Advanced Protection TWL Installation Guide

TWL S eries Installation Guide

Tower Light Controller Protectors

Also See TWL Datasheet and Configuration Sheet

The TWL Surge Suppressor is probably different than anything you have seen before.

You will save substantial installation time & rework by understanding the intent behind its

design & installation. Each individual installation is likely to approach a custom installation.

There is reasonable chance that a design team congured and ordered the TWL, as well as multiple individual Surge Protective

Devices (SPDs). Please take a few moments to understand the TWL’s function and the application of each individual SPD.

The TWL is a high quality, high energy, surge suppressor hub assembly. Individual SPDs are connected to the TWL. The purpose

of the TWL is to provide a common ground reference point for individual SPDs, thus ensuring maximum protection to the tower

lighting controller. The TWL also provides the most cost effective ground-level surge protection to uptower lighting equipment.

The TWL is designed to use off-the-shelf APT SPDs in a modular manner. Individual SPDs can be replaced, added to, or eld

retrot. APT SPDs are extremely robust and readily available in a broad application range. This avoids one-off units, which

create cost and availability barriers, and avoids obsolescence issues.

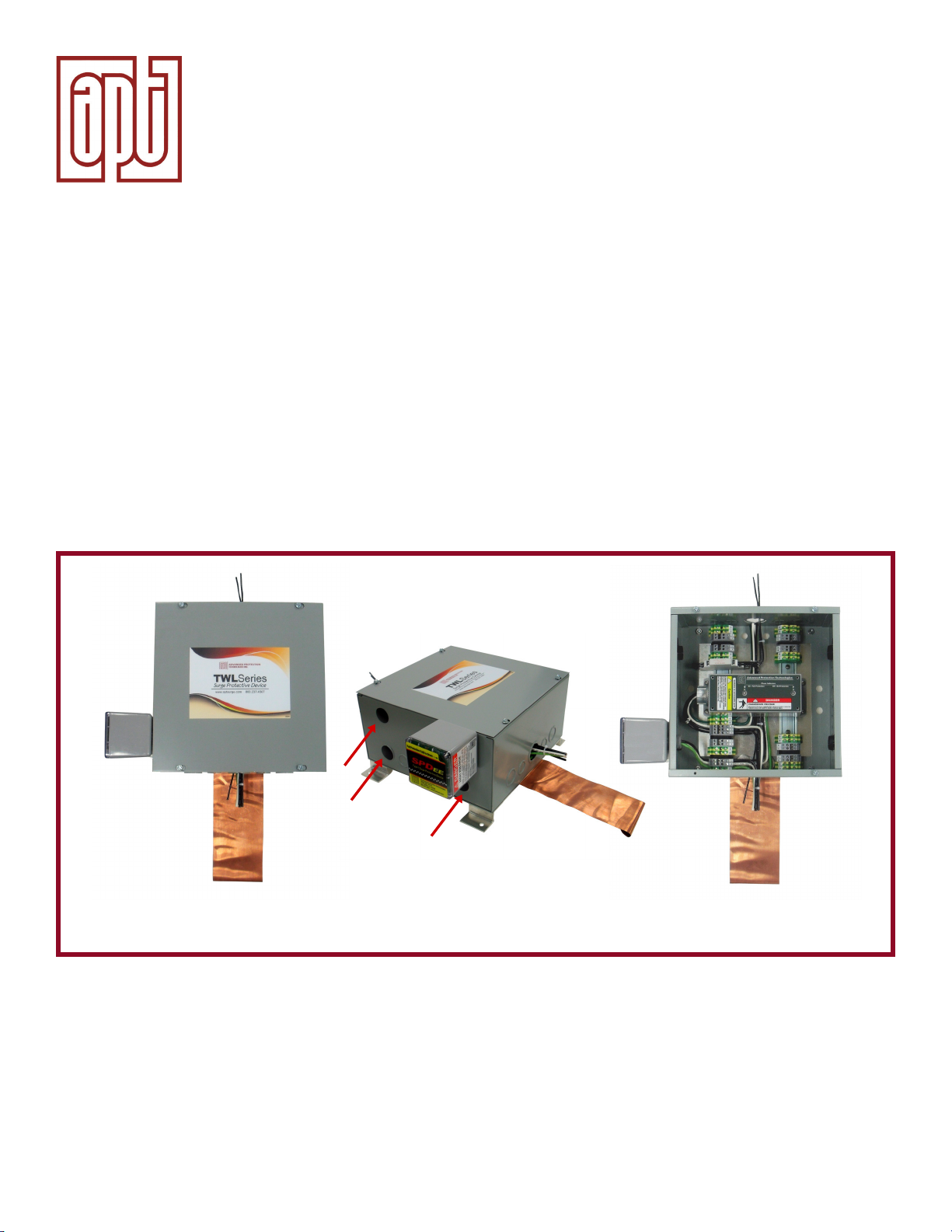

Mounting holes for

additional SPDs.

4 mounting locations

located on opposite side.

Cover in place

For demonstration purposes, the standard TWL pictured above is displayed with one SPDee on left side, AC Power AC XCS inside and with copper ground strap - not included.

Thank you for choosing an APT TWL Surge Protective Device (SPD). Proper installation is important to maximize performance.

Please follow steps outlined herein. These instructions are not intended to replace national or local codes. Follow all applicable

electrical codes to ensure compliance.

TWL may include several different voltage SPDs including AC and DC voltages. Incorrect initial installation may

result in immediate SPD failure upon start up, not covered by warranty, and/or ineffective surge protection.

APT Welcomes Questions & Pre-installation Discussion at 800.237.4567 or Info@aptsurge.com.

Side view

Cover removed

WARNING – IMPORTANT – PLEASE READ – WARNING

Safety First – Hazardous Voltage & Shock Hazard

• Only qualied licensed electricians should install or service SPDs

• Hazardous voltages exist within SPDs

• SPDs should never be installed or serviced when energized

• Use appropriate safety precautions including Personal Protection Equipment

• Failure to follow these instructions can result in death, serious injury, and/or equipment damage

• This manual shall be read in entirety prior to installing

Bonding and Grounding Hazard

Verify that the neutral conductor in the AC voltage service entrance equipment is bonded to ground in accordance

with guidelines established by the National Electric Code (NEC®). This is intended to provide the power system with

a dened reference to ground.

There may be circumstances where the Authority Having Jurisdiction (AHJ), for example, a DOT, supercedes the NEC

and or local codes. We caution that deviations from North American, industry-accepted bonding & grounding and surge

suppression techniques may yield undesirable and unexpected results.

Verify that the neutral terminal (XO) on the secondary side of distribution transformers are grounded to the system

ground in accordance with the NEC® and all applicable codes.

During installation into an electrical system, the SPD must not be energized until the electrical system is completely

installed, inspected and tested. All conductors must be connected and functional including the neutral (if required).

The voltage rating of the SPD and system must be veried before energizing the SPD.

Failure to follow these guidelines can lead to abnormally high voltages at the SPD. This may cause the SPD to fail. The

warranty is voided if the SPD is incorrectly installed and/or if the neutral conductor in the service entrance equipment

or downstream of separately derived systems is not bonded to ground in accordance with the NEC®.

Do Not Hi-Pot Test SPDs

Any factory or on-site testing of power distribution equipment that exceeds normal operating voltage such as highpotential insulation testing, or any other tests where the suppression components will be subjected to higher voltage

than their rated Maximum Continuous Operating Voltage (MCOV) must be conducted with the SPD disconnected from

the power source. The neutral connection at the SPD must also be disconnected prior to performing high-potential

testing and then reconnected after test completion.

Failure to disconnect SPD and associated components during elevated voltage testing will damage the SPD and will

void the warranty.

(APT is unaware of any SPD manufacturer that permits Hi-Pot testing of SPDs.)

Table of Contents

PRE-INSTALLATION & PLANNING .........................................................................................................................1

INSTA LLATION .........................................................................................................................................................2

Step 1 - Verify that all correct components are in hand: ........................................................................................................... 2

Step 2 - Identify appropriate mounting location for TWL (See Figure 1) ................................................................................... 3

Step 3 - Mount TWL to Wall ....................................................................................................................................................... 3

Step 4 - Connect 4” copper ground strap to TWL (Figure 2)......................................................................................................3

Step 5 - Run wire bundles into TWL, MARKING ALL conductors ..............................................................................................3

Step 6 - Connect individual SPDs ..............................................................................................................................................3

PHOTOCELL SPD (FIGURES 3,4 & 5) ..................................................................................................................... 5

INDIVIDUAL LIGHT SPD(S) (FIGURE 6) .................................................................................................................. 7

AC POWER SPD (FIGURE 7)...................................................................................................................................8

Step 7 Double check work – Label conductors & SPDs - Energize Tower Light Controller .......................................................9

ADVANCED TOPICS ...............................................................................................................................................9

REMOTE SPD DIAGNOSTIC INDICATION .............................................................................................................9

FIGURES

FIGURE 1: You will Need Sufcient Space on Wall for TWL & SPDs ......................................................................2

FIGURE 2: Ground Strap Attachment .......................................................................................................................4

FIGURE 3: Photocell SPD Mounting Location .......................................................................................................... 5

FIGURE 4: Standard Photocell SPD Installation ...................................................................................................... 6

FIGURE 5: Optional SPD Installation .......................................................................................................................6

FIGURE 6: Individual Light SPDs .............................................................................................................................7

FIGURE 7: AC Power SPD .......................................................................................................................................8

FIGURE 8: Bonding Multiple TWLs Together ...........................................................................................................9

Questions?? Need Assistance?? Contact APT at 800.237.4567 or Info@aptsurge.com.

INSTALLATION PRE-PLANNING OVERVIEW:

This Surge Suppressor is probably different than anything you have seen before. You will save substantial installation time

& rework by understanding the intent behind its design and installation.

• Need to meet all applicable Codes and Regulations

• Intended for indoor use – If outdoor, the TWL assembly can be mounted in an appropriate weather-resistant

enclosure with appropriate weathertight sealing apparatus.

• Intended to be a central grounding hub for multiple individual SPDs

• There will be multiple conduits and wiring to and from the TWL

• Need appropriate wall space. There will probably be multiple SPDs attached to the side of the TWL – do not try

to cram into too small of space

• Need appropriate path to ground grid or ground – intended to use 4” copper ground strap to connect to existing

grounding grid. This path needs to be straight line, not bends or kinks.

• TWL was intended for wires to enter one side of the TWL and exit the opposite side:

- AC Power – Intended to come from upstream service entrance SPD, enter the TWL, connect to TWL-housed AC power

SPD, and conductors exit TWL to the Tower Light Controller.

- Photocell – Intended for lead from photocell to enter the DIN Rail mounted SPD, which is a series SPD. The load travels

through this SPD, which is different than the other SPDs, which are parallel-connected. The lead from the SPD goes

to the Tower Light Controller. (This SPD is ‘directional’. If the Unprotected and Protected ends are miss-connected,

the SPD will provide decreased surge protection. Direction is important!)

- Uptower loads: Leads are intended to enter the TWL at the bottom, connect to appropriate SPDs within the TWL, then

the leads exit at the top of the TWL to Uptower.

- There may be more than one way to do this. TWL includes many knockouts for customized appropriate installation.

• Commingling lower and higher voltage lines – Follow all applicable Codes

Following may be useful:

NEC 300.3(C) Conductors of Different Systems.

(1) 600 Volts, Nominal, or Less. Conductors of circuits rated 600 volts, nominal, or less, ac circuits, and DC circuits

shall be permitted to occupy the same equipment wiring enclosure, cable, or raceway. All conductors shall have

an insulation rating equal to at least the maximum circuit voltage applied to any conductor within the enclosure,

cable, or raceway.

NEC 800.53 Lightning Conductors. Where practicable, a separation of at least 1.8 m (6ft) shall be maintained

between communication wires and cables on buildings and lightning conductors.

NEC 800.133 – Communication Conductor Separation from Other Conductors

Page 1

Loading...

Loading...