Page 1

CLEI Code: SILCHL0DAA

TA 850 System Installation and Maintenance

61200376L1-5B

Issue 2, June 2000

Contents

1. General...........................................................................1

2. Product Overview ........................................................ 1

3. Installation..................................................................... 2

4. Specifications.................................................................6

5. Maintenance..................................................................6

6. Warranty and Customer Service................................6

7. Limited Product Warranty.......................................... 7

8. Regulatory Requirements............................................7

Figures

Figure 1. TA 850................................................................1

Figure 2. TA 850 Backplane.............................................2

Figure 3. TA 850 Component Layout and Cable Con-

nections.............................................................. 3

Figure 4. Connector Pinout.............................................5

Figure 5. T1 Connections................................................. 5

Figure 6. Alternate Power Connection.......................... 5

Figure 7. Office Alarm Connections .............................. 6

Tables

Table 1. TA 850 Backplane Connections....................... 4

Table 2. Wire Wrap Identification.................................. 6

Table 3. Alarm Notification............................................. 6

Table 4. Specifications and Part Numbers.................. 10

1. GENERAL

This practice provides installation and maintenance

procedures for the ADTRAN Total Access850 (TA850)

System. The Specifications and Part Numbers Table

(Table 4on page 10)showspart numbers for equipment

and documents referenced in this practice. Referenced

practices shouldbe on-hand during system installation.

NOTE

This is not an operationalmanual. Toobtain an

operational manual, contact ADTRAN Technical

Support at (888) 4ADTRAN.

Revision History

This is the initial release of this document. Future revisions to this document will be described in this subsection.

TA 850 system benefits integrated communications

providers,such as CLECs,ILECs, andISPs, who require

a customer premises device that integrates voice and

data functions, and provides a viable migration path

from TDM to packet-basedtechnology. The TA 850

features remote management, an integrated IP/IPX

router, and special services slots.

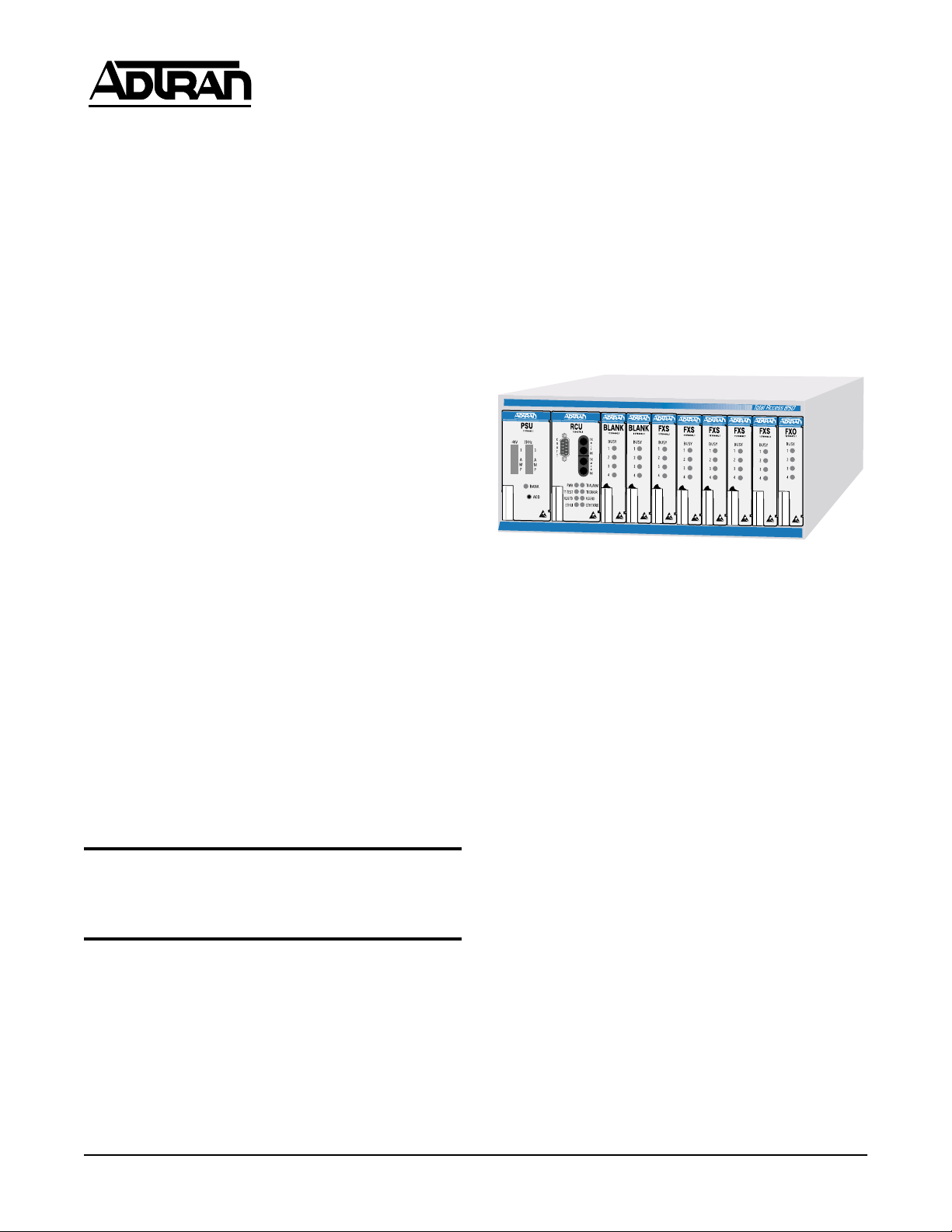

Figure 1. TA 850

TheTA 850 is a modular device,with two common slots

and eight access slots. Common cards required for operation are a powersupply unit (PSU) and a routercontrol unit (RCU). The RCU is a card that currently

supports TDM-based applications, but can be easily upgraded to an ATM-based controller as requirements

change. The RCU includes a T1 network interface,

DSX-1PBXinterface,Nx56/64V.35interface,andbuiltin IP/IPX router. Six access slots allow the user to combine a variety of voiceand data services. Up to six Quad

FXS or Quad FXO access modules can be installed to

support up to 24 analog voice lines. Other access modules for data applications include the OCU DP and

ISDN U-BR1TE. The other two access slots are for future hardware options.

Using local or remote inband management, carriers can

turn features, functions, and access ports on and off.

Easy access to modules, common cards, power supplies, and the battery back-up system simplify maintenance procedures. Hot-swappable modules may be

replaced without disrupting other units. The four-circuit-per-module desig n ensures that only four analog

circuits are affected when replacing a module.

2. PRODUCT OVERVIEW

The TA 850 system (see Figure1) is an integratedaccess

device designed for cost-effective deployment of voice

and data services at the customer’s premises. The

61200376L1-5B 1

Trademarks: Any brand names andproductnamesincludedin thisdocument are

trademarks, registered trademarks, or trade names of their respective holdres.

A compact, NEBS-compliant cabinet suitable for the

customer premises or thecentral office provides added

safety and reliability. The 2U design uses little rack

space. When wall mounted, the 8.5-inch by 11-inch

Page 2

chassis occupies a space the size of a piece of n otebook

paper. Two TA 850 systemscan be mounted side-byside in either 19-inch or 23-inch relay racks.

Preconfigured packages are available.

Features

TheTA850includesthefollowingfeatures:

• T1/FT1 integrated access

•TDMtoATMmigration

• Modular network interface for future xDSL compatibility

• Integrated IP/IPX router

• Integrated DSX-1 PBX interface

• V.35 Nx56/64 DTE interface

• TR-08 signaling support

• Analog FXS and FXO voice expansion (four per

board)

• SNMP management

• NEBS and UL 1950 compliance

• Industry leading 10-year warranty

Functional Description

The TA 850 System comprises the chassis, common

cards, and access modules. Associatedwith the system

are additional elements including an AC to DC power

supplyandbatterychargingunitandabatterypackfor

backup power.

WARNING

On TA 850 installations that do not use all chassis

slots, UL 1950/NEBS requires that the empty slots

must have a TA 850 blank unit (part number

1175099L1) installedin the opening.

External AC and DC Power. The ADTRAN AC/DC

Power Supply/Battery Charging unit receives its power from a standard 115 VAC outlet. During operation,

the power supply maintains -54 VDC to the PSU. The

power supply battery charging circuit maintains the

battery pack at peak charge. In the event ofan AC power failure, the battery backup circuit automatically provides battery power to the PSU for up to 8hours. When

AC power is restored, input power automatically returns to the AC supply and the battery charging circuit

will recharge the battery to peak.

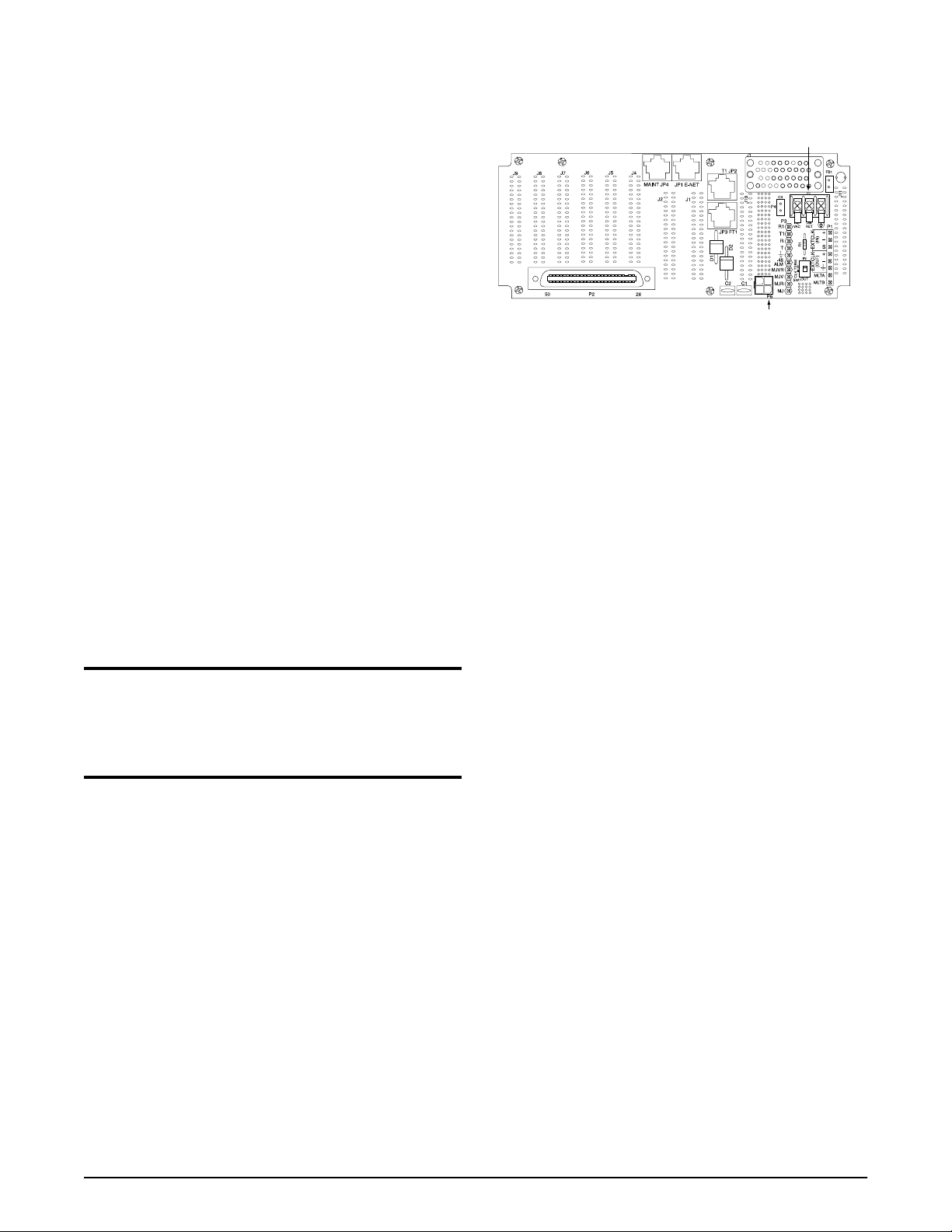

On the TA 850 chassis, the incoming power termination

point is on either of two backplane connections: P7 or

P6. (See Figure 2.) Both sources connect directly to the

PSU.ConnectorP6isusedwhenthechassisispowered

by the ADTRAN AC/DC Power Supply unit (P/N

1175043L1) which mounts externally to the chassis.

ConnectorP7 is used when-48 VDC is available on site

and screw-type terminal connections are required.

P7

P6

Figure 2. TA 850 Backplane

PSU. The Power Supply Unit supplies -48 VDC and

20 Hz ringing voltage to the Router Controller Unit

(RCU) and the access modules. The PSU converts

-48 VDC input to the required voltages needed to operate all common units and access modules. The ring generator circuit provides 20 Hz ring voltage to the analog

access modules.

ThePSUfaceplate(seeFigure1onpage1)showsthe

following: two GMT fuses (one for power and one for

20 Hz ringvoltage), a channel bank status LED, and an

alarm cutoff (ACO) pushbutton switch. The separately

fusedring generator supplies upto 20 REN tothe access

modules.

RCU.The Router Controller Unit isa dual boardassembly that provides the networkinterface. The RCU can

provision, test, and provide status for any card in the

channelbank. The faceplate hasa DB-9

CRAFT

port connection, dual bantam jack connection, plus network,

V.35, and Ethernet LEDs.

Access Modules. The TA 850 is designed to support

Quad FXS, Quad FXO, OCU DP, and UBR1TE access

modules.

3. INSTALLATION

Before installing the TA 850, carefully inspect the

TA 850 Base Unit for shipping damage. If you suspect

damage, file a claim immediately with the carrier and

then contact ADTRAN Customer and Product Service.

( See “Warranty and Customer Service” on page 6.) If

possible, keep the original shipping container for returningthe TA 850 for repair or for verificationof damage during shipment.

Your ADTRAN shipment includes the following items

(if the unit is not purchased directly from ADTRAN, it

may be packaged differently):

• TA 850 chassis, PSU, RCU, and blanks

• TA 850 System Installation and Maintenance Practice

2 Issue 2, June 2000 61200376L1-5B

Page 3

Grounding Instructions

This section provides grounding instruction information from the Underwriters' Laboratory UL 1950 Standard for Safety: Information Technology Equip ment .

An equipment grounding conductor that is not smaller

in size than the ungrounded branch-circuit supply conductorsistobeinstalledaspartofthecircuitthatsupplies the productor system. Bare,covered,or insulated

grounding conductors are acceptable. Individually

covered or insulated equipment grounding conductors

shall have a continuous outer finish thatis eithergreen,

or green with one or more yellow stripes. The equipmentgroundingconductoris tobe connectedto ground

at the service equipment.

The attachment-plug receptacles in the vicinity of the

product or system areall to beof a grounding type, and

the equipment grounding conductors serving these receptacles are to be connected to earth ground at the service equipment.

A supplementary equipment grounding conductor

shall be installed between the product or system and

ground that is in addition to the equipment grounding

conductor in the power supply cord.

The supplementary equipment grounding conductor

shall not be smaller in size than the ungrounded

branch-circuit supply conductors. The supplementary

equipment grounding conductor shall be connected to

the product at the terminal provided, and shall be connected to ground in a manner that will retain the

ground connection when the product is unplugged

from the receptacle. The connection to ground of the

supplementary equipment grounding conductor shall

bein compliance with the rules for terminating bonding

jumpers at Part K or Article 250 of the National Electrical Code, ANSI/NFPA 70. Termination of the supplementary equipment grounding conductor is permitted

to be made to building steel, to a metal electrical raceway system, or to any grounded item that is permanently and reliably connected to the electrical service

equipment ground.

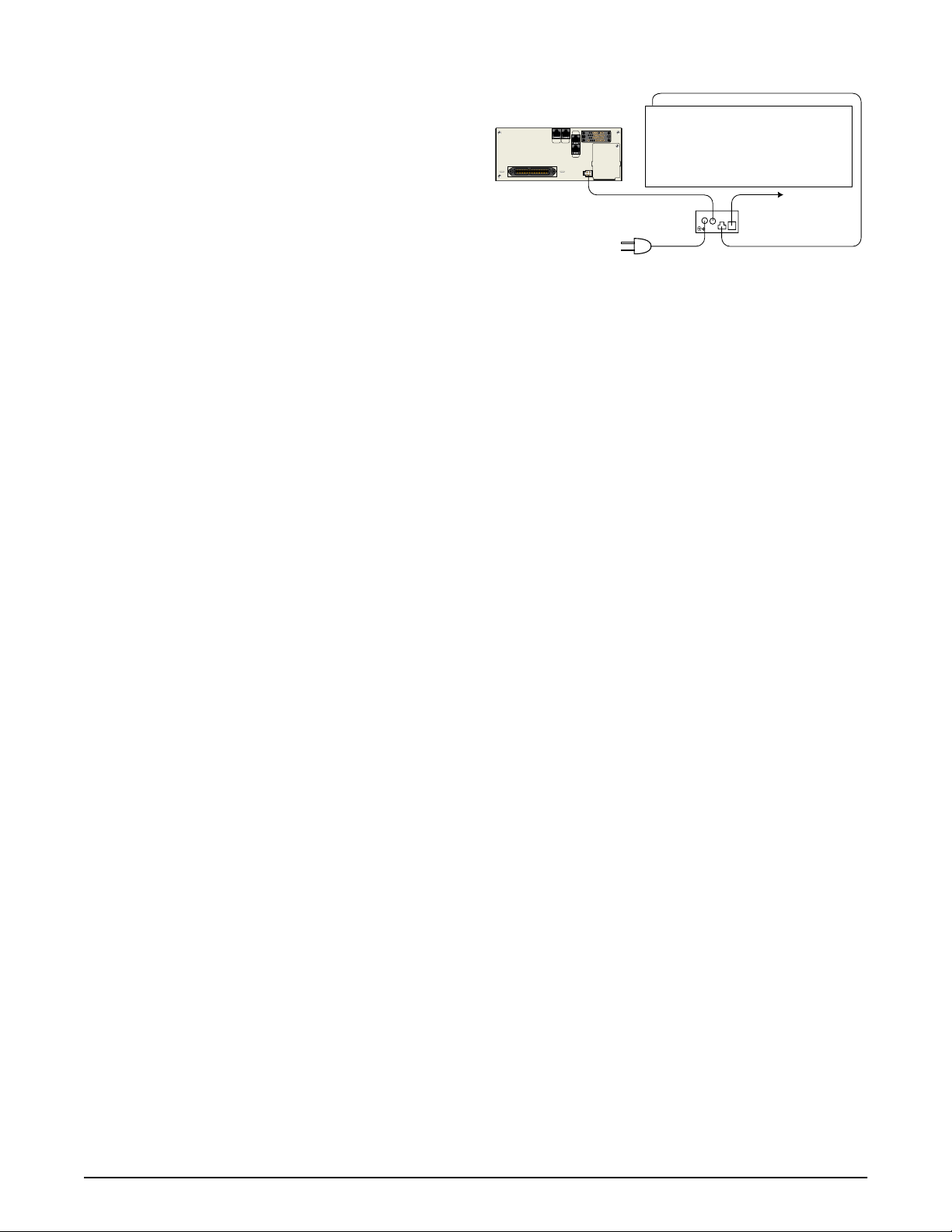

TA850

AAEEKK

W

M

C

H

S

T1

MM

CC

HH

AEK

PUY

BB

FF

LL

DJN

X

T

DSX-1

DC

POWER

V.35

BFLRVZDDJJNN

-54 VDCOutput to TA850

AC/DC PowerSupply

Battery Charging Unit

AC PowerInput

-48 VDCBackup Battery Pack

-54VDC

120VAC/

OUTPUT

2A60HZINPUT

ACALARM

BATTERY

OUTPUT

INPUT

GROUND

-

+

ToAlarms

-54 VDCBattery

Charging/Discharging Line

WARNING:

20HzFUSE

CRAFT 10 BASE T

MUSTBEREMOVED

BEFOREREARCOVER

CAUTION

DuringTA 850 wall installation,

position chassis so front

panels face UP.

Figure 3. TA 850 Component Layout and Cable

Connections

Mounting Brackets. The TA 850 chassis includes wall

mount brackets. If rack mount bracketsare needed,use

part number 1175045L1or 1175046L1 for 19-inch or

23-inch, respectively.

Tools Needed (Wall-Mount). The TA 850 chassis

mountsand connects withstandard fastenersand hand

tools:

• Four #8 x 3/4 inch pan-head wood screws

• Drill and drill bit set

• Flat head screwdriver (medium)

• Two Phillips head screwdrivers (small /medium)

• Wire-wrap gun (optional)

• 5-pair male amphenol cable (customer connection)

• Selected punch-down block and tool

Mount the Chassis. Installthechassisasfollows:

1.Position the chassis at the desired location; observe

required clearances an d ensure cable plugs reach

their designated sockets.

2.Ensure the chassis is plumb; then mark through the

flange mounting holes to identify where the pilot

holes will be drilled.

3.Using a 1/16 inch bit, drill pilot holes at the marked

locations.

4.Mount the chassis using the four #8 by 3/4 inch pan-

head wood screws.

Install the Chassis

Standard installation is a single unit wall mount. Position the chassis with the access modules facing up.

Mount on heavy plywood (3/4 inch minimum). Refer

to Figure 3 for component layout.

Required Clearances. A minimum 10-inch clearance

is required on thefrontend for access module insertion

and withdrawal. On the backplane end, a five-inch

clearance is required for wiring access to the V.35 connector. For those units installed in a communications

bay, standard bay clearances are satisfactory.

Connections. Allconnectionsaremade throughterminals, jacks, and wire-wraps on the backplane. Refer to

Figure 2 on page 2 for backplane connections. Refer to

Table 1 on page 4 for backplane reference designator

descriptions and functions supported.

A removable rear cover provides access to the backplane, and an access panelthat mountsto the rearcover

allows access to wire-wrap strips P1, P3, andP5,power

terminal strip P7, and clock termination switch SW1

without removing themain rearcover. MostCPE applications will not require removal of the rear cover.

61200376L1-5B Issue 2, June 2000 3

Page 4

Table 1. TA 850 Backplane Connections

Ref Des Device/Label Technology

P1 wire-wrap strip clock/tests

P2 50 pin amphenol FXO, FXS, etc.

P3 wire-wrap strip alternate T1 interface

P5 wire-wrap strip alarms

P6 4 pin jack primary -48 V in

P7 3-lug terminal alternate -48 V in

JP1 RJ-48/E-NET 10BaseT Ethernet

JP2 RJ-48/T1 primary T1 interface

JP3 RJ-48/FT1 DSX1 interface

JP4 RJ-48/MAINT RS 232 craft interface

J1 V.35 Nx56K/64K

UL 1950 Deployment Guidelines. One of the following two powering schemes shall be used when powering this equipment:

1. Use the ADTRAN power supply (part number

1175043L1).

2. Do the following:

a.Connect the unit to a reliably grounded -48 Vdc

source which is electrically isolated from the AC

source.

b.A readily accessible disconnect device, suitably

approved and rated, shall be incorporated in the

input source wiring.

c. The branch circuit overcurrent protection shall be a

fuse or circuit breaker rated minimum 48 V, maximum 20 A.

d.This unit shall be installed in accordance with the

requirements of NEC NFPA 70.

The installation configurations codes are given below:

Alternate Connections. For wire-wrap or screw

terminal connections,the rear cover does not need to be

removed; only the terminal access cover needs to be

removed. Make wire-wrap or screw terminal

connections as follows:

1.Unscrew the access cover hold-down screw.

2.Slide the access cover down slightly to disengage the

lock-tabs from their slots.

CAUTION

Use wire gauge suitable for the application.

3.Identify the wire-wrap pins designated for use, and

make the connectionsstartingwith thepinsclosest to

the exit port to avoid wiring interference as work

progresses.

4.If alternate power connection to P7 is to be used,

make those terminal connections last.

5.Carefully route wiring through the exit port.

6.Position and align the access cover tabs to the slots;

insert the tabs and slide the cover up slightly until

the screw holes arealigned. Ensurethatexit wiring is

not pinched or damaged.

7.Reinsert the hold-down screw.

Customer Connection. One 50-pin male amphenol

connector (P2) provides the interconnect wiring for the

access modules located in slots 1 through6 of the chassis. This connector is usually terminated with a punchdown block for premises wiring or connected directly

to a cross-connect or main distribution frame. Figure 4

on page 5 details the connector pinout.

T1 Connection. There are two termination pointsfor

connecting the network T1 to the chassis: the primary

RJ-48 connector (JP2) and the alternate wire-wrap pins

on terminal strip P3 (as shown in Figure 2 on page 2).

Only one connector type is used (not both).

In Out

PC FC

TheT1primary connection is viathe RJ-48 connector labeled

T1 (JP2). This arrangement provides a convenient T1 connection for those installations wherea T1Smart Jack is used.

IC E-

TC XX

The RCU common module provides termination for

DSX-1and DS1 signals. Forwire-wrap connections,shield

is provided bythegroundpin adjacent to the DSX-1/DS1

pin set (see Figure 5 on page 5). Linebuild-out andequalization settings are provisioned on the RCU.

CAUTION

Both Power and T1 services have two connection

points. In all cases, only one of the connection

points is used. Adhere to the instructions in the

following subsections to ensure correct installation.

Power Connection. There are two power connec-

tions on the backplane: a modular DC plug (P6), and a

three lug terminal strip (P7). (Refer to Figure 2 on page 2.)

The primary connection is the modular plug, which

receives -48 VDC from the ADTRAN power supply/

battery charging unit (P/N 1175043L1). The alternate

4 Issue 2, June 2000 61200376L1-5B

Page 5

connection is screw terminal P7, which can be u sed if

-48 Vdc is available as in central office applications. The

screw terminal connectionis shown inFigure 6 on page 5.

CAUTION

During installation, power should be the last

connection made after all other wire-wrap

connections are completed.

5025

P

4924

P

4823

P

4722

P

4621

P

4520

P

4419

P

4318

P

4217

P

4116

P

4015

P

3914

P

3813

P

3712

P

3611

3510

349

338

327

316

305

294

283

272

261

Slot 3

P

P

P

P

Slot 2

P

P

P

P

Slot 1

P

P

RECEPTACLE

Slot 6

Slot5

Slot 4

50 PIN

AMP

NC

R

Circuit 4

T

R

Circuit 3

T

R

Circuit 2

T

R

Circuit 1

T

R

Circuit 4

T

R

Circuit 3

T

R

Circuit 2

T

R

Circuit 1

T

R

Circuit 4

T

R

Circuit 3

T

R

Circuit 2

T

R

Circuit 1

T

R

Circuit 4

T

R

Circuit 3

T

R

Circuit 2

T

R

Circuit 1

T

R

Circuit 4

T

R

Circuit 3

T

R

Circuit 2

T

R

Circuit 1

T

R

Circuit 4

T

R

Circuit 3

T

R

Circuit 2

T

R

Circuit 1

T

Figure 4. Connector Pinout

To DSX-1/DS1

16 AWG

RING LUG

16 AWG

STRANDED

RED

-48V

BLKFGBLK

GRD

TO FUSE

PANEL

20 AWG

RING LUG

20 AWG

SOLID

TO WIRE WRAP

FRAME GROUND

Figure 6. Alternate Power Connection

NOTE

The following section is for information only, and

the features d escribed are not necessary for typical

applications.

Office Alarms. Backplane alarm connections(P5) are

labeled as shown inTable 2 on page 6 and illustrated in

Figure 7 on page 6. Alarm relay contacts are open during normal operation. Thealarm relaycontacts closein

the event of a local alarm condition or the receipt of an

alarm from the T1 carrier. In a carrier alarm condition

suchas a Red, Yellow, orBlue (unframed all 1s), various

alarm contacts in the PSU close. Carrier alarm conditions cause the TA 850 to initiate trunk processing. The

following chain of events then occur:

1.MJ will be directly shorted to MJR.

2.MJV will be directly shorted to MJVR.

Contacts MJ and MJR can be overridden manually dur-

ing an alarm condition by pressing the ACO pushbutton on the PSU faceplate. If the 3-Amp power fuse on

the PSU trips, the -48ALM relay will close, providing a

-48 VDC signal on that pin. This alarm cannot be overridden by the ACO pushbutton. Refer to Table 3 on

page 6 for alarm notifications.

R1

T1

R

T

Figure 5. T1 Connections

61200376L1-5B Issue 2, June 2000 5

Page 6

Table 2. Wire Wrap Identification

P3 Wire-Wrap Connections

T1 Connections

1 R1 DS1 Ring input from network

2 T1 DS1 Tip input from network

3 R DS1 Ring output from network

4 T DS1 Tip output from network

5 Gnd Ground

P5 Wire-Wrap Connections

Alarm Connections

1 -48 ALM DC Alarm output

2 MJVR Major Alarm Visual Common

3 MJV Major Alarm Visual

4 MJR Major Alarm Audible Common

5 MJ Major Alarm Audible

To customer designed remote alarms

Install any Option Modules

After installing the TA 850 Base Unit and connecting

the required cables, you can install your choice of option modules.

WARNING

Remove the 20 Hz fuse before exposing backplane or

accessing channel units.

Individual access modules insert from the front. A locking bar holds the modules in place for added security.

Disengaging the captured screw allows removal of the

locking bar. All wiring connections terminate on the

backplane. Refer to Table 2 on page 6 for wire-wrap

connections, and refer to Figure 2 on page 2 for backplane layout. Refer to Table 1 on page 4 for backplane

reference designator descriptions and functions supported.

Power-Up

As shipped, the T A850 is set to factory default conditions. After installing the TA 850 Base Unit and any option modules, the TA 850 is ready for power-up.

4. SPECIFICATIONS

Table 4 on page 10 gives specifications and relevant

part numbers.

MJ

-48VALM

MJVR

MJV

MJR

Figure 7. Office Alarm Connections

Table 3. Alarm Notification

Alarm Condition Relays Activated

MJR MJVR -48 ALM

Red Alarm X X

Yellow Alarm X X

AIS Alarm X X

PSU Power Fuse Fails X X X

Alarms ACO Deactivates X X

Note: ACO will not deactivate MJR after a power fuse

failure.

5. MAINTENANCE

The TA 850 System does not required programmed

maintenance for design operation.

ADTRAN does not recommendthat repairs be attemptedin the field. Repair servicesare obtained byreturning

the defective unit to ADTRAN Customer Service.

6. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product withinten

years from the date ofshipment if theproduct doesnot

meet its published specifications or if it fails while in

service. For detailed warranty,repair, and return information refert o the ADTRAN Equipment Warranty and

Repair and Return Policy Procedure.

Return Material Authorization(RMA) isrequired prior

to returning equipment to ADTRAN.

For service, RMA requests, or more information,seethe

following sections for the correct toll-free contact number.

6 Issue 2, June 2000 61200376L1-5B

Page 7

Product Support Information

Pre-Sales Inquiries and Applications Support.

Please contact your local distributor, ADTRAN Applications Engineering, or ADTRAN Sales:

Applications Engineering (800) 615-1176

Sales (800) 827-0807

Post-Sale Support. Please contact your local distributorfirst.Ifyourlocaldistributorcannothelp,please

contact ADTRAN Technical Supportand have the unit

serial number available.

Technical Support (888) 4ADTRAN

Repair and Return. If ADTRAN Technical Support

determines that a repair is needed, Technical Support

will coordinate with the Customer and Product Service

(CAPS) departmenttoissue anRMA number. For information regarding equipment currently in house or possible fees associated with repair, contact CAPS directly

at the following number:

CAPS Department (256) 963-8722

Identify the RMA number clearly on the package (below address), and return to the following address:

ADTRAN, Inc.

6767 Old Madison Pike

Progress Center

Building #6 Suite 690

Huntsville, Alabama 35807

RMA # _____________

7. LIMITED PRODUCT WARRANTY

ADTRAN warrants that for ten years from the date of

shipment to Customer, all products manufactured by

ADTRAN will be free from defects in materials and

workmanship. ADTRAN also warrants that products

will conform to the applicable specifications and drawings for such products, as contained in the Product

Manual or in ADTRAN's internal specifications and

drawings for such products (which may or may not be

reflected in the Product Manual). This warranty only

applies if Customer gives ADTRAN written notice of

defects during the warranty period. Upon such notice,

ADTRAN will, at its option, either repair or replacethe

defective item. If ADTRAN is unable, in a reasonable

time, to repair or replaceany equipment to a condition as

warranted,Customer isentitled to afullrefundof the pur-

chase price upon retur nof the equipment to ADTRAN.

This warranty applies only to the original purchaser and

is not transferable without ADTRAN's express written

permission. This warranty becomes null and void if Customermodifiesoralterstheequipmentinanyway,other

than as specifi cal lyauthorized by ADTRAN.

EXCEPTFOR THELIMITED WARRANTY DESCRIBED

ABOVE, THE FOREGOING CONSTITUTESTHE SOLE

AND EXCLUSIVE REMEDY OF THE CUSTOMER

AND THE EXCLUSIVE LIABILITY OF ADTRAN AND

IS IN LIEU OF ANY AND ALL OTHER WARRANTIES

(EXPRESSED OR IMPLIED). ADTRAN SPECIFICALLY

DISCLAIMS ALL OTHER WARRANTIES, INCLUDING (WITHOUT LIMITATION), ALL WARRANTIES

OF MERCHANTABILITYAND FITNESS FOR A PARTICULAR PURPOSE. SOME STATES DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES,

SO THIS EXCLUSION MAY NOT APPLY TO CUSTOMER.

In no event will ADTRAN or its suppliers be liable to

Customer for any incidental, special, punitive, exemplary or consequential damages experienced by either

Customerora third party(including,butnot limitedto,

loss of data or information, loss of profits, or loss of

use).ADTRANisnotliablefordamagesforanycause

whatsoever (whether based in contract, tort, or otherwise)inexcessoftheamountpaidfortheitem.Some

states do not allow the limitation or exclusion of liabilityfor incidental or consequential damages,so the above

limitation or exclusion may not apply to Customer.

8. REGULATORY REQUIREMENTS

Affidavit Requirements for Connection to Digital

Services

• An affidavit is required to be given to the telephone

company whenever digital terminal equipment without encoded analog content and billing protection is

used to transmit digital signals containing encoded

analog content which are intended for eventual conversion into voiceband analog signals and transmitted on the network.

• The affidavit shall affirm that either no encoded analogcontentor billing information is beingtransmitted

or thatthe output of the device meets Part 68 encoded

analog content or billing protection s pecifications.

• End user/customer will be responsible for filing an

affidavit with the local exchange carrier when connecting unprotected customer premise equipment

(CPE) to 1.544 Mbps or subrate digital services.

• Untilsuch timeas subrate digitalterminal equipment

is registered for voice applications, the affidavit requirement for subrate services is waived.

61200376L1-5B Issue 2, June 2000 7

Page 8

Affidavit for Connection of Customer Premises

Equipment to 1.544 Mbps and/or Subrate Digital

Services

Forthework to beperformed in the certified territory of

________________________(telco name)

State of ________________

County of ________________

( ) D. In lieu of the preceding training requirements,

the operator(s)/maintainer(s) is (are) under the

control of a supervisor trained in accordance

with _________ (circle one) above.

I agree to provide _ _____________________ (telco’s

name) with proper documentation to demonstratecompliance with the information as provided in the preceding paragraph, if so requested.

I, _____________________________(name),

__________________________________(business address),

____________________ (telephone number) being duly

sworn, state:

I have responsibility for the operationand maintenance

of the terminal equipment to be connected to 1.544

Mbps and/or ________subrate digital services. The terminal equipment to be connectedcomplies with Part68

of the FCC rules except for the encoded analog content

and billing protection specifications.With respect toencoded analog content and billing protection:

( ) I attest that all operations associated with the

establishment, maintenance, and adjustment ofthe

digital CPE with respect to analog content and

encoded billing protection information continuously complies with Part 68 of the FCC Rules and

Regulations.

( ) The digital CPE does not transmit digital signals

containing encoded analog content or billing information which is intended to be decoded within the

telecommunications network.

( ) The encoded analog content and billing pr otecti onis

factory set and is not under the control of the customer.

I attest that the operator(s)/maintainer(s) of the digital

CPE responsible for the establishment, maintenance,

and adjustment of the encoded analog content and billing information has (have) been trained to perform

these functions by successfully having completed one

of the following (check appropriate blocks):

( ) A. A training course provided by the manufac-

turer/grantee of the equipment used to encode

analog signals; or

( ) B. A training course provided by the customer or

authorized representative, using training

materials and instructions provided by the

manufacturer/grantee of the equipment used

to encode analog signals; or

( ) C. An independent training course (e.g., trade

school or technical institution)recognized by

the manufacturer/grantee of the equipment

used to encode analog signals; or

_________________________________Signature

_________________________________Title

_________________________________Date

Transcribed a nd sworn to before me

This ________ day of ________, ________

_________________________________

Notary Public

My commission expires:

_________________________________

FCC regulations require that the following

information be provided in thi s manual to the

customer:

1.This equipment complies with Part 68 of the FCC

rules.The required label is affixed to the bottom of

the chassis.

2.An FCC-complianttelephone cordand modularplug

is provided with this equipment. This equipment is

designed to be connected to the telephone network

or premises wiring using a compatible modular jack

which is Part 68-compliant. See Chapter 2, Installation, for details.

3.If your telephone equipment (TA 850)causesharm to

the telephone network, the telephone company may

discontinue your service temporarily. If possible,

they will notifyyou in advance. But if advance notice

isn’t practical, you will be notified as soon as possible. You will be advised of your right to file a complaint with the FCC.

4.Y our telephone company may make changes in its

facilities, equipment, operations,or procedures that

could affect the proper operation of your equipment.

If they do, you will be given advance notice to give

you an opportunity to maintain uninterrupted service.

5. If you experience troublewith this equipment (TA 850),

please contact ADTRAN at (256) 963-8000 for repair/

warranty information. The telephone company may

ask you to disconnect this equipment from the network

until the problem has been corrected or until you are

sure the equipment is not malfunctioning.

6.This unit contains no user-serviceable parts.

8 Issue 2, June 2000 61200376L1-5B

Page 9

7.The following information may be required when

applying to your local telephone company for leased

line facilities.

For a T1 Port:

Service Type REN/

SOC

1.544 Mbps - SF 6.0N 04DU9-BN RJ-48C

FIC USOC

Shielded cables must be used with this unit to ensure

compliance with Class A FCC limits.

WARNING

Change or modifications to this unit not expressly

approved by the party responsible for compliance

could void the user’s authority to operate the

equipment.

1.544 Mbps - SF and

B8ZS

1.544 Mbps - ESF 6.0N 04DU9-1KN RJ-48C

1.544 Mbps - ESF

and B8ZS

ISDN 6.0N 04DU9-ISN RJ-48C

6.0N 04DU9-DN RJ-48C

6.0N 04DU9-1SN RJ-48C

For an FT1 Port:

Service Type REN/

SOC

1.544 Mbps - SF 6.0N 04DU9-BN

1.544 Mbps - SF and B8ZS 6.0N 04DU9-DN

1.544 Mbps - ESF 6.0N 04DU9-1KN

1.544 Mbps - ESF and B8ZS 6.0N 04DU9-1SN

ISDN 6.0N 04DU9-ISN

FIC

NOTE

When connecting FT1 port towards the network, a

suitable crossover cable is required.

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection againstharmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can

radiateradio frequency energy and, if not installedand

used in accordance with the instruction manual, may

cause harmful interference to radio frequencies. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will

be required to correct the interference at his own expense.

Canadian Equipment Limitations

NOTE

The Industry Canada Certification label identifies

certified equipment. This certification means that

the equipment meets certain telecommunications

network protective, operational, and safety

requirements. The Department of Commerce does

not guarantee the equipment will operate to the

user's satisfaction.

Before installing this equipment, users should ensure

that it is permissible to be connected to the facilities of

the local telecommunications company. The equipment

must also be installed using an acceptable method of

connection. In some cases, the company's inside wiring

associatedwithasinglelineindividualservicemaybe

extended by means of a certified connector assembly

(telephone extension cord). The customer should be

aware that compliance with the above conditions may

not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an

authorized Canadian maintenance facility designated

by the supplier. Any repairs or alterations made by the

user to this equipment, or equipment malfunctions,

may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the

electrical ground connections of the power utility, telephone lines and internal metallic waterpipe system, if

present,are connectedtogether. This precautionmay be

particularly important in rural areas.

CAUTION

Users should not attemptto make such connections

themselves, but should contact the appropriate

electric inspection authority, or an electrician, as

appropriate.

61200376L1-5B Issue 2, June 2000 9

Page 10

TheLoadNumber(LN)assignedtoeachterminaldevice denotes the percentage of the total load to be connected to a telephone loop which is used by the device,

to prevent overloading.The termination on a loop may

consist ofanycombination of devices subject only tothe

equipment that the total of the LNs of all devices does

not exceed 100.

The ringer equivalence number (REN) assign e d toeach

terminal adapter is used to determine the total number

of devices that may be connected to each circuit. The

sum of the RENs from all devices in the circuit should

not exceed a total of 5.0.

Table 4. Specifications and Part Numbers

Environmental

Operating Temperature

Storage Temperature

RelativeHumidity 95% maximum, noncondensing

Dimensions 8 3/4” W x 3 5/8” H x 11” D

Weight(fully loaded) 8 pounds

Weight(empty) 5 pounds

TA 850 Relevant P art Numbers

TA 850 Chassis 1200375L1

RCU 1200376L1, User Manual 61200376L1-1A

PSU 1175006L1

Quad FXS 1175408L1, User Manual 61175408L1-1A

Quad FXO 1175407L1, User Manual 61175407L1-1A

AC Power Supply/Battery Charger 1175043L1/L2

BackupBattery Pack 1175044L1/L2

Single Unit 19” Rack Mount Brackets 1175045L1

Single Unit 23” Rack Mount Brackets 1175046L1

System Configuration Part Numbers

TA 850 DC Chassis Bundle 4200376L1

TA 850 AC Chassis Bundle 4200376L1#AC

TA 850 DC Chassis Bundle + 12 FXS 4200376L2

TA 850 AC Chassis Bundle + 12 FXS 4200376L2#AC

TA 850 DC Chassis Bundle + 16 FXS 4200376L3

TA 850 AC Chassis Bundle + 16 FXS 4200376L3#AC

Canadian Class A Products

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de laclasse Aest conformeá la

norme NMB-003 du Canada.

-40to70oC (-40 to 158oF)

o

-30to70

Physical

C (-22 to 158oF)

10 Issue 2, June 2000 61200376L1-5B

Loading...

Loading...