Advanced Protection XRL User Manual [en, es]

ENGLISH

TEXA, TEXB,

TEXR, TEXW

Series

Surge Protective Device (SPD)

Installation, Operation

& Maintenance Manual

WARNING – IMPORTANT – PLEASE READ – WARNING

Safety First – Hazardous Voltage & Shock Hazard

• Only qualied licensed electricians should install or service SPDs

• Hazardous voltages exist within SPDs

• SPDs should never be installed or serviced when energized

• Use appropriate safety precautions including Personal Protection Equipment

• Failure to follow these instructions can result in death, serious injury, and/or equipment damage

• This manual shall be read in its entirety prior to installing

V

Bonding and Grounding Hazard

Verify that the neutral conductor in the service entrance

equipment is bonded to ground in accordance with the

National Electric Code (NEC®) and all applicable codes.

Verify that the neutral terminal (XO) on the secondary side of

distribution transformers are grounded to the system ground in

accordance with the NEC® and all applicable codes.

During installation into an electrical system the SPD must

not be energized until the electrical system is completely

installed, inspected and tested. All conductors must be

connected and functional including the neutral (if required).

The voltage rating of the SPD and system must be veried

before energizing the SPD.

Failure to follow these guidelines can lead to abnormally high

voltages at the SPD. This may cause the SPD to fail. The

warranty is voided if the SPD is incorrectly installed and/or if

the neutral conductor in the service entrance equipment or

downstream of separately derived systems is not bonded to

ground in accordance with the NEC®.

Do Not Hi-Pot Test SPDs

Any factory or on-site testing of power distribution

equipment that exceeds normal operating voltage such as

high-potential insulation testing, or any other tests where the

suppression components will be subjected to higher voltage

than their rated Maximum Continuous Operating Voltage

(MCOV) must be conducted with the SPD disconnected

from the power source. For 4-wire systems, the neutral

connection at the SPD must also be disconnected prior to

performing high-potential testing and then reconnected after

test completion.

Failure to disconnect SPD and associated components

during elevated voltage testing will damage the SPD and

will void the warranty.

Advanced Protection Technologies

14550 58th Street North

(800) 237-4567·(727) 535-6339 · Fax (727) 539-8955

UL is a registered trademark of Underwriters Laboratories, NEC® and National Electrical Code are

registered trademarks of National Fire Protection Association, C62.41.1-2002, C62.41.2-2002,

C62.45-2002, C62.72-2007 are registered trademarks of IEEE.

www.aptsurge.com · info@apttvss.com

Clearwater, Florida 33760

·

European Authorized Representative

Obelis s.a.

Boulevard Général Wahis 53

1030 Brussels, BELGIUM

Tel: +(32) 2. 732.59.54

Fax: +(32) 2. 732.60.03

E-Mail: mail@obelis.net

01.24.13.lh #8169

INTRODUCTION

Thank you for choosing an APT Surge Protective Device

(SPD). This is a high quality, high energy surge suppressor

designed to protect sensitive equipment from damaging

transient overvoltages.

Proper installation is important to maximize performance.

Please follow steps outlined herein.

This entire Operation & Maintenance Manual should be

read prior to beginning installation. These instructions are

not intended to replace national or local codes. Follow

all applicable electrical codes to ensure compliance.

Installation of this SPD should only be performed by

qualied electrical personnel.

APT SPDs are extensively tested in accordance with

industry standards such as ANSI/IEEE C62.41.1, C62.41.2,

C62.45, C62.62, C62.72, UL 1449, UL 1283, IEC 61643, etc.

This SPD is a single-port parallel-connected device

intended for service entrance, panelboard or downstream

installation for IEEE Category C, B or A applications.

Major Industry Nomenclature Changes

Effective 2008-2009

Be aware that UL 1449 Third Edition and 2008 NEC® Article

285 generated substantial changes.

▪ The term TVSS changed to SPD

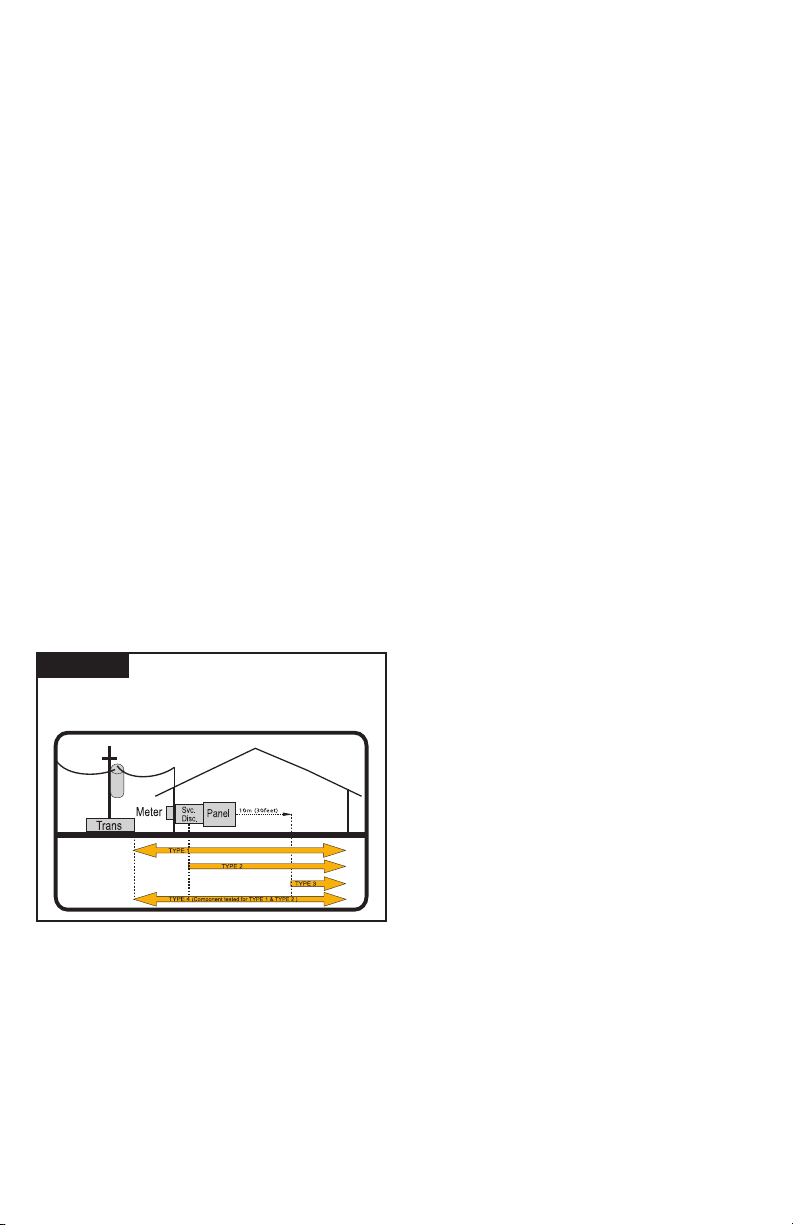

▪ Types 1, 2, 3 & 4 SPDs are created

▪ UL 1449 clamping voltage performance testing

changed from 500A to 3,000A

▪ UL 1449 added new I nominal testing (I

consists of more rigorous duty-cycle testing

Figure 1

(also coincides with ANSI/IEEE C62.41.2 - 2002 Categories C, B & A)

This SPD complies with the latest regulatory actions and

is UL Listed as such.

For further information, please review latest editions of

NEC® Article 285, UL 1449 or contact APT Tech Support

at (800) 237-4567.

GENERAL INFORMATION

Product Family Outline

XA – Single Module in enclosure

XB – Two Modules in enclosure

XR – Single small module for integration by OEM

XW – Single large module for integration by OEM

2

NEC® Article 285 & UL 1449-3

SPD Types: Types 1, 2, 3, & 4

Based on Location within electrical distribution system

), which

n

Each is available with an ‘S’ or ‘L’ sufx, which designate

Standard modes (most common) or discrete 10-modes

(specic application) respectively. For example, XAS is SPD

in enclosure with Standard modes of protection; XRL is SPD

without enclosure to go inside host gear having discrete ten

mode protection.

XR & XW versions without enclosures are available for

internal mounting within electrical gear. The XR version is

rated 100-300kA. The XW version is rated 300-500kA. Both

are available with S or L designations.

The XA & XB families are intended for use as a Type 1 external

mount SPD. XR and XW families are Type 4 SPDs intended for

Type 1 applications. See Model Number Decoder in Table 1.

Type 1 SPD

Type 1 SPDs include internal overcurrent protection and

have been evaluated by UL to more stringent requirements.

Type 1 SPDs are suitable for installation on the line side

or load side of the service disconnect overcurrent device.

Type 1 SPDs may be used in Type 2 applications.

Internal Protection

This device features internal overcurrent and

overtemperature protection that will disconnect effected

surge suppression components at the end of their useful

life, but will maintain power to the load – now unprotected. If

this situation is undesirable for the application, follow these

instructions for servicing or replacing the device.

Service Guidelines

Service of this unit consists of replacing the internal module(s),

disconnect switch (if equipped) and/or display assembly.

There are no user-serviceable parts inside the replaceable

module. Do not attempt to disassemble the module as it

stores charge.

Simplied Explanation of Operation

SPDs sense overvoltage and create a momentary short

circuit to redirect harmful surge energy. SPDs reset

automatically and wait for the next surge. This is similar to

the pressure relief valve on a water heater: pressure goes

up, valve opens to relieve pressure and then resets. In

an electrical system, an SPD senses overvoltage, shorts

temporarily, which equalizes damaging voltages and

then resets. SPDs are capable of repeating this function

thousands of times.

Parallel Connection

This is a Parallel connected SPD – not series connected.

As outlined above, an SPD ‘drains off’ excessive voltage

from an electrical system. Because of parallel connection,

installation of the SPD anywhere near the equipment to be

protected is satisfactory. This effect is similar to ushing

any toilet in a house; pressure in the shower goes down.

In an electrical system, a parallel connected SPD will

remove excessive voltage off the entire system (assuming

reasonable proximity).

Tip: It is very important that wiring leads be congured as short

& straight as possible. Avoid long leads. Avoid sharp bends.

Route SPD conductors in the same conduit. Leads do not have

to be sized for the entire load – this SPD is parallel connected,

not series connected. As a generalization, 6 AWG works ne.

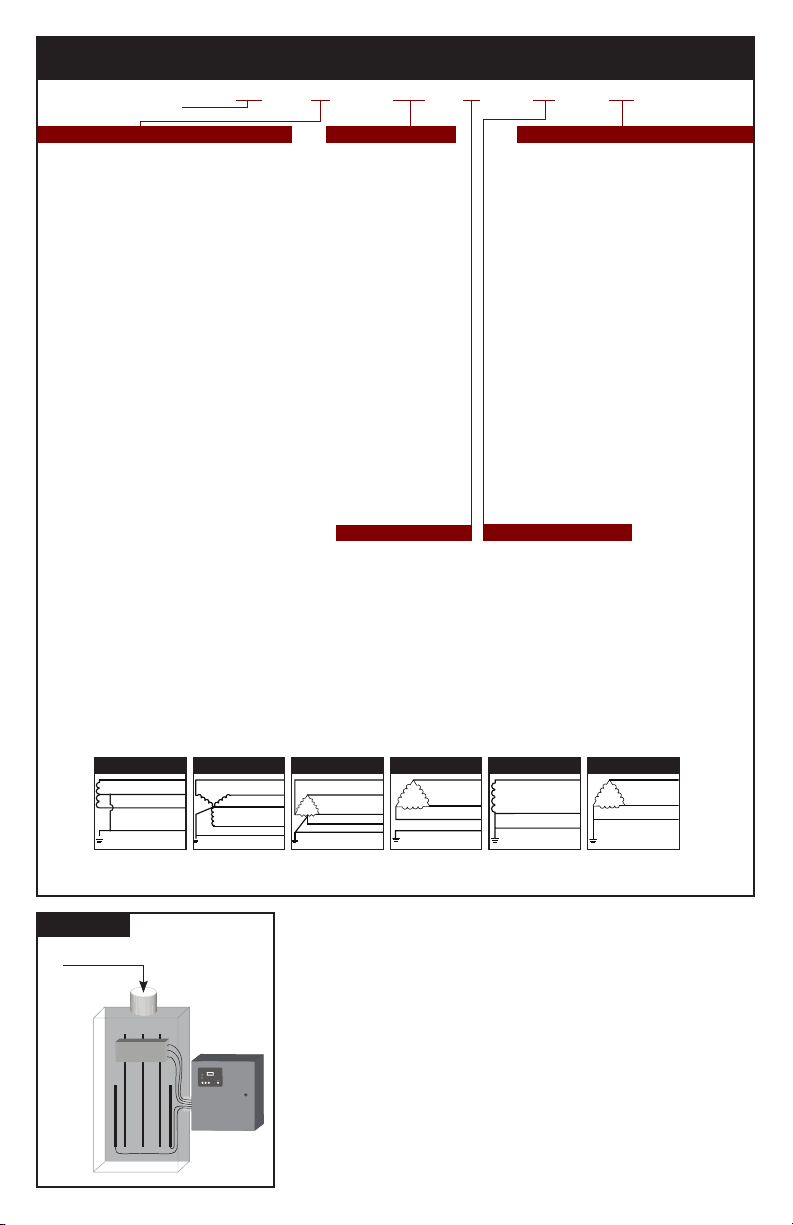

Do not create model numbers from this chart as all features are not available on all models

TABLE 1: MODEL NUMBER DECODER

Transient Eliminator

Voltage Code for Electrical System Model Family Options

Common North American Systems:

01 = 240/120V Split Phase - 1Ø, 3W+Grnd, (Fig 1)

02 = 208Y/120V Wye - 3Ø 4W+Grnd, (Fig 2)

03 = 240/120V High Leg Delta (B High), (Fig 3)

04 = 480Y/277V Wye - 3Ø 4W+Grnd, (Fig 2)

05 = 480V Delta - 3Ø 3W+Grnd, (Fig4) & HRG Wye

08 = 600Y/347V Wye - 3Ø 4W+Grnd, (Fig2)

Other Available Systems - Conrmation encouraged:

15 = 254/127V Split Phase - 1Ø 3W+Grnd, (Fig 1)

18 = 480/240V Split Phase, or Two legs of Wye, (Call)

21 = 220Y/127V Wye - 3Ø 4W+Grnd (Fig 2)

41 = 520Y/300V Wye - 3Ø 4W+Grnd (Fig 2)

42 = 415Y/240V Wye - 3Ø 4W+Grnd (Fig 2)

43 = 400Y/230V Wye - 3Ø 4W+Grnd (Fig 2)

44 = 440Y/250V Wye - 3Ø 4W+Grnd (Fig 2)

51 = 480V B Corner Grnd Delta, 3Ø 3W+Grnd (Fig 6)

06 = 240V Delta - 3Ø 3W+Grnd (Fig 4)

61 = 240V B Corner Grnd Delta, 3Ø 3W+Grnd (Fig 6)

07 = 380Y/220V Wye - 3Ø 4W+Grnd (Fig 2)

09 = 600V Delta - 3Ø 3W+Grnd (Fig 4) & HRG Wye

(Available: 100kA, 150kA, 200kA, 250kA)

91 = 600V B Corner Grnd Delta, 3Ø 3W+Grnd (Fig 6)

(Available: 100kA, 150kA, 200kA, 250kA)

11 = 120V Single Phase (Fig 5)

12 = 240V Single Phase (Fig 5) - Not split phase

13 = 127V Single Phase (Fig 5)

14 = 300V Single Phase (Fig 5)

16 = 277V Single Phase (Fig 5)

17 = 480V Single Phase (1 Hot, 1 Neu, 1 Grnd) (Fig 5)

TE 02 XAS 20 E1 XD

XAS = External Mount SPD

Standard Modes

XAL = External Mount SPD

10 Mode

XBS = External Mount SPD

Two Modules

Standard mode

XBL = External Mount SPD

Two Modules

10 Mode

For Internal Mount

(No Enclosures):

XRS = Component SPD,

UL Recognized

Standard Modes

XRL = Component SPD,

UL Recognized

10 Modes

XWS = Component SPD,

UL Recognized

Standard Modes

XWL = Component SPD,

UL Recognized

10 Modes

Surge Current Rating

10 = 100kA/Phase

15 = 150kA/Phase

20 = 200kA/Phase

25 = 250kA/Phase

30 = 300kA/Phase

31 = 300kA/Phase

40 = 400kA/Phase

45 = 450kA/Phase

50 = 500kA/Phase

60 = 600kA/Phase

80 = 800kA/Phase

90 = 900kA/Phase

1K = 1000kA/Phase

X = Surge Counter, six-digit LCD counter

includes maintenance-free Eprom memory

backup

Z = Surge Counter, plus External Surge

Counter Signal

E = Remote Locatable Display on 6 ft Cable

custom cable lengths available

M = Mount Display on SPD instead of cable

F = Noise Filtering - Extended Range &

Attenuation

D = Rotary Disconnect Switch

Bussman, UL98

T = Thru-door Rotary Disconnect Switch

Bussman, UL 98, NEMA 1/12/3R only

K = Rotary Disconnect Switch

Katco, UL 508

S = Thru-door Rotary Disconnect Switch

Katco, UL 508, NEMA 1/12/4 only

Delete Options

L = Delete L-N Protection (reduces kA rating)

G = Delete L-G Protection (reduces kA rating)

N = Delete N-G Protection (reduces kA rating)

J = Delete Noise Filter

Enclosure Rating

E1 = NEMA 1/12/3R/4

4X = NEMA 4X Non-Metallic

4S = NEMA 4X Stainless Steel

FM = NEMA 1 Flush Mount

P1 = NEMA 1 pullbox ‘indoor'

Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6

Phase A (BLK)

Phase B (BLK)

B

A

Neutral (WHT)

N

V

}

Phase C (BLK)

C

Ground (GRN)

WYE

3 Hots, 1 Neu, 1 Grnd

TYPICAL PARALLEL

ELECTRICAL PANEL

BC

Advanced Protection Technologies

Phase A

Surge Counter

Phase B

Phase C

Service

GN

Silence

TestCountReset

Figure 2

To

Protected

Loads

Hot (BLK)

V

}

Neutral (WHT)

}

V

Hot (BLK)

Ground (GRN)

SPLIT

2 Hots, 1 Neu, 1 Grnd

CONNECTED SPD ON

A

BREAKER

Phase A (BLK)

Phase B (ORNG)

V

}

Phase C (BLK)

Neutral (WHT)

Ground (GRN)

HI-LEG DELTA (B High)

3 Hots, (B HIGH),

1 Neu, 1 Grnd

Phase A (BLK)

V

}

Phase B (BLK)

Phase C (BLK)

Ground (GRN)

DELTA & HRG WYE

3 Hots, 1 Grnd

V

}

SINGLE POLE

1 Hot, 1 Neu, 1 Grnd

Precautionary Statement Regarding SPDs on Ungrounded Systems

Caution – Ungrounded systems are inherently unstable and can produce

excessively high line-to-ground voltages during certain fault conditions. During

these fault conditions, any electrical equipment including an SPD, may be

subjected to voltages which exceed their designed ratings. This information

is being provided to the user so that an informed decision can be made

before installing any electrical equipment on an ungrounded power system.

Cascade Surge Protection

For optimum surge protection, cascade or staged surge suppression should

be implemented at the service entrance and downstream locations as

appropriate. Known or expected surge sources, as well as sensitive loads,

should also have localized surge suppression. For interconnected electronic

loads (data cabling), SPDs should also be utilized to protect the devices on

either end of the interconnecting data cables.

Hot (BLK)

Neutral (WHT)

Ground (GRN)

Phase A (BLK)

V

}

Phase C (BLK)

Ground (GRN)

CORNER GROUND

DELTA (B grounded)

2 Hots, 1 Grnd

3

Unpacking & Preliminary Inspection

Inspect the entire shipping container for damage or signs

of mishandling. Remove the packing materials and further

inspect the unit for any obvious shipping damages.

If any damage was found and is a result of shipping

or handling, immediately le a claim with the shipping

company and forward a copy to APT.

Storage Environment

This SPD should be stored in a clean, dry environment.

Storage temperature range is -40°C (-40°F) to +60°C

(+140°F). Avoid exposure to high condensation.

PRE-INSTALLATION & INSTALLATION PLANNING

Operating Environment

The standard unit uses a Type 1/12/3R/4 enclosure.

Non-metallic polycarbonate 4X, stainless steel and Type

1 ush-mount or pull box enclosures are available as

options. Before installing, ensure that your enclosure type

and application are appropriate per NEMA 250 with regard

to moisture, dirt, excessive dust, ammable materials or

atmospheres, corrosive vapors, etc. Please consult factory

if enclosure needs to be changed.

This SPD is designed in an ambient temperature range

of -40°C (-40°F) to +60°C (+140°F) with a relative

humidity of 0% to 95% (non-condensing). Excessive

temperature may inadvertently operate internal thermal

overtemperature protectors.

On rare occasions in high temperature climates, SPDs

inside clear cover polycabonate enclosures have

experienced internal temperatures exceeding 200°F

(94°C). We recommend positioning the unit so that the

clear front avoids direct summer sunlight by shading or

not facing west.

Line Side versus Load Side Installation

The XA & XB family SPDs are tested and qualied as

Type 1 SPDs per UL 1449 Third Edition and 2008 NEC®.

This SPD can be installed on the Line Side of the service

overcurrent device per 2008 NEC® Article 285. Type 1

SPDs may also be installed in Type 2 applications. As

a generalization, it is more practical to install as Type 2

on load side of main overcurrent device for maintenance

reasons. Such installations would be similar to traditional

TVSS installations. (Note: cUL models are Type 2 due to

different cUL criteria.)

XR and XW SPD modules are Type 4 components that

have been evaluated by UL for use in Type 1 applications.

(XR’s and XW’s are essentially XA’s without enclosures for

installation within host electrical equipment.)

There may be circumstances where Line Side installation

is desirable. Follow all applicable Code requirements for

Line Side installation. We generally recommend that the

SPD be installed with a disconnecting mechanism for

servicing purposes.

Tip: APT offers an optional Disconnect Switch that has been

UL evaluated as part of the SPD. This includes SCCR and

Line Side suitability. If you do not use the APT Disconnect

option, select a disconnect switch rated for line side (UL

98) having appropriate SCCR rating including any required

overcurrent protection. This may be more time consuming

and expensive than anticipated. The optional Disconnect

Switch is fully engineered and almost certainly easier, smaller

and less expensive. Please contact APT Technical Support

as appropriate.

Audible Noise

SPD background noise is negligible or non-existent, and

does not restrict the location of installation.

Mounting, Dimensions, and Weight

The XA & XB series include enclosures and are intended for

wall mounting. The XR & XW series are component SPDs

intended for installation within other electrical gear already

having enclosures. See Table 2. Mechanical drawings are

included in back of this manual (page 12).

TABLE 2: DIMENSIONS & WEIGHTS

XA H/W/D (in. / mm.) Weight

Standard (and w/

Opt. Disc. Switch

& <300kA)

With Opt. Disc.

Switch & >300kA

4X Non-Metallic

(std.)

(>300kA w/disc.)

4X Stainless

(>300kA w/disc.)

Pullbox & Flush

mount

(>300kA w/disc.)

12"x12"x6.5"

(305x305x165)

16"x14"x6.5"

(406x356x165)

14"x12"x7" (356x305x178)

16"x14"x7" (406x356x178)

12"x12"x7.5"

(305x305x191)

16"x14"x7.5"

(406x356x191)

12"x12"x6" (305x305x152)

16"x14"x6" (406x356x152)

23 lbs

(10.4 kg)

32 lbs

(14.5 kg)

14 lbs (6.4)

21 lbs (9.5)

24 lbs (10.9)

33 lbs (15)

21 lbs (9.5)

29 lbs (13.2)

XB H/W/D (in. / mm.) Weight

Standard

(includes Disc.

Switch)

4X Non-Metallic

4X Stainless

Pullbox & Flush

mount

20" x 20" x 7.5"

(508 x 508 x 191)

24" x 24" x 8"

(610 x 610 x 203)

20" x 20" x 7.5"

(508 x 508 x 191)

20" x 20" x 6"

(508 x 508 x 152)

52 lbs

(23.6 kg)

52 lbs

(23.6 kg)

53 lbs

(24 kg)

43 lbs

(19.5 kg)

XR H/W/D (in. / mm.) Weight

Standard

With Opt. Disc.

Switch on alum.

backplane

6.5" x 11" x 4.5"

(165 x 279 x 114)

10.75" x 10.88" 4.5"

(273 x 276 x 114)

5 lbs

(2.3 kg)

9 lbs

(4.1 kg)

XW H/W/D (in. / mm.) Weight

Standard

With Opt. Disc.

Switch on alum.

backplane

9" X 11" X 4.5"

(229 x 279 x 114)

14.75" X 12.9" X 5.25"

(375 x 328 x 133)

Service Clearance

Service clearance is needed at the front of the unit; 36

inches minimum is the required distance for clearance

pursuant to the NEC®.

Lead Lengths & Maximizing SPD Performance

SPDs must be located as close to the circuit as possible

to minimize parasitic losses. Surges are high current, high

frequency events that cause substantial voltage drops

across conductors. This hurts SPD performance. Use the

shortest & straightest possible leads. Pre-Plan installations

7 lbs

(3.2 kg)

11 lbs

(5 kg)

4

and ensure that nearest breaker positions are used. If new

construction, adjust breaker locations as appropriate.

Tip: Voltage drops for normal 120V or 277V lines might be 2-3V

per hundred feet. In surge applications, voltage drops might

be 100-150V per foot. These voltage drops add to clamping

voltage, thus hurting performance. Make every effort to keep

leads short and straight.

As distribution gear becomes larger, shorter leads are more

difcult to accomplish. When longer leads are unavoidable,

gently twist leads together (one to two twists per foot), or

tie-wrap leads together.

Tip: surges create magnetic elds per the ‘right-hand rule’.

When current goes in direction of thumb, magnetic eld is

in direction of curl of ngers. As surge current goes to SPD,

elds are created in one direction. When the SPD sends those

currents to neutral and/or ground, current goes in the opposite

direction. If ‘coming & going’ are on the same axis, the magnetic

elds can be cancelled, thus avoiding performance decrease.

Gentle twists, bundling & tie-wraps accomplish this.

Shortest Leads Possible

▪ Leads must be as short and straight as possible -

See NEC® Art. 285.12

▪ Pretend wire is $1000 per foot coming out of your pocket.

▪ No long leads

▪ No sharp bends

▪ No wire nuts

▪ How short is short enough? As short as you can make it.

▪ How long is too long? If anyone else can make it shorter.

Overcurrent Protection

SPDs draw very little current under normal conditions and

conduct for a brief duration upon encountering a transient

surge current. This SPD contains internal overcurrent and

overtemperature protection to protect against abnormal

voltage conditions.

Supplemental overcurrent protection is not required to protect

this SPD. However, connecting conductors require protection

in Type 2 or 4 applications. Follow applicable codes.

Voltage Rating

Before installing SPD, verify that it has the same voltage

rating as the power distribution system. Compare the SPDs

nameplate voltage or model number and ensure that SPD

conguration matches the intended power source. See Table 1.

The specier or the user of the device should be familiar with

the conguration and arrangement of the power distribution

system in which any SPD is to be installed. The system

conguration of any power distribution system is based strictly

on how the secondary windings of the transformer supplying

the service entrance main or load are congured. This includes

whether or not the transformer windings are referenced to

earth via a grounding conductor. The system conguration is

not based on how any specic load or equipment is connected

to a particular power distribution system.

480V System Example: SPDs should be installed per

the electrical system, not per a load or motor’s wiring

connection. For example, a 480V three phase motor might

appear to be connected as a 480V Delta. In actuality, the

serving distribution system might be a 480Y/277V grounded

Wye, with or without a neutral pulled to the motor or MCC.

The system is still a 480Y/277V Wye, even though the load

is connected as a Delta. A grounded Wye has a dened

reference to ground (i.e., neutral is bonded to ground).

Some Delta systems are ungrounded, which have no

reference to ground and are known to become unstable in

certain situations. Such instability can cause line to ground

voltage uctuations that may prematurely fail SPDs. For this

reason, the NEC® Article 285 has placed SPD restrictions

on ungrounded systems. As generalizations, SPDs for

ungrounded systems can be installed on grounded systems

with a clamping performance penalty. However, SPDs for

grounded systems installed on ungrounded systems are

almost certainly destined for premature failure. Call APT

Tech Support at (800) 237-4567 for further information.

Circuit Breaker and Disconnect Switch

The XA & XB family SPDs are tested and qualied as a Type

1 SPD per UL 1449 Third Edition and 2008 NEC®. This SPD

can be installed on the line side of the service overcurrent

device per 2008 NEC® Article 285. As a generalization, it

is more practical to install on load side of main overcurrent

device for maintenance reasons.

When connected on load side of main disconnect, we suggest

connecting via a 60A circuit breaker. The circuit breaker is

the intended disconnect switch and provides short circuit

protection to the connecting conductors. These SPDs have

internal overload protection elements within the product. A

breaker or disconnect is not required for the SPDs overcurrent

protection. These SPDs have demonstrated 200kA Short

Circuit Current Ratings (SCCRs). 120V & 120/240V models

have demonstrated 100kA SCCRs. Refer to label on unit.

Terminals

Terminals will accept 14 - 2 AWG conductor and are provided

for line (phase), neutral (if used), and equipment safety ground

connections. 8 AWG is the minimum recommended wire size

because UL testing and evaluation was performed using 8 AWG.

Wire Size and Installation Torque

This is a parallel-connected SPD; it is not series-connected.

The size of the SPD wiring is independent of the ampere

rating of the protected circuit. Recommended wire is 6

AWG for phase, neutral and ground connections. Torque

connections to 18 inch-pounds. Conductor length should

be as short as possible.

If other wire sizes are used, we recommend that all

conductors be the same gauge. Note that larger conductor

might appear to be benecial. However, large conductor

tends to have the same inductance as smaller conductor,

thus netting limited improvement in exchange for being more

difcult to work with. Terminals accept 14 - 2 AWG conductor

with 6 AWG being preferred. Coordinate conductor size and

overcurrent protection per applicable codes.

If equipped, Disconnect Switch will accept 6 AWG to 1/0

AWG, with 6 AWG preferred. Torque connections to 18

inch-pounds. Do Not overtorque connections on Disconnect

Switch as it Will Break the Disconnect Switch and will not

be covered by warranty.

System Grounding

An equipment grounding conductor must be used on all

electrical circuits connected to the SPD.

For the best performance, use a single point ground system

where the service entrance grounding electrode system is

connected to and bonded to all other available electrodes,

building steel, metal water pipes, driven rods, etc. (for

reference see: IEEE Std 142-2007).

5

For sensitive electronics and computer systems, we

recommend that the ground impedance measurement be

as low as possible. When metallic raceway is used as an

additional grounding conductor, an insulated grounding

conductor should be run inside the raceway and sized per

the NEC®. Adequate electrical continuity must be maintained

at all raceway connections. Do not use isolating bushings

to interrupt a metallic raceway run.

A separate isolated ground for the SPD is NOT recommended.

Proper equipment connections to grounding system and

ground grid continuity should be veried via inspections and

testing on a regular basis as part of a comprehensive electrical

maintenance program.

On 4-Wire Power Systems, neutral to ground bonding (Main

Bonding Jumper) must be installed per the NEC®. Failure

to do so WILL damage SPDs.

Internal Mounting of XR and XW Component SPD

XR’s and XW’s are essentially XA’s without enclosures. XR’s

and XW’s are intended for installation within host electrical

equipment having suitable enclosures.

The experienced integrator will appreciate the simplicity

of XR/XW. XR/XW’s are Type 4 SPDs and have been

evaluated by UL for use as Type 1 (or Type 2) SPDs

when installed in appropriate enclosures. All UL required

safety testing is complete without needing additional

safety apparatus. Contact factory for UL le Engineering

Considerations. Mount SPD in appropriate enclosure,

mount Diagnostic Display in appropriate location and follow

appropriate instructions, including short leads. UL evaluation

within your completed product should be easy and trouble

free. Do not Hi-Pot test with SPD in circuit.

In many instances, a disconnecting means is appropriate

for future service. A breaker serves this function, as well

as provides overcurrent protection to the connecting

conductors. If a breaker or optional Disconnect Switch are

not used, consider a disconnect or safety switch having

appropriate SCCR rating including any required overcurrent

protection. Line side is likely to require a UL 98 switch where

load side is likely to require a UL 508 (or UL 98) switch.

This may be more time consuming, more expensive and

physically larger than anticipated. APT offers an optional

Disconnect Switch that has been UL evaluated as part of the

SPD. The optional Disconnect Switch is fully engineered and

almost certainly easier, smaller and less expensive. Please

contact APT Technical Support as appropriate.

Mounting Diagnostic Display: Mount the Display in a

user-friendly location, with consideration to weather and

vandalism. Dimensions are in Figure 4 (page 7). A Display

with a 6’ connector cable is typically included. Longer lengths

are available. The Display is also mountable directly on the

XR/XW module (shorter cables required). The standard

Display includes mounting thru-holes and is not weather

resistant. Contact factory for weather resistant NEMA 4 rated

Display (with mounting studs instead of thru-holes and label

material including UL 746C(f1) & UL 94-5VA ame rating).

UL 1283 required language concerning the installation

of EMI Filters

a) An insulated grounding conductor that is identical in size

and insulation material and thickness to the grounded and

ungrounded circuit supply conductors, except that it is green

with or without one or more yellow stripes, is to be installed

as part of the circuit that supplies the lter. Reference should

be made to Table 250-122 of the National Electrical Code

regarding the appropriate size of the grounding conductor.

b) The grounding conductor mentioned in item a is to

be grounded to earth at the service equipment or other

acceptable building earth ground such as the building frame

in the case of a high-rise steel-frame structure.

c) Any attachment-plug receptacles in the vicinity of the

lter are to be of a grounding type, and the grounding

conductors serving these receptacles are to be connected

to earth ground at the service equipment or other acceptable

building earth ground such as the building frame in the case

of a high-rise steel-frame structure.

d) Pressure terminal or pressure splicing connectors and

soldering lugs used in the installation of the lter shall be

identied as being suitable for the material of the conductors.

Conductors of dissimilar metals shall not be intermixed in a

terminal or splicing connector where physical contact occurs

between dissimilar conductors unless the device is identied

for the purpose and conditions of use.

Optional Flush Mount Installation Considerations

The XA & XB are approximately 6” deep. The unit will not

mount ush unless there is at least 6” of depth clearance.

The XA & XB are not designed to mount ush on a typical

2 x 4 stud wall.

Back Flange Mounting: Mount as close as possible to

protected panel. Create a wall opening slightly larger than

SPD. See Figure 4. Congure a robust backing plate inside

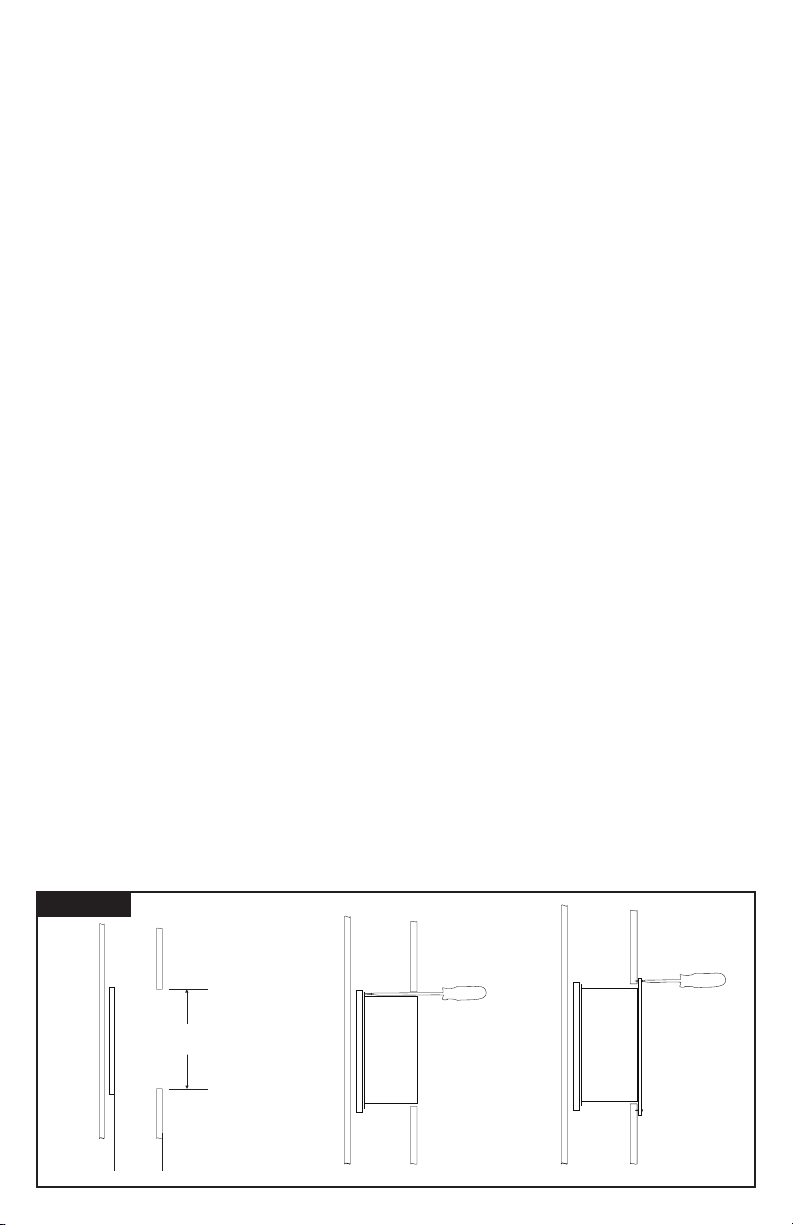

Figure 3

6

FLUSH MOUNT INSTALLATION

STEP 1:

Prepare Wall

- Must support

25-55lbs

Cutout slightly larger than

SPD base

Mounting Plate

6 1/16” from

outside of front

wall

STEP 2:

Mount SPD

STEP 3:

Install Flush

Mount Plate

& Cover

the wall cavity 6 1/16” from the wall face such that the SPD

0.000

0.000

1.384

1.699

2.014

2.329

3.437

0.951

4.618

0.559

0.250

4.875

0.250

3.690

0.180 THRU 4 PL.

R0.375 4 PL.

Count Reset

3.963

1.798

2.861

CLEAR WINDOW TYP.

Phase C

Service

Phase B

Phase A

Test

Silence

Surge Counter

0.497

0.654

1.324

1.994

Ø.50 BLACK BORDER TYP.

1.660

BLACK LETTERS (SURGE COUNTER)

BACKGROUND TO BE PANTONE 441C

RED LETTERS (ALARM SILENCE ONLY)

PANTONE 185C

BACKGROUND TO BE PANTONE 445C

PANTONE 441C 4 PLACES

R0.062 4 PL.

BLACK BORDER

2.999

2.077

2.737

2.545

2.269

0.125 TRANSLUCENT WINDOW 5 PL.

is supported from its back. Note the mounting holes on the

back ange. Also note that the SPD weighs 22-52 lbs. Be

careful not to drop the SPD into the wall.

Disconnect Switch

(Opt. on XA, Std. on XB)

The disconnect switch provides manual disconnection

means for phase conductors and the neutral conductor.

Ground is not switched.

Special care should be taken while pre-planning installation

to ensure that leads are as short as possible. Most XA’s &

XB’s in ‘square’ enclosures have backplanes that can be

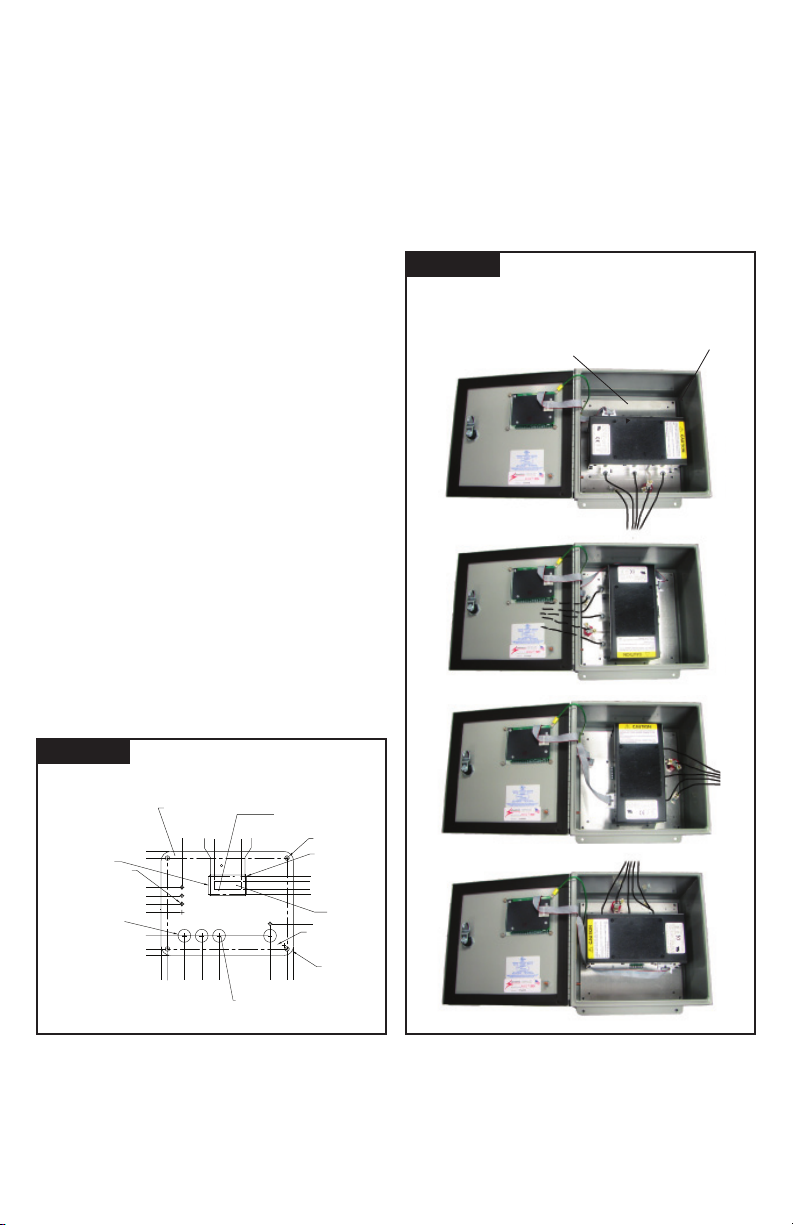

removed and repositioned to reduce leads. See Figure 8.

(Models with rectangular enclosures may be repositioned

by inverting only.) (Excludes thru-door handle options.)

There is limited working space around the Disconnect

Switch. This is a consequence of reducing internal size

and lead lengths. Please be patient.

Disconnect switch will accept 6 AWG to 1/0 AWG, with 6

AWG preferred. Torque connections to 18 inch-pounds.

OVER-TORQUING connections WILL BREAK the

Disconnect Switch and will not be covered by warranty.

The disconnect switch is mounted on DIN-rail. It may be

removed by gently pulling out the mounting tab at the

bottom of the switch assembly.

APT is one of few SPD manufacturers that make Disconnect

Switches available as a fully UL qualied option. The

Disconnect Switch was included during UL certication

and testing. The Short Circuit Current Rating posted on

the UL label of the SPD includes the Disconnect Switch

and supersedes any rating on the individual Disconnect

Switch. When used in a Type 1 line-side application, the

SPD including its Disconnect Switch has been UL tested

and approved. Further evaluation is not required by UL, nor

is a separate UL 98 rated switch required.

Module Rotation Feature

Installation lead wire length must be minimized because

longer leads hurt performance. Lead length may be reduced

by rotating the module inside the enclosure. SPD ships with

terminals pointing down. If installation lends itself toward

other orientation, the module’s aluminum backplane can be

unscrewed and reoriented. For example, if leads enter from

top, rotate module assembly such that leads are shortest.

Be careful with ribbon cable connector and take care to

retighten screws & secure ribbon cable. Mounting screws

are in four corners. Rectangular enclosures may be rotated

up or down only. See Figure 5.

Figure 5

ROTATING MODULE

DESIGN ALLOWS FOR

SHORTER LEADS

Diagnostic Cable Connector

Mounting Screws

in Corners

Figure 4

INTERNAL MOUNT

DISPLAY DIMENSIONS

7

INSTALLATION

Pre-Plan your installation. You will need to accomplish the following:

▪ Meet all National and Local codes. (NEC

®

Article 285 addresses SPDs)

▪ Mount SPD as close to panel or equipment as possible to keep leads short.

▪ Ensure leads are as short and straight as possible, including neutral and ground.

Consider a breaker position that is closest to the SPD and the panel’s neutral & ground.

▪ Suggested breaker & conductor size is 60A-30A with 6 AWG.

▪ Make sure system is grounded per NEC

®

and clear of faults before energizing SPD.

Certain options or implementations require extra consideration. See appropriate sections

within this manual:

▪ Line Side Installation (page 4)

▪ Internal or Integral Mount Installation inside electrical gear (page 7)

▪ Disconnect Switch Option (page 7)

▪ Flush Mount Option (page 6)

▪ Retro-t where no breaker positions are available (page 11)

▪ UL/NEMA 3R Drain Holes (page 10)

1. Use a voltmeter to check all voltages to ensure correct SPD.

2. If SPD has Dry Contact, Remote Monitoring or Remote Display, pre-plan their installation.

3. Remove power for panel. Conrm panel is deenergized.

4. Identify connection/breaker location and SPD location.

5. Make sure leads are short. Reducing inches matters. Pretend that connector leads cost you

$1000/foot to make leads short!

Installation Tips: SPD module is mounted on backplane within its enclosure. In many cases, the backplane assembly

can be unbolted and rotated in two or four directions to yield shortest leads. See Fig 8. Carefully disconnect ribbon

cable(s) and unbolt backplane assembly. Various congurations have limited work space. Please be patient. Installation

may be easier if disconnect switch is temporarily removed from DIN-rail, or module/backplane is temporarily removed.

6. Remove an appropriately sized knockout from panel. Create an appropriately sized and located hole in the SPD enclosure.

7. Mount SPD. Connect to equipment using an approved wiring method, including seals appropriate for

the enclosure rating. Carefully reinstall backplane or disconnect switch as appropriate.

8. Connect conductors as appropriate – short and straight as possible

(Note that Hi-Legs are Phase B).

9. Label or mark conductors as appropriate

(neutral: white, ground: green, energized: black, hi-leg: orange).

10. Make sure system is bonded per NEC® and is clear of hazards or faults before energizing (N-G

bonding not per NEC® will fail SPDs: #1 cause of SPD failures).

11. Energize and conrm proper operation of indicators and/or options. If Red LED ashes &

Audible Alarm cycles, deenergize immediately and call for help.

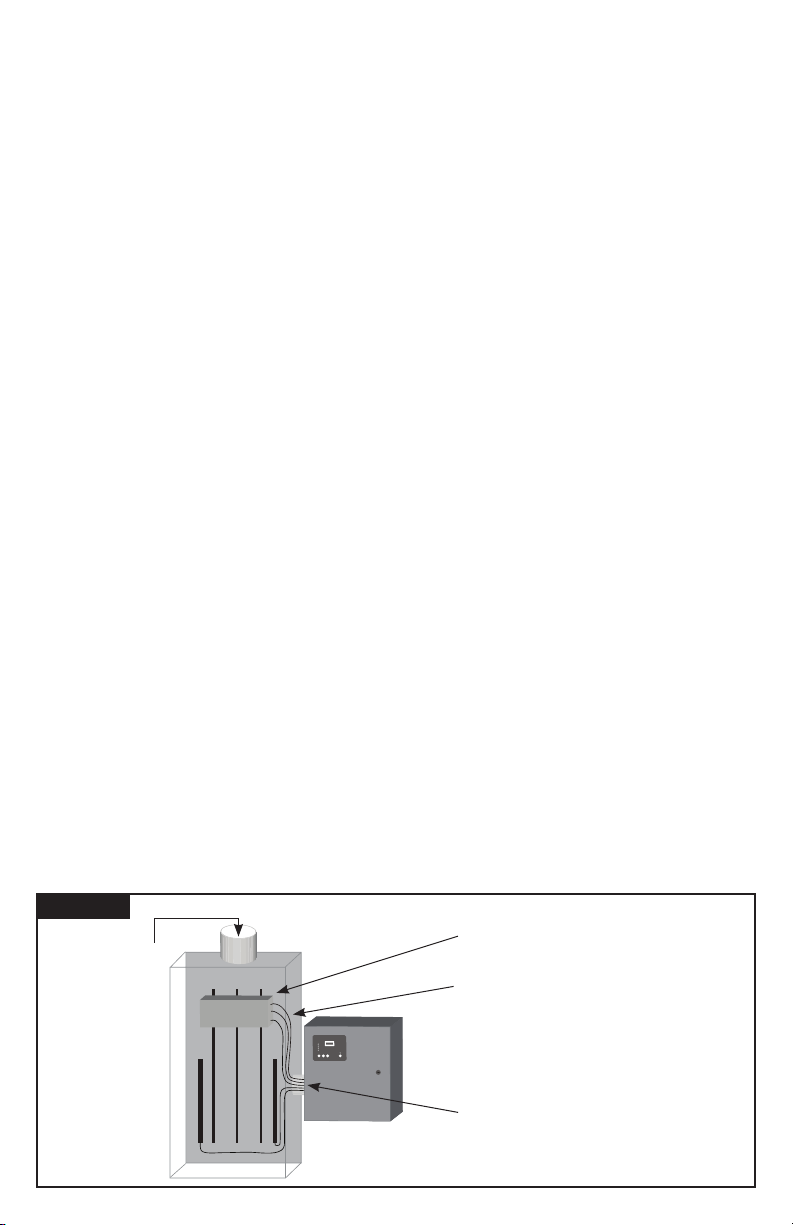

Figure 6

To Protected Loads

8

TYPICAL PANEL INSTALLATION

BC

A

BREAKER

Advanced Protection Technologies

Phase A

Surge Counter

Phase B

Phase C

Service

GN

Silence

Test CountReset

▪ Use closest breaker to SPD

▪ Locate SPD close to intended breaker

▪ Keep Leads Short as Possible

▪ Avoid Sharp Bends

▪ Outdoor installation requires appropri-

ate weather sealing at nipple (o-ring,

sealing condulet, etc.)

}

}

Figure 7

C

Advanced Protection Technologies, Inc.

Clearwater, Florida

Listed

56E3

TVSS

U

R

L

N

CAUTION

G

A

TWO POLE

2

1

3

46

5

7

8

Advanced Protection Technologies, Inc.

Clearwater, Florida

Listed

56E3

U

R

L

G

CAUTION

CB NA

THREE POLE W/ DS

N

CAUTION

B

N

CAUTION

BA

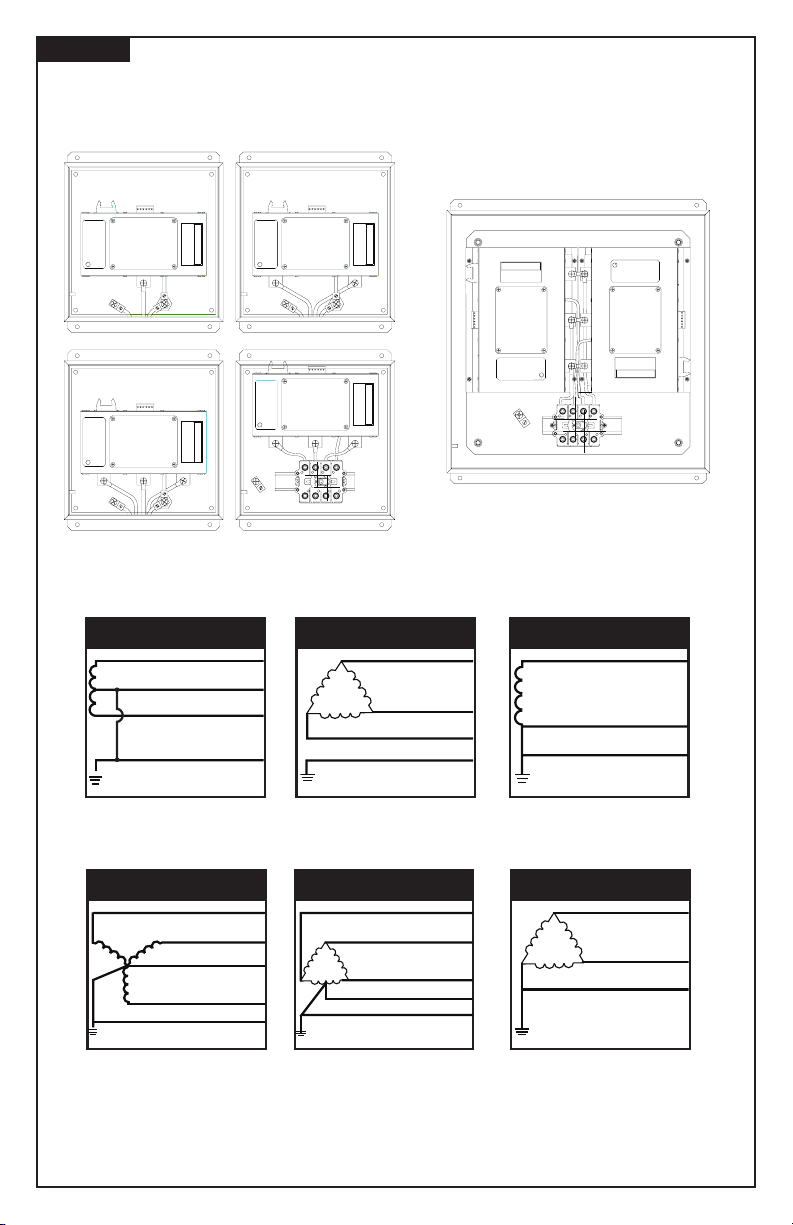

ELECTRICAL DRAWINGS FOR CUSTOMER CONNECTIONS

SINGLE POLE

Advanced Protection Technologies, Inc.

Clearwater, Florida

56E3

Listed

U

R

L

B

G

THREE POLE

Advanced Protection Technologies, Inc.

Clearwater, Florida

56E3

Listed

U

R

L

C

BA

G

Hot (BLK)

V

}

Neutral (WHT)

}

V

Hot (BLK)

Ground (GRN)

SPLIT

2 Hots, 1 Neu, 1 Grnd

CAUTION

N

CAUTION

N

TWO POLE

Advanced Protection Technologies, Inc.

Clearwater, Florida

TVSS

56E3

Listed

U

R

L

C

G

THREE POLE W/ DS

Advanced Protection Technologies, Inc.

Clearwater, Florida

56E3

Listed

U

R

L

3

1

5

7

2

46

G

CB NA

DELTA & HRG WYE

3 Hots, 1 Grnd

CAUTION

Advanced Protection Technologies, Inc.

G

Clearwater, Florida

THREE POLE

A

N

B

C

TVSS

U

L

56E3

R

Listed

3

1

5

2

4 6

Clearwater, Florida

Listed

Advanced Protection Technologies, Inc.

R

56E3

L

U

TVSS

A

B

N

C

CAUTION

7

8

CAUTION

A

N

CAUTION

ABNC

8

Phase A (BLK)

V

Phase B (BLK)

Phase C (BLK)

Ground (GRN)

Hot (BLK)

V

Neutral (WHT)

Ground (GRN)

SINGLE POLE

1 Hot, 1 Neu, 1 Grnd

Phase A (BLK)

A

Phase B (BLK)

B

Neutral (WHT)

N

V

}

Phase C (BLK)

C

Ground (GRN)

WYE

3 Hots, 1 Neu, 1 Grnd

Phase A (BLK)

Phase B (ORNG)

V

}

Phase C (BLK)

Neutral (WHT)

Ground (GRN)

HI-LEG DELTA (B High)

3 Hots, (B HIGH),

1 Neu, 1 Grnd

Phase A (BLK)

V

}

Phase C (BLK)

Ground (GRN)

CORNER GROUND

DELTA (B grounded)

2 Hots, 1 Grnd

9

Loading...

Loading...