Advantech ADAM CPU 821 NET, ADAM CPU 821 DP, ADAM CPU 821 DPM, ADAM CPU 8214, ADAM CPU 8215 Series Manual

...Page 1

CPU ADAM 821x Chapter 1 Principles

Chapter 1 Principles

Outline

Contents

This introduction contains references on the handling and information about

application areas and usage of the CPU modules.

It also provides certain suggestions on the approach when programming

the module and the CPU specifications that are important in this respect.

Below follows a description of:

• Safety information for users

• Construction and operation of the CPU 821x

• Programming principles

Topic Page

Chapter 1 Principles ............................................................................... 1-1

Safety information for users................................................................... 1-2

Hints for the deployment of the MPI interface........................................ 1-3

Hints for the deployment of the Green Cable ........................................ 1-4

Overview System 82xx .......................................................................... 1-5

General description of the System 82xx................................................ 1-6

Overview CPU 821x .............................................................................. 1-7

Hints for project engineering.................................................................. 1-8

Application fields.................................................................................. 1-11

Features .............................................................................................. 1-12

Operating modes of a CPU.................................................................. 1-13

CPU 821x programs ............................................................................ 1-14

CPU 821x operands ............................................................................ 1-14

ADAM 8000 Manual CPU 821x – Rev 1.1 1-1

Page 2

Chapter 1 Principles CPU ADAM 821x

Safety information for users

Handling of

electrostatically

sensitive modules

Shipping of

modules

ADAM modules make use of highly integrated components in MOStechnology. These components are extremely sensitive to over-voltages

that may occur during electrostatic discharges.

The following symbol is attached to modules that can be destroyed by

electrostatic discharges:

The symbol is located on the module, the module rack or on packing

material and it indicates the presence of electrostatically sensitive

equipment.

It is possible that electrostatically sensitive equipment is destroyed by

energies and voltages that are far less than the human threshold of

perception. These voltages may occur where persons do not discharge

themselves before handling electrostatically sensitive modules and they

may damage components thereby causing the module to become

inoperable or unusable. Modules that have been damaged by electrostatic

discharge are usually not detected immediately. The respective failure may

become apparent after a period of operation.

Components damaged by electrostatic discharges can fail after a

temperature change, mechanical shock or changes in the electrical load.

Only the consistent implementation of protective devices and meticulous

attention to the applicable rules and regulations for handling the respective

equipment is able to prevent failures of electrostatically sensitive modules.

Please ship the modules exclusively in the original packing material.

Measurements

and alterations on

electrostatically

sensitive modules

1-2 ADAM 8000 Manual CPU 821x – Rev 1.1

When you are conducting measurements on electrostatically sensitive

modules you should take the following precautions:

• Floating instruments must be discharged before use.

• Instruments must be grounded.

You should only use soldering irons with grounded tips when you are

making modifications on electrostatically sensitive modules.

Attention!

Personnel and instruments should be grounded when working on

electrostatically sensitive modules.

Page 3

CPU ADAM 821x Chapter 1 Principles

Hints for the deployment of the MPI interface

2

What is MP

I?

Deployment as

MP interface

The MP

2

I jack combines 2 interfaces in 1:

• MP interface

• RS232 interface

Please regard that the RS232 functionality is only available by using the

Green Cable from Advantech.

The MP interface provides the data transfer between CPUs and PCs. In a

bus communication you may transfer programs and data between the

CPUs interconnected via MPI.

Connecting a common MPI cable, the MPI jack supports the full MPI

functionality.

Important notes for the deployment of MPI cables!

Deploying MPI cables at the ADAM CPUs from Advantech, you have to

make sure that Pin 1 is not connected. This may cause transfer problems

and in some cases damage the CPU!

Especially Profibus cables from Siemens, like e.g. the 6XV1 830-1CH30,

must not be deployed at MP

2

I jack.

For damages caused by nonobservance of these notes and at improper

deployment, ADAM does not take liability!

Deployment as

RS232 interface only

via "Green Cable"

For the serial data transfer from your PC, you normally need a MPI

transducer. Fortunately you may also use the "Green Cable" from

Advantech You can order this under the order no. ADAM-8950-0KB00.

The "Green Cable" supports a serial point-to-point connection for data

transfer via the MP

2

I jack exclusively for ADAM 8xxx CPUs.

Please regard the hints for the deployment of the "Green Cable" on the

following page.

ADAM 8000 Manual CPU 821x – Rev 1.1 1-3

Page 4

Chapter 1 Principles CPU ADAM 821x

Hints for the deployment of the Green Cable

What is the

Green Cable?

The Green Cable is a green connection cable, manufactured exclusively for

the deployment at ADAM System components.

The Green Cable is a programming and download cable for ADM CPUs

8xxx and ADAM fieldbus masters. The Green Cable from Advantech is

available under the order no. ADAM-8950-0KB00.

The Green Cable allows you to:

• transfer projects serial

Avoiding high hardware needs (MPI transducer, etc.) you may realize a

serial point-to-point connection via the Green Cable and the MP

This allows you to connect components to your ADAM CPU that are able

to communicate serial via an MPI adapter like e.g. a visualization

system.

• execute firmware updates of the CPUs and fieldbus masters

Via the Green Cable and an upload application you may update the

firmware of all recent CPUs 8xxx and certain fieldbus masters (see

Note).

Important notes for the deployment of the Green Cable

Nonobservance of the following notes may cause damages on system

components.

For damages caused by nonobservance of the following notes and at

improper deployment, Advantech does not take liability!

2

I jack.

Note to the application area

The Green Cable may exclusively deployed directly

1-4 ADAM 8000 Manual CPU 821x – Rev 1.1

of the ADAM components (in between plugs are not permitted).

At this time, the following components support the Green Cable:

CPUs 8xxx and the fieldbus masters ADAM 8208-1xx01 from Advantech.

Note to the lengthening

The lengthening of the Green Cable with another Green Cable res. The

combination with further MPI cables is not permitted and causes damages

of the connected components!

The Green Cable may only be lengthened with a 1:1 cable (all 9 Pins are

connected 1:1).

at the concerning jacks

Page 5

CPU ADAM 821x Chapter 1 Principles

Overview System 82xx

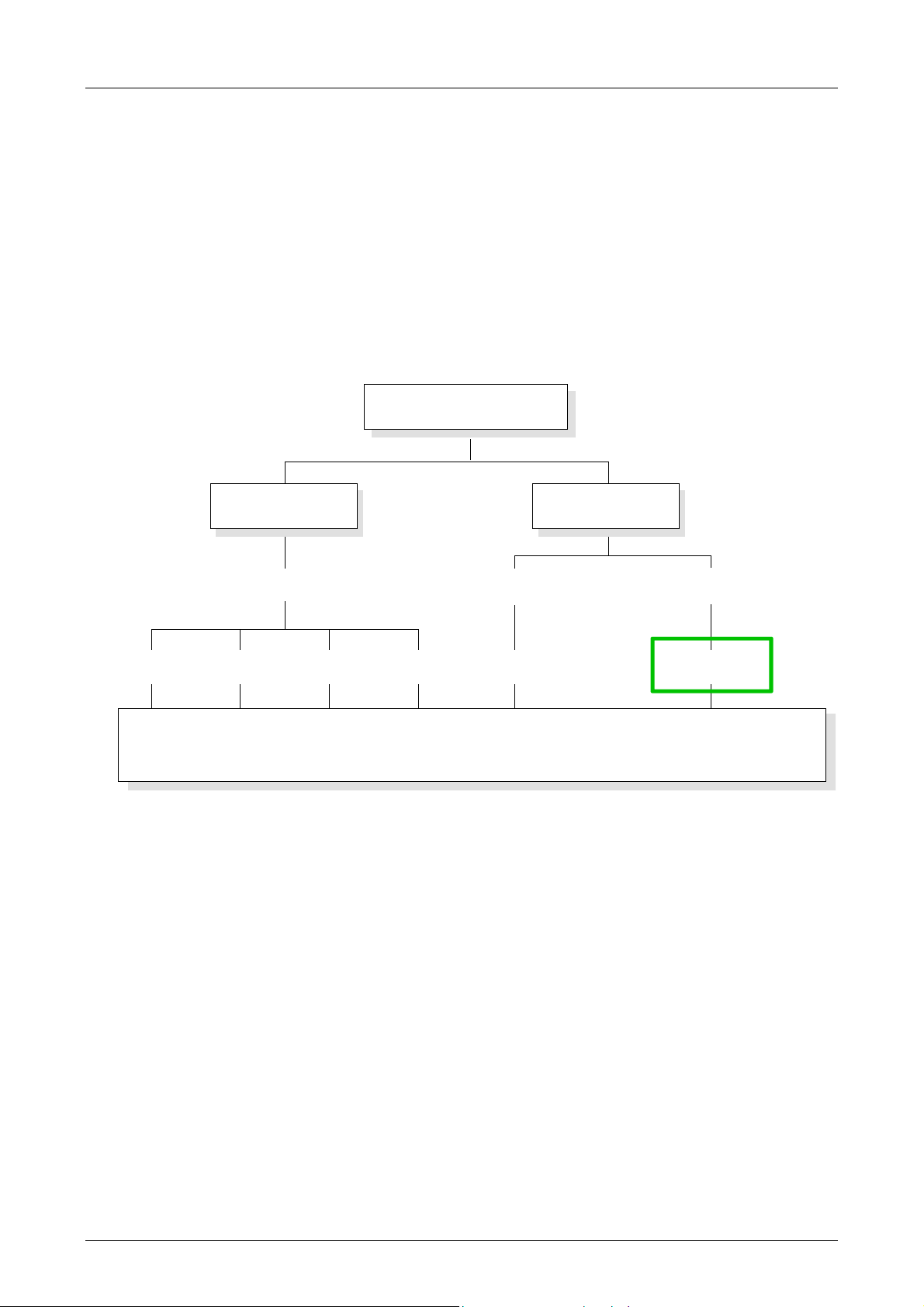

The System 82xx

The System 82xx is a modular automation system for low and middle range

of performance that you may use either centralized or decentralized. The

single modules are directly clipped to a 35mm DIN rail and are connected

together with the help of special bus clips.

The following picture shows the range of performance of the System82xx:

System 8000

decentral

DP 8xxx

Profibus DeviceNet CAN Interbus PC-CPU PLC-CPU

on demand

on demand

PC 8xxx

central

PLC 8xxx

for STEP®7 of Siemens

Overview

Manuals

peripheral

Dig. IN / Dig. OUT / Anal. IN / Anal. OUT / FM / CP

The current manual describes the PLC-CPU family CPU 821x compatible to

STEP

The peripheral modules, PCs and decentralized peripheral equipment are

to find in the manual HB97 "System82xx". This manual also contains hints

for installation and commissioning of the System82xx.

7 by Siemens.

ADAM 8000 Manual CPU 821x – Rev 1.1 1-5

Page 6

Chapter 1 Principles CPU ADAM 821x

General description of the System 82xx

Structure /

Dimensions

Installation

• Norm profile head rail 35mm

• Peripheral modules with labeling strip

• Measurements basic module:

Single width: (HxWxD) in mm: 76x25.4x76; in inches: 3x1x3

Double width: (HxWxD) in mm: 76x50.8x76; in inches: 3x2x3

Please note, that you have to plug in the CPU only at plug-in location 1

resp. 1 and 2 (if double width).

1

2

3

[1] CPU if double width

[2] CPU single width

[3] peripheral modules

[4] leading bars

D

V

I

M

E

M

O

ER

R

Y

RD

D

K

DE

P

B

D

NET

X2

X2

34

34

ADAM-8216-2BP01

VIPA 288-2BL10

4

IM 253 CAN

CPU 8216

PW

R

ER

S

RD

BA

PW

SF

FC

MC

ADR.

DC24V

+

DC

+

24V

-

X5

-

X2

67

34

VIPA 253-1CA00

ADAM-8216-2BA01

PC 288

CPU 8216 DP

R

PW

S

RN

BA

PW

SF

FC

M

O

MC

U

S

E

OFF

D

DC

+

C

+

24V

24

-

-

V

MMC

01

MMC

RN

ST

MR

M

2

P

I

X1

1

1

2

2

RN

C

ST

O

MR

M

1

M

2

P

I

ON

X1

1

2

SM 8221

DI 8xDC24V

.0

.1

.2

.3

.4

.5

.6

.7

X2

34

ADAM-8221-1BF00

SM 8221

DI 8xDC24V

.0

.1

.2

.3

.4

.5

.6

.7

X2

34

ADAM-8221-1BF00

SM 8221

DI 8xDC24V

1

.0

2

.1

3

.2

4

.3

5

.4

6

.5

7

.6

8

.7

9

I0

X2

34

ADAM-8221-1BF00

SM 8221

DI 8xDC24V

1

.0

2

.1

3

.2

4

.3

5

.4

6

.5

7

.6

8

.7

9

I0

X2

34

ADAM-8221-1BF00

SM 8221

DI 8xDC24V

1

.0

2

.1

3

.2

4

.3

5

.4

6

.5

7

.6

8

.7

9

I0

X2

34

ADAM-8221-1BF00

SM 8221

DI 8xDC24V

1

.0

2

.1

3

.2

4

.3

5

.4

6

.5

7

.6

8

.7

9

I0

X2

34

ADAM-8221-1BF00

SM 8221

DI 8xDC24V

1

.0

2

.1

3

.2

4

.3

5

.4

6

.5

7

.6

8

.7

9

I0

X2

34

ADAM-8221-1BF00

SM 8221

DI 8xDC24V

1

.0

2

.1

3

.2

4

.3

5

.4

6

.5

7

.6

8

.7

9

I0

X2

34

ADAM-8221-1BF00

1

2

3

4

5

6

7

8

9

I0

1

2

3

4

5

6

7

8

9

I0

Operating security

• Plug in via CageClamps at the front-facing connector, core cross-section

0.08...2.5mm

2

resp. 1.5 mm2 (18pin plug)

• Total isolation of the cables during module changes

• Potential separation of all modules to the backplane bus

• EMC-proof ESD/Burst acc. EN61000-4-2/EN61000-4-4

to Level 3: 8kV/2.5kV

• Shock resistance acc. IEC 60068-2-6 / IEC 60068-2-27 (1G/12G)

Environmental

conditions

• Operating temperature: 0... +55°C

• Storage temperature: -40... +85°C

• Relative humidity: 95% without condensation

• fan-less operation

1-6 ADAM 8000 Manual CPU 821x – Rev 1.1

Page 7

CPU ADAM 821x Chapter 1 Principles

Overview CPU 821x

Products

Performance

specification

Data CPU 8214 CPU 8215 CPU 8216

RAM 40kByte 80kByte 192kByte

Load memory 32kByte 64kByte 128kByte

Cycle time, bit/word operations 0.18µs / 0.78µs

Bit memory/marker 2048Bit (M0.0...M255.7)

Timer 128 (T0...T127)

Counter 256 (Z0...Z255)

Number of blocks FB / FC / DB 1024 / 1024 / 2047

Total addressing space

inputs / outputs

PA Inputs 1024Bit (E0.0...E127.7)

PA Outputs 1024Bit (A0.0...A127.7)

Order data

CPU 21x ADAM-8214-1BA01 ADAM-8215-1BA01 ADAM-8216-1BA01

CPU 21xNET ADAM-8214-2BT01 ADAM-8215-2BT01 ADAM-8216-2BT01

CPU 21xDPM ADAM-8214-2BM01 ADAM-8215-2BM01 ADAM-8216-2BM01

CPU 21xDP ADAM-8214-2BP01 ADAM-8215-2BP01 ADAM-8216-2BP01

General

information

The ADAM CPU 821x is available in four different versions also differing in

view:

• CPU 821x PLC-CPU

• CPU 821xNET PLC-CPU with Ethernet interface

• CPU 821xDPM PLC-CPU with Profibus-DP master

• CPU 821xDP PLC-CPU with Profibus-DP slave

Every CPU 821x is available in 3 CPU performance specifications: 214,

215 and 216. There is no visual difference between these units. The

performance of the CPU 821x increases along with an increase of the

number.

1024 / 1024 with 128Byte process image (PA) each

Note!

If not especially specified, the information in this manual refers to all the

CPUs of the ADAM CPU 821x family!

The instruction set of the CPU 821x is compatible with STEP

and is being configured by means of the Siemens STEP

7 of Siemens

7 manager. A

large function library is included with the CPU.

The CPU employs a Multi Media Card (MMC) as external storage medium.

The MMC is available from Advantech.

The project engineering of the Ethernet components takes place by means

of the ADAM project configuration tool WinNCS. The data may be

transferred into the CPU via MPI.

The CPU 821x has an integrated power supply that requires DC 24V via

the front panel. It is protected against reverse polarity and short circuits.

ADAM 8000 Manual CPU 821x – Rev 1.1 1-7

Page 8

Chapter 1 Principles CPU ADAM 821x

Hints for project engineering

Outline

Preconditions

For the project engineering of the CPU 821x and the other System 82xx

modules connected to the same bus, you use the hardware configurator

from Siemens.

To address the directly plugged peripheral modules, you have to assign a

special address in the CPU to every one.

The address allocation and the parameterization of the modules takes

place in the STEP

7 manager from Siemens in form of a virtual Profibus

system. For the Profibus interface is standardized software sided, the

functionality is guaranteed by including a GSD-file into the STEP

7

manager from Siemens.

Transfer your project into the CPU via the MPI interface.

For the project engineering of your CPU 821x the following requirements

have to be fulfilled:

• STEP

7 manager from Siemens is installed at your PC resp. PU.

• The GSD-file for the System 82xx is included to the hardware

configurator

• serial connection to the CPU (e.g. via "Green Cable")

Note!

The configuration of the CPU requires a thorough knowledge of the

Siemens STEP

7 manager and the hardware configurator!

Compatibility to

STEP

7 manager

from Siemens via

GSD-file

®

The CPU 821x is configurable via the STEP7

manager from Siemens.

This means the programming and parameterization of a System ADAM

82xx and the parameterization and project engineering under Profibus-DP.

The project engineering of a CPU 821x takes place via the STEP

®

7 manager from Siemens in form of a virtual Profibus system with the CPU 3152DP as basic.

Due to the standardized Profibus interface ADAM is able to support the

complete functionality of the System 82xx family in the STEP

®

7 manager

from Siemens by including a GSD-file.

To be compatible with the STEP7 configuration tool from

Siemens, the following steps have to take place:

• Project the Profibus-DP master system with CPU 315-2DP

(6ES7 315-2AF01).

• Add Profibus slave with address 1.

• Include the CPU 821x at slot 0 of the slave system.

1-8 ADAM 8000 Manual CPU 821x – Rev 1.1

Page 9

CPU ADAM 821x Chapter 1 Principles

Project

engineering

CPU 821x with

central periphery

The following steps are necessary to project a CPU 821x in the hardware

configurator from Siemens:

• Start the hardware configurator from Siemens

• Load the delivered ADAM GSD-file from Advantech

• Create a Profibus-DP master system with the CPU 315-2DP

• Include the slave system "ADAM_DP8000" from the hardware catalog in

your master system. You find this slave system in the hardware catalog

under Profibus-DP > Additional field devices > I/O > ADAM

• Assign the address 1 to your slave system, so that the CPU is able to

recognize the system as central periphery system

• Add your modules to the slave system in the same order you have

assembled them. Start with the CPU at plug-in location 0

• Include your System 82xx modules starting at plug-in location 1

CPU 821x

DP200V

Slot Module

PBAdr.:2

PBAdr.:1

Master projecting

of the CPU

821xDPM

0 821x-xxxx

1

. Expansion

. modules

.

3

When projecting a CPU 821xDPM you include the central modules like

described above. Slave systems that shall be connected to the master are

added to the already existing master system:

CPU 821xDPM central

DP slaves decentral ...

ADAM 821x ADAM821xDP

PBAdd.:2

PBAdd.:1

DP200V

Slot M odule

0 821x-2BM0 1

1

. ce ntral

. pe riphery

.

32

DP200V

PBAdr.:3 ... 12 5

ADAM 8000 Manual CPU 821x – Rev 1.1 1-9

Page 10

Chapter 1 Principles CPU ADAM 821x

Project

engineering of the

CPU 821xDP in a

master system

Master system

When configuring a CPU 821xDP, the central plugged-in modules are

parameterized like shown above.

Slave parameterization

As intelligent slave, the Profibus section maps its data areas into the

memory area of the CPU 821xDP. The assignment of the areas is fixed via

the propierties of the CPU 821xDP. These areas have to be provided with

an according PLC program.

Attention!

The length values of input and output area have to be identical to the byte

values of the master project engineering. Otherwise no Profibus communication is possible (slave failure).

Steps of project engineering in the DP master

• Configure the CPU with DP master system (address 2)

• Add Profibus slave 821xDP (GSD-file required)

• Assign Profibus input and output area starting with plug-in location 0

The following picture illustrates the project engineering:

Slave System

PBAddr.:2

Slot Module

0 Output (Bytes)

1 Input (Bytes)

Master projecting

of the CPU

821xNET

CPU21x

PBAddr.:3

PBAddr.:1

Slot Module

0 CPU 821xDP

1

. Expansion

. modules

.

3

The project engineering of network connections via TCP/IP takes place via

the configuration tool WinNCS from Advantech.

DP200V

1-10 ADAM 8000 Manual CPU 821x – Rev 1.1

Page 11

CPU ADAM 821x Chapter 1 Principles

Application fields

This series of CPU modules provides access to the peripheral modules of

the ADAM System 8xxx. You can use a set of standard commands and

programs to interrogate sensors and actuators. One single CPU may

address a maximum of central 32 modules.

Application

example

Compact centralized configuration

CPU

AI 4 AO 4 DIO 8 DO 16

CPU 21x

DO 8 Count

Decentralized configuration using Profibus

CPU IM 208

1,3

IM 253

Input/output periphery

1

CPU IM 208

2,4

IM 253

Input/output periphery

4

IM 253

Input/output periphery

2

CPU IM 208

Input/output periphery

5

CPU 21x DP

Input/output periphery

3

CPU 21x DP

Input/output periphery

5

ADAM 8000 Manual CPU 821x – Rev 1.1 1-11

Page 12

Chapter 1 Principles CPU ADAM 821x

Application based on TCP/IP or H1

Visualization and

shop floor data collection

via DDE-server

H1 / TCP/IP

TCP/IP/H1

Hub

Features

System 82xx

CPU 821x NET

System 82xx

H1 / TCP/IP

CPU 821x NET

The PLC-CPUs are employed as program executor.

They support the input/output modules and process the data from the

function modules.

• Quick programming due to the compatibility with Siemens STEP

7.

• The compact construction requires less space.

• Enhanced flexibility provided by up to 32 function modules (DIG I/O,

ANA I/O, SSI, pulse counter, communication modules, etc.).

• Additional function modules can be added quickly and easily by means

of plug-in bus extension options.

• User-friendly maintenance using a PC via MPI.

• Optional Ethernet or Profibus interface.

1-12 ADAM 8000 Manual CPU 821x – Rev 1.1

Page 13

CPU ADAM 821x Chapter 1 Principles

Operating modes of a CPU

General

Cyclic processing

Timer processing

These CPUs are intended for small and medium sized applications and are

supplied with an integrated 24V power supply. The CPU contains a

standard processor with internal program memory. In combination with the

System 82xx peripherals the unit provides a powerful solution for process

automation applications within the System 82xx family.

A CPU supports the following modes of operation:

• cyclic processing

• timer processing

• alarm controlled processing

• priority based processing

Cyclic processing represents the major portion of all the processes that are

executed in the CPU. Identical sequences of operations are repeated in a

never ending cycle.

Where a process requires control signals at constant intervals you can initiate

certain operations based upon a timer, e.g. not critical monitoring functions

at one-second intervals.

Alarm controlled

operation

Priority based

processing

If a process signal requires a quick response you would allocate this signal

to an alarm controlled procedure. An alarm may activate a procedure in

your program.

The above processes are handled by the CPU in accordance with their

priority. Since a timer or an alarm event requires a quick reaction the CPU

will interrupt the cyclic processing when these high-priority events occur to

react to the event. Cyclic processing will resume once the reaction has

been processed. This means that cyclic processing has the lowest priority.

ADAM 8000 Manual CPU 821x – Rev 1.1 1-13

Page 14

Chapter 1 Principles CPU ADAM 821x

CPU 821x programs

Overview

System routine

User program

The program that is present in every CPU is divided as follows:

• System routine

• User program

The system routine organizes all those functions and procedures of the

CPU that are not related to a specific control application.

This consists of all the functions that are required for the processing of a

specific control application. The operating modules provide the interfaces to

the system routines.

CPU 821x operands

Overview

The following operands are available for programming the CPU 821x:

• Process image and periphery

• Bit memory/marker

• Timers and counters

• Data blocks

Process image

and periphery

1-14 ADAM 8000 Manual CPU 821x – Rev 1.1

The user program can quickly access the process image of the inputs and

outputs PAA/PAE. You may manipulate the following types of data:

- individual bits

- bytes

- words

- double words

You may also gain direct access to peripheral modules via the bus from

your user program. The following types of data are available:

- bytes

- words

- blocks

Page 15

CPU ADAM 821x Chapter 1 Principles

Bit memory

Timer and counter

Data blocks

Bit memory is an area of memory that is accessible to the user program by

means of certain operations. Bit memory is intended to store frequently

used working data.

You may access the following types of data:

- individual bits

- bytes

- words

- double words

With your program you may load a time cell with a value between 10ms and

9990s. As soon as the user program executes a start operation the value of

this timer is decremented by the interval that you have specified until it

reaches zero.

You may load counter cells with an initial value (max. 999) and increment

or decrement this when required.

A data block contains constants or variables in form of bytes, words or

double words. You may always access the current data block by means of

operands.

You may access the following types of data:

- individual bits

- bytes

- words

- double words

ADAM 8000 Manual CPU 821x – Rev 1.1 1-15

Loading...

Loading...