Cesar® Generator

Air-Cooled

User Manual

January 2013 57023916-00B

®

Cesar

Generator

Air-Cooled

User Manual

January 2013 57023916-00B

Advanced Energy

COPYRIGHT

This manual and the information contained herein are the proprietary property of Advanced

Energy Industries, Inc.

No part of this manual may be reproduced or copied without the express written permission of

Advanced Energy Industries, Inc. Any unauthorized use of this manual or its contents is

strictly prohibited. Copyright © 2011-2013 Advanced Energy Industries, Inc. All Rights

Reserved.

DISCLAIMER AND LIMITATION OF LIABILITY

The information contained in this manual is subject to change by Advanced Energy

Industries, Inc. without prior notice. Advanced Energy Industries, Inc. makes no warranty of

any kind whatsoever, either expressed or implied, with respect to the information contained

herein. Advanced Energy Industries, Inc. shall not be liable in damages, of whatever kind, as

a result of the reliance on or use of the information contained herein.

PRODUCT USAGE STATEMENT

WARNING :

Read this entire manual and all other publications pertaining to the work to

be performed before you install, operate, or maintain this equipment. Practice

all plant and product safety instructions and precautions. Failure to follow

instructions can cause personal injury and/or property damage. If the

equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired. All personnel who

work with or who are exposed to this equipment must take precautions to

protect themselves against serious or possibly fatal bodily injury.

Advanced Energy Industries, Inc., (AE) provides information on its products

and associated hazards, but it assumes no responsibility for the after-sale

operation of the equipment or the safety practices of the owner or user.

NEVER DEFEAT INTERLOCKS OR GROUNDS.

TRADEMARKS

is a registered trademark of Advanced Energy Industries, Inc.

Cesar® is a registered trademark of Advanced Energy Industries, Inc.

iv 57023916-00B

Dressler® is a registered trademark of Advanced Energy Industries, Inc.

Epic® is a registered trademark of the Lapp Group.

HPG™ is a trademark of Advanced Energy Industries, Inc.

Modbus® is a registered trademark of Gould, Inc.

Navigator® is a registered trademark of Advanced Energy Industries, Inc.

Navio™ is a trademark of Advanced Energy Industries, Inc.

Neutrik® is a registered trademark of Neutrik Aktiengesellschaft.

Rectus® is a registered trademark of RECTUS, GmbH.

SERTO® is a registered trademark of SERTO Ltd.

Siemens® is a registered trademark of Siemens AG.

VarioMatch™ is a trademark of Advanced Energy Industries, Inc.

Windows® is a registered trademark of the Microsoft Corporation.

Cesar® Generator

Windows NT® is a registered trademark of the Microsoft Corporation.

CUSTOMER FEEDBACK

Advanced Energy’s technical writing staff has carefully developed this manual using

research-based document design principles. However, improvement is ongoing, and the

writing staff welcomes and appreciates customer feedback. Please send any comments on the

content, organization, or format of this user manual to:

• tech.writing@aei.com

To order a manual, please contact Technical Support:

• technical.support@aei.com

57023916-00B v

Advanced Energy

vi 57023916-00B

Cesar® Generator

Table of Contents

Chapter 1. Safety and Product Compliance Guidelines

Products Documented in this Manual ................................................................... 1-1

Important Safety Information ................................................................................. 1-1

Danger, Warning, and Caution Boxes in the Manual ............................................ 1-1

Safety Guidelines .................................................................................................. 1-2

Rules for Safe Installation and Operation ....................................................... 1-2

Interpreting Product Labels ................................................................................... 1-2

Product Compliance .............................................................................................. 1-3

Product Certification ....................................................................................... 1-3

Safety and EMC Directives and Standards .................................................... 1-4

Electromagnetic Compatibility (EMC) Directives and Standards ............. 1-4

Safety Directives and Standards .............................................................. 1-4

Conditions of Use ........................................................................................... 1-5

Interlocks and Limiting Conditions ........................................................................ 1-6

Chapter 2. Product Overview

General Description .............................................................................................. 2-1

Theory of Operation .............................................................................................. 2-2

Chapter 3. Specifications

Physical Specifications .......................................................................................... 3-1

Electrical Specifications ........................................................................................ 3-2

Cooling Specifications ........................................................................................... 3-4

Environmental Specifications ................................................................................ 3-4

Chapter 4. Communication Controls

Diagnostic Interface .............................................................................................. 4-1

Matching Interface ................................................................................................. 4-1

Matching Interface Connector ........................................................................ 4-1

Matching Interface Pin Descriptions ............................................................... 4-1

User Port ............................................................................................................... 4-3

25-Pin User Port ............................................................................................. 4-4

User Port Connector ................................................................................ 4-4

Satisfying Minimal Requirements for the 25-pin User Port ...................... 4-4

25-pin User Port Cabling Requirements .................................................. 4-5

Activating the 25-Pin User Port ................................................................ 4-5

Resolving Error Displays When Using the 25-Pin User Port ................... 4-6

57023916-00B viiTable of Contents

Advanced Energy

25-pin User Port Pin Descriptions and Wiring Diagrams ......................... 4-6

15-Pin User Port ........................................................................................... 4-18

User Port Connector .............................................................................. 4-18

Satisfying Minimal Requirements for the 15-pin User Port .................... 4-18

15-pin User Port Cabling Requirements ................................................ 4-20

Activating the 15-Pin User Port .............................................................. 4-20

Resolving Error Displays When Using the 15-Pin User Port ................. 4-21

15-pin User Port Pin Descriptions and Wiring Diagrams ....................... 4-21

Cesar Generator Host Port ................................................................................. 4-31

RS-232 Interface .......................................................................................... 4-31

RS-232 Connector ................................................................................. 4-32

RS-232 Port Pin Descriptions ................................................................ 4-32

AE Bus Transmission Parameters ......................................................... 4-32

AE Bus Protocol ..................................................................................... 4-33

Creating an Ideal Communications Transaction .................................... 4-35

PROFIBUS Interface .................................................................................... 4-37

PROFIBUS Connector ........................................................................... 4-38

PROFIBUS Port Pin and Signal Descriptions ........................................ 4-38

PROFIBUS Cabling and Termination .................................................... 4-38

AE PROFIBUS Protocol ......................................................................... 4-39

PROFIBUS Command Structure ........................................................... 4-42

Ethernet Interface ......................................................................................... 4-44

Ethernet Connector and Indicators ........................................................ 4-44

Understanding AE TCP Commands and Register Types (FC23) .......... 4-45

Using Modbus/TCP FC23 ...................................................................... 4-46

AE Bus Commands ...................................................................................... 4-50

Activating Host Port Remote Control (AE Bus Command 14) ............... 4-51

AE Bus Command Status Response (CSR) Codes ............................... 4-53

AE Bus Port Command Set ................................................................... 4-54

Chapter 5. Installation, Setup, and Operation

Preparing to Install the Unit ................................................................................... 5-1

Spacing Requirements ................................................................................... 5-1

Dimensional Drawings .................................................................................... 5-1

Installation Requirements ............................................................................... 5-3

Tools Required for Installation ........................................................................ 5-3

Unpacking the Unit ......................................................................................... 5-4

Lifting the Unit .......................................................................................... 5-4

Installing the Unit ................................................................................................... 5-5

Mounting ......................................................................................................... 5-5

Grounding ....................................................................................................... 5-5

Connecting Output Power .............................................................................. 5-6

To Connect Output Power ....................................................................... 5-6

Connecting Communication Interfaces ........................................................... 5-8

To Connect the Communication Interfaces .............................................. 5-8

Connecting the Generator to a System Interlock Loop ................................... 5-9

Satisfying the Interlock With a 25-pin User Port ...................................... 5-9

Satisfying the Interlock With a 15-pin User Port ...................................... 5-9

viii 57023916-00BTable of Contents

Cesar® Generator

Connecting a VarioMatch or Navio Match Network (Optional) ....................... 5-9

Connecting Common Exciter (CEX) Circuitry (Optional) .............................. 5-10

To Make the CEX Connections .............................................................. 5-10

Connecting AC Input (Mains) Power ............................................................ 5-11

Connecting and Setting Ethernet (Modbus/TCP) Communication ............... 5-12

To Connect for Ethernet Communication ............................................... 5-12

Setting the IP Configuration for Ethernet Communication ..................... 5-12

First Time Operation ........................................................................................... 5-13

Operating the Cesar Generator for the First Time With the User Port ......... 5-14

To Operate the Cesar Generator for the First Time With the 25-pin

User Port .............................................................................................. 5-14

To Operate the Cesar Generator for the First Time With the 15-pin

User Port .............................................................................................. 5-15

Operating the Cesar Generator for the First Time With the Host Port .......... 5-16

Operating the Cesar Generator for the First Time With the Front Panel . ..... 5-17

Cesar Generator Front Panel .............................................................................. 5-18

Front Panel Control Elements ...................................................................... 5-19

Using the Front Panel Program Menu .......................................................... 5-20

Accessing the Program Menu ................................................................ 5-20

Entering Values in the Program Menu ................................................... 5-21

Front Panel Program Menu Tree ........................................................... 5-22

Viewing Measurements in the Display .......................................................... 5-23

Remote Control Operation .................................................................................. 5-24

Viewing and Using the Front Panel when in Remote Control Mode ............. 5-24

RF Control and Resetting Errors .................................................................. 5-25

Normal Operation ................................................................................................ 5-26

Setting Regulation Mode .............................................................................. 5-26

Determining the Regulation Mode Setting ............................................. 5-27

To Set Regulation Mode ........................................................................ 5-28

Setting the Pulse Function ............................................................................ 5-29

Selecting Internal or External Pulsing .................................................... 5-29

Changing the Pulse Input Configuration Settings .................................. 5-30

To Turn Off Pulsing ................................................................................ 5-31

Creating Recipes (RF on/off, Slew Rate, Power Ramping) .......................... 5-31

Creating an RF On/Off Ramp Recipe .................................................... 5-32

Creating a Slew Rate Recipe ................................................................. 5-32

Creating a Power Ramp Recipe ............................................................ 5-33

To Turn Off the Recipe Settings Feature ............................................... 5-34

Recipe Settings Operating Screen ......................................................... 5-34

Setting and Disabling Remote Control Override ........................................... 5-35

Selecting Remote Control Override ....................................................... 5-35

Disabling Remote Control Override ....................................................... 5-36

Setting and Turning Off the Target Lifetime Feature .................................... 5-37

Setting Target Lifetime Parameters ....................................................... 5-37

To Turn Off the Target Lifetime Feature ................................................ 5-37

Resetting a Target Lifetime .................................................................... 5-38

Changing Reflected Power Settings ............................................................. 5-38

Changing the Device Configuration Settings ................................................ 5-39

To Change the Default Device Configuration Settings .......................... 5-40

Setting and Using Preset Generator Settings for Different Applications . ..... 5-41

57023916-00B ixTable of Contents

Advanced Energy

To Store a Preset ................................................................................... 5-41

To Erase a Preset .................................................................................. 5-42

To Use a Preset ..................................................................................... 5-42

Controlling a VarioMatch or Navio Match Network Attached to the

Generator .......................................................................................................... 5-42

Determining the Current Match Network Tune Setting ................................. 5-43

Setting Tune Control ..................................................................................... 5-43

Determining Automatic Tuning Presets ........................................................ 5-45

Adjusting the Capacitors When in Manual Tune .......................................... 5-45

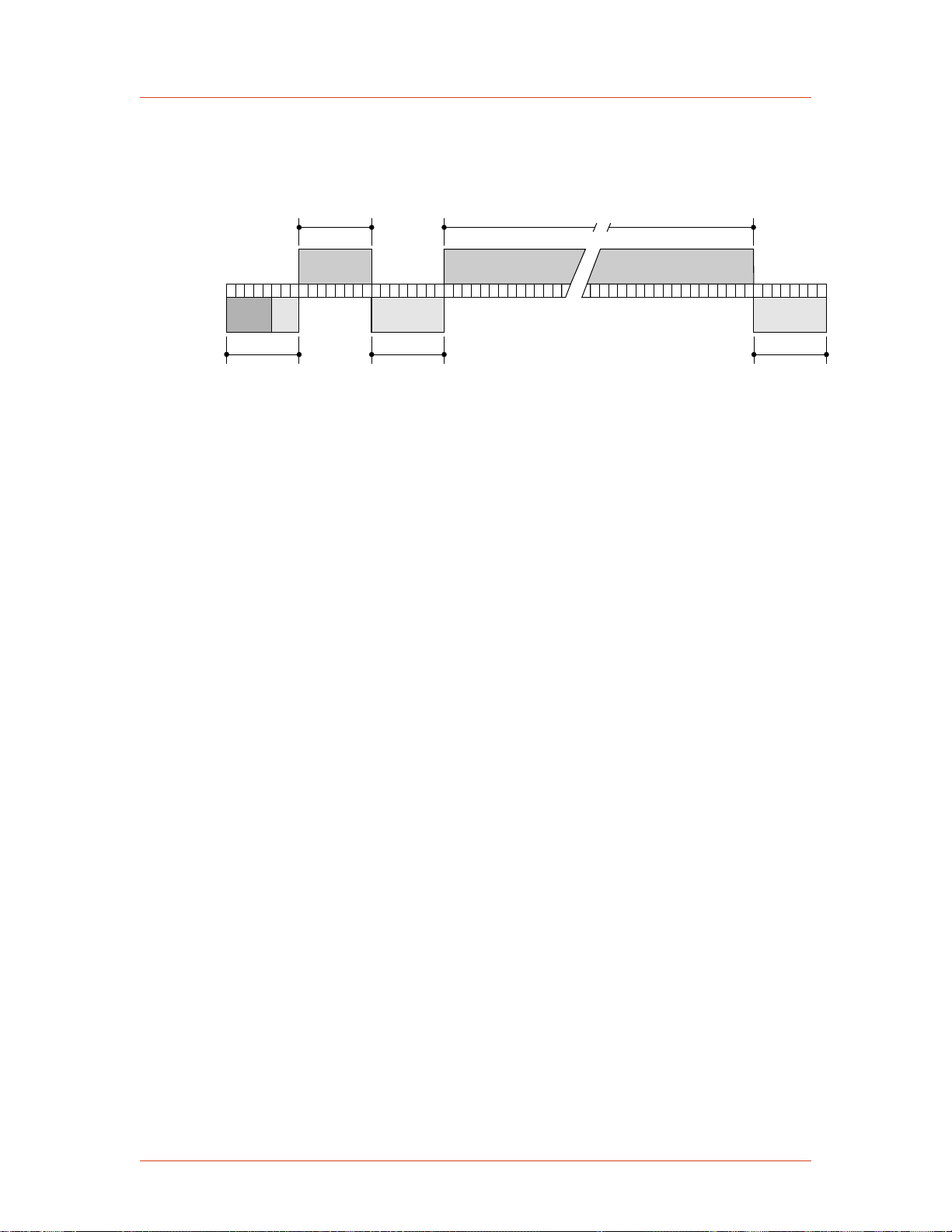

Using the Cable Attenuation Feature .................................................................. 5-47

Cable Attenuation Description ...................................................................... 5-47

Forward Power Calculation .................................................................... 5-48

Reflected Power Calculation .................................................................. 5-48

Cable Attenuation and Reflected Power Settings ......................................... 5-49

Connecting to an Ethernet-Enabled Unit With a Web Browser ........................... 5-49

Chapter 6. Troubleshooting and Global Services

Before Contacting AE Global Services ................................................................. 6-1

Checks With Power Off .................................................................................. 6-1

Checks With Power On .................................................................................. 6-2

Troubleshooting Checklists ............................................................................ 6-2

General Troubleshooting ......................................................................... 6-2

Matching Network Troubleshooting ......................................................... 6-3

Interlock Not Satisfied ..................................................................................... 6-3

Front Panel Display (LCD) Not Lit .................................................................. 6-4

Fuse is Blown ................................................................................................. 6-4

Communication Problems .............................................................................. 6-4

Capacitor Failure ............................................................................................ 6-5

Incorrect Input Voltage ................................................................................... 6-5

Improper Impedance Range ........................................................................... 6-5

Improper RF Connection or Cabling ............................................................... 6-6

Improper Grounding ....................................................................................... 6-6

Improper Matching Interface Connection ....................................................... 6-6

Improper Tuning Adjustment .......................................................................... 6-7

Troubleshooting Using Error Codes ...................................................................... 6-7

Fault and Warning Types and Clearing Faults ............................................... 6-7

Error Code Descriptions and Resolutions ...................................................... 6-8

Warning Message Descriptions and Resolutions ......................................... 6-10

Communication Warning Descriptions and Resolutions ............................... 6-12

AE Global Services ............................................................................................. 6-14

Returning Units for Repair ................................................................................... 6-15

Decommissioning the Unit .................................................................................. 6-15

x 57023916-00BTable of Contents

Cesar® Generator

List of Tables

Table 1-1. Cesar limiting conditions ...................................................................... 1-7

Table 3-1. Physical specifications ......................................................................... 3-1

Table 3-2. Electrical specifications ........................................................................ 3-2

Table 3-3. Air cooling specifications ...................................................................... 3-4

Table 3-4. Environmental standard specifications ............................................... 3-4

Table 3-5. Climatic specifications .......................................................................... 3-4

Table 4-1. Matching interface pin descriptions ...................................................... 4-1

Table 4-2. User Port Signal Specifications ............................................................ 4-7

Table 4-3. 25-Pin User Port Pin Descriptions ...................................................... 4-8

Table 4-4. 15-Pin User Port Pin Descriptions .................................................... 4-21

Table 4-5. Setting regulation mode with 15-pin User Port pins 1 and 2 .............. 4-24

Table 4-6. RS-232 port pin descriptions .............................................................. 4-32

Table 4-7. AE Bus byte structure ........................................................................ 4-35

Table 4-8. PROFIBUS port pin and signal descriptions ...................................... 4-38

Table 4-9. Baud rate and cable lengths .............................................................. 4-38

Table 4-10. PROFIBUS status LEDs .................................................................. 4-40

Table 4-11. Configuration of PROFIBUS download packet bytes ....................... 4-42

Table 4-12. PROFIBUS upload packet status bit flags ...................................... 4-43

Table 4-13. Packet format for FC23 send ........................................................... 4-46

Table 4-14. Packet format for FC23 response .................................................... 4-47

Table 4-15. Packet format for FC23 exception error ........................................... 4-48

Table 4-16. Packet format for command 168 send ............................................. 4-49

Table 4-17. Packet format for command 168 response ...................................... 4-50

Table 4-18. AE Bus command 14 remote control settings, resets, and

overrides ............................................................................................................ 4-52

Table 4-19. AE Bus command status response (CSR) codes ............................ 4-53

Table 4-20. AE Bus Commands .......................................................................... 4-54

Table 4-21. Remote control override settings (command 29) ............................. 4-81

Table 5-1. Input connector pin description ......................................................... 5-11

Table 5-2. Remote control mode displayed on the front panel ........................... 5-25

Table 5-3. RF on/off control ................................................................................ 5-26

Table 5-4. Adjusting VarioMatch match network capacitors .............................. 5-46

Table 6-1. Error codes .......................................................................................... 6-8

Table 6-2. Warning messages ............................................................................ 6-11

Table 6-3. Communication warning messages ................................................... 6-12

Table 6-4. AE Global Services 24 X 7 contact information ................................. 6-15

57023916-00B xiList of Tables

Advanced Energy

xii 57023916-00BList of Tables

Cesar® Generator

List of Figures

Figure 2-1. Cesar block diagram ........................................................................... 2-2

Figure 4-1. Matching interface connector .............................................................. 4-1

Figure 4-2. User Port connector, 25 Pin ................................................................ 4-4

Figure 4-3. Reflected power monitor (pins 2 and 15) .......................................... 4-13

Figure 4-4. Forward/Load power monitor (pins 3 and 16) ................................... 4-13

Figure 4-5. RF POWER ON signal wiring (pins 4 and 17) .................................. 4-13

Figure 4-6. SET POINT signal wiring (pins 5 and 18) ......................................... 4-14

Figure 4-7. RF FORWARD POWER/DC BIAS REGULATION wiring (pins 6

and 19) .............................................................................................................. 4-14

Figure 4-8. DC BIAS MONITOR signal wiring (pins 7 and 20) (units with DC

Bias In) .............................................................................................................. 4-14

Figure 4-9. DC BIAS MONITOR signal wiring (pins 7 and 20) (units with DC

Bias Out) ............................................................................................................ 4-15

Figure 4-10. RF FORWARD/LOAD REGULATION signal wiring (pins 8 and

21) ..................................................................................................................... 4-15

Figure 4-11. INTERLOCK LOOP signal wiring (pins 10 and 23) ........................ 4-16

Figure 4-12. +15 VOLT DC signal wiring (pins 13 and 21) ................................. 4-16

Figure 4-13. SET POINT STATUS signal wiring (pins 14 and 1) ........................ 4-17

Figure 4-14. OVERTEMPERATURE signal wiring (pins 22 and 9) ..................... 4-17

Figure 4-15. INTERLOCK SATISFIED signal wiring (pins 24 and 11) ................ 4-17

Figure 4-16. BLANKING/PULSING signal wiring (pins 25 and 19) ..................... 4-18

Figure 4-17. User Port connector, 15 Pin ............................................................ 4-18

Figure 4-18. Interlock interface connector ........................................................... 4-19

Figure 4-19. OPERATING MODE A wiring diagram (pins 1 and 8) .................... 4-25

Figure 4-20. OPEATING MODE B wiring diagram (pins 2 and 8) ....................... 4-25

Figure 4-21. READY STATUS wiring diagram (pins 3 and 8) ............................. 4-26

Figure 4-22. ERROR wiring diagram (pins 4 and 8) ........................................... 4-26

Figure 4-23. MAXIMUM POWER LEVEL REACHED wiring diagram (pins 5

and 8) ................................................................................................................ 4-27

Figure 4-24. RF ON wiring diagram (pins 6 and 8) ............................................. 4-27

Figure 4-25. INTERFACE VOLTAGE wiring diagram (pins 7 and 8) .................. 4-28

Figure 4-26. BLANKING/PULSING MODE wiring diagram (pins 9 and 8) .......... 4-28

Figure 4-27. RF POWER ON wiring diagram (pins 10 and 8) ............................. 4-29

Figure 4-28. DC BIAS SET POINT wiring diagram (pins 11 and 8) .................... 4-29

Figure 4-29. RF POWER SET POINT wiring diagram (pins 12 and 8) ............... 4-29

Figure 4-30. TEST VOLTAGE FOWARD POWER wiring diagram (pins 13

and 8) ................................................................................................................ 4-30

Figure 4-31. TEST VOLTAGE REFLECTED POWER wiring diagram (pins

14 and 8) ........................................................................................................... 4-30

Figure 4-32. TEST VOLTAGE FOR DC BIAS wiring diagram (pins 15 and

8) ....................................................................................................................... 4-31

Figure 4-33. RS-232 port connector .................................................................... 4-32

Figure 4-34. Graphic representation of a message packet ................................. 4-34

Figure 4-35. AE Bus communications transaction .............................................. 4-36

Figure 4-36. Communications transaction example ............................................ 4-37

57023916-00B xiiiList of Figures

Advanced Energy

Figure 4-37. PROFIBUS port connector ............................................................. 4-38

Figure 4-38. Example of a segment .................................................................... 4-39

Figure 4-39. Ethernet connector and indicators .................................................. 4-45

Figure 5-1. Cesar unit dimensions ........................................................................ 5-2

Figure 5-2. Cesar rear view ................................................................................... 5-3

Figure 5-3. RF Output connector .......................................................................... 5-6

Figure 5-4. RF cover ............................................................................................. 5-6

Figure 5-5. RF / User Port interlock adapter cable ................................................ 5-7

Figure 5-6. RF / User Port interlock adapter cable, attached to unit ..................... 5-8

Figure 5-7. CEX Connector ................................................................................. 5-10

Figure 5-8. AC Input (Mains) connector .............................................................. 5-11

Figure 5-9. Front panel ........................................................................................ 5-19

Figure 5-10. Front panel program menu tree ...................................................... 5-22

Figure 5-11. Front panel program menu tree (continued) ................................... 5-23

Figure 5-12. Generator with no cable attenuation ............................................... 5-48

Figure 5-13. Generator with cable attenuation .................................................... 5-48

Figure 6-1. Input (Mains) connector and fuse box ................................................ 6-4

xiv 57023916-00BList of Figures

Cesar® Generator

1027

Chapter

Safety and Product Compliance Guidelines

PRODUCTS DOCUMENTED IN THIS MANUAL

This user manual documents air-cooled Cesar generators.

The following part numbers include some non-standard features, which will be called

out where they apply:

• 61300129: DC Bias Out on the User Port. All other part numbers: DC Bias In

on the User Port.

• 61300121: 0 V to 5 V scaling on the User Port. All other part numbers: 0 V to

10 V scaling on the User Port.

1

IMPORTANT SAFETY INFORMATION

To ensure safe installation and operation of the Advanced Energy Cesar unit, read

and understand this manual before attempting to install and operate this unit. At a

minimum, read and follow the safety guidelines, instructions, and practices.

DANGER, WARNING, AND CAUTION BOXES IN THE MANUAL

This symbol represents important notes concerning potential harm to people, this

unit, or associated equipment. Advanced Energy includes this symbol in Danger,

Warning, and Caution boxes to identify specific levels of hazard seriousness.

DANGER:

DANGER indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury. DANGER is limited to the most extreme

situations.

57023916-00B Safety and Product Compliance Guidelines 1‑1

Advanced Energy

WARNING:

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and/or property damage.

CAUTION:

CAUTION indicates a potentially hazardous situation that, if not avoided,

could result in minor or moderate injury, and/or property damage. CAUTION

is also used for property-damage-only accidents.

SAFETY GUIDELINES

Review the following information before attempting to install and operate the

product.

Rules for Safe Installation and Operation

Please note the following rules:

• Do not attempt to install or operate this equipment without proper training.

• There are no user-serviceable parts inside the unit. Refer servicing to trained

service personnel.

• Ensure that this unit is properly grounded.

• Ensure that all cables are properly connected.

• Verify that input line voltage and current capacity are within specifications

before turning on the power supplies.

• Use proper electrostatic discharge (ESD) precautions.

• Always be careful around this equipment.

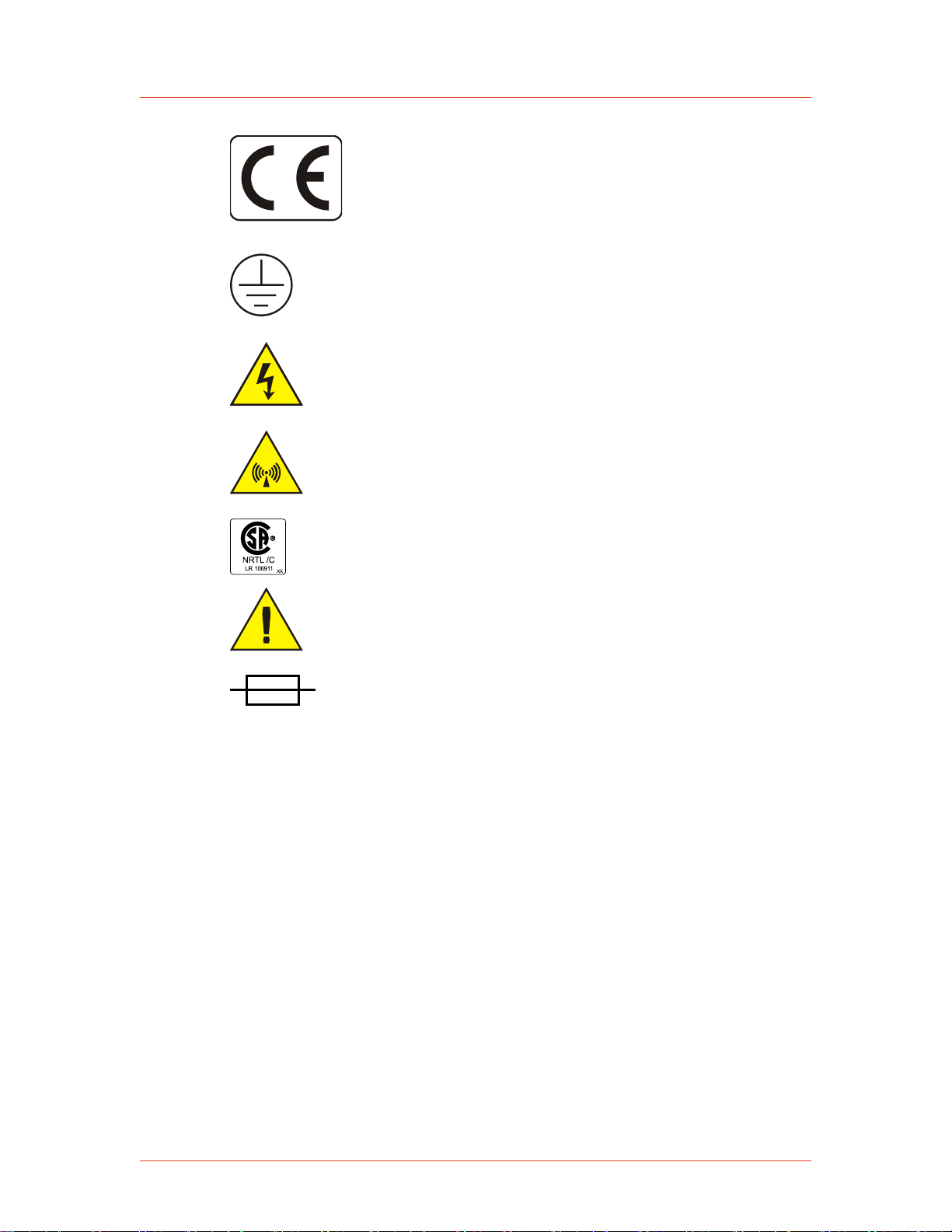

INTERPRETING PRODUCT LABELS

The following labels may appear on your unit:

1‑2 Safety and Product Compliance Guidelines 57023916-00B

1020

CE label

1029

1028

1030

1027

Protective Earth ground

Hazardous voltage

Nonionizing radiation

Cesar® Generator

PRODUCT COMPLIANCE

The following sections include information about unit compliance and certification,

including the conditions of use required to be in compliance with the standards and

directives.

Product Certification

NRTL: Nationally Recognized Testing

Laboratory

Refer to manual for more information

Electrical fuse

Certain options of this product may be certified according to the list below.

For more information, refer to the Certificate or Letter of Conformity (US) or

Declaration of Conformity (EU) accompanying the product.

• NRTL – Safety certified by CSA International, a Nationally Recognized

Testing Laboratory

• CE Marking – Self-declaration, assessed by AE Corporate Compliance

57023916-00B Safety and Product Compliance Guidelines 1‑3

Advanced Energy

• EMC measurements – Verified by the AE Corporate Compliance Lab and/or an

accredited third party lab

Safety and EMC Directives and Standards

Certain options of this unit have been tested for and comply with the following

electromagnetic compatibility (EMC) and safety directives and standards and

industry guidelines.

☞ Important

This device must be installed and used only in compliance with the directives

and standards listed in addition to EN 60204 (IEC 60204) and applicable

requirements.

☞ Important

This equipment must be installed and used in accordance with the Conditions

of Use described in this manual. If this equipment is expanded, modified, or

installed into a larger system, the user is responsible to guarantee the

compliance of the overall system. If this equipment is used with external

components, the user must ensure that the Safety and EMC requirements are

not violated.

ELECTROMAGNETIC COMPATIBILITY (EMC) DIRECTIVES AND STANDARDS

• 2004/108/EC

EC Council directive on the approximation of the laws of the Member States

relating to electromagnetic compatibility (EMC Directive)

• 47 CFR Part 18

Code of Federal Regulations—Limits and methods of measurement of radio

interference characteristics of industrial, scientific, and medical equipment

• EN 55011

Limits and methods of measurement of radio disturbance characteristics of

industrial, scientific, medical (ISM) radio frequency equipment (Class A, Group

2) (CISPR 11)

• EN 61000-6-2

Electromagnetic Compatibility (generic immunity standard—industrial)

SAFETY DIRECTIVES AND STANDARDS

• 2006/95/EC

EC Council directive on the harmonization of the laws of the Member States

relating to electrical equipment designed for use within certain voltage limits

(LVD - Low Voltage Directive)

• EN 61010-1

1‑4 Safety and Product Compliance Guidelines 57023916-00B

Safety requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use - Part 1: General Requirements

Conditions of Use

To comply with the stated directives and standards, you must meet the following

conditions of use:

DANGER:

RISK OF DEATH OR BODILY INJURY. Disconnect and lockout/tagout all

sources of input power before working on this unit or anything connected to

it.

• Before making any other connection to this device, connect the auxiliary

Protective Earth ground terminal to a local earth ground with a copper wire that

is sized according to the applicable requirements.

• Install and operate this device only in accordance with the listed safety

guidelines and all other applicable directives and standards specific to your

process and application.

Cesar® Generator

• Install and operate this device in an overvoltage category II or better

installation.

• Install and operate this device only in a pollution degree 2 or better

environment, which means an indoor location such as a computer room, office,

or factory floor where only nonconductive pollution occurs during operation.

Occasionally, condensation causes temporary conductivity when the device is

not operating.

• Install this device so that it is fully enclosed by a rack or other enclosure. The

rack or enclosure must be metal and either reinforced or of sufficient thickness

to resist both of the following tests:

◦ A steady force of 445 N, applied through a steel hemisphere 12.7 mm in

diameter

◦ An impact of 7 J, applied by dropping or swinging a 0.53 kg, 50 mm diameter

steel sphere

◦ Following the tests, there must be still a minimum clearance of 12.7 mm

between the rack or enclosure and the power supply. There shall be no

deformation of the power supply.

• The on/off power switch does not completely disconnect the AC input. If the

AC power cord is not accessible after installation, a separate external switch is

required to disconnect AC power.

• The AC line cord must be terminated according to the applicable requirements.

• Use only shielded cables on the serial and user communications interfaces.

57023916-00B Safety and Product Compliance Guidelines 1‑5

Advanced Energy

• Install and operate this device with a 16 A (maximum) circuit breaker switch on

the AC input to provide the required over-current protection. The circuit breaker

switch must be easily accessible and near the device.

• Install this device so that the input power connection is inaccessible to the user.

• Install this device so that the output power connection is inaccessible to the

user.

INTERLOCKS AND LIMITING CONDITIONS

WARNING:

Advanced Energy products only include interlocks when required by product

specification. Interlocks in Advanced Energy products are not intended to

meet or satisfy safety requirements. Where interlocks exist, you must still

meet and satisfy safety requirements. The presence of interlocks does not

imply operator protection.

All Cesar generators have an Interlock interface. This interface allows you to

integrate any Cesar generator into a system interlock loop that can interrupt the

delivered RF power.

Even if you do not connect this Cesar generator into a larger system interlock loop,

you must make the proper interlock loop connections for the unit to enable RF power.

The Cesar generator may be shipped with an interlock jumper plug that provides a

connection between the User Port interlock pins. You can use this jumper plug to

satisfy the interlock and enable operation in situations where you do not intend to

connect the remaining pins on this port.

☞ Important

Using the interlock jumper plug disables the interlock function.

☞ Important

Interlock does not switch the generator on/off. If an interlock is not satisfied,

the Cesar generator will issue an interlock error. Interlock errors must be

resolved, so you must switch RF off (via the RS-232 or User Port) or resolve

the error (via the front panel) before you can switch on RF power again.

Your unit may include an RF cover. For units with an RF cover:

• RF output is disabled when the cover is removed. Ensure that the RF cover is in

place.

• In addition to the interlock jumper plug for the User Port and the RF cover,

your unit uses an RF / User Port interlock adapter cable. For information on

connecting this cable, see “Connecting Output Power” on page 5-6.

1‑6 Safety and Product Compliance Guidelines 57023916-00B

Cesar® Generator

In addition, the Cesar generator includes specific limits that are described in

Table 1-1. The errors generated by exceeding these limits are described in

“Troubleshooting Using Error Codes” on page 6-7.

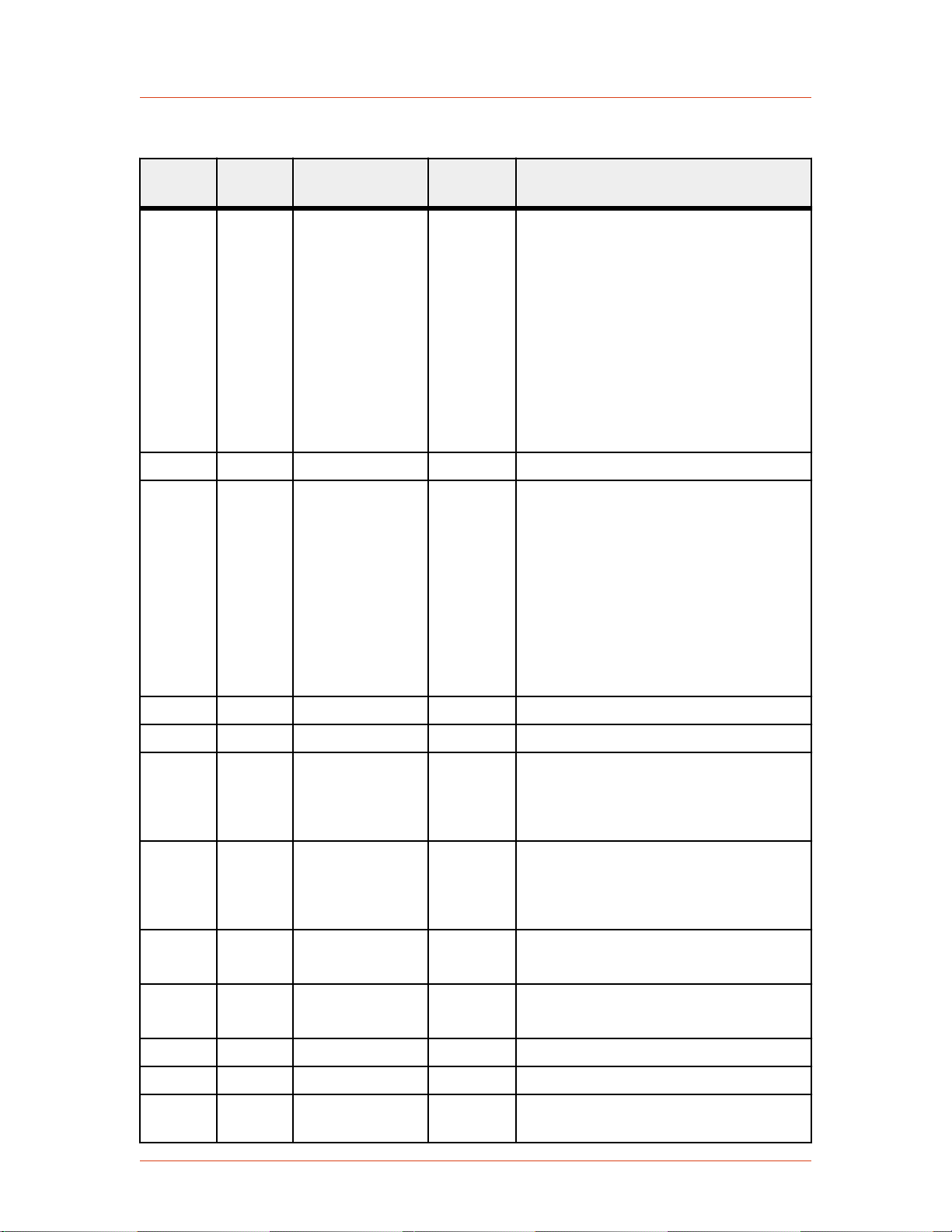

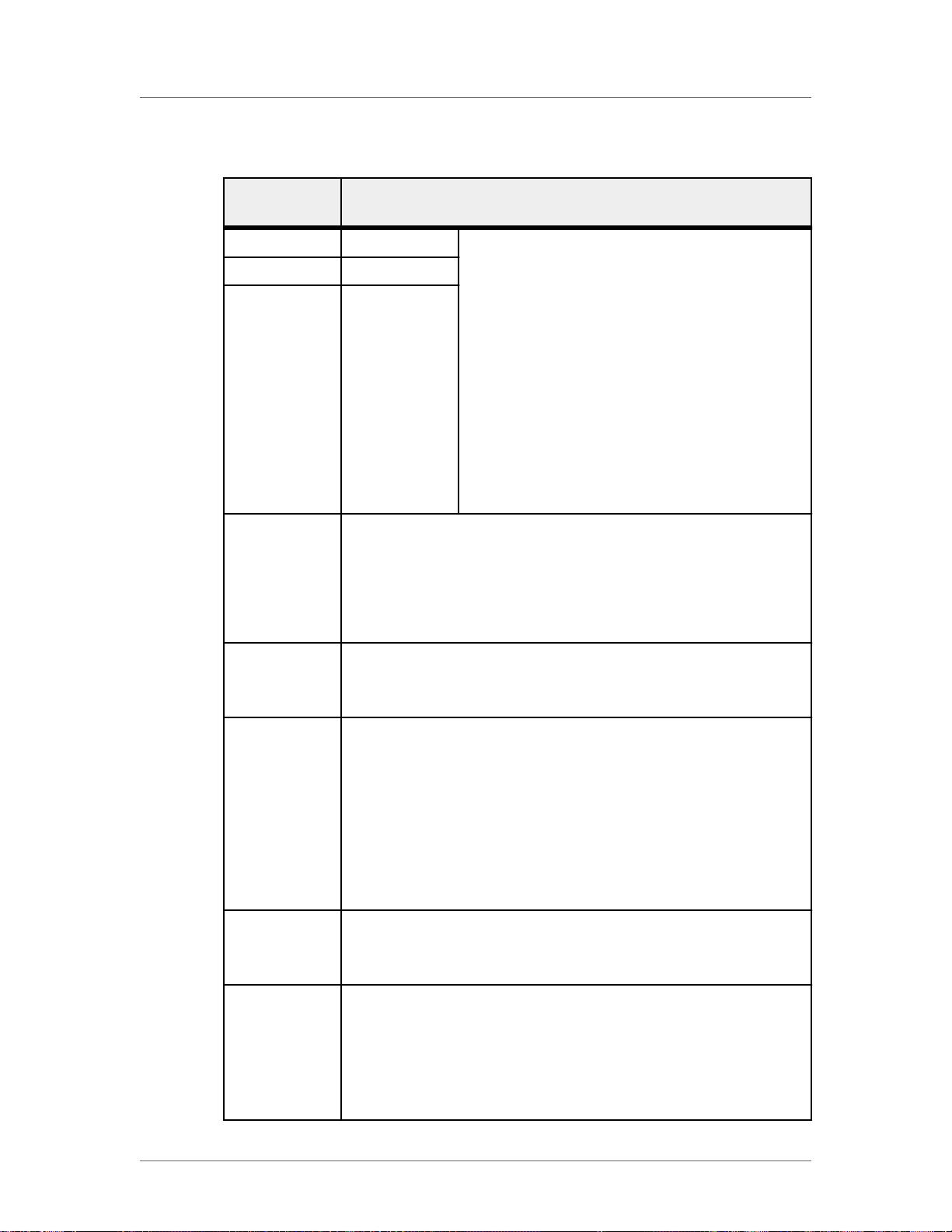

Table 1‑1. Cesar limiting conditions

Limit Unit Response and User Resolution

RF power limit When the unit reaches the forward or reflected power limit, the

unit reduces forward power to remain within the limits. Output

is not at set point.

Overtemperature When the unit exceeds the specified maximum temperature, RF

power shuts off, and the unit displays an error code.

Current limit When the voltage or the current exceeds the limit of the

internal SMPS, the unit reduces output to remain within the

limits. Output is not at set point.

External pulse frequency limit When the external pulse frequency exceeds the limit, the unit

turns RF power off.

Target lifetime limit The target lifetime warning occurs when the target lifetime

reaches the user-set limit. This warning does not affect the

operation of the unit.

57023916-00B Safety and Product Compliance Guidelines 1‑7

Advanced Energy

1‑8 Safety and Product Compliance Guidelines 57023916-00B

Cesar® Generator

Chapter

Product Overview

GENERAL DESCRIPTION

AE Cesar RF power generators are Class E Switched Mode Amplifiers for Radio

Frequency (CESAR), a new generation of versatile RF power supplies for

semiconductor production, and general plasma processing. This generator employs

parallel excited circuitry in a compact, 19″ rack-mountable designs. Typical

applications include sputtering, reactive ion etching, RF bias, plasma

polymerization, plasma surface treatment, and CO2 laser systems.

The Cesar generator incorporates advanced switch mode technology. This highly

efficient, resonant switching concept results in reduced energy costs, reduced

downtimes, and a longer lifetime for the unit.

Designed to regulate power into a broad range of output impedances, the Cesar

generator can operate in forward power, real power, or DC bias regulation mode In

addition, you can add a cable attenuation variable to the power regulation setting.

2

Both manual and automatic tuning control support operation into a fixed impedance

matching network, which simplifies system complexity, increases reliability, and

improves process-to-process repeatability.

You can control and configure the Cesar generator using any of the following

methods:

• Remotely through an analog User Port.

• Remotely through a communication host port.

• Using the front panel, which features a liquid crystal display (LCD) with an

easy-to-use menu.

The Cesar generator operates from an AC power source. The unit can tolerate

arbitrary phase rotation of the input power connections. The generator is air-cooled

and has all power and interface-port connections at the rear of the generator.

57023916-00B Product Overview 2‑1

2965

(2)

Driver/Exciter

(1)

Analog I/O

(5)

Digital

Controller

(3)

RF

Amplifiers

(4)

RF Power

Measurement

(6)

Sensor

Electronics

User Port

Host Port

RF Output

Advanced Energy

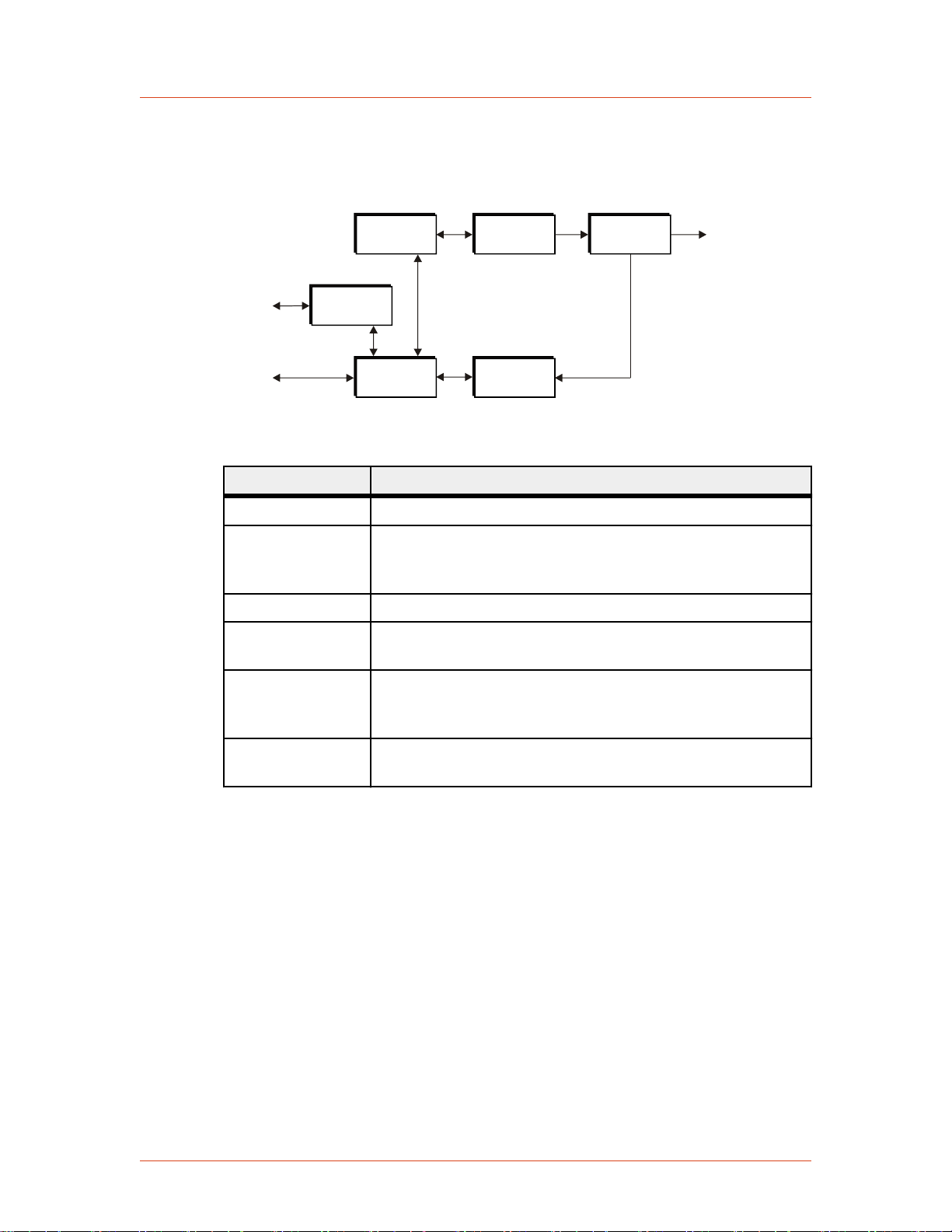

THEORY OF OPERATION

Figure 2‑1. Cesar block diagram

Module Description

(1) Analog I/O This module provides the User interface.

(2) Driver/Exciter This module generates power at the designated output

frequency to drive the main RF sections and contains the

CEX functions.

(3) RF Amplifiers This module generates RF power.

(4) RF Power

Measurement

(5) Digital

Controller

This module samples the output signal and sends it to the

sensor electronics.

This module is the main processor and data acquisition

section. It also provides host communications through a host

port.

(6) Sensor

Electronics

This module detects RF samples and sends them to the

microprocessor.

2‑2 Product Overview 57023916-00B

Cesar® Generator

Chapter

Specifications

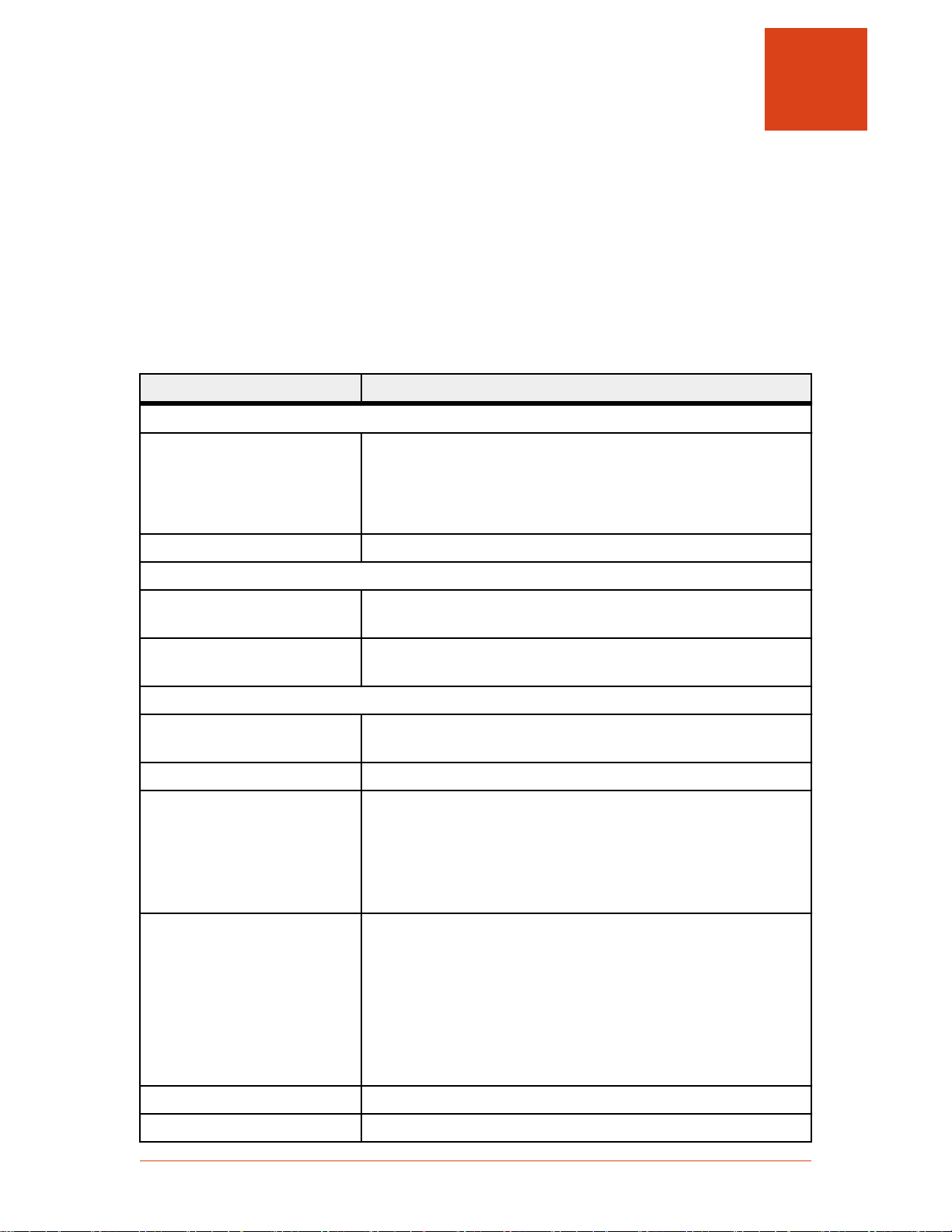

PHYSICAL SPECIFICATIONS

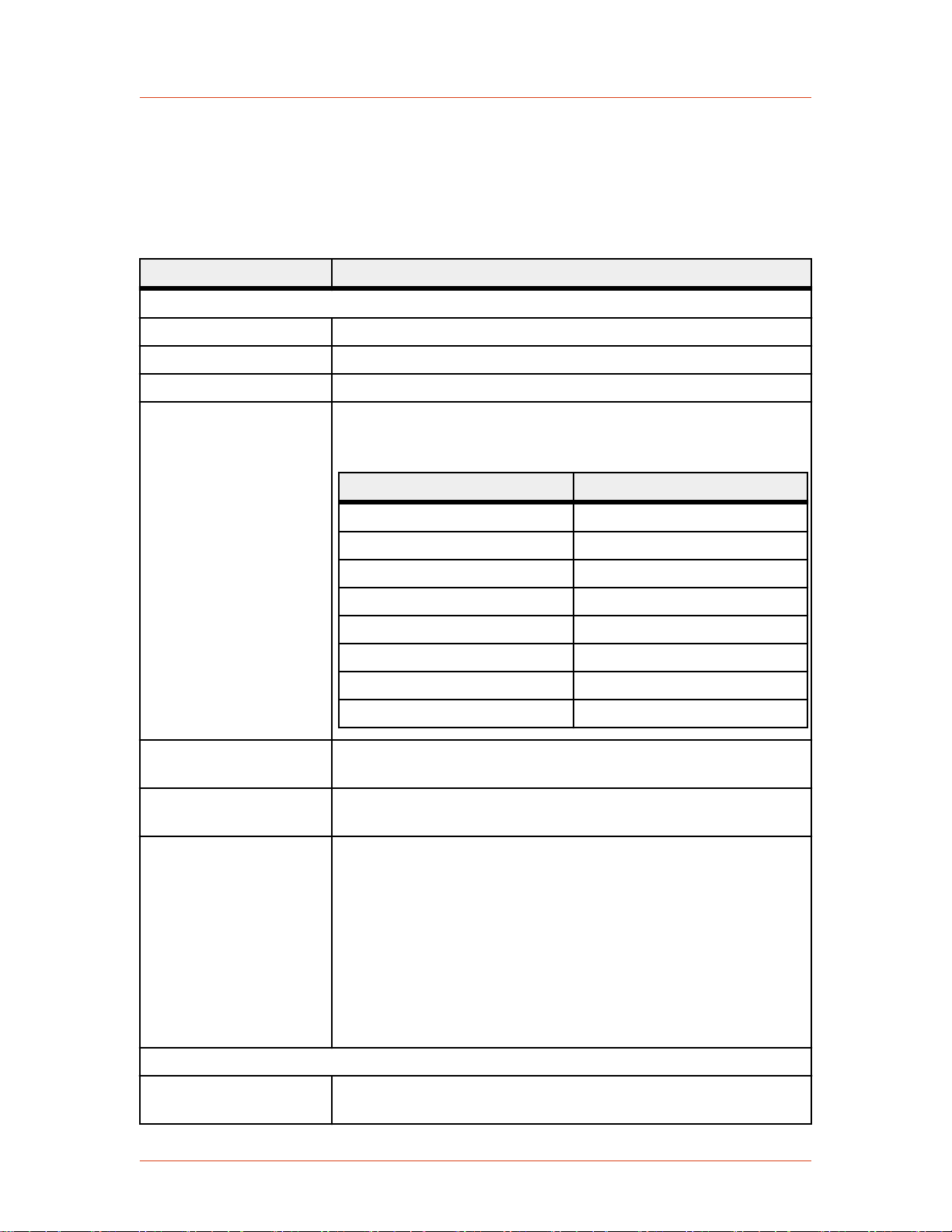

Table 3‑1. Physical specifications

Description Specification

General physical specifications

Size 88 mm (H) x 483 mm (W) x 500 mm (D)

3.5″ (H) x 19″ (W) x 19.7″ (D)

Dimensions include front panel mounting extensions.

Dimensions do not include RF output, fan, connectors.

3

Weight 19.2 kg (42 lb)

Mounting

Clearance 6 cm (2.36″) required on each side for airflow; 10.16 cm (4″)

required at rear for cable connections

Mounting 19″ rack-mounting holes are provided on the generator front

panel.

Connectors

AC input power IEC 60320 C14 inlet; mates with IEC 60320 C13 connector on

power cord

RF output N-Type, female connector

User port connection (Analog

I/O)

Host port connection (serial I/O)The Cesar generator has three host port communication

There are two analog interface options available for the Cesar

generator:

• 25-pin subminiature-D male

• 15-pin subminiature-D male

interface options:

• An RS-232 9-pin, female, shielded, subminiature-D

connector

• A PROFIBUS 9-pin, female, subminiature-D connector

• An Ethernet Modbus/TCP connection

CEX CEX BNC, female

Front panel display LCD graphic display

57023916-00B Specifications 3‑1

Advanced Energy

ELECTRICAL SPECIFICATIONS

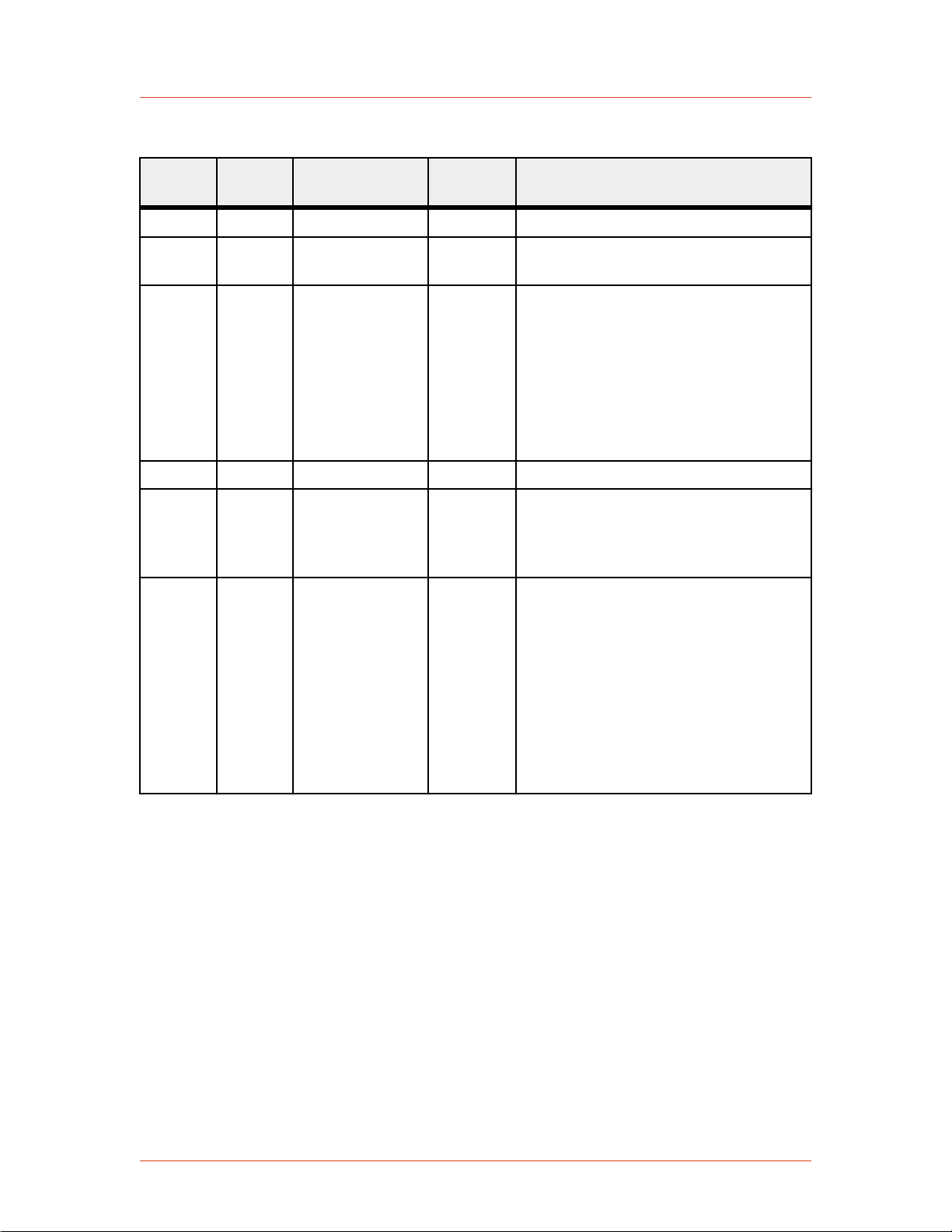

Table 3‑2. Electrical specifications

Description Specification

Electrical requirements

AC input voltage 230 VAC (187 VAC to 253 VAC), 1 φ, neutral, with ground (PE)

AC line frequency 50 Hz to 60 Hz

AC input current See the product label on your unit for the AC Current

Input power Varies by your unit's AC input current. See the product label on

your unit for the AC Current. The input power specification is

based on full rated power and nominal line into 50 Ω load.

AC input current Input power

2.8 A 650 VA

3 A 680 VA

4.6 A 1050 VA

4.8 A 1100 VA

6.5 A 1490 VA

6.8 A 1550 VA

8 A 1780 VA

10 A 2225 VA

Power factor 97% to 99% at full rated power, mid-frequency, and nominal line

into 50 Ω load

Overcurrent protection 10 A, 250 V, T, high breaking capacity H electrical fuse (for

example, Schurter 0001.2514)

Efficiency (line to load) Varies by unit. Effeciency listed below is typical at full-rated

power nominal line, into a 50 Ω load.

• 56% — Models 605, 6010

• 58% — Models 403, 405, 4010

• 63% — Models 273, 276, 2710 6

• 65% — Models 026, 046, 133, 136

• 66% — Models 0210, 0410, 1310, 1312

Power specifications

RF frequency See your unit’s product label for the RF Frequency. Accuracy is

± 0.005%

3‑2 Specifications 57023916-00B

Table 3‑2. Electrical specifications (Continued)

Description Specification

Minimum output power 1% of your unit’s maximum output power.

The Cesar generator can operate below this level, but accuracy is

not guaranteed.

Maximum output power See your unit’s product label for the RF Power.

Cesar® Generator

Delivered power into

mismatch

Varies by output power (see your unit's label for RF Power)

RF power Delivered power

300 W 33% of nominal power

500 W 30% of nominal power

600 W 33% of nominal power

1000 W 20% of nominal power

1200 W 16% of nominal power

Maximum reflected

power

Varies by power (see your unit's label for RF Power)

RF power Maximum reflected power

300 W 100 W

500 W 175 W

600 W, 1000 W, 1200 W 200 W

Load impedance 50 Ω

Harmonics At full rated output, all harmonics are 45 dB below the RF output

signal when operated into a 50 Ω, nonreactive load impedance. All

spurious (nonharmonic) outputs are 60 dB below the RF output

signal.

RF power regulation 1.0% of set point or 0.1% of full rated power, whichever is greater

RF power stability 1.0% of set point or 0.2% of full rated power, whichever is greater

RF pulse frequency

• 1 Hz to 10 kHz for units with RF Frequency of 2 MHz through

4 MHz

• 1 Hz to 30 kHz for units with RF Frequency of 13.56 MHz

through 60.0 MHz

RF pulse duty cycle 1% to 99%

CEX Specifications

CEX input signal

• TTL or Sine; 0 to + 19 dBm, 50 Ω for models 2710, 403, 405,

4010

• TTL for all other models

57023916-00B Specifications 3‑3

Advanced Energy

Table 3‑2. Electrical specifications (Continued)

Description Specification

CEX output signal

• Sine; 7 dBm ± 3dB, 50 Ω for models 2710, 403, 405, 4010

• TTL for all other models

COOLING SPECIFICATIONS

Table 3‑3. Air cooling specifications

Description Specification

Cooling medium Air

Minimum air flow

118 m3/h (69.45 cfm)

ENVIRONMENTAL SPECIFICATIONS

Table 3‑4. Environmental standard specifications

Description Specification

Overvoltage Category II

Pollution degree 2

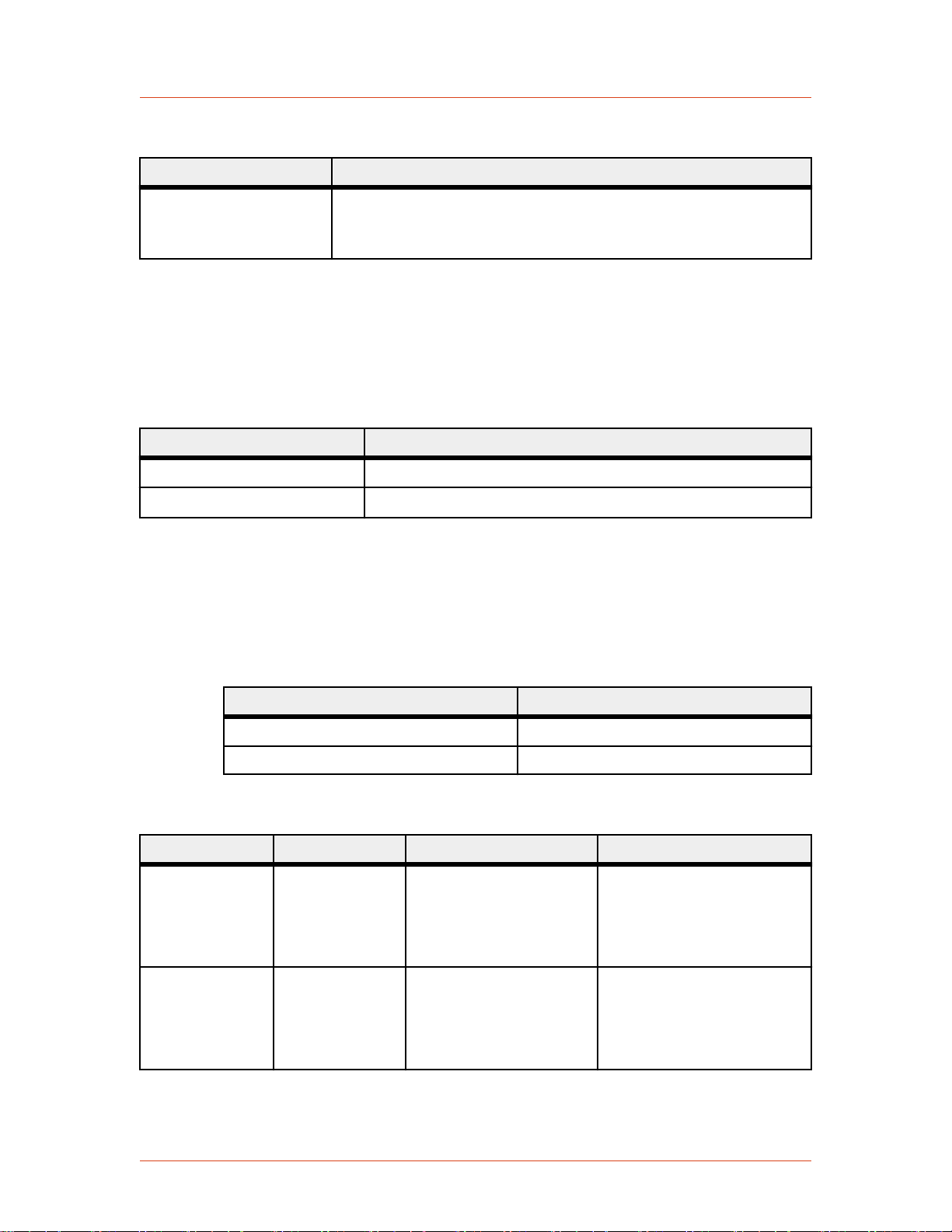

Table 3‑5. Climatic specifications

Temperature Relative Humidity Air Pressure

Operating 5°C to +35°C

+41°F to +95°F

5% to 85%

+1 g/m3 to +25 g/m

note 1

78.8 kPa to 106 kPa

3

788 mbar to 1060 mbar

Equivalent altitude: 2000 m

to -500 m (6562′ to -1640′)

Storage -25°C to +55°C

-13°F to +131°F

5% to 95%

+1 g/m3 to +29 g/m

78.8 kPa to 106 kPa

3

788 mbar to 1060 mbar

Equivalent altitude: 2000 m

to -500 m (6562′ to -1640′)

3‑4 Specifications 57023916-00B

Table 3‑5. Climatic specifications (Continued)

Temperature Relative Humidity Air Pressure

Cesar® Generator

Transportation -25°C to +70°C

-13°F to +158°F

note 2

95%

+60 g/m3

note 3

65.6 kPa to 106 kPa

656 mbar to 1060 mbar

Equivalent altitude: 3500 m

to -500 m (11480′ to -1640′)

note 1

Non-condensing, no formation of ice

note 2

Maximum relative humidity when the unit temperature slowly increases, or when the unit

temperature directly increases from -25°C to +30°C

note 3

Maximum absolute humidity when the unit temperature directly decreases from +70°C to +15°C

57023916-00B Specifications 3‑5

Advanced Energy

3‑6 Specifications 57023916-00B

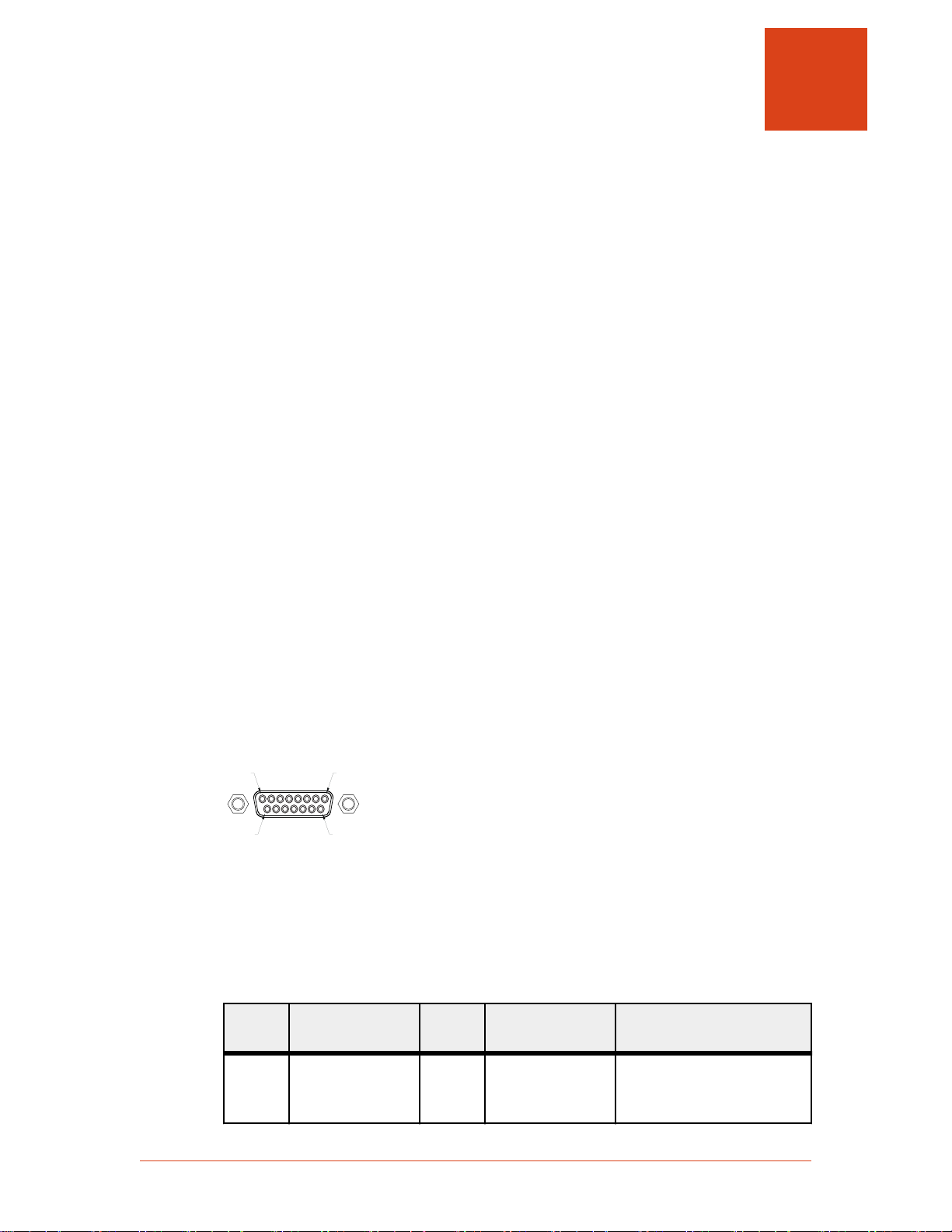

Pin 8 Pin 1

Pin 9

Pin 15

Cesar® Generator

Chapter

Communication Controls

DIAGNOSTIC INTERFACE

Each Cesar generator has a Diagnostic interface for use only at authorized service

centers. Technicians can check internal commands, calibrate the unit, or flash

software using this interface.

MATCHING INTERFACE

Each Cesar generator provides a Matching interface that allows full communication

between the Cesar generator and a VarioMatch or Navio matching network (or other

electrically and functionally compatible matching network).

4

☞ Important

This interface will not work with other matching networks unless they are

electrically and functionally compatible.

Matching Interface Connector

The Matching interface is a 15-pin, subminiature-D, female connector

Figure 4‑1. Matching interface connector

Matching Interface Pin Descriptions

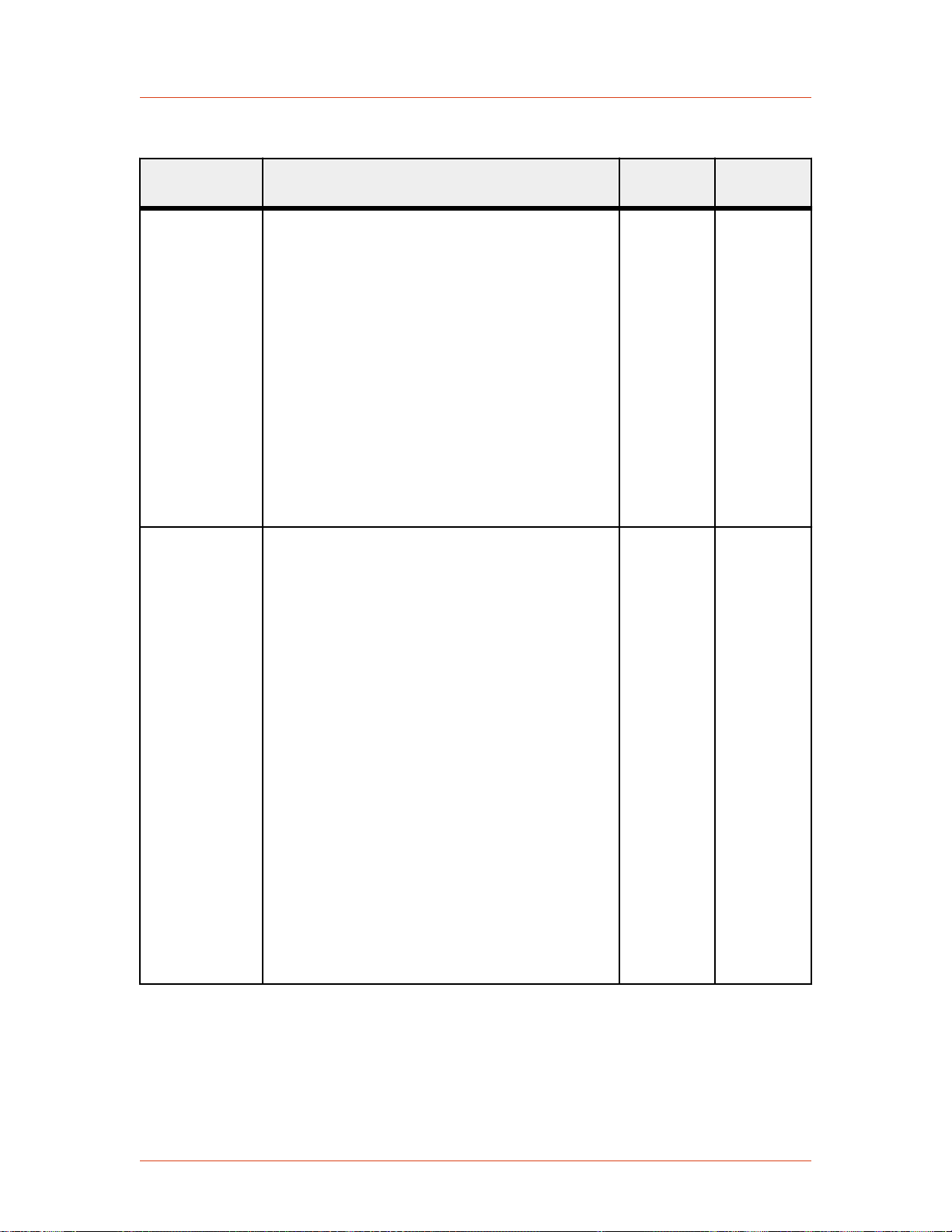

Table 4‑1. Matching interface pin descriptions

Pin Name Signal

type

Level Description

1 GROUND Connect to the shield of

the cable (for example, RC

cable).

57023916-00B Communication Controls 4‑1

Advanced Energy

Table 4‑1. Matching interface pin descriptions (Continued)

Pin Name Signal

Level Description

type

2 DECREASE

C

Load

Digital

Output

Open collector

30 V capable

The output is connected to

ground to turn the Load

motor counter clockwise.

3 INCREASE

C

Load

Digital

Output

Open collector

30 V capable

The output is connected to

ground to turn the Load

motor clockwise.

4 DECREASE

C

Tune

Digital

Output

Open collector

30 V capable

The output is connected to

ground to turn the Tune

motor counter clockwise.

5 INCREASE

C

Tune

Digital

Output

Open collector

30 V capable

The output is connected to

ground to turn the Tune

motor clockwise.

6 MEASURE

GROUND

Reference ground for the

measurement of analog

signals at pins 12 to 14.

7 NO

CONNECTION

8 MANUAL TUNE Digital

Output

Open collector

30 V capable

To set the VarioMatch or

Navio matching network

to manual tune control,

connect this pin to ground.

To set the VarioMatch or

Navio matching network

to automatic tune control,

leave this pin

unconnected.

9 CASE GROUND Connect to the shield of

the cable.

10 NO

CONNECTION

11 STATUS Digital

Input

+15 V This pin connects the

+15 V output voltage of

the VarioMatch or Navio

matching network to

indicate if a match

network is connected.

4‑2 Communication Controls 57023916-00B

Cesar® Generator

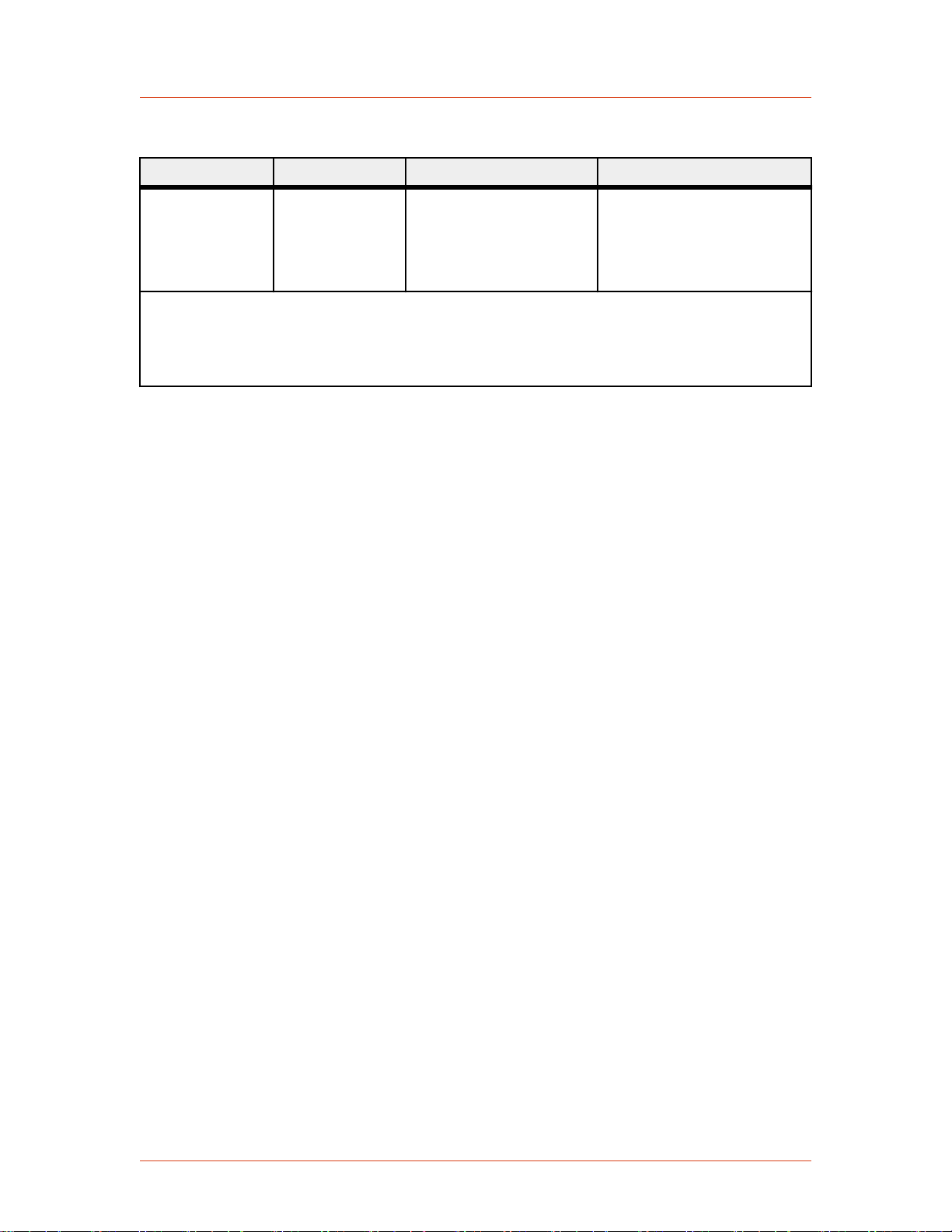

Table 4‑1. Matching interface pin descriptions (Continued)

Pin Name Signal

12 DC BIAS

MEASURE

VOLTAGE

13 POSITION OF

TUNE

CAPACITOR

Analog

Input

Analog

Input

type

Level Description

0 V to 10 V This pin reads a test

voltage of the DC self bias

voltage. The scaling is

adjustable. For example,

in the default

configuration of the

VarioMatch or Navio

matching network, 4000 V

bias voltage is equal to

10 V test voltage and is

displayed on the front

panel as 4000.

0 V to 10 V The voltage at this input is

proportional to the

position of the Tune

capacitor. A 10 V reading

at this pin is equal to

100% on the front panel

display.

14 POSITION OF

LOAD

CAPACITOR

15 MATCH IS

ACTIVE

USER PORT

The User Port on the Cesar generator provides analog and digital signals for

controlling and monitoring the unit.

Analog

Input

Digital

Input

0 V to 10 V The voltage at this input is

proportional to the

position of the Load

capacitor. A 10 V reading

at this pin is equal to

100% on the front panel

display.

Pull up to 5 V This input is switched to

ground when the

VarioMatch or Navio

matching network is active

(motors are running) and it

floats when the matching

procedure is complete.

There are two User Port options available for the Cesar generator:

• A 25-pin User Port

57023916-00B Communication Controls 4‑3

Pin 1 Pin 13

Pin 14

Pin 25

Advanced Energy

• A 15-pin User Port

This section describes both User Port connectors, the minimal connections required

to operate the unit, cabling requirements, and detailed information about the User

Port signals.

Related Links

• “25-Pin User Port” on page 4-4

• “15-Pin User Port” on page 4-18

25-Pin User Port

USER PORT CONNECTOR

The User Port uses a 25-pin, shielded, female, subminiature-D connector.

Figure 4‑2. User Port connector, 25 Pin

SATISFYING MINIMAL REQUIREMENTS FOR THE 25-PIN USER PORT

If you do not use the User Port to control or monitor the Cesar generator, you still

must satisfy the User Port INTERLOCK LOOP signal to operate the generator.

WARNING:

Advanced Energy products only include interlocks when required by product

specification. Interlocks in Advanced Energy products are not intended to

meet or satisfy safety requirements. Where interlocks exist, you must still

meet and satisfy safety requirements. The presence of interlocks does not

imply operator protection.

The Cesar generator may be shipped with an interlock jumper plug that provides a

connection between the interlock pins. You can use this jumper plug to satisfy the

interlock and enable operation in situations where you do not intend to connect the

remaining pins on this port.

Units with an optional RF cover: In addition to the interlock jumper plug for the User

Port, your unit uses an RF / User Port interlock adapter cable.

4‑4 Communication Controls 57023916-00B

Using the interlock jumper plug disables the interlock function.

Cesar® Generator

Interlock does not switch the generator on/off. If an interlock is not satisfied, the

Cesar generator will issue an interlock error. Interlock errors must be resolved, so

you must switch RF off (via the User Port or host port) or resolve the error (via the

front panel) before you can switch on RF power again.

If you will be using the User Port, see pins 10 and 23 in the pin descriptions.

When the interlock is opened and then closed again, you must resolve the interlock

error before using the generator again. To resolve the error with the User Port, you

must switch RF power from on to off. For this reason, never physically connect the

RF POWER ON pin with INTERLOCK. If you do so you many not be able to switch

on the generator.

Your unit includes an RF/User port interlock adapter cable, which connects to the

unit’s RS-232 and the RF cover. You will use the RS-232 connector on the cable in

the same way as described in this section.

Your unit includes an RF cover. You must connect the unit’s RS-232 to the RF cover.

Related Links

RF/User Port Interlock (Units with Optional RF Cover)

• “To Connect Output Power” on page 5-6

25-PIN USER PORT CABLING REQUIREMENTS

The cable used to connect the generator’s User Port to the system controller must be

a shielded, 25-wire I/O cable.

Recommendations:

• Shielded twisted-pair wiring may be used but is not mandatory.

• Signal losses should be minimized by keeping the cable length as short as

possible. The maximum recommended cable length between the generator and

the controller is 10 meters (33´).

• Signals at the User Port can be sensitive to environmental noise. Take standard

preventive measures against electro-magnetic interference (EMI), including

using shielded cabling to prevent errors from being induced into the User Port.

• Grounding the User Port at the power supply reduces noise interference. To

avoid ground loop problems, you should typically ground only one end of the

cable.

ACTIVATING THE 25-PIN USER PORT

The Cesar generator can run in front panel control mode, User Port remote control

mode, or host port remote control mode. You can activate the User Port remote

control mode using either of the following methods:

• The front panel

57023916-00B Communication Controls 4‑5

Advanced Energy

• Host port command 14

If User Port remote control is activated, it remains active even if the generator is

switched off and on. You can deactivate User Port remote control via either the front

panel or host port command 14.

RESOLVING ERROR DISPLAYS WHEN USING THE 25-PIN USER PORT

If the Cesar generator encounters an error while being operated via the User Port, the

generator displays the error message on the front panel display and turns off RF

power. The Cesar generator continues to show the error message on the front panel

until both of the following conditions are met:

WARNING:

RISK OF DEATH OR BODILY INJURY. The Cesar unit will deliver RF power

immediately at system power up when all of the following conditions are met:

User port is activated; pin 4 (

(

INTERLOCK LOOP

) is activated.

RF POWER ON

) is activated; and pin 10

• The error condition is gone

• The RF on signal is deactivated

Once the above two conditions are met, the error message is deleted and the Cesar

generator shows the normal display.

25-PIN USER PORT PIN DESCRIPTIONS AND WIRING DIAGRAMS

User Port Signal Specifications

Unless otherwise specified, all analog signals are 0 V to 10 V while all digital signals

are 5 V or V

Interface

.

4‑6 Communication Controls 57023916-00B

Cesar® Generator

Table 4‑2. User Port Signal Specifications

Signal Type Description

Analog Inputs By default, the User Port set point and DC bias input signals

(pins 5 and 7) are scaled 0 V to 10 V (physically limited to 10 V).

These signals are scalable from 0 V to 2 V up to 0 V to 20 V

(physically limited to 10 V) in increments of 0.5 V. You can set

the scaling through the RS-232 port or the PROFIBUS port (host

port command 30) or through the front panel menu commands.

☞ Important

Using lower input voltages decreases resolution.

☞ Important

Use a range of 0 V to 20 V only for special purposes such

as cable attenuation.

Analog

Outputs

By default, the User Port analog output signals (pins 2 and 3) are

scaled 0 V to 10 V (physically limited to 10 V). These signals are

scalable from 0 V to 2 V up to 0 V to 20 V (physically limited to

10 V) in increments of 0.5 V. You can set the scaling through the

RS-232 port or the PROFIBUS port (host port command 30) or

through the front panel menu commands.

☞ Important

Using lower input voltages decreases resolution.

☞ Important

Use a range of 0 V to 20 V only for special purposes such

as cable attenuation.

These signals are driven by operational amplifiers capable of

driving high-capacitance loads such as those expected in shielded

interface applications. The user’s receiver must present a 10 kΩ

(or higher) impedance to these signals. The readback signals

represent the forward and reflected power as measured at the

output of the generator.

Digital Inputs Pins 4, 6, 8, and 10 are opto-coupled. The user’s signal drives the

LED in the opto-coupler through a 4.7 kΩ resistor. A signal level

of 4 V to 30 V applied to the input pin activates the signal.

Digital Outputs The status signals provided by the generator (pins 12, 14, 22, and

24) are opto-coupled with NPN transistor outputs. The collector

and emitter of each transistor are provided to the user interface.

Each transistor can provide a maximum of 8 mA of collector

current and may be operated with a collector-to-emitter voltage of

up to 30 V.

Pulse Input The pulse input (pin 25) is a high-speed opto-coupled input. The

user’s signal drives the LED in the opto-coupler through a 1.2 kΩ

resistor. A signal level of 0 V to 1 V corresponds to low and 4 V

to 20 V corresponds to high.

57023916-00B Communication Controls 4‑7

Advanced Energy

Table 4‑2. User Port Signal Specifications (Continued)

Signal Type Description

Interlock The interlock signal (pins 10 and 23) enables the RF power

generation. Pin 10 is tied to the generator’s +15 V supply.

Connecting pin 10 to pin 23 closes the loop, enabling RF power.

User Port Pin Descriptions

This table provides the connector pin descriptions for the 25-pin User Port.

Table 4‑3. 25-Pin User Port Pin Descriptions

Signal

Pin

Return

Pin

Name Signal

Type

1 Return for pin 14 See pin 14

2 15 REFLECTED

POWER

Analog

output

MONITOR

Description

This signal provides a linearly scaled

read back of reflected power as measured

at the generator output.

The default range is 0 V to 10 V, but you

can change this range.

Default setting: 0 V to 10 V = 0 W to

maximum rated power output

Units with 0 V to 5 V scaling only: The

default range is 0 V to 5 V. Default

setting: 0 V to 5 V = 0 W to 1000 W. To

see if your unit has 0 V to 5 V scaling,

see “Products Documented in this

Manual” on page 1-1.

Pin 15 must be grounded.

3 16 FORWARD/

LOAD POWER

MONITOR

Analog

output

This signal provides a linearly scaled

read back of forward power or real

power (sometimes called load power) as

measured at the generator output. To

change control settings, see pin 8.

The default range is 0 V to 10 V, but you

can change this range.

Default setting: 0 V to 10 V = 0 W to

maximum rated power output.

Units with 0 V to 5 V scaling only: The

default range is 0 V to 5 V. Default

setting: 0 V to 5 V = 0 W to 1000 W. To

see if your unit has 0 V to 5 V scaling,

see “Products Documented in this

Manual” on page 1-1.

Pin 16 must be grounded.

4‑8 Communication Controls 57023916-00B

Table 4‑3. 25-Pin User Port Pin Descriptions (Continued)

Signal

Pin

Return

Pin

Name Signal

Type

Cesar® Generator

Description

4 17 RF POWER ON Digital

input

5 18 SET POINT Analog

input

This signal enables or disables RF

output. To enable RF output, apply a

positive voltage of 4 V to 30 V to this

pin. To disable RF output, apply a

voltage of 1.5 V or less to this pin

☞ Important

The interlocks must be satisfied

and the setpoint must be within

the output power range before

unit will deliver power.

Pin 17 must be grounded.

This signal sets the RF output set point.

Depending on the regulation mode, the

set point refers to forward power, real

power, or DC Bias regulation. The

default range is 0 V to 10 V, but you can

change this range.

A 0 V to 10 V signal applied to this pin

linearly controls the set point of the

generator.

Default setting: 0 V to 10 V = 0 W to

maximum rated power output

6 19 RF FORWARD

POWER/ DC

BIAS

REGULATION

Digital

input

For DC bias regulation, the scaling of the

set point must be the same as for the DC

bias signal (see pin 7).

Use this signal to select DC bias or

forward power regulation mode. To

regulate on DC bias input, apply a

positive voltage of 4 V to 30 V to this

pin. To regulate on forward or real

power, apply a voltage of 1.5 V or less or

an open connection.

See pin 8 for switching between forward

and real power regulation.

57023916-00B Communication Controls 4‑9

Advanced Energy

Table 4‑3. 25-Pin User Port Pin Descriptions (Continued)

Signal

Pin

Return

Pin

Name Signal

Type

Description

7 20 DC BIAS INPUT Analog

input

If your unit uses DC Bias Out, see the

next row.This input signal is used for DC

bias regulation, where the set point is

given by pin 5 (scaling must be the

same). The signal closes the control loop

around external components in the RF

path. The default range is 0 V to 10 V,

but you can change this range.

Default setting: 0 V to 10 V = 0 V to

4000 V

Units with 0 V to 5 V scaling only: The

default setting: 0 V to 10 V = 0 V to

3333 V. To see if your unit has 0 V to

5 V scaling, see “Products Documented

in this Manual” on page 1-1.

Typically, matching networks provide a

DC bias voltage monitor signal. When

this scaled representation of the DC bias

voltage is used for DC bias regulation

(see pin 6), the scaling must be the same

as for the set point (see pin 5).

VarioMatch and Navio matching

networks provide a DC bias voltage

monitor signal for regulation through the

Matching interface.

7 20 DC BIAS

OUTPUT

Analog

output

(If your unit uses DC Bias Out. All other

part numbers see previous row. See

“Products Documented in this Manual”

on page 1-1 to see if your unit uses DC

Bias Out.) This signal provides a linearly

scaled readback of DC Bias voltage as

measured at the matching network. The

default range is 0 V to 10 V, but you can

change this range.

Default setting: 0 V to 10 V = 0 V to

4000 V

Pin 20 must be grounded.

4‑10 Communication Controls 57023916-00B

Table 4‑3. 25-Pin User Port Pin Descriptions (Continued)

Signal

Pin

Return

Pin

Name Signal

Type

Cesar® Generator

Description

8 21 RF FORWARD/

LOAD POWER

REGULATION

Digital

input

Use this signal to select between RF

forward power or real power (sometimes

called load power) regulation. Apply a

positive DC voltage between 4 V and

30 V to regulate on real power. An open

connection to pin 8 or a DC input voltage

of less than 1.5 V causes forward power

regulation.

Real power is defined as forward power

minus reflected power.

Pin 6 also changes the regulation mode.

9 Return for pin 22 See pin 22.

10 23 INTERLOCK

LOOP

Digital

input

To satisfy the interlock and enable RF

power in the generator, close an external

loop from pin 23 to pin 10. A resistance

of 15 Ω or less across this pin closes the

loop. Pin 23 feeds this loop via a current

limiting circuit (maximum 120 mA).

Alternatively, you can satisfy the

interlock by applying a voltage of +4 V

to +30 V (referenced to ground) to pin

10.

11 Return for pin 24 See pin 24.

12 RESERVED

13 21 +15 VDC

SUPPLY

Supply A nominal +15 VDC output referenced

to chassis ground, auxiliary supply for

external use (50 mA maximum); no

internal limit.

14 1 SET POINT

STATUS

Digital

output

When the generator is out of set point, a

low (opto-coupler output) impedance is

created between this pin and pin 1 (8 mA

maximum).

15 Return for pin 2 See pin 2.

Pin 15 must be grounded at the host.

16 Return for pin 3 See pin 3.

Pin 16 must be grounded at the host.

17 Return for pin 4 See pin 4.

18 Return for pin 5 See pin 5.

19 N/A DC GROUND Chassis

ground

DC ground connection common to

chassis ground.

57023916-00B Communication Controls 4‑11

Advanced Energy

Table 4‑3. 25-Pin User Port Pin Descriptions (Continued)

Signal

Pin

Return

Pin

Name Signal

Type

20 Return for pin 7 See pin 7.

Description

21 N/A CHASSIS

GROUND

22 9 OVERTEMP Digital

Chassis

ground

output

DC ground connection common to

chassis ground.

When an internal overtemperature

shutdown condition is detected, a low

(opto-coupler output) impedance is

created between this pin and pin 9 (8 mA

maximum).

The overtemperature condition can occur

in the RF driver, SMPS, or final

amplifier.

23 10 Return for pin 10 See pin 10.

24 11 INTERLOCK

SATISFIED

Digital

output

When the interlock is satisfied, a low

(opto-coupler output) impedance is

created between this pin and return pin

11 (8 mA maximum).

25 19 BLANKING/

PULSING

Pulse input When the unit is set for external pulsing,

this pin allows you to pulse (blank) the

RF power. Set the required logic for RF

on and off through the front panel menu.

When the unit is set for internal pulsing,

this pin allows you to switch between

internal pulsing and continuous wave

operation. Select the appropriate function

and signal level in the Pulse Settings

selection in the front panel menu.

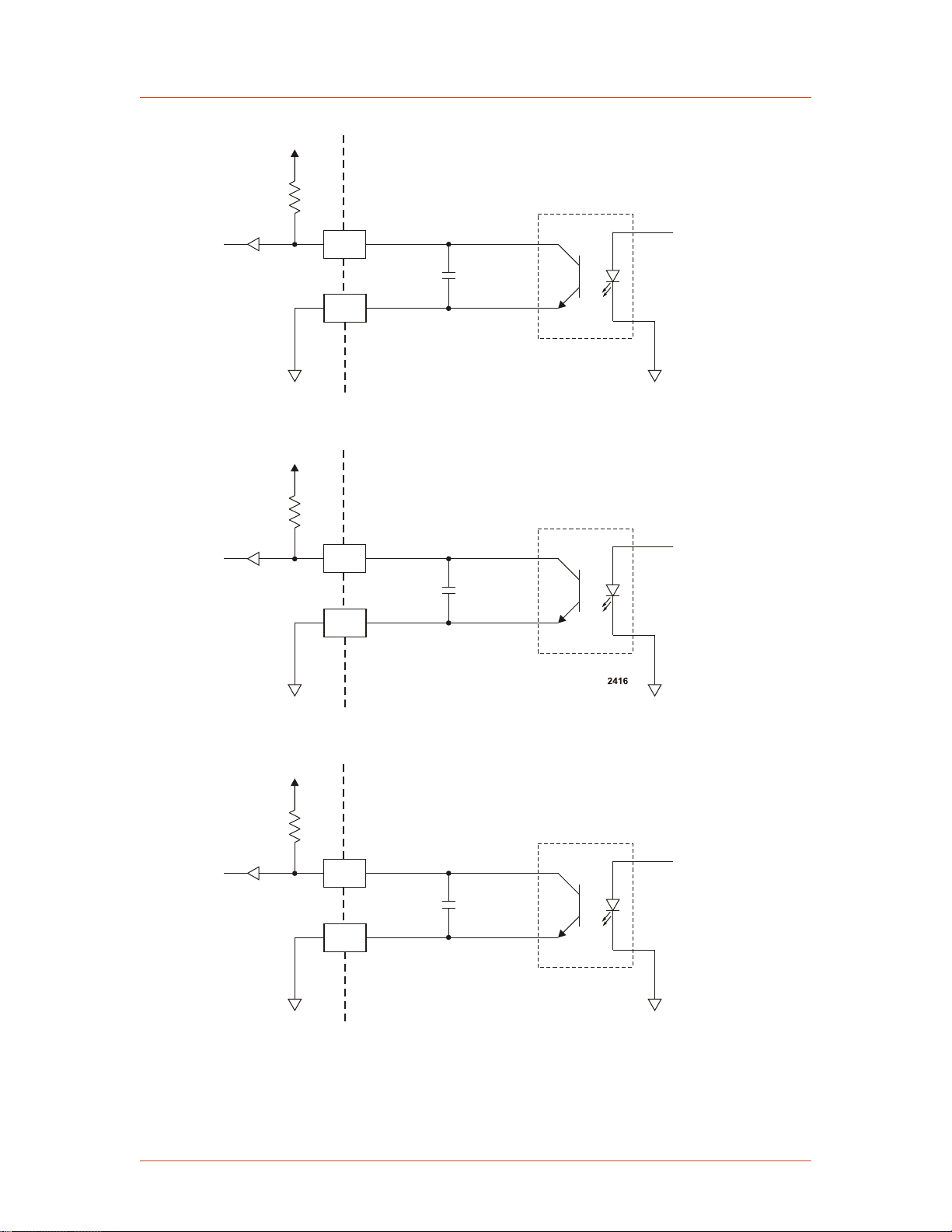

Wiring Diagrams for the 25-Pin User Port

The diagrams in this section provide wiring information to connect to the 25-pin

User Port.

4‑12 Communication Controls 57023916-00B

_

+

2

15

1 nF

1 nF

+15 V

+15 V

10 k

220 220

10 k

10 nF

10 k

10 k

Voltage Measurement Device

(see pin description

for scaling)

Pin 15 must be grounded

Figure 4‑3. REFLECTED POWER MONITOR (pins 2 and 15)

2407

_

+

3

16

1 nF

1 nF

+15 V

+15 V

10 k

220 220

10 k

10 nF

10 k

10 k

Voltage Measurement Device

(see pin description

for scaling)

Pin 16 must be grounded

2408

4

17

1 nF

+4 V to +30 V

4 k7

Cesar® Generator

Figure 4‑4. FORWARD/LOAD POWER MONITOR (pins 3 and 16)

Figure 4‑5. RF POWER ON signal wiring (pins 4 and 17)

57023916-00B Communication Controls 4‑13

2411

_

+

+15 V

+15 V

18

5

100 k

+

_

10 k

10 k

1 nF

1 nF

See pin description for scaling

2409

6

19

1 nF

+4 V to +30 V

4 k7

2412

_

+

+15 V

+15 V

20

7

100 k

10 k

10 k

In

In

1 nF

1 nF

User-defined feedback

Advanced Energy

Figure 4‑6. SET POINT signal wiring (pins 5 and 18)

Figure 4‑7. RF FORWARD POWER/DC BIAS REGULATION wiring (pins 6 and 19)

Figure 4‑8. DC BIAS MONITOR signal wiring (pins 7 and 20) (units with DC Bias In)

4‑14 Communication Controls 57023916-00B

3647

_

+

7

20

1 nF

1 nF

+15 V

+15 V

10 k

220 220

10 k

10 nF

10 k

10 k

Voltage Measurement Device

(see pin description

for scaling)

Pin 20 must be grounded

2410

8

21

1 nF

+4 V to +30 V

4 k7

Cesar® Generator

Figure 4‑9. DC BIAS MONITOR signal wiring (pins 7 and 20) (units with DC Bias

Out)

Figure 4‑10. RF FORWARD/LOAD REGULATION signal wiring (pins 8 and 21)

57023916-00B Communication Controls 4‑15

2413

+15 V

23

10

120 mA

1 nF

4 k7

+4 V to +30 V

Interlock

Interlock Return

(alternatively)

1838

+15 V

13

21

+15 V provided to user

Advanced Energy

Figure 4‑11. INTERLOCK LOOP signal wiring (pins 10 and 23)

Figure 4‑12. +15 VOLT DC signal wiring (pins 13 and 21)

4‑16 Communication Controls 57023916-00B

2415

14

1

1 nF

+ 30 V Maximum

Figure 4‑13. SET POINT STATUS signal wiring (pins 14 and 1)

22

9

1 nF

+ 30 V Maximum

2417

24

11

1 nF

+ 30 V Maximum

Cesar® Generator

Figure 4‑14. OVERTEMPERATURE signal wiring (pins 22 and 9)