Page 1

61200373L1-5B

Issue 2, August 2001

CLEI Code: SIUXJKEBAA

Total AccessTM 850 Bank Controller Unit Installation and Operation

Contents

1. GENERAL ..................................................................... 1

2. INSTALLATION/OPERATION................................ 1

3. OPTIONS....................................................................... 2

4. TESTING........................................................................ 3

5. SPECIFICATIONS........................................................ 5

6. MAINTENANCE ......................................................... 5

7. WARRANTY AND CUSTOMER SERVICE............. 5

8. LIMITED PRODUCT WARRANTY .......................... 6

9. REGULATORY REQUIREMENTS ............................ 6

Figures

Figure 1. TA 850 BCU ...................................................... 1

Figure 2. Bantam Jack Monitoring Points ..................... 3

Figure 3. DB-9 Connector Pinout ................................... 5

Tables

Table 1. Pinout Connectors for RJ-48 T1 Interface....... 3

Table 2. LED Indication ................................................... 3

Table 3. DIP Switch S1 Options...................................... 4

Table 4. Specifications...................................................... 5

1. GENERAL

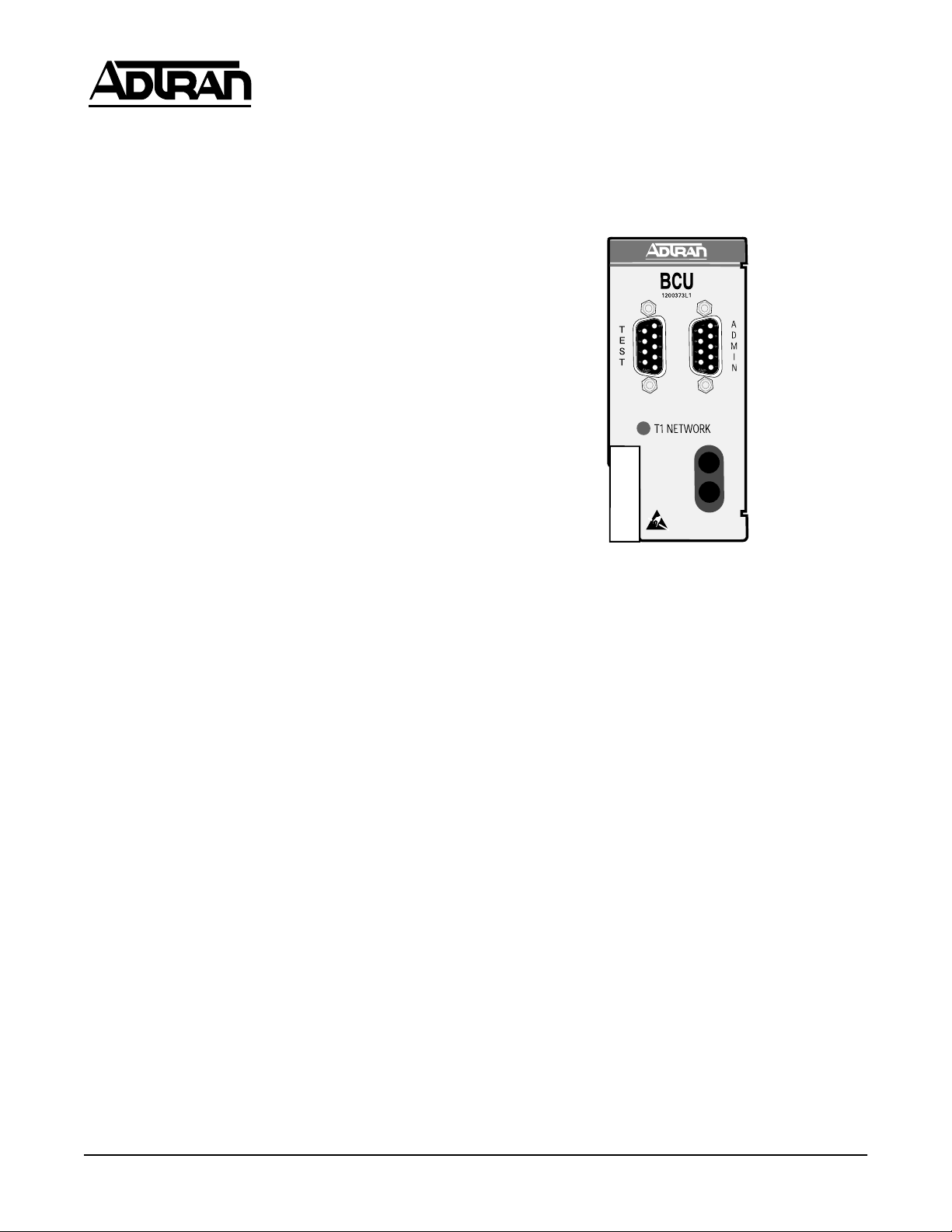

This practice provides installation and operation procedures for the ADTRAN TA 850 Bank Controller Unit

(BCU) common module, List 1. The TA 850 BCU module is designed specifically for the ADTRAN Total Access 850 and is not used in any other product. Figure 1

is an illustration of the TA 850 BCU.

Revision History

This is the initial release of this document. Future revisions to this document will be explained in this subsection.

Features

The TA 850 BCU, part number 1200373L1, includes the

following features:

• Controls all common equipment and access modules.

• T1 network termination.

• Built-in Channel Service Unit (CSU).

• Provides VT 100 craft interface via faceplate DB-9

connector.

• Bantam Jacks provide access to Network T1.

• LED network status indication.

• T1 performance monitoring.

• Supports TR-08 signaling.

• NEBS Level 3 and UL 1950 compliant.

•

DS1

TX

M

O

N

RX

TX

M

O

N

RX

DS1

Figure 1. TA 850 BCU

General Description

The TA 850 BCU is a common module plug-in unit designed for the TA 850. The BCU, with a built-in CSU,

provides all control functions for the TA 850 common

units and all individual access modules. A faceplate

ADMIN DB-9 provides access for a VT100 terminal for

screen menu provisioning, and bantam test jacks provide transmit and receive monitoring. An additional

TEST DB-9 provides timing for DS0 test equipment. A

network LED shows status information for the network

T1. The unit comprises a main circuit board and daughter card and inserts directly into the BCU slot on the TA

850 shelf. An 8-position DIP switch is mounted on the

daughter card and is used for T1 provisioning and

clocking.

Functional Description

The TA 850 BCU provisions, operates, monitors, and

tests all TA 850 access modules including Quad FXS,

Quad FXO, OCU DP, DS0 DP, and Nx56/64 DSU DP.

The BCU programs T1 bandwidth use between the various access modules and data ports.

2. INSTALLATION/OPERATION

After unpacking the unit, inspect it for damage. If damage is noted, file a claim with the carrier, then notify

ADTRAN Customer Service (see “WARRANTY AND

CUSTOMER SERVICE” on page 5).

61200373L1-5B 1

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

Page 2

The TA 850 BCU plugs directly into the controller slot

in the common module area of the TA 850 chassis. To

insert, hold the unit by the faceplate while supporting

the bottom side. Align the card edges to the guide

grooves for the designated slot. Insert into the chassis

until the edge connector seats firmly into the backplane.

Lock the unit in place by pushing in on the locking lever.

CAUTION

This product is intended for installation in Restricted Access Locations only and is intended to be

installed in equipment with a Type "B" or "E" installation code.

3. OPTIONS

The TA 850 BCU can be provisioned from either an 8-position Dual In-line Package (DIP) switch (S1) mounted on

the PCB, or through screen menus accessed via the faceplate craft interface port. Basic T1 provisioning, clock

source, and CSU loopback options are found on the DIP

switch. Refer to Table 3 on page 4 for DIP switch S1 pro-

visioning information. Additional and more in-depth

provisioning options for the BCU as well as access modules are available through the craft ADMIN interface.

DIP switch S1 must be provisioned while the BCU is

withdrawn from the chassis. Once installed, any software provisioning made will override the DIP switch

settings. If the unit is withdrawn and reinserted (power

cycled), the software options remain in effect. If a DIP

switch setting is changed while withdrawn, the new

DIP switch setting takes effect. If none of the DIP switch

settings were changed, the unit will be provisioned for

the last software settings.

Electronic Provisioning

The ADMIN interface on the TA 850 BCU is used to

change factory selected options and obtain access module status through menu screens. To access the menu

screens, connect a VT 100 terminal or computer running

a terminal emulation program to the craft interface port

using a standard male-to-male RS-232 DB-9 cable. Craft

port settings are as follows:

• 9600 Baud

•No parity

•8 Data bits

•1 Stop bit

CAUTION

The BCU retains provisioning setup when removed from the chassis. If inserted into another

chassis, the provisioning setup is invoked on that

chassis' access modules.

Windows Hyperterminal. Windows Hyperterminal

can be used as a VT 100 terminal emulation program.

Open Hyperterminal by selecting PROGRAMS / ACCESSORIES / HYPERTERMINAL. Refer to the Help

section of Hyperterminal for additional questions.

NOTE

To ensure proper display background in Windows

Hyperterminal, select VT 100 terminal emulation

under SETTINGS.

Password. When connected, enter the password. The

factory default is PASSWORD in all capital letters. The

password can be changed to a user selected password

once connected.

Menu Navigation. To traverse through the menus, se-

lect the desired entry and press Enter. To work backwards in the menu, press the Esc (escape) key.

Time Slot Assignment (Plug and Play Environment). The TA 850 can support a plug and play envi-

ronment for slots 1-6 of the TA 850 bank for the various

access modules (i.e., FXS, FXO, OCU DP, DSO DP,

UBRITE, E&M, etc.). Each card that is plugged in to

slots 1-6 will consecutively take 4 Time Slots automatically when installed in the TA 850 bank, depending on

the card that is plugged into the shelf.

Time Slot Assignment - Software Assignment

(Non-Plug and Play Environment). Slots 1-6 of the TA

850 Bank are for the various access modules supported

by the the TA 850 (i.e., FXS, FXO, OCU DP, DSO DP,

UBRITE, E&M, etc.). The T1 interface on the TA 850

BCU supports 24 Time Slot Assignment which can be

allocated to the access modules, to the DSX-1, or to the

Nx64 module. The TA 850 BCU can override the plug

and play assignments through the software menus via

the ADMIN port on the TA 850 BCU.

Slot Time Slot

1 1-4 FXS, FXO, OCU DP, DSO DP,

2 5-8 FXS, FXO, OCU DP, DSO DP,

3 9-12 FXS, FXO, OCU DP, DSO DP,

4 13-16 FXS, FXO, OCU DP, DSO DP,

5 17-20 FXS, FXO, OCU DP, DSO DP,

6 21-24 FXS, FXO, OCU DP, DSO DP,

A/B

(special

slot)

BCU 1-24 BCU or BCU w/DSX-1

Available

UBRITE, E&M, etc.

UBRITE, E&M, etc.

UBRITE, E&M, etc.

UBRITE, E&M, etc.

UBRITE, E&M, etc.

UBRITE, E&M, etc.

1-24 Nx56/64

Access Module

2 Issue 2, August 2001 61200373L1-5B

Page 3

Access

Module

Maximum Number of DS0s that can

be used per m odule

FXS 4

FXO 4

*OCU-DP 1

*DSO-DP 1

*U-BRITE 1

*E&M 1

Nx56/64

24

(special slot)

*Supported in TA 850 Q300.

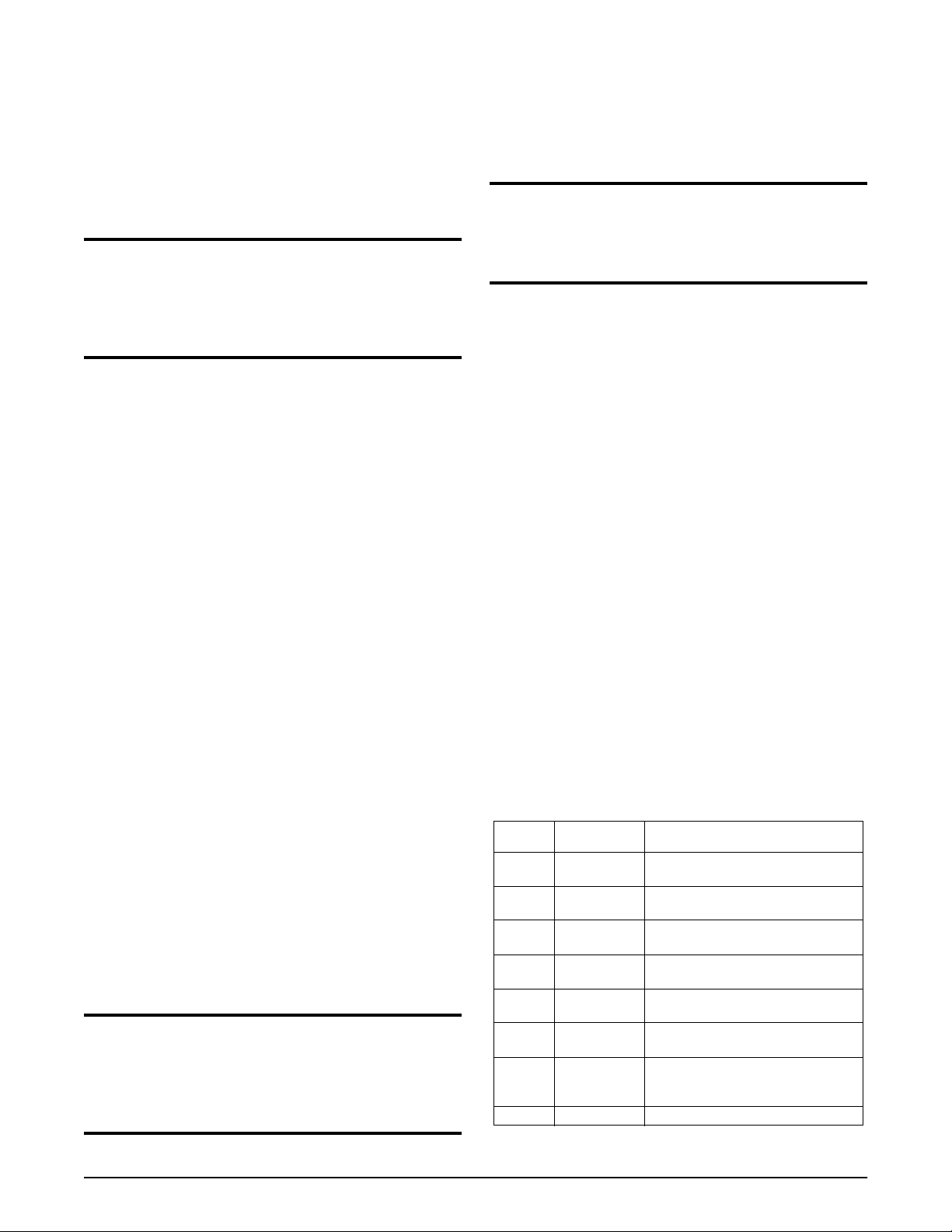

Figure 2 on page 3 displays where the bantam jacks

monitor the T1.

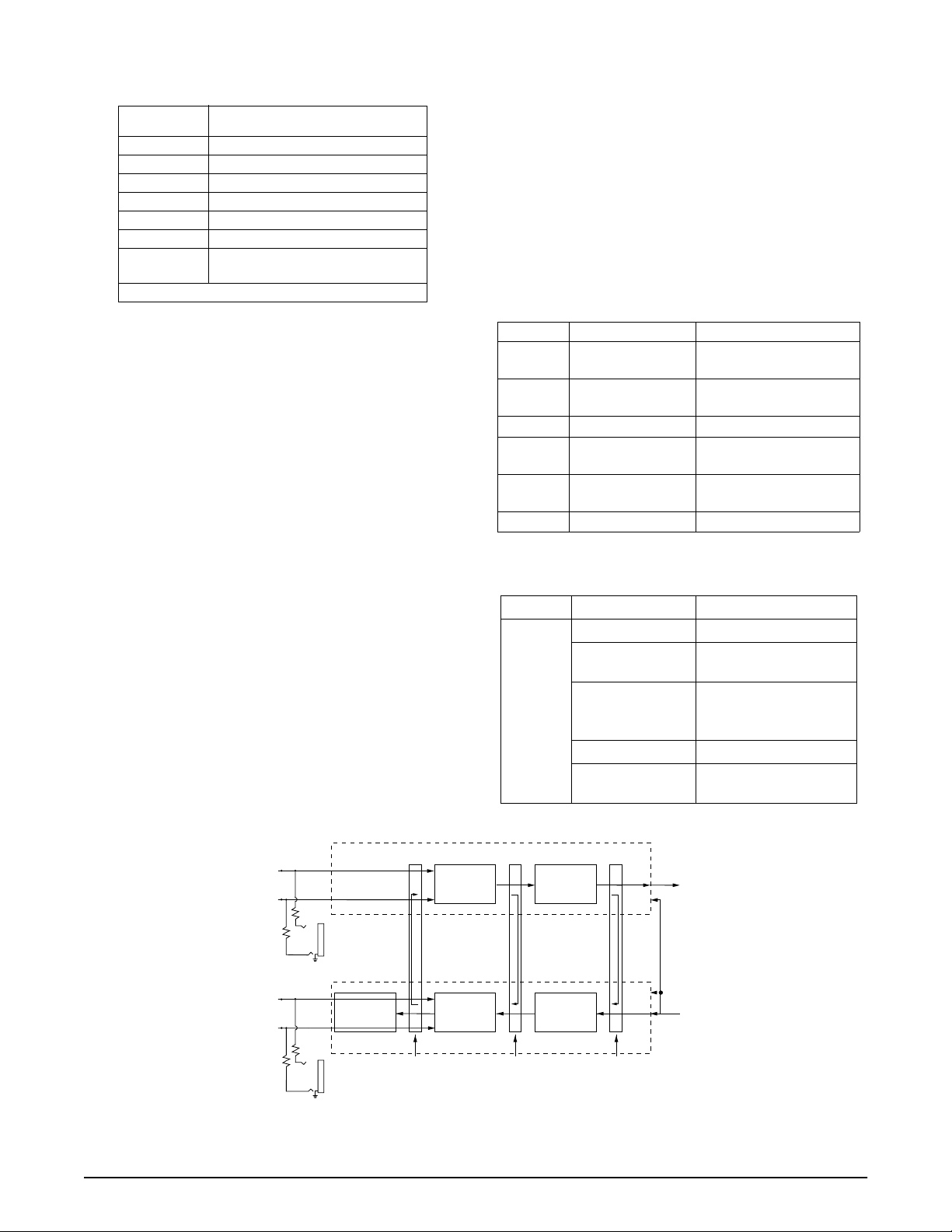

Faceplate TEST connector

The faceplate DB-9 female TEST connector provides the

necessary clock output required by standard DSO Logic

Test equipment such as a TPI 108/109 test set. Specifically, the TEST connector outputs 8 kHz and 64 kHz

clock reference signal. Figure 3 on page 5 illustrates the

DB-9 TEST connector.

Table 1. Pinout Connectors for RJ-48 T1 Interface

Connections

All TA 850 BCU connections are made through the

backplane connector. With the exception of power and

the V.35 connector, all of the TA 850 rear panel connectors terminate on the BCU. These include Network T1,

Clock source, Alarms, Fractional T1, and Management.

Refer to the TA 850 System Installation and Maintenance Practice, part number 64200376L1- 5A, for additional information on rear panel connections. Table 1

describes the T1 pinout connections.

Faceplate LED

The faceplate Network LED labeled T1 Network provides status information for the network T1 using a color coded message format. Refer to Table 2.

4. TESTING

The TA 850 BCU provides a variety of test options for

both the Network T1 and DS0 access modules. The faceplate of the BCU provides a bantam jack for local T1 test

access. DS0 test access for the digital access modules

(OCU DP, DS0 DP, U-BR1TE) is provided via bantam

jacks on the faceplate of each unit.

Faceplate Bantam Jack

The faceplate bantam jack provides a means to monitor

the network T1 connected to the rear of the TA 850 chassis. The jacks accept standard 310-type bantam plugs.

Pin Name Description

1 R1 - RING1 Receive data from

Network DS1

2 T1 - TIP1 Receive data from

Network DS1

3 unused 4 R - RING T ransmit d ata to Network

DS1

5 T - TIP T rans mit data to Network

DS1

6, 7, 8 unused -

Table 2. LED Indication

LED Condition Description

OFF No power.

RED Unit in Red Alarm (T1

Network

T1

YELLOW Receiving Yellow Alarm

GREEN Normal Operation.

FLASHING

GREEN

down or not connected.)

(far end unit in Red

Alarm.)

Network T1 in Test.

Receiver Circuitry

T1

T1

RX

PAIR

T1

TX

PAIR

R1

MON IN

Test Jack

T

R

Equalizer

MON OUT

Test Jack

Clock and Data

Recovery

DJAT

Transmitter Circuitry

Local

Loopback

Point

Line

Loopback

Point

Line Format

Decoder

Line Format

Encoder

Payload/CSU

Loopback

Point

To

Backplane

From

Backplane

Figure 2. Bantam Jack Monitoring Points

61200373L1-5B Issue 2, August 2001 3

Page 4

Table 3. DIP Switch S1 Options

Switch Function Description

S1-1 Framing Format Enables either Extended Superframe Format (ESF) or Superframe

S1-2 Line Code

Format

S1-3 TR-08 Signaling Enables TR-08 signaling optio n. When enabled, S1-1 is ignored.

S1-4 CSU Loopback Enab les the CSU Loop back Functio n. Unit will resp ond to CSU loopba ck

Timing Mode

Format (SF). This op tion m ust be confi gured i dentic ally with al l other T1

network equipment o n this circuit.

On* SF

Off ESF

Enables Bipolar Eight-Zero Substitution (B8ZS), which allows fo r Clear

Channel operation for the T1 carrier system, or enables Alternate Mark

Inversion (AMI). This option mus t be configur ed ident icall y with all other

T1 network equipment on thi s cir cui t.

On* AMI

Off B8ZS

On* Enabled

Off Disabled

sent from a remote ne tw o rk device or test equipment.

Off* Enabled

On Disabled

Determines clock so urce for TA 850.

S1-5

S1-6

S1-7

S1-8

*Denotes fa ctory default s etti ng.

Timing A

Timing B

DS1 Attenuation

LBO A

LBO B

S1-5

Off Off Loop timing: Derives timing from T1

On Off External timing: Derives timing from external BITS

Off On Local timing: Clock gener ated f rom internal timi ng

On* On* Loop timing: Derives timing from T1.

Selects attenuation to set receiver sensitivity in decibels (dB).

S1-7

Off Off 0 dB/0-133 ft (LBO)

On Off -7.5 dB

Off On -15 dB

On* On* -22.5 dB

(Note: Additional LBO settings can be provisioned through the menu

interface.)

S1-6 Function

clock.

source.

S1-8 Setting

4 Issue 2, August 2001 61200373L1-5B

Page 5

TEST

1

6

2

7

3

8

4

9

5

+5 V

GND

64 kHz

8 kHz

Figure 3. DB-9 Connector Pinout

DS0 test equipment is used to test DS0 access modules

such as the OCU DP, DS0 DP, or U-BR1TE. Once the test

equipment is connected to the reference clock source,

individual tests can be performed on DS0 access modules using the faceplate bantam jacks on each unit.

T1 Loopbacks

The TA 850 supports several T1 loopbacks via the craft

interface. These loopbacks include:

• Initiating a remote payload or line loopback command (ESF mode only).

• Responding to a remote payload or line loopback

command (ESF mode only).

• Responding to a remote CSU loopback command.

Figure 2 on page 3 displays where the various loopbacks occur in the TA 850 BCU circuitry.

Self Test

The BCU goes into self test when inserted into an active

TA 850 chassis. The self test checks internal BCU circuitry. A failed test causes the faceplate Network T1 LED to

blink red.

5. SPECIFICATIONS

Refer to Table 4 for TA 850 BCU specifications.

6. MAINTENANCE

The TA 850 BCU does not require routine maintenance

for design operation.

ADTRAN does not recommend that repairs be attempted in the field. Repair services are obtained by returning

the defective unit to ADTRAN Customer Service department.

Flash Upload

The TA 850 BCU can flash upload firmware to the unit

using the front panel VT 100 craft interface. Flash upload is useful for product upgrade or enhancements.

Flash upload procedures are as follows:

1. Obtain firmware, available by diskette or email, from

ADTRAN Customer Service.

2. Connect to the craft interface port using instructions

found in “OPTIONS” on page 2.

3. Once connected, enter the Bank Controller submenu

and select Upload Code.

4. To upload code, select Load new code and follow the

instructions on the screen. The user is offered the

opportunity to increase the baud rate from 9600 to

19.2 K, 38.4 K, or 57.6 K. Be sure that your terminal

device can support a higher speed before selecting.

Also, some terminal emulation packages (such as

Hyperterminal) require that the current session be

disconnected and reconnected after changing from

one baud rate to another.

5. Continue to follow the instructions on the screen,

noting that the TA 850 BCU uses the XMODEM protocol to transfer code.

6. After successfully uploading code, the TA 850 Bank

Controller will reset itself and resume operation.

Table 4. Specifications

ADTRAN will replace or repair this product within 10

years from the date of shipment if it does not meet its

7. WARRANTY AND CUSTOMER SERVICE

Mechanical

Dimensions 1 11/16” W x 3” H x 10” L

Weight 1 lb

Environmental

Operating Tempera t ure

Storage Temperature

Relative Humidity Up to 95%, noncondensing

Configuration Codes

Power Code (PC) IN: F, OUT: C

Telecommunication Code

(TC)

Installation Code (IC) IN: A, OUT: -

61200373L1-5B Issue 2, August 2001 5

-40 to 65

-40 to 85

IN: X, OUT: X

o

C

o

C

published specifications or fails while in service. For detailed warranty, repair, and return information refer to

the ADTRAN Equipment Warranty and Repair and Return Policy Procedure.

Return Material Authorization (RMA) is required prior

to returning equipment to ADTRAN.

For service, RMA requests, or more information, see the

following sections for the correct toll-free contact number.

Page 6

Product Support Information

Pre-Sales Inquiries and Applications Support.

Please contact your local distributor, ADTRAN Applications Engineering, or ADTRAN Sales:

This warranty applies only to the original purchaser and

is not transferable without ADTRAN's express written

permission. This warranty becomes null and void if Customer modifies or alters the equipment in any way, other

than as specifically authorized by ADTRAN.

Applications Engineering (800) 615-1176

Sales (800) 827-0807

Post-Sale Support. Please contact your local distribu-

tor first. If your local distributor cannot help, please

contact ADTRAN Technical Support and have the unit

serial number available.

Technical Support (888) 4ADTRAN

Repair and Return. If ADTRAN Technical Support

determines that a repair is needed, Technical Support

will coordinate with the Customer and Product Service

(CAPS) department to issue an RMA number. For information regarding equipment currently in house or possible fees associated with repair, contact CAPS directly

at the following number:

CAPS Department (256) 963-8722

Identify the RMA number clearly on the package (below address), and return to the following address:

EXCEPT FOR THE LIMITED WARRANTY DESCRIBED

ABOVE, THE FOREGOING CONSTITUTES THE SOLE

AND EXCLUSIVE REMEDY OF THE CUSTOMER

AND THE EXCLUSIVE LIABILITY OF ADTRAN AND

IS IN LIEU OF ANY AND ALL OTHER WARRANTIES

(EXPRESSED OR IMPLIED). ADTRAN SPECIFICALLY

DISCLAIMS ALL OTHER WARRANTIES, INCLUDING (WITHOUT LIMITATION), ALL WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SOME STATES DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES,

SO THIS EXCLUSION MAY NOT APPLY TO CUSTOMER.

In no event will ADTRAN or its suppliers be liable to

Customer for any incidental, special, punitive, exemplary or consequential damages experienced by either

Customer or a third party (including, but not limited to,

loss of data or information, loss of profits, or loss of

use). ADTRAN is not liable for damages for any cause

whatsoever (whether based in contract, tort, or otherwise) in excess of the amount paid for the item. Some

states do not allow the limitation or exclusion of liability for incidental or consequential damages, so the above

limitation or exclusion may not apply to Customer.

ADTRAN, Inc.

6767 Old Madison Pike

Progress Center

Building #6 Suite 690

Huntsville, Alabama 35807

RMA # _____________

8. LIMITED PRODUCT WARRANTY

ADTRAN warrants that for ten years from the date of

shipment to Customer, all products manufactured by

ADTRAN will be free from defects in materials and

workmanship. ADTRAN also warrants that products

will conform to the applicable specifications and drawings for such products, as contained in the Product

Manual or in ADTRAN's internal specifications and

drawings for such products (which may or may not be

reflected in the Product Manual). This warranty only

applies if Customer gives ADTRAN written notice of

defects during the warranty period. Upon such notice,

ADTRAN will, at its option, either repair or replace the

defective item. If ADTRAN is unable, in a reasonable

time, to repair or replace any equipment to a condition as

warranted, Customer is entitled to a full refund of the purchase price upon return of the equipment to ADTRAN.

9. REGULATORY REQUIREMENTS

Affidavit Requirements for Connection to Digital

Services

• An affidavit is required to be given to the telephone

company whenever digital terminal equipment without encoded analog content and billing protection is

used to transmit digital signals containing encoded

analog content which are intended for eventual conversion into voiceband analog signals and transmitted on the network.

• The affidavit shall affirm that either no encoded analog content or billing information is being transmitted

or that the output of the device meets Part 68 encoded

analog content or billing protection specifications.

• End user/customer will be responsible for filing an

affidavit with the local exchange carrier when connecting unprotected customer premise equipment

(CPE) to 1.544 Mbps or subrate digital services.

• Until such time as subrate digital terminal equipment

is registered for voice applications, the affidavit requirement for subrate services is waived.

6 Issue 2, August 2001 61200373L1-5B

Page 7

Affidavit for Connection of Customer Premises

Equipment to 1.544 Mbps and/or Subrate Digital

Services

For the work to be performed in the certified territory of

________________________(telco name)

State of ________________

County of ________________

( ) D. In lieu of the preceding training requirements,

the operator(s)/maintainer(s) is (are) under the

control of a supervisor trained in accordance

with _________ (circle one) above.

I agree to provide ______________________ (telco’s

name) with proper documentation to demonstrate compliance with the information as provided in the preceding paragraph, if so requested.

I, _____________________________ (name),

__________________________________(business address),

____________________ (telephone number) being duly

sworn, state:

I have responsibility for the operation and maintenance

of the terminal equipment to be connected to 1.544

Mbps and/or ________ subrate digital services. The terminal equipment to be connected complies with Part 68

of the FCC rules except for the encoded analog content

and billing protection specifications. With respect to encoded analog content and billing protection:

( ) I attest that all operations associated with the

establishment, maintenance, and adjustment of the

digital CPE with respect to analog content and

encoded billing protection information continuously complies with Part 68 of the FCC Rules and

Regulations.

( ) The digital CPE does not transmit digital signals

containing encoded analog content or billing information which is intended to be decoded within the

telecommunications network.

_________________________________Signature

_________________________________Title

_________________________________ Date

Transcribed and sworn to before me

This ________ day of ________, ________

_________________________________

Notary Public

My commission expires:

_________________________________

( ) The encoded analog content and billing protection is

factory set and is not under the control of the customer.

I attest that the operator(s)/maintainer(s) of the digital

CPE responsible for the establishment, maintenance,

and adjustment of the encoded analog content and billing information has (have) been trained to perform

these functions by successfully having completed one

of the following (check appropriate blocks):

( ) A. A training course provided by the manufac-

turer/grantee of the equipment used to encode

analog signals; or

( ) B. A training course provided by the customer or

authorized representative, using training

materials and instructions provided by the

manufacturer/grantee of the equipment used

to encode analog signals; or

( ) C. An independent training course (e.g., trade

school or technical institution) recognized by

the manufacturer/grantee of the equipment

used to encode analog signals; or

61200373L1-5B Issue 2, August 2001 7

Page 8

FCC regulations require that the following

information be provided in this manual to the

customer:

1. This equipment complies with Part 68 of the FCC

rules. The required label is affixed to the bottom of

the chassis.

2. An FCC-compliant telephone cord and modular plug

is provided with this equipment. This equipment is

designed to be connected to the telephone network

or premises wiring using a compatible modular jack

which is Part 68-compliant. See Chapter 2, Installation, for details.

3. If your telephone equipment (TA 850) causes harm to

the telephone network, the telephone company may

discontinue your service temporarily. If possible,

they will notify you in advance. But if advance notice

isn’t practical, you will be notified as soon as possible. You will be advised of your right to file a complaint with the FCC.

4. Your telephone company may make changes in its

facilities, equipment, operations, or procedures that

could affect the proper operation of your equipment.

If they do, you will be given advance notice to give

you an opportunity to maintain uninterrupted service.

5. If you experience trouble with this equipment (TA 850),

please contact ADTRAN at (256) 963-8000 for repair/

warranty information. The telephone company may

ask you to disconnect this equipment from the network

until the problem has been corrected or until you are

sure the equipment is not malfunctioning.

6. This unit contains no user-serviceable parts.

7. The following information may be required when

applying to your local telephone company for leased

line facilities.

For a T1 Port:

Service Ty pe REN/

1.544 Mbps - SF 6.0N 04DU9-BN RJ-48C

1.544 Mbps - SF and

B8ZS

1.544 Mbps - ESF 6.0N 04DU9-1KN RJ-48C

1.544 Mbps - ESF

and B8ZS

ISDN 6.0N 04DU9-ISN RJ-48C

SOC

6.0N 04DU9-DN RJ-48C

6.0N 04DU9-1SN RJ-48C

FIC USOC

For an FT1 Port:

Service Type REN/

SOC

1.544 Mbps - SF 6.0N 04DU9-BN

1.544 Mbps - SF and B8ZS 6.0N 04DU9-DN

1.544 Mbps - ESF 6.0N 04DU9-1KN

1.544 Mbps - ESF and B8ZS 6.0N 04DU9-1SN

ISDN 6.0N 04DU9-ISN

FIC

NOTE

When connecting FT1 port towards the network, a

suitable crossover cable is required.

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may

cause harmful interference to radio frequencies. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will

be required to correct the interference at his own expense.

Shielded cables must be used with this unit to ensure

compliance with Class A FCC limits.

WARNING

Change or modifications to this unit not expressly

approved by the party responsible for compliance

could void the user’s authority to operate the

equipment.

8 Issue 2, August 2001 61200373L1-5B

Page 9

Canadian Equipment Limitations

NOTE

The Industry Canada Certification label identifies

certified equipment. This certification means that

the equipment meets certain telecommunications

network protective, operational, and safety

requirements. The Department of Commerce does

not guarantee the equipment will operate to the

user's satisfaction.

Before installing this equipment, users should ensure

that it is permissible to be connected to the facilities of

the local telecommunications company. The equipment

must also be installed using an acceptable method of

connection. In some cases, the company's inside wiring

associated with a single line individual service may be

extended by means of a certified connector assembly

(telephone extension cord). The customer should be

aware that compliance with the above conditions may

not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an

authorized Canadian maintenance facility designated

by the supplier. Any repairs or alterations made by the

user to this equipment, or equipment malfunctions,

may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the

electrical ground connections of the power utility, telephone lines and internal metallic waterpipe system, if

present, are connected together. This precaution may be

particularly important in rural areas.

CAUTION

Users should not attempt to make such connections

themselves, but should contact the appropriate

electric inspection authority, or an electrician, as

appropriate.

The Load Number (LN) assigned to each terminal device denotes the percentage of the total load to be connected to a telephone loop which is used by the device,

to prevent overloading. The termination on a loop may

consist of any combination of devices subject only to the

equipment that the total of the LNs of all devices does

not exceed 100.

The ringer equivalence number (REN) assigned to each

terminal adapter is used to determine the total number

of devices that may be connected to each circuit. The

sum of the RENs from all devices in the circuit should

not exceed a total of 5.0.

61200373L1-5B Issue 2, August 2001 9

Page 10

10 Issue 2, August 2001 61200373L1-5B

Loading...

Loading...