Page 1

ADT Security Services, Inc.

1750 Clint Moore Road

Boca Raton, FL 33431

(561) 988-3600

Unimode 400 Multi-Net

Analog Fire Panel

Operations Manual

Document 50709

12/15/99 Revision:

PN 50709:A1 ECN 99-551

A

Page 2

Installation Precautions

- Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be connected to the fire alarm

control panel. Disconnect all sources of power before servicing. Control unit and

associated equipment may be damaged by removing and/or inserting cards,

modules, or interconnecting cables while the unit is energized. Do not attempt to

install, service, or operate this unit until this manual is read and understood.

CAUTION - System Reacceptance Test after Software Changes: To ensure

proper system operation, this product must be tested in accordance with NFPA 721993 Chapter 7 after any programming operation or change in site-specific software.

Reacceptance testing is required after any change, addition or deletion of system

components, or after any modification, repair or adjustment to system hardware or

wiring.

All components, circuits, system operations, or software functions known to be

affected by a change must be 100% tested. In addition, to ensure that other

operations are not inadvertently affected, at least 10% of initiating devices that are

not directly affected by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49O C/32-120O F and

at a relative humidity of 85% RH (non-condensing) at 30

useful life of the system's standby batteries and the electronic components may

be adversely affected by extreme temperature ranges and humidity. Therefore,

it is recommended that this system and its peripherals be installed in an

environment with a nominal room temperature of 15-27

Verify that wire sizes are adequate for all initiating and indicating device loops.

Most devices cannot tolerate more than a 10% I.R. drop from the specified device

voltage.

O

C/86O F. However, the

O

C/60-80O F.

Like all solid state electronic devices, this system may operate erratically or can

be damaged when subjected to lightning induced transients. Although no system is

completely immune from lightning transients and interferences, proper grounding will

reduce susceptibility. Overhead or outside aerial wiring is not recommended, due to

an increased susceptibility to nearby lightning strikes. Consult with the Technical

Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or inserting circuit boards.

Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing, reaming, or punching

of the enclosure. When possible, make all cable entries from the sides or rear.

Before making modifications, verify that they will not interfere with battery,

transformer, and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Over tightening may damage

threads, resulting in reduced terminal contact pressure and difficulty with screw

terminal removal.

This system contains static-sensitive components. Always ground yourself with a

proper wrist strap before handling any circuits so that static charges are removed

from the body. Use static suppressive packaging to protect electronic assemblies

removed from the unit.

Follow the instructions in the installation, operating, and programming manuals.

These instructions must be followed to avoid damage to the control panel and

associated equipment. FACP operation and reliability depend upon proper

installation.

Fire Alarm System Limitations

An automatic fire alarm system - typically made up of smoke detectors, heat

detectors, manual pull stations, audible warning devices, and a fire alarm control

with remote notification capability can provide early warning of a developing fire.

Such a system, however, does not assure protection against property damage or

loss of life resulting from a fire.

Any fire alarm system may fail for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot reach the detectors such

as in chimneys, in walls, or roofs, or on the other side of closed doors. Smoke

detectors also may not sense a fire on another level or floor of a building. A second

floor detector, for example, may not sense a first floor or basement fire. Furthermore, all types of smoke detectors - both ionization and photoelectric types, have

sensing limitations. No type of smoke detector can sense every kind of fire caused

by carelessness and safety hazards like smoking in bed, violent explosions,

escaping gas, improper storage of flammable materials, overloaded electrical

circuits, children playing with matches, or arson.

IMPORTANT! Smoke detectors must be installed in the same room as the

control panel and in rooms used by the system for the connection of alarm

transmission wiring, communications, signaling, and/or power. If detectors are

not so located, a developing fire may damage the alarm system, crippling its

ability to report a fire.

While installing a fire alarm system may make lower insurance rates

possible, it is not a substitute for fire insurance!

FCC Warning

Audible warning devices such as bells may not alert people if these devices are

located on the other side of closed or partly open doors or are located on another

floor of a building.

A fire alarm system will not operate without any electrical power. If AC power fails,

the system will operate from standby batteries only for a specified time.

Rate-of-Rise heat detectors may be subject to reduced sensitivity over time. For

this reason, the rate-of-rise feature of each detector should be tested at least once

per year by a qualified fire protection specialist.

Equipment used in the system may not be technically compatible with the control.

It is essential to use only equipment listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a premise to a central

monitoring station may be out of service or temporarily disabled.

The most common cause of fire alarm malfunctions, however, is inadequate

maintenance. All devices and system wiring should be tested and maintained by

professional fire alarm installers following written procedures supplied with each

device. System inspection and testing should be scheduled monthly or as required

by National and/or local fire codes. Adequate written records of all inspections should

be kept.

WARNING: This equipment generates, uses, and can radiate radio frequency

energy and if not installed and used in accordance with the instruction manual, may

cause interference to radio communications. It has been tested and found to comply

with the limits for class A computing device pursuant to Subpart B of Part 15 of FCC

Rules, which is designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user will be required

to correct the interference at his own expense.

Technical Publishing Document PRECAULG.PM6 12/31/96

Canadian Requirements

This digital apparatus does not exceed the Class A limits for radiation noise

emissions from digital apparatus set out in the Radio Interference Regulations of the

Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les

limites applicables aux appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministere des Communications du Canada.

Page 3

1. Introduction

Overview ......................................................................................................................1

Operating Features ........................................................................................................ 1

Components...................................................................................................................1

2. Using the Control Panel

Overview ......................................................................................................................3

System Status Indicator LEDs ......................................................................................3

Control Keys .................................................................................................................4

3. Operating Modes

Normal Operation ......................................................................................................... 5

Trouble Operation ........................................................................................................5

Fire Alarm ....................................................................................................................6

Supervisory Signal ........................................................................................................ 7

Non-Alarm Point Operation .........................................................................................7

Trouble Monitor Point Operation ................................................................................. 7

Notification Appliance Circuit (NAC) Operation ........................................................ 8

Control-By-Event Operation ........................................................................................ 8

Releasing Functions ...................................................................................................... 8

Intelligent Detector Functions .................................................................................... 10

Pre-Alarm Operation (AWACS) ................................................................................ 11

Time Functions ........................................................................................................... 11

Table of Contents

Overview ............................................................................................................11

Operating Coding Functions .............................................................................. 12

Presignal/Positive Alarm Sequence (PAS) Operation .......................................12

Special System Timers ....................................................................................... 13

Waterflow Circuits Operation ............................................................................ 13

Disable/Enable Operation ..................................................................................13

Style 6 Operation ............................................................................................... 13

4. Read Status

Overview ....................................................................................................................15

How to Enter Read Status ........................................................................................... 15

Read Status Options ...................................................................................................15

Read Status for Points and Zones ......................................................................16

Read Status for a Detector, Module, or Output .................................................16

Read History ...................................................................................................... 18

View Alarm History ........................................................................................... 18

View or Print Hidden History ............................................................................ 18

Presignal Delay ..................................................................................................19

Releasing Zones ................................................................................................. 19

Time Control Zones ...........................................................................................19

Holiday Zones .................................................................................................... 20

NAC Coding Zone .............................................................................................20

Pre-Alarm Zone .................................................................................................20

System Parameters ............................................................................................. 21

Annunciator Display Selections ......................................................................... 22

Example of Annunciator Display Selections .....................................................22

Unimode 400 Operations PN 50709:A1 12/15/99 iii

Page 4

Table of Contents 5. Voice Alarm Systems

5. Voice Alarm Systems

Overview ....................................................................................................................23

Operating Features ...................................................................................................... 23

In this Section ............................................................................................................. 23

Before you Begin ........................................................................................................24

AMG-1/AMG-EAudio Message Generator .............................................................. 25

AMG-1/AMG-E Overview ................................................................................ 25

AMG-1/AMG-E Operating Features .................................................................25

Operating the AMG-1 ........................................................................................ 26

Selecting AMG Group Functions ............................................................................... 27

Selecting AMG Tones and Messages.......................................................................... 28

ATG-2 Audio Tone Generator ...................................................................................31

ATG-2 Overview ............................................................................................... 31

How to Operate the ATG-2 ................................................................................32

Selecting Tones for the ATG-2 ..........................................................................32

Selecting a Primary (Evac) Channel Tone.......................................................... 33

Selecting a Secondary (Alert) Channel Tone .....................................................33

Select Operating Mode ......................................................................................33

Fire Fighter's Telephones (FFT-7/FFT-7S) ................................................................ 34

Overview ............................................................................................................34

FFT-7 Operating Components ........................................................................... 34

How to Operate the FFT-7 ................................................................................. 34

Audio Amplifiers ........................................................................................................35

Overview ............................................................................................................35

Audio Amplifier Features .................................................................................. 35

AA-30 Audio Amplifiers ............................................................................................ 36

AA-100/AA-120 Audio Amplifiers ...........................................................................37

Adjusting the Audio Gain Level (AA-30, AA-100/AA-120) ....................................38

Selecting the AA-100/AA-120 Backup Tone ............................................................. 38

AMG Voice Message Options .................................................................................... 39

Overview ............................................................................................................39

Installation .........................................................................................................39

iv Unimode 400 Operations PN 50709:A1 12/15/99

Page 5

1. Introduction

Overview

The Unimode400 is a modular, intelligent Fire Alarm Control Panel (FACP) with an

extensive list of powerful features. The CPU module, power supply module, and

cabinet combine to create a complete fire control system for most applications.

Optional modules mount to the chassis to provide additional output circuits.

Operating Features

• Alarm Verification selection per point, with tally.

• Positive Alarm Sequence (PAS) and Presignal per NFPA 721993.

• Silence Inhibit timer and Auto Silence timer.

• March time/temporal code for Notification Appliance Circuits (NACs).

• Zone coding for NACs if using an optional ADT-UZC-256.

• Alarm Silence/System Reset/Alarm Activate functions through M500M monitor

modules.

• Automatic time-of-day and day-of-week control functions, with holiday option.

• User-defined password and key-protected nonvolatile memory.

• AWACS (Advanced Warning Addressable Combustion Sensing) with nine field-

adjustable Pre-Alarm levels with programmable Control-by-Event (CBE)

• Operate automatic smoke or heat detector sounder base on action Pre-Alarm level,

with general evacuation on alarm level.

• Security alarm point option with separate audible signal code.

• Centralized voice paging and audible alarm signaling options.

• Programmable Control-by-Event control of outputs from individual alarm or

supervisory addressable devices.

Components

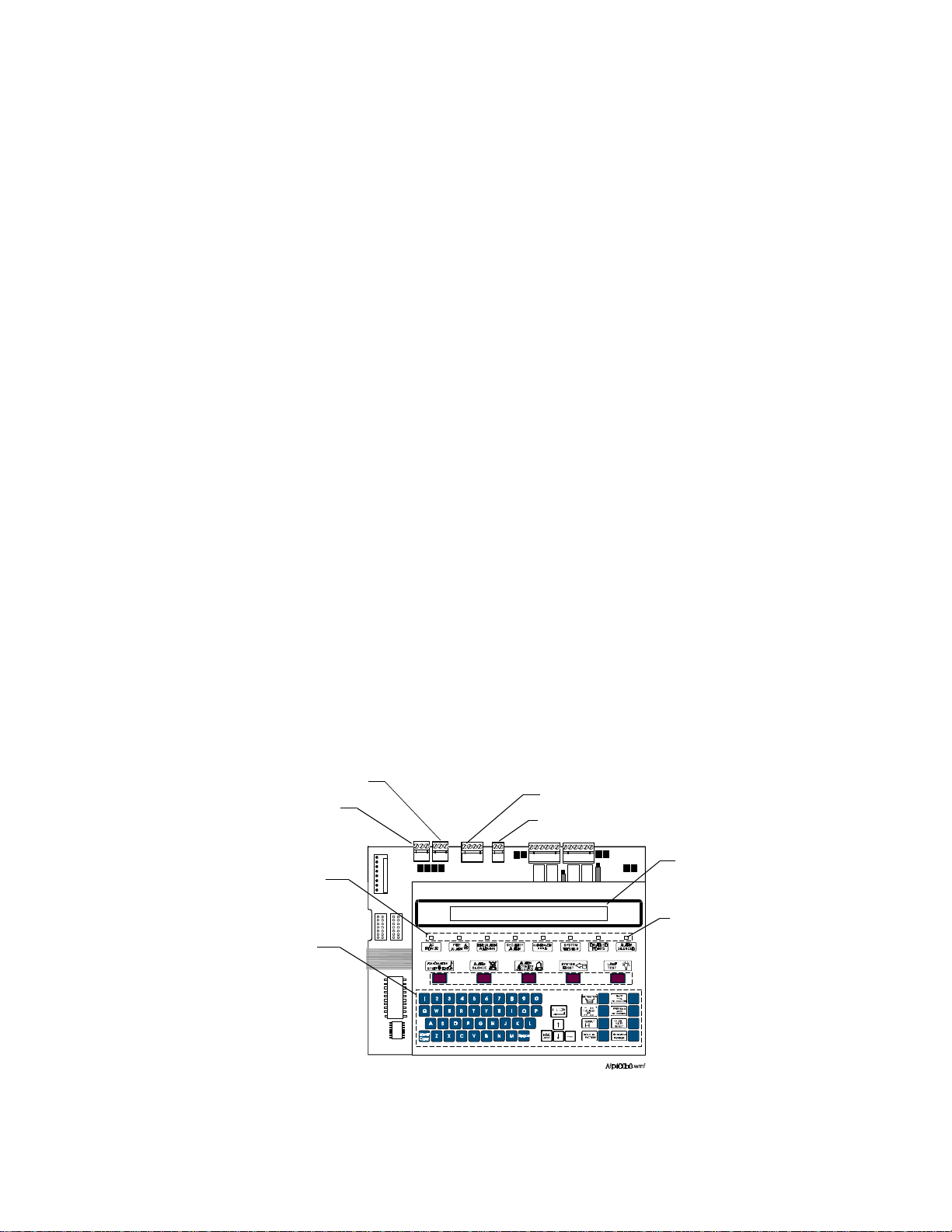

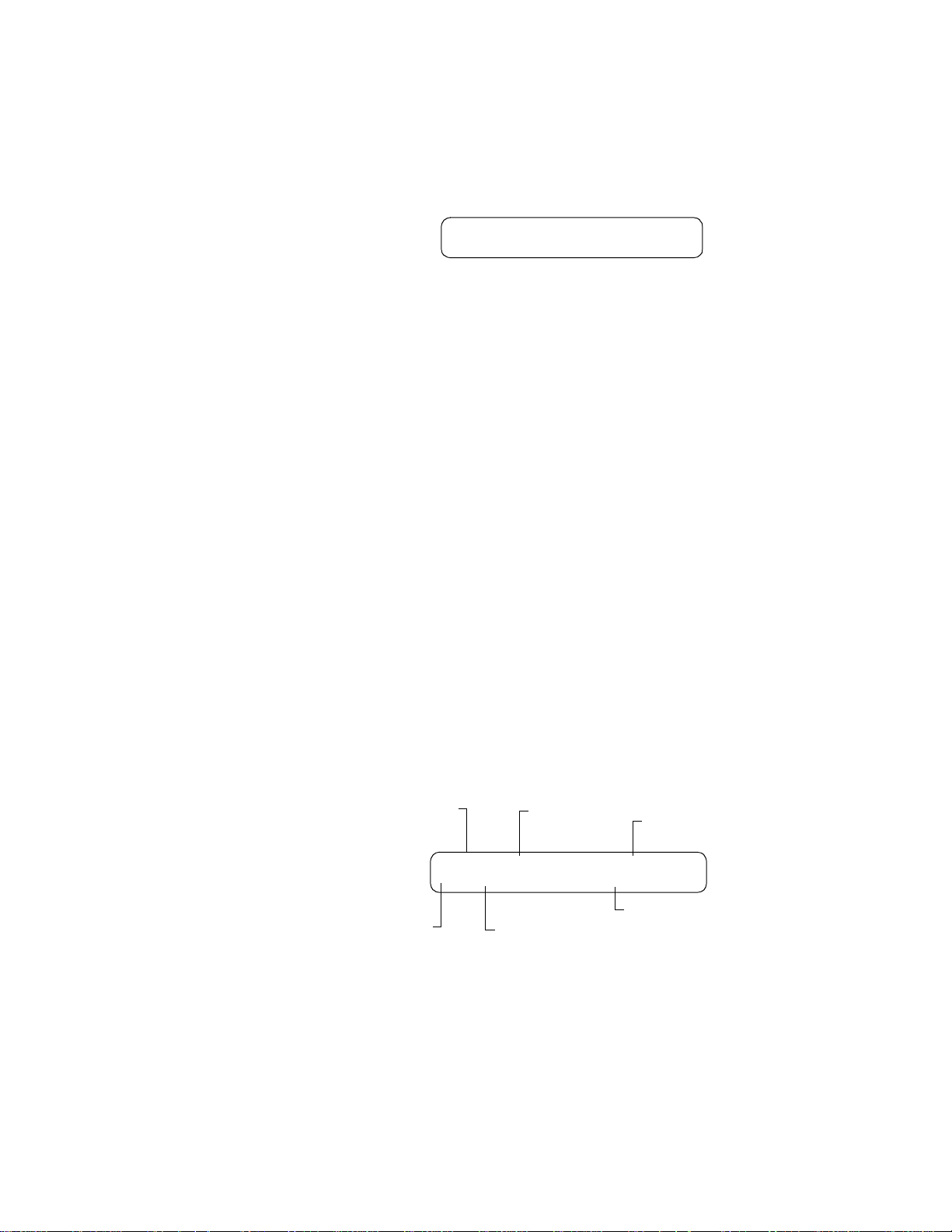

Figure 1 shows components that affect operation of the control panel:

EIA-232 PC/Terminal Port

EIA-232 Printer Port

Control

Keys

Programming

Keypad

EIA-485 Terminal Mode Port

EIA-485 ACS Port

80-character (2 x 40) Liquid

Crystal Display (LCD)

System Status

LED Indicators

Figure 1 Control Panel Components

Unimode 400 Operations PN 50709:A 10/20/97 1

Page 6

Notes

2 Unimode 400 Operations PN 50709:A 10/20/97

Page 7

2. Using the Control Panel

Overview

Table 1 lists the controls and indicators and where to find information on their use:

Controls/Indicators Covered in...

Eight System Status Indicator LEDs System Status Indicator LEDs on page 3.

Five control keys Control Keys on page 4.

A panel sounder with a piezo that

Section 3. Operating Modes on page 5.

provides unique sounds for alarm,

trouble and supervisory/security

conditions

Table 1 Control and Indicators

System Status Indicator LEDs

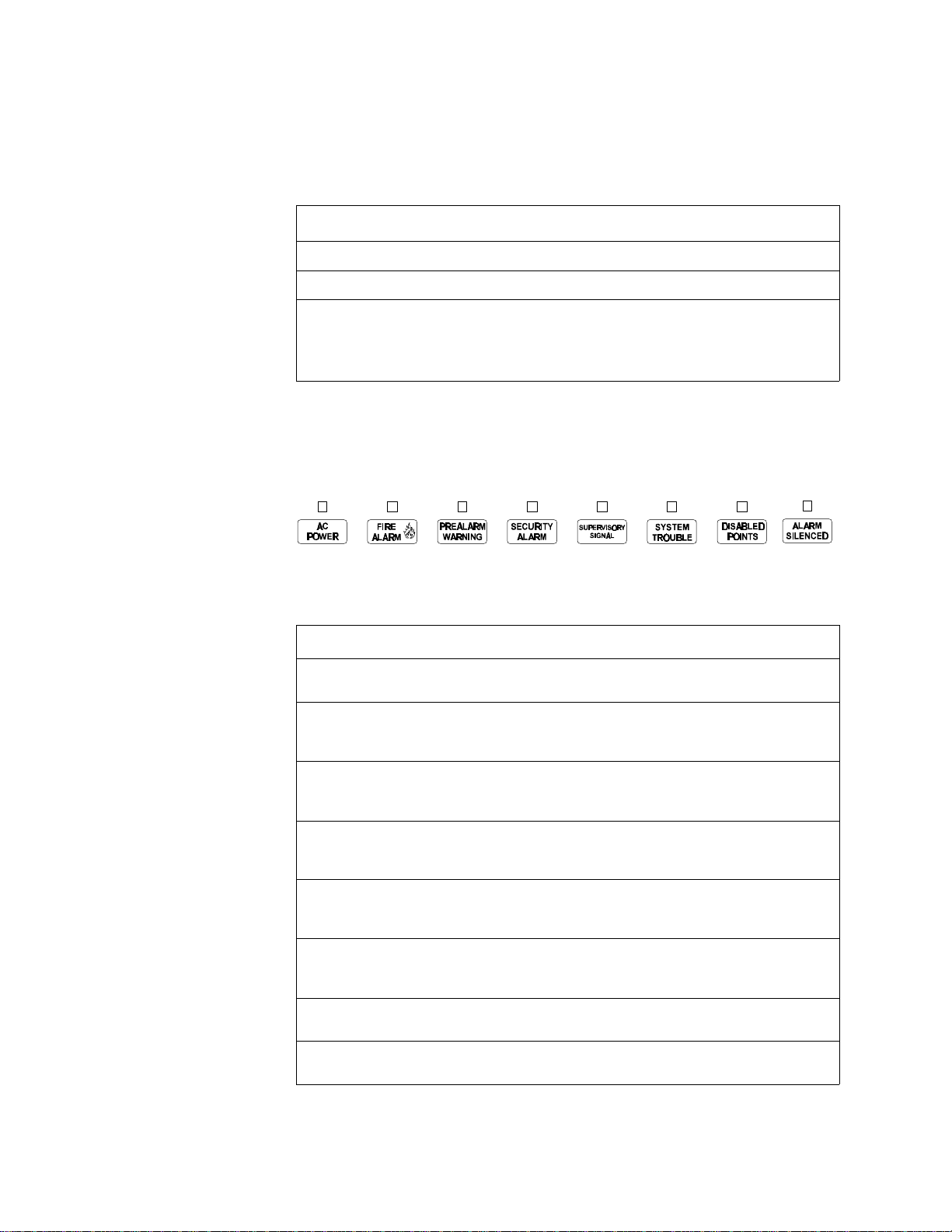

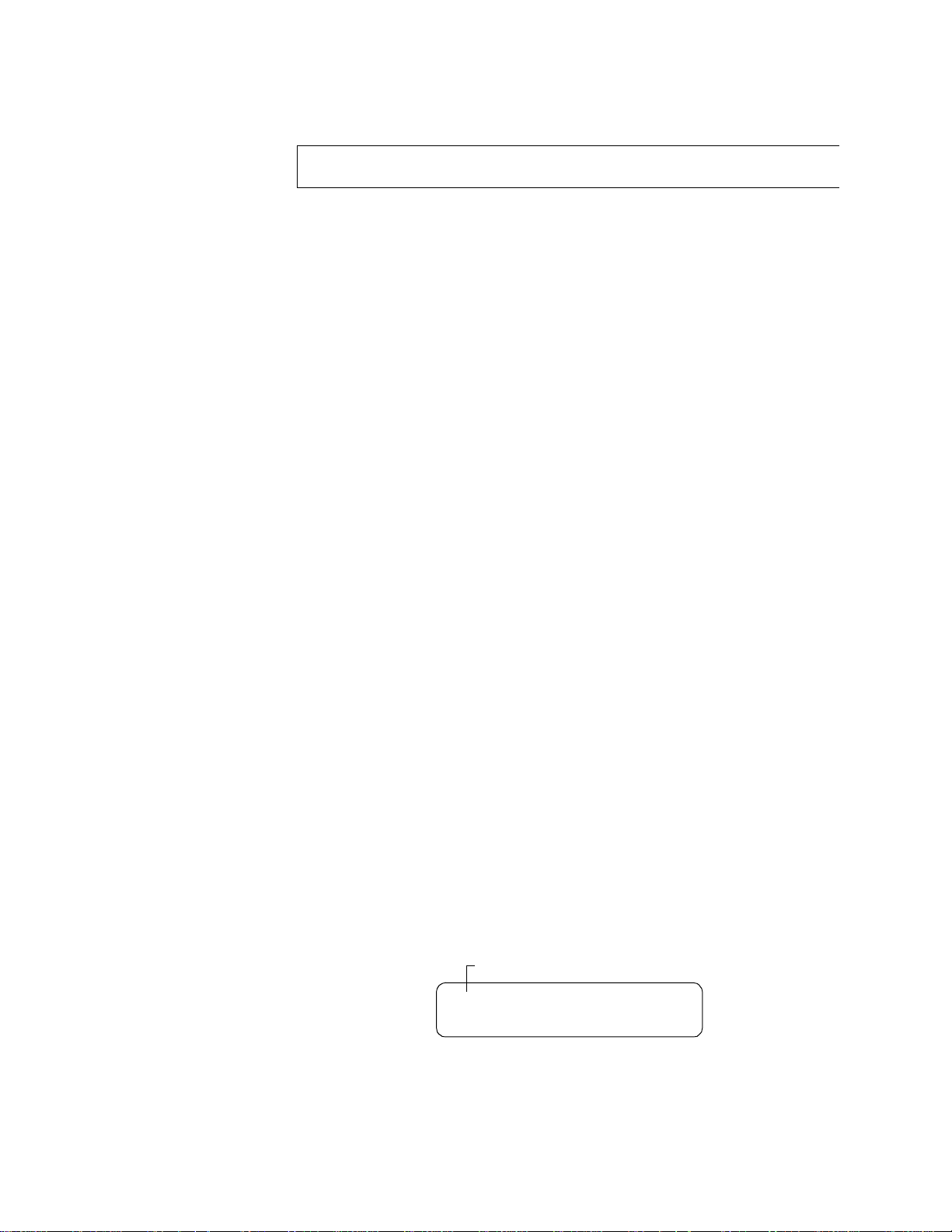

The control panel contains eight LED indicators with labels as shown in Figure 2:

Figure 2 System Status Indicator LEDs

Table 2 contains descriptions of the System Status Indicator LEDs:

Indicator Color When Active... To Turn Off...

AC Power Green Lights when the proper primary AC

power is applied.

Fire Alarm Red Flashes when a non-acknowledged Fire

Alarm exists. Lights steadily after you

acknowledge the alarm.

Turn off AC power.

Clear the alarm condition and

reset the system.

Pre-Alarm

Warning

Security

Alarm

Supervisory

Signal

System

Trouble

Disabled

Points

Alarm

Silenced

Yellow Flashes when a non-acknowledged

Pre-Alarm exists. Lights steadily after

you acknowledge the Pre-Alarm.

Blue Flashes when a non-acknowledged

Security Alarm exists. Lights steadily

after you acknowledge the alarm.

Yellow Flashes when a non-acknowledged

Supervisory Alarm exists. Lights

steadily after you acknowledge the alarm.

Yellow Flashes when a non-acknowledged

System Trouble exists. Lights steadily

after you acknowledge the trouble.

Yellow Lights when one or more system devices

are disabled.

Yellow Lights after an alarm condition occurs

and after pressing <Alarm Silence>.

Clear the alarm condition.

(Action Pre-Alarm requires a

system reset.)

Clear the Security Alarm

condition and reset the system.

Clear the signal. (Tamper

inputs require a system reset.)

Clear the trouble condition.

Enable or remove the disabled

device.

Press <Alarm Activate> or

<System Reset>.

Table 2 Descriptions of System Status Indicator LEDs

Unimode 400 Operations PN 50709:A 10/20/97 3

Page 8

2. Using the Control Panel Control Keys

Control Keys

The control panel provides five control keys, Acknowledge/Step, Alarm Silence, Alarm

Activate, System Reset, and Lamp Test.

Acknowledge Step Use the <Acknowledge/Step> key to respond to new alarm or

trouble signals. Pressing <Acknowledge/Step> causes the control panel to do the

following:

• silence the control panel sounder;

• change all indicators from flashing to steady;

• send an Acknowledge message to the history file, an optional printer, and an

optional ADT-LCD-80; and

• send a signal to silence the sounder on the ADT-LCD-80 and ACS annunciators.

You can also press the <Acknowledge/Step> key to display multiple alarms or troubles.

If more than one alarm or trouble exists, the control panel displays the next alarm or

trouble for 3 seconds (or until you press <Acknowledge/Step>), then displays the next

alarm or trouble.

Alarm Silence Use the <Alarm Silence> key to silence the control panel sounder as

well as sounders connected to Notification Appliance Circuits. Pressing <Alarm

Silence> causes the control panel to do the following:

• turn off the control panel sounder;

• turn off all silenceable output circuits;

• light the Alarm Silenced LED; and

• send an Alarm Silenced message to the history file, optional printer, and an

optional ADT-LCD-80.

Alarm Activate Use the <Alarm Activate> key to test notification appliances. Press

and hold the Alarm Activate switch for 2 seconds (to prevent accidental activation).

The control panel does the following:

• turns on all silenceable NACs;

• turns off the Alarm Silenced LED; and

• sends a Manual Evacuate message to the history file, optional printer, and an

optional ADT-LCD-80.

System Reset Use the <System Reset> key to reset the control panel. Press <System

Reset> and the control panel does the following:

• turns off all alarm-activated M500CH modules and NAC circuits;

• breaks resettable power to four-wire detectors; and

• sends an All Systems Normal message to the history file, optional printer, and an

optional ADT-LCD-80.

Any alarm or trouble that exists after a System Reset reactivates NACs, control outputs,

and panel audio and visual indicators.

Lamp Test Use the <Lamp Test> key to test the control panel LEDs and sounder.

Press and hold <Lamp Test> and the control panel does the following:

• lights all control panel LEDs;

• turns on the control panel sounder; and

• lights all segments of the LCD display.

4 Unimode 400 Operations PN 50709:A 10/20/97

Page 9

3. Operating Modes

Normal Operation

The system operates in Normal mode when no alarms or troubles exist. In Normal

mode, the control panel displays a system message as follows:

YOUR CUSTOM FORTY CHARACTER MESSAGEHERE

ALL SYSTEMS NORMAL11:30A TUE 02/11/97

Figure 3 All Systems Normal Message

In Normal mode, the control panel does the following functions at regular intervals:

• Polls all Signaling Line Circuit (SLC) devices and the four NACs to check for valid

replies, alarms, troubles, circuit integrity, and so on.

• Checks power supply troubles and batteries every 10 seconds.

• Sends a supervisory query on the ADT-LCD-80 and verifies proper response.

• Refreshes the LCD and the optional ADT-LCD-80 display and updates time.

• Scans the keypad for a System Reset or an Enter key press.

• Performs a detector automatic test operation.

• Tests system memory.

Note: M500CH modules report

both open and short circuit

messages.

Trouble Operation

The system goes into Trouble mode when the control panel detects an electrical or

mechanical fault. With no alarms, a control panel in Trouble mode does the following:

• Produces a pulsed audible tone;

• The System Trouble LED flashes;

• The trouble relay activates (MPS-400, TB5); and

• Sends a message to the LCD display, an optional ADT-LCD-80, an optional

printer, and the history file.

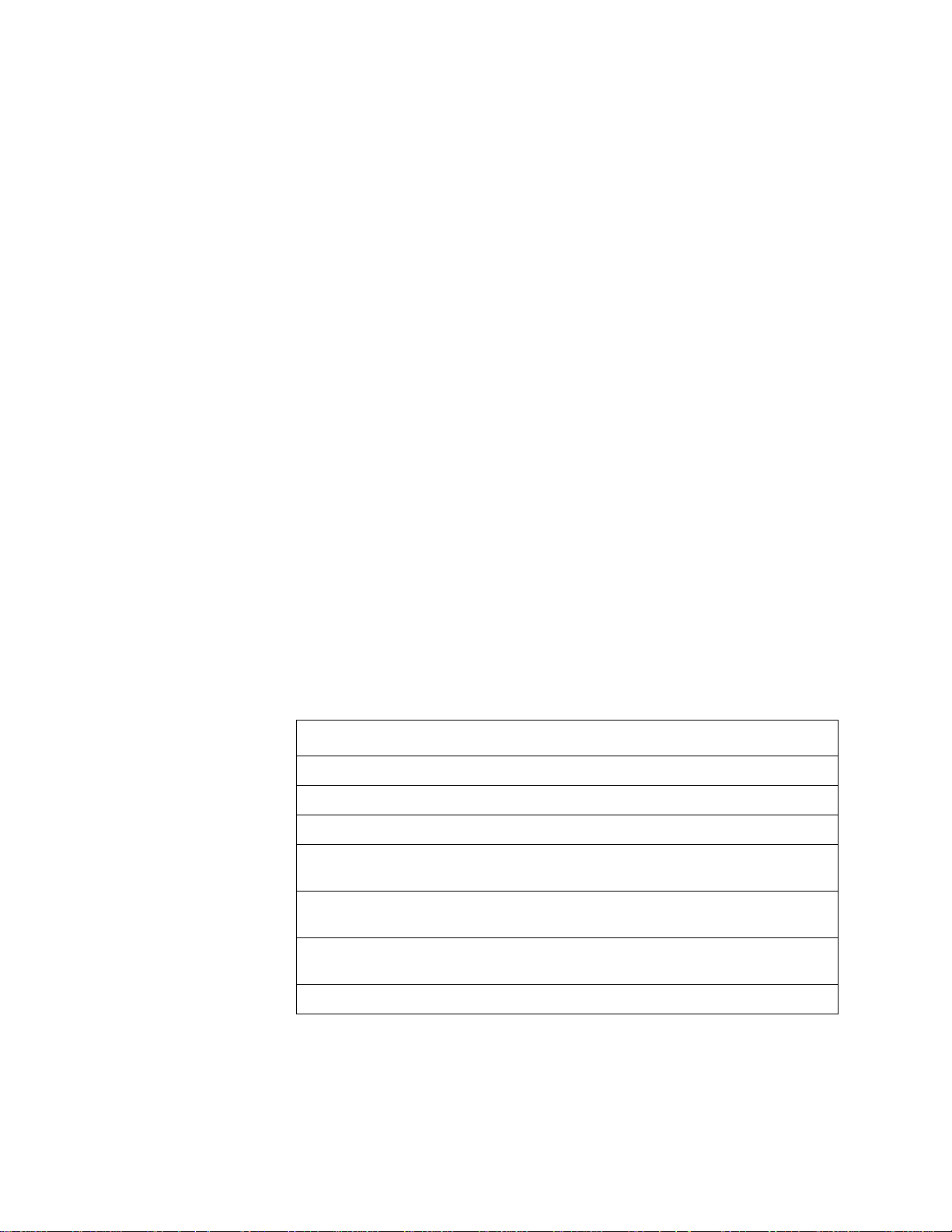

Figure 4 shows a typical Trouble message:

Type of event (trouble)

TROUBL PULL STATION I.C.U. WEST WING

Z1 INVALID REPLY 11:45PM TUE 02/11/97

Software zone

assigned (Zone 1)

Figure 4 Trouble Message

1. Press <Acknowledge/Step> to silence the panel sounder and switch the System

Trouble LED from flashing to steady—regardless of the number of troubles,

alarms, and supervisory signals.

Type of device

Custom descriptor for this

device location

Time and date

Type of trouble

2. Pressing <Acknowledge/Step> while at least one new alarm or trouble exists,

causes the control panel to send an Acknowledge message to the history file and an

optional printer.

Unimode 400 Operations PN 50709:A 10/20/97 5

Page 10

3. Operating Modes Fire Alarm

If the trouble clears (before or after pressing <Acknowledge/Step>), the control panel

sends a Clear Trouble message to the printer. Figure 5 shows a sample Trouble

Message:

TROUBL CONTROL MODULE ADDRESS 21 Z00 OPEN CIRCUIT 08:10A 08/20/95 M21

TROUBL CONTROL MODULE ADDRESS 22 Z00 OPEN CIRCUIT 08:12A 08/20/95 M22

Figure 5 Sample Trouble Message

If all troubles clear and no supervisory or fire conditions exist, the control panel does

the following:

• Returns to Normal mode;

• Sends an “All Systems Normal” message to the LCD display, the history file, an

optional ADT-LCD-80, an optional printer; and

• Restores troubles automatically even if troubles are not acknowledged.

Pressing <Alarm Silence> when only troubles exist, gives the same result as pressing

<Acknowledge/Step>. The Alarm Silenced LED does not light unless an alarm exists

in the system.

If multiple trouble conditions exist in the system, the LCD and optional ADT-LCD-80

displays automatically step through each trouble event every 3 seconds in the following

order:

1. Alarms, in order of address;

2. Supervisory, in order of address; or

3. Troubles, in order of address.

Press <Acknowledge/Step> and the display stops on the current trouble event for

1minute. Press <Acknowledge/Step> to continue.

Fire Alarm

The system goes into Fire Alarm mode when the control panel detects a fire alarm.

During Fire Alarm mode, the control panel does the following:

• Produces a steady audible tone;

• Activates the System Alarm relay (MPS-400, TB3) and flashes the System Alarm

LED;

• Displays Alarm in the status banner on the LCD display;

• Latches alarms so they cannot clear until the alarm initiating device returns to its

normal condition and the operator resets the control panel;

• Initiates any Control-by-Event actions;

• Starts timers (such as Silence Inhibit, Auto Silence); and

• Activates the general alarm zone (Z00).

Status banner ALARM

ALARM:PULL STATION I.C.U. WEST WING

VISITORS LOUNGE 11:55PM TUE 02/11/97

Figure 6 Fire Alarm Display

6 Unimode 400 Operations PN 50709:A 10/20/97

Page 11

Supervisory Signal 3. Operating Modes

Supervisory Signal

Note: You can program

Supervisory signals as Tracking

or Latching.

Supervisory signals cause the control panel to do the following:

• Produce a warbling audible tone;

• Turn on the Supervisory relay (MPS-400, TB4) and flash the Supervisory LED;

• Display “Active” in the status banner on the control panel; and

• Turn off the panel sounder for all Silenced alarms.

Status banner ACTIVE

ACTIVE TAMPER I.C.U. WEST WING

VISITORS LOUNGE 11:55PM TUE 02/11/97

Figure 7 Typical Supervisory Signal Display

Non-Alarm Point Operation

Non-Alarm points are M500M addressable modules that activate Control-by-Event.

These points do not activate the System Alarm LED or the panel sounder. Non-Alarm

points use three type codes: Non-Fire, Hazard Alert, and Fire Control.

Type Code Does this... Used for...

Non-fire

(Tracking)

Hazard Alert

(Latched)

Fire Control

(Tracking)

Activates Control-by-Event only. Energy management or other

non-fire situations.

Sends a message to the LCD display,

history file, printer, and ADT-LCD80 (status – Active), and overrides

code selection for NACs, regardless

of the zone F8 coding selection.

Sends messages to the LCD, history

file, printer and ADT-LCD-80.

Monitoring critical processes or

other hazardous situations, such

as a tornado.

Air handler shutdown, intended

to override automatic fire

functions.

Table 3 Non-Alarm Points

Trouble Monitor Point Operation

Trouble Monitor-type M500M modules monitor remote power supplies or other

external equipment. These types of M500M modules operate like troubles—but with

the following differences:

• The LCD display status banner displays “Active”;

• The type code is “Trouble Mon”;

• The modules latch—until the troubles are returned to normal condition and an

operator resets the control panel; and

• M500M modules can have Control-by-Event.

Unimode 400 Operations PN 50709:A 10/20/97 7

Page 12

3. Operating Modes Notification Appliance Circuit (NAC) Operation

Notification Appliance Circuit (NAC) Operation

The four NACs (TB7-TB10 on the MPS-400) have Control-by-Event and trouble

functions like M500CH addressable modules on the SLC loop. NAC circuits differ

from M500CH modules in the following ways:

• Addresses (last three characters in LCD field) are B01, B02, B03, or B04;

• The default type code field is “Bell Circuit”; and

• Control panel NACs, except those controlled with M500CH modules, can be used

for coded functions (March Time, California Code, Temporal, and Two-stage).

Control-By-Event Operation

Note: Zones F0-F9 are reserved

for special functions such as

cross-zoning (refer to the

Unimode400 Programming

Manual).

Control-by-event (CBE) control is done through 99 software zones. Each input point

(detector, M500M) and output point (M500CH, NAC) can be programmed to list up to

five software zones. Non-Alarm or Supervisory points do not activate software zone

Z00 (general alarm). You can list zone Z00 for output points, but you do not need to list

Z00 for input points.

Input and output devices with listed software zones work as follows:

• Inputs – When an input device (detector or M500M) activates, so do all software

zones listed to the input device.

Note: Refer to Appendix A for

more information about

releasing functions.

• Outputs – When a software zone activates, the output device turns on.

CBE Example Detector D102 lists zone Z05. B01 lists zone Z05 and zone Z07.

1. Detector D102 activates.

2. Zone Z05 activates.

3. B01 activates.

Releasing Functions

Overview Zones R0-R9 are reserved for releasing zones—providing up to ten

independent releasing operations. Each releasing zone includes the following options:

Option Description

Cross-zoning Select one of three types of cross-zoning. Refer to Table 5.

Delay Timer Select a 0–60 second delay before activating a zone.

Abort An abort switch-type code used to abort activation of a zone.

Manual Release Allows immediate zone activation by overriding the abort function,

cross-zone function, and delay timer.

Man. Rel. Delay Same as Manual Release, except releasing occurs 10 seconds after

“Man. Rel. Delay” is activated.

Soak Timer Automatically shuts off the releasing device. Select 0001-9999 seconds

for a Soak Timer or 0000 seconds for no Soak Timer.

Second Shot Reactivates release output after the Soak Timer times out.

Table 4 Cross Zoning Options

8 Unimode 400 Operations PN 50709:A 10/20/97

Page 13

Releasing Functions 3. Operating Modes

Using Cross Zoning Options Cross Zoning lets you program the control panel to

activate a releasing zone after two initiating devices are tripped. (If not using Cross

Zoning, set CROSS= to N.) Table 5 contains a summary of the types of cross zoning

and the conditions for activating a releasing zone.

Type Activates when...

Y Two or more detectors, all mapped to one of the ten releasing zones (R0-R9), are

tripped.

Z Two or more detectors, mapped to two different software zones and one of the ten

releasing zones (R0-R9), are tripped.

H At least one smoke detector and at least one heat detector, all mapped to one of the

ten releasing zones (R0-R9), are tripped.

Table 5 Cross Zoning Types

Note: Only the first non-special

zone listed in the zone map is

used to determine Cross=Z.

Cross Zoning Example Table 6 lists examples of devices mapped to releasing zones

(ZR1 stands for Releasing Zone 1).

Device Address Device Type Zone Mapping

D101 Detector Smoke ZR1 Z01

D102 Detector Smoke ZR1 Z01

D103 Detector Smoke ZR1 Z02

D104 Detector Heat ZR1 Z02

B01 Output Circuit (Rel Ckt) ZR1

Table 6 Devices Mapped to Releasing Zones

The following explanations apply to the examples listed in Table 6:

Cross=N An alarm from any detector activates the releasing circuit.

•

Cross=Y An alarm from any two detectors activates the releasing circuit.

•

Cross=Z Release requires the activation of two detectors mapped to different

•

zones: D101 and D102 cannot activate the releasing circuit because both detectors

are mapped to Z01; D101 and D103 can activate the releasing circuit because they

are mapped to different zones.

Cross=H Release requires activation of heat detector D104 and one smoke

•

detector (D101, D102, or D103).

Unimode 400 Operations PN 50709:A 10/20/97 9

Page 14

3. Operating Modes Intelligent Detector Functions

Intelligent Detector Functions

Note: For instructions on

selecting Intelligent Detector

Functions, refer to the

Unimode400 Programming

Manual.

Table 7 contains descriptions for intelligent detector functions used with the control

panel.

Function Description

Analog Display The control panel reads and displays analog information from the

198 analog detectors. The display shows the percent of the alarm

threshold for each detector.

Sensitivity Adjust Nine selections for manually setting intelligent detector alarm

levels within the UL range. If using Ionization detectors in duct

applications, set Sensitivity Adjust to Level 1.

Day/Night Sensitivity

Operation

Maintenance Alert When compensation reaches the limit of the amount of drift

Automatic Test

Operation

Type Code

Supervision

LED Control

Operation

Alarm Verification

and Counter Operation

You can program the system to automatically force smoke detectors

to minimum sensitivity during the day. Refer to “Time Control

Zones” on page 19.

compensation that can be safely applied, the control panel reports a

special trouble condition, per national fire code standards. This

condition also activates if the detector remains at very high or very

low measured air levels for an extended time.

The control panel performs an automatic test of each detector every

256 minutes. Failure to meet the test limits causes an AUTO TEST

Fail trouble.

The control panel monitors hardware device type codes (500 Series

detectors, 200 Series detectors, 3251 detectors, M500M, and

M500CH) for each installed device at regular intervals (an interval

can take up to 30 minutes for full capacity system). If a mismatch of

type compared to the program occurs, the control panel generates a

point trouble labelled Invalid Type.

A global program selection to prevent detector LEDs from blinking

during normal operation. A typical application is a sleeping area

where a blinking light can distract people. As a standard function,

the control panel allows all LEDs to turn on in alarm.

The control panel performs alarm verification on programmed

500Series, 200 Series, and 3251 intelligent smoke detectors. The

verification time is a global program selection of 0–30 seconds.

Each detector includes a verification counter, which displays the

number of times that a detector entered verification but did not

time-out to alarm. The counter increments to 99 and holds.

Table 7 Intelligent Detector Functions

10 Unimode 400 Operations PN 50709:A 10/20/97

Page 15

Pre-Alarm Operation (AWACS) 3. Operating Modes

Pre-Alarm Operation (AWACS)

Note: Refer to the

Unimode400 Programming

manual for more information on

AWACS applications.

If an 1251/2251 or 1551/2551 detector exceeds the programmed Pre-Alarm level, a PreAlarm condition occurs: the panel sounder and zone F9 activate; and the Pre-Alarm

LED lights. Figure 8 shows a sample Pre-Alarm message—sent to the LCD display,

optional ADT-LCD-80, optional printer, and history file—for a control panel

programmed for an Alert Pre-Alarm.

PREALARM SMOKE (PHOTO) I.C.U WEST WING

ALERT 105%/5 12:01A02/01/97D101

Detector programmed for a Pre-Alarm level of 5.

Shows the detector has reached 105%

of the programmed Pre-Alarm level.

The 105% is a real-time display and

tracks smoke levels.

Note: ALERT Pre-Alarms

automatically restore.

Shows the detector

programmed for ALERT

Pre-Alarm level.

Figure 8 Alert Pre-Alarm Message

If programming a control panel for an ACTION Pre-Alarm, the display remains the

same, but the word “Action” replaces “Alert”. The control panel latches for ACTION

Pre-Alarms and applies the programmed control functions.

Time Functions

Overview The control panel includes a real-time clock that provides time-of-day, date, and day-

of-week. The clock includes a lithium battery backup. Time normally displays in a

12-hour time format with month/day/year. Table 8 contains descriptions and typical

uses for time functions.

Time

Function

Time Control

Command

Description Typical Uses

Zones F5 and F6 are reserved for

control-by-time special functions,

intended for ancillary (non-fire)

applications (such as lighting

control, setting a thermostat, and so

forth).

For example, program zones F5

and F6 to activate at one time of

day and deactivate at another time,

on certain days of the week. You

can turn a non-fire control point on

and off, by using zone F5 or F6.

Day/Night

Sensitivity

Adjust

Holiday The control panel reserves zone F7

If a 1551/2551, 1251/2251, or 3251

detector CBE lists zone F5 or F6,

the control panel sets the detector

sensitivity to the minimum (low)

setting when zone F5 or F6 is

activated by the programmed date/

time in its CBE. When zone F5 or

F6 deactivates, the detector

sensitivity returns to the

programmed setting.

for setting holiday dates (up to 9

days). When the current date

matches any of the nine holiday

dates, the control panel activates

zone F7.

For day/night sensitivity use,

consider zones F5 and F6 as Day

zones.

Other uses for zone F7 include: a

special day-of-year control; or an

8th day in programming zones F5

and F6.

Table 8 Control Time Functions

Unimode 400 Operations PN 50709:A 10/20/97 11

Page 16

3. Operating Modes Time Functions

Operating Coding

Functions

Zone F8—reserved for NAC coding functions—is only used by panel NAC circuits

listing zone F8. You can select one of the four code types listed in Table 9:

Code Signal

March Time (default) 120 PPM (Pulses Per Minute)

Two-Stage Alert signal – 20 PPM; General alarm signal: Steady on

California 10 sec. on, 5 sec. off, repeats

Temporal 0.5 on, 0.5 off, 0.5 on, 0.5 off, 0.5 on, 1.5 off, repeats

Table 9 Zone F8 Type Codes

Notes on using coding functions:

M500CH modules Zone F8 does not work if listed in the CBE of M500CH modules.

Two-Stage When an alarm occurs, an NAC programmed for two-stage, and not

activated by another zone, pulses at 20 PPM. After 5minutes, the NAC changes to

steady on unless you press <Acknowledge/Step>. Pressing <Alarm Activate> on the

control panel changes the NAC pulse to steady. ICM-4/ICE-4 modules do not support

Two-Stage and turn on steady.

ICM-4/ICE-4 modules To enable California Code, cut D35 on the ICM-4 modules. If

D35 is not cut, ICM-4/ICE-4 modules turn on steady.

Presignal/Positive Alarm

Sequence (PAS)

Operation

Zone F0 is reserved for Presignal functions. Zone F0 can be used to delay control points

until an operator verifies an active control point. If including zone F0 in an M500CH or

NAC CBE list, zone F0 overrides all other CBE actions. Detectors and monitor modules

must list zone F0 in the CBE to be included in the Presignal/PAS operation.

If... And/or... Zone F0

an alarm occurs and there is no PAS inhibit type M500M activates

a second alarm activates or you press the alarm activate key, goes false

you select PAS and you do not press ACKNOWLEDGE

within 15seconds

goes false

Table 10 Presignal Operation

At the first alarm, a programmable 0–180 second timer starts. If a Signal Silence

occurs, the timer stops. If the delay timer expires, manual activation will activate

outputs mapped to zone F0. The System Alarm relay, the 4XTM Polarity Reversal

Alarm Output, and the 4XTM Municipal Box Output delay if PAS is selected, but do

not delay for Presignal operations

12 Unimode 400 Operations PN 50709:A 10/20/97

Page 17

Time Functions 3. Operating Modes

Special System Timers The control panel can operate with special system timers: Silence Inhibit, Auto Silence,

and Alarm Verification. Table 11 contains descriptions of how each timer works.

Timer Duration If selected...

Silence Inhibit 0-300 seconds Starts at first alarm and restarts with each new

alarm. Disables the Alarm Silence switch.

Waterflow Circuits

Operation

Disable/Enable

Operation

Auto Silence 600-900

seconds(0=no timer

selected)

Alarm

Verification

0-30 seconds The control panel ignores 1551/2551, 1251/

Automatically shuts off outputs selected as

silenceable after the programmed time elapses.

To restart the timer, press <Alarm Activate>.

2251, or 3251 smoke detectors for the Alarm

Verification time. If another point alarm occurs

during the Alarm Verification time, the control

panel dumps the timer and activates the alarm. If

a time-out and an alarm exist, the initiating

device CBE executes all standard functions. If at

time-out an alarm no longer exists in the alarm

initiating devices, the control panel increments a

verification counter (1-99) for the device and

returns to normal operation.

Table 11 Special System Timers

If an alarm originates from a monitor point with a waterflow type code, the control

panel disables the Alarm Silence switch. Refer to the Unimode400 Installation Manual

for information on Waterflow Circuits.

Disabled input points do not cause an alarm or any Control-by-Event activity. The

control panel does the following:

• holds all disabled output points in the off-state; and

• handles all disabled points as troubles, but displays DISABL in the status banner.

Caution: Disabling a zone disables all input and output devices associated with the

!

zone.

Style 6 Operation The control panel will detect a trouble in an SLC wired and programmed for Style 6 or

Style 7 and drive both ends of the line to maintain communication over the loop. The

trouble latches and displays on the panel as a Style 6 trouble type until you press

<System Reset>. Style 7 requires use of M500X modules.

Unimode 400 Operations PN 50709:A 10/20/97 13

Page 18

Notes

14 Unimode 400 Operations PN 50709:A 10/20/97

Page 19

Note: Refer to the

Unimode400 Programming

Manual for information on

Alarm and Pre-Alarm sensitivity.

Note: If attempting to read a

point that is not installed, the

control panel displays NOT

INSTALLED.

4. Read Status

Overview

Read Status functions do not require a password. The control panel will continue to

provide fire protection while in Read Status. You can enter Read Status while in Fire

Alarm or Trouble mode. If a new alarm or trouble occurs during these functions, the

control panel automatically exits Read Status.

How to Enter Read Status

Press <Enter>. The control panel displays the following screen:

1=PROGRAMMING 2=READ STATUS ENTRY

(ESCAPE TO ABORT)

Figure 9 Programming Entry Screen

From the Programming Entry Screen, press <2>. The control panel displays the

following screen:

READ POINT=0 HIST=2 ALARM HIST=4 <ENTER>

PRNT POINT=1 HIST=3 ALARM HIST=5 <ENTER>

Figure 10 Read Status Screen

Read Status Options

To do a Read Status, follow the instructions in Table 12:

To... Do this...

Read Point

Print Points

Read History

Print History

Read Alarm History

Print Alarm History

1. Press

2. Press H J I or z

3. Enter the device or zone address.

Press

Press

Press

Press

Press

0 C

1 C

2 C

3 C

4 C

5 C

Table 12 Read Status Options

During all Read Status operations (except print operations) the control panel starts a

2-minute timer each time you press a key. If the control panel does not detect a key

press for 2 minutes, the panel leaves the current operation and returns to the previous

display.

• Press <Esc> to delete the previous entry.

• Press <System Reset> to abort Read Status.

Unimode 400 Operations PN 50709:A 10/20/97 15

Page 20

4. Read Status Read Status Options

Read Status for Points

and Zones

Read Status for a

Detector, Module, or

Output

Read Point options let you display point and zone status on the display, but the

information is not sent to the serial ports or the history file. To read the status of points

and zones, press <0> then <Enter> from the Read Status screen. The control panel

displays the Read Point screen (Figure 11):

ZONE=Z,AA,E DETECTORS=*,AAA,E

MODULE=#,AAA,E OUTPUT CKT=&,A-A,E

Figure 11 Read Point Screen

• To read a detector, press H then enter the detector address.

• To read a module, press

• To read an output circuit, press

I then enter the module address.

J then enter the output circuit address.

From the Read Status screen, press 0; then press <Enter>. You can then read the status

of a detector, module, or output. For example, to read the status of a detector at D101,

H, enter the address (D101), then press <Enter>. The control panel displays

press

information about the detector as shown in Figure 12:

Custom Label for the detector

Address (01-99)

SLC loop number

D (Detector) or M (Module

or Output

Default Zone

Selection

Type Code

NORMAL SMOKE (PHOTO) DETECTOR ADDR 101

Z03 Z Z Z Z 000%AL:5PA:0 *V D101

Alarm Sensitivity Level

Pre-Alarm Sensitivity Level

Alarm Verification selection

Multidetector selection

Figure 12 Detector Read Status Sample Screen

16 Unimode 400 Operations PN 50709:A 10/20/97

Page 21

Read Status Options 4. Read Status

Table 13 contains descriptions of the fields shown in Figure 12:

Field Description

SMOKE (PHOTO) Type code of the detector.

DETECTOR ADDR 101 Default custom label: 101 (1=loop 1; 01=address 01).

Z03 Default zone selection:

Zone 01 (Heat detectors)

Zone 02 (Ion detectors)

Zone 03 (Photo detectors)

Zone 05 (Multi detectors)

You can change zones as well as add four more zones for each

detector’s CBE.

AL:5 The Alarm sensitivity level, with 9 the least sensitive Alarm

level and 1 the most sensitive Alarm level.

PA:0 Shows the Pre-Alarm level setting—a number between 0 and

9—as follows:

0 – no Pre-Alarm.

1 – most sensitive Pre-Alarm level.

9 – least sensitive Pre-Alarm level.

Note: Press L to read a point

or zone with next highest

address; or press M to read a

point or zone with next lowest

address.

*V * The asterisk (*) indicates the cooperative multidetector mode:

A combines the detector's alarm decision with the next address

above.

B combines the detector's alarm decision with the next address

below.

C combines the detector's alarm decision with the next address

above and the next address below.

V – indicates Alarm Verification (V=on, *=off).

Table 13 Default Read Status Values for a Detector

Read Status for a Zone Address

From the Read Point screen, press z, then enter the zone address (01-99) Figure 13

shows the default Read Status display for a zone:

Zone status (ON or OFF)

OFF SOFTWARE ZONE FLOOR 5 MAIN BLDG

Z04

Zone number

Figure 13 Read Status Display for a Zone Address

Unimode 400 Operations PN 50709:A 10/20/97 17

Page 22

4. Read Status Read Status Options

Read History The control panel maintains a history file of the last 800 events, each with a time and

date stamp. History events include the following:

• All alarms, troubles and operator actions, such as: Acknowledge, Reset, Signal

Silence, Alarm Activate, and Walk Test.

• Programming entries, along with a number (0-9) indicating the programming

submenu (for example, 0=Clear).

The control panel contains two event buffers: a History buffer that can store up to 800

events (all types); and an Alarm buffer that can store up to 200 alarm events.

View Event History From the Read Status screen, press <2>; then, press <Enter> to

display the Event History screen. Figure 14 shows a sample Event History screen:

EVENT HISTORY START

EVENTS IN HISTORY : 800

The number of events in the

History buffer

Figure 14 Event History Screen

View Alarm History From the Read Status screen, press <4>; then, press <Enter> to display the Event

History screen. Figure 15 shows a sample Event History screen:

ALARM HISTORY START (ESCAPE TO ABORT)

ALARMS IN HIST : 200

The number of events in the

Alarm buffer

View or Print Hidden

History

Figure 15 Alarm History Screen

If you clear History, events remain in a shadow file—known as a Hidden History file.

To display or print a Hidden History file, follow the instructions in Table 14. To clear

the history file, refer to the instructions in the Unimode400 Programming Manual.

To... Press...

Read Hidden Alarm history

Print Hidden Alarm history

Read Hidden Normal history

Print Hidden Normal history

6 C

7 C

8 C

9 C

Table 14 Hidden History Selections

Viewing and printing Hidden History is similar to Read Point. Once you read a Hidden

History, you can do the following:

• Press

• Press

L to view the next event in sequence; or

M to view the previous event in sequence.

18 Unimode 400 Operations PN 50709:A 10/20/97

Page 23

Read Status Options 4. Read Status

Presignal Delay Figure 16 shows a typical format for displaying software zone F0 (Presignal Delay):

OFFPRESIGNALFUNCT PRESIGNAL DELAY

DELAY=180 PAS=NO F00

Figure 16 Presignal Delay Screen

• DELAY=180 shows the programmed Presignal delay of 180 seconds.

• PAS=Yes shows that Positive Alarm Sequence (PAS) operation is selected in the

program; PAS=No shows that PAS operation is not selected in the program.

Releasing Zones Figure 17 shows the typical format for displaying Releasing Zones R0-R9:

OFF SOFTWARE ZONE RELEASE CONTROL

DELAY=30 ABORT=ULI CROSS=Y SOAK=000 R0

Figure 17 Releasing Zone Screen

Note: Refer to the

Unimode400 Programming

Manual for information on

Releasing Zones and the Soak

Timer.

• DELAY=30 shows the programmed delay time, in seconds.

• ABORT=ULI shows the abort function (ULI, IRI, NYC, or AHJ, if an abort switch

is mapped to this zone.

• CROSS=Y indicates that cross zoning is used (requires two or more detectors

programmed to this zone in alarm to activate the zone).

• SOAK specifies the Soak Timer (automatic shut off of device) value

(0000-9999seconds; 0000 = no Soak Timer).

Time Control Zones Figure 18 shows the typical format for displaying time control zones F5 and F6:

OFF TIME FUNCTION TIME CONTROL

ON=07:00 OFF=18:00 DAYS=MTWTF H FO5

Indicates zone F5

Holiday schedule defined

by zone F7

Note: Refer to the

Unimode400 Programming

Manual for information on

detector sensitivity settings.

The ON time for devices

programmed for zone F5

The OFF time for devices

programmed for zone F5

Figure 18 Time Control Screen

The Time Control screen provides the following information:

ON=7:00 OFF=18:00 shows the programmed times—in 24-hour (military)

•

format—when zone F5 automatically turns on and off each day.

DAYS= MTWTF H shows the programmed days-of-week when the On/Off times

•

are effective. H is a holiday schedule defined by the program for zone F7.

You can also select zone F5 or F6 for detector day/night sensitivity. For example, you

can do the following:

1. List zone F5 in the CBE of an initiating device, such as a smoke detector.

2. Set the On time for F5 to 07:00 and the Off time for F5 to 19:00.

3. When zone F5 is active at 07:00, the control panel forces the detector sensitivity of

any initiating device listed for zone F5 to the least sensitive setting. When zone F5

goes off at 19:00, the detector sensitivity returns to it’s original setting.

Unimode 400 Operations PN 50709:A 10/20/97 19

Page 24

4. Read Status Read Status Options

Holiday Zones Figure 19 shows the typical format for displaying software zone F7 (Holiday zone):

A Day/Month program selection for “Holiday”

days of the month.

OFF HOLIDAY FUNCT 01/01 03/38 05/26

06/03 07/04 09/04 11/23 11/24 12/25

Figure 19 Holiday Zone Screen

NAC Coding Zone Figure 20 shows the typical format for displaying NAC coding using software zone F8:

OFF CODING FUNCTION CODE TYPE

MARCH TIME F08

Indicates the NAC coding selection

Refer to “Operating Coding

Functions” on page 12.

Indicates NAC coding zone F8

Figure 20 NAC Coding Zone Screen

The NAC coding selection indicates the type of coding applied to each of the four panel

Notification Appliance Circuits that list zone F8 in their CBE. Zone F8 does not affect

addressable control modules. NAC coding selections include the following:

• March Time (default) – 120 PPM (Pulses Per Minute)

• Alert signal – 20 PPM; General alarm signal: Steady on

• California – 10 sec. on, 5 sec. off, repeats

• Temporal – 0.5 on, 0.5 off, 0.5 on, 0.5 off, 0.5 on, 1.5 off, repeats

Pre-Alarm Zone Figure 21 shows the typical format for displaying software zone F9 (Pre-Alarm):

OFF PRE-ALARM FUNCT ALERT

F09

Figure 21 Pre-Alarm Zone Screen

Note: Refer to the

Unimode400 Programming

Manual for more information on

Pre-Alarm settings.

You can list zone F9 in the CBE of any control point. The Pre-Alarm zone turns on if

any detector reaches a Pre-Alarm threshold. Zone F9 indicates the beginning of an

alarm, or when the detector needs maintenance.

20 Unimode 400 Operations PN 50709:A 10/20/97

Page 25

Read Status Options 4. Read Status

System Parameters To read System Parameters, follow these steps.

1. Select Read Point from the Read Status screen to display the Read Point screen

(Figure 11):

2. Press <Z>, <S0>, <Enter> to display the System Parameters screen, which

typically displays as shown in Figure 22:

SIL INH=060 AUTO=600 VERIFY=30 USA TIME

TERM SUPERV=NO LocT BLINK=Y ST=4 ACS=N

Figure 22 System Parameters Screen 0

Table 15 contains descriptions of the items shown on System Parameter Screen (Figure

22):

Parameter Description Set to...

SIL INH=060 Silence Inhibit timer in

seconds. Required in

Canada and some areas of

the USA.

AUTO=600 Automatic Silence timer in

seconds.

VERIFY=30 Alarm Verification timer 0 – no timer; or the timer duration

USA TIME Time/date display format USA TIME or EUR TIME

TERM_SUPERV=YES Terminal supervision YES – To supervise the wiring of

LocT One of three operating

modes of a PC or terminal

connected to the control

panel (through TB2 PC/

Terminal). For a complete

list of functions, refer to the

Unimode400 Installation

Manual.

BLINK=Y Blink LEDs on intelligent

devices during polling (for

certain applications).

0 – no timer; or the timer duration

in seconds.

0 – no timer; or the timer duration

in seconds.

in seconds.

a terminal mode ADT-LCD-80.

NO – No Terminal mode and no

ADT-LCD-80 supervision.

LocT – terminal connected to

control panel and located in the

same room as the control panel.

LocM – terminal connected to

control panel but requires

password for operation.

RemT – terminal connected

through a modem for Read Status

operations only.

Y – blink LED; or

N – do not blink LED.

ST=4 NFPA wiring style operation

for the SLC loop

ACS=N Use ACS Selection Groups

(refer to the Unimode400

Installation Manual for

details).

4 – Style 4 SLC loop; or

6 – both Style 6 and Style 7 SLC

loop.

N – No annunciator selected; or

Y – Select and display ACS

Selection Groups.

Table 15 System Parameters

Unimode 400 Operations PN 50709:A 10/20/97 21

Page 26

4. Read Status Read Status Options

Annunciator Display

Selections

Note: Refer to Appendix A,

Annunciators in the

Unimode400 Installation

Manual for detailed instructions

on using an AMG-1 in ACS

mode. For programming

instructions, refer to the

Unimode400 Programming

Manual.

Press <Z>, <S1>, <Enter> to display Annunciator Selection 1 Screen which typically

displays as shown in Figure 23:

A=Address

ANNUN SELECTION1: A1=* A2=* A3=* A4=*

A5=* A6=* A7=* A8=* A9=* A10=* UDACT=N

Figure 23 Annunciator Selection 1 Screen

If UDACT=N, the control panel displays the Annunciator Selection 2 Screen, addresses

A11–A19, as shown in Figure 24:

ANNUN SELECTION2: A11=* A12=* A13=*

A14=* A15=* A16=* A17=* A18=* A19=*

Figure 24 Annunciator Selection 2 Screen

Use the Annunciator Selection screen to select information that will display on the ACS

annunciators. Table 16 contains the ACS display selections.

ACS Selection

Group

1 CPU status and zones 1-56

2 Zones 57 to 99, NAC circuits 1-4 and 16 special zones

Annunciator Display

Example of Annunciator

Display Selections

3 Intelligent modules 101 to 164

4 Intelligent modules 201 to 264

5 Intelligent modules 165 to 196 and 265 to 296

6 Detectors 101 to 164 on SLC 1

7 Detectors 201 to 264 on SLC 2

8 Detectors 165 to 196 and 265 to 296

9 NAC/panel output circuit modules (64 points)

* or 0 Annunciator not installed at address

Table 16 ACS Selection Groups

Figure 25 shows an example of ACS selections in Annunciator Selection Screen 1:

ANNUN SELECTION1: A1=6 A2=3 A3=9 A4=*

A5=* A6=* A7=* A8=* A9=* A10=* UDACT=Y

Figure 25 Annunciator Selection Screen 1 Example

Figure 25 shows annunciator selections for addresses A1-A3 (addresses A4-A10 are

not selected).

• Annunciators set to Address 1 display the status of detectors 1-64 on SLC 1 (ACS

Selection Group 6);

• Annunciators set to Address 2 display the status intelligent modules 101-164 (ACS

Selection Group 3); and

• Annunciators set to Address 3 display the status of the panel modules (ACS

Selection Group 9).

22 Unimode 400 Operations PN 50709:A 10/20/97

Page 27

5. Voice Alarm Systems

Overview

The Voice Alarm System (VAS) provides a voice evacuation subsystem for the

Unimode400 Fire Alarm Control Panel. Operating features include automatic

evacuation messages, local and fire fighter control of paging, and two-way

communications in an emergency situation. A paging microphone, a master telephone

handset and control unit, coupled with a fully electronic emergency message recorder,

ACS annunciator for speaker and fire phone control, and easy-to-use operator controls

provide the Unimode400 with a state-of-the-art emergency communications

subsystem.

Operating Features

All field circuits—speaker circuits or telephone circuits—are fully supervised and

power limited by the control panel. The Fire Fighters Command Center is fully field

programmable, and does not require special tools or equipment. Operating features

include the following:

• Prerecorded evacuation message

• Page-by-phone from anywhere in a building

• Dual channel option

• Style Y or Z speaker circuit operation

• Audio Amplifiers with switch-mode power supplies

• All Call voice paging switch

• Field configurable and programmable modules

In this Section

This section contains operating instructions for using audio features through the control

panel and covers the following topics:

Topic Refer to page...

Automatic Message Generators (AMG-1, AMG-E) 25

Automatic Tone Generators (ATG-2) 31

Fire Fighter's Telephone (FFT-7, FFT-7S) 34

Audio Amplifiers (AA-30, AA-100, and AA-120) 35

Voice Message Options 39

Table 17 Voice Alarm System Topics

Unimode 400 Operations PN 50709:A 10/20/97 23

Page 28

5. Voice Alarm Systems Before you Begin

Before you Begin

Before operating the VAS, make sure the system is fully installed according to the

instructions in the Unimode400 Installation manual. For more information about audio

system components, configurations, connections, and programming, refer to the

following manuals:

For information on the following... Refer to...

Installing Voice Alarm System

Unimode400 Installation Manual

components, including speaker/

telephone circuits, amplifiers, and

modules.

Programming speaker and

Unimode400 Programming Manual

telephone circuits

VROM (Voice ROM) Series Messages Document 15945

Table 18 Additional Sources of Information

24 Unimode 400 Operations PN 50709:A 10/20/97

Page 29

AMG-1/AMG-EAudio Message Generator 5. Voice Alarm Systems

AMG-1/AMG-EAudio Message Generator

AMG-1/AMG-E

Overview

AMG-1/AMG-E

Operating Features

An AMG-1/AMG-E produces tones and messages. You can set up an AMG to

automatically activate programmed tones or messages through an EIA-485

communications circuit loop or manually select tones and messages. Operating the

AMG involves viewing the LEDs for status information and operating the microphone

and switches.

Each AMG-1 contains one output channel. To set up a secondary channel for dual

channel operation, install an additional AMG-1 or AMG-E. Each AMG can directly

drive up to fifty audio amplifiers.

An AMG can store and use up to four digitally-recorded voice messages. Each voice

message can be up to 24 seconds long. Table 19 contains details of the two types of

digital messages available:

Type of Message Hardware Requirements How to Create

Factory VROM memory chips Pre-recorded, factory-supplied.

Field Programmable VRAM-1 memory chips Record directly into the AMG via

the built-in microphone; or record

on a standard audio cassette

recorder and load into the AMG.

Table 19 Types of AMG-1/AMG-E Messages

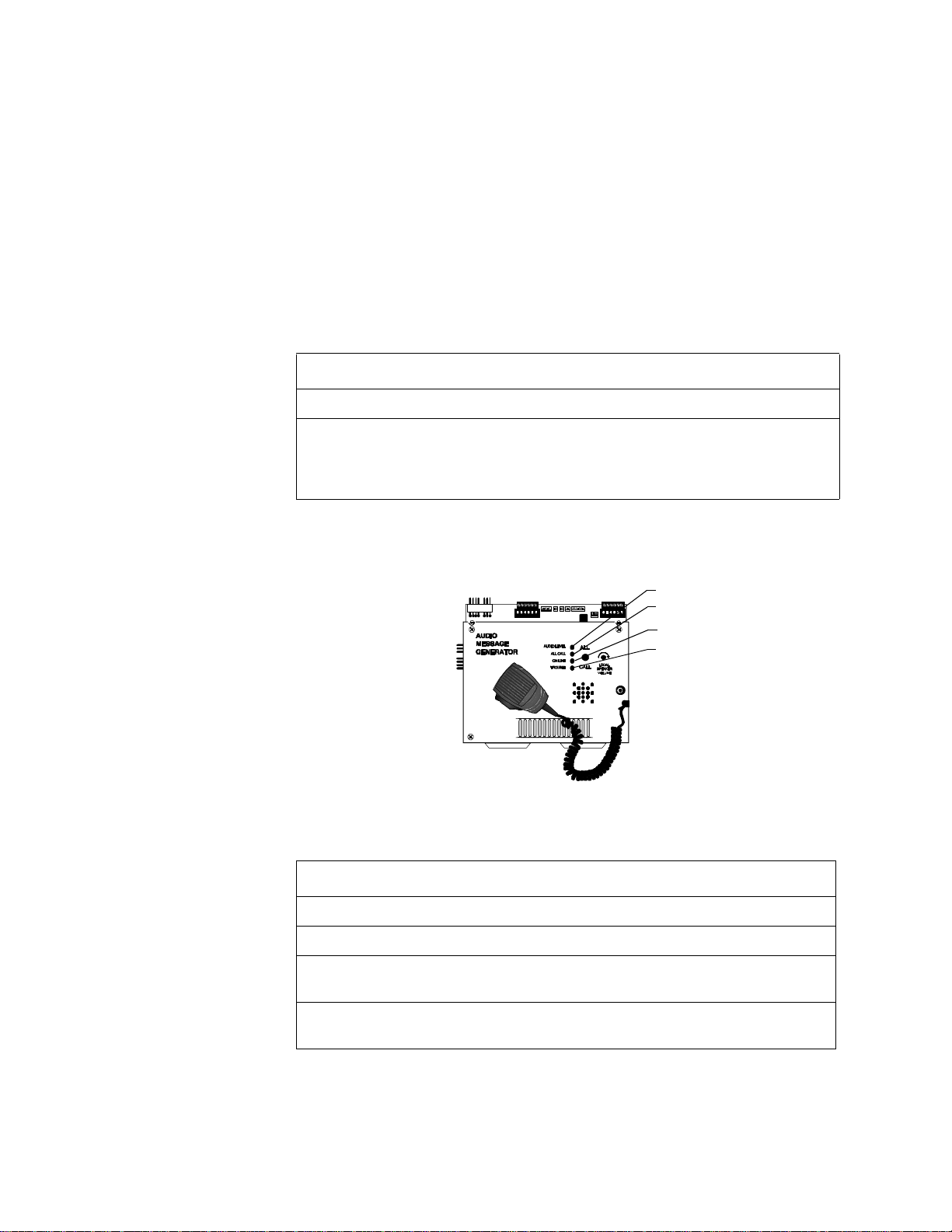

Figure 26 shows the AMG-1 System Status Indicator LEDs:

Audio Level

All Call

On Line

Trouble

Figure 26 AMG-1 LEDs

Table 20 lists descriptions of the AMG-1 LEDs:

LED Lights...

AUDIO LEVEL When the audio level is correct.

ALL CALL Toggles on or off each time you press the All Call switch.

ON LINE To show communication between the control panel and the AMG-1

over the EIA-485 communications circuit.

TROUBLE To show a trouble signal in local audio subsystem equipment (AMG-1,

AA-30/AA-100/AA-120, FFT-7/FFT-7S).

Table 20 Description of AMG-1 LEDs

Unimode 400 Operations PN 50709:A 10/20/97 25

Page 30

5. Voice Alarm Systems AMG-1/AMG-EAudio Message Generator

Operating the AMG-1 Figure 27 shows the AMG-1 operating controls:

All Call Switch

Local Speaker

Volume Control

Microphone switch

J1 – tape recorder

input

Figure 27 AMG-1 Operating Components

Table 21 contains instructions for operating the AMG-1.

To Do this... Comments

Turn on speakers Toggle the ALL CALL switch

until the ALL CALL LED goes

on.

Turn off speakers Toggle the ALL CALL switch

until the ALL CALL LED goes

off.

Adjust the volume

of the AMG-1

Turn the Local Speaker Volume

Control knob.

speaker

Page through the

system

1. Press the ALL CALL

switch.

2. Press the switch on the

side of microphone.

3. Speak into the

microphone.

Select the speaker

circuit for paging

Select the control switches on

the respective VCM-4 module

connected to the AMG-1.

Table 21 AMG-1 Operating Instructions

The ALL CALL switch activates all

speaker circuits (that are not switch

inhibited) or a specific programmed

group of speakers. For dual-channel

applications, press either ALL

CALL switch.

If an alarm exists, speaker circuits

remain on until you turn them off or

reset the system.

If necessary, turn the volume down

to prevent feedback during paging.

Talk loudly enough to cause the

green Audio Level LED to light.If

the AUDIO LEVEL LED remains

off for 15 seconds, a system trouble

can result.

Refer to the Unimode400

Installation and Programming

Manuals for instructions.

26 Unimode 400 Operations PN 50709:A 10/20/97

Page 31

Selecting AMG Group Functions 5. Voice Alarm Systems

Selecting AMG Group Functions

Selecting Factory-Programmed Messages (VROM) Operation of tones and

messages available in a voice alarm application depends on the following:

• The type and number of VROM chips installed; and

• The functional groups selected by AMG-1 DIP switch settings.

Note: If a digitally-stored voice

message fails, the AMG-1

automatically switches to the

primary evacuation tone, and

generates a trouble signal.

Installing one or two optional VROMs lets you select a factory-programmed message

by setting rocker switches 6, 7, and 8 on the AMG-1. (Refer to Selecting AMG Tones

and Messages.) For example, Figure 28 on page 27 shows the text of factory-recorded

VROM-101 message in a male voice:

“MAY I HAVE YOUR ATTENTION PLEASE. MAY I HAVE YOUR ATTENTION PLEASE. THERE HAS

BEEN A FIRE REPORTED ON YOUR FLOOR. THERE HAS BEEN A FIRE REPORTED ON YOUR

FLOOR. PLEASE PROCEED TO THE STAIRWAYS AND EXIT THE BUILDING. DO NOT USE THE

ELEVATORS.”

Figure 28 Sample VROM-101 Message

Refer to Document 15945 for a complete description of all VROM Series messages.

Note: A VRAM message can be

up to 24 seconds long.

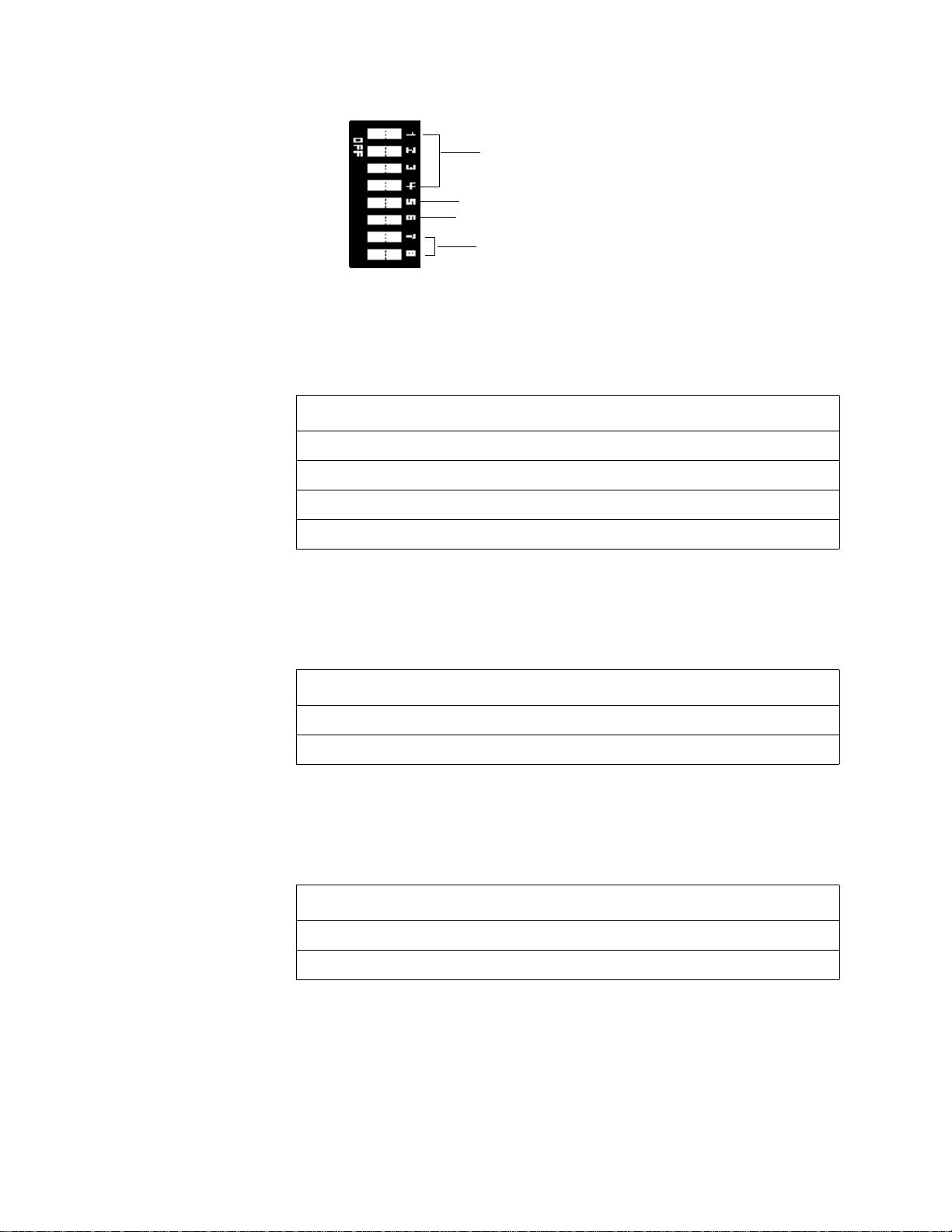

VRAM-A Enable

(if installed)

Recording Custom Messages (VRAM option) You can record custom messages

through the AMG-1 microphone or load a message recorded on an audio cassette

recorder. To do so, you must install at least one VRAM chip in U12 (VRAM-A) or U13

(VRAM-B) on the AMG-1 (Figure 29). For example, if the AMG-1 contains a

VRAM-A chip in U12, record a message as follows:

1. If loading a message from a tape recorder, connect the tape recorder to J1 on the

AMG-1. (Figure 29)

2. Set the Voice RAM Enable rocker switch 4 (VRAM-A) or 5 (VRAM-B) on the

AMG DIP Switch (SW2) to the ON position. The AMG-1 starts to record input to

VRAM-A or VRAM-B from a tape recorder or from the AMG-1 microphone.

3. Record a message through the AMG-1 microphone or load a message from a tape

recorder connected to J1.

4. When finished recording or loading the message, set the Voice RAM Enable switch

to the OFF position.

Figure 29 shows the location of connectors and chips on the AMG-1:

Microphone

connector

AMG DIP Switch(SW2)

Connector J1 for tape

recorder input cable

VRAM-B Enable

(if installed)

AMG DIP Switch (SW2) for

loading custom messages.

Optional Voice Message 1

Fact.-programmed (VROM-A)

Optional Voice Message 2

Fact.-programmed (VROM-B)

Optional Voice Message 2

User-programmed (VRAM-B)

Optional Voice Message 1

User-programmed (VRAM-A)

Figure 29 AMG-1 PC Board

Unimode 400 Operations PN 50709:A 10/20/97 27

Page 32

5. Voice Alarm Systems Selecting AMG Tones and Messages

Selecting AMG Tones and Messages

Note: Refer to Appendix A,

Annunciators in the

Unimode400 Installation

Manual for detailed instructions

on using an AMG-1 in ACS

mode. For programming

instructions, refer to the

Unimode400 Programming

Manual.

Overview You can select AMG tones and messages by setting AMG DIP switches. An

AMG appears as an annunciator to the system and operates on annunciator address01.

Operating an AMG, therefore, affects control panel programming and annunciator

switch settings.

1. Select ACS=Y in the System Function screen (Figure 30):

SIL INH=000 AUTO=000 VERIFY=00 USA TIME

TERM_SUPERV=NO LocT BLINK=Y ST=4 ACS=Y

Toggle between N (default) or Y

Figure 30 System Function Screen

2. Enter Annunciator Selection Group 1 for Annunciator Address 1(Figure 31):

Annunciator Address 1

ANNUN SELECTION1: A1=1 A2=* A3=* A4=*

A5=* A6=* A7=* A8=* A9=* A10=* UDACT=Y

Figure 31 Annunciator Selection Screen

Annunciator Selection Group 1

Setting the AMG DIP Switch (SW2) Set the rocker switches on the AMG DIP Switch

(SW2) as follows:

• To set a switch on, push the rocker switch to On.

• To set Message Select switches, refer to Table 23 or Table 24. For example, if you

set switch 2 to Off, refer to the settings in Table 23 for setting switches 6-8.

Switch Number On Off

1 – Low level Audio Four-wire supervision of Low

Level Audio.

2 – Tone/Message select

3 – Receive Only Disables the AMG All Call

4 – Voice RAM Enable A Record a message in VRAM-A Disabled

5 – Voice RAM Enable B Record a message in VRAM-B Disabled

6 – Message Select

7 – Message Select

8 – Message Select

Refer to

switches 6-8

function.

See

See

See

Table 23 for setting

Table 23 or Table 24 for settings.

Table 23 or Table 24 for settings.

Table 23 or Table 24 for settings.

Disabled

Refer to Table 24 for

setting switches 6-8

Disabled

Table 22 AMG DIP SW2 Rocker Switch Settings

28 Unimode 400 Operations PN 50709:A 10/20/97

Page 33

Selecting AMG Tones and Messages 5. Voice Alarm Systems

AMG-1 and AMG-E Tone/Message Selections (AMG-1 SW2=Off) Table 23 lists

the tone and message selections available when SW2 rocker switch2 (Tone/Message

Switch) is Off.

AMG-1 SW2 Rocker

Switches

System

Status

NAC 1 (B01)

Condition

S6 S7 S8

X X X No Alarm Off Standby

Off

Off

Off

Off

Off

Off

Off

Off

OffOnOn

Off

OffOnOn

Off

OffOnOnOnOn

On

Off

On

Off

On

Off

On

OffOOn

On

OnOnOff

On

On

OnOnOnOnNo Alarm

On

X = Indicates that switch or control point can be On or Off.

Off

Off

Off

Off

Off

Off

No Alarm

Alarm

No Alarm

Alarm

No Alarm

Alarm

No Alarm

Alarm

No Alarm

Alarm

No Alarm

Alarm

No Alarm

Alarm

Alarm

On

X

On

X

On

X

On

X

On

X

On

X

On

X

On

X

1000 Hz 0.5 sec on, 0.5 sec off

Slow whoop

Horn

120 ppm (March Time)

Horn

Yelp

Yelp

Wail

3 slow whoops, VRAM-B plays

3 slow whoops, VRAM-A plays

VROM-B message plays VROM-A

message plays

20 ppm (Two-Stage) VROM-A and

VROM-B play

Horn

NFPA Uniform Code 3

Temporal pattern fast whoop

Audio Tone or Message

Table 23 Setting AMG Tones and Messages (AMG-1 SW2=Off)

1. MPS-400 Notification Appliance Circuit 1 (NAC1) can be manually selected with

an ADT-ACM16AT to produce a desired tone or can be activated through Controlby-Event by a non-alarm input.

2. If selecting a VROM or VRAM, and a VROM or VRAM chip is not installed, a

trouble indication appears at the AMG-1 when the message is due to begin and the

AMG-1 generates the 1 kHz default tone.

Unimode 400 Operations PN 50709:A 10/20/97 29

Page 34

5. Voice Alarm Systems Selecting AMG Tones and Messages

AMG-1 and AMG-E Tone/Message Selections (AMG-1 SW2=On) Table 24 lists

the tone and message selections available when SW2 rocker switch 2 (Tone/Message

Switch) is On.

AMG-1 SW2 Rocker

Switches

System

Status

NAC 1 (B01)

Condition

S6 S7 S8

X X X No Alarm Off Standby

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

On

On

On

On

On

On

Off

Off

Off

Off

On

On

On

On

On

On

Off

Off

Off

Off

Off

Off

Off

On

On

On

Off

Off

Off

On

On

On

Off

Off

Off

On

On

On

No Alarm

Alarm

No Alarm

Alarm