Page 1

Total Access® 3010 LTU

High-bit-rate Digital Subscriber Line

Transceiver Unit for the Central Office

Installation and Maintenance

CONTENTS

1. GENERAL ............................................................................ 1

2. INSTALLATION .................................................................. 2

3. OPERATION ........................................................................ 3

4. HDSL SYSTEM TESTING .................................................. 4

5. SCU CONTROL PORT OPERATION (HDSL) ................. 5

6. HDSL DEPLOYMENT GUIDELINES ............................. 17

7. MAINTENANCE ............................................................... 17

8. PRODUCT SPECIFICATIONS ......................................... 17

9. WARRANTY AND CUSTOMER SERVICE ................... 17

Appendix A. HDSL H-LSS Circuit Configuration and Turnup

for G.703 Fed Systems .................................... A-1

Appendix B. HDSL H-LSS Circuit Configuration and Turnup

for DS3-Fed Systems ...................................... B-1

FIGURES

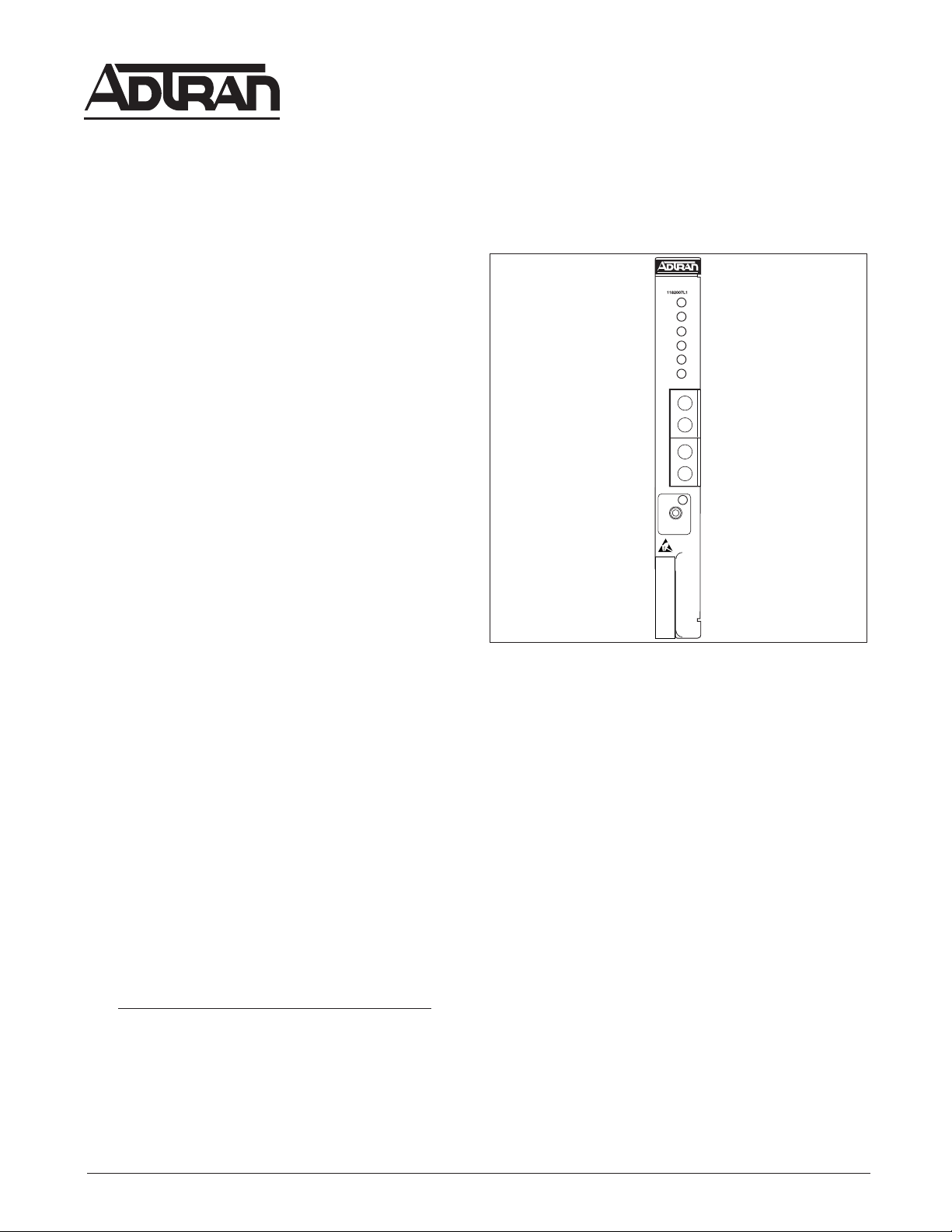

Figure 1. ADTRAN Total Access 3010 LTU ........................... 1

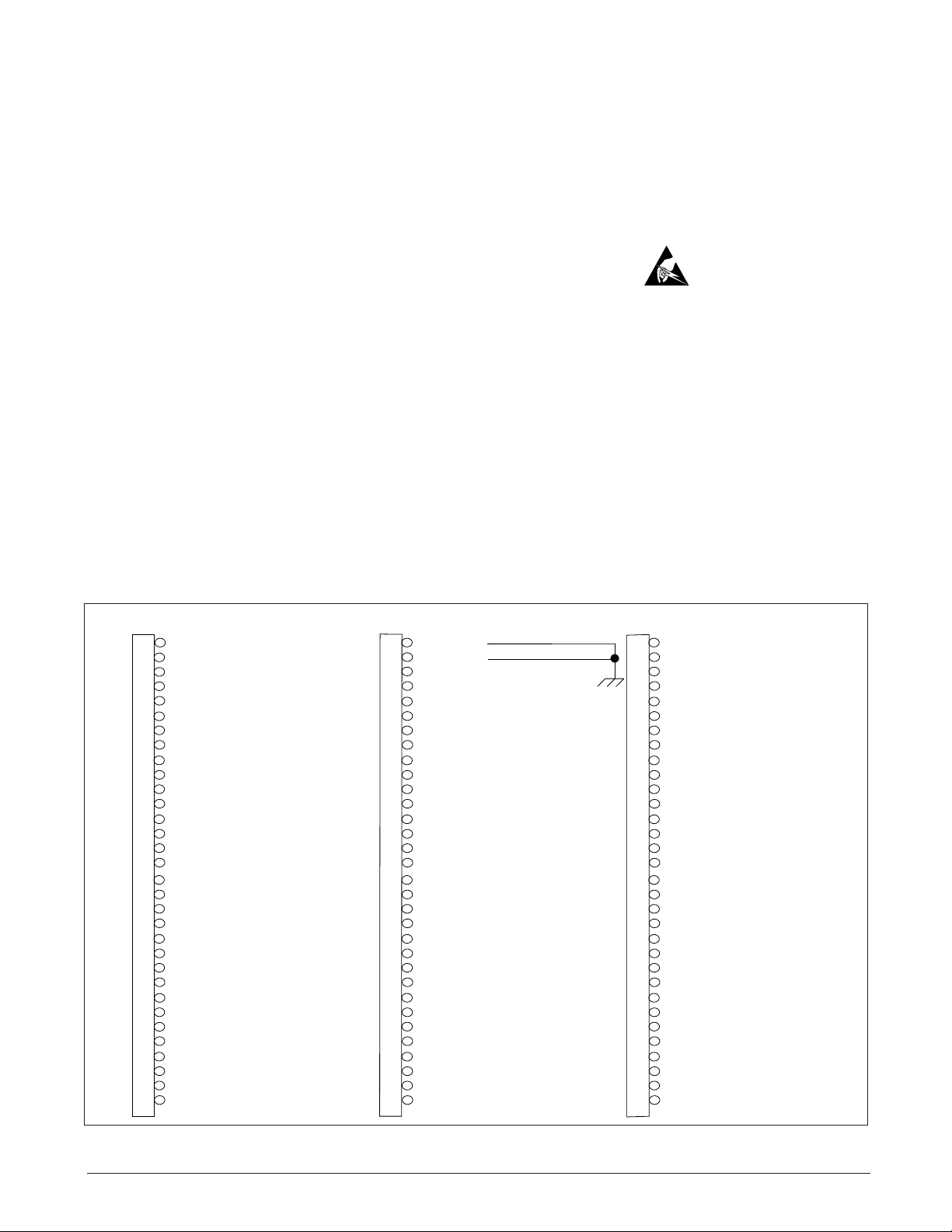

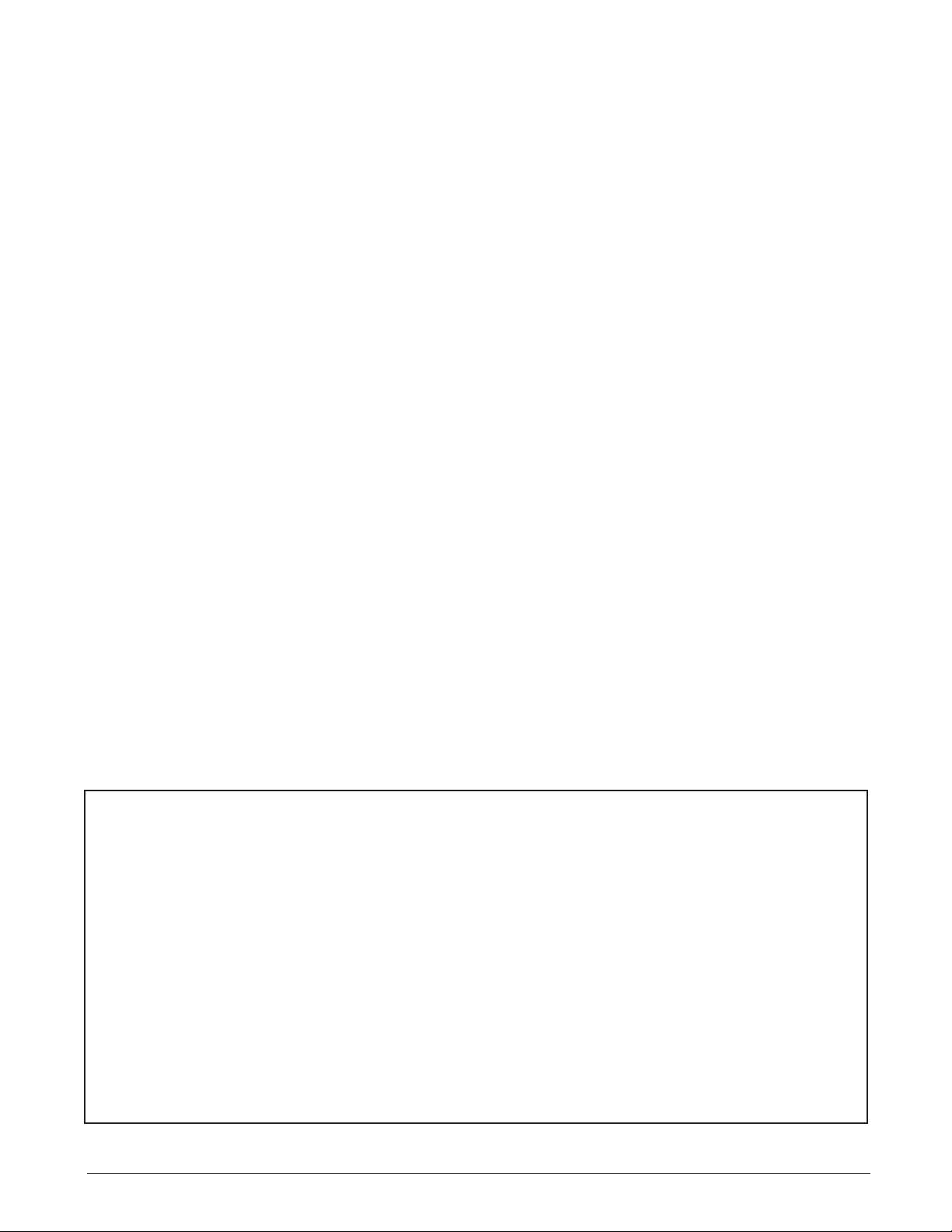

Figure 2. LTU Edge Connector Wiring .................................... 2

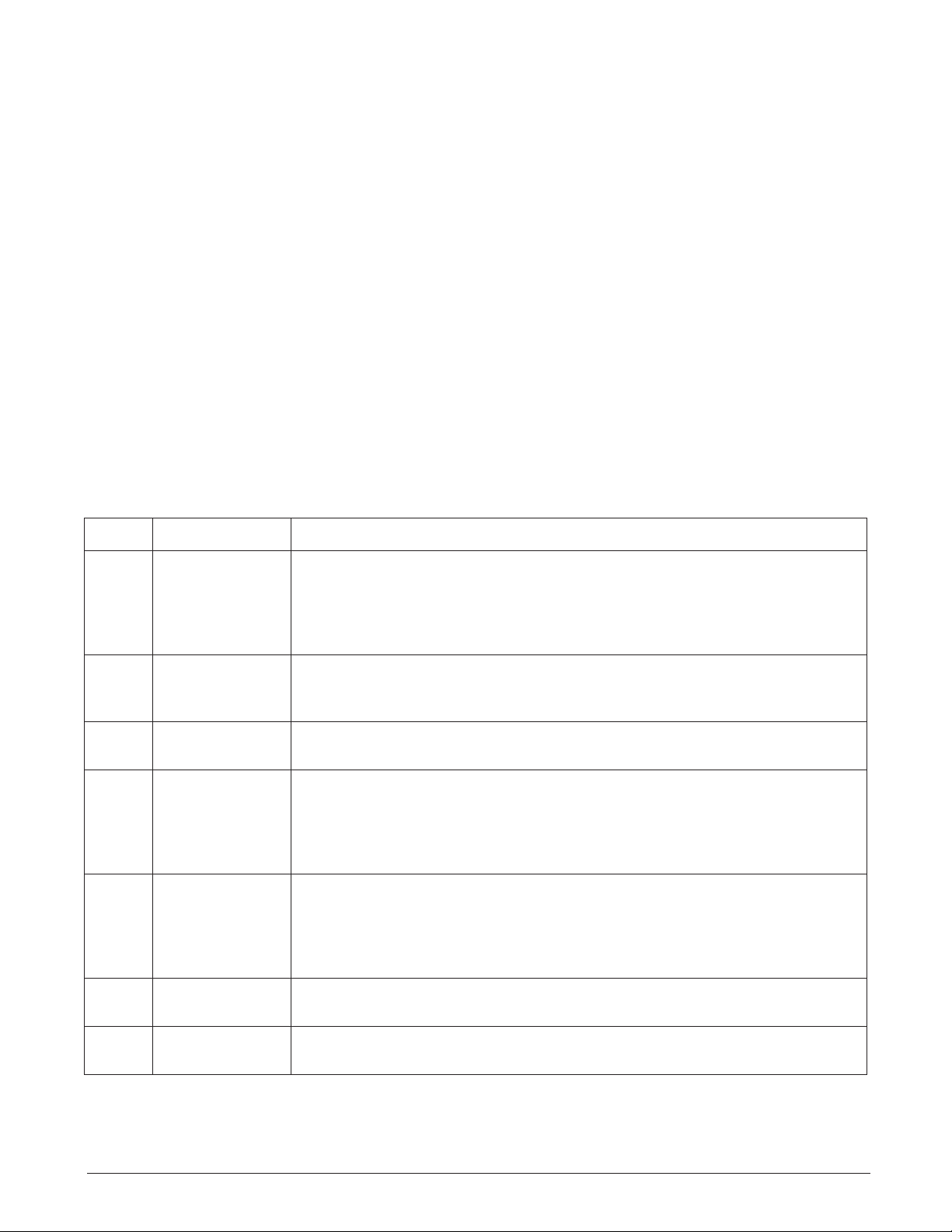

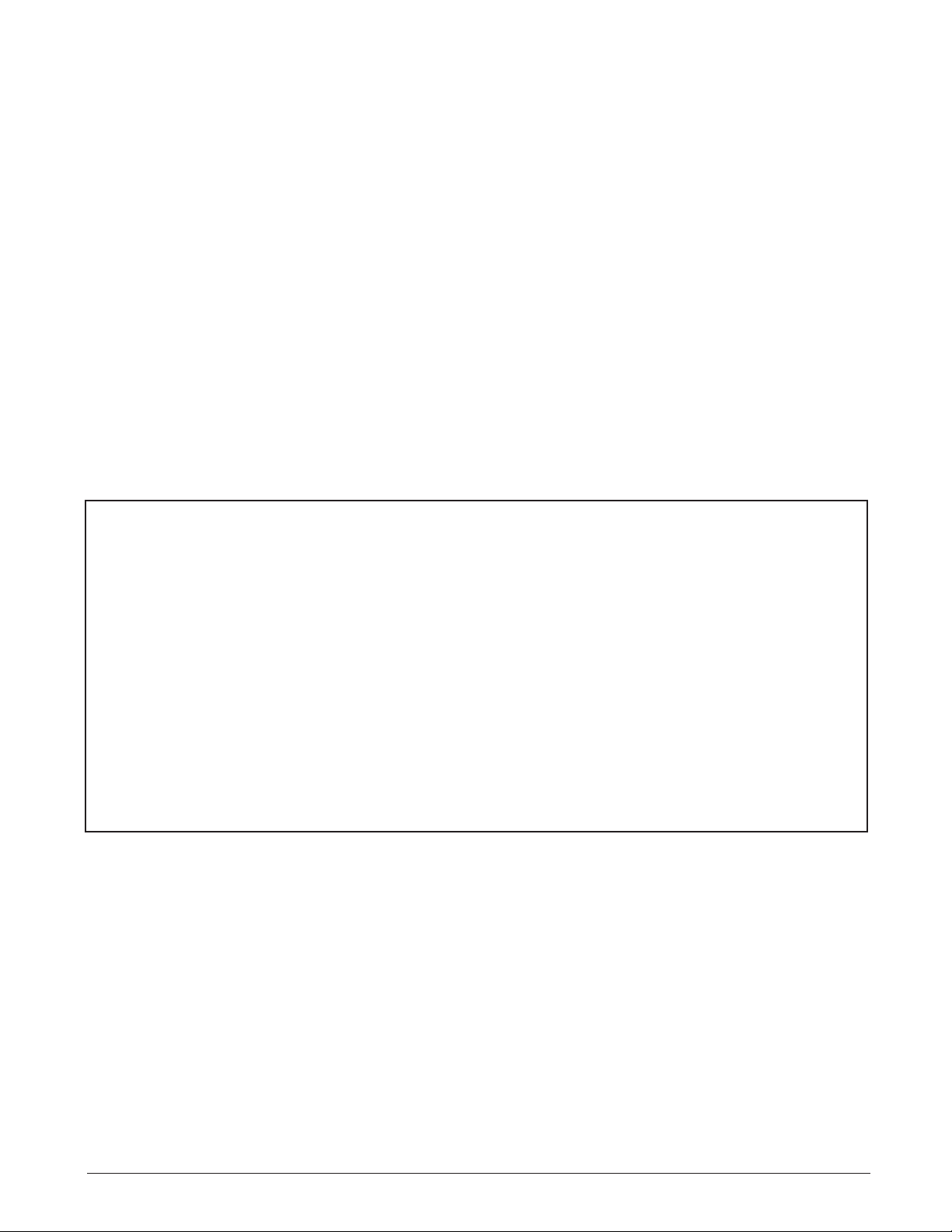

Figure 3. LTU Span Powering Diagram ................................... 4

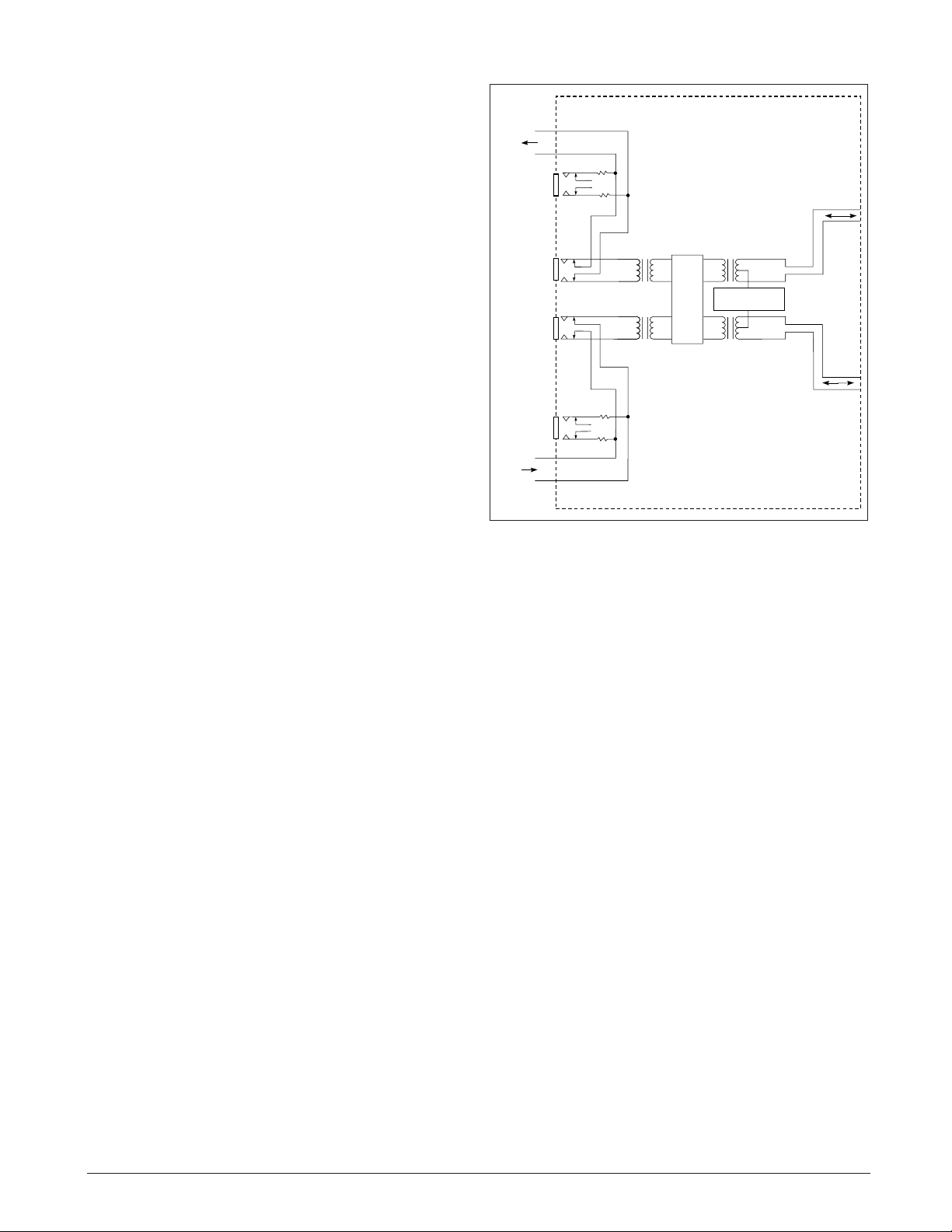

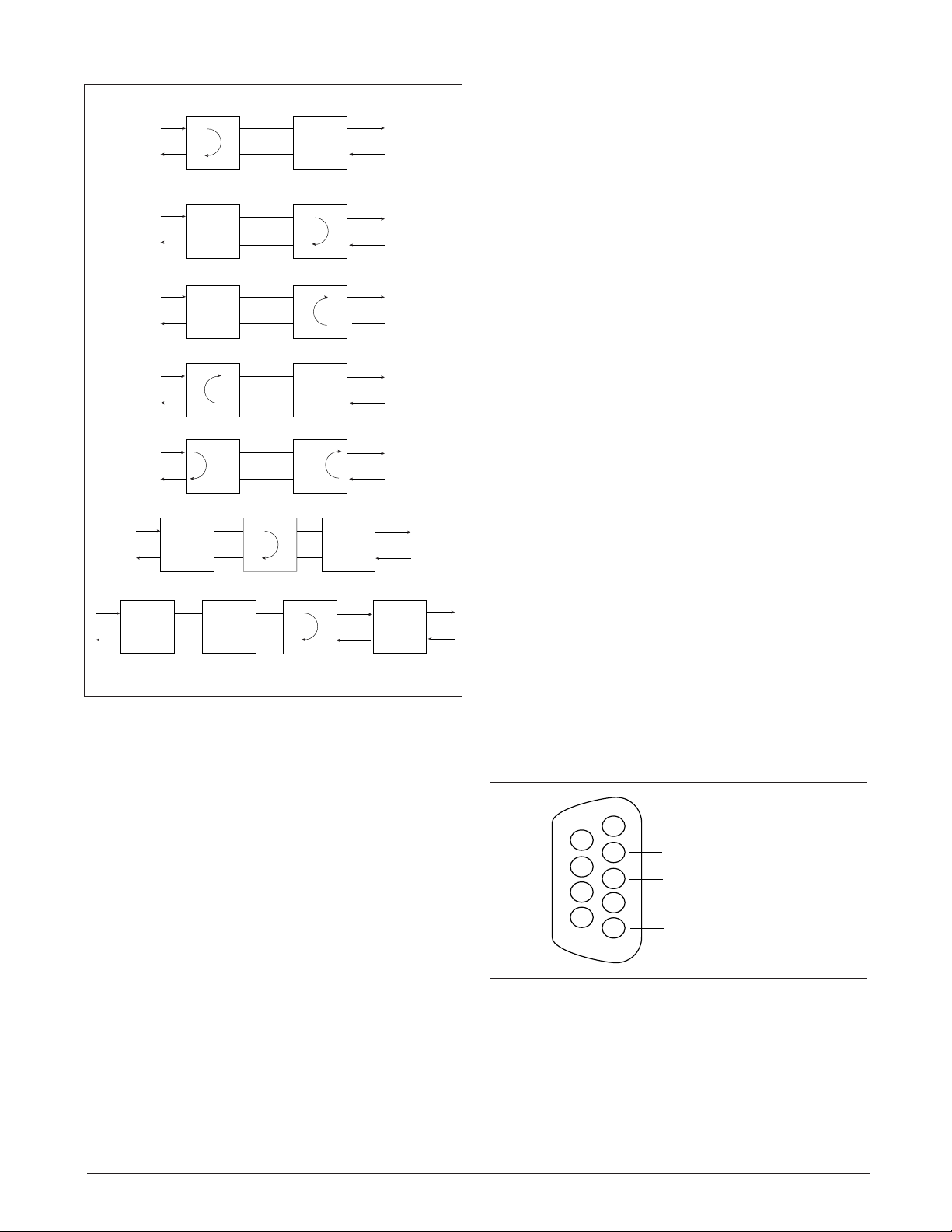

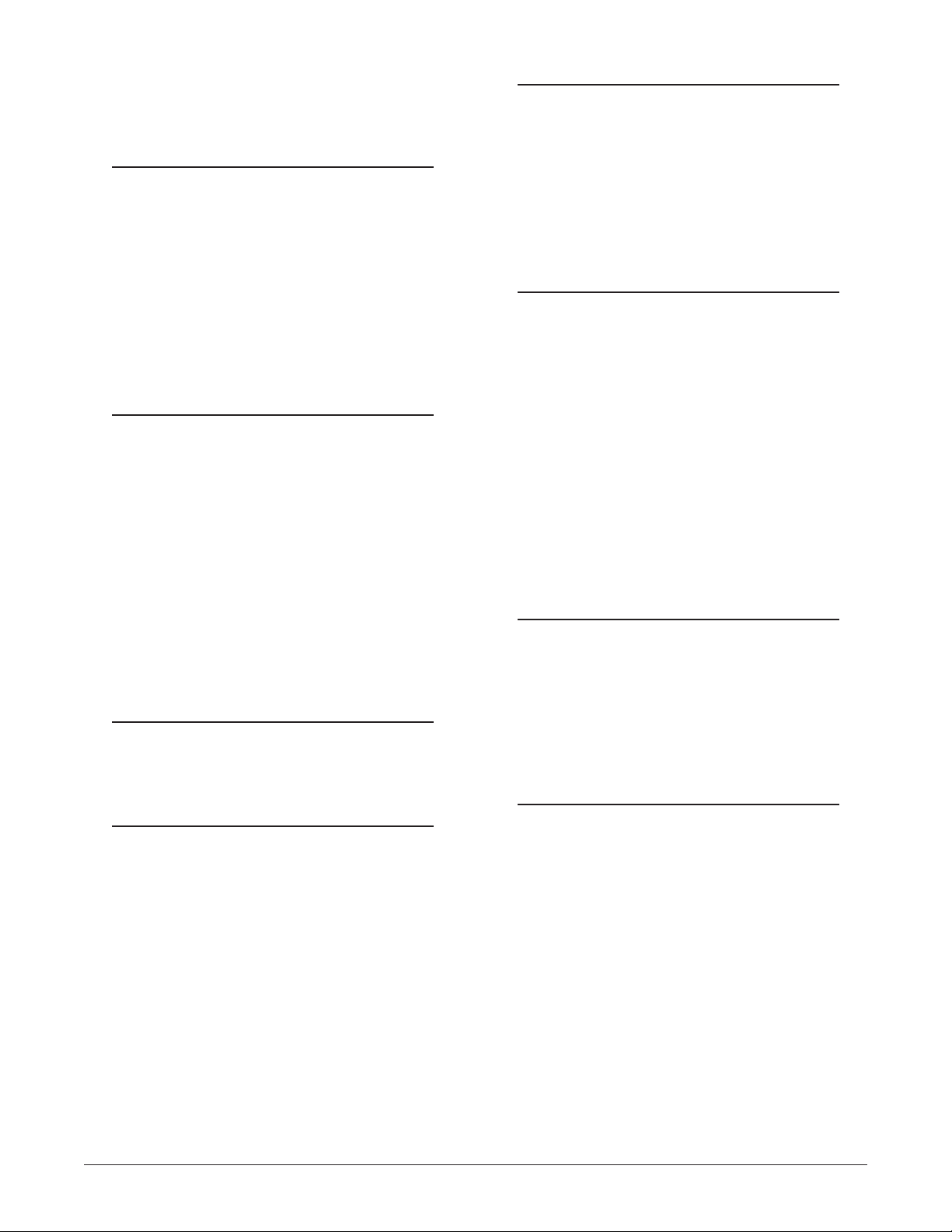

Figure 4. HDSL Loopbacks ...................................................... 5

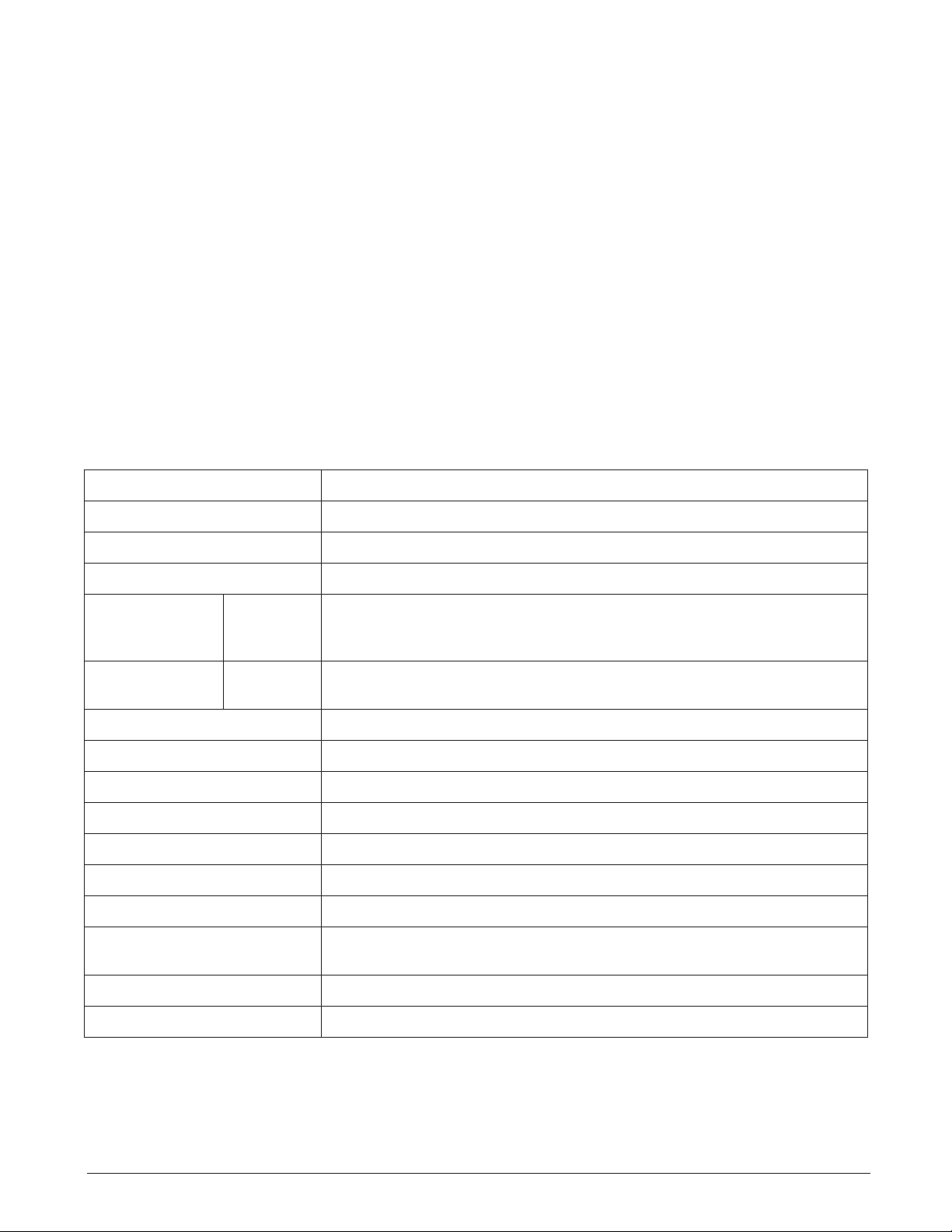

Figure 5. RS-232 (DB-9) Pin Assignments .............................. 5

Figure 6. Logon Screen ............................................................. 7

Figure 7. Total Access Screen ................................................... 7

Figure 8. Access Module Menus Screen................................... 8

Figure 9. HDSL Main Menu Screen ......................................... 9

Figure 10. Configuration Screen ................................................. 9

Figure 11. Provisioning Screen ................................................. 10

Figure 12. Network Source Screen ........................................... 10

Figure 13. Status Screen ............................................................ 11

Figure 14. REG #1 Status Screen.............................................. 11

Figure 15. Alarms Screen .......................................................... 12

Figure 16. Test Screen............................................................... 13

Figure 17. Performance History Screen.................................... 13

Figure 18. Protection Configuration Screen – Main ................ 14

Figure 19. Protection Configuration Screen – Auxiliary ......... 14

Figure 20. Set Circuit ID Screen ............................................... 16

Figure 21. Alarm Option Screen ............................................... 17

TABLES

Table 1. Faceplate LED Indicators .......................................... 3

Table 2. Screen Abbreviations ................................................. 6

Table 3. LP1 and LP2 Guidellines ......................................... 12

Table 4. Protection Configuration Option Settings ............... 15

Table 5. Total Access 3010 LTU Specifications................... 18

Table B-1. Faceplate LED Indicator ....................................... B-2

Section 61182007L1-5A

Issue 1, June 2001

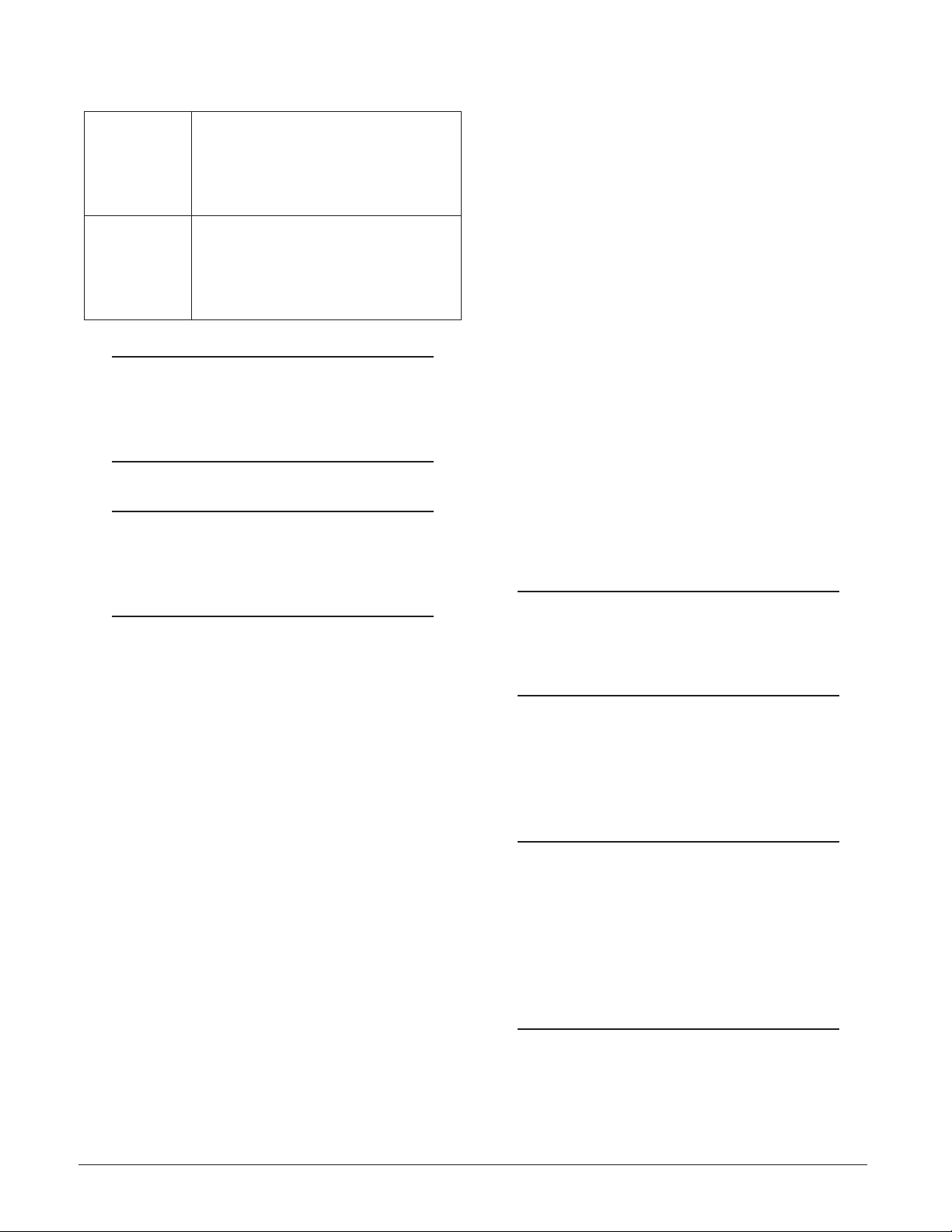

LT U

1182007L1

PWR

G703

TST

LP1

LP2

ALM

TX

E

Q

RX

TX

M

O

N

RX

ACT

A

P

S

GRN = NORM

YEL = MAN

Figure 1. ADTRAN Total Access 3010 LTU

The E1 input signal is supplied from the network via

individual G.703 lines or an E3 multiplexer. The

HDSL signals are provided to the local loop. The

Total Access 3010 LTU works in conjunction with the

ADTRAN NTU and REG to provide an E1 service up

to 9.4 km on the local loop.

The LTU works with multiple list versions of the

HDSL unit Remote end (NTU) and HDSL Range

Extender (REG) as listed below:

• 1245043Lx Low Voltage T400 REG

• 1245031Lx, Low Voltage T200 NTU

• 1245033Lx, Nx64 NTU

• 1245044L3, 4th Gen - T400 NTU

• 1245035Lx, 5th Gen - T200 NTU

1. GENERAL

The ADTRAN Total Access 3010 HDSL Transceiver

Unit for the Central Office (LTU), part number

1182007L1, is the Central Office (CO) unit used to

deploy an HDSL E1 circuit using 4-wire metallic

facilities. See Figure 1.

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

The Total Access 3010 LTU can be deployed in

circuits consisting of one LTU and one NTU or in a

protection configuration requiring two LTUs and two

NTUs. When deployment requires the HDSL Range

Extender (REG), this LTU can be deployed with one

or two REGs and one NTU.

1Section 61182007L1-5, Issue 161182007L1-5A

Page 2

The HDSL local loop operates as two independent

subsystems each operating over a single twisted pair.

The LTU communicates over these two twisted pairs

to the HDSL Transceiver Unit - Remote end (NTU).

Each subsystem carries half of the total bandwidth

along with a small amount of overhead used for

maintenance and performance monitoring.

NTU at less than -120 Vdc. Span powering voltages

meet all requirements of IEC 950.

REVISION HISTORY

This is the first issue of this practice. Future changes

to this document will be summarized in this

paragraph.

System power and alarm bus connections are made

2. INSTALLATION

through the backplane of the Total Access 3010 shelf.

E1 and HDSL signals are connected through the 50pin shelf connectors related to each individual slot.

The LTU contains onboard fuses. If a fuse opens, it

supplies a -48 Vdc voltage to the fuse alarm bus and

all front panel indicators will be Off. These fuses are

not field replaceable.

The Total Access 3010 LTU uses a DC-to-DC

converter to derive its internal logic and span

powering voltages from the -48 Vdc office supply.

The Total Access 3010 LTU can span power REGs

and NTUs as listed above. When used with REGs and

NTUs, the LTU can span power one REG and an

After unpacking the unit, inspect it for damage. If

damage is discovered, file a claim with the carrier,

then contact ADTRAN. See Warranty and Customer

Service.

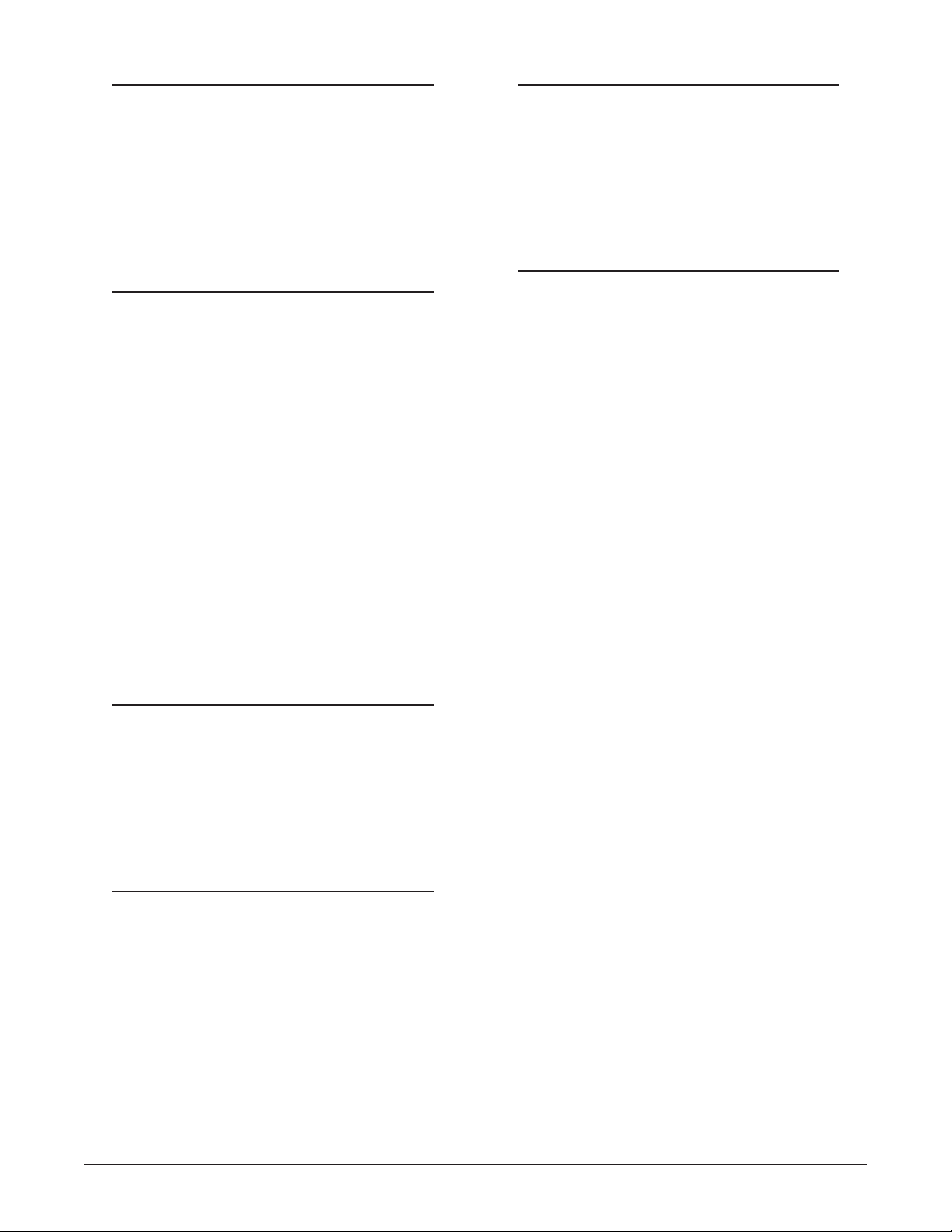

The Total Access 3010 LTU occupies one line card

slot in a Total Access 3010 shelf. Power and alarm

signals are provided to the card through the backplane

of the shelf. E1 and HDSL loop signals are connected

to the mass termination shelf connectors

corresponding to the slot the unit occupies. See

Figure 2 for LTU edge connector wiring.

P2, Row A P2, Row B P2, Row C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

- 48 Volt return

1

Chassis ground

2

Chassis ground

3

4

5

6

HDSL Loop 2 Ring (facility)

7

8

9

10

Fuse alarm

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Receive G.703 Ring backup connection

Transmit G.703 Ring backup connection

26

27

28

Receive G.703 Ring normal connection

29

Transmit G.703 Ring normal connection

30

31

- 48 Volt return

32

C A U T I O N !

SUBJECT TO ELECTROSTATIC DAMAGE

OR DECREASE IN RELIABILITY.

HANDLING PRECAUTIONS REQUIRED.

1

- 48 Volt DC A

2

- 48 Volt DC A

3

4

HDSL Loop 1 Ring (facility)

5

HDSL Loop 1 Tip (facility)

6

HDSL Loop 2 Tip (facility)

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Receive G.703 Tip backup connection

25

Transmit G.703 Tip backup connection

26

27

28

Receive G.703 Tip normal connection

29

Transmit G.703 Tip normal connection

30

- 48 Volt DC B

31

- 48 Volt DC B

32

Figure 2. LTU Edge Connector Wiring

2 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 3

3. OPERATION

Powering Options

The unit features automatic sensing based on the

current load detected on the HDSL circuit. Span

powering at less than -120 Vdc allows for span

powering of circuits without REGs or with one REG.

LTU Alarm Outputs

Pin B10 of the LTU edge connector interface provides

a fuse alarm signal that connects -48 Vdc to this pin in

the presence of a blown fuse. This indicates the card

has malfunctioned and should be replaced.

Front Panel Operation Using the Total Access

3010 SCU (P/N 1181017L1)

The front panel interface consists of a 4-character

alphanumeric LED display and a 3-position switch

that controls the display.

Table 1. Faceplate LED Indicators

DELnoitacidnInoitpircseD

The switch positions are:

Center OFF

Up MODE

Down SELECT

The switch is spring-loaded to the center (OFF)

position. The display is used to report the loop

margins (dB), and other operational conditions.

Faceplate Indicators

The Total Access 3010 LTU has seven faceplate

LEDs, illustrated in Table 1, which indicate

operational status.

The Total Access 3010 LTU plugs directly into the

Total Access 3010 shelf. No installation wiring is

required.

RWPffO

307GffO

TSTffO

1PLffO

2PLffO

MLAffO

dracotrewopoN

neerG

wolleY

neerGgnihsalF

wolleYgnihsalF

tiucricLSDHeht

neerGgnihsalF

wolleY

deR

wolleY

neerG

gnihsalF

deR

wolleY

neerG

gnihsalF

deR

ecivreS-nI,tneserprewoP

dengissanuroecnanetniaM,ecivreS-fo-tuO,tneserprewoP

DCFUCSybdesseccagniebdraC,ecivreS-nI

DCFUCSybdesseccagniebdraC,ecivreS-fo-tuO

fogninoisivorpehthctamtonseodtahttamrofafosirotnesbasilangis1Eedis-krowteN

langis1EdeviecernodetcetedrorreCRCrororretibemarF

etatsdemrarokcabpoolnitonsitinU

evitcasikcabpool)UTL(lacoL

1pooLnoUTNdnaUTLehtneewtebnoitazinorhcnysoN

(1pooLnoytilauqlangisrooP ≤ )REB7-01

(1pooLnoytilauqlangislanigraM ≤ )REB7-01evobanigramBd2

)REB7-01evobanigramBd2>(1pooLnoytilauqlangisdooG

ylfeirbknilbotDELsihtesuaclliw1pooLfodnerehtienodetcetedrorrenA

2pooLnoUTNdnaUTLehtneewtebnoitazinorhcnysoN

(2pooLnoytilauqlangisrooP ≤ )REB7-01

(2pooLnoytilauqlangislanigraM ≤ )REB7-01evobanigramBd2

)REB7-01evobanigramBd2>(2pooLnoytilauqlangisdooG

ylfeirbknilbotDELsihtesuaclliw2pooLfodnerehtienodetcetedrorrenA

detcetedsnoitidnocmralaoN

)UTNdnaUTL(yletomerdnayllacolro,)UTL(yllacolrehtiedetcetednoitidnocmralA

TCAneerG

noitarepolamroN

wolleY

noitarepolaunaM

3Section 61182007L1-5, Issue 161182007L1-5A

Page 4

Status Mode

After selecting the LTU from the SCU, the display

enters Status mode. It alternately displays loop margin

for each HDSL loop, any active alarm condition, and

general status conditions.

The HDSL loop margin is displayed for each loop that

is active with the messages “1=xx” and “2=xx” where

xx is the HDSL loop margin for that loop. The loop

margin is held on the display for 2 seconds. The loop

margin will not be displayed if that loop is in start-up

or LOS condition.

E1 Core Frame Mapping

The function of E1 core frame mapping is to assign

2048 kbps framed E1 data to a 2304 kbps core frame

filled with 2048 kbps data. This converts a 32-byte E1

frame into a 36-byte core frame (a ratio of 1:1.125).

The extra four bytes are filled with TSO, TS16, or

AIS data. Once the 36-byte core frame data block

reaches the HDSL loops, the data is split between the

two HDSL loop pairs.

G.703

G.703

T1

R1

G.703

G.703

T

R

MON

MON

LTU

DATA

PUMP

LTU

LOOP DC

POWER SOURCE

HDSL

LOOP 1

HDSL

LOOP 2

HDSL

LOOP 1

HDSL

LOOP 2

RX

EQ

RX

EQ

TX

TX

4. HDSL SYSTEM TESTING

The ADTRAN HDSL system provides extensive

ability to monitor the status and performance of the

G.703 signals and HDSL loop signals. Detailed

performance monitoring is provided by the V.24

Control Port on the ADTRAN System Controller Unit

(SCU). These features are valuable in troubleshooting

and isolating any system level problems that may

occur at installation or during operation of the HDSL

system.

LTU G.703 Bantam Jack

The LTU provides two dual Bantam jacks on the front

panel. These jacks provide a metallic splitting and

test access of the G.703 interface for connecting test

equipment to transmit and receive signals with the

LTU. See Figure 3.

HDSL Loopbacks

The E1 LTU offers five diagnostic loopbacks for use

in verifying proper data path operation. These

loopbacks are activated via the V.24 craft interface.

Figure 3. LTU Span Powering Diagram

NTU Local Loopback

The NTU HDSL transceivers are looped back at a

point immediately before the HDSL termination. This

loopback enables a complete checkout of the NTU

data path. The NTU Local Loopback is activated via

the V.24 craft interface.

NTU Remote Loopback

The NTU HDSL transceivers are looped back at a

point immediately before the G.703 termination. This

loopback enables a complete checkout of the NTU

data path, the HDSL link, and the LTU data path. The

NTU Remote Loopback is activated via the V.24 craft

interface.

LTU Local Loopback

The LTU HDSL transceivers are looped back at a

point immediately before the HDSL termination. This

loopback enables a complete checkout of the LTU

data path. The LTU Local Loopback is activated via

the V.24 craft interface.

These loopbacks disrupt normal data transmission.

Make sure that you receive prior authorization to

place an HDSL circuit out of service prior to

activating any loopback. These loopbacks remain

active until cleared or by expiration of the loopback

timeout period. See Figure 4.

LTU Remote Loopback

The LTU HDSL transceivers are looped back at a

point immediately before the G.703 termination. This

loopback enables a complete checkout of the NTU

data path, the HDSL link, and the LTU data path. The

LTU Remote Loopback is activated via the V.24 craft

interface.

4 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 5

LTU Network-Side Loopback

G.703

LTU

NTU Network-Side Loopback

G.703

LTU

NTU Customer-Side Loopback

X

AIS

LTU

LTU Customer-Side Loopback

X

LTU

LTU and NTU Bilateral Loopback

LTU

REG Network-Side Loopback

LTU

Dual REG Network-Side Loopback

G.703

LTU

Figure 4. HDSL Loopbacks

NTU

NTU

NTU

NTU

NTU

X

X

NTU

AIS

G.703

AIS

G.703

G.703

G.703AIS

G.703G.703

AIS

G.703G.703

X

X

X

LOCAL

LOOP

LOCAL

LOOP

LOCAL

LOOP

LOCAL

LOOP

LOCAL

LOOP

REG

REG NTU

X = Signal Inactive

REG

AIS

G.703

LOS2 No synchronization of LTU and NTU on

loop 2

HER1 HDSL loop1 error

HER2 HDSL loop2 error

1=XX* Loop 1 in Sync

2=XX* Loop 2 in Sync

* XX is the Signal Quality Level of the loop and

ranges from 0-20, where 0 is an indicator of poor

signal quality and 20 represents good signal quality.

Display Off Mode

The display enters Display Off Mode from Status

Mode after 5 minutes with no activity on the display

switch. While in this mode, the display is completely

off.

The display will return to Status Mode under the

following conditions:

• When either MODE or SELECT is activated.

Display starts again when the switch is released

• When a message other than loop margin is to be

displayed

5. SCU CONTROL PORT OPERATION (HDSL)

The Total Access 3010 SCU provides a faceplatemounted DB-9 connector that supplies an RS-232

interface for connection to a controlling terminal. The

pinout of the DB-9 is illustrated in Figure 5. The

terminal interface operates at data rates from 1.2 kbps

to 19.2 kbps. The asynchronous data format is fixed at

8 data bits, no parity, and 1 stop bit. The supported

terminal type is VT100 or compatible.

REG Loopback

The REG HDSL transceivers are looped back toward

the LTU. This loopback enables a complete checkout

of the LTU data path, the HDSL link between the

LTU and the REG, and the REG data path. The REG

loopback is activated via the V.24 craft interface.

Front Panel

Display Message/Condition:

LLOS LTU E1 Loss of Sync

NLOS NTU E1 Loss of Sync

LERR LTU E1 error

NERR NTU E1 error

LBPV LTU E1 Bipolar violation (BPV)

NBPV LTU E1 Bipolar violation (BPV)

LOS1 No synchronization of LTU and NTU on

loop 1

1

6

2

7

3

8

4

9

5

TXD (Transmit Data)

RXD (Receive Data)

SGN (Signal Ground)

Figure 5. RS-232 (DB-9) Pin Assignments

5Section 61182007L1-5, Issue 161182007L1-5A

Page 6

Many portable personal computers use power-saving

programs that are known to interfere with applications

running on the personal computer. If using a portable

personal computer with terminal emulation capability,

communication between the computer and the HDSL

unit may be periodically disrupted if power-saving

programs are being used on the personal computer.

The symptoms may include misplaced characters

appearing on the screen and/or the occurrence of

screen timeouts. These symptoms are not disruptive to

the operation of the circuit and are avoidable if the

power-saving options are disabled or removed.

Menus

For abbreviations used in the screen diagrams, see

Table 2.

Table 2. Screen Abbreviations

noitaiverbbAnoitinifeD

SEsdnoceSderorrE

The screens illustrated in Figure 6 through Figure 18

are for an HDSL circuit deployed with ADTRAN’s

Low Voltage HDSL technology. The circuit includes

an LTU, NTU, and two REG. This scenario was

chosen for inclusiveness of functionality. However,

other configurations are possible, such as one REGs,

and the display will vary slightly from those shown in

this section.

SESsdnoceSderorrEylereveS

SAUsdnoceSelbaliavanU

GNIMARFSCC

SAC

demarfnU

EDOC3BDH

IMA

4CRCnoitcetedrorre4kcehCycnadnudeRcilcyC

MFC )1dohteM,0dohteM(gnippaMemarFeroC

VPBnoitaloiVralopiB

N/SrebmuNlaireS

M51doirepetuniM-neetfiF

H42doirepruoH-ruof-ytnewT

smralAsutatsnoitidnocmralatnerrucstsiL

0Bd0-sinigramesioN:ytilauqlangisrooP

8-1 BdniREB7-01evobatnemerusaemnigraM

9 01evobaBd9sinigraM:ytilauqlangistnellecxE

gnilangiSlennahCnommoC

gnilangiSdetaicossAlennahC

noitarepO1EdemarfnU

3redrOralopiBytisneDhgiH

noisrevnIkraMetanretlA

)REB7-013(

7-

REB

6 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 7

Accessing the HDSL circuit information via the Total

Access SCU requires Logon and a Password using the

After successful logon, the Total Access System

Screen will appear as illustrated in Figure 7.

SCU Control Port. See Figure 6, Logon Screen.

Shelf: 77 Total Access System 04/07/01 15:44

Unacknowledged Alarms: MAJOR MINOR INFO

Total Access System

Account Name:

‘?’ - System Help Screen

Figure 6. Logon Screen

Shelf: 77 Total Access System 04/07/01 15:45

Unacknowledged Alarms: MAJOR MINOR INFO

Total Access

1. System Controller

2. Common A - [DS3MX]

3. Common B - [DS3MX]

4. Access Modules

5. System Alarms

6. Logoff

Selection:

‘?’ - System Help Screen

Figure 7. Total Access Screen

7Section 61182007L1-5, Issue 161182007L1-5A

Page 8

From the Total Access System Screen, select Access

Modules by typing the number corresponding to the

option followed by <Enter>. This will display the

Access Module Menu Screen, illustrated in

Shelf: 77 Total Access System 04/07/01 15:46

Unacknowledged Alarms: MAJOR MINOR INFO

Access Module Menus

Figure 8, which will display the Access Modules

occupying the Total Access 3010 shelf. Select the

corresponding channel slot number for an LTU.

1 - LTU......... [Major] 15 - ............ [None]

2 - ............ [None] 16 - ............ [None]

3 - ............ [None] 17 - ............ [None]

4 - ............ [None] 18 - ............ [None]

5 - ............ [None] 19 - ............ [None]

6 - ............ [None] 20 - ............ [None]

7 - ............ [None] 21 - ............ [None]

8 - ............ [None] 22 - ............ [None]

9 - ............ [None]

10 - ............ [None]

11 - ............ [None]

12 - ............ [None]

13 - ............ [None]

14 - ............ [None]

Enter Channel Slot Number :

Inverse = Busy Modules

Figure 8. Access Module Menus Screen

8 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 9

This will display the ADTRAN HDSL Main Menu as

illustrated in Figure 9.

From the ADTRAN HDSL Main Menu, the following

screens can be accessed.

1. Configuration

2. Provisioning

3. Status

4. Alarms

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:05

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

HDSL Line Termination Unit

1. Configuration

2. Provisioning

3. Status

4. Alarms

5. Test

6. Performance Monitoring

7. Protection Configuration

8. Circuit ID

9. Alarm Options

5. Test

6. Performance Monitoring

7. Protection Configuration

8. Circuit ID

9. Alarm Options

The Configuration Screen, illustrated in Figure 10,

provides serial numbers and the manufacturing date

for each component in the HDSL circuit.

Selection:

‘?’ - System Help Screen

Figure 9. HDSL Main Menu Screen

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:30

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Configuration

Unit Name LTU Unit Name NTU

Part Number 1182007L1 Serial Number 0100001481

Serial Number HW098765432109 Product Revision 01

Product Revision HW Manufacture Date 10/00

Software Revision A

Manufacture Date 01/95

Unit Name REG1 Unit Name REG2

Serial Number 0100748669 Serial Number 0100477236

Product Revision 01 Product Revision 01

Manufacture Date 10/00 Manufacture Date 10/00

‘?’ - System Help Screen

Figure 10. Configuration Screen

9Section 61182007L1-5, Issue 161182007L1-5A

Page 10

The Provisioning Screen, as illustrated in Figure 11,

displays current provisioning settings and allows for

changing the system configuration. Provisioning

changes are only allowed at the CO end of the circuit.

The unit retains the last provisioning changes to

determine its operating mode.

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:06

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Provisioning

1. Framing CAS

2. CRC4 Enabled

3. Coding HDB3

4. G.703 Clock Internal

5. Loopback Timeout None

6. Service State In Service

7. Network Source G.703

8. G.703 External Alarms Disabled

9. Core Frame Mapping Method 1

The Network Source Screen, illustrated in Figure 12,

allows the user to provision the unit to receive its

network signal from either MUX or a G.703 source.

Selection:

‘?’ - System Help Screen

Figure 11. Provisioning Screen

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:27

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Network Source

1. G.703

2. MUX A

3. MUX B

Selection:

‘?’ - System Help Screen

Figure 12. Network Source Screen

10 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 11

The Status Screen, illustrated in Figure 13, provides

quick access to status information for both the LTU

and NTU, in addition to any regenerators.

Type “3” to view the status screen for REG #1, as

illustrated in Figure 14. If the circuit involves a

second REG, press “4” from the REG #1 Status

Screen to view the REG#2 Status Screen.

Figure 13 and Figure 14 consolidate current

information for the HDSL and E1 interfaces. A key to

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:15

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

LTU LTU/NTU Status NTU

Loop 1 <Network> Loop 2 Loop 1 <Customer> Loop 2

01 dB 01 dB <- Loss -> 01 dB 01 dB

Yes Yes <- Sync -> Yes Yes

000/00000 000/00000 <-ES 15M/24H -> 000/00000 000/00000

000/00000 000/00000 <-SES 15M/24H -> 000/00000 000/00000

000/00000 000/00000 <-UAS 15M/24H -> 000/00000 000/00000

Loopbacks Inactive Sealing Current Present Loopbacks Inactive

LTU Signal Quality LTU E1 NTU E1 NTU Signal Quality

[X] 9 [X] [X] 9 [X]

[X] 8 [X] CAS <- Frame -> CAS [X] 8 [X]

[X] 7 [X] HDB3 <- Code -> HDB3 [X] 7 [X]

[X] 6 [X] ENABLED <- CRC4 -> ENABLED [X] 6 [X]

[X] 5 [X] METH1 <- CFM -> METH1 [X] 5 [X]

[X] 4 [X] 00000 <- BPV -> 00000 [X] 4 [X]

[X] 3 [X] 00000 <- ES -> 00000 [X] 3 [X]

[X] 2 [X] 00000 <- SES -> 00000 [X] 2 [X]

[X] 1 [X] 00000 <- UAS -> 00000 [X] 1 [X]

[X] 0 [X] None <- Alarms -> None [X] 0 [X]

1. Zero Registers Selection: 3. REG1 Status

2. LTU/NTU Status ‘?’ - System Help Screen 4. REG2 Status

the information provided is found in the center of the

screen. Arrows indicate the key statistics, which

apply to both the remote and customer site

components.

Indications of Loopback and Sealing Current (if

present) are given at the bottom of the first key

column. Status and configuration information for the

LTU and NTU E1 signals are located in the center of

the Status Screen near the bottom.

Figure 13. Status Screen

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:14

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Loop 1 <Network> Loop 2 Loop 1 <Customer> Loop 2

00 dB 00 dB <- Loss -> 00 dB 00 dB

Yes Yes <- Sync -> Yes Yes

000/00000 000/00000 <-ES 15M/24H -> 000/00000 000/00000

000/00000 000/00000 <-SES 15M/24H -> 000/00000 000/00000

000/00000 000/00000 <-UAS 15M/24H -> 000/00000 000/00000

Loopback Inactive Sealing Current Present Loopback Inactive

[X] 9 [X] [X] 9 [X]

[X] 8 [X] [X] 8 [X]

[X] 7 [X] ____ LP1 ____ LP1 ____ ____ [X] 7 [X]

[X] 6 [X] |LTU | |REG1| |REG2| |NTU | [X] 6 [X]

[X] 5 [X] | |===N| |C===| |====| | [X] 5 [X]

[X] 4 [X] | | | | | | | | [X] 4 [X]

[X] 3 [X] | |===N| |C===| |====| | [X] 3 [X]

[X] 2 [X] |____| |____| |____| |____| [X] 2 [X]

[X] 1 [X] LP2 LP2 [X] 1 [X]

[X] 0 [X] [X] 0 [X]

1. Zero Registers Selection: 3. REG1 Status

2. LTU/NTU Status ‘?’ - System Help Screen 4. REG2 Status

Figure 14. REG #1 Status Screen

11Section 61182007L1-5, Issue 161182007L1-5A

Page 12

Predicting performance based upon signal quality

varies with each loop. Generally, a noise margin of 0

or higher will support a bit error rate (BER) of better

than 10-7. The following guidelines correspond to the

operation of the LTU faceplate LEDs labeled LP1 and

LP2. See Table 3.

Table 3. LP1 and LP2 Guidellines

nigraMroloCytilauQ

0<nigraMdeRytilauQpooLrooP

2<nigraM<0wolleYytilauQpooLlanigraM

2>nigraMneerGytilauQpooLdooG

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:16

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Alarms

Figure 15 and Figure 16 depict the HDSL Alarms

and Test Screens. Current alarm conditions are

displayed on the Alarms Screen, while a self test or

loopbacks may be initiated or terminated using the

Test Screen.

NO ALARM CONDITIONS

_____ _____ _____ _____

| LTU | |REG 1| |REG 2| | NTU |

| | | | | | | |

--->| |<===>| |<===>| |<===>| |<— | | | | | | | |

NET | | | | | | | | CUST

| | | | | | | |

<---| |<===>| |<===>| |<===>| |—>

| | | | | | | |

|_____| |_____| |_____| |_____|

‘?’ - System Help Screen

Figure 15. Alarms Screen

12 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 13

At each 15-minute interval, the performance

information is transferred to the 15-minute

performance data register accessed from the

Performance History screen. At each 24-hour

interval, the performance data is transferred into the

24-hour performance data register also accessed using

the Performance History screen. The Performance

History screen is shown in Figure 17.

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:16

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Test

1. Selftest

2. Loopback to Network at LTU = Inactive

3. Loopback to Customer at LTU = Inactive

4. Loopback to Network at NTU = Inactive

5. Loopback to Customer at NTU = Inactive

6. Loopback to Network at REG-1 = Inactive

7. Loopback to Network at REG-2 = Inactive

_____ _____ _____ _____

| LTU | LP1 |REG 1| LP1 |REG 2| LP1 | NTU |

--->|-----|<=====>|-----|<=====>|-----|<=====>|-----|<— | | | | | | | |

NET | | | | | | | | CUST

| | LP2 | | LP2 | | LP2 | |

<---|-----|<=====>|-----|<=====>|-----|<=====>|-----|—>

|_____| |_____| |_____| |_____|

Type the corresponding number to view the

Performance History data for customer or network

loops.

From the Status Screen, type “1” to reset the current

performance registers to zero on the Status and

Performance History Screens.

Selection:

‘?’ - System Help Screen

Figure 16. Test Screen

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:17

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

LTU G.703 Performance Data

15 Minute History

Current Error Regs ES SES UAS BPV

Menu ES SES UAS BPV 09:15 000 000 000 000

1. LTU G.703 15 Min: 000 000 000 000 09:00 --- --- --- ---

2. LTU Loop 1 24 Hr: 00000 00000 00000 00000 08:45 --- --- --- ---

3. LTU Loop 2 08:30 --- --- --- ---

4. NTU G.703 08:15 --- --- --- ---

5. NTU Loop 1 24 Hour History 08:00 --- --- --- ---

6. NTU Loop 2 ES SES UAS BPV 07:45 --- --- --- ---

7. REG1 NET Lp1 09/21 ----- ----- ----- ----- 07:30 --- --- --- ---

8. REG1 NET Lp2 09/20 ----- ----- ----- ----- 07:15 --- --- --- ---

9. REG1 CST Lp1 09/19 ----- ----- ----- ----- 07:00 --- --- --- ---

10. REG1 CST Lp2 09/18 ----- ----- ----- ----- 06:45 --- --- --- ---

11. REG2 NET Lp1 09/17 ----- ----- ----- ----- 06:30 --- --- --- ---

12. REG2 NET Lp2 09/16 ----- ----- ----- ----- 06:15 --- --- --- ---

13. REG2 CST Lp1 09/15 ----- ----- ----- ----- 06:00 --- --- --- ---

14. REG2 CST Lp2 05:45 --- --- --- -- 05:30 --- --- --- -- B. Page back Selection: Page 1

F. Page forward ‘?’ - System Help Screen most recent data

Figure 17. Performance History Screen

13Section 61182007L1-5, Issue 161182007L1-5A

Page 14

The Protection Configuration Screen - Main,

illustrated in Figure 18, displays the current settings

for Protection Mode, BER Threshold and BER

Interval. The BER Threshold allows the user to select

a bit error rate that, when exceeded, will cause a

switchover to an auxiliary circuit. The BER Interval

defines the interval over which errors will be

accumulated for comparison with the BER Threshold.

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:19

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Protection Configuration

1. Protection Mode Disabled

2. BER Threshold 1E-4

3. BER Interval 15 Min(s)

The option settings for BER Threshold and BER

Interval are detailed in Table 4.

The Protection Configuration Screen – Auxiliary,

illustrated in Figure 19, displays the current settings

for Protection Mode, Minimum Hold-in Time, BER

Threshold, BER Interval, Lock-in Hours, Switch-to

-Aux Limit, and Lock-in Check Interval. A History

count for Switchovers, Reversions, Failures, and

Lockouts is provided, while the Lock-in Options and

Selection:

‘?’ - System Help Screen

Figure 18. Protection Configuration Screen – Main

Shelf: 1 Slot: 6 Total Access System 04/07/01 09:20

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Protection Configuration

1. Protection Mode Manual Disable

2. Minimum Hold-in Time 01 minutes

3. BER Threshold 1E-4

4. BER Interval 15 minutes

5. Lock-in Time 12 hours

6. Switch-to-Aux Limit 03 (1-9)

7. Lock-in Check Interval 20 minutes

Current System Status History

[ Prot Disabled ] Switchovers: 00 Reversions: 00

Failures: 00 Lockouts: 00

Current Lock-in Option Setting

Lock-in for 12 hours if 03 switchovers occur in 20 minutes.

Selection:

‘?’ - System Help Screen

Figure 19. Protection Configuration Screen – Auxiliary

14 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 15

Table 4. Protection Configuration Option Settings

snoitpOnoitcetorPsgnitteSnoitpircseD

edoMnoitcetorPotuA .noitnevretniresuonhtiwXUAotniaMmorfsehctiwsyllacitamotuametsyS

dloHotuA tahttpecxe,edoMotuAotlacitnedinoitcetorpmetsyssedivorpdloHotuA

niaMlaunaM resuybtiucricXUAehtotrevohctiwslaunamseriuqerniaMlaunaM

XUAlaunaM ehtlitnuerehtniamerlliwdnatiucricXUAehtotdecrofyllaunamsiataD

elbasiDlaunaM

.dlohserhTREBgnideecxeroniaMnocnysfossolybdetaitinisihctiwS

edoMotuA.UCSehtaivdetarenegeranoitacifitonrevohctiwsdnasmralA

rorreehtrodehsilbatseersicnysecnoniaMotkcabnoisreverswollaosla

.dlohserhTREBehtwolebspordtnuoc

ecnO.noitnevretniresutuohtiwniaMehtotdewollatonerasnoisrever

ybdetreverebylnonacatad,tiucricXUAehtotderruccosahrevohctiws

ehtnonottubhsupehtybroneercslanimretehtnonoitpoynagniyfidom

.UTLehtfoetalpecaf

nottubhsupetalpecafehtaivdehsilpmoccaebnacrevohctiwS.noitnevretni

tiucricniaMafonoitacifitonekamlliwUCSehT.neercslanimretehtro

otdehctiwsyllaunamsiatadehtlitnurevohctiwstropertonlliwtub,eruliaf

.tiucricXUAeht

.etalpecafehtnonottubhsupybroneercslanimretehtaivdegnahcsiedom

.edomsihtnielihwderongierasgnittesnoitporehtollA

owtsatcastiucricXUAdnaniaMeht,edomelbasiDlaunaMehtnI

gnitceffatuohtiwtiucricrehtienonurnacatadetarapeS.stinutnednepedni

sihtnielihwderongierasgnittesnoitporehtollA.rehtoehtfonoitarepoeht

.edom

emiTni-dloHmuminiMsetunim99-1 sihT.tiucricXUAehtnoniamerlliwatadtahtemitmuminimehtsenifeD

dlohserhTREB,6-E1,5-E1,4-E1

7-E1

lavretnIREBsetunim51,01,5 htiwnosirapmocrofetalumuccalliwsrorrehcihwrevolavretniehtsenifeD

sruoHni-kcoL99-0 othctiwSehtgnihcaernoputiucricXUAehtotgnikcolfonoitarudsenifeD

XUAothctiwS9-1timiL ehtrevoXUAotniaMmorfrucconachctiwssemitforebmunehtsenifeD

lavretnIkcehCni-kcoL99-1 erofebderapmocsitimiLXUAothctiwSehthcihwrevolavretniehtsenifeD

.sedoMnoitcetorPdloHotuArootuAninehwdilavylnosinoitpo

ehtmorfrevohctiwsesuaclliwtahtetaRrorrEtiBehttesotresuehtswollA

morfteseboslanacdlohserhTREB.dedeecxenehwtiucricXUAotniaM

ehthtiwedicniocdluohsdnanoitarugifnocnoitcetorps'dracniaMeht

.dracXUAehtnodesusgnittes

s'dracniaMehtmorfteseboslanaclavretnIREB.gnittesdlohserhTREBeht

ehtnodesusgnittesehthtiwedicniocdluohsdnanoitarugifnocnoitcetorp

.dracXUA

.timiLXUA

XUAehtotdekcolsimetsysehterofeblavretnIkcehCgnikcoLdenifed

.sruoHgnikcoLdenifedehtroftiucric

.noitarudsruoHgnikcoLehtroftiucricXUAehtotatadehtnignikcol

15Section 61182007L1-5, Issue 161182007L1-5A

Page 16

System Current Status are also displayed beneath the

Current Settings summary. The Current System

Status message displays the current operational state

(Normal, Switched to AUX, Locked Out, Forced to

Main, Forced to AUX, Locked to Main). The

following messages are displayed according to the

current status of the protection system.

• NORMAL OPERATION – Unit is in AUTO

mode with data passing over the MAIN circuit.

• SWITCHED TO AUX – Data has been switched

to the AUX circuit because of an auto switch or

the protection mode has been set to MANUAL

AUX.

• LOCKED OUT – The system has violated the

lock-in option settings and has locked data to the

AUX circuit for the user-defined lock-in hours.

• FORCED TO MAIN – The MAIN unit’s button

has been pressed once and is forced online. An

additional press of the MAIN unit’s button will

revert to software control.

• FORCED TO AUX – the AUX unit’s button has

been pressed once and is forced online. An

additional press of the AUX unit’s button will

revert to software control.

• LOCKED TO MAIN – The protection mode is

set to MANUAL MAIN which doesn’t auto

switch to the AUX circuit but relies on manual

intervention to switch the data to the AUX

circuit; however, alarm indications will be

updated.

A detailed description of the Protection Configuration

parameter settings is included in Table 3.

The Protection Configuration Screen – Auxiliary also

displays a history of switching occurrences. The

following conditions are shown with a history count

of occurrences:

• Switchovers – Number of times data has been

switched from the Main to the Auxiliary circuit.

Switchovers will only occur in the Auto and Auto

Hold protection modes.

• Reversions – Number of times data has been

switched from the Auxiliary back to the Main

circuit. Reversions will only occur in the Auto

protection mode.

• Failures – Number of times the APS system has

attempted to switch data from either the Main to

Auxiliary circuit or from the Auxiliary to Main

circuit. A failure would typically occur as a

result of an HTU-R in the circuit that was not

compatible for APS service. Only the

1245026LX HTU-R’s should be used when

deployed in APS circuits. Failures can occur in

any protection mode.

• Lockouts – Number of times a lockout has

occurred due to the number of APS switches

exceeding the Switch to AUX Limit over the

preset Lock-in Check Interval. Lockouts can

only occur in Auto or Auto Hold protection

modes.

Figure 20 illustrates the Set Circuit ID Screen. The

Circuit ID can be defined using up to 25 characters,

and will be displayed on each of the Total Access

HDSL Screens.

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:21

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

Set Circuit ID

Enter ID:

‘?’ - System Help Screen

Figure 20. Set Circuit ID Screen

16 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 17

Figure 21 illustrates the Alarm Options Screen. This

option allows the user to first set a 15-minute

threshold for both ES and SES alarms and

subsequently to categorize the crossing of those

thresholds as a MINOR or MAJOR alarm. Setting a

threshold to 900 will disable it.

6. HDSL DEPLOYMENT GUIDELINES

The ADTRAN HDSL system is designed to provide

E1 services over loops designed to comply with ETSI

guidelines. Deployment guidelines are given below.

1. All loops are non-loaded only.

2. For loops with 0.4 mm cable, the maximum loop

length including bridged tap lengths is 2.7 km.

3. For loops with 0.5 mm cable, the maximum loop

length including bridged tap lengths is 4.7 km.

4. Any single bridged tap is limited to 500 m.

5. Maximum number of bridged taps is 2.

Shelf: 1 Slot: 5 Total Access System 04/07/01 09:22

Unacknowledged Alarms: MAJOR MINOR

Circuit ID:

7. MAINTENANCE

The ADTRAN Total Access LTU requires no routine

maintenance. In case of equipment malfunction, use

the faceplate Bantam jack connectors to help locate the

source of the problem.

ADTRAN does not recommend that repairs be

performed in the field. Repair services may be obtained

by returning the defective unit to the ADTRAN

Customer Service RMA Department.

Alarm Options Current Settings

1. ES Alarm Level = Major

2. SES Alarm Level = Major

3. ES Alarm Threshold = 000

4. SES Alarm Threshold = 000

Selection:

‘?’ - System Help Screen

Figure 21. Alarm Options Screen

17Section 61182007L1-5, Issue 161182007L1-5A

Page 18

8. PRODUCT SPECIFICATIONS

Product specifications are detailed in Table 4.

Table 5. Total Access 3000 LTU Specifications

Loop Interface

Modulation Type ............................... 2B1Q

Mode .................................................. Full Duplex, Echo Canceling

Number of Pairs ................................. Two

Bit Rate ..............................................1168 kbps per pair

Baud Rate .......................................... 584K baud per pair

Service Range ....................................2.7 km over 0.4 mm cable;* 4.7 km over 0.5 mm cable*

Loop Loss .......................................... 27 dB maximum @ 150 kHz

Bridged Taps ..................................... 2 Taps, 500 meters maximum each

Performance ....................................... Compliant with ETSI TS 135 101

HDSL Tx Signal Level ......................13.5 dBm

Input Impedance ................................ 135 Ω

Return Loss ........................................ 20 dB (40 kHz to 200 kHz)

Network Interface

4-wire E1 ........................................... 2.048 Mbps CCITT G.703 and G.704 compatible

E1 Output Level ................................ 0 dB

Impedance .......................................... 75 or 120 Ω

E1 Core Frame ................................... Method 0, Method 1 (see Section 5)

E1 Line Code .....................................AMI, HDB3

E1 Format .......................................... CCS, CAS, Unframed

E1 Error Checking .............................CRC4

Power

Total Power ....................................... -48 Vdc @ 10 W typical

E1 LTU Power Dissipation ............... <7 W maximum

E1 LTU -48 Vdc Current Drain ......... < .3 A maximum

Sealing Current ..................................current limited at 10 mA

Span Power ........................................-120 Vdc (internally generated) current limited at 60 mA (CE compliant)

Clock

Clock Sources ....................................Internal, E1 Derived

Internal Clock Accuracy .................... + 25 ppm (Stratum 4)

Tests

Diagnostics ........................................ Self-Test, Local Loopback (LTU), Remote Loopback (NTU)

Physical

Dimensions ........................................6 in. (152.4 mm) high x 5/8 in. (15.9 mm) wide x 10 in. (254 mm) deep

Weight ............................................... Less than 1 lb.

Environment

Temperature ....................................... Operating (Standard): -40°C to +70°C; Storage: -40°C to +85°C

Safety .................................................In conformance with EN41003 and EN60950, IEC 950

Overvoltage Protection ......................In conformance with CCITT K.20

EMC .................................................. In conformance with EN55022 and EN50082

Part Number

Total Access LTU .............................. 1182007L1

18 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 19

9. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within

five (5) years from the date of shipment if it does not

meet its published specifications or fails while in

service. (See ADTRAN International Equipment

Warranty, document 60000003-3).

Contact Customer And Product Services (CAPS) prior

to returning equipment to ADTRAN.

Canada - Quebec

1 877 923-8726 toll free

1 514 940-2888 voice

1 514 940-2890 fax

sales.quebec@adtran.com

Canada - Other Provinces

1 877 923-8726 toll free

sales.canada@adtran.com

For service, CAPS requests, or further information,

contact one of the following numbers:

ADTRAN, Inc.

Attention: International Department

901 Explorer Boulevard

Huntsville, Alabama 35806

USA

www.adtran.com

Asia Pacific - Hong Kong

852 2824-8283 voice

852 2824-8928 fax

sales.asia@adtran.com

Canada - Ontario

1 416 290-0585 voice

1 416 296-1259 fax

sales.ontario@adtran.com

Europe - Zurich, Switzerland

41 1 880 27 77 voice

41 1 880 27 78 fax

sales.europe@adtran.com

Latin America

1 954 746-5355 voice

1 954 746-7540 fax

sales.latin@adtran.com

Mexico/Caribbean

1 954 577-0357 voice

1 954 577-0358 fax

sales.mexico@adtran.com

U. S. Headquarters

1 256 963-2500 voice

1 256 963-6300 fax

1 256 963-8200 fax back

international@adtran.com

19Section 61182007L1-5, Issue 161182007L1-5A

Page 20

20 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 21

Appendix A

HDSL H-LSS Circuit Configuration and Turnup

for G.703 Fed Systems

Introduction

This section provides step-by-step instructions for the

configuration and turnup of an HDSL Loop Support

System (H-LSS) circuit on an HDSL loop fed from

the network via individual G.703. Configuration

procedures include installing appropriate line and

remote cards, configuring the Total Access LTU cards

for protection switching operation and enabling the

protection switching feature.

Protection pairs on the Total Access 3010 system are

adjacent odd-even slots, indicated on the Total Access

3010 front shelf screening. The odd slot on the left is

the MAIN circuit; the even slot to the right is the

AUX, or backup circuit.

Prerequisite Procedures

Before beginning the configuration and turnup

procedure described in this NTP, the user should

ensure that a Total Access 3010 shelf is properly

installed and wired for G.703 network feeds. Also,

ensure the SCU is installed and provisioned.

NOTE

Valid protection pairs are the adjacent odd-even

slots in the Total Access 3010 shelf, and are

further designated by the “brackets” on the lower

front silkscreen of the Total Access 3010 chassis.

The left (odd-numbered) slot in the pair is the

MAIN; the right (even-numbered) slot is the

AUX circuit for the pair. Thus, Slots 1 and 2 are

a valid protection pair, but Slots 6 and 7 are not.

The pair must have the odd-numbered slot to the

left in the pair.

NOTE

This procedure assumes that the technician

turning up the protected circuit knows which

pair of slots has been assigned to the circuit, and

that a single G.703 signal from the appropriate

source, generally a G.703 cross connect, has

been routed and wired to the appropriate pairs of

pins on backplane connectors labeled Pair 7 and

Pair 8. For a protected circuit, the appropriate

pin pairs that should receive the G.703 from the

network are the odd numbered pins

corresponding to the MAIN, odd numbered slot.

Materials Required

• Total Access 3010 chassis installed and wired,

with SCU.

• Two Total Access 3010 LTUs.

• Two protection switching capable NTUs. These

NTUs are the following - 1246035L1 T200

mechanics.

• One dual-slot remote housing, ADTRAN P/N

1245034L2.

1. INSTALL THE LTUs INTO TOTAL ACCESS

3010

Electronic modules can be damaged by static

electrical discharge. Before handling modules, wear

an antistatic discharge wrist strap to prevent damage

to electronic components. Place modules in antistatic

packing material when transporting or storing. When

working on modules, always place them on an

approved antistatic mat that is electrically grounded.

1.1 Gently but firmly push the LTU into the

appropriate odd-numbered slot (which will be

the MAIN HDSL circuit). Compatible slots

can be any slot pair that starts with an odd

number (MAIN) and includes the adjacent (to

the right) even-numbered slot (AUX).

Compatible slot pairs are further designated

by the bracket notation around the slot pairs

on the silk screen just below the physical slots

on the front of the Total Access 3010.

Simultaneous thumb pressure at the top

(above the PWR LED) and bottom (below the

ACT LED) of the unit will ensure a good seat

of the LTU pins into the backplane connector.

Repeat this step for the AUX LTU to be

installed in the adjacent (even, to the right)

slot.

1.2 Push the ejector tab up and closed against

the LTU faceplate.

2. PROVISION THE LTU

If Module Auto-Provisioning is enabled on the SCU,

and if the new cards are of the same type as the

former, the provisioning of the former access cards of

the two Total Access 3010 slots will be written to the

new access cards upon installation.

61182007L1-5A Section 61182007L1-5, Issue 1 A-1

Page 22

If this is an initial installation, the units will require

provisioning to appropriately configure them out of

the factory default states.

2.1 Logon to Total Access system.

2.2 Check to ensure the LTU line cards are

correctly provisioned according to circuit

parameters. Under the Provisioning menu, set

numbered option, Network Source, to G.703.

This option causes the LTU to look to the

individual G.703 backplane connector for its

data feed.

2.3 Ensure the provisioning of both the

MAIN and AUX LTUs is identical,

except for the following options:

a. Provision the MAIN unit to OUT OF

SERVICE-MAINTENANCE (OOS-M)

mode.

b. Provision the AUX unit to the OUT OF

SERVICE-UNASSIGNED (OOS-U) mode.

2.4 Enable protection switching

a. Access the MAIN Menu of the LTU in the

odd-numbered (MAIN) slot.

b. Select Option 7, Protection

Configuration.

c. Select Option 1, Protection Mode.

d. To enable protection switching, select

Option 1, ENABLE.

NOTE

Unless the AUX circuit is in the OOS-U mode,

the operator will not be able to change the

Protection mode of the MAIN LTU.

e. Set Options 2 and 3, BER Threshold and

BER Interval (see Table 3 in the

Installation and Maintenance practice for

definitions).

f. Back out of the menu for the MAIN slot

and access the LTU in the even-numbered

(AUX) slot.

g. Select Option 7, Protection Configuration.

h. Option 1, Protection Mode, will have been

set to AUTO. If you desire to provision a

different H-LSS mode, select Option 1,

and choose between Auto, Manual AUX,

Manual Main, and Auto Hold.

i. Set Options 2-7 as desired on the AUX

unit.

2.5 From the provisioning menu of the AUX

circuit, reset the AUX unit to OOS-M.

2.6 Logoff the system

a. From the Total Access Menu, select

Option 7, Logoff, and press <Enter>.

b. From the Exit and Logoff screen, select

“Y” and press <Enter>.

3. INSTALL THE DUAL-SLOT STANDALONE

HOUSING

See the associated Installation and Maintenance

practice, P/N 61245034L2-5, for mounting and wiring

instructions.

4. INSTALL THE NTU

The NTU terminates local loop HDSL signals

originating from the Central Office (CO) unit and

transforms the HDSL signal into traditional G.703

signals to be delivered to the customer.

4.1 Install the NTU into the Dual-Slot

Remote Housing

Electronic modules can be damaged by static

electrical discharge. Before handling modules,

wear an antistatic discharge wrist strap to

prevent damage to electronic components.

Place modules in antistatic packing material

when transporting or storing. When working

on modules, always place them on an

approved antistatic mat that is electrically

grounded.

4.1.1 Connect the individual 4-wire HDSL

circuits to the HDSL terminal block

inside the Dual slot remote housing.

The 4-wire MAIN circuit will connect

to the Loop 1 and Loop 2 terminals

labeled “MAIN” and the 4-wire AUX

circuit will connect to the Loop 1 and

Loop 2 terminals labeled “AUX.”

4.1.2 Gently but firmly push the NTU

into the lower dual slot remote

housing slot. Repeat this step for the

second NTU in the upper slot.

4.1.3 The LTUs will transfer provisioning

data to the NTUs upon power up.

Some provisioning of the NTU,

however, may be necessary due to

hardware DIP switches and jumpers.

See the Installation and Maintenance

practice for the specific NTU utilized

by your company.

A-2 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 23

4.1.4 Upon provisioning of the NTUs,

the faceplate LEDs should read as

shown in Table 1.

NOTE

The condition of the ALM, G.703 and G.703

LEDs depends upon the status of the equipment

on the ends of the installed circuit. If both

terminations of the circuit are appropriately

configured and prepared to pass data, the LTU

ALM LEDs will be out, the LTU G.703 LEDs

will be green (MAIN) and Off (AUX), the MAIN

NTU G.703 LED will be green and ALM off,

while the AUX NTU G.703 will be off, and

ALM red.

5. RESET ALL EQUIPMENT TO OPERATING

CONDITION

When the customers at both ends of the circuit have

turned up their equipment and are running data (or test

patterns, or are in loopbacks, or some other condition

that will preclude the generation of alarms), the LTUs

can be placed In Service to restore the alarm

generating functions of the equipment to the network.

CAUTION

Ensure that data has been removed from the

AUX circuit before proceeding with the next

step. Disabling PROTECTION SWITCHING

before removing data from the AUX Loop will

cause a loss of signal condition on that loop.

Under normal circumstances, the data on the

HLSS circuit will be running on the MAIN

HDSL circuit, and this precaution is unnecessary.

6.1 Disabling Protection Switching

a. Access the AUX LTU and select Option 2,

Provisioning, from the HDSL Main Menu.

b. From the Provisioning menu, choose the

Service State option.

c. Select Option 3, Out Of Service-Unassigned.

d. Escape out of the AUX LTU menus and

proceed to the MAIN LTU menu.

e. From the Main Menu, select Option 7,

Protection Configuration.

f. From the Protection Configuration menu,

select Option 1, Protection Mode.

g. Choose Option 2, Disable.

5.1 From the Total Access 3010 LTU

Provisioning Screen for both the MAIN and

AUX LTUs, select the Service State option,

and place both LTUs In Service.

NOTE

Placing the LTUs In Service will change the

PWR LED from slow flashing green to steady

green.

6. DISABLING PROTECTION SWITCHING

Disabling the protection switching mode from the

circuit converts both the MAIN and AUX circuits into

independent standalone HDSL circuits.

NOTE

There is no provisioning required at the NTUs to

remove protection-switching capability. Upon

completion of the above procedure, the MAIN

circuit is an independent, non-protected HDSL

circuit. The AUX circuit is also now independent,

with protection switching disabled, and currently

OOS-U.

6.2 Adjust Wiring at Dual Remote Housing

Once protection switching has been disabled in the

LTUs, the housing is internally wired to provide a

G.703 signal to both the MAIN G.703 and

AUXILIARY/TEST G.703 RJ-48 jacks. Connect the

customer’s equipment to the AUX RJ-48 jack or the

AUX G.703 terminal strip in the housing to complete

a second independent HDSL circuit.

61182007L1-5A Section 61182007L1-5, Issue 1 A-3

Page 24

A-4 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 25

Appendix B

HDSL H-LSS Circuit Configuration and Turnup

for DS3-Fed Systems

1. UNPACK AND INSPECT THE THE TOTAL

ACCESS DS3 MUX MODULES

Each DS3 MUX Module is shipped in its own

cardboard shipping carton. Open the carton carefully

and avoid puncturing the carton with sharp objects.

After removing the unit from the carton, unwrap the

antistatic bubble-wrap and pull the unit from the

protective plastic bag.

After unpacking the unit, inspect it for damage. If

damage is discovered, file a claim with the carrier,

then contact ADTRAN. See Warranty and Customer

Service.

2. INSTALL THE DS3 MUX MODULES

2.1. Install the DS3 MUX Module into Total

Access 3010. Electronic modules can be

damaged by static electrical discharge. Before

handling modules, wear an antistatic

discharge wrist strap to prevent damage to

electronic components. Place modules in

antistatic packing material when transporting

or storing. When working on modules, always

place them on an approved antistatic mat that

is electrically grounded.

The procedure below assumes that the DS3

MUX is being newly installed into the Total

Access 3010. If the MUX is already up and

running, begin with Step 2.1.2.

2.1.1. Gently but firmly push the DS3 MUX

into the second slot, slot A, at the left

end of the shelf. Simultaneous thumb

pressure at the top (above the POWER

LED) and bottom (below the Test/

Enable button) of the unit will ensure a

good seat of the DS3 pins into the

backplane connector. Push the ejector

tab up and closed against the DS3 `

faceplate.

2.1.2 Ensure that MUX A is in the Out of

Service-Maintenance (OOS-M)

mode. Placing the MUX in OOS-M

will prevent the MUX from

generating alarms back to the

network, and will allow loopbacks to

be initiated and taken down. Data

traffic on other embedded G.703

circuits will not be disturbed. Note

that while the DS3 MUX is in the

OOS-M mode, no alarms will be

passed to the network, including those

of circuits that may already be in

service on the MUX. After the APS

circuit is turned up, be sure to reset the

MUX to the In Service (IS) mode as

indicated in Step 6.0.1 to regain alarm

notification.

NOTE

If a single multiplexer module is used, skip Step

2.1.3. For redundant MUX applications, continue

with 2.1.3 below. When using a single

multiplexer, disregard all references to the

Offline MUX.

2.1.3 Ensure that Linked Provisioning is

“Enabled” on MUX A, and install the

second MUX in Slot B of the Total

Access 3010, using Steps 2.1.1 and

2.1.2 above for the B slot MUX. This

will allow MUX B to be configured as

MUX A when MUX B is installed.

Linked Provisioning is factory

defaulted to Enable, however, Linked

Provisioning does not affect Service

States. The factory default Service

State for MUX B is Out of

Service-Unassigned. Both muxes are

now to be configured identically, and

in the OOS-M service state. At this

point, faceplate LED indicators for

MUX A (Online) and MUX B

(Offline) will be as in Table B-1.

61182007L1-5A Section 61182007L1-5, Issue 1 B-1

Page 26

Table B-1. Faceplate LED Indicators

wolleY-REWOP

neerG-SUTATS

ENILNO

ENILFFO

ffO-TSET

ffO-TUOKCOL

neerG-ENILNO

wolleY-REWOP

neerG-SUTATS

ffO-TSET

ffO-TUOKCOL

ffO-ENILNO

NOTE

Only one DS3 MUX is required for any data

circuit to be operational. Two modules are used

for electronics redundancy of the DS3 circuit.

2.2 Provision the DS3 MUX

NOTE

There are no settings on the SCU that will affect

APS operation of either the DS3 MUX units or

the LTU line cards.

2.2.1 Logon to Total Access system.

2.2.2 If you are building a new DS3 circuit,

provision the DS3 MUX modules

according to circuit parameters. If the

HDSL H-LSS circuit is to be turned up

in an existing Total Access 3010 with

DS3 feed, assume that the parameters

have already been set for the DS3

circuit. Disregard this step and

continue.

2.2.3 When channel mapping the DS3 MUX

to individual slots configured for

protection switching, it is necessary to

map a channel only to the MAIN (oddnumbered) slot. If a fault condition

occurs and a protection switch is made

from the MAIN circuit to the AUX

circuit, the channel is temporarily

mapped by the DS3 MUX into the

AUX (even-numbered) slot and a

Failure notice attached to the MAIN

(odd) slot. Follow the steps below for

mapping a channel to the MAIN slot.

For this procedure, the technician

needs to know which embedded G.703

in the incoming DS3 data stream to

map to the appropriate APS slot in the

Total Access 3010. Do not continue

without this information. In a newly

installed DS3 MUX, thathas not been

changed from factory defaults, the

embedded G.703s in the DS3 will be

mapped to the like-numbered slot (i.e.

G.703#1 to Slot 1, G.703#2 to Slot 2,

up to G.703#28 to Slot 28).

a. Access the Main Menu of the

DS3 MUX module and select

Option 8, Channel Mapping.

b. At the bottom of the screen where

you see “Selection or Enter

Mapping (E1#/Slot#)”, enter the

number of the embedded G.703

followed by “/” and the

appropriate slot number, then

<Enter>. This action will assign

the desired G.703 to the slot in the

Total Access 3010.

WARNING

Assigning the incorrect embedded G.703 from

the DS3 to a slot in the Total Access 3010 could

disrupt existing traffic.

2.2.4 APS configuration of the DS3 MUX

units is NOT required for the LTUs to

be in H-LSS configuration. The two

APS configurations operate

independently of each other.

NOTE - APS Faceplate Pushbutton -

1. When activated with the Test/Enable switch

on the Offline unit, it forces a switch to protection.

(Offline MUX becomes Online MUX).

2. When activated with the Test/Enable switch

from the ONLINE unit, it toggles the APS

Lockout Status.

B-2 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 27

3. INSTALL THE LTU

The Total Access 3010 LTU delivers an E1 signal

over an HDSL local loop. The local loop in the H-LSS

configuration includes two independent 4-wire

circuits. The two LTUs communicate to their

respective remote units, the NTUs. When an H-LSS

switch occurs, the AUX circuit takes over transmitting

the data load from the MAIN circuit until the MAIN

circuit is restored.

3.1 Install The LTUs into Total Access

3010

Electronic modules can be damaged by static

electrical discharge. Before handling modules,

wear an antistatic discharge wrist strap to

prevent damage to electronic components.

Place modules in antistatic packing material

when transporting or storing. When working

on modules, always place them on an

approved antistatic mat that is electrically

grounded.

3.1.1 Gently but firmly push the LTU into

the appropriate odd-numbered slot

(which will be the MAIN HDSL

circuit). Compatible slots can be any

slot pair that starts with an odd number

(MAIN) and includes the adjacent (to

the right) even-numbered slot (AUX).

Compatible slot pairs are further

designated by the bracket notation

around the slot pairs on the silk screen

just below the physical slots on the

front of the Total Access 3010.

Simultaneous thumb pressure at the

top (above the PWR LED) and bottom

(below the ACT LED) of the unit will

ensure a good seat of the LTU pins

into the backplane connector. Repeat

this step for the AUX LTU to be

installed in the adjacent (even, to the

right) slot.

3.1.2 Push the ejector tab up and closed

against the LTU faceplate.

3.2 Provision the LTU

If Module Auto-Provisioning is enabled on

the SCU, and if the new cards are of the same

type as the former, the provisioning of the

former access cards of the two Total Access

3010 slots will be written to the new access

cards upon installation.

If this is an initial installation, the units will

require provisioning to appropriately

configure them out of the factory default

states.

3.2.1 Logon to Total Access system.

3.2.2 Check to ensure the LTU line cards are

correctly provisioned according to

circuit parameters. Under the

Provisioning Menu, set numbered

option, Network Source, to Auto

MUX. This option causes the LTU to

look to the ON-LINE MUX for its data

in the event of a protection switch

between the MUX modules.

3.2.3 Ensure the provisioning of both the

MAIN and AUX LTUs is identical,

except for the following options:

a. Provision the MAIN unit to

OOS-M mode.

b. Provision the AUX unit to the

OOS-U mode.

3.2.4 Enable protection switching.

a. Access the MAIN Menu of the

LTU in the odd-numbered (MAIN)

slot.

b. Select Option 7, Protection

Configuration.

c. Select Option 1, Protection Mode.

d. To enable protection switching,

select Option1, Enable.

Unless the AUX circuit is in the

OOS-U mode, the operator will

not be able to change the

Protection mode of the MAIN

LTU.

e. Set Options 2 and 3, BER

Threshold and BER Interval (see

Table 2).

f. Back out of the menu for the

MAIN slot and access the LTU in

the even-numbered (AUX) slot.

g. Select Option 7, Protection

Configuration.

h. Option 1, Protection Mode, will

have been set to AUTO. If you

desire to provision a different

H-LSS mode, select Option 1, and

choose between Auto, Manual

AUX, Manual Main, or Auto Hold.

i. Set Options 2-7 as desired on the

AUX unit. (see Table 2).

61182007L1-5A Section 61182007L1-5, Issue 1 B-3

Page 28

3.2.5 From the provisioning menu of the

AUX circuit, reset the AUX unit to

OOS-M.

3.2.6 Logoff the system.

a. From the Total Access Menu,

select Option 7, Logoff, and press

<Enter>.

b. From the Exit and Logoff screen,

select “Y” and press <Enter>.

4. INSTALL THE DUAL-SLOT STANDALONE

HOUSING

See the associated Installation and Maintenance

practice, P/N 61245034L2-5, for mounting and wiring

instructions.

5. INSTALL THE NTU

The NTU terminates local loop HDSL signals

originating from the Central Office (CO) unit and

transforms the HDSL signal into traditional E1 signals

to be delivered to the customer.

5.1 Install the NTU into the Dual-Slot

Remote Housing

Electronic modules can be damaged by static

electrical discharge. Before handling modules,

wear an antistatic discharge wrist strap to

prevent damage to electronic components.

Place modules in antistatic packing material

when transporting or storing. When working

on modules, always place them on an

approved antistatic mat that is electrically

grounded.

5.1.1 Connect the individual 4-wire HDSL

circuits to the HDSL terminal block

inside the Dual slot remote housing.

The 4-wire MAIN circuit will connect

to the Loop 1 and Loop 2 terminals

labeled “MAIN” and the 4-wire AUX

circuit will connect to the Loop 1 and

Loop 2 terminals labeled “AUX”.

5.1.2 Gently but firmly push the NTU into

the lower dual slot remote housing

slot. Repeat this step for the second

NTU in the upper slot.

5.1.3 The LTUs will transfer provisioning

data to the NTUs upon power-up.

Some provisioning of the NTU,

however, may be necessary due to

hardware DIP switches and jumpers.

See the Installation and Maintenance

practice for the specific NTU utilized

by your company.

5.1.4 Upon provisioning of the NTUs, the

faceplate LEDs should read as shown

in Table 3.

NOTE

The condition of the ALM, DSX and E1 LEDs

depends upon the status of the equipment on the

ends of the installed circuit. If both terminations

of the circuit are appropriately configured and

prepared to pass data, the LTU ALM LEDs will

be out, the LTU DSX LEDs will be green, the

MAIN NTU E1 LED will be green and ALM

off, while the AUX NTU E1 will be off, and

ALM red.

6. RESET ALL EQUIPMENT TO OPERATING

CONDITION

When the customers at both ends of the circuit have

turned up their equipment and are running data (or test

patterns, or are in loopbacks, or some other condition

that will preclude the generation of alarms), the LTUs

and DS3 MUX can be placed In Service to restore the

alarm generating functions of the equipment to the

network.

6.0.1 From the Total Access 3010 DS3 MUX

Provisioning Screen, select Option 4,

Service State, and place the DS3

MUX into In Service. If dual

multiplexers are being utilized, place

MUX B In Service.

6.0.2 From the Total Access 3010 LTU

Provisioning Screen for both the MAIN

and AUX LTUs, select the Service State

option, and place both LTUs In Service.

Placing the DS3 multiplexers In Service will change

the Power LED from yellow to green. Placing the

LTUs In Service will change the PWR LED from slow

flashing green to steady green.

7. DISABLING PROTECTION SWITCHING

Disabling the protection switching mode from the

circuit converts both the MAIN and AUX circuits into

independent standalone HDSL local loops.

B-4 Section 61182007L1-5, Issue 1 61182007L1-5A

Page 29

NOTE

Ensure that data has been removed from the

AUX circuit before proceeding with the next

step. Disabling protection switching before

removing data from the AUX loop will cause a

loss of signal condition on that loop. Under

normal circumstances, the data on the H-LSS

circuit will be running on the MAIN HDSL

circuit, and this precaution is unnecessary.

7.0.1 Disabling protection switching.

a. Access the AUX LTU and select

Option 2, Provisioning, from the

HDSL Main Menu.

b. From the Provisioning Menu,

choose the Service State option.

c. Select Option 3, Out Of

Service-Unassigned.

d. Escape out of the AUX LTU

menus and proceed to the MAIN

LTU Menu.

e. From the Main Menu, select

Option 7, Protection

Configuration.

f. From the Protection Configuration

menu, select Option 1, Protection

Mode.

g. Choose Option 2, Disable.

NOTE

G.703 DS3 multiplexer channel mapping to the

even-numbered (formerly AUX) slot in the Total

Access 3010 chassis will not automatically be

restored. Assignment of an embedded G.703 in

the DS3 data stream to the even slot will have to

be made prior to using the slot as a DS3-fed

HDSL circuit.

NOTE

There is no provisioning required at the NTUs to

remove protection switching capability. Upon

completion of the above procedure, the MAIN

circuit is an independent, non-protected HDSL

circuit. The AUX circuit is also now independent,

with protection switching disabled, and currently

OOS-U.

7.0.2 Adjust wiring at Dual remote housing.

Once protection switching has been

disabled in the LTUs, the housing is

internally wired to provide an E1signal

to both the MAIN E1 and

AUXILIARY/TEST E1 RJ-48 jacks.

Connect the customer’s equipment to

the AUX RJ-48 jack or the AUX E1

terminal strip in the housing to

complete a second independent HDSL

circuit.

61182007L1-5A Section 61182007L1-5, Issue 1 B-5

Page 30

B-6 Section 61182007L1-5, Issue 1 61182007L1-5A

Loading...

Loading...