Page 1

Instructions Manual

EFC 635

EFC 935

Page 2

EN

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS......................................................................................................................3

CHARACTERISTICS..............................................................................................................................................................4

INSTALLATION ......................................................................................................................................................................6

USE.........................................................................................................................................................................................9

2

2

Page 3

EN

650 mm min.

RECOMMENDATIONS AND SUGGESTIONS

INSTALLATION

• The manufacturer will not be held liable for any damages resulting

from incorrect or improper installation.

• The minimum safety distance between the cooker top and the extrac tor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated on the

rating plate fixed to the inside of the hood.

• For Class I applianc es, c heck t hat th e domes tic po wer suppl y gua rantees adequate earthing.

Connect the extractor to the ex haust flue through a pi pe of minimum

diameter 120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carryi ng combustion fumes (boilers, fireplaces, etc.).

• If the extractor is used in conj unction with non-electrical appliances

(e.g. gas burning appliances), a suffici ent degree of aeration must be

guaranteed in the room in order to prevent the backflow of exhaust

gas. The kitchen must have an opening communicating directl y with

the open air in order to guarantee the entry of clean air.

USE

• The extractor hood has been designe d ex cl usi vely for domesti c us e to

eliminate kitchen smells.

• Never use the hood for purposes ot her than for which it has ben designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only,

making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

• The hood should not be used by chil dren or persons not inst ructed in

its correct use.

• The appliance is not intended for us e by young chil dren or infirm persons without supervision.

• Young children should be supervised to ens ure that they do not pl ay

with the appliance.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

3

3

Page 4

EN

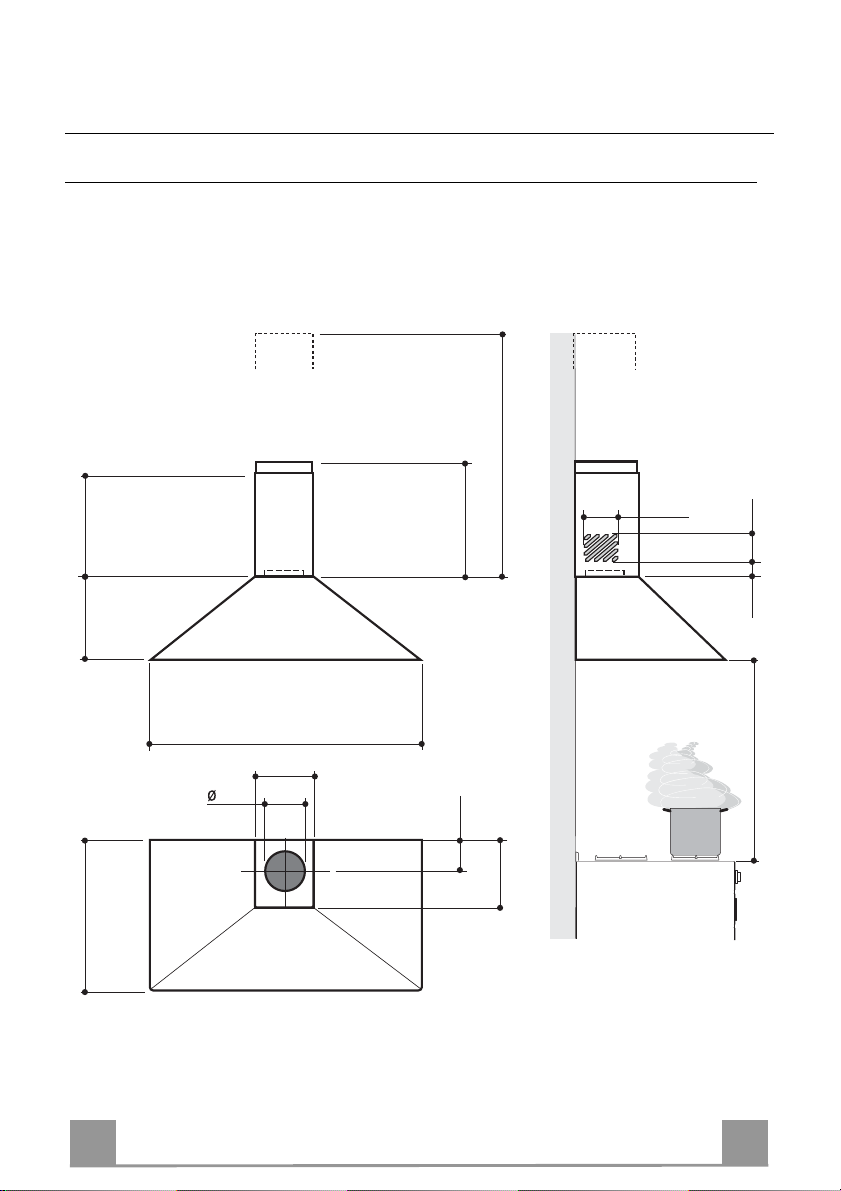

CHARACTERISTICS

Dimensions

530

270

490

598 / 898

150

190

max. 730

min. 530

100

222

126

84

75

650 min.

4

4

Page 5

EN

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

Filters

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

9 1 Reducer Flange ø 150-12 0 mm

15 1 Air Outlet Connecti on

17 2 Lower Chimney Fixing Bush

Ref. Q.ty Installat i on Comp o nent s

7.1 1 Hood Body Fixing Brackets

7.2.1 2 Upper Chimney Section Fixing Brackets

11 6 Wall Plugs

12a 6 Screws 4.2 x 44,4

12c 6 Screws 2.9 x 9.5

Q.ty Documentation

1 Instruction Manual

12a 11

7.2.1

15

9

2.1

2

2.2

17

1

12e

7.1

5

5

Page 6

EN

INSTALLATION

Wall drilling and bracket fixing

7.2.1

7.1

650 min.

Wall marking:

• Draw a vertical line on the supporting wall up to the ceiling, or as high as practical, at the

centre of the area in which the hood will be installed.

• Draw a horizontal line at 650 mm above the hob for installation without the back panel, or at

height H (H = height of the visible part of the panel) for installation with the back panel.

• Place bracket 7.1 on the wall as shown, 265 mm above the horizontal reference line, align-

ing the centre (notch) with the vertical reference line.

• Mark t he wall at the centres of the holes in the bracket.

• Place bracket 7.2.1 on the wall as shown about 1-2 mm from the ceiling or upper limit align-

ing the centre (notch) with the vertical reference line.

• Mark t he wall at the centres of the holes in the bracket.

• Place bracket 7.2.1 on the wall as shown at X mm below the first bracket (X = height of the

upper chimney section supplied), aligning the centre (notch) with the vertical line.

• Mark t he wall at the centres of the holes in the bracket.

1÷2

X

265

H

REAR PANEL (OPTIONAL)

The Rear Panel must be fitted before fixing the hood body and, for both upper an lower positiion fixing, must be fitted at the correct height prior to installing the bases. As this operation is

rather complex, it should be carried out either by the kitchen installer or a qualified person

who knows the final dimensions of the units.

For the upper fixing posi tion , proceed as follows:

• Rest the back pan el on the base, in serting th e lower plat e between the u pper surface an d the

wall, centring it on the vertical reference line.

• Mark the centres of the two holes in the upper plate.

• Drill ø 8 mm holes at all the centre points marked.

• Insert the wall plugs 11 in the holes.

• Fi x the brackets using the 12a screws (4,2 x 44,4) supplied.

• Fix the back panel (where present) using the 12a (4,2 x 44,4) screws supplied.

6

6

Page 7

EN

Vf

Vr

ø 120ø 150

9

15

Mounting the hood body

• Before hooking up the hood body, adjust the two screws Vr

located on the hood body connection points so that they are at

the half way point.

• Hook the hood body to the mounted bracket.

• Adjust the screws Vr to level the hood body.

• Tighten the lock screw Vf.

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the

chimney using either a flexible or rigid pipe ø 150 or 120 mm,

the choice of which is left to the installer.

• To install a ø 120 mm air exhaust connection, insert the reducer flange 9 on the hood body outlet.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

• Remove any activated charcoal filters.

RECIRCULATION VERSION AIR OUTLET

• Push fit the air outlet fitting 15 onto the air outlet of the hood

body.

• Ensure that the activated charcoal filters have been inserted.

7

7

Page 8

EN

1

12c

17

2.1

2.2

2

7.2.1

12c

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

• Re move the grease filters (see paragraph Maintenance) being

sure that the conn ector of the feeding cable is correctly inserted

in the socket placed on th e side of the fan.

Chimney assembly

Upper chimney section

• Slightly widen the two sides of the upper chimney and hook

them behind the brackets 7.2.1, making sure that they are prop erly housed.

• Secure the sides to the br ackets using the 4 screws 12e (2,9 x

9,5) supplied.

Lower ex haust flue

• Insert the lower flue fixing bush 17 in the top of the hood body

and rotate it 90° clockwise as far as it will go.

• Slightly widen the two sides of the chimney and hook them

between the upper chimney section and the wall, making sure

that they are properly housed.

• Secure the sides of the botto m section to the bushes provided

using the 2 screws 12c (2,9 x 9,5) supplied.

8

8

Page 9

EN

USE

3

2

1

1

0

1

0

V

M

L

L Light Switches the lighting system on and off

M Motor Switches the extractor motor on and off

V Speed Sets the operating speed of the extractor:

1. Low speed, used for a co ntinu ous and silent air ch ange i n the presen ce o f

light cooking vapour.

2. Medium speed, suitable for most operating conditions given the optimum

treated air flow/noise level ratio.

3. Maximum speed, used for eliminating the highest cooking vapour emission, including long periods.

9

9

Page 10

EN 110

A

B

Grease filters

CLEANING META L SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heav y usage, and can be

washed in a dishwasher.

• Remove the filters one at a time by pushing them towards

the back of the group and pulling down at the same time.

• Wash the filters, taking care not to bend th em. Allow them

to dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculation version)

These filters are not washable and cannot be regenerated, and

must be replaced approximatel y every 4 months of operati on, or

more frequently with heavy usage.

REPLACING THE ACTIVATED CHARCOAL FILTE R

• Remove the metal grease filters

• Remove the saturated activated charcoal filter as shown (A).

• Fit the new filters (B).

• Replace the metal grease filters.

Lighting

LIGHT REPLACEMENT

40 W incandescent light.

• Remove the metal grease filters.

• Unscrew the bulb s and replace th em with new on es having the

same characteristics.

• Replace the metal grease filters.

Page 11

Page 12

436003098_ver1

Loading...

Loading...