Page 1

ADAM 4000

Data Acquisition Modules

User's Manual

Page 2

ADAM 4000 Series

Data Acquisition Modules

User’s Manual

Copyright Notice

This document is copyrighted, 1997, by Advantech Co., Ltd. All rights are

reserved. Advantech Co., Ltd., reserves the right to make improvements to the

products described in this manual at any time without notice.

No part of this manual may be reproduced, copied, translated or transmitted in

any form or by any means without the prior written permission of Advantech Co.,

Ltd. Information provided in this manual is intended to be accurate and reliable.

However, Advantech Co., Ltd. assumes no responsibility for its use, nor for any

infringements upon the rights of third parties, which may result from its use.

CE Notification

The ADAM-4000 series developed by Advantech Co., Ltd. has passed the CE

test for environmental specifications when operated within an industrial enclosure

(ADAM-4950-ENC). Therefore, in order to protect the ADAM modules from

being damaged by ESD (Electric Static Discharge), we strongly recommend that

the use of CE-compliant industrial enclosure products when using any ADAM

module.

Acknowledgments

ADAM is a trademark of Advantech Co., Ltd.

IBM and PC are trademarks of International Business

Machines Corporation.

Edition 10.7

May 2008

Page 3

Table of Contents

Chapter 1 Introduction ..….....……..................…..................…….. 1-1

1.1 Overview .......................…................................….........….…… 1-2

1.2 Applications ..................….........................…….............…....... 1-4

Chapter 2 Installation Guideline ...................….................…... .... 2-1

2.1 System Requirements to set up an ADAM network ..…....... 2-2

2.2 Basic configuration and hook-up ....................……............... 2-6

2.3 Baud rate and Checksum .................................……............... 2-9

2.4 Multiple Module Hookup ...............................………............... 2-11

2.5 Programming Example.....................................……................ 2-12

Chapter 3 I/O Modules ..................................................…............. 3-1

3.1 ADAM-4011/4011D Thermocouple Input Modules ...…......... 3-3

3.2 ADAM-4012 Analog Input Module ………………..…............... 3-10

3.3 ADAM-4013 RTD Input Modules .......………………….…….... 3-15

3.4 ADAM-4015 6-channel RTD Input Module .…………….......... 3-17

3.5 ADAM-4015T 6-channel Thermistor Input Module ....…........ 3-20

3.6 ADAM-4016 Analog Input/Output Module....………….…....... 3-22

3.7 ADAM-4017/4017+/4018/4018M/4018+ 8-channel Analog Input

Modul es ........……………………………………………………..... 3-27

3.8 ADAM-4019+ 8-channel Universal Analog Input

Module ..................................................................................... 3-37

3.9 ADAM-4021 Analog Output Module ........................…........... 3-41

3.10 ADAM-4024 4-channel Analog Output Module ................... 3-44

3.11 ADAM-4050 Digital I/O Module ……………………………..... 3-47

3.12 ADAM-4051 16-channel Isolated Digital Input Module ..…. 3-49

3.13 ADAM-4052 Isolated Digital Input Module ……………..…... 3-51

3.14 ADAM-4053 16-channel Digital Input Module …..……..…... 3-53

3.15 ADAM-4055 16-channel Isolated Digital I/O Module ……... 3-56

3.16 ADAM-4056S 12-channel Sink Type Isolated Digital Output

Module …………………………………………………….……..... 3-61

Page 4

3.17 ADAM-4056SO 12-ch. Source Type Isolated Digital Output

Module ………….…………………………………………..……... 3-63

3.18 ADAM-4060/4068 Relay Output Module ................…........... 3-65

ADAM-4069 8-channel Relay Output Module ………………. 3-69

3.19

3.20 ADAM-4080/4080D Counter/Frequency Input Modules ….. 3-72

Chapter 4 Command Set ..................................................…......... 4-1

4.1 Introduction.................................................................….......... 4-2

4.2 Syntax .........................................................................….......... 4-2

4.3 I/O Module Commands Search Table ......................….......... 4-4

Chapter 5 Analog Input Module Command Set ........….............. 5-1

5.1 Analog Input Command Set ................................……............ 5-2

5.2 Analog Input Data Logger Command Set ............….…......... 5-34

5.3 Digital I/O, Alarm and Event Command Set ......………......... 5-47

5.4 Excitation Voltage Output Command Set ............…….......... 5-61

Chapter 6 AO commands......................................... .........…......... 6-1

6.1 Analog Output Module Command for ADAM-4021…............ 6-2

6.2 Analog Output Module Command for ADAM-4024...…......... 6-19

Chapter 7 Digital IO, Relay & Counter commands.........…......... 7-1

7.1 Configuration, Counter Input and Display Command Set ... 7-2

7.2 Counter/Frequency Module Command.................................. 7-28

7.2.1 Configuration, Counter Input and Display Command Set…... 7-28

7.2.2 Counter Setup Command Set................................................... 7-40

7.2.3 Digital Filter and Programmable Threshold Command Set….7-49

7.2.4 Digital Output and Alarm Command Set.................................. 7-60

Page 5

Chapter 8 Calibration .............................. .............…..................... 8-1

8.1 Analog Input Module Calibration ............................…........... 8-2

8.2 Analog Input Resistance Calibration .................................... 8-5

8.3 Analog Input Thermistor module Calibration ....................… 8-7

8.4 Analog Output Calibration ..................................................... 8-13

Appendix A Technical Specifications..............................…......... A-1

A.1 ADAM-4011 Thermocouple Input Module ................…......... A-2

A.2 ADAM-4011D Thermocouple Input Module with LED

Display .......................................................................……...... A-5

A.3 ADAM-4012 Analog Input Module ......................................... A-8

A.4 ADAM-4013 RTD Input Module ......................................….... A-10

A.5 ADAM-4016 Strain Gauge Input Module .....................…...... A-12

A.6 ADAM-4017/4017+ 8-Channel Analog Input Module ..…..... A-14

A.7 ADAM-4018/4018+ 8-channel Analog Input Module ...…..... A-16

A.8 ADAM-4018M 8-channel Analog Input Data Logger ....…... A-19

A.9 ADAM-4019+ 8-channel Universal Analog Input Module A-22

A.10 ADAM-4021/4024 Analog Output Module ........................... A-24

A.11 ADAM-4050 Digital I/O Module.................................…......... A-28

A.12 ADAM-4051/4052 Isolated Digital Input Module ................. A-30

A.13 ADAM-4053 16-channel Digital Input Module ............…..... A-32

A.14 ADAM-4055 16-channel Digital I/O Module ............…......... A-34

A.15 ADAM-4056S 12-channel Sink Type Isolated Digital Output

Module .......…………………………………………………...….. A-36

A.16 ADAM-4056SO 12-channel Source Type Isolated Digital Output

Module ........……………………………………………….…...... A-38

A.17 ADAM-4060 Relay Output Module........................................ A-40

A.18 ADAM-4068/4069 8-channel Relay Output Module ............ A-42

A.19 ADAM-4080 Counter/Frequency Input Module ................... A-44

A.20 ADAM-4080D Counter/Frequency Input Module with LED

Display …................................................................................ A-46

Appendix B Data Formats and I/O Ranges ..................…............ B-1

B.1 Analog Input Formats.............................................…............. B-2

Page 6

B.1.1 Engineering Units .............................................................…….......... B-2

B.1.2 Percent of FSR .................................................................…............. B-3

B.1.3 Twos complement hexadecimal .....................................……............ B-4

B.1.4 Ohms ..............................................................................……............ B-5

B.2 Analog Input Ranges.............................................….............. B-6

B.3 Analog Output Formats ..............................................…........ B-11

B.3.1 Engineering Units ............................................................………........ B-11

B.3.2 Percent of Span ........................................................…….................. B-11

B.3.3 Hexadecimal ............................................................………............... B-11

B.4 Analog Output Ranges .......................................…................ B-12

Appendix C Technical Diagrams .................................…............. C-1

C.1 ADAM Dimensions ..............................................…................ C-2

C.2 Installation .............................................................….............. C-3

C.2.1 DIN-Rail Mounting ......................................................…...….............. C-3

C.2.2 Panel Mounting .............................................................…….............. C-5

C.2.3 Piggyback Stack ....................................................….....…................. C-7

Appendix D Utility Software .................................…..................... D-1

D.1 ADAM-4000 Utility Software ......................…......................... D-2

D.2 The procedure for ADAM-4000 series installation guide…..D-6

Appendix E RS-485 Network .............................…........................ E-1

E.1 Basic Network Layout ................................…......................... E-3

E.2 Line Termination .........................................…........................ E-5

E.3 RS-485 Data Flow Control ..................................................... E-7

Appendix F How to use the Checksum feature ..........…............ F-1

F.1 Checksum Enable/Disable ......................................…............ F-2

Appendix G ADAM-4000 I/O Modbus Mapping Table ....…......... G-1

Appendix H Changing Configuration to Modbus Protocol ....... H-1

Page 7

Introduction 1

Page 8

Introduction

1.1 Overview

The ADAM Series is a set of intelligent sensor-to-computer

interface modules containing built-in microprocessor. They are

remotely controlled through a simple set of commands issued in ASCII

format and transmitted in RS-485 protocol. They provide signal

conditioning, isolation, ranging, A/D and D/A conversion, data

comparison, and digital communication functions. Some modules

provide digital I/O lines for controlling relays and TTL devices.

Software Configuration and Calibration

By merely issuing a command from the host computer, you can

change an analog input module to accept several ranges of voltage input,

thermocouple input or RTD input. All of the module’s configuration

parameters including I/O address, communication speed, HI and LO

alarm, calibration parameters settings may be set remotely. Remote

configuration can be done by using either the provided menu-based

software or the command set’s configuration and calibration commands.

By storing configuration and calibration parameters in a nonvolatile

EEPROM, modules are able to retain these parameters in case of power

failure.

Watchdog Timer

A watchdog timer supervisory function will automatically reset the

ADAM modules in the event of system failure. Maintenance is thus

simplified.

Power Requirements

Although the modules are designed for standard industrial

unregulated 24 V

supplies power within the range of +10 to +30 V

power supply, they accept any power unit that

DC

. The power supply

DC

ripple must be limited to 5 V peak-to-peak, and the immediate ripple

voltage should be maintained between +10 and +30 V

DC

.

Connectivity and Programming

ADAM modules can connect to and communicate with all computers

and terminals. They use RS-485 transmission standards, and

communicate with ASCII format commands. The command set for

every module type consists of approximately ten different commands.

1-

2

ADAM 4000 Series User’s Manual

Page 9

Chapter 1

The command set for input modules is larger because it incorporates

alarm functions. All communications to and from the module are

performed in ASCII, which means that ADAM modules can be

virtually programmed in any high-level language.

RS-485 Network

The RS-485 network provides lower-noise sensor readings, as

modules can be placed much closer to the source. Up to 256 ADAM

modules may be connected to an RS-485 multi-drop network by using

the ADAM RS-485 repeater which extends the maximum

communication distance up to 4,000 ft. The host computer is connected

to the RS-485 network with one of its COM ports through the ADAM452x module (RS-232 to RS-422/485 converter).

To boost the network’s throughput, ADAM RS-485 repeater uses a

logical RTS signal to manage the repeater’s direction. The only two

wires that are needed for the RS-485 network, DATA+ and DATA-, are

inexpensive shielded twisted pair.

Panel/DIN Rail mounting

Chapter 1 Introduction 1

-3

Page 10

Introduction

ADAM modules can be mounted on any panels, brackets, or DIN

rails. They can also be stacked together.

The RS-485 network, together with screw-terminal plug connectors,

allows for system expansion, reconfiguration, and repair without

disturbing field wiring.

Protection against the environment

Since all the configurations are controlled by software, the

protection provided by the packaging is very important. The plastic

outer shell enhances resistance against corrosive materials, moistures

and vibrations. ADAM modules’ low power requirements help them to

operate in temperatures from 0 to 70 ℃

(non-condensing). They are compactly built using automated SMT

technology. Therefore, they can be implemented in water-tight and

explosion-proof industrial enclosures.

1.2 Applications

• Remote data acquisition

• Process monitoring

• Industrial process control

• Energy management

• Supervisory control

• Security systems

• Laboratory automation

• Building automation

• Product testing

• Direct digital control

and in humidity from 0 to 95%

,

1-

4

ADAM 4000 Series User’s Manual

Page 11

Installation Guideline 2

Page 12

Installation Guideline

This chapter provides guidelines to what is needed to set up and

install an ADAM network. A quick hookup scheme is provided that lets

you configure modules before they are installed in a network. To help

you connect ADAM modules with sensor inputs, several wiring

examples are provided. At last, you will find a programming example

using the ADAM command set at the end of this chapter.

Be sure to plan the layout and configuration of your network

carefully before you start. Guidelines regarding layout are given in

Appendix E: RS-485 Network.

2.1 System Requirements to set up an ADAM network

The following list gives an overview of what is needed to setup,

install and configure an ADAM environment.

• ADAM modules

• A host computer, such as an IBM PC/AT compatible, that can

output ASCII characters with a RS-232C or RS-485 port.

• Power supply for the ADAM modules (+10 to +30 V

• ADAM Series Utility software

• ADAM Isolated RS-232/RS-485 Converter (optional)

• RS-232/RS-485 ADAM Repeater (optional)

DC

)

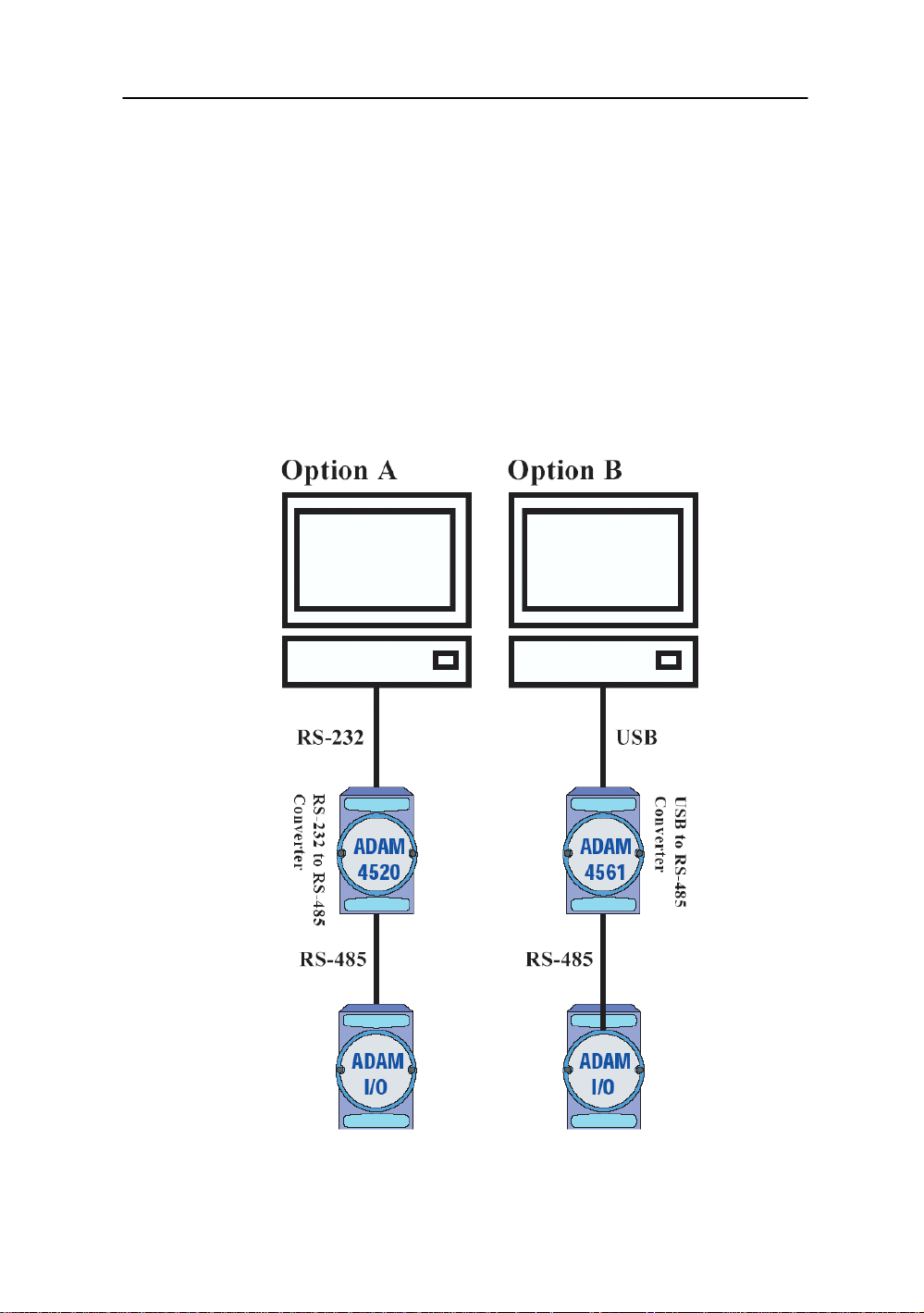

Host computer

Any computer or terminal that can output in ASCII format over

either RS-232 or RS-485 can be connected as the host computer. When

only RS-232 is available, an ADAM RS-232/RS-485 Converter is

required to transform the host signals to the correct RS-485 protocol.

The converter also provides opto-isolation and transformer-based

isolation to protect your equipment.

2-

2

ADAM 4000 Series User’s Manual

Page 13

Chapter 2

Power supply

For the ease of use in industrial environments, the ADAM modules

are designed to accept industry standard +24 V

Operation is guaranteed when using any power supply between +10 and

+30 V

. Power ripples must be limited to 5 V peak to peak while the

DC

voltage in all cases must be maintained between +10 and +30 V

power supply specifications are referenced at module connector. When

modules are powered remotely, the effects of DC voltage drops must be

considered.

All modules use on-board switching regulators to sustain good

efficiency over the 10 to 30 V input range; therefore, we can assume

that the actual drawn current is inversely proportional to the DC voltage.

The following example shows how to calculate the required current that

a power supply should provide.

Assume that a +24 V

is used for five ADAM-4011 Analog Input

DC

Modules, and the distance between modules and power supply is not

significant enough to cause a DC voltage drop. One ADAM-4011

module consumes a maximum of 1.2 Watts (W). The total required

power will equal to 5 x 1.2=6 W. A power supply of +24 V

therefore be able to supply a minimal current of 6 / 24=0.25 Amps.

Small systems may be powered by using wall-mounted modular

power supplies. Also, when modules operate in long communication

lines (>500 feet), it is often more reliable to obtain power locally

through modular power supplies. These inexpensive units can be easily

obtained from any electronic retail stores.

The power cables should be selected according to the length of the

power lines and the number of modules connected. When implementing

a network with long cables, the use of thicker wire is more suitable due

to the limitation of DC voltage drop. Furthermore, long wires can also

cause interference with communication wires.

Chapter 2 installation Guideline 2

, unregulated power.

DC

. All

DC

should

DC

-3

Page 14

Installation Guideline

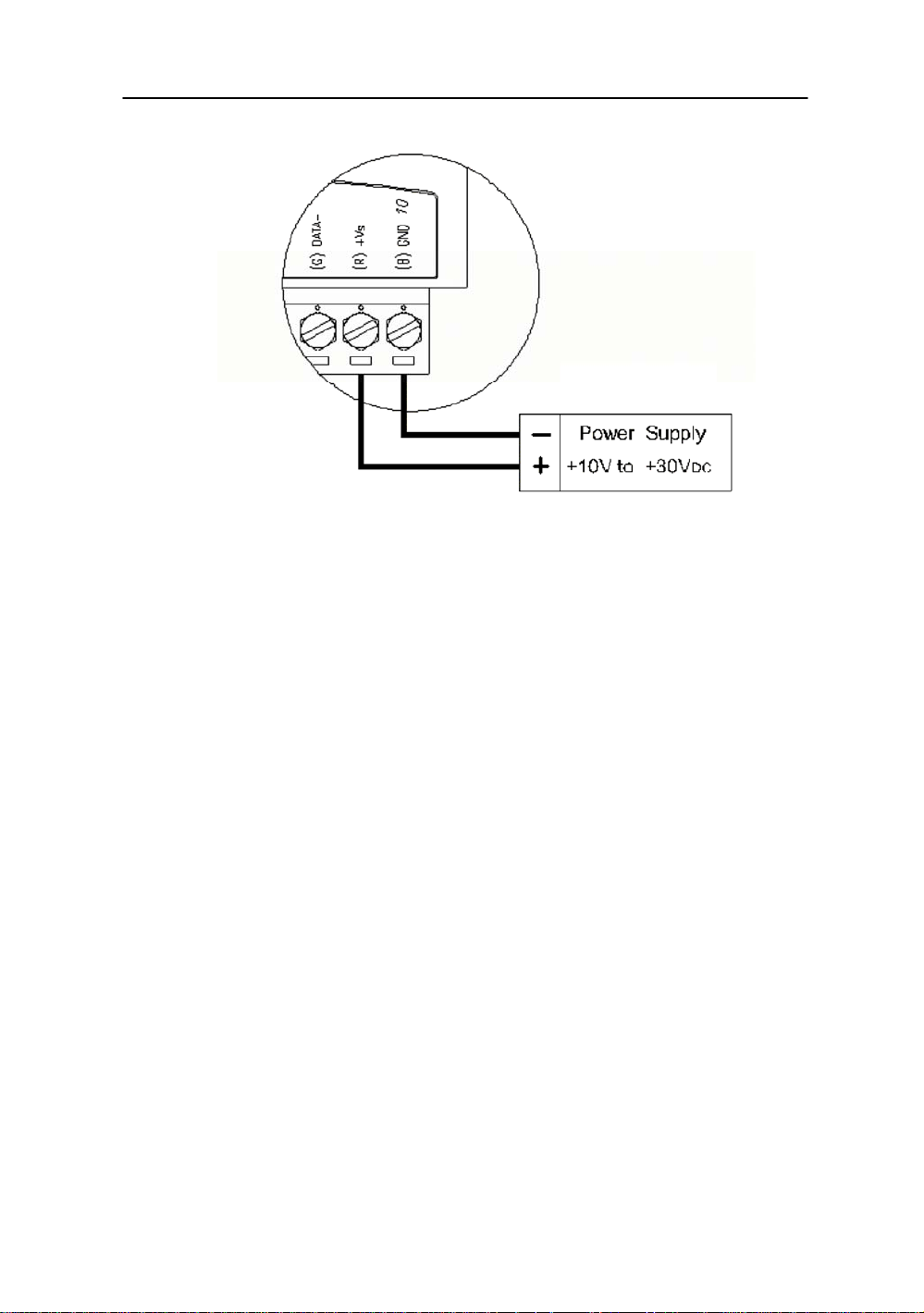

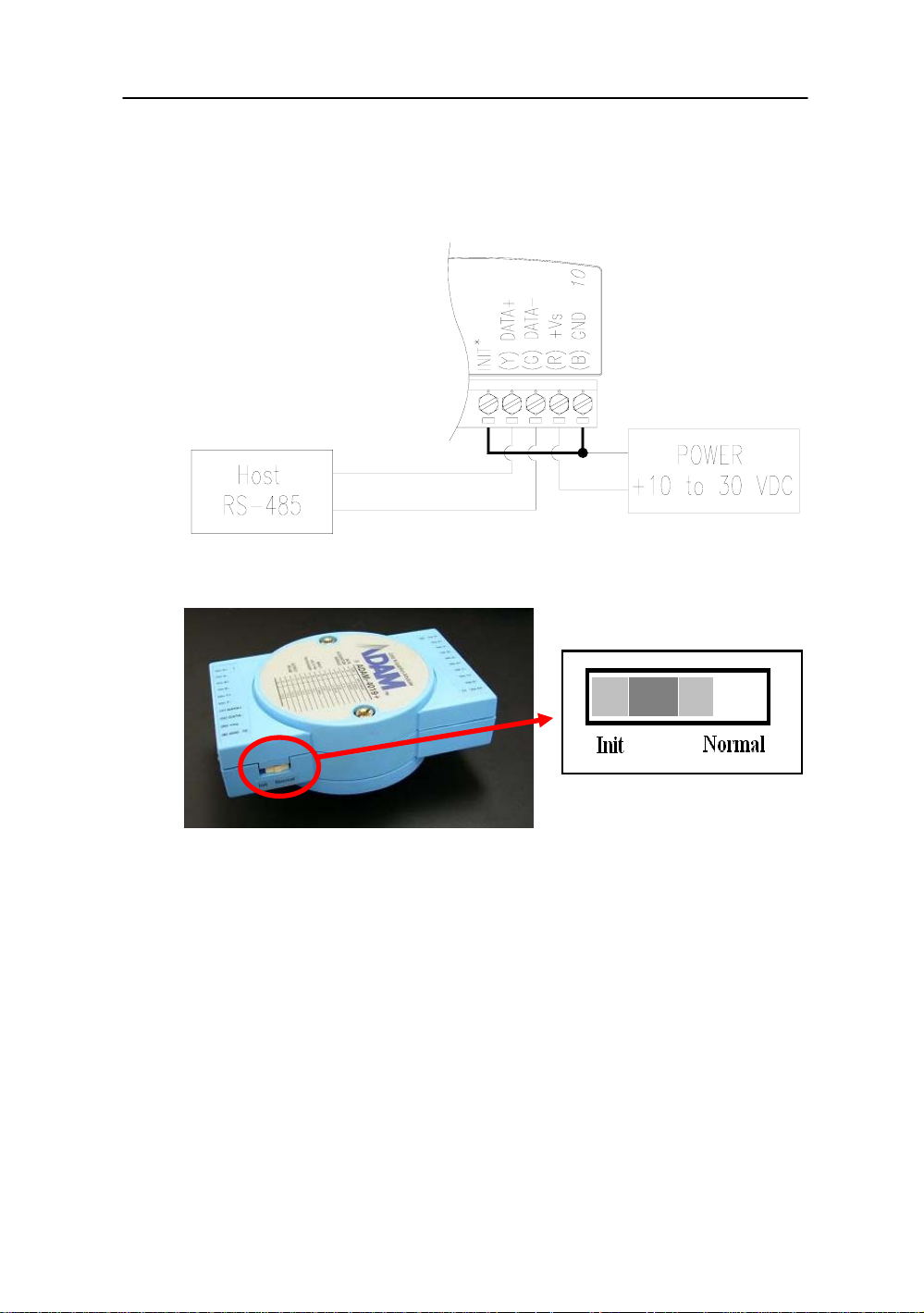

Figure 2-1 Power Supply Connections

We advise the following standard colors (as indicated on the

modules) for each power line:

+Vs (R) Red

GND (B) Black

Communication Wiring

We recommend the use of shielded-twisted-pair cable in the ADAM

network for reducing interference purpose, but the cable has to comply

with the EIA RS-485 standard. Furthermore, only one set of twistedpair cable is required for transmitting Data. We advise the following

standard colors (as indicated on the modules) for each the

communication line:

DATA+ (Y) Yellow

DATA- (G) Green

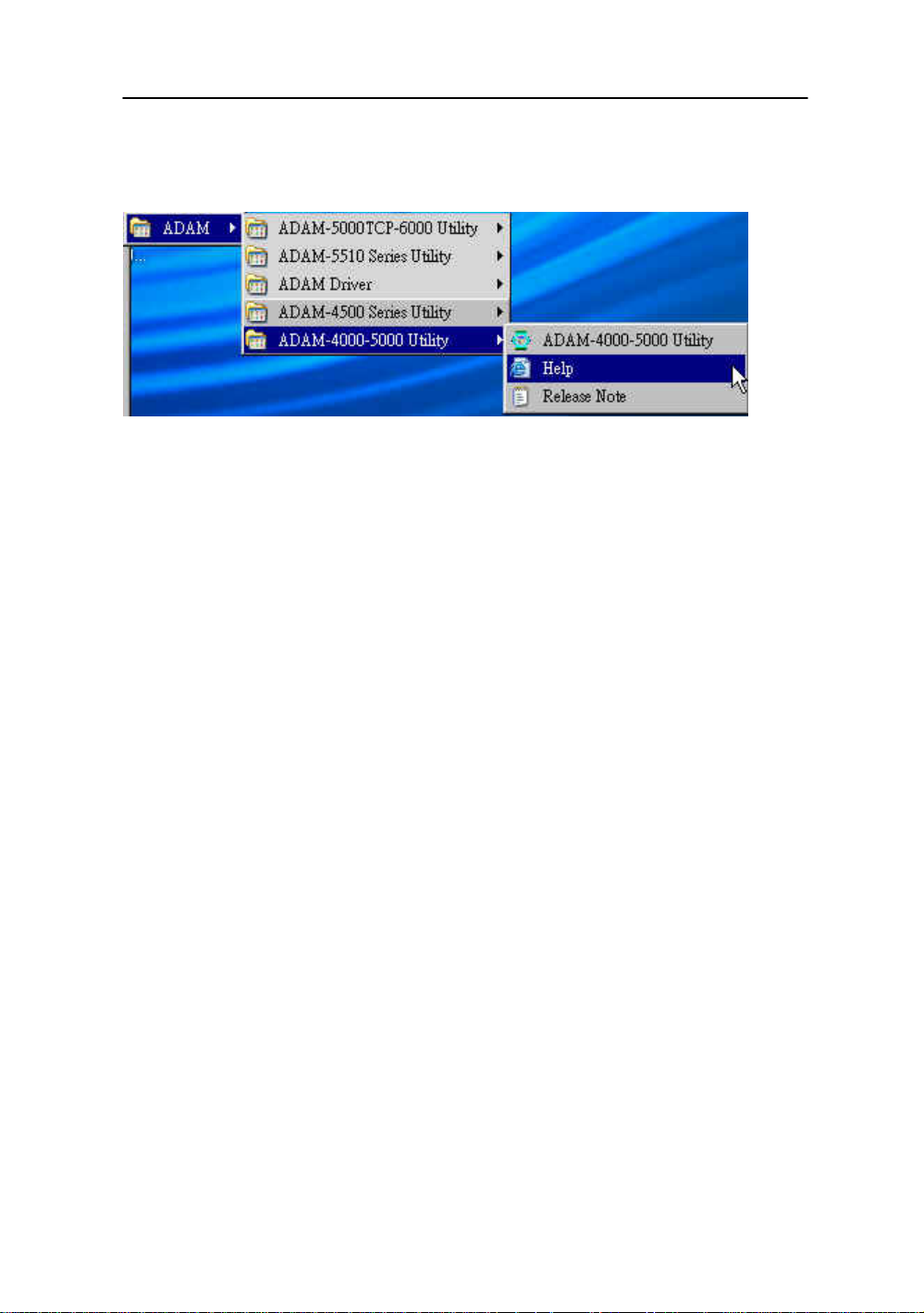

ADAM Utility Software

A menu-driven utility program is provided for ADAM module

configuration, monitoring and, calibration. It also includes a terminal

emulation program that lets you communicate through the ADAM

command set. (See Appendix D, Utility Software and online help)

2-

4

ADAM 4000 Series User’s Manual

Page 15

Chapter 2

Notice: User can refer our help file to see more details for explanation of

Utility operation.

ADAM Communication Speed

In ADAM series, the baud rate can be configured from 1200 bps to

38.4 Kbps. However, the baud rate of all modules in an RS-485

network must be the same.

ADAM Isolated RS-232/RS485 Converter (optional): ADAM-452x

When the host computer or terminal only has a RS-232 port, an

ADAM Isolated RS-232/RS-485 Converter is required. Since this

module is not addressable by the host, the baud rate must be reset using

a switch inside the module. The factory default setting is 9600 baud.

ADAM Repeater (optional): ADAM-451x

When communication lines exceed 4000 ft (1200 meter) or more

than 32 ADAM modules are connected, a repeater should be

implemented. In a network, up to eight Repeater modules can be

connected allowing connection up to 255 ADAM modules. As with the

Converter module, the Repeater module is not addressable by the host

and the baud rate must be reset by changing the switch inside the

module. The factory default setting is 9600 baud.

Chapter 2 installation Guideline 2

-5

Page 16

Installation Guideline

2.2 Basic configuration and hook-up

Before placing a module in an existing network, the module should

be configured. Though all modules are initially configured at the

factory, it is recommended to check if the baud rate is set correctly

beforehand.

Default Factory Se tt in gs

Baud rate: 9600 Bit/sec.

Address: 01 (hexadecimal)

The basic hook-up for module configuration is shown below.

Figure 2-2 Basic Hook-up of ADAM Module to Host Switches

2-

6

ADAM 4000 Series User’s Manual

Page 17

Chapter 2

The following items are required to configure a module: an ADAM

converter module, a personal computer with RS-232 port (baud rate set

to 9600) and the ADAM utility software.

Configuration with the ADAM Utility Software

The easiest way to configure the ADAM module is by using the

ADAM utility software. It is a user friendly structured menu program

that will guide you through every step of the configuration. (See

Appendix D, Utility Software)

Changing the protocol from ADAM ASCII to Modbus

Some ADAM-4000 modules support both ADAM ASCII and

Modbus protocols, and the factory default setting of these modules is

ADAM ASCII protocol. If you would like to configure the modules to

Modbus protocol, please refer to Appendix H which describes how to

change the protocol in ADAM utility.

Configuration with the ADAM command set

ADAM modules can also be configured by issuing direct commands

through a terminal emulation program that is part of the ADAM utility

software. The following example will guide you through the setup of an

analog input module. Assume an ADAM-4011 Analog Input module

still has its default settings (baud rate 9600 and address 01h), and you

are being requested to send its default settings before any

reconfiguration is made.

NOTICE: An analog input module requires a maximum of 7 seconds

to perform auto calibration and ranging after reboot or start up.

During this time span, the module can not be addressed to perform

any other actions.

Example:

Make sure that the module is properly connected and turn on all the

connected devices. Then, start the terminal emulation program, and

type in the following command:

$012(cr)

The command above requests the module with address 01 to send its

configuration status

!01050600

Chapter 2 installation Guideline 2

-7

Page 18

Installation Guideline

Module at address 01 responds that it is configured for an input

range of +/-2.5 V, baud rate of 9600, integration time of 50 ms (60 Hz).

The code also shows engineering units and no checksum checking or

generation.

To change the configuration setting of the analog input module, the

following command is issued:

%01070F0600(cr)

% = change configuration

01 = target module at address 00 to:

07 = change address to 07 hexadecimal

0F = set input range to Type K thermocouple

06 = set baud rate to 9600

00 = set integration time to 50 ms (60 Hz)

disable checksum

set data format to engineering units

(Please refer to Chapter 4, a full description of Command set syntax for

an analog input module)

When the module received the configuration command, it will

respond with its new address as shown below:

!07(cr)

Before giving more commands to the module, please wait for 7

seconds to let the new configuration settings to take effect.

NOTICE: All reconfiguration except for changing baud rate and

checksum values can be done dynamically, and the modules are not

required to reset. However, all the connected devices are required to

reset by turning power off and on after the baud rate or checksum

values are changed. The baud rate or checksum values should be the

same for all the connected devices after the reconfiguration. See the

next page for a strategy in changing baud rate and che cksum of the

network.

2-

8

ADAM 4000 Series User’s Manual

Page 19

Chapter 2

2.3 Baud rate and Checksum

ADAM modules contain EEPROMs to store configuration

information and calibration constants. The EEPROM replaces the

conventional array of switches and pots that are originally used for

specifying baud rate, input and output range… etc.

Since there is no visual indication of a module’s configuration status,

it is impossible to know the baud rate, address and other settings just by

looking at it. It might not be possible to establish communications with

a module whose baud rate and address are unknown. To overcome this

problem, most modules have an input terminal labeled INIT*. Booting

the module while connecting the INIT* terminal with the module’s

GND terminal forces the configuration into a known state called the

INIT* state. Besides, some newer modules have INIT switch which you

can set “Init” or “Normal” (See Figure 2.4). If you set the switch to

“Init”, then it becomes INIT* state.

INIT* state defaults:

Baud rate: 9600

Address: 00h

Checksum: disabled

Forcing the module in INIT* state does not change any parameters

in the module’s EEPROM. When the module is in the INIT* state with

its INIT* and GND terminals shorted, all configuration settings can be

changed, and the module will respond to all other commands normally.

Changing Baud rate and Checksum

Baud rate and checksum settings have several things in common:

• They should be the same for all modules and host computer.

• Their settings can only be changed by putting a module in the INIT*

state.

• Changed settings can only take effect after a module is rebooted

To alter baud rate or checksum settings, you must perform the

following steps:

Chapter 2 installation Guideline 2

-9

Page 20

Installation Guideline

• Power on all components except the ADAM Module.

• Power the ADAM module on while shorting the INIT* and GND

terminals (See Figure 2-3) or set the INIT switch to “Init” (See

Figure 2-4)

Figure 2-3 Grounding the INIT* Terminal

Figure 2-4 Set INIT switch to “Init”

• Configure the checksum status and/or the baud rate.

• Switch the power OFF to the ADAM Module.

• Remove the grounding of the INIT* terminal and turn on the

module, or set the INIT switch to “Normal”.

• Check the settings (If the baud rate has changed, the settings on the

host computer should be changed accordingly).

2-

10

ADAM 4000 Series User’s Manual

Page 21

Chapter 2

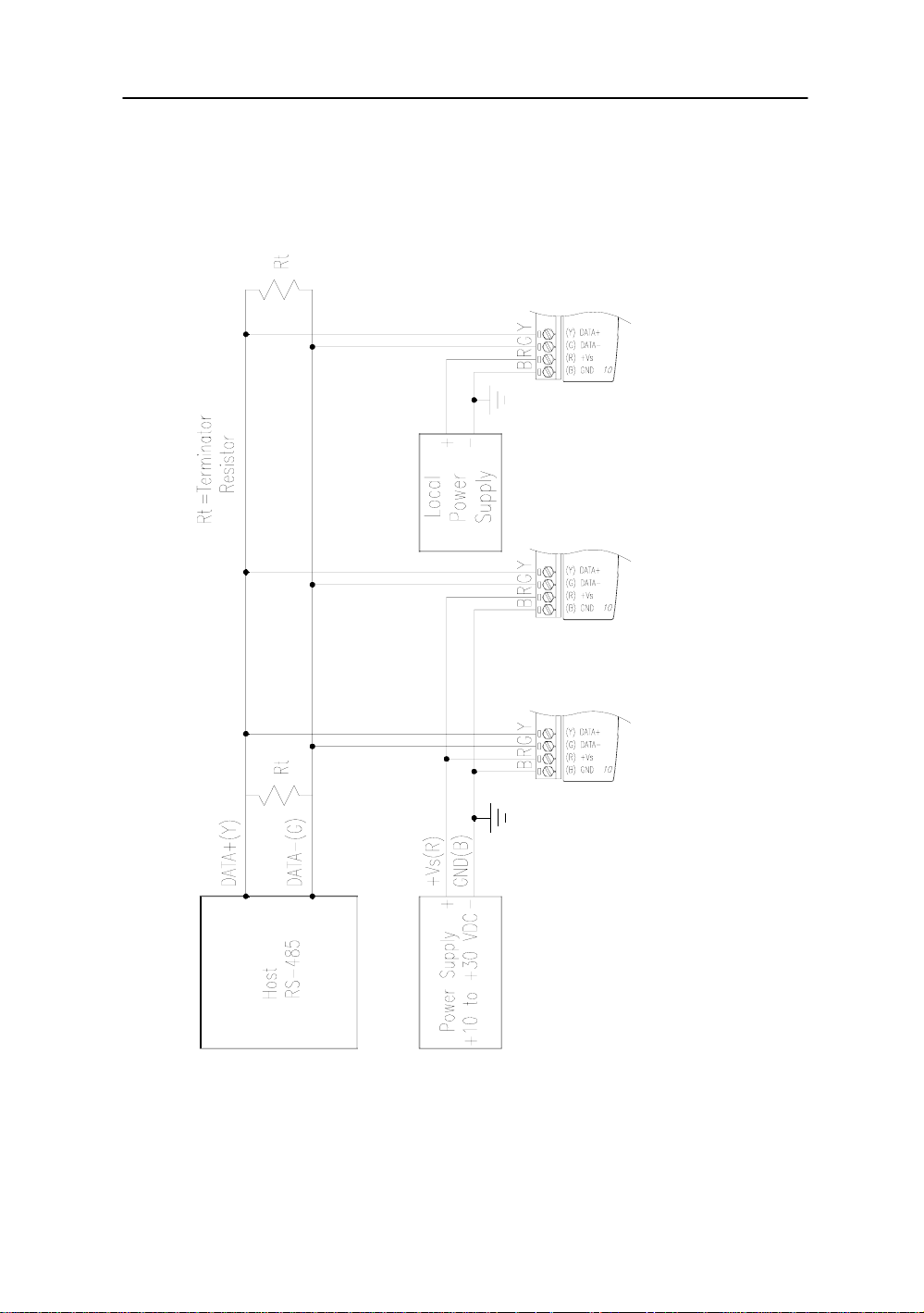

2.4 Multiple Module Hookup

The Figure below is an example of how ADAM modules are connected

in a multiple module network:

Figure 2-5 Multi-module Connection

Chapter 2 installation Guideline 2

-11

Page 22

Installation Guideline

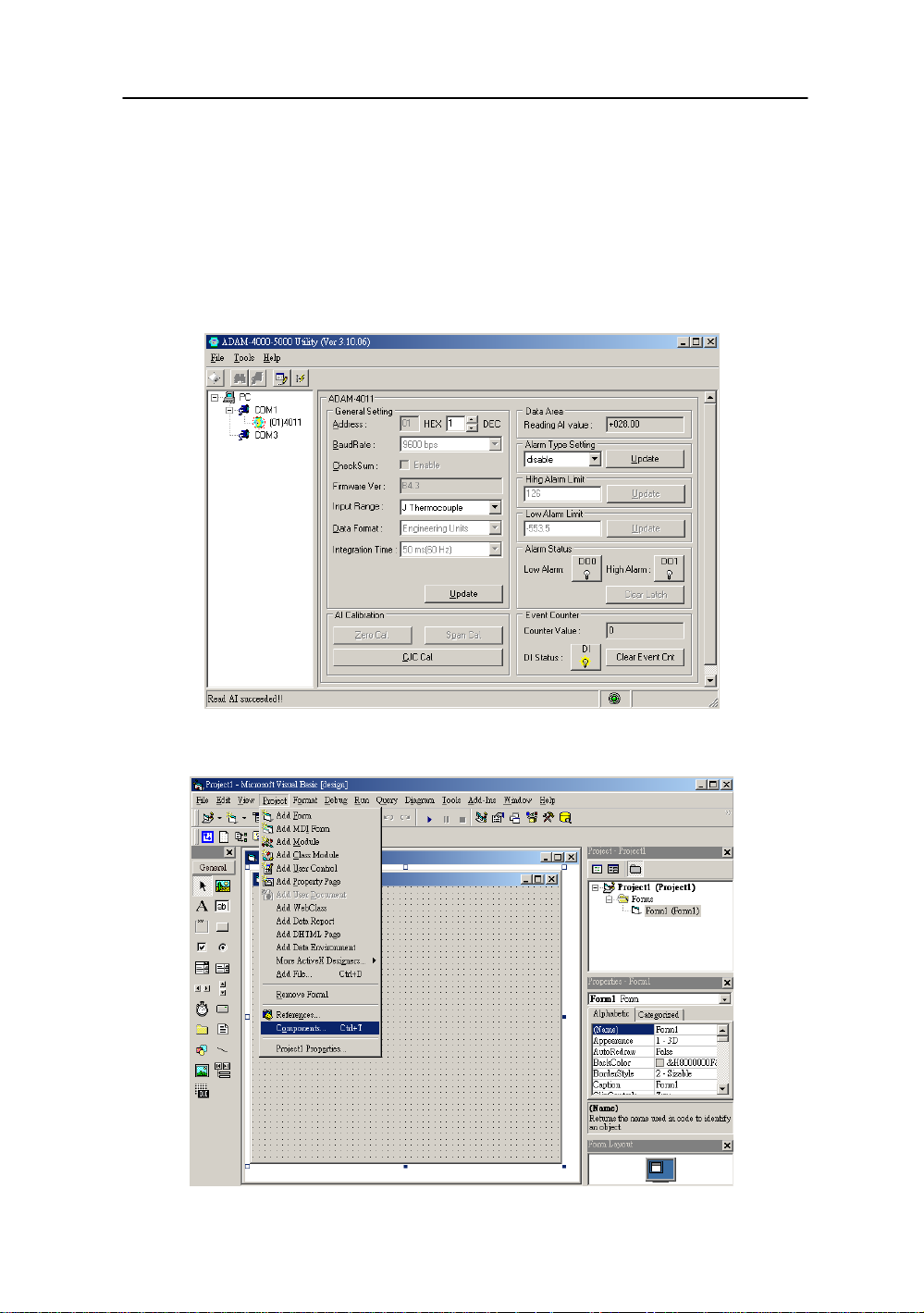

2.5 Programming Example

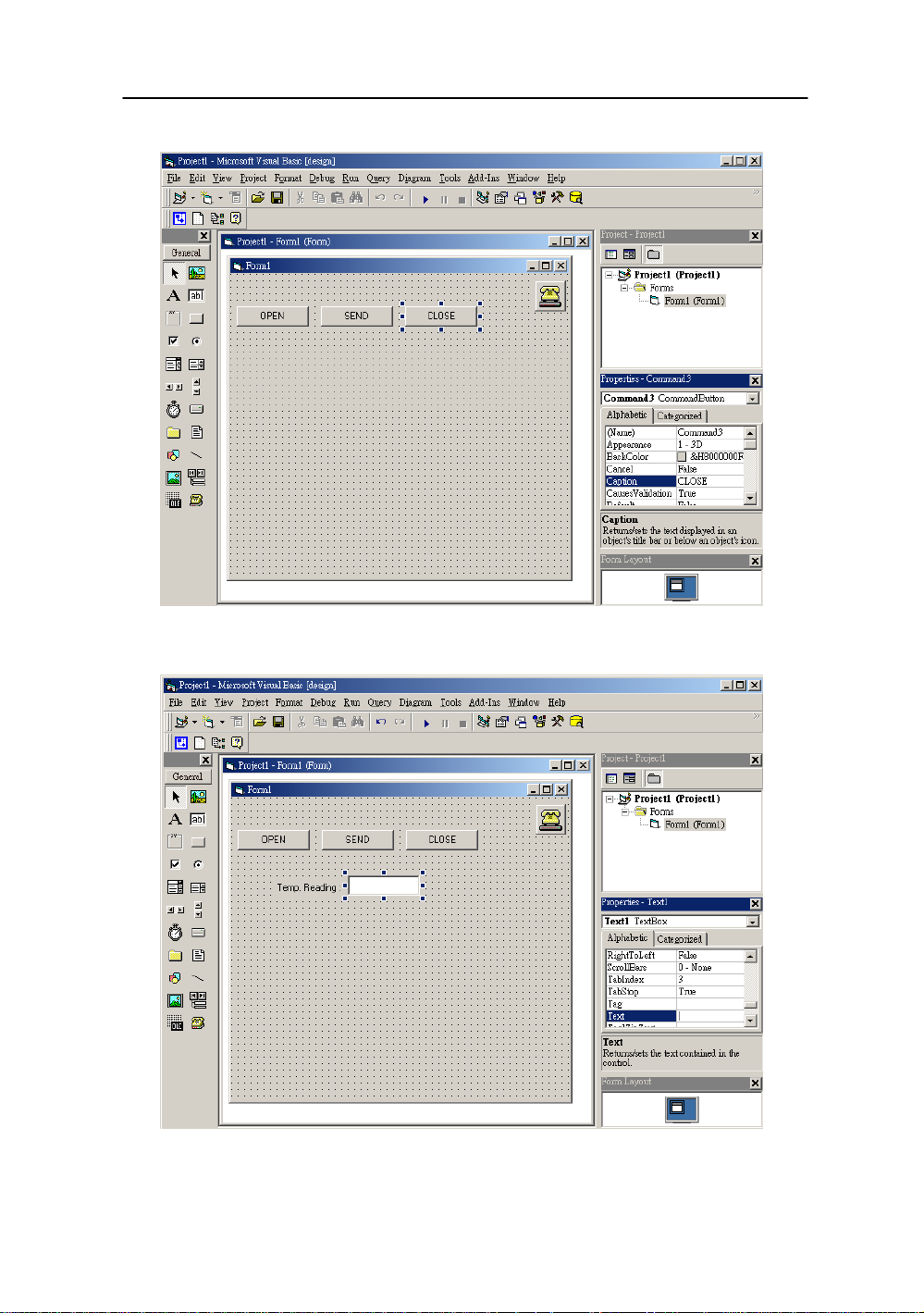

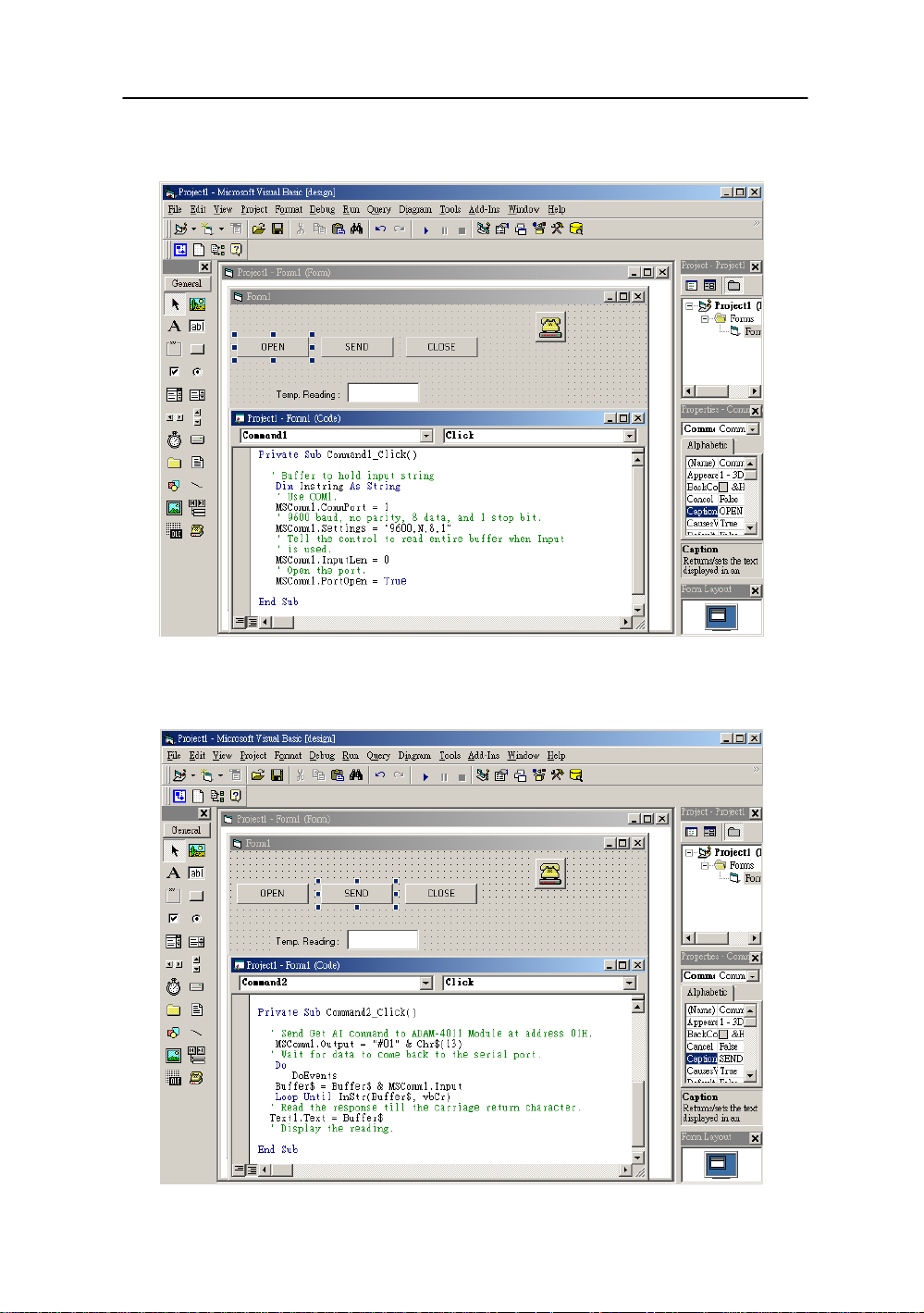

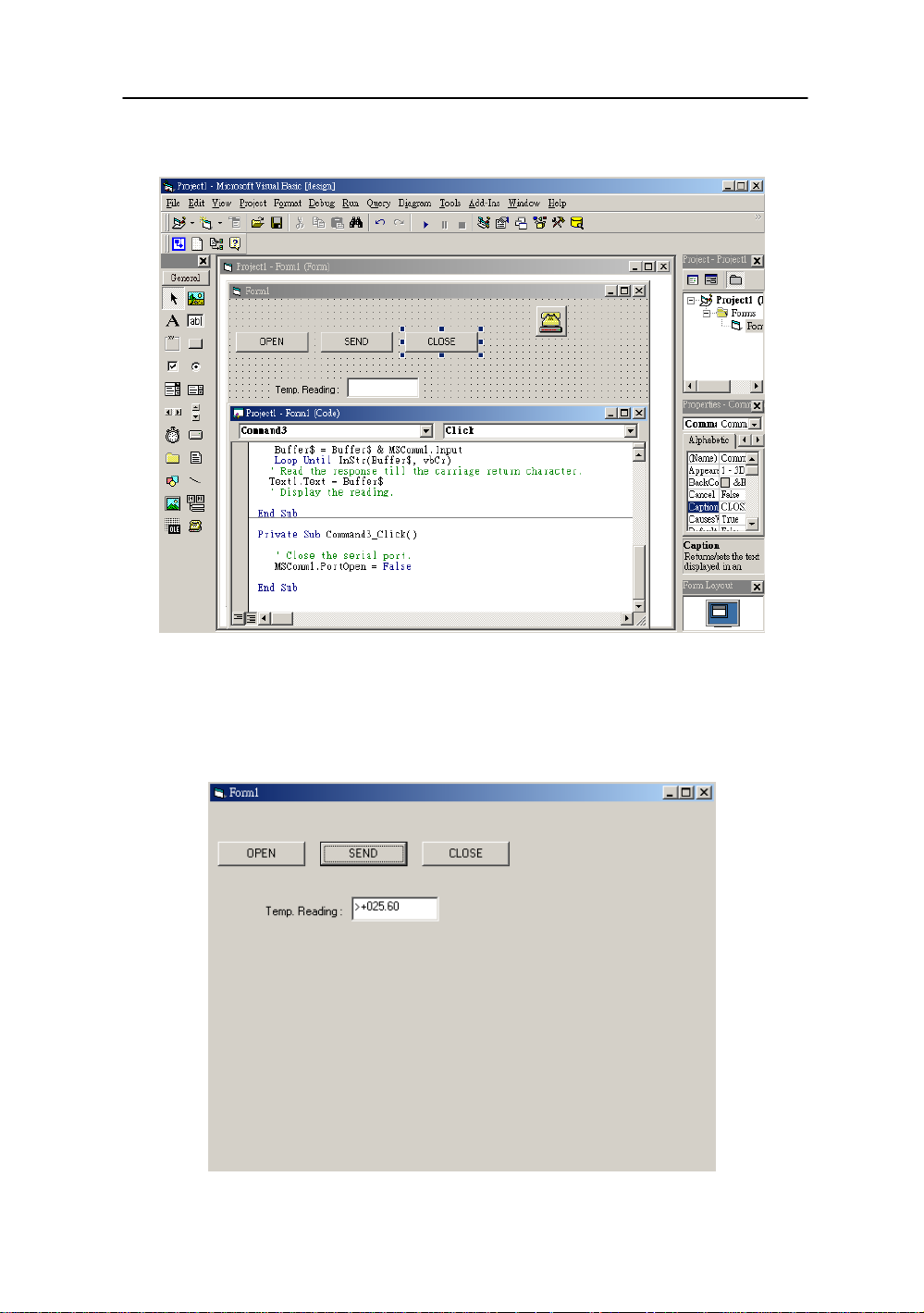

The following example is a simple program written in Visual Basic 6.0

that demonstrates how to get temperature reading which is stored in the

address of 01H from ADAM-4011 module.

Step 1. Using ADAM Utility to check the settings as the following below:

“Address = 01H”, “Baud rate = 9600” and “Checksum = Disabled”.

Step 2. Run VB 6.0 and add a control via “Project\Component”.

2-

12

ADAM 4000 Series User’s Manual

Page 23

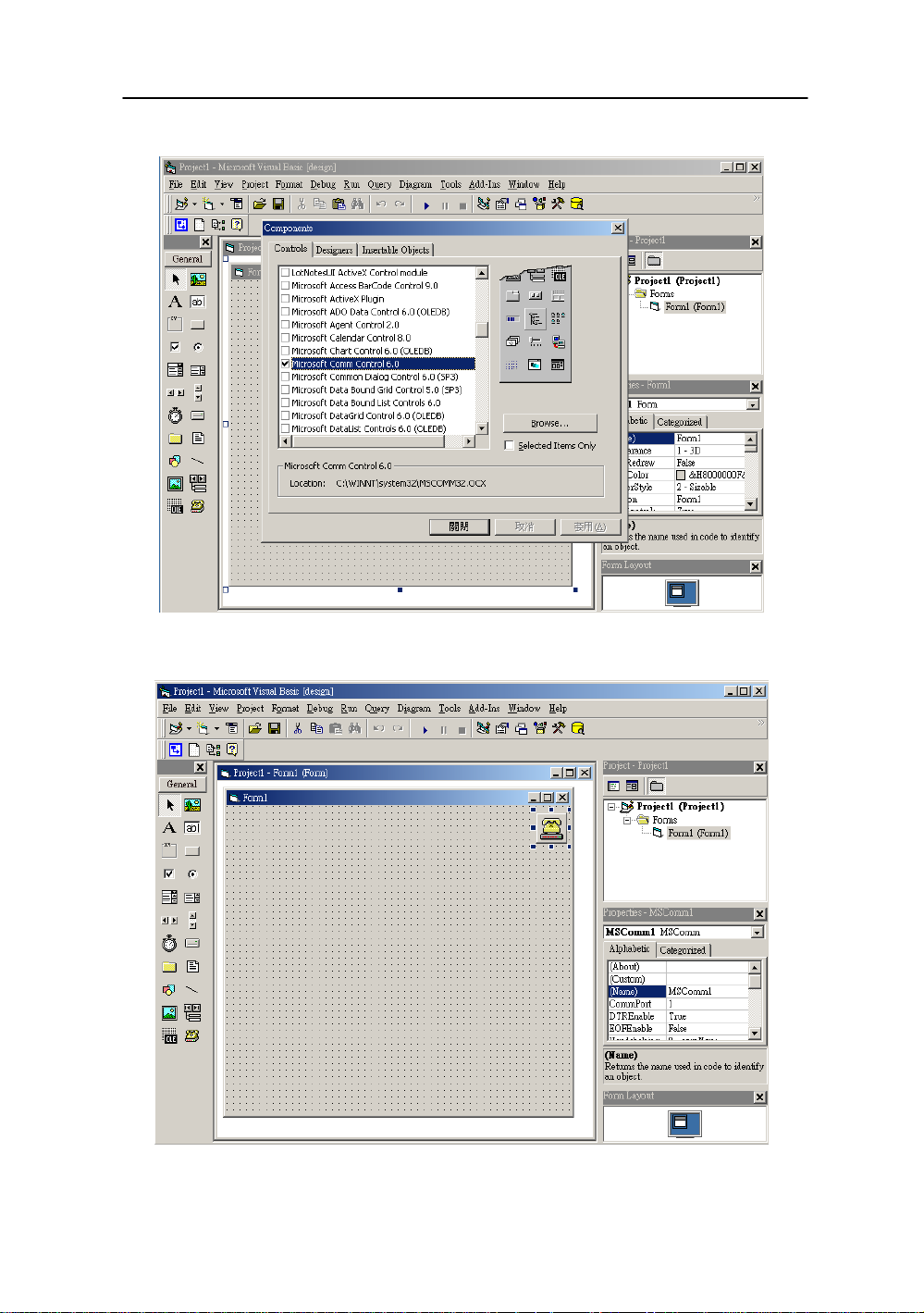

Step 3. Select “Microsoft Comm Control”

Step 4. Add the Comm Control on the form.

Chapter 2

Chapter 2 installation Guideline 2

-13

Page 24

Installation Guideline

Step 5. Add three Command Buttons on the form as shown below

Step 6. Add one Label and one Text on the form as shown below.

2-

14

ADAM 4000 Series User’s Manual

Page 25

Chapter 2

Step 7. Click OPEN Button and type in the following codes. The source

codes are listed at the end of this section.

Step 8. Click SEND Button and type in the following codes. The source

codes are listed at the end of this section.

Chapter 2 installation Guideline 2

-15

Page 26

Installation Guideline

Step 9. Click CLOSE Button and type in the following codes. The source

codes are listed at the end of this section.

Step 10. Run the Project → Click OPEN to open COM1 → Click SEND to

send the Get Temperature Reading Command. Now, you will find the

reading the same as the displayed format shown below.

2-

16

ADAM 4000 Series User’s Manual

Page 27

Program Source Codes:

OPEN Command Button:

Private Sub Command1_Click()

' Buffer to hold input string

Dim Instring As String

' Use COM1.

MSComm1.CommPort = 1

' 9600 baud, no parity, 8 data, and 1 stop bit.

MSComm1.Settings = "9600,N,8,1"

' Tell the control to read entire buffer when Input

' is used.

MSComm1.InputLen = 0

' Open the port.

MSComm1.PortOpen = True

End Sub

SEND Command Button:

Private Sub Command2_Click()

' Send Get AI command to ADAM-4011 Module at address 01H.

MSComm1.Output = "#01" & Chr$(13)

' Wait for data to come back to the serial port.

Do

DoEvents

Buffer$ = Buffer$ & MSComm1.Input

Loop Until InStr(Buffer$, vbCr)

' Read the response till the carriage return character.

Text1.Text = Buffer$

' Display the reading.

End Sub

CLOSE Command Button

Private Sub Command3_Click()

' Close the serial port.

MSComm1.PortOpen = False

End Sub

Chapter 2

Chapter 2 installation Guideline 2

-17

Page 28

I/O Modules 3

Page 29

I/O Modules

3.0 The common specification of ADAM-4000 I/O Series

Communication:

z RS-485 (2-wire) to host

z Speeds: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 bps

(ADAM-4080, ADAM-4080D only support up to 38400 bps)

z Max. communication distance: 4000 feet (1.2 km)

z Power and communication LED indicator

z ASCII command/response protocol

z Communication error checking with checksum

z Asynchronous data format: 1 start bit, 8 data bits, 1 stop bit, no parity

(N, 8, 1)

z Up to 256 multidrop modules per serial port

z Online module insertion and removal

z Transient suppression on RS-485 communication lines

Power Requirement:

z Unregulated +10 ~ +30 V

z Protected against power reversal

Mechanical:

z Case ABS+PC with captive mounting hardware

z Plug-in screw Accepts 0.5 mm2 to 2.5 mm2,

Terminal block #14 ~22 or #14~28 AWG

Environment

z EMI Meets FCC Class A or CE

z Operating Temperature -10 ~ 70° C (14 ~ 158° F)

z Storage Temperature -25 ~ 85° C (-13 ~ 185° F)

z Humidity 5 ~ 95%, non-condensing

DC

3-

2

ADAM 4000 Series User’s Manual

Page 30

Chapter 3

3.1 ADAM-4011/4011D Thermocouple Input Modules

The ADAM-4011/4011D Thermocouple Input Modules use a

microprocessor-controlled integrating A/D converter to convert sensor

voltage, current or thermocouple signal into digital data. The digital

data is then translated into either two’s complement hexadecimal

format or percentage of full-scale range (FSR) according to the

module’s configuration. When prompted by the host computer, the data

is sent through a standard RS-485 interface.

The ADAM-4011/4011D Thermocouple Input Modules offer signal

conditioning, A/D conversion, ranging, and RS-485 digital

communication functions. They protect your equipment from power

surges at the ground terminal by providing opto-isolation of the A/D

input and transformer based isolation up to 3000 V

has transformer-based isolation up to 500 V

DC

)

Open Thermocouple Detection and Input Surge Protection

(ADAM-4011D only)

The ADAM-4011D provides an open thermocouple detection

function. Users can use a simple command to detect whether the

thermocouple is opened or closed. The module also provides surge

protection on its input channel. Internal high-speed transient suppressor

on its input channel protects the module from dangerous spikes and

voltages.

. (ADAM-4011

DC

Front Panel LED Indicator (ADAM-4011D only)

The 4½ digits LED display on the back of the ADAM-4011D lets

you monitor the process readings right at their source. The module

displays readings in a wide variety of formats as well as high-low alarm

messages. The ADAM-4011D offers flexibility, easy installation, and

direct availability of process data. For critical process monitoring, this

module is the ideal choice.

Digital Input/Output

The ADAM-4011/4011D Thermocouple Input Modules also contain

two digital outputs and one digital input. Outputs are open-collector

transistor switches that may be controlled by the host computer. They

can control solid-state relays, which may be used to control heaters,

pumps, and other electrical powered equipment. The digital inputs may

be read by the host computer and used to sense the state of a remote

digital signal.

Chapter 3 I/O Modules

3-3

Page 31

I/O Modules

Event counting

The event counter is connected to the Digital Input channel and can

be used to keep track of the total amount of external low-speed pulses.

Its accumulated maximal count is 65535. The count will maintain at

65535 even if the actual number of events exceeds 65535. The counter

can be read or reset to zero by the host computer.

Since the Event counter’s data are not stored in EEPROM, the event

counter is cleared and set to zero after every reset or start up of the

analog input module.

Alarm signaling

Analog input modules include High and Low alarm functions. High

and Low alarm limits may be downloaded into the module’s EEPROM

by the host computer.

The alarm functions can be enabled or disabled remotely. When the

alarm function is enabled, both Digital Output channels are used to

indicate the High and Low alarm state. Digital Output channel 1 (DO1)

equals to High alarm state, and Digital Output channel 0 (DO0) equals

to Low alarm state. The High and Low alarm states can be read at any

time by the host computer.

Every A/D conversion will be followed by a comparison with the

High and Low limit. When the input value exceeds one of these limits,

the High or Low alarm state is set to ON.

There are two alarm mode options, Momentary and Latching. If the

alarm is in Latching mode, the alarm will stay on even if the input value

returns within the limits. An alarm in Latching mode can be turned OFF

by giving a Clear Alarm command from the host computer. A Latching

alarm is cleared by the module when the opposite alarm is set. When

the module receives a value that is lower than the Low alarm limit, it

will clear the High alarm and turn the Low alarm ON.

When the alarm is in Momentary mode, the alarm will be turned

OFF as soon as the input value returns within the limits.

The arrangement of coupling High and Low alarm states with

Digital Output lines may be utilized to build ON/OFF controllers that

can operate without the involvement of host computer.

3-

4

ADAM 4000 Series User’s Manual

Page 32

Chapter 3

Function Description for the ADAM-4011 Thermocouple Input

Module

To provide a better understanding of the ADAM module functions,

the following is a description of the module ADAM-4011 with the most

extensive set of functions.

All analog input data first flow through the PGA (programmable

gain amplifier). The amplifier can vary its gain from 1 to 128. The PGA

then automatically adjusts the signal to a range from -2.5 V to +2.5 V.

This ensures an optimal input voltage and resolution for the A/D

converter.

The A/D conversion is supervised by the microprocessor that holds

the calibration software. Two kinds of calibrations, Auto Zero and Auto

Span calibrations, take place automatically in startup or reset. Normal

calibration is used to adjust the signal according to calibration

parameters defined by the user.

The digital 10 Hz filter provides a steady state output by using the

function.

Before the data enter the microprocessor, they pass through an

optical isolation device which prevents the chance of circuit damaging

caused by power surges from the ground terminal.

The microprocessor has six basic functions:

- Linearization of T/C (Thermocouple)

- Communication software and command set

- Calibration software

- Alarm monitoring

- Event counting

- Management of the EEPROM device that holds the system parameters

- Data transformation

After data have been transformed to the right data format, they are

being passed on to the RS-485 output port.

If an input value exceeds the High alarm setting or falls below the

Low alarm setting, a flag is set in one of the Digital Output channels.

Finally, the on-board switching regulator accepts voltage between +10

and +30 V

equipment from damages caused by power surges.

, and it has an isolation value of 500 VDC to protect your

DC

Chapter 3 I/O Modules

3-5

Page 33

I/O Modules

ADAM-4011 Thermocouple Input Module

Figure 3-1 ADAM-4011 Thermocouple Input Module

Accepts:

- J, K, T, E, R, S and B thermocouples

- Millivolt inputs: ±15 mV, ±50 mV, ±100 mV and ±500 mV

- Volt inputs: ±1 V and ±2.5 V

- Current input: ±20 mA (Requires a 125 resistor)

Two digital output channels and one digital input channel are provided.

Depending on the module’s configuration setting, it can forward the

data to the host computer in one of the following formats:

o

- Engineering units (

C, mV, V or mA)

- Percent of full-scale range (FSR)

- Two’s complement hexadecimal

3-

6

ADAM 4000 Series User’s Manual

Page 34

ADAM-4011D Thermocouple Input Module

Chapter 3

Figure 3-2 ADAM-4011D Thermocouple Input Module with LED Display

Accepts:

- J, K, T, E, R, S and B thermocouples

- Millivolt inputs: ±15 mV, ±50 mV, ±100 mV and ±500 mV

- Volt inputs: ±1 V and ±2.5 V

- Current input: ±20 mA (Requires a 125 resistor)

Two digital output channels and one digital input channel are provided.

Depending on the module’s configuration setting, it can forward the

data to the host computer in one of the following formats:

o

- Engineering units (

C, mV, V, or mA)

- Percent of full-scale range (FSR)

- Two’s complement hexadecimal

Chapter 3 I/O Modules

3-7

Page 35

I/O Modules

Application Wiring

Figure 3-3 ADAM-4011/4011D Thermocouple Input Wiring Diagram

Figure 3-4 ADAM-4011/4011D Millivolt and Volt Input Wiring Diagram

Figure 3-5 ADAM-4011/4011D Process Current Input Wiring Diagram

3-

8

ADAM 4000 Series User’s Manual

Page 36

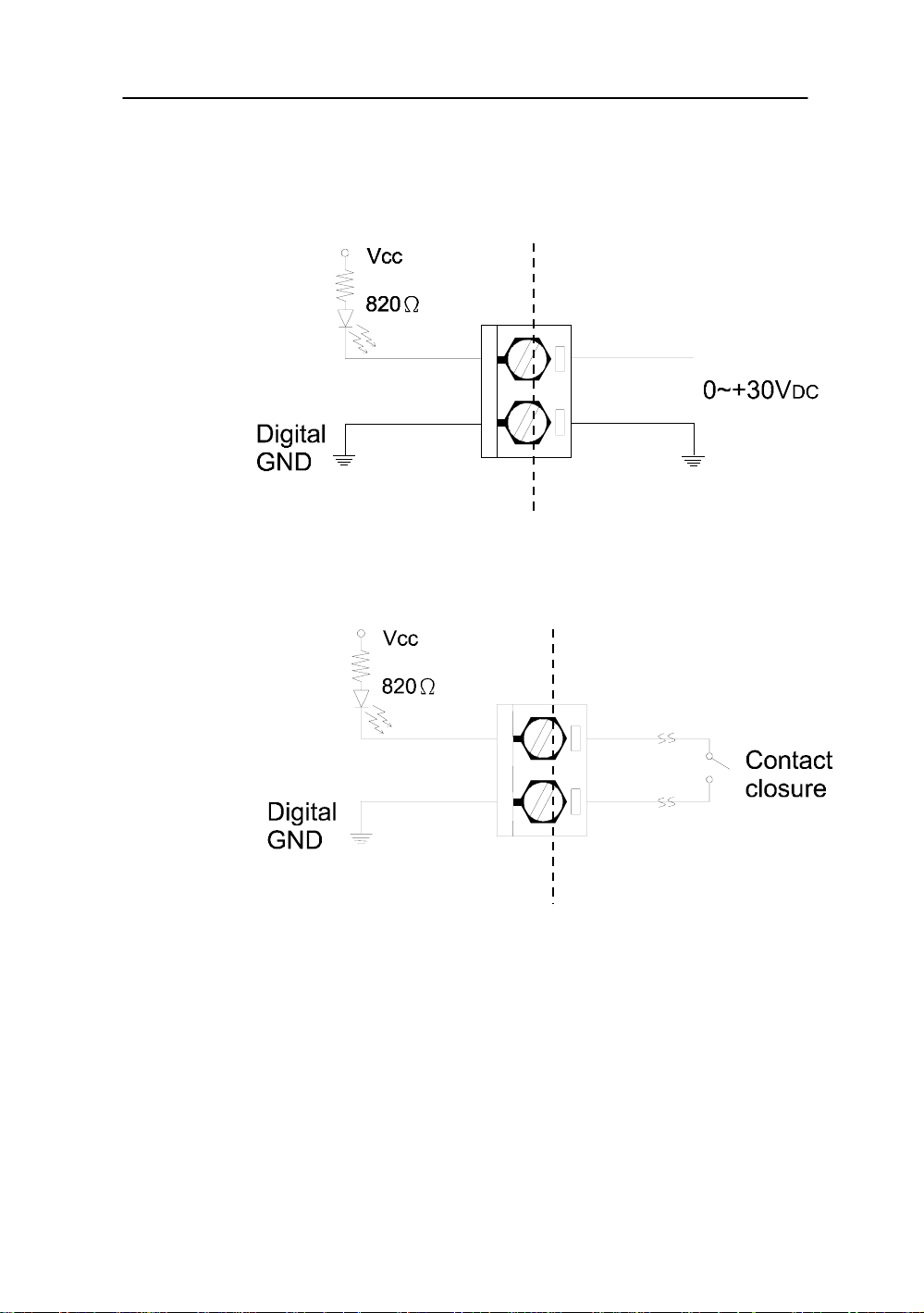

Chapter 3

Figure 3-6 ADAM-4011/4011D Digital Output Wiring Diagram

Used with SSR (HI-LO alarm)

Figure 3-7 ADAM-4011/4011D Digital Input Wiring Diagram

Used with TTL

Figure 3-8 ADAM-4011/4011D Digital Input Wiring Diagram

Used with Dry contact

Chapter 3 I/O Modules

3-9

Page 37

I/O Modules

3.2 ADAM-4012 Analog Input Module

The ADAM-4012 Analog Input Modules use a microprocessorcontrolled integrating A/D converter to convert sensor voltage or

current signals into digital data. The digital data are then translated into

either two’s complement hexadecimal format or percentage of full-scale

range (FSR) according to the module’s configuration. When prompted

by the host computer, the data are sent through a standard RS-485

interface.

The ADAM-4012 Analog Input Modules offer signal conditioning,

A/D conversion, ranging, and RS-485 digital communication functions.

They protect your equipment from power surges at the ground terminal

by providing opto-isolation of the A/D input and up to 3000 V

transformer based isolation.

Digital Inputs/Outputs

The ADAM-4012 also contains two digital outputs and one digital

input. Outputs are open-collector transistor switches that may be

controlled by the host computer. They can control solid-state relays,

which can be applied to heaters, pumps, and other electrical powered

equipment. The digital inputs may be read by the host computer and

used to sense the state of a remote digital signal.

DC

Event counting

The event counter is connected to the Digital Input channel and can

be used to keep track of the total amount of external low-speed pulses.

Its accumulated maximal count is 65535. The number 65535 is held

even if the actual number of events exceeds 65535. The counter can be

read or reset to zero by the host computer.

Since the Event counter’s data are not stored in EEPROM, the event

counter is cleared and set to zero after every reset or start up of the

analog input module.

3-

10

ADAM 4000 Series User’s Manual

Page 38

Chapter 3

Alarm signaling

Analog input modules include High and Low alarm functions. High

and Low alarm limits may be downloaded into the module’s EEPROM

by the host computer.

The alarm functions can be enabled or disabled remotely. When the

alarm function is enabled, both Digital Output channels are used to

indicate the High and Low alarm states. Digital Output channel 1 (DO1)

equals to High alarm state, and Digital Output channel 0 (DO0) equals

to Low alarm state. The High and Low alarm states can be read at any

time by the host computer.

Every A/D conversion will be followed by a comparison with the

High and Low limit. When the input value exceeds one of these limits,

the High or Low alarm state is set to ON.

There are two alarm mode options, Momentary and Latching.

If the alarm is in Latching mode, the alarm will stay on even when

the input value returns within the limits. It can also be turned OFF by

issuing a Clear Alarm command from the host computer. A Latching

alarm is cleared by the module when the opposite alarm is set.

When the module receives a value that is lower than the Low alarm

limit, it will clear the High alarm and turn the Low alarm ON.

When the alarm is in Momentary mode, the alarm will be turned OFF

as soon as the input value returns within the limits.

The arrangement of coupling High and Low alarm states with

Digital Output lines may be utilized to build ON/OFF controllers that

can operate without involving the host computer.

Chapter 3 I/O Modules

3-11

Page 39

I/O Modules

ADAM-4012 Analog Input Module

Figure 3-9 ADAM-4012 Analog Input Module

Accepts:

- Millivolt inputs ± 150 mV and ±500 mV

- Volt inputs: ±1 V, ±5 V and ±10 V

- Current input: ±20 mA (requires a 125 resistor)

Two digital output channels and one digital input channel are provided.

Depending on the module's configuration setting, it can forward the

data to the host computer in one of the following formats:

- Engineering units (mV, V, or mA)

- Percent of full-scale range (FSR)

- Two’s complement hexadecimal

3-

12

ADAM 4000 Series User’s Manual

Page 40

Application Wiring

Figure 3-10 ADAM-4012 Millivolt and Volt Input Wiring Diagram

Chapter 3

Figure 3-11 ADAM-4012 Process Current Input Wiring Diagram

Figure 3-12 ADAM-4012 Digital Output Wiring Diagram

Used with SSR (HI-LO alarm)

Chapter 3 I/O Modules

3-13

Page 41

I/O Modules

Figure 3-13 ADAM-4012 Digital Input Wiring Diagram Used with TTL

Figure 3-14 ADAM-4012 Digital Input Wiring Diagram

3-

14

ADAM 4000 Series User’s Manual

Used with Dry contact

Page 42

Chapter 3

3.3 ADAM-4013 RTD Module

The ADAM-4013 RTD Input Module supports one Pt or Ni RTD

input channel for temperature measurement. This module can accept

RTD sensors with two, three, or four wires. The module offers signal

conditioning, A/D conversion, ranging, and RS-485 digital

communication functions. It protects your equipment from power

surges at the ground terminal by providing opto-isolation of the A/D

input and up to 3000 V

transformer based isolation.

DC

Figure 3-15 ADAM-4013 RTD Input Module

Accepts:

- Input from platinum and nickel RTDs

Depending on the module’s configuration setting, it can forward the

data to the host computer in one of the following formats:

- Engineering units (°C)

- Percent of full-scale range (FSR)

- Two’s complement hexadecimal

Chapter 3 I/O Modules

3-15

Page 43

I/O Modules

Application Wiring

Figure 3-16 ADAM-4013 RTD Inputs Wiring Diagram

3-

16

ADAM 4000 Series User’s Manual

Page 44

Chapter 3

蚓

蚓

3.4 ADAM-4015 6-channel RTD Input Module

A RTD module is popularly used for temperature measurement.

Unlike the traditional design, the ADAM-4015 RTD Input Module

provides six RTD input channels for different types of RTD signal like

as Pt, Ni, Balco. It is an effective solution in industrial & building

automation. Normally, broken external wire will lead to an inaccurate

current value; however, the ADAM-4015 provides a broken wire

detecting function. Therefore, users can easily fix the broken wire

problems. This module can accept RTD sensors that have two or three

wires. After the V2.04 of ADAM-4015, ADAM-4015 can support the

“BA1 -200~600℃”

-

-

-

3

2

+

D

3

3

N

D

M

D

G

T

O

T

R

C

R

6

2

1

+

2

2

D

M

M

D

T

O

O

T

R

C

R

C

-

0

+

+

1

0

1

D

T

R

0

D

M

D

D

T

O

T

T

R

R

C

R

4

1

TYPE

A

/

N

Pt 100

Pt 1000

BALCO 500

Ni

Ni

A

/

N

RANGE

蚓

- 150

-50

0蚓 - 100

蚓

0蚓 - 200

蚓

0蚓 - 400

蚓

-

-200蚓 - 200

-

-40蚓 - 160

蚓

-30蚓 - 120

蚓

-80蚓 - 100

蚓

0蚓 - 100

蚓

3

+

-

1

A

s

A

D

T

T

V

N

A

A

+

*

D

G

D

T

I

N

I

)

)

)

)

Y

G

R

B

(

(

(

(

CODE

(IEC/JIS) 3 0 /3 5

(IEC/JIS) 3 0 /3 5

(IEC/JIS) 3 0 /3 5

(IEC/JIS) 3 0 /3 5

(IEC/JIS) 3 0 /3 5

40

41

42

43

1

4

5

-

+

-

4

M

D

O

T

C

R

+

4

5

5

M

D

D

D

O

T

T

T

R

R

C

R

Figure 3-17 ADAM-4015 6-channel RTD Input Module

Chapter 3 I/O Modules

3-17

Page 45

I/O Modules

Application Wiring

Figure 3-18 ADAM-4015 RTD Input Module Wiring Diagram

3-

18

ADAM 4000 Series User’s Manual

Page 46

Chapter 3

Technical specification of ADAM-4015

Channel Number 6 differential

Support Protocol ADAM ASCII and MODBUS/RTU

Input Type Pt100, Pt1000, BALCO500, Ni

Input Connections 2 or 3 wires

Wire Burnout Detection Yes

Pt100: -50 to 150° C

0 to 100° C

0 to 200° C

0 to 400° C

-200 to 200° C

Input Type and

Temperature Range

Isolation Voltage 3000 VDC

Pt1000: -40 to 160° C

Balco500: -30 to 120° C

Ni 50 RTD: -80 to 100° C

Ni 508 RTD: 0 to 100° C

Sampling Rate 10 sample/second (total)

Input Impedance 10 M

Resolution 16-bit

Accuracy ±0.1% or better

CMR@50/60Hz 120 dB

NMR@50/60Hz 100 dB

Span Drift

Zero Drift

Watchdog Timer System (1.6 second) and Communication

Power Input +10~+30 V

Power Consumption 1.2 W @ 24VDC

± 25 ppm/℃

± 3 V/℃

(non-regulated)

DC

Table 3-1 Technical specification of ADAM-4015

Chapter 3 I/O Modules

3-19

Page 47

I/O Modules

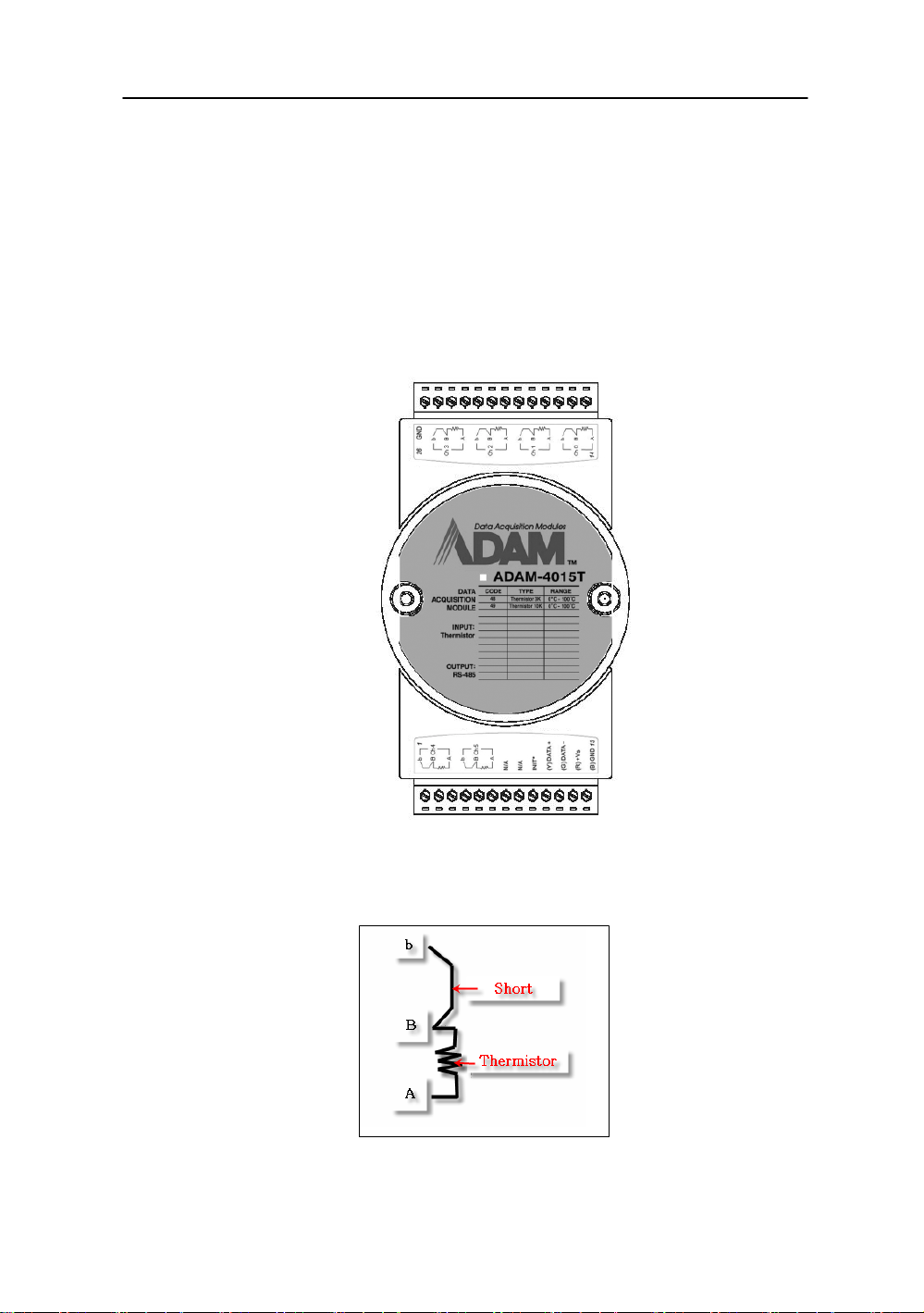

3.5 ADAM-4015T 6-channel Thermistor Input Module

A Thermistor Module is popularly used for temperature

measurement. Unlike the traditional design, the ADAM-4015T

provides six thermistor input channels for thermistor signal. It is an

effective solution in industrial & building automation. Normally,

broken external wires will lead to an inaccurate current value. The

ADAM-4015T provides a broken wire detecting function, so users

can easily fix the problems.

Figure 3-19 ADAM-4015T 6-channel Thermistor Input Module

Application Wiring

Figure 3-20 ADAM-4015T Thermistor Input Module Wiring Diagram

3-

20

ADAM 4000 Series User’s Manual

Page 48

Chapter 3

Technical specification of ADAM-4015T

Channel Number 6 differential

Support Protocol ADAM ASCII and MODBUS/RTU

Input Type Thermistor

Input Connections 2 or 3 wires

Wire Burnout Detection Yes

Input Type and

Temperature Range

Isolation Voltage 3000 VDC

Sampling Rate 10 sample/second (total)

Input Impedance 10 M

Resolution 16-bit

Accuracy ±0.1% or better

CMR@50/60Hz 120 dB

NMR@50/60Hz 100 dB

Span Drift

Zero Drift

Watchdog Timer System (1.6 second) and Communication

Power Input +10~+30 V

Power Consumption 1.2 W @ 24VDC

Thermistor 3k 0~100℃

Thermistor 10k 0~100℃

± 25 ppm/℃

± 3 V/℃

(non-regulated)

DC

Table 3-2 Technical specification of ADAM-4015T

Chapter 3 I/O Modules

3-21

Page 49

I/O Modules

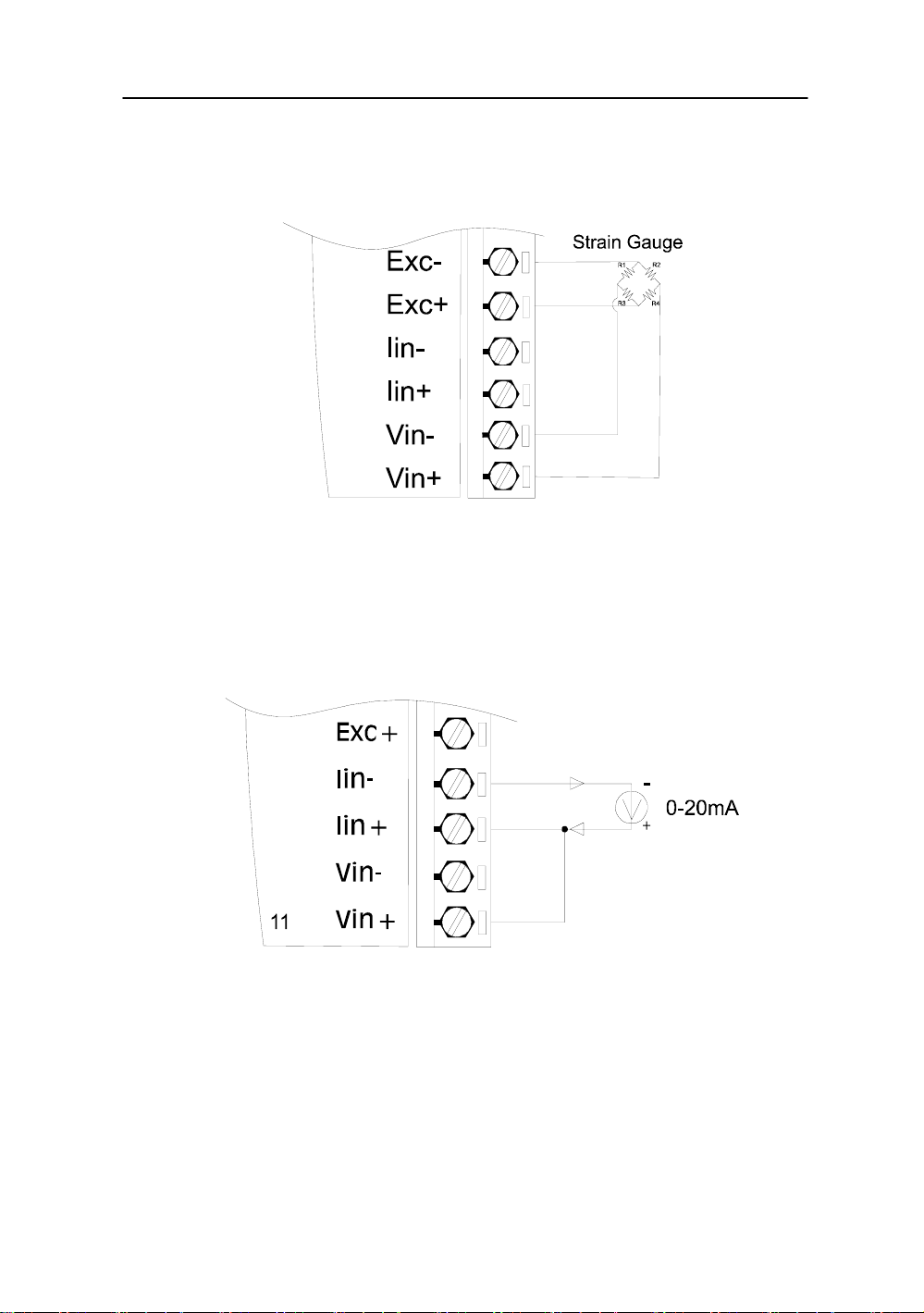

3.6 ADAM-4016 Analog Input/Output Module

A strain gauge input module uses a microprocessor-controlled

integrating A/D converter to convert sensor voltage or current signals

into digital data for load cell and stress measurement. The digital data

are then translated into either, two’s complement hexadecimal format or

percentage of full-scale range (FSR) according to the module’s

configuration. When prompted by the host computer, the data are sent

through a standard RS-485 interface.

The strain gauge input module offers signal conditioning, A/D

conversion, ranging, and RS-485 digital communication functions.

They protect your equipment from power surges at the ground terminal

by providing opto-isolation of the A/D input and up to 3000 V

transformer based isolation.

Excitation Voltage Output

A strain gauge input module can supply single channel voltage

output for excitation. The module receives digital input from the host

computer, and the format of the data is engineering units. It then uses

its microprocessor-controlled D/A converter to convert the digital data

into output signals.

Strain gauge input modules protect your equipment from power

surges at the ground terminal by providing opto-isolation of the D/A

output and up to 3000 V

transformer-based isolation.

DC

DC

Digital Outputs

A strain gauge input module also contains four digital outputs.

Outputs are open-collector transistor switches that may be controlled by

the host computer. They can control solid-state relays which can be

applied to heaters, pumps, and other electrical controlled equipments.

Alarm signaling

Strain Gauge input modules include High and Low alarm functions.

High and Low alarm limits may be downloaded into the module’s

EEPROM by the host computer.

The alarm functions can be enabled or disabled remotely. When the

alarm function is enabled, both Digital Output channels are used to

indicate the High and Low alarm states. Digital Output channel 1 (DO1)

equals to High alarm state and Digital Output channel 0 (DO0) equals

to Low alarm state. The High and Low alarm state can be read at any

time by the host computer.

3-

22

ADAM 4000 Series User’s Manual

Page 50

Chapter 3

Every A/D conversion will be followed by a comparison with the

High and Low limits. When the input value exceeds one of these limits,

the High or Low alarm state is set to ON.

There are two alarm mode options, Momentary and Latching. If the

alarm is in Latching mode, the alarm will stay on even when the input

value returns within limits. An alarm in Latching mode can be turned

OFF by issuing a Clear Alarm command from the host computer. A

Latching alarm is cleared by the module when the opposite alarm is set.

When the module receives a value that is lower than the Low alarm

limit, it will clear the High alarm and turn the Low alarm ON.

When the alarm is in Momentary mode, the alarm will be turned

OFF as soon as the input value returns to within limits.

The arrangement of coupling High and Low alarm states with

Digital Output lines may be utilized to build ON/OFF controllers that

can operate without the host computer involvement.

Chapter 3 I/O Modules

3-23

Page 51

I/O Modules

ADAM-4016 Analog Input/Output Module

Figure 3-21 ADAM-4016 Analog Input/Output Module

Accepts:

- Millivolt inputs: ±15 mV, ±50 mV, ±100 mV, ±500 mV

- Current input: ±20 mA

Excitation voltage output: 0 ~ 10 V

Four digital output channels are provided.

Depending on the module’s configuration setting, it can forward the

data to the host computer in one of the following formats:

- Engineering units (mV or mA)

- Percent of full-scale range (FSR)

- Two’s complement hexadecimal

3-

24

ADAM 4000 Series User’s Manual

Page 52

Chapter 3

Application Wiring

Figure 3-22 ADAM-4016 Strain Gauge Voltage Input Wiring Diagram

Figure 3-23 ADAM-4016 Strain Gauge Current Input Wiring Diagram

Chapter 3 I/O Modules

3-25

Page 53

I/O Modules

Figure 3-24 ADAM-4016 Digital Output Wiring Diagram Used with SSR

3-

26

ADAM 4000 Series User’s Manual

Page 54

Chapter 3

3.7 ADAM-4017/4017+/4018/4018M/4018+ 8-channel Analog Input Modules

ADAM-4017/4018 8-channel Analog Input Module

The ADAM-4017/4018 is a 16-bit, 8-channel analog input module

that provides programmable input ranges on all channels. This module

is an extremely cost-effective solution for industrial measurement and

monitoring applications. Its opto-isolated inputs provide 3000 V

isolation between the analog input and the module, and protect the

module and peripherals from damaging due to high input-line voltages.

The ADAM-4017/4018 offers signal conditioning, A/D conversion,

ranging and RS-485 digital communication functions. The module

protects your equipment from power surges at the ground terminal by

providing opto-isolation of A/D input and up to 3000 V

based isolation.

The ADAM-4017/4018 uses a 16-bit microprocessor-controlled

sigma-delta A/D converter to convert sensor voltage or current into

digital data. The digital data are then translated into engineering units.

When prompted by the host computer, the module sends the data to the

host through a standard RS-485 interface.

transformer

DC

DC

of

ADAM-4018M 8-channel Analog Input Data logger

The ADAM-4018M is a 16-bit, 8-channel analog input data logger

featuring programmable input ranges on all channels. This reliable and

easy to use analog input logger can store up to 38,000 measurements

for a maximum duration of 20 years.

The ADAM-4018M can accept various analog inputs such as

thermocouple, mV, V and mA. It also offers three configurable logging

modes, standard log, event log, and mixed log. Optically isolated inputs

provide 3000 V

of isolation between the module and the analog input,

DC

and protect the module and peripherals from damaging due to high

voltages on the input lines.

The ADAM-4018M is an extremely cost-effective solution for

industrial measurement and monitoring applications.

Chapter 3 I/O Modules

3-27

Page 55

I/O Modules

ADAM-4017+ 8-channel Differential Analog Input Module

Here comes a solution to the demand for more analog input channels.

Similar to its counterpart, the ADAM-4017+ enables eight differential

channels with multiple input ranges. This multi-channel/multi-range

structure allows channels with different input ranges at the same time.

For example, channel 1 can have the range ± 5V meanwhile the others

are ± 10V and ± 20 mA.

Instead of leaving two single-ended channels in ADAM-4017

module due to the limit number of pins, ADAM-4017+ uses a switch

to switch AGND and INIT* to Vin6- and Vin7- respectively to allow 8channel input. Moreover, the ADAM-4017+ has been expanded to

accept 4 ~ 20 mA, so the user can employ it in various applications

ADAM-4018+ 8-channel Thermocouple Input Module

Here comes a solution to the demand for more thermocouple input

channels. Similar to its counterpart, the ADAM-4018+ enables eight

differential channels with multiple input types. This multichannel/multi-type structure allows synchronizing channels with

different types of input. For example, channel 1 has K type of input

meanwhile the others have R and S types.

ADAM-4018+ is an 8-channel T/C input module. Comparing with

the universal analog input module ADAM-4019, it is more dedicated to

T/C and 4 ~ 20 mA inputs for those with special request. It improves

ADAM-4018 with the traditional design of six differential and two

single-ended channels. It also enhances the steadiness and reliability of

the wiring. Normally, broken external wires will lead to an inaccurate

current value. ADAM-4018+, however, provides burned-out detection

that allows users to fix the problems easily. ADAM 4018+ has build in

Shunt.

3-

28

ADAM 4000 Series User’s Manual

Page 56

ADAM-4017 8-channel Analog Input Module

Chapter 3

Figure 3-25 ADAM-4017 8-channel Analog Input Module

Channels:

- Six differential, two single-ended

Accepts:

- Millivolt inputs: ±150 mV and ±500 mV

- Volt inputs: ±1 V, ±5 V, and ±10 V

- Current input: ±20 mA (requires a 120 resistor)

The module forwards the data to the host computer in engineering units

(mV, V or mA)

Chapter 3 I/O Modules

3-29

Page 57

I/O Modules

A

A

V

V

A

A

ADAM-4017+ 8-channel Differential Analog Input Module

Vin4-

Vin3-

Vin2-

Vin1-

Vin4+

STRAIN GAUGE

Vin5+

Vin3+

DATA

ACQUISITION

MODULE

INPUT:

mV, V, m

OUPUT:

RS-485

Vin5-

Vin6+

Vin2+

DAM-4017+

CODE INPUT RANGE

08

09

0A

0B

0C

0D

07 4 ~20 m

Vin6-

Vin7+

Vin1+

±10 V

±5 V

±1 V

±500 m

±100 m

±20 m

Vin7-

(Y)Data+

Vin0-

Vin0+

(G)Data-

(R)Vs+

(B)GND

Figure 3-26 ADAM-4017+ 8-ch. differential analog input module

Jumper setting (ADAM-4017+)

1. JP0~JP7

JP0~

JP7

Mapping to

Channel

2. JP12 can Enable/Disable Watchdog Timer Function. The default

setting is closed, i.e., Watchdog Timer Function Enabled. Please

always keep JP12 closed and enable/disable the watchdog timer

function in ADAM-utility.

3-

30

ADAM 4000 Series User’s Manual

20 mA Input Range

Voltage Input range

Ch.1 Ch.2 Ch.3 Ch.

Ch.5 Ch.6 Ch.7 Ch.8

4

JP 0 JP 2 JP 4 JP 6 JP 1 JP 3 JP 5 JP 7

Page 58

Chapter 3

Technical specification of ADAM-4017+

Channel 8

Input Type mV, V, mA

Input Range ±150 mV, ±500 mV, ±1 V, ±5 V, ±10 V,

±20 mA, 4 ~ 20 mA

Isolation Voltage 3000 VDC

Fault and Over-voltage

protection

Sampling Rate 10 sample/sec (total)

Input Impedance Voltage: 20 M, Current: 120

Accuracy ±0.1% or better

Power Consumption 1.2 W@ 24V

I/O Connector Type 10 pin plug-in terminal

Table 3-3 Technical specification of ADAM-4017+

With stands over-voltage up to ±35 V

DC

Chapter 3 I/O Modules

3-31

Page 59

I/O Modules

ADAM-4018 8-channel Analog Input Module

Vin 4-

Vin 3-

DATA

MODULE

INPUT:

mV, V, mA

OUPUT:

RS-485

Vin 3+

Vin 2-

ADAM-4018

CODE INPUT RANGE

00

01

02

03

04

05

06

DE

DF

10

11

12

13

14

Vin 4+

ACQUISITION

Thermocouple

Vin 0-

Vin 1-

Vin 2+

?5 mV

?0 mV

?00 mV

?00 mV

? V

?.5 V

?0 mA

T/C J

T/C K

T/C T

T/C E

T/C R

T/C S

T/C B

Vin 0+

Vin 1+

Vin 5+

Vin 5-

Vin 6+

AGND

(Y) DATA+

Vin 7+

INIT*

(B) GND

(G) DATA-

(R) +Vs

Figure 3-27 ADAM-4018 8-channel Thermocouple Input Module

Channels:

- Six differential, two single-ended

Accepts:

- J, K, T, E, R, S and B thermocouples

- Millivolt inputs: ±15 mV, ±50 mV, ±100 mV and ±500 mV

- Volt inputs: ±1 V and ±2.5 V

- Current input: ±20 mA (requires a 125 resistor)

The module forwards the data to the host computer in engineering units

o

C, mV, V or mA)

(

3-

32

ADAM 4000 Series User’s Manual

Page 60

ADAM-4018M 8-channel Analog Input Data logger

Vin 0-

Vin 4-

Vin 3-

Vin 4+

ACQUISITION

MODULE

mV, V, mA

Thermocouple

OUPUT:

RS-485

Vin 3+

DATA

INPUT:

Vin 1-

Vin 2-

ADAM-4018M

CODE INPUT RANGE

00

01

02

03

04

05

06

DE

DF

10

11

12

13

14

Vin 1+

Vin 2+

?5 mV

?0 mV

?00 mV

?00 mV

? V

?.5 V

?0 mA

T/C J

T/C K

T/C T

T/C E

T/C R

T/C S

T/C B

Vin 0+

Chapter 3

Vin 5+

Vin 5-

Vin 6+

AGND

(Y) DATA+

Vin 7+

INIT*

(B) GND

(G) DATA-

(R) +Vs

Figure 3-28 ADAM-4018M 8-channel Analog Input Data Logger

Channels:

- Six differential, two single-ended

Accepts:

- J, K, T, E, R, S and B thermocouples

- Millivolt inputs: ±15 mV, ±50 mV, ±100 mV, ±500 mV

- Volt inputs: ±1 V and ±2.5 V

- Current input: ±20 mA (requires a 125 resistor)

The module forwards the data to the host computer in engineering units

o

C, mV, V, or mA)

(

Storage Capacity:

- 128 KB flash memory

Chapter 3 I/O Modules

3-33

Page 61

I/O Modules

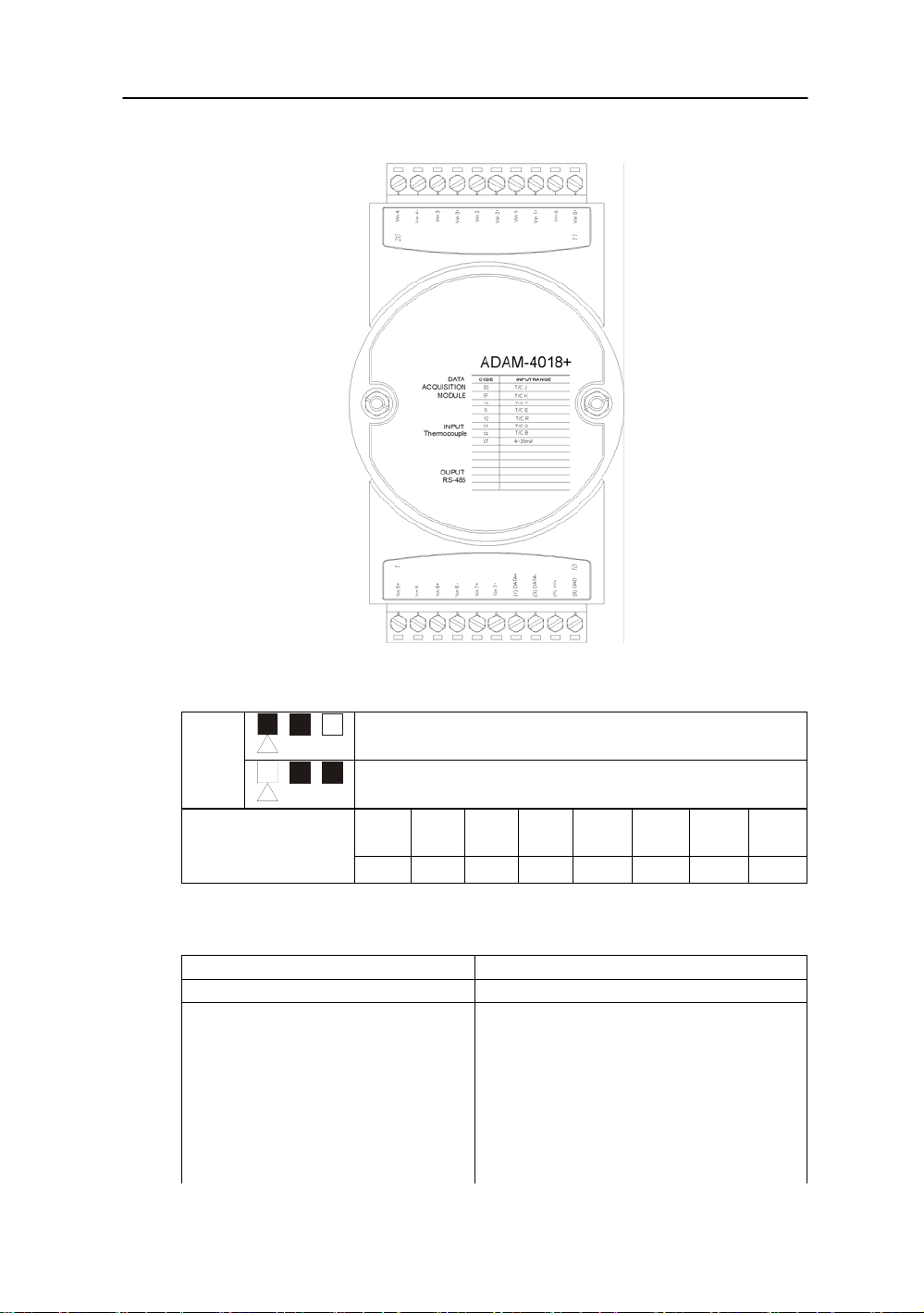

ADAM-4018+ 8-channel Thermocouple Input Module

Figure 3-29 ADAM-4018+ 8-ch. thermocouple input module

JP0~

JP7

Mapping to

Channel

4~20 mA Input Range

Voltage Input range

Ch.1 Ch.2 Ch.3 Ch.

JP 0 JP 2 JP 4 JP 6 JP 1 JP 3 JP 5 JP 7

Technical specification of ADAM-4018+

Channel 8

Input Type Thermocouple

Input range and T/C type ±20 mA, 4~20 mA

3-

34

ADAM 4000 Series User’s Manual

Ch.5 Ch.6 Ch.7 Ch.8

4

J 0 ~ 760° C

K 0 ~ 1370° C

T -100 ~ 400° C

E 0 ~ 1000° C

R 500 ~ 1750° C

S 500 ~ 1750° C

B 500 ~ 1800° C

Page 62

Chapter 3

Isolation Voltage 3000 V

Fault and over-voltage protection Withstands over voltage up to ±35 V

Sampling Rate 10 sample/sec (total)

Input Impedance Voltage: 20 M, Current: 120

Accuracy ±0.1% or better

Power Consumption 0.8 W @ 24VDC

I/O Connector Type 10 pin plug-in terminal

Table 3-4 Technical specification of ADAM-4018+

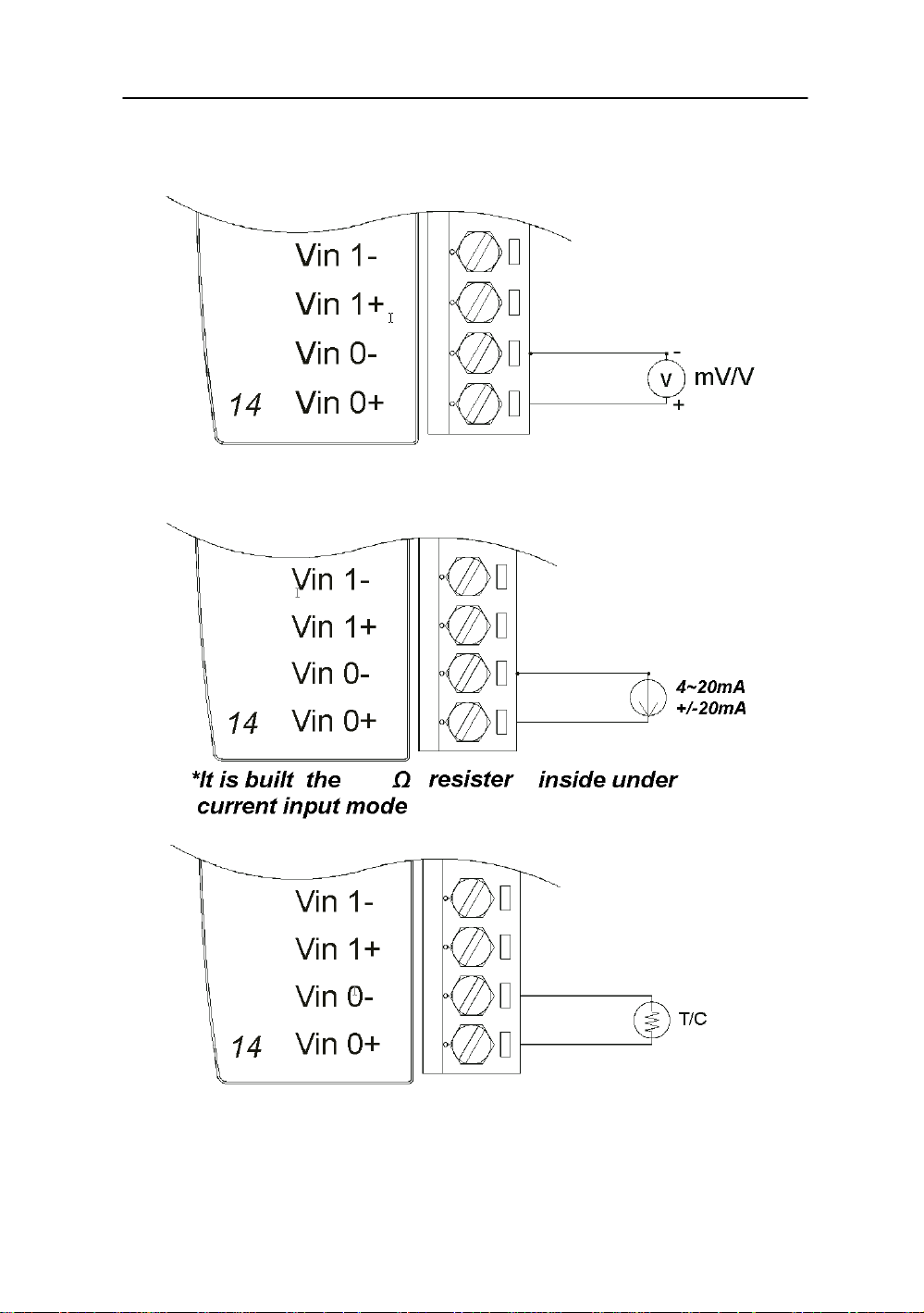

Application Wiring

DC

Figure 3-30 Current Input Wiring Diagram of ADAM-4017

-

Vin0-

11

V

Vin0+

mV/V

+

Figure 3-31(a) ADAM-4017 Differential Input Wiring Diagram (Ch0 ~ Ch5)

Chapter 3 I/O Modules

3-35

Page 63

I/O Modules

V

1

mV/V

Vin5+

+

-

Vin5-

Vin6+

AGND

Vin7+

Figure 3-31(b) ADAM-4017 Single-ended Input Wiring Diagram (Ch6 and Ch7)

Vin 1-

Vin 1+

-

11

Vin 0-

Vin 0+

mV/V

+

Vin 1-

Vin 1+

-

Vin 0-

±

4~20 mA

11

Vin 0+

+

Built-in 125 Ohm Resister

Figure 3-32 ADAM-4017+ Voltage and Current Input Wiring Diagram

3-

36

ADAM 4000 Series User’s Manual

Page 64

Chapter 3

A

Vin 1-

Vin 1+

Vin 0-

-

T/C or 4~20m

Vin 0+

11

Figure 3-33 ADAM-4018+ Thermocouple Input Wiring Diagram

3.8 ADAM-4019+ 8-channel Universal Analog Input Module

The ADAM-4019+ is universal analog input module to integrate

with various AI modules into one. It not only reduces the hardware cost,

but also simplifies the wiring complexity. Furthermore, the ADAM4019+ provides the burnt-out detection functionality for 4~20mA and

all thermocouple input.

+

Chapter 3 I/O Modules

3-37

Page 65

I/O Modules

Figure 3-34 ADAM-4019+ 8-channel Universal Analog Input

The jumper setting of ADAM-4019+ for input type selection:

JP0~JP7 20mA Input Range

Voltage Input range

Mapping to Channel Ch.0 Ch.1 Ch.2 Ch.3 Ch.4 Ch.5 Ch.6 Ch.7

JP 0 JP 1 JP 2 JP 3 JP 4 JP 5 JP 6 JP 7

*It is built the 120Ω resister inside under current input mode

3-

38

ADAM 4000 Series User’s Manual

Page 66

Application Wiring

Chapter 3

120

Figure 3-35 ADAM-4019+ Universal Analog Input Wiring Diagram

Chapter 3 I/O Modules

3-39

Page 67

I/O Modules

Technical specification of ADAM-4019+

Channel 8

Resolution 16 bits

Input Type V, mV, mA, T/C

Input type and temperature range

Isolation Voltage 3000 VDC

Sampling Rate

Input Impedance Voltage: 20 M, Current: 120

Accuracy

Power Consumption 1.0W @ 24VDC

I/O Connector Type 10 pin plug-in terminal

Burn-out Detection

V: ±1 V , ±2.5 V, ±5 V , ±10 V

mV: ±100 mV , ±500 mV

mA: ±20 mA (with 120 Ω resister)

4~20mA (with 120 Ω resister)

Thermocouple:

J 0 to 760 °C

K 0 to 1370 °C

T -100 to 400 °C

E 0 to 1000 °C

R 500 to 1750 °C

S 500 to 1750 °C

B 500 to 1800 °C

10 samples/sec (total)

±0.1% or better

4~20mA and all thermocouple input

Table 3-5 Technical specification of ADAM-4019+

3-

40

ADAM 4000 Series User’s Manual

Page 68

Chapter 3

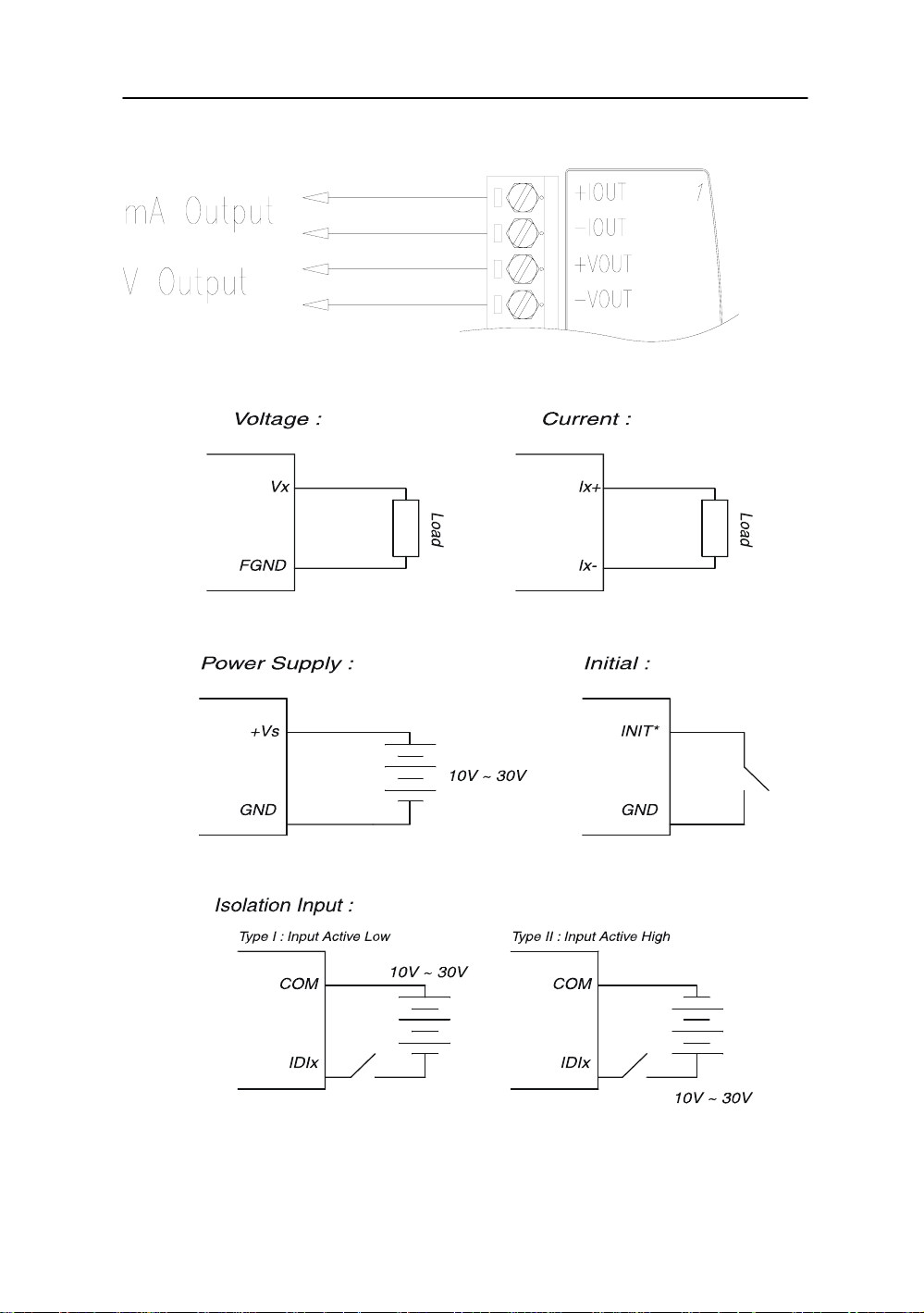

3.9 ADAM-4021 Analog Output Module

Analog output module receives its digital input through an RS-485

interface from the host computer. The format of the data is either two’s

complement hexadecimal format or percentage of full-scale range

(FSR), depending on the module’s configuration. It then uses its

microprocessor-controlled D/A converter to convert the digital data into

output signals.

You will get a true read-back of the analog output signal from the

unit’s ADC, which monitors the output independently. You can also

specify slew rates and start up currents through the configuration

software. The Analog Output Module can supply single-channel analog

output in a range of voltages or currents.

Furthermore, it will protect your equipment from power surges at

the ground terminal by providing opto-isolation of the D/A output and

up to 3000 V

Slew Rate

The slew rate is defined as the discrepancy between the present

number of milliamps (or Volts) per second and the required output

currents (or voltages). An ADAM analog output module may be

configured for a specific slew rate.

transformer based isolation.

DC

Chapter 3 I/O Modules

3-41

Page 69

I/O Modules

ADAM-4021 Analog Output Module

Figure 3-36 ADAM -4021 Analog Output Module

Depending on its configuration settings the module accepts the

following formats from the host computer:

- Engineering units

- Percent of full-scale range (FSR)

- Two’s complement hexadecimal format,

Output types:

- Voltage: 0 ~ 10 V

(Slew rate: 0.0625 to 64 V/sec)

- Currents: 0 ~ 20 mA, or 4 ~ 20 mA.

(Slew rate: 0.125 to 128 mA/sec)

3-

42

ADAM 4000 Series User’s Manual

Page 70

Application Wiring

Figure 3-37 ADAM-4021 Analog Output Wiring Diagram

Chapter 3

Chapter 3 I/O Modules

3-43

Page 71

I/O Modules

3.10 ADAM-4024 4-channel Analog Output Module

ADAM-4024 is a 4-channel analog output module with mixed type

I/O. Currently, there is not any ADAM-4000 series module that provides

more than one analog output channel. Under some circumstances, it is,

however, a demand for multiple analog outputs to fulfill particular

applications without many duplicate modules. ADAM-4024 is designed

to achieve this purpose by integrating four A/O channels and four

isolated D/I channels into only one module. The four digital input

channels function as an interlock for emergency latch output.

ADAM-4024 inherited from ADAM-4021, but provide multi-range

AO support, allows its four A/O channels working at the same time with

different and more output ranges. For example, it can have 4~20 mA and

±10 V at its output. To ensure the operation of machines and facilities,

ADAM-4024 has the functionality of slew rate control. Output slope is

programmable through ramping/clamping the slew rate. Unlike

traditional mechanism, ADAM-4024 permits users to substitute its

default value at the start up. Users can easily set up and configure the

module to be more adaptive.

Figure 3-38 ADAM-4024 4-channel Analog Output Module

3-

44

ADAM 4000 Series User’s Manual

Page 72

Technical specification of ADAM-4024

• Resolution: 12-bit

• Output Type: mA, V

• Output Range: 0~20 mA, 4~20 mA, and ±10V

• Isolation Voltage: 3000 V

DC

• Output Impedance: 0.5 Ω

• Accuracy:

±0.1% of FSR for current output

±0.2% of FSR for voltage output

• Zero Drift:

Voltage output: ±30 µV/°C

Current output: ±0.2 µA/°C

• Span Temperature Coefficient: ±25 ppm/°C

• Output Slope Rate:

0.125 ~ 128 mA/sec.

0.0625 ~ 64 V/sec.

• Current Load Resistor: 0 to 500

• Built-in Watchdog Timer

Isolation Digital Input

•

Channel: 4

Level 0: +1V max

Level 1: +10~30 V

DC

Chapter 3

Chapter 3 I/O Modules

3-45

Page 73

I/O Modules

Application Wiring

Figure 3-39 ADAM-4024 Pin Define and Wiring Diagram

3-

46

ADAM 4000 Series User’s Manual

Page 74

Chapter 3

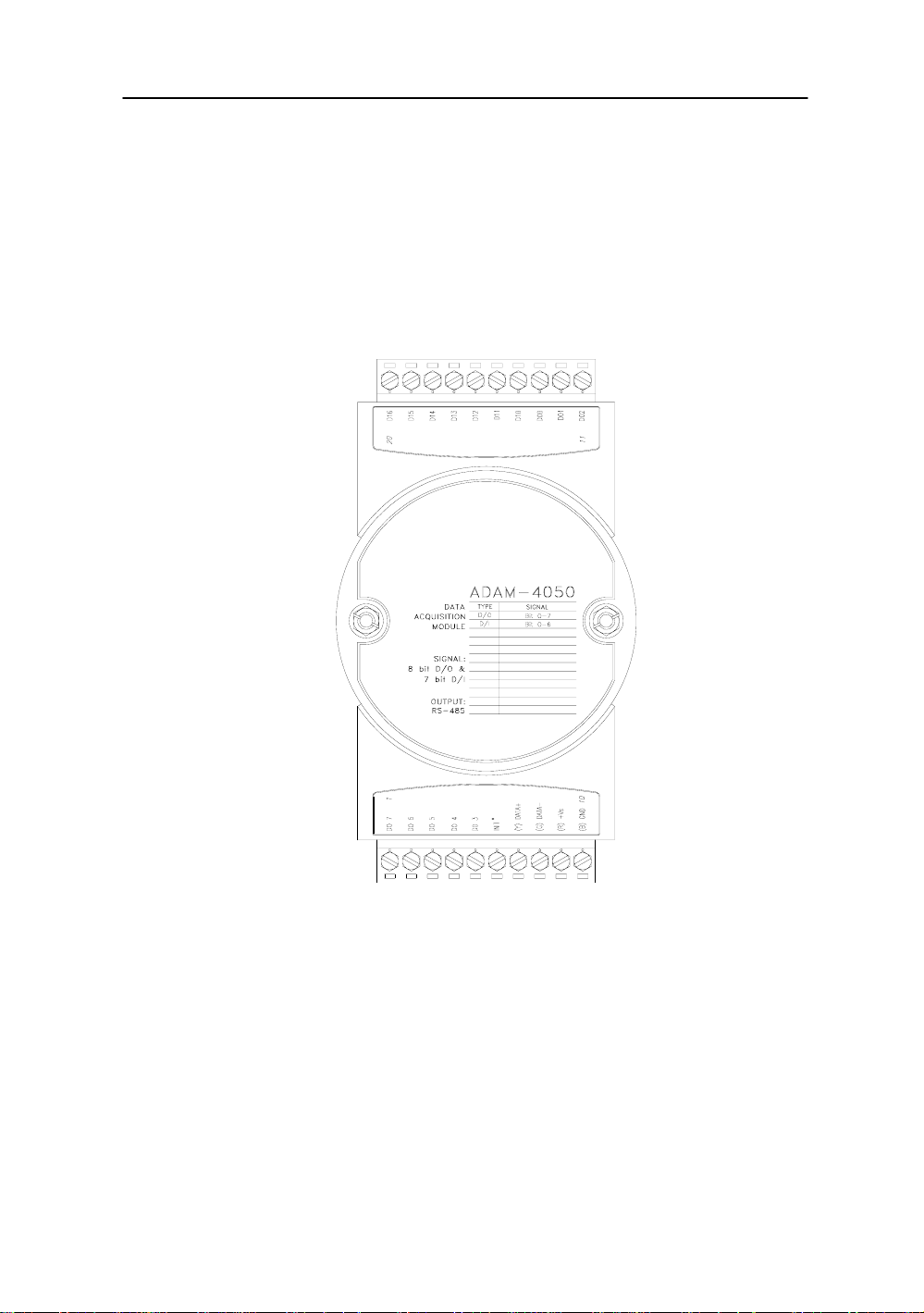

3.11 ADAM-4050 Digital I/O Module

The ADAM-4050 features seven digital input and eight digital

output channels. The outputs are open-collector transistor switches that

you can control from the host computer. You can also use the switches

to control solid-state relays, which can be applied to equipments such as

heaters and pumps. The host computer can use the module's digital

inputs to determine the states of limit, safety switches, and remote

digital signals.

Figure 3-40 ADAM-4050 Digital I/O Module

Channels:

- 7 input channels

- 8 output channels

Digital Input:

- Logic level 0: +1 V max.

- Logic level 1: +3.5 ~ 30 V

Digital Output:

- Open collector to 30 V, 30 mA max. load

Chapter 3 I/O Modules

3-47

Page 75

I/O Modules

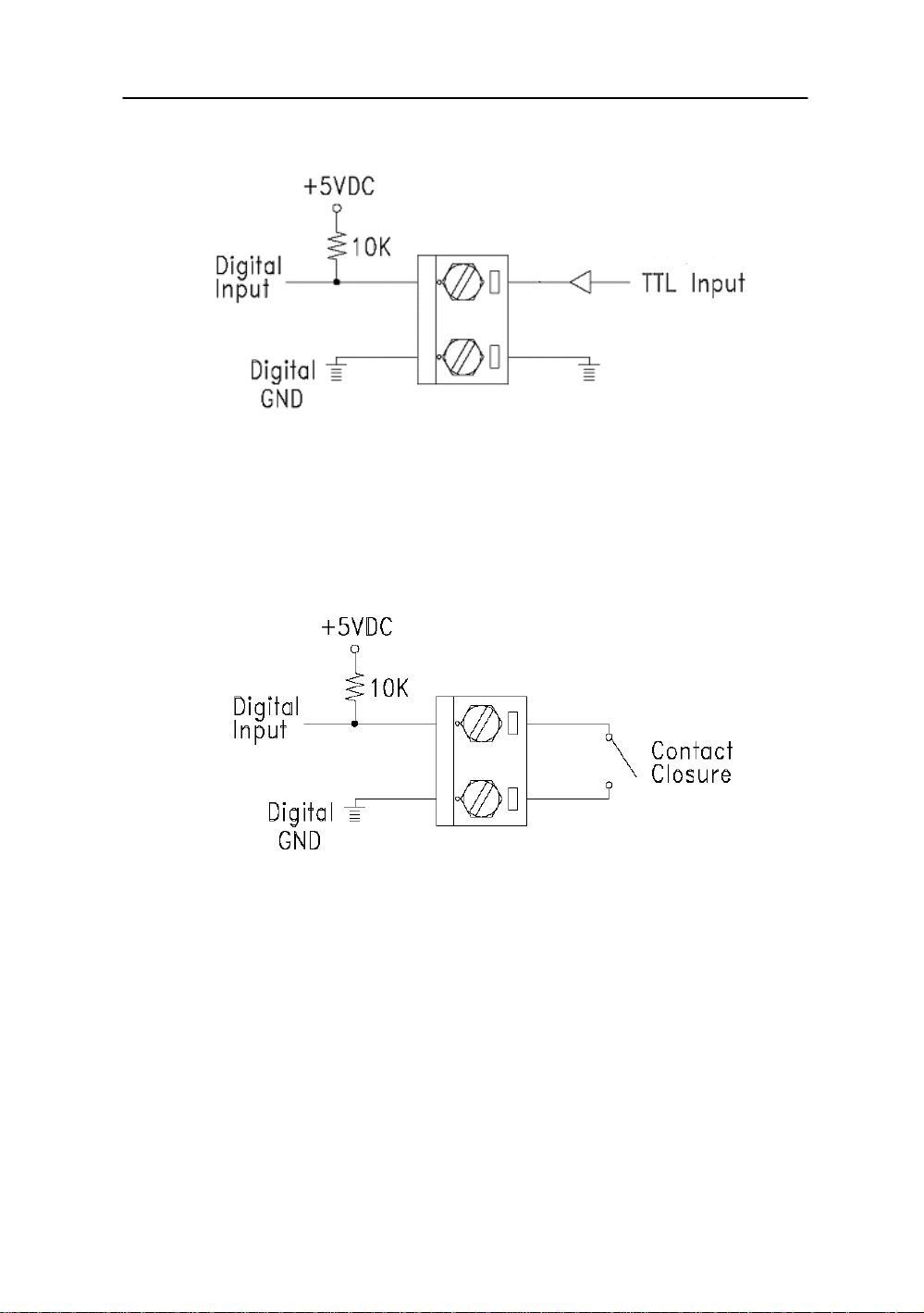

Application Wiring

Figure 3-41 ADAM-4050 TTL Input Wiring Diagram

Figure 3-42 ADAM-4050 Contact Closure Input Wiring Diagram

Figure 3-43 ADAM-4050 Digital Output Wiring Diagram Used with SSR

3-

48

ADAM 4000 Series User’s Manual

Page 76

Chapter 3

3.12 ADAM-4051 16-channel Isolated Digital Input Module

The ADAM-4051 is a 16 channel Digital Input Module. It is built

with 2500V

The main difference from other modules is that ADAM-4051 accepts

10 ~ 50V input voltage to fit various digital signals like 12 V, 24 V, and

48 V. Moreover, users can read the current status from the LED

indicators on the front panel.

optical isolation, and it is suitable for critical applications.

DC

Figure 3-44 ADAM-4051 16-channel Isolated Digital Input Module

• Channel: 16 (4-channel/group)

• Optical Isolation: 2500 V

DC

• Opto-isolator response time: 25 s

• Over-voltage Protect: 70 V

• ESD (Electro Static Discharge): 2000 V

DC

DC

• LED Indicator: On: Active; Off: Non-active

• Input Voltage:

Dry Contact Logic level 1: close to GND, Logic level 0: open

Wet Contact Logic level 1: 10 ~ 50 V, Logic level 0: 3 V

• Power consumption: 1W @ 24 V

DC

• I/O Connector Type: 13 pin plug-in terminal*2

Chapter 3 I/O Modules

3-49

Page 77

I/O Modules

Application Wiring

Figure 3-45 ADAM-4051 Dry Contact Wiring Diagram

Figure 3-46 ADAM-4051 Wet Contact Wiring Diagram

3-

50

ADAM 4000 Series User’s Manual

Page 78

Chapter 3

3.13 ADAM-4052 Isolated Digital Input Module

The ADAM-4052 provides eight digital input channels. Among

these eight channels, six of them are fully independent isolated

channels and the other two are isolated channels with a common ground.

They all have 5000 V

input lines

isolation to prevent power surges from the

RMS

Figure 3-47 ADAM-4052 Isolated Digital Input Module

Channels: 8

- 6 differential channels (fully independent isolated channels)

- 2 single-ended channels (isolated channels with common ground)

Digital Input:

- Logic level 0: +1 V max.

- Logic level 1: +3 ~ 30 V

Chapter 3 I/O Modules

3-51

Page 79

I/O Modules

Application Wiring

Figure 3-48 ADAM-4052 Isolation Digital Input Wiring Ground

3-

52

ADAM 4000 Series User’s Manual

Page 80

Chapter 3

3.14 ADAM-4053 16-channel Digital Input Module

The ADAM-4053 provides 16 digital input channels for dry contact

or wet contact signals. For dry contact, the effective distance from DI

to contact point is up to 500 m.

Figure 3-49 ADAM-4053 16-channel Digital Input Module