Page 1

1xN Remote Protection Switch

Pro-Cap

Installation and Maintenance

CONTENTS

1. GENERAL ................................................................ 1

2. INSTALLATION ....................................................... 3

3. CONFIGURATION ................................................... 4

4. OPERATIONAL DESCRIPTION .............................5

5. NORMAL OPERATION ........................................... 6

6. PROTECT OPERATION ........................................... 6

7. PROTECTION SWITCH ...........................................8

8. SWITCHBACK ........................................................10

9. AUTO-PROTECT OPERATION ............................ 11

10. SPECIFICATIONS ..................................................12

11. MAINTENANCE .....................................................12

12. WARRANTY AND CUSTOMER SERVICE ......... 12

FIGURES

Figure 1. 1xN Pro-Cap....................................................1

Figure 2. SCIM Card Elements ......................................4

Figure 3. Normal Operation ........................................... 6

Figure 4. Arming Operation ...........................................8

Figure 5. Protect Operation .......................................... 10

Figure 6. Switchover.....................................................10

Figure 7. Total Access 3000 Auto-protect Switching .. 11

Section 61190860L1-5B

Issue 2, January 2002

CLEI Code: NCM5NTDD_ _

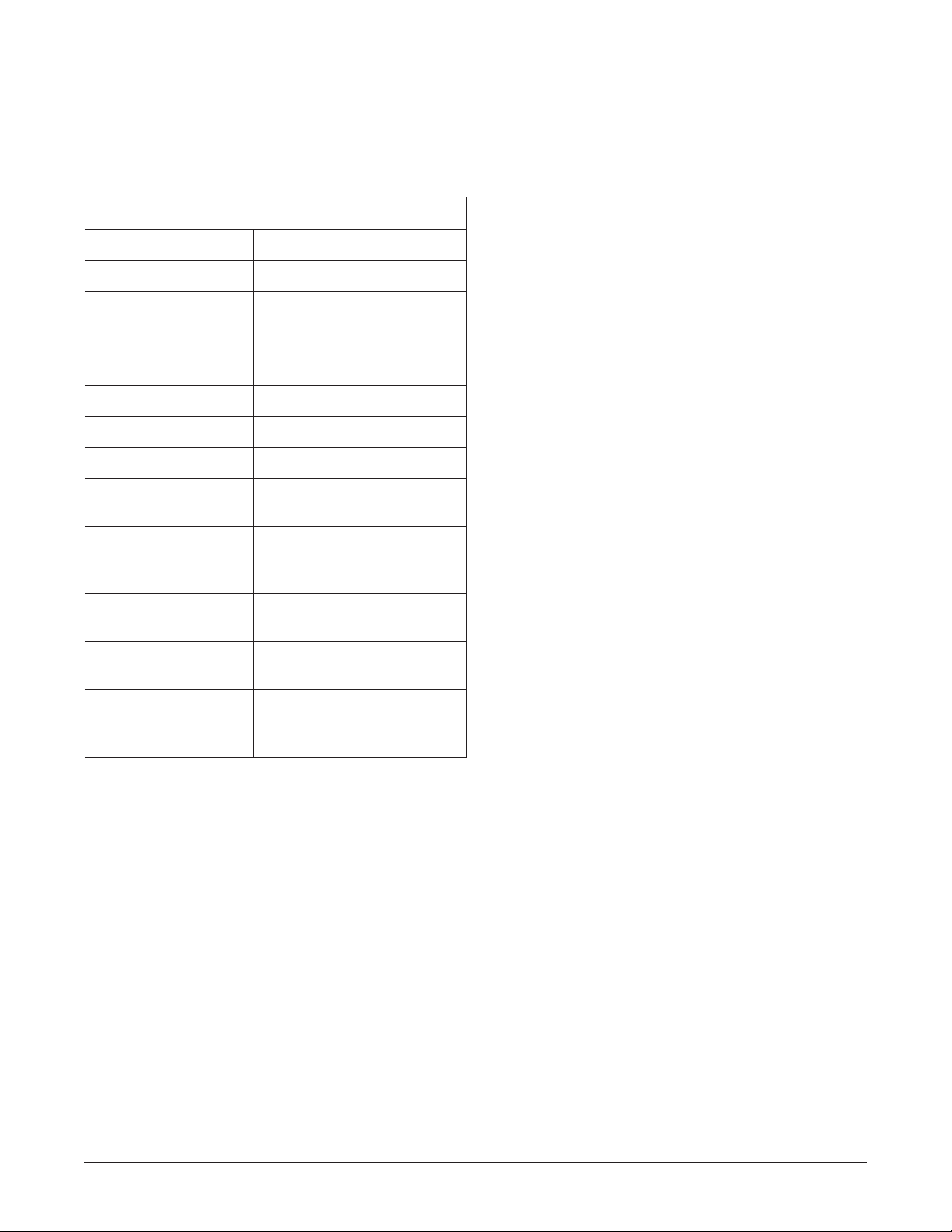

TABLES

Table 1. LED Indication ................................................ 3

Table 2. In-Band Commmands ..................................... 7

Table 3. Out-Of-Band Commands ................................7

Table 4. In-Band Enable/Disable Protocol ................... 8

Table 5. In-Band Protection Switch Protocol ...............9

Table 6. Out-Of-Band Enable/Disable Protocol ...........9

Table 7. Out-Of-Band Protection Switch Protocol ....... 9

Table 8. In-Band Protection Release Protocol ............ 11

Table 9. Out-Of-Band Protection Release Protocol ... 11

Table 10. Specifications ................................................12

1. GENERAL

This practice provides installation and operational

procedures for the ADTRAN‚

Remote 1xN Pro-Cap

protection switch multi-mount housing (P/N

1190860L1). See Figure 1. Pro-Cap initiates remote

switching of a DS1 or HDSL circuit to a standby line

following detection of a fault. This eliminates the

immediate need for a vehicle dispatch to investigate

trouble or provide standby service. The shelf also

accommodates DDS and ISDN technologies but

without protection.

Figure 1. 1xN Pro-Cap

Pro-Cap can be used in conjunction with the

®

ADTRAN Total Access

3000 Carrier Class

Broadband Multiservice Access

Platform, or any standard Office Repeater Bay (ORB)

with T1 or HDSL to provide a Protection Switching

Network Interface (PSNI).

The Pro-Cap housing accepts eight T200 type circuit

cards or four dual slot T400 DS-1, HDSL, or HDSL2

circuit cards. The unit is a wall mounted assembly

that provides convenient access to CPE connections.

The assembly incorporates a circuit board backplane

that provides a choice of amphenol connector or

wire-wrap pins for facility wiring hook-up.

The Pro-Cap accepts -48 VDC local power or a

modular power supply that inserts into the POWER

slot at the far right of the shelf. The power supply

module includes an AC power cord that plugs into a

standard 110 VAC grounded outlet.

The Switch Customer Interface Module (SCIM) can

mount to either the left or right side of the Pro-Cap

housing to facilitate access to all CPE connections.

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

161190860L1-5B Section 61190860L1-5, Issue 2

Page 2

The SCIM can be locally powered by -48 VDC, or

span powered from the standby unit in slot 8 if

equipped for span power. Slide switch S1 selects

between local or span power. CPE receive and

transmit connections are either amphenol or RJ-48C

jacks.

Revision History

Issue 2 adds Auto-Protect information when the

Pro-Cap is configured in a Total Access 3000 network.

Features

The 1xN Pro-Cap includes these features:

• Protection module.

• Compact and lightweight assembly that

accommodates eight T200 mechanics or four

T400 mechanics modules.

• Reversible SCIM for right side or left side

assembly.

• Prewired backplane to minimize wiring errors and

installation time.

• Protect module can function as standard channel

module.

• Dedicated slot for modular power supply.

• LEC facility connections are made by 25-pair

Amphenol XMT/RCV connectors or wire-wrap

pins.

• CPE connections are made to RJ-48C modular

jacks or 25-pair Amphenol XMT/RCV

connectors.

• Auto-Protect Switching with Total Access 3000

applications.

• Swing open tinted Plexiglas front cover.

• Available with key-locking metal cover (List 4

Option).

• Includes standard 10-year warranty.

Physical Description

The 1xN Pro-Cap consists of four elements:

1. Mounting-Plate

The mounting-plate attaches to a customer

premises backboard.

2. Shelf

The shelf has slots for seven channel modules,

one standby (protect) module, and one power

module, plus two external edge connectors for

the SCIM. The power terminal strip has

connections for power, alarm, and ground. The

shelf attaches to the mounting-plate.

3. Switch Customer Interface Module

This module inserts into one of the SCIM edge

connectors located on either side of the shelf. It

has both amphenol and RJ-48C interface

connections to the customer loop. Behind an

access panel is a power connection terminal

strip, a slide switch for either span or local

power, protect ON/OFF switch, and a

pushbutton for selecting individual module

protection or resetting the protect configuration.

Selection and status is indicated with associated

LEDs on the SCIM front panel.

4. Housing Cover

The Plexiglas swing door housing cover

encloses the shelf allowing viewing and access

to the shelf modules.

Functional Description

During normal customer and network transmission,

data is transported through the active modules in slots 1

through 7. The module in slot 8 is the standby

(protect) unit. If a fault is detected on an active line a

series of facility initiated manual commands switch the

standby module to an active mode in place of the

faulted unit. When the faulted unit malfunction is

resolved another series of manually initiated

commands (or the reset switch) returns it to active

service and the standby unit is returned to standby

status. The LED bank shows module status during

normal and standby conditions. When circuit

protection mode is disabled the Pro-Cap unit can be

used as a standard 8-slot T200 mounting.

Auto-Protect Switching

When the Pro-Cap is used in association with the

ADTRAN Total Access 3000 platform, certain Total

Access 3000 cards initiate an automatic protect

function with the Pro-Cap. These cards send the same

protect enable/disable, arming, and switching codes as

sent in the manual switching mode. The Pro-Cap does

not require configuration changes to support the

auto-protect feature. The same configuration

supporting manual switching also supports automatic

switching. Additional information is in Section 9 of

this practice.

Listed here are Total Access 3000 cards that initiate the

auto-protect codes:

• H2TUC 1181112L5

• H2TUR 1222026L7

• H2TUR 1221026L7

2 61190860L1-5BSection 61190860L1-5, Issue 2

Page 3

Documentation associated with the listed cards

C A U T I O N

provides information on implementing the auto-protect

function.

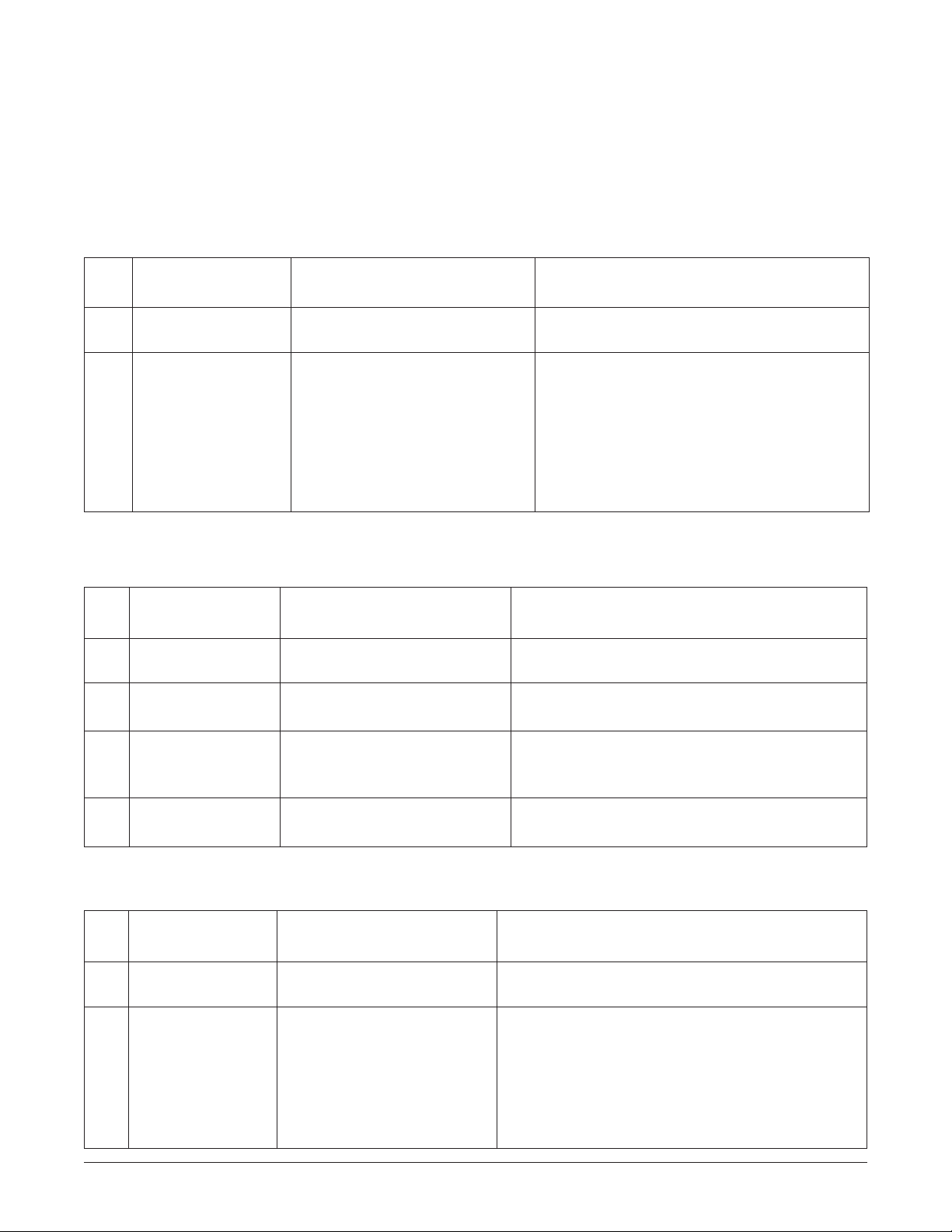

LED Indication

Table 1 describes LED indication.

• All LEDs OFF indicates no power to the SCIM.

• All LEDs flashing red indicates the protect card is

disabled and SCIM power is local -48 VDC.

2. INSTALLATION

C A U T I O N

SUBJECT TO ELECTROSTATIC DAMAGE

OR DECREASE IN RELIABILITY.

HANDLING PRECAUTIONS REQUIRED.

!

After unpacking the unit inspect it for damage. If

damage is noted, file a claim with the carrier then

notify ADTRAN. Refer to Warranty and Customer

Service.

Mounting Procedure

The 1xN Pro-Cap installs at the remote location using

the following procedure:

NOTE

All component fasteners are spring-loaded,

captured thumb screws.

3. The shelf assembly lifts away from the mountingplate by disengaging the chassis tabs from the

mounting-plate support hooks.

4. Using the mounting-plate as a template, position

the mounting-plate at the desired location and

mark four pilot holes. Ensure the unit is level and

that cable plugs will reach their designated

sockets.

5. Using an appropriate bit, drill the four pilot holes.

6. Align the mounting-plate to the pilot holes and

attach to the wall with appropriate fasteners.

7. Reassemble the unit by reversing steps

1 through 3.

Cable Connections

Frame Ground

Both the shelf and SCIM have separate ground

connections. Each must be connected to a known

approved ground location. Verify metal to metal

contact on all connections and ensure ground circuit

continuity.

The shelf has various openings for wire route options

along with tie-wrap anchor points and extrusions for

securing cables and connectors.

Specific wiring arrangements are customer developed.

CAUTION

1. Remove the housing from the shelf by unscrewing

the two thumb screws on the side of the housing.

The housing pulls out and away from the shelf.

Transmit and receive loops to both facility and

CPE have two connection schemes. Only one

connection method is to be used, not both.

2. Remove the shelf from the mounting-plate by

unscrewing the thumb screw at the top center of

the shelf bay. It is not necessary to remove the

SCIM assembly unless its position is to be

reversed to the other side of the shelf.

Facility Side

Amphenol Connection – The to-facility and

from-facility amphenols can be either left-side or

right-side oriented.

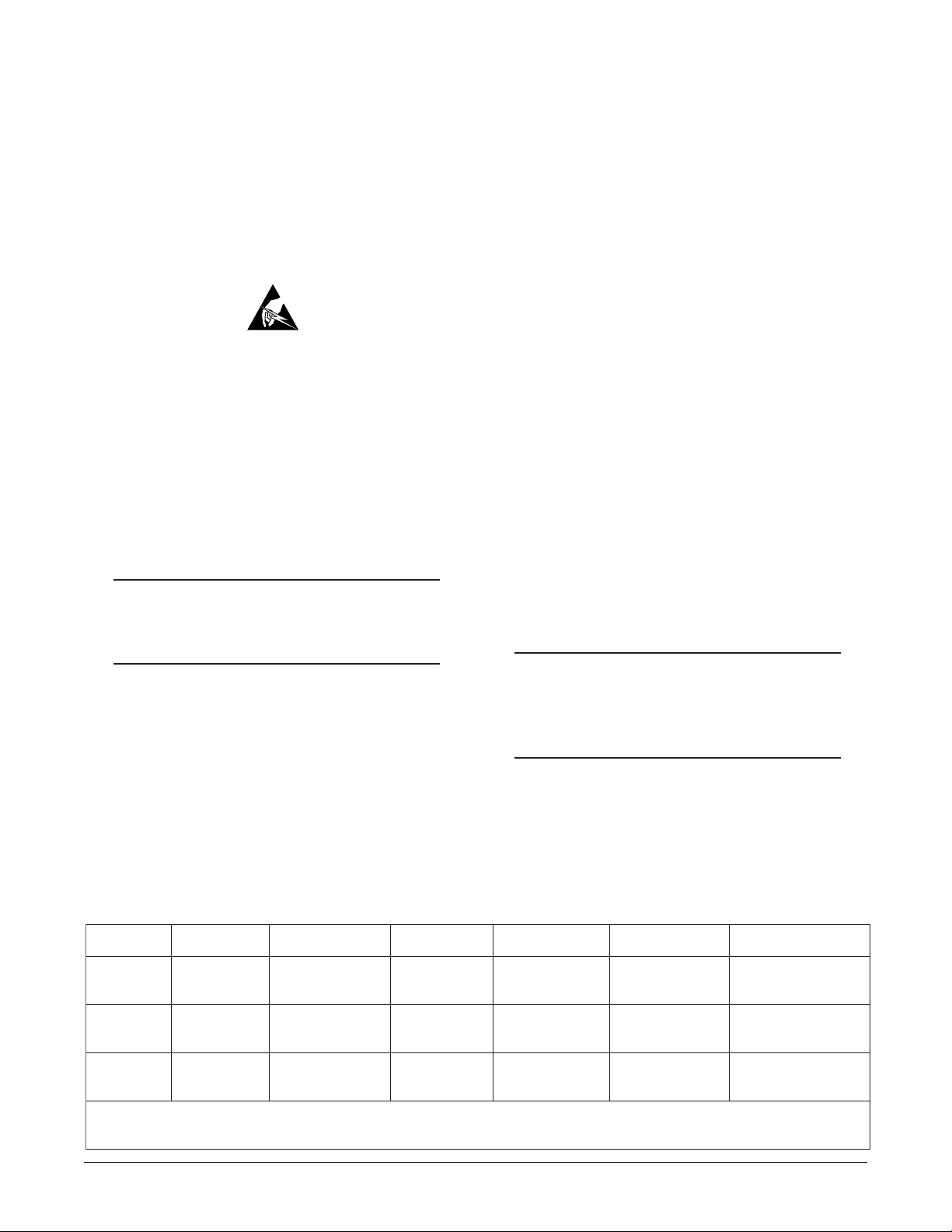

Table 1. LED Indication

DELtolSFFOneerGhsalFneerGdiloSdeRhsalFdeRdiloSneerG/deRhsalF

7-1

TORP8

LIAF

tcetorP

detceleseD

krowteNoN

langiS

tcetorP

lanoitarepO

.FFO3ShctiwstcetorP**

ottseuqeR

elbanEtcetorP

tcetorP

detavitcA

A/NA/N

tcetorP

delbanE

nItcetorP

ybdnatS

draCtcetorP

**delbasiD

draCtcetorP

**delbasiD

draCtcetorP

**delbasiD

.edoMtcetorPniebnac7hguorht1stolsniemitataeludomenoylnO*

tcetorPnI

*edoM

A/NdemrAdraCtcetorP

eruliaFtcetorPA/N

A/N

361190860L1-5B Section 61190860L1-5, Issue 2

Page 4

Wire-Wrap – The to-facility and from-facility

wire-wraps are an alternate method in lieu of the

amphenol connections.

Customer Side

Amphenol Connection – The to-CPE and from-CPE

amphenols should be left-side oriented to prevent

SCIM panel removal interference after amphenol

installation.

RJ-48C – These modular jacks are an alternate method

in lieu of the amphenol connections.

Shelf Cards

Channel cards are individually configured to meet

network or customer requirements. Certain cards only

receive power from network span power. These cards

do not have pin contacts for shelf power.

CAUTION

It must be determined if channel cards can receive

both span power and shelf power. Some cards

may malfunction under that condition.

-48 VDC Terminal

Local DC power connects to terminal strip TB1 at the

bottom of the shelf backplane. This power source is

distributed across the backplane to slots 1 through 8

and can jumper to the SCIM TB1 to power the

controller card.

NOTE

Both the shelf backplane and the SCIM card each

have a TB1 terminal strip. This practice identifies

the specific TB1 when referenced in the text.

3. CONFIGURATION

Shelf

There are no configuration selections on the shelf

backplane. If -48 VDC is connected to TB1 on the

shelf card there is no need for the power card unless

for a spare power source.

Power Card

The PWR card has an AC power cord that inserts into

a standard 110 volt AC grounded wall outlet. When

AC power is in use, local power should not be

connected to TB1 on the shelf card. The PWR card

also applies power to the same TB1 shelf terminals,

which in turn can be jumpered to TB1 on the SCIM

card.

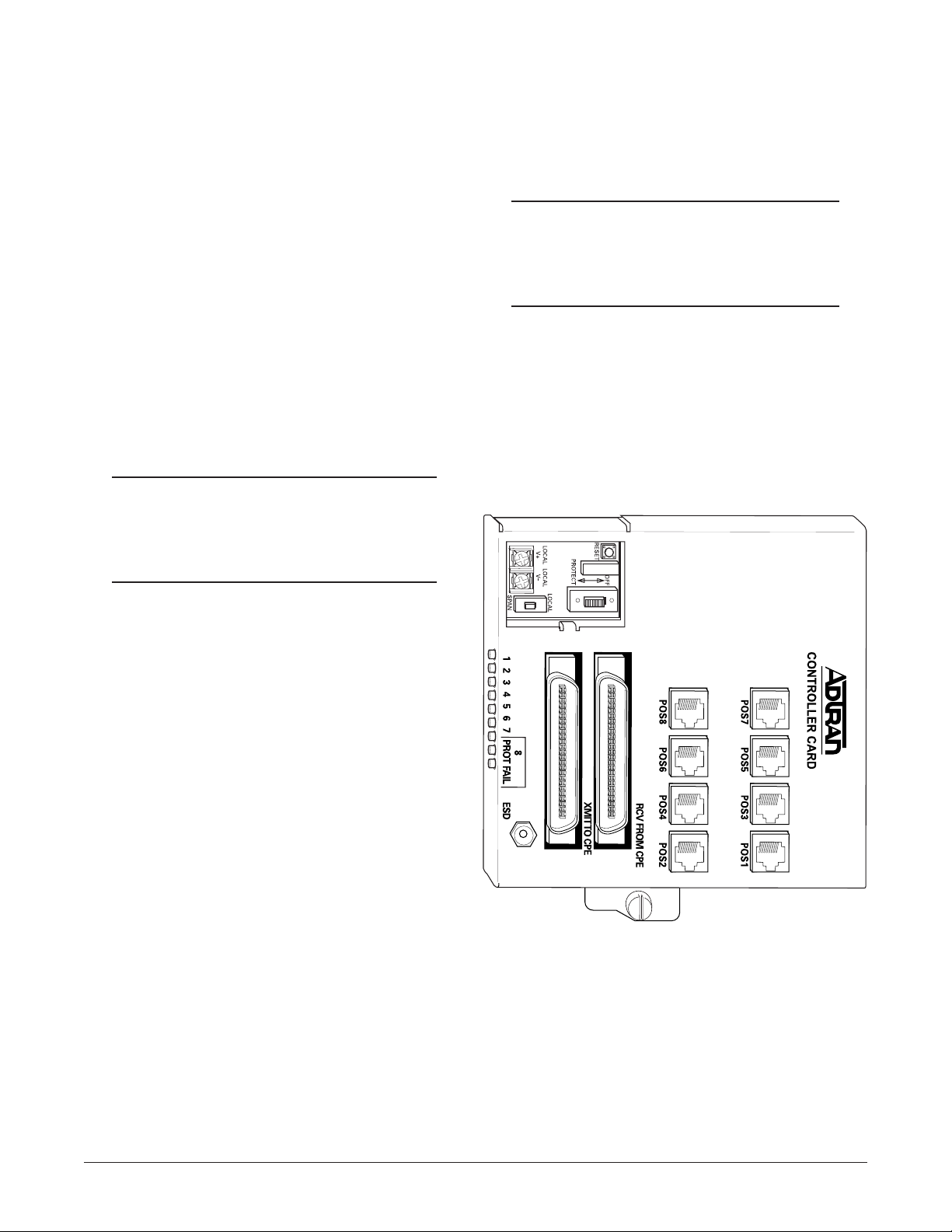

SCIM Controller Card

Option switches on the SCIM controller circuit board

are located behind an access panel. Remove the

housing from the shelf to gain access to the panel’s

thumb screw fastener (refer to Step 1 of the Mounting

Procedure). See Figure 2 for SCIM Card connections,

terminals, indication, and switches.

Protect Card

The protect card can receive power from either the

Figure 2. SCIM Card Elements

network (span) or from the backplane (-48 VDC). To

initiate the protect feature the card in slot 8 must

support the technology of the channel cards that are

enabled for protection. The protect card should also

have span power capability to power the SCIM should

that configuration be used.

4 61190860L1-5BSection 61190860L1-5, Issue 2

Page 5

Span Power Switch S1

This switch selects between span power or local

power.

SPAN – The SCIM receives power from the

protect card in slot 8.

LOCAL – The SCIM receives power from local

-48 VDC to terminal strip TB1 on the

SCIM card.

NOTE

Local -48 VDC can be jumpered from the shelf

TB1 terminals.

Protection Select/Reset Switch S2

The first function of this pushbutton switch enables or

disables standby protection for individual slots (1

through 7). Protection for selected slots can be

disabled if cards of a different technology occupy

those slots, or to meet SLA agreements. Protection is

selected using the following procedure:

OFF – The standby module in slot 8 is cut through

and detection circuitry disabled. If the

standby card was supplying span power to

the SCIM, all the LEDs will be OFF. If the

SCIM was receiving local -48 VDC power,

all the LEDs will flash red.

NOTE

The protect card in slot 8 should have span power

capability either permanent or as an enabled

option.

Local Power

Terminal strip TB1 on the SCIM card accepts local -48

VDC power. Installation requires that wiring (14 to 26

AWG) be routed from the back of the SCIM housing.

This arrangement is an alternative to span power the

SCIM receives from the protect card. Slide switch S1

selects between span power or the -48 VDC supply.

SCIM frame ground is attained through a separate

ground terminal.

1. Depress S2 for 5 seconds. Slot 1 LED will start to

flash green; all other LEDs will be OFF. Release

S2.

2. To enable protection for slot 1, press and release

S2. Slot 1 LED will turn solid green and the LED

for slot 2 will begin to flash.

3. To pass over a slot that is not to be protect

enabled, wait several seconds while that slot’s

LED is flashing. The LED turns OFF and the next

LED begins to flash green.

4. Continue this process until the LEDs for all slots

designated for protection are ON.

The protect configuration, once established, is

maintained in memory.

The second function of this switch is to reset the

protect configuration in the event the protect card was

enabled to temporarily replace a malfunctioning shelf

card. After the system is returned to normal,

depressing S2 for a minimum 5 seconds resets the

protect configuration stored in memory. Immediately

release the pushbutton when the LEDs return to the

protect configuration.

4. OPERATIONAL DESCRIPTION

The SCIM card is a component of the Pro-Cap

assembly that provides T1 drops to the customer

through an RJ-48C or Amphenol connector. The T1

1x7 Controller Card is an enhanced SCIM that also

performs manual 1x7 protection switching on T1

(HDSL) services. The controller card is designed to

function as a manual protection switch and does not

have the capability to address an automatic protection

switch function.

T1 protection switching is accomplished through two

network elements:

• Central Office Element (COE)

• Remote Element (RE).

The COE functions as the master of the protection

switching operation by initiating all commands. The

RE will only respond to the COE commands. The

controller card and a Network Interface Unit (NIU)

represent the RE. A Digital Test Access Unit (DTAU),

a Digital Cross-connect, or a T1 Test Set can represent

the COE.

Protect Switch S3

This switch controls the protect feature.

ON – All standby and protect functions are active.

The controller card uses the card in slot 8 of the

Pro-Cap mounting as the standby service. The NIU in

slot 8 will provide the appropriate physical layer

interface to the network (i.e. HDSL2, HDSL, or T1

AMI) and 4-Wire T1 AMI physical layer interface to

561190860L1-5B Section 61190860L1-5, Issue 2

Page 6

the controller card. The controller card will

continuously monitor the network receive T1

transmission service in slot 8 (i.e. standby line) for

commands. Upon the receipt of these commands, the

controller card will initiate the T1 service switchover

from the requested line (1 through 7) to the standby

line. The controller card when optioned for protect

will conduct the following:

1. Monitor the incoming network signal to

determine if the protect line is operational. If the

line is operational the FAIL LED will be OFF. If

no signal is present, the slot 8 PROT LED will be

OFF and the FAIL LED will be ON.

2. Provide a loopback to the network as long as a

transmit signal is not present from the CPE. If a

signal is placed on the slot 8 CPE transmit to the

network, the loopback will be released and

normal transmission to and from the network can

occur. Upon removal of the transmit signal,

loopback will be activated.

Normal Receive Path

The receive path is non-protected and transformer

coupled between the network and the customer. The

receive path is monitored for in-band or ESF

bit-patterned datalink messages. The receive path

toward the network will be terminated with a 100 ohm

resistor. This 100 ohm termination increases the

reliability of T1 signal recovery and minimizes

crosstalk. The receive path toward the customer will

be an open termination.

Normal Transmit Path

The transmit path is non-protected and transformer

coupled between the network and the customer.

Passive Mode

The controller card can be configured to establish a

passive transmission path by detecting a T1 signal from

the customer. The transition from normal to passive

mode will require the loopback to the network removed

and the receive path to the customer to be reconnected.

The SCIM controller card can be locally or remotely

provisioned to either enable or disable slot-switching

capability. If a slot is protect enabled, when a switch

request for that slot is received on the protect channel,

the slot will switch. If the slot is protect disabled, it

cannot be switched.

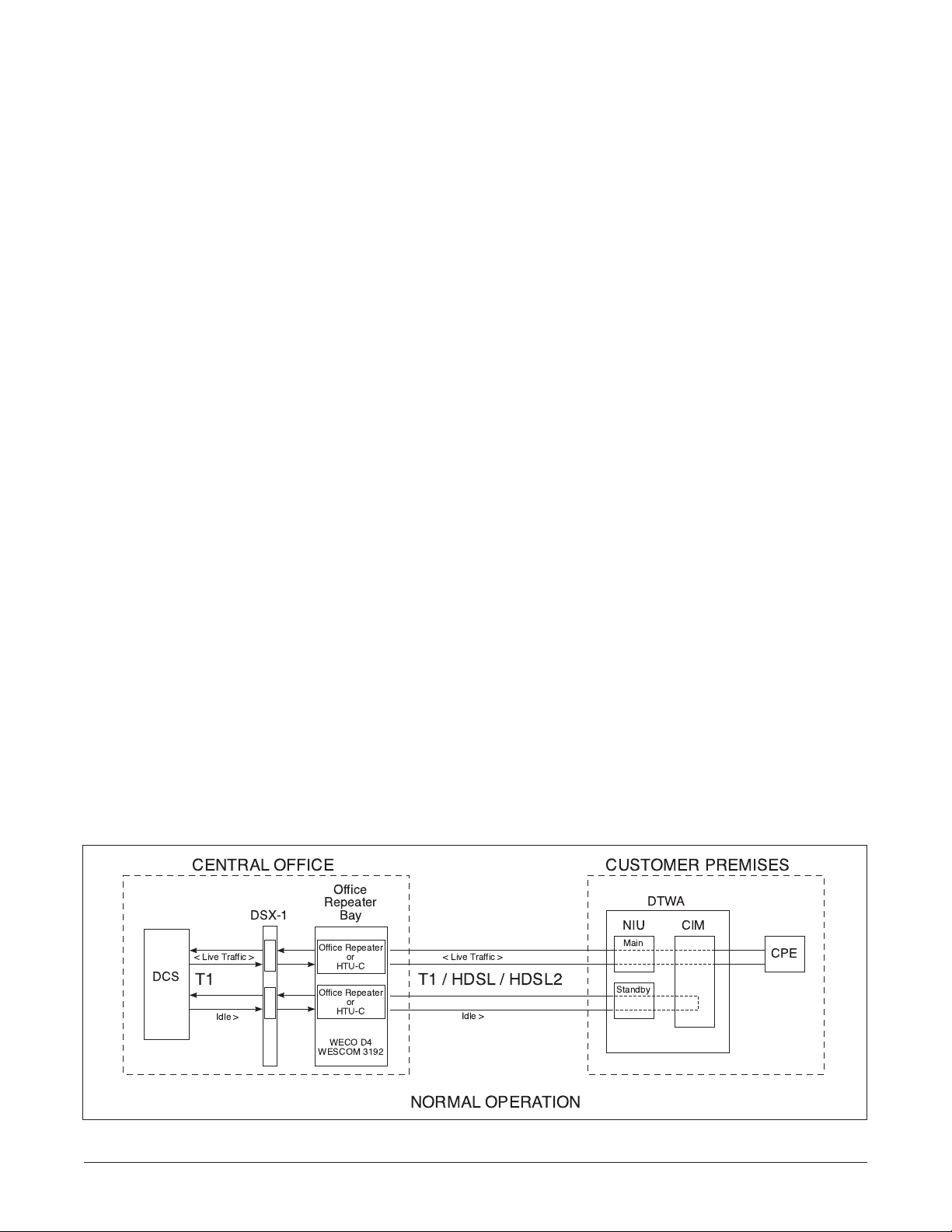

5. NORMAL OPERATION

Data is transported from the network to the customer

through an assigned slot (slot 1 through slot 7). The

standby line is transported through slot 8

(see Figure 3).

CENTRAL OFFICE CUSTOMER PREMISES

Office

Repeater

DSX-1

< Live Traffic > < Live Traffic >

DCS

T1 T1 / HDSL / HDSL2

Idle >

Bay

Office Repeater

or

HTU-C

Office Repeater

or

HTU-C

WECO D4

WESCOM 3192

Passive Mode to Normal Operation

The controller card will return to normal operation by

detection of a loss-of-signal from the customer.

6. PROTECT OPERATION

Protect operation is defined as the transport of data

from the network to the customer using a standby line

connected to Slot 8. Communication between the COE

and RE will be based upon in-band or out-of-band

(ESF datalink) commands. Upon detection of a fault

on an active line, the controller card will not

automatically switch the customer’s data onto the

standby line. A remote provisioning command must be

used to switch the customer’s data onto the standby

line. Once the customer’s data is on the standby line,

DTWA

NIU

Main

Standby

Idle >

CIM

CPE

NORMAL OPERATION

Figure 3. Normal Operation

6 61190860L1-5BSection 61190860L1-5, Issue 2

Page 7

this condition will be locked until a remote

provisioning command orders the controller card to

switch the customer data back onto the main line, or a

signal failure of greater than 30 seconds occurs on the

protect Slot 8.

Protect Receive Path

The receive path is non-protected and transformer

coupled between the network and the customer. The

receive path is monitored for in-band or ESF

bit-patterned datalink messages. The receive path will

be a passive transmission path.

Protect Transmit Path

The transmit path is non-protected and transformer

coupled between the network and the customer. The

transmit path will be a passive transmission path.

In-Band Commands

The in-band commands are based on a 16-bit repeating

binary pattern. These patterns were selected to avoid

random data replication and yellow alarm generation.

In-band code qualifications involve receiving the codes

for 5 contiguous seconds. The in-band codes can be

transmitted using SF/ESF framing or unframed. See

Table 2 for in-band commands.

Out-of-Band Commands

The out-of-band commands are based on the ANSI

T1.403-1995 standard on T1 protection switching.

ANSI T1.403-1995, Table 4, specifies the command

and response messages for T1 protection switching.

Out-of-band code qualifications involve receiving the

codes for greater than 4 consecutive messages. See

Table 3 for out-of-band commands.

Table 3. Out-Of-Band Commands

Table 2. In-Band Commands

dnammoC

gnimrAhctiwS044C0000001000100011

elbanEtolS045C0000001010100011

elbasiDtolS046C0000001001100011

esaeleRhctiwSF44C1111001000100011

noitavitcAhctiwS

edoC

1eniL144C1000001000100011

2eniL244C0100001000100011

3eniL344C1100001000100011

xeH

nrettaP

dnammoC

nrettaPyraniB

gnimrAhctiwSFF811111111100011000

elbanEtolSFF871111111100011110

elbasiDtolSFFA71111111101011110

esaeleRhctiwSFF621111111101100100

noitavitcAhctiwS

edoC

teseRFF421111111100100100

1eniLFF241111111101000010

2eniLFF441111111100100010

3eniLFF641111111101100010

xeH

nrettaP

nrettaPyraniB

4eniL444C0010001000100011

5eniL544C1010001000100011

6eniL644C0110001000100011

7eniL744C1110001000100011

4eniLFF841111111100010010

5eniLFFA41111111101010010

6eniLFFC41111111100110010

7eniLFFE41111111101110010

761190860L1-5B Section 61190860L1-5, Issue 2

Page 8

7. PROTECTION SWITCH

Remote provisioning for a protection switch can be

accomplished by sending a specific sequence of

in-band or out-of-band messages. These remote

provisioning commands are transmitted to the

controller card from a remote test facility or a T1 test

set at a DSX panel.

Arming

Arming the controller card prevents an inadvertent

protection switch operation. The controller card can

be armed with the presence of the appropriate in-band

or out-of-band pattern on the network receive

interface. Disarming the controller card can be

accomplished with the presence of an in-band (11100)

or out-of-band (ESF datalink) NIU loop down pattern

on the network receive interface, a 1-hour time out, a

protection switch, or a manual reset. See Figure 4 for

arming activation.

CENTRAL OFFICE CUSTOMER PREMISES

Office

Repeater

DSX-1

< Live Traffic > < Live Traffic >

DCS

T1 T1 / HDSL / HDSL2

< Arming Code >

Bay

Office Repeater

or

HTU-C

Office Repeater

or

HTU-C

< Arming Codes >

In-Band Slot Enable/Disable Protocol

See Table 4 for in-band slot enable/disable protocol.

DTWA

NIU

Main

Standby

CIM

CPE

WECO D4

WESCOM 3192

TEST

ARMING OPERATION

Figure 4. Arming Operation

Table 4. In-Band Enable/Disable Protocol

petS

1edoCgnimrAdneSxeH044C.edoCgnimrAehtkcabpooL

2

3

4nrettaPevomeR

dnaB-nIEOC

snrettaPdnammoC

roelbanEtolSdneS

edoCelbasiD

eniLnoitcetorPdneS

XerehwX44ChctiwS

rebmunenil=

elbanExeH045C

elbasiDxeH046C

xeHX44C

rebmuNeniL=X

nrettaPdnaB-nIdraCrellortnoC

neht,ceS5rofedocelbasiD/elbanEehtkcabpooL

sinrettaplitnutaepeR.ceS5rofcnySoN

.devomer

rebmunenil=XerehwedocX44CehtkcabpooL

litnutaepeR.ceS5rofcnySoNneht,.ceS5rof

.devomersinrettap

noitcetorprofdelbasiDrodelbanEwonsitolS

.gnihctiws

8 61190860L1-5BSection 61190860L1-5, Issue 2

Page 9

In-band Protection Switch Protocol

See Table 5 for in-band protection switch protocol.

Out-of-Band Enable/Disable Protocol

See Table 6 for out-of-band slot enable/disable

protocol.

Table 5. In-Band Protection Switch Protocol

Out-of-Band Protection Switch Protocol

See Table 7 for out-of-band protection switch

protocol.

petS

1edoCgnimrAdneSxeH044C.edoCgnimrAehtkcabpooL

2eniLnoitcetorPdneS

dnaB-nIEOC

snrettaPdnammoC

xeHX44C

edoChctiwS

delbanEtolS

delbasiDtolS

rebmuNeniL=X

nrettaPdnaB-nIdraCrellortnoC

Table 6. Out-Of-Band Enable/Disable Protocol

petS

1edoCgnimrAdneS1111111100011000 .SIAybdewollofsm004rofedoCgnimrAkcabpooL

2

dnaB-nIEOC

snrettaPdnammoC

roelbanEtolSdneS

edoCelbasiD

nrettaPknilataDdetneirO-tiBdraCrellortnoC

1111111100011110elbanE

1111111101011110elbasiD

.rebmunenil=XerehwedocX44CehtkcabpooL

.cnysfossoL.retalsdnoces5revohctiwsmrofreP

XerehwedocX44CehtfokcabpooLsuounitnoC

.cnysfossolondnarevohctiwsoN.rebmunenil=

sm004rofedocelbasiD/elbanEehtkcabpooL

.SIAybdewollof

eniLnoitcetorPdneS

3

4

hctiwS

)3elbaTees(

nrettaPevomeR noitcetorprofdelbasiDrodelbanEwonsitolS

111111110XXX0010

rebmuNeniL=XXX

Table 7. Out-Of-Band Protection Switch Protocol

dnaB-nIEOC

petS

1edoCgnimrAdneS1111111100011000 .SIAybdewollofsm004rofedoCgnimrAkcabpooL

2eniLnoitcetorPdneS

edoChctiwS

snrettaPdnammoC

111111110XXX0010

rebmuNeniL=XXX

)3elbaTees(

delbanEtolS

delbasiDtolS

nrettaPknilataDdetneirO-tiBdraCrellortnoC

.SIAybdewollofsm004rofedoc#enilkcabpooL

.gnihctiws

:edoc#enilkcabpooL

segassemevitcesnoc4retfarevohctiwsmrofreP

.deviecer

.revohctiwsoN.SIAybdewollofedoc#enilkcabpooL

961190860L1-5B Section 61190860L1-5, Issue 2

Page 10

See Figure 5 and Figure 6 for switchover codes

and traffic results.

8. SWITCHBACK

Switchback operation is defined as the

re-establishment of the T1 transmission path between

the network and the customer using the regularly

assigned line. Communication between the COE and

RE will be based upon in-band or out-of-band (ESF

datalink) commands.

NOTE

Communication using in-band codes will override

the customer’s data during the switchback

operation. The customer’s data will be overridden

for 10 seconds. These remote provisioning

commands are transmitted to the controller card

from a remote test facility or a T1 test set at a DSX

panel.

Switchback Receive Path

Remote

Switchback operation is accomplished by sending a

specific sequence of SF in-band patterns or ESF

datalink messages over the standby line.

CENTRAL OFFICE CUSTOMER PREMISES

Office

Repeater

DSX-1

< Live Traffic > < Live Traffic >

DCS

< Acknowledge

Switch Code >

TEST

Bay

Office Repeater

or

HTU-C

Office Repeater

or

HTU-C

WECO D4

WESCOM 3192

T1 / HDSL / HDSL2

Local

Depressing S2 on the SCIM card for a minimum 5

seconds resets the protect configuration in memory.

DTWA

NIU

Main

Standby

Switch Codes >

CIM

CPE

PROTECT OPERATION

Figure 5. Protect Operation

CENTRAL OFFICE CUSTOMER PREMISES

Office

Repeater

DSX-1

DCS

< Live Traffic >

TEST

Bay

Office Repeater

or

HTU-C

Office Repeater

or

HTU-C

WECO D4

WESCOM 3192

T1 / HDSL / HDSL2

< Live Traffic >

SWITCHOVER

Figure 6. Switchover

10 61190860L1-5BSection 61190860L1-5, Issue 2

NIU

Main

Standby

DTWA

CIM

CPE

Page 11

In-band Release Protocol

See Table 8 for return to normal operation.

Out-of-Band Release Protocol

See Table 9 for return to normal operation.

Signal Transmit

The controller card will transmit a 0 dB signal.

Line Build Out (LBO)

The controller card will not provide LBO functions.

The controller card will rely upon the NIU to provide

LBO.

Table 8. In-Band Protection Release Protocol

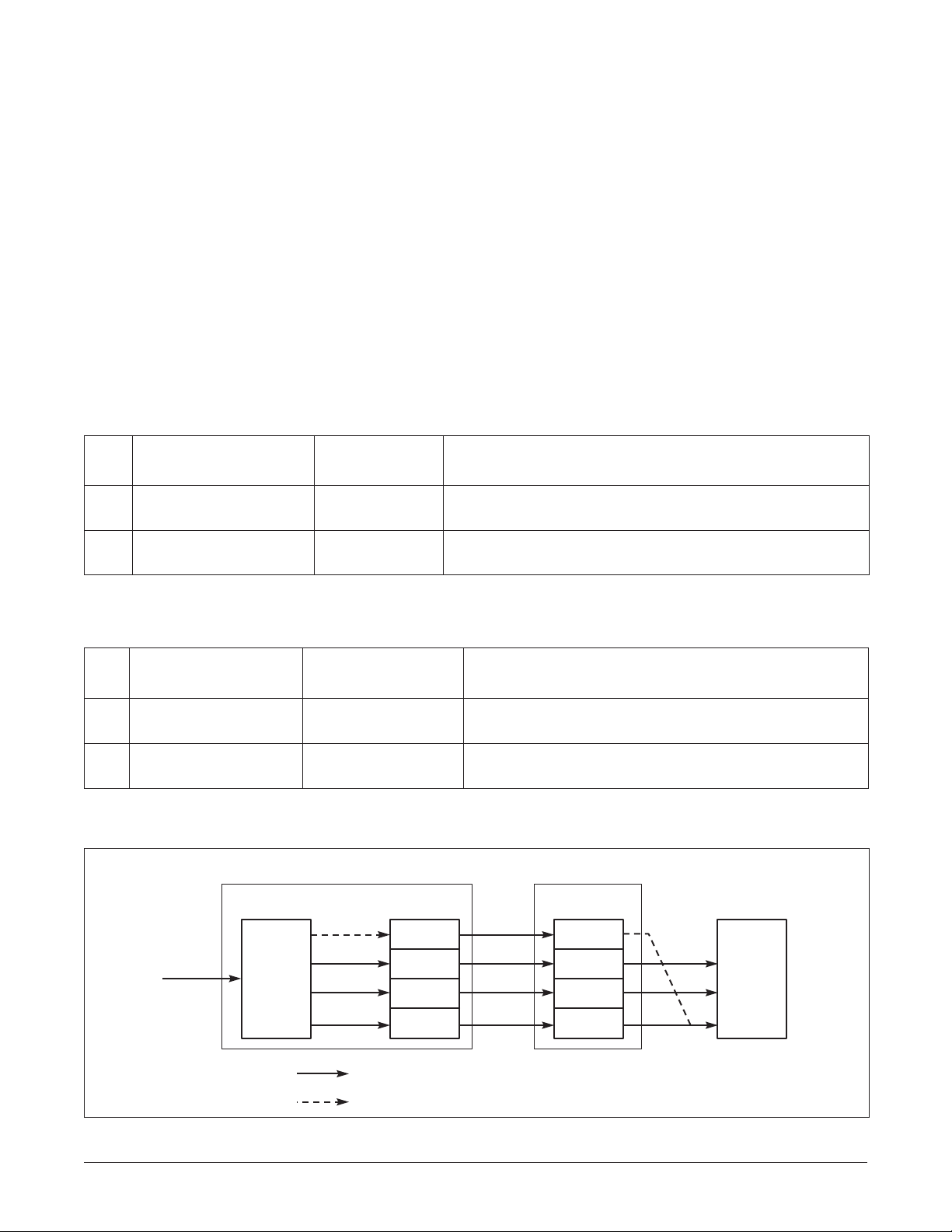

9. AUTO-PROTECT OPERATION

When the Pro-Cap is configured in a Total Access

3000 network optioned for the auto-protect feature, the

TA 3000 will re-map a failed loop's data to the TA

3000 protect unit which in turn sends the protect

initiate codes to the Pro-Cap. The Pro-Cap will put its

protect unit online to complete the standby

transmission loop to the customer. Loss of data

transmission on a particular loop for any reason

initiates the protect function. See Figure 7. Normal

transmission is automatically restored when the failure

is corrected.

petS

1edocesaelerhctiwsdneSxeHF44C.retalsdnoces5kcabhctiwsmrofreP.edoCesaeleRkcabpooL

2nrettapevomeR .noitarepolamronotdenrutersitolS

dnaB-nIEOC

snrettaPdnammoC

nrettaPdnaB-nIdraCrellortnoC

Table 9. Out-Of-Band Protection Release Protocol

petS

1edocesaelerhctiwsdneS1111111101100100 .deviecersegassemevitucesnoc4retfakcabhctiwsmrofreP

2nrettapevomeR .noitarepolamronotdenrutersitolS

DS3

Feed

dnaB-nIEOC

snrettaPdnammoC

Total Access 3000 Pro-Cap

H2TU-Cs

L2

MUX

knilataDdetneirotiB

nrettaP

4

3

2

1

draCrellortnoC

Remote

Units

D

C

B

A

R4

R3

R2

R1

CPE

Normal Operation

Auto-Protect Operation (Loop A Failure)

Figure 7. Total Access 3000 Auto-protect Switching

1161190860L1-5B Section 61190860L1-5, Issue 2

Page 12

10. SPECIFICATIONS

See Table 10 for Specifications.

11. MAINTENANCE

The Pro-Cap does not require maintenance for normal

operation.

Table 10. Specifications

noitacificepS

:ecafretnIlacisyhPeriW-4

:langiSralopiB1T

:gnidoCelbitapmocSZ8BroIMA

:gnimarFdemarfnUro,FSE,FS

:etaReniLmpp05@s/bM445.1

:langiStimsnarTBd0

:ssoLnoitresnIzHk277taxamBd5.1

:ecnadepmIeniLzHk277ta)%02±(smho001

rorrEtceteDmumixaM

:etaR

:rewoPAm36ot75tarewoPnapS

:)derewoP

:ytidimuH

:ecnailpmoCLU

:ecnailpmoCCCF

12. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within ten

(10) years from the date of shipment if it does not meet

its published specifications or fails while in service.

Refer to ADTRAN U.S. and Canada Carrier Networks

Equipment Warranty, document 60000087-10.

Contact Customer And Product Service (CAPS) prior to

returning equipment to ADTRAN.

For service, CAPS requests, or further information,

contact one of the following numbers:

ADTRAN Sales

Pricing/Availability

(800) 827-0807

3-

01<

ADTRAN Technical Support

Pre-sales Applications/Post-sales Technical Assistance

(800) 726-8663

otCDV42±tarewoPlacoL

CDV65

napS(porDegatloVCD

Am06taCDV42

Standard hours: Monday-Friday, 7 a.m. - 7 p.m. CST

Emergency hours: 7 days/week, 24 hours/day

ADTRAN Repair/CAPS

Return for Repair/Upgrade

:erutarepmeTgnitarepO

C°56+otC°04-

gnisnednocnon%59otpU

dr

30591LU

noitidE

stnemeriuqeRA

(256) 963-8722

Repair and Return Address

ADTRAN, Inc.

ssalC,BtrapbuS,51traPCCF

CAPS Department

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

12 61190860L1-5BSection 61190860L1-5, Issue 2

Loading...

Loading...