Page 1

ATLAS 800 SERIES

System Manual

1200780L1 ATLAS 830 System, AC

1200781L1 ATLAS 830 System, DC

1200321L1 ATLAS 890 System

1200322L1 AT LAS 890 System Controller Module

1200185L3 Quad T1/PRI Option Module

1200264L1 Quad E1/PRA Option Module

1200184L1 Quad Nx 56/64 Option Module

4200261Lx Quad USSI Option Module

1200186L2 Octal Basic Rate ISDN (U-Interface) Option Module

1200343L1 Octal Basic Rate ISDN (S/T Interface) Option Module

1200223L1 T3 Option Module

1200225L1 T3 Option Module with Drop and Insert Interface

4200773Lx Dual Video Option Module

1200771L1 NxT1 HSSI/V .35 Option Module

1200338L1 Octal FXS Option Module

1200221Lx 8,16,24,32 Channel Voice Compression Resource Modules

1200262L1 Nx 56/64 BONDing Resource Module

1200222L1 HDLC Resource Module

1200181L1 Modem-16 Resource Module

1200782L1 Modem-24 Resource Module

1200182L1 Async-232 Option Module

61200780L1-1C

August 2004

Page 2

ATLAS 800 Series System Manual Trademarks

Trademarks

Any brand names and product names included in this manual are trademarks, registered trademarks, or

trade names of their respective holders.

To the Holder of the Manual

The contents of this manual are current as of th e date of publication. ADTRAN reserves the right to change

the contents without prior notice. In no event will ADTRAN be liable for any special, incidental, or

consequential damages or for commercial losses even if ADTRAN has been advised thereof as a result of

issue of this publication.

About this Manual

This manual provides a complete description of the ATLAS 800 Series System and system software. The

purpose of this manual is to provide the technician, system administrator, and manager with general and

specific information related to the planning, installation, operation, and maintenance of the ATLAS 800

Series. This manual is arranged so that needed information can be quickly and easily found.

Viewing Menu information

The ATLAS 800 Series System menus are hierarchical in nature, and information about the menus is

presented in the same succession. Main menus are numbered with submenus following. Also, hyperlinked

menu trees are provided for the first two menu levels.

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (256) 963-8000

© 2004 ADTRAN, Inc.

All Rights Reserved.

Printed in U.S.A.

61200780L1-1C © 2004 ADTRAN, Inc. 2

Page 3

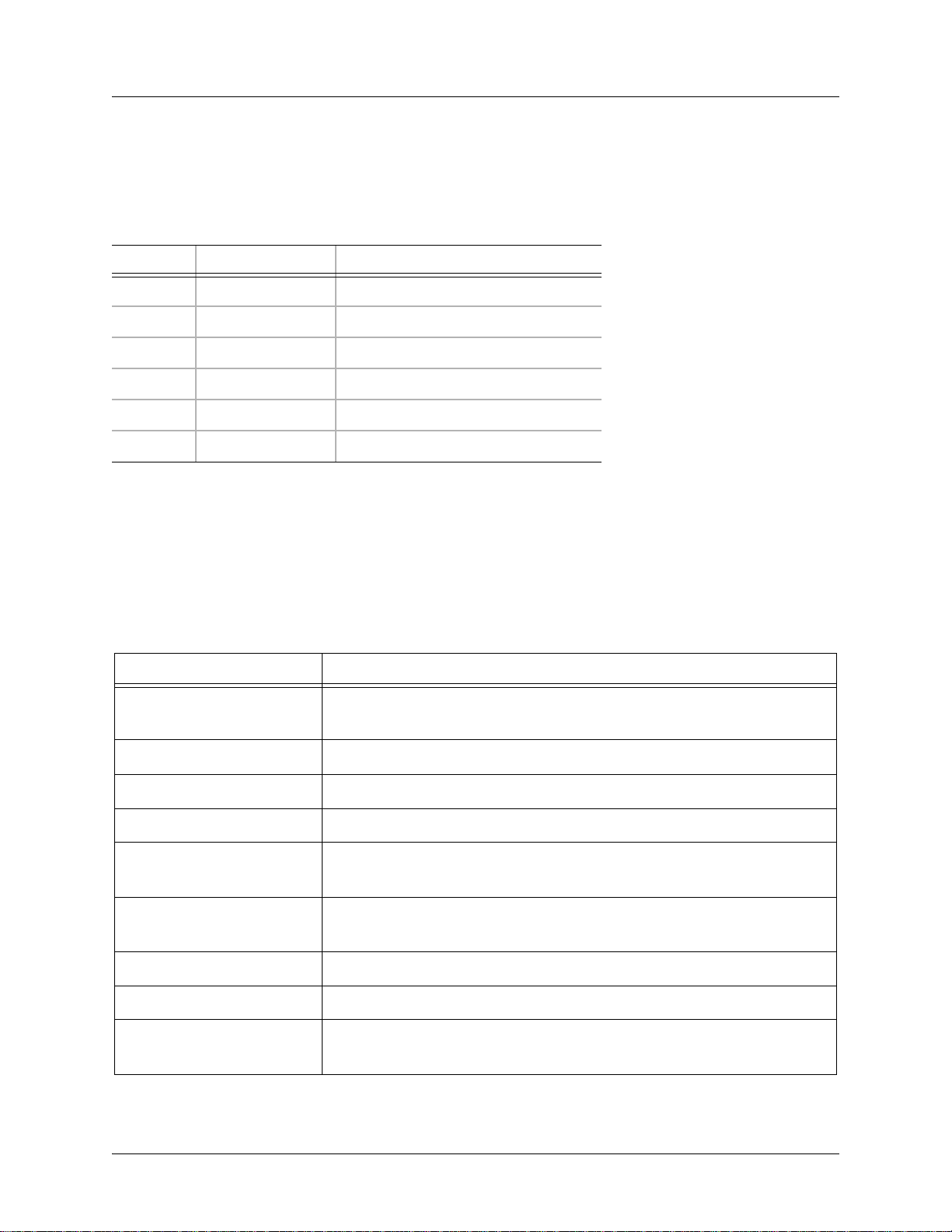

ATLAS 800 Series System Manual Revision History

Revision History

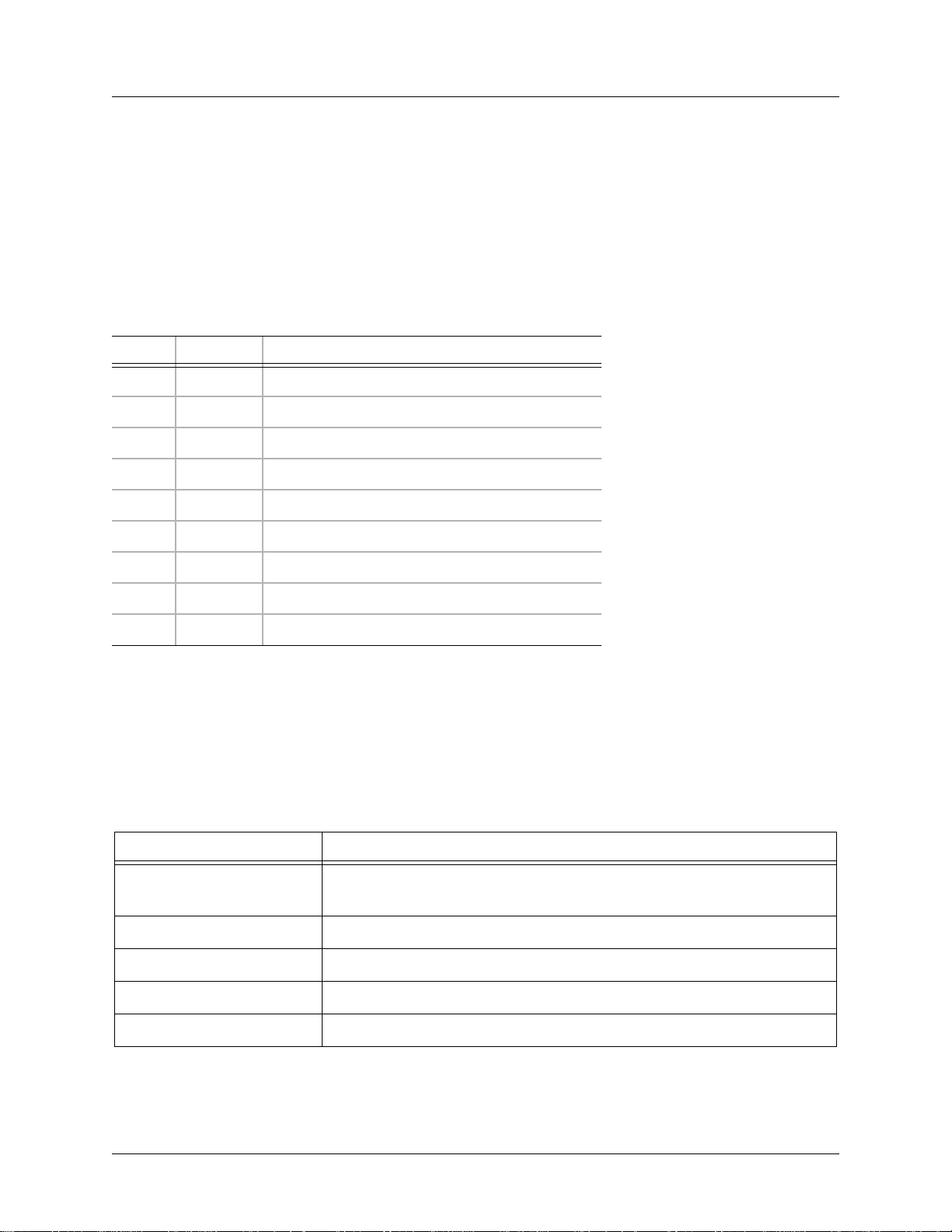

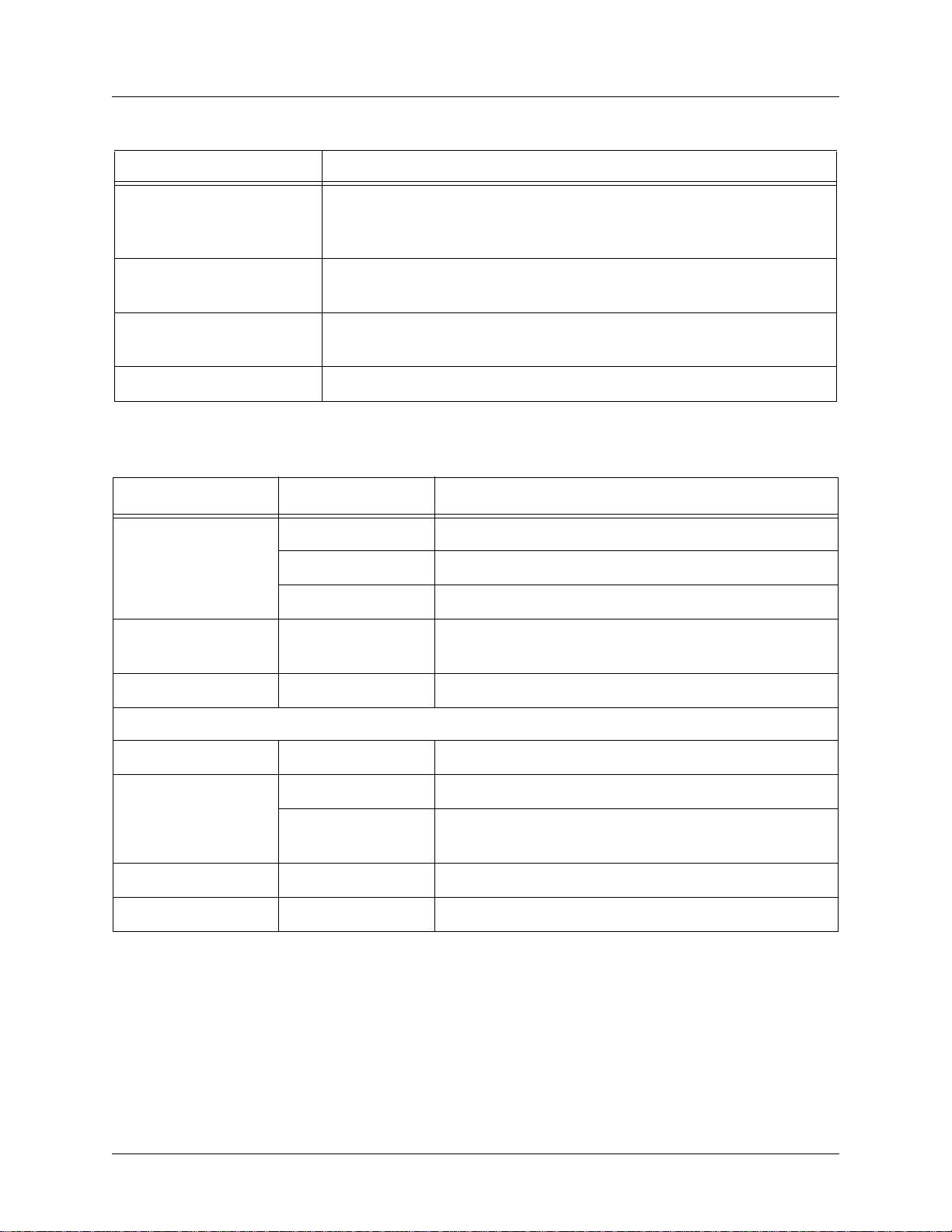

Document

Revision

A Aug 2002 Initial release.

B Jan 2004 Added Modem-24 Module.

C Aug 2004 Corrections to menu selections.

D

E

F

G

Conventions

Notes provide additional useful information.

Date Description of Changes

Combined ATLAS 830 and ATLAS 890 into one manual.

Cautions signify information that could prevent service interruption.

Warnings provide information that could prevent damage to the equipment or

endangerment to human life.

61200780L1-1C © 2004 ADTRAN, Inc. 3

Page 4

ATLAS 800 Series System Manual Safety Instructions

Safety Instructions

When using your telephone equipment, please follow these basic safety precautions to reduce the risk of

fire, electrical shock, or personal injury:

1. Do not use this product near water, such as a bathtub, wash bowl, kitchen sink, laundry tub, in a

wet basement, or near a swimming pool.

2. Avoid using a telephone (other than a cordless-type) during an electrical storm. There is a remote

risk of shock from lightning.

3. Do not use the telephone to report a gas leak in the vicinity of the leak.

4. Use only the power cord, power supply, and/or batteries indicated in the manual. Do not dispose of

batteries in a fire. They may explode. Check with local codes for special disposal instructions.

Save These Important Safety Instructions

61200780L1-1C © 2004 ADTRAN, Inc. 4

Page 5

ATLAS 800 Series System Manual FCC-Required Information

FCC-Required Information

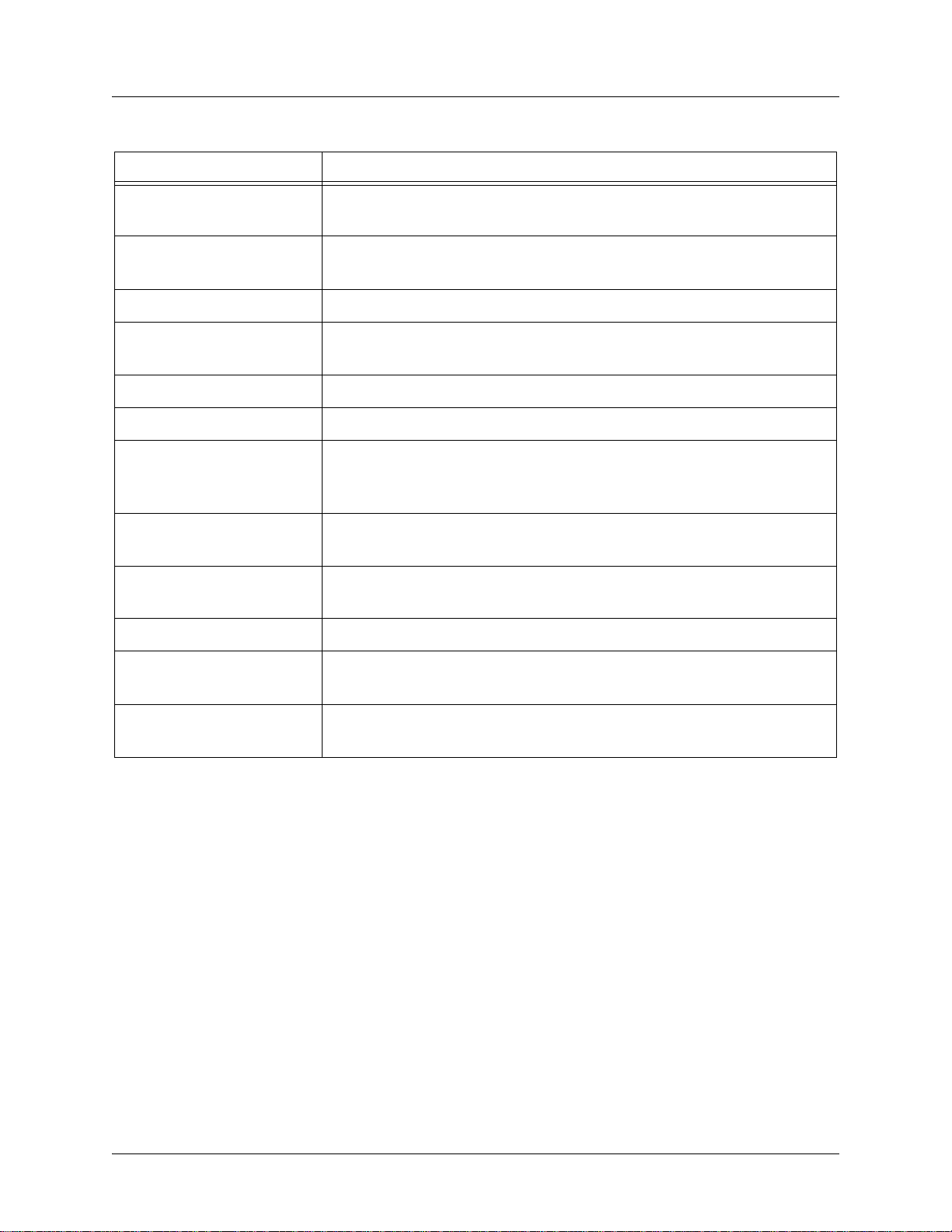

Product: ATLAS 830 (1200780L1/1200781L1) and ATLAS 890 (1200321L1)

FCC regulations require the following information be provided in this manual:

1. This equipment complies with Part 68 of FCC rules and requirements adopted by ACTA. Each of

the registered modules has a label showing the FCC registration number and ringer equivalence

number (REN). If requested, provide this information to the telephone company.

2. If this equipment causes harm to the telephone network, the telephone company may temporarily

discontinue service. If possible, advance notification is given; otherwise, notification is given as

soon as possible. The telephone company will advise the customer of the right to file a complaint

with the FCC.

3. The telephone company may make changes in its facilities, equipment, operations, or procedures

that could affect the proper operation of this equipment. Advance notification and the opportunity

to maintain uninterrupted service are given.

4. If experiencing difficulty with this equipment, please contact ADTRAN for repair and warranty

information. The telephone company may require this equipment to be disconnected from the

network until the problem is corrected or it is certain the equipment is not malfunctioning.

5. This unit contains no user-serviceable parts.

6. An FCC compliant telephone cord with a modular plug is provided with this equipment. This

equipment is designed to be connected to the telephone network or premises wiring using an FCC

compatible modular jack, which is compliant with Part 68 and requirements adopted by ACTA.

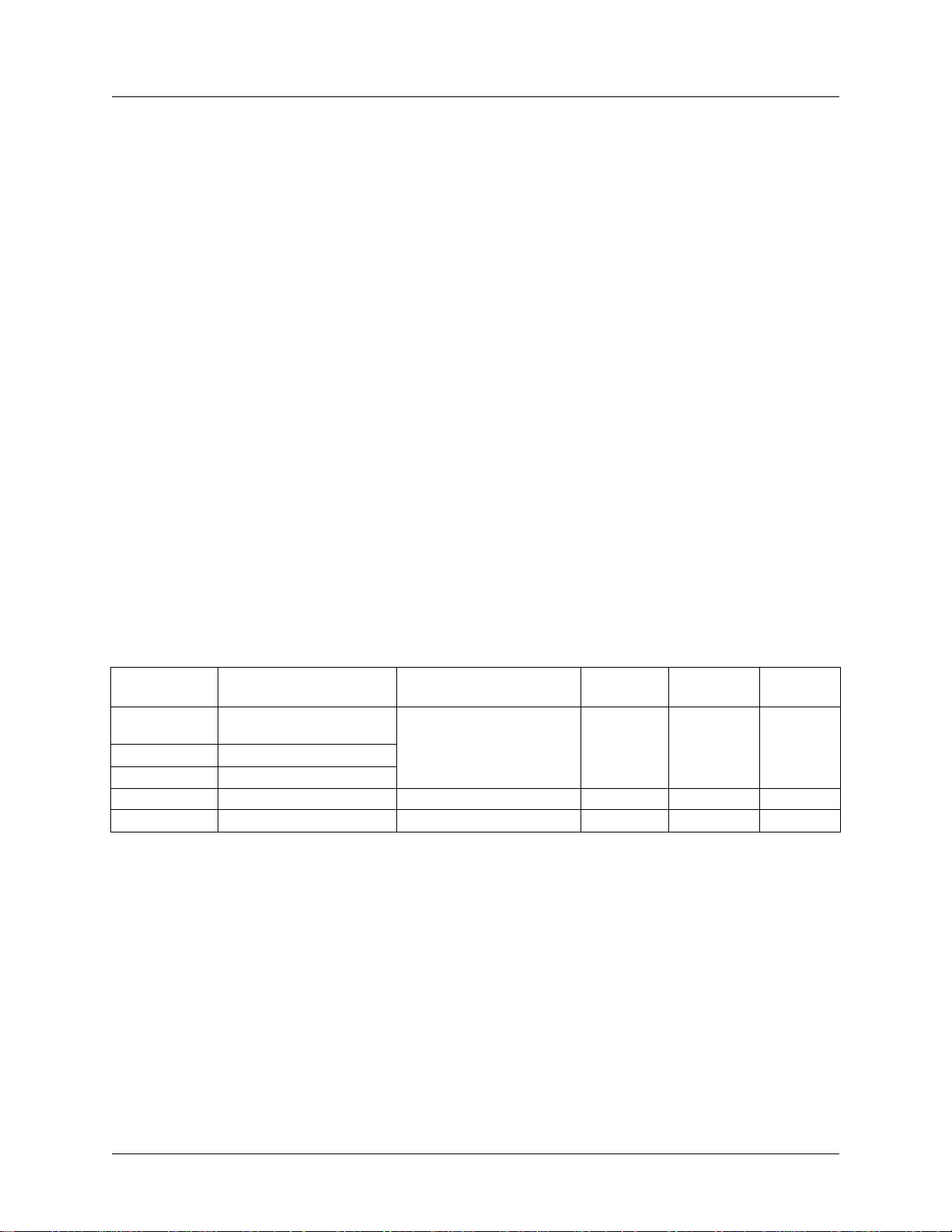

7. The following information may be required when applying to the local telephone company for

service:

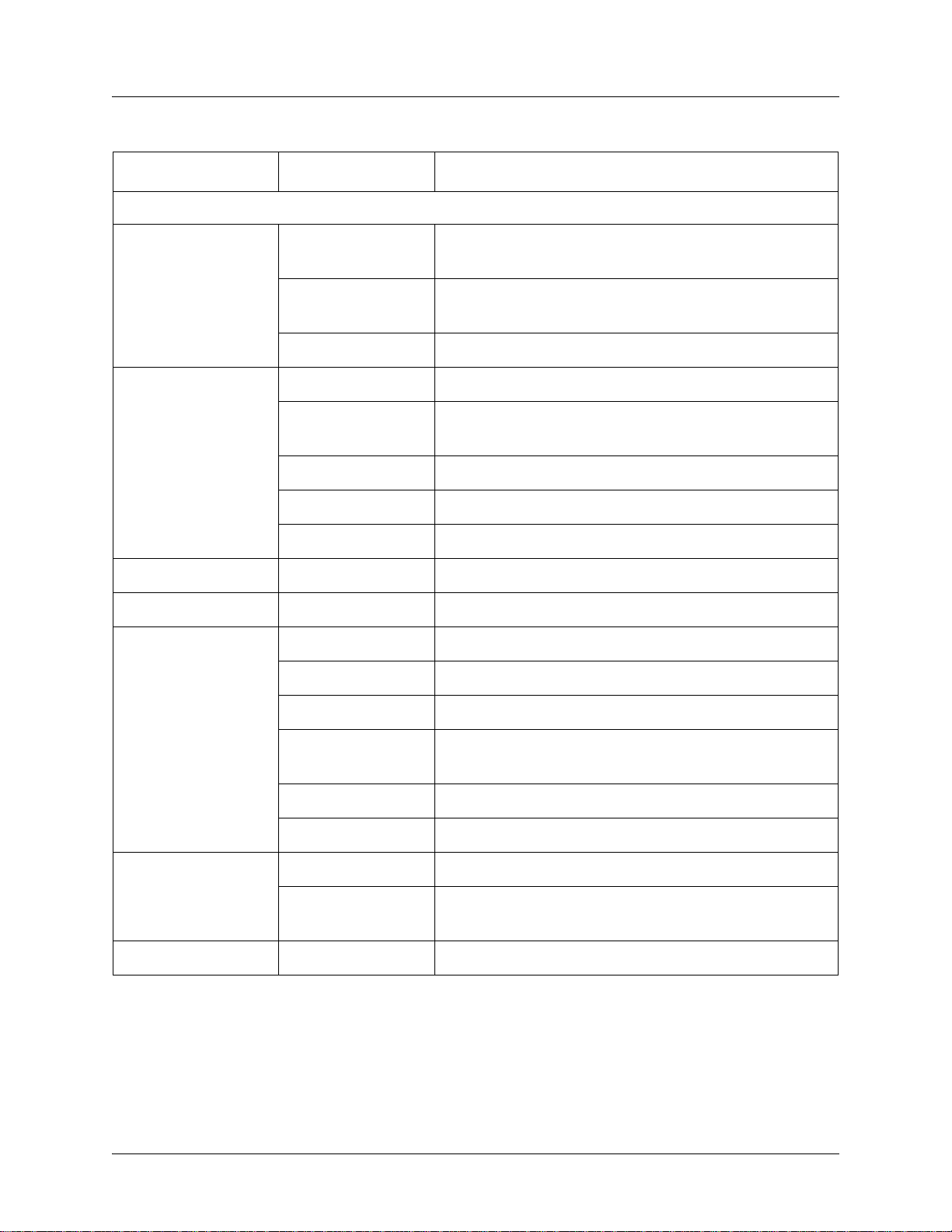

Registration

Part Number

1200780L1 /

1200781L1

1200185L3 HDCUSA-31934-DE-N

1200771L1 US: HDCDENAN1200346L1

1200186L2 HDCUSA-32227-DE-N Basic Rate ISDN 6.0 N 02IS5 RJ-49C

1200343L1 US: HDCXDNAN1200343L1 ISDN BRI S/T 6.0F N/A N/A

US: HDCDENAN1200780L1

Number Service Type REN/SOC FIC USOC

1.544 Mbps - SF

1.544 Mbps - SF and B8ZS

1.544 Mbps - ESF

1.544 Mbps - ESF and B8ZS

6.0 N

04DU9-BN

04DU9-DN

04DU9-1KN

04DU9-1SN

RJ-48C

8. The REN is useful in determining the quantity of devices you may connect to your telephone line

and still have all of those devices ring when your number is called. In most areas, the sum of the

RENs of all devices should not exceed five. To be certain of the number of devices you may

connect to your line as determined by the REN, call your telephone company to determine the

maximum REN for your calling area.

9. This equipment may not be used on coin service provided by the telephone company. Connection

to party lines is subject to state tariffs. Contact your state public utility commission or corporation

commission for information.

61200780L1-1C © 2004 ADTRAN, Inc. 5

Page 6

ATLAS 800 Series System Manual FCC-Required Information

FCC Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio frequencies. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with Class A FCC limits.

Changes or modifications to this unit not expressly appr oved by the party responsible

for compliance could void the user’s authority to operate the equipment.

61200780L1-1C © 2004 ADTRAN, Inc. 6

Page 7

ATLAS 800 Series System Manual Affadavits

Affadavits

Affidavit Requirements Connection to Digital Services

• An affidavit is required to be given to the telephone company whenever digital terminal equipment

without encoded analog content and billing protection is used to transmit digital signals containing

encoded analog content which are intended for eventual conversion into voiceband analog signal and

transmitted on the network.

• The affidavit shall affirm that either no encoded analog content or billing information is being

transmitted or that the output of the device meets Part 68 encoded analog content or billing protection

specifications.

• End user/customer will be responsible to file an affidavit with the local exchange carrier when

connecting unprotected CPE to a 1.544 Mbps or subrate digital service.

• Until such time as subrate digital terminal equipment is registered for voice applications, the affidavit

requirements for subrate services are waived.

61200780L1-1C © 2004 ADTRAN, Inc. 7

Page 8

ATLAS 800 Series System Manual Affadavits

Affidavit for Connection of Customer Premises Equipment

to 1.544 Mbps and/or Subrate Digital Services

For the work to be performed in the certified territory of ___________________ (telco name)

State of ________________

County of ________________

I, _______________________ (name), ____________________________________ (business address),

____________________ (telephone number) being duly sworn, state:

( ) I have responsibility for the operation and maintenance of the terminal equipment to be connected to 1.544 Mbps and/or

________ subrate digital services. The terminal equipment to be connected complies with Part 68 of the FCC rules except for

the encoded analog content and billing protection specifications. With resp ec t to encoded analog content and billing

protection:

( ) I attest that all operations associated with the establishmen t, maintenance, and adjustment of the digital CPE with respect to

analog content and encoded billing protection information continuously complies with Part 68 of the FCC Rules and

Regulations.

( ) The digital CPE does not transmit digital signals containing encoded analog content or billing information which is intended

to be decoded within the telecommunications network.

( ) The encoded analog content and billing protection is factory set and is not under the control of the customer.

I attest that the operator(s)/maintainer(s) of the digital CPE responsible for the establishment, maintenance, and adjustment of the

encoded analog content and billing information has (have) been trained to perform these functions by successfully having

completed one of the following (check appropriate blocks):

( ) A. A training course provided by the manufacturer/grantee of the equipment used to encode analog signals; or

( ) B. A training course provided by the customer or authorized representative, using training materials and instructions

provided by the manufacturer/grantee of the equipment used to encode analog signals; or

( ) C. An independent training course (e.g., trade school or technical institution) recognized by the manufacturer/grantee of

the equipment used to encode analog signals; or

( ) D. In lieu of the preceding training requirements, the operator(s)/maintainer(s) is (are) under the control of a supervisor

trained in accordance with _________ (circle one) above.

I agree to provide ______________________ (telco’s name) with proper documentation to demonstrate compliance with the

information as provided in the preceding paragraph, if so requested.

_________________________________Signature

_________________________________Title

_________________________________ Date

Transcribed and sworn to before me

This ________ day of _______________, _______

_________________________________

Notary Public

My commission expires:

_________________________________

61200780L1-1C © 2004 ADTRAN, Inc. 8

Page 9

ATLAS 800 Series System Manual Industry Canad a Compliance Information

Industry Canada Compliance Information

Notice: The Industry Canada label applied to the product (identified by the Industry Canada logo or the

“IC:” in front of the certification/registration number) signifies that the Industry Canada technical

specifications were met.

Notice: The Ringer Equivalence Number (REN) for this terminal equipment is supplied in the

documentation or on the product labeling/markings. The REN assigned to each terminal device indicates

the maximum number of terminals that can be connected to a telephone interface. The termination on an

interface may consist of any combination of devices subject only to the requirement that the sum of the

RENs of all the devices should not exceed five (5).

Canadian Emissions Requirements

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus

as set out in the interference-causing equipment standard entitled “Digital Apparatus,” ICES-003 of the

Department of Communications.

Cet appareil numérique respecte les limites de bruits radioelectriques applicables aux appareils numériques

de Class A prescrites dans la norme sur le materiel brouilleur: “Appareils Numériques,” NMB-003 edictee

par le ministre des Communications.

61200780L1-1C © 2004 ADTRAN, Inc. 9

Page 10

ATLAS 800 Series System Manual Product Warranty

Product Warranty

ADTRAN will repair and return this product within the warranty period if it does not meet its published

specifications or fails while in service. Warranty information can be found at www.adtran.com

.

Product Registration

Registering your product helps ensure complete customer satisfaction. Please take time to register your

products on line at www.adtran.com

. Click Service and Support on the top of the page, and then click

Product Registration under Support.

Customer Service, Product Support Information, and Training

ADTRAN will repair and return this product within the warranty period if it does not meet its published

specifications or fails while in service. Warranty information can be found at www.adtran.com/warranty.

A return material authorization (RMA) is required prior to returning equipment to ADTRAN. For service,

RMA requests, training, or more information, use the contact information given below.

Repair and Return

If you determine that a repair is needed, please contact our Customer and Product Service (CaPS)

department to have an RMA number issued. CAPS should also be contacted to obtain information

regarding equipment currently in house or possible fees associated with repair.

CaPS Department (256) 963-8722

Identify the RMA number clearly on the package (below address), and return to the following address:

ADTRAN Customer and Product Service

901 Explorer Blvd. (East Tower)

Huntsville, Alabama 35806

RMA # _____________

61200780L1-1C © 2004 ADTRAN, Inc. 10

Page 11

ATLAS 800 Series System Manual Pre-Sales Inquiries and Applications Support

Pre-Sales Inquiries and Applications Support

Your reseller should serve as the first point of contact for support. If additional pre-sales support is needed,

the ADTRAN Support web site provides a variety of support services such as a searchable knowledge

base, latest product documentation, application briefs, case studies, and a link to submit a question to an

Applications Engineer. All of this, and more, is available at:

http://support.adtran.com

When needed, further pre-sales assistance is available by calling our Applications Engineering

Department.

Applications Engineering (800) 615-1176

Post-Sales Support

Your reseller should serve as the first point of contact for support. If additional support is needed, the

ADTRAN Support web site provides a variety of support services such as a searchable knowledge base,

updated firmware releases, latest product documentation, service request ticket generation and

trouble-shooting tools. All of this, and more, is available at:

http://support.adtran.com

When needed, further post-sales assistance is available by calling our Technical Support Center. Please

have your unit serial number available when you call.

Technical Support (888) 4ADTRAN

Installation and Maintenance Support

The ADTRAN Custom Extended Services (ACES) program offers multiple types and levels of installation

and maintenance services which allow you to choose the kind of assistance you need. This support is

available at:

http://www.adtran.com/aces

For questions, call the ACES Help Desk.

ACES Help Desk (888) 874-ACES (2237)

61200780L1-1C © 2004 ADTRAN, Inc. 11

Page 12

ATLAS 800 Series System Manual Training

Training

The Enterprise Network (EN) T echnical T raining Department offers training on our most po pular products.

These courses include overviews on product features and functions while covering applications of

ADTRAN's product lines. ADTRAN provides a variety of training options, including customized training

and courses taught at our facilities or at your site. For more information about training, please contact your

Territory Manager or the Enterprise Training Coordinator.

Training Phone (800) 615-1176, ext. 7500

Training Fax (256) 963-6700

Training Email training@adtran.com

61200780L1-1C © 2004 ADTRAN, Inc. 12

Page 13

Table of Contents

Section 1 Engineering Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Assists network designers in incorporating the ATLAS 800 Series System into

existing networks. Includes pinouts.

Section 2 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Provides managers with an overview of the ATLAS 800 Series System.

Section 3 Network Turnup Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Provides step-by-step instructions for installing and powering up the ATLAS 800

Series System.

Section 4 User Interface Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Provides detailed descriptions of all menu options and configuration parameters for

the ATLAS 800 Series System.

Section 5 Detail Level Procedures (DLP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Provides the detailed instruction for performing various unit functions such as

upgrading firmware.

Section 6 System Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Explains System Event Log messages and describes configuration of the Event

Log.

Section 7 ADTRAN Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Provides instructions for configuring and using the ADTRAN utilities (Telnet,

VT100, Syslog, and TFTP).

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .377

61200780L1-1C © 2004 ADTRAN, Inc. 13

Page 14

SECTION 1 ENGINEERING GUIDELINES

Assists network designers in incorporating the ATLAS 800 Series System into

existing networks. Includes pinouts.

Table of Contents

ATLAS 830 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Equipment Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power Requirements (AC System). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power Requirements (DC System). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ATLAS 830 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ACO Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CRAFT Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ATLAS 830 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Admin Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10/100BaseT Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Alarm Relay Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

MON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

T1/PRI Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ATLAS 830 At-A-Glance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ATLAS 890 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Equipment Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power Requirements (AC System). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power Requirements (DC System). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ATLAS 890 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ACO Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

CRAFT Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ATLAS 890 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Admin In Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10/100BaseT Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Alarm Relay Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

External Input Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ATLAS 890 At-A-Glance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Option Module Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Quad T1/PRI Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Quad E1/PRA Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Quad Nx 56/64 Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Quad USSI Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Octal BRI ISDN (U-Interface) Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Octal BRI ISDN (S/T Interface) Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Async-232 Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

T3 Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

T3 Drop and Insert Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Dual Video Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

NxT1 HSSI/V.35 Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Octal FXS Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

61200780L1-1C © 2004 ADTRAN, Inc. 14

Page 15

ATLAS 800 Series System Manual

Engineering Guidelines

List of Pinouts

Pinout 1. ATLAS 830 CRAFT Port (DB-9, female) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pinout 2. ATLAS 830 Admin Port (DB-9, female) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pinout 3. ATLAS 830 Ethernet (RJ-45) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pinout 4. ATLAS 830 Alarm Relay Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pinout 5. ATLAS 830 T1/PRI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pinout 6. ATLAS 890 CRAFT Port (RJ-48C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pinout 7. ATLAS 890 Admin In (RJ-48C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Pinout 8. ATLAS 890 Ethernet (RJ-48C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Pinout 9. ATLAS 890 Alarm Relay Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pinout 10. ATLAS 890 External Relay Monitor Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pinout 11. Quad T1/PRI Module (USOC RJ-48C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pinout 12. Quad E1/PRA Module (DB-15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pinout 13. Quad E1/PRA Module (DB-62) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pinout 14. Quad Nx 56/64 Module (V.35 Winchester) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Pinout 15. Quad Nx 56/64 Module (DB-78) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Pinout 16. Quad USSI Module (DB-78). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Pinout 17. Quad USSI Module (EIA-530) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pinout 18. Quad USSI Module (RS-449/V.36) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pinout 19. Quad USSI Module (RS-232). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Pinout 20. Quad USSI Module (CCITT X.21 V.11). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Pinout 21. Octal BRI (U-Interface) Module (RJ-45). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pinout 22. Octal BRI (S/T Interface) Module (RJ-45) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pinout 23. Async-232 Option Module (DB-25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pinout 24. T3 Module (BNC pair, female) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pinout 25. T3 Drop and Insert Module (BNC pair, female) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pinout 26. Dual Video Module (RS-366, DB-25). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pinout 27. Dual Video Module (V.35 Winchester). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Pinout 28. Dual Video Module (EIA-530) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Pinout 29. Dual Video Module (RS-449). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Pinout 30. NxT1 HSSI/V.35 Module (RJ-48C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Pinout 31. NxT1 HSSI/V.35 Module (50-pin SCSI-II and V.35 Winchester) . . . . . . . . . . . . . . . . . . . . . . 55

Pinout 32. Octal FXS Module (8-pin modular). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

List of Figures

Figure 1. ATLAS 830 Front Panel Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 2. ATLAS 830 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 3. ATLAS 890 Front Panel Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 4. ATLAS 890 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

List of Tables

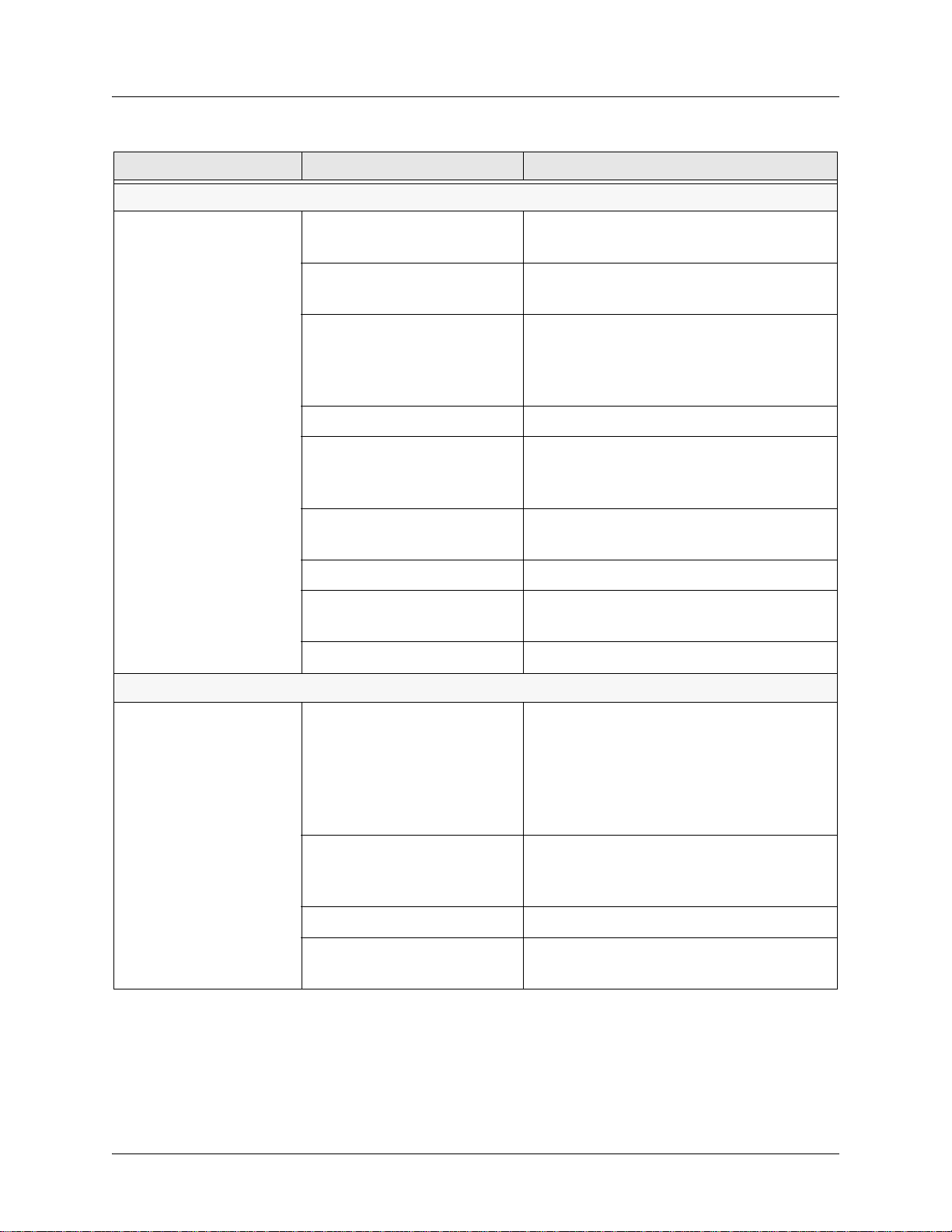

Table 1. ATLAS 830 Front Panel LEDs’ Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2. ATLAS 830 LED Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 3. ATLAS 830 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

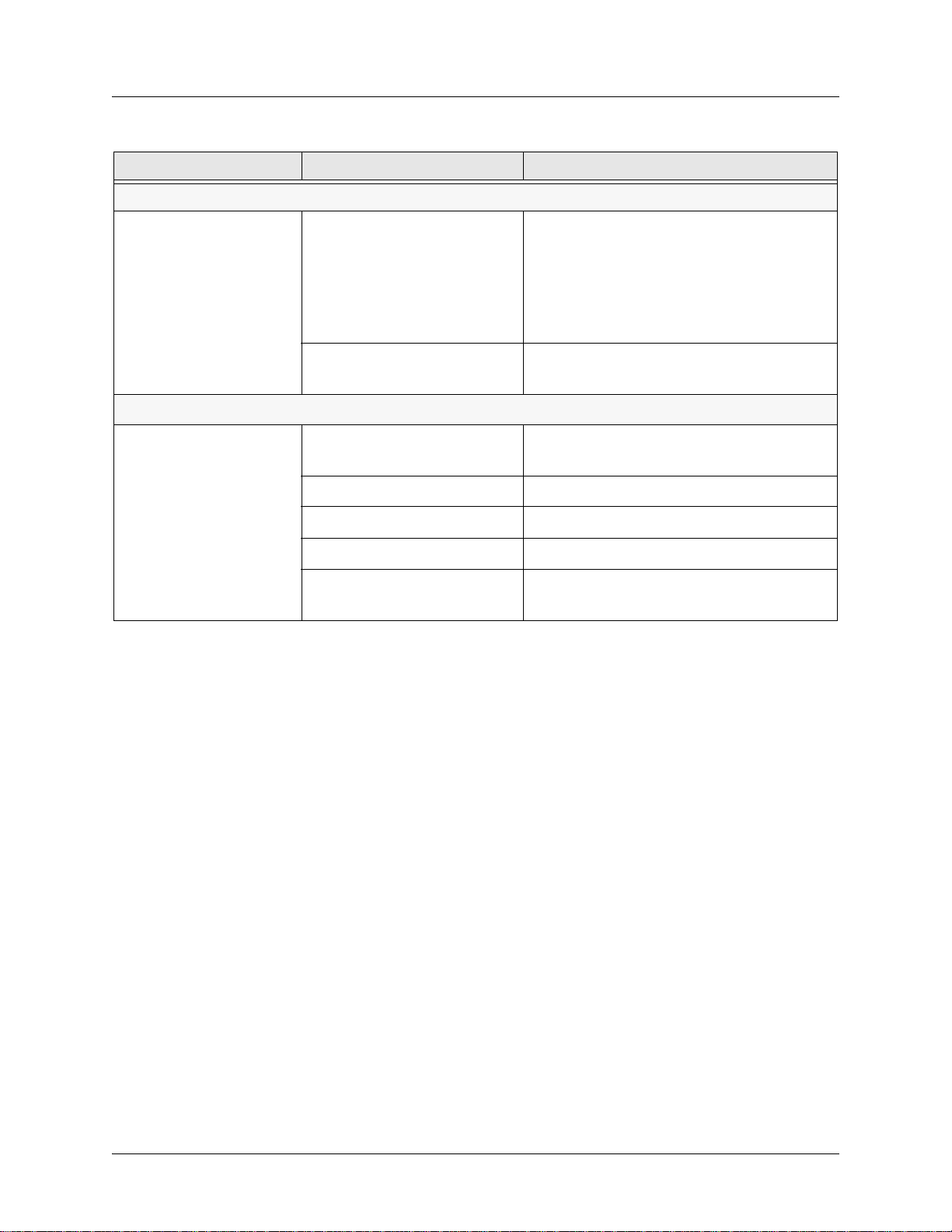

Table 4. ATLAS 890 Front Panel LEDs’ Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 5. ATLAS 890 LED Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 6. ATLAS 890 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

61200780L1-1C © 2004 ADTRAN, Inc. 15

Page 16

1. ATLAS 830 DESCRIPTION

Equipment Dimensions

The ATLAS 830 is 17.5” W, 12.5” D, and 5.5” H and is equipped for table top use or for mounting in a

19-inch rack (mounting brackets are included in the shipment). All option modules fit inside the unit.

Power Requirements (AC System)

Regardless of the option modules configuration installed in the unit, the ATLAS 830 AC system has a

maximum power consumption of 200 W and a maximum current draw of 3.5 A. With no option modules

installed, the AC-powered ATLAS 830 has a power consumption of 50 W and a current draw of 0.64 A,

maximum at 115 Vrm s.

Power Requirements (DC System)

Regardless of the option modules configuration installed in the unit, the ATLAS 830 DC system has a

maximum power consumption of 200 W and a maximum current draw of 4.2 A at -48 VDC. With no

option modules installed, the DC-powered ATLAS 830 has a power consumption of 45 W at -48 VDC.

2. ATLAS 830 FRONT PANEL

The ATLAS 830 front panel contains the Alarm Cut-off (ACO) switch, the CRAFT port, and status LEDs

for the system (

MODULE). Figure 1 locates these features and Table 1 on page 17 further describes their functions.

ule (

POWER, SYSTEM, ETHERNET, and REMOTE), network (NETWORK), and option mod-

CRAFT port

Network LEDs

(Slot 0, Ports 1&2)

NET WORK

1

System

LEDs

POWER

SYSTEM

ETHERNET

REMOTE

ACO

CRAFT

ACO

Switch

OK

TEST

ERROR

ALARM

2

OK

TEST

ERROR

ALARM

STATUS

ONLINE

1

TEST

Module Status LEDs

MODULES

3

5

2

4

7

6

8

ATLAS 830

Figure 1. ATLAS 830 Front Panel Layout

61200780L1-1C © 2004 ADTRAN, Inc. 16

Page 17

ATLAS 800 Series System Manual ATLAS 830 Front Panel

Engineering Guidelines

ACO Switch

The ACO switch clears the Alarm Relay (located on the rear panel) after an alarm condition has occurred.

If an alarm condition is corrected and then reoccurs, the Alarm Relay activates again.

CRAFT Port

Use the CRAFT port (see Pinout 1) to configure the system via an EIA-232 connection.

Pinout 1. ATLAS 830 CRAFT Port (DB-9, female)

Pin Name Description

1 DCD Data Carrier Detect (output)—not connected

2 RD Receive Data (output)

3 TD Transmit Data (input)

4 DTR Data T erminal Ready (input)—not connected

5 SG Signal Ground

6 DSR Data Set Ready (output)—not connected

7 RTS Request to Send (input)—not connected

8 CTS Clear to Send (output)— not connected

9 RI Ring Indicate (output)—not connected

Front Panel LEDs

With the ATLAS 830 powered-up, the front panel LEDs provide visual information about the status of the

ATLAS 830 and any option modules that may be installed. Table 1 describes the purpose of the front panel

LEDs, and Table 2 on page 19 provides information about the meaning of the LED colors.

Table 1. ATLAS 830 Front Panel LEDs’ Purpose

LED Purpose

System

Power Indicates the status of the power supply.

System Indicates the status of the unit controller and other system parameters.

Displays the status of the power supply, controller, and other system

parameters for the ATLAS 830 (see Table 2 on page 19).

Ethernet Indicates the status of the Ethernet port.

Remote Indicates whether a user (Telnet or VT100) is logged into the unit.

61200780L1-1C © 2004 ADTRAN, Inc. 17

Page 18

ATLAS 800 Series System Manual ATLAS 830 Front Panel

Engineering Guidelines

Table 1. ATLAS 830 Front Panel LEDs’ Purpose (Continued)

LED Purpose

Network

Displays the status of the two built-in T1/PRI interfaces on the rear panel

of the unit. (These are referred to in the menus as Slot 0, Ports 1 and 2.)

OK Indicates that the network interface has passed self-test and is operating

correctly.

Test Indicates that there is an active test on the T1/PRI interface.

Error Blinks to indicate the occurrence of error events such as clock slip

seconds (CSS), bipolar violations (BPV), errored seconds (ES), etc.

Alarm Indicates an active alarm condition on the T1/PRI interface.

ACO

Modules

Indicates the status of the ACO switch.

Displays by row the operational condition of each module installed in the

option slots. All LEDs will be off if no option module is installed or

configured.

Status Indicates the operational condition of modules installed in the option

slots.

Online Indicates whether the module is available for use or is currently in use. If

the module is manually taken offline, this LED is turned off.

Test Indicates that one or more ports within a module are in test.

ACO

CRAFT

Clears the Alarm Relay connection located on the rear panel of the

ATLAS 830.

Allows the ATLAS 830 to connect to a computer using a VT100 terminal

or terminal emulator.

61200780L1-1C © 2004 ADTRAN, Inc. 18

Page 19

ATLAS 800 Series System Manual ATLAS 830 Front Panel

Engineering Guidelines

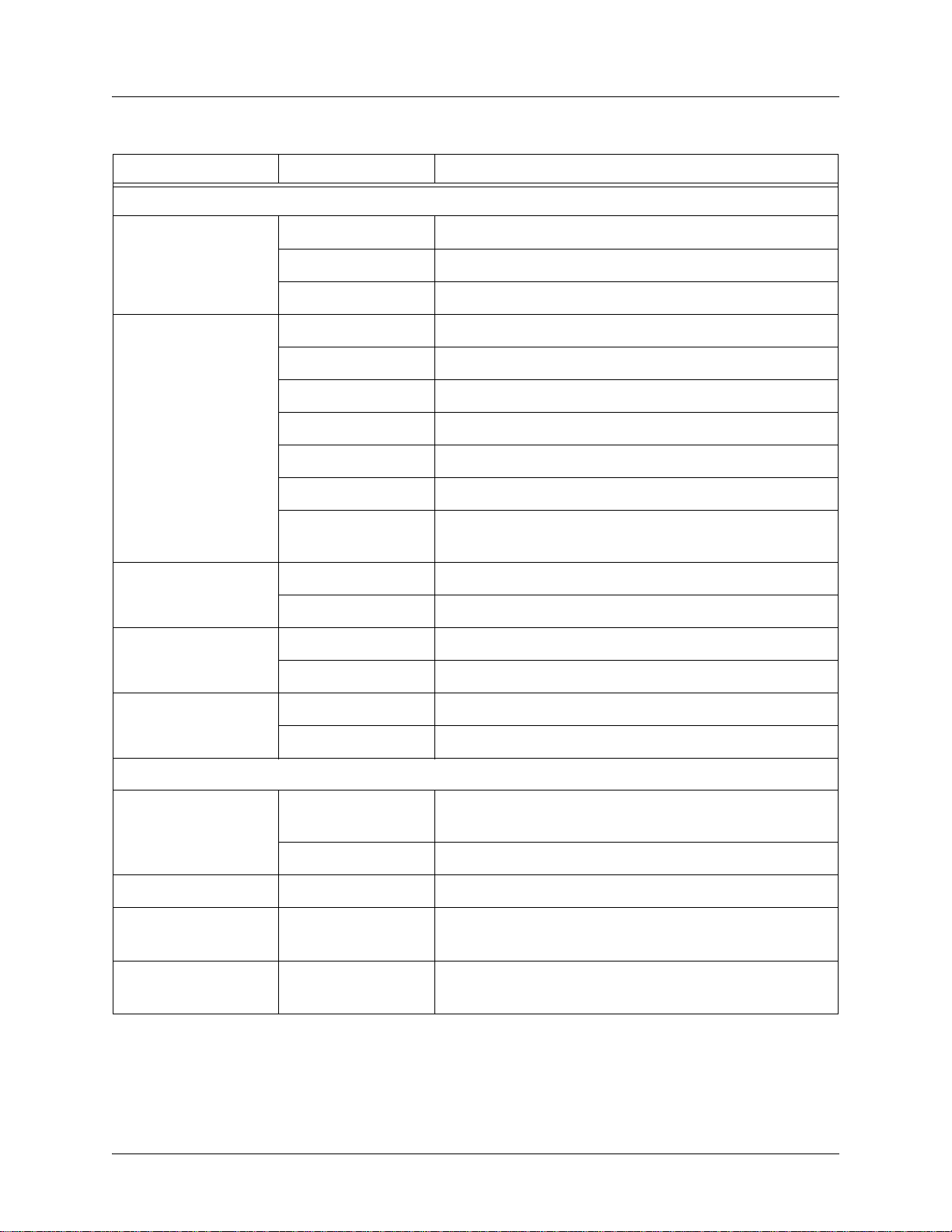

Table 2. ATLAS 830 LED Descriptions

For these LEDs... This color light... Indicates that...

System

Power Red (solid) Power supply error condition or temperature alarm.

Green The unit is on and connected to a power source.

Off The unit is off.

System Green (solid) No diagnosed system faults were found.

Green (fast blink) System Controller is offline.

Yellow (fast blink) Flash download is in progress.

Yellow (solid) Se lf-test in progress.

Red (solid) Internal error condition.

Red (fast blink) Flash download or flash error condition.

Off Power is not currently supplied to the system or the

power switch is in the off position.

Ethernet Green Link has been established.

Off Link has not been established.

Remote Yellow A user is logged into the unit via Telnet or VT100.

Off No users are logged into the unit.

ACO

Yellow ACO switch is depressed.

Off ACO switch is not depressed.

Network

OK Green (solid) The network T1/PRI interface is operating normally with

error-free operation.

Off The interface has experienced an alarm.

TEST Yellow (solid) The T1/PRI interface is in a test mode.

ERROR Red (blinking) Blinks with the occurrence of an error event including

BPV, CRC, and ES.

ALARM Red (solid) The T1/PRI interface is experiencing an alarm such as

loss of frame (LOF), loss of signal (LOS), etc.

61200780L1-1C © 2004 ADTRAN, Inc. 19

Page 20

ATLAS 800 Series System Manual ATLAS 830 Rear Panel

Engineering Guidelines

Table 2. ATLAS 830 LED Descriptions (Continued)

For these LEDs... This color light... Indicates that...

Modules

Status Green (solid) Module is present.

Green (fast blink) Module has been manually taken offline by the user.

Red (solid) Module is in an alarm state.

Red (fast blink) Module has no response, has been removed, or is not

supported.

Red (slow blink) Module is not ready.

None No module occupies the slot.

Online Green (solid) Module has an active connection.

Green (fast blink) Module has invalid flash memory or is downloading

firmware.

Test Yellow (solid) Module is in a test mode.

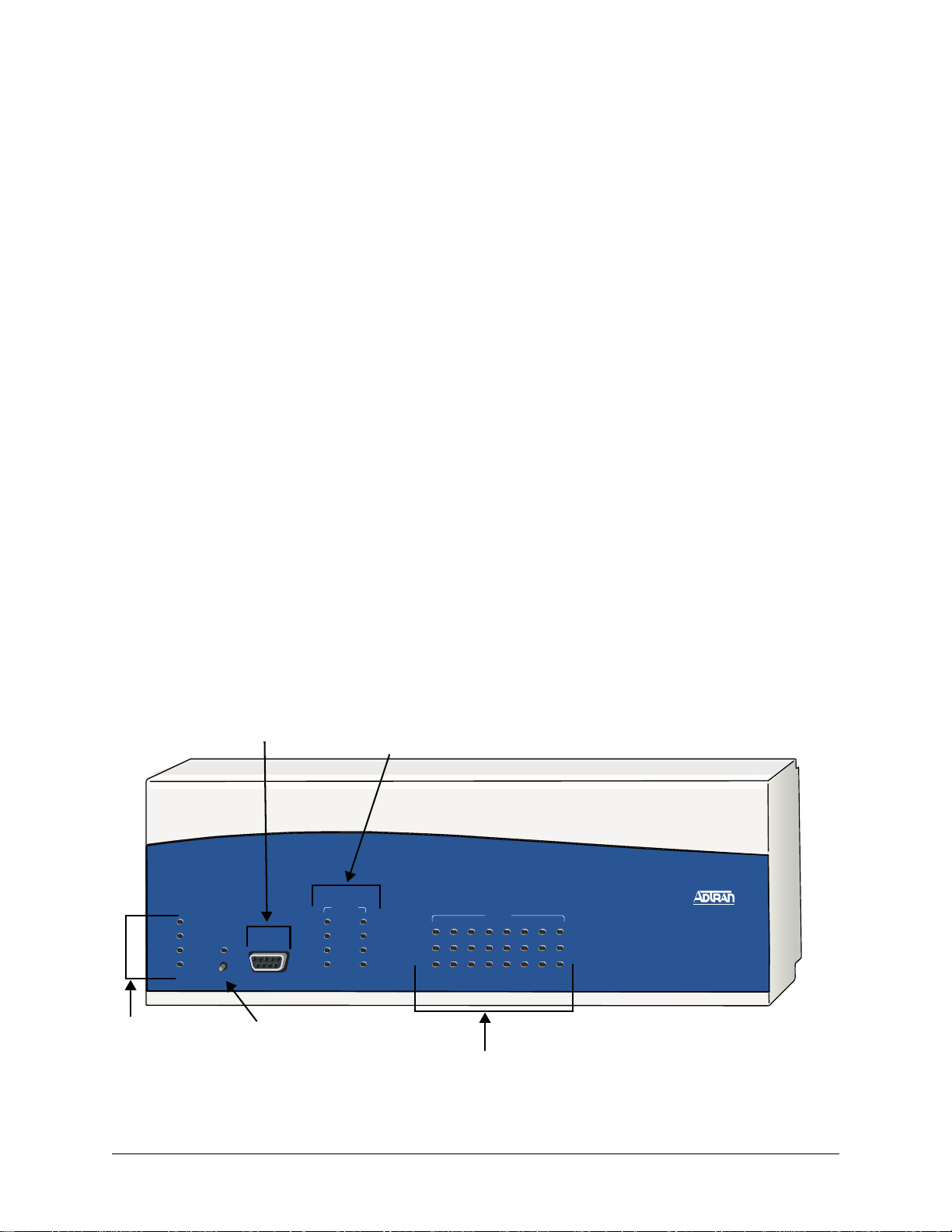

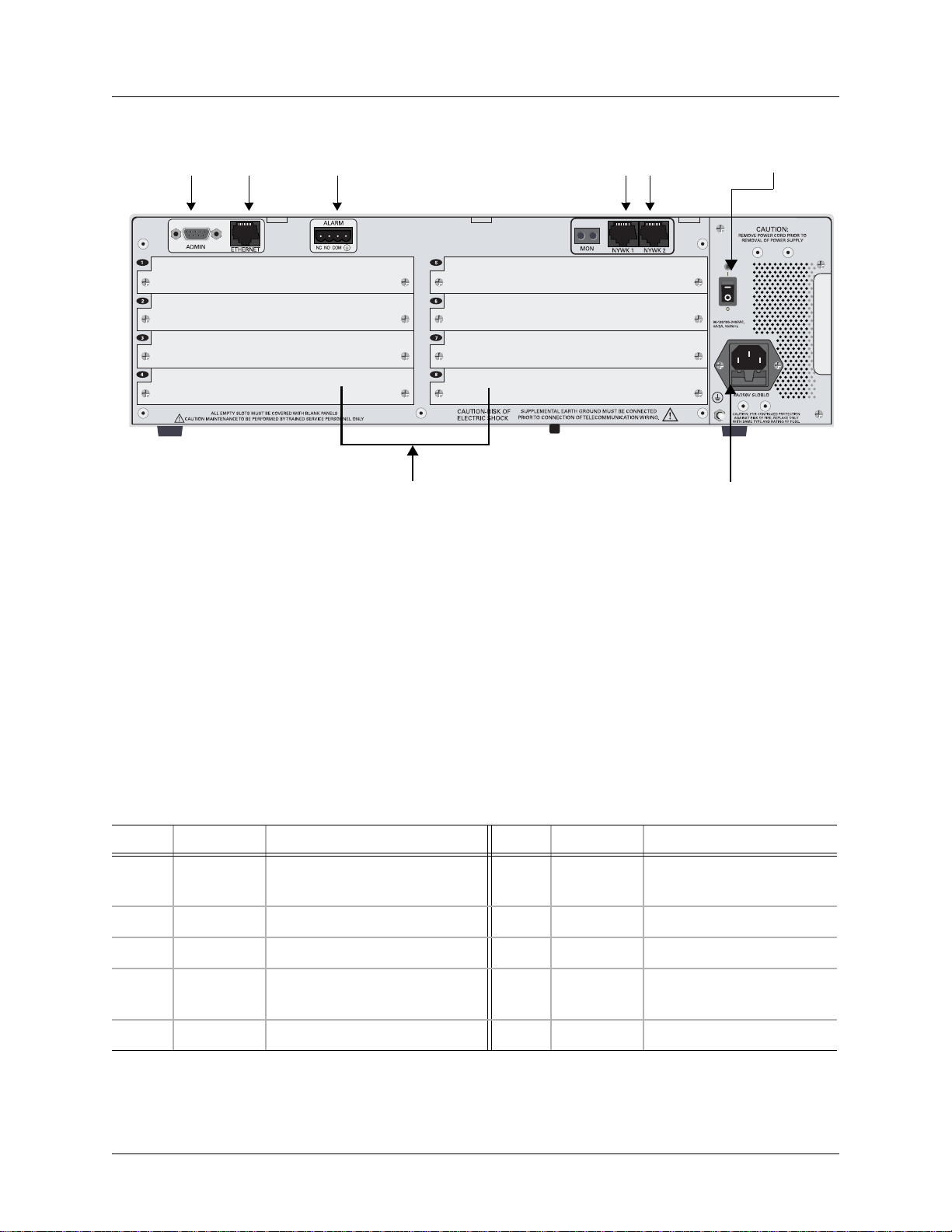

3. ATLAS 830 REAR PANEL

The ATLAS 830 rear panel (see Figure 2) contains an ADMIN port for connecting to a VT100 terminal (or

terminal emulator) or modem, a 10/100BaseT interface for

built-in T1/PRI network interfaces (

NTWK1 and NTWK2) and eight slots for housing option modules

which provide a variety of additional resources and data ports. All slots are functionally identical. An

optional redundant power supply may be installed in slots 7 and 8. In addition, the

POWER SUPPLY are located on the rear panel.

ETHERNET access, ALARM contacts, two

ON/OFF switch and

61200780L1-1C © 2004 ADTRAN, Inc. 20

Page 21

ATLAS 800 Series System Manual ATLAS 830 Rear Panel

Engineering Guidelines

ADMIN

Port

Ethernet

Port

Slot 1

Slot 2

Slot 3

Slot 4

Alarm

Contacts

Option Module Slots

Figure 2. ATLAS 830 Rear Panel

Slot 5

Slot 6

Slot 7

Slot 8

T1/PRI

Interfaces

Power Supply

Power On/Off

Switch

Admin Port

The ADMIN port (EIA-232, see Pinout 2 on page 21) connects to a computer or modem and provides the

following functions:

• Accepts EIA-232 input from a PC or a modem for controlling the ATLAS 830.

• Operates at 2400, 9600, 19200, or 38400 bps.

• Acts as input for either VT100 or PC control.

• Acts as an interface for flash memory software downloads using XMODEM.

Pinout 2. ATLAS 830 Admin Port (DB-9, female)

Pin Name Description Pin Name D escription

1DCDData Carrier Detect (output) 6DSRData Set Ready (output

— not connected

2RDReceive Data (output) 7RTSRequest to Send (input)

3TDTransmit Data (input) 8CTSClear to Send (output)

4DTRData Terminal Ready (input) 9RI Ring Indicate (output)

— not connected

5SG Signal Ground

61200780L1-1C © 2004 ADTRAN, Inc. 21

Page 22

ATLAS 800 Series System Manual ATLAS 830 Rear Panel

Engineering Guidelines

10/100BaseT Connection

The 10/100BaseT port (RJ-45) provides a 10/100BaseT Ethernet LAN connection, whic h is used for IP

Routing, TFTP, SNMP, and Telnet connections (see Pinout 3).

Pinout 3. ATLAS 830 Ethernet (RJ-45)

Pin Name Description

1 TX1 Transmit Positive

2 TX2 Transmit Negative

3 RX1 Receive Positive

4, 5 Unused —

6 RX2 Receive Negative

7, 8 Unused —

Alarm Relay Connection

This connection alerts the user when a pre-selected alarm condition exists (see Pinout 4). The four-pin,

removable terminal block connects with external wiring. Refer to DLP-11, Connecting the Alarm

Contacts, on page 344 for detailed instructions. Clear the alarm condition by pressing the ACO switch

located on the front panel of the ATLAS 830.

Pinout 4. ATLAS 830 Alarm Relay Connector

Pin Name Description

1 NC Normally closed, but opens when a pre-selected alarm condition is present.

2 NO Normally open, but closes when a pre-selected alarm condition is present.

3 COM Common connection between external circuitry and NC or NO terminal.

4 GND The chassis ground.

MON

The MON IN and OUT Bantam test jacks provide a bridged access jack for nonintrusive monitoring of the

incoming T1. When connected to this jack, configure the test equipment for bridged termination.

T1/PRI Connections

Each of the T1/PRI ports, NTWK1 and NTWK2, uses a single eight-position modular jack to connect to the

T1 or PRI circuit. Pinout 5 shows the pinout for this connector.

61200780L1-1C © 2004 ADTRAN, Inc. 22

Page 23

ATLAS 800 Series System Manual ATLAS 830 At-A-Glance Specifications

Engineering Guidelines

Pinout 5. ATLAS 830 T1/PRI

Pin Name Description

1 RxData-Ring (R) Receive data from the network

2 RxData-Tip (T) Receive data from the network

3 Unused —

4 TxData-Ring (R1) Send data towards the network

5 TxData-Tip (T1) Send data towards the network

6,7,8 Unused —

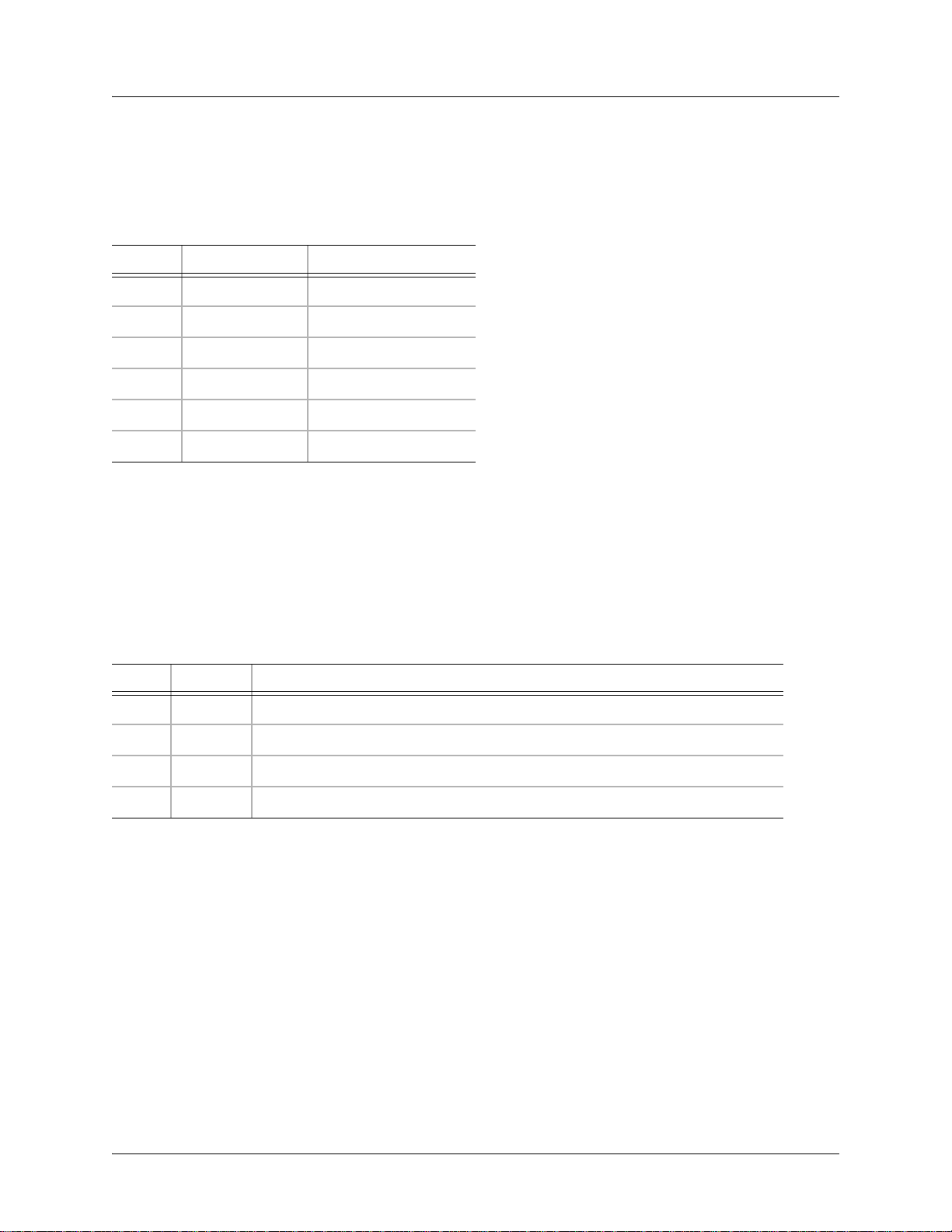

4. ATLAS 830 AT-A-GLANCE SPECIFICATIONS

Table 3 lists the specifications for the ATLAS 830 system.

Table 3. ATLAS 830 Specifications

Application Feature Specification

Operating Specifications

Temperature Operation: 0°C to 45°C

Relative Humidity To 95% noncondensing

TDM Applications

TDM bandwidth 46 Mbps Full duplex

Dedicated map connections 766 dedicated DS0 map connections in each

Storage: -40°C to 70°C

of the 5 maps

61200780L1-1C © 2004 ADTRAN, Inc. 23

Page 24

ATLAS 800 Series System Manual ATLAS 830 At-A-Glance Specifications

Engineering Guidelines

Table 3. ATLAS 830 Specifications (Continued)

Application Feature Specification

Switching Applications

ISDN signaling types National ISDN

Lucent 5E

AT&T 4ESS (PRI Only)

Northern DMS-100 (Nortel Custom)

Euro ISDN

T1 signaling types Loop-Start

Ground-Start

E&M Wink

E&M Immediate

Feature Group D

DSP Features DTMF/MF tones support

Progress tone generation

32 available DSP channels

27 simultaneous dial tones

BRI Connections

(recommended)

PRI Connections

(recommended)

RBS T1 Connections

(recommended)

64 connections

345 B channels and 15 D channels

120 DS0 connections

61200780L1-1C © 2004 ADTRAN, Inc. 24

Page 25

ATLAS 800 Series System Manual ATLAS 830 At-A-Glance Specifications

Engineering Guidelines

Table 3. ATLAS 830 Specifications (Continued)

Application Feature Specification

Frame Relay

Packet throughput 7900 pkts/sec (based on 64 byte size

packets)

PPP

Management signaling

interfaces

UNI (user and network)

NNI

Management signaling types ANSI T1.617-D (Annex D)

ITU-T Q.933-A (Annex A)

LMI (Group of four)

Auto

Encapsulation RFC 1490

PVC support 24 PVCs per packet endpoint (DS0 limited,

24 PVCs for T1).

992 is the limit of PVCs allowed in the unit.

Congestion control FECN / BECN

Discard eligible (DE)

Quality of service (QOS) Prioritization on a per-PVC basis

Testing (ADTRAN

proprietary)

PVC loopback

Round trip delay measurement

SNMP support RFC 1315

Connection support 35 PPP connections to the internal router

(not exceeding 3200 packets per second)

100 PPP connections to the internal router

(requires HDLC Module and cannot exceed

3200 packets per second)

Authentication support PAP

CHAP

EAP

Keepalive support On/Off

Interface support Numbered interfaces

Unnumbered interfaces

61200780L1-1C © 2004 ADTRAN, Inc. 25

Page 26

ATLAS 800 Series System Manual ATLAS 890 Description

Engineering Guidelines

Table 3. ATLAS 830 Specifications (Continued)

Application Feature Specification

IP Routing

Route discovery RIP V1

RIP V2

ICMP

ARP

IARP

UDP Relay

SNMP support RFCs 1315, 1213, 1406

Adtran Enterprise MIB

Voice Compression

Algorithm Voice Compression Module

G.723.1 or Netcoder (proprietary)

Number of channels supported Up to 64 compression channels

PCM coding µ-Law

Fax support 9600 bps

DTMF generation and

TIA 464A

detection

5. ATLAS 890 DESCRIPTION

Equipment Dimensions

The ATLAS 890 base unit is 17.08” W, 11.67” D, and 10.5” H and can be mounted in a 19-inch or 23-inch

rack (mounting brackets are included in the shipment). All other equipment (option modules) fit inside the

base unit.

Power Requirements (AC System)

Regardless of the option modules configuration installed in the base unit, the A T LAS 890 AC system has a

maximum power consumption of 400 W and a maximum current draw of 7 A.

Power Requirements (DC System)

Regardless of the option modules configuration installed in the base unit, the A T LAS 890 DC system has a

maximum power consumption of 325W and a maximum current draw of 8 A at -48 VDC.

61200780L1-1C © 2004 ADTRAN, Inc. 26

Page 27

ATLAS 800 Series System Manual ATLAS 890 Front Panel

Engineering Guidelines

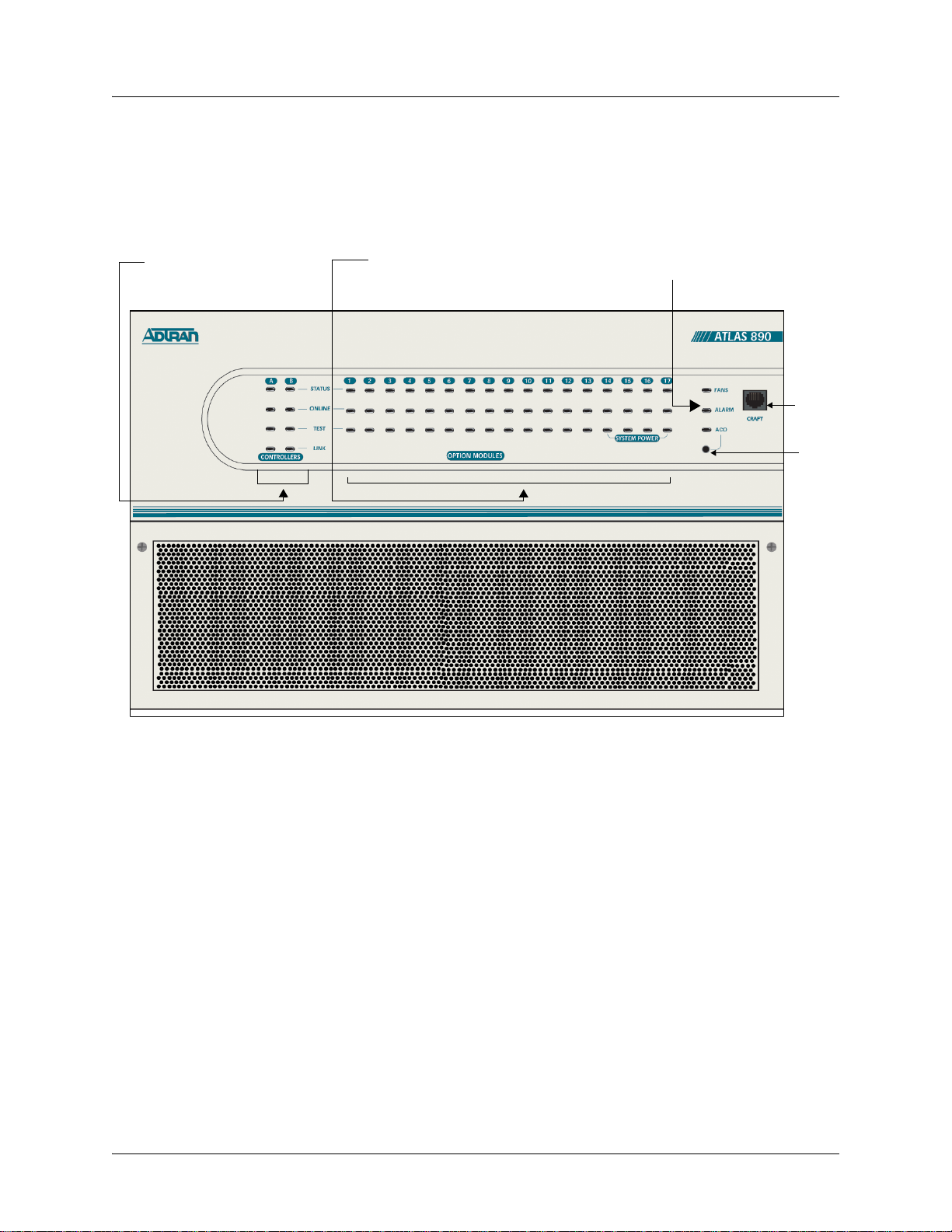

6. ATLAS 890 FRONT PANEL

The front panel contains the Alarm Cut-off (ACO) switch, the CRAFT port, and the controller and option

modules, and system (fans and alarm) status

ATLAS 890 base unit and any option module that may be installed. Figure 3 identifies these features.

LEDS. The LEDs provide visual information about the

Controller LEDs Option Module LEDs

System LEDs

CRAFT

Port

ACO

Switch

Figure 3. ATLAS 890 Front Panel Layout

ACO Switch

The ACO switch deactivates (clears) the Alarm Relay, located on the rear panel, after an alarm condition

has occurred. If an alarm condition is corrected and then reoccurs, the Alarm Relay activates again.

61200780L1-1C © 2004 ADTRAN, Inc. 27

Page 28

ATLAS 800 Series System Manual ATLAS 890 Front Panel

Engineering Guidelines

CRAFT Port

Use the CRAFT port (see Pinout 6) to connect to a computer to configure the system via an EIA-232

connection or to connect to a modem.

Pinout 6. ATLAS 890 CRAFT Port (RJ-48C)

Pin Name Description

1,2 Unused —

3 RXDATA Data received by the ATLAS 890

4Unused—

5 TXDATA Data transmitted by the ATLAS 890

6,7 Unused —

8Unused—

Front Panel LEDs

With the ATLAS 890 powered-up, the front panel LEDs provide visual information about the status of the

unit and any option modules that may be installed. Ta ble 4 describes the purpose of the front panel LEDs,

and Table 5 on page 29 provides information about the meaning of the LED colors.

Table 4. ATLAS 890 Front Panel LEDs’ Purpose

LED Purpose

System

Displays the status of the fans, alarm, and ACO buttons for the

ATLAS 890. (See Table 5 on page 29.)

Fans

Alarm

ACO

Controller Module

Indicates the fans are operational.

Indicates a triggered alarm condition for the alarm relays.

Indicates the alarm cut-off switch is pressed.

Displays the status of the network interface. All LEDs are off if no

network module is installed. (See Table 2 on page 19.)

Status

Indicates the operational condition of the controller installed in the

controller slot.

Online

Test

Indicates whether the module is available for use or is currently in use.

Indicates that the module is in test.

Link

Indicates there is an active 10/100 Ethernet connection on the installed

controller module.

61200780L1-1C © 2004 ADTRAN, Inc. 28

Page 29

ATLAS 800 Series System Manual ATLAS 890 Front Panel

Engineering Guidelines

Table 4. ATLAS 890 Front Panel LEDs’ Purpose (Continued)

LED Purpose

Option Module

Displays by row the operational condition of each module installed in the

option slots. All LEDs will be off if no option module is installed. (See

Table 5 on page 29.)

Status

Indicates the operational condition of modules installed in the option

slots.

Online

Indicates whether the module is available for use or is currently in use. If

the module is manually taken offline, this LED is turned off.

Test

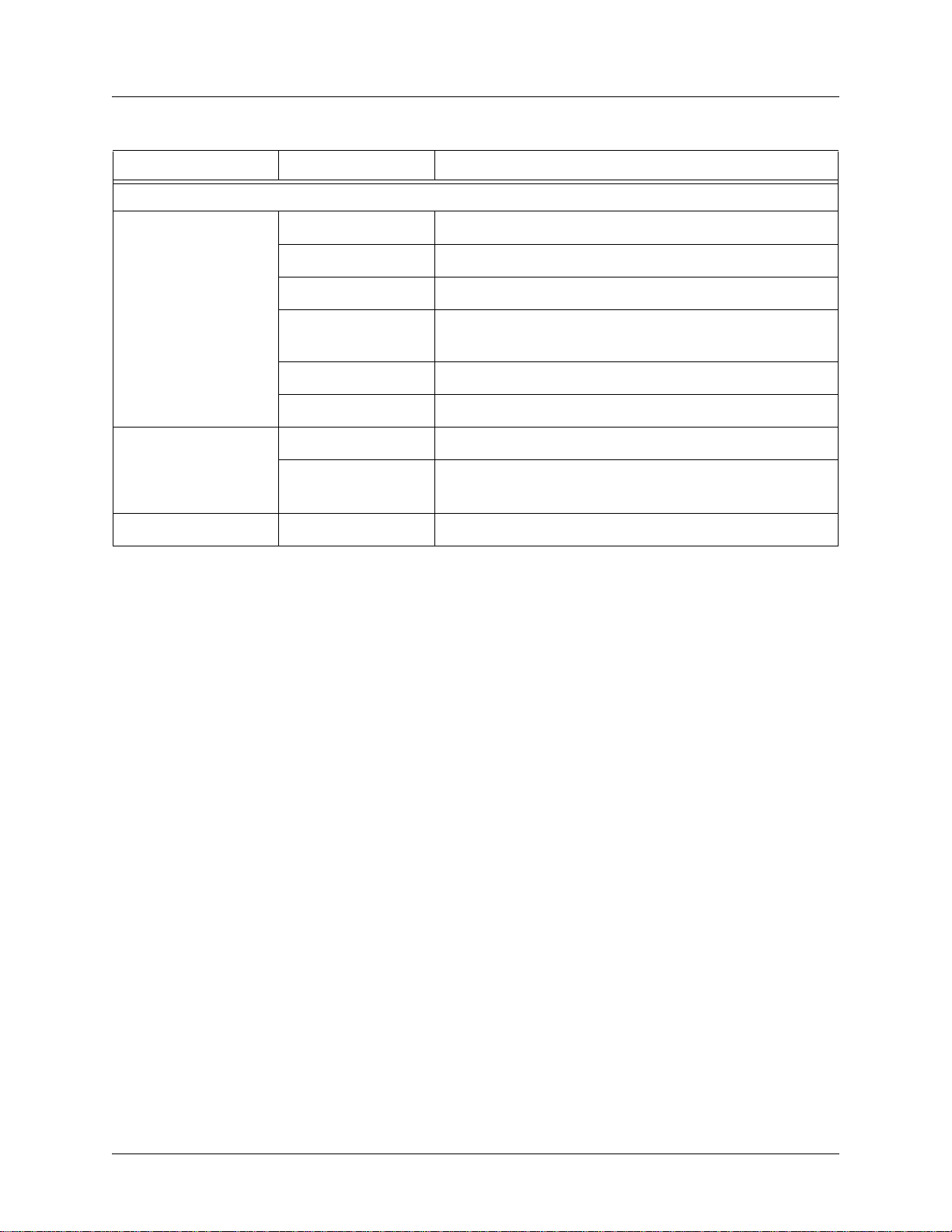

Table 5. ATLAS 890 LED Description

For These Leds... This Color Light... Indicates That...

Fans

Indicates that one or more ports within a module are in test.

Red (solid) Fan speed is too low or fan is disconnected.

Amber (solid) Fan speed is too high.

Green (solid) All fans are functioning properly.

Alarm

Red (solid) A fan, external input, or power supply error has occurred.

LED will remain red until the ACO button is pressed.

ACO

Stand-by controller

Status

Online

Test

Link

Amber ACO button is being pressed.

Green (slow blink) Stand-by controller is present.

Green (solid) Stand-by controller operational for redundancy.

Red (fast blink) Controller cannot automatically become the active

controller while the current active controller is installed.

N/A N/A

Green (solid) Ethernet link detected.

61200780L1-1C © 2004 ADTRAN, Inc. 29

Page 30

ATLAS 800 Series System Manual ATLAS 890 Front Panel

Engineering Guidelines

Table 5. ATLAS 890 LED Description (Continued)

For These Leds... This Color Light... Indicates That...

Active controller

Status

Online

Test

Link

Module Status

Green

Card is not ready.

(slow blink)

Green

Card is not supported.

(fast blink)

Green (solid) Active controller present.

Amber (solid) Controller is in test mode.

Amber

Card is upgrading firmware.

(fast blink)

Red (fast blink) Flash parameters are not compatible.

Green (fast blink) Card is unresponsive or not supported.

Red (fast blink) Card is not ready .

Amber (solid) Controller is in test mode.

Green (solid) Ethernet link detected.

Green (solid) Module is present.

Green (fast blink) Module has been manually taken offline by the user.

Module Online

Module Test

Red (solid) Module failed self-test.

Red (fast blink) Module has no response, has been removed, or is not

supported.

Red (slow blink) Module is not ready.

None No module occupies the slot.

Green (solid) Module has an active connection.

Green (fast blink) Module has invalid flash memory or is downloading

firmware.

Yellow (solid) Module is in a test mode.

61200780L1-1C © 2004 ADTRAN, Inc. 30

Page 31

ATLAS 800 Series System Manual ATLAS 890 Rear Panel

Engineering Guidelines

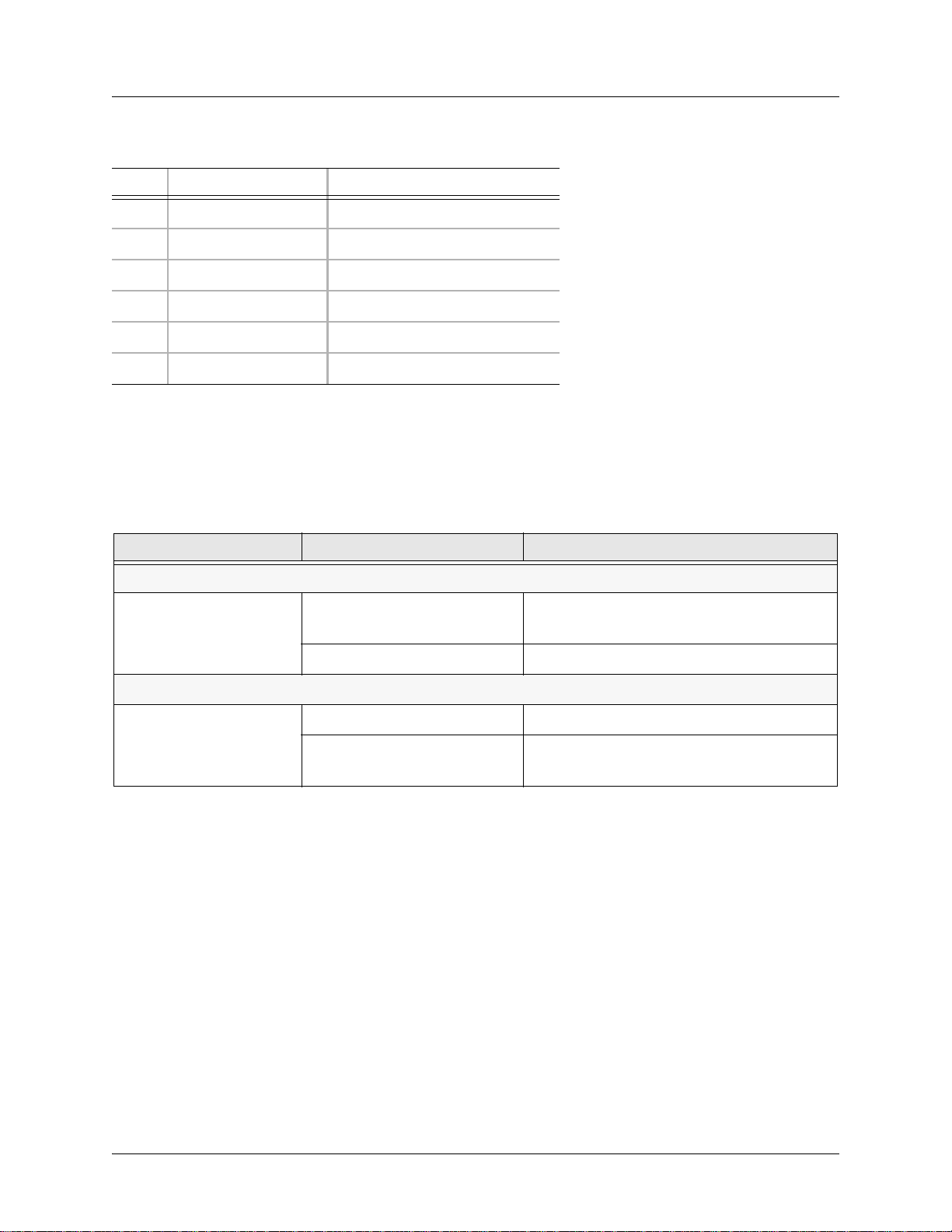

7. ATLAS 890 REAR PANEL

The ATLAS 890 rear panel contains 16 slots for housing option modules which provide a variety of

additional resources and data ports (see Figure 4). All slots are functionally identical. The ATLAS 890 also

contains two slots for housing controller modules and a single slot dedicated for power supply use only.

The most common configuration is a fully redundant system with two system controllers and two power

supplies. A fully redundant AC-powered ATLAS 890 provides 13 option slots. A fully redundant

DC-powered ATLAS 890 provides 15 option slots.

ADMIN In

Port

Power

Connection

10/100BaseT

Port

Alarm Relay

Outputs

External

Input

Figure 4. ATLAS 890 Rear Panel

Chassis

Ground

Admin In Port

The ADMIN IN port (EIA-232) connects to a computer or modem (see Pinout 7 on page 32). The control

port input provides the following functions:

• Accepts EIA-232 input from a PC or a modem for controlling the ATLAS 890.

• Operates at 2400, 9600, 19200, or 38400 bps.

• Acts as input for either VT100 or PC control.

• Acts as an interface for flash memory software downloads using XMODEM.

61200780L1-1C © 2004 ADTRAN, Inc. 31

Page 32

ATLAS 800 Series System Manual ATLAS 890 Rear Panel

Engineering Guidelines

Pinout 7. ATLAS 890 Admin In (RJ-48C)

Pin Name Description

1 GND Ground—connected to unit chassis

2 RTS Request to send—low control

3 RxData Data received by the ATLAS 890

4 DTR Data terminal ready

5 TxDATA Data transmitted by the ATLAS 890

6 CD Carrier detect

7Unused—

8 CTS Clear to send—flow control

10/100BaseT Connection

The 10/100BaseT port (RJ-48C) provides a 10/100BaseT Ethernet LAN connection, which is used for IP

Routing, TFTP, SNMP, and Telnet connections (see Pinout 8).

Pinout 8. ATLAS 890 Ethernet (RJ-48C)

Pin Name Description

1 Tx1 Transmit Positive

2 Tx2 Transmit Negative

3 Rx1 Receive Positive

4, 5 Unused —

6 Rx2 Receive Negative

7, 8 Unused —

61200780L1-1C © 2004 ADTRAN, Inc. 32

Page 33

ATLAS 800 Series System Manual ATLAS 890 Rear Panel

Engineering Guidelines

Alarm Relay Connection

This connection alerts the user when a pre-selected alarm condition exists. The four-pin, removable

terminal block connects with external wiring (see Pinout 9). Refer to DLP-12, Connecting to the

ATLAS 890 External Input, for detailed instructions. Clear the alarm condition by pressing the ACO switch

located on the front panel of the ATLAS 890.

Pinout 9. ATLAS 890 Alarm Relay Connector

Pin Name Description

1 NC Normally closed, but opens when a preselected alarm condition is present.

2 NO Normally open, but closes when a preselected alarm condition is present.

3 COM Common connection between external circuitry and NC or NO terminal.

4 GND Chassis Ground

External Input Connection

This connection alerts the user when a pre-selected external alarm condition exists and could be used, for

example, to monitor a UPS with dry contacts or another ATLAS 890. The three-pin, removable terminal

block connects with external wiring (see Pinout 10). Refer to DLP-12, Connecting to the ATLAS 890

External Input, for detailed instructions. Clear the alarm condition by pressing the ACO switch located on

the ATLAS 890 front panel.

Pinout 10. ATLAS 890 External Relay Monitor Connector

Pin Name Description

1 Input Monitors for the presence or absence of -48 VDC

2 Vout -48 VDC @ 1 mA

3 GND Chassis Ground

61200780L1-1C © 2004 ADTRAN, Inc. 33

Page 34

ATLAS 800 Series System Manual ATLAS 890 At-A-Glance Specifications

Engineering Guidelines

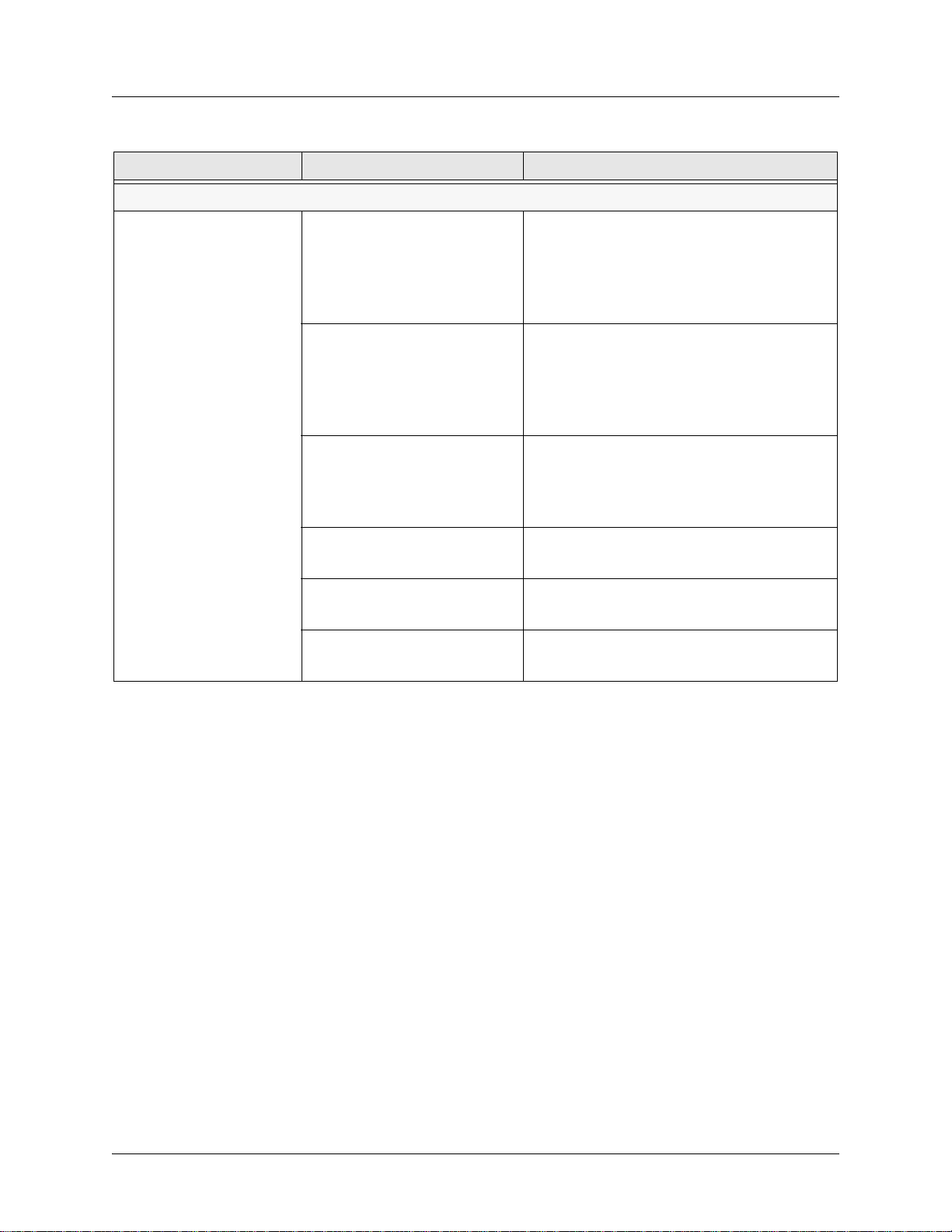

8. ATLAS 890 AT-A-GLANCE SPECIFICATIONS

Table 6 lists the specifications for the ATLAS 890 system.

Table 6. ATLAS 890 Specifications

Application Feature Specification

TDM Applications

TDM bandwidth 49 Mbps Full duplex

Dedicated map connections 766 dedicated DS0 map connections in

each of the 5 maps

Switching Applications

ISDN signaling types National ISDN

Lucent 5E

AT&T 4ESS (PRI Only)

Northern DMS-100 (Nortel Custom)

ETSI/DSS1

T1 signaling types Loop-Start

Ground-Start

E&M Wink

E&M Immediate

Feature Group D

DSP Features DTMF/MF tones support

Progress tone generation

32 available DSP channels

BRI Connections 128 connections

PRI Connections 766 DS0 connections

RBS T1 Connections 766 DS0 connections

27 simultaneous dial tones

61200780L1-1C © 2004 ADTRAN, Inc. 34

Page 35

ATLAS 800 Series System Manual ATLAS 890 At-A-Glance Specifications

Engineering Guidelines

Table 6. ATLAS 890 Specifications (Continued)

Application Feature Specification

Frame Relay

Packet throughput 11,700 pkts/sec (64-1500 size packets)

PPP

Management signaling

interfaces

UNI (user and network)

NNI

Management signaling types ANSI T1.617-D (Annex D)

ITU-T Q.933-A (Annex A)

LMI (Group of four)

Auto

Encapsulation RFC 1490

PVC support 990 PVCs per packet endpoint

Congestion control FECN / BECN

Discard eligible (DE)

Quality of service (QOS) Prioritization on a per-PVC basis

Testing (ADTRAN

proprietary)

PVC loopback

Round trip delay measurement

SNMP support RFC 1315

Connection support 35 PPP connections to the internal router

(not exceeding 11,700 packets per second)

100 PPP connections to the internal router

(requires HDLC Module and cannot exceed

11,700 packets per second)

Authentication support

PAP

CHAP

EAP

Keepalive support On/Off

Interface support Numbered interfaces

Unnumbered interfaces

61200780L1-1C © 2004 ADTRAN, Inc. 35

Page 36

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Table 6. ATLAS 890 Specifications (Continued)

Application Feature Specification

IP Routing

Route discovery RIP V1

RIP V2

ICMP

ARP

IARP

UDP Relay

SNMP support RFCs 1315, 1213, 1406

Adtran Enterprise MIB

Voice Compression

Algorithm Voice Compression Module

G.723.1 or Netcoder (proprietary)

Number of channels supported Up to 64 compression channels

PCM coding µ-Law

Fax support 9600 bps

DTMF generation and

TIA 464A

detection

9. OPTION MODULE PINOUTS

Pinouts for all of the available options modules are included here.

Quad T1/PRI Option Module

Each port of the Quad T1/PRI Option Module (P/N 1200185L3) uses a single, eight-position modular jack

to connect to the T1 or PRI circuit (see Pinout 11).

Pinout 11. Quad T1/PRI Module (USOC RJ-48C)

Pin Name Description

1 RxData-Ring (R) Receive data from the network

2 RxData-Tip (T) Receive data from the network

3Unused —

4 TxData-Ring (R1) Send data towards the network

5 TxData-Tip (T1) Send data towards the network

6,7,8 Unused —

61200780L1-1C © 2004 ADTRAN, Inc. 36

Page 37

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Quad E1/PRA Option Module

Using the provided adapter cables, the DB-62 port of the Quad E1/PRA Option Mo dule (P/N 1200264L1)

supplies a DB-15 connection (see Pinout 12). See Pinout 13 for the DB-62 interface pinout.

Pinout 12. Quad E1/PRA Module (DB-15)

Pin Name Description

1 RT Receive Tip

2 GND Ground

3 TT Transmit Tip

4 GND Ground

5 GND Ground

7 GND Ground

9 RR Receive Ring

11 TR Transmit Ring

Pinout 13. Quad E1/PRA Module (DB-62)

Pin Name Description Pin Name Description

1

1

P4 TT Port 4 Transmit Tip 42 GND Ground

2P4 TRPort 4 Transmit Ring 43 P4 RT Port 4 Receive Tip

3 GND Ground 44 P4 RR Port 4 Receive Ring

6 GND Ground 45 GND Ground

7P3 TTPort 3 Transmit Tip 48 GND Ground

8P3 TRPort 3 Transmit Ring 49 P3 RT Port 3 Receive Tip

9 GND Ground 50 P3 RR Port 3 Receive Ring

12 GND Ground 51 GND Ground

13 P2 TT Port 2 Transmit Tip 54 GND Ground

14 P2 TR Port 2 Transmit Ring 55 P2 RT Port 2 Receive Tip

15 GND Ground 56 P2 RR Port 2 Receive Ring

18 GND Ground 57 GND Ground

19 P1 TT Port 1 Transmit Tip 60 GND Ground

20 P1 TR Port 1 Transmit Ring 61 P1 RT Port 1 Receive Tip

21 GND Ground 62 P1 RR Port 1 Receive Ring

1

Pins that are not identified are not used. P(1-4) indicates the Port

61200780L1-1C © 2004 ADTRAN, Inc. 37

Page 38

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Quad Nx 56/64 Option Module

Using the provided adapter cables, each DB-78 port of the Quad Nx 56/64 Option Module

(P/N 1200184L1) supplies a V.35 Winchester-style connection (see Pinout 14). Pinout 15 shows the DB-78

interface pinout.

Pinout 14. Quad Nx 56/64 Module (V.35 Winchester)

Pin CCITT Description Pin CCITT Description

A 101 Protective ground (PG) V 115 RX clock (RC-A) to DTE

B 102 Signal ground (SG) X 115 RX clock (RC-B) to DTE

C 105 Request to send (RTS) from

DTE

P 103 Transmitted data (TD-A) from

DTE

D 106 Clear to send (CTS) to DTE S 103 Transmitted data (TD-B) from

DTE

E 107 Data set ready (DSR) to DTE Y 114 TX clock (TC-A) to DTE

F 109 Received line signal detector

AA 114 TX clock (TC-B) to DTE

(DCD) to DTE

H — Data terminal ready (DTR)

from DTE

U 113 External TX clock (ETC-A) from

DTE

J — Ring indicator (RI) W 113 External TX clock (ETC-B) from

DTE

R 104 Received data (RD-A) to DTE NN — Test mode (TM) to DTE

T 104 Received data (RD-B) to DTE

Pinout 15. Quad Nx 56/64 Module (DB-78)

Pin Signal Pin Signal

1

1

RXD-A 2/4 42 GND

2 RXD-B 2/4 43-48 Not used

3 RXC-A 2/4 49 MOD2

4 RXC-B 2/4 50 MOD0

5 TXD-A 2/4 51 EXT-TXC-A 1/3

6 TXD-B 2/4 52 DTR-B 1/3

7 TXC-A 2/4 53 DTR-A 1/3

8 TXC-B 2/4 54 DCD-B 1/3

9 EXT-TXC-A 2/4 55 DCD-A 1/3

61200780L1-1C © 2004 ADTRAN, Inc. 38

Page 39

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Pinout 15. Quad Nx 56/64 Module (DB-78) (Continued)

Pin Signal Pin Signal

10 EXT-TXC-A 2/4 56 DSR-B/RI 1/3

11-17 Not used 57 DSR-A 1/3

18 GND 58 CTS-B 1/3

19 GND 59 CTS-A 1/3

20 CHASIS GND 60 CHASIS GND

21 CTS-A 2/4 61 GND

22 CST-B 2/4 62-68 Not used

23 DSR-A 2/4 69 MOD1

24 DSSR-B/RI 2/4 70 EXT-TXC-B 1/3

25 DCD-A 2/4 71 TXC-B 1/3

26 DCD-B 2/4 72 TXC-A 1/3

27 DTR-A 2/4 73 TXD-B 1/3

28 DTR-B 2/4 74 TXD-A 1/3

29-37 Not used 75 RXC-B 1/3

38 RTS-A 1/3 76 RXC-A 1/3

39 RTS-B 1/3 77 RXD-B 1/3

40 RTS-A 2/4 78 RXD-A 1/3

41 RTS-B 2/4

1

1/3 or 2/4 indicates the port on the Nx 56/64 Module

61200780L1-1C © 2004 ADTRAN, Inc. 39

Page 40

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Quad USSI Option Module

Pinouts 16 through 20 on the following pages describe the available interfaces for the Quad USSI Option

Module (P/N 4200261Lx).

Pinout 16. Quad USSI Module (DB-78)

Pin Signal Description Pin Signal Description Pin

1

1

RXD-A 2/4 25 DCD-A 2/4 57 DSR-A 1/3

Signal

Description

2 RXD-B 2/4 26 DCD-B 2/4 58 CTS-B 1/3

3 RXC-A 2/4 27 DTR-A 2/4 59 CTS-A 1/3

4 RXC-B 2/4 28 DTR-B 2/4 60 CHASIS GND

5 TXD-A 2/4 29-37 Not used 61 GND

6 TXD-B 2/4 38 RTS-A 1/3 62-68 Not used

7 TXC-A 2/4 39 RTS-B 1/3 69 MOD1

8 TXC-B 2/4 40 RTS-A 2/4 70 EXT-TXC-B 1/3

9 EXT-TXC-A 2/4 41 RTS-B 2/4 71 TXC-B 1/3

10 EXT-TXC-A 2/4 43-48 Not used 72 TXC-A 1/3

11-17 Not used 49 MOD2 73 TXD-B 1/3

18 GND 50 MOD0 74 TXD-A 1/3

19 GND 51 EXT-TXC-A 1/3 75 RXC-B 1/3

20 CHASIS GND 52 DTR-B 1/3 76 RXC-A 1/3

21 CTS-A 2/4 53 DTR-A 1/3 77 RXD-B 1/3

22 CST-B 2/4 54 DCD-B 1/3 78 RXD-A 1/3

23 DSR-A 2/4 55 DCD-A 1/3

24 DSSR-B/RI 2/4 56 DSR-B/RI 1/3

1

1/3 or 2/4 indicates the port on the USSI Module

61200780L1-1C © 2004 ADTRAN, Inc. 40

Page 41

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Pinout 17. Quad USSI Module (EIA-530)

Pin Signal Description Pin Signal Description Pin Signal Description

1 Shield (Ground) 10 Carrier Detect (B) 19 Request to Send (B)

2 Transmit Data (A) 11 Ext. Transmit Clock (B) 20 DTE Ready (A)

3 Receive d Data (A) 12 Transmit Clock (B) 21 Remote Loopback

4 Request to Send (A) 13 Clear to Send (B) 22 DCE Ready (B)

5 Clear to Send (A) 14 Transmit Data (B) 23 DTE Ready (B)

6 DCE Ready (A) 15 Transmit Clock (A) 24 Ext. Transmit Clock (A)

7 Signal Ground 16 Received Data (B) 25 Test Mode

8 Carrier Detect (A) 17 Receive Clock (A)

9 Received Clock (B) 18 Local Loopback

Pinout 18. Quad USSI Module (RS-449/V.36)

Pin Signal Description Pin Signal Description Pin Signal Description

1 Shield (Ground) 14 Remote Loopback 2 7 Clear to Send (B)

2 Signaling Rate

15 Ring Indicator 28 Terminal in Service

Indicator

3 Not Used 16 Select Frequency 29 DCE Ready (B)

4 Transmit Data (A) 17 Ext. Transmit Clock (A) 30 DTE Ready (B)

5 Transmit Clock (A) 18 Test Mode 31 Carrier Detect (B)

6 Received Data (A) 19 Signal Ground 32 Select Standby

7 Request to Send (A) 20 Receive Common 33 Signal Quality

8 Receive Clock (A) 21 Not Used 34 New Signal

9 Clear to Send (A) 22 Transmit Data (B) 35 Ext. Transmit Clock (B)

10 Local Loopback 23 Transmit Clock (B) 36 Standby/Indicator

11 DCE Ready (A) 24 Receive Data (B) 37 Send Common

12 DTE Ready (A) 25 Request to Send (B)

13 Carrier Detect (A) 26 Receive Clock (B)

61200780L1-1C © 2004 ADTRAN, Inc. 41

Page 42

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Pinout 19. Quad USSI Module (RS-232)

Pin Signal Description Pin Signal Description

1 Shield (Ground) 14 Sec. Transmit Data

2 Transmit Data 15 DCE Transmit Clock

3 Received Data 16 Sec. Received Data

4 Request to Send 17 Receive Signal Element Timing

5 Clear to Send 18 Not used

6 Data Set Ready 19 Sec. Request to Send

7 Signal Ground 20 Data Terminal Ready

8 Received Line Signal Detector 21 Signal Quality Detector

9 + Voltage 22 Ring Indicator

10 - Voltage 23 Data Signal Rate Selector

11 Not used 24 DTE Transmit Clock

12 Sec. Received Line Signal Indicator 25 Not used

13 Sec. Clear to Send

Pinout 20. Quad USSI Module (CCITT X.21 V.11 )

Pin Signal Description Pin Signal Description

1 Shield (Ground) 8 Signal Ground

2 Transmit Data (A) 9 Transmit Data (B)

3 Request to Send (A) 10 Request to Send (B)

4 Received Data (A) 11 Received Data (B)

5 Carrier Detect (A) 12 Carrier Detect (B)

6 Transmit/Receive Clock (A) 13 Transmit/Received Clock (B)

7 Ext. Transmit Clock (A) 14 Ext. Transmit Clock (B)

15 Not Used

61200780L1-1C © 2004 ADTRAN, Inc. 42

Page 43

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Octal BRI ISDN (U-Interface) Option Module

Each port of the Octal BRI ISDN (U-Interface) Option Module (P/N 1200186L2) uses a single RJ-45 jack

to connect to a standard BRI U interface circuit (see Pinout 21).

Pinout 21. Octal BRI (U-Interface) Module (RJ-45)

Pin Name Description

1, 2, 3, 6, 7, 8 Unused —

4 Ring Ring to and from the Network Interface

5 Tip Tip to and from the Network Interface

Octal BRI ISDN (S/T Interface) Option Module

Each port of the Octal BRI ISDN (S/T Interface) Option Module uses a single RJ-45 jack to connect to a

standard BRI S/T interface circuit (see Pinout 22). The Octal BRI ISDN (S/T Interface) Option Module is

only available for use in NT mode (User Term) applications.

Pinout 22. Octal BRI (S/T Interface) Module (RJ-45)

Pin Name Description

1, 2, 7, 8 Unused —

3, 6 Receive Receive for User Term (NT Mode)

4, 5 Transmit Transmit for User Term (NT Mode)

61200780L1-1C © 2004 ADTRAN, Inc. 43

Page 44

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Async-232 Option Module

Using the provided adapter cables, each Async-232 Option Module (P/N 1200182L1) in terface p rovides a

DB-25 (see Pinout 23).

Pinout 23. Async-232 Option Module (DB-25)

Pin Name Description

1 Shield Shielded ground connection

2 TXD Transmit data from DTE

3 RXD Receive data to DTE

4 RTS Request to send from DTE

5 CTS Clear to send to DTE

6 DSR Data set ready to DTE

7 GND Ground

8 DCD Data carrier detect to DTE

9—19, 21, 23—25 Unused n/a

20 DTR Data terminal ready from DTE

22 RI Ring indicator to DTE

T3 Option Module

Using the provided RG 59, 75-Ohm cables (P/N 3125I054), each T3 Option Module (P/N 1200223L1)

provides BNC connectors for transmit and receive connections (see Pinout 24).

Pinout 24. T3 Module (BNC pair, female)

Name Description

RX IN Receive data from the network, 75 ohms ± 5%, unbalanced

TX OUT Transmit data to the network, 75 ohms ± 5%, unbalanced

61200780L1-1C © 2004 ADTRAN, Inc. 44

Page 45

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

T3 Drop and Insert Option Module

Using the provided RG-59, 75-Ohm cables (P/N 3125I054), each T3 Drop and Insert Option Module

(P/N 1200225L1) provides BNC connectors for primary and secondary transmit and receive connections

(see Pinout 25

Pinout 25. T3 Drop and Insert Module (BNC pair, female)

).

Name Description

Primary RX IN Primary receive data from the network, 75 ohms ± 5%, unbalanced

Primary TX OUT Primary transmit data to the network, 75 ohms ± 5%, unbalanced

Secondary RX IN Secondary receive data from the network, 75 ohms ± 5%, unbalanced

Secondary TX OUT Secondary transmit data to the network, 75 ohms ± 5%, unbalanced

Dual Video Option Module

The Dual Video Option Module (P/N 4200773Lx) provides a standard RS-366 dialing interface (DB-25)

and a DTE interface (provided through adapter cables). Pinout 26 shows the RS-366 dialing interface and

Pinouts 27 through 29 on the following pages show pinouts for the other available interfaces.

Pinout 26. Dual Video Module (RS-366, DB-25)

Pin Name Description Pin Name Description

1 Shield Shielded Ground Connection 14 NB1 Digit Signal Circuit 1

2 DPR Digit Present 15 NB2 Digit Signal Circuit 2

3 ACR Abandon Call and Retry 16 NB4 Digit Signal Circuit 4

4 CRQ Call Request 17 NB8 Digit Signal Circuit 8

5 PND Present Next Digit 18 RC Receive Common

6 PWI Power Indication 19 SC Send Common

7 SG Signal Ground 20-21 Unused n/a

8-12 Unused n/a 22 DLO Data Link Occupied

13 DSC Distant Station Connection 23-25 Unused n/a

61200780L1-1C © 2004 ADTRAN, Inc. 45

Page 46

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Pinout 27. Dual Video Module (V.35 Winchester)

Pin CCITT Name Description

A101PG Protective ground

B102SG Signal ground

C105RTSRequest to send from DTE

D106CTSClear to send to DTE

E107DSRData set ready to DTE

F109DCDReceived line signal detector to DTE

H— DTRData terminal ready from DTE

J— RI Ring indicator

R104RD-AReceived data to DTE

T104RD-BReceived data to DTE

V 115 RC-A RX clock to DTE

X 115 RC-B RX clock to DTE

P 103 TD-A Transmitted data from DTE

S103TD-BTransmitted data from DTE

Y114TC-ATX clock to DTE

AA 114 TC-B TX clock to DTE

U 113 ETC-A External TX clock from DTE

W 113 ETC-B External TX clock from DTE

NN — TM Test mode to DTE - (Not Supported)

61200780L1-1C © 2004 ADTRAN, Inc. 46

Page 47

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Pinout 28. Dual Video Module (EIA-530)

Pin Signal Description Pin Signal Description Pin Signal Description

1 Shield (Ground) 10 Carrier Detect (B) 19 Request to Send (B)

2 Transmit Data (A) 11 Ext. Transmit Clock (B) 20 DTE Ready (A)

3 Received Data (A) 12 Transmit Clock (B) 21 Not Used

4 Request to Send (A) 13 Clear to Send (B) 22 DCE Ready (B)

5 Clear to Send (A) 14 Transmit Data (B) 23 DTE Ready (B)

6 DCE Ready (A) 15 Transmit Clock (A) 24 Ext. Transmit Clock (A)

7 Signal Ground 16 Received Data (B) 25 Not Used

8 Carrier Detect (A) 17 Receive Clock (A)

9 Received Clock (B) 18 Not Used

Pinout 29. Dual Video Module (RS-449)

Pin Signal Description Pin Signal Description Pin Signal Description

1 Shield (Ground) 14 Remote Loopback

27 Clear to Send (B)

(Not Supported)

2 Not Used 15 Ring Indicator 28 Not Used

3 Not Used 16 Not Used 29 DCE Ready (B)

4 Transmit Data (A) 17 Ext. Transmit Clock (A) 30 DTE Ready (B)

5 Transmit Clock (A) 18 Test Mode

31 Carrier Detect (B)

(Not Supported)

6 Received Data (A) 19 Signal Ground 32 Not Used

7 Request to Send (A) 20 Not Used 33 Not Used

8 Receive Clock (A) 21 Not Used 34 Not Used

9 Clear to Send (A) 22 Transmit Data (B) 35 Ext. Transmit Clock (B)

10 Local Loopback

23 Transmit Clock (B) 36 Not Used

(Not Supported)

11 DCE Ready (A) 24 Receive Data (B) 37 Not Used

12 DTE Ready (A) 25 Request to Send (B)

13 Carrier Detect (A) 26 Receive Clock (B)

61200780L1-1C © 2004 ADTRAN, Inc. 47

Page 48

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

NxT1 HSSI/V.35 Option Module

The NxT1 HSSI/V/35 Option Module (P/N 1200771L1) uses a single 50 pin SCSI-II interface (or V.35

interface using an optional adapter cable) to combine eight T1s of data (a combination of eight using the

four NxT1 HSSI/V.35 Module T1 ports and other T1 ports installed in the system). See Pinouts 30 and 31.

Pinout 30. NxT1 HSSI/V.35 Module (RJ-48C)

Pin Name Description

1 RxData - Ring (R) Receive data from the network

2 RxData - Tip (T) Receive data from the network

3Unused —

4 TxData - Ring (R1) Send da ta towards the network

5 TxData-Tip (T1) Send data towards the network

6,7,8 Unused —

Pinout 31. NxT1 HSSI/V.35 Module (50-pin SCSI-II and V.35 Winchester)

Pin

(+ Side)

Pin

(- Side)

Direction Description

1 26 — HSSI SG - Signal Ground

2 27 O HSSI RT - Receive Timing

3 28 O HSSI CA - DCE Available

4 29 O HSSI RD - Receive Data

5 30 O HSSI LC - Loopback Circuit C

6 31 O HSSI ST - Send Timing

7 32 — HSSI SG - Signal Ground

8 33 I HSSI TA - DTE Available

9 34 I HSSI TT - Terminal Timing

10 35 I HSSI LA - Loopback Circuit A

11 36 I HSSI SD - Send Data

12 37 I HSSI LB - Loopback Circuit B

13 38 — HSSI SG - Signal Ground

— 39 — Ancillary to DCE (Reserved)

14 — I V.35 RTS - Request to Send

15 40 I V.35 TT Terminal Timing

61200780L1-1C © 2004 ADTRAN, Inc. 48

Page 49

ATLAS 800 Series System Manual Option Module Pinouts

Engineering Guidelines

Pinout 31. NxT1 HSSI/V.35 Module (50-pin SCSI-II and V.35 Winchester) (Continued)

Pin

(+ Side)

Pin

(- Side)

Direction Description