Page 1

English

For your safety

This new appliance is easy to use, however, make sure to read this handbook before installing and using it for the first

time. In this way you can obtain best use, avoid incorrect operations, use the appliance in complete safety and respect

the environment.

Installation

• Appliance installation and connection to the power supply

must only be carried out by QUALIFIED PERSONNEL.

Before carrying out any operation, make sure the appliance

is DISCONNECTED from the power supply.

• Make sure air can circulate freely around the appliance.

Poor ventilation creates a lack of oxygen.

• Make sure the appliance is fed with the type of gas specified

on the special sticker located near the gas connection pipe.

• The use of a gas cooking appliance produces heat and

humidity in the room where it is installed. Ensure good

ventilation in the room by keeping air inlets open and

efficient, or install an extractor hood with exhaust flue.

• In case of intensive and prolonged appliance use, room

ventilation must be made more efficient by opening a

window or increasing the power of the electric exhaust fan,

if present.

• After unpacking the appliance, make sure it is not damaged

and that the power cable is in perfect condition. Otherwise,

contact the dealer before using the appliance.

• The Manufacturer declines any liability if the accidentprevention regulations are not respected.

• After using the appliance, make sure all the controls are in

the “CLOSED” or “OFF” position.

• When using a power socket near this appliance, make sure

the cords of any electrical appliances being used do not

touch it and are far enough away from its hot parts.

Advice for safeguarding

the environment

• All the materials used are environmentally friendly and

recyclable. Please make your contribution to safeguarding

the environment by using the special differentiated waste

collection channels.

• Appliances that are no longer used or unusable are not

worthless waste. Through ecological disposal, various

materials used in manufacturing your appliance can be

recovered.

• Find out about the possibilities of disposal from your

specialised dealer or local Council.

• When disposing of the appliance, make it unusable by

cutting off the power cable.

Children’s safety

• This appliance must only be used by adults. Make sure

children do not play with the appliance or touch the controls.

• The exposed parts of this appliance become hot during

cooking and remain hot for a certain amount of time even

after the appliance is turned off. Keep children away until

it has cooled.

During use

• This instruction handbook must be kept with the appliance

for any future consultation. If the appliance is sold or given

to another person, make sure the handbook goes with it,

so that the new user can know how to use the appliance with

the relevant instructions.

• This product is designed for non-professional home use,

for cooking food.

• Modifying or attempting to change the characteristics of this

product is hazardous.

• Keep the appliance clean. Food residuals can create the

risk of fire.

• In case of faults, never try to repair the appliance on your

own. Repairs carried out by unqualified persons can cause

damage and accidents. Firstly, consult this handbook. If

you do not find the necessary information, contact the

nearest Assistance Centre. Assistance for this appliance

must be carried out by an authorised Technical Assistance

Centre. Always demand the use of original spare parts.

Do not use it for any other purpose.

• The symbol

that it should not be treated as normal household waste

but must be taken to an appropriate collection point for

the recycling of electrical and electronic equipment.

Correct disposal of this appliance will help prevent

possible negative consequences for the environment and

the health of persons. For more detailed information about

the recycling of this product, contact your local council

office or waste disposal service, or the shop where you

purchased the product.

on the product or on the packing indicates

Instruction guide

The following symbols will help you quickly find the

main information.

Safety instructions

Step by step instructions

!

Useful advice and suggestions

Information on protecting the environment

These instructions are only valid for countries whose

identification symbols appear on the handbook cover

and on the appliance.

21

Page 2

Contents

For the installer

For the user

For your safety 21

Operating instructions 22

Cleaning and maintenance 23

Periodical maintenance 24

Assistance and spare parts 24

Warranty terms 24

This appliance complies with the following EEC

Directives:

-73/23 and 90/683 (Low Voltage);

-89/336

-90/396 (Gas Appliances)

-93/68 (General Standards)

and subsequent amendments.

(Electromagnetic Compatibility);

Technical specifications 25

Instructions for the installer 25

Electrical connection 27

Conversion to different types of gas 28

Building In 29

Operating instructions

Cooktop

control knobs

The knobs for the gas rings are located on the front part

of the top. The symbols on the knobs have the following

meaning:

• no gas

max. gas

min. gas

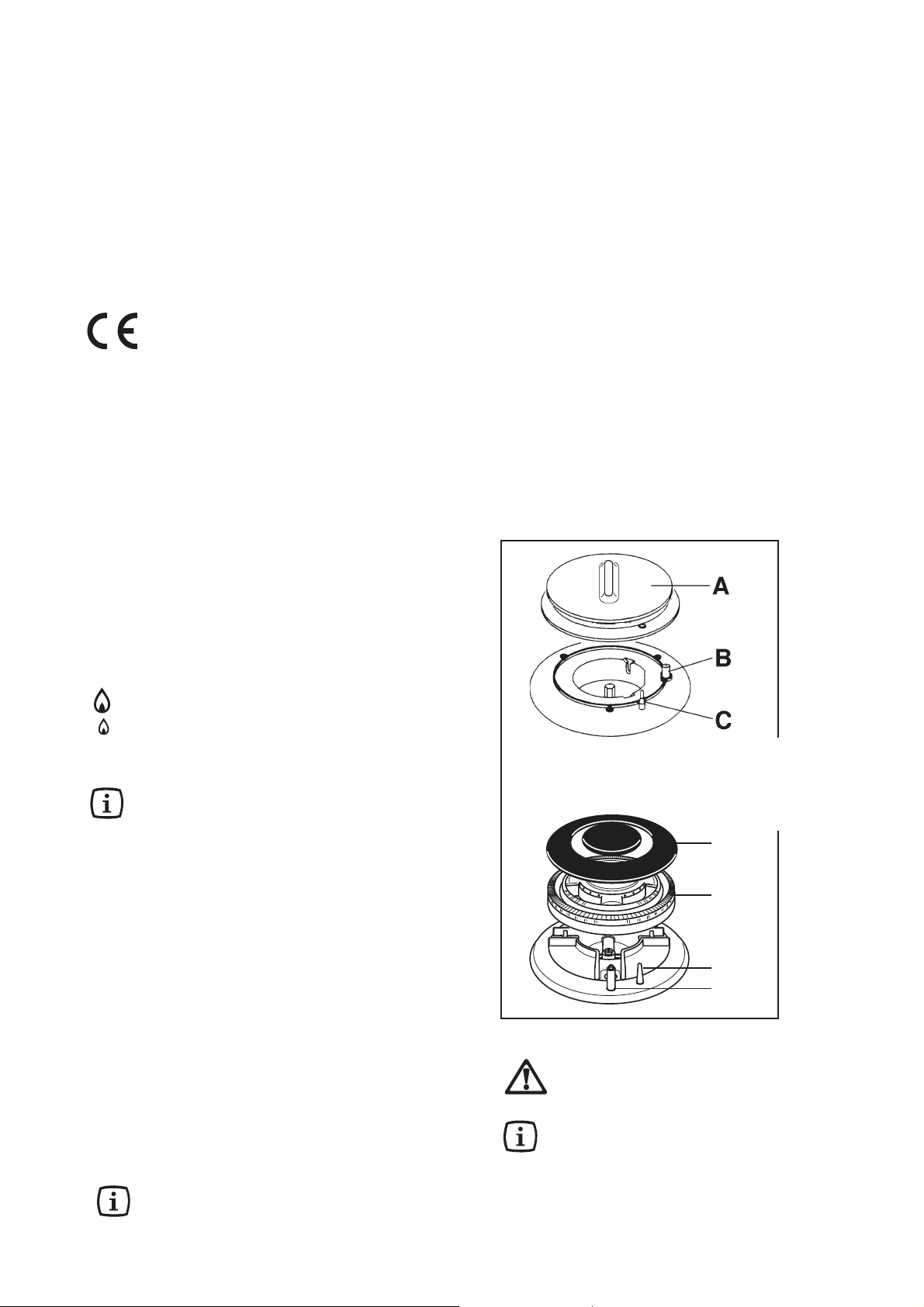

Lighting the rings

To obtain the flame more easily, light the

ring before placing a recipient on the grate.

Press the knob corresponding to the ring and

turn it anticlockwise to the “max” symbol.

After lighting the flame, keep the knob pressed

for about 5 seconds; this time is necessary for

heating the “thermocouple” (Fig. 1, C) and deactivating the safety valve, which would otherwise stop the delivery of gas.

Then, make sure the flame is even and turn

the knob to the required setting.

In case of a power failure, bring a flame to

the burner and proceed as already described.

If the flame does not light after several attempts, make sure the burner “cap” (fig.1, A) is

in the correct position.

To turn off the flame, turn the knob clockwise

to the symbol •.

Always lower the flame or turn it off before

removing recipients from the rings.

FO 2295

A - Burner cap

B - Spark generator

C - Thermocouple

D - Crown

A

D

C

B

FO 2329

Watch over your food during cooking with

fats or oils, because these substances can

catch fire when very hot.

Prolonged cooking with potstones,

earthenware pans or cast-iron plates is

inadvisable. Also, do not use aluminium foil

to protect the top during use.

Fig. 1

22

Page 3

For correct use of the rings

To ensure lower gas consumption and better efficiency,

only use flat bottom recipients of suitable size for the

rings, as given in the table at the foot of the page.

Also, as soon as a liquid starts to boil, lower the flame

enough to keep it on the boil.

Burner min max

Triple crown 160 mm. 260 mm.

Medium (semirapid) 120 mm. 220 mm.

Small (auxiliary) 80 mm. 160 mm.

Cleaning and maintenance

Before carrying out any operation, disconnect

the appliance from the power supply and

allow it to cool.

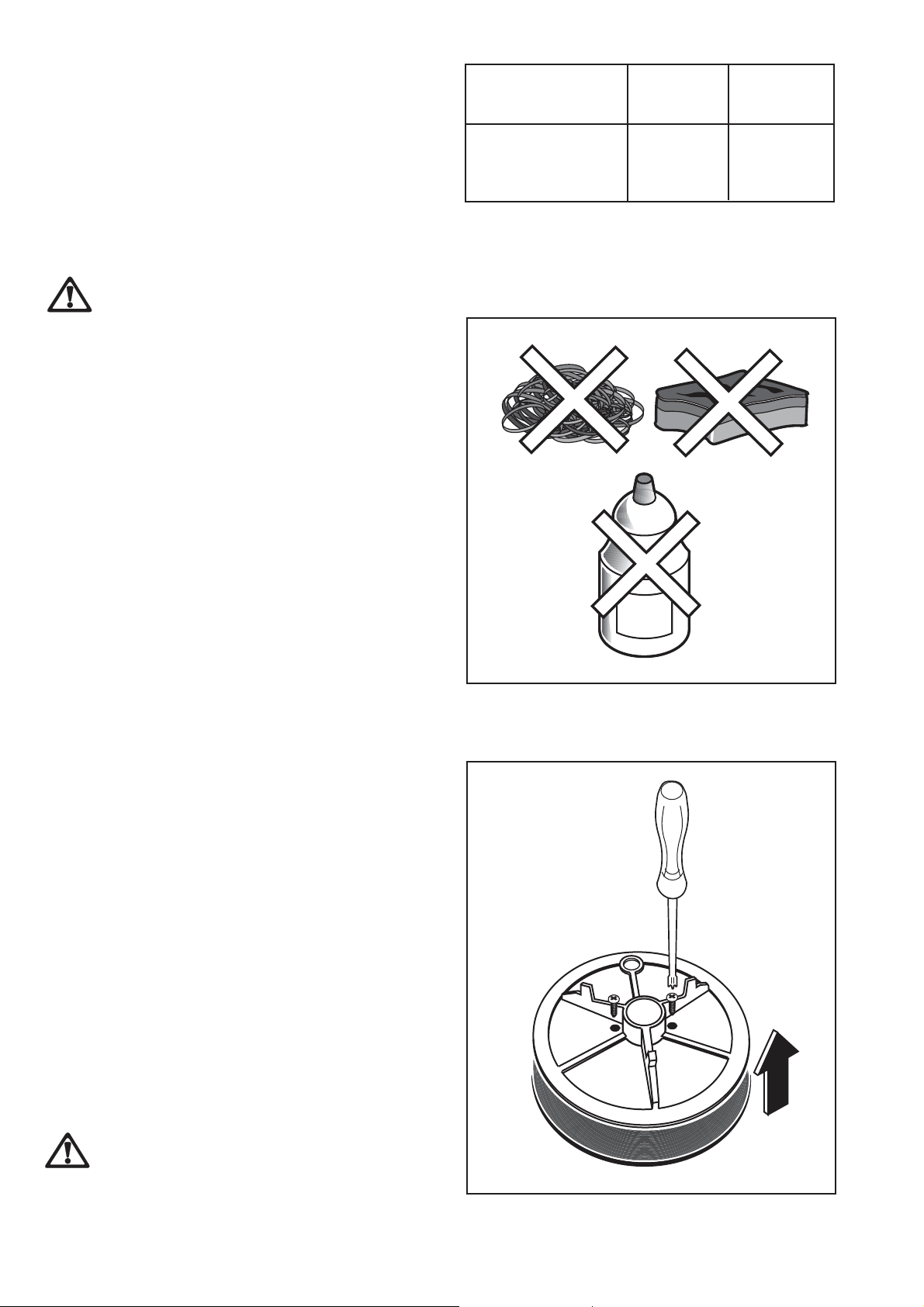

General cleaning

Clean the enamelled parts with lukewarm water and

detergent; do not use abrasive products which could

damage them. Clean the flame spreader and caps

frequently with boiling water and detergent, making sure

to remove all deposits.

The worktop grates can be placed in a dishwasher.

For stubborn stains, use normal non-abrasive

detergents or specific products, readily available on the

market.

DO NOT use scouring pads, steel wool or acids.

Automatic ring lighting is ensured by the

presence of a ceramic igniter plug and a

metal electrode (Fig. 1, B). Carefully clean

these parts of the top periodically. Also, to

prevent difficulty in lighting, make sure the

burner cap holes are not clogged.

To remove deposits from the burner cap holes

(auxiliary and semirapid), remove the two fixing screws at the bottom of the cap and separate the two parts (Fig. 3). After cleaning, reassemble the two parts and refit them correctly

on the burner.

After washing, refit the top grates, making sure they

are correctly positioned.

FO 2094

diameter diameter

A

C

O

I

D

Fig. 2

Worktop

Clean the glass top regularly with a soft cloth soaked in

lukewarm water and a little liquid detergent. Do not use

the following products:

- household detergents or bleaches;

- soapy scouring pads not suitable for non-stick

recipients;

- steel wool;

- bath or sink stain removers.

If the glass top is very dirty, use specific products

available on the market.

If you note breakage or cracks on the glass

top, immediately disconnect the appliance,

contact a Technical Assistance Centre and do

not use the appliance until it is repaired.

FO 2265

Fig. 3

23

Page 4

Periodical maintenance

Have the state and efficiency of the gas pipe and the

pressure regulator (if present) periodically checked. If

any anomalies are detected, have the faulty part replaced

(and not repaired).

To guarantee correct operation and safety, periodically

grease the gas adjustment cocks.

· Periodical lubrication of the cocks must only be

carried out by QUALIFIED PERSONNEL; contact

only qualified personnel in case of anomalies in

appliance operation.

Assistance and spare parts

Before leaving the factory, the appliances are inspected

and prepared by specialised personnel, in order to

ensure best operating results. Any subsequent repairs

or preparation becoming necessary must be carried out

with maximum care and attention.

Therefore it is advisable to always see your local dealer

or the nearest Assistance Centre, specifying the type of

problem, the appliance model (Mod.), product number

(Prod. No.) and serial number (Ser. No.). This

information is given on the plate located on the back

cover, under the warranty terms.

Original spare parts,

certified by the product

manufacturer, and

identified by this mark, are

only available at our

Technical Assistance

Centres and Authorised

Spare Parts Shops.

Warranty terms

Your new appliance is covered by a warranty. The

warranty terms are given in full in the documents

placed inside the appliance.

Carefully keep, together with the warranty

documents, the receipt or the waybill, that serve to

document the purchase of your appliance and the

date of purchase.

In case of Assistance Service intervention, show

these documents to the personnel. If you do not

follow this procedure, the Assistance Service will

have to charge you for any repairs.

24

Page 5

Technical specifications

Gas burner power

Triple crown burner 3.8 kW

Semirapid burner (medium) 1.9 kW

Auxiliary burner (small) 1.0 kW

Power supply

230 V 50 Hz

Dimensions of opening for

fitting

Appliance class 3

Category II2H3+

Appliance setting

Natural gas G20 / 20 mbar

Gas inlet connection G 1/2"

Width 560 mm.

Depth 480 mm.

Instructions for the installer

IMPORTANT: This appliance can only be

installed and used in permanently ventilated

places.

Appliance installation and connection to the

power supply must only be carried out by

QUALIFIED PERSONNEL. Before carrying out

any operation, make sure the appliance is

DISCONNECTED from the power supply.

The Manufacturer declines any liability for

possible damage due to installation not

complying with the current standards or

failure to respect the accident-prevention

regulations.

Place of installation

For correct operation of the gas appliance, the air

necessary for gas combustion must be able to flow

naturally in the room. (The installer must comply with the

current standards).

The air must flow into the room through openings made

in the external walls . These openings must have a free

open section of at least 100 cm2 .

This opening must be located near the floor, preferably

on the opposite side to fume extraction, and be made in

such a way that it is not obstructed from the inside or

outside.

25

Page 6

If the opening cannot be made in the room where the

appliance is installed, the necessary air can come from

and adjacent room, provided:

• it is not a bedroom or a dangerous environment;

• it is not in depression;

• the ventilation between the room where the appliance

is installed and the adjacent room is ensured by

means of permanent openings.

Fume exhaust

Gas cooking appliances must exhaust the fumes

through hoods directly connected to flues or directly to

the outside.

If a hood cannot be installed, it is necessary to use

electric exhaust fans applied to the external wall or the

window of the room, provided conditions exist so that the

opening for ventilation can be increased in proportion to

the performance of the electric fan.

The electric exhaust fan performance must be able to

guarantee an hourly air exchange, for a kitchen, equal

to 3 - 5 times its volume.

Connection

Make the connection to the gas system using a rigid

metal pipe and fittings complying with Standard, or with

a s/steel flexible tube complying with Standard‘, limited

to those not longer than 2 m. When using flexible metal

tubes make sure they are not in contact with movable

parts or squashed. Pay the same attention also when

an oven and top combination is provided for.

The gas inlet union for the appliances is 1/2" cylindrical

male thread.

Make the connection, avoiding any kind of stress on the

appliance.

IMPORTANT

· After installation, always check the perfect seal of

all unions using a soapy solution. Never carry out

this check with a flame.

Gas supply connection

The gas connection must be carried out in compliance

with current standards. The appliances leave the factory,

tested and adjusted for the type of gas specified on the

plate located in the bottom protection, near the gas

connection pipe. Make sure the type of gas used is the

same as that specified on the plate.

Otherwise, proceed according to the instructions given

in the section “Converting to different types of gas”.

To ensure maximum efficiency and lower consumption,

make sure the gas supply pressure respects the values

given in the “Burner specifications” table.

If the pressure of the gas used is different (or variable)

from that provided for, a suitable pressure regulator for

the piped gas (NOT LPG), complying with Standard

must be installed on the inlet piping.

The use of pressure regulators for liquified gases (LPG)

is allowed provided they comply with Standard.

The union is fitted on the end part of the gas train, with a

G 1/2" threaded nut, interposing the seal between the

components as shown in Fig.4. Screw the parts without

forcing, turn the union in the required direction, then

tighten everything.

FO 0264

A) Gas train end with nut

B) Seal

C) Adjustable union

Fig. 4

26

Page 7

Electrical connection

The appliance is arranged to operate on a 230 V singlephase power supply. Connection must be made in

compliance with current standards and regulations.

Before carrying out the connection, make sure:

1) the limiter valve and the electrical system can take

the appliance load (refer to the serial no. plate);

2) the supply system is equipped with an efficient

earth connection in compliance with current

standards;

3) the socket or omnipolar switch used are easily

accessible with the appliance installed.

Fit the cable with a plug suitable for the load and connect

it to a suitable safety socket.

To connect directly to the mains, a suitable omnipolar

switch with contact gap of at least 3 mm complying with

current standards must be installed between the

appliance and the network.

The yellow/green earth wire must not be interrupted by

the switch.

The brown phase wire (coming from terminal “L” on the

terminal block) must always be connected to the power

supply phase wire.

In any case the power cable must be positioned in such

a way that no part of it reaches a temperature of more

than 90°C.

An example of an optimum path is given in Fig. 5. The

cable is guided by means of clamps fixed to the side of

the cabinet, in order to avoid any contact with the

equipment beneath the cooktop.

YES

RIGID COPPER PIPE OR

FLEXIBLE PIPE IN STAINLESS

STEEL

REPLACING THE POWER CABLE

When replacing the power cable only use H05V2V2-F

T90 type cables suitable for the load and operating temperature. Also, the yellow/green earth wire must be

approx. 2 cm longer than the phase and neutral wires

(Fig. 6).

After connection, test the heating elements by operating

them for about 3 minutes.

FO 0238

Fig. 5

Neutral

Earth (yellow/green)

FO 0073

Fig. 6

27

Page 8

Conversion to other types of gas

Replacing nozzles

1. Remove the grates.

2. Remove the burner caps and flame spreaders.

3. Using a 7 mm socket wrench, unscrew and remove

(Fig. 7) the nozzles, replacing them with those required

for the type of gas used (refer to the table on this page).

4. Refit the parts by carrying out the above operations in

reverse order.

5. Then replace the rating plate (located near the gas

connection) with that corresponding to the new type of

gas. The latter is included in the bag of injectors

supplied.

If the pressure of the gas used is different (or variable)

from that provided for, a suitable pressure regulator for

the piped gas (NOT LPG) complying with Standard must

be installed on the inlet piping.

The use of pressure regulators for liquified gases (LPG)

is allowed provided they comply with Standard.

Minimum flame adjustment

To adjust the minimum flame, proceed as follows.

1. Light the burner as previously described.

2. Turn the cock to the min. flame position.

3. Extract the knobs.

4. Adjust the by-pass pin indicated in Fig. 8.

• When converting from natural gas to LPG, screw

down the by-pass pin clockwise.

• When converting from LPG to natural gas, unscrew

the by-pass pin 1/4 turn (approx.).

• In any case, the result must be a small and even

flame on all the burner crown.

5. Lastly, check that the burner does not go off when

quickly turning the cock from max. to min.

The above adjustment operations can be easily performed,

whatever the positioning or fixing of the cooktop to the

cabinet.

FO 0392

Fig. 7

Fig. 8

By-pass pin

for min. flame adjustment

By-pass diameters

Burner Ø Cock

by-pass

in hundredths

Auxiliary 28

Semirapid 32

Triple crown 56

TYPE OF TYPE OF NOZZLE NOMINAL REDUCED NOMINAL NOMINAL

GAS BURNER MARKING HEATING HEATING PRESSURE

1/100 mm CAPACITY kW FLOWRATE mbar

NATURAL

GAS

(Methane)

LIQUIFIED

GAS

(Butane/

Propane)

CAPACITY kW

Triple crown 146 3.8 1.20 0.362 -

Semirapid (medium) 96 1.9 0.45 0.181 - 20

Auxiliary (small) 70 1.0 0.33 0.095 -

Triple crown 98 3.8 1.20 - 273

Semirapid (medium) 71 1.9 0.45 - 137 28-30/37

Auxiliary (small) 50 1.0 0.33 - 72

m3/h g/h

28

Page 9

Building In

SR

SR

TC

A

SR

510

680

Dimensions in mm

A = Auxiliary burner

SR = Semirapid burner

TC = Triple crown burner

These tops are designed for fitting on modular kitchen

cabinets having a depth of between 550 and 600 mm. and

appropriate characteristics.

The side walls of the cabinets on which the cooktop is

installed must not be higher than the worktop. Side walls

higher than the top must be at least 150 mm. from the

opening in the top.

The dimensions of the top and the opening are given in

fig. 9.

FO 2038

Fig. 9

FO 2320

FITTING AND FIXING

Before fitting the top in the opening, apply the special

adhesive seal on the bottom edge of the glass top. This

seal must be fixed evenly without breaks or overlapping,

in order to prevent liquid from entering under the cooktop.

1) Remove the burner caps and grates and turn the

!

cooktop over, taking care not to damage the

igniter plugs.

2) Apply the seal on the bottom edge of the glass

top as shown in Fig. 10.

3) Arrange the cooktop in the cabinet opening,

making sure it is centred.

4) Fix the top to the cabinet with the special

brackets (see Fig. 11).

When refitting the grate of the triple crown burner,

make sure to match the hollow part of the grate

with the reference located on the plate fixed to the

glass. (Fig. 12)

Fig. 10

seal

FO 2321

Fig. 11

Fig. 12

FO 2817

29

Page 10

FITTING POSSIBILITIES

(Dimensions in mm)

Fig. 13

Fig. 14

On base cabinet with door

Adequate arrangements must be

provided for in the construction of

the cabinet to prevent possible

contact with the overheated

housing of the top during operation.

A possible solution for avoiding this

problem is illustrated in fig. 13.

The panel under the top must be

easily removed to allow securing

and release of the top in case of

technical assistance intervention.

On base cabinet with oven

The compartment must have the

dimensions given in figs. 14 and 17

and must be equipped with

supports for allowing efficient

ventilation.

To avoid excessive overheating, it

is advisable to carry out installation

as shown in Figs. 15 and 16.

The electrical connection of the top

and that of the oven must be

carried out separately, for electrical

reasons and to facilitate frontal

oven removal.

FO 1013 FO 2043

a) removable cabinet panel

b) possible space useful for

connections

Fig. 15

Fig. 16

480

380

140

30

593

595

Wall units or extractor hoods must

be at least 650 mm from the

cooktop (Fig. 18).

Fig. 17

FO 0939 FO 0938

Fig. 18

FO 0198

30

FO 2099

Page 11

31

Page 12

32

Grafiche MDM - Forlì

10/06

Loading...

Loading...