Page 1

ADAM-5000 Series

RS-485 Based Data Acquisition

and Control System

User’s Manual

Page 2

Copyright Notice

This document is copyrighted, 2001, by Advantech Co.,

Ltd. All rights are reserved. Advantech Co., Ltd., reserves the

right to make improvements to the products described in this

manual at any time without notice.

No part of this manual may be reproduced, copied, translated

or transmitted in any form or by any means without the prior

written permission of Advantech Co., Ltd. Information

provided in this manual is intended to be accurate and

reliable. However, Advantech Co., Ltd. assumes no

responsibility for its use, nor for any infringements upon the

rights of third parties which may result from its use.

Acknowledgment

ADAM is a trademark of Advantech Co., Ltd. IBM and PC

are trademarks of International Business Machines Corporation.

CE Nonification

The ADAM-5000 series developed by Advantech Co.,

Ltd. has passed the CE test for environmental specifications. Test

conditions for passing included the equipment being operated

within an industrial enclosure, using shielded twisted-pair RS-485

cables and having SFC-6 sleeve core clamps added to the power

cable and the RS-485 cable. In order to protect the ADAM-5000

system from being damaged by ESD (Electrostatic Discharge) and

EMI leakage, we strongly recommend the use of CE-compliant

industrial enclosure products, shielded twisted-pair RS-485 cables,

and core clamps.

Edition 7.3

Aug. 2007

Page 3

A Message to the Customer…..

Advantech Customer Services

Each and every Advantech product is built to the most exacting

specifications to ensure reliable performance in the unusual and

demanding conditions typical of i ndustri al envir onm ents. Whet her

your new Advantech equipment is destined for the laboratory or

the factory floor, you can be assured that your product will provide

the reliability and ease of operation for which the name Advantech

has come to be known.

Your satisfaction is our number one concern. Here is a guide to

Advantech’s customer services. To ensure you get the full benefit

of our services, please follow the instructions below carefully .

Technical Support

W e want you to get t he maximum performance from your products .

So if you run into technical difficulties, we are here to help. For

most frequently asked questions you can easily find answer s in

your product documentation. These answers are normally a lot

more detailed than the ones we can give over the phone.

So please consult this manual first. If you still can’t find the answer ,

gather all the information or que stions that apply t o y our pro blem

and, with the product close at hand, call your dealer . Our dealers

are well trained and ready to give you the support you need to get

the most from your Advantech prod ucts. In f act, m ost pr obl em s

reported are minor and are able to be easily solved over the phone.

In addition, free technical s upport is availabl e from Advant ech

engineers every business day. We are always ready to give advice

on application requirements or specific information on the installation and operation of any of our p roduc ts.

Page 4

Product Warranty

Advantech warrants to you, the original purchaser, that each of its

products will be free from defects in materials and workmanship for

one year from the date of purchase.

This warranty does not apply to any products which have been

repaired or altered by other t han repair personnel authorized by

Advantech, or which have been subject to misuse, abuse, accident

or improper installation. Advantech assumes no liability as a

consequence of such events under the terms of this Warranty.

Because of Advantech’s high quality-control standards and

rigorous testing, most of our customers never need to use our

repair service. If an Advantech product ever does prove defective,

it will be repaired or replaced at no charge during the warranty

period. For out-of-warranty repairs, you will be billed according to

the cost of replacement materials, service time and freight. Please

consult your dealer for more details.

If you think you have a defective product, follow these steps:

1 . Collect all the information about the problem encountered

(e.g. type of PC, CPU speed, Advantech products used, other

hardware and software used etc.). Note a nythi ng abnorm al and

list any on-screen messages you get when the problem occurs.

2 . Call your dealer and describe the problem. Please have your

manual, product, and any helpful information readil y available.

3. If your product is diagnosed as defective, you have to

request an RAM number . When requesting a n RMA (Return

Material Authorization) number, please access ADVANTECH's

RMA website: http://www.advantech.com.tw/rma. If the web

sever is shut down, please contact our of fice directly. Y ou

should fill in the "Problem Repair F orm", desc ribing in detail

the applicatio n environm ent, config uration, a nd probl ems

encountered. Note that error descriptions such as "does not

work" and "failure" are so general that we are then required to

apply our internal standard repair process.

Page 5

4 . Carefully pack the defective product, a completely filled-out

Repair and Replacement Order Card and a photocopy of da ted

proof of purchase (such as your sales receipt) in a shippable

container. A product returned without dated proof of purchase

is not eligible for warranty service.

5 . Write the RMA number visibly on the outsi de of the

package and ship it prepaid to your dealer.

Page 6

Contents

Chapter 1 Introduction ……………………………………… 1-1

Chapter 2 Installation Guideline….…………………………2-1

Chapter 3 ADAM-5000 System….…………………………... 3-1

Chapter 4 I/O Modules………..….…………………………. 4-1

Chapter 5 Software Utilities………..….……………………. 5-1

1.1 Overview........................................................................1-2

1.2 System Configuration....................................................1-3

1.3 A Few Steps to a Successful System............................ 1-4

2.1 General ......................................................................... 2-2

2.2 Module Installation ...................................................... 2-6

2.3 I/O Slots and I/O Channel Numbering ......................... 2-6

2.4 Mounting....................................................................... 2-7

2.5 Wiring and Connections ............................................... 2-9

3.1 Overview ...................................................................... 3-2

3.2 Major Features of the ADAM-5000 System ................ 3-2

3.3 System Setup ................................................................ 3-6

3.4 Technical Specifications of the ADAM-5000 ……..... 3-7

5.1 ADAM-4000 and ADAM-5000 Windows Utility….. 5-2

5.1.1 Overview ..................................................................... 5-3

5.1.2 Save Function ............................................................. 5-3

5.1.3 COM Port Settings ........................................................ 5-4

5.1.4 Search Connected modules .............................. ............ 5-5

Page 7

5.1.5 Terminal Emulation ..................................................... 5-7

5.1.6 Data Scope ................................................................... 5-8

5.1.7 Saving a Module’s Configuration to File .................. 5-10

5.1.8 Load Module’s Configuration File ............................ 5-12

5.1.9 Module Configuration ................................................ 5-14

5.1.10 Module Calibration .................................................... 5-15

5.1.11 Data Input and Output ................................................ 5-19

5.1.12 Alarm Settings ........................................................... 5-21

5.1.13 Download Procedure .................................................. 5-22

5.2 DLL (Dynamic Link Library) Driver ......................... 5-25

5.3 DDE (Dynamic Data Exchange) Server ..................... 5-25

Chapter 6 Command Set……………….………………………6-1

6.1 Introduction .................................................................. 6-2

6.2 Syntax .......................................................................... 6-2

6.3 CPU Command Set....................................................... 6-4

6.4 ADAM-5013 RTD Input Command Set …................ 6-19

6.5 Analog Input Command Set ...................................... 6-37

6.6 ADAM-5017H Analog Input Command Set …......... 6-57

6.7 Analog Input Alarm Command Set ........................... 6-71

6.8 Analog Output Command Set .................................... 6-90

6.9 Digital Input/Output Command Set ................. ......... 6-107

6.10 ADAM-5080 Counter/Frequency Command Set...... 6-115

Chapter 7 Troubleshooting…………..….……………………….7-1

7.1 Hardware Diagnosis...................................................... 7-2

7.2 Software Diagnosis ...................................................... 7-2

7.3 System Indicators ......................................................... 7-3

7.4 Communication Problems ........................................... 7-5

7.5 I/O Module Troubleshooting ....................................... 7-6

Page 8

Appendix A Quick Start Example….….………………………. A-1

A.1 System Requirements to Setup an ADAM-5000 System…. A-2

A.2 Basic Configuration Hook-up ..................................... A-5

A.3 Baud Rate and Checksum ........................................... A-8

A.4 A Distributed ADAM-5000 Network System Hook-up .... A-11

Appendix B Data Format and I/O Ranges……………………. B-1

B.1 Analog Input Formats ................................................... B-2

B.2 Analog Input Ranges - ADAM-5017, 5 0 1 8 and 5018P......

B-4

B.3 Analog Input Ranges of ADAM-5017H and 5017UH.. B-7

B.4 Analog Output Formats ...... .......................................... B-8

B.5 Analog Output Ranges ................................................. B-8

B.6 ADAM-5013 RTD Input Format and Ranges ............. B-9

Appendix C RS-485 Network……………….…………….…. C-1

C.1 Basic Network Layout ................................................ C-3

C.2 Line Termination ........................................................ C-6

C.3 RS-485 Data Flow Control ............................................ C-9

Appendix D How To Use Checksum Features.…………….… D-1

D.1 Checksum Enable/Disable .......................................... D-2

Appendix E ADAM-4000/5000 System Grounding Installation… E-1

E. 1 Power Supplies For relevant wiring issues, please refer to

t h e following schem e:.......... ............ .. .....E-2

E.2 Grounding Installation ....................................................E-2

E.3 External DI, DO, AI, AO Wiring Reference ..............E-3

E.4 Requirements for RS-485 signal wires ..........................E-3

Page 9

E.5 Grounding reference (Ground bar for the factory, environment

should have a standard resistance below W)…………….E-5

E.6 Some Suggestions on Wiring Layout ..........................E-6

Appendix F Grounding Reference………………………….…. F-1

F.1 Grounding ................................................................. F-3

F.2 Shielding ................................................................... F-9

F.3 Noise Reduction Techniques.................................... F-14

F.4 Check Point List ...................................................... F-15

Appendix G Grounding Reference………………………….….G-1

G.1

G.2

G.3

G.4

The ADAM-5000 series main system’s DIP Switch

Setting

Modbus Commands for 5000 Series

Modbus Address Mapping

...................................................................... G-2

.................. G-3

.....................................G-5

Address mapping of ADAM-5080 For ADAM-5000

ModBus

..................................................................... G-8

Page 10

Figures

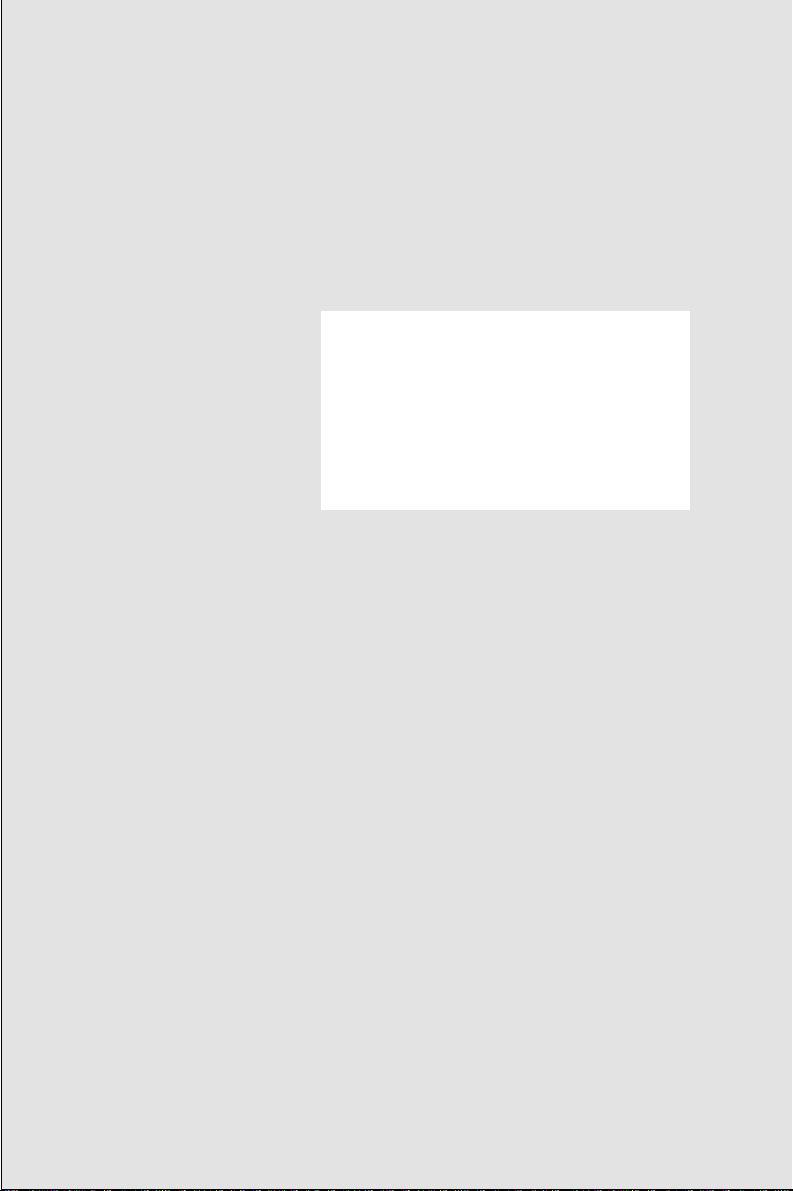

Figure 1-1 ADAM-5000 Configurations……………….…………..1-3

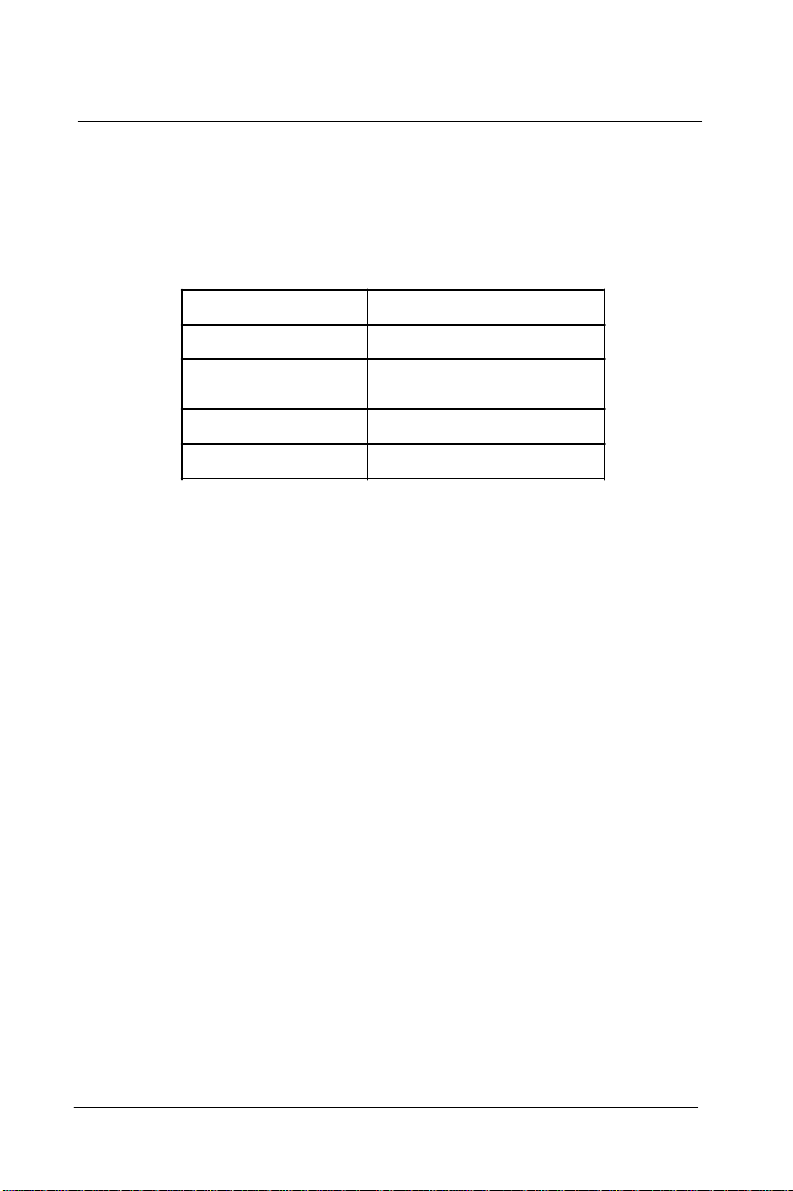

Figure 2-1 ADAM-5000 Diagnostic indicators……….…………..2-3

Figure 2-2 ADAM-5000 Network address DIP switch.………….2-4

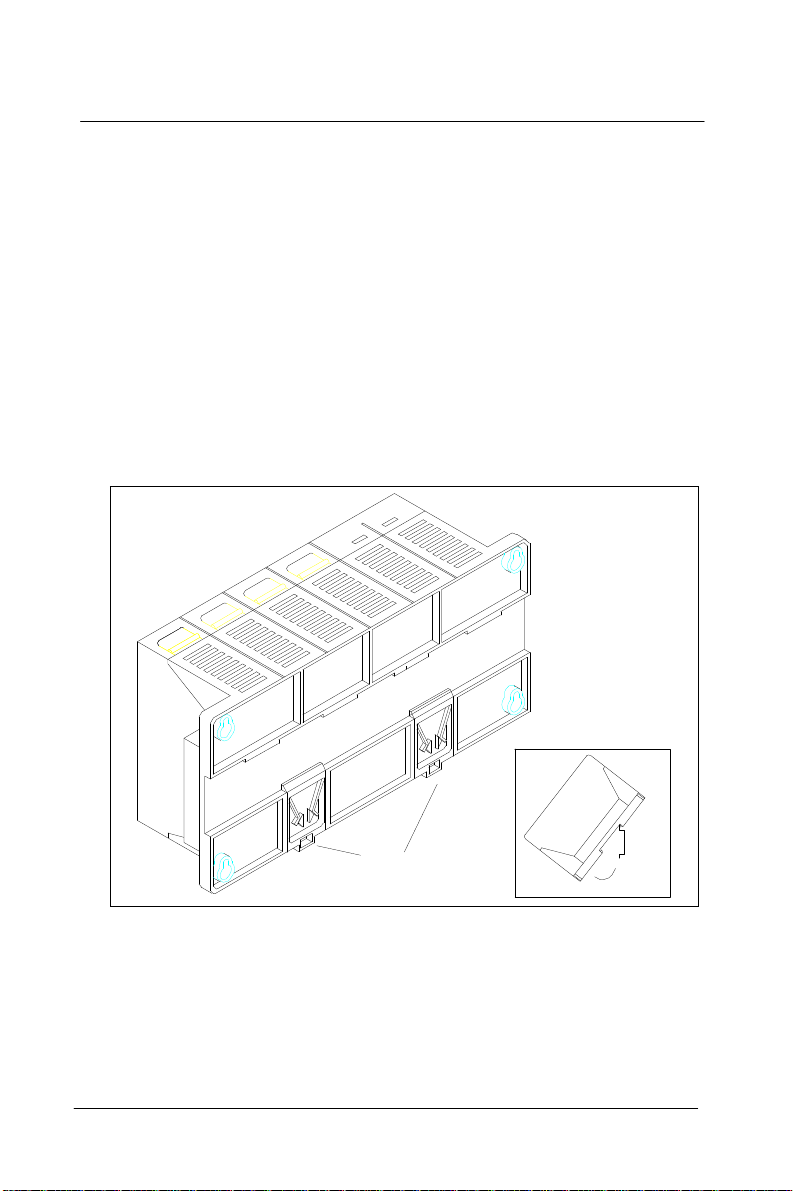

Figure 2-3 Module alignment and installation………………..…..2-6

Figure 2-4 ADAM-5000 Panel mounting.………………………..2-7

Figure 2-5 ADAM-5000 Rail mounting.…………………..……..2-8

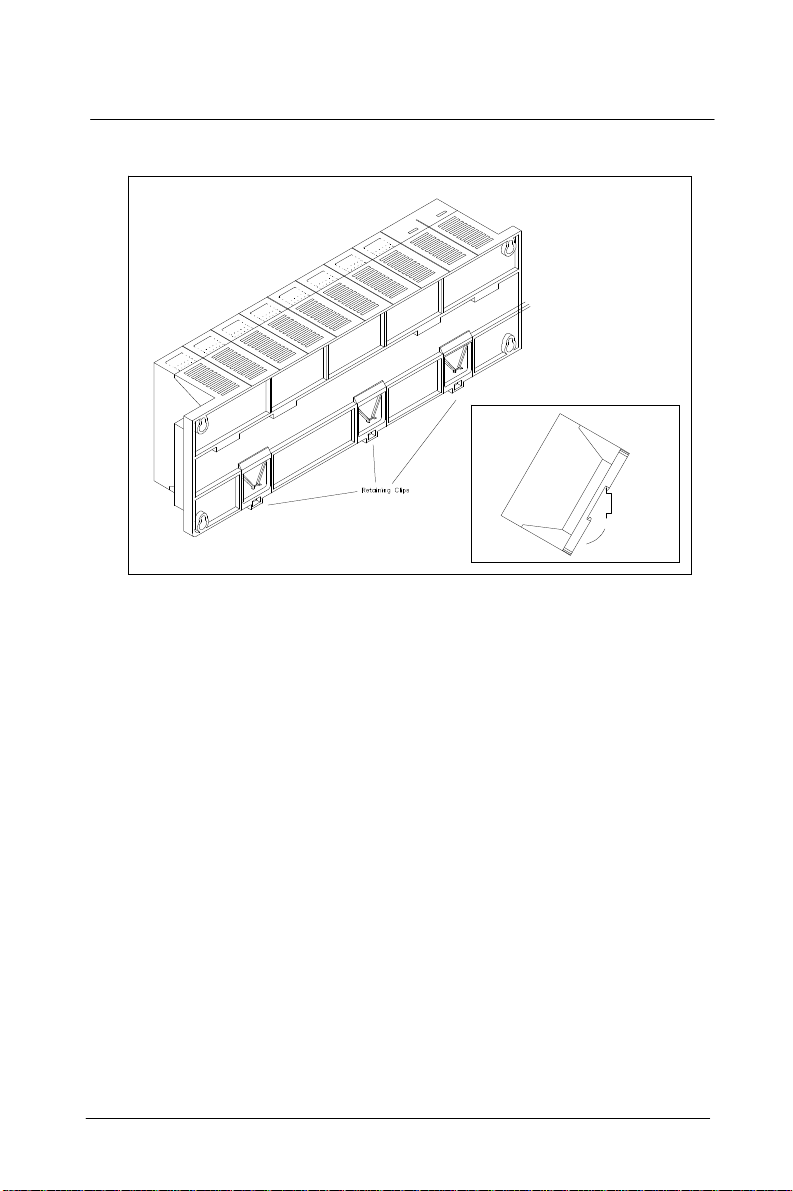

Figure 2-6 ADAM-5000E Rail mounting..………………………..2-9

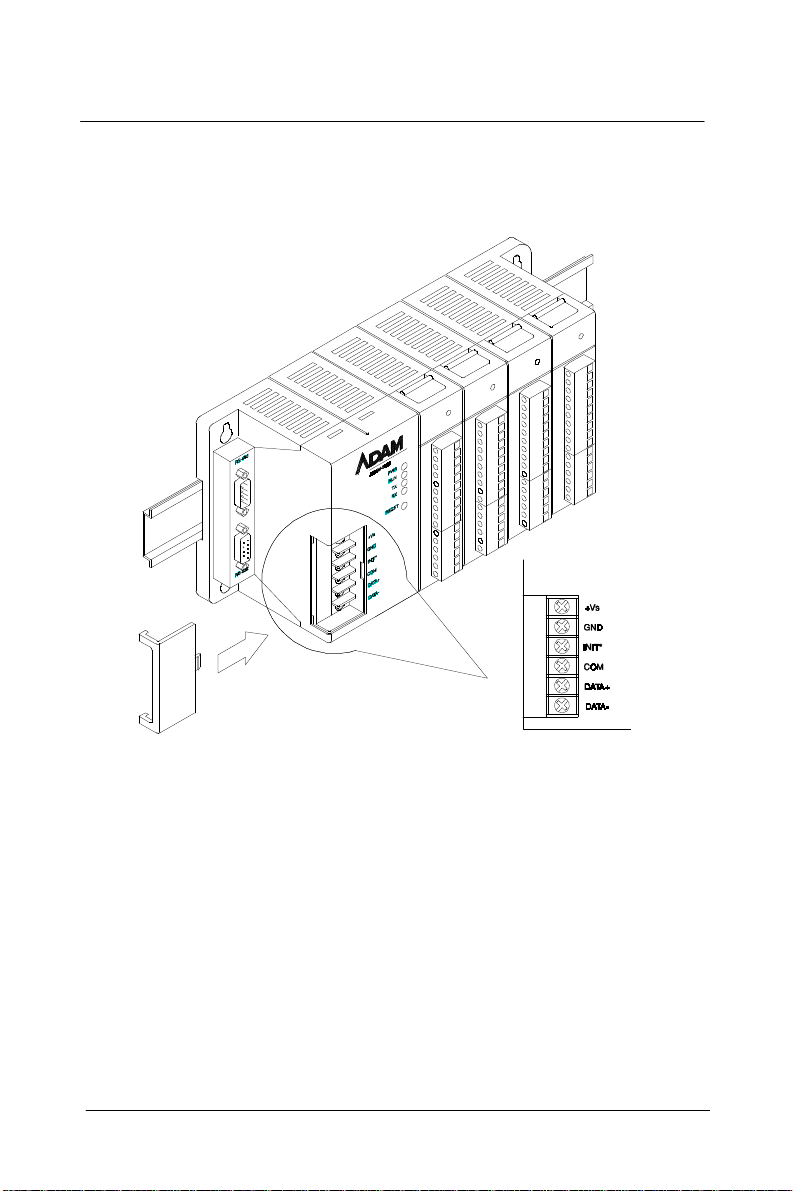

Figure 2-7 ADAM-5000 Wiring and connections..……………….2-10

Figure 2-8 Built-in Communication Ports for Diagnostic…… …..2-13

Figure 2-9 Flexible Communication Port Function Connection….2-14

Figure 3-1 Function block diagram..………………………..…..3-8

Figure 5-1 Display the connected module…………………....…..5-4

Figure 5-2 Save the information of connected modules to txt file....5-4

Figure 5-3 Setup options………………………………….…..…..5-4

Figure 5-4 Checksum function enabled……………..………..…..5-8

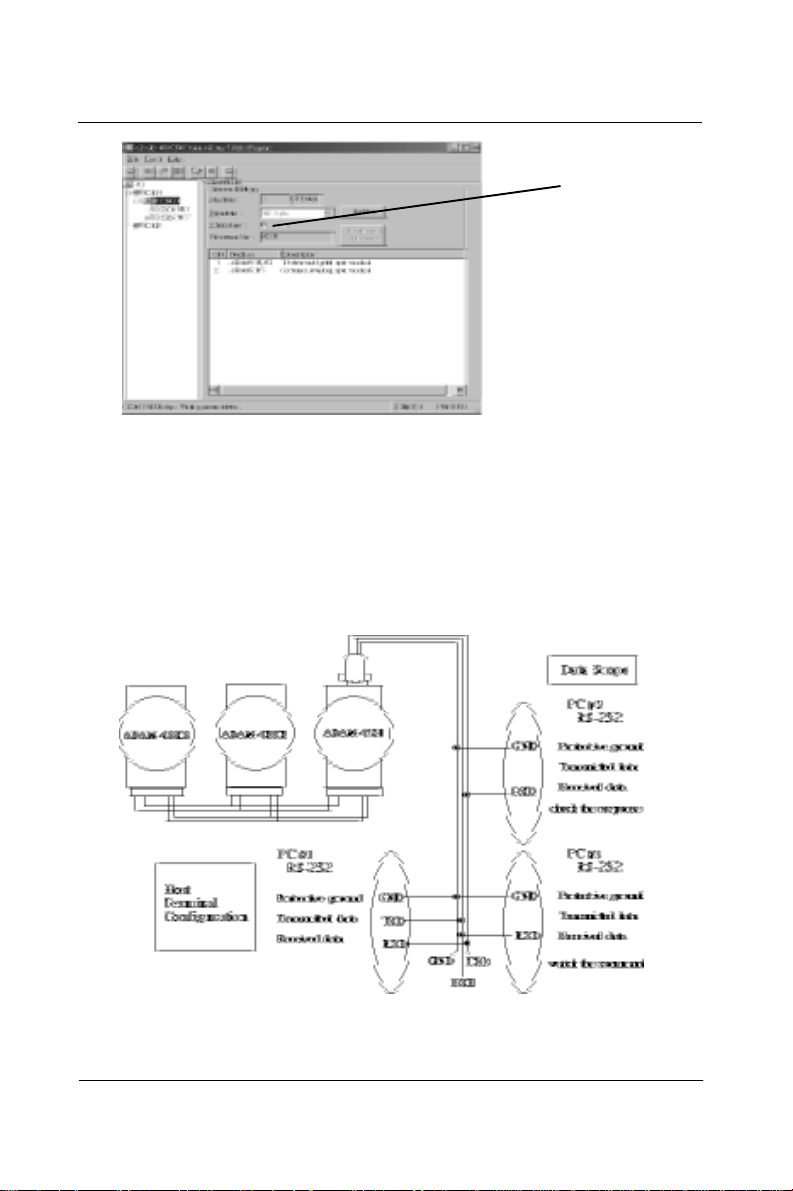

Figure 5-5 The connection for the Data Scope function……...…..5-8

Figure 5-6 Monitor the issing commands from PC#1…………....5-9

Figure 5-7 Zero Calibration………………………………....…..5-16

Figure 5-8 Execute Zero Calibration………………………..…..5-16

Figure 5-9 Span Calibration……………………………..…..…..5-16

Page 11

Figure 5-10 Execute Span Calibration……………………...…..5-17

Figure 5-11 CJC Calibration…………………………….…..…..5-17

Figure 5-12 Execute CJC Calibration……………….………..…..5-18

Figure 5-13 RTD Module Calibration………………….…..…..5-18

Figure 5-14 Analog Output Calibration……………………..…..5-18

Figure 6-1 Baud rate codes………………………….………..…..6-6

Figure 6-2 Analog module error codes……….……………..…..6-18

Figure 6-3 Data format for 8-bit parameters……..…………..…..6-38

Figure 6-2 Data format of 8-bit parameters……..…………..…..6-92

Figure A-1 Power supply connections……………..…………..…..A-4

Figure A-2 ADAM-5000 system hook-up and configuration..…….A-6

Figure A-3 Grounding the INIT* terminal………..………..…..A-10

Figure A-4 ADAM-5000 network system hook-up.…..…….…..A-11

Figure C-1 Daisy chaining………………………..…………..…..C-3

Figure C-2 Star structure ………..……………………….…..…..C-4

Figure C-3 Random structure……………………….………..…..C-5

Figure C-4 ADAM-4000 and ADAM-5000 in a network..………..C-6

Figure C-5 Signal distortion…………………………………..…..C-7

Figure C-6 Termination resistor location……………………..…..C-8

Figure C-7 RS-485 data floe control with RTS…..……………...C-9

Page 12

1

Introduction

Page 13

Introduction

1.1 Overview

The ADAM-5000 series is a complete product l ine that provides a wide

variety of features in a data acquisition and control application. It

includes 4 I/O-slots ADAM-5000/485 and 8 I/O-slots ADAM-5000E. They

are remotely controlled by the host computer through a set of commands

and transmitted in a RS-485 network. The system kernel is small, but

offers many good features to the users. The modulardesign also provides

more flexibility in the system configuration. The following is a sum mary

of the major ADAM-5000 system components.

ADAM-5000 System Kernel

The ADAM-5000/485 system kernel includes a CPU card, a power

regulator, a 4-slot base, a built-in RS-232 comm unication port and one

built-in RS-485 communication port. The ADAM-5000E system

includes all of the above components, except i t has an 8-slo t base.

Details of the system kernel features and more are covered in Chapter 3 .

I/O Configuration

The ADAM-5000/485 CPU ca n support up to 64 I/O points with the 4-

slot base currently available.The ADAM-5 000E CPU can support up to

128 I/O points with the 8-slot base currently available. These points

can be assigned as input or output points.

I/O Module

The ADAM-5000 series has a complete range of I/O modules for your

applications. A full range of digita l modules which suppo rt 10 to

30 V

and relay outputs are offered. The analog mod ules provide

DC

16-bit resolution and programmable input and output signal ranges

(including bipolar).

Software Utility

Based on the Modbus standard, the ADAM-5000 and ADAM-5000E

firmware is a built-in Modbus/RTU . Therefore, Advantech provides

the necessary OPC Server, and Windows Utility for users for client

data for the ADAM-5000 and ADAM-5000E. Users can configure this

DA&C system via Windows Utility; integrate with HMI software

package via Modbus/RTU driver or Modbus/RTU OPC Server. and

the DDE (Dynamic Data Exchange) server provides links to popular

Windows packages such as Intouch, FIX DMACS, Advantech

GeniDAQ, etc.

1-2 ADAM-5000

Page 14

Chapter 1

1.2 System Configuration

The following diagram shows the system configurations possible with

the ADAM-5000.

Note:

To avoid system ov er heating, only f our AD AM-5 024

are allowed to be installed on AD AM-5000E.

ADAM-5000 1-3

Page 15

Introduction

1.3 A Few Steps to a Successful System

Step 1:Review the installation Guideline

You should always make safety your first priority in any system

application. Chapter 2 provides several guidelines that will

help provide a safer, more reliable system.

Step 2: Understand the System Kernel

The system module is the heart of ADAM-5000 system. Make sure

you take time to understand the various features and setup requirements.

Step 3: Understand the I/O System Configurations

important to understand how y our I/ O m odules can be c onfigure d. It is

also important to understand how the system power budget is

calculated. This can affect your I/O configuration.

Step 4: Understand the Utility Software

Before you begin to link y our appli cations in your host computer with

the ADAM-5000 systems, it is very helpful t o understa nd how t he

DOS and Windows utility software helps you configure your

ADAM-5000.

Step 5: Review the Programming Concepts

All control systems differ in some areas. The ADAM-5000 system

allows you to develop your applications in DOS or Windows.It

provides an ASCII command set, DLL (Dynamic Library Link) and DDE

(Dynamic Data Exchange) server to you.

Step 6: Understand the Troubleshooting Procedures

Many things can be happened on the factory floor: switches fail, the

power supply is incorrect, etc. In most cases, the majority of the

troubleshooting time is spent trying to locate the problems.The

ADAM-5000 system has some built-in features that help you quickly

identify problems.

1-4 ADAM-5000

It is

Page 16

2

Installation Guideline

Page 17

Installation Guideline

2.1 General

Environmental Specifications

The following table lists the environmental specifications that general ly

2-2 ADAM-5000

apply to the ADAM-5000 system (System kernel and I/O modules).

Specification

Storage temperature -13 to 185°F (-25 to 85°C)

Ambient operating

temperature

Ambient humidity*

Atmosphere

Rating

14 to 158°F (-10 to 70°C)

5 to 95%, non-condensing

No corrosive gases

* Equipment will operate below 30% humidity. However, static

electricity problems occur much more frequently at lower humidity

levels. Make sure you take adequate precautions before you touch

the equipment. Consider using ground straps, antistatic floor

cover- ings, etc. if you use the equipment in low humidity

environments.

Power Requirements

Although the ADAM-5000 systems are designed for standard

industrial unregulated 24 V

that supplies within the range of +10 to +30V

power supply, they accept any power unit

DC

. The power supply

DC

ripple must be limited to 100 mV peak-to-peak, and the immediate ripple

voltage should be maintained between +10 and +30 V

.

DC

Diagnostic Indicators

Diagnostic indicators are located on the front panel of the ADAM

system. They show both normal operation and system status in your

remote I/O system. The indicators are:

•

System status (PWR, RUN)

•

Communication status (TX, RX)

•

I/O module status

Page 18

Chapter 2

A complete description of the diagnostic indicators and how to use them

for troubleshooting is e xplained in Chapter 7.

Figure 2-1 ADAM-5000 Diagnostic indicators

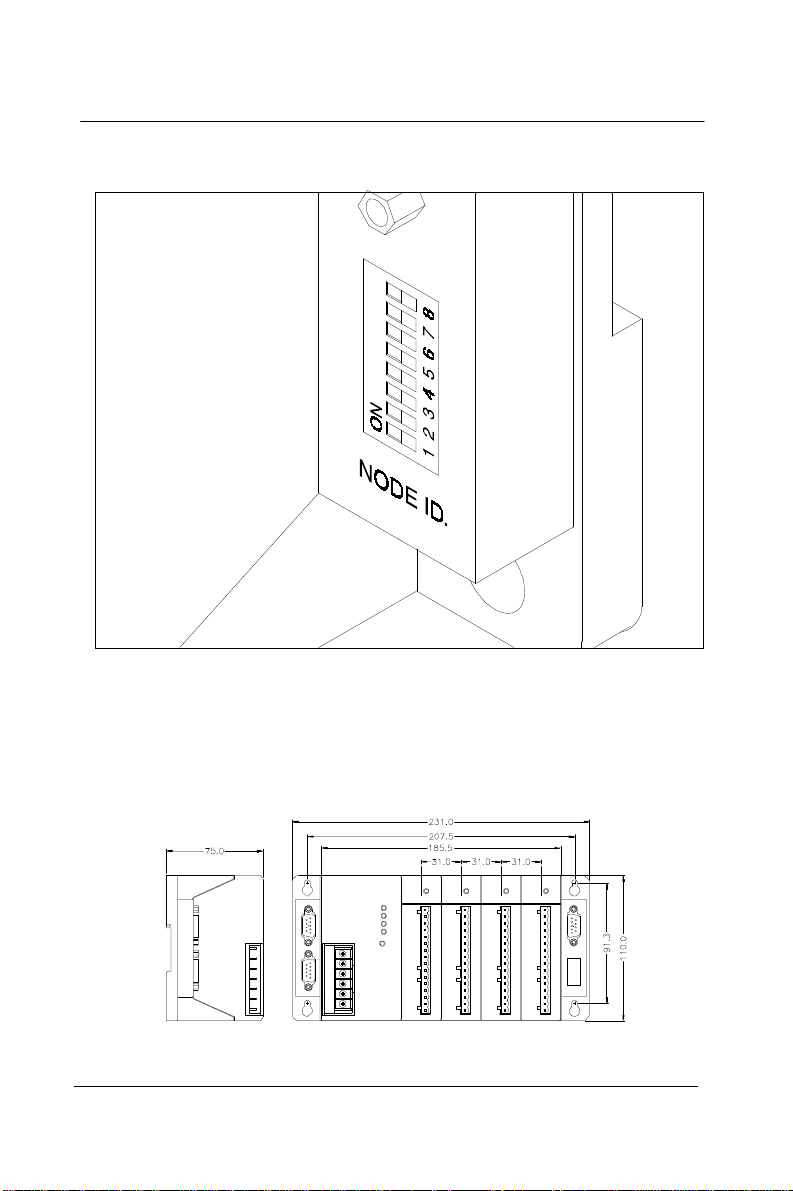

Setting the Network Address Switch

Set DIP switch 8 to OFF to install Avvantech Protocol , Set the network

address using the 8-pin DIP swi tch. Valid settings range from 0 to 127

(00h to 7Fh) where ON in any of the 8 DIP switch positions equates to a

binary 1, and OFF equates to a binary 0.

Note: 00h is special for initial setting. If 00h is setting by user, the baud

rate setting will be fixed to 9600 bps. It is recommand to setting the range

from 1 to 127 (01h to 7 Fh).

Setting the Network Address Switch

Set DIP switch 8 to ON to install Modbus function , Set the Modbus

address using the 8-pin DIP swi tch. Valid settings range from 0 to 127

(00h to 7Fh) where ON in any of the 8 DIP switch positions equates to a

binary 1, and OFF equates to a binary 0.

ADAM-5000 2-3

Page 19

Installation Guideline

Figure 2-2 ADAM-5000 Network address DIP switch

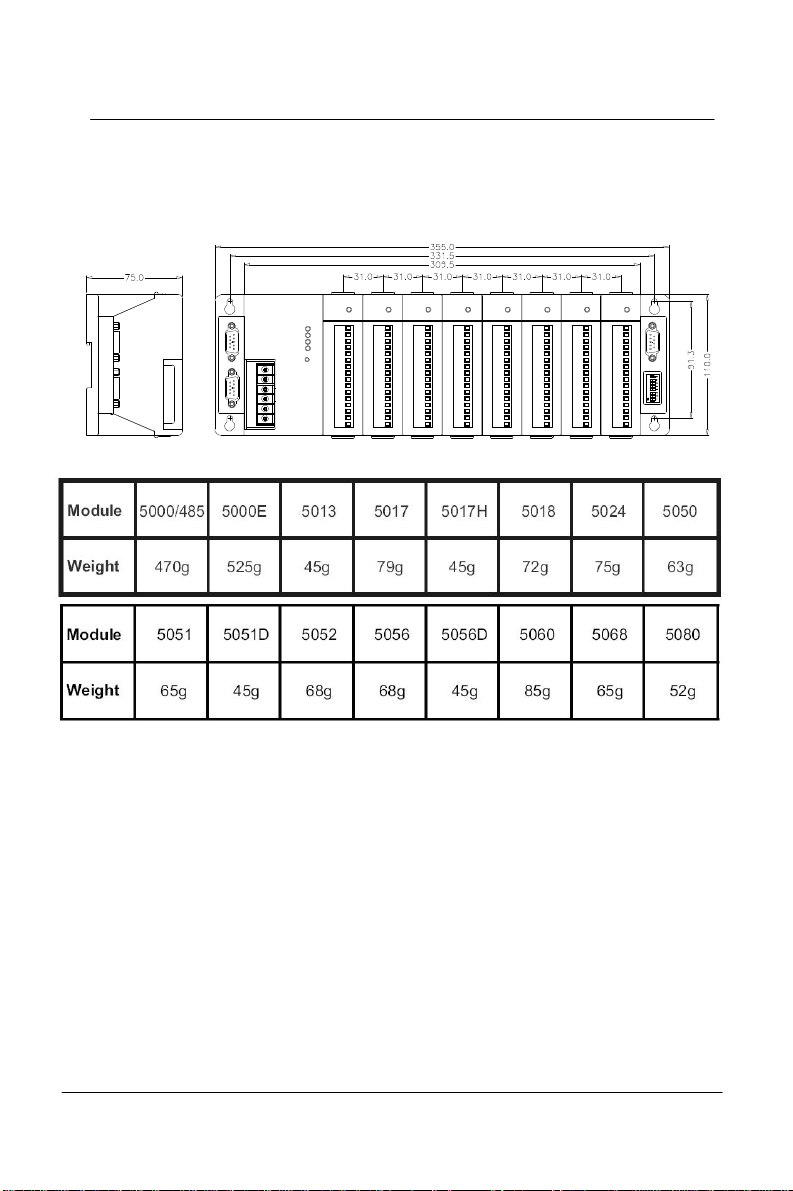

Dimensions and Weights(ADAM-5000)

The following diagrams show the dimensions of the system unit and

an I/O unit of the ADAM-5000. All dimensions are in millimeters.

2-4 ADAM-5000

Page 20

Chapter 2

Dimensions and Weights(ADAM-5000E)

The following diagrams show the dimensions of the system unit and

the I/O unit of the ADAM-5000E. All dimensions are in millimeters.

ADAM-5000 2-5

Page 21

Installation Guideline

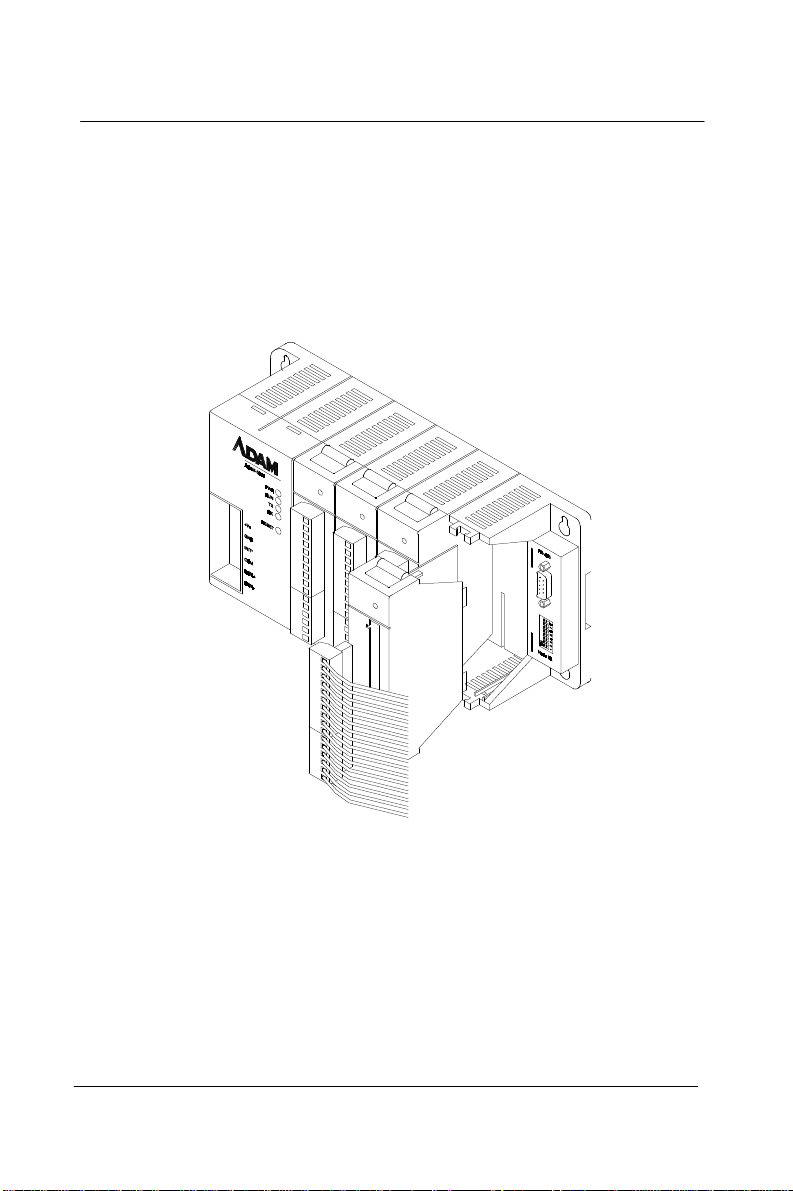

2.2 Module Installation

When inserting modules into the system , align t he PC board of the

module with the grooves on the top and bottom of the system. Push

the module straight into the system until it is firm ly seated in the

backplane connector. Once the module is inserted into the system, push

in the retaining clips (located at the top and bottom of the module) to

firmly secure the module to the system .

Figure 2-3 Module alignment and installation

2.3 I/O Slots and I/O channel Numbering

The ADAM-5000/485 system each provides 4 slots for use with I/O modules.

The I/O slots are numbered 0 thru 3, and the channel numbering of any I/O

module in any slot starts from 0. The ADAM-5000E system each provides 8

slots for use with I/O modules. The slots are num bered 0 thru 7 . For

example, ADAM-5017 is a 8-channel analog input module, its channel

numbering is 0 thru 7.

ADAM-5000

2-6

Page 22

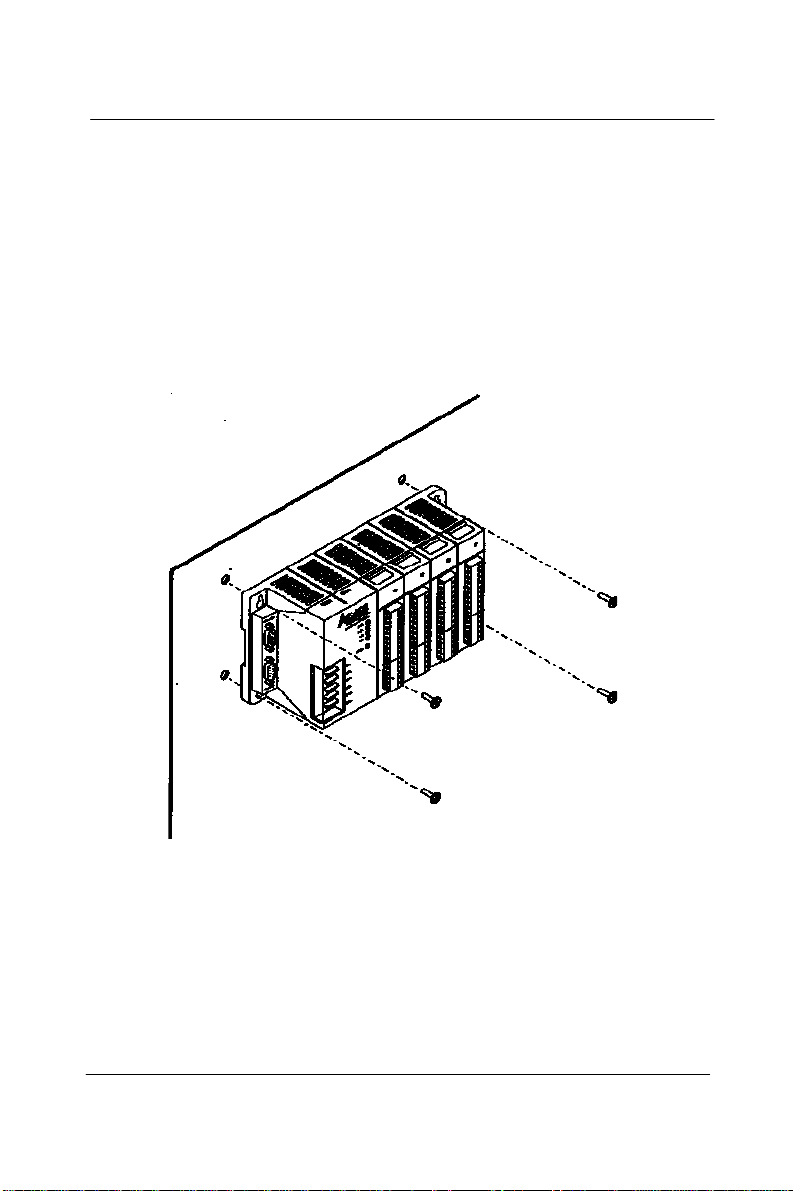

2.4 Mounting

The ADAM-5000 system can be installed on a panel or DIN rail.

Panel Mounting

Mount the system on the panel horizontally to provide proper ventilation. You cannot mount the system vertically, upside down or on a flat

horizontal surface. A standard #7 tating screw (4mm diameter) should

be used.

Chapter 2

Figure 2-4 ADAM-5000 panel mounting

ADAM-5000 2-7

Page 23

Installation Guideline

DIN Rail Mounting

The system can also be secured to the cabinet by using mounting rails.

If you mount the system on a rail, y ou sh oul d also c o nside r using e nd

brackets on each end of the rail. The end brackets help keep the system

from sliding horizontally along the rail. This helps minimize the

possibility of accidentally pulling the wiring loose. If you examine the

bottom of the system, you will notice two small retainingclips. To secure

the system to a DIN rail, place the system onto the rail and gently push

up on the retaining clips. The clips lock the system on the rail. To

remove the system, pull down on the retaining clips, lift up on the base

slightly, and pull it away from the rail.

2-8 ADAM-5000

Figure 2-5 ADAM-5000Rail mounting

Page 24

Chapter 2

2.5 Wiring and Conections

Figure 2-6 ADAM-5000E Rail mountings

This section provides basic inform ation on wiri ng the power s upply

and I/O units, and on connecting the network.

DC Power Supply Unit Wiring

Be sure that the DC power supply voltage remains within the allowed

fluctuation range of between 10 to 30 V

for power supply wiring.

. Terminals +VS and GND are

DC

Note: The wire(s) used should be at least 2mm2.

ADAM-5000 2-9

Page 25

Installation Guideline

INIT* is used for changi ng ba ud rate an d checks um. C OM is pr ovided

as reference to the RS-485 ground signal. DATA+ and DATA- are

provided for the RS-485 twisted pair connection.

Figure 2-7 ADAM-5000 Wiring Connections

I/O Module Wiring

The system uses plug-in screw terminal blocks for the interface

between I/O module and field devices . The following inf ormation

must be considered when connecting electrical devices to I/O modules.

1. The terminal block accepts 0.5 mm2 to 2.5 mm2 wires

2. Always use a continuous length of w ire, do not co mbine wires to

attain needed length

3. Use the shortest possible wire length

4 . Use the wire trays for routing where possible

2-10 ADAM-5000

Page 26

Chapter 2

5 . Avoid running wi res near high ener gy wi ring

6 . A void running i nput wiring in close pr oximity to

output wiring where possible

7. Avoid creating sharp bends in the wires

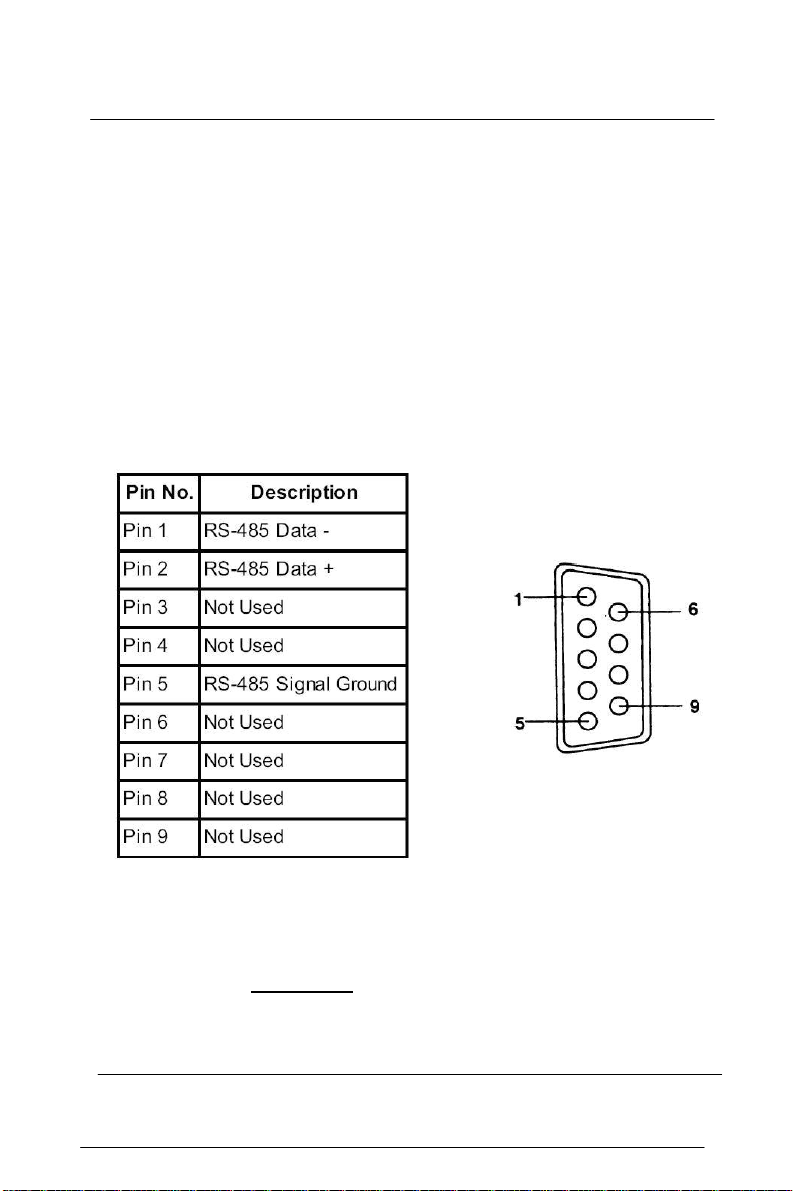

RS-485 Port Connection

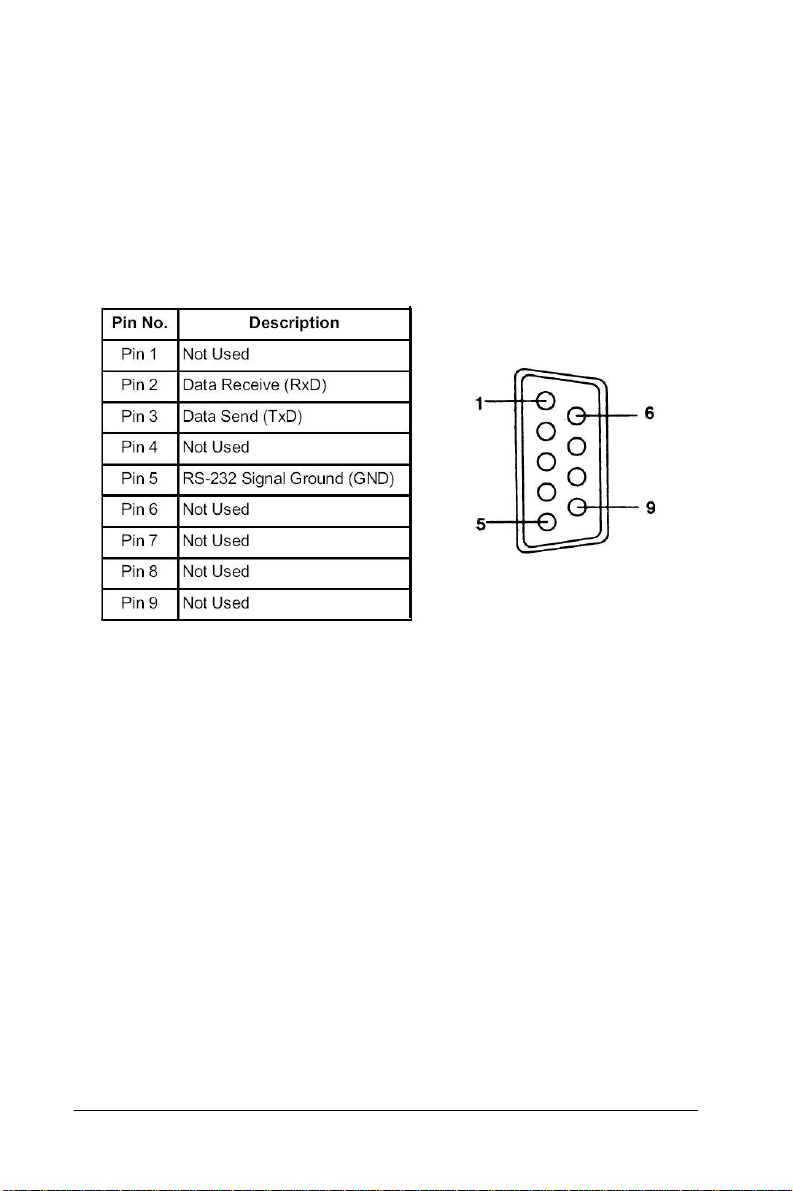

There is a pair of DB9 ports in the ADAM-5000 system. The ports are

designed to link the RS-485 through a cable to a network in a system.

The pin assignment of the port is as follows:

Note:

The wiring of the RS-485 should be through a twisted

pair. To reduce electrical noise, it should be twisted

as tightly as possible

ADAM-5000 2-11

Installation Guideline

Page 27

RS-232 Port Connection

The RS-232 port is designed for field configuration and diagnostics.

Users may connect a notebook PC to the RS-232 port to configure or

troubleshoot your system in the fiel d. Further , the ADAM-5000

system can also be configu red as th e slav e of the host compute r

through this port connection. The pin assignment of the port is as

follows:

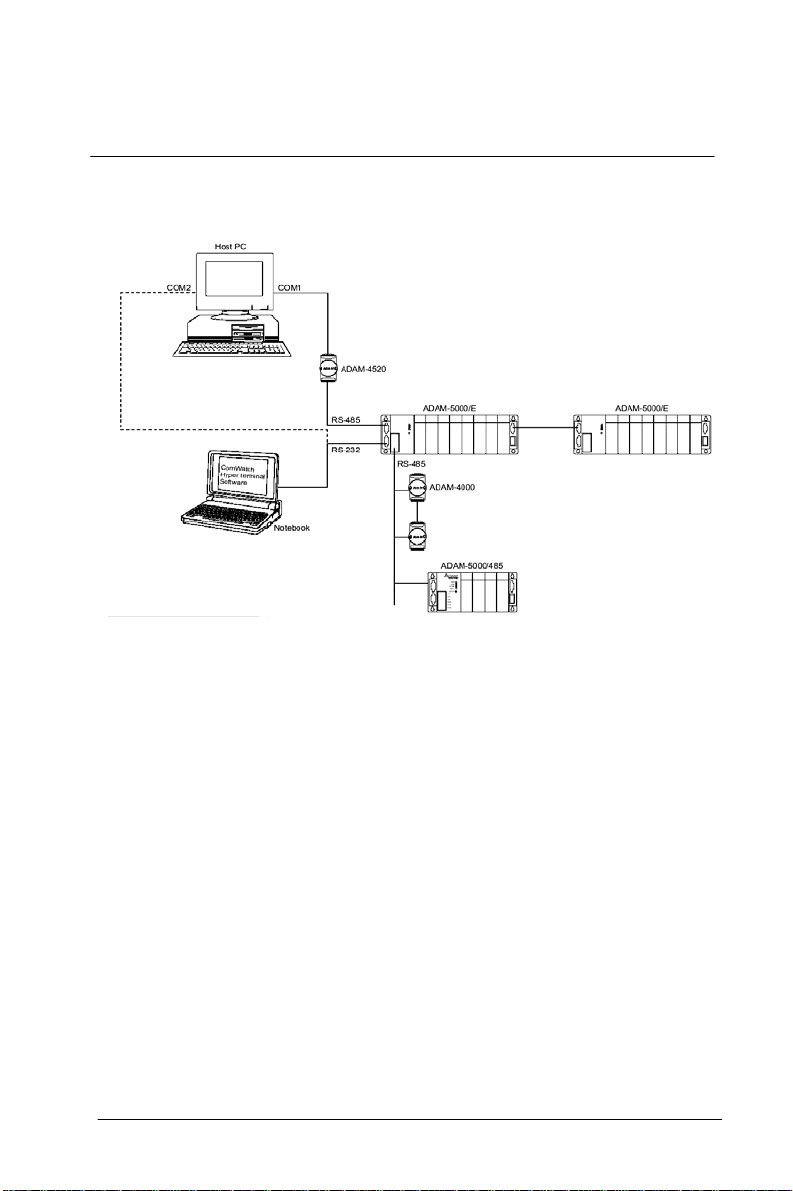

Build-in Communication Ports for Diagnostic

Connection (ADAM-5000E only)

The Built-in Communication Ports for Diagnostic Function enables

users to perform a quick diagnostics to locate where the sys tem is at

fault.

This Diagnostic Function requires the RS-485 port of ADAM-5000E

to be connected to COM1 of host PC, and the RS-23 2 port of

ADAM-5000E to COM2 of the previous host PC or othe r PCs.

Then you should install software such as ComWatch or

Hyperterminal and so on to monitor the commands that are being

issued and the subse- quent responses from connected modules.

2-12 ADAM-5000

Page 28

Chapter 2

Figure 2-8 Build-in Communication Ports for Diagnostic

Connection

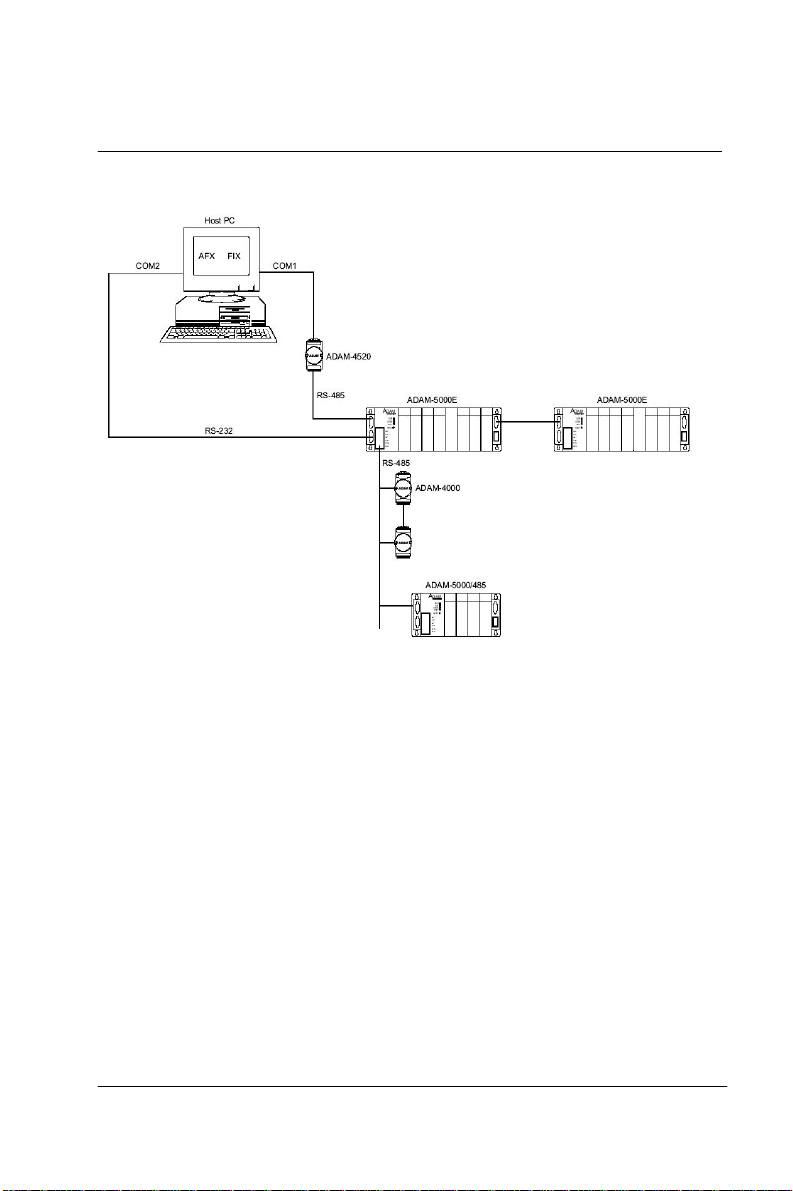

Flexible Communication Port Function

Connection(ADAM-5000E only)

The Flexible Communication Port Function prevents ADAM-5000E

from system glitches due to communication line problem s.

This function enables simultaneous connections via COM1 and COM2

port of your host PC to the RS-232 and RS-485 port of ADAM-5000E

specifically. While working in conjunction with specific HMI software

(e.g. AFX, FIX) that offers COM Port Backup Function, A D AM -5000E

can circumvent failed comm unication on one port by switching t o

another available port to continue p rogram execution.

ADAM-5000 2-13

Page 29

Installation Guideline

Figure 2-9 Flexible Communication Port Function Connection

2-14 ADAM-5000

Page 30

3

ADAM-5000 System

Page 31

ADAM-5000 System

3.1 Overview

The ADAM-5000 series is a data acquisition and control system which

can control, monitor and acquire data through multichannel I/O

modules. Encased in rugged industrial grade plastic base s, the

systems provide intelligent signal conditioning, analog I/O, digital I/O,

RS-232 and RS-485 communication. The ADAM-5000/485 can handle up

to any 4 combinations of I/O m odules (64 I/O points), whi le the

ADAM-5000E can handle up to 8 combinations of I/O modules (128 I/

O points). The systems communicate with their controlling host over

a multi-drop RS-485 network.

3.2 Major Features of the ADAM-5000 System

The ADAM-5000 system consists of two m ajor pa rts: the system

kernel and I/O modules. The sy stem kernel includes a CPU c ard, power

regulator, 4-slot base, 8-slot base, bui lt-in RS-232 communication port,

and a pair of built-in RS-485 ports. It also offers the following major

features:

The CPU’s Basic Functions

The CPU is the heart of the system and has the following basic

3-2 ADAM-5000

functions:

•

Data acquisition and control for all I/O modules in the system

•

Linearization of T/C (Thermocouple)

•

Communication software and command set

•

Calibration software and command set

•

Alarm monitoring

•

Management of the EEPROM device that holds the syst em

parameters

•

Data transformation

•

Diagnosis

Page 32

Chapter 3

Diagnosis

There are 4 LEDs (indicated as PWR, RUN, TX and RX) to provide

visual information on the general operation of the ADAM-5000

system. The LEDs also indicate the error status when the

ADAM-5000 system performs the self test. Besides the LED

indica- tors, the system also offers software diagnosis via the RS232 port. For details, refer to Chapter 7.

3-Way Isolation and Watchdog Timer

Electrical noise can enter a system in many different ways. It may enter

through an I/O module, a power supply connection or the com munication ground connection. The ADAM-5000 system provides isol ation

for I/O modules (3000 V

communication power connection (3000 V

design prevents ground loops and reduces the effect of electrical

noise to the system. It also offers better surge protection to prevent

dangerous voltages or spikes from harming your system. The system

also provides a W atchdog timer to monitor the microprocessor. It will

automatically reset the microprocessor in ADAM-5000 system if the

system fails.

Remote Software Configuration and Calibration

The ADAM-5000 system merely issues a command from the host

computer, you can change an analog input module to accept several

ranges of voltage input, current i nput, the rmocouple i nput or RTD

input. With the except ion of system node address, all the param eters

including speed, parity, HI and LO al arm, and calibration parameters

setting may be set remotely. Remote configuration can be done by

using either the provided menu-based software or the command set's

configuration and calibration commands. By storing configuration

and calibration parameters in a nonvolatile EEPROM, the systems are

able to retain these parameters in case of power failure.

Flexible Alarm Setting

The ADAM-5000 system provides a flexible alarm setting method via

an utility software (ADAM.EXE) between analog input modules and

digital output modules. The user may configure a point of any

digital output module plugged into any slot as t he Hi g h alarm or Low

alarm

ADAM-5000 3-3

), communication connection (2500 VDC) and

DC

). The 3-way isolation

DC

Page 33

ADAM-5000 System

output of a channel of an anal og i nput module. The relationship

and their High/Low alarm limits may be downloaded into the

system‘s EEPROM by the host computer.

The alarm functions can be enabled or disabled rem otely. When the

alarm function is enabled, the user may select whether the digital

output is triggered. If the digital outputs are enabled, they are used

to indicate the High and Low Alarm state. The High and Low alarm

states can be read at any time by the host computer.

Every A/D conversion will be followed by a comparison with the High

and Low limit. When the input value is over the High limit or below

the Low limit, the High or Low alarm state is set to ON.

There are two alarm mode opti ons: Momentary and Latc hing.

If the alarm is in Latching mode, the alarm will stay on even when the

input value returns within limits. An alarm in Latching mode can be

turned OFF by issuing a Clear Alarm command from the host computer.

A Latching alarm is cleared by the microprocessor when the opposite

alarm is set

For example, the alarm is in latching mode and the High alarm is turned

ON. When the module receives a value that is lower tha n the Low

alarm limit, the microprocessor will clear the High alarm and turn the

Low alarm ON.

When the alarm is in Momentary mode, the alarm will be turned ON

when the input value is outside of alarm limits and OFF while the input

value remains within alarm limits. The arrangement of coupling High

and Low alarm states with digital outputs may be utilized to build ON/

OFF controllers that can operate without host computer involvement.

Connectivity and Programming

ADAM-5000 systems can connect to and communicate with all

computers and terminals. They use either RS-232 or RS-485 transmission standards and communicate with ASCII format commands.

However, users can only select and use one comm unicat ion port at

any time. All communications to and from the system are performed in

ASCII, which means that ADAM-5000 systems can be

3-4 ADAM-5000

Page 34

Chapter 3

programmed in virtually any high-level language. The details of all

commands will be covered in Chapter 6.

Flexible Communication Connection

ADAM-5000’s built-in RS-232/485 conversion capability enables users

to freely choose either RS-232 port or RS-485 port to connect with host

PC. When user select either port to connect with their host PC, the

other port could be utilized according to their specific needs.

For example, if RS-232 port is selected for connecti on with host PC,

the RS-485 port can be used for connection with DA&C module s (such

as ADAM-5000/485, ADAM-5000, ADAM-4000 modules). Thus users

save extra costs for another RS-232/4 85 conversion device (e.g.

ADAM-4520).

Or if users select RS-485 port for host PC connection, the RS-232 port

can then have different usage such as described in the following

sections (see Built-in Communication Ports for Field Diagnostics and

Flexible Communication Port)

Built-in Communication Ports for Diagnostics

(ADAM-5000E only)

When users utilize application software to control their system,

ADAM-5000E can provide anot her port to let user monitor a t any time

the communication quality and condition as a reference to maintenance and test. When er ro r o ccu r s in th e s ys tem, users can perform a

quick diagnostics to locate the fault. A consid erable am ount of

troubleshooting efforts can be saved . For e xam ple, usin g popular

ComW atch s oftware, users can watc h the current execution and

response of a certain comm and. It is very conveni ent to identi fy

whether it is communication or the hardware pr oduct that i s causing

the problem.

Flexible Communication Port(ADAM-5000E on ly )

ADAM-5000E provides a further application. Users can simultaneously connect COM1 and COM2 of host PC to RS-232 and RS-485 port of

ADAM-5000E. When host PC issues a command through one of the

COM ports but receives no response (the other port will serve as

backup), the COM Port Backup Function of HMI software (e.g. AFX,

FIX) will automatically switch to another COM port to continue

ADAM-5000 3-5

Page 35

ADAM-5000 System

program execution without undue influence on your system. Probability of a system crash has thus minimized.

3.3 System Setup

3-6 ADAM-5000

A Single System Setup thru the RS-232 Port

If users would like to use a PC to locally control and monitor a simple

application, the ADAM-5000 system provide s up to 64 points or 12 8

points and front-end wiring thro ugh the RS -232 port t o the host

computer.

A Distributed I/O Setup thru the RS-485 Network

The RS-485 network provides lower-noise sensor readings as the

systems can be placed much closer to the source. Up to 256

ADAM-5000 systems may be connected to an RS-485 multi-drop

network by using the ADAM-4510/4510S RS-485 repeaters, extending

the maximum communication distance to 4,000 ft. The host computer

is connected to the RS-485 network from one of its COM ports through

the ADAM-4520/4522 RS-232/RS-485 converter.

T o boost the network's throughput, the ADAM-4510/4510S RS-485

repeaters use a logical R TS signal to manage the re peater's direction.

Only two wires are needed for the RS-485 network: DATA+ and

DA T A-. Inexpensive, shielded twisted-pair wiring is employed.

Page 36

3.4 Technical Specification of the ADAM-5000

Processor

Communication

Chapter 3

ADAM-5000 3-7

Page 37

ADAM-5000 System

Isolation

Diagnosis

Basic Function Block Diagram

Figure 3.1 Function block diagram

3-8 ADAM-5000

Page 38

4

I/O modules

Page 39

This manual introdu ces the detail specifications function s and

application wiring of each ADAM-5000 I/O m odules. To organize an

ADAM-5510 Series Controller, you need to select I/O modules to

interface the main unit with field devices or processes that you have

previously determined. Advantech provides 19 types of ADAM5000 I/O modules for various applications so far. Following table is the

I/ O modules support list we provided f or user’s choice.

More detailed specification and user’s guides, please refer the

user’s manual of ADAM-5000 IO Module. It had integrated and

collected this information.

Module Name Specification Reference

ADAM-5013 3-ch. RTD input Isolated

ADAM-5017 8-ch. AI Isolated

Analog I/O

Digital I/O

Relay Output

Counter/Frequency ADAM-5080 4-ch. Counter/Frequency Isolated

Serial I/O ADAM-5090 4-port RS232 Non-isolated

ADAM-5000

ADAM-5017H 8-ch. High speed AI Isolated

ADAM-5017UH 8-ch. Ultra High speed AI Isolated

ADAM-5018 7-ch. Thermocouple input Isolated

ADAM-5024 4-ch. AO Isolated

ADAM-5050 7-ch. D I/O Non-isolated

ADAM-5051 16-ch. DI Non-isolated

ADAM-5051D 16-ch. DI w/LED Non-isolated

ADAM-5051S 16-ch. Isolated DI w/LED Isolated

ADAM-5052 8-ch. DI Isolated

ADAM-5055S 16-ch. Isolated DI/O w/LED Isolated

ADAM-5056 16-ch. DO Non-isolated

ADAM-5056D 16-ch. DO w/LED Non-isolated

ADAM-5056S 16-ch. Isolated DO w/LED Isolated

ADAM-5056SO 16-ch. Iso. DO w/LED (source) Isolated

ADAM-5060 6-ch. Relay output Isolated

ADAM-5068 8-ch. Relay output Isolated

ADAM-5069 8-ch. Relay output Isolated

Table 4-1: I/O M odule S up po r t Li s t

4-

2

Page 40

5

Software Utilities

Page 41

Software Utilities

There is a software utility available to the ADAM-5000 systems. The

Windows utility software helps you to configure your ADAM-5000.

A DLL (Dynamic Link Library) driver is provided to write Windows

applications, and a DDE (Dynamic Data Exchange) server is a service

that links the ADAM-5000 system s to popul ar Windows packages

such as Intouch, FIX DMACS, ONSPEC, Genesis and Excel.

5.1 ADAM-4000 and ADAM-5000 Windows Utility

The ADAM-4000 and 5000 Windows Utility offers a graphical interface

that helps you configure the ADAM-4000 and ADAM-5000 DA&C

Modules. This windows utility makes it very convenient to monitor

your Data Acquisition and Control system. The following guidelines

will give you some brief instructions on how to use the utility.

•

5-2 ADAM-5000

Overview

•

COM port settings

•

Search connected modules

•

Terminal emulation

•

Data Scope

•

Save module’ s configuration to file

•

Load module’s configuration files to configure module

•

Module configuration

•

Module calibration

•

Data input and output

•

Alarm settings

•

Download procedure

Page 42

Chapter 5

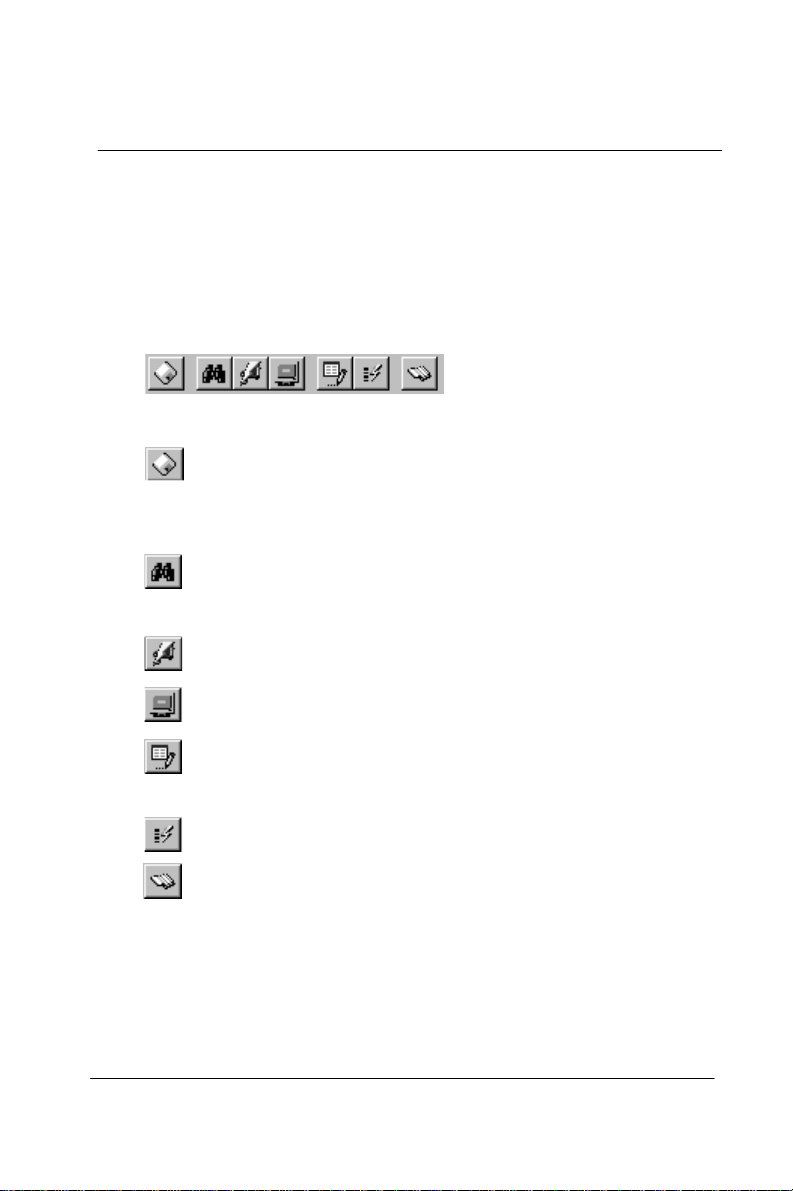

5.1.1 Overview

Main Menu

The window utility consists of a toolbar on the top and a display area

that shows forth the relevant information about the connected

modules. The utility’ s main toolbar is as shown below:

The main toolbar buttons are shortcuts to some commonly used menu

items:

Save: Saves the connected m odule t o PC.

Save the information of all connected modules to .txt file .By doing

this; users can keep track of every different setting environ ment.

Search: Search for the address of connected modules

on network.

Terminal: Issue commands and receives response.

Data Scope: Display the current data.

Save Configuration: Saves the configuration of

selected module into txt file.

Load Configuration: Download the previous configuration file

Help: Display the Online Help for the ADAM utility .

5.1.2 Save Function

Save the settings of current module (e.g. Baud rate, Address, Modules

Name) to txt file.

ADAM-5000 5-3

Page 43

Software Utilities

Example:

Figure 5-1 Display the connected module

Figure 5-2 Save the information of co nnected m odule s to txt file

5.1.3 COM Port Settings

Figure 5-3 Setup options

5-4 ADAM-5000

Page 44

Chapter 5

Baud rate:

The communication speed (baud rate) can be configured fro m 1200 bps

to 115.2 Kbps.

Prefix Char:

The Prefix Char is added to each ADAM command as follows:

[Prefix Char] + [A D AM Command]

Note:

This is a special command only for AD AM-4521,

ADAM-4541 and ADAM-4550.

Timeout:

Timeout means the time limit for waiting a response after the system

has issued a command. If no response has been received when timeout

has passed, we’ll see the “Timeout!” message on the screen.

5.1.4 Search connected modules

When you use the Search command, it will search for any connected

modules on network and di splay their dat a. T here are three ways t o

search for:

1 . Click the Toolbar button:

ADAM-5000 5-5

Page 45

Software Utilities

2 . Click the right mouse button:

3 . Click the To ols menu and choose the Search command:

4. The connected modules on netwo rk are current ly bei ng

searched:

5-6 ADAM-5000

Page 46

Chapter 5

5.1.5 Terminal Emulation

You ca n issue commands and receive response by clicking the

T erminal button. There are two ways to issue commands:

1 . Issue single command:

2. Batch command

Users can compose a sequence of commands and save them into a .txt

file. Just click the Browse button to list all the .txt files available and

select the file for continuous execution of the batch of commands

therein.

3.

Back to the main menu.

Note:

If you select the checksum function on previous

main menu, you have to select the checksum

function in this menu.

ADAM-5000 5-7

Enable or

Disable

Page 47

Software Utilities

Figure 5-4 Checksum function enabled

5.1.6 Data Scope

Data Scope enables you to monitor the issue of commands and the

responses on another connected PC within your system. The following example illustrates the working connection for the Data Scope

function:

Enable or

Disable

5-8 ADAM-5000

Figure 5-5 The connection for Data Scope function

Page 48

Chapter 5

When you issue commands from PC#1, you will get response.

: Send single command or batch command.

: Send a single command or batch command repeatedly.

: Stop issuing commands.

: Save history of the terminal emulation to txt file.

On PC#3, you can observe all commands issued from PC#1. Meanwhile, you can also observe all responses received at PC#2.

Figure 5-4 Checksum function enabled

ADAM-5000 5-9

Address of

selected

modules

Page 49

Software Utilities

When your system is connected with multiple ADAM-4000 or

ADAM-5000 modules, just c lick the ad dresses of t he modules t o see

relevant information (multiple selection from 00 to FF is allowed). Then

check the Filter option and click Update button to see relevant

information of the modules. Note that the information about other

unselected modules won’t show forth.

5.1.7 Saving module’s Configuration to file

•

Save the input range, baud rate, data format, checksum status

and/ or integration time and Alarm Status for a specified analog

input module.

•

Save the output range, baud rate, data format, checksum status and

slew rate for a specified analog output module.

•

Save the baud rate and checks um stat us for a digit al I/O m odule.

•

Save the input mode, baud rate, checksum status and/or frequency

gate time, input signal mode, gate m ode, alarm status, etc. for a

specified counter/frequency module.

There are three ways to save a configuration file:

1 . Click the Toolbar button

2 . Click the right mouse button

5-10 ADAM-5000

Page 50

3 . Click the Tools m enu. Choose the “Save Configuration file”

command

Chapter 5

and then specify the file name.

The configuration file is now save d.

ADAM-5000 5-11

Page 51

Software Utilities

5.1.8 Load Module’s Configuration File

•

Reload previous settings. Sets th e inpu t range, baud rate, d ata

format, checksum status and/or integration time and al arm status

for a specified analog input module.

•

Sets the output range, baud rate, data format, checksum status and

slew rate for a specified analog output module.

•

Sets the baud rate and c hecks um status for a di gital I/ O m odule.

•

Sets the input mode, baud rate, checksum status and/or frequency

gate time, input signal mode, gate m ode, alarm status, etc. for a

specified counter/frequency module.

Note:

Baud rate and checksum can only be changed i n the

INIT* state. Changed settings can only take eff ect

after a module is rebooted.

There are three ways to load a configuration file:

1 . Click the Toolbar button:

2 . Click the right mouse button:

5-12 ADAM-5000

Page 52

Chapter 5

3 . Click the T ools menu and choose Download configu ration file

to set the environment command:

4 . Choose the file name:

The configuration file is now loaded.

ADAM-5000 5-13

Page 53

Software Utilities

5.1.9 Module Configuration

•

Sets the input range, baud rate, data format, checksum status, and/

or integration time for a specified anal og input module.

•

Sets the output range, baud rate, data format, checksum status and

slew rate for a specified analog output module.

•

Sets the baud rate and checksum status for a digital I/O module.

•

Sets the input mode, baud rate, checksum status and/or frequency

gate time for a specified counter/frequency module.

Note:

Baud rate and Checksum can only be changed in the

INIT* state. Changed settings only take effect after a

module is rebooted.

For Example: The configuration of ADAM-4011

5-14 ADAM-5000

Page 54

Chapt er 5

•

Address: Represents the address of the module. The Range is from

•

Baudrate: Represents the baud rate.

•

Checksum: Represents the checksum status, i.e., Disabled/

•

Firmware V er: Represents the version of firmware.

•

Input range: Represents the input range of modules. You can refer

•

Data format: Represents the data format (e.g. engineering format).

0 to 255.

Enabled.

to Chapter 4.

Y ou can re fer to Chapter 4.

5.1.10 Module Calibration

Calibration is to adjust the accuracy of A DAM module. There are

several modes for module’ s calibration: Zero calibration and span

calibration. Only analog input and outp ut modules can be ca librated.

Note: The calibrating function supports ADAM-5013/5017/5017H/

5018/5024.

Zero Calibration:

(1). Apply power to the m odule and let it warm up for about 30 minute s.

(2). Make sure that the module is correctly i nstalled and is properly

configured for the input range you want to calibrate.

(3). Use a precision voltage so urce to apply a cal ibration volt age to t he

modules’ terminals of the specific channel.

(4). Click the “Zero Calibration” button. See Figure 5-7

5-16 ADAM-5000

Page 55

Software Utilities

Figure 5-7 Zero Calibration

(5). Click the Execute button to begin the calibration

Figure 5-8 : Execute Zero Calibration

Span Calibration:

(1). Use a precision voltage so urce to apply a cal ibration volt age to t he

modules’ terminals of the specific channel.

(2). Click the “Span Calibration” button. See Figure 5-9

Figure 5-9 : Span Calibration

5-16 ADAM-5000

Page 56

Chapter 5

(3). Click the Execute button to begin the calibration

Figure 5-10 : Execute Span Calibration

CJC Calibration:

CJC (cold junction sens or) calibration only a pplies to the ADAM-5 018

(1). Prepare a voltage source which is accurate to the mV level.

(2). Run the zero calibration and span calibration function.

(3). Use a temperature emulation device (such a s Micro-10) to se nd a

temperature signal to the ADAM module and then compare this signal

with the reading from the ADAM module. If the reading value is

different from the signal, ad just the CJC value to improve i t.

(4). Click the “CJC Calibration” button. See Figure 5-11.

Figure 5-11 : CJC Calibration

.

ADAM-5000 5-17

Page 57

Software Utilities

(5). Click the Execute button to begin the calibration

Figure 5-12 : Execute CJC Calibration

Analog Input Resistance Calibration:

R TD sensor calibratio n only applies to t he ADAM-5013

Figure 5-13 : RTD Module Calibration

.

Analog Output Calibration:

4~20 mA: ADAM 5024

Figure 5-14 : Analog Output Calibration

5-18 ADAM-5000

Page 58

5.1.11 Data Input and Output

Analog Input Module with Digital Output

•

The function can only be used when the alarm status is “Disable”.

Chapter 5

Digital Output Module

•

Click the item to turn it on or off.

Analog Output Module

ADAM-5000 5-19

Page 59

Software Utilities

•

•

Fast Decrease

Enter a valu e that u sers wan t to get

decrease

increase

•

fast increase

5-20 ADAM-5000

Page 60

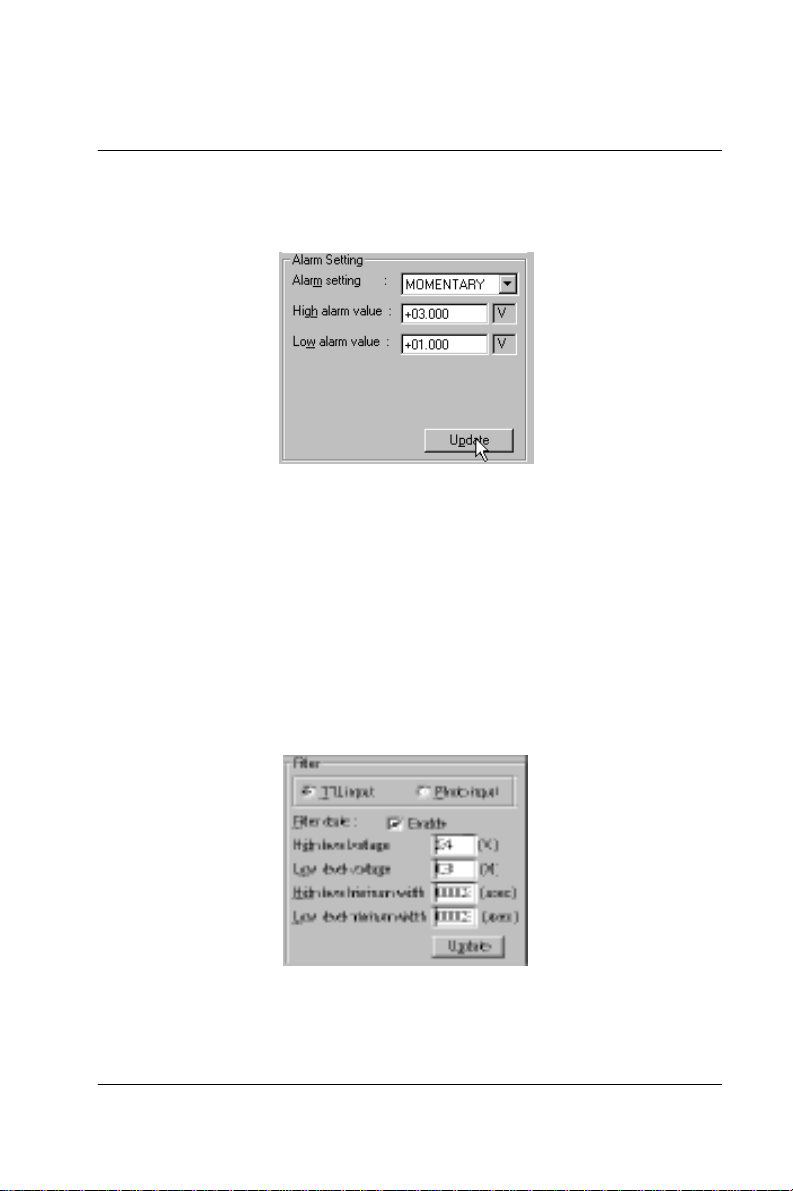

5.1.12 Alarm Setting

•

Set the alarm status, high alarm value, low alarm value, and then

click the Update button.

Chapter 5

•

Alarm setting: Disables or enables the alarm either in Latching or

Momentary mode.

•

High alarm value: Downloads the high alarm limit value into the

module. The format is always in engineering

units.

•

Low alarm value: Downloads the low alarm limit value into the

module. The format is always in engin eer ing un its.

Digital Filter

•

High level voltage: Set the high trigger level for non-isolated input

signals. The range is from 0.1 V to 5.0 V . This

high trigger level must be higher than the low

trigger level at all times.

ADAM-5000 5-19

Page 61

Software Utilities

•

Low level voltage: Set the low trigger level for non-isolated input

•

High level minimum width: Set the minimum width at hig h level.

•

Low level minimum width: Set the minimum width at low level. The

signals. The range is from 0.1 V to 5.0 V .

The unit is µsec (microseconds) and

its resolution is 1 µsec. Users can set

value from 2 to 65535.

unit is µsec (microseconds) and its

resolution is 1 µsec. Users can set

value from 2 to 65535.

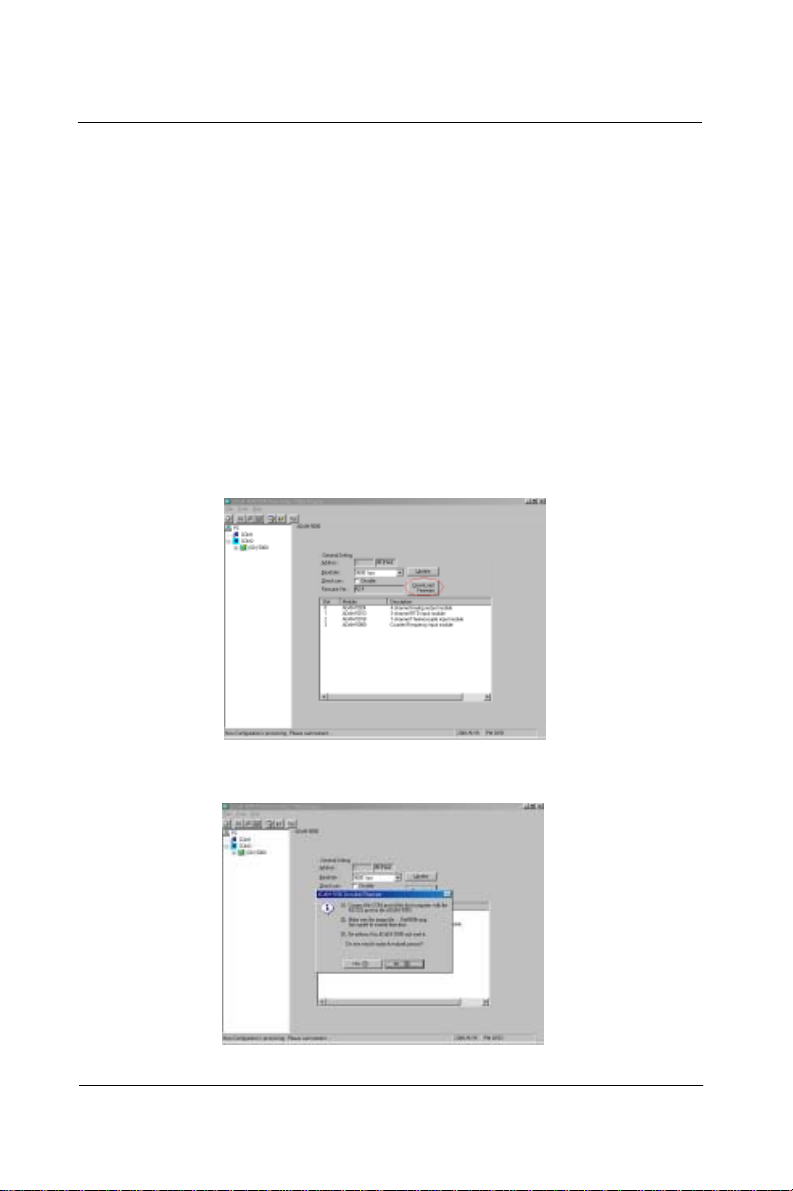

5.1.13 Download Procedure

1. Click the Download Firmware button.

2. Click Yes.

5-22 ADAM-5000

Page 62

3. Choose the b aud rate.

Chapter 5

4 . Choose Download file.

ADAM-5000 5-23

Page 63

Software Utilities

Firmware downloads in progress.

Firmware downloads complete.

NOTICE: THE FIRMWARE UPGRAD OPERATION IS ONLY

USED BY RS-232 PORT.

5-24 ADAM-5000

Page 64

Chapter 5

5.2 DLL (Dynamic Link Library) Driver

The ADAM-5000 API Dynamic Link Library (DLL) enables you

to quickly and easily write Windows applications for ADAM-

5000 systems. The library supports both C++ and Visual Basic.

Since ADAM-5000 systems communicate with a host computer

through the host‘s COM port, no additional driver (DRV or

VxD) needs to be installed. The DLL includes all necessary

function calls to utilize the ADAM-5000 systems to their fullest

extent.

T ogether with the DLL driver you‘ll find the source code of a

V isual Basic example on your diskette. The example provides

several control windows to communicate wi t h all ty pes of

ADAM-5000 m odules. You can customize the source code to

create your own tailor-made

ADAM-5000 setup program or monitoring system.

For details on the ADAM-5000 function calls refer to the

Help file included on the ADAM-5000 API diskette.

5.3 DDE (Dynamic Data Exchange) Server

The ADAM-5000 DDE server takes advantage of DDE, a built-in

Windows comm unication service. The DDE server acquires data

from the ADAM-5000 systems and passes i t t o your

application program via the hot link (DDE). The so f t w a re can

also pass control and configuration commands to the ADAM-

5000 systems using the DDE protocol. You can now use ADAM-

5000 systems wit h most W i ndows- based data acquisition

software that supports DDE. Examples include Intelluti on' s

FIX DMACS, W onderware’ s InTo uch, ONSPEC, Paragon and

Excel.

For details on the ADAM-5000 DDE server refer to the DDE

server manual for the ADAM-5000.

ADAM-5000 5-25

Page 65

Software Utilities

5-26 ADAM-5000

Page 66

6

Command Set

Page 67

Command Set

6.1 Introduction

T o a void com m unicati on conflic ts when se veral devi ces try t o send

data at the same time, all actions are instigated by the host com puter.

The basic form is a command/response protocol with the host initiating the sequence.

When systems are not transmitting they are in listen mode. The host

issues a command to a system with a specified address and waits a

certain amount of time for the syst em to resp ond. If no response

arrives, a time-out aborts the sequence and returns control to the host.

Changing ADAM-5000/5000E system's configurati on might require the

system to perform auto calibra tion bef ore change s can ta ke effect.

This is especially true when changing the range as the system has to

perform all stages of auto calibration that it performs when booted.

When this process is underway, the system does not respond to any

other commands. The command set includes information on the

delays that might occur when systems are reconfigured.

6.2 Syntax

Command Syntax: [delimiter character][address][slot][channel]

[command][data][checksum][carriage return]

Every command begins with a delimiter character. There are four valid

characters: $, #, % and @.

The delimiter character is followed by a two character address (hexadecimal) that specifies the target system. The two characters

following the address specify the module slot and channel.

Depending on the command, an optional data segment may follow the

command string. An optional two character checksum may also be

appended to the command string. Every command is terminated with

a carriage return (cr).

Note:

All commands should be issued in UPPERCASE

characters only!

6-2 ADAM-5000

Page 68

Chapter 6

The command set is divided into the follo wing five categories:

•

CPU Command Set

•

Analog Input Comm and Set

•

Analog Input Alarm Command Set

•

Analog Output Modules Command Set

•

Digital I/O Modules Command Set

Every command set category starts with a command summary of the

particular type of module, followed by datasheets that give detailed

information about individual commands.

Although commands in different subsections sometime share the same

format, the effect they have on a certain module can be completely

different than that of another. Therefore, the full command set for

each type of module is listed along with a description of the effect the

command has on the given module.

Note:

Before setting commands, the user needs to know

the type of main unit being used. If AD AM-5000/485

is being used, the "i" in Si can be set at 0 to 3 . If

ADAM-5000E is being used, the "i" in Si can be set

at 0 to 7.

This is illustrated in the table belo w:

ADAM-5000 6-3

Page 69

Command Set CPU

6.3 CPU Command Set

6-4 ADAM-5000

Page 70

Chapter 6

%aannccff

Name Configuration

Description Sets baud rate and checksum status for a specified

Syntax %aannccff(cr)

Response !aa(cr) if the command is valid.

ADAM-5000 6-5

ADAM-5000 system.

% is a delimiter character .

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system you want to

configure.

nn is reserved fo r system use. Its default value is 00h.

cc represents the baud rate code.

ff is a hexadecimal number that equals the 8-bit parame-

ter representing checksum stat us. The sixth bit represents the checksum status; 1 means enabled while 0

means disabled. The other bits are not used and are

set to 0.

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid parameter was entered or if the

INIT* terminal was not grounded when attempting to

change baud rate or checksum settings. There is no

response if the module detects a syntax error , com munication error or if the specified address does not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

in- valid.

aa (range 00-FF) represents the 2-character hexadecimal

address of an ADAM-5000 system.

Page 71

Command Set CPU

%aannccff

Example command: %23000A40(cr)

Note:

(cr) is the terminating character, carriage return (0Dh).

response: !23(cr)

The ADAM-5000 system with address 23h is configured

to a baud rate of 115.2 Kbps and with checksum generation or validation.

The response indicates that the command was

received. Wait 7 seconds to let the new configuration

setting take effect before issuing a new command to the

system.

All configuration parameters can be changed dynamically , e xcept chec ksum and baud rate pa rameters.

They can only be altered when the INIT* terminal is

grounded.

6-6 ADAM-5000

Figure 6-1 Baud rate codes

Page 72

Chapter 6

$aa2

Name Conf igu ration Statu s

Description Returns the configuration status for a specified system

Syntax $aa2(cr)

Response !aaccff(cr) if the command is valid.

ADAM-5000 6-7

module.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadeci-

mal address of the ADAM-5000 system you want to

interrogate.

2 is the Configuration Status command.

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax

error, communication error or if the specified address

does not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

in- valid.

aa (range 00-F F) represents the 2-character hexadecimal address of an ADAM-5000 system.

cc represents the baud rate code.

ff is a hexadecimal number that equals the 8-bit parame-

ter representing checksum stat us. The sixth bit represents the checksum status; 1 means enabled while 0

means disabled. The other bits are not used and are

set to 0.

(cr) is the terminating character, carriage return (0Dh).

Page 73

Command Set CPU

$aa2

Example command: $452(cr)

6-8 ADAM-5000

(See also the %aannccff configuration command)

response: !450600(cr)

The command requests the ADAM-5000 system at

address 45h to send its configuration status.

The ADAM-5000 system at address 45h responds with a

baud rate of 9600 bps and with no check sum function or

checksum generation.

Page 74

Chapter 6

$aaM

Name Read Module Name

Description Returns the module name from a specified ADAM-5000

Syntax $aaM(cr)

Response !aa5000(cr) if the command is valid.

ADAM-5000 6-9

system.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system you want to

interrogate.

M is the Module Name command.

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax

error, communication error or if the specified address

does not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

in- valid.

aa (range 00-FF) represents the 2-character hexadecimal

address of an ADAM-5000 system.

(cr) is the terminating character, carriage return (0Dh).

Page 75

Command Set CPU

#aaF

6-10 ADAM-5000

Example command: $15M(cr)

response: !155000(cr)

The command requests the system at address 15h to

send its module name.

The system at address 15h responds with module name

5000 indicating that there is an ADAM-5000 at address

15h.

Page 76

Chapter 6

$aaF

Name Read Firmware V ersion

Description Returns the firmware version code from a specified

Syntax $aaF(cr)

Response !aa(version)(cr) if the command is valid.

ADAM-5000 6-11

ADAM-5000 system.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadeci-

mal address of the ADAM-5000 system you want to

interrogate.

F is the Firmware V ersion command.

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax

error, communication error or if the specified address

does not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

in- valid.

aa (range 00-FF) represents the 2-character hexadecimal

address of an ADAM-5000 system.

(version) represents the firmware version of the ADAM5000 system.

(cr) is the terminating character, carriage return (0Dh).

Page 77

Command Set CPU

$aaF

6-12 ADAM-5000

Example command: $17F(cr)

response: !17A1.06(cr)

The command requests the system at address 17h to

send its firmware version.

The system responds with firmware version A1.06.

Page 78

Chapter 6

$aaT

Name Read I/O Type

Description Returns the I/O module no. of all slots for a specified

Syntax $aaT(cr)

Response !aabbccddee(cr) if the command is valid.

ADAM-5000 6-13

ADAM-5000 system.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadeci-

mal address of the ADAM-5000 system you want to

interrogate.

T is the I/O Module T y pes command.

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax

error, communication error or if the specified address

does not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

in- valid.

aa (range 00-F F) represents the 2-character hexadecimal address of an ADAM-5000 system.

bb, cc, dd, ee represent the I/O Module No. of all slots

from slot 0 thru 3 of the ADAM-5000 system .

(cr) is the terminating character, carriage return (0Dh).

Page 79

Command Set CPU

$aaT

6-14 ADAM-5000

Example command: $12T(cr)

response: !1218245160(cr)

The command requests the ADAM-5000 system at

address 12h to send all existing I/O module numbers.

The system at address 12h responds wit h I/O m odul e

numbers 18, 24, 51 and 60 in slots 0 -3. This means

that the ADAM-5000 system contains an ADAM-5018,

ADAM-5024, ADAM-5051 and ADAM-5060 in slots 0

thru 3.

Page 80

Chapter 6

$aa5

Name Reset Status

Description Checks the reset status of the addressed ADAM-5000

system to see whether it has been reset since the last

Reset Status command was issued to the ADAM-5000

Syntax $aa5(cr)

Response !aas(cr) if the command is valid.

ADAM-5000 6-15

system.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadecima l

address of the ADAM-5000 system whose Reset Status

is to be returned.

5 is the Reset Status command.

(cr) is the terminating character, carriage return (0Dh)

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax error

or communication error or i f the specified address does

not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

invalid.

aa (range 00-FF) represents the 2-character hexadecimal

address of an ADAM-5000 system.

s represents the Status bit that is returned by the

ADAM-5000 system. If s=1, the system has been

reset or powered up since the last time it was issued a

Reset Status command. If s=0, the system has not been

reset.

(cr) is the terminating character, carriage return (0Dh)

Page 81

Command Set CPU

$aa5

Example command: $395(cr)

response: !391(cr)

The ADAM-5000 system at address 39h was reset or

powered up since the last Reset Status command was

issued.

6-16 ADAM-5000

Page 82

Chapter 6

$aaE

ADAM-5000 6-17

Name Software Diagnostics

Description Requests the specified ADAM-5000 system to return

the error status

Syntax $aaE(cr)

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system you want to

interrogate.

E is Software Diagnostics command.

(cr) is the terminating character, carriage return (0Dh)

Response !aabbccddee(cr) if the command is valid.

?aa(cr) if an invalid operation was entered.

There is no response if the system detects a syntax error

or communication error or i f the specified address does

not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

invalid.

aa (range 00-FF) represents the 2-character hexadecimal

address of an ADAM-5000 system.

bbccddee are hexadecimal numbers representing the error

code from slot 0 thru slot 3 of the sy stem.

(cr) is the terminating character, carriage return (0Dh)

Page 83

Command Set CPU

Figure 6-2 Analog module erro r code s

Example: command: $01E(cr)

response: !0100000001

The command diagnoses the system at address 01h and

responds with its error status code.

The system responds that the module in slot 3 has a

span calibration error.

6-18 ADAM-5000

Page 84

Chapter 6

6.4 ADAM-5013 RTD Input Command Set

ADAM-5000 6-19

Page 85

Command Set

5013 RTD Input

Note:

The ADAM-5013 module also has "Alarm Setting"

functions. The alarm command set f o r the AD AM5013 is the same as that f or the AD AM- 5017, AD AM5017H, and the ADAM-5018. Please refer to pages

6-71 to 6-89 for this set of commands.

6-20 ADAM-5000

Page 86

Chapter 6

$aaSiArrff

Name RTD Configuration

Description Sets slot index, input range, data format and integration

time for a specified R TD input module in a specified

Syntax $aaSiArrff(cr)

Response !aa(cr) if the command is valid.

ADAM-5000 6-21

system.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system you want to

configure.

Si identifies the desired slot i (i:0to3).

A represents the I/O m odule c on figurat io n co m mand.

rr represents the 2-character hexadecimal code of the

input range. (See Appendix B)

ff is a hexadecimal number that equals the 8-bit parame-

ter representing data format. Bits 0 and 1 represent

data format. Bit 7 represents integration time. The

layout for the 8-bit parameter is shown in Figure 6-3

(See page 6-

38). The other bits are not used and are set to 0. (cr) i s

the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax error

or communication error or i f the specified address does

not exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

invalid.

aa (range 00-FF) represents the 2-character hexadecimal

Page 87

Command Set

5013 RTD Input

$aaSiArrff

Example command: $35S3A2000(cr)

address of an ADAM-5000 system.

(cr) is the terminating character, carriage return (0Dh).

response: !35(cr)

The RTD input module in slot 3 of the ADAM-5000

system at address 35h is configured to an RTD type

Pt -100 to 100° C, engineering unit data format, and

integration time 50ms (60Hz). The response indicates

6-22 ADAM-5000

that the command has been received.

Page 88

Chapter 6

$aaSiB

Name RTD Configuration Status

Description Returns the configuration parameters for a s pecified

Syntax $aaSiB(cr)

Response. !aarrff(cr) if the command is valid.

ADAM-5000 6-23

R TD input module in a specified system.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system you want to

interrogate.

Si identifies the desired slot i (i:0to3)

B represents the configuration status command

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax error or

communication error or if the specified address does not

exist.

! delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

invalid.

aa (range 00-FF) represents the 2-character hexadecimal

address of an ADAM-5000 system.

rr represents the 2-character hexadecimal code of the

input range. (See Appendix B)

ff is a hexadecimal number that equals the 8-bit parameter

representing data format. Bits 0 and 1 represent data

format. Bit 7 represents integration time (See R TD

Configuration Command $aaSiArrff).

Page 89

Command Set

5013 RTD Input

$aaSiB

Example command: $35S3B(cr)

6-24 ADAM-5000

(cr) is the terminating character, carriage return (0Dh).

response: !352000(cr)

The R TD input module in slot 3 of the ADAM-5000

system at address 35h responds with an RTD type Pt

-100 to 100° C, engineering unit data format, and

integration time 50ms (60Hz).

Page 90

Chapter 6

$aaSi

Name All RTD Data In

Description Returns the input values of all channels of a specified

R TD input m odule in a specified syst em in engineeri ng

Syntax $aaSi(cr)

Response. >(data)(data)(data)(cr) if the command is valid.

ADAM-5000 6-25

units only.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system you want to

interrogate.

Si is the I/O slot of the ADAM-5000 system you want to

read.

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax error

or communication error or i f the specified address does

not exist.

> delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

invalid.

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system.

(data) is the input value in engineering units of the

interrogated module of the specified system. The (data)

from all channels is shown in sequence from 0 to 2. If

(data)=“ ”, it means the channel is invalid.

(cr) is the terminating character, carriage return (0Dh).

Page 91

Command Set

5013 RTD Input

$aaSi

Example command: $35S3(cr)

response: >+80.01 +20.00 -40.12(cr)

The command requests the RTD input module in slot 3

of the ADAM-5000 system at address 35h to return the

6-26 ADAM-5000

input values of all channels.

The R TD input module respon ds with input values of al l

channels in sequence from 0 to 2 : +80.01° C, +20.00° C,

-40.12° C.

Page 92

Chapter 6

$aaSiCj

Name Specified RTD Data In

Description Returns the input value of a specified channel for a

specified R T D input modul e of a specified sy stem in

Syntax $aaSiCj(cr)

Response. >(data)(cr) if the comm and is valid.

ADAM-5000 6-27

engineering units only.

$ is a delimiter character.

aa (range 00-FF) represents the 2-character hexadecimal

address of the ADAM-5000 system you want to

interrogate.

SiCj identifies the desired slot i (i:0 to 3) and the desired

channel j (j:0 to 2) of the module you want to interrogate.

(cr) is the terminating character, carriage return (0Dh).

?aa(cr) if an invalid operation was entered.

There is no response if the module detects a syntax error

or communication error or i f the specified address does

not exist.

> delimiter character indicating a valid command was

received.

? delimiter character indicating the command was

invalid.

aa (range 00-FF) represents the 2-character hexadecimal