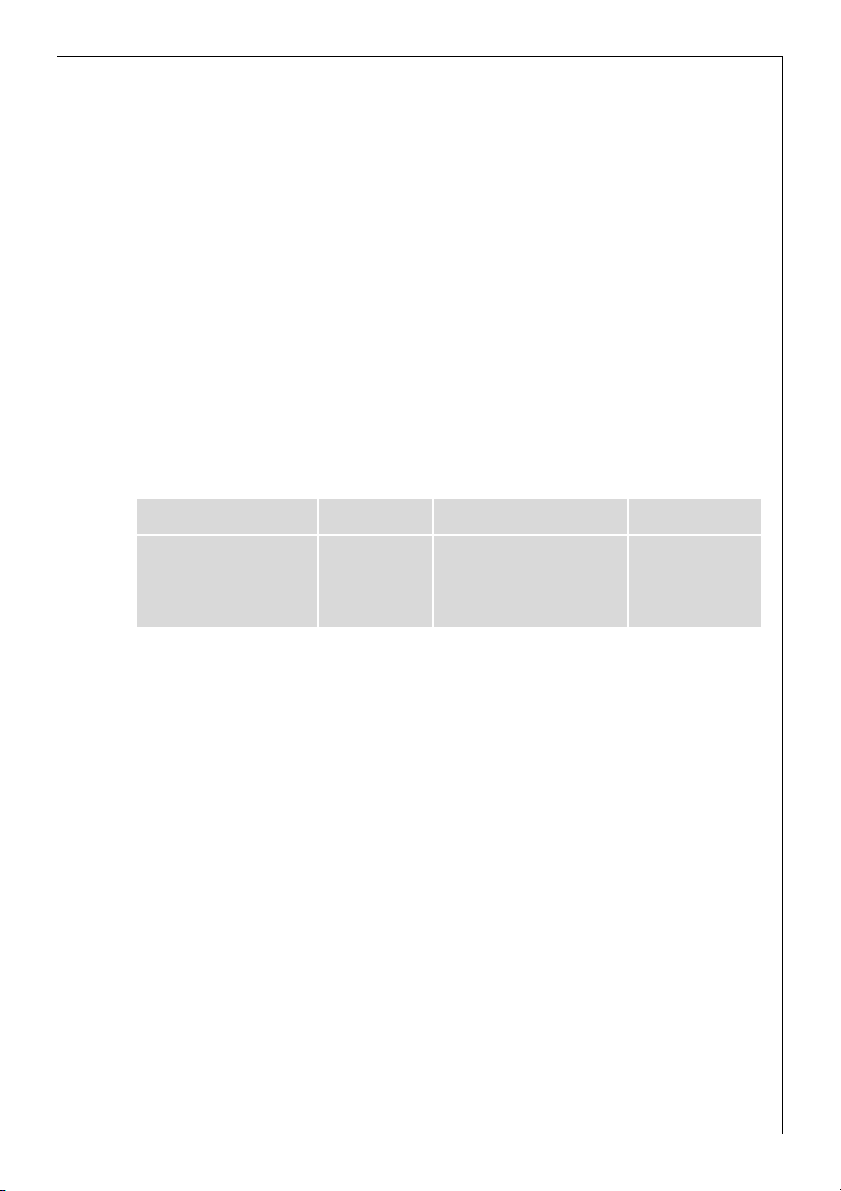

Consumption values

The consumption values have been established under standard conditions. They may deviate when the machine is operated in domestic circumstances.

Programme

24

COTTONS STORAGE DRY

(KATOEN KASTDROOG)

COTTONS HAND IRON

(KATOEN STRIJKDROOG £)

EASY CARES STORAGE DRY

(MENGWEEFSELS KASTDROOG)

1) pre-drained at 800 rpm

2) pre-drained at 1000 rpm

1)

Loading volume

in kg

6 3,84

1)

2)

6 3,10

3 1,55

Energy

consumption

in kWh

Page 25

Installation and connection instructions

1 Installation safety instructions

• Before first starting up, all parts of the transport safety equipment

must be removed. The machine may otherwise be damaged.

• Before starting up for the first time, ensure that the nominal voltage

and type of current specified on the machine type plate match the

nominal voltage and type of current at the installation site. The electrical fuses required can also be found on the type plate.

• Always connect the plug into a protection contact socket which has

been installed as specified.

• With permanent connections: A permanent connection may only be

established by an authorised specialist electrician.

• Do not install machine in rooms at risk of frost.

• Ensure that the door of the machine cannot be blocked by interior

doors of the house or the doors of other appliances.

• Do not install on carpets with high piles. Air circulation will be hindered at the ventilation slots.

• Ensure that the machine is not placed on its mains cable.

• Install the machine horizontally.

Removing transport safety equipment

1

Caution! Before first starting up,

all parts of the transport safety

equipment must be removed.

1. Open loading door

2. Pull off adhesive strips from inside

machine on top of drum.

25

Page 26

3. Remove foil hose and polystyrene

padding from the machine.

Electrical connection

Details on mains voltage, type of current and the fuses required should

be taken from the type plate. The type plate is fitted near the loading

aperture (see “Machine description” section).

Changing door stop

Warning! The door stop may only be changed by a specialist.

1

If necessary, please contact our after-sales service or your specialist

dealer.

Warning! Before changing the door stop, disconnect the mains plug;

with a permanent connection: fully unscrew or deactivate the fuse.

1. Open loading door.

2. Unscrew hinge A from the front of

the machine and take off the loading door.

3. Remove cover plates B and C. To do

this, insert a thin screwdriver into

the slots as shown in the illustration, press downwards slightly and

pry out the cover plates.

4. Use an appropriate tool and exert

pressure to unfasten locking block

D from the snap-on fixture, take

out and reinsert on the other side

having rotated the block through

180°.

26

Page 27

5. Unscrew hinge A from the loading door, rotate through 180°, reinsert

on the opposite side and screw down.

6. Reinsert cover plates B and C on the opposite site having first rotated

them through 180°.

7. Unscrew cover plates E from the

front of the machine, rotate

through 180°, screw on the

opposite side.

8. Unscrew door lock F, push down

slightly and remove from the front

of the machine.

9. Disconnect cable connector from

door lock F.

10. Press snap-in button G in and

down, press cover down slightly

and remove from front of the machine.

11. Disconnect cable connector from

cover G.

12. Change door lock F over to the opposite side, insert the cable connector and screw down the door

interlock.

13. On the other side, insert the cable connector in cover G, insert cover

and allow snap-in button to lock into place.

14. Insert loading door and hinges into recesses on the front of the machine and screw down.

15. Once the door stop has been replaced, check the function of the DOOR

(DEUR) button.

Note regarding contact protection: The machine is only secure for

operations again once all plastic parts have been inserted.

27

Page 28

Special accessories

The following special accessories are available from your Service Force

Centre or your specialist dealer:

Intermediate installation kits for stacked washer and

dryer:

These intermediate installation kits can be used to arrange the dryer

and an automatic AEG-Electrolux washing machine (60cm wide, front

loading) as a space-saving washer/dryer stack. The automatic washing

machine is at the bottom and the dryer is at the top.

Two versions can be supplied:

– without stacker plate 916.018 902

– with extractable stacker plate 916.018 903

Installation kit for external condensate drain

Installation kit (125 122 510) for direct draining of condensate into a

basin, siphon, gully, etc. The condensate tank then no longer has to be

drained, it must however remain in its intended position in the machine. Refer to the “Programme options” section for how to deactivate

the EMPTY WATER (RESERVOIR) display.

Max. displacement height: 1m from the base of the dryer; max. displacement length: 3m

28

Page 29

Guarantee conditions

Belgium

DECLARATION OF GUARANTEE TERMS.

Our appliances are produced with the greatest of care. However, a defect may still occur. Our consumer services department will repair this upon request, either during or after the guarantee period. The service life of the appliance will not, however, be reduced as a result.

This declaration of guarantee terms is based on European Union Directive 99/44/EC and the provisions of the Civil Code. The statutory rights that the consumer has under this legislation are not

affected by this declaration of guarantee terms.

This declaration does not affect the vendor's statutory warranty to the end user. The appliance is

guaranteed within the context of and in adherence with the following terms:

1. In accordance with provisions laid down in paragraphs 2 to 15, we will remedy free of charge any

defect that occurs within 24 months from the date the appliance is delivered to the first end user.

These guarantee terms do not apply in the event of use for professional or equivalent purposes.

2. Performing the guarantee means that the appliance is returned to the condition it was in before

the defect occurred. Defective parts are replaced or repaired. Parts replaced free of charge become

our property.

3. So as to avoid more severe damage, the defect must be brought to our attention immediately.

4. Applying the guarantee is subject to the consumer providing proof of purchase showing the pur-

chase and/or delivery date.

5. The guarantee will not apply if damage caused to delicate parts, such as glass (vitreous ceramic),

synthetic materials and rubber, is the result of inappropriate use.

6. The guarantee cannot be called on for minor faults that do not affect the value or the overall reliability of the appliance.

7. The statutory warranty does not apply when defects are caused by:

• a chemical or electrochemical reaction caused by water,

• abnormal environmental conditions in general,

• unsuitable operating conditions,

• contact with harsh substances.

8. The guarantee does not apply to defects due to transport which have occurred outside of our responsibility. Nor will the guarantee cover those caused by inadequate installation or assembly, lack

of maintenance or failure to respect the assembly instructions or directions for use.

9. Defects that result from repairs or measures carried out by people who are not qualified or expert

or defects that result from the addition of non-original accessories or spare parts are not covered

by the guarantee.

10. Appliances that are easy to transport may be delivered or sent to the consumer services department. Home repairs are only anticipated for bulky appliances or built-in appliances.

11 . If the appliances are built-in, built-under, fixed or suspended in such a way that removing and re-

placing them in the place where they are fitted takes more than half an hour, the costs that result

therefrom will be charged for. Connected damage caused by these removal and replacement operations will be the responsibility of the user.

12. If, during the guarantee period, repairing the same defect repeatedly is not conclusive, or if the repair costs are considered disproportionate, in agreement with the consumer, the defective appliance may be replaced with another appliance of the same value.

In this event, we reserve the right to ask for a financial contribution calculated according to the

length of time it has been used.

13. A repair under guarantee does not mean that the normal guarantee period will be extended nor

that a new guarantee period begins.

14. We give a twelve month guarantee for repairs, limited to the same defect.

15. Except in the event where liability is legally imposed, this declaration of guarantee terms excludes

any compensation for damage outside the appliance for which the consumer wishes to assert his

rights. In the event of legally admitted liability, compensation will not exceed the purchase price

paid for the appliance.

29

Page 30

These guarantee terms are only valid for appliances purchased and used in Belgium. For exported

appliances, the user must first make sure that they satisfy the technical conditions (e.g.: voltage,

frequency, installation instructions, type of gas, etc.) for the country concerned and that they can

withstand the local climatic and environmental conditions. For appliances purchased abroad, the

user must first ensure that they meet the qualifications required in Belgium. Non-essential or requested adjustments are not covered by the guarantee and are not possible in all cases.

Our consumer services department is always at your disposal, even after the guarantee period has

expired.

Address for our consumer services department:

ELECTROLUX HOME PRODUCTS BELGIUM

Bergensesteenweg, 719 - 1502 LEMBEEK

Tel.: 02.363.04.44

Customer services

Belgium

Electrolux Home Products Belgium

ELECTROLUX SERVICE

Bergensesteenweg 719

1502 Lembeek

E-mail:

consumer.services@electrolux.be

Consumer services 02/363.04.44 02/363.04.00

Tel.: Fax.:

02/363.04.60

30

Page 31

Service

In the event of technical faults, please first check whether you can

remedy the problem yourself with the help of the operating instructions (section “What to do if…”).

If you were not able to remedy the problem yourself, please contact the

Customer Care Department or one of our service partners.

In order to be able to assist you

quickly, we require the following

information:

– Model description

– Product number (PNC)

– Serial number (S No.)

(for numbers, see rating plate)

– Type of fault

– Any error messages displayed by

the appliance

So that you have the necessary reference numbers from your appliance

at hand, we recommend that you write them in here:

Model description: .....................................

PNC: .....................................

S No.: .....................................

31

Page 32

From the Electrolux Group. The world´s No.1 choice.

The Electrolux Group is the world´s largest producer of powered appliances for kitchen, cleaning and outdoor

use. More than 55 million Electrolux Group products (such as refrigerators, cookers, washing machines,

vacuum cleaners, chain saws and lawn mowers) are sold each year to a value of approx. USD 14 billion in more

than 150 countries around the world.

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg-electrolux.de

© Copyright by AEG

822 944 821-01-220705-01

Subject to change without notice

Loading...

Loading...