Page 1

®

Total Access 1500 Dual Line Interface Unit (LIU)

Installation and Maintenance Practice

CONTENTS

1. General .................................................................... 1

2. Installation............................................................... 2

3. Provisioning ............................................................ 4

4. Alarms ................................................................... 10

5. Tests ...................................................................... 10

6. Maintenance .......................................................... 10

7. Specifications ........................................................ 11

8. Warranty and Customer Service ........................... 11

FIGURES

Figure 1. Dual LIU Front Panel .................................. 1

Figure 2. DIP Switches................................................ 4

Figure 3. Dual LIU Menu Tree ................................... 6

TABL ES

Table 1. Compliance Codes ........................................ 2

Table 2. Front Panel LEDs.......................................... 3

Table 3. Dual LIU Switch Settings ............................. 5

Table 4. Dual LIU Specifications.............................. 11

Section 61180009L1-5D

Issue 4, May 2006

CLEI Code: VAL2HF0A_ _

1. GENERAL

This practice is an installation and maintenance guide

for the ADTRAN

®

Total Access 1500® Dual Line

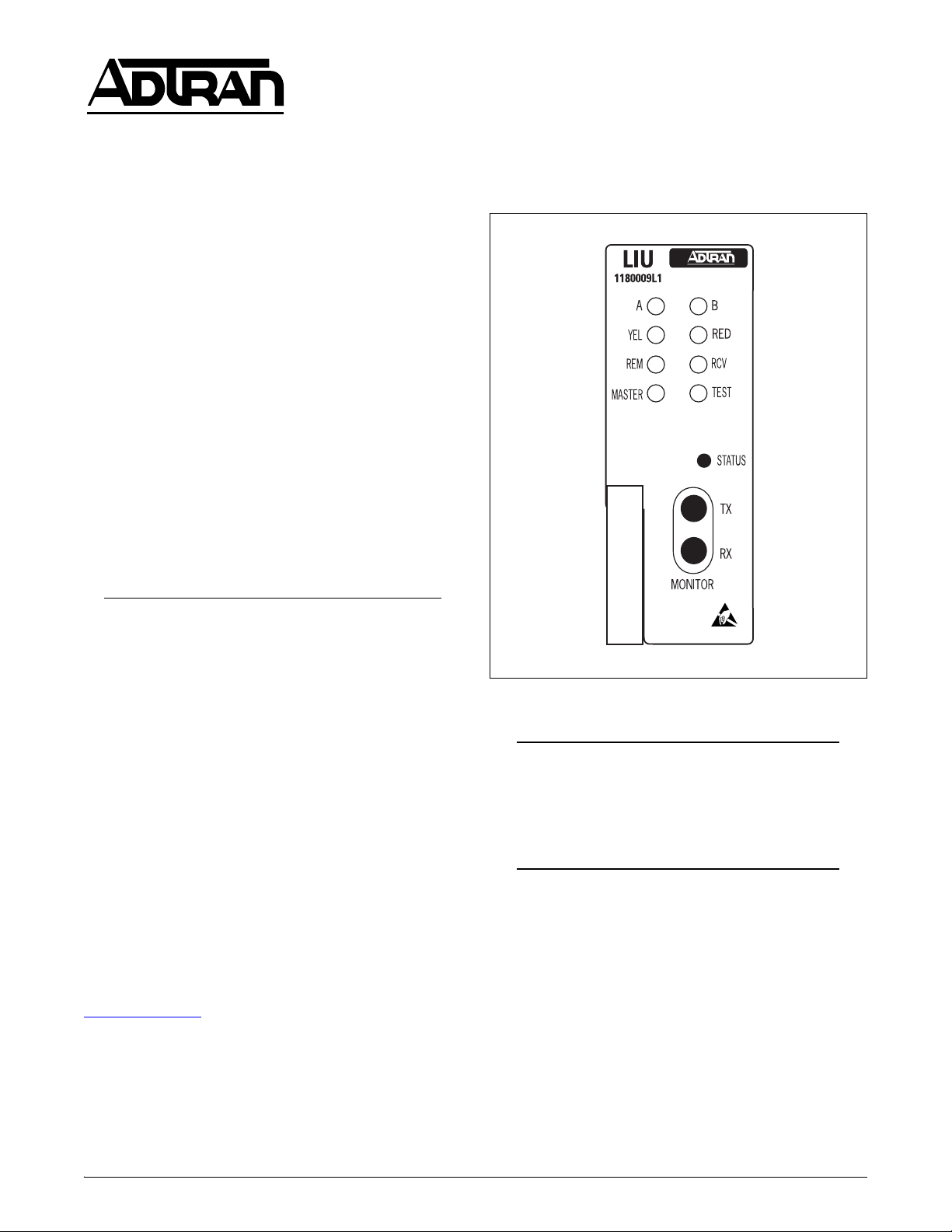

Interface Unit (LIU) Common Module. Figure 1 shows

the Dual LIU (P/N 1180009L1) front panel.

Revision History

This is the fourth issue of this practice. This issue

reflects updates to the Total Access 1500 System

Software Release 3.0, Dual LIU software T07D, and

incorporates the addition of new features including:

• Changed

CLK OOS Alarm in Alarms menu to

Disable as factory default

• Incorporation of automatic mapping for 2B+D

ISDN when in Dual T1 mode

• Removed signaling bits from 4-wire TO

A full list of features is detailed in Total Access 1500

System Release 3.0 Release Notes available at

www.adtran.com

.

Figure 1. Dual LIU Front Panel

NOTE

This release of the LIU software is designed to

operate with System Controller Unit (SCU)

software release V08 or later to support these

feature enhancements.

Description

The Dual LIU is a common module for the Total Access

1500 chassis (P/N 1180001L1) or the Total Access

1500 19-inch chassis (P/N 1180019L1).

The Dual LIU connects the chassis to a T1 line at the

DSX-1 or DS1 level. All data formatting and line

encoding as well as backplane timing and control are

performed by the Dual LIU.

61180009L1-5D 1

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

Page 2

Features

The basic features of the Dual LIU include the

following:

2. INSTALLATION

• Terminates up to 2 T1 lines providing DSX-1 or

DS1 interface to the network

• Supports up to 48 DS0s

• SF or ESF data framing formats

• AMI or B8ZS line code formats

• Local and remote loopbacks

• Front panel bantam jacks for monitoring T1s

• Local, loop, or external timing modes

• Supports ANSI T1.403 in-band payload and line

loopback

Compliance

Table 1 shows the compliance codes for the Dual LIU.

The Dual LIU is NRTL listed to the applicable UL

Listing.

The Total Access 1500 chassis frame ground terminal

must be connected to an earth ground to ensure that the

front panel of the Dual LIU is properly grounded via the

backplane connector.

Table 1. Compliance Codes

Code Input Output

Power Code (PC) F C

Telecommunication Code (TC) – X

C A U T I O N !

SUBJECT TO ELECTROSTATIC DAMAGE

OR DECREASE IN RELIABILITY.

HANDLING PRECAUTIONS REQUIRED.

After unpacking the Dual LIU, inspect it for damage. If

damage has occurred file a claim with the carrier, then

contact ADTRAN Customer Service. Refer to the

Warranty and Customer Service section for further

information. If possible, keep the original shipping

container for returning the Dual LIU for repair or for

verification of shipping damage.

Shipping Contents

The contents include the following items:

•Dual LIU

• Dual LIU Installation and Maintenance Practice

CAUTION

Electronic modules can be damaged by ESD.

When handling modules, wear an antistatic

discharge wrist strap to prevent damage to

electronic components. Place modules in

antistatic packing material when transporting

or storing. When working on modules, always

place them on an approved antistatic mat that is

electrically grounded.

Installation Code (IC) A –

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

1. This device cannot cause harmful interference.

2. This device must accept any interference received,

including interference that can cause undesired

operation.

Changes or modifications not expressly approved by

ADTRAN could void the user’s authority to operate this

equipment.

Instructions for Installing the Module

The Dual LIU plugs directly into the Total Access 1500

channel bank. No installation wiring is required.

The Dual LIU should be installed in the Total Access

1500 channel bank in the slot labeled

LIU-A or LIU-B.

Refer to Provisioning on page 4 prior to card insertion.

CAUTION

This release of the LIU software is designed to

operate with SCU software release V08 or later

to support feature enhancements. SCU

software can be found at www.adtran.com

under the Service/Support page.

To install the Dual LIU, perform the following steps:

1. If present, remove the LIU Blank (P/N 1180010L1)

from the appropriate LIU common module slot of

the Total Access 1500 chassis.

2 Issue 4, May 2006 61180009L1-5D

Page 3

2. Hold the Dual LIU by the front panel while

supporting the bottom edge.

3. Align the Dual LIU card edges to the guide

grooved for the slot designated

LIU-A.

4. Insert the Dual LIU until the edge connector seats

firmly into the backplane.

5. Push the ejector in place to ensure the Dual LIU is

fully seated.

NOTE

An additional

LIU-B slot is also provided for

optional redundancy. For dual operation, only

Dual LIUs of the same software revision

should be installed.

Table 2. Front Panel LEDs

Label Condition Description

When the Dual LIU first powers up it performs the

power up self-tests, which check the DRAM and

checksum. Once the power up self-test is complete, the

status LEDs will reflect the true state of the hardware.

Front Panel LEDs

The front panel LEDs provide status and alarm information. See Table 2 for LED descriptions.

Front Panel Pushbutton

A pushbutton switch labeled

STATUS is accessible

from the front panel to aid in test and troubleshooting.

MONITOR TX and RX bantam jacks are provided

The

for T1 access.

NOTE

TX = Transmit (Out) and RX = Receive (In)

A

B

RED

YEL

RCV

REM

TEST

MASTER

Red

Yellow

Green

Flashing

Off

Red

Yellow

Green

Flashing

Off

Red ON = Monitored T1 in Red Alarm

Yellow ON = Monitored T1 in Yellow Alarm

Red ON = Monitored T1 bipolar or logic error detected

Green

Off

Yellow ON = Test Mode Active

Green

ON = T1-A in Red Alarm

ON = T1-A in Yellow Alarm

ON = T1-A Active

FLASHING = T1-A in Test

OFF = In Monitor Mode

ON = T1-B in Red Alarm

ON = T1-B in Yellow Alarm

ON = T1-B Active

FLASHING = T1-B in Test

OFF = In Monitor Mode

ON = Remotely Provisioned (Craft or Network)

OFF = Locally Provisioned (DIP Switches)

ON = Online Unit

Flashing

STATUS

61180009L1-5D Issue 4, May 2006 3

Switch Momentary activation cycles through the T1s for monitoring purposes. Activating

FLASHING = Provisioning in progress. Failover not possible.

the switch for two or more seconds will cause provisioning to toggle between local

and remote.

Page 4

3. PROVISIONING

All options on the Dual LIU are provisionable either

manually, using internal DIP switches, or electronically

using the SCU

ADMIN port.

Windows HyperTerminal

Windows HyperTerminal can be used as a VT100

terminal emulation program. Refer to the Help section

of HyperTerminal for additional information.

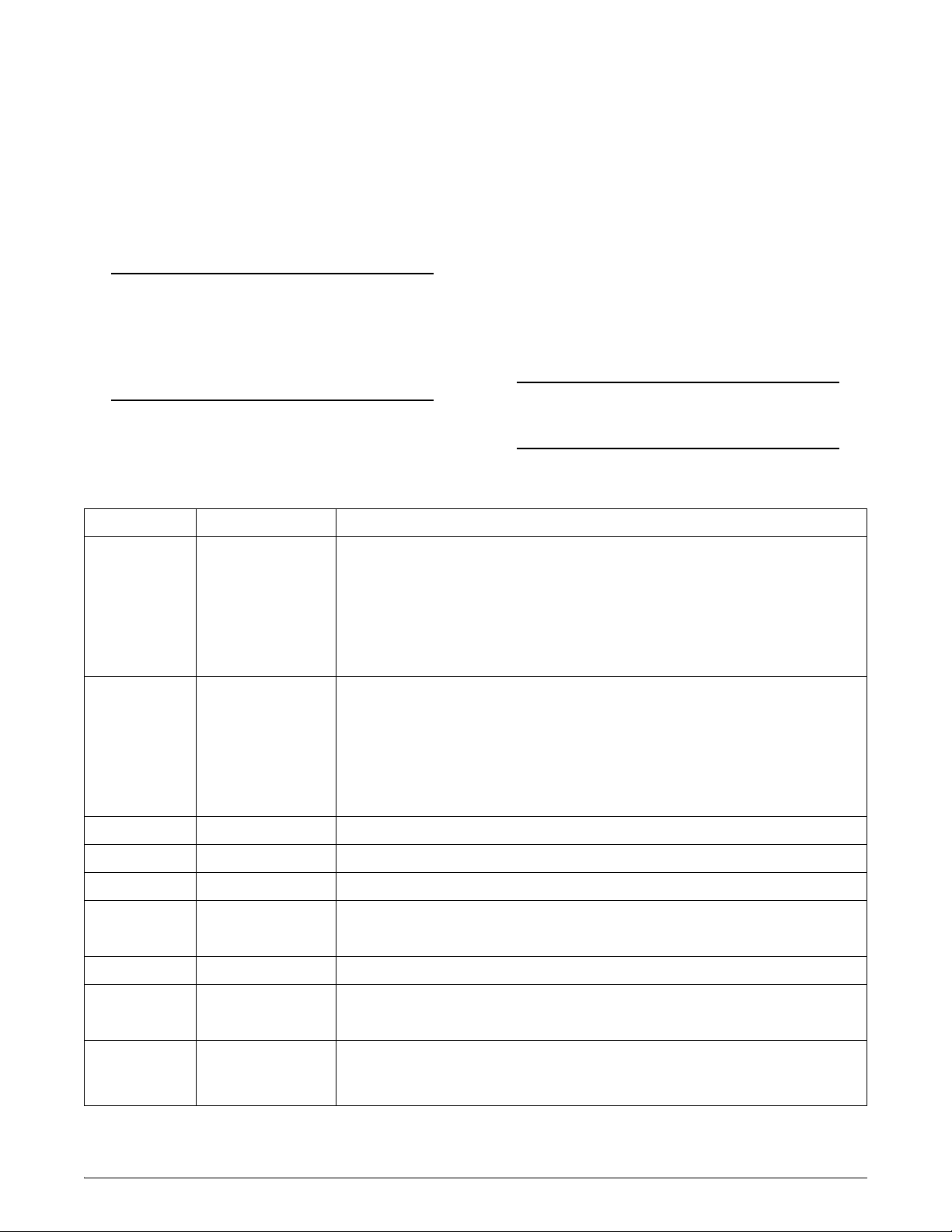

Manual Provisioning

The DIP switches SW1 and SW2 provide the Total

Access 1500 with the necessary option settings for

DSX/DS1 modes of operation. Figure 2 shows the

orientation of the DIP switches. Ta bl e 3 on page 5

shows the available DIP switch settings.

ON

123

OFF

12345678

Figure 2. DIP Switches

NOTE

DIP switch settings can be used for the initial

turn up of the system, and will automatically

assign time slots to physical slots, depending

on the setting selected. If any setting is

changed via the VT100 interface, the

REM

LED on the front panel will light indicating

that the settings have changed.

Electronic Provisioning

The craft ports on the Total Access 1500 SCU are used

to change default options and obtain access module

status through menu screens. To access the menu

screens, connect a VT100 terminal or computer running

a terminal emulation program to the SCU front panel

ADMIN port using a standard male RS-232, DB-9 cable.

ADMIN port settings are as follows:

• 9600 baud

• No parity

• 8 data bits

• 1 stop bit

• No flow control

NOTE

To ensure proper display background, select

VT100 terminal emulation under Settings.

Password and User ID

Password protection is a function of the SCU and is

factory disabled. If password authentication is enabled,

then the SCU will display the Logon screen. A valid

User Name and Password are required to access menus.

NOTE

The factory default User Name is “user”, and

the default Password is “password”. The User

Name and Password are not case sensitive.

Menu Navigation

To traverse through the menus, select the desired entry

and press

the

Enter. To work backward in the menu press

Esc key.

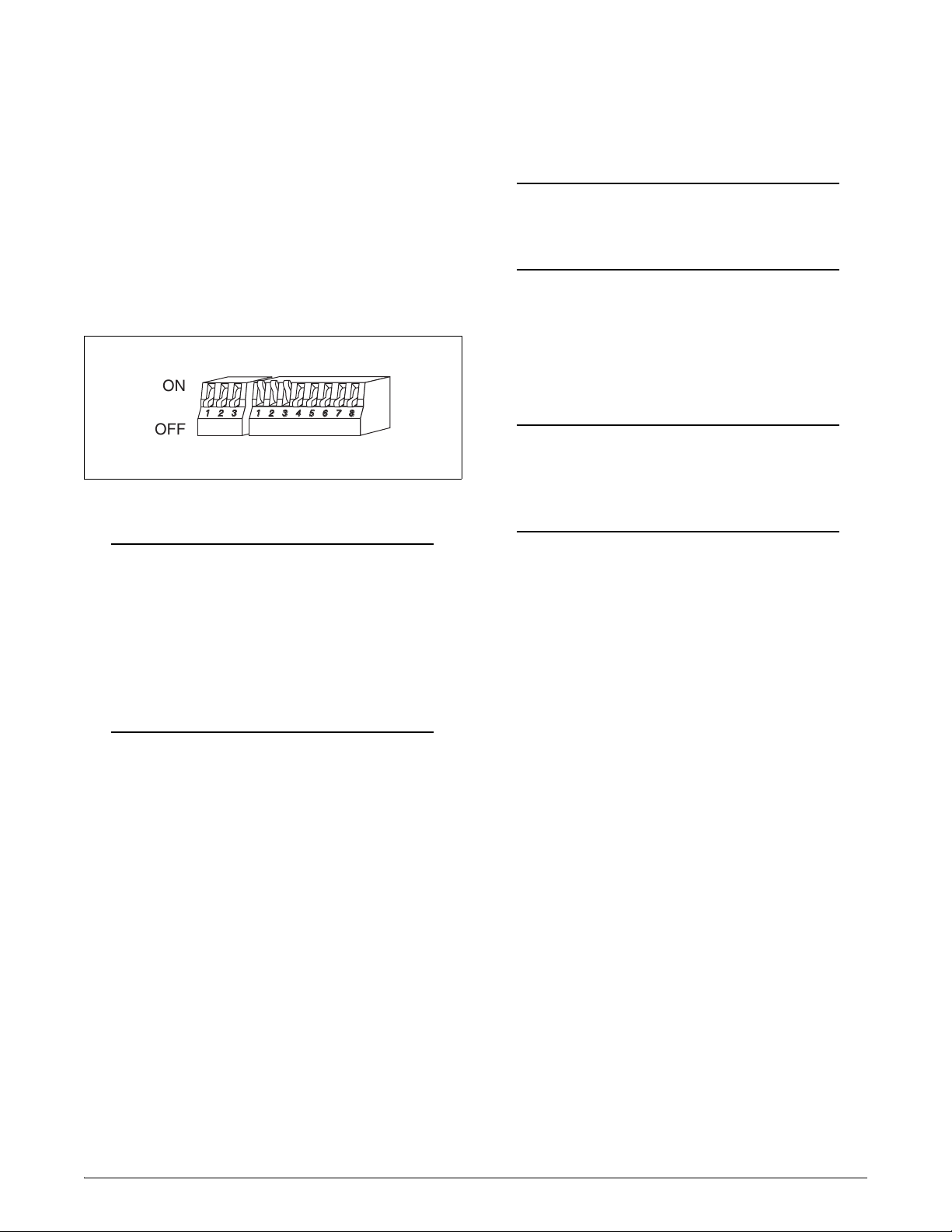

The menu tree in Figure 3 on page 6 illustrates the path

to every provisioning, performance, and test access

point in the Total Access 1500 Dual LIU menu.

Menus

The following subsections describe the Dual LIU menu

screens.

Main Menu

The LIU main menu provides access to the Dual LIU for

various functions such as viewing configuration, provisioning, viewing the current status of the module, setup

of alarms, testing, and performance monitoring.

Configuration Screen

The LIU Configuration screen is a read-only display. It

provides configuration data pertaining to the Dual LIU

and cannot be changed. Information such as unit name,

CLEI code, part number, product revision, and software

revision are displayed. Items such as Software Revision

will reflect new software revisions as upgrades are

performed.

4 Issue 4, May 2006 61180009L1-5D

Page 5

Table 3. Dual LIU Switch Settings

Switch Function Description

SW1 DSX-1 Line Build Out

and DS1 Attenuation

SW2-1

OFF

ON

SW2-2

OFF

ON

Line Code Format

AMI

B8ZS*

Framing Format

SF

ESF*

Selects the Line Build Out in feet; Attenuation in Decibels (dB)

Distance SW1-1 SW1-2 SW1-3

0-133 (Feet)/0 dB* OFF OFF OFF

133-266 OFF OFF ON

266-399 OFF ON OFF

399-533 OFF ON ON

533-655 ON OFF OFF

–7.5 dB ON OFF ON

–15 dB ON ON OFF

–22.5 dB ON ON ON

Enables Bipolar Eight Zero Substitution (B8ZS), which allows for Clear Channel

operation for the T1 carrier system, or Alternate Mark Inversion (AMI). This

option must be configured identically with all other T1 network equipment on this

circuit.

Enables either Extended Superframe Format (ESF) or Superframe Format (SF).

This option must be configured identically with all other T1 network equipment on

this circuit.

SW2-3

SW2-4

SW2-5

SW2-6

SW2-7

* Denotes factory default settings

Note: SW1-1 through SW2-4 set up both T1s identically.

Timing Mode Determines a clock source for the Total Access 1500 channel bank.

Function SW2-3 SW2-4

Local clock – provided by local LIU OFF OFF

Loop A clock – uses recovered clock from T1 bit

stream*

External clock input ON OFF

Terminal Mode Select the appropriate Terminal Type and counting mode for the Total Access 1500

system.

Terminal Mode Counting SW2-5 SW2-6 SW2-7

D4* D4 OFF OFF OFF

D4 D1D OFF OFF ON

Dual D4 D4 OFF ON OFF

OFF ON

61180009L1-5D Issue 4, May 2006 5

Page 6

1. Configuration

Unit Name

CLEI Code

Part Number

Product Revision

Software Revision

2. Provisioning

1. Bank Provisioning

2. DS1 Circuit Provisioning

1. Bank Mode

2. Counting Sequence

3. Inband Loopback

1. Circuit Select

2. Operation State

3. Line Buildout

1. Single T1

2. Dual T1

3. Manual Map

1. D4

2. D1D

1. Enable

2. Disable

1. Circuit A

2. Circuit B

1. Enable

2. Disable

1. 0-133 ft.

2. 133-266 ft.

3. 266-399 ft.

4. 399-533 ft.

5. 533-655 ft.

6. 0 dB

7. -7.5 dB

8. -15 dB

9. -22.5 dB

4. Line Code

5. Framing

1. Clock Mode

3. Timing Provisioning

2. Primary Timing Source

3. Secondary Timing Source

4. Time Slot Assignment

A

1. Assign by Card Slot

2. Assign T1 A

3. Assign T1 B

1. B8ZS

2. AMI

1. ESF

2. SF

1. Non-revertive

2. Revertive

1. Local

2. Loop A

3. Loop B

4. CLK

Figure 3. Dual LIU Menu Tree

6 Issue 4, May 2006 61180009L1-5D

Page 7

A

3. Status

4. Alarms

5. Test

Circuit A

Circuit B

Timing Source

Bank Mode

1. CLK OOS Alarm

1. T1 Loopbacks

2. T1 Monitor Select

Line Buildout

LIne Code

Framing

Inband Loopback

Loopback

Loop Status

Primary

Secondary

Current

1. Enable

2. Disable

1. T1-A

2. T1-B

1. None

2. T1 A

3. T1 B

1. None

2. Local

3. Line & Local

4. Payload

5. Line

6. Remote Inband

7. Remote Line*

8. Remote Payload*

6. Performance Monitoring

* Not available in SF Framing.

4. LIU Reset

1. Daily

2. Far-End Daily

3. Qtr-Hour

4. Far-End Qtr-Hour

5. Daily Threshold

6. FE Daily Threshold

7. Qtr-Hour Threshold

8. FE Qtr-Hour Threshold

9. Reset Performance Registers

10. Restore Factory Default Thresholds

11. Enable all LIU Threshold Alarms

12. Disable all LIU Threshold Alarms

13. Select T1

1. T1-A

2. T1-B

Figure 3. Dual LIU Menu Tree (continued)

61180009L1-5D Issue 4, May 2006 7

Page 8

Provisioning Menu

The Dual LIU Provisioning menu is a top-level provisioning screen which contains several other provisioning categories that allow users to make provisioning

changes to the Dual LIU.

The provisioning categories are listed below with all

respective submenus listed under each category.

3. Line Buildout: This option is used to select the

line length or the attenuation loss of the selected

T1. Option include the following:

• 0-133 feet

• 133-266 feet

• 266-399 feet

Bank Provisioning

The Bank Provisioning menu items are used to set

general channel bank provisioning settings. Options

include the following:

1. Bank Mode: This option is used to select the bank

mode for the Total Access 1500. Options include

the following:

•Single T1

•Dual T1

•Manual Map

NOTE

If Manual Map is selected, time slots must be

assigned using the

Time Slot Assignment

option from the LIU Provisioning menu.

2. Counting Sequence: This option is used to select

the counting sequence of the selected T1. The

options include the following

•D4

•D1D

3. In-band Loopback: This option is used to enable

or disable ANSI T1.403 in-band loopbacks.

• 399-533 feet

• 533 - 655 feet

•0 dB

• –7.5 dB

•–15 dB

• –22.5 dB

4. Line Code: This option is used to select the line

coding type. Options include the following:

• B8ZS: This option is used to enable Bipolar Eight

Zero Substitution (B8ZS), which allows for Clear

Channel operation for the T1 carrier system. This

option must be configured identically with all

other T1 network equipment on this circuit.

• AMI: This option is used to enable Alternate

Mark Inversion (AMI). This option must be

configured identically with all other T1 network

equipment on this circuit.

5. Framing: This option is used to select the framing

format for the selected T1. This setting must be

configured identically with all other T1 network

equipment on this circuit. Options include the

following:

• ESF: This option is used to enable Extended

Superframe Format.

DS1 Circuit Provisioning

The DS1 Circuit Provisioning menu items are used to

• SF: This option is used to enable Superframe

Format.

provision the DS1 circuit. Options include the

following:

Timing Provisioning

The Timing Provisioning menu items are used to

1. Circuit Select: This option is used to select the

circuit to be provisioned. The options include the

establish the clock mode and primary and secondary

timing source. Options include the following:

following:

1. Clock Mode: Options include Non-revertive or

• Circuit A

• Circuit B

2. Operation State: This option is used to enable or

disable the operation state of circuits A and B.

8 Issue 4, May 2006 61180009L1-5D

Revertive clock mode. This decision should be

based on whether a primary and secondary timing

source are available. In the event that the primary

timing source is lost, the Dual LIU will automatically switch to the secondary timing source.

Page 9

• Revertive: This option allows the unit to revert to

the primary timing source if and when it becomes

available.

• Non-revertive: This option allows the unit to

remain on the secondary timing source. If Nonrevertive is chosen and the secondary timing

source becomes active due to a primary timing

source failure and the secondary source fails, the

unit will switch to the primary timing source if it

has become available.

2. Primary Timing Source: This option is used to

select the primary timing source for the T1s.

Options include the following:

•Local

• Loop A

• Loop B

•CLK

3. Secondary Timing Source: This option is used to

select the secondary timing source for the T1s.

Options include the following:

•Local

• Loop A

• Loop B

•CLK

This timing source will become the current timing

source if the primary timing source is lost. If both

timing sources are lost, the timing reverts to local.

As timing sources are regained, the current timing

source reverts to the primary or secondary timing

source as they become available.

Time Slot Assignment

Used to assign time slots when the bank is in manual

map mode. This option allows time slots to be assigned

by T1-A, T1-B, or by the card slot.

Status Screen

The Dual LIU Status screen is used to quickly view the

status of the loops, the provisioned settings for each T1,

the bank mode, M.T.A. status, the settings for primary

and secondary timing, and the status of the timing

source.

Alarms Menu

The Dual LIU Alarms menu is used to enable or disable

the external clock alarms. These alarms should be

enabled when a timing source is connected to the

external clock pins.

Test Menu

The Dual LIU Test menu is used to perform loopbacks,

select which T1 is monitored by the front panel monitor

jacks, or reset the Dual LIU.

Performance Monitoring Menu

The Dual LIU collects and stores the Performance

Monitoring (PM) information statistics for each of the

T1s. This PM information is stored in non-volatile

memory and is accessible through the Performance

Monitoring menu. A brief description of the various

options follows:

1. Daily: This option is used to display daily counts

of multiple performance monitoring statistics.

2. Far-End Daily: This option is used to display

daily counts of multiple performance monitoring

statistics associated with the far-end.

3. Qtr-Hour: This option is used to display counts of

performance monitoring statistics in seven 15minute intervals.

4. Far-End Qtr-Hour: This option is used to display

counts of performance monitoring statistics in

seven 15-minute intervals associated with the farend.

5. Daily Threshold: This option is used to set

threshold points for daily counts and enable or

disable an alarm that would occur when this

threshold is exceeded.

6. FE Daily Threshold: This option is used to set

threshold points for far-end daily counts and enable

or disable an alarm that would occur when this

threshold is exceeded.

7. Qtr-Hour Threshold: This option is used to set

threshold points for 15-minute counts and enable

or disable an alarm that would occur when this

threshold is exceeded.

8. FE Qtr-Hour Threshold: This option is used to

set far-end threshold points for 15-minute counts

and enable or disable an alarm that would occur

when this threshold is exceeded.

9. Reset Performance Registers: This option is used

to reset all performance registers.

10. Restore Factory Default Thresholds: This option

is used to reset thresholds back to factory defaults.

11. Enable all LIU Threshold Alarms: This option is

used to enable all Dual LIU threshold alarms.

12. Disable all LIU Threshold Alarms: This option is

used to disable all Dual LIU threshold alarms.

61180009L1-5D Issue 4, May 2006 9

Page 10

13. Select T1: This option is used to select the T1 for

which performance monitoring statistics will be

displayed.

For each statistic, the following specific data is stored:

Payload Loopback

For a Payload Loopback, the T1 data is looped back

toward the network. The framing pattern, CRC6 calculation, and FDL bits are not looped back.

• Near End – Line: Code Violations (BVP), Errored

Seconds (ES), and Severely Errored Seconds (SES)

• Near End – Path: Code Violation (BVP), Errored

Seconds (ES), Severely Errored Seconds (SES),

Bursty Errored Seconds (BES), Severely Errored

Framing Seconds (SEFS), Controlled Slip Seconds

(CSS), and Unavailable Seconds (US)

• Far End – Path: Code Violation (BVP), Errored

Seconds (ES), Severely Errored Seconds (SES),

Bursty Errored Seconds (BES), Severely Errored

Framing Seconds (SEFS), Controlled Slip Seconds

(CSS), and Unavailable Seconds (US)

The threshold for each statistic can be independently

enabled, disabled, or have a specific value entered.

When enabled, and crossing of the threshold value will

result in a threshold entry into the Total Access 1500

Alarm Log. All thresholds are defaulted to disabled.

4. ALARMS

The Dual LIU supports an external clock input out-ofservice alarm and can be enabled or disabled. When the

alarms are enabled, an alarm condition will be created

when the external timing source is lost.

5. TESTS

The Test menu controls testing for the Dual LIU. The

Test menu allows the user to select either T1 A or B for

testing, perform local and remote loopbacks, select

which T1 to monitor, and reset the Dual LIU. The

loopbacks are described below.

Line Loopback

For a Line Loopback, the T1 data is looped back toward

the network with framing and line coding unchanged.

Remote In-band Loopback

A Remote In-band Loopback initiates the transmission

of an in-band line loopback code toward the far end as

specified in ANSI T1.403.

Remote Line Loopback

A Remote Line loopback initiates the transmission of a

Facility Data Link (FDL) line loop up toward the ar end

as specified ANSI T1.403. This loopback is only

available when the Total Access 1500 is provisioned for

Extended Superframe (ESF).

Remote Payload Loopback

A Remote Payload Loopback initiates the transmission

of a FDL Payload loop up code toward the far end as

specified in ANSI T1.403. This loopback is only

available when the Total Access 1500 is provisioned for

Extended Superframe (ESF).

6. MAINTENANCE

The Dual LIU requires no routine maintenance for

normal operation.

ADTRAN does not recommend that repairs be

attempted in the field. Repair services can be obtained

by returning the defective unit to ADTRAN. Refer to

the Warranty and Customer Service section for further

information.

Loopback Tests

The Dual LIU supports loopback tests to aid circuit

turnup and maintenance efforts. These tests are initiated

from the Total Access Site Manager or the Total Access

1500 local

ADMIN port on the SCU.

Local Loopback

T1 data is looped back toward the customer. The

transmit data is looped back after it has passed through

the framer and Dual LIU circuitry.

Line and Local Loopback

The Dual LIU supports a bi-directional loopback via

menu access only. The loopback in the network

direction will be of a line loopback type.

10 Issue 4, May 2006 61180009L1-5D

Page 11

7. SPECIFICATIONS

Specifications for the Dual LIU are detailed in Table 4.

Table 4. Dual LIU Specifications

Specification Description

Environmental

Operating Temperature:

–40°C to +65°C

8. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within the

warranty period if it does not meet its published specifications or fails while in service. Warranty information

can be found at www.adtran.com/warranty

.

Refer to the following subsections for sales, support,

Customer and Product Service (CAPS) requests, or

further information.

Storage Temperature:

Relative Humidity:

Maximum Current Draw

@ –48 VDC:

Maximum Heat

Dissipation:

Physical

Dimensions:

Weig ht :

Part Number

Total Access 1500

Dual LIU: 1180009L1

–40°C to +85°C

95 percent maximum @

50°C, noncondensing

Online: 0.042 amps

Offline: 0.025 amps

Online: 2.02 watts

Offline: 1.21 watts

Height: 3.125 inches

Width: 1.14 inches

Depth: 10.1 inches

0.9 pounds

ADTRAN Sales

Pricing/Availability:

800-827-0807

ADTRAN Technical Support

Pre-Sales Applications/Post-Sales Technical

Assistance:

800-726-8663

Standard hours: Monday - Friday, 7 a.m. - 7 p.m. CST

Emergency hours: 7 days/week, 24 hours/day

ADTRAN Repair/CAPS

Return for Repair/Upgrade:

(256) 963-8722

Repair and Return Address

Contact CAPS prior to returning equipment to

ADTRAN.

ADTRAN, Inc.

CAPS Department

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

61180009L1-5D Issue 4, May 2006 11

Page 12

®

12 Issue 4, May 2006 61180009L1-5D

Loading...

Loading...