Advanced Protection SPDee User Manual [en, es]

ENGLISH

Surge Protective Device (SPD)

Installation, Operation

& Maintenance Manual

Thank you for choosing an APT SPDee Surge Protective Device (SPD). SPDee is a high quality, high

energy surge suppressor designed to protect sensitive equipment from damaging transient overvoltages.

SPDee is parallel connected such that circuit ampacity is unlimited. Proper installation is important to

maximize performance. Please follow steps outlined herein. These instructions are not intended to replace

national or local codes. Follow all applicable electrical codes to ensure compliance.

UL 1449 Third Edition (Sept 2009) and 2008

WARNING

▪Only qualied licensed electricians should install or service SPDs

▪SPDs should never be installed or serviced when energized or during electrical storms

▪Use appropriate safety precautions including Personal Protection Equipment

▪Failure to follow these instructions can result in death, serious injury, and/or

equipment damage

▪When used in outdoor applications, customer must seal the conduit nipple using

watertight ttings (not included) to ensure a watertight connection

▪Read this manual in its entirety prior to installing

– Risk of Electric Shock

®

NEC

Article 285 generated substantial

changes regarding SPDs.

SPDee complies with latest regulatory

actions and is UL 1449 Listed as such

(VZCA.E321351). There is new emphasis

on installation location, identied as Types

1, 2, 3 and 4, outlined below.

Type 1: Installation on the line side or load side of the service

disconnect overcurrent device and may be used in Type 2

or Type 4 installations. Examples: surge arrestors, lightning

arrestors, meter hubs, metering cabinets, ran out of breaker

positions, etc.

Type 2: Downstream of service disconnect; probably will

connect via breaker. Examples: switchboards, power panels,

panelboards, equipment, motors, pumps, etc.

Type 3: Plug-in SPD

Type 4: Usually treated as a UL Recognized component

in a larger UL Listed nished product. Examples: UL 508

control panels, medical equipment, wind turbines, signage,

conveyers, elevators, etc. DIN-Rail mounting may be handy.

Advanced Protection Technologies

14550 58th Street North

(800) 237-4567·(727) 535-6339 · Fax (727) 539-8955

UL is a registered trademark of Underwriters Laboratories, NEC® and National Electrical Code are

registered trademarks of National Fire Protection Association, C62.41.1-2002, C62.41.2-2002,

C62.45-2002, C62.72-2007 are registered trademarks of IEEE.

www.aptsurge.com · info@aptsurge.com

· Clearwater, Florida 33760

NEC® Article 285 & UL 1449-3

SPD Types: Types 1, 2, 3, & 4

Based on Location within electrical distribution system

(also coincides with ANSI/IEEE C62.41.2 - 2002 Categories C, B &A)

European Authorized Representative

Boulevard Général Wahis 53

1030 Brussels, BELGIUM

Fax: +(32) 2. 732.60.03

E-Mail: mail@obelis.net

Obelis s.a.

Tel: +(32) 2. 732.59.54

7.11.13.lh #8073

A

BC

GN

BREAKER

INSTALLATION

Pre-Plan your installation. You need to accomplish the following:

▪ Meet all National and Local codes (NEC

▪ Conrm System voltage to SPD voltage (120V SPD will fail instantly on 240V, 277V, etc.).

▪ Mount SPD as close to panel or equipment as possible to keep leads short.

(long leads hurt performance substantially).

▪ Ensure leads are as short and straight as possible, including neutral and ground. If using a

breaker, use a breaker position that is close to the SPD and the panel’s neutral & ground.

▪ If using a breaker, recommended breaker size is 30A due to 10 AWG conductor.

▪ Make sure system is grounded per NEC

(inadvertent system problem may fail SPD).

▪ Never Hi-Pot test Any SPD. (will prematurely fail SPD).

1. Use voltmeter to check voltages and ensure correct SPD. See Data Sheet for specs and wire-outs.

2. Determine Mounting method (See Figure 5) – weather resistant equipment may be required.

3. If SPD has optional Dry Contact, pre-plan its installation.

4. Remove power from panel/source. Conrm panel/source is deenergized.

5. Identify breaker location and SPD location. Position SPD such that LED is best visible.

6. Mount SPD – weather resistant applications require additional sealing, o-rings, etc. (not included)

- Remove an appropriately sized knockout from panel.

- Connect conductors as appropriate – short and straight as possible (Hi-Legs are Phase B).

7. Label or mark conductors as appropriate (neutral: white, ground: green, energized: black, hi-leg: orange).

8. Make sure system is bonded per NEC® and is clear of hazards or faults before energizing.

(N-G bonding not per NEC® will fail SPDs: #1 cause of SPD failures)

9. Energize and conrm proper operation of green LED indicator and/or options.

(Afx supplemental label accessory if appropriate. See Figure 5.)

®

Article 285 and UL 1449 address SPDs).

®

and clear of faults before energizing SPD.

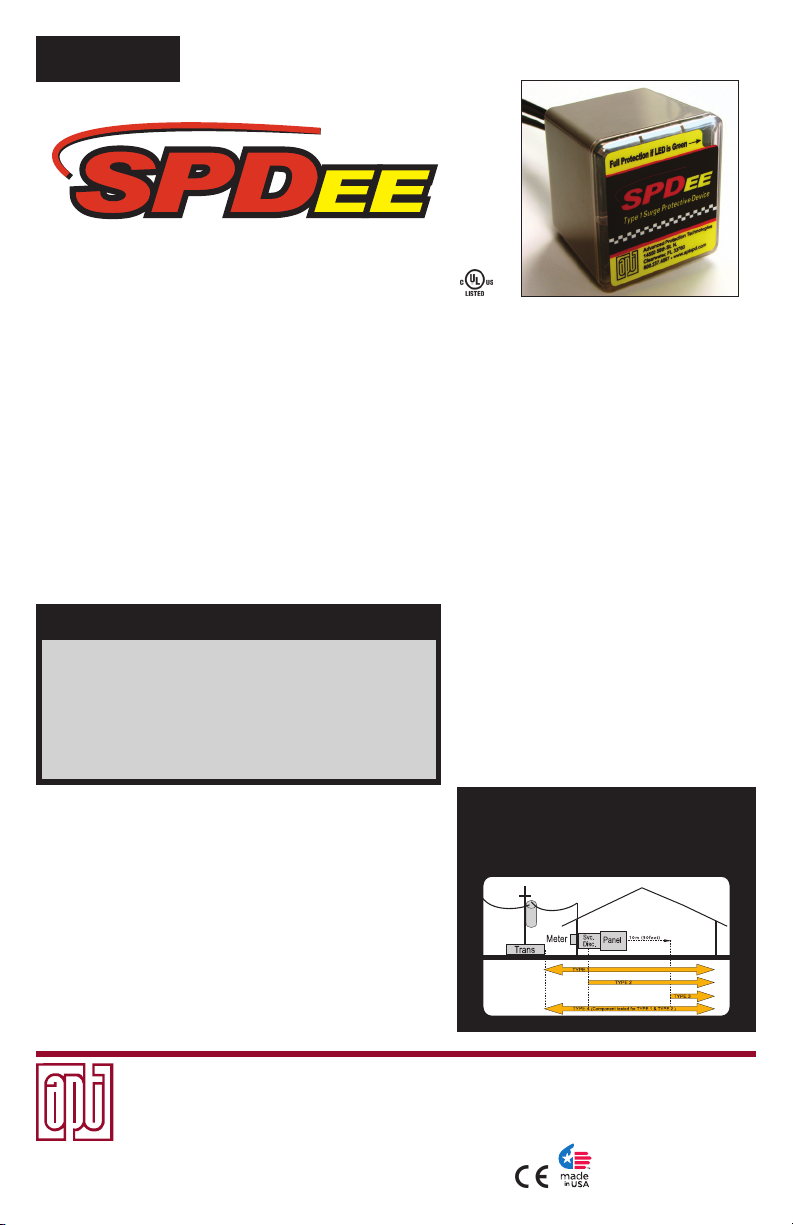

Figure 1

(Type 1 or individual equipment installations may vary)

To Protected Loads

TYPICAL PANEL

INSTALLATION

▪ Use closest

breaker to SPD

▪ Locate SPD close

to intended breaker

▪ Keep Leads Short

as Possible

▪ Avoid Sharp Bends

▪ Rotate SPD

that LED indicator

is most visible

▪

Outdoor installation requires appropriate weather

sealing at nipple (gasket, sealing conduit, etc.)

WARNING

V

ee

▪ Conrm XO N-G Bonding at Upstream Transformer

▪ Do Not Hi-Pot Test

▪ Resulting Damage is not Covered Under Warranty

2

such

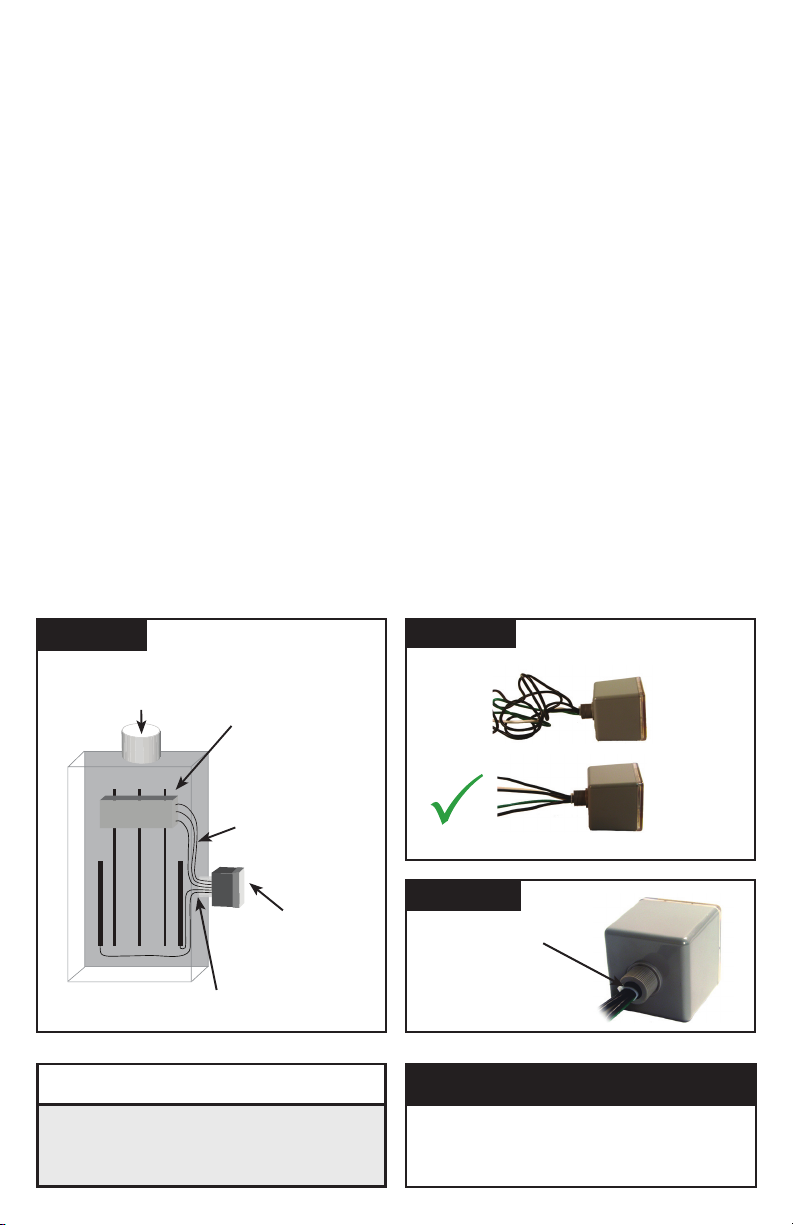

Figure 2

X

NOT

LEADS SHORT & STRAIGHT

Cut off

Excess Length

Do Not Loop

or Coil

GOOD

Short

& Straight

GOOD

Figure 3

Sealing gasket:

two choices

1.) At 3/4" nom.

thread: ID is 1.05"

2.) At 0.14" high 'base

step': ID is 1.25"

V

VERIFY THAT ALL POWER CIRCUITS ARE

DEENERGIZED BEFORE MAKING CONNECTIONS

All electrical connections should be performed by a qualied

(licensed) electrician or technician. All wiring must comply with

the National Electrical Code (NEC

WARNING

®

) and applicable local codes.

SPDee is a Type 1 SPD. SPDee is suitable for

use almost anywhere (not as a plug-in SPD).

Type 1 SPDs are evaluated more rigorously by

UL 1449 for NEC® Article 285 compliance. Type

1 SPDs and their connecting leads have been

evaluated for line side applications without need

for supplemental overcurrent protection. Type 1

SPDs include internal overcurrent protection. As

a generalization, there are practical maintenance

reasons for installing on the load side of the main

overcurrent device (i.e. Type 2 installation). When

connected on load side of main disconnect, we

recommend connecting via a 30A circuit breaker

due to 10 AWG conductors. The circuit breaker

serves as a disconnect switch and provides NEC®

imposed short circuit protection to the conductors

in Type 2 or 4 applications. (cUL units are Type 2

due to different cUL criteria.)

Simplied Explanation of Operation: SPDs sense

overvoltage and create a momentary short circuit

to redirect harmful surge energy to earth ground.

They reset automatically and wait for the next surge.

This is similar to the pressure relief valve on a water

heater: pressure goes up, valve opens to relieve

pressure and then resets. In an electrical system, an

SPD senses overvoltage, shorts temporarily sending

energy to ground and then resets. SPDs are capable

of repeating this function thousands of times.

Specications

Temperature Operating -40oC (-40oF) to 60oC (+140oF)

Temperature Storage -55

Wire Size & Installation Torque 10 AWG; 18 inch-pounds

Appropriate Circuit Breaker

based on conductor size

NEMA 250 Enclosure Rating

Figure 4

3.26”

Figure 5

• 3/4” pipe nipple (conduit nut included)

• With L-bracket mounting kit accessory

- Standard 35mm DIN-Rail (not included)

L-bracket tightens onto DIN-Rail

- Standard at mounting surface

Attach L-bracket to surface via mounting holes

DIMENSIONS & WEIGHT

Weight: 1.60 lbs

3.31”3.57”

SPDee MOUNTING OPTIONS

o

C (-67oF) to 65oC (+149oF)

30A (SPD includes internal OCP)

Type 4X with appropriate

sealing & sealing condulets

4.13”

(0.73 kg)

Sized for std 35mm DIN-Rail

3.26”

3/4”-14

1.15”

Parts List

1 - SPDee suppressor including 3’ (~1m) conductors

1 - 3/4” conduit nut

1 - L bracket mounting kit; includes two panhead

screws

1 - Data Sheet

1 - Installation Sheet (this document)

Most SPDees have demonstrated 200kA &

100kA Short Circuit Current Ratings (SCCR)

including leads. See UL Label markings on SPD

or see Data Sheet for specs.) Supplemental

overcurrent protection is not required to protect

this SPD. However, NEC® convention requires

that connecting conductors have overcurrent

protection in Type 2 or 4 applications. Follow

applicable codes.

This device features internal overcurrent and

overtemperature protection that will disconnect

effected surge suppression components at the end

of their useful life, but will maintain power to the load

– now unprotected. If this situation is undesirable

for the application, follow these instructions for

replacing the device. SPDee is ultrasonically welded

closed and contains no user serviceable parts.

Std. 3/4”-14 Nipple DIN-Rail Mount

Supplemental Product Label may be afxed if standard

top label is not viewable

(rail not incl.)

Bracket Mount

for at surfaces

Voltage Rating & Application

Before installing SPD, verify by nameplate voltage

or model number that it has the same voltage rating

as the power distribution system. See attached Data

Sheet or call APT Tech Support at (800) 237-4567 as

appropriate. The SPD’s specier or user should be

familiar with the conguration and arrangement of

the power distribution system. The system is dened

by how the secondary windings of the transformer

supplying the service entrance main or load are

congured. This includes whether or not the transformer

windings are referenced to earth via a grounding

conductor. The system conguration is not based on

how any specic load or equipment is connected to a

particular power distribution system. SPDs should be

installed per the distribution system, not per a load or

motor’s wiring connection.

3

Loading...

Loading...