Page 1

Cover

R3267 Series

Spectrum Analyzer

Operation Manual (Vol.2)

MANUAL NUMBER

Applicable models

R3264

R3267

R3273

FOE-8335034D00

1998

C

ADVANTEST CORPORATION

All rights reserved.

First printing October 1, 1998

Printed in Japan

Page 2

Safety Summary

No. ESF00

Safety Summary

To ensure thorough understanding of all functions and to ensure efficient use of this instrument, please read the

manual carefully before using. Note that Advantest b ear s absolutely no responsibility for the result of oper ations

caused due to incorrect or inappropriate use of this instrument.

If the equipment is used in a manner not specified by Advantest, the protection provided by the equipment may

be impaired.

• Warning Labels

Warning labels are applied to Advantest products in locations where specific dangers exist. Pay

careful attention to these label s during handling . Do not remove or tear these l abels. If yo u have

any questions regarding warning labels, please ask your nearest Advantest dealer. Our address

and phone number are listed at the end of this manual.

Symbols of those warning labels are shown below together with th eir meaning.

DANGER: Indicates an imminently hazardous situation which will result in death or serious

WARNING: Indicates a potentially hazardous situation which w ill result in death or serious

CAUTION: Indicates a potentially hazardous situation which will result in personal injury or

• Basic Precautions

Please observe the following precautions to prevent fire, burn, electric shock, and personal injury.

• Use a power cable rated for the voltage in question. Be sure however to use a power cable

conforming to safety standards of your nation when using a product overseas.

• When in serting the plug into the electrical outlet, fir st turn the power switch OFF and then

insert the plug as far as it will go.

• When removing the plug from the electrical outlet, first turn the power switch OFF and then

pull it out by gripping the plug. Do not pull on the power cabl e its el f. Make sure your hand s

are dry at this time.

• Before turning on the power, be sure to check that the supply voltage matches the voltage

requirements of the instrument.

personal injury.

personal injury.

a damage to property including the product.

• Be sure to plug the power cable into an electrical outlet which has a safety ground terminal.

Grounding will be defeated if you use an extension cord which does not include a safety

ground ter minal.

• Be sure to use fuses rated for the voltage in question.

• Do not use this instrument with the case open.

• Do not place objects on top of this product. Also, do not place flower p ots or other containers

containing liquid such as chemicals near this product.

Safety-1

Page 3

Safety Summary

• When the prod uct has ventilation outlets, do not stick or drop metal or easily flammable objects into the ventilation outlets.

• When using the product on a cart, fix it with belts to avoid its drop.

• When connecting the product to peripheral equipment, turn the power off.

• Caution Symbols Used Within this Manual

Symbols indicating items requiring caution w hich are used in this m anual are s hown below to gether with their meaning.

DANGER: Indicates an item where there is a danger of serious personal injur y (d eath or seri-

ous injury).

WARNING: Indicates an item relating to personal safety or health.

CAUTION: Indicates an item relating to possible damage to the product or instrument or relat-

ing to a restriction on operation.

• Safety Marks on the Product

The following safety marks can be found on Advantest products.

: ATTENTION - Refer to manual.

: Protective ground (earth) terminal.

: DANGER - High voltage.

: CAUTION - Risk of electric shock.

• Replacing Parts with Limited Life

The following parts used in the instrument are main parts with limited life.

Replace the parts listed below after their expected lifespan has expired.

Note that the estimated lifespan for the parts listed below may be shortened by factors such as

the environment where the instrument is stored or used, and how often the instrument is used.

The parts inside are not user-replaceable. For a part replacement, please contact the Advantest

sales office for servicing.

There is a possibility that each product uses different parts with limited life. For more information, refer to Chapter 1.

Safety-2

Page 4

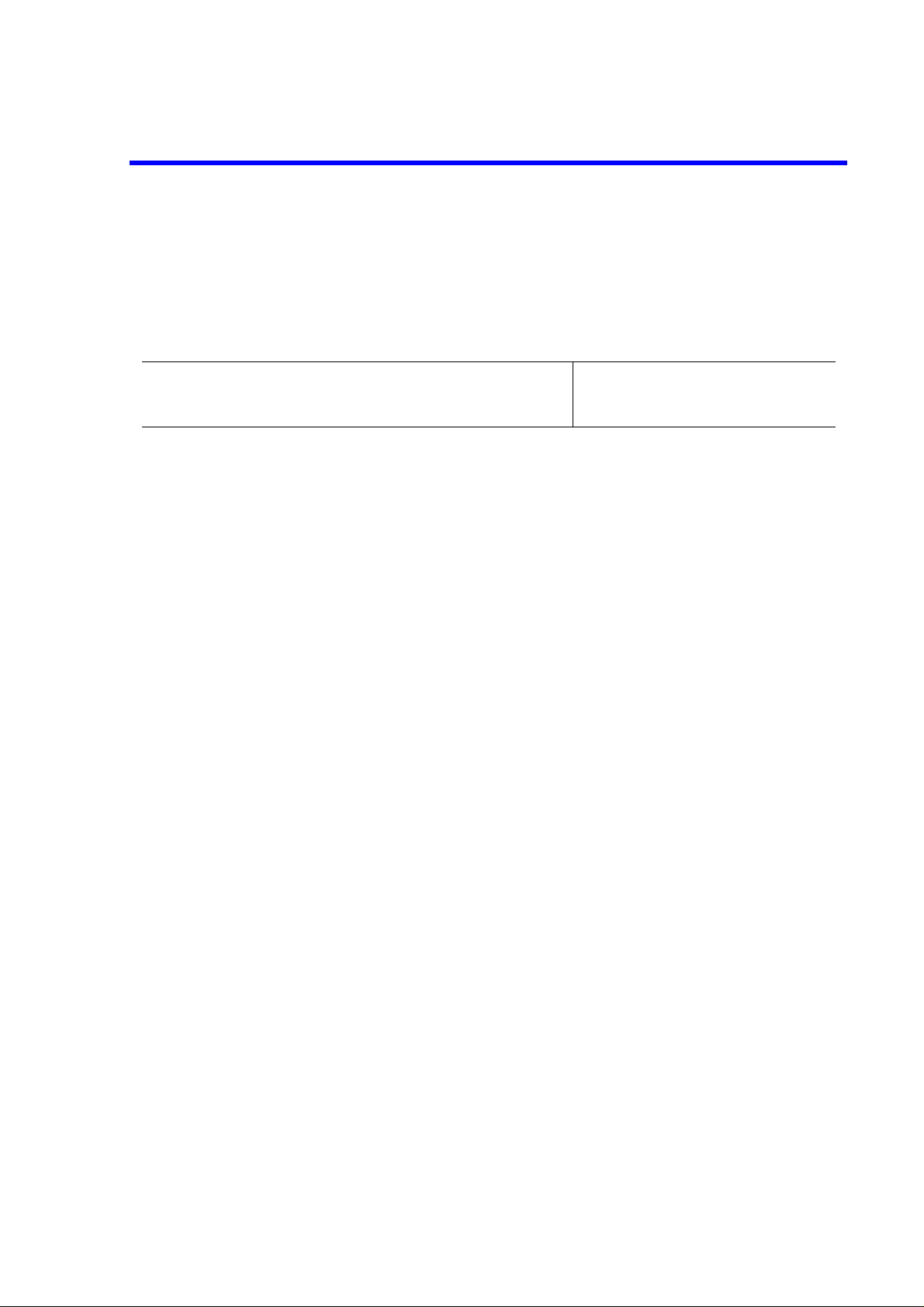

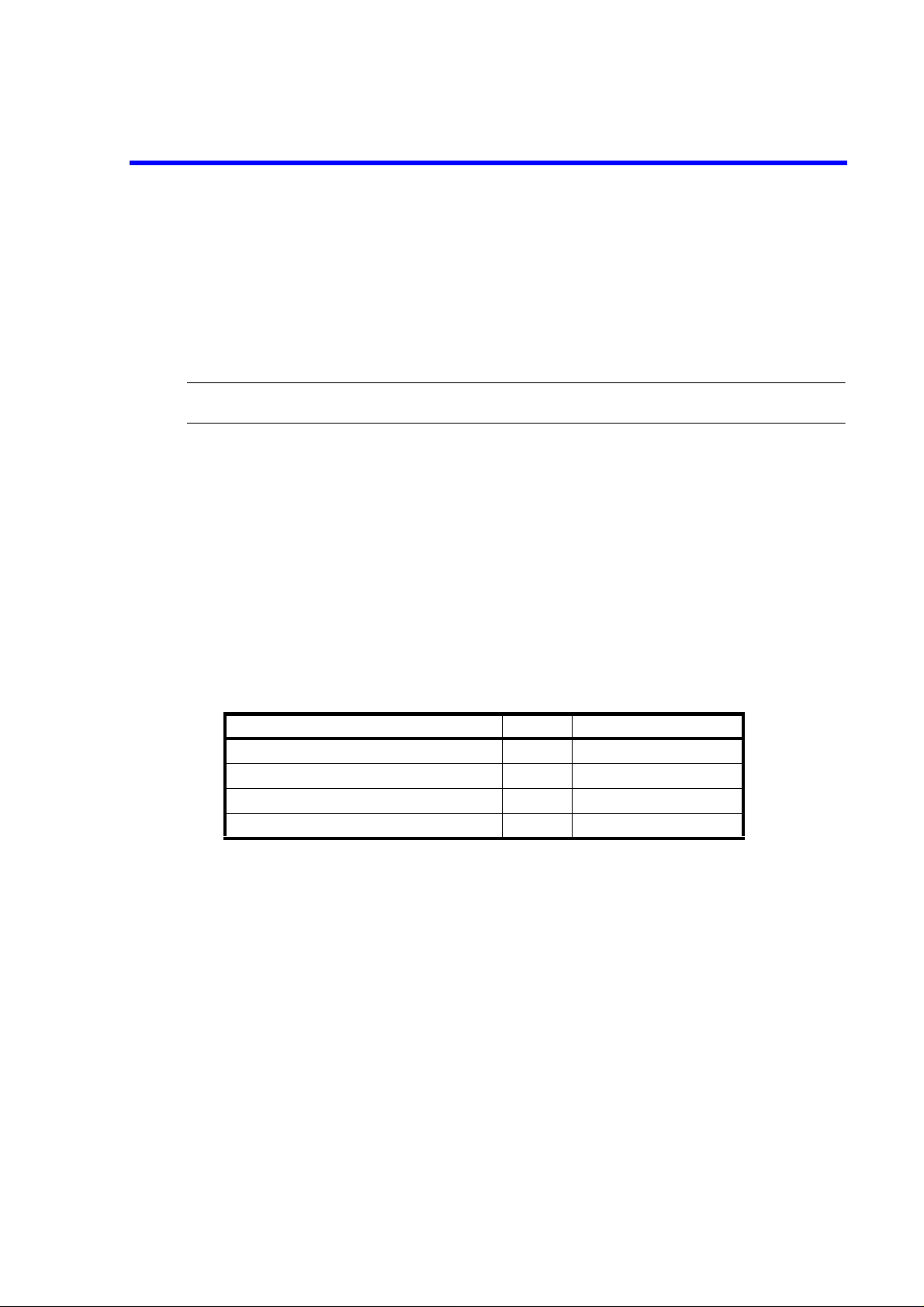

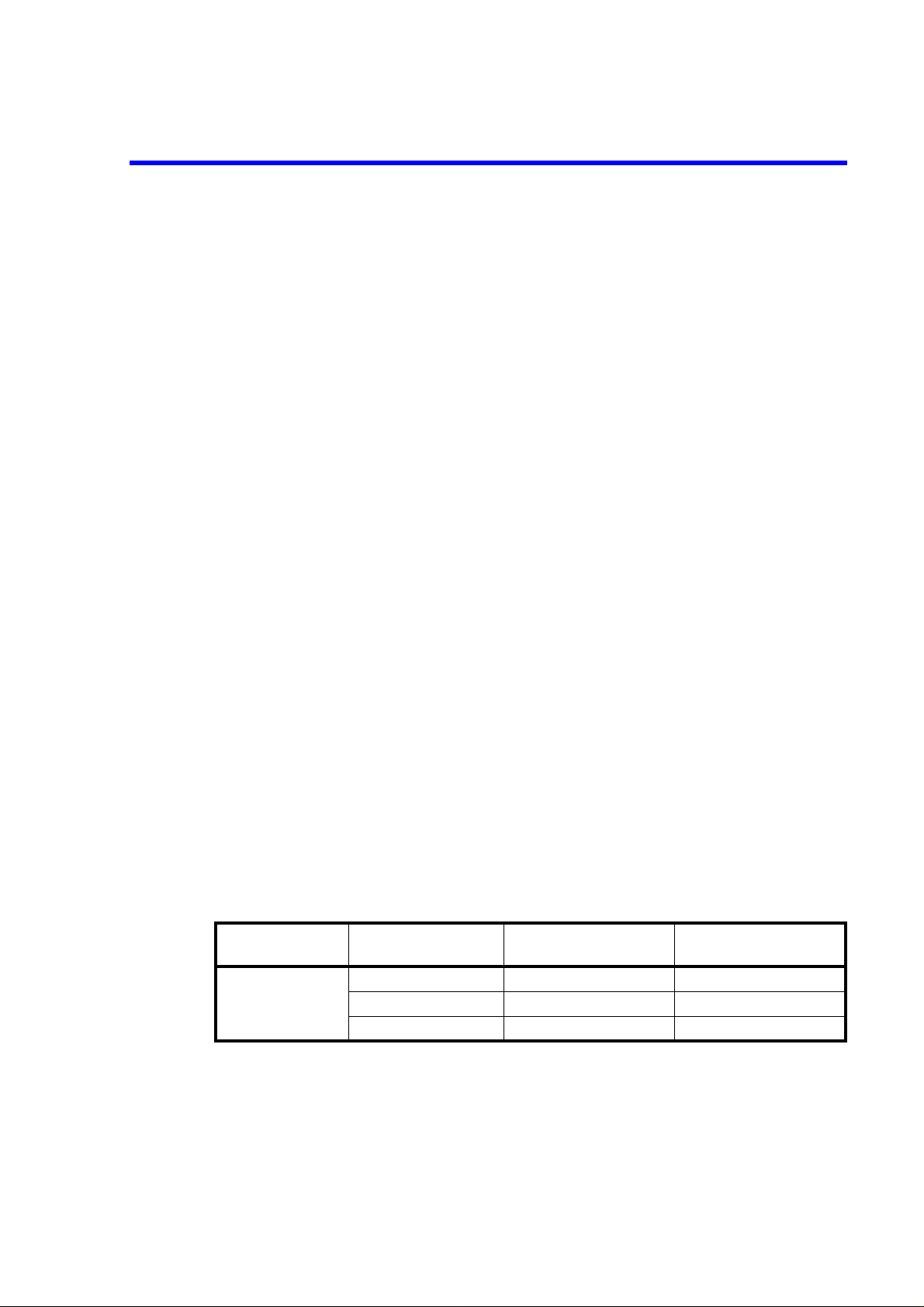

Main Parts with Limited Life

Part name Life

Unit power supply 5 years

Fan motor 5 years

Electrolytic capacitor 5 years

LCD display 6 years

LCD backlight 2.5 years

Floppy disk drive 5 years

• Hard Disk Mounted Products

The operational warnings are listed below.

• Do not move, shock and vibrate the product while the power is turned on.

Reading or writing data in the hard disk unit is performed with the memory disk turning at a

high speed. It is a very delicate process.

Safety Summary

• Store and operate the products under the following environmental conditions.

An area with no sudden temperature changes.

An area away from shock or vibrations.

An area free from moisture, dirt, or dust.

An area away from magnets or an instrument which generates a magnetic field.

• Make back-ups of important data.

The data stored in the dis k may b ecome damag ed if the prod uct is mishand led. The h ard di sc

has a limited life span which depends on the operational conditions. Note that there is no

guarantee for any loss of data.

• Precautions when Disposing of this Instrument

When disposing of harmful substances, be sure dispose of them properly with abiding by the

state-provided law.

Harmful substances: (1) PCB (polycarbon biphenyl)

(2) Mercury

(3) Ni-Cd (nickel cadmium)

(4) Other

Items possessing cyan, organic phosphorous and hexadic chromium

and items which may leak cadmium or arsenic (excluding lead in sol

der).

Example: fluorescent tubes, batteries

Safety-3

Page 5

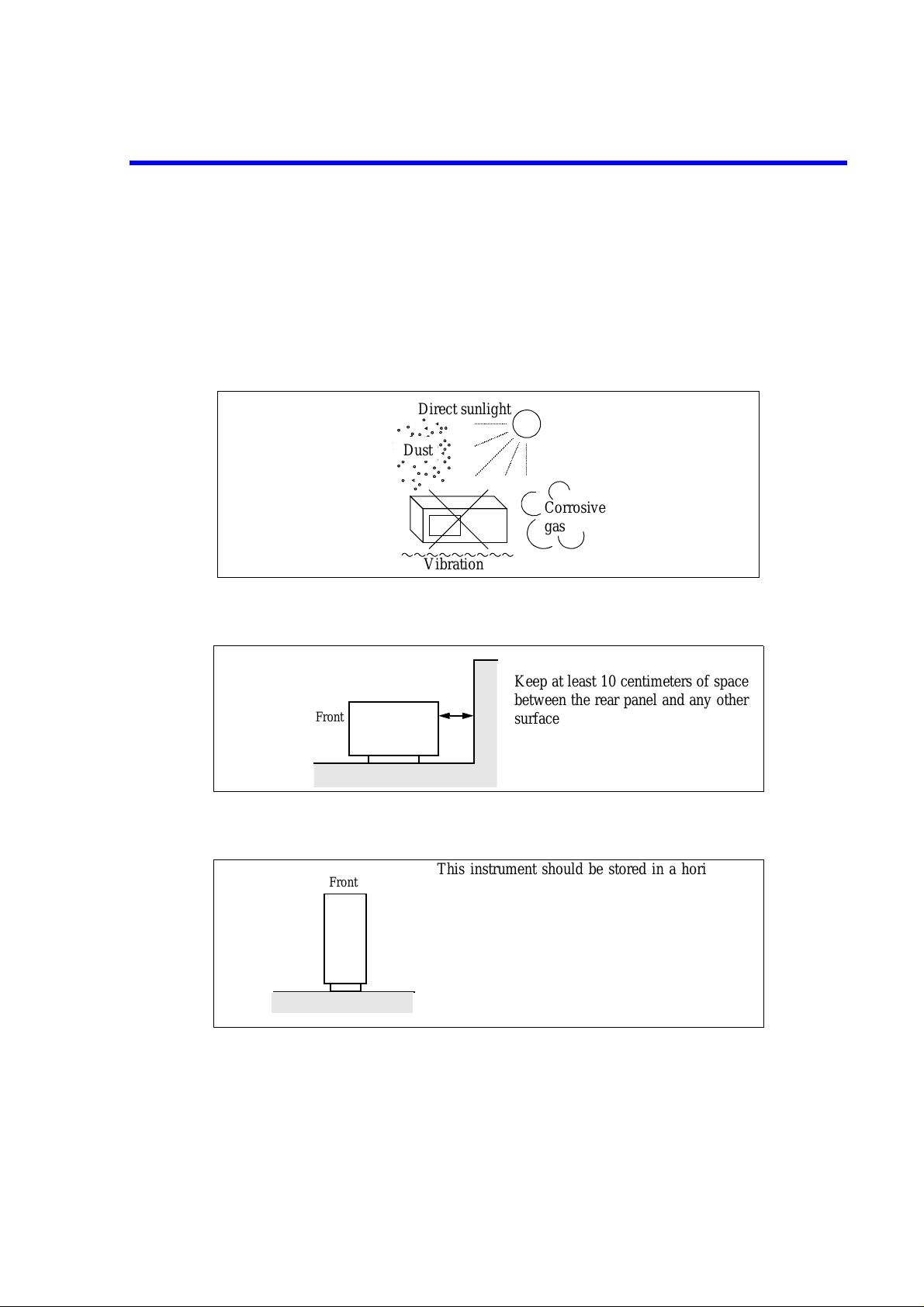

Environmental Conditions

This instrument should be only be used in an area which satisfies the following conditions:

• An area free from corrosive gas

• An area away from direct sunlight

• A dust-free area

• An area free from vibrations

Direct sunlight

Dust

Corrosive

gas

Vibration

Figure-1 Environmental Conditions

• Operating position

Keep at least 10 centimeters of space

between the rear panel and any other

Front

Figure-2 Operating Position

• Storage position

Front

This instrument can be used safely under the following conditions:

• Altitude of up to 2000 m

This instrument should be stored in a horizontal

position.

When placed in a vertical (upright) position for

storage or transportation, ensure the instrument is

stable and secure.

-Ensure the instrument is stable.

-Pay special attention not to fall.

Figure-3 Storage Position

surface

Safety-4

• Installation Categories II

• Polluti on Degree 2

Page 6

PREFACE

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

PREFACE

This manual (VOL.2) describes how to test the performance of the R3267 Series.

A separate volume (VOL.1) describes the oper ations, perfo rmance and remote prog ramming of the R326 7 Series.

(1) Configuration of this manual

1. Performance Verification Describes how to test performance.

(2) Typeface conventions used in this manual

• Panel keys and soft keys are printed in a contrasting typestyle to make them stand out from the text as

follows:

Panel keys: Boldface type Example: FREQ, FORMAT

Soft keys: Boldface and italic type Example: Center, Trace Detector

• When a series of key operations are described using a comma between two keys.

• There are various soft menus used to switch between two states such as ON/OFF and AUTO/MNL.

For example, when turning off the Display ON/OFF function, the annotation "Display ON/

OFF(OFF)" is used.

When switching the RBW AUTO/MNL function to MNL, the annotation "RBW AUTO/MNL(MNL)"

is used.

Preface-1

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1 PERFORMANCE VERIFICATION

1.1 Preparation ........................................................................................................... 1-1

1.2 Procedure ............................................................................................................. 1-4

1.2.1 Frequency Reference Output Accuracy ........................................................ 1-4

1.2.2 Frequency Reference Output Accuracy

(when the OPT21, OPT22 and OPT23 are installed) ................................... 1-6

1.2.3 Accuracy of Frequency Readout and Frequency Counter ............................ 1-8

1.2.4 Frequency Span Accuracy ............................................................................ 1-11

1.2.5 Calibration Amplitude Accuracy .................................................................. 1-14

1.2.6 IF Gain Uncertainty ...................................................................................... 1-15

1.2.7 Input Attenuator Switching Accuracy .......................................................... 1-18

1.2.8 Frequency Response ..................................................................................... 1-21

1.2.9 Scale Fidelity ................................................................................................ 1-26

1.2.10 RBW Switching Uncertainty ........................................................................ 1-31

1.2.11 RBW Accuracy and Selectivity ................................................................... 1-33

1.2.12 Noise Sidebands ............................................................................................ 1-36

1.2.13 Displayed Average Noise Level ................................................................... 1-39

1.2.14 Residual FM .................................................................................................. 1-43

1.2.15 Residual Response ........................................................................................ 1-46

1.2.16 Gain Compression ......................................................................................... 1-49

1.2.17 Second Harmonic Distortion ........................................................................ 1-53

1.2.18 Third Order Intermodulation Distortion ....................................................... 1-57

1.2.19 Image, Multiple and Out of Band Responses (For the R3267/73) ............... 1-62

1.2.20 Sweep Time Accuracy .................................................................................. 1-68

1.3 Performance Check Sheet .................................................................................... 1-71

1.3.1 Frequency Reference Output Accuracy ........................................................ 1-71

1.3.2 Frequency Readout Accuracy and Frequency Counter Marker .................... 1-71

1.3.3 Frequency Span Accuracy ............................................................................ 1-72

1.3.4 Calibration Amplitude Accuracy .................................................................. 1-73

1.3.5 IF Gain Uncertainty ...................................................................................... 1-73

1.3.6 Input Attenuator Accuracy ............................................................................ 1-75

1.3.7 Frequency Response ..................................................................................... 1-76

1.3.8 Scale Fidelity ................................................................................................ 1-84

1.3.9 Resolution Bandwidth Switching ................................................................. 1-85

1.3.10 Resolution Bandwidth Accuracy and Selectivity ......................................... 1-86

1.3.11 Noise Sidebands ............................................................................................ 1-86

1.3.12 Displayed Average Noise Level ................................................................... 1-87

1.3.13 Residual FM .................................................................................................. 1-87

1.3.14 Residual Response ........................................................................................ 1-87

1.3.15 Gain Compression ......................................................................................... 1-88

1.3.16 Second Harmonics Distortion ....................................................................... 1-88

1.3.17 Third Order Intermodulation Distortion ....................................................... 1-88

.......................................................... 1-1

C-1

Page 8

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

Table of Contents

1.3.18 Image, Multiple, Out of Band ....................................................................... 1-89

1.3.19 Sweep Time Accuracy .................................................................................. 1-90

ALPHABETICAL INDEX

.................................................................................... I-1

C-2

Page 9

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

LIST OF ILLUSTRATIONS

No. Title Page

1-1 Setup for Measuring a Frequency Reference Output Accuracy ....................................... 1-5

1-2 Connections for Measuring the Frequency Reference Output Accuracy

(when the OPT21, OPT22 and OPT23 are installed) ....................................................... 1-6

1-3 Setup for Measuring a Frequency Readout Accuracy and Frequency Counter ................ 1-8

1-4 Setup for Measuring a Frequency Span Accuracy ............................................................ 1-11

1-5 Setup for Measuring a IF Gain Uncertainty ...................................................................... 1-15

1-6 Setup for Measuring an Input Attenuator Accuracy ......................................................... 1-19

1-7 Setup for Measuring a Frequency Response ..................................................................... 1-22

1-8 Setup for Measuring a Scale Fidelity ......................................................... ...... ..... ............ 1-26

1-9 Setup for Measuring a Noise Sidebands ........................................................................... 1-37

1-10 Setup for Measuring a Residual FM ........................ .................................. ...... ................. 1-43

1-11 Setup for the Gain Compression ....................................................................................... 1-50

1-12 Setup for Measuring a Second Harmonics Distortion ...................................................... 1-54

1-13 Setup for Measuring a Third Order Intermodulation Distortion ....................................... 1-58

1-14 Setup for Measuring a Image, Multiple, Out of Band ...................................................... 1-62

1-15 Setup for Measuring a Sweep Time Accuracy ................................................................. 1-68

F-1

Page 10

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

List of Tables

No. Title Page

1-1 Instrument Required ......................................................................................................... 1-1

1-2 Frequency Span Setting at a Center Frequency of 2 GHz ................................................ 1-9

1-3 Center/Span Frequencies for the R3267 ........................................................................... 1-12

1-4 Center/Span Frequencies for the R3273 ........................................................................... 1-13

1-5 IF Gain Uncertainty Setting ................................................. ..... .................................. ...... 1-17

1-6 RBW Setting ..................................................................................................................... 1-17

1-7 Input Attenuator Setting .................................................................................................... 1-20

1-8 1 dB Step Scale Fidelity Setting ....................................................................................... 1-28

1-9 HP8495H and HP3325B Settings ..................................................................................... 1-29

1-10 Settings on the HP3325B in relation to the Reference Output Level ............................... 1-30

1-11 RBW Switching Uncertainty Setting ................................................................................ 1-32

1-12 3 dB Band Width Setting .................................................................................................. 1-34

1-13 60 dB Band Width Setting ................................................................................................ 1-35

1-14 Offset Setting at a Center Frequency of 1 GHz ............................................................... 1-38

1-15 Center Frequency Setting for Displayed Average Noise Level ........................................ 1-41

1-16 Start and Stop Frequencies Setting ................................................................................... 1-42

1-17 Third Order Intermodulation Distortion ........................................................................... 1-59

1-18 Third Order Intermodulation Distortion (When the Preselector is Used) ....................... 1-61

1-19 Image, Multiple, Out of Band Setting (Center Frequency: 2 GHz) .................................. 1-64

1-20 Image, Multiple, Out of Band Setting for the R3273 ....................................................... 1-65

1-21 Image, Multiple, Out of Band Setting for the R3267 ....................................................... 1-66

1-22 Sweep Time Setting .......................................................................................................... 1-70

T-1

Page 11

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1 PERFORMANCE VERIFICATION

This chapter explains how to check the R3267 Series. We recommend that you have a copy of the performance check sheet with you when performing these checks . If a prob lem occurs with th e R3267 Seri es, contact ADVANTEST service center with measurement data filled out on the performance check sheet

(including the model, s erial n umber and so on ). For i nformati on on how to s hip the R3267 Series for repa irs,

refer to Section 1.5.3, "Transporting" in Vol.1.

NOTE: Perform the CAL ALL before starting this performance verification tests.

1.1 Preparation

This chapter decribes the instruments using on this performance verification tests.

NOTE:

1. The R3267 Series to be tested should be warmed up for at least 30 minutes before starting tests. Any additional

instrument used for this performance verification tests should be warmed up as appropriate.

2. Make sure that the test instrument used meets its own published specifications and that all connectors are clean,

before starting test. All connectors should be firmly connected.

1.1 Preparation

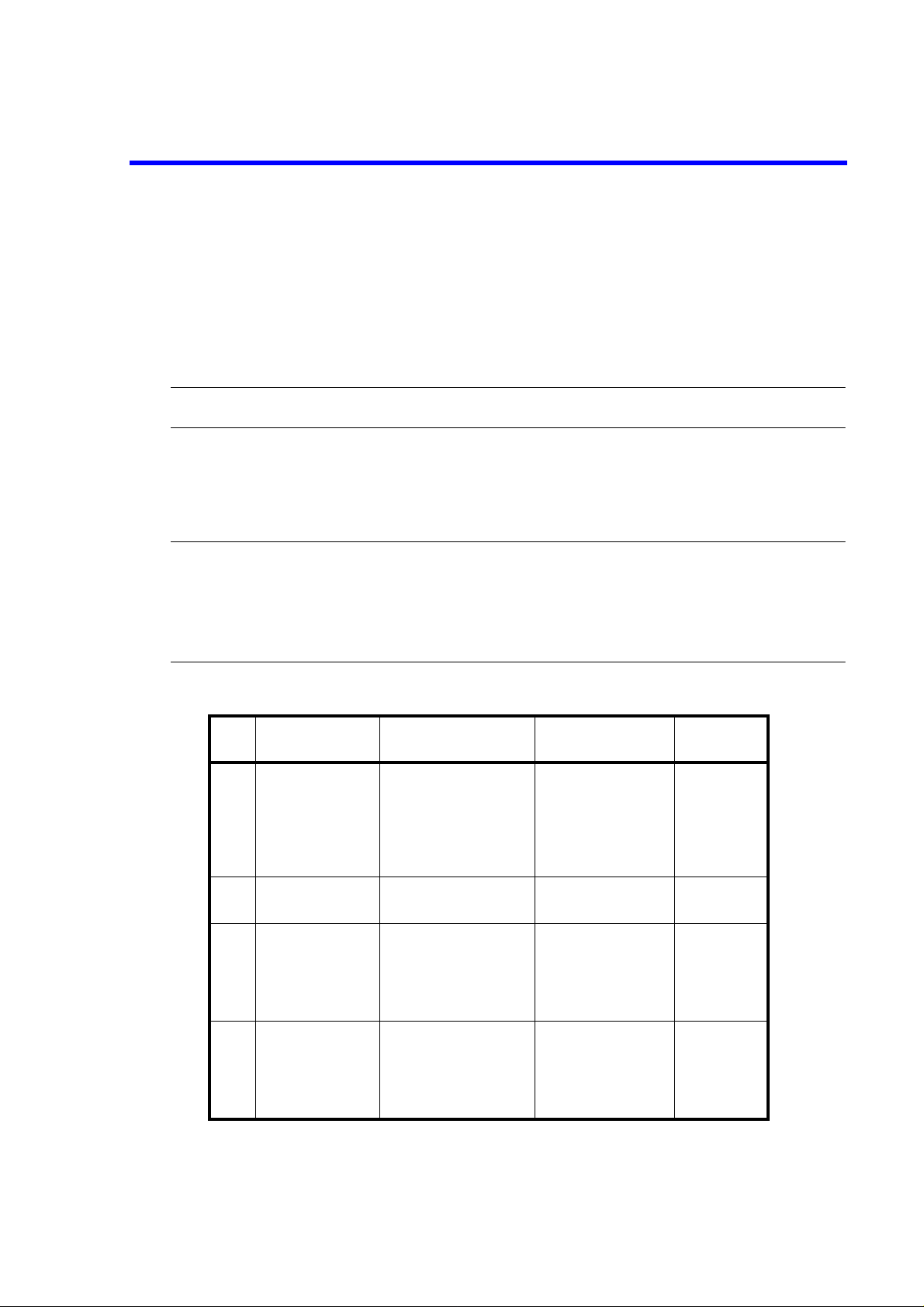

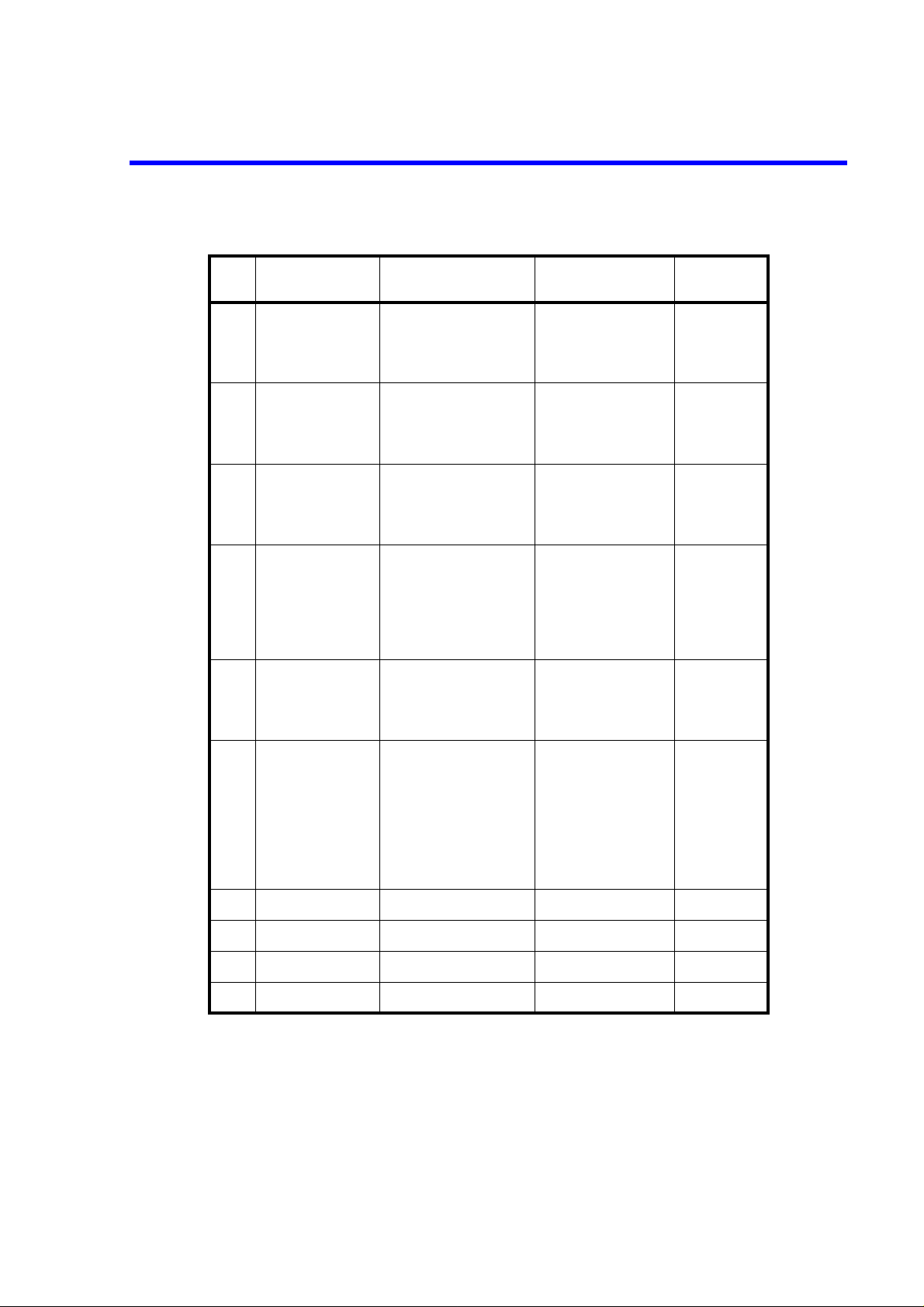

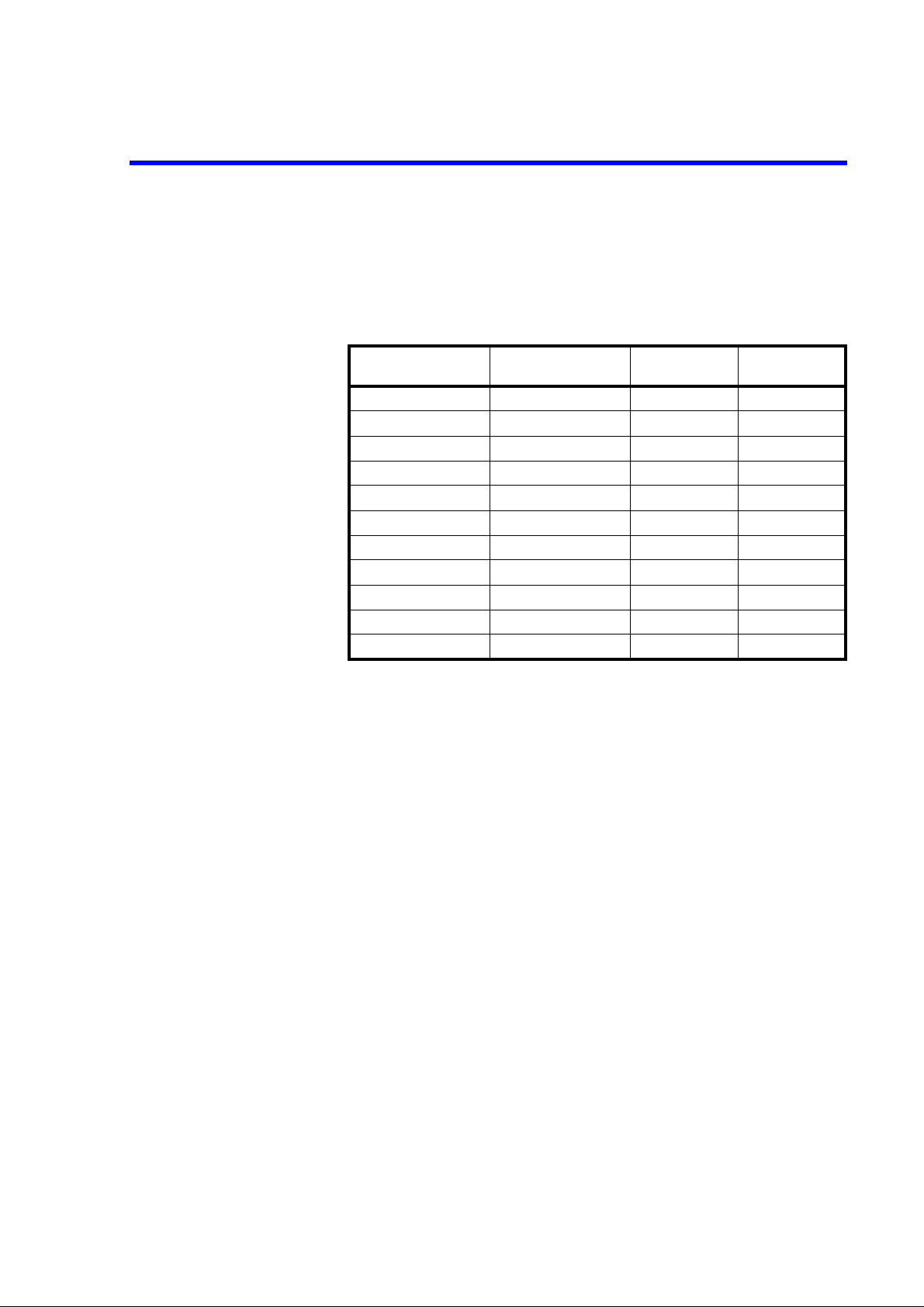

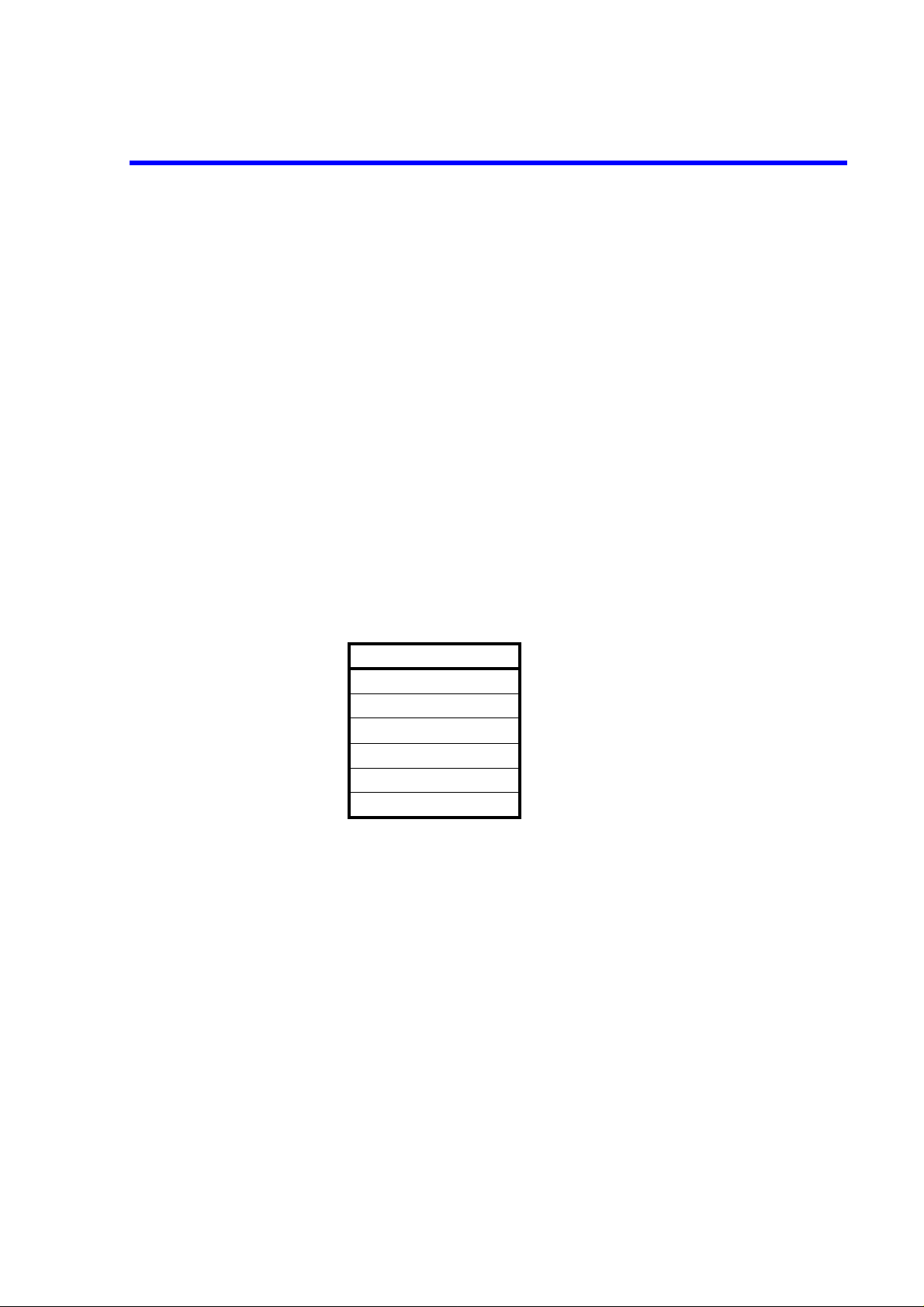

Table 1-1 Instrument Required (1 of 3)

No. Instrument Specification

1Frequency

Standard

2Frequency

Counter

3 Signal Generator Frequency Range:

4 Signal Generator Frequency Range:

Output Frequency :

10 MHz

Stability: 5×10

Output Impedance : 50

Ω Output Level:

1 Vpp or more

Resolution: 0.1 Hz R5372

10 MHz to 18 GHz

Output Level:

-15 dBm to +10 dBm

Stability: 1×10

10 MHz to 27 GHz

Output Level:

-15 dBm to +10 dBm

Stability: 1×10

-10

-6

-6

/ day

/ year

/ year

Recommended

Model

R3031

ADVANTEST

ADVANTEST

SMP02

(with B11 option)

Rohde&Schwarz

SMP03

(with B11 option)

Rohde&Schwarz

Quantity

1

1

1

1

1-1

Page 12

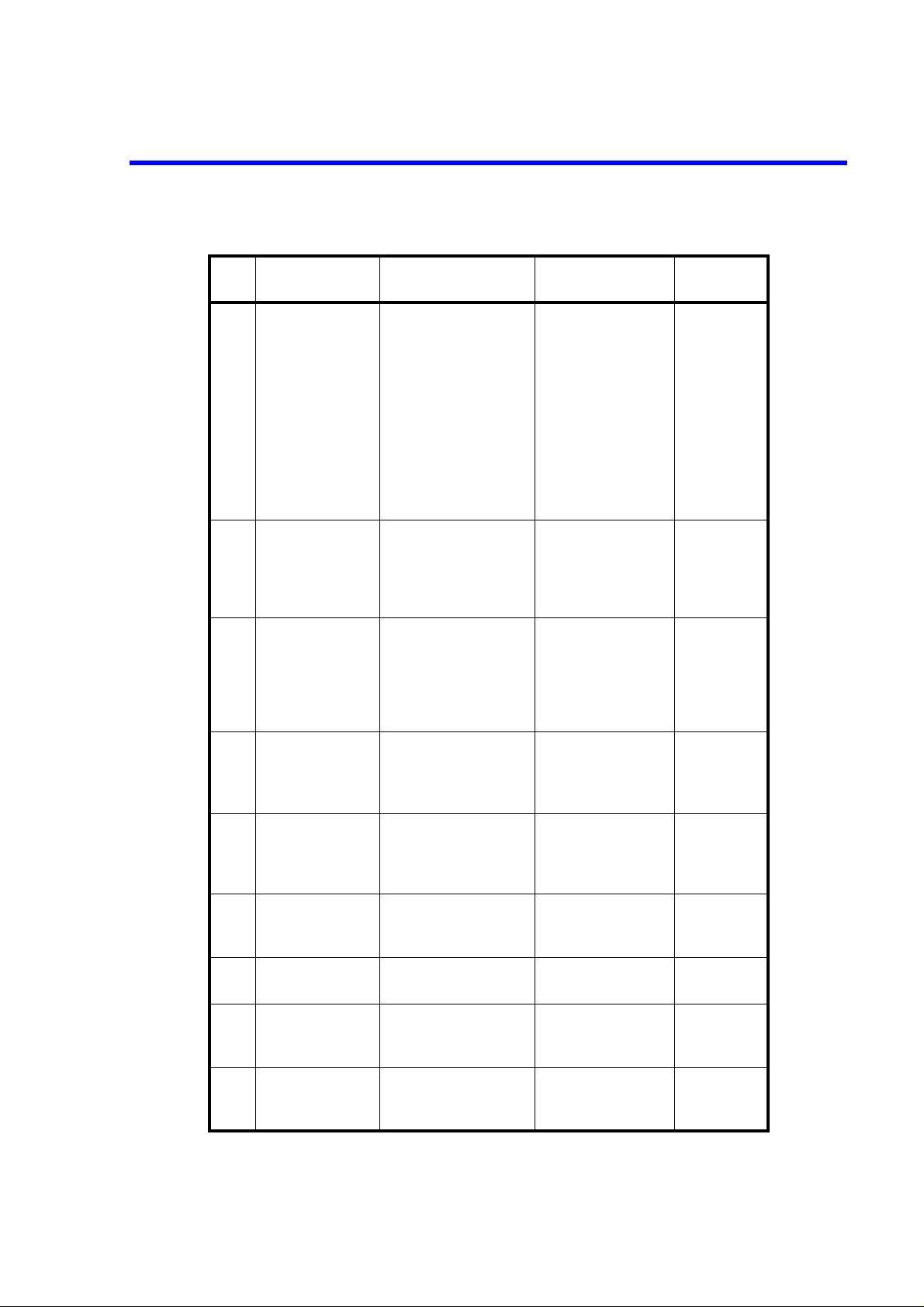

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.1 Preparation

Table 1-1 Instrument Required (2 of 3)

No. Instrument Specification

5 Signal Generator Frequency Range:

10 MHz to 2.5 GHz

Output Level:

-20 dBm to +1 0 dB m

Residual SSB

Phase Noise

at 1 kHz offset:

less than -115 dBc/Hz

at 10 kHz offset:

less than -124 dBc/Hz

at 100 kHz offs et:

less than -130 dBc/Hz

6Function

Generator

7Power Meter

Power Sensor

Frequency Range:

10 mHz to 20 MHz

Output Level:

-10 dBm to +1 3 dB m

Stability: 5×10-6/ year

Frequency Range:

10 MHz to 26.5 GHz

Input Level:

1µW to 100 mW

Maximum SWR:

1.25 (26.5 GHz)

Recommended

Model

HP8663A

Hewlett Packard

HP3325B

Hewlett Packard

NRVS

NRV-Z52

Rohde&Schwarz

Quantity

1

1

1

81 dB Step

Attenuator

9 10 dB Step

Attenuator

10 Attenuator Driver HP11713A

11 Terminator Impedance: 50 Ω RNA

12 3 dB Attenuator Impedance: 50 Ω

13 20 dB Attenuator Impedance: 50 Ω

Attenuation Range:

0 dB to 12 dB

Frequency Range:

DC to 18 GHz

Attenuation Range:

0 dB to 70 dB

Frequency Range:

DC to 18 GHz

Attenuation: 3 dB

SMA(m)-SMA(f)

Attenuation: 20 dB

SMA(m)-SMA(f)

HP8494H

Hewlett Packard

HP8495H

Hewlett Packard

Hewlett Packard

Rohde&Schwarz

DEF-000685-1

ADVANTEST

DEE-000480-1

ADVANTEST

1

1

1

1

1

1

1-2

Page 13

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

Table 1-1 Instrument Required (3 of 3)

1.1 Preparation

No. Instrument Specification

14 Power Splitter Frequency Range:

10 MHz to 26.5 GHz

Insertion Loss:

6 dB (nominal)

15 Power Devider Frequency Range:

20 MHz to 1.5 GHz

Isolation:

greater than 18 dB

16 Power Devider Frequency Range:

2 GHz to 18 GHz

Isolation:

greater than 18 dB

17 Low-pass Filter Cutoff Frequency:

2.2 GHz

Rejection (3 GHz):

greater than 40 dB

Rejection (3.8 GHz):

greater than 80 dB

18 RF Cable Impedance: 50 Ω

BNC(m)-BNC(m)

Length:

Approx. 1.5 m

Recommended

Model

1579

Weinschel

DDUL-20A-100

Merrimac

DDUL-24M-10G

Merrimac

DEE-001172-1

ADVANTEST

MI-09

ADVANTEST

Quantity

1

1

1

1

2

19 RF Cable Impedance: 50 Ω

SMA(m)-SMA(m)

Frequency Range:

DC to 26.5 GHz

Maximum SWR:

1.45 at 26.5 GHz

Length:

Approx. 0.7 m

20 Adapter N(m)-SMA(f) Generic

21 Adapter SMA(f)-SMA(f) Generic

22 Adapter N(f)-BNC(m) Generic

23 Adapter N(m)-BNC(f) Generic

A01002

ADAVNTEST

3

5

1

1

3

1-3

Page 14

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2 Procedure

1.2 Procedure

This section describes the method of how to test the performance verification of the R3267 Series.

NOTE: In the following procedure, the values used are for the recommended instruments.

When using other instruments, use the values conforming to the specifications of each instrument.

1.2.1 Frequency Reference Output Accuracy

This section explains how to check the reference frequency accuracy of the spectrum analyzer using the

calibration signal.

For checking the frequency reference output accuracy when the OPT21 , OPT22 an d OPT 23 ar e installed,

refer to Section 1.2.2, "Frequency Reference Output Accuracy (when the OPT21, OPT22 and OPT23 are

installed)."

CAUTION: If the frequency reference of the R3267 Series is set to EXT, perform 15 minutes wa rm-up opera-

tion after instrument preset.

Specifications:

30 MHz ± 3 Hz

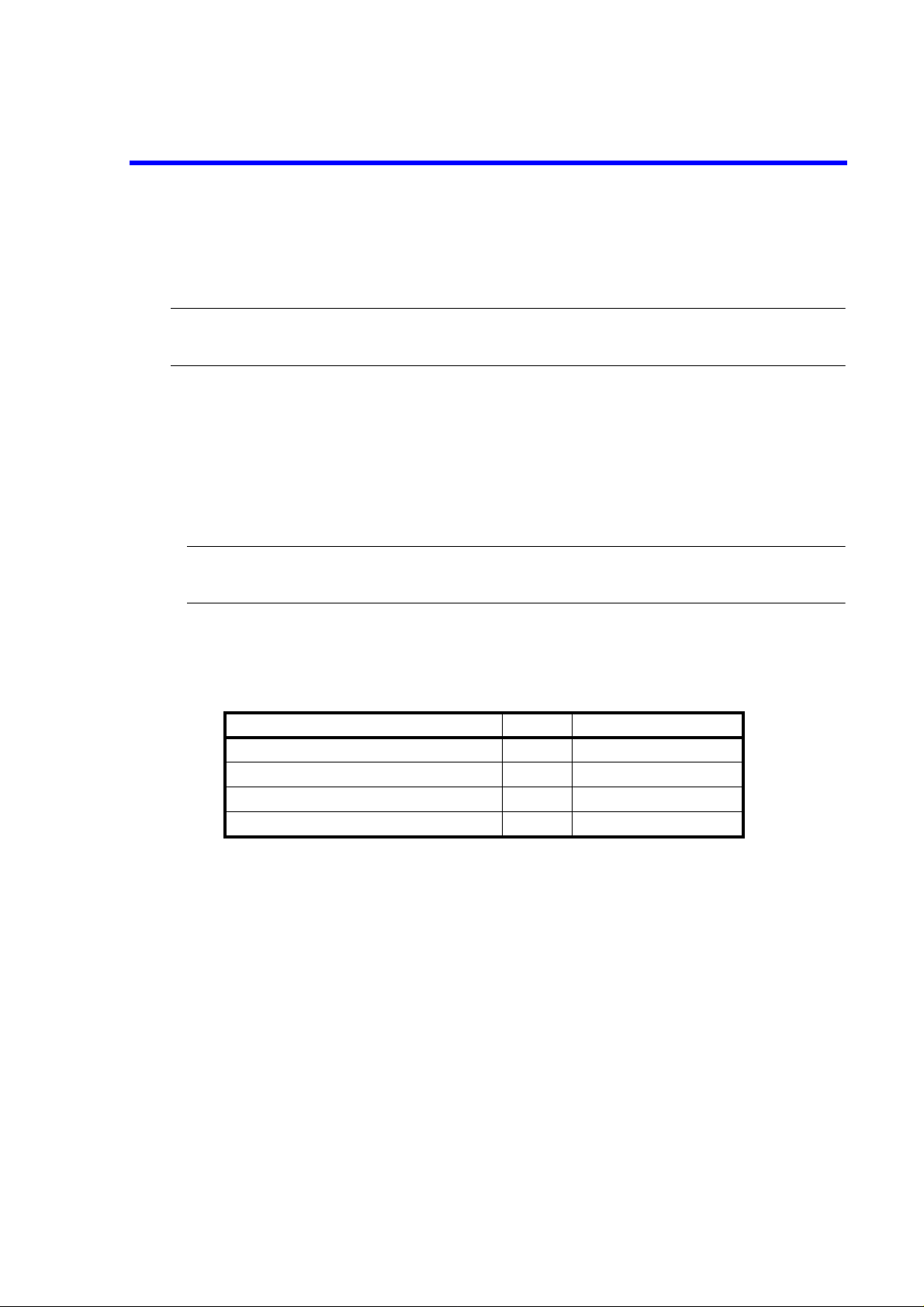

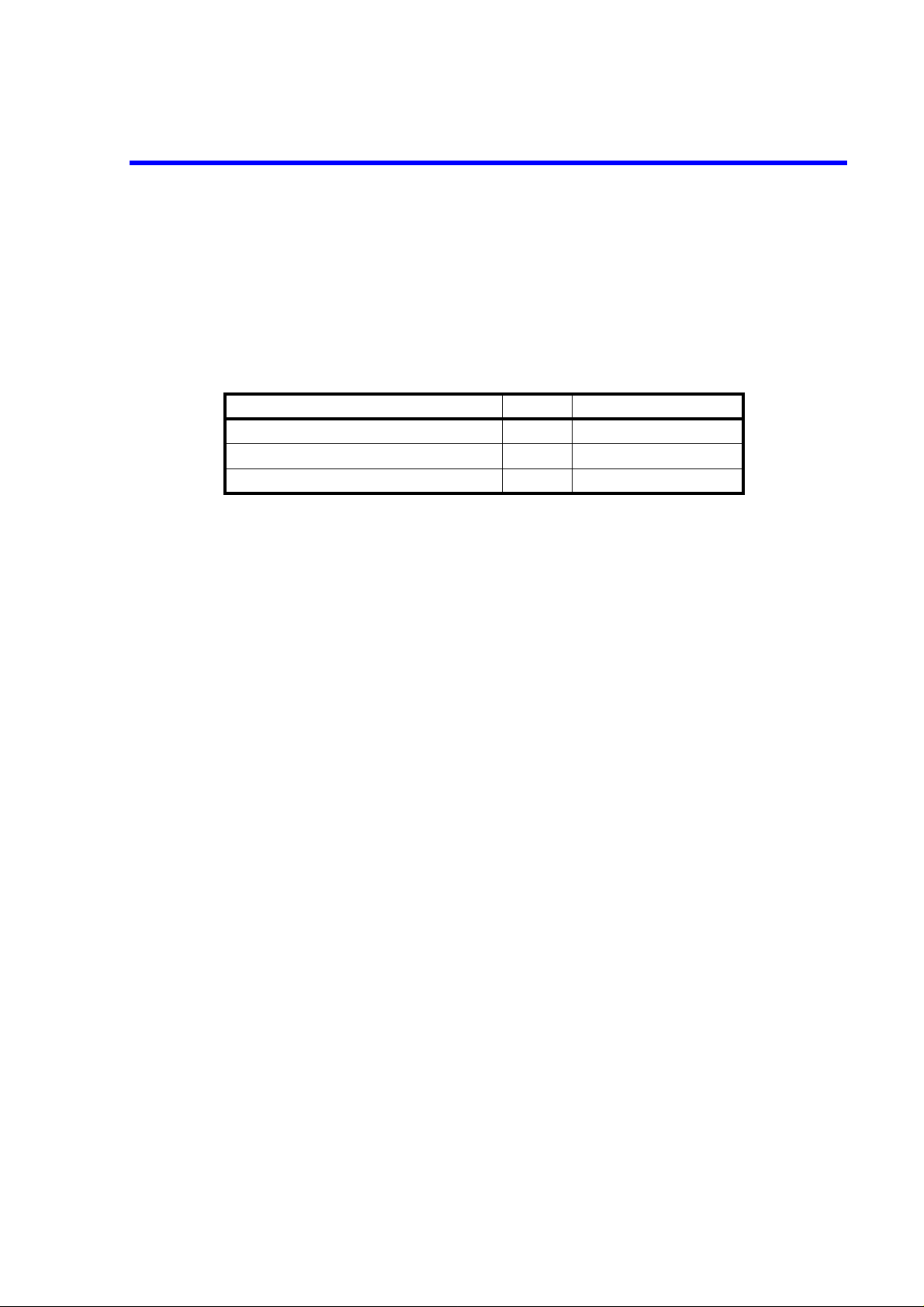

Instruments Required

Instruments QTY Recommended Model

Frequency Standard 1 R3031

Frequency Counter 1 R5372

RF Cable BNC(m)-BNC(m) 2 MI-09

Adapter N(m)-BNC(f) 1

1-4

Page 15

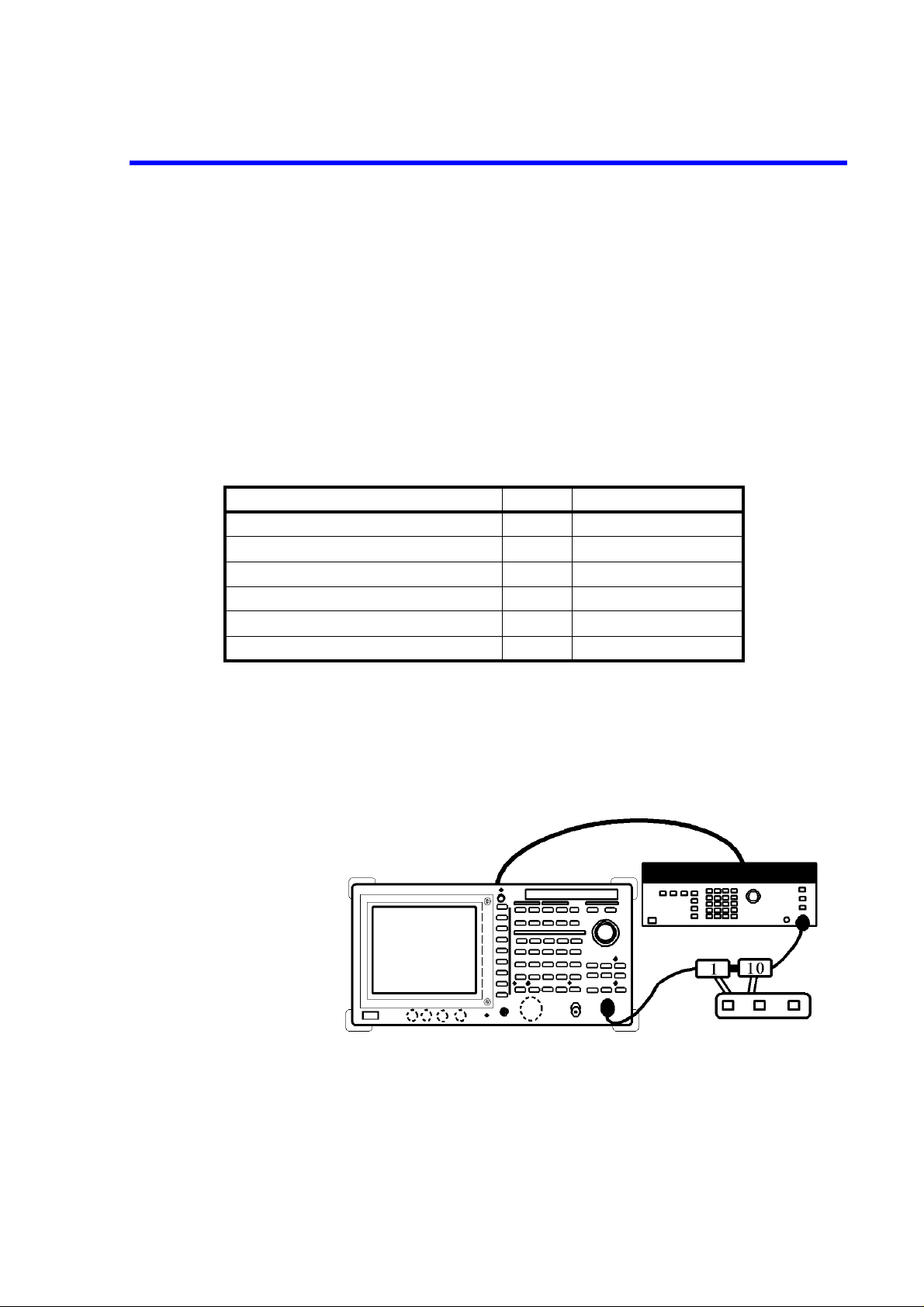

Procedures:

Setup

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.1 Frequency Reference Output Accuracy

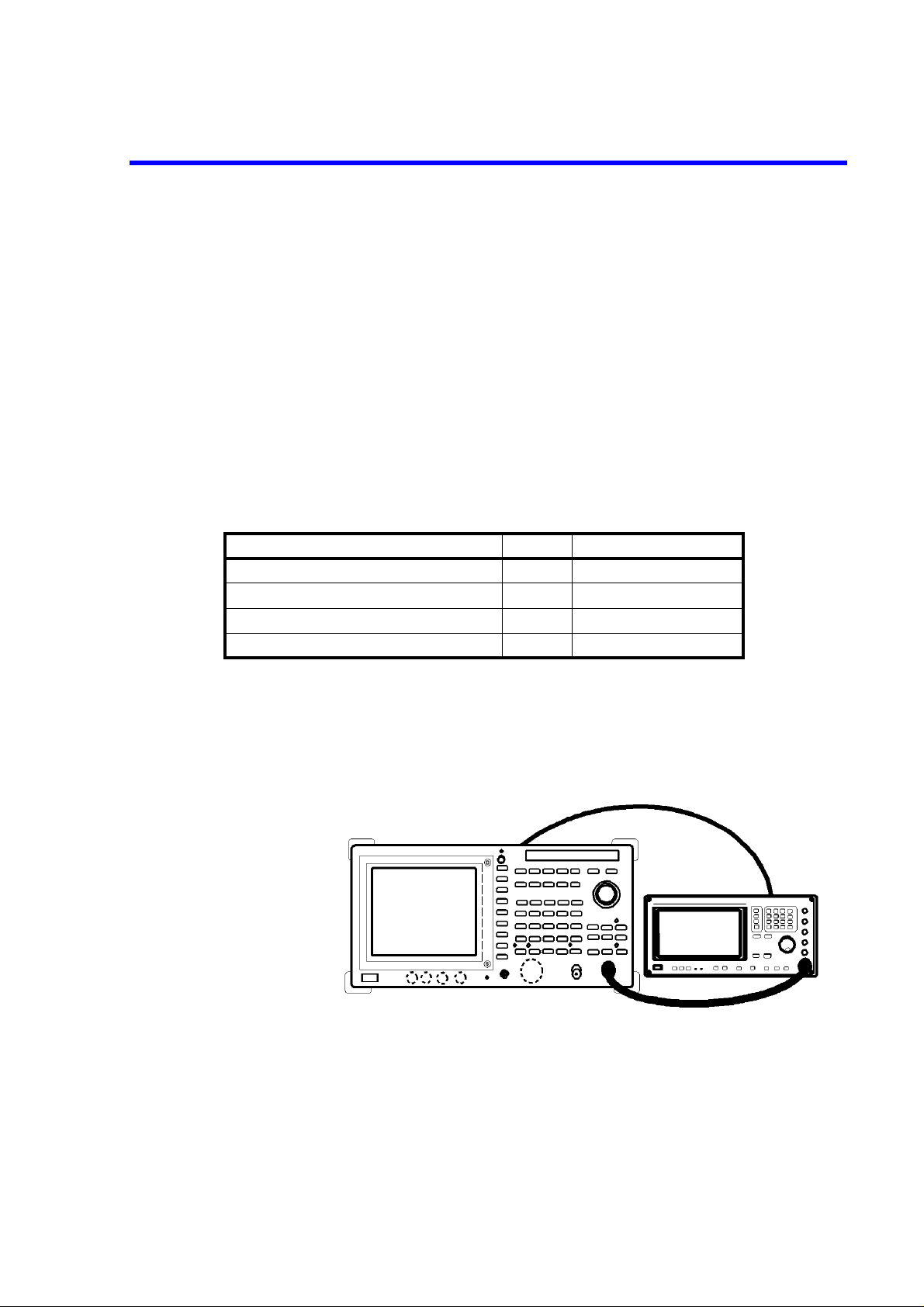

1. C onnect th e frequency counter and t he frequ ency stand ard as sh own in Figu re 1-

1.

Figure 1-1 Setup for Measuring a Frequency Reference Output Accuracy

Setting the Frequency Counter

2. Set the R5372 controls as follows:

Input: B

Resolution: 0.1 Hz

10 MHz Reference: External

Initialization

3. Press SHIFT and CONFIG(PRESET).

4. Wait for the frequency counter to settle down.

5. Record the counter reading on the performance check sheet.

1-5

Page 16

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.2 Frequency Reference Output Accuracy (when the OPT21, OPT22 and OPT23 are installed)

1.2.2 Frequency Reference Output Accuracy

(when the OPT21, OPT22 and OPT23 are installed)

This section explains how to check the freq uency r eference ou tput accuracy when the OPT21, OPT22 and

OPT23 are installed. Input the signal from the s ignal g enerato r into the s pectrum analy zer, an d meas ur e it

using the counter function of the spectrum analyzer.

CAUTION: If the frequency reference of the R3267 Series is set to EXT, perform 15 minutes wa rm-up opera-

tion after instrument preset.

Specifications:

1 GHz ± 80Hz (OPT21)

1 GHz ± 20Hz (OPT22)

1 GHz ± 5Hz (OPT23)

Instruments Required

Instruments QTY Recommended Model

Frequency Standard 1 R3031

Signal Generator 1 SMP03

RF Cable BNC(m)-BNC(m) 1 A01002

RF Cable SMA(m)-SMA(m) 1 MI-09

Adapter N(m)-SMA(f) 1

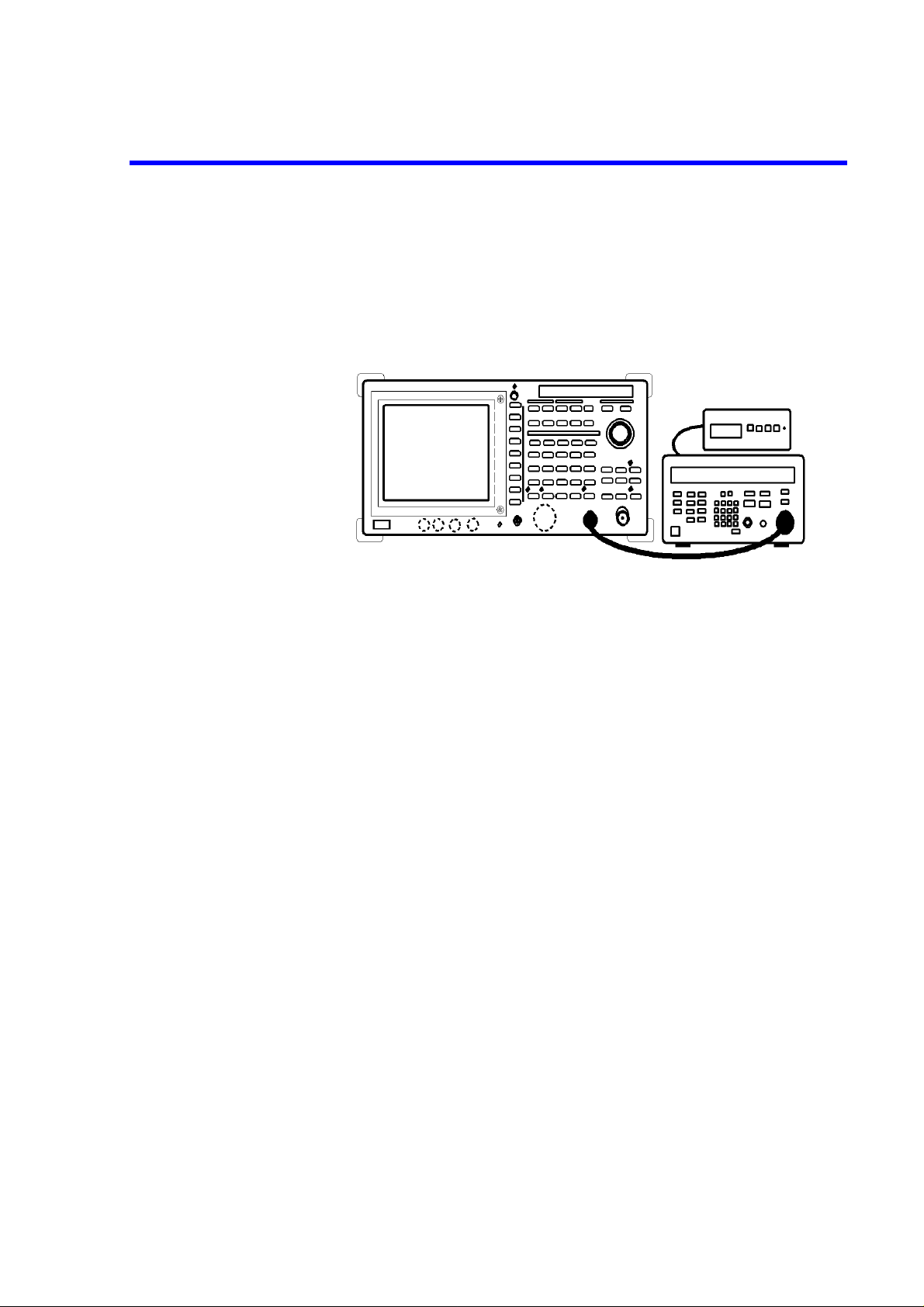

Procedures:

Setup

1. Connect the signal generator as shown in Figure 1-2.

Figure 1-2 Connections for Measuring the Frequency Reference Output

Accuracy (when the OPT21, OPT22 and OPT23 are installed)

1-6

Page 17

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.2 Frequency Reference Output Accuracy (when the OPT21, OPT22 and OPT23 are installed)

Initialization

2. Press SHIFT and CONFIG(PRESET).

Measurement using a center frequency of 1 GHz

3. Set the SMP03 controls as follows:

Frequency: 1 GHz

Output level: -10 dBm

10 MHz Reference: External

4. Press FREQ, 1 and GHz.

5. Press SPAN, 1 and MHz.

6. Press SCRH.

7. Press MEAS, Counter and Resolution 1 Hz.

8. Press Counter ON/OFF(ON).

9. Record the frequency of the counter marker reading on the performance check

sheet.

10. Press Counter ON/OFF(OFF).

1-7

Page 18

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.3 Accuracy of Frequency Readout and Frequency Counter

1.2.3 Accuracy of Frequency Readout and Frequency Counter

This section explains how to check the accura cy of the frequency readout a nd frequ ency cou nter using the

signal generator.

Specifications:

Accuracy of Frequency Readout

± (0.01 × Frequency span + 0.15 × Resolution bandwidth + 10 Hz)

Accuracy of Frequency Counter marker SPAN < 1 GHz : S/N > 25 dB

± (5 Hz × N + 1 LSD)

N: Harmonic order

Instruments Required

Instruments QTY Recommended Model

Signal Generator 1 SMP03

RF Cable BNC(m)-BNC(m) 1 A01002

RF Cable SMA(m)-SMA(m) 1 MI-09

Adapter N(m)-SMA(f) 1

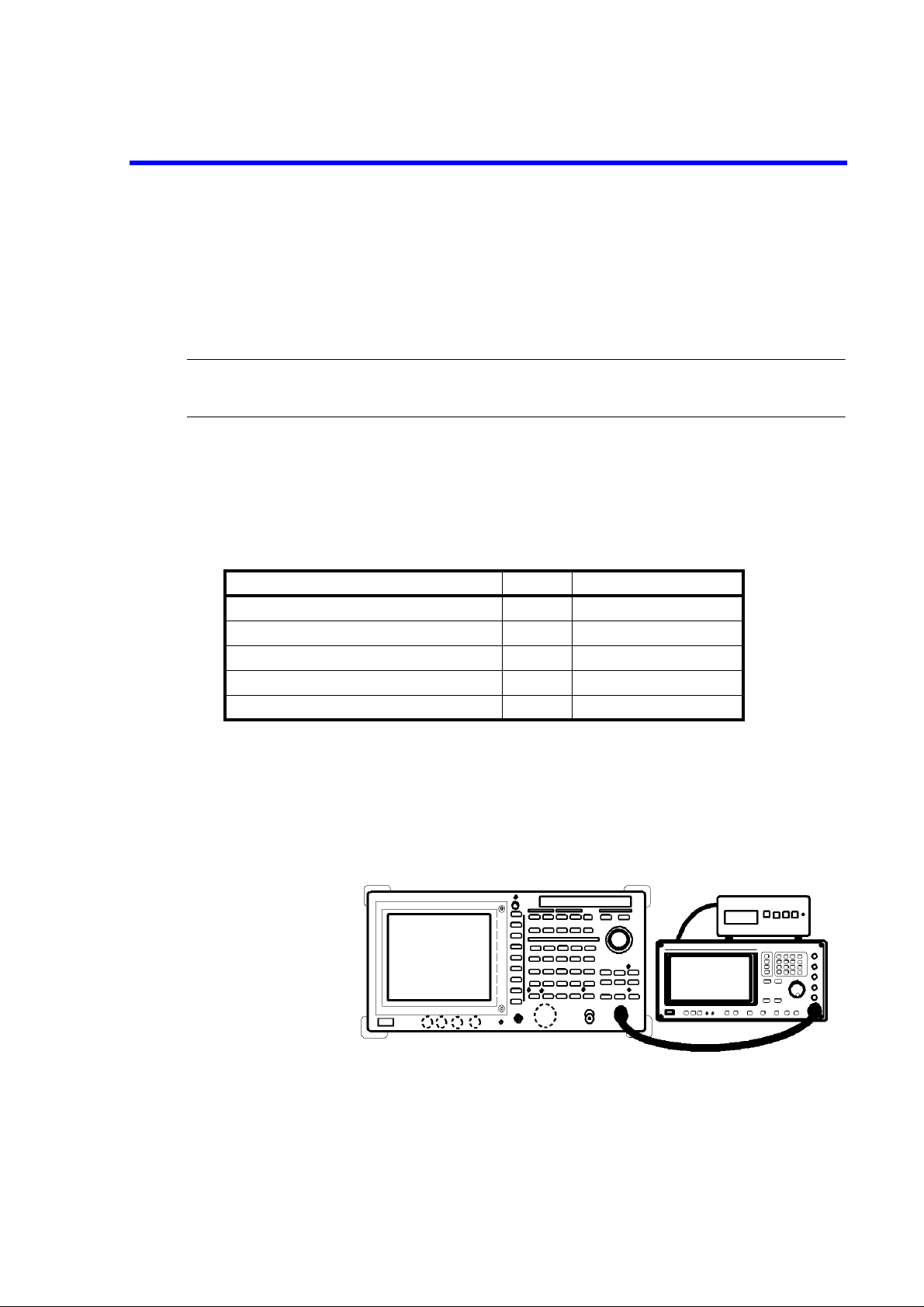

Procedures:

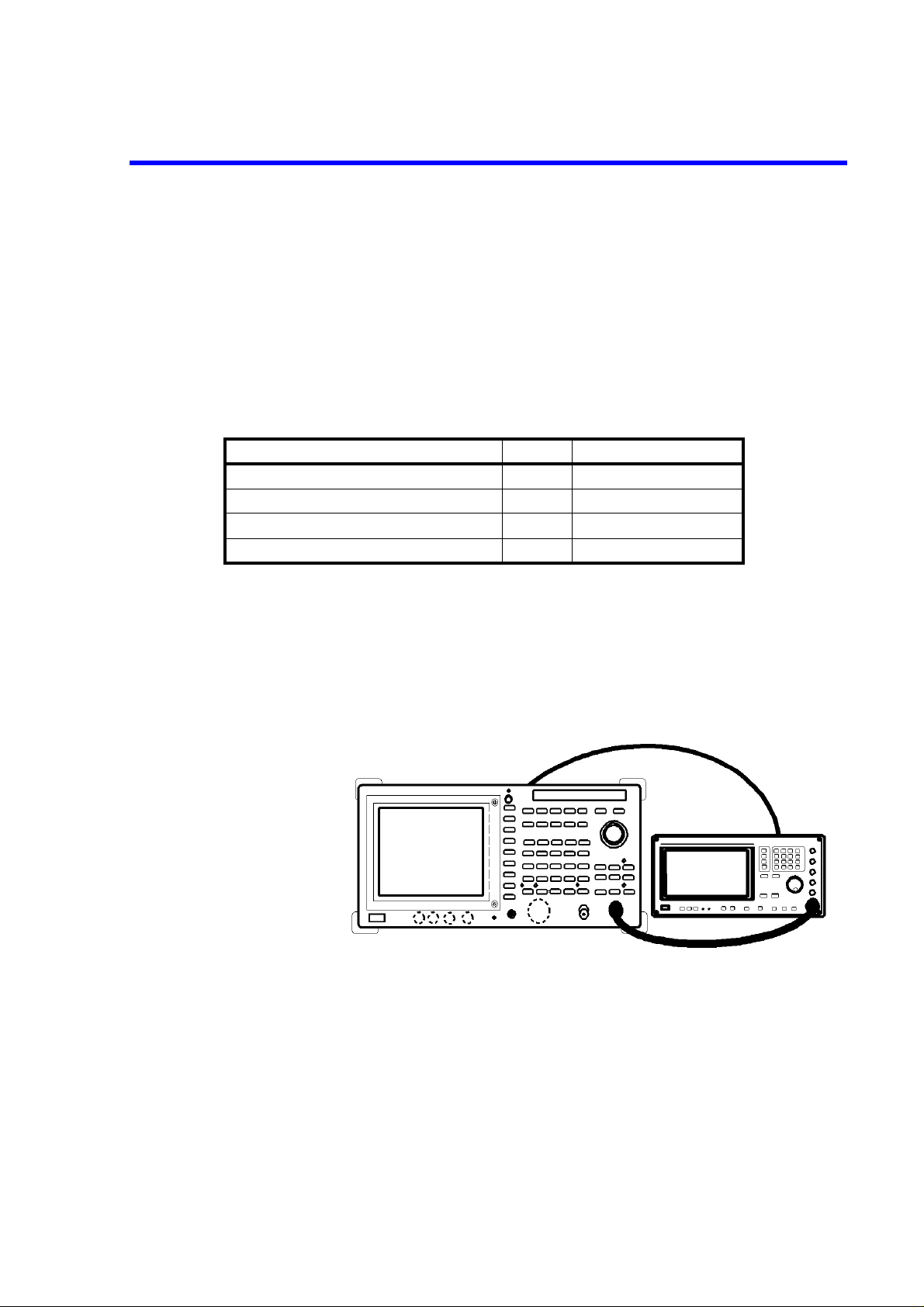

Setup

Initialization

1. Connect the signal generator as shown in Figure 1-3.

Figure 1-3 Setup for Measuring a Frequency Readout Accuracy and

Frequency Counter

2. Press SHIFT and CONFIG(PRESET).

1-8

Page 19

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.3 Accuracy of Frequency Readout and Frequency Counter

Measurement using a center frequency of 2 GHz

3. Set the SMP03 controls as follows:

Frequency: 2 GHz

Output level: -10 dBm

10 MHz Reference: External

4. Press FREQ, 2 and GHz.

5. Press SPAN, 1 and MHz.

6. Press SCRH.

7. Record the frequency of the marker reading on the performance check sheet.

8. Repeat steps 5 through 7 for each frequency setting listed on Table 1-2.

Table 1-2 Frequency Span Setting at a Center Frequency of 2 GHz

Frequency span

10 MHz

20 MHz

50 MHz

100 MHz

2 GHz

Frequency measurement using the counter marker

9. Press SPAN, 1 and MHz.

10. Press SRCH.

11. Press MEAS, Counter and Resolution 1 Hz.

12. Press Counter ON/OFF(ON).

13. Record the frequency of the counter marker reading on the performance check

sheet.

14. Press Counter ON/OFF(OFF).

For the R3267/73

Measurement using a center frequency of 5 GHz

15. Set both the frequency on the SMP03 and the center frequency to 5 GHz and

repeat steps 3 through 14.

1-9

Page 20

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.3 Accuracy of Frequency Readout and Frequency Counter

For the R3273 only

Measurement using a center frequency of 11 GHz and 18 GHz

16. Set the frequency on the SMP03 and the center frequency to 11 GHz and repeat

steps 3 through 14.

17. Set the frequency on the SMP03 and the center frequency to 18 GHz and repeat

steps 3 through 14.

1-10

Page 21

1.2.4 Frequency Span Accuracy

This section explains how to check the frequency span accuracy using signals from the signal generator

and the delta marker.

Check the span accuracy using the signal frequency difference measured with the delta marker function.

Specifications:

less than ± 1 % of the frequency span setting

Instruments Required

Instruments QTY Recommended Model

Signal Generator 1 SMP03

RF Cable BNC(m)-BNC(m) 1 A01002

RF Cable SMA(m)-SMA(m) 1 MI-09

Adapter N(m)-SMA(f) 1

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.4 Frequency Span Accuracy

Procedures:

Setup

1. Connect the signal generator as shown in Figure 1-4.

Figure 1-4 Setup for Measuring a Frequency Span Accuracy

Setting the signal generator

2. Set the SMP03 controls as follows:

Output level: -5 dBm

10 MHz Reference: External

Initialization

3. Press SHIFT and CONFIG(PRESET).

1-11

Page 22

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.4 Frequency Span Accuracy

Measurement of the span accuracy

4. Set the frequency of the SMP03 to 1.999992 GHz.

5. Press FREQ, 2 and GHz.

6. Press SPAN, 2, 0 and kHz.

7. Press SINGLE.

8. Press SRCH, after the sweep has completed.

9. Press MKR, Delta Marker and Delta Marker ON/OFF (ON).

10. Set the frequency of the SMP03 to 2.000008 GHz.

11. Press SINGLE.

12. Press SRCH, after the sweep has completed.

13. Record the frequency of the delta marker reading on the performance check

sheet.

14. Repeat steps 4 through 13 for each frequency setting listed on Table 1-3.

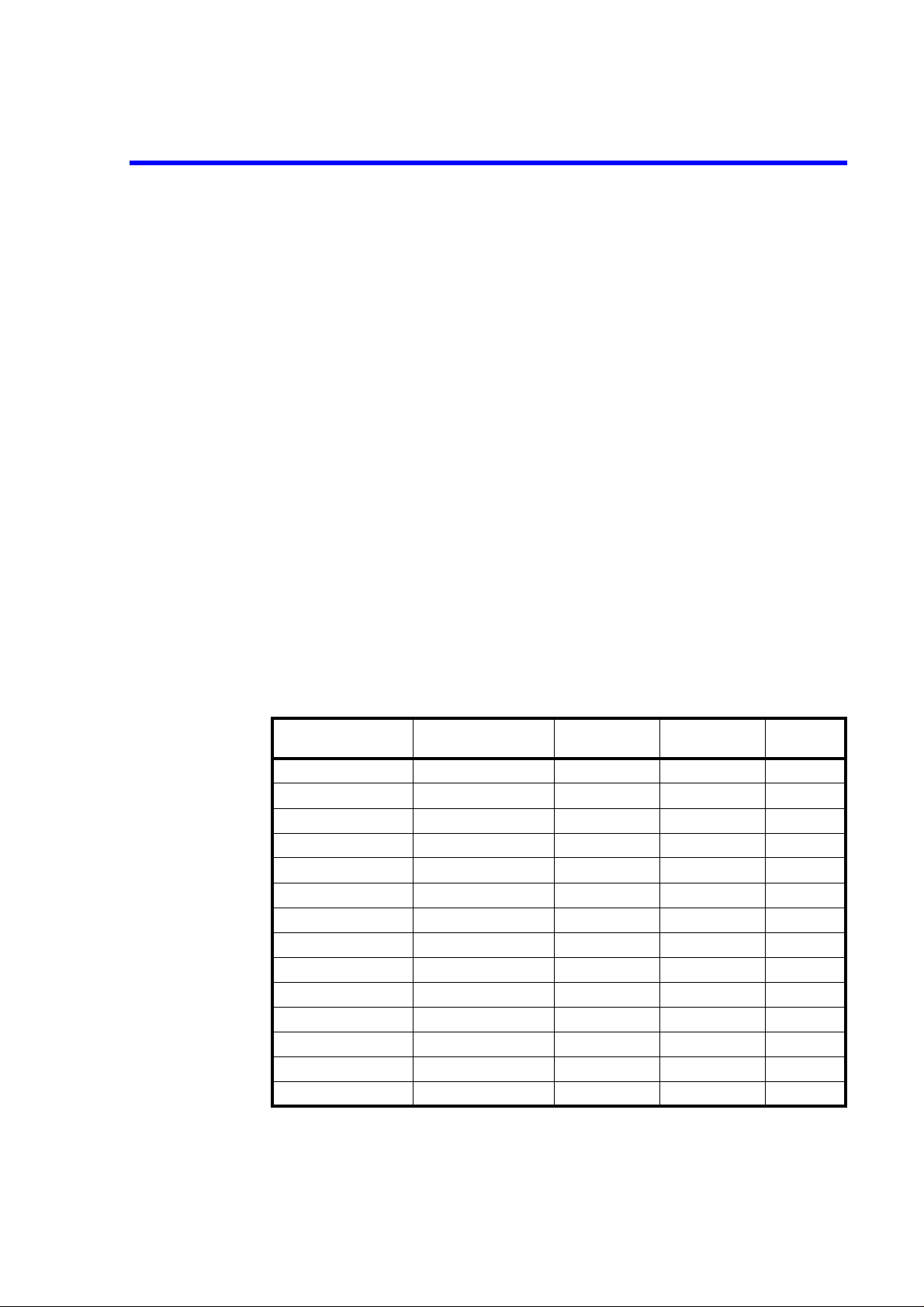

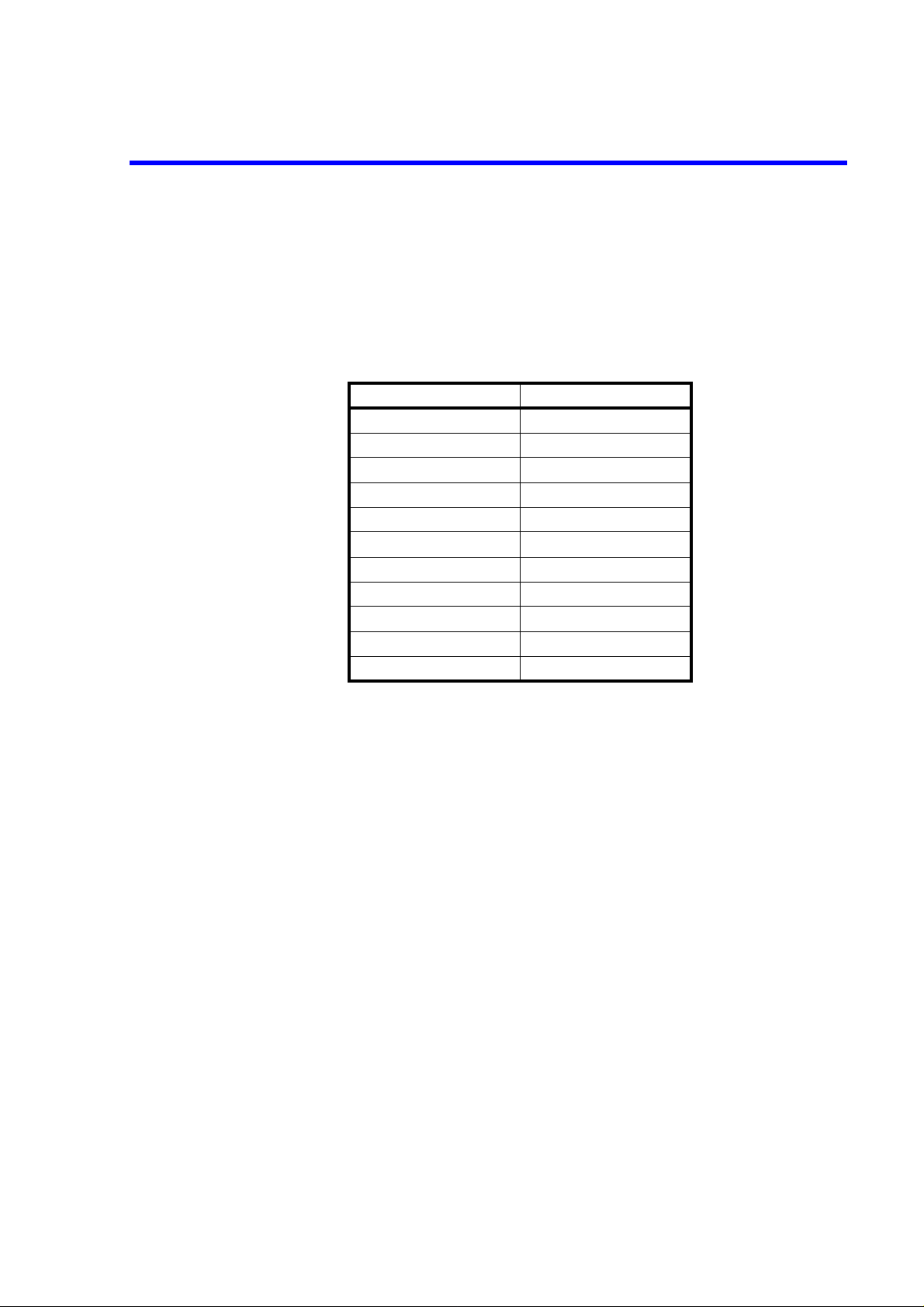

Table 1-3 Center/Span Frequencies for the R3267

SMP03

1st Frequency

1.999980 GHz 2.000020 GHz 2 GHz 50 kHz

1.999940 GHz 2.000160 GHz 2 GHz 400 kHz

1.9992 GHz 2.0008 GHz 2 GHz 2 MHz

1.998 GHz 2.002 GHz 2 GHz 5 MHz

1.996 GHz 2.004 GHz 2 GHz 10 MHz

1.992 GHz 2.008 GHz 2 GHz 20 MHz

1.98 GHz 2.02 GHz 2 GHz 50 MHz

1.96 GHz 2.04 GHz 2 GHz 100 MHz

1.92 GHz 2.08 GHz 2 GHz 200 MHz

1.8 GHz 2.2 GHz 2 GHz 500 MHz

1.6 GHz 2.4 GHz 2 GHz 1 GHz

1.2 GHz 2.8 GHz 2 GHz 2 GHz

2.4 GHz 5.6 GHz 4 GHz 4 GHz R3267/73

0.8 GHz 7.2 GHz 4 GHz 8 GHz R3267/73

SMP03

2nd Frequency

Center

Frequency

Frequency

Span

Remarks

1-12

Page 23

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

For the R3273 only

Measurement for a center frequency of 10 GHz and 17 GHz.

15. Repeat steps 4 through 13 for each frequencies setting listed on Table 1-4.

Table 1-4 Center/Span Frequencies for the R3273

1.2.4 Frequency Span Accuracy

SMP03

1st Frequency

9.996 GHz 10.004 GHz 10 GHz 10 MHz

9.96 GHz 10.04 GHz 10 GHz 100 MHz

9.6 GHz 10.4 GHz 10 GHz 1 GHz

9.2 GHz 10.8 GHz 10 GHz 2 GHz

16.996 GHz 17.004 GHz 17 GHz 10 MHz

16.96 GHz 17.04 GHz 17 GHz 100 MHz

16.6 GHz 17.4 GHz 17 GHz 1 GHz

16.2 GHz 17.8 GHz 17 GHz 2 GHz

8 GHz 12 GHz 10 GHz 5 GHz

6 GHz 14 GHz 10 GHz 10 GHz

2.4 GHz 17.6 GHz 10 GHz 19 GHz

SMP03

2nd Frequency

Center

Frequency

Frequency

Span

1-13

Page 24

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.5 Calibration Amplitude Accuracy

1.2.5 Calibration Amplitude Accuracy

This section explains how to check the output level accuracy of the calibration signal.

Specifications:

-10 dBm ± 0.3 dB

Instruments Required

Instruments QTY Recommended Model

Power Meter and Power Sensor 1 NRVS / NRV-Z52

Adapter N(f)-BNC(m) 1

Adapter N(m)-SMA(f) 1

Procedures:

Initialization

1. Set the unit to dBm on the NRVS.

2. Perform the zeroing of the NRVS.

3. Press SHIFT and CONFIG(PRESET).

Measuring of the CAL OUT level

4. Connect the power sensor to CAL OUT connector through the adapter, N(f)BNC(m) and N(m)-SMA(f) .

5. Set the correction frequency to 30 MHz on the NRVS.

6. Record the level of the power meter reading on the performance check sheet.

1-14

Page 25

1.2.6 IF Gain Uncertainty

This section explains how to check IF gain errors in the RBWs of 1 MHz, 300 kHz and 3 kHz. If the reference level is reduced, the IF gain is increased. The IF gain error can be measured if you deduce the inpu t

level in steps of 1 dB or 10 dB in order to reduce the reference level in steps of 1 dB or 10 dB as in the

input level. In addition, the frequency reference source signal of the generator is supplied from the spectrum analyzer.

Specifications:

Less than ± 0.5 dB Range: 0 to -50 dBm 10 dB Attenuation

Less than ± 0.7 dB Range: 0 to -80 dBm 10 dB Attenuation

Instruments Required

Instruments QTY Recommended Model

Function Generator 1 HP3325B

1 dB Step Attenuator 1 HP8494H

10 dB Step Attenuator 1 HP8495H

Attenuator Driver 1 HP11713A

RF Cable BNC(m)-BNC(m) 3 MI-09

Adapter N(m)-BNC(f) 3

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.6 IF Gain Uncertainty

Procedures:

Setup

1. Connect the signal generator and step attenuator as shown in Figure 1-5.

Figure 1-5 Setup for Measuring a IF Gain Uncertainty

1-15

Page 26

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.6 IF Gain Uncertainty

Setting the function generator

2. Set the HP3325B controls as follows:

Frequency: 11 MHz

Output level: -5 dBm

10MHz Reference:External

Setting the step attenuator

3. Set the HP8494H and HP8495H to 0 dB using the HP11713A.

Initialization

4. Press SHIFT and CONFIG(PRESET).

Setting the measurement conditions

5. Press FREQ, 1, 1 and MHz.

6. Press SPAN and Zero Span.

7. Press LEVEL, dB/div and 1dB/div.

8. Press COUPLE, RBW AUTO/MNL(MNL), 1 and MHz.

9. Press VBW AUTO/MNL(MNL), 1 and Hz.

10. Adjust the output level on the HP3325B to position the trace peak to a level 5

11. Press SINGLE .

12. Press SINGLE, after the sweep is completed.

13. Press A, View A and SRCH, after the sweep is completed.

14. Record the marker readout at the reference value box on the performance check

15. Press B, Write B and MKR.

16. Press Delta Marker, RETURN and Trace Marker Move.

IF gain error measurement

17. Set the attenuation level to 1 dB on the HP11713A.

divisions below the reference line.

sheet.

1-16

18. Press LEVEL, 1 and MHz(-dBm) to set the reference level to -1 dBm.

19. Press SINGLE .

Page 27

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.6 IF Gain Uncertainty

20. Press SINGLE, after the sweep is completed.

21. Press SRCH, after the sweep is completed.

22. Record the marker readout on the performance check sheet.

23. Repeat steps 17 through 22 for each frequency setting listed on Table 1-5.

24. Repeat steps 2 through 23 for each frequency setting listed on Table 1-6.

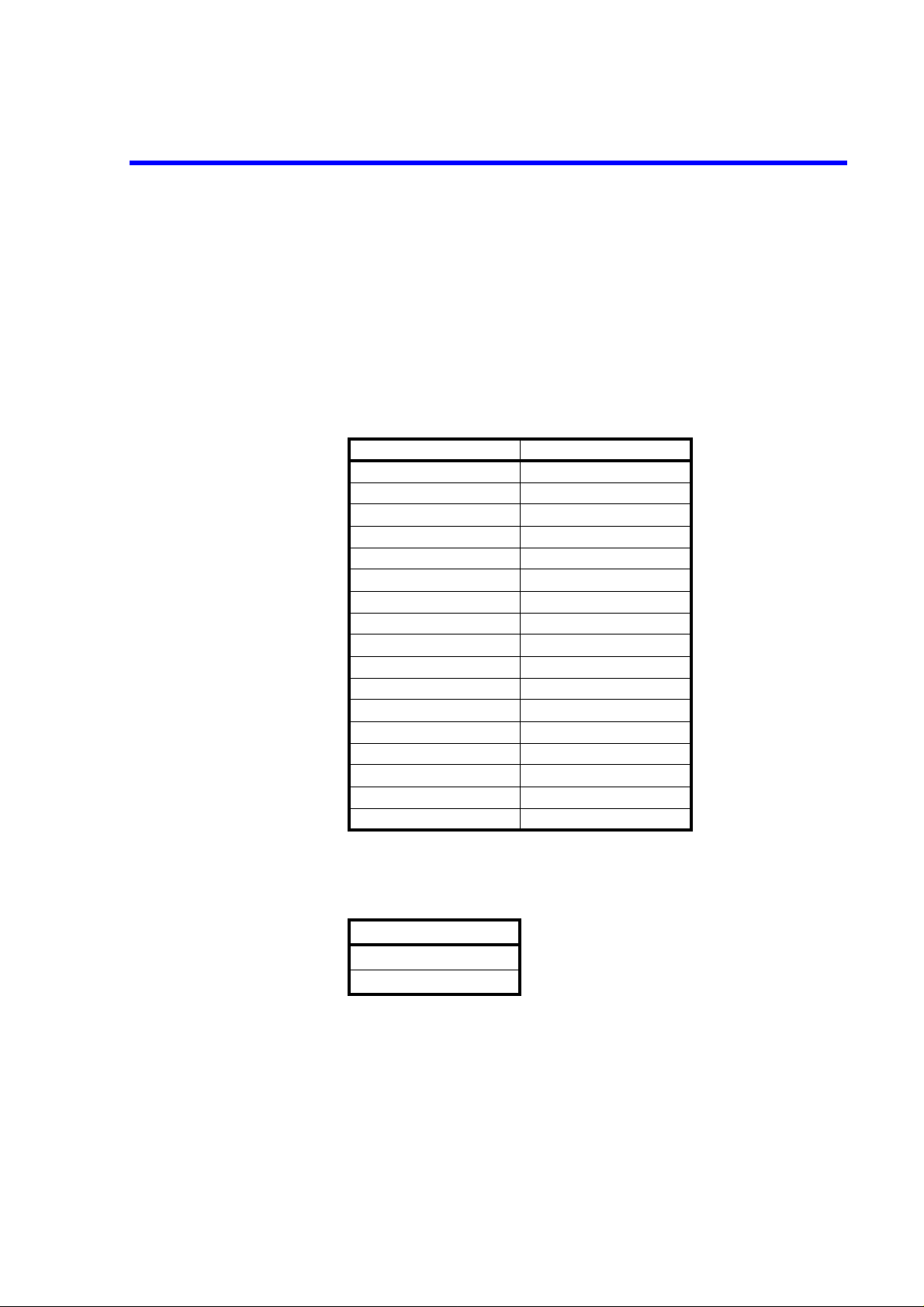

Table 1-5 IF Gain Uncertainty Setting

Step attenuator Reference level

1 dB -1 dBm

2 dB -2 dBm

3 dB -3 dBm

4 dB -4 dBm

5 dB -5 dBm

6 dB -6 dBm

7 dB -7 dBm

8 dB -8 dBm

9 dB -9 dBm

10 dB -10 dBm

20 dB -20 dBm

30 dB -30 dBm

40 dB -40 dBm

50 dB -50 dBm

60 dB -60 dBm

70 dB -70 dBm

80 dB -80 dBm *

*: Make a measurement only when the RBW is

at 3 kHz.

Table 1-6 RBW Setting

RBW setting

3 kHz

300 kHz

1-17

Page 28

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.7 Input Attenuator Switching Accuracy

1.2.7 Input Attenuator Switching Accuracy

This section explains how to check the input attenuator switching accuracy . The signal generator freque ncy reference source is supplied from the spectru m analyzer. The input attenuator switching accuracy is calculated based on the 10 dB attenuator.

IF Gain uncertainty is measured when the resolution bandwidth is set to 3kHz and the result is filled in on

the IF Gain uncertainty of the performance check sheet.

NOTE: You may hear some clicking noises during the tests. This is normal.

Specifications:

Reference to 10 dB input attenuation, in the range of 20 dB to 70 dB.

R3264

Less than ± 1.1 dB/5 dB step 9 kHz to 3.5 GHz: Maximum deviation ± 2 dB

R3267

Less than ± 1.1 dB/5 dB step 100 Hz to 8 GHz: Maximum deviation ± 2 dB

R3273

Less than ± 1.1 dB/10 dB step 100 Hz to 12.4 GHz: Maximum deviation ± 2 dB

Less than ± 1.3 dB/10 dB step 12.4 GHz to 18 GHz: Max. deviation ± 2.5 dB

Less than ± 1.8 dB/10 dB step 18 GHz to 26.5 GHz: Max. deviation ± 3.5 dB

Instruments Required

Instruments QTY Recommended Model

Signal Generator 1 SMP02

RF Cable SMA(m)-SMA(m) 2 A01002

RF Cable BNC 1 MI-09

Adapter N(m)-SMA(f) 2

Procedures:

Setup

1. Connect the signal generator as shown in Figure 1-6.

1-18

Page 29

Figure 1-6 Setup for Measuring an Input Attenuator Accuracy

Setting the signal generator

2. Set the SMP03 controls as follows:

Frequency: 2 GHz(R3264 )

Output level: -5 dBm

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.7 Input Attenuator Switching Accuracy

4 GHz(R3267 /73)

Initialization

3. Press SHIFT and CONFIG(PRESET).

Setting the measurement conditions

4. Press FREQ, 2 and GHz(R3264).

Press FREQ, 4 and GHz(R3267/73).

5. Press SPAN 1, 0 and kHz.

6. Press LEVEL, 0, MHz(-dBm), dB/div and 1 dB/div.

7. Press COUPLE, RBW AUTO/MNL(MNL) and 3 and kHz.

8. Press VBW AUTO/MNL(MNL), 1, 0 and Hz.

9. Adjust the output level on the SMP02 to position the trace peak to a level 5 divisions below the reference line.

10. Press SINGLE.

11. Press SINGLE, after the sweep has completed.

12. Press SRCH, after the sweep has completed.

13. Record the marker readout at the reference value box on the performance check

sheet.

1-19

Page 30

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.7 Input Attenuator Switching Accuracy

14. Press ATT and ATT AUTO/MNL(MNL).

Measuring the attenuator switching accuracy

15. Press ATT, 2, 0 and GHZ(dB) to change the attenuator setting.

16. Press SINGLE.

17. Press SINGLE, after the sweep has completed.

18. Press SRCH, after the sweep has completed.

19. Calculate the switching accuracy using the marker readout and the expression

shown below.

Switching accuracy = Reference Value ( in st ep 13 ) - Mar ker read out (in step 18)

+ IF gain uncertainty (in section 1.2.5)

20. Record the switching accuracy on the performance check sheet.

21. Repeat steps 15 through 20 for each frequency setting listed on Table 1-7.

Table 1-7 Input Attenuator Sett ing

Input Attenuator

Step-to-step accuracy calculation

22. Calculate the step-to-step accuracy for the 20, 30, 40, 50, 60 an d 70 dB ATT settings using the switching accuracy calculated in step 19 together with the following expression, and record the results on the performance check sheet.

Step-to-step accuracy for an input attenuation of x dB = A - B

A: Switching accuracy for an input attenuation of x dB

B: Switching accuracy for an input attenuation of (x -10) dB

For the R3273

20 dB

30 dB

40 dB

50 dB

60 dB

70 dB

1-20

23. Repeat steps 2 thru 22 for a frequency of 15 GHz ( which is set o n the SMP02 and

used as the center frequency).

24. Repeat steps 2 thru 22 for a frequency of 18 GHz ( which is set o n the SMP02 and

used as the center frequency).

Page 31

1.2.8 Frequency Response

This section explains how to check the frequency response of the spectrum analyzer. The s ignal generator

signal is fed through a power splitter and the power level is monitored with a power meter. A signal of 30

MHz is positioned at the display center of the spectrum analyzer so that its level can be used as the reference value.

For each frequency band, a signal with the specified frequency is set so that it can always be displayed in

the display center of the spectrum analyzer and the level relative to the 30 MHz signal is measured.

Specifications:

Set the input attenuator to 10 dB. The frequency ranges for frequency bands 1 thru 3 are valid only

after the preselector has been adjusted.

R3264 Frequency range Frequency band

± 1.5 dB 9 kHz to 3.5 GHz 0

Frequency response relative to the 30 MHz: less than ± 3 dB

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.8 Frequency Response

R3267 Frequency range Frequency band

± 1.5 dB 100 Hz to 3.5 GHz 0

± 1.0 dB 50 MHz to 2.6 GHz 0

± 1.5 dB 1.6 GHz to 3.5 GHz 1

± 1.5 dB 3.5 GHz to 7.0 GHz 2

± 1.5 dB 6.9 GHz to 8.0 GHz 3

Frequency response relative to the 30 MHz: less than ± 3 dB

Band switching incertainly: less than ± 0.5 dB

R3273 Frequency range Frequency band

± 1.5 dB 100 Hz to 3.5 GHz 0

± 1.0 dB 50 MHz to 2.6 GHz 0

± 1.5 dB 3.5 GHz to 7.5 GHz 1

± 3.5 dB 7.4 GHz to 15.4 GHz 2

± 4.0 dB 15.4 GHz to 26.5 GHz 3

Frequency response relative to the 30 MHz: less than ± 5 dB

Band switching incertainly: less than ± 0.5 dB

Instruments Required

Instruments QTY Recommended Model

Signal Generator 1 SMP03

Power Meter and Power Sensor 1 NRVS / NRV-Z52

Power Splitter 1 1579

RF Cable SMA(m)-SMA(m) 2 A01002

Adapter N(m)-SMA(f) 3

1-21

Page 32

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.8 Frequency Respons e

Procedures:

Initializing the Power meter with the sensor

1. Set the unit to dBm on the NRVS.

2. Perform the zeroing of the NRVS.

Setup

3. Connect the signal generator as shown in Figure 1-7.

Figure 1-7 Setup for Measuring a Frequency Response

Initialization

4. Press SHIFT and CONFIG(PRESET).

Setting the measurement conditions

5. Press FREQ, 3, 0 and MHz.

6. Press SPAN, 4, 0 and MHz.

7. Press LEVEL, 5 and MHz(-dBm).

8. Press COUPLE, RBW AUTO/MNL(MNL), 3 and MHz.

9. Press VBW AUTO/MNL(MNL), 1 and kHz.

10. Press LEVEL, dB/div and 1 dB/div.

11. Press FREQ, CF St e p Si ze AUTO/MNL(MNL), 1, 0, 0 and MHz.

12. Set the SMP03 controls as follows:

Frequency: 30 MHz

Output Level: -4 dBm

Frequency step size: 100 MHz

1-22

Page 33

13. Set the correction frequency to the 30 MHz on the NRVS.

14. Press SRCH.

15. Press Cont Peak ON/OFF(ON).

16. Adjust the output level on the SMP03 using the data knob to obtain a marker

readout of -10±0.09 dBm on the spectrum analyzer.

17. Set the display mode of the NRVS to the relative.

Measuring the frequency band 0

18. (For the R3267 only) Pr ess FREQ, more 1/2 and Pre selector 1.6 G/3 .6 G(3.6G).

19. Press FREQ, 1, 0, 0 and MHz.

20. Set the frequency of the SMP03 to 100 MHz.

21. Set the correction frequency on the NRVS to 100 MHz.

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.8 Frequency Response

22. Adjust the output level on the SMP03 (using the data knob) so that the level of

the marker readout is -10 dBm±0.09 dB.

23. Record the reverse sign value of the power meter reading on the performance

check sheet.

24. Press FREQ and .

25. Increase the frequency on the SMP03 by one step.

26. Set the correction frequency of the NRVS to the entire frequency.

27. Repeat steps 22 through 26 up to the center frequency to 3.5 GHz.

Calculating the maximum deviation

28. Calculate the maximum deviation for each of the frequency bands, 100 Hz thru

3.5 GHz and 50 MHz thru 2.6 GHz, by subtracting the minimum value from the

maximum value and then dividing the difference by 2. Record the result on the

performance check sheet.

NOTE: Perform the measurement from step 29 onwards for the R3267 and R3273 only.

Measuring the frequency band 1

29. (For the R3267 only) Pr ess FREQ, more 1/2 and Preselector 1.6 G/3.6 G(1.6G).

30. Press FREQ, 1, ., 7 and GHz(R3267), FREQ, 3, ., 6 and GHz(R3273).

1-23

Page 34

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.8 Frequency Respons e

31. Set the frequency of the SMP03 to 1.7 GHz(R3267), 3.6 GHz(R3273).

32. Set the correction frequency on the NRVS t o 1.7 GHz(R32 67), 3.6 G Hz(R3273).

33. Press FREQ, more1/ 2, Pres el Tune and Auto Tune.

34. After the auto tuning is completed, ad just the outp ut level o n th e SMP03 ( using

the data knob) so that the level of the marker readout is -10 dBm±0.09 dB.

35. Record the reverse sign value of the power meter on the perf ormance check sheet.

36. Press FREQ and .

37. Increase the frequency on the SMP03 by one step.

38. Set the correction frequency of the NRVS to entire frequency.

39. Repeat steps 33 through 38 up to the following frequency.

R3267: 3.5 GHz

R3273: 7.4 GHz

Calculating the maximum deviation

40. Calculate the maximum deviation by subtracting the minimum value from the

maximum value on the performance check sheet and then divi ding the difference

by 2. Record the result on the performance check sheet.

Measuring the frequency band 2

41. Press FREQ, 3, ., 6 and GHz(R3267), FREQ, 7, ., 5 and GHz(R3273).

42. (For the R3273 only) Press CF Stepsize AUTO/MNL(MNL), 2, 0, 0 and MHz.

43. Set the frequency of the SMP03 to 3.6 GHz(R3267), 7.5 GHz(R3273).

44. (For the R3273 only) Set the frequency step size on the SMP03 to 200 MHz.

45. Set the correction frequency on the NRVS t o 3.6 GHz(R32 67), 7.5 G Hz(R3273).

46. Press FREQ, more1/ 2, Pres el Tune and Auto Tune.

47. After the auto tuning is completed, ad just the outp ut level o n th e SMP03 ( using

the data knob) so that the level of the marker readout is -10 dBm±0.09 dB.

48. Record the reverse sign value of the power meter on the perf ormance check sheet.

1-24

49. Press FREQ and .

50. Increase the frequency on the SMP03 by one step.

51. Set the correction frequency of the NRVS to entire frequency.

Page 35

52. Repeat steps 46 through 51 up to the following frequency.

R3267: 6.9 GHz

R3273: 15.3 GHz

Calculating the maximum deviation

53. Calculate the maximum deviation by subtracting the minimum value from the

maximum value on the performance check sheet and then divi ding the difference

by 2. Record the result on the performance check sheet.

Measuring the frequency band 3

54. Press FREQ, 7 and GHz(R3267), FREQ, 1, 5, ., 4 and GHz(R3273).

55. Set the frequency of the SMP03 to 7 GHz(R3267), 15.4 GHz(R3273).

56. Set the correction frequen c y o n th e NRVS t o 7 GHz (R3 26 7), 15.4 GH z(R 327 3).

57. Press FREQ, more1/ 2, Pres el Tune and Auto Tune.

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.8 Frequency Response

58. After the auto tuning is completed, ad just the outp ut level o n th e SMP03 ( using

the data knob) so that the level of the marker readout is -10 dBm±0.09 dB.

59. Record the reverse sign value of the power meter on the perf ormance check sheet.

60. Press FREQ and .

61. Increase the frequency on the SMP03 by one step.

62. Set the the correction frequency of the NRVS to entire frequency.

63. Repeat steps 57 through 62 up to the following frequency.

R3267: 7.9 GHz

R3273: 26.4 GHz

Calculating the maximum deviation

64. Calculate the maximum deviation by subtracting the minimum value from the

maximum value on the performance check sheet and then divi ding the difference

by 2. Record the result on the performance check sheet.

1-25

Page 36

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.9 Scale Fidelity

1.2.9 Scale Fidelity

This section explains how to check the display accuracy for 1 dB/div and 10 dB/div in the log scale and

x1 in the linear scale.

The function generator frequency reference source is supplied from the spectrum analyzer.

Specifications:

log scales

Less than ± 0.2 dB/1 dB

Less than ± 0.85 dB over 0 dB to 90 dB range

Linear scales

Less than ± 5% of Reference Level

Instruments Required

Instruments QTY Recommended Model

Function Generator 1 HP3325B

1 dB Step Attenuator 1 HP8494H

10 dB Step Attenuator 1 HP8495H

Attenuator Driver 1 HP11713A

RF Cable BNC(m)-BNC(m) 3 MI-09

Adapter BNC(f)-N(m) 3

Procedures :

Setup

1. Connect the signal generator and step attenuator as shown in Figure 1-8.

Figure 1-8 Setup for Measur i ng a Scale Fid elity

1-26

Page 37

Setting the function generator

2. Set the HP3325B controls as follows:

Frequency: 11 MHz

Output level: 0 dBm

3. Set the HP8494H and HP8495H to 0 dB using the HP11713A.

Initialization

4. Press SHIFT and CONFIG(PRESET).

Setting the measurement conditions

5. Press FREQ, 1, 1 and MHz.

6. Press SPAN and Zero Span.

7. Press LEVEL, 0, MHz(-dBm), dB/div and 1dB/div.

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.9 Scale Fidelity

8. Press COUPLE, RBW AUTO/MNL(MNL), 1 and MHz.

9. Press VBW AUTO/MNL(MNL), 1 and Hz.

10. Press MKR.

Measuring the 1 dB/div Scale fidelity

11. Adjust the output level on the HP3325B so that the marker readout is 0.00±0.1

dB.

12. Press A, View A, B, Write B, MKR, Delta Marker, RETURN and Trace

Marker Move.

13. Increase the attenuation of the HP8494H by 1 dB.

14. Press SINGLE.

15. Press SINGLE, after the sweeping has completed.

16. Record the level of the delta marker reading in the performance check sheet.

17. Calculate the incremental error according to the following formula.and recor d the

result on the performance check sheet.

Incremental error = (the level of the current delta marker reading) - (previous

delta marker level) + 1 dB

18. Repeat steps 13 through 17 for each output level setting listed on Table1-8.

1-27

Page 38

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.9 Scale Fidelity

Table 1-8 1 dB Step Scale Fidelity Setting

HP8494H output level

2 dB

3 dB

4 dB

5 dB

6 dB

7 dB

8 dB

9 dB

10 dB

Measuring the 10 dB/div scale fidelity

19. Adjust the HP8494H output level to 0 dB.

20. Press REPEAT.

21. Press LEVEL and 10 dB/div.

22. Press COUPLE, RBW AUTO/MNL(MNL), 3, kHz, A, Write A, B, Blank B,

MKR and Normal Marker.

23. On the HP3325B, adjust the amplitude until the marker reading 0.00 dBm

exactly.

24. Record the HP3325B setting level at the reference output level on the performance check sheet.

25. Press A, View A, B , Write B, MKR, Delta Marker, RETURN and Marke Trace

Move.

26. Adjust the HP8495H output level to 10 dB.

27. Press SINGLE.

28. Press SINGLE, after the averaging has completed.

29. Record the level of the delta marker reading on the performance check sheet.

30. Repeat steps 26 through 29 for each attenuation level setting listed o n T able 1 -9.

1-28

Page 39

Table 1-9 HP8495H and HP3325B Settings

HP8495H Setting

Measuring the linear scale fidelity

31. Set the HP8494H and HP8495H to 0 dB using the HP11713A.

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.9 Scale Fidelity

HP3325B Setting

(With reference to the

reference output level)

20 dB 0 dB

30 dB 0 dB

40 dB 0 dB

50 dB 0 dB

60 dB 0 dB

70 dB 0 dB

80 dB -10 dB

90 dB -20 dB

32. Set the HP3325B controls as follows:

Frequency: 11 MHz

Level: 0 dBm

33. Press SHIFT and CONFIG(PRESET).

34. Press FREQ, 1, 1 and MHz.

35. Press SPAN, 1, 0 and kHz.

36. Press ATT, ATT AUTO/MNL(MNL), 2, 0 and GHz(dB).

37. Press LEVEL, 0, GHz(+dBm), Linear and x1.

38. Press COUPLE, RBW AUTO/MNL(MNL), 1 and kHz.

39. Press VBW AUTO/MNL (MNL), 1 and kHz.

40. Press SRCH, Cont Peak ON/OFF(ON).

41. Adjust the output level on the HP3325B so that the trace peak is aligned with the

reference level.

42. Press SINGLE.

43. Record the setting level used in the HP3325B at the reference output level box

on the performance check sheet.

44. Reduce the output level on the HP3325B by 0.92 dB in relation to the reference

output level.

1-29

Page 40

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.9 Scale Fidelity

45. Press SINGLE.

46. Press SINGLE, after the averaging has completed.

47. Record the level of the maker reading on the performance check sheet.

48. Repeat steps 44 through 47 for each level setting listed on Table 1-10.

Table 1-10 Settings on the HP3325B in relation to the Reference

Output Level

HP3325B set level

-1.94 dB

-3.10 dB

-4.44 dB

-6.02 dB

-7.96 dB

-10.46 dB

-13.98 dB

-20 dB

1-30

Page 41

1.2.10 RBW Switching Uncertainty

This section explains how to check the RBW switching uncertainty using the calibration output. The

switching accuracy is calculated based on an RBW of 300 kHz.

Specification:

less than ± 0.3 dB 100 Hz to 5 MHz RBW setting : RBW 300 kHz reference

less than ± 1.0 dB 30 Hz RBW setting : RBW 300 kHz reference

Instruments Required

Accessories (BNC cable and adapter)

Procedures :

Initialization

1. Press SHIFT and CONFIG(PRESET).

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.10 RBW Switching Uncertainty

Connecting calibration signal

2. Connect the BNC cable from the CAL OUT connector to the INPUT connector.

3. Press SHIFT, 7(CAL), Cal Each Item and RBW Switching.

Setting the reference value (RBW = 300 kHz)

4. Press FREQ, 3, 0 and MHz.

5. Press SPAN, 1 and MHz.

6. Press LEVEL, 5, MHz(-dBm), dB/div, and 1 dB/div.

7. Press COUPLE, RBW AUTO/MNL(MNL), 3, 0, 0 and kHz.

8. Press SINGLE, SRCH and Cont Peak ON/OFF(ON).

9. Press MKR, Delta Marker and Fixed Mark er O N/OF F(ON).

Measurement the RBW switching uncertainty

10. Press COUP L E , RBW AUTO/MNL(MNL), 5 and MHz.

11. Press SPAN, 8 and MHz.

12. Press SINGLE.

13. After the sweeping has completed, record the level of the delta marker reading

on the performance check sheet.

1-31

Page 42

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.10 RBW Switching Uncertainty

14. Repeat steps 10 through 13 for each bandwidth and span frequency setting listed

on Table 1-11.

Table 1-11 RBW Switching Uncertainty Setting

RBW setting Frequency span

5 MHz 8 MHz

3 MHz 5 MHz

1 MHz 2 MHz

100 kHz 200 kHz

30 kHz 50 kHz

10 kHz 20 kHz

3 kHz 5 kHz

1 kHz 2 kHz

300 Hz 500 Hz

100 Hz 200 Hz

30 Hz 200 Hz

1-32

Page 43

1.2.11 RBW Accuracy and Selectivity

This section explains how to check a bandwidth of 3 dB and the selectivity. To calculate the selectivity, a

bandwidth of 60 dB is measured first and then the selectivity is calculated (Selectivity = 60 dB BW divided

by 3 dB BW).

Specifications:

Range

10 Hz to 10 MHz; 1, 3, 10 Sequence and 5 MHz

Accuracy

± 15% : 100 Hz, 300 Hz, 1 kHz, 3 kHz, 10 kHz, 30 kHz, 100 kHz, 300 kHz, 1 MHz

± 25% : 30 Hz, 3 MHz, 5 MHz Note: 30 Hz at 25 °C±10 °C

Selectivity

less than 15:1 (RBW = 100 Hz, 300 Hz, 1 kHz, 3 kHz, 10 kHz, 30 kHz, 100 kHz, 300 kHz, 1

MHz, 3 MHz, 5MHz)

less than 20:1 (RBW = 30 Hz)

Instruments Required

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.11 RBW Accuracy and Selectivity

Accessories (BNC cable and adapter)

Procedures:

Connecting calibration signal

1. Connect the BNC cable from the CAL OUT connector to the INPUT connector.

Initialization

2. Press SHIFT and CONFIG(PRESET).

Setting the measurement conditions

3. Press FREQ, 3, 0 and MHz.

4. Press LEVEL, 5, MHz(-dBm), dB/div and 1 dB/div.

5. Press A, Trace A Detector and Sample.

Measurement for accuracy of Resolution Bandwidth

6. Press SPAN, 1, 0 and MHz.

7. Press COUPLE, RBW AUTO/MNL(MNL), 5 and MHz.

8. Press SRCH.

9. Press MEAS, x dB Down and Continuous Down ON/OFF(ON).

1-33

Page 44

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.11 RBW Accuracy and Selectivity

10. Press SINGLE.

11. After sweep has completed, record the frequency of the marker reading on the

performance check sheet.

12. Repeat steps 10 and 11 for each frequency setting listed on Table 1-12.

Table 1-12 3 dB Band Width Setting

RBW setting Frequency span

3 MHz 5 MHz

1 MHz 2 MHz

300 kHz 500 kHz

100 kHz 200 kHz

30 kHz 50 kHz

10 kHz 20 kHz

3 kHz 5 kHz

1 kHz 2 kHz

300 Hz 500 Hz

100 Hz 200 Hz

30 Hz 200 Hz

Measuring the 60 dB bandwidth

13. Press SHIFT and CONFIG(PRESET).

14. Press FREQ, 3, 0 and MHz.

15. Press SPAN, 3, 0 and MHz.

16. Press COUPLE RBW AUTO/MNL(MNL), 5 and MHz.

17. Press VBW AUTO/MNL (MNL), 1, 0 and kHz.

18. Press A, Trace Detector and Sample.

19. Press SRCH.

20. Press MEAS, x dB Down, x dB Down, 6, 0, GHz(dB) and Continuous Down

ON/OFF(ON).

21. Press SINGLE.

22. Record the frequency of the marker reading on the performance check sheet.

1-34

Page 45

Calculation of the selectivity

23. For each set Resolution Bandwidth, calculate the selectivity using the following

formula. And record the result on the performance check sheet.

(Selectivity) = (60 dB Band Width) / (3 dB Band Width)

24. Repeat steps 15 through 23 for each frequency setting listed on Table 1-13.

Table 1-13 60 dB Band W idth Setting

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.11 RBW Accuracy and Selectivity

RBW setting Frequency span

3 MHz 25 MHz

1 MHz 20 MHz

300 kHz 5 MHz

100 kHz 1 MHz

30 kHz 500 kHz

10 kHz 200 kHz

3 kHz 50 kHz

1 kHz 20 kHz

300 Hz 5 kHz

100 Hz 2 kHz

30 Hz 1 kHz

1-35

Page 46

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.12 Noise Sidebands

1.2.12 Noise Sidebands

This section explains how to check noise sidebands for a signal of 1.5 GHz and 0 dBm with the offset of

1 kHz, 10 kHz, 100 kHz and 1 MHz.

Specifications:

R3264

Offset 9 kHz ≤ f ≤ 1 GHz 1 GHz< f ≤ 2.6 GHz 2. 6 GHz < f ≤ 3.5 GHz

1 kHz < -100 dBc/Hz < -100 dBc/Hz < -98 dBc/Hz

10 kHz < -113 dBc/Hz < -110 dBc/Hz < -108 dBc/Hz

100 kHz < -118 dBc/Hz < -118 dBc/Hz < -112 dBc/Hz

1 MHz < -135 dBc/Hz < -135 dBc/Hz < -135 dBc/Hz

R3267

Offset 100 Hz ≤ f ≤ 1 GHz 1 GHz< f ≤ 2.6 GHz 2.6 GHz < f ≤ 8 GHz

1 kHz < -100 dBc/Hz < -100 dBc/Hz < -98 dBc/Hz

10 kHz < -113 dBc/Hz < -110 dBc/Hz < -108 dBc/Hz

100 kHz < -118 dBc/Hz < -118 dBc/Hz < -112 dBc/Hz

1 MHz < -135 dBc/Hz < -135 dBc/Hz < -135 dBc/Hz

R3273

Offset 100 Hz ≤ f ≤ 1 GHz 1 GHz< f ≤ 2.6 GHz 2.6 GHz ≤ f < 7.5 GHz

1 kHz < -100 dBc/Hz < -100 dBc/Hz < -98 dBc/Hz

10 kHz < -113 dBc/Hz < -110 dBc/Hz < -108 dBc/Hz

100 kHz < -118 dBc/Hz < -118 dBc/Hz < -112 dBc/Hz

1 MHz < -135 dBc/Hz < -135 dBc/Hz < -135 dBc/Hz

Offset 7.4 GHz ≤ f < 15.4 GHz 15.2 GHz ≤ f < 26.5 GHz

1 kHz < -89 dBc/Hz < -83 dBc/Hz

10 kHz < -102 dBc/Hz < -96 dBc/Hz

100 kHz < -106 dBc/Hz < -100 dBc/Hz

1 MHz < -129 dBc/Hz < -123 dBc/Hz

1 kHz offset and 10 kHz offset : SPAN ≤ 150 kHz

100 kHz offset : 150 kHz < SPAN ≤ 2 MHz

1 MHz offset : SPAN > 2 MHz

1-36

Page 47

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

Instruments Required

Instruments QTY Recommended Model

Signal Generator 1 HP8663A

RF Cable SMA(m)-SMA(m) 1 A01002

RF Cable BNC(m)-BNC(m) 1 MI-09

Adapter N(m)-SMA(f) 2

Procedures:

Setup

1. Connect the signal generator as shown in Figure 1-9.

1.2.12 Noise Sidebands

Figure 1-9 Setup for Measurin g a Noise Sidebands

2. Set the HP8663A controls as follows:

Frequency: 1.5 GHz

Output level: - 5 dBm

Initialization

3. Press SHIFT and CONFIG(PRESET).

Setting measurement conditions

4. Press FREQ, 1, ., 5 and GHz.

5. Press SPAN, 2, 5, 0 and kHz.

Since the measurement is made for each of 1kHz, 10kHz, 100kHz and 1MHz offset frequency, set the frequency span to 2.5 times each offset frequency, or 2.5

kHz, 25 kHz, 250 kHz and 2.5 MHz. Keep other settings unchanged.

Measurement of Noise Sidebands

The following procedur e is used to measure noise s idebands with an offset of 1 00

kHz.

1-37

Page 48

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.12 Noise Sidebands

6. Press SRCH.

7. Press MKR → and Marker → Ref.

8. Press SRCH.

9. Press MEAS, Noise/Hz, dBc/Hz, 1, 0, 0 and kHz.

10. Press LEVEL,

and

.

11. Press A, Average A, 2, 0, and Hz(ENTR).

12. Record the level of the marker reading on th e perf orman ce check sh eet, after the

sweep has completed.

13. Press A, Write A, Level, 0, GHz(dBm), SHIFT and MKR(OFF).

14. Repeat steps 5 through 13 for each frequency setting listed on Table 1-14.

Table 1-14 Offset Setting at a Center Frequency of 1 GHz

Offset Frequency span

1 kHz 2.5 kHz

10 kHz 25 kHz

1000 kHz 2500 kHz

1-38

Page 49

1.2.13 Displayed Average Noise Level

This section explains how to check the displayed average nois e level o f the spectr um analyzer. Terminate

the spectrum analyzer input with a 50 Ω terminator to check the displayed average noise levels at 1 kHz,

10 kHz, 100 kHz, 1 MHz and the frequency at which the noise level is the maximum within the measurement bandwidth.

Specifications:

R3264:less than -100 dBm 10 kHz

less than -101 dBm 100 kHz

less than -125 dBm 1 MHz

less than -(130-2f) dBm 10 MHz to 3.5 GHz f: GHz

R3267: less than -90 dBm 1 kHz

less than -100 dBm 10 kHz

less than -101 dBm 100 kHz

less than -125 dBm 1 MHz

less than -(130-f) dBm 10 MHz to 3.5 GHz f: GHz

less than -125 dBm 3.5 GHz to 8 GHz

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.13 Displayed Average Noise Level

R3273: less than -90 dBm 1 kHz

less than -100 dBm 10 kHz

less than -101 dBm 100 kHz

less than -(130-f) dBm 10 MHz to 3.5 GHz f: GHz

less than -125 dBm 3.5 GHz to 7.5 GHz

less than -122 dBm 7.4 GHz to 15.4 GHz

less than -120 dBm 15.2 GHz to 22.0 GHz

less than -117 dBm 22.0 GHz to 26.5 GHz

RBW 100 Hz, VBW 1Hz, Input attenuator 0 dB settings

Instruments Required

Instruments QTY Recommended Model

50 Ω Terminator 1 RNA

Procedures:

Setup

1. Connect the RNA to the RF INPUT.

Initialization

2. Press SHIFT and CONFIG(PRESET).

NOTE: Skip to step 14 for the R3264.

Setting the measurement conditions

3. Press FREQ, 1 and kHz.

1-39

Page 50

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.13 Displayed Average Noise Level

4. Press SPAN and ZERO SPAN.

5. Press ATT, Min ATT ON/OFF(OFF), ATT AUTO/MNL(MNL), 0 and

GHz(dB).

6. Press LEVEL, 6, 0 and MHz(-dBm).

7. Press COUPLE, RBW AUTO/MNL(MNL), 3, 0 and Hz.

8. Press VBW AUTO/MNL(MNL), 1 and Hz.

9. Press SWP, Sweep Time Auto/MNL(MNL), 1 and MHz(sec).

Measurement the noise level, 100 Hz to 3.5 GHz Band

10. Press A, AVERAGE A, 1, 0 and Hz(ENTER).

11. Press SRCH, after the averaging has completed.

12. Record the level of the marker reading on the performance check sheet.

13. Press SHIFT and CONFIG(PRESET).

14. Press SPAN and ZERO SPAN.

15. Press ATT, Min ATT ON/OFF(OFF), ATT AUTO/MNL(MNL), 0 and

GHz(dB).

16. Press LEVEL, 6, 0 and MHz(-dBm).

17. Press COUPLE, RBW AUTO/MNL(MNL), 1, 0, 0 and Hz.

18. Press VBW AUTO/MNL(MNL), 1 and Hz.

19. Press SWP, Sweep Time AUTO/MNL(MNL), 1 and MHz(Sec).

20. Press A, Average A, 1, 0 and Hz(ENTR).

21. Press FREQ, 1, 0 and kHz.

22. Press SRCH, after the averaging has completed.

23. Record the level of the marker reading on the performance check sheet.

24. Repeat steps 21 through 23 for each frequency setting listed on Table 1-15.

1-40

Page 51

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.13 Displayed Average Noise Level

Table 1-15 Center Frequency Setting for Displayed Average Noise Level

Center frequency

100 kHz

1 MHz

10.1 MHz

101 MHz

501 MHz

1001 MHz

1.5 GHz

2.0 GHz

2.5 GHz

3.0 GHz

3.5 GHz

NOTE: Perform the measurement from step 25 onwards for the R3267 and R32 73 only.

25. Press SHIFT and CONFIG(PRESET).

26. Press FREQ, Start, 3, ., 5, 0, 1 and GHz.

27. Press Stop, 8 and GHz.

For the R3273, the stop frequency is set to 7.5 GHz.

28. Press ATT, Min ATT ON/OFF(OFF), ATT AUTO/MNL(MNL), 0 and

GHz(dB).

29. Press LEVEL, 4, 0 and GHz(-dBm).

30. Press COUPLE, RBW AUTO/MNL(MNL), 3 and MHz.

31. Press VBW AUTO/MNL (MNL), 1, 0, 0 and kHz.

32. Press A, AVERAGE A, 1, 0 and Hz(ENTER).

33. Press SRCH, after the averaging has completed.

34. Press MKR → and MKR → CF.

35. Press A and WRITE A.

36. Press SPAN and Zero Span.

37. Press LEVEL, 6, 0 and MHz(-dBm).

1-41

Page 52

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.13 Displayed Average Noise Level

38. Press COUPLE, RBW AUTO/MNL(MNL), 1, 0, 0 and Hz.

39. Press VBW AUTO/MNL (MNL), 1 and Hz.

40. Press SWP, Sweep Time AUTO/MNL(MNL), 1 and MHz(sec).

41. Press SINGLE.

42. Press SRCH, after the sweep has completed.

43. Record the level of the marker reading on the performance check sheet.

For R3273 only, Display Average noise level for remaining bands

44. Repeat steps 25 through 43 for each frequency setting listed on Table 1-16.

Table 1-16 Start and Stop Frequencies Setting

BAND Start frequency Stop frequency

7.5 GHz to 15.4 GHz 7.501 GHz 15.4 GHz

15.2 GHz to 22 GHz 15.201 GHz 22.0 GHz

22 GHz to 26.5 GHz 22.0 GHz 26.5 GHz

1-42

Page 53

1.2.14 Residual FM

This section explains how to check the residual FM of an internal local os cillator in Zero Span Mode. Connect a stable signal to the input and perform a slope detection in Zero Span Mode to measure the residual

FM. The residual FM is expressed as the product of the IF filter slope (Hz/dB) and the change in the measured signal amplitude.

Specifications:

less than 3 Hz × N

Instruments Required

Signal Generator 1 HP8663A

RF Cable SMA(m)-SMA(m) 1 A01002

RF Cable BNC(m)-BNC(m) 1 MI-09

Adapter N(m)-SMA(f) 2

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

/0.1 sec

P-P

Instruments QTY Recommended Model

1.2.14 Residual FM

Procedures :

Setup

1. Connect the signal generator as shown in Figure 1-10.

Figure 1-10 Setup for Measuring a Residual FM

Setting the signal generator

2. Set the HP8663A controls as follows:

Frequency: 2.5 GHz

Output level: -10 dBm

Initialization

3. Press SHIFT and CONFIG(PRESET).

1-43

Page 54

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.14 Residual FM

Setting the measurement conditions

Determining the IF filter slope

4. Press FREQ, 2, ., 5 and GHz.

5. Press SPAN, 1, 0, 0 and kHz.

6. Press SRCH.

7. Press MKR, more 1/2 and Signal Track ON/OFF(ON).

8. Press SPAN, 1 and kHz.

9. Press COUPLE, RBW AUTO/MNL(MNL), 3, 0 and Hz.

10. Press MKR and Signal Track ON/OFF (OFF).

11. Press LEVEL, 5, MHz(-dBm) , dB/div and 1 dB/div.

12. Press SPAN, 2, 0, 0 and Hz.

13. Press SRCH.

14. Press MKR → and MKR → REF.

15. Press SRCH.

16. Press MKR → and MKR → REF.

17. Press SINGLE.

18. Press MKR, more2/ 2, D e l t a Ma rk e r and Delta Marker ON/OFF (ON).

19. Rotate the data knob counter clockwise until the marker reads - 3 dB±0.1 dB.

20. Press MKR, Del ta Marker, Delta Mark er ON/OFF(ON) and rotate the data

knob counter clockwise until the marker reads -6 dB±0.1 dB.

21. Record the frequency and the level of the delta marker reading on the performance check sheet.

22. Calculate the Slope using the follo wing for mula and record the res ult on the performance check sheet.

1-44

Slope =

(the frequency of the delta marker reading)

(the level of the delta marker reading)

[Hz/dB]

Page 55

Measuring the Residual FM

23. Press SHIFT and MKR(OFF).

24. Press REPEAT.

25. Press SPAN and Zero Span.

26. Press COUPLE, VBW AUTO/MNL(MNL), 3, 0, 0 and Hz.

27. Press SWP, Sweep Time AUTO/MNL(MNL), 1, 0, 0 and kHz(ms).

28. Press FREQ and turn the data knob slowly counter-clockwise so that the trace

peak can be positioned to a level 6 divisions below the reference level.

29. Press SINGLE.

30. Press SRCH.

31. Press MKR, Delta Marker and Delta Marker ON/OFF(ON).

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.14 Residual FM

32. Press SRCH and Min Peak.

33. Record the level, ∆Level of the Delta Marker reading on the performance check

Calculation Residual FM

34. Calculate the residual FM using the following formula.

sheet.

Residual FM = Slope × ∆Level

[Hz] [Hz/dB] [dB]

1-45

Page 56

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.15 Residual Response

1.2.15 Residual Response

This section explains how to check the residual respo nse of a narrow frequency span and narrow reso lution

bandwidth using the display line. Connect a 50 Ω terminator to the spectrum analyzer input connector.

Specifications:

with no signal at input and 0 dB input attenuation

R3264

less than -100 dBm Range: 1 MHz to 3.5 GHz

less than - 90 dBm Range: 300 kHz to 3.5 GHz

R3267

less than -100 dBm Range: 1 MHz to 3.5 GHz

less than - 90 dBm Range: 300 kHz to 8 GHz

R3273

less than -100 dBm Range: 1 MHz to 3.5 GHz

less than - 90 dBm Range: 300 kHz to 26.5 GHz

Instruments Required

Instruments QTY Recommended Model

50 Ω Terminator 1 RNA

Procedures :

Initialization

1. Press SHIFT and CONFIG(PRESET).

Connecting calibration signal

2. Connect the BNC cable from the CAL OUT connector to the INPUT connector.

Checking the CALL OUT signal level

3. Press FREQ, 3, 0 and MHz.

4. press SPAN, 1, 0 and kHz.

5. Press LEVEL, 1, 0 and MHz(-dBm).

6. Press COUPLE, RBW AUTO/MNL(MNL), 3, 0, 0 and Hz.

7. Press ATT, Min ATT ON/OFF(OFF), ATT AUTO/MNL(MNL), 1, 0 and

GHz(dB).

1-46

8. press SRCH.

9. Check the marker level within -10.0dBm±0.3dB

Page 57

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

10. If the level is out of range, press SHIFT, 7(CAL) and Cal All.

Measurement the residual response on the 1 MHz to 3.5 GHz range

11. Connect the 50 Ω terminator to the input, after the calibration has completed.

12. Press FREQ, 1, ., 3 and MHz.

13. Press SPAN, 2 and MHz.

14. Press ATT, ATT AUTO/MNL(MNL), 0 and GHz(dB).

15. Press LEVEL, 5, 0 and MHz(-dBm).

16. Press COUPLE, RBW AUTO/MNL(MNL), 1, 0, and kHz.

17. Press VBW AUTO/MNL (MNL), 3, 0, 0 and Hz.

18. Press FREQ, CF St e p Si ze AUTO/MNL(MNL), 1, ., 9 and MHz.

1.2.15 Residual Response

19. Press FORMAT, Display Line ON/OFF(ON), 1, 0, 0 and MHz(-dBm).

20. Press SINGLE.

The noise level should be at least 3 dB below the display lin e. If is not, it will

necessary to reduce the Span and RBW setting to reduce the noise level. Set the

frequency step size to 95% or less of the frequency span.

21. If a residual is suspected, press SINGLE again. A residual response presist, but

a noise peak will not.

22. Record any frequency responses above the d isplay line on the perfor mance check

sheet.

23. If a response is marginal, verify the response amplitude as follows. If not, go to

step 34.

24. Press SHIFT, RCL(SAVE), 1 and Hz(ENTR).

25. Press REPEAT and MKR.

26. Move the marker to the trace peak using the data knob.

27. Press MKR → and MKR → CF.

28. Press COUPLE, RBW AUTO/MNL(MNL) and RBW AUTO/MNL(AUTO).

29. Press SPAN and to make the frequency span narrower until th e RBW is set

to 300 Hz.

30. Press SRCH.

1-47

Page 58

R3267 Series Spectrum Analyzer Operation Manual (Vol.2)

1.2.15 Residual Response

31. Press MKR → and MKR → CF.

32. Record any frequency responses above the d isplay line on the perfor mance check

sheet.

33. Press RCL, 1 and Hz(ENTR).

34. Press FREQ and .

35. Repeat steps 20 through 34 until a center frequency of 3.5 GHz is set.

NOTE: Perform the measurement from step 36 onwards for the R3267 and R3273 only.

Residual Response in a range between 3.5 GHz to 7.5 GHz

36. Press FREQ, 3, ., 5, 2, 5 and GHz.

37. Press SPAN, 5, 0 and MHz.

38. Press COUPLE, RBW AUTO/MNL(MNL), 3, 0, 0 and kHz.

39. Press VBW AUTO/MNL (MNL), 3, 0, 0 and Hz.

40. Press FREQ, CF St e p Si ze AUTO/MNL(MNL), 4, 7, ., 5 and MHz.

41. Press FORMAT, Display Line ON/OFF(ON), 9, 0 and MHz(-dBm).

42. Repeat steps 20 through 34 until a center frequency of 7.425 GHz is set.

1-48

Page 59

1.2.16 Gain Compression

This section explains how to check the gain compression. The gain compression is measured as follows:

two signals with a difference of 1 MHz are merged using a power splitter.