Page 1

Instructions Manual

Manuel d’Instructions

Bedienungsanleitung

Gebruiksaanwijzing

Kullanim Kilavuku

EFA 90540 X

EFA 12540 X

Page 2

EN

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS......................................................................................................................7

CHARACTERISTICS..............................................................................................................................................................8

INSTALLATION ....................................................................................................................................................................10

USE.......................................................................................................................................................................................14

MAINTENANCE....................................................................................................................................................................16

2

2

Page 3

FR

Manuel d’Instructions

SOMMAIRE

CONSEILS ET SUGGESTIONS ..........................................................................................................................................18

CARACTERISTIQUES.........................................................................................................................................................19

INSTALLATION ....................................................................................................................................................................21

UTILISATION........................................................................................................................................................................25

ENTRETIEN..........................................................................................................................................................................27

3

3

Page 4

DE

Bedienungsanleitung

INHALTSVERZEICHNIS

EMPFEHLUNGEN UND HINWEISE....................................................................................................................................29

CHARAKTERISTIKEN..........................................................................................................................................................30

MONTAGE............................................................................................................................................................................32

BEDIENUNG.........................................................................................................................................................................36

WARTUNG............................................................................................................................................................................38

4

4

Page 5

NL

Gebruiksaanwijzing

INHOUDSOPGAVE

ADVIEZEN EN SUGGESTIES.............................................................................................................................................40

EIGENSCHAPPEN...............................................................................................................................................................41

INSTALLATIE .......................................................................................................................................................................43

GEBRUIK..............................................................................................................................................................................47

ONDERHOUD ......................................................................................................................................................................49

5

5

Page 6

TR

Kullanim Kilavuku

IÇERIKLER

TAVSIYELER VE ÖNERILER ..............................................................................................................................................51

ÖZELLIKLER........................................................................................................................................................................52

MONTAJ...............................................................................................................................................................................54

KULLANIM............................................................................................................................................................................58

BAKIM...................................................................................................................................................................................60

6

6

Page 7

EN

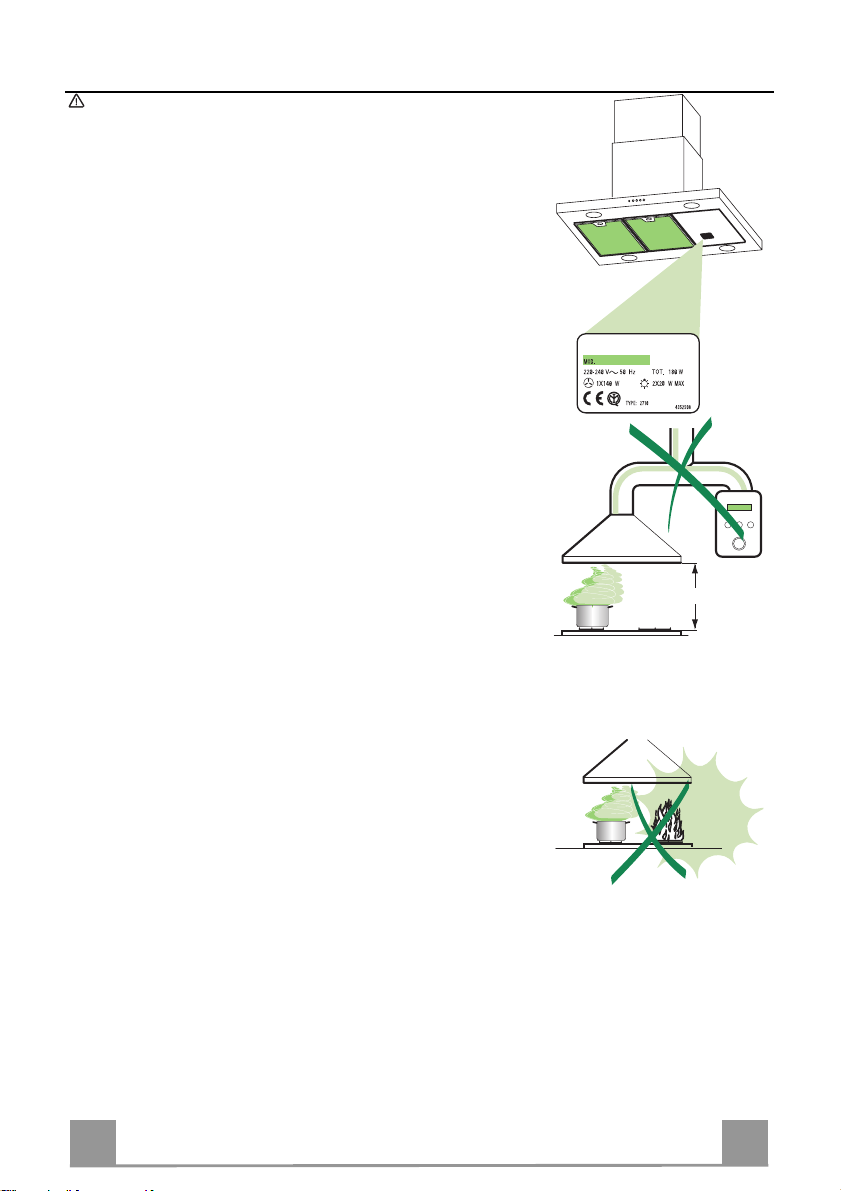

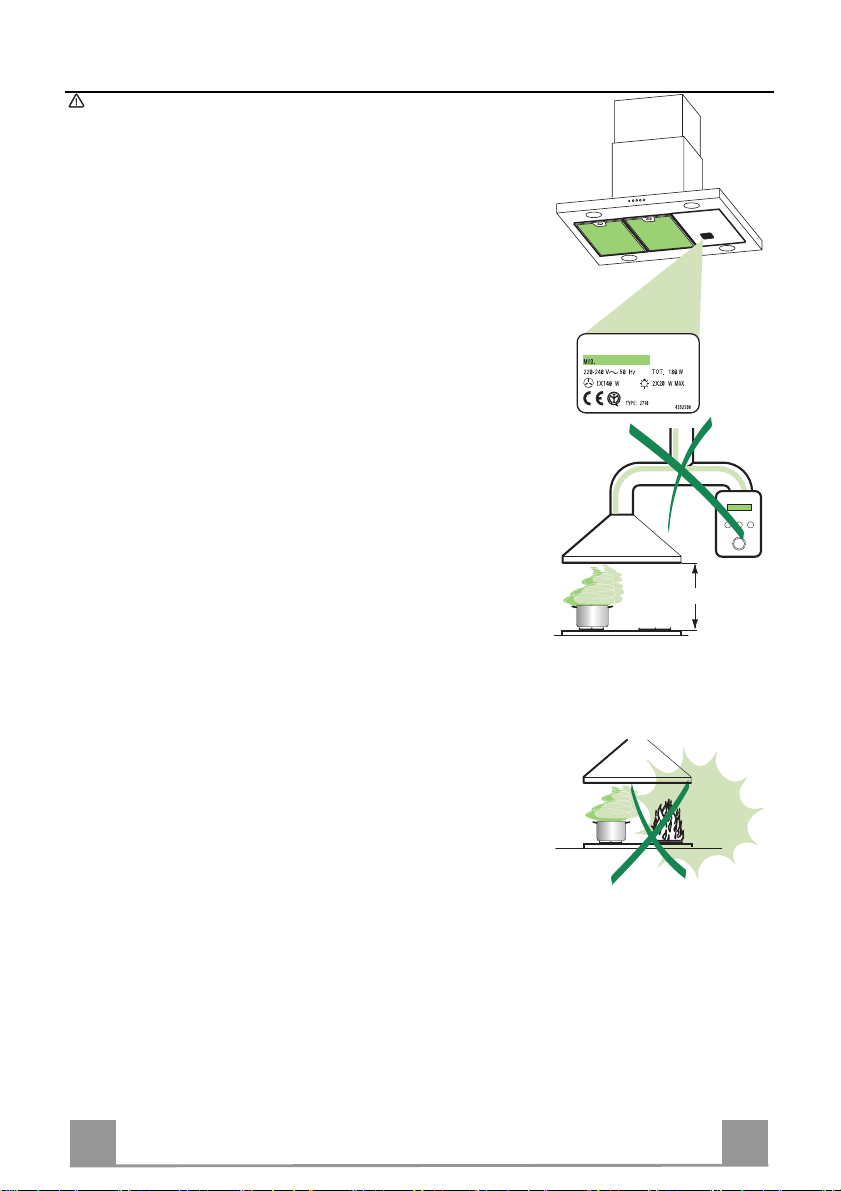

RECOMMENDATIONS AND SUGGESTIONS

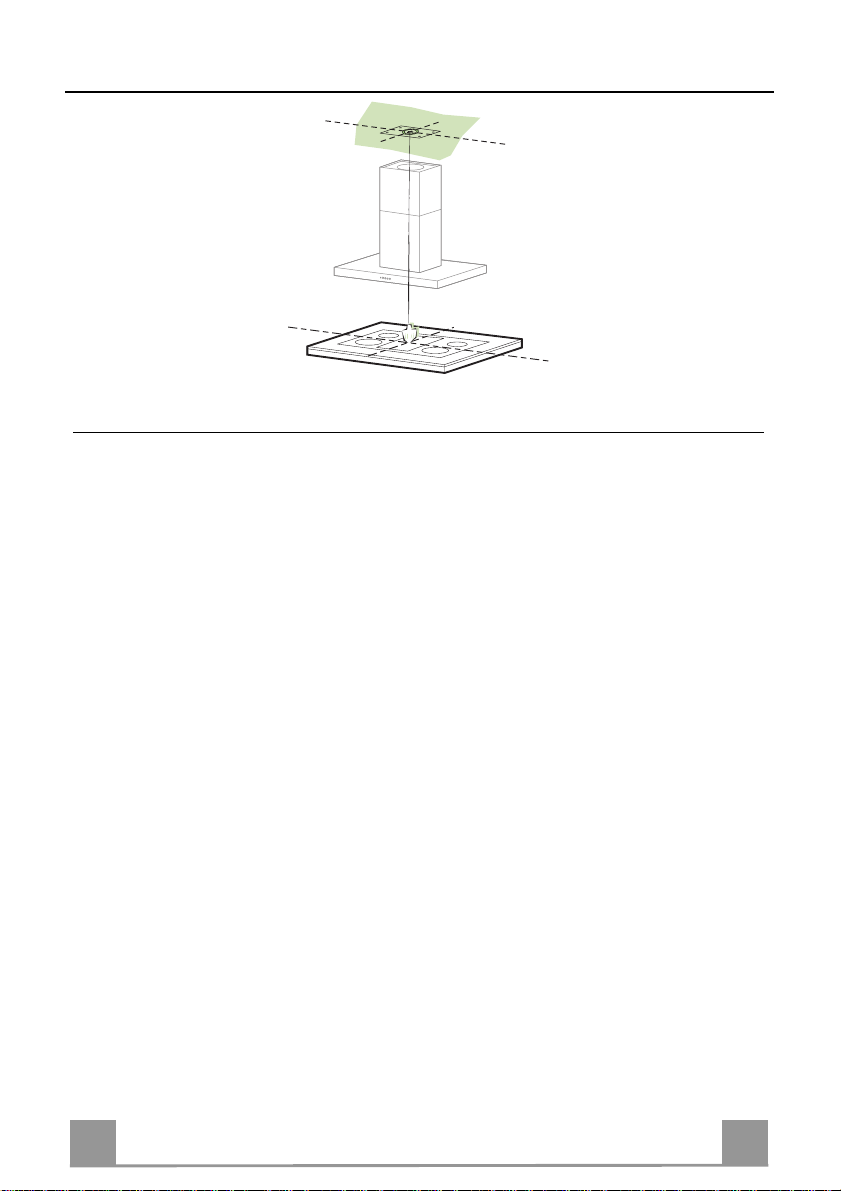

650 mm min.

The Instructions for Use apply to several versions of thi s appliance. Ac-

cordingly, you may find descriptions of individual features that do not apply to your specific appliance.

INSTALLATION

• The manufacturer will not be held liable for any damages resulting fr om

incorrect or improper installation.

• The minimum safety distance b etween the cooker top and the extr actor

hood is 650 mm.

• Check that the mains voltage corres ponds to that i ndicated on the rati ng

plate fixed to the inside of the hood.

• F or Class I appliances, check t hat the domestic power s upply guara ntees

adequate earthing.

Connect the extractor to the exhaust fl ue through a pipe of minimum di -

ameter 120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion

fumes (boilers, fireplaces, etc.).

• If the extractor is us ed in conjunction with non -electrical appliances (e. g.

gas burning appliances), a sufficie nt degree of aeration must be guara nteed in the room in order to prevent the backflow of exhaust g as. The

kitchen must have an opening communicati ng directly wi th the open air in

order to guarantee the entry of clean air.

USE

• The extractor hood has been designe d exclusively for domestic use to

eliminate kitchen smells.

• Never use the hood for purposes other than for which it has ben designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, m aking sure that it does not engulf the sides.

• Deep fat fryers must be continuously moni tor ed du ring use: overheated oil

can burst into flames.

• Do not flambè under the range hood; risk of fire

• This appliance is not intended f or use by pe rsons (incl uding c hildr en) wit h

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not pl ay with the

appliance

MAINTENANCE

• Switch off or unplug the appl iance from the m ains supply before carrying

out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

7

7

Page 8

EN

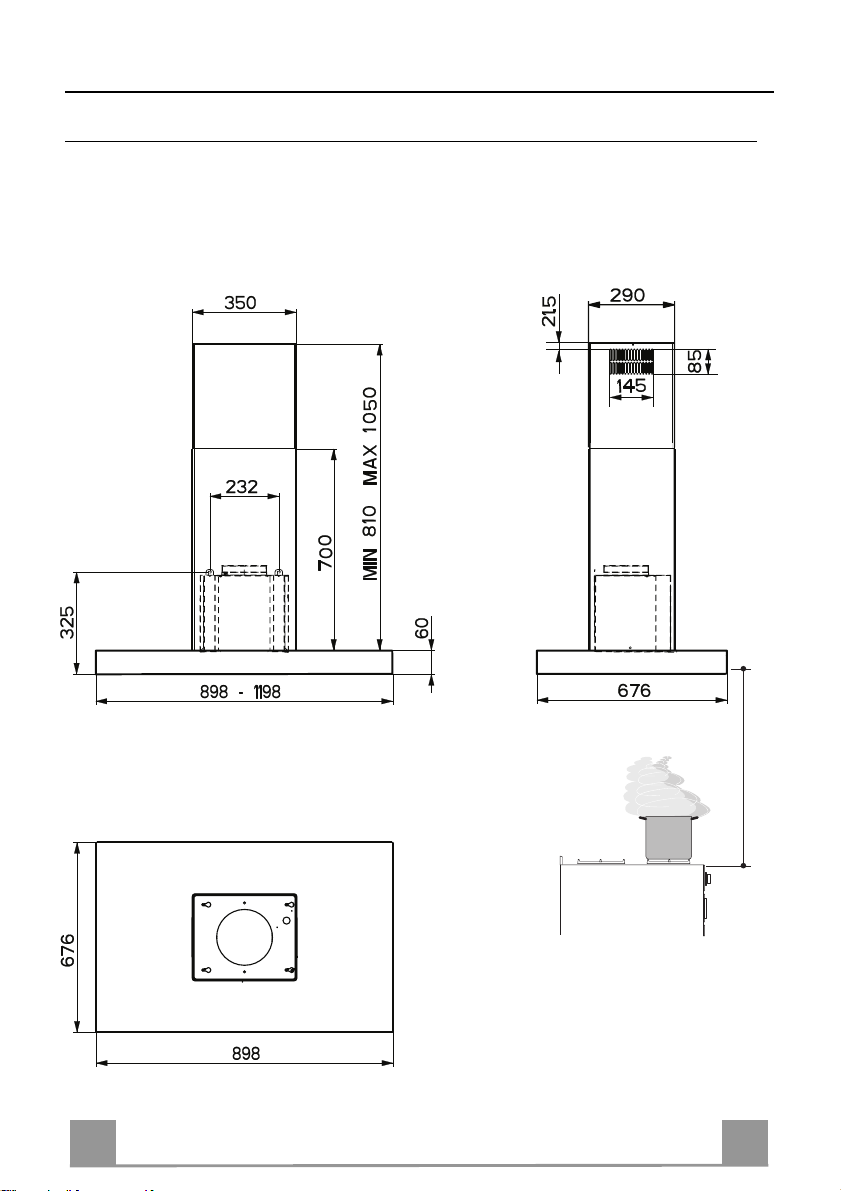

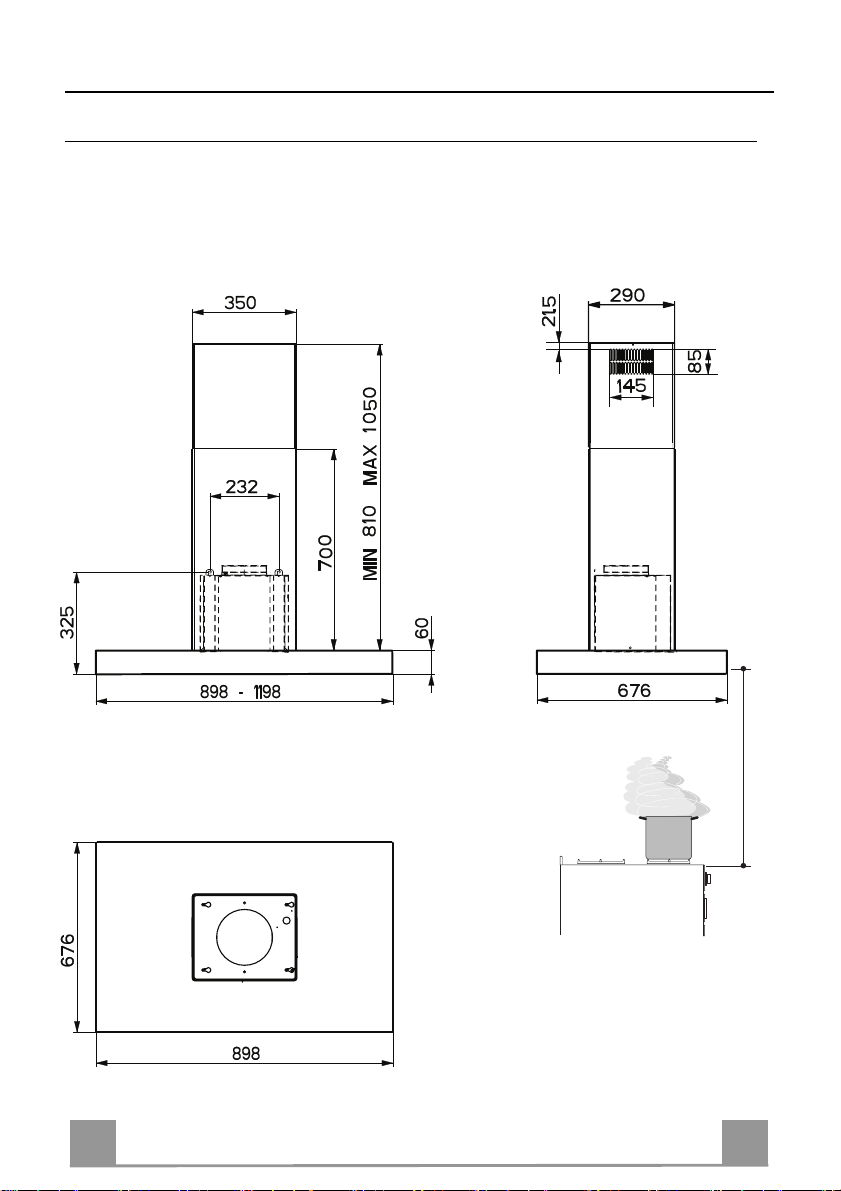

CHARACTERISTICS

Dimensions

650 min.

8

8

Page 9

EN

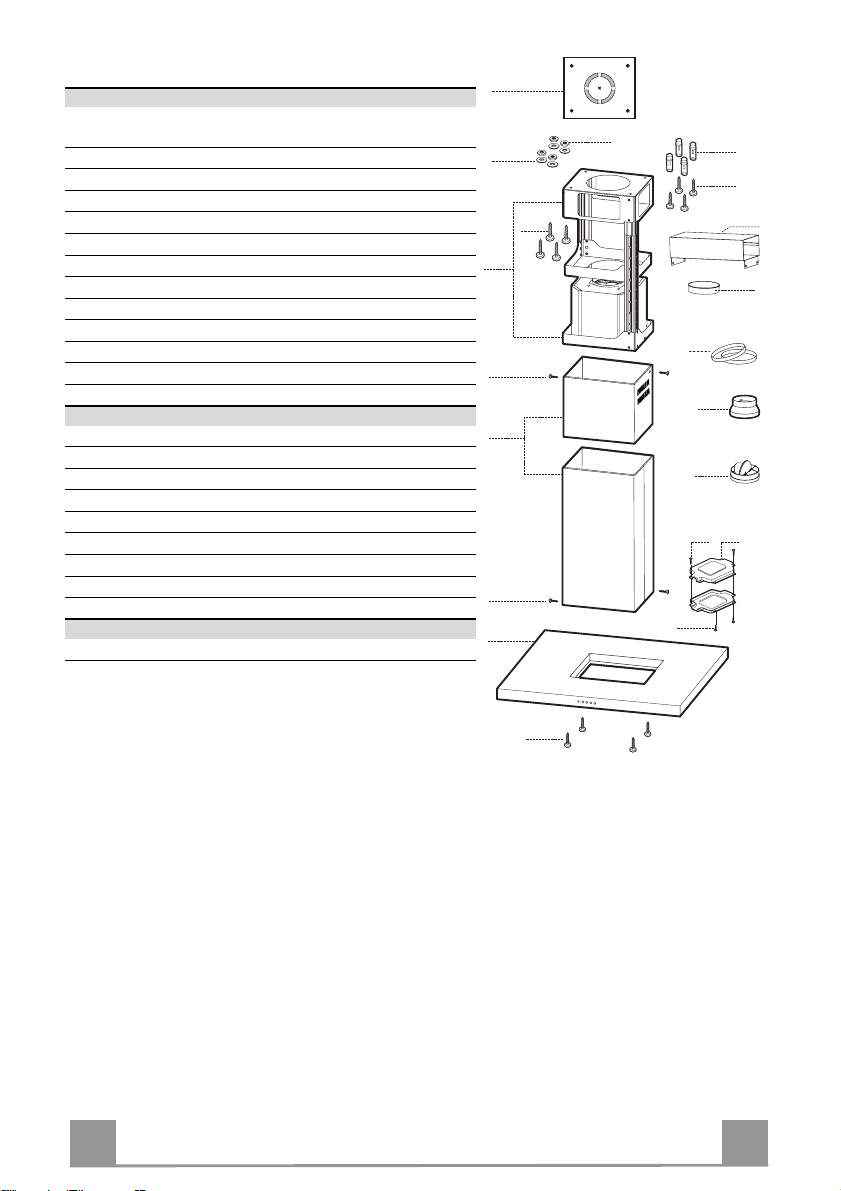

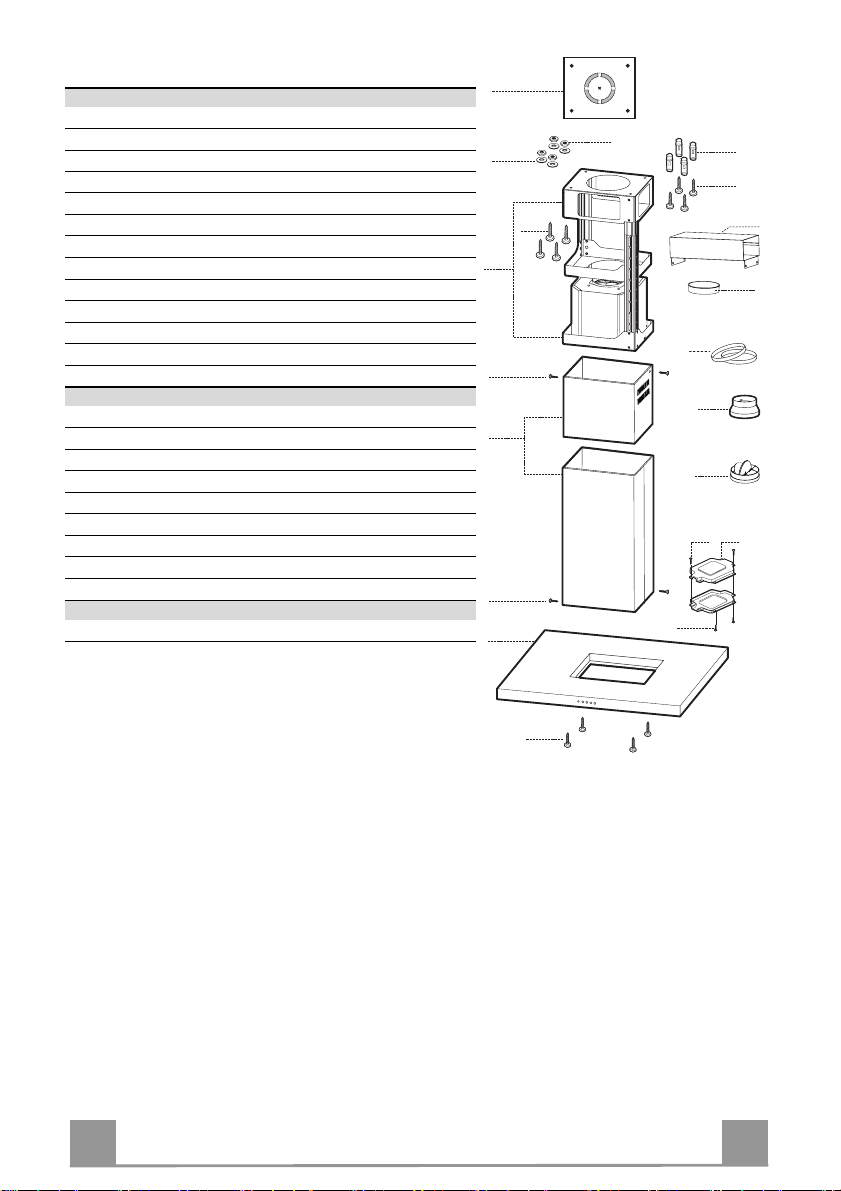

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

Filters

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

7.1 1 Telescopic frame compl ete with extractor, consi sting of:

7.1a 1 Upper frame

7.1b 1 Lower frame

9 1 Reducer Flange ø 150-120 mm

10 1 Flange ø 150

10a 1 Dumper ø 150mm

15 1 Air Outlet Connection

24 1 Junction box

25 2 Pipe clamps

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

12c 6 Screws 2,9 x 6,5

12e 2 Screws 2,9 x 9,5

12f 4 Screws M6 x 10

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

21 1 Drilling template

22 4 6.4 mm int. di a washers

23 4 M6 nuts

Q.ty Documentation

1 Instruction Manual

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

23

12c

25

12e

11

12h

15

10

9

10a

24

12f

9

9

Page 10

EN 110

INSTALLATION

Drilling the Ceiling/shelf and fixing the frame

DRILLING THE CEILING/SHELF

• Use a plumb line to mark the centre of the hob on the ceiling/support shelf.

• Place the drilling template 21 provided on the ceiling/support shelf, making sure that the

template is in the correct position by lining up the axes of the template with those of the hob.

• Mark the centres of the holes in the template.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to the screw size.

• For hollow brick ceilings with wall thickness of 20 mm: drill ø 10 mm(immediately insert

the Dowels 11 supplied).

• For wooden beam ceilings, drill according to the wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted Versio n), drill according to t he diameter of the external air exhaust duct connection.

• Insert two screws of the following type, crossing them and leaving 4-5 mm from the ceiling:

• For concrete ceilings, use the appropriate plugs for the screw size (not provided).

• for Cavity ceiling with inner space, with wall thickness of approx. 20 mm, Screws 12h,

supplied.

• For wooden beam ceilings, use 4 wood screws (not provided).

• For wooden shelf, use 4 screws 12g with washers 22 and nuts 23, provided.

Page 11

EN 111

Fixing the frame

2

2

1

1

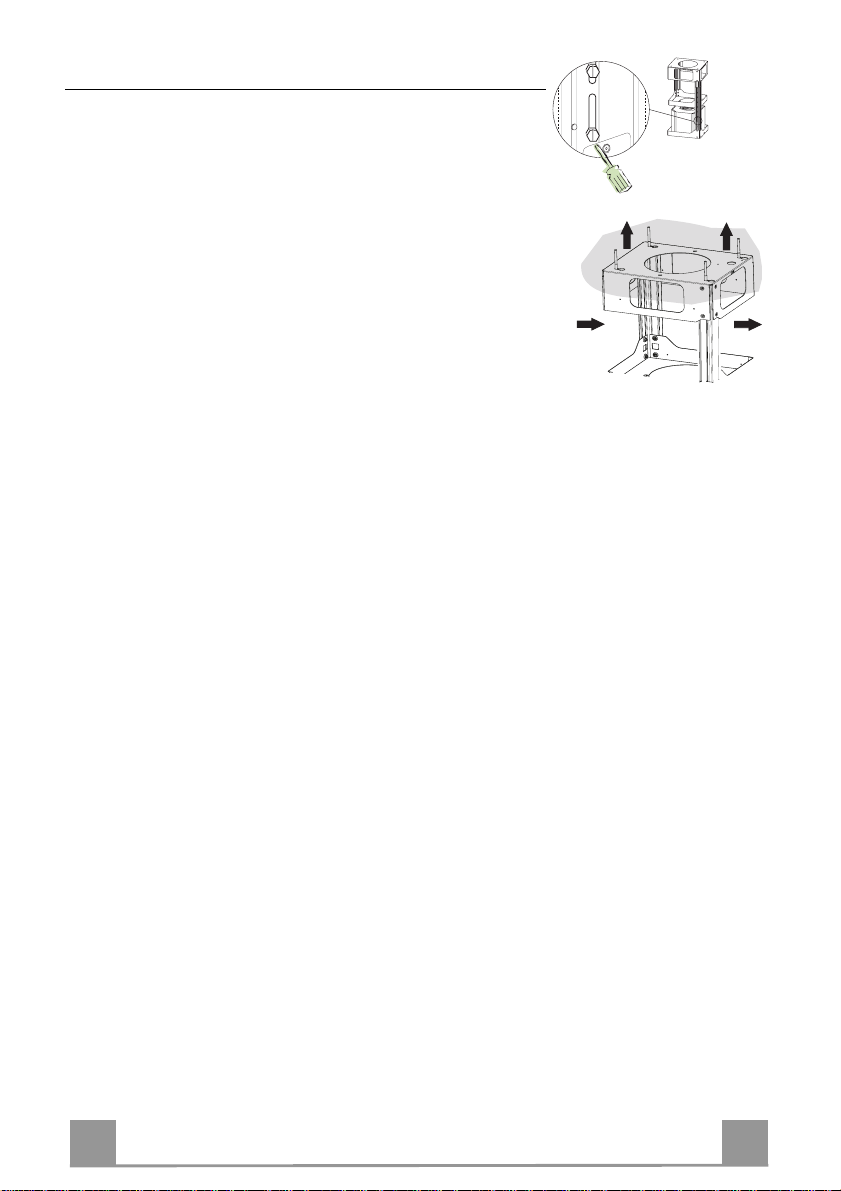

• Loosen the two screws fasten ing the lower chimney and remove this from the lower frame.

• Loosen the two screws fastening the upper chimney and remove this from the upper frame.

If you wish to adjust the height o f the frame, proceed as follows:

• Unfasten the eight metric screws joining the two columns, located at the sides of the frame.

• Adjust the frame to the h eight required, then replace all t he

screws removed as above.

• Insert the upper chimney stack from above, and leave it running free on the frame.

• Lift up the frame, fit the frame slots onto the screws up to the

slot end positions.

• Tighten the two screws and fasten the other two screws provided with the hood.

Before tightening the screws completely it is possible to adjust

the frame by turning it. Make sure that the screws do not come

out of their seats in the slotted holes.

• The frame mountings must be secure to withstand the weight

of the hood and any stresses caused by the occasional side

thrust applied to the device.

On completion, check that the base is stab le, even if the frame

is subjected to bending.

• In all cases where the ceiling is not strong enough at the suspension point, the installer must provide strengthening using

suitable plates and backing pieces anchored to the structurally

sound parts.

Page 12

EN 112

Connections

ø 120

25

9

10a

10a

ø 150

25

15

10

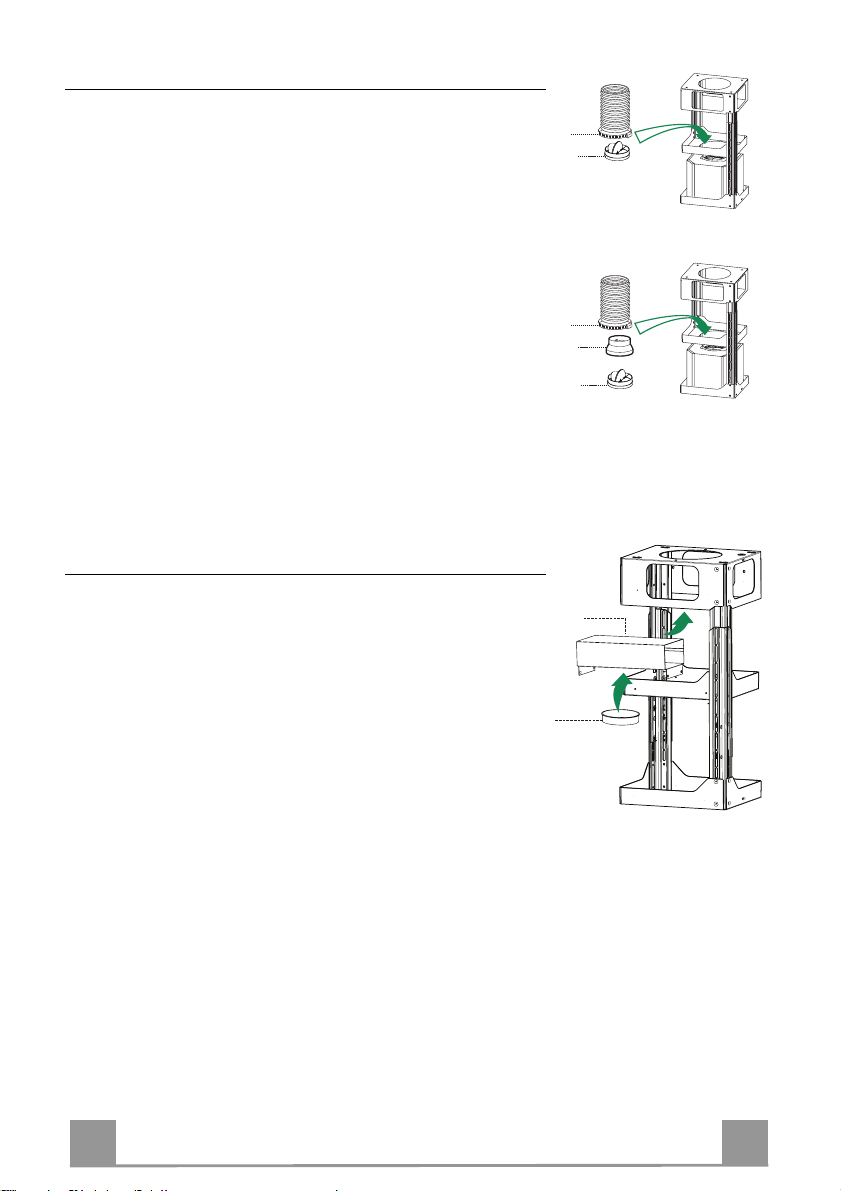

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the

chimney using either a flexible or rigid pipe ø 150 or 120mm, the

choice of which is left to the installer.

To install a ø 150

• To install the dumper 10a.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

To install a ø 120

• To install a ø 120 mm air exhaust connection, insert the reducer flange 9 on the dumper 10a.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

• Remove any activated charcoal fil ters.

Recirculation version air outlet

• Fix the connection 15 to the frame using the 4 screws provided.

• Fix the flange 10 to the lower opening of the connection 15.

• Connect the hood air outlet to the flange in the lower part of

the junction using a rigid or flexible ø 150 tube (by installer’s

choice).

Page 13

EN 113

Flue assembly - Mounting the hood body

12f

12c

12c

24

12e

Cmd

12c

Lux

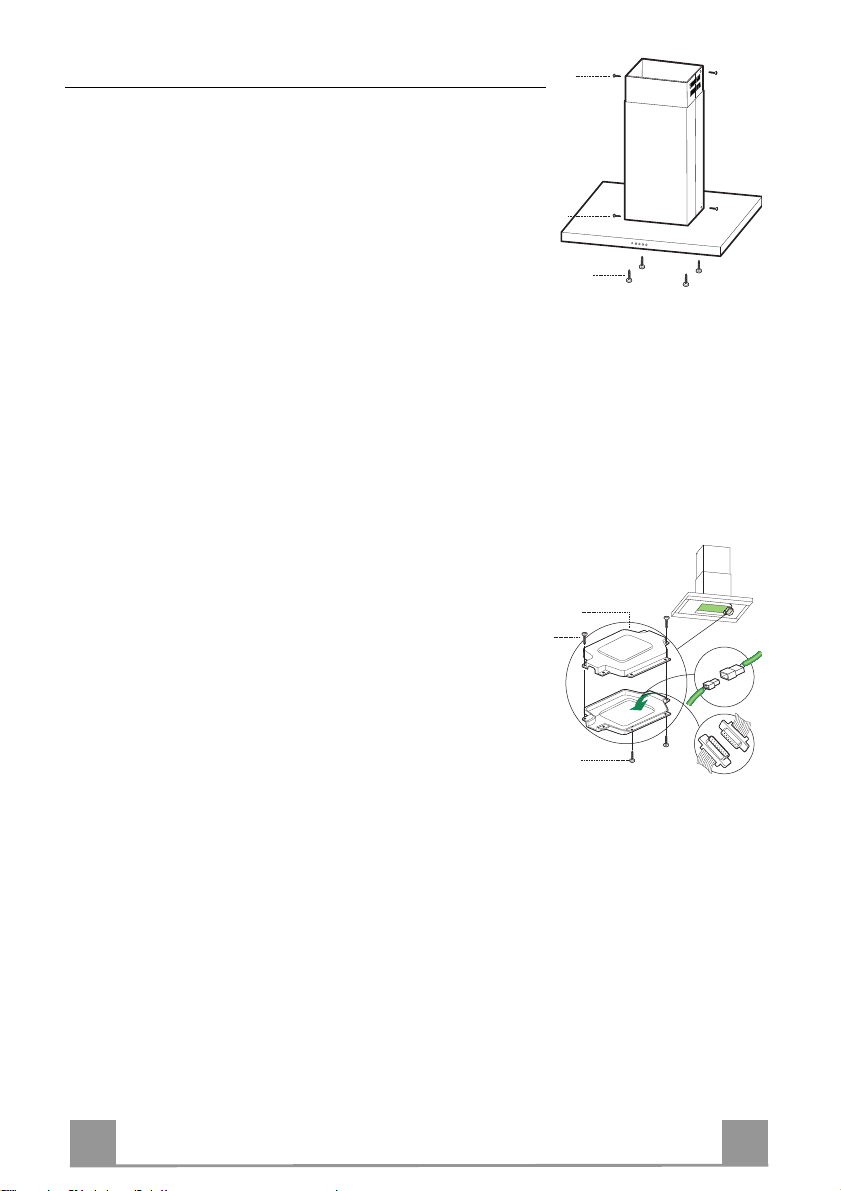

• Position the upper chimney section and fix the upper part to the

frame using the 2 screws 12c (2,9 x 6,5) provided.

• Similarly, position the lower chimney section and fix the

lower part to the frame using the 2 screws 12c (2,9 x 6,5) provided.

Before fixing the hood body to the frame:

• Remove the grease filters from the hood body.

• Remove any activated charcoal fil ters.

• From below, use the 4 screws 12f (M6 x 10)provided to fix the

hood body to the frame.

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

• Re move the grease filters (see paragraph Maintenance) being

sure that the conn ector of the feeding cable is correctly inserted

in the socket placed on th e side of the fan.

• Connect the control connector Cmd.

• Connect the lights connecto r Lux.

• Place th e connectors in the junction box 24 and close it using

the 2 screws 12e (2,9 x 9,5) provided.

• Fix the junction box to the hood body using the 2 screws 12c

(2,9 x 6,5) provided.

• For the recirculation version, fit the activated carbon odour filter.

• Replace the grease filters.

Page 14

EN 114

USE

Dual Function

L T1 T2 T3 T4 T5 F

The hood can be switched on pushing directly onto the requested speed without firstly having to select 0/1 button .

Touch

control

T1

T2

T3

T4

Basic functions

When briefly pressed it switches the lighting system

L

on and off.

When pressed for 2 seconds it starts the lighting

system in “courtesy light” mode. The lamps are

fed at a reduced power of approximately 5W.

Such function can be stopped by pressing the

touch control for 2 seconds or just by pressing it

shortly in order to return to the normal lighting

mode. In courtesy light mode the touch control is

not lit.

When pressed the motor is stopped, regardless of the

speed it is set to.

When pressed the motor is set to the first speed

By a brief pressing the motor is set to the second

speed.

By pressing the touch control for approximately 2

seconds the Delay function is enabled, i.e dela-

yed shutdown of the appliance ensuring a com-

plete elimination of the residual odours. This fun-

ction can be activated at OFF-position and at 1°,

2° and 3°speeds. It can be stopped in advance

by pressing any of the touch controls (T) with the

exception of T3. The Delay function works accor-

ding to the following scheme:

1°speed / OFF = 20 minuets

2°speed = 15 minutes

3°speed = 5 minutes

When pressed the motor is set to the third speed

Indicator lights

Touch control unlit Lights off

Touch control lit Lights on

Touch control unlit Courtesy light on

Touch control lit Motor on

Touch control unlit Motor off

Touch control lit

Touch control lit Second speed on

Flashing touch

control

Touch control lit

Delay function on

Page 15

EN 115

Touch

Touch control lit

control

T5

Basic functions Indicator lights

When pressed the motor is set to the intensive speed

timed to 5 minutes. At the end of 5 minutes of intensive speed the hood starts again at the speed it was set

to previously. In case the hood is set to the intensive

speed directly from OFF-state it will then start from

the first speed after 5 minutes of intensive speed.

When pressed for 4 seconds it resets the filter alarm

F

signal indicated by flashing of the touch control T1.

This procedure can be carried out only when the

motor is stopped.

Flashing touch

control

Touch control lit

Metal grease filters saturation alarm. Metal gr e ase

filters need to be washed.

The alarm star ts up after

100 working hours.

Charcoal odour filter saturation alarm. Char coal

filter has to be replaced

and metal grease filters

washed. The alarm starts

up after 200 working

hours. (Activation; chec k

the paragraph “Odour

filter”)

Page 16

EN 116

MAINTENANCE

REMOTE CONTROL (OPTIONAL)

The appliance can be controlled using a remote control powered

by a 1.5 V carbon-zinc alkaline batteries of the standard LR03AAA type.

• Do not place the remote control near to heat sources.

• Used batteries must be disposed of in the proper manner.

Grease filters

CLEANING OF THE METAL CASSETTE FILTERS

Alarm reset

• Stop the motor.

• Press the F -touch control for at least 4 seconds until the T1 -

touch control flashes.

Cleaning the filters

• Filters can be washed in the dish machine. They need to be

washed every 2 mont hs o r even more fr equ en tly in case of particularly intensive use of the hood.

• Remove the filters one by one pushing them towards the back

side of the unit and simultaneously pulling downwards.

• Any kind of bending of the filters has to be avoided when

washing them. Before fitting them again into the hood make

sure that they are completely dry.

• When fitting the filters into the hood pay attention that they are

mounted in correct position and that the handle faces outwards.

Page 17

EN 117

Odour filter (Recirculation Version)

This filter cannot be washed or regenerated, and must be replaced when the F touch control starts

to flash, or at least once ev e ry 4 months. The alarm is only trigge re d w he n the m otor is on.

Enabling/Disabling the alarm signal

• In Recirculation Version Hoods, the Filter saturation Alarm must be enabled at the time of

installation or later.

• Switch off the lights and the motor.

• Disconnect the mains power supply to the hood by removing the motor unit power supply

cable connector, switching off the power supply at the Mains or turning the Main switch off.

• Restore the connection, pressing and holding T2.

• Release the touch control, touch controls L, T2 and F will light up normally.

• Within 3 seconds press the touch control F until the key itself flashes to confirm as follows:

• 2 flashes – Charcoal odour Filter saturation Alarm ENABLED

• 1 flash - Charcoal odour Filter saturation Alarm DISABLED

REPLACING THE CHARCOAL ODOUR FILTER

Reset the alarm signal

• Stop the motor.

• P ress the touch control F for at least 4 seconds, until the touch

control T1 flashes.

Replace the Filter

• Remove the metal grease filters.

• Remove the saturated charcoal filter, turn ing the fasteners p rovided.

• Fit the new filter and fasten it its correct position.

• Put the metal grease filters in their seats.

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Rep lace the Support, fixing it in place with the two screws removed as above.

Page 18

FR 118

CONSEILS ET SUGGESTIONS

650 mm min.

La présente notice d'emploi vaut pour plusieurs versions de l'appareil. Elle

peut contenir des de scriptions d'acce ssoires ne figuran t pas dans votre appareil.

INSTALLATION

• Le fabricant décline toute responsabilité en cas de dommage dû à une installation non corr ecte ou non conforme aux rè gles de l’art.

• La distance minimale de sécurité entre le plan de cuisson et la hotte doit être

de 650 mm au moins.

• Vérifier que la tension du secteur correspond à la valeur qui figure sur la plaquette apposée à l’intérieur de la hotte.

• Pour les Appareil s appartenant à la I

mise à la te rre de l’installation électrique domestiqu e ait été effectuée confor-

mément aux normes en vigueur.

• Connecter la hotte à la sortie d’air aspiré à l’aide d’une tuyauterie

d’un diamètre égal ou supérieur à 120 mm. Le parcour s de la

tuyauterie doit être le pl us court possible.

• Eviter de connecter la hotte à des conduites d’évacuation de fumées

issues d’un e combustion tel que (Chaudière, cheminée, etc…).

• Si vous utilisez des appareils qui ne fonctionnent pas à l’électricité

dans la pièc e ou est installée la hotte (par exemple: des appareil s

fonctionnant au gaz), vous devez prévoir une aération suffisante du milieu. Si

la cuisine en est dépourvue, pratiquez une ouverture qui communique avec

l’extérieur pour garantir l’infiltration de l’air pur.

UTILISATION

• La hotte a été conçue exclusivement pour l’usage domestique, dans le but

d’éliminer les odeurs de l a cuisine.

• Ne jamais utiliser abusivement la hotte.

• Ne pa s laisser les flammes libres à forte intensité quand la ho tte est en service.

• Toujours régler les flammes de manière à éviter toute sortie latérale

de ces derni ères par rapp ort au fond des marmites.

• Contrôler les friteuses lors de l’utilisation car l’huile surchauffée

pourrait s’enflammer.

• Ne pas préparer d’aliments flambés sous la hotte de cuisine : risque d’ incendie

• Cet appareil ne d oit pa s être utilisé pa r des personn es (y comp ris le s en fants)

ayant des capacités psych iques, sen sorielles ou mentale s réduites, ni pa r des

personnes n’ayant pas l’expérience et la connaissance de ce type d’appareils,

à moins d'être sous le contrôle et la formation de personnes responsables de

leur sécurité.

• Les enfants doivent être surveillés pour s'assurer qu'ils ne jouent pas avec

l'appareil.

ENTRETIEN

• Avant de procéder à toute opération d’entretien, retirer la hotte en retirant la

fiche ou en actionnant l’interrupteur général.

• Effectuer un entretien scrupuleux et en temps dû des Filtres, à la cadence

conseillée.

• Pour le nettoyage des surfaces de la hotte , il suffit d’u tiliser un ch iffon humide

et détersif liquide neutre.

ère

Classe, veiller à ce que la

Page 19

FR 119

CARACTERISTIQUES

Encombrement

650 min.

Page 20

FR 220

Composants

Réf. Q.té Composants de Produit

1 1 Corps Hotte équipé de: Comandes, Lumière, Filtres

2 1 Cheminée Télescopique formée de :

2.1 1 Cheminée Supérieure

2.2 1 Cheminée Inf érieure

7.1 1 Treillis télescopique avec Aspirateur, formé par:

7.1a 1 Treillis supérieur

7.1b 1 Treillis inférieur

9 1 Flasque de Réduction ø 150- 1 2 0 mm

10 1 Flasque ø 150

10a 1 Buse avec c lapet ø 150

15 1 Raccord Sortie Air

24 1 Boîte connexions

25 2 Colliers de serrage serre-tube

Réf. Q.té Composants pour l’installation

11 4 Chevilles ø 10

12c 6 Vis 2,9 x 6,5

12e 2 Vis 2,9 x 9,5

12f 4 Vis M6 x 10

12g 4 Vis M6 x 80

12h 4 Vis 5,2 x 70

21 1 Gabarit de p erçage

22 4 Rondelles øi 6,4

23 4 Écrous M6

Q.té Documentation

1 Manuel d’instructions

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

23

12c

25

12e

11

12h

15

10

9

10a

24

12f

Page 21

FR 221

INSTALLATION

Perçage Plafond/Étagère et Fixation Treillis

PERÇAGE PLAFOND/ETAGERE

• À l’aide d’un Fil à plomb, reporter sur le Plafond/Étagère de support le centre du Plan de

Cuisson.

• Poser contre le Plafond/Étagère le Gabarit de Perçage 21 fourni avec l’appareil, en faisant

coïncider son centre avec le centre projeté et en alignant les ax es du Gabarit avec les axes du

Plan de Cuisson.

• Marquer les centres des Trous du Gabarit.

• Percer les trous qui ont été marqués:

• Plafond en Béton massif: en fonction des Goujons pour Béton utilisés.

• Plafond en Briques avec chambre à air, avec épaisseu r résistant e de 20 mm: ø 10 mm (in-

sérer immédiatement les Chevilles 11 fournies avec l’appareil).

• Plafond en Poutrage en Bois: en fonction des Vis à Bois utilisées.

• Étagère en Bois: ø 7 mm.

• Passage du Câble électrique d’Alimentation: ø 10 mm.

• Sortie Air (Version Aspirante): en fonction du diamètre de la connexion avec les Tuyaux

d’Évacuation Externe.

• Visser deux vis en les croisant et en laissant 4-5 mm. de distance par rapport au plafond:

• pour le Béton massif, des Goujons pour Béton, non fournis avec l’appareil.

• pour Briques percées, ayant u ne épaisseur résistante de 20 mm. en viron, utiliser les Vis

12h, fournies avec l'appareil.

• pour le Poutrage en bois, 4 Vis à bois, non fournies avec l’appareil.

• pour l’Étagère en Bois, 4 Vis 12g avec Rondelles 22 et Écrous 23, fournis avec l’appareil.

Page 22

FR 222

FiXATION TREILLIS

2

2

1

1

• Dévisser les deux vis qui fixent la cheminée inférieure et sortir

cette dernière du treillis (depuis la partie inférieure).

• Dévisser les deux vis qui fixent la cheminée supérieure et sortir

cette dernière du treillis (depuis la partie supérieure).

Si l’on souhaite régler la hauteur du treillis, effectuer les opérations suivantes:

• Dévisser l es huit vis métriques qui un issent les deux colonnes,

qui se trouvent sur les côtés du treillis.

• Régler la hauteur souhaitée du treillis et revisser les vis qui ont

été précédemment retirées.

• Insérer la cheminée supérieure depuis le haut et la laisser libre

sur le treillis.

• Soulever le treillis, encastrer les oeillets sur les vis et faire coulisser jusqu’à la butée;

• Serrer les deux vis et visser les autres deux vis fournies avec

l’appareil;

Avant de serrer définitivement les vis, il est possible d’effectuer

des réglages, en dépl açant le tr eillis, tou t en cont rôlan t qu e les vis

ne sortent pas du logement de l’œillet de réglage.

• La fixation du Treillis doit être solide, en fonction du poids de

la Hotte et des contraintes provoquées par les poussées latérales occasionnelles auxquelles l’Appareil monté sera soumis.

Après avoir effectué la fixation, vérifier que la base soit stable,

même si le Treillis est soumis à des contraintes de flexion.

• Dans tous les cas où le Plafond ne devait pas être suffisamment

robuste en correspondance du point d’accrochage, l’Installateur

devra se charger de le rendre plus solide au moyen de plaques

et contre-plaques spéciales, ancrées sur les parties structuralement résistantes.

Page 23

FR 223

Branchements

ø 120

25

9

10a

10a

ø 150

25

15

10

SORTIE AIR VERSION ASPIRANTE

En cas d’installation en version aspirante, brancher la hotte à la

tuyauterie de sortie via un tube rigide ou flexible de ø 150 ou 120

mm, au choix de l’installateur.

Branchement avec un tube de ø150

• Insérer la buse avec clapet 10a.

• Fixer le tube par des colliers appropriés. Le matériau nécessaire n’est pas fourni.

Branchement avec un tube de ø120

• Insérer le flasque de réduction 9 sur la buse avec clapet 10a.

• Fixer le tube par des colliers appropriés. Le matériau nécessaire n’est pas fourni.

• Retirer les éventuels filtres anti-odeur au charbon actif.

Sortie air version Filtrante

• Fixer le raccord 15 au Treillis à l’aide des 4 Vis fournies avec

l’appareil.

• Bloquer la bride 10 dans le trou inférieur de le raccord 15.

• Joindre la sortie d ’air de la hotte avec la bride placée sou s la

rallonge par un tuyau rigide ou flexible ø 150 ( le choix est de

l’installateur).

Page 24

FR 224

Montage Cheminée - Montage Corps Hotte

12f

12c

12c

24

12e

Cmd

12c

Lux

• Positionner la Cheminée supérieure et fixer cette dernière dans

la partie supérieure du Treillis à l’aide de 2 Vis 12c (2,9 x 6,5)

fournies avec l’appareil.

• De la même façon, positionner la Cheminée inférieure et fixer

cette dernière dans la partie inférieure du Treillis à l’aide de 2

Vis 12c (2,9 x 6,5) fournies avec l’appareil.

Avant de fixer le Corps de la Hotte au Treillis:

• Retirer les Filtres anti-graisse du Corps de la Hotte.

• Retirer les éventuels Filtres Anti-odeur au Charbon actif.

• Ensuite, fixer par le bas, au moyen de 4 Vis 12f (M6 x 10)

fournies avec l’appareil, le Corps de la Hotte au Treillis prévu.

BRANCHEMENT ELECTRIQUE

• Brancher la hotte sur le secteur en interpo sant un interrupteur

bipolaire avec ouvertu re des contacts d’au moins 3 mm.

• Enlever les filtres à graisse (voir "Entretien") et s'assurer que le

connecteur du câble d'alimentation soit bien branché dans la

prise du diffuseur.

• Connecter le Connecteur des Commandes Cmd.

• Connecter le Connecteur de l’Eclairage Lux.

• Ranger les Connecteurs dans la Boîte de protection 24 en la

fermant à l’aide des 2 Vis 12e (2,9 x 9,5) fournies avec

l’appareil.

• Fixer la Boîte de protection au Corps de la Hotte à l’aide des 2

Vis 12c (2,9 x 6,5) fournies avec l’appareil.

• Pour la Version Filtrante, monter le Filtre Anti-odeur au Charbon actif.

• Remonter les Filtres Anti-graisse.

Page 25

FR 225

UTILISATION

L T1 T2 T3 T4 T5 F

Il est possible d’allumer la hotte directement à la vitesse demandée en pressant la touche

sans devoir d’abord utiliser la touche 0/1.

Touche

Fonction base

Témoins lumineux

Double fonction

Appuyer brièv ement sur cette touche pour allumer et

L

éteindre les lumières.

Appuyer sur cette touche pendant 2 secondes

pour allumer les lumières en mode « lumièr e de

courtoisie » La puissanc e des lampes est alors

réduite à envi ron 5W. Cette fonction peut être

désactivée en appuyant à n ouveau brièvement

sur la touche pour passer au mode normal

d’éclairage. Dans ce mode d’ éclairage de courtoisie, la touche n’est pas allumée.

Eteint le moteur fonctionnant à n’importe quelle vi-

T1

tesse

Fait fonctionner le moteur en première vitesse

T2

Appuyer brièv ement pour faire fonctionner le moteur

T3

en deuxième vites s e

Appuyer sur cette touche pendant env. 2 secondes pour d éclencher la fonction “Retard”, c-àd. l’arrêt retardé de l’app areil. Utile pour achever

d’éliminer toute odeur rés iduelle. Peut être activée depuis la position « Arr êt » ou les vitesses

1,2,3 ; pour dés activer cette fonction, i l suffit

d’appuyer sur n’importe quelle touche (T), sauf la

T3. Le Retard prend effet selon les modalités

suivantes:

1° vitesse / arrêt (OFF) = 20 minut es

2°vitesse = 15 minutes

3°vitesse = 5 minutes

Fait fonctionner le moteur en troisième vitesse

T4

Voyant éteint Lumières éteintes

Voyant allumé Lumières allumées

Voyant éteint Lumière de courtoisie

Voyant allumé Moteur actif

Voyant éteint Moteur inactif

Voyant allumé Deuxième vitesse active

Voyant cligno-

tant

allumée

Voyant allumé

Fonction Retar d

Active

Voyant allumé

Page 26

FR 226

Touche

T5

F

Fonction base

Fait fonctionner le moteur en vitesse intensive

pendant 5 minut es. Après 5 minutes, l’appareil

retourne à la v itesse choisie auparavant. Si la

mise en marche es t effectuée quand l’app areil est

éteint, après 5 minutes le système retourne à la

première vitesse.

Appuyer sur cette touche pendant 4 secondes

pour rétabli r le signal d’alarme des f iltres, le témoin lumineux T1 clignotera. Cette procédure

peut être eff ectuée seule m ent quand le moteur

est éteint.

Témoins lumineux

Voyant allumé

Voyant allumé Signale que les Filtres à

Voyant clignotant

Graisse Métalliques sont saturés et qu’il est temps de les

laver. L’alarme se déclenche

après 100 heures de foncti onnement effectif de la Hotte.

Quand il est ac tivé, l’alarme

signale que le Filtre anti-odeur

au charbon actif doit être remplacé ; les Filtres à Graisse

Métalliques doivent égal ement

être lavés. L’alarme indiquant

la saturation des Filtres Antiodeur au charbon actif s e déclenche après 200 de fonct ionnement effectif de la Hotte.

(Pour la mise en marche voir

leparagraphe Filtre anti-odeur)

Page 27

FR 227

ENTRETIEN

TELECOMMANDE (FOURNIE SUR DEMANDE)

Il est possible de commander cet appareil au moyen d’une télécommande, alimentée avec des piles alcalines zinc-charbon 1,5 V

du type standard LR03-AAA.

• Ne pas ranger la télécommande à proximité de sources de chaleur.

• Ne pas jeter les piles; il faut les déposer dans les récipients de

récolte spécialement prévus à cet effet.

Filtres à graisse

NETTOYAGE FILTRES A GRAISSE METALLIQUES

Rétablissement du signal d’alarme

• Éteindre le Moteur d’aspiration.

• Appuyer sur la touche F pendant au moins 4 secondes, jusqu’à

ce que le voyant T1 clignote pour confirmer la mise en marche.

Nettoyage Filtres

• Ils sont lavables même en lave-vaisselle et doivent être lavés

environ tous les 2 mois ou plus souvent, en cas d’utilisation

particulièrement intensive.

• Retirer les Filtres, un à un, en les poussant vers la partie postérieure du groupe tout en tirant vers le bas.

• Laver les Filtres en évitant de les plier, et les faire sécher avant

de les remonter.

• Remonter les Filtres en faisant attention de tenir la poignée

vers la partie externe visible.

Page 28

FR 228

Filtre anti-odeur (Version Filtrante)

Il ne peut être ni lavé ni récupéré, il faut le changer quand la touche F clignote ou au moins

tous les 4 mois. L’alarme fonctionne seulement quand le Moteur d’aspiration est en marche

Activation/Désa cti vation du signal d’alarme

• Pour les Hottes en Version Filtrante, l’alarme indiquant la saturation des Filtres doit être activée au moment de l’installation ou ultérieurement.

• Éteindre les lumières et le Moteur d’asp i ration.

• Débrancher la Hotte en retirant la prise du groupe moteur ou en éteignant l’Interrupteur bipolaire de la hotte ou du réseau électrique.

• Rétablir le branchement en appuyant sur la touche T2.

• Relâcher la touche, les touches L, T2 et F s’allument sans clignoter.

• Dans les 3 secondes qui suivent, appuyer sur la touche F jusqu’à ce qu’elle clignote pour

confirmer la mise en marche :

• Le voyant clignote deux fois : MISE EN MARCHE alarme saturatio n Filtre anti-odeur au

Charbon

• Le voyant clignote une fois : EXTINCTION alarme saturation Filtre anti-odeur au Char-

bon

REMPLACEMENT FILTRE ANTI- ODEUR AU CHAR BON ACTIF

Rétablissement du signal d’alarme

• Éteindre le Moteur d’aspiration.

• Appuyer sur la touche F pendant au moins 4 secondes, jusqu’à

ce que le voyant T1 clignote pour confirmer la mise en marche.

Changement du Filtre

• Retirer les Filtres à graisse métalliques.

• Retirer le Filtre anti-odeur au Charbon actif saturé en agissant

sur les crochets qui le tiennent en place.

• Mettre le nouveau Filtre en l’accrochant bien en place.

• Remonter les Filtres à graisse métalliques.

Eclairage

REMPLACEMENT LAMPES

Lampe halogène de 20 W.

• Retirer les 2 Vis qui fixent le Support éclairage et ôter ce d ernier de la Hotte.

• Extraire la Lampe du Support.

• Re mplacer par un e nouvelle lampe possédant les mêmes caractéristiques, en veillant à ce que les deux fiches soient correctement insérées dans le logement de la Douille.

• Remonter le Support en le fixant à l’aide des deux Vis précédemment retirées.

Page 29

DE 229

EMPFEHLUNGEN UND HINWEISE

650 mm min.

Diese Gebrauchsanleitung gilt für mehrere Geräte-Ausführungen. Es ist mög-

lich, dass einzelne Ausstattungsmerkmale beschrieben sind, die nicht auf Ihr

Gerät zutreffen.

MONTAGE

• Der Hersteller haftet nicht für Schäden, die auf eine fehlerhafte und unsachgemäße Montage zurückzuführen sind.

• De r minimale Sicherhei tsabstand zwischen Ko chmulde und Haube mu ss 650

mm betragen.

• Prüfen, ob die Netzspannung mit dem Wert auf dem im Haubeninneren angebrachten Schild üb er ei ns ti mmt.

• Bei Geräten der Klasse I ist sicherzustellen, dass die elektrische Anlage des

Wohnhauses über eine vorschriftsmäßige Erdung verfügt.

• Das Anschlussrohr der Haube zur Luftaustrittsöffnung muss einen Durchmesser von 120 mm oder darüber aufweisen. Der Rohrverlauf muss so kurz wie

möglich sein.

• Die Haube darf an keine Entlüftungsschächte ange schlossen werden, in die

Verbrennungsgase (Heizkessel, Kamine usw.) geleit et werden.

• Werden im Raum außer der Dunstabzugshaube andere, nicht elektrisch betriebene (z.B. gasbetrie bene) Geräte verwendet, mu ss für eine ausreichende

Belüftung gesorgt werden. Sollte die Küche diesbezüglich nicht entsprechen,

ist an einer Aussenwand eine Öffnung anzubringen, die Frischluftzufuhr gewährleistet.

BEDIENUNG

• Die Dunstabzugshaube ist aussch ließlich zum Einsatz im privaten Haushalt

und zur Beseitigung von Küchengerüchen vorgesehen.

• Unsachgemäßer Einsatz der H aube ist zu unterlassen.

• Große Flammen bei eingeschalteter Haube ni emals unbedeckt lassen.

• Die Intensivität der Flamme ist so zu regulieren, dass sie den Topfboden nicht

überragt.

• Frittiergeräte müssen während des Gebrauchs stets beaufsichtigt werden:

überhitztes Öl kann sich entzünden.

• Keine flambierten Speisen u nter der Abzu gshaube zubereiten: Brandgefahr.

• Dieses Gerät darf n icht von Person en, auch Kind ern, m it verm inderte n psych ischen, sensorischen und geistigern Fähigkeiten, oder von Personen ohne Erfahrung und Kenntnisse benutzt werden, sofern sie nicht von für ihre Sicherheit verantwortlichen Personen beaufsichtigt und beim Gebrauch des Geräts

angeleitet werden.

• Kinder dürfen sich ni cht unbeau fsichtigt in der Nähe des Ge räts aufha lten und

auf keinen Fall mit dem Gerät spielen.

WARTUNG

• Bevor Wartungsarbeiten durchgeführt werden, muss die Stromzufuhr zur Haube unterbrochen werden, indem der Stecker gezogen oder der Hauptschalter

abgeschaltet wird.

• Bei der Filterwartung müssen die vom Hersteller empfohlenen Zeiträume zum

Austauschen der Filter genauestens eingehalten werden.

• Zur Reinigung der Haubenflächen Wir empfehlen ein feuchtes Tuch und ein

mildes Flüss igreinigungsmittel.

Page 30

DE 330

CHARAKTERISTIKEN

Platzbedarf

650 min.

Page 31

DE

331

Komponenten

Pos. St. Produktkomponenten

1 1 Haubenkörper mit Schaltern,

2 1 Teleskopkamin bestehend aus:

2.1 1 oberer Kaminteil

2.2 1 unterer Kaminteil

7.1 1 Teleskopgerüst komplet t mit Gebläse, bestehend aus:

7.1a 1 oberer Gerüstteil

7.1b 1 unterer Gerüstteil

9 1 Reduzierflansch ø 150-1 20 mm

10 1 Flansch ø 150

10a 1 Flansch mit Ruckstauklappe ø 150

15 1 Luftaustritt-Anschlussstück

24 1 Verbindungsdose

25 2 Rohrschellen

Pos. St. Montagekomponenten

11 4 Bügel ø 10

12c 6 Schrauben 2,9 x 6,5

12e 2 Schrauben 2,9 x 9,5

12f 4 Schrauben M6 x 10

12g 4 Schrauben M6 x 80

12h 4 Schrauben 5,2 x 70

21 1 Bohrschablone

22 4 Unterlegscheiben ø 6,4

23 4 Schraubenmuttern M6

St. Dokumentation

1 Bedienungsanleitung

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

23

12c

25

12e

11

12h

15

10

9

10a

24

12f

Page 32

DE 332

MONTAGE

Bohren der Decke/Trägerplatte und Montage des Teleskopgerüsts

BOHREN DER DECKE/TRAGERPLATTE

• Mit Hilfe eines Lots den Kochmulden-Mittelpunkt an der Decke oder Trägerplatte ermitteln

und kennzeichnen.

• Die mitgelieferte Bohrschablone 21 so auf die Decke/Trägerplatte legen, dass die Schablo nenmitte mit dem gekennzeichneten Mittelpunkt übereinstimmt und die Schablonenseiten

auf die Seiten der Kochmulde ausrichten.

• Die Mitte der Schablonenbohrungen kennzeichnen.

• Die gekennzeichneten Punkte bohren:

• Massivbeton-Decke: je nach verwendeten Beton-Dübeln.

• Decke aus Hohlkammer-Ziegeln mit 20 mm Wandungsstärke: ø 10 mm (sofort die mitge-

lieferten Dübel 11 einfügen).

• Holzbalkendecke: je nach verwendeten Holzschrauben.

• Holz-Trägerplatte: ø 7 mm.

• Durchgang für das Speisekabel: ø 10 mm.

• Luftaustritt (Abluftversion): je nach Durchmesser des Anschlussrohres für die Luftablei-

tung.

• Zwei sich gegenüberliege nde Sc hr a ube n festziehen und 4-5 mm Fre ira um z ur De ck e be las se n:

• bei Massiv-Betondecken mit speziellen Betondübeln, die nicht mitgeliefert werden;

• für Hohlkammer-Ziegeln mit ca. 20 mm Wandungsstärke die mitgelieferten Schrauben

12h verwenden;

• bei Holzbalken-Decken mit 4 Holzschrauben, die nicht mitgeliefert werden;

• bei Holz-Trägerplatten mit 4 Schrauben 12g, Unterlegscheiben 22 und Schraubenmuttern

23, die im Lieferumfang enthalten sind.

Page 33

DE 333

Montage des Teleskopgerüsts

2

2

1

1

• Die beiden Schrauben lösen, die den unteren Gerüstteil fixieren

und diesen aus dem Gerüst ziehen (an der Unterseite)

• Die beiden Schrauben lösen, die den oberen Gerüstteil fixieren

und diesen aus dem Gerüst ziehen (an d er Oberseit e).

Für eine eventuelle Regulierung der Gerüsthöhe folgendermaßen

vorgehen:

• Die acht Stellschrauben an den Gerüstseiten, die die beiden

Säulen vereinen, lösen.

• Den oberen Gerüstteil von oben einfügen und frei auf dem Gerüst lassen.

• Das Gerüst heben, die Langlöcher bei den Schrauben einrasten

und bis zum Anschlag laufen lassen;

• Die beiden Schrauben festziehen und die beiden anderen mitgelieferten Schrauben einschrauben;

Bevor die Schrauben definitiv festgezogen werden, kann eine

Regelung durch Bewegen des Gerüstes erfolgen, wobei darauf zu

achten ist, dass die Schrauben nicht aus dem Sitz des Regellangloches austreten.

• Wir verweisen auf die Notwendigkeit einer absolut sicheren

Befestigung des Teleskopgerüsts, die sowohl dem Eigengewicht der Haube wie auch dem seitlichen Druck, der auf das

Gerät einwirken kann , entsprechen muss. Nach erfol gter Montage ist zu prüfen, ob das Teleskopgerüst auch bei Biegebeanspruchung stabil ist.

• Sollte die Decke am Befestigungspunkt nicht robust genug

sein, muss der Installateur geeignete Platten und Gegenplatten

verwenden, die an strukturell widerstandsfähigen Teilen verankert werden.

Page 34

DE 334

Anschlüsse

ø 120

25

9

10a

10a

ø 150

25

15

10

ANSCHLUSS IN ABLUFTVERSION

Bei Abluftbetrieb kann die Haube vom Installateur wahlweise

mittels Rohr oder Schlauch (ø150 oder 120mm) an die Außenrohrleitung angeschlossen werden.

Anschlussrohres ø 150

• Den Flansch mit Ruckstauklappe 10a anbringen.

• Das Rohr mit geeignet en Rohrschellen fixieren.Das hi erzu erforderliche Material wird nicht mitgeliefert.

Anschlussrohres ø 120

• Bei Verwendung eines Anschlussrohres ø 120 den Reduzierflansch 9 am Flansch mit Ruckstauklappe 10a anbringen.

• Das Rohr mit geeignet en Rohrschellen fixieren.Das hi erzu erforderliche Material wird nicht mitgeliefert.

• Eventuell vorhandene Aktivkohlefilter entnehmen.

Anschluss in Umluftversion

• Der Anschluß 15 an das Teleskopgerüst mit den 4 beiliegenden

Schrauben befestigen.

• Den Flansch 10 an die untere Bohrung des Anschluß 15 an-

bringen.

• Den Haubenluftaustritt mit Hilfe eines Rohres oder Schlauches

Ø 150 (die Wahl bleibt dem Installateur überlassen) mit dem

Flansch, der sich unter dem Umlenkteil befindet, verbinden.

Page 35

DE 335

Kaminmontage und Montage des Haubenkörpers

12f

12c

12c

24

12e

Cmd

12c

Lux

• Den oberen Kaminteil positionieren und beim oberen Gerüstteil mit Hilfe der 2 mitgelieferten Schrauben 12c (2,9 x 6,5) fixieren.

• Gleichermaßen den unteren Kaminteil positionieren und beim

unteren Gerüstteil mit Hilfe der 2 mitgelieferten Schrauben 12c

(2,9 x 6,5) fixieren.

Vor der Montage des Haubenkörpers am Teleskopgerüst:

• Die Fettfilter entnehmen.

• Eventuell vorhandene Aktivkohle-Geruchsfilter entnehmen.

• Dann den Haubenkörper mit Hilfe der 4 mitgelieferten Schrauben 12f (M6 x 10) von unten her am Teleskopgerüst fixieren.

ELEKTROANSCHLUSS

• Bei Anschluss der Haube an das Stromn etz muss ein zweipoliger Schalter mit einem Öffnungsweg von mindestens 3 mm

zwischengeschaltet werden.

• Entfernen Sie die Fettfilter (s. Abschnitt „Wartung“) und versichern Sie sich, daß di e Kabelverbindung in die Steckd ose des

Gebläses einwandfrei eingesteckt wird.

• Den Verbinder der Steuerungen Cmd anschlie- ßen.

• Den Verbinder der Beleuchtung Lux anschließen.

• Den Verbinder wieder in die Verbindungsdose 24 stecken und

diese mit den 2 mitgelieferten Schrau-ben 12e (2,9 x 9,5) verschließen.

• Die Verbindungsdose mit den 2 beiliegenden Schrauben 12c

(2,9 x 6,5) am Haubenkörper fixieren.

• Bei Umluftbetrieb den Aktivkohle-Geruchsfilter montieren.

• Die Fettfilter wieder montieren.

Page 36

DE 336

BEDIENUNG

L T1 T2 T3 T4 T5 F

Die Haube kann direkt auf die gewünschte Stufe eingeschaltet werden ohne daß man vorher

auf die Gebläsetaste 0/1 drückt.

Grundfunktion

Taste

Doppelfunktion

Ein kurzer Tas tendruck schaltet die Bel euchtungsanlage

L

ein und aus.

Wird die Taste 2 Sekunden lang gedrückt, schaltet sich

die “Nachtbeleuchtung” ein. Die Lampen werde n mit

einer verringerten Leistung von cirka 5W gespeist. Diese Funktion kann deakti viert werden , indem die Taste 2

Sekunden lang gedrückt wird bzw. kurz gedrückt wird,

um auf den normalen Beleuchtungsmodus überzugehen. Im Modus „Nachtbeleuchtung“ leuchtet die Taste

nicht auf.

Schaltet den Motor unabhängig von der Gebläsestuf e ab

T1

Aktiviert den Motor mit der ersten Gebläsestufe

T2

Bei kurzem Drüc ken dieser T aste wird der Mot or mit der

T3

zweiten Gebläsestufe aktiviert

Wird die Tast e cirka 2 Sekun den lang gedrückt, akti viert

sich die Funkt ion Delay, d.h. die verzögerte Abschaltung des Gerätes. Eignet sich zur kompletten Beseitigung von Rest gerüchen. Kann in der Position OFF und

den Gebläses tufen 1, 2, 3 aktiviert werd en; kann vorzeitig durch Drüc ken jeder beliebigen Taste (T) (mit Aus-

nahme der Tas te T3) deaktiviert werden. Die DelayFunktion erfolgt nach nachstehendem Zeitplan:

1. Stufe / OFF = 20 Minuten

2. Stufe = 15 Minuten

3. Stufe = 5 Minuten

Aktiviert den Motor mit der dr itten Gebläsestufe

T4

Taste erloschen

Taste leuchtet auf

Taste erloschen

Taste leuchtet auf

Taste erloschen

Taste leuchtet auf

Taste blinkt Delay-Funkt ion ak t iv ier t

Leuchtsignale

Beleuchtung abgeschalt et

Beleuchtung eingeschal tet

Nachtbeleuc ht ung ei n geschaltet

Motor aktiviert

Motor deaktivi ert

Taste leuchtet auf

Zweite Gebläsestufe aktiviert

Taste leuchtet auf

Page 37

DE 337

Taste

T5

Grundfunktion

Aktiviert den Motor mit der 5 Minuten dauernden Intensivstufe. Nach Ablauf der 5 Min uten läuft das Gerät wieder

mit der zuvor eingestellten Sauggeschwindigkeit. Wird

diese Funktion bei ab ges c hal tetem Gerät aktiv ier t, wird

nach Ablauf der 5 Minute n auf die ers te Gebläsestufe

übergegangen.

Wird die Taste 4 Sekunden lang gedrückt , erfolgt die

F

Rückstellung des Filteralarms, der durch Blinken der Taste T1 angezeigt wird. Dieses Ver fahren kann nur bei abgeschaltete m Motor durchg eführt werden.

Leuchtsignale

Taste leuchtet auf

Taste leuchtet auf

Taste blinkt Sättigungsanzeige der Ak-

Sättigungsanzeige der M etallfettfilter, die gewaschen

werden müssen. Der Alarm

erfolgt nach 100 effektiven

Arbeitsstund en der Ha ube.

tivkohle-Geruchsfilter , falls

diese aktiv iert wurde; die

Filter sind auszutauschen;

die Metallfettfilter müssen

ebenfalls gewaschen werden. Die Sättigungsanzeige

des AktivkohleGeruchsfilters erfolgt nach

200 effektiven Arbeitsstunden der Haube. (Aktivierung

siehe Abschn.

Geruchsfilter)

Page 38

DE 338

WARTUNG

FERNBEDIENUNG (OPTION)

Dieses Gerät kann mit einer Fernbedienung gesteuert werden,

welche mit alkalischen Zink-Kohle-Batterien 1,5 V des Standardtyps LR03-AAA versorgt wird.

• Die Fernbedienung nicht in die Nähe von Hitzequellen legen.

• Batterien müssen vorschriftsmäßig entsorgt werden.

Fettfilter

REINIGUNG DER SELBSTTRAGENDEN METALLFETTFILTER

Rückstellen der Sättigungs anzeige

• Den Gebläsemotor abschalten.

• Die Taste F mindestens 4 Sekunden lang drücken, bis die Taste

T1 als Bestätigung zu blinken beginnt.

Filterreinigung

• Die Filter können auch im Geschirrspüler gereinigt werden und

sollten cirka alle 2 Monate - bzw. bei sehr intensivem Einsatz

auch häufiger - gereinigt werden.

• Die Filter einzeln entnehmen, indem sie zur Rückseite der

Gruppe geschoben und gleichzeitig nach unten gezogen werden.

• Die Filter waschen, darauf achten, sie nicht zu verbiegen und

vor der Remontage trocknen lassen.

• Bei der Remontage darauf achten, dass sich der Griff an der

sichtbaren Außenseite befindet.

Page 39

DE 339

Geruchsfilter (Umluftbetrieb)

Dieser Filter ist weder wasch- noch wiederverwendbar und ist auszutauschen, wenn die Taste

F blinkt oder zumindest alle 4 Monate. Die Sättigungsanzeige erfolgt nur, wenn der Gebläsemotor eingeschaltet ist.

Aktivierung/Deaktivierungder S ättigungsa nzeige

• Bei Hauben mit Umluftbetrieb erfolgt die Aktivierung der Sättigungsanzeige bei der Installation oder später.

• Die Beleuchtung und den Gebläsemotor abschalten.

• Die Haube vom Stromnetz trennen, indem der Verbinder des Speisekabels der Motorgruppe

gezogen oder der zwischengeschaltete zweipolige Schalter oder der Hauptschalter betätigt

wird.

• Den Anschluss wieder herstellen, während die Taste T2 gedrückt gehalten wird.

• Die Taste loslassen; die Tasten L, T2 und F leuchten pausenlos auf.

• Innerhalb v o n 3 Sekunden die Taste F solange drücken, bis sie als Bestätigung zu blinken

beginnen:

• 2-maliges Blinken – Sättigungsanzeige Aktivkohle-Geruchsfilter AKTIVIERT

• 1-maliges Blinken – Sättigungsanzeige Aktivkohle-Geruchsfilter DEAKTIVIERT

AUSTAUSCHEN DES AKTIVKOHLE-GERU CHSF IL T ER

Rückstellen der Sättigungs anzeige

• Den Gebläsemotor abschalten.

• Die Taste F mindestens 4 Sekunden lang drücken, bis die Taste

T1 als Bestätigung zu blinken beginnt

Filterwechsel

• Die Metallfettfilter entfernen.

• Den gesättigten Aktivkohle-Geruchsfilter anhand der entsprechenden Anhakvorrichtungen demontieren.

• Den neuen Filter montieren, indem er in seinem Sitz eingehakt

wird.

• Die Metallfettfilter wieder montieren.

Beleuchtung

Halogenlampe 20 W

• Vor dem Auswechseln der Lampen, die beiden Schrauben der

Lampenhalterung loesen und die Lampenhalterung aus der

Dunstabzugshaube ziehen.

• Die Lampe aus der Halterung nehmen.

• Die Lampe durch eine gleichwertige ersetzen und bei der Remontage darauf achten, daß die beiden Steckerstifte vorschriftsmäßig in die Lampenfassung eingeführt werden.

• Die Lampenhalterung wieder montieren, indem die beiden zuvor entfernten Schraub en wieder angezogen werden.

AUSWECHSELN DER LAMPEN

Page 40

NL 440

ADVIEZEN EN SUGGESTIES

650 mm min.

D eze gebruiksaa nwijzing geldt vo or verschillende uitvoeringen van het appa -

raat. Het is mogelijk dat er een aantal kenmerke n worden besch reven die nie t

van toepassing zijn op uw a pparaat.

INSTALLATIE

• D e fabrikant aanvaa rdt geen enkele aa nsprakelijkheid voo r schade die voo rtkomt uit onjuiste of niet overeenkomstig de regels der kunst uitgevoerde installaties.

• De minimale veiligheidsafstand tussen de kookplaat en de wasemkap bedraagt 650 mm.

• Contro leer of de netspan ning correspondeert met de spanning d ie aangegeven is op het pl aatje aan de bi nnenkant van de wasemkap.

• Voor apparaten van klasse I dient u zich ervan te verzekeren dat het elektriciteitsnet in uw huis over een goede aardi ng beschikt .

• Verbind de wasemkap met de luchtuitlaat door middel van een leiding met een

diameter van 120 mm of groter. De leiding moet een zo kort mogelijke route afleggen.

• Sluit de wasemkap niet aan op afvoerpijpen van rook die geproduceerd is door

verbranding ( verwarmingsketels, open haarden etc.).

• Als er in het vertrek zowel de wasemkap als apparaten die niet op elektriciteit

werken (bijvoorbeeld gasapparaten) worden gebruikt, moet ervoor worden gezorgd dat het ver trek voldoe nde geventil eerd wordt. Indien de keuken geen gat

in de buitenmuur hee ft om de aanvoer van schon e lucht te garande ren, dient

dit gemaakt te worden.

GEBRUIK

• De wasemkap is uitsluitend on tworpen voor huishoudelijk gebruik, voor het

elimineren van kookgeuren. Gebruik de kap nooit op oneigenlijke wijze.

• Laat geen hoog brandende branders onbedekt onder de wasemkap

terwijl deze in werking is.

• Regel de vlammen altij d zo dat ze niet langs de pannen omhoogkomen.

• Controleer frituurpannen tijdens het gebruik: de oververhitte olie zou vlam

kunnen vatten.

• Er mag niet onder de afzuigkap geflambeerd worden; brand gevaar

• Dit apparaat mag niet worden gebruikt door personen (inclusief kinderen) met

beperkte psychisch e, sensorische en geestelijke vermo ge n s, o f door personen

zonder ervaring en kennis, tenzij ze onder toezich t staan of worden ge ïnstrueerd over het gebruik van het apparaat door personen die verantwoordelijk zijn

voor hun veiligheid.

• Kinderen moeten worden gecontroleerd om er zeker van te zijn dat ze niet met

het apparaat spelen.

ONDERHOUD

• Alvorens onderhoudswerkzaamheden uit te voeren, moet de wasemkap uitgeschakeld worden door de stekker uit het stopcontact te halen of de hoofdschakelaar om te zetten.

• Voer het onderhoud van de filters altijd tijdig en nauwgezet uit,volgens de

aanbevolen intervallen.

• Om de oppervlakken van de kap schoon te maken is het voldoende een vochtige doek en een neutraal reinigingsmi ddel te gebruiken.

Page 41

NL 441

EIGENSCHAPPEN

Buitenafmetingen

650 min.

Page 42

NL 442

Onderdelen

Ref. Productonderdelen

1 1 Wasemkap compleet met: Bedieningen, Licht, Filters

2 1 Telescopische Sc hou w Bes t aan de ui t:

2.1 1 Bovenstuk

2.2 1 Onderstuk

7.1 1 Telescopisch frame compleet met afzuiginrichting,

bestaand uit:

7.1a 1 Bovenste frame

7.1b 1 Onderste frame

9 1 Reductieflens ø 150- 120 mm

10 1 Flens ø 150

10a 1 Toom met Klep ø 150

15 1 Verbindingsstuk Luchtuitlaat

24 1 Aansluitdoos

25 2 Leidingklemmen

Ref. Installatieonderdelen

11 4 Pluggen ø 10

12c 6 Schroeven 2,9 x 6,5

12e 2 Schroeven 2,9 x 9,5

12f 4 Schroeven M6 x 10

12g 4 Schroeven M6 x 80

12h 4 Schroeven 5,2 x 70

21 1 Boormal

22 4 Ringen øi 6,4

23 4 Moeren M6

Documentatie

1 Gebruiksaanwijzing

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

23

12c

25

12e

11

12h

15

10

9

10a

24

12f

Page 43

NL 443

INSTALLATIE

Gaten boren in plafond/plank en bevestiging frame

GATEN BOREN IN PLAFOND/PLANK

• Teken met behulp van een looddraad op het plafond/de draagplank het midden van de kookplaat af.

• Houd de bijgeleverde boormal 21 tegen het plafond/de plank, en laat het midden hiervan

samenvallen met het afgetekende punt en lijn de assen van de boormal uit met de assen van

de kookplaat.

• Teken de middelpunten van de gaten van de boormal af.

• Boor gaten in de afgetekende punten:

• Plafond van massief beton: volgens de gebruikte betonpluggen.

• Plafond van steen met luchtkamer, met resistente dikte van 20 mm: ø 10 mm.(schuif on-

middellijk de bijgeleverde pluggen 11 in de ga te n).

• Plafond van houten balken: afhankelijk van de gebruikte houtschroeven.

• Houten planken: ø 7 mm.

• Doorvoer van de elektri sche voedingskabel: ø 10 mm.

• Luchtuitlaat (Afzuigversie): overeenkomstig de diameter van de verbinding met de af-

voerleiding naar buiten.

• Zet de twee schroeven vast in kruisvorm, maar laat een ruimte vrij van 4-5 mm tussen de

schroef en het plafond:

• voor massief beton, betonpluggen, niet bijgeleverd.

• voor bakstenen muur met luchtkamer, met een resistente dikte van ongeveer 20 mm, wor-

den de schroeven 12h bijgeleverd.

• voor houten balken, 4 houtschroeven, niet bijgeleverd.

• voor houten plank, 4 schroeven 12g met ringen 22 en moeren 23, bijgeleverd.

Page 44

NL 444

BEVESTIGING FRAME

frame aan

2

2

1

1

• Draai de twee schroeven los die het onderstuk vasthouden aan

het frame en verwijder het (langst de onderkant)

• Draai de twee schroeven los die het bovenstuk vasthouden aan

het frame en verwijder het (langst de bovenkant)

Als U de hoogte van het frame wil bijstellen, gaat als volgt te

werk:

• Draai de acht metriche schroeven los die de twee kolommen

met elkaar verbinden . Deze bevinden zich aan de zijkant van

het frame.

• Om het frame stabieler te maken, moet U de vier veiligheidsschroeven vastzetten in het laatste vrije gat.

• Til het frame op, plaats de haken over de schroeven en schuif

verder tot de schroeven blokkeren;

• Schro ef deze twee schroeven go ed aan en zet ook de andere

twee bijgeleverde schroeven vast;

Vooraleer U de schroeven definitief vastschroeft, kan U nog bijpassen door het frame rond te draaien. Let wel op dat de schroeven niet uit de bevestigingshaken schuiven.

• De bevestiging van het frame moet zowel berekend zijn op het

gewicht van de wasemkap als op de belastingen die veroorzaakt worden door eventuele stoten tegen de zijkant van het

gemonteerde apparaat. Controleer na het bevestigen van het

frame of de basis stabiel is, ook als er tegen het

wordt geduwd.

• In alle gevallen waarin het plafond niet stevig genoeg is op het

punt waar de kap wordt opgehangen, dient de installateur het

plafond te verstevigen met platen en tegenplaten die verankerd

worden aan delen met een resistente structuur.

Page 45

NL 445

Aansluitingen

ø 120

25

9

10a

10a

ø 150

25

15

10

LUCHTUITLAAT AFZUIGVERSIE

Bij installatie in afzuigversie, moet u de wasemkap met de uitlaatleiding verbinden door middel van een starre of buigzame

leiding van ø 150 of 120 mm, naar keuze van de installateur.

Leiding van ø150

• De Toom met Klep 10a worden aangebracht.

• Zet de leiding vast met geschikt leidingklemmen.

Het benodigde materiaal wordt niet bij de wasemkap geleverd.

Leiding van ø120

• Voor verbinding met een leiding van ø120 mm, moet de reductieflens 9 op de Toom met Klep 10a worden aangebracht.

• Zet de leiding vast met geschikt leidingklemmen.

Het benodigde materiaal wordt niet bij de wasemkap geleverd.

• Verwijder de eventuele geurfilters met actieve koolstof.

Luchtuitlaat Filterversie

• Bevestig verbindingsstuk 15 aan de frame met behulp van de 4

bijgeleverde schroeven.

• Zet de flens 10 vast in de daarvoor bestemde opening onderaan

het verbindingsstuk 15.

• Verbind de luchtuitlaat van de wasemkap met de flens onderaan het verbindingsstuk door middel van een onbuigbare of

flexibele leiding van ø 150 mm; naar keuze van de installateur.

Page 46

NL 446

Montage van de schouw - Montage van de Wasemkap

12f

12c

12c

24

12e

Cmd

12c

Lux

• Breng het bovenste gedeelte van de schouw in positie en zet dit

aan de bovenkant vast aan het frame met 2 van de bijgeleverde

schroeven 12c (2,9 x 6,5).

• Breng op dezelfde manier het onderste gedeelte van d e schouw

in positie en zet dit aan de onderkant vast aan het frame met 2

van de bijgeleverde schroeven 12c (2,9 x 6,5).

Alvorens de wasemkap aan h et frame te bevestigen:

• Haal de vetfilters uit de wasemkap;

• Verwijder eventuele geurfilters met actieve koolstof.

• Zet vervolgens via de onderkant de wasemkap vast aan het

frame met 4 bijgeleverde schroeven 12f (M6 x 10).

ELEKTRISCHE AANSLUITING

• Sluit de wasemkap aan op de netspanning met een tweepolige

schakelaar ertussen met een opening tussen de contacten van

tenminste 3 mm.

• Verwijder de vetfilters (zie par. "Onderhoud") en verzeker u

ervan dat de stekker van de voedingskabel goed in de contactdoos van de afzuigkap is gestoken.

• Sluit de connector van de bedieningen Cmd aan.

• Sluit de connector van de verlichting Lux aan.

• Plaats de connector in de beschermdoos 24 en sluit deze met de

2 bijgeleverde schroeven 12e (2,9 x 9,5).

• Bevestig de beschermdoos aan de wasemkap met 2 van de bijgeleverde schroeven 12c (2,9 x 6,5).

• V oor de filterversie monteert u het geurfilter met actieve koolstof.

• Zet de vetfilters weer op hun plaats.

Page 47

NL 447

GEBRUIK

L T1 T2 T3 T4 T5 F

De wasemkap kan rechtstreeks ingeschakeld worden op de gewenste snelheid, door de desbetreffende toets in te drukken zonder eerst de toets 0/1 motor te bedienen.

Basisfunctie Toets

Lichtsignalen

Dubbele Functie

Als U deze toets even indrukt , wordt de verlichting aan-

L

of uitgeschakeld.

Als U deze toets 2 seconden ingedrukt houdt, wordt

er een “beleefdheidsverlichting” aangeschakeld.

De lampen branden dan met een gereduceerd vermogen van ong eveer 5W. Deze f unctie kan w eer

uitgeschakeld worden do or de toets opnieuw gedurende 2 secon den ingedrukt te houden of door even

op de toets te dr ukken en zo over te schakelen naar

de normale lic htintensitei t. Als deze b eleefdheidsverlichting brandt, is de led uit.

Schakelt de zuigmotor uit van op elke ingestelde snelheid

T1

Activeert de zuigmotor in de eerste snelheid

T2

Als U deze toets even indrukt, activeert U de zuigmotor in

T3

de tweede snelheid

Als U deze toets ongeveer 2 ‘’ ingedrukt houdt, activeert U de Delay functie, dit staat voor een vertraagde uits chakeling va n het toestel. Deze functie is

zeer geschikt om restgeurt jes te verwijderen. De Delay functie kan geactiveerd worden als het toestel

UIT staat, of als het werkt op de 1ste, 2de of 3de

snelheid; U k an de functie v oortijdig uitschakelen

door eender welke toets (T) in te drukken, met uitzondering van toets T3. De vertraagde uitschakeling

gebeurt volgens het volgende schema:

1° snelheid / UIT = 20 minut en

2° snelheid = 15 minuten

3° snelheid = 5 minuten

Activeert de zuigmotor in de derde snelheid

T4

Led uit Lichten uit

Led brandt Lichten aan

Led uit Beleefdheidsverlichting aan

Led brandt Motor aan

Led uit Motor uit

Led brandt

Led brandt De tweede snelheid is actief

Led knippert De vertr aagde uitschake-

lingsfunct ie is actief

Led brandt

Page 48

NL 448

Toets Basisfunctie Lichtsignalen

Activeert de zuigmotor ge durende 5 minuten in

T5

de intensieve snelheid. Na afloop van d eze 5

minuten, sch akelt het toestel over op de daarvoor ingestelde snelheid. Als U de wasemkap

Led brandt

meteen instel de in de intensieve snelheid, dan

schakelt het systeem na 5 minuten over op de

eerste snelheid.

Als U deze toets gedurende 4 seconden inge-

F

drukt houdt, wordt het alarmsignaal voor de

filters hernomen en begint toets T1 te knipperen. Deze procedure is alleen mogelijk als de

zuigmotor uitgeschakeld is.

Led brandt Signaleert het alarm verzadiging

metalen vetfilters, wat inhoudt dat

deze moeten w orden schoongemaakt. Dit alar m wordt geactiveerd

na 100 effectieve werk i ngs ur en va n

de wasemkap.

Led knippert Signaleert, wanneer hij geactiveerd

wordt, het alarm verzadiging actieve

koolstoffilter, wat inho udt dat deze

filter moet worden vervan gen; ook

moeten de metalen vetfilters worden

schoongemaakt. Het alarm verzadiging actieve k oolstoffil ter wordt

geactiveerd na 20 0 effec ti ev e w erkingsuren va n de wasemkap. ( Voor

de activering van het alar m zie paragraaf Geurfil ters)

Page 49

NL 449

ONDERHOUD

AFSTANDSBEDIENING (OPTIE)

Dit apparaat kan met behulp van een afstandsbediening worden

bestuurd. Deze werkt op al kaline zinkkoolstof bat terijen van 1,5

V van het standaardtype LR03-AAA.

• Bewaar de afstandsbediening niet in de buurt van warmtebronnen.

• De batterijen mogen na gebruik niet in het milieu terechtkomen, gooi ze in de hiervoor bestemde afvalbakken.

Vetfilters

SCHOONMAAK ZELFDRAGENDE METALEN VETFILTERS

Reset van het alarmsignaal

• Schakel de motor van de wasemkap uit.

• Druk gedurende minstens 4 seconden op toets F, tot de led van

toets T1 knippert ter bevestiging.

Schoonmaken filters

• De filters moeten om de 2 maanden of, bij bijzonder intensief

gebruik, vaker gereinigd worden, en kunnen ook in de vaatwasmachine worden schoongemaakt.

• Verwijder de filters één voor één door ze naar de achterkant

van de groep te duwen en ze tergelijkertijd omlaag te trekken.

• Was de filters af zonder ze te vouwen en laat ze drogen alvorens ze weer terug te plaatsen.

• Plaats de vetfilters terug, maar zorg ervoor dat de handgreep

zichtbaar blijft.

Page 50

NL 550

Geurfilters met actieve koolstof (Filterversie)

Deze filter is niet afwasbaar en kan niet herb ruikt worden. De koolstoffilter moet vervangen

worden als toets F knippert of minstens eenmaal in de 4 maanden. Het alarmsignaal wordt alleen aangegeven als de zuigmotor actief is.

Activering/Desa c tivering van het alarmsignaal

• Bij wasemkappen met luchtcirculatie moet het alarmsignaal dat aangeeft dat de filters verzadigd zijn, geactiveerd worden op het moment van de installatie of daarna.

• Schakel de verlichting en de zuigmotor uit.

• Sluit de wasemkap van het elektriciteitsnet af door de connector van de voedingskabel uit de

motorgroep te verwijderen, of door de 2-polige schakelaar uit te schakelen die tussen de

netvoeding staat, ofwel door de hoofdschakelaar uit te schakelen.

• Sluit de wasemkap weer aan op het net door toets T2 ingedrukt te houden.

• Laat de toets los, de leds van de toetsen L, T2 en F branden nu voortdurend.

• Druk binnen 3 seconden op de toets F totdat de led gaat knipperen ter bevestiging:

• 2 maal knipperen – Alarm verzadiging geurfilter met actieve koolstof GEACTIVEERD

• 1 maal knipperen – A larm verzadiging geurfilter met ac tieve k ools tof GE DE SACTIVEERD

VERVANGING GEURFILTER MET ACTIEVE KOOLSTOF

Reset van het alarmsignaal

• Schakel de zuigmotor uit.

• Druk gedurende minstens 4 seconden op toets F, tot de led van

toets T1 knippert ter bevestiging.

Vervanging filter

• Verwijder de metalen vetfilters.

• Verwijder de verzadigde geurfilter met actieve koolstof door

de bevestigingshaakjes los te maken.

• Zet de nieuwe filter vast op zijn plaats.

• Plaats opnieuw de metalen vetfilters.

Verlichting

VERVANGING VAN DE LAMPEN

Halogeenlamp van 20 W.

• Verwijder de 2 schroeven waarmee de lamphouder is bevestigd

en verwijder de houder uit de kap.

• Trek de lamp uit de houder.

• Vervang de lamp door een nieuwe lamp met dezelfde eigenschappen en let er hierbij op dat de twee pinnen correct in de

behuizing van de worden gestoken.

• Monteer de houder door hem te bevestigen met de twee eerder

verwijderde schroeven.

Page 51

TR 551

TAVSIYELER VE ÖNERILER

650 mm min.

Bu kullanma talimatι birden fazla cihaz modeli için geçerlidir.

Cihazιnιza uymayan bazι donanιm özellikleri tarif edilmiş olabilir.

MONTAJ

• Yalnιş veya eksik montajdan doğan herhangi bir z ararιn sorumluluğu

üreticiye ait değildir.

• Davlumbaz ile pişirici cihazιn ocak kιsmι arasιndaki minimum güvenlik

mesafesi 650 mm.dir.

• Besleme voltajιnιn, davlumbaz içerisine yerleştirilen bilgi etiketinde

belirtilenle aynι olup olmadιğιnι kontrol edin.

• Sιnιf I elektrikli aletleri için, güç kaynağιnιn yeterli topraklamayι

sağlayιp sağlamadιğιnι kontrol edin. Minimum 120 mm çapιnda bir

boru yoluyla davlumbazι çιkιş bacasιna bağlayιn. Baca bağlantιsι

mümkün oldu- ğunca kιsa olmalιdιr.

• Davlumbaz borusunu yanιcι duman taşιyan baca deliğine (buhar

kazanι, şömine, vb.) bağlamayιn.

• Davlumbazιn elektrikle çalιşmayan aletlerle (örneğin; gazlι cihazlar)

bağιntιlι olarak kullanιlmamasι halinde çιkιş gazιnιn geri tepmesini

önlemek amacιyla odada yeterl i bir havalandιrma sağlanmalιdιr. Temiz hava girişini temin etmek için mutfakta doğrudan dιşarιya açιlan

bir açιklιk bulunmalιdιr.

KULLANIM

• Davlumbaz mutfaktaki kokularιn emilmesi amacιyla evlerde kullanιm

için tasarlanmιştιr.Ticari ve endüstriyel amaçlar için kullanmayιnιz.

• Davlumbazι tasarlandιğι amaçlarιn dιşιnda kesinlikle kullanmayιnιz.

• Davlumbaz çalιşιrken altιnda kesinlikle yüksek çιplak ateş

bιrakmayιn.

• Alev yoğunluğunu doğrudan tencerenin altιnda kalacak şekilde

ayarlayιn, kenarlarιnι sarmadιğιndan emin olun.

• Yağda kιzartma tavalarιnι kullanιrken sürekli olarak takip edin: fazl a

ιsιnan yağ tutuşabilir.

• Kapağın altında kıvılcımdan kaçının, yangın riski

• Bu alet, güvenliklerinden so rumlu kişiler tarafı ndan kontrol edilmedi kleri veya eğitilmedikleri sürece; fiziksel, duyumsal ve zi hinsel kapasitesinde kısıtlama olan (çocuk lar dahil) veya aleti kullanma tecrübes i

ve bilgisi olmayan kişiler tarafından kullanılamaz.

• Bebeklerin, aletle oyna madıklarından emi n olmak için kontrol edilmeli

gerekir.

BAKIM

• Herhangi bir bakιm işlemini gerçekleştirmeden önce davlumbazι

kapatιn veya fişini çιkarιn.

• Filtreleri belirtilen zamanlarda temizleyin ve / veya değiştirin.

• Cihazι nemli bir bez ve nötr bir sιvι deterjan kullanarak temizleyin.

Page 52

TR 552

ÖZELLIKLER

Boyutlar

650 min.

Page 53

TR 553

Parçalar

Ref. Adet Ürün Parçaları

1 1 Şunlardan oluşan Davlumbaz Gövdesi: Kumandalar,

Lamba, Filtreler

2 1 Şunlardan oluşan Teleskopik Bac a:

2.1 1 Üst Baca

2.2 1 Alt Baca

7.1 1 Şunlardan oluşan Aspiratörlü teleskopik kafes:

7.1a 1 Üst kafes

7.1b 1 Alt kafes

9 1 Redüksiyon Flanşı ø 150-120 mm

10 1 Flanş ø 150

10a 1 Valfli flanş ø 150 mm

15 1 Hava Çıkışı Rakoru

24 1 Bağlantı kutusu

25 2 Boru kelepçeleri

Ref. Adet Montaj Parçaları

11 4 Dübeller ø 10

12c 6 Vidalar 2, 9 x 6,5

12e 2 Vidalar 2,9 x 9,5

12f 4 Vidalar M6 x 10

12g 4 Vidalar M6 x 80

12h 4 Vidalar 5,2 x 70

21 1 Delik açma şablonu

22 4 Rondelalar øi 6,4

23 4 Somunlar M6

Adet Belge

1 Talimat El Kitapçığı

7.1

21

22

12c

2

12c

1

7.1a

12g

7.1b

2.1

2.2

12f

23

12c

25

12e

11

12h

15

10

9

10a

24

Page 54

TR 554

MONTAJ

Tavan / Konsol delme işlemi ve Kafesin Sabitlenmesi

TAVANIN YADA KONSOLUN DELİNMESİ

• Bir şakül yardımıyla tavana ya da destek konsolüne pişirme tezgahının merkezini işaretleyi-

niz.

• Tavana veya konsola donanımla birlikte verilen delik delme şablonunu (21) dayayınız ve

bunun merkeziyle işaretlenen merkezi birbirine çakıştırınız. Yani şablonun ekseni ile pişir-

me tezgahı ekseni bir hizaya gelmiş olsun.

• Delik delme şablonuyla delikleri duvara işaretleyiniz.

• Şu şekilde delik deliniz:

• Masif beton tavan: beton dübelleri kullanarak.

• Direnç kalınlığı 20 mm ve üstte hava boşluğu olan tuğla tavan: 10 mm çapında delik (do-

nanımla verilmiş dübelleri (11) hemen takınız)

• Ahşap tavan: ahşap dübelleri kullanarak.

• Ahşap konsola: 7 mm çapında delik deliniz.

• Elektrik besleme kablosunun geçişi için: ø 10 mm çapında.

• Hava Çıkışı ( Aspiratörlü model): Dış hava tahliye borusu bağlantısının çapına göre.

• Tavana çaprazlamasına iki vida takıp 4-5 mm dışarıda bırakınız. Bu vidal ar şöyle olmalıdır:

• Masif beton için buna uygun vida ve dübeller; bunlar donanımla verilmemiştir.

• Hava boşluklu tuğla tavan - yaklaşık 20 mm direnç kalınlıklı - bunun için donanımla ve-

rilmiş vidaları (12h) kullanınız.

• Ahşap tavana uygun vidalar: donanımda yoktur.

• Ahşap konsola: donanımdaki vidalar (12g), rondelalar (22) ve cıvatalar (23).

Page 55

TR 555

Kafesin Sabitlenmesi

2

2

1

1

• Alt bacayı sabitleyen iki adet vidayı söküp kafesten çıkarınız

(alt kısımdan).

• Üst bacayı sabitleyen iki adet vidayı söküp kafesten çıkarınız

(üst kısımdan).

Kafesin yüksekliği ayarlanmak istenirse, şu şekilde hareket edilmelidir:

• Kafesin iki yanında bulunan sütunları birleştiren sekiz adet

metrik vidayı sökünüz;

• Kafesin yüksekliğini istediğiniz seviyede ayarlayıp daha önce

sökmüş olduğunuz sekiz adet vidayı tekrar takarak sıkınız;

• Yu karı kısımdan üst b acayı geçirini z ve kafes üzerinde serb est

bırakınız;

• Kafesi yukarı kaldırınız, delikleri vidalara geçirip dayanana

kadar kaydırınız;

• İki adet vidayı sıkıp bilahare cihaz donanımıyla verilmiş olan

iki adet diğer vidayı da takınız;

Vidaları nihai olarak sıkmadan önce, kafesi ayar delikleri vidalardan çıkmadan kaydırmaya özen göstererek ayarlamak mümkündür.

• Kafesin sabitlenmesi hem Davlumbazın ağırlığını kaldırabilecek, hem de cihazın montajından sonra yandan gelebilecek

sarsmalara dayanacak şekilde mümkün olduğunca sağlam yapılmalıdır. Sabitleme işlemi bittikten sonra, Kafesi sarsınca ve

esnetince bile kaidenin sabit ve sağlam şekilde durduğunu

kontrol ediniz.

• Askı noktasında tavanın yeterince sağlam olmadığı hallerde,

montör buraya uygun sıkı bağlantılı levha ve plakalar uygula-

mak suretiyle tavan sağlamlığını arttırma yoluna gitmelidir.

Page 56

TR 556

Anschlüsse

ø 120

25

9

10a

10a

ø 150

25

15

10

ANSCHLUSS IN ABLUFTVERSION

Bei Abluftbetrieb kann die Haube vom Installateur wahlweise

mittels Rohr oder Schlauch (ø150 oder 120mm) an die Außenrohrleitung angeschlossen werden.

Anschlussrohres ø 150