Page 1

PCI-8154

Advanced & Modulized

4-Axis Servo / Stepper

Motion Control Card

User’s Manual

Manual Rev. 2.00

Revision Date: February 22, 2006

Part No: 50-11146-1000

Advance Technologies; Automate the World.

Page 2

Copyright 2007 ADLINK TECHNOLOGY INC.

All Rights Reserved.

The information in this document is subject to change without prior

notice in order to improve reliability , design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, elec tronic, or other means in a ny form

without prior written permission of the manufacturer.

Trademarks

NuDAQ, NuIPC, DAQBench are registered trademarks of ADLINK

TECHNOLOGY INC.

Product names mentioned herein are used for identification pur-

poses only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK Technology Inc.

Please contact us should you require any service or assistance.

ADLINK TECHNOLOGY INC.

Web Site: http://www.adlinktech.com

Sales & Service: Service@adlinktech.com

TEL: +886-2-82265877

FAX: +886-2-82265717

Address: 9F, No. 166, Jian Yi Road, Chungho City,

Taipei, 235 Taiwan

Please email or FAX this completed service form for prompt and

satisfactory service.

Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX:

Web Site

Product Information

Product Model

OS:

Environment

M/B: CPU:

Chipset: BIOS:

Please give a detailed description of the problem(s):

Page 4

Page 5

Table of Contents

Table of Contents..................................................................... i

List of Tables........................................................................... v

List of Figures........................................................................ vi

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 4

1.2 Specifications....................................................................... 6

1.3 Supported Software............................................................. 8

Programming Library ........................................ ... ...........8

MotionCreatorPro ........................................................... 8

1.4 Available Terminal Board..................................................... 8

2 Installation .......................................................................... 9

2.1 Package Contents ............................................................... 9

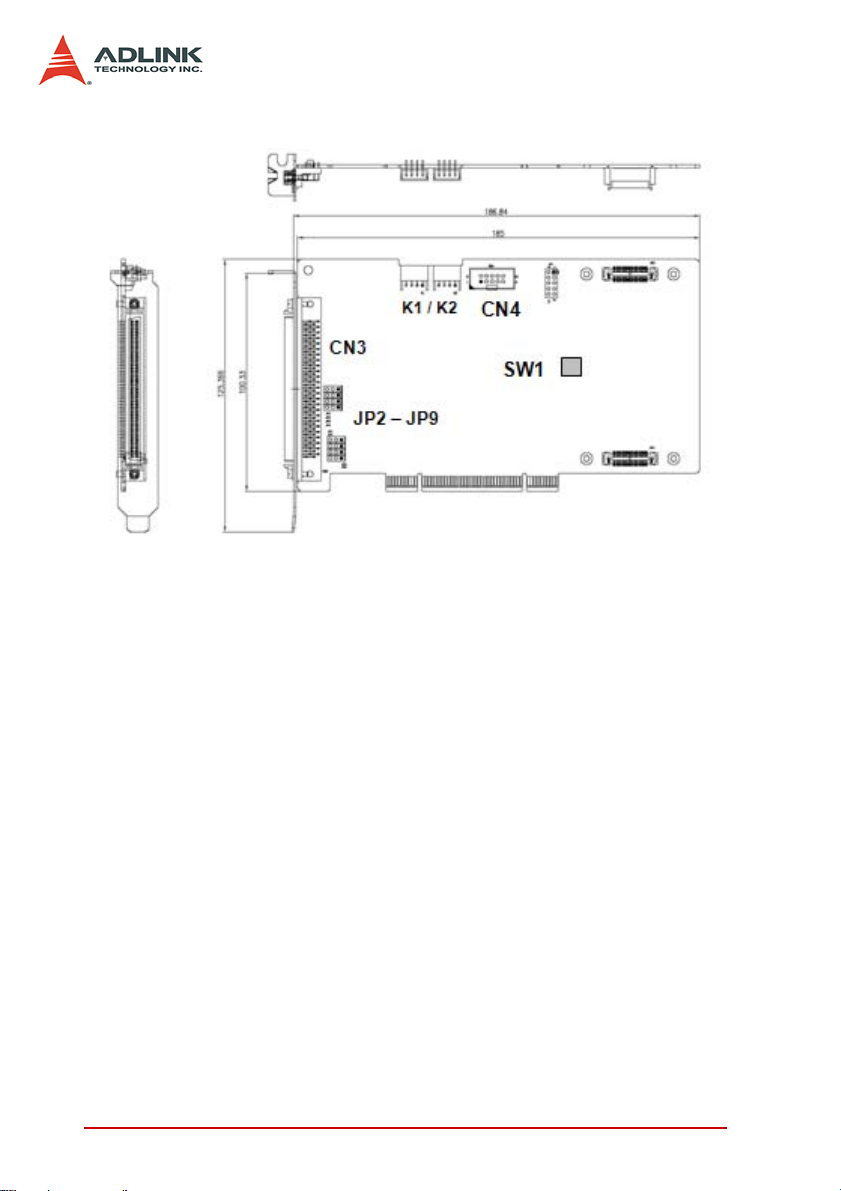

2.2 PCI-8154 Outline Drawing................................................. 10

2.3 PCI-8154 Hardware Installation......................................... 11

Hardware configuration .................................................11

PCI slot selection ................. ... ... .... ... ... ... ......................11

Installation Procedures .................................................11

Troubleshooting4: ................................ ......................... 11

2.4 Software Driver Installation................................................ 13

2.5 CN3 Pin Assignments: Main Connector ............................ 13

2.6 K1/K2 Pin Assignments: Simultaneous Start/Stop ............ 15

2.7 JP2 to JP9 Jumper Setting for Pulse Output ..................... 15

2.8 SW1 Card Index Selection................................................. 16

2.9 CN4 Manual Pulsar............................................................ 17

3 Signal Connections.......................................................... 19

3.1 Pulse Output Signals OUT and DIR .................................. 20

3.2 Encoder Feedback Signals EA, EB and EZ....................... 23

3.3 Origin Signal ORG............................................................. 26

3.4 End-Limit Signals PEL and MEL........................................ 27

3.5 In-position Signal INP ........................................................ 28

3.6 Alarm Signal ALM.............................................................. 29

3.7 Deviation Counter Clear Signal ERC................................. 30

3.8 General-purpose Signal SVON............... ... ... ... .... ... ... ... .... . 31

Table of Contents i

Page 6

3.9 General-purpose Signal RDY ............................................ 32

3.10 Multi-Functional output pin: DO/CMP ................................ 33

3.11 Multi-Functional input pin: DI/LTC/SD/PCS/CLR/EMG...... 34

3.12 Pulser Input Signals PA and PB (PCI-8154)...................... 35

3.13 Simultaneously Start/Stop Signals STA and STP.............. 36

4 Operation Theory.............................................................. 39

4.1 Classifications of Motion Controller.................................... 39

Voltage motion control interface ................................... 39

Pulse motion control interface ......................................40

Network motion control interface .................................. 40

Software real-time motion control kernel ..................... .41

DSP motion control kernel ............................................41

ASIC motion control kernel ...........................................41

Compare Table of all motion control types ...................42

PCI-8154 motion controller type ...................................42

4.2 Motion Control Modes........................................................ 43

Coordinate system ........................................................43

Absolute and relative position move .............................44

Trapezoidal speed profile .............................................45

S-curve and Bell-curve speed profile .................. .......... 46

Velocity mode ...............................................................48

One axis position mode ................................................49

Two axes linear interpolation position mode .................50

Two axes circular interpolation mode ...........................51

Continuous motion ........................................................52

Home Return Mode ......................................................55

Home Search Function .................................................62

Manual Pulser Function ................................................63

Simultaneous Start Function .........................................63

Speed Override Function ..............................................64

Position Override Function ...........................................65

4.3 The motor driver interface.................................................. 66

Pulse Command Output Interface ................................66

Pulse feedback input interface ......................................69

In position signal ... .... ... ... ... .... ... ... ... ..............................71

Servo alarm signal ........................................................71

Error clear signal ...........................................................72

Servo ON/OFF switch ..................... ..............................72

Servo Ready Signal ......................................................73

ii Table of Contents

Page 7

Servo alarm reset switch ..............................................73

4.4 Mechanical switch interface............................................... 74

Original or home signal .................................................74

End-Limit switch signal .................................................74

Slow down switch .........................................................74

Positioning Start switch .................................. ... ... ... .... .. 75

Counter Clear switch ....................................................75

Counter Latch switch ....................................................75

Emergency stop input ...................................................75

4.5 The Counters................................................... .... ... ... ... .... . 76

Command position counter ...........................................76

Feedback position counter .......................................... .. 77

Command and Feedback error counter ........................77

General purpose counter .............................................. 78

Target position recorder ............................. .... ... ... ... .... .. 78

4.6 The Comparators............................. .................................. 79

Soft end-limit comparators ............................................79

Command and feedback error counter comparators ....79

General comparator ......................................................79

Trigger comparator .......................................................80

4.7 Other Motion Functions ..................................................... 81

Backlash compensation and slip corrections ................81

Vibration restriction function .........................................81

Speed profile calculation function .................................82

4.8 Interrupt Control................................................................. 83

4.9 Multiple Card Operation..................................................... 87

5 MotionCreatorPro............................................................. 89

5.1 Execute MotionCreatorPro ..................... ... ... ..................... 89

5.2 About MotionCreatorPro.................................................... 90

5.3 MotionCreatorPro Introduction........................................... 91

Main Menu ....................................................................91

Select Menu .................................................................. 92

Card Information Menu .................................. ............... 93

Configuration Menu .......... ... ... ... .... ... ... ... ... .... ... ... ... .... .. 94

Single Axis Operation Menu .......................................100

Two-Axis and Four-Axis Operation Menu ................... 108

2D_Motion Menu ........................................................112

Help Menu ..................................................................119

Table of Contents iii

Page 8

6 Function Library.............................................................. 121

6.1 List of Functions. ... ... ... .......................................... .... ... ... . 122

6.2 C/C++ Programming Library............................................ 131

6.3 System and Initialization.................................................. 132

6.4 Pulse Input/Output Configuration..................................... 136

6.5 Velocity mode motion................................ ... ... ... ... .... ... ... . 139

6.6 Single Axis Position Mode ............................................... 142

6.7 Linear Interpolated Motion............................................... 146

6.8 Circular Interpolation Motion.... .... ... ... ... .... ... .................... 155

6.9 Helical Interpolation Motion.......................... .................... 162

6.10 Home Return Mode...................................... ... ... ... .... ... ... . 166

6.11 Manual Pulser Motion............................... ... ... ... ... .... ... ... . 169

6.12 Motion Status................................................................... 172

6.13 Motion Interface I/O ......................................................... 174

6.14 Interrupt Control................................................. .............. 182

6.15 Position Control and Counters......................................... 186

6.16 Position Compare and Latch............................................ 191

6.17 Continuous motion........................................................... 196

6.18 Multiple Axes Simultaneous Operation............................ 198

6.19 General-Purpose DIO.................................. ... ... ... .... ... ... . 201

6.20 Soft Limit............ ... ... ... .... ... ... ... .... .................................... 203

6.21 Backlash Compensation / Vibration Suppression........... . 205

6.22 Speed Profile Calculation................................................. 207

6.23 Return Code.................................... ... .............................. 211

7 Connection Example ...................................................... 213

7.1 General Description of Wiring.. .... ... ... ... .... ... .................... 213

7.2 Terminal Board User Guide............................................. 213

Warranty Policy ................................................................... 215

iv Table of Contents

Page 9

List of Tables

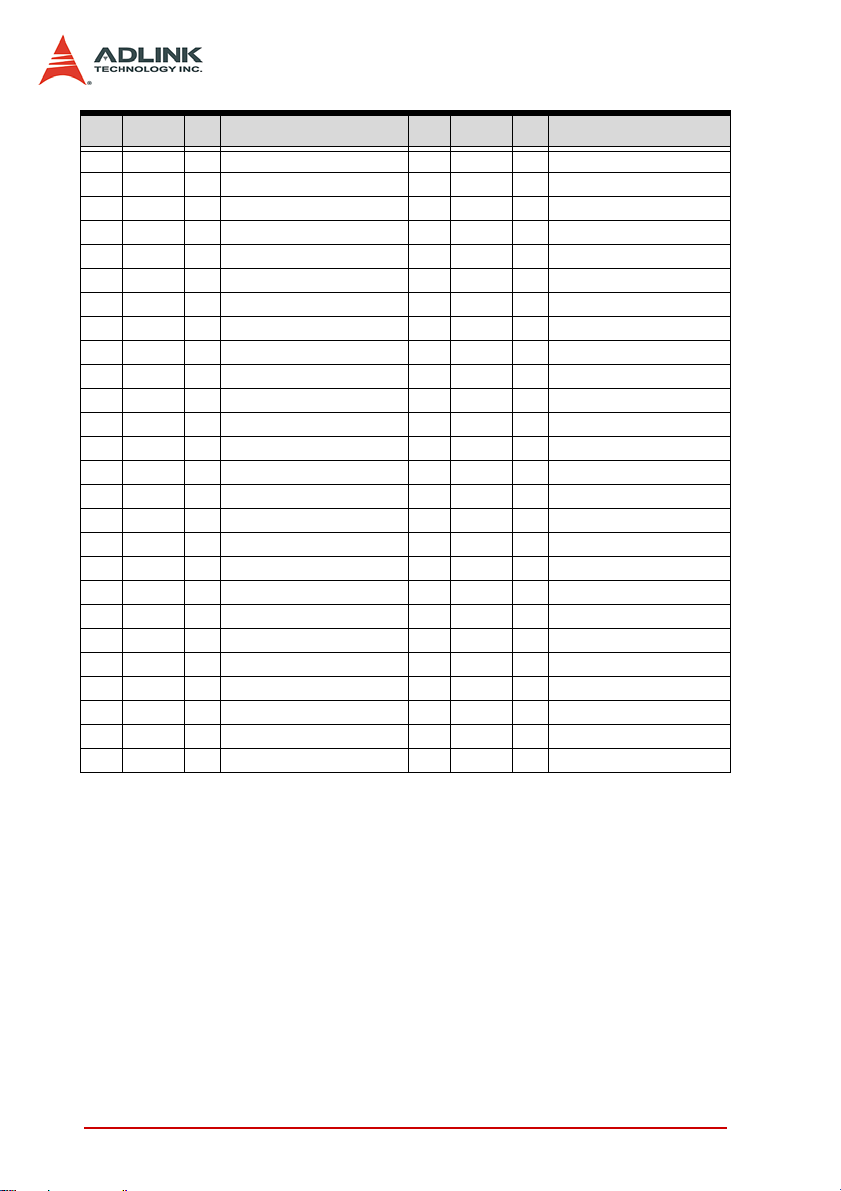

Table 2-1: CN3 Pin Assignments: Main Connector ................. 13

Table 2-2: K1/K2 Pin Assignments: Simultaneous Start/Stop . 15

Table 2-3: SW1 Card Index ..................................................... 16

Table 2-4: CN4 Manual Pulsar ................................................ 17

Table 4-1: Motion Interrupt Source Bit Settings ....................... 84

Table 4-2: Error Interrupt return codes .................................... 85

Table 6-1: Data type definitions ............................................. 131

List of Tables v

Page 10

List of Figures

Figure 1-1: PCI-8154 Block Diagram ........................................... 2

Figure 1-2: Flow chart for building an application ........................ 3

Figure 2-1: PCB Layout of the PCI-8154 ................................... 10

vi List of Figures

Page 11

1 Introduction

The PCI-8154 is an advanced & modulized 4-axis motion controller card with a PCI interface. It can generate high frequ ency pulses

(6.55MHz) to drive stepper or servomotors. As a motion controller,

it can provide 4-axis linear and circular interpolation and continu ous interpolation for continuous velocity. Also, changing position/

speed on the fly is available with a single axis operation.

Multiple PCI-8154 cards can be used in one system. Incremental

encoder interfaces on all eight axes provide the ability to correct

positioning errors generated by inaccurate mechanical transmissions.

The PCI-8154 is a completely new design. This carrier board has

4-axis pulse train output control channels. For additional functions,

such as high-speed triggering or distributed I/O control, you can

add on a daughter board based on requirement. This board has

position compare function. Like the line scan application, the application needs motion controller to generate high speed triggering

pulse and gain the high resolution images. In this situation, you

can adopt a DB-8150 to extend the function on PCI-8154. In addition to motion control, sensors and actuators are key elements in

machine automation. There typically needs to I/O to integrate the

sensors and actuators in the contro ller. ADLINK also provides you

another way to connect these devices: distributed I/O. Using

daughter board, distributed I/O can be achieved with PCI-8154.

This cost-effective configuration can reduce wiring ef fort and physical controller size.

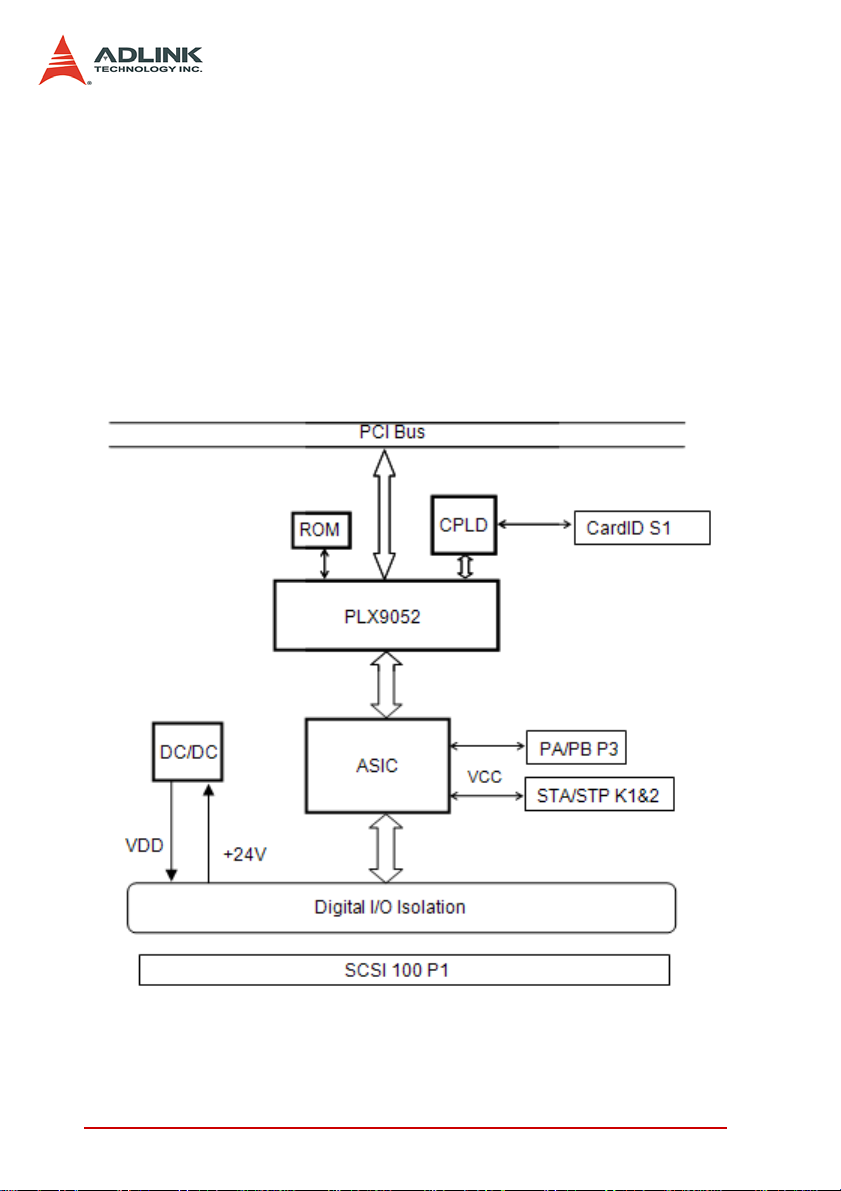

Figure 1-1 shows the functional block diagram of the PCI-8154

card. The motion control functions include trapezoidal an d S-curve

acceleration/deceleration, linear and circular interpolation between

two axes and continuous motion positioning, and 13 home return

modes. All these functions and complex computations are performed internally by the ASIC, thus it can save CPU loading.

The PCI-8154 also offers three user-friendly functions.

1. Card Index Setting:

Introduction 1

Page 12

The card index value of the PCI-8154 can be set with a DIP

switch to a value between 0 and 15. This is useful for machine

makers if the whole control system is very huge.

2. Emergency Input

An emergency input pin can be wired to an emergency button

to stop sending pulse output once activated.

3. Software’s Security Protection

To secure applications, a 16-bit value can be set in the

EEPROM to prevent copying of custom programs.

Figure 1-1: PCI-8154 Block Diagram

2Introduction

Page 13

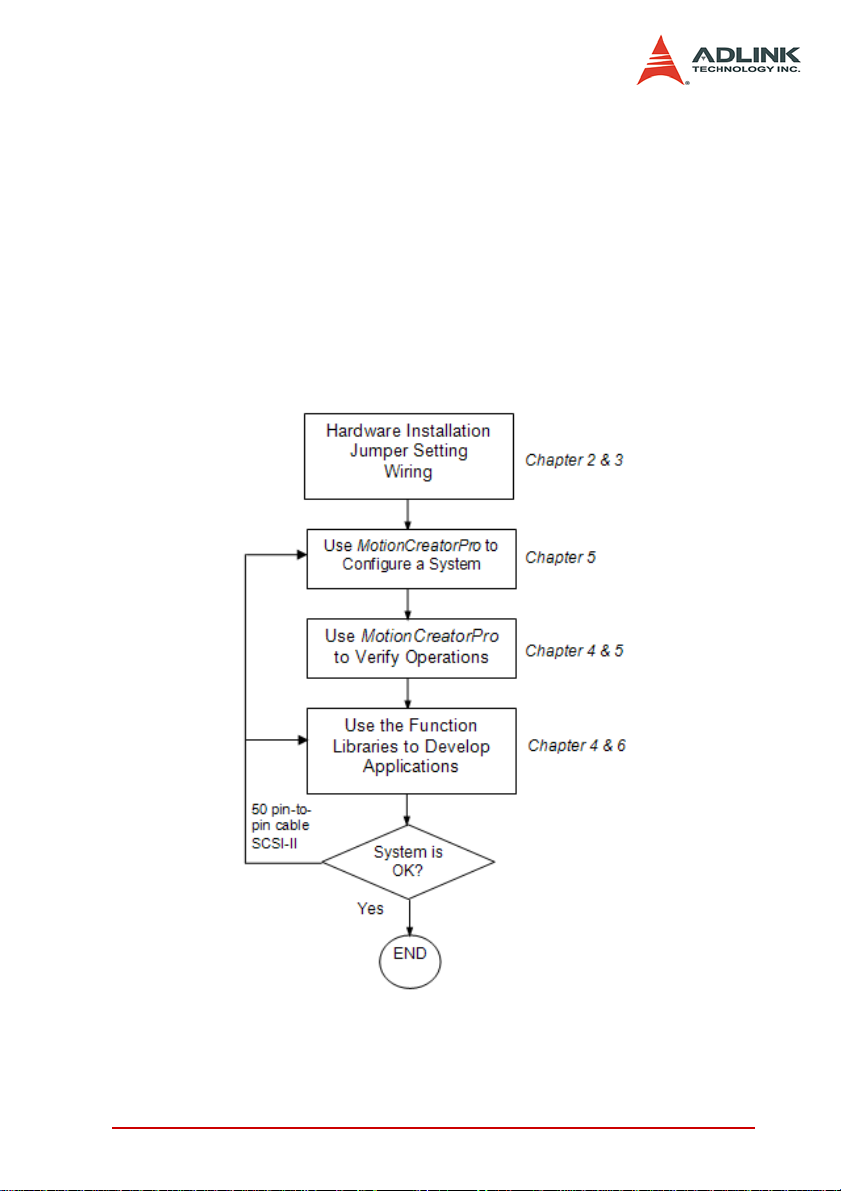

MotionCreatorPro is a Windows-based application development

software package included with the PCI-8154. MotionCreatorPro

is useful for debugging a motion control system during the design

phase of a project. An on-screen display lists all installed axes

information and I/O signal status of the PCI-8154.

Windows programming libraries are also provided for C++ compilers and Visual Basic. Sample programs are provided to illustrate

the operations of the functions.

Figure 1-2 illustrates a flow chart of the recommended process in

using this manual in developing an application. Refer to the

related chapters for details of each step.

Figure 1-2: Flow chart for building an application

Introduction 3

Page 14

1.1 Features

The following list summarizes the main features of the PCI- 8154

motion control system.

X 32-bit PCI bus Plug-and-Play (Universal)

X 4 axes of step and direction pulse output for controlling

stepping or servomotor

X Maximum output frequency of 6.55MPPS

X Pulse output options: OUT/DIR, CW/CCW, AB phase

X Pulse input options: CW/CCW, AB phase x1, x2, x4

X Maximum pulse input frequency of 3.2Mhz in CW/CCW or

AB phase X1 mode (AB phase x4 can reach 6.5Mhz).

X Programmable acceleration and deceleration time for all

modes

X Trapezoidal and S-curve velocity profiles for all modes

X 2 to 4 axes linear interpolation

X 2 axes circular interpolation

X Continuous interpolation for contour following motion

X Change position and speed on the fly

X 13 home return modes with auto searching

X Hardware backlash compensator and vibration suppression

X 2 software end-limits for each axis

X 28-bit up/down counter for incremental encoder feedback

X Home switch, index signal (EZ), positive, and negative end

limit switches interface on all axes

X 4-axis high speed position latch input

X 4-axis position compare and trigger output

X All digital input and output signals are 2500V

X Programmable interrupt sources

X Simultaneous start/stop motion on multiple axes

X Manual pulser input interface

X Card index selection

X Security protection on EERPOM

isolated

rms

4Introduction

Page 15

X Dedicated emergency input pin for wiring

X Software supports a maximum of up to 12 PCI-8154 cards

operation in one system

X Compact PCB design

X Includes MotionCreatorPro, a Microsoft Windows-based

application development software

X PCI-8154 libraries and utilities for Windows 2000/XP/Vista.

Introduction 5

Page 16

1.2 Specifications

Applicable Motors:

X Stepping motors

X AC or DC servomotors with pulse train input servo drivers

Performance:

X Number of controllable axes: 4

X Maximum pulse output frequency: 6.55MPPS, linear, trape-

zoidal, or S-Curve velocity profile drive

X Internal reference clock: 19.66MHz

X 28-bit up/down counter range: 0-268, 435, 455 or –134,

217, 728 to +134, 217, 727

X Position pulse setting range (28-bit): -134, 217, 728 to

+134, 217, 728

X Pulse rate setting range (Pulse Ratio = 1: 65535):

Z 0.1 PPS to 6553.5 PPS. (Multiplier = 0.1)

Z 1 PPS to 65535 PPS. (Multiplier = 1)

Z 100 PPS to 6553500 PPS. (Multiplier = 100)

6Introduction

Page 17

I/O Signales:

X Input/Output signals for each axis

X All I/O signal are optically isolated with 2500Vrms isolation

voltage

X Command pulse output pins: OUT and DIR

X Incremental encoder signals input pins: EA and EB

X Encoder index signal input pin: EZ

X Mechanical limit/home signal input pins: ±EL, ORG

X Composite pins: DI / LTC (Latch) / SD (Slow-down) / PCS

(Position Change Signal) / CLR (Clear) / EMG (Emergency

Input)

X Servomotor interface I/O pins: INP, ALM, and ERC

X General-purposed digital output pin: SVON, DO

X General-purposed digital input pin: RDY, GDI

X Pulse signal input pin: PA and PB (with Isolation)

X Simultaneous Start/Stop signal: STA and STP

General Specifications

X Connectors: 100-pin SCSI-type connector

X Operating Temperature: 0°C - 50°C

X Storage Temperature: -20°C - 80°C

X Humidity: 5 - 85%, non-condensing

Power Consumption

X Slot power supply (input): +5V DC ±5%, 900mA max

X External power supply (input): +24V DC ±5%, 500mA max

X External power supply (output): +5V DC ±5%, 300mA, max

PCI-8154 Dimensions (PCB size):

X 185mm(L) X 100 mm(W)

Introduction 7

Page 18

1.3 Supported Software

1.3.1 Programming Library

Windows 2000/XP/Vista DLLs are provided for the PCI-8154.

These function libraries are shipped with the board.

1.3.2 MotionCreatorPro

This Windows-based utility is used to setup cards, motors, and

systems. It can also aid in debugging hardware and software problems. It allows users to set I/O logic parameters to be loaded in

their own program. This product is also bundled with the card.

Refer to Chapter 5 for more details.

1.4 Available Terminal Board

ADLINK provides the servo & steppers use terminal board for

easy connection. For steppers, we provide DIN-100S which is pinto-pin terminal board. For servo users, ADLINK offers DIN-814M,

DIN-814M-J3A, DIN-814Y and DIN-814P-A4. The suitable servos

are listed as follows:

Mitsubishi J2 Super DIN-814M

Mitsubishi J3A DIN-814M-J3A

Ya skawa Sigma II DIN-814Y

Panasonic MINAS A4 DIN-8 14P-A4

8Introduction

Page 19

2 Installation

This chapter describes how to install PCI-8154. Please follow

these steps below:

X Check what you have (section 2.1)

X Check the PCB (section 2.2)

X Install the hardware (section 2.3)

X Install the software driver (section 2.4)

X Understanding the I/O signal connections (chapter 3) and

their operation (chapter 4)

X Understanding the connector pin assignm e nts (the rem a in-

ing sections) and wiring the connections

2.1 Package Contents

In addition to this User’s Guide, the package also includes the following items:

X PCI-8154: advanced 4-axis Servo / Stepper Motion Control

Card

X ADLINK All-in-one Compact Disc

Note: The terminal board is an optional accessory and would not

be included in PCI-8154 package.

If any of these items are missing or damaged, contact the dealer

from whom you purchased the product. Save the shipping materials and carton to ship or store the product in the future.

Installation 9

Page 20

2.2 PCI-8154 Outline Drawing

Figure 2-1: PCB Layout of the PCI-8154

X CN3: Input / Output Signal Connector (100-pin)

X K1 / K2: Simultaneous Start / Stop Connector

X CN4: Manual Pulsar

X SW1: DIP switch for card index selection (0-15)

X JP2-JP9: Pulse output selection jumper (Line Driver / Open

Collector)

10 Installation

Page 21

2.3 PCI-8154 Hardware Installation

2.3.1 Hardware configuration

The PCI-8154 is fully Plug-and-Play compliant. Hence, memory

allocation (I/O port locations) and IRQ channel of the PCI card are

assigned by the system BIOS. The address assignment is done

on a board-by-board basis for all PCI cards in the system.

2.3.2 PCI slot selection

Some computer system may hav e both PC I and ISA slots. Do not

force the PCI card into a PC/AT slot. The PCI-8154 can be used in

any PCI slot.

2.3.3 Installation Procedures

1. Read through this manual and setup the jumper according to your application

2. Turn off your computer. Turn off all accessories (printer,

modem, monitor, etc.) connected to computer. Remove

the cover from the computer.

3. Select a 32-bit PCI expansion slot. PCI slots are shorter

than ISA or EISA slots and are usually white or ivory.

4. Before handling the PCI-8154, discharge any static

buildup on your body by touching the metal case of the

computer. Hold the edge of the card and do not touch

the components.

5. Position the board into the PCI slot you have selected.

6. Secure the card in place at the rear panel of the system

unit using screws removed from the slot.

2.3.4 Troubleshooting4:

If your system doesn’t boot or if you experience erratic operation

with your PCI board in place, it’s most likely caused by an interrupt

conflict (possibly an incorrect ISA setup). In general, the solution,

once determined it is not a simple oversight, is to consult the BIOS

documentation that comes with your system.

Installation 11

Page 22

Check the control panel of the Windows system if the card is listed

by the system. If not, check the PCI settings in the BIOS or use

another PCI slot.

12 Installation

Page 23

2.4 Software Driver Installation

1. Autorun the ADLINK All-In-One CD. Choose Driver

Installation -> Motion Control -> PCI-8154.

2. Follow the procedures of the installer.

3. After setup installation is completed, rest art windows.

Note: Please download the latest software from ADLINK website if

necessary.

2.5 CN3 Pin Assignments: Main Connector

CN3 is the main connector for the motion control I/O signals.

No. Name I/O Function No. Name I/O Function

1 VDD O +5V power supply output 51 VDD O +5V power supply output

2 EXGND - Ext. power ground 52 EXGND - Ext. power ground

3 OUT0+ O Pulse signal (+) 53 OUT2+ O Pulse signal (+)

4 OUT0- O Pulse signal (-) 54 OUT2- O Pulse signal (-)

5 DIR0+ O Dir. signal (+) 55 DIR2+ O Dir. signal (+)

6 DIR0- O Dir. signal (-) 56 DIR2- O Dir. signal (-)

7 SVON0 O Servo On/Off 57 SVON2 O Servo On/Off

8 ERC0 O Dev. ctr, clr. Signal 58 ERC2 O Dev. ctr, clr. signal

9 ALM0 I Alarm signal 59 ALM2 I Alarm signal

10 INP0 I In-position signal 60 INP2 I In-position signal

11 RDY0 I Multi-purpose Input signal 61 RDY2 I Multi-purpose Input signal

12 EXGND Ext. power ground 62 EXGND Ext. power ground

13 EA0+ I Encoder A-phase (+) 63 EA2+ I Encoder A-phase (+)

14 EA0- I Encoder A-phase (-) 64 EA2- I Encoder A-phase (-)

15 EB0+ I Encoder B-phase (+) 65 EB2+ I Encoder B-phase (+)

16 EB0- I Encoder B-phase (-) 66 EB2- I Encoder B-phase (-)

17 EZ0+ I Encoder Z-phase (+) 67 EZ2+ I Encoder Z-phase (+)

18 EZ0- I Encoder Z-phase (-) 68 EZ2- I Encoder Z-phase (-)

19 VDD O +5V power supply output 69 VDD O +5V power supply output

20 EXGND - Ext. power ground 70 EXGND - Ext. power ground

21 OUT1+ O Pulse signal (+) 71 OUT3+ O Pulse signal (+)

22 OUT1- O Pulse signal (-) 72 OUT3- O Pulse signal (-)

23 DIR1+ O Dir. signal (+) 73 DIR3+ O Dir. signal (+)

24 DIR1- O Dir. signal (-) 74 DIR3- O Dir. signal (-)

Table 2-1: CN3 Pin Assignments: Main Connector

Installation 13

Page 24

No. Name I/O Function No. Name I/O Function

25 SVON1 O Servo On/Off 75 SVON3 O Servo On/Off

26 ERC1 O Dev. ctr, clr. Signal 76 ERC3 O Dev. ctr, clr. signal

27 ALM1 I Alarm signal 77 ALM3 I Alarm signal

28 INP1 I In-position signal 78 INP3 I In-position signal

29 RDY1 I Multi-purpose Input signal 79 RDY3 I Multi-purpose Input signal

30 EXGND Ext. power ground 80 EXGND Ext. power ground

31 EA1+ I Encoder A-phase (+) 81 EA3+ I Encoder A-phase (+)

32 EA1- I Encoder A-phase (-) 82 EA3- I Encoder A-phase (-)

33 EB1+ I Encoder B-phase (+) 83 EB3+ I Encoder B-phase (+)

34 EB1- I Encoder B-phase (-) 84 EB3- I Encoder B-phase (-)

35 EZ1+ I Encoder Z-phase (+) 85 EZ3+ I Encoder Z-phase (+)

36 EZ1- I Encoder Z-phase (-) 86 EZ3- I Encoder Z-phase (-)

37 PEL0 I End limit signal (+) 87 PEL2 I End limit signal (+)

38 MEL0 I End limit signal (-) 88 MEL2 I End limit signal (-)

39 GDI0 I DI/LTC/PCS/SD/CLR0 89 GDI2 I DI/LTC/PCS/SD/CLR2

40 DO0 O General Output 0 90 DO2 O General Output 2

41 ORG0 I Origin signal 91 ORG2 I Origin signal

42 EXGND Ext. power ground 92 EXGND Ext. power ground

43 PEL1 I End limit signal (+) 93 PEL3 I End limit signal (+)

44 MEL1 I End limit signal (-) 94 MEL3 I End limit signal (-)

45 GDI1 I DI/LTC/PCS/SD/CLR1/EMG 95 GDI3 I DI/LTC/PCS/SD/CLR3

46 DO1 O General Output 1 96 DO3 O General Output 3

47 ORG1 I Origin signal 97 ORG3 I Origin signal

48 EXGND - Ext. power ground 98 EXGND - Ext. power ground

49 EXGND - Ext. power ground 99 E_24V - Isolation power Input, +24V

50 EXGND - Ext. power ground 100 E_24V - Isolation power Input, +24V

Table 2-1: CN3 Pin Assignments: Main Connector

14 Installation

Page 25

2.6 K1/K2 Pin Assignments: Simultaneous Start/ Stop

K1 and K2 are for simultaneous st ar t/stop signals for mu ltiple axes

or multiple cards.

No. Name Function

1 +5V PCI Bus power Output (VCC)

2 S TA Simultaneous start signal input/output

3 STP Simultaneous stop signal input/output

4 GND PCI Bus power ground

T able 2-2: K1/K2 Pin Assignments: Simultaneous Start/Stop

Note: +5V and GND pins are provided by the PCI Bus power.

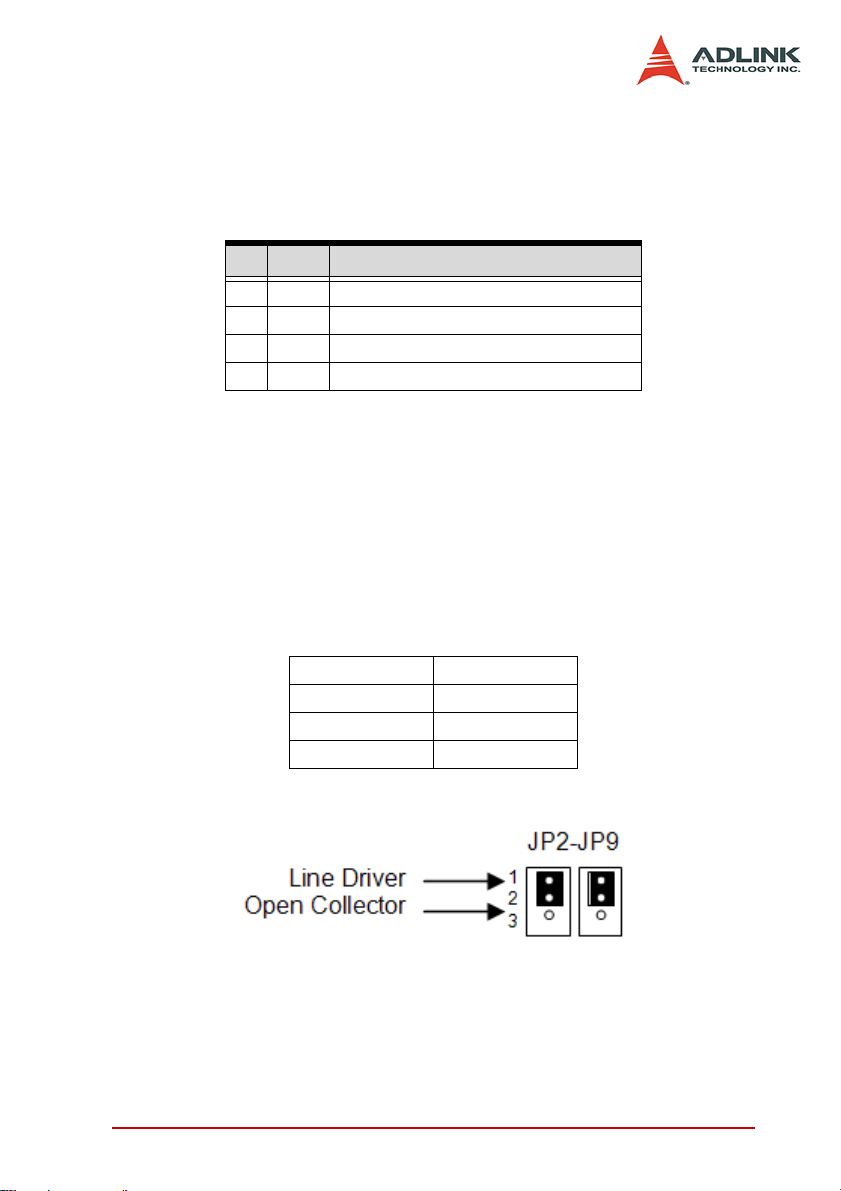

2.7 JP2 to JP9 Jumper Setting for Pulse Output

JP2-JP9 are used to set the type of pulse output signals (DIR and

OUT). The output signal type can either be differential line driver

or open collector output. Refer to section 3.1 for detail jumper settings. The default setting is differential line driver mode. The mapping table is as follows:

JP6 & JP7 Axis 0

JP4 & JP5 Axis 1

JP8 & JP9 Axis 2

JP2 & JP3 Axis 3

Installation 15

Page 26

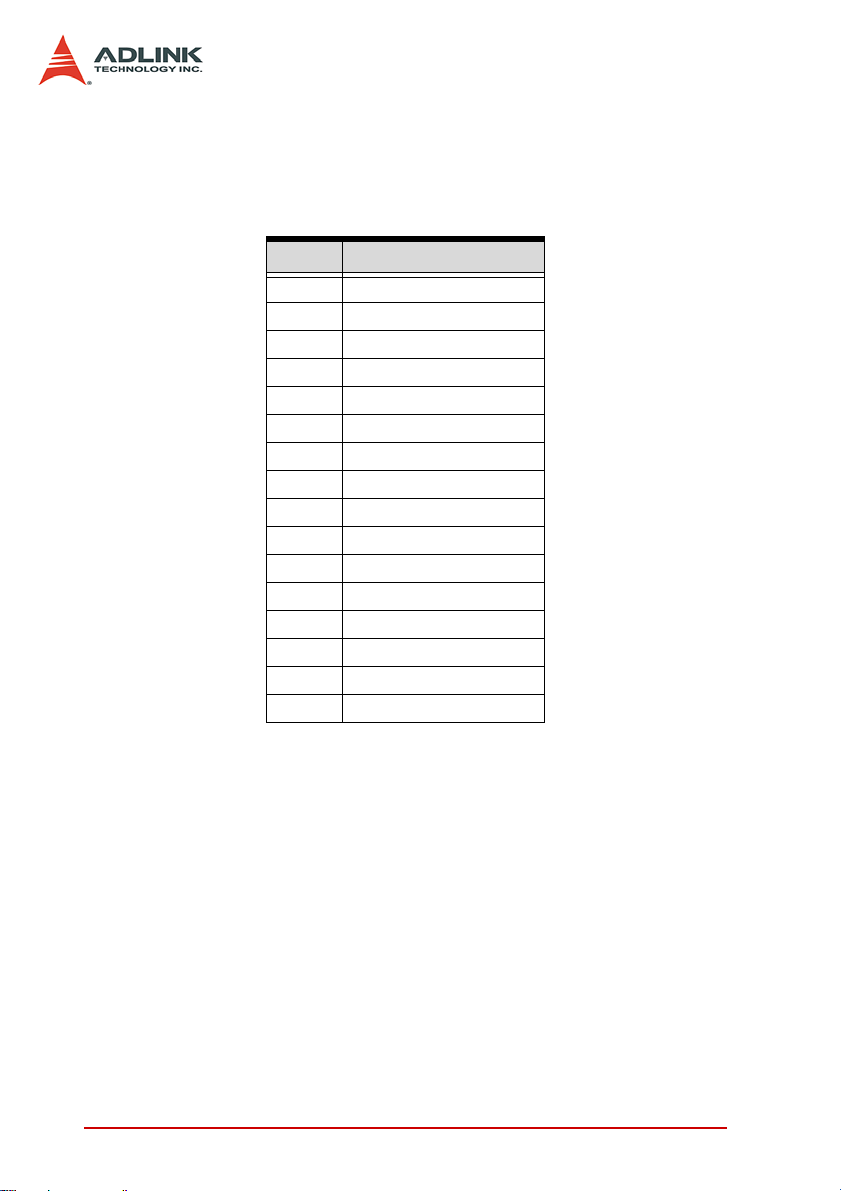

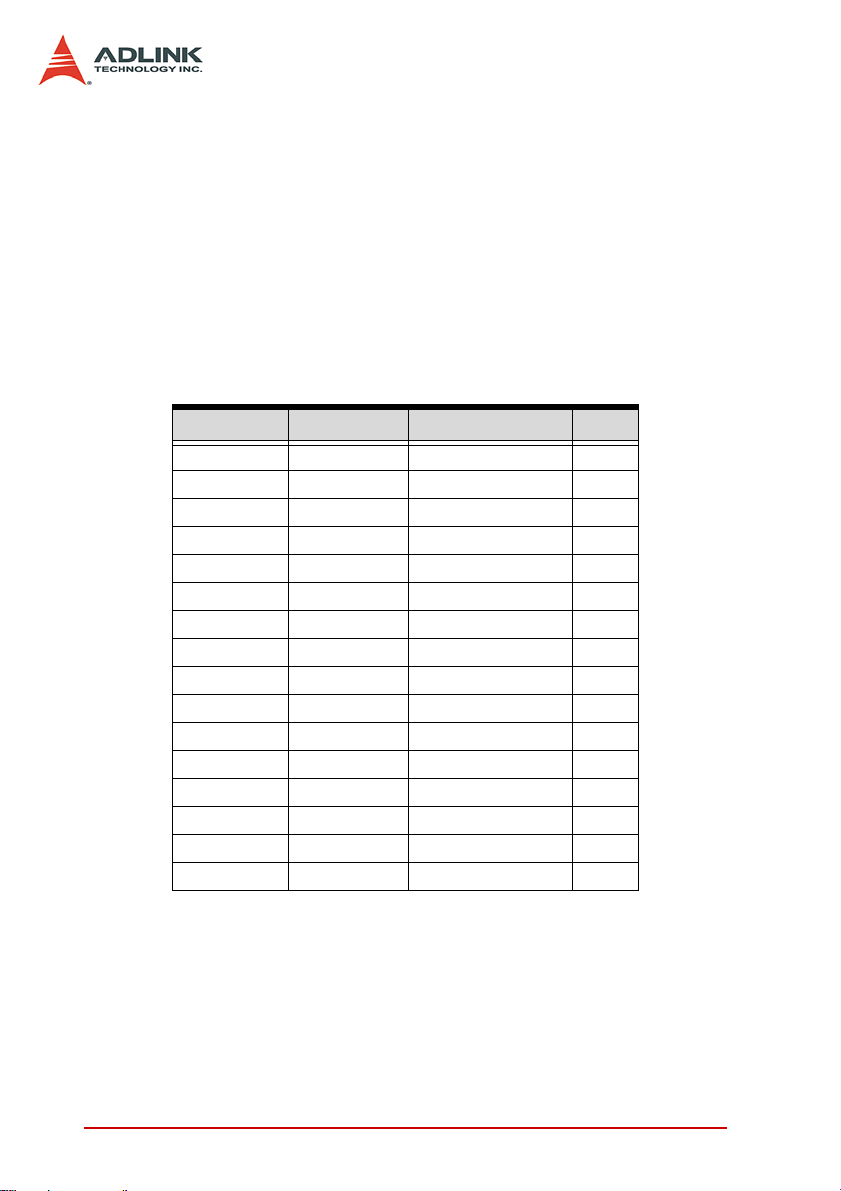

2.8 SW1 Card Index Selection

The SW1 switch is used to set the card index. For example, if 1 is

set to ON and the others are OFF, that card index is 1. The index

value can be from 0 to 15. Refer to the following table for details.

Card ID Switch Sett ing (ON=1)

00000

10001

20010

30011

40100

50101

60110

70111

81000

91001

10 1010

11 1011

12 1100

13 1101

14 1110

15 1111

T able 2-3: SW1 Card Index

16 Installation

Page 27

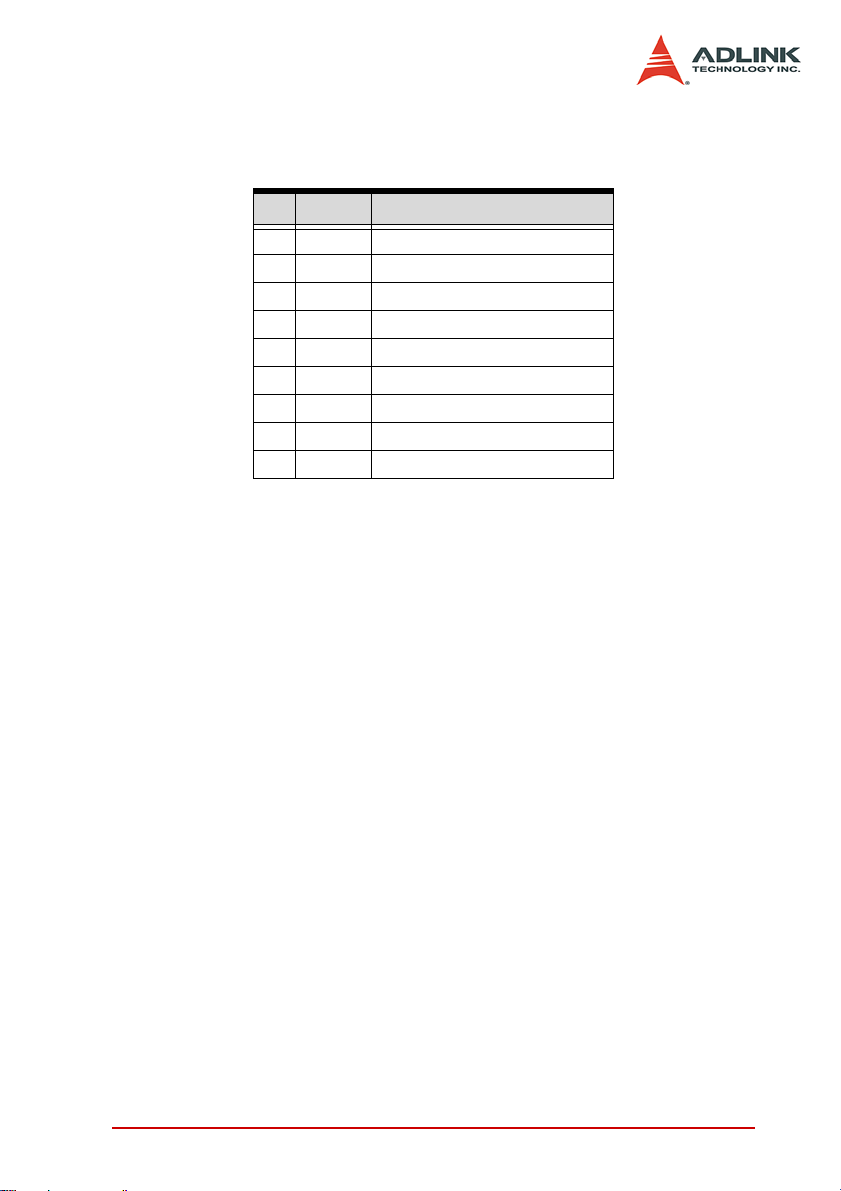

2.9 CN4 Manual Pulsar

The signals on CN4 are for manual pulsar input.

No. Name Function (Axis)

1 VDD Isolated Power +5V

2 PA+ Pulser A+ pha se signal input

3 PA- Pulser A-phase signal input

4 PB+ Pulser B+ phase signal input

5 PB- Pulser B-phase signal input

6 EXGND External Ground

7 N/A Not Available

8 N/A Not Available

9 N/A Not Available

T able 2-4: CN4 Manual Pulsar

Note: The +5V and GND pins are directly given by the PCI-bus

power. Therefore, these signals are not isolated.

Installation 17

Page 28

18 Installation

Page 29

3 Signal Connections

Signal connections of all I/O’s are described in this chapter. Refer

to the contents of this chapter before wiring a ny cable between the

PCI-8154 and any motor driver.

This chapter contains the following sections:

Section 3.1 Pulse Output Signals OUT and DIR

Section 3.2 Encoder Feedback Signals EA, EB and EZ

Section 3.3 Orig in Sign al ORG

Section 3.4 End- Lim it Signa ls PEL an d MEL

Section 3.5 In-position signals INP

Section 3.6 Alarm sign al ALM

Section 3.7 Devia tio n coun te r clea r signal ERC

Section 3.8 general-purpose signals SVON

Section 3.9 Gen e ra l-p ur po se s ign al RDY

Section 3.10 Multifunction output pin: DO/CMP

Section 3.11 Multifunction input signal DI/LTC/SD/PCS/CLR/EMG

Section 3.12 Pulse input signals PA and PB

Section 3.13 Simultaneous start/stop signals STA and STP

Signal Connections 19

Page 30

3.1 Pulse Output Signals OUT and DIR

There are 4 axes pulse output signals on the PCI-8154. For each

axis, two pairs of OUT and DIR differential signals are used to

transmit the pulse train and indicate the direction. The OUT and

DIR signals can also be programmed as CW and CCW signal

pairs. Refer to section 4.1.1 for details of the logical characteristics

of the OUT and DIR signals. In this section, the electrical charac teristics of the OUT and DIR signals are detailed. Each signal consists of a pair of differential signals. For example, OUT0 consists

of OUT0+ and OUT0- signals. The following table shows all pulse

output signals on CN3.

CN3 Pin No. Signal Name Description Axis #

3 OUT0+ Pulse signals (+) 0

4 OUT0- Pulse signals (-) 0

5 DIR0+ Direction signal (+) 0

6 DIR0- Direction signal (-) 0

21 OUT1+ Pulse signals (+) 1

22 OUT1- Pulse signals (-) 1

23 DIR1+ Direction signal (+) 1

24 DIR1- Direction signal (-) 1

53 OUT2+ Pulse signals (+) 2

54 OUT2- Pulse signals (-) 2

55 DIR2+ Direction signal (+) 2

56 DIR2- Direction signal (-) 2

71 OUT3+ Pulse signals (+) 3

72 OUT3- Pulse signals (-) 3

73 DIR3+ Direction signal (+) 3

74 DIR3- Direction signal (-) 3

The output of the OUT or DIR signals can be configured by jumpers as either differential line driver s or open collector outp ut. Users

20 Signal Connections

Page 31

can select the output mode either by jumper wiring between 1 and

2 or 2 and 3 of jumpers JP2-JP9 as follows:

For differential line driver

Output Signal

OUT0+ JP6 JP6

DIR0+ JP7 JP7

OUT1+ JP4 JP4

DIR1+ JP5 JP5

OUT2+ JP9 JP9

DIR2+ JP8 JP8

OUT3+ JP3 JP3

DIR3+ JP2 JP2

output, close breaks

between 1 and 2 of:

For open collector out-

put, close breaks

between 2 and 3 of:

The default setting of OUT and DIR is set to differential line driver

mode.

The following wiring diagram is for OUT and DIR signals of axis.

PCI-8154:

NOTE: If the pulse output is set to open collector output mode,

OUT- and DIR- are used to transmit OUT and DIR signals. The

sink current must not exceed 20mA on the OUT- and DIR- pins.

The default setting is 1-2 shorted.

Signal Connections 21

Page 32

Suggest Usage: Jumper 2-3 shorted and connect OUT-/DIR- to a

470 ohm pulse input interface’s COM of driver. See the following

figure. Choose OUT-/DIR- to connect to driver’s OUT/DIR.

Warning: The sink current must not exceed 20mA or the 26LS31

will be damaged!

22 Signal Connections

Page 33

3.2 Encoder Feedback Signals EA, EB and EZ

The encoder feedback signals include EA, EB, and EZ. Every axis

has six pins for three differential pairs of phase-A (EA), phase-B

(EB), and index (EZ) inputs. EA and EB are used for position

counting, and EZ is used for zero position indexing. Its relative signal names, pin numbers, and axis numbers are shown in the following tables:

CN3 Pin No Signal Name Axis # CN3 Pin No Signal Name Axis #

13 EA0+ 0 14 EA0- 0

15 EB0+ 0 16 EB0- 0

31 EA1+ 1 32 EA1- 1

33 EB1+ 1 34 EB1- 1

63 EA2+ 2 64 EA2- 2

65 EB2+ 2 66 EB2- 2

81 EA3+ 3 82 EA3- 3

83 EB3+ 3 84 EB3- 3

CN3 Pin No Signal Name Axis # CN3 Pin No Signal Name Axis #

17 EZ0+ 0 18 EZ0- 0

35 EZ1+ 1 36 EZ1- 1

67 EZ2+ 2 68 EZ2- 2

85 EZ3+ 3 86 EZ3- 3

The input circuit of the EA, EB, and EZ signals is shown as follows:

Signal Connections 23

Page 34

Please note that the voltage across each differential pair of

encoder input signals (EA+, EA-), (EB+, EB-), and (EZ+, EZ-)

should be at least 3.5V. Therefore, the output current must be

observed when connecting to the encoder feedback or motor

driver feedback as not to over drive the source. The differential

signal pairs are converted to digital signals EA, EB, and EZ; then

feed to the motion control ASIC.

Below are examples of connecting the input signals with an external circuit. The input circuit can be connected to an encoder or

motor driver if it is equipped with: (1) a differential line driver or (2)

an open collector output.

Connection to Line Driver Output

To drive the PCI-8154 encoder input, the driver output must provide at least 3.5V across the differential pairs with at least 8mA

driving capacity. The grounds of both sides must be tied together.

The maximum frequency is 3Mhz or more depends on wiring distance and signal conditioning.

24 Signal Connections

Page 35

Connection to Open Collector Output

To connect with an open collector output, an external power supply is necessary. Some motor drivers can provide the power

source. The connection between the PCI-8154, encoder, and the

power supply is shown in the diagram below . Note that an external

current limiting resistor R is necessary to protect the PCI-8154

input circuit. The following table lists the suggested resistor values

according to the encoder power supply.

Encoder Power (V) External Resistor R

I

= 8mA

f

+5V

+12V

+24V

0

Ω (None)

1.5kΩ

3.0kΩ

For more operation information on the encoder feedback signals,

refer to section 4.4.

Signal Connections 25

Page 36

3.3 Origin Signal ORG

The origin signals (ORG0-ORG3) are used as input signals for the

origin of the mechanism. The following table lists signal names,

pin numbers, and axis numbers:

CN3 Pin No Signal Name Axis #

41 ORG0 0

47 ORG1 1

91 ORG2 2

97 ORG3 3

The input circuit of the ORG signals is shown below. Usually, a

limit switch is used to indicate the origin on one axis. The specifications of the limit switch should have contact capacity of +24V @

6mA minimum. An internal filter circuit is used to filter out any high

frequency spikes, which may cause errors in the operation.

When the motion controller is operated in the home return mode,

the ORG signal is used to inhibit the control output signals (OUT

and DIR). For detailed operations of the ORG signal, refer to section 4.3.3.

26 Signal Connections

Page 37

3.4 End-Limit Signals PEL and MEL

There are two end-limit signals PEL and MEL for each axis. PEL

indicates the end limit signal is in the plus direction and ME L indicates the end limit signal is in the minus direction. The signal

names, pin numbers, and axis numbers are shown in the table

below:

CN3 Pin No Signal Name Axis # CN3 Pin No Signal Name Axis #

37 PEL0 0 38 MEL0 0

43 PEL1 1 44 MEL1 1

87 PEL2 2 88 MEL2 2

93 PEL3 3 94 MEL3 3

A circuit diagram is shown in the diagram below. The external limit

switch should have a contact capacity of +24V @ 8mA minimum.

Either ‘A-type’ (normal open) contact or ‘B- type’ (normal closed)

contact switches can be used. To set the active logic of the external limit signal, please refer to the explanation of

_8154_set_limit_logic function.

Signal Connections 27

Page 38

3.5 In-position Signal INP

The in-position signal INP from a servo motor driver indicates its

deviation error. If there is no deviation error then the servo’s position indicates zero. The signal names, pin numbers, and axis

numbers are shown in the table below:

CN3 Pin No Signal Name Axis #

10 INP0 0

28 INP1 1

60 INP2 2

78 INP3 3

The input circuit of the INP signals is shown in the diagram below:

The in-position signal is usually generated by the servomotor

driver and is ordinarily an open collector output signal. An external

circuit must provide at least 8mA current sink capabilities to drive

the INP signal.

28 Signal Connections

Page 39

3.6 Alarm Signal ALM

The alarm signal ALM is used to indicate the ala rm status from the

servo driver. The signal names, pin numbers, and axis numbers

are shown in the table below:

CN3 Pin No Signal Name Axis #

9ALM00

27 ALM1 1

59 ALM2 2

77 ALM3 3

The input alarm circuit is shown below. The ALM signal usually is

generated by the servomotor driver and is ordinarily an open collector output signal. An external circuit must provide at least 8mA

current sink capabilities to drive the ALM signal.

Signal Connections 29

Page 40

3.7 Deviation Counter Clear Signal ERC

The deviation counter clear signal (ERC) is active in the following

4 situations:

1. Home return is complete

2. End-limit switch is active

3. An alarm signal stops OUT and DIR signals

4. An emergency stop command is issued by software

(operator)

The signal names, pin numbers, and axis numbers are shown in

the table below:

CN3 Pin No Signal Name Axis #

8 ERC0 0

26 ERC1 1

58 ERC2 2

76 ERC3 3

The ERC signal is used to clear the deviation counter of the se rvomotor driver. The ERC output circuit is an open collector with a

maximum of 35V at 50mA driving capacity.

30 Signal Connections

Page 41

3.8 General-purpose Signal SVON

The SVON signal can be used as a servomotor-on control or general purpose output signal. The signal names, pin numbers, and

its axis numbers are shown in the following table:

CN3 Pin No Signal Name Axis #

7SVON00

25 SVON1 1

57 SVON2 2

75 SVON3 3

The output circuit for the SVON signal is shown below:

Signal Connections 31

Page 42

3.9 General-purpose Signal RDY

The RDY signals can be used as motor driver ready input or general purpose input signals. The signal names, pin numbers, and

axis numbers are shown in the following table:

CN3 Pin No Signal Name Axis #

11 RDY0 0

29 RDY1 1

61 RDY2 2

79 RDY3 3

The input circuit of RDY signal is shown in the following diagram:

32 Signal Connections

Page 43

3.10 Multi-Functional output pin: DO/CMP

The PCI-8154 provides 4 multi-functional output channels: DO0/

CMP0 to DO3/CMP3 corresponds to 4 axes. Each of the output

pins can be configured as Digit Output (DO) or as Comparison

Output (CMP) individually. When configured as a Comparison Output pin, the pin will generate a pulse signal when the encoder

counter matches a pre-set value set by the user.

The multi-functional channels are located on CN3. The signal

names, pin numbers, and axis numbers are shown below:

CN3 Pin No Signal Name Axis #

40 DO/CMP0 0

46 DO/CMP1 1

90 DO/CMP2 2

96 DO/CMP3 3

The following wiring diagram is of the CMP on the first 2 axes:

Signal Connections 33

Page 44

3.11 Multi-Functional input pin: DI/LTC/SD/PCS/CLR/ EMG

The PCI-8154 provides 4 multi-functional input pins. Each of the 4

pins can be configured as DI (Digit Input) or LTC (Latch) or SD

(Slow down) or PCS (Target position override) or CLR (Counter

clear) or EMG (Emergency). To select the pin function, please

refer to 6.12.

The multi-functional input pins are on CN3. The signal names, pin

numbers, and axis numbers are shown in the following table:

CN3 Pin No Signal Name Axis #

39 DI/LTC/SD/PCS/CLR/EMG_0 0

45 DI/LTC/SD/PCS/CLR/EMG_1 1

89 DI/LTC/SD/PCS/CLR/EMG_2 2

95 DI/LTC/SD/PCS/CLR/EMG_3 3

The multi-functional input pin wiring diagram is as follows:

34 Signal Connections

Page 45

3.12 Pulser Input Signals PA and PB (PCI-8154)

The PCI-8154 can accept differential pulser input signals through

the pins of CN4 listed below. The pulser behaves like an encoder.

The A-B phase signals generate the positio ning info rmation, wh ich

guides the motor.

CN4 Pin No Signal Name Axis # CN4 Pin No Signal Name Axis #

2PA+0-33PA-0-3

4 PB+ 0-3 5 PB- 0-3

The pulser signals are used for Axis 0 to Axis 3. User can decide

to enable or disable each axis pulser with

_8154_disable_pulser_input function.

The wiring diagram of the differential pulser input pins are as followed.

Signal Connections 35

Page 46

3.13 Simultaneously Start/Stop Signals STA and STP

The PCI-8154 provides STA and STP signals, which enable simultaneous start/stop of motions on multiple axes. The STA and STP

signals are on K1/K2.

The STP and STA signals are both input and output signals. To

operate the start and stop action simultaneously, both software

control and external control are needed. With software control, the

signals can be generated from any one of the PCI-8154. Users

can also use an external open collector or switch to drive the STA/

STP signals for simultaneous start/stop.

If there are two or more PCI-8154 cards, connect the K2 conne ctor

on the previous card to K1 connector on the following card. The

K1 and K2 connectors on a same PCI-8154 are connected internally.

You can also use external start and stop signals to issue a crosscard simultaneous motor operation. Just connect external start

36 Signal Connections

Page 47

and stop signals to STA and STP pins on the K1 connector of the

first PCI-8154 card.

Signal Connections 37

Page 48

38 Signal Connections

Page 49

4 Operation Theory

This chapter describes the detail operation of the motion controller

card. Contents of the following sections are as follows:

Section 4.1: Classifications of Motion Controller

Section 4.2: Motion Control Modes

Section 4.3: M ot or Drive r Int er face

Section 4.4: M ec ha n ical switch Interface

Section 4.5: T he Cou n ter s

Section 4.6: The Comparators

Section 4.7: Other Motion Functions

Section 4.8: Interrupt Control

Section 4.9: Multiple Cards Operation

4.1 Classifications of Motion Controller

When motor/stepper control first started, motion control was

widely discussed instead of motor control. Motor control was separated into two layers: motor control and motion control. Motor control relates to PWM, power stage, closed loop, hall sensors, vector

space, etc. Motion control relates to speed profile generating, trajectory following, multi-axes synchronizat ion , an d co ordin a ting .

4.1.1 Voltage motion control interface

The interfaces between motion and motor control are changing

rapidly. Early on, a voltage singal was used as a command to the

motor controller. The amplitude of the signal means how fast a

motor is rotating and the time duration of the voltage changes

means how fast a motor acceleration from one speed to the other

speed. Voltage signal as a command to motor driver is so called

“analog” motion controller. It is much eaiser to integrate into an

analog circuit of motor controller; however noise is sometimes a

big problem for this type of motion control. Also, to do positioning

control of a motor, the analog motion controller must ha ve a feedback signal with position information and use a closed loop control

algorithm to make it possible. This increased the complexity of

motion control and not easy to use for a beginner.

Operation Theory 39

Page 50

4.1.2 Pulse motion control interface

The second interface of motion and motor control is a pulse train

type. As a trend of digital world, pulse trains represent a new concept to motion control. The counts of pulses show how many ste ps

of a motor rotates and the frequency of pulses show how fast a

motor runs. The time duration of frequency changes represent the

acceleration rate of a motor. Because of this interface, a servo or

stepper motor can be easier than an analog type for positioning

applications. It means that motion and motor control can be separated more easily by this way.

Both of these two interfaces need to provide for gains tuning. For

analog position controllers, the control loops are built inside and

users must tune the gain from the controller. For pulse type position controllers, the control loops are built outside on the motor

drivers and users must tune the gains on drivers.

For more than one axes’ operation, motion control seems more

important than motor control. In industial applications, reliable is a

very important factor. Motor driver vendors make good performance products and a motion controller vendors make powerful

and variety motion software. Integrated two products make our

machine go into perfect.

4.1.3 Network motion control interface

Recently, there was a new control interface was introduced--a network motion controller. The command between motor driver and

motion controller is not analog or pulses signal any more. It is a

network packet which contents position information and motor

information. This type of controller is more reliable because it is

digitized and packetized. Because a motion controller must be

real-time, the nerowrk must have real-time capacity around a cycle

time below 1 mini-second. This means that non-commercial networks cannot do this job. It must have a specific network, such as

Mitsubishi SSCNET. The network may also be built with fiberoptics

to increase communication reliability.

40 Operation Theory

Page 51

4.1.4 Software real-time motion control kernel

For motion control kernel, there are three ways to accomplish it:

DSP, ASIC, and software real-time.

A motion control system needs an absolutely real-time control

cycle and the calculation on controller must provide a control data

at the same cycle. If not, the motor will not run smoothly. Many

machine makers will use PC’s computing power to do this. A feedback counter card can simply be used and a voltage output or

pulse output card to make it. This method is very low-end and

takes much software effort. For sure their realtime performance,

they will use a real-time software on the system. It increases the

complexity of the system too. But this method is the most flexible

way for a professional motion control designers. Most of these

methods are on NC machines.

4.1.5 DSP motion control kernel

A DSP-based motion controller kernel solves real-time software

problem on computer. DSP is a micro-processer itself and all

motion control calculations can be done on it. There is no real-time

software problem because DSP has its own OS to arrange all the

procedures. There is no interruption from other inputs or context

switching problem like Windows based computer. Although it has

such a perfect performance on real-time requirements, its calculation speed is not as fast as PC’s CPU at this age. The software

interfacing between DSP controller’s vendors and users is not

easy to use. Some controller vendors provide some kind of

assembly languages for users to learn and some controller vendors provide only a handshake documents for users to use. Both

ways are not easy to use. DSP based controller provide a bette r

way than software kernel for machine makers to build they applications.

4.1.6 ASIC motion control kernel

An ASIC motion control kernel is falls between software kernel

and DSP kernel in terms of difficulty. It has no real-time problem

because all motion functions are done via the ASIC. Users or controller’s vendors just need to set some parameters which the ASIC

requires and the motion control will be done easily. This kind of

Operation Theory 41

Page 52

motion control separates all system integration problems into 4

parts: Motor driver’s performance, ASIC outputting profile, vendor’s software parameters to the ASIC, and users’ command to

vendors’ software. It makes motion controller co-operated more

smoothly between devices.

4.1.7 Compare Table of all motion control types

Software ASIC DSP

Price Fair Cheap Expensive

Functionality Highest Low Normal

Maintenance Hard Easy Fair

Analog Pulses Network

Price High Low Normal

Signal Quality Fair Good Reliable

Maintenance Hard Easy Easy

4.1.8 PCI-8154 motion controller type

The PCI-8154 is ASIC based, pulse type motion controller made

into three blocks: motion ASIC, PCI card, software motion library.

The motion ASIC can be accessed via our software motion libra y

under many kinds of Windows NT/2000/XP, Linux, and RTX driver.

Our software motion library provides one-stop-function for controlling motors. All the speed parameter calculations are done via our

library.

For example, to perform a one-axis point to point moition with a

trapezoidal speed profile, only fill the target position, speed, and

acceleration time in one function. Then the motor will run as the

profile. It takes no CPU resources because every control cycle

pulse generation is done by the ASIC. The precision of target position depends on motor drivers’ closed loop control performance

and mechnical parts, not on motion controller’s command because

the motion controller is only responsible for sending correct pulses

counts via a desired speed profile. So it is much e asier for programmers, mechnical or electrical engineers to find out problems.

42 Operation Theory

Page 53

4.2 Motion Control Modes

Motion control makes the motors run according to a specific speed

profile, path trajectory and synchronous condition with other axes.

The following sections describe the motion control modes of this

motion controller could be performed.

4.2.1 Coordinate system

The Cartesian coordinate is used and pulses are in the unit of

length. The physical length depends on mechanical parts and

motor’s resolution. For example, if a motor is on a screw ball, and

the pitch of screw ball is 10mm and the pulses needed for a round

of motor are 10,000 pulses. One pulse’s physical unit is equal to

10mm/10,000p =1 mm.

Just set a command with 15,000 pulses for motion controller if we

want to move 15mm. How about if we want to move 15.0001mm?

Simple! The motion controller will keep the residue value less

than 1 pulse and add it to next command.

The motion controller sends incremental pulses to motor drive rs. It

means that we can only send relative command to motor driver.

But we can solve this problem by calculating the difference

between current position and target position first. Then send the

differences to motor driver. For example, if current position is 1000

and we want to move a motor to 9000, you can use an absolute

command to set a target position of 9000. Inside the motion controller, it will get current position 1000 first then calculate the difference from target position. The result is +8000. So, the motion

controller will send 8000 pulses to motor driver to move the position of 9000.

Sometimes, users need to install a linear scale or external

encoder to check machine’s position. But how do you to build this

coordinate system? If the resolution of external encoder is 10,000

Operation Theory 43

Page 54

pulses per 1mm and the motor will move 1mm if the motion controller send 1,000 pulses, It means that when we want to move 1

mm, we need to send 1,000 pulses to motor driver then we will get

the encoder feedback value of 10,000 pulses. If we want to use an

absolute command to move a motor to 10,000 pulses position and

current position read from encoder is 3500 pulses, how many

pulses will it send to motor driver? The answer is (10000 – 3500 ) /

(10,000 / 1,000)=650 pulses. The motion controller will calculate it

automatically if users set “move ratio” already. The “move ratio”

means the (feedback resolution/command resolution).

4.2.2 Absolute and relative position move

In the coordinate system, we have two kinds command for users

to locate the target position. One is absolute and the other is relative. Absolute command means that user give the motion controller a position, then the motion controller will move a motor to that

position from current position. Relative command means that user

give the motion controller a distance, then the motion controller

will move motor by the distance from current position. During the

movement, users can specify the speed profile. It means user can

define how fast and at what speed to reach the position.

44 Operation Theory

Page 55

4.2.3 Trapezoidal speed profile

Trapezodial speed profile means the acceleration/deceleration

area follows a 1st order linear velocity profile (constant acceleration rate). The profile chart is shown as below:

The area of the velocity profile represents the distance of this

motion. Sometimes, the profile looks like a triangle because the

desired distance from user is smaller than the area of given speed

parameters. When this situation happens, the motion controller

will lower the maximum velocity but keep the acceleration rate to

meet user’s distane requirement. The chart of this situation is

shown as below:

This kind of speed profile could be applied on velocity mode, position mode in one axis or multi-axes linear interpolation and two

axes circular interpolation modes.

Operation Theory 45

Page 56

4.2.4 S-curve and Bell-curve speed profile

S-curve means the speed profile in accelerate/decelerate area follows a 2nd order curve. It ca n reduce vibration at the beginning of

motor start and stop. In order to speed up the acceleration/deceleration during motion, we need to insert a linear part into these

areas. We call this shape as “Bell” curve. It adds a linear curve

between the upper side of s-curve and lower side of s-curve. This

shape improves the speed of acceleration and also reduces the

vibration of acceleration.

For a bell curve, we define its shape parameters as below:

X Tacc: Acceleration time in second

X Tdec: Deceleration time in second

X StrVel: Starting velocity in PPS

X MaxVel: Maximum velocity in PPS

X VSacc: S-curve part of a bell curve in deceleration in PPS

X VSdec: S-curve part of a bell curve in deceleration in PPS

46 Operation Theory

Page 57

If VSacc or VSdec=0, it means acceleration or deceleration use

pure S-curve without linear part. The Acceleration chart of bell

curve is shown below:

The S-curve profile motion functions are designed to always produce smooth motion. If the time for acceleration parameters combined with the final position don’t allow an axis to reach the

maximum velocity (i.e. the mov ing distance is too small to reach

MaxVel), then the maximum velocity is automatically lowered (see

the following Figure).

The rule is to lower the value of MaxVel and the Tacc, Tdec,

VSacc, VSdec automatically, and keep StrVel, acceleration, and

jerk unchanged. This is also applicable to Trapezoidal profile

motion.

This kind of speed profile could be applied on velocity mode, position mode in one axis or multi-axes linear interpolation and two

axes circular interpolation modes.

Operation Theory 47

Page 58

4.2.5 Velocity mode

Veloctiy mode means the pulse command is continuously outputing until a stop command is issued. The motor will run without a

target position or desired distance unless it is stopped by other

reasons. The output pulse accelerates from a starting velocity to a

specified maximum velocity. It can be follow a linear or S-curve

acceleration shape. The pulse output rate is kept at maximum

velocity until another velocity command is set or a stop command

is issued. The velocity could be overrided by a new speed setting.

Notice that the new speed could not be a reversed speed of original running speed. The speed profile of this kind of motion is

shown as below:

48 Operation Theory

Page 59

4.2.6 One axis position mode

Position mode means the motion controller will output a specific

amount of pulses which is equal to users’ desired position or distance. The unit of distance or position is pulse internally on the

motion controller. The minimum length of distance is one pulse.

However, in PCI-8154, we provide a floating point function for

users to transform a physical length to pulses. Inside our software

library, we will keep those distance less than one pulse in register

and apply them to the next motion function. Besides positioning

via pulse counts, our motion controller provides three types of

speed profile to accomplish positioning. There are 1st order trapezoidal, 2nd order S-curve, and mixed bell curve. Users can call

respective functions to perform that. The following char shows the

relationship between distance and speed profile. We use trapezoidal shape to show it.

The distance is the area of the V-t diagram of this profile.

Operation Theory 49

Page 60

4.2.7 Two axes linear interpolation position mode

“Interpolation between multi-axes” means these axes start simultaneously, and reach their ending points at the same time. Linear

means the ratio of speed of every axis is a constant value.

Assume that we run a motion from (0,0) to (10,4). The linear interpolation results are shown as below.

The pulses output from X or Y axis remains 1/2 pulse difference

according to a perfect linear line. The precision of linear interpolation is shown as below:

If users want to stop an interpolation group, just call a stop function on first axis of the group.

As in the diagram below, 4-axis linear interpo lation means to move

the XY position from P0 to P1. The 2 axes start and stop simultaneously, and the path is a straight line.

50 Operation Theory

Page 61

The speed ratio along X-axis and Y-axis is (ΔX: ΔY), respectively,

and the vector speed is:

When calling 4-axis linear interpolation functions, the ve ctor speed

needs to define the start velocity, StrVel, and maximum velocity,

MaxVel.

4.2.8 Two axes circular interpolation mode

Circular interpolation means XY axes simultaneously start from initial point, (0,0) and stop at end point, (1800,600). The path

between them is an arc, and the MaxVel is the tangential speed.

Notice that if the end point of arc is not at a proper position, it will

move circularly without stopping.

Y

(1800,600)

(0,0)

Center

(1000,0)

X

The motion controller will move to the final point user desired even

this point is not on the path of arc. But if the final point is not at the

location of the shadow area of the following graph, it will run circularly without stopping.

Operation Theory 51

Page 62

The command precision of circular interpolation is shown below.

The precision range is at radius ±1/2 pulse.

4.2.9 Continuous motion

Continuous motion means a series of motion command or po sition

can be run continuously. Users can set a new command right after

previous one without interrupting it. The motion controller can

make it possible because there are three command buffers (preregisters) inside.

When first command is executing, users can set second command

into first buffer and third command into second buffer. Once the

first command is finished, the motion controller will push the second command to the executing register and the third command to

first buffer. Now, the second buffer is empty and user can set the

4th command into 2nd buffer. Normally, if users have enough time

52 Operation Theory

Page 63

to set a new command into 2nd buffer before executing register is

finished, the motion can run endlessly. The following diagram

shows this architecture of continuous motion.

Besides position command, the speed command should be set

correctly to perform a speed continuous profile. For the following

example, there are three motion command of this continuous

motion. The second one has high speed than the others. The

interconnection of speed between these three motion functions

should be set as the following diagram:

Operation Theory 53

Page 64

If the 2nd command’s speed value is lower than the others, the

settings would be like as following diagram:

For 4-axis continuous arc interpolation is the same concept. You

can set the speed matched between two command speed settings.

If the INP checking is enabled, the motion will have some delayed

between each command in buffers. INP check enabled make the

desired point be reached but reduce the smoothing between each

command. If users don’t need this delay and need the smoothing,

please turn INP checking off.

54 Operation Theory

Page 65

4.2.10 Home Return Mode

Home return means searching a zero position point on the coordinate. Sometimes, users use a ORG, EZ or EL pin as a zero position on the coordinate. At the beginning of machine power on, the

program needs to find a zero point of this machine. Our motion

controller provides a home return mode to make it.

We have many home modes and each mode contents many control phases. All of these phases are done by ASIC. No software

efforts or CPU loading will be taken. After home return is finished,

the target counter will be reset to zero at the desired condition of

home mode. For example, a raising edge when ORG input. Sometimes, the motion controller will still output pulses to make

machine show down after resetting the counter. When the motor

stops, the counter may not be at zero po int but the home return

procedure is finished. The counter value you see is a reference

position from machine’s zero point already.

The following figures show the various home modes: R means

counter reset ( command and position counter ). E means ERC

signal output.

Operation Theory 55

Page 66

Home mode=0: ( ORG Turn ON then reset counter )

X When SD is not installed

X When SD is installed and SD is not latched

56 Operation Theory

Page 67

Home mode=1: (Twice ORG turn ON then reset counter)

Home mode=2: (ORG ON then Slow down to count EZ numbers and reset counter)

Operation Theory 57

Page 68

Home mode=3: (ORG ON then count EZ numbers and reset

counter)

Home mode=4: (ORG On then reverse to count EZ number

and reset counter)

58 Operation Theory

Page 69

Home mode=5: (ORG On then reverse to count EZ number

and reset counter, not using FA Speed)

Home mode=6: (EL On then reverse to leave EL and reset

counter)

Home mode=7: (EL On then reverse to count EZ number and

reset counter)

Operation Theory 59

Page 70

Home mode=8: (EL On then reverse to count EZ number and

reset counter, not using FA Speed)

Home mode=9: (ORG On then reverse to zero position, an

extension from mode 0)

60 Operation Theory

Page 71

Home mode=10: (ORG On then counter EZ and reverse to

zero position, an extension from mode 3)

Home mode=11: (ORG On then reverse to counter EZ and

reverse to zero position, an extension from mode 5)

Operation Theory 61

Page 72

Home mode=12: (EL On then reverse to count EZ numbe r a nd

reverse to zero position, an extension from mode 8)

4.2.11 Home Search Function

This mode is used to add auto searching function on normal home

return mode described in previous section no matter which position the axis is. The following diagram is shown the example for

home mode 2 via home search fu nction. The OR G offset can’t be

zero. Suggested value is the double length of ORG area.

62 Operation Theory

Page 73

4.2.12 Manual Pulser Function

Manual pulser is a device to generate pulse trains by hand. The

pulses are sent to motion controller and re-directed to pulse outp ut

pins. The input pulses could be multiplied or divided before sending out.

The motion controller receives two kinds of pulse trains from manual pulser device: CW/CCW and AB phase. If the AB phase input

mode is selected, the multiplier has additional selection of 1, 2, or

4.

The following figure shows pulser ratio block diagram.

4.2.13 Simultaneous Start Function

Simultaneous motion means more than one axis can be starte d by

a Simultaneous signal which could be external or internal signals.

For external signal, users must set move parameters first for all

axes then these axes will wait an extern start/stop command to

start or stop. For internal signal, the start command could be from

a software start function. Once it is issued, all axes which are in

waiting synchronous mode will start at the same time.

Operation Theory 63

Page 74

4.2.14 Speed Override Function

Speed override means that users can change command’s speed

during the operation of motion. The change parameter is a percentage of original defined speed. Users can define a 100% sp eed

value then change the speed by percentage of original speed

when motion is running. If users didn’t define the 100% speed

value. The default 100% speed is the latest motion command’s

maximum speed. This function can be applied on any motion function. If the running motion is S-curve or bell curve, the speed override will be a pure s-curve. If the running motion is t-curve, the

speed override will be a t-curve.

64 Operation Theory

Page 75

4.2.15 Position Override Function

Position override means that when users issue a positioning command and want to change its target position during this operation.

If the new target position is behind current position when override

command is issued, the motor will slow down then reverse to new

target position. If the new target position is far away from current

position on the same direction, the motion will remain its speed

and run to new target position. If the override timing is on the

deceleration of current motion and the target position is far away

from current position on the same direction, it will accelerate to

original speed and run to new target position. The operation examples are shown as below. Notice that if the new target position’s

relative pulses are smaller than original slow down pulses, this

function can’t work properly.

Operation Theory 65

Page 76

4.3 The motor driver interface

We provide several dedicated I/Os which can be connected to

motor driver directly and have their own functions. Motor drivers

have many kinds of I/O pins for external motion controller to use.

We classify them to two groups. One is pulse I/O signals including

pulse command and encoder interface. The other is digital I/O signals including servo ON, alarm, INP, servo ready, alarm reset and

emergency stop inputs. The following sections will describe the

functions these I/O pins.

4.3.1 Pulse Command Output Interface

The motion controller uses pulse command to control servo/stepper motors via motor drivers. Please set the drivers to position

mode which can accept pulse trains as position command. The

pulse command consists of two signal pairs. It is defined as OUT

and DIR pins on connector. Each signal has two pins as a pair for

differential output. There are two signal modes for pulse output

command: (1) single pulse output mode (OUT/DIR), and (2) dual

pulse output mode (CW/CCW type pulse output). The mode must

be the same as motor driver. The modes vs. signal type of OUT

and DIR pins are listed in the table below:

Mode Output of OUT pin Output of DIR pin

Dual pulse output

(CW/CCW)

Single pulse output

(OUT/DIR)

Pulse signal in plus

(or CW) direction

Pulse signal Direction signal (level)

Pulse signal in minus

(or CCW) direction

66 Operation Theory

Page 77

Single Pulse Output Mode (OUT/DIR Mode)

In this mode, the OUT pin is for outputting command pulse chain.

The numbers of OUT pulse represent distance in pulse. The frequency of the OUT pulse represents speed in pulse per second.

The DIR signal represents command direction of positive (+) or

negative (-). The diagrams below show the output waveform. It is

possible to set the polarity of the pulse chain.

Operation Theory 67

Page 78

Dual Pulse Output Mode (CW/CCW Mode)

In this mode, the waveform of the OUT and DIR pins represent

CW (clockwise) and CCW (counter clockwise) pulse output

respectively. The numbers of pulse represent distance in pulse.

The frequency of the pulse represents speed in pulse per second.

Pulses output from the CW pin makes the motor mo ve in positive

direction, whereas pulse output from the CCW pin makes the

motor move in negative direction. The following diagram shows

the output waveform of positive (+) commands and negative (-)

commands.

The command pulses are counted by a 28-bit command counter.

The command counter can store a value of total pulses outputting

from controller.

68 Operation Theory

Page 79

4.3.2 Pulse feedback input interface

Our motion controller provides one 28-bit up/do wn cou nter of each

axis for pulse feedback counting. This counter is called position

counter. The position counter counts pulses from the EA and EB

signal which have plus and minus pins on connector for differential

signal inputs. It accepts two kinds of pulse types. One is dual

pulses input (CW/CCW mode) and the other is AB phase input.

The AB phase input can be multiplied by 1, 2 or 4. Multiply by 4 AB

phase mode is the most commonly used in incremental encoder

inputs.

For example, if a rotary encoder has 2000 pulses per rotation,

then the counter value read from the position counter will be 8000

pulses per rotation when the AB phase is multiplied by four.

If users don’t use encoder for motion controller, the feedback

source for this counter must be set as pulse command output or

the counter value will always be zero. If it is set as pulse command

output, users can get the position counter value from pulse command output counter because the feedback pulses are internal

counted from command output pulses.

The following diagrams show these two types of pulse feedback

signal.

Operation Theory 69

Page 80

Plus and Minus Pulses Input Mode (CW/CCW Mode)

The pattern of pulses in this mode is the same as the Dual Pulse

Output Mode in the Pulse Command Output section except that

the input pins are EA and EB.

In this mode, pulses from EA pin cause the counter to count up,

whereas EB pin caused the counter to count down.

90° phase difference signals Input Mode (AB phase Mode)

In this mode, the EA signal is a 90° phase leading or lagging in

comparison with the EB signal. “Lead” or “lag ” of phas e difference

between two signals is caused by the turning direction of the

motor. The up/down counter counts up when the phase of EA signal leads the phase of EB signal.

The following diagram shows the waveform.

The index input (EZ) signal is as the zero reference in linear or

rotary encoder. The EZ can be used to define the mechanical zero

position of the mechanism. The logic of signal must also be set

correctly to get correct result.

70 Operation Theory

Page 81