Page 1

DD8692-M

Kamin-Dunstabzugshaube

Cappa a camino

Canopy Hood

Hotte avec cheminée

Wasemkap met schouw

Benutzerinformation

Libretto di istruzioni

Instruction Manual

Manuel d’instructions

Instructieboekje

Page 2

Dear Customer,

Please read this instruction manual carefully and particularly the chapter on “Safety” at

the beginning. In addition, you are advised to keep this manual to be able to consult it

when required and, where relevant, pass it on to any subsequent owner of the hood.

The danger triangle and/or the written warnings (Warning!, Danger!, Attention!) indi-

cate important safety information for the user or for the operating capacity of the hood,

these warnings must be strictly adhered to.

1. This symbol will guide you step by step in the use of the hood.

2. ..........

3. ..........

After this symbol additional information regarding the use of the hood will be supplied.

The clover sign indicates useful information regarding economic and ecological use of

the hood.

This manual also contains useful advice on solving certain problems. Please refer to the

chapter “Troubleshooting”. If further advice is required, please contact the two Focal

Points at any time, and you will be given the assistance you require.

We are available:

from Monday to Friday from 8.00 a.m. to 8.00 p.m.

Saturday from 10.00 a.m. to 2.00 p.m.

An advisor will be available to answer your questions regarding the equipment and use

of the hood. Naturally, we will also take note of your requests and suggestions. Our aim

is the continual improvement of our products and services, to the benefit of our customers.

For technical assistance, please contact your nearest CUSTOMER SERVICES (the

addresses and telephone numbers are provided in the chapter, “Customer Service

Centres”). See also the chapter, “Service”.

Printed on recycled paper. He who thinks ecologically, acts accordingly ...

35

Page 3

Instructions for use

INSTRUCTIONS FOR USE

Safety

The safety requirements of this hood conform to recognised technical regulations and to

the safety laws governing the appliance. However, as manufacturer of the hood, our

company considers it advisable to provide the following customer safety information.

Electrical safety

• Where the hood is to be permanently connected to the electrical supply, the electrical

installation must be carried out exclusively by an authorised electrician. This warning

should be strictly adhered to ensure the validity of the guarantee.

• Repairs should be carried out exclusively by specialised technicians. Poor workmanship

and inadequately carried out repairs can be extremely dangerous. We recommend you

contact our Customer Services or your usual dealer for all repair work.

Safety during use

• Overheating may cause the hood to ignite.

We therefore recommend that you observe the following warnings:

- never do flambé cooking under the hood.

- lit burners should always be covered when the hood is in use. In the case of gas oil, gas

and coal cookers, naked flames must be avoided at all times.

- never leave frying pans unattended during use: overheated fats and oils ignite easily.

The danger of ignition is particularly high if the oil is dirty.

• Before carrying out any kind of work on the hood, even the simple replacement of a

bulb, the apparatus must be isolated from the electrical supply (pull out the plug, remove

the fuse from the fuse box or switch off at the mains).

• Always adhere to the recommended cleaning or filter replacement intervals to avoid the

risk of fire when the filters are saturated with grease.

Safety during cleaning

For safety reasons it is not permitted to clean the hood with steam spray or high pressure

devices.

Disposal

Disposal of the packaging

• All parts of the packaging are recyclable. The plastic film wrapping and the foam plastic

items are clearly marked. The packaging material and any used equipment should be

disposed of correctly.

• Respect the national and regional regulations and the markings on the materials

(separation of the materials, differentiated collection, collection points for recyclable

materials).

Warnings on disposal

• The hood should not be disposed of with household waste.

• Information regarding collection dates or on the collection points can be requested from

the local refuse collection departments or from the town hall.

• Warning! Used appliances should be deactivated before being disposed of. The power

cable should be removed (after removing the plug or, in the case of a permanent

connection, after having the hood disconnected by a technician).

36

Page 4

Instructions for use

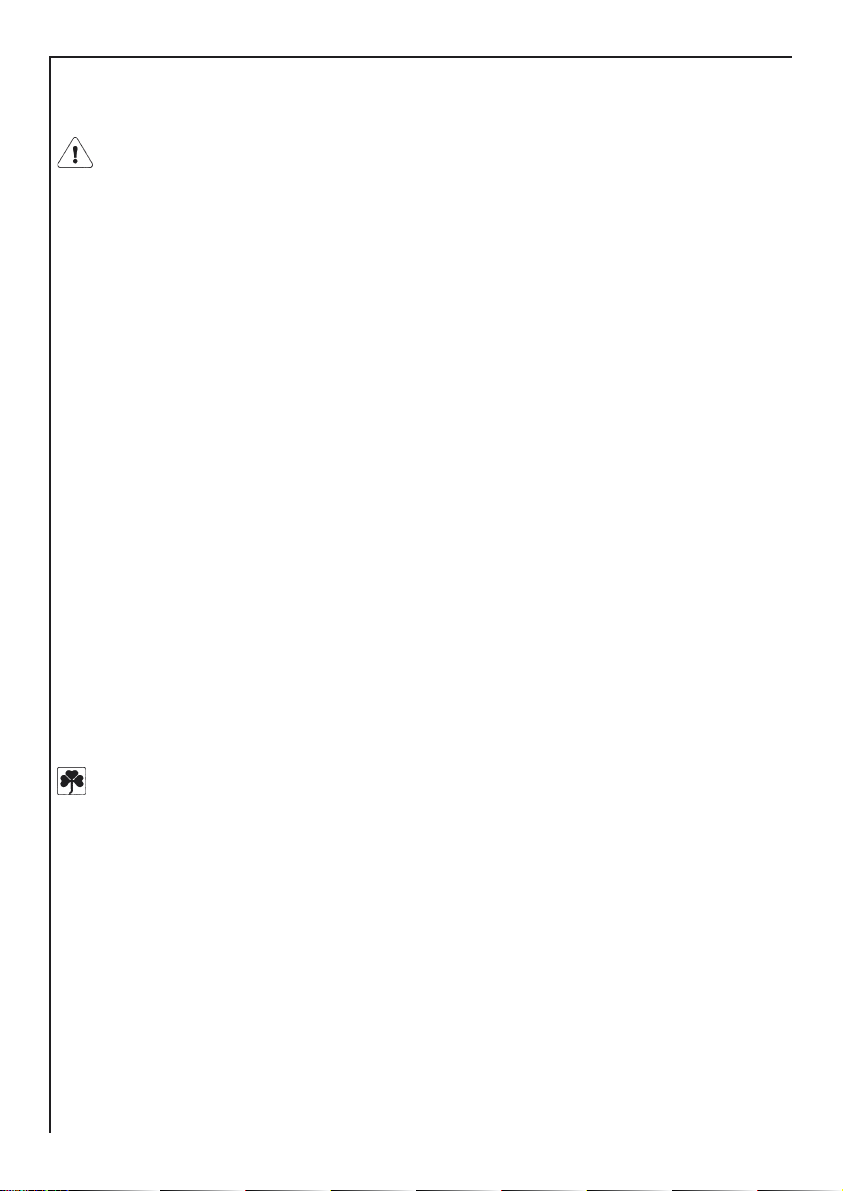

Description of the hood

Control panel

Lighting

Metal grease filter

Lighting

Control panel

Key L = Turns the lighting system on and off

Key V1 = Turns the motor on/off and the saturation metal grease filter alarm

(LED starts to flash)

Key V2 = Second speed

Key V3 = Third speed

Key I = Intensive speed with timed stoppage and saturation charcoal filter

alarm (LED starts to flash). Suitable to deal with maximum

vapour emission, this turns off automatically 10 minutes after

starting operation.It can be disabled by pressing the key I .

V1 V2 V3 IL

37

Page 5

Instructions for use

MAINTENANCE

Constant maintenance guarantees proper operation and longterm reliability. Particular

attention should be paid to the metal grease filters and, for recirculation hoods only, to

the activated charcoal filters. The appliance is equipped with a system that indicates

automatically when it is time to carry out maintenance operations.

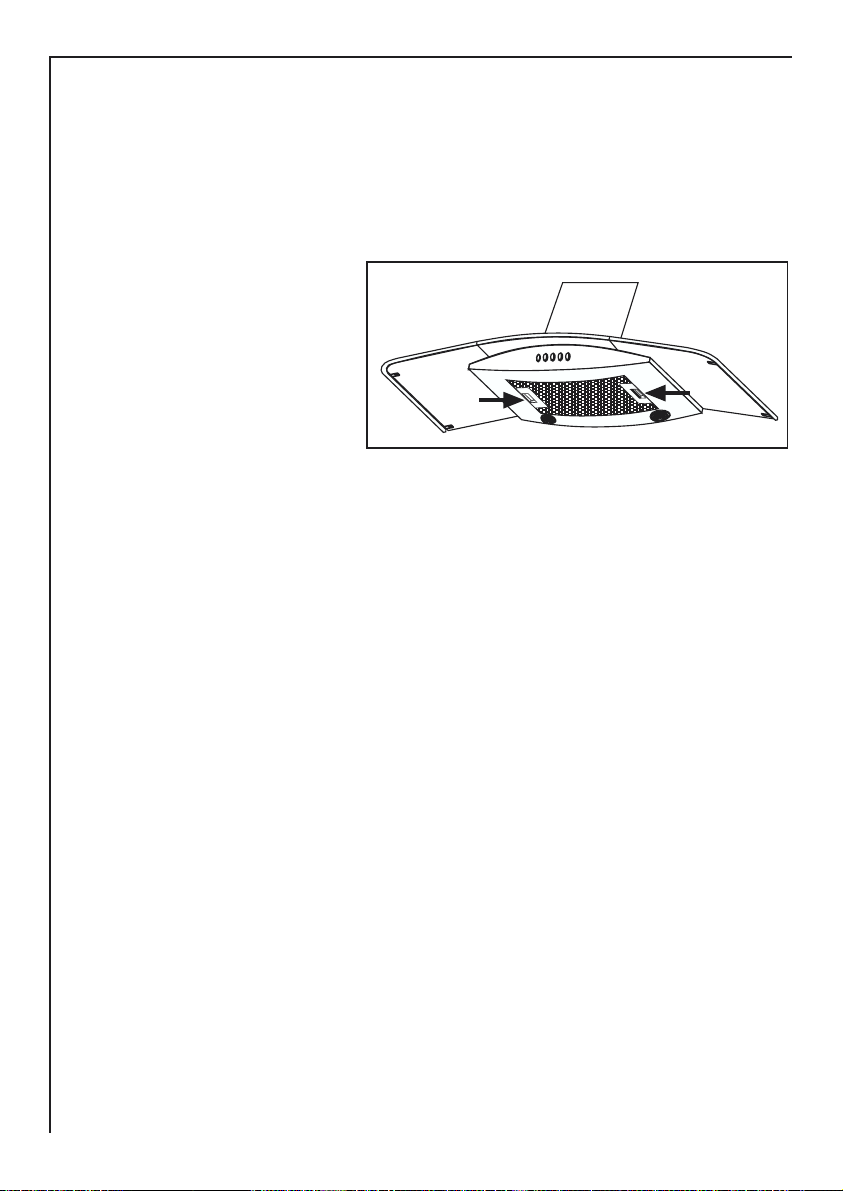

Metal grease filter

• Cleaning

This filter must be washed when

LED V1 starts to flash, or at the

most once every 2 months, using

a normal household detergent; its

compact size also enables it to

be washed in a dishwasher.

• Replacement

Remove the filter, pushing the

handle towards the rear of the

hood. When replacing, ensure

that the handle faces outwards.

• Enabling the alarm signal

The hood is already set up to trigger an alarm indicating saturation of the metal grease

filters,so this function does not need to be enabled.

• Resetting the alarm signal

To turn the alarm signal off, proceed as follows:

- Turn off the Lights L and the Suction Motor V1;

- Press the Speed V3 for at least 3 seconds, until the Leds flash in confirmation. In any

case the saturated filters alarm will only come into operation when the suction motor is

turned on.

ATTENTION - There could be a possible fire hazard if the filters are not replaced

according to these instructions.

S07_06

Active carbon filter

• Operation

The activated charcoal filter is only fitted in recirculation type hoods.It will retain odours

until it becomes saturated. It cannot be washed or regenerated, and must be replaced

when the Intensive Speed LED I starts to flash, or at least once every 4 months of

use. Attention: in recirculation type hoods the V1 Motor LED may start to flash as well as

the Speed + V3 LED. This indicates that as well as replacing the activated charcoal

filter, it is also necessary to perform maintenance operations on the metal grease filters

(see paragraph Metal grease Filter).

38

Page 6

Instructions for use

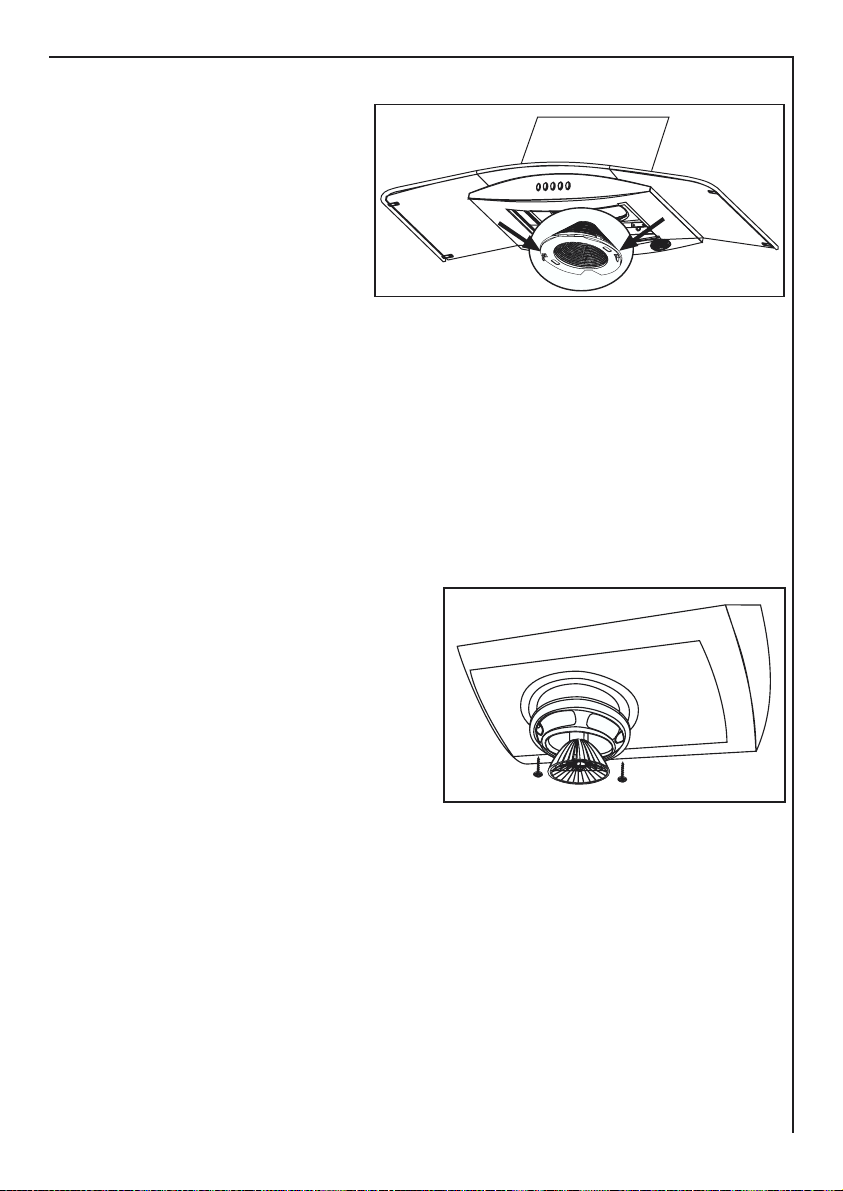

• Replacing

Take off the metal grease filter and

remove the activated charcoal

filter from its housing by turning

the clips provided. Fit the new

activated charcoal filter and

replace the metal grease filter.

• Enabling the alarm signal

S07_31

In recirculation type hoods the

saturated filters alarm must be

enabled as indicated below:

• Turn off the lights L and the Suction Motor V1;

• Press and hold the button V3 for at least 10 seconds, until the Leds start to flash.

Note the number of flashes:

- 2 flashes of the LED Activated charcoal filter saturation alarm ENABLED

- 1 flash of the LED Activated charcoal filter saturation alarm DISABLED

• Resetting the alarm signal

To turn the alarm signal off, proceed as follows:

- Press the button V3 for at least 3 seconds, until the Leds flash in confirmation. In any

case the saturated filters alarm will only come into operation when the suction motor is

turned on.

ATTENTION - There could be a possible fire hazard if the filters are not replaced

according to these instructions.

Lighting

1 - It consists of 2 20 W-halogen spotlights.

2 - Replacement

Remove the two screws that lock the metal

ring, take the spotlight out of its holder by

pulling slightly. When replacing, make sure

that both pins are well inserted in the holder

seat.

S07_28

Special accessories

Wall housing MKZ 125 Serial no. 610 899 004

Height x width in mm

External dimensions 250 x 220

Wall aperture 185 x 210

Outlet duct ABS 120 Serial no. 942 118 611

Ø 120 mm aluminium

Outlet duct ABS 125 Serial no. 942 118 612

Ø 125 mm aluminium

39

Page 7

Instructions for use

Installation Instructions

Safety warnings for the electrician

Electrical connection

Voltage 230 V ~ Connect using:

• a fixed power cable with a Schuko plug (European type) or

• a fixed connection (by an authorised electrician).

Fixed connection

• Where a fixed connection is necessary, an authorised electrician, registered with the

competent electrical authority, must carry out the work.

• For the installation, a single-pole switch with a minimum distance between the contacts

of 3 mm must be used, to enable the appliance to be isolated from the mains.

This function can be carried out, for example, by using automatic circuit breaker switches,

fuses (the fuses should be removed from the fuse box), and contact breaker switches.

Safety Warnings for the kitchen fitter

Minimum Distance from the hob

• When fitting the hood the following minimum distances from the upper edge of the cooking

hob to the lower edge of the hood must be respected:

- electric hobs: 650 mm

- gas hobs: 650 mm

- coal /gas-oil cookers: 700 mm

Air outlet

For the air outlet the following regulations must be observed:

• The discharged air should not be directed into flues or outlet ducts for combustion gases.

• It is not permitted to direct the discharged air into a duct that is used for ventilation of

areas in which combustion apparatus is installed.

• In case of the discharged air being emitted into a flue or outlet duct for combustion

gases which is no longer used, it is recommended that you consult a competent heating

engineer first.

• The hood can only operate at optimum efficiency if the following rules are respected:

- use short straight sections for the outlet duct.

- keep bends in the discharge ducting to a minimum.

- do not use ducts with sharp curves, use slightly curved sections.

- use large diameter ducts of large diameters where possible.

• Non adherence to these basic rules will compromise hood performance and increase

the noise levels produced.

Air Inlet

• A sufficiently large ventilation hole must be provided, of dimensions approximately equal

to the outlet hole.

40

Page 8

Instructions for use

Operation of hoods and appliances connected to a chimney

in the same room

• Regional building regulations require that the use of hoods in rooms where combustion

appliances are installed and connected to a chimney, for example coal, gas-oil, gas

heaters, etc., be subject to specific restrictions.

• The Regulations on combustion installations requires that these rooms must not exceed

a maximum negative pressure of 0.04 mbar.

• Safe use of hoods in conjunction with appliances connected to a chimney assumes that

the area and/or the house (combined recirculation system) is ventilated from the exterior

via an aperture of suitable dimensions, of approximately 500-600 cm

negative pressure during the use of the hood.

• In case of doubt consult an authorised heating engineer or the local building authorities.

• In rooms where combustion appliances are not installed the following rule should be

applied: “Ventilation hole of dimensions not exceeding those of the outlet hole“, an aperture of dimensions exceeding 500-600 cm2 may compromise performance of the suction

unit.

2

, in order to avoid

Technical Specifications

Working Dimensions

Width 900 mm.

Depth 500 mm.

Height 680-1080 mm.

Power cable length 200 cm.

Weight 19,4 Kg

Connected power

Total connected power 180 W

Motor 1 x 140 W

Lighting 2 x 20 W

Voltage 220 V ~

Discharge System Ø 120 mm /125 mm

Directives, regulations, instructions

This hood complies with the following European Directives:

• EEC 73/23 dated 19.02.1973 (low voltages)

• EEC 89/336 dated 03.05.1989 (electromagnetic compatibility, including

the modification directive EEC 92/31)

41

Page 9

Instructions for use

Installation

Fitting Materials / Accessories

1 connector flange Ø 120 mm F

1 reduction flange Ø 120-125 mm

1 side connector flange R

1 ventilator fixing bracket S

1 plastic guard D

1 cable clamp

3 dowels T

2 plastic caps Ø 11 mm

1 fitting support

1 transparent seal for chimney connection

4 canopy hood body/chimney fixing screws

2 O rings to hang the hood

1 screw V to fix the bracket to the wall

1 screw for fixing the bracket to the ventilator

2 screws 3.5x9.5 K to fix the fitting support

Fitting Instructions

42

C

73

898

A

Ø 270

195

65

92

Ø 200

min. 650

450

450 - 850

180

500

Page 10

Instructions for use

Preparations for the outlet duct

Before fitting the hood the fixing holes must be drilled and a hole must be made through

the external wall for installation of the wall housing (air outlet/inlet).

Preparations for the wall housing/Hole through the ceiling

If cooking vapours are to be discharged into the open-air through the external wall, a

telescopic wall housing must be used (available as a special accessory).

For discharge System Ø 120 mm /125 mm:

MKZ 125 ( with air outlet/inlet) Serial no. 610 899 004

43

Page 11

Installation

INSTALLATION

The versatility of the ducting fan unit on this hood enables it to be installed in one of two

different ways:

1 - Air outlet directed towards the wall.

2 - Air outlet directed to the right or left.

For correct installation of the hood, please proceed in the following stages:

4.1 - Selection of the type of installation

4.2 - Installation of the hood canopy C

4.3 - Installation of the chimney A

4.4 - Ducting or recirculation fitting

4.5 - Electrical connection and testing

Selecting the type of installation

1 - Air discharge towards the wall (fig.2)

2-Side air discharge, Left or Right (fig.3a-b).

S07_03

S07_04

3a 3b

4a 4b

R R

2

Installation of the hood canopy C

1 - Drilling the wall

a) Using the cardboard template

provided, mark on the wall the

centres of holes 1 for fixing of the

hood canopy C. The centre of hole 2

for fixing the chimney, (fig.4a) air

outlet towards the wall, (fig. 4b-c) air

outlet to the right or left hand side,

must be marked at a distance X from

Z

the line between holes 1, obtained

by measuring the extension of the

chimney required for installation, plus

13 mm X=Z+20-7. Using a Ø 8 mm

40

650

drill bit, drill the points marked in this

way.

b) When installed with the air outlet

directed towards the wall (fig.4a), it

A08_05

will be necessary to drill an air

ducting opening, measuring Ø120 or 125 mm, according to the diameter of the flange F

provided.

120

ø

7

2

1 1

100

100

ø150

X

1

18

ø 8

105

2

1

4a 4b 4c

105

2

1

1

44

Page 12

L = 44 mm

V

S

2

A08_07

S07_08

Installation

2 - Fitting the fixing elements

a) Insert the rawl plugs provided into holes 1 and 2.

b) Fit the eye bolts O (fig.5).

c) Fix the wall bracket S in hole 2 using the screw V provided

(fig.6).

3 - Fitting the hood canopy C to the wall

a) Remove the metal grease filter (see the paragraph on

Maintenance).

b) Fit the support rod B using the two screws K (3,5x9,5)

provided (fig. 7).

c) Hook the hood canopy C to the eye bolts O fixed in holes 1

(fig. 8).

d) Adjust the support rod B so that it pushes against the wall

(fig. 9).

e) Adjusting position (fig. 10). There are two adjustable hooks

7

B

K

8

O

O

A08_08

S07_09

at the rear of the

hood, which can be used to adjust its position as follows:

• Turn the screws L until the position of screws N coincides

with the lower access holes.

• Turn the screws N to adjust the vertical and horizontal

position of the hood.

• Lock the screws L to fasten the hood against the wall.

• Insert the plugs T provided in the holes giving access

N

to screws N.

Installation of the chimney A

No matter which type of installation is being used,

T

any wooden shelves in the area where the hood is to

be fitted must first be removed, drilled and later

replaced.

A08_11

1 - Drilling the shelves:

a) Using the cardboard template provided, and

taking hole “B” as a point of reference, drill the

11

shelves along the central axis to allow the

passage of the chimney. The chimney must be

inserted into the shelves before it is fixed to the

hood canopy C (fig.11).

5

1

O

A08_06

6

O

A08_10

B

9

L

L

N

T

L

N

10

45

Page 13

S07_14

Installation

2 - Direction and position of the ducting fan unit

a) The hood is normally supplied with the air outlet directed towards

the wall (fig. 2), if it is to be installed with the air outlet directed to

the right or left (fig. 3a-b), it will be necessary to change the direction

of the ducting fan unit, proceeding as follows:

• Unscrew the screws U (fig. 12);

• Turn the ducting fan unit 60° to the right or left;

• Replace the screws U.

b) The ducting fan unit air outlets must be arranged according to the

type of installation to be carried out.

• Air outlet directed towards the wall (fig. 2).

• Remove the plastic frame from the air outlet (fig.14).

• Remove the plug from the upper part of the ducting fan unit

(fig.13), as it is not possible to insert the flange F with the plug in

place.

• Fit the flange F Ø120 mm (fig.16), replace the plug.

• Air outlet directed to the right or left hand side (fig. 3a-b).

• Remove the four screws fastening the plastic frame, as

shown in fig. 14.

• Fit the ducting spigot R (fig.17) and replace the four screws

removed as above.

3 - Fixing the chimney

a) Loosen the screws M fixing the two parts of the chimney

and pull the inner

section I (fig.18)

almost all the way

out. Remove the

protective film P.

b) Rest the lower

S07_16

section of the

chimney in its

housing on the top of

15

the hood canopy.

Lower the ducting fan unit until it reaches the

wall bracket S and fix it using the screw H

provided (fig.19). Fit the cover D (provided) on

the wall bracket S (fig.20).

17

S07_19

12

U

U

A08_14

13

S07_22

14

16

R

46

I

M

A08_20

S

P

18

S

A08_21

H

19

Page 14

c) Fix chimney stack A to the hood unit C using four of the screws

D

A08_22

provided E (fig.21).

d) Insert the transparent seal Q (provided), so as to eliminate any

play between the two parts of the chimney (fig. 22). Lock the

screws M.

e) Remove the support rod B.

Installation

20

Ducting or recirculation fitting

1 - Ducting fitting.

This is possible for all forms of installation:

a) Connect the air outlet to the external ducting

system.

b) Remove the activated charcoal filter (if there is

one) inside the hood canopy (see Maintenance).

2 - Recirculation fitting

This is only possible with the air outlet directed

upwards. Fit the venting grille G onto the air outlet (Fig. 23).

The activated charcoal filter should be fitted inside the hood

canopy after connection to the power supply.

A08_23

E

E

Connection to power supply and checking of

good working order

1 - It is absolutely necessary to follow the warnings 3.2, 3.3 and 3.4 of

paragraph 3, concerning safety measures.

2 - Loosen the two locking screws and remove the metal cover (fig.24).

Connect the hood connection to the engine connection (fig.25a).

Correctly place the connectors under the cover and tighten the two

locking screws (fig. 25b).

3 - Once electrical connection has been carried out, check that lights,

engine and change of speed work

4 - Fit the antigrease filter (see Maintenance).

E

E

21

22

Q

Q

A08_24

G

S07_24

24

23

25a

25b

S07_34

47

Page 15

Customer Service Centres

CUSTOMER SERVICE CENTRES

Dear Customer,

The AEG Hausgeräte Customer Service Department is decentralised to offer you a quick

and reliable service everywhere. By calling the following free phone number:

0800 234 73 78

You can speak to one our specialists or associates in charge of technical assistance.

To order spare parts please contact our switchboard on the following number:

0180 5 00 10 76

For freezer breakdowns or breakdowns in the freezer compartment of your fridge or in

your heating system, an emergency service is available, which can be reached on

Saturdays or Sundays on the free phone number: 0800 820 20 00.

Yours faithfully,

Your AEG Customer Services

In addition, you can visit one of our Service Centres.

01099 Dresden Industriegelände,W.-Hartmann-Straße

04356 Leipzig Walter-Köhn-Straße 4c

07548 Gera* Südstraße 11

08066 Zwickau* Talstraße 24

09117 Chemnitz* Rosmarinstraße 4

14482 Potsdam-Babelsberg Wetzlarer Straße 14-16

22525 Hamburg-Bahrenfeld Holstenkamp 40

28208 Bremen Emil-von-Behring-Straße 3

30179 Hannover Wiesenauer Straße 13

34123 Kassel-Bettenhausen Lilienthalstraße 150

35745 Herborn-Burg Junostraße 1

41541 Dormagen-St. Peter Sachtlebenstraße 1

44805 Bochum-Gerthe Josef-Baumann-Straße 37

46562 Voerde* Friedrich-Wilhelm-Straße 22

48165 Münster* Zum Kaiserbusch 1

49084 Osnabrück* Pferdestraße 23

52068 Aachen* Auf der Hüls 197

56068 Koblenz* Rheinstraße 17

57072 Siegen* Sandstraße 173

60326 Frankfurt Mainzer Landstraße 349

66115 Saarbrücken-Malstatt* Ludwigstraße 55-57

*) Here, one of our technical assistance associates will be pleased to assist you.

48

Page 16

Customer Service Centres

67663 Kaiserslautern* Pariser Straße 200

68309 Mannheim-Käfertal Heppenheimer straße 31-33

71034 Böblingen-Hulb Dornierstraße 7

76185 Karlsruhe-Mühlburg Neureuther Straße 5-7

79108 Freiburg* Tullastraße 84

80634 München-Neuhausen Arnulfstraße 205

86159 Augsburg* Piccardstraße 15a

87437 Kempten* Brodkorbweg 22

88213 Ravensburg* Henri-Dunant-Straße 6

90429 Nürnberg Muggenhofer Straße 135

91788 Pappenheim* Neudorf 79

92260 Ammerthal* Nikolausstraße 2

93059 Regensburg* Im Gewerbepark B54

94032 Passau* Kühberg 1

95038 Hof* Pinzigweg 49

97078 Würzburg* Versbacher Straße 22a

99096 Erfurt* Arnstädter Straße 28

*) Here, one of our technical assistance associates will be pleased to assist you.

03058 Kickebusch 03222 Groß Klessow

06429 Wispitz 06896 Wittenberg-Reinsdorf

15517 Fürstenwalde 16515 Oranienburg

17039 Ihlenfeld 18055 Rostock

18069 Rostock 19057 Schwerin

24354 Rieseby 25770 Hemmingstedt

25980 Westerland/Sylt 26639 Wiesmoor

27726 Worpswede 30900 Wedemark

32825 Blomberg 34497 Korbach

36043 Fulda 39114 Magdeburg

49377 Vechta 63906 Erlenbach

74549 Wolpertshausen 78244 Bietingen

84307 Eggenfelden 87549 Rettenberg

89542 Herbrechtingen 99819 Ettenhausen

49

Page 17

Service

SERVICE

The chapter “Troubleshooting“ gives a table of simple problems that you may be able to

solve without assistance. Always consult this table before calling for technical assistance.

Technical Problems

For technical problems contact your Customer Service Centre (the addresses and

telephone numbers are listed in the chapter “Customer Service Centres”). We advice

customers to prepare the telephone call carefully in advance to facilitate diagnosis and

the subsequent decision regarding whether or not technical intervention is necessary.

Some important points to describe are the following:

• How did the problem manifest itself?

• In what circumstances did the problem manifest itself?

Before making the telephone call please make a note of the following information printed

on the appliance rating plate:

• PNC number (9 digits),

• F-No number (8 digits).

The rating plate is located on the interior of the hood and can be accessed after removing

the metal grease filters.

We recommend you make a note of these numbers on this page, so that they are ready

to hand.

PNC ... ... ...

F-No ... ... ...

In what circumstances are you liable for expenses during the guarantee period?

• If the problem could have been solved by the customer, based on the indications provided

in the table on “Troubleshooting”,

• If the technician had to make more than one journey because detailed information was

not supplied to him before the intervention and he therefore had to procure replacement

parts later, for example. These repeated journeys can be avoided if the telephone call is

prepared carefully in advance, as described above.

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

http://www.aeg.hausgeraete.de

@ Copyright by AEG

50

Page 18

83

Page 19

436002473_01 - 050119

Loading...

Loading...