Page 1

61200062L1-1E

May 2001

DSU 56/64

Data Service Unit

User Manual

Part Number 1200062L1

Page 2

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

(256) 963-8000

© 2001 ADTRAN, Inc.

All Rights Reserved.

Printed in U.S.A.

Page 3

The following conventions are used in this manual.

Notes provide additional useful information.

Cautions signify information th at cou ld prevent service interruption.

Warnings provide information that could prevent damage to the equipment or endangerment to h uman life.

Important Safety Instructions

When using your telephone equipment, please follow these basic safety precautions

to reduce the risk of fire, electrical shock, or personal injury:

1. Do not use this product nea r water, such as near a bathtub, wash bowl, kitchen

sink, laundry tub, in a wet basement, or near a swimming pool.

2. Avoid using a telephone (other than a cordless-type) during an electrical storm.

There is a remote risk of shock from lightning.

3. Do not use the telephone to report a gas leak in the vicinity of the leak.

4. Use only the power cord, power supply , and/or batteries indicated in the manual.

Do not dispose of batteries in a fire. They may explode. Check with local codes for

special disposal instructions.

Save These Important Safety Instructions

iii

Page 4

Affidavit Requirements for Connection to Digital Services

• An affidavit is required to be given to the telephone company whenever digital

terminal equipment without encoded analog content and billing protection is

used to transmit digital signals containing encoded analog content which are

intended for eventual conversion into voice band analog signal and transmitted

on the network.

• The affidavit shall affirm that either no encoded analog content or billing information is being transmitted or that the output of the device meets Part 68 encoded

analog content or billing protection specification.

• End user/customer will be responsible to file an affidavit with the local exchange

carrier when connecting unprotected CPE to a 1.544 Mbps or subrate digital service.

• Until such time as subrate digital terminal equipment is registered for voice applications, the affidavit requirements for subrate services are waived.

iv

Page 5

Affidavit for Connection of Customer Premises Equipment to 1.544 MBPS and/

or Subrate Digital Services

For the work to be performed in the certified territory of ______________ (telco name)

State of ________________________________

County of ______________________________

I, _______________________ (name), ____________________ (business address),

_____________________ (telephone number) being duly sworn, state:

I have the responsibility for the operation and maintenance of the terminal equipment

to be connected to 1.544 Mbps and/or __________________ subrate digital services.

The terminal equipment to be connected complies with Part 68 of the FCC rules

except for the encoded analog content and billing protection specificati on. With

respect to encoded analog content and billing protection:

( ) I attest that all opera tions associated with the establishment, maintenance and adjustment of the digital CPE with respect to encoded analog content and billing protection

information continuously comp lies with Part 68 of the FCC rules and Regulations.

( ) The digital CPE does not transmit digital signals containing encod ed a nalog content or billing information which is in tend ed to be decoded within the telecommunications network.

( ) The encoded analog content and billing protection is factory set and is not under

the control of the customer.

I attest that the operator(s) maintainer(s) of the digital CPE responsible for the establishment, maintenance and adjustment of the encoded analog content and billing

information has (have) been trained to perform these functions by successfully having

completed one of the following (check appropriate blocks):

( ) A. A training course provided by the manufacturer/grantee of the equipment used

to encode analog signals; or

( ) B. A training course provided by the customer or authorized representative, using

training materials and instructions provided by the manufacturer/grantee of the

equipment used to encode analog signals; or

( ) C. An independent training course (e.g., trade school or technical institution) recognized by the manufacturer/grantee of the equipment used to encode analog signals; or

v

Page 6

( ) D. In lieu of the proceeding training requirements, the operator(s)/maintainer(s) is

(are) under the control of a supervisor trained in accordance with _______________

(circle one) above.

I agree to provide ____________________ (telco’s name) with proper documentation

to demonstrate compliance with the information in the preceding paragraph, if so

requested.

_______________ ______ Signature

_______________ ______ Title

_____________________ Date

Subscribed and sworn to before me

This _________ day of ___________________, 20__

_______________________________________

Notary Public

My commission expires: _________ ________________

vi

Page 7

FCC regulations require that the following information be provided in this manual:

1. This equipment complies with Part 68 of the FCC rules. On the bottom of the

equipment housing is a label that shows the FCC registration number and Ringer

Equivalence Number (REN) for this equipment, if applicable. If required, this

information must be given to the telepho ne company.

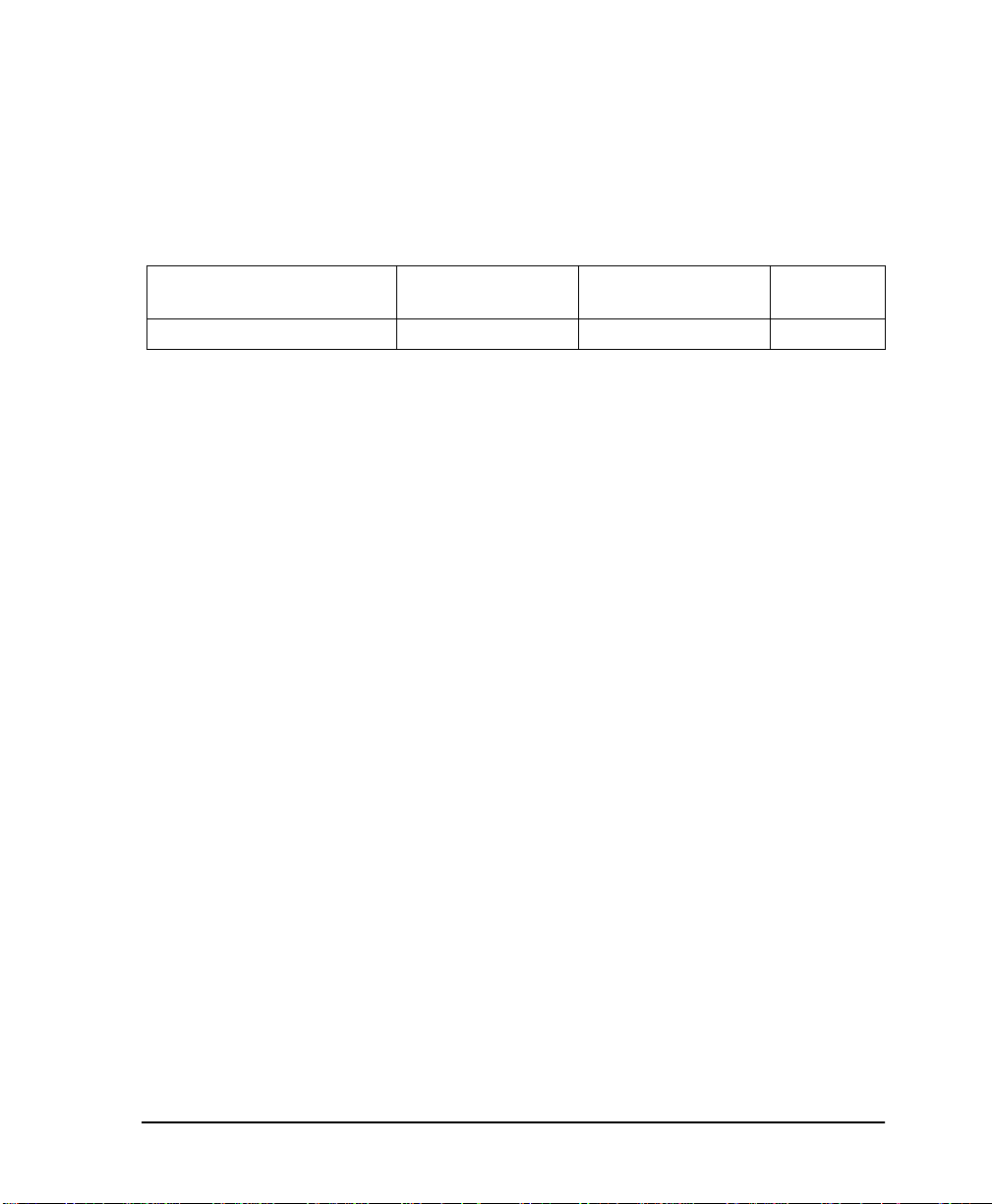

2. The following information may be required when applying to the local telephone

company for leased line facilities.

Service Type Digital Facility

Interface Code

56 kbps Digital Interface 04DU5-56 6.0F RJ-48S

Service Order Code Network

Jacks

3. An FCC compliant telephone cord with a modular plug may be provided with

this equipment. This equipment is designed to be connected to the telephone network or premises wiring using a compatible modular jack, which is FCC Part 68

compliant. See Chapter 2, Installation on page 2-1 for details.

4. If this equipment causes harm to the telephone networ k, the telephone company

may temporarily discontinue service. If possible, advance notification is given;

otherwise, notification is given as soon as possible. The telephone company will

advise the customer of the right to file a complaint with the FCC.

5. The telephone company may make changes in its facilities, equipment, operations,

or proce d ures that coul d af fe c t the p r op e r ope ra t io n of thi s eq uipm e nt . If th is ha p pens, the telephone company will provide advance notification and the opportunity

to make the necessary modifications to maintain uninterrupted service.

6. If experiencing difficulty with this equipment, please contact ADTRAN for repair and

warranty informatio n. If the equipment is causing harm to the network, the te lephone

company may r e quest thi s e qui pme nt to b e di sc onnec te d from the network un ti l th e

problem is resolved or it is certain that the equipment is not malfunctioning.

7. This unit contains no user serviceable parts.

8. The FCC recommends that the AC outlet to which equipment requiring AC

power is to be installed is provided with an AC surge arrester.

vii

Page 8

Federal Communications Commission Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interferen ce when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio frequencies. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with Class A FCC

limits.

Change or modifications to this unit not expressly approved by the party responsible for complian c e co uld void the user’s authority to operate the equipment.

Canadian Emissions Requirements

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus as set out in the interference-causing equipment standard entitled “Digital Apparatus," ICES-003 of the Department of Communications.

Cet appareil nuerique respecte les limites de bruits radioelectriques applicables aux

appareils numeriques de Class A prescrites dans la norme sur le materiel brouilleur:

"Appareils Numeriques," NMB-003 edictee par le ministre des Communications.

viii

Page 9

Canadian Equipment Limitations

Notice: The Canadian Industry and Science Canada label identifies certified equipment. This certification means that the equipment meets certain telecommunications

network protective, operational, and safety requirements. The Department does not

guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local telecommunications company . The equipment must

also be installed using an acceptable methods of connection. In some cases, the company’s inside wiring associated with a single line individual service may be extended

by means of a certified connector assembly (telephone extension cord). The customer

should be aware that compliance with the above limitations may not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier. Any repairs or alterations made by the user

to this equipment, or equipment malfunctions, may give the telecommunications

company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of

the power utility, telephone lines and internal metallic water pipe system, if present,

are connected together. This precaution may be particularly important in rural areas.

Users should not attempt to make such connections th emselves, but

should contract the appropriate electric inspection authority, or an electrician, as appropriate.

The Load Number (LN) assigned to each terminal device denotes the percentage of

the total load to be connected to a telephone loop which is used by the device, to prevent overloading. The termination on a loop may consist of any combination of

devices subject only to the requirement that the total of the Load Numbers of all

devices does not exceed 100.

ix

Page 10

Limited Product Warranty

ADTRAN warrants that for five (5) years from the date of shipment to Customer, all

products manufactured by ADTRAN will be free from defects in materials and workmanship. ADTRAN also warrants that products will conform to the applicable specifications and drawings for such products, as contained in the Product Manual or in

ADTRAN's internal specifications and drawings for such products (which may or

may not be reflected in the Product Manual). This warranty only applies if Customer

gives ADTRAN written notice of defects during the warranty period. Upon such

notice, ADTRAN will, at its option, either repair or replace the defective item.

If ADTRAN is unable, in a reasonable time, to repair or replace any equipment to a

condition as warranted, Customer is entitled to a full refund of the purchase price

upon return of the equipment to ADTRAN. This warranty applies only to the original

purchaser and is not transferable without ADTRAN's express written permission.

This warranty becomes null and void if Customer modifies or alters the equipment in

any way, other than as specifically authorized by ADTRAN.

EXCEPT FOR THE LIMITED WARRANTY DESCRIBED ABOVE, THE FOREGOING

CONSTITUTES THE SOLE AND EXCLUSIVE REMEDY OF THE CUSTOMER AND

THE EXCLUSIVE LIABILITY OF ADTRAN AND IS IN LIEU OF ANY AND ALL

OTHER WARRANTIES (EXPRESSED OR IMPLIED). ADTRAN SPECIFICALLY DISCLAIMS ALL OTHER W ARR ANTIES, INCLUDING (WITHOUT LIMITATION),

ALL WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. SOME STATES DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES, SO THIS EXCLUSION MAY NOT APPLY TO CUSTOMER.

In no event will ADTRAN or its suppliers be liable to Customer for any incidental,

special, punitive, exemplary or consequential damages experienced by either Customer or a third party (including, but not limited to, loss of data or information, loss

of profits, or loss of use). ADTRAN is not liable for damages for any cause whatsoever

(whether based in contract, tort, or otherwise) in excess of the amount paid for the

item. Some states do not allow the limitation or exclusion of liability for incidental or

consequential damages, so the above limitation or exclusion may not apply to Customer.

x

Page 11

Customer Service, Product Support Information, and Training

ADTRAN will replace or repair this product within five years from the date of shipment if the product does not meet its published specification, or if it fails while in service.

A return material authorization (RMA) is required prior to returning equipment to

ADTRAN. For service, RMA requests, training, or more information, see the toll-free

contact numbe r s gi v e n be lo w.

Presales Inquiries and Applications Support

Please contact your local distributor, ADTRAN Applications Engineering, or ADTRAN Sales:

Applications Engineering (800) 615-1176

Sales (800) 827-0807

Post-Sale Support

Please contact your local distributor first. If your local distributor cannot help, please

contact ADTRAN Technical Support and have the unit serial number available.

Technical Support (888) 4ADTRAN

The Custom Extended Services (ACES) program offers multiple types and levels of service plans which allow you to choose the kind of assistance you need. For questions,

call the ACES Help Desk.

ACES Help Desk (888) 874-2237

Repair and Return

If ADTRAN Technical Support determines that a repair is needed, Technical Support

will coordinate with the Custom and Product Service (CAPS) department to issue an

RMA number. For information regarding equipment currently in house or possible

fees associated with repair, contact CAPS directly at the following number:

CAPS Department (256) 963-8722

xi

Page 12

Identify the RMA number clearly on the package (below address), and return to the following address:

ADTRAN Customer and Product Service

901 Explorer Blvd.

Huntsville, Alabama 35806

RMA # _____________

Training

The Enterprise Netw or k (EN) T ec hni cal Tra ini ng Dep ar tme nt of fe rs train in g on our

most popular products. These courses include overviews on product features and functions while covering applications of ADTRAN's product lines. ADTRAN provides a variety of training options, including customized training and courses taught at our

facilities or at your site. For more information about training, please contact your Territory Manager or the Enterprise Training Coordinator.

Training - phone (800) 615-1176, ext. 7500

Training - fax (256) 963 7941

Training - email training@adtran.com

xii

Page 13

Table of Contents

List of Figures ......................................................................................................................xv

List of Tables ......................................................................................................................xvii

Chapter 1. Introduction

Product Overview ...............................................................................................................1-1

Front Panel ...........................................................................................................................1-2

LED Identification .............................................................................................. ...1-2

DTE Status (Green) ........................................................................................ 1-2

Network Status (Red) ..................................................... ...............................1-2

Test Status/Error (Yellow/Red) .................................................................. 1-3

Test Switches .........................................................................................................1-3

Rear Panel .............................................................................................................................1-4

Chapter 2. Installation

Unpack, Inspect, Power Up ............................................................................................... 2-1

Contents of Shipping Package ....................................................................................2-1

Customer Provides .......................................................................................................2-1

Power Up........................................................................................................................2-2

Configuration .......................................................................................................................2-2

Clear To Send (CS) - SW 1 ................................................................................... 2-2

Down - Normal ..................................................................... ..... ....................2-2

Up - On ............................................................................................................2-2

Clear to Send Delay (CS Delay) - SW 2 ...................................................... ..... ...2-2

Switch Position ...............................................................................................2-2

Down - Short ........................... .................................. ...... ...... .........................2-2

Up - Long ........................................................................................................2-2

Antistream - SW 3 .................................................................................................2-3

Down - Off ............................... ...... .................................. ...... .........................2-3

Up - On ............................................................................................................2-3

61200062L1-1 DSU 56/64 User Manual xiii

Page 14

Table of Contents

Carrier Detect (CD) - SE 4 ....................................................................................2-3

Down - Normal ............................................................................................. .2-3

Up - On ............................................................................................................2-3

Data Set Ready (SR) - SW 5 ..................................................................................2-3

Down - On ................................................... .................................. ..... ...... .......2-3

Up - Normal ....................................................................................................2-3

Remote Digital Loopback (RDL) - SW 6 ............................................................2-4

Down - Enable ............................................................. .................................. .2-4

Up - Disable ....................................................................................................2-4

Loop Rate - SW 7 ...................................................................................................2-4

Down - 56 Kbps ...................................................................... ...... ..................2-4

Up - 64 kbps ....................................................................................................2-4

Scrambler - SW 8 ...................................................................................................2-4

Down - On ................................................... .................................. ..... ...... .......2-4

Up - Off ............................................................................................................2-4

Network Connections .........................................................................................................2-5

DTE Connections .................................................................................................................2-5

Chapter 3. Test Modes

Self Test ............................................................ ..... .................................. ..............................3-1

Near End Tests .....................................................................................................................3-2

DTE Only Test ......................................................................................................................3-2

DTE with Test Pattern (TP) ................................................................................................3-3

DTE and Loop Test (LL) .....................................................................................................3-4

Loop Only Test (RT) ............................................................................................................3-6

Far End Tests ........................................................................................................................3-7

Remote Digital...............................................................................................................3-7

RDL with Test Pattern (TP)..........................................................................................3-7

Test Pattern (PTRN)......................................................................................................3-8

Remote Tests ........................................................................................................................3-9

Appendix A. Pinouts..................................... .................................. ................................. A-1

Appendix B. Specifications...................................................................... ...................... B-1

Index ............................................................................................................................Index-1

xiv DSU 56/64 User Manual 61200062 L1-1

Page 15

List of Figures

Figure 1-1. DSU 56/64 Unit ..............................................................................................1-2

Figure 1-2. DSU 56/64 Rear Panel...................................................................................1-4

Figure 3-1. DTE Only Test Diagram.................................................................................3-2

Figure 3-2. DTE with TP Test Diagram ...........................................................................3-4

Figure 3-3. DTE and Loop Test Diagram ........................................................................3-5

Figure 3-4. Loop Only Test Diagram ...............................................................................3-6

61200062L1-1 DS U 56/64 User Manual xv

Page 16

List of Figures

xvi DSU 56/64 User Manual 61200062L1-1

Page 17

List of Tables

Table 2-1. Default Option Switch Settings .................................................................... 2-5

Table A-1. Pinouts for RJ-48S Network Connections..................................................A-1

Table A-2. V.35 DTE Pinouts...........................................................................................A-2

61200062L1-1 DSU 56/64 User Manual xvii

Page 18

List of Tables

xviii DSU 56/64 User Manual 6120006 2L1-1

Page 19

Chapter 1 Introduction

PRODUCT OVERVIEW

The ADTRAN DSU 56/64, shown in Figure 1-1 on page 1- 2, is a

technologically advanced, high performance Data Service/Channel

Service Unit (DSU/CSU) that provides the interface between telco

provided Digital Data Service (DDS) and the customer’s Data

Terminal Equipment (DTE).

The DSU 56/64 supports both 56 kbps and 64 kbps loop service

rates with the DTE interface rate matching the selected loop rate. A

synchronous V.35 interface is provided for the DTE interface.

All setup or configuration is accomplished with a single eightposition DIP switch that is accessible from the back panel of the

unit.

61200062L1-1 DSU 56/64 User Manual 1-1

Page 20

Chapter 1. Introduction

FRONT PANEL

As shown in Figure 1-1, the front panel of the DSU 56/64 contains

eleven light emitting diode (LED) indicators that display DTE

interface, network, and test status. These indicators are defined in

the LED Identification section, below.

DSU 56/64

LED Identification

CDRDTDCSRS ALM

TEST

LOOPDTE

ERRORPTRNRDL

SELECT

TEST

Figure 1-1. DSU 56/64 Unit

DTE Status (Green)

Indicator Definition Source

RS

CS

TD

RD

CD

Request To Send

Clear To Send

Transmit Data

Receive Data

Carrier Detect

DTE

DSU

DTE

DSU

DSU

The active state for the status indicators (RS, CS, and CD) is On while

the on state for the data indicators (TD and RD) represents a Space condition.

Network Status (Red)

N

ALM O

indicates a problem on the local loop or within the

DDS network.

FF

O

indicates normal loop and network conditions .

1-2 DSU 56/64 User Manual 61200062L1-1

Page 21

Test Status/Error (Yellow/Red)

Chapter 1. Introduction

Test Switches

DTE O

N SOLID

LASHING

F

indicates DTE interface test in progress.

indicates Loop Interface test (CSU Loop-

back) has been initiated by telco.

Loop O

N SOLID

indicates loop interface test has been initiat-

ed from local DSU.

LASHING

F

indicates loop interface test (CSU or DSU

Loopback) has been initiated by telco.

RDL O

N SOLID

indicates remote digital loopback test has

been initiated from the local DSU.

F

LASHING

indicates remote digital loopback test has

been initiated from the remote DSU.

PTRN O

N SOLID

indicates that integ ral pattern generator is

being utilized for testing.

N

Error O

indicates that errors are being detected during a

test or that a test can not be properly initiated.

T ests defined by the above indicators ar e explained in greater detail

in Chapter 3, Test Modes on page 3-1.

The front panel also contains two push-button switches for

selecting and controlling the various test modes for the DSU 56/64.

The descriptions of these switches are as follows:

Select Each time this switch is activated, a valid test mode is in-

dicated by one or more LEDs being turned on solid.

ELECT

Pressing the S

button from within an active test in-

jects a bit error.

Test Once the desired test mode is displayed on the test sta-

tus indicators, the test is initiated by activating this

EST

switch. Pressing the T

button again will terminate

any test in progress.

61200062L1-1 DSU 56/64 User Manual 1-3

Page 22

Chapter 1. Introduction

REAR PANEL

The rear panel of the DSU 56/64 is shown in Figure 1-2.

RIMARY

P

V.35, a thirty-four pin connector, provides the

synchronous DTE interfa ce .

The eight-pin modular jack (RJ-48S) labeled T

ELCO

connects the

DSU 56/64 to the DDS network.

For pinouts to these connectors, see Table A-1, Pinouts for RJ-48S

Network Connections, on page A-1 and Table A-2, V.35 DTE Pinouts,

on page A-2.

TELCO OPTIONS

(LISTED ON BOTTOM)

12345678

PRIMARY V.35

115 VAC

60HZ .06A

Figure 1-2. DSU 56/64 Rear Panel

All setup or configuration parameters for the DSU 56/64 are

selected with an eight-position DIP switch. This switch, labeled

O

PTIONS

, is accessible from the rear panel. The label also references

the options chart located on the bottom of the unit. The individual

options are explained in detail in Chapter 2 in the section

Configuration on page 2-2.

The power cord on the r ear pa nel of the DSU 56/ 64 is mechan icall y

secured to the back panel and provides the connections to the

integral AC/DC power supply.

1-4 DSU 56/64 User Manual 61200062L1-1

Page 23

Chapter 2 Installation

UNPACK, INSPECT, POWER UP

Carefully insp ect the DSU 56/64 fo r any shippi ng damages. If

damage is suspected, file a claim immediately with the carrier and

then contact ADTRAN Customer and Product Service (CAPS). If

possible, keep the original shipping container for use in returning

the unit for repair or for verification of damage during shipment.

Contents of Shipping Package

The following items are included in ADTRAN shipments of the

DSU 56/64:

• The DSU 56/64 unit

• Network interface cable

• An 8-position modular to 8-position modular cable

• The DSU 56/64 User Manual

Customer Provides

•V.35 cable

61200062L1-1 DSU 56/64 User Manual 2-1

Page 24

Chapter 2. Installation

Power Up

The DSU 56/64 is equipped with a captive six-foot power cord that

is terminated with a three-prong plug for connecting to a grounded

power receptacle.

Ensure that a gr ounded, 1 15 VAC, 6 0 Hz rece ptacle is used for powe ring

the DSU 56/64 unit.

CONFIGURATION

The DSU 56/64 has eight options for controlling the operation of

both the network and DTE interfaces. These options are selected by

setting individual switches on either position DIP switch that is

accessible from the rear panel. A chart showing the options and

switch settings is attached to the bottom of the unit.

Clear To Send (CS) - SW 1

Down - Normal

In the down position, CS follows the RS lead with the selected

amount of delay. The only exceptions to this occur when network

or test conditions prevent data from being transferred over the DTE

interface. During these conditions CS is turned off.

Up - On

CS is forced on all the time.

Clear to Send Delay (CS Delay) - SW 2

Switch Position

RS to CS Delay

Down - Short

250

s + 125 µs

µ

Up - Long

s

10 ms + 125

2-2 DSU 56/64 User Manual 61200062L1-1

µ

Page 25

Antistream - SW 3

The Antistream option is used to select the antistream time out. The

antistream time out is the maximum time the DSU 56/64 is allowed

to transmit data from the DTE into the network. This feature

prevents one DTE device on a multi-drop network from

continuously tying up the transmit circuit from a remote DSU back

to the master DSU.

The antistream timer is reset to zero when RS transitions to the

active state and is updated every second while RS is active. When

the antistream ti m e out expi res, the DSU 56/64 st o p s tr ans m it t i ng

DTE data into the network. It does, however, continue to accept

data. CS is maintained in the active state until the DTE deactivates

the RS input.

Down - Off

The Antistream timer is disabled.

Up - On

The Antistream timer is enabled an d se t for 45 +/- 0.5 seconds .

Carrier Detect (CD) - SE 4

Chapter 2. Installation

Down - Normal

CD is on any time customer data is being received and off when the

receive circuit is idle, not carrying customer data.

Up - On

CD is forced on all the time.

Data Set Ready (SR) - SW 5

Down - On

SR is forced on all the time.

Up - Normal

SR is only turned off when the network is out of service or a test is

in progress.

61200062L1-1 DSU 56/64 User Manual 2-3

Page 26

Chapter 2. Installation

Remote Digital Loopback (RDL) - SW 6

Down - Enable

The DSU 56/64 accepts the industry standard V.54 RDL command

from the far end of the circuit.

Up - Disable

The DSU 56/64 does not respond to the V.54 loopback command

from the far end of the circuit.

Loop Rate - SW 7

Down - 56 Kbps

The networ k in te rfa ce o f t he DSU 5 6/6 4 is co nf igu r ed for op erat ion

at 56 kbps.

Up - 64 kbps

The networ k interface is configur ed for 64 kbps operation.

Scrambler - SW 8

For 64 kbps clear channel operation, there is a possibility that the

DTE data sequenced might mimic network loop maintenance

functions and erroneously cause other network elements to activate

loopbacks. To prevent this, the Scrambler switch should be set to

the Down (On) position.

The S

CRAMBLER ON

option mus t be set the same fo r bo th the local

and remote 56/64 DSUs for the situation described above.

The option is only valid when the 64 kbps rate is selected.

Down - On

The scrambler is enabled.

Up - Off

The scrambler is disabled.

2-4 DSU 56/64 User Manual 61200062L1-1

Page 27

Switch Position Setting

1

2

3

4

5

6

7

8

Down

Down

Down

Down

Up

Down

Down

Down

NETWORK CONNECTIONS

This interface consists of four leads that are paired to provide

separate transmit and receive circuits. The four leads are provided

on the eight-position modular jack DSU RJ-48S labeled T

the rear panel of the DSU 56/64.

The pinouts for this connector are shown in Table A-1 on page A-1.

Chapter 2. Installation

Table 2-1. Default Option Switch Settings

Clear to Send (CS) Normal

CS Delay Short

Anti-stream Timer Of f

Carrier Detect (CD) Normal

Data Set Ready (SR) Normal

Remote Digital Loopback (RDL) Ena bl ed

Loop Rate 56 Kbps

Scrambler Enabled

ELCO

on

DTE CONNECTIONS

The Data Terminal Equipment (DTE) is attached to the connector

labeled P

The pinout for the V.35 DTE connector is shown in Table A-2 on

page A-2.

A shielded V.35 cable is required to prevent possible radio frequency interference emissions.

61200062L1-1 DSU 56/64 User Manual 2-5

RIMARY

V.35 at the rear of the DSU 56/64.

Page 28

Chapter 2. Installation

2-6 DSU 56/64 User Manual 61200062L1-1

Page 29

Chapter 3 Test Modes

In addition to a self-test mode, the DSU 56/64 has other extensive

test modes which are designed to help isolate problems to specific

components of the communications circuit. These various test

modes for the DSU 56/64 are initiated and terminated from the

front panel using the S

ELECT

SELF TEST

A self-test goes through the following cycle.

1. When the DSU 56/64 is powered on, all LEDs on the front

panel turn on simultaneously for approximately two seconds.

2. After two seconds, all the LEDs turn off briefly.

3. The LEDs then cycle on in pairs with a fan-out pattern away

from the A

4. Next, the LEDs cycle off in pairs with a fan-in pattern back

towards the A

These patterns are repeated four times for visual verification that

all LEDs are functioning properly.

LM

indicator.

LM

indicator.

and T

EST

buttons.

At the completion of the LED test patterns, the PTRN LED is on,

which indicates that the DTE with TP test is being performed.

If the test is successful, the E

If the DTE

WITH

TP test fails, the RS, ALM, DTE, PTRN, an d E

RROR

indicator does not turn on.

RROR

indicators all flash.

61200062L1-1 DSU 56/64 User Manual 3-1

Page 30

Chapter 3. Test Modes

PROM CHECKSUM

If an E

ALM, PTRN, and E

test.

NEAR END TESTS

The local DSU 56/64 can perform the following near end tests:

•DTE Only

• DTE with Test Pattern

• DTE and LOOP (LL)

• Loop Only (RT)

DTE ONLY TEST

failure is detected during self test, CS,

RROR

indicators all flash at the end of the self

The DTE O

NLY

test can test both the DTE interface of the local DSU

56/64 plus its loop transmitter and receiver. For this test, the loop

transmit data is connected to the loop receive data at a point close

to the physical network interface.

The loopback point and the signal paths for this test are shown in

Figure 3-1.

DTE or Test

Equipment

Interface

RD

DTE

Transmit

TD

Interface

DTE

Receive

Interface

56/64 DSU

DTE

Only

Loop

Transmit

Interface

Loop

Receive

Interface

Figure 3-1. DTE Only Test Diagram

Network

Interface

Loop TX

Loop RX

3-2 DSU 56/64 User Manual 61200062L1-1

Page 31

Chapter 3. Test Modes

To initiate the DTE O

1. Press S

2. Press T

ELECT

EST

NLY

test, perform the following steps:

once to turn on the DTE test indicator.

while the test indicator is on.

3. To terminate the test, press T

Test data from the terminal or test equipment is routed through the

DTE section of the DSU 56/64 and then to the output of the loop

transmitter section where the signal is encoded for transmission.

The output of the loop transmitter is coupled back to the loop

receiver input. The received test signal is then decoded and

returned to the terminal or test equipment where it is checked for

any bit errors.

DTE WITH TEST PATTERN (TP)

The DTE

Figure 3-1 on page 3-2. It is initiated at the local DSU 56/64 and is

used to independently test the operation of the DSU 56/64.

To initiate the DTE

1. Press S

2. Press T

3. To terminate this test, press T

WITH

ELECT

indicators.

EST

TP test is similar to the DTE O

WITH

TP test, perform the following steps:

twice to turn on both the DTE and PTRN test

while these test indicators are on.

EST

EST

.

NLY TEST

described in

.

Instead of using data from the terminal or test equipment, this test

utilizes an internal test pattern generator and detector in the DSU

56/64. The loopback point and the data paths for this test are

illustrated in Figure 3-2 on page 3-4.

61200062L1-1 DSU 56/64 User Manual 3-3

Page 32

Chapter 3. Test Modes

DTE or Test

Equipment

Interface

Test

Pattern

Generator

DTE

Transmit

TD

Interface

DTE

with

Test Pattern

56/64 DSU

Loop

Transmit

Interface

Network

Interface

Loop TX

RD

DTE

Receive

Interface

Test

Pattern

Detector

Loop

Receive

Interface

Loop RX

Figure 3-2. DTE with TP Test Diagram

The internal test pattern generator and detector of the DSU 56/64

operate with a 2047 data pattern. When this test is initiated, the test

pattern detector examines the receive data stream until

synchronization to the 2047 pattern occurs. Once synchronized, the

detector continues to check the receive data and reports any

detected bit errors by turning on the E

RROR

LED.

Once a test is initialized with the internal test pattern generator and

detector, errors can be injected into the transmit data stream by

pressing S

ELECT

and observed by watching the E

RROR

LED turn

on for a brief period of time. As previously mentioned, the DTE

WITH

TP is automatically performed during the self-test sequence

for the DSU 56/64.

DTE AND LOOP TEST (LL)

This test is initiated at the local DSU 56/64 and allows independent

testing of the separate sections of the DSU 56/64. This includes

testing of the local DTE interface with data from the terminal or test

equipment and testing of the loop interface section of the local DSU

3-4 DSU 56/64 User Manual 61200062L1-1

Page 33

Chapter 3. Test Modes

56/64 from the remote site over the actual communications circuit.

Testing from the remote end of the circuit is performed with test

data generated by the remote DSU or terminal type test equipment.

The DTE

AND LOOP

test splits the DSU 56/64 into separate DTE and

Loop interface sections and then loops the transmit data of each

interface back to its respective receive data. Figure 3-3 illustrates

the loopback points and the signal paths for this test. The DTE

OOP

L

LEDs flash during initialization of the test and turn on solid

once the test is in progress.

56/64 DSU

DTE or Test

Equipment

Interface

TD

RD

DTE

Transmit

Interface

DTE

Receive

Interface

DTE

and

Loop

Loop

Transmit

Interface

Loop

Receive

Interface

Figure 3-3. DTE and Loop Test Diagram

AND

Network

Interface

Loop TX

Loop RX

To initiate the DTE

1. Press S

ELECT

AND LOOP

test, perform the following steps:

three times to turn on both the DTE

AND LOOP

test indicators.

2. Press T

3. To terminate this test, press T

61200062L1-1 DSU 56/64 User Manual 3-5

EST

while these test indicators are on.

EST

.

Page 34

Chapter 3. Test Modes

LOOP ONLY TEST (RT)

DTE or Test

Equipment

Interface

RD

The L

OOP ONLY

test or R

EMOTE LOOPBACK

test (RT) is used to test

the loop interface and a major portion of the DTE interface of the

local DSU 56/64 from the remote site over the actual digital data

circuit.

For the L

OOP ONLY

test, the network receive data is looped to the

network transmit data inside the DTE interface section of the DSU

56/64. The physical DTE interface is ignored for this test. The L

LED flashes during initialization of the test and turns on solid once

the test is in progress. Figure 3-4 illustrates the loopback point and

the signal paths for this test.

56/64 DSU

DTE

Transmit

Interface

TD

Loop

Only

DTE

Receive

Interface

Loop

Transmit

Interface

Loop

Receive

Interface

OOP

Network

Interface

Loop TX

Loop RX

Figure 3-4. Loop Only Test Diagram

To initiate the L

1. Press S

2. Press T

3. To t erminate this test, press T

3-6 DSU 56/64 User Manual 61200062L1-1

OOP ONLY

ELECT

four times to turn on the L

EST

while this test indicator is on.

test, perform the following steps:

EST

OOP

test indicator.

.

Page 35

FAR END TESTS

Remote Digital

When the RDL test is initiated at the local DSU 56/64, it commands

the remote DSU into loopback with the industry standard V.54

loopback pattern. The loopback point and the signal paths for the

remote DSU are the same as the L

shown in Figure 3-4 on page 3-6. This Loopback

with data from the terminal or te st equipment. The RDL LED

flashes during initialization of the test and turns on solid once the

test is in progress.

To initiate the RDL test, perform the following steps:

OOP ONLY

Chapter 3. Test Modes

test for a local DSU,

test is performed

1. Press S

2. Press T

ELECT

five times to turn on the RDL test indicator.

EST

while this test indicator is on.

3. To terminate this test, press T

RDL with Test Pattern (TP)

When the RDL

local DSU commands the remote DSU into loopback with the

industry standard V.54 loopback pattern. The loopback point and

the signal paths for the remote DSU are the same as the L

test for a local DSU; see Figure 3-4 on page 3-6. This L

is performed with data from the internal test pattern generator and

error detector. The RDL and PTRN LEDs flash during initialization

of the test and turn on solid once the test is in progress.

To initiate the RDL

1. Press S

indicators.

2. Press T

3. To terminate this test, press the T

WITH

WITH

ELECT

six times to turn on both the RDL and PTRN test

EST

while these test indicators are on.

EST

.

TP test is initiated at the local DSU 56/64, the

OOP ONLY

OOPBACK

test

TP test, perform the following steps:

EST

switch.

61200062L1-1 DSU 56/64 User Manual 3-7

Page 36

Chapter 3. Test Modes

Test Pattern (PTRN)

When the PTRN test is initiated, the local DSU 56/64 uses the

integral test pattern generator to transmit a standard 2047 test

pattern to the DSU on the far end of the circuit. The local DSU 56/

64 then exam ines the received d a ta for th e standard 2047 patte rn .

Once this pattern is detected and synchronization is achieved, the

E

RROR

indicator is turned off. The E

errors in the receive data pattern are detected. While this test is

active, errors can be injected into the transmit data stream by

pressing the S

initialization of the test and turns on solid once the test is in

progress.

To initiate the PTRN test, perform the following steps:

RROR

indicator turns on when

ELECT

push-button. The PTRN LED flashes during

1. Press S

2. Press the T

ELECT

seven times to turn on the PTRN test indicator.

EST

switch while this test indicator is on.

3. To t erminate this test, press T

EST

.

3-8 DSU 56/64 User Manual 61200062L1-1

Page 37

REMOTE TESTS

The DSU 56/64 responds to three remotely activated tests.

• Remote Digital Loopback (RDL)

•CSU Loopback (LL)

• DSU Loopback (RT)

The RDL test is initiated by a remote DSU and causes the local DSU

56/64 to loopback. The loopback point is the sa me as the loop only

point. See Figure 3-4 on page 3-6. This test is run to test the end-toend performance of the circuit.

Chapter 3. Test Modes

Both the CSU L

OOPBACK

and the DSU L

OOPBACK

tests are

activated from the telephone company diagnostic test equipment

and are used to isolate trouble on a circuit.

The CSU L

loopback points as the DTE

OOPBACK

, commonly called the LL test, has the same

AND LOOP

test. It is used by the

telephone company to test the integrity of the local loop.

The DSU L

loopback point as the L

OOPBACK

, commonly called the RT test, has the same

OOP ONLY

test and is used by the telephone

company to test the operation of both the local loop and DTE

interface sections.

61200062L1-1 DSU 56/64 User Manual 3-9

Page 38

Chapter 3. Test Modes

3-10 DSU 56/64 User Manual 61200062L1-1

Page 39

Appendix A Pinouts

Table A-1. Pinouts for RJ-48S Network Connections

Pin Number Function Signal Direction

1 Transmit Data (R) From Customer to Network Interface

2 Transmit Data (T) From Customer to Network Interface

3-6 Not Used N/A

7 Receive Data (T-1) From Network Interface to Customer

8 Receive Data (R-1) From Network Interface to Customer

61200062L1-1 DSU 56/64 User Manual A-1

Page 40

Appendix A. Pinouts

Table A-2. V.35 DTE Pinouts

Pin CCITT Description

A 101 Protective Ground

B 102 Signal Ground (SG)

C 105 Request to Send (RS)

D 106 Clear to Send

E 107 Data Se t Ready (SR)

F 1 09 Receive Line Signal Detect or (CD)

R 104 Received Data (RD-A)

T 104 Received Data (RD-B)

V 115 Receiver Signal element Timing (SCR-A)

X 115 Receiver Signal Element Timing (SCR-B)

P 103 Tra nsmitted Data (SD-A)

S 103 Tra nsmitted Data (SD-B)

Y 114 Tra nsmitter Signal ele ment Timing (SCT-A)

AA 114 Transmitter Signal element Timing (SCT-B)

U 113 External TX Signal element Timing (SCX-A)

W 113 External TX Signal element Timing (SCX-B)

A-2 DSU 56/64 User Manual 61200062L1-1

Page 41

Appendix B Specifications

SPECIFICATIONS AND FEATURES

The DSU 56/64 is a single stand-alone unit designed to be used

either on a desktop or mounted on a wall.

This section describes the standard specifications and features

incorporated in the DSU 56/64.

Loop Interface

• 4-wire, full duplex

Line Requirements

• Local loop specifications per AT&T Pub 62310

Loop Rates

• 56 kbps or 64 kbps

Receiver Sensitivity

•-45 dB

DTE Interfaces

• V.35 synchron ous

DTE Operating Modes

• Full or half duplex

DTE Data Rates

• 56 kbps or 64 kbps synchronous

61200062L1-1 DSU 56/64 User Manual B-1

Page 42

Appendix B. Specifications

Diagnostics

Network test center activated:

• CSU loopback on sealing current reversal in local loop

• DSU loopback

User activated:

• Self test,

• Local loopback,

• V.54 activated remote loopback with 2047 test pattern

• DTE data/data from external test set

Power

•115 VAC

• 4 Watts (maximum)

Environment

• Operating Temperature: 0

• Storage Tem perature: - 20

o

C to 50o C (32o F to 122o F

o

C to 70o C (-4o F to 158o F)

• Relative Humidity: Up to 95%, non-condensing

Hardware Specifications

• Dimensions: 1.56 inches H, 6.50 inches W, 8.32 inches L

•Weight: 1.5 pounds

B-2 DSU 56/64 User Manual 61200062L1-1

Page 43

Index

A

ACES help desk, xi

affidavit

connection for digital services,

connection of CPE equipment ,

antistream - SW-1,

Applications engineering

how to contact,

C

cables

included with shipment,

provided by customer,

Canadian emissions requirements,

Canadian equipment limitations,

CAPS department

how to contact,

carrier detect (CD) - SE-4,

clear to send (CS) SW-1,

clear to send delay (CS delay) - SW-2,

configuration

for network and DTE interfaces,

customer service,

D

data set ready (SR) - SW-5, 2-3

diagnostics, of DSU 56/64,

DTE and Looptest

DTE connection s,

DTE status

LED identification,

DTE with TP test

DTE-only test

E

environmental specifica t ions, B-2

F

Far End Tests 3-7

FCC radio frequency interference,

2-3

xi

2-1

2-1

ix

xi

2-3

2-2

xi

B-2

3-4

2-5

1-2

3-3

3-2

viii

iv

v

viii

vii

FCC regulations,

features of DSU 56/64,

front panel

description and drawing,

LED identification,

test switches,

B-1

1-2

1-2

1-3

H

help desk

how to contact,

xi

L

LED identification

DTE status

for front panel,

Network Status,

test status/error

Loop Only Test

loop rate - SW-7,

1-2

1-2

1-2

1-3

3-6

2-4

N

2-2

2-2

network connections, 2-5

Network status

LED identification,

1-2

P

pinouts

RJ-48S network connections,

V.35 DTE,

power cord

description of,

power features,

product overview,

product warranty,

PTRN test

A-2

2-2

B-2

1-1

x

3-8

A-1

R

rear panel

description and graphic,

remote digital loopback (RDL) - SW-6,

remote digital test

3-7

1-4

2-4

61202062L1-1 DS U 56/64 User Manual Index-1

Page 44

Index

3-9

pinouts,

A-1

xi

remote tests

repair and return information,

RJ-48S network connections,

RMA requests

S

safety instructio ns, iii

scrambler - SW-8,

self-test mode

service type information

shipping damage

what to do

shipping package

contents of,

specifications

3-1

B-1

2-4

vii

2-1

2-1

T

technical support

how to contact,

test modes

3-1

xi

DTE and Loop Test,

xi

DTE with T est patte rn test,

DTE-only test,

Far End Tests,

loop only test,

PTRN test,

remote digital,

remote tests,

self-test

test status/error

LED identification,

test switches

on front panel

training information

how to contact,

3-8

3-1

3-4

3-3

3-2

3-7

3-6

3-7

3-9

1-3

xii

1-3

V

V.35 DTE pinouts, A-2

W

warranty, x

Index-2 DSU 56/64 User Manual 61202062 L1-1

Loading...

Loading...