Page 1

NEON-1020/1040

Quad Core x86 Smart Camera

User’s Manual

Manual Rev.: 2.00

Revision Date: June 13, 2014

Part No: 50-1Z168-2000

Advance Technologies; Automate the World.

Page 2

Revision History

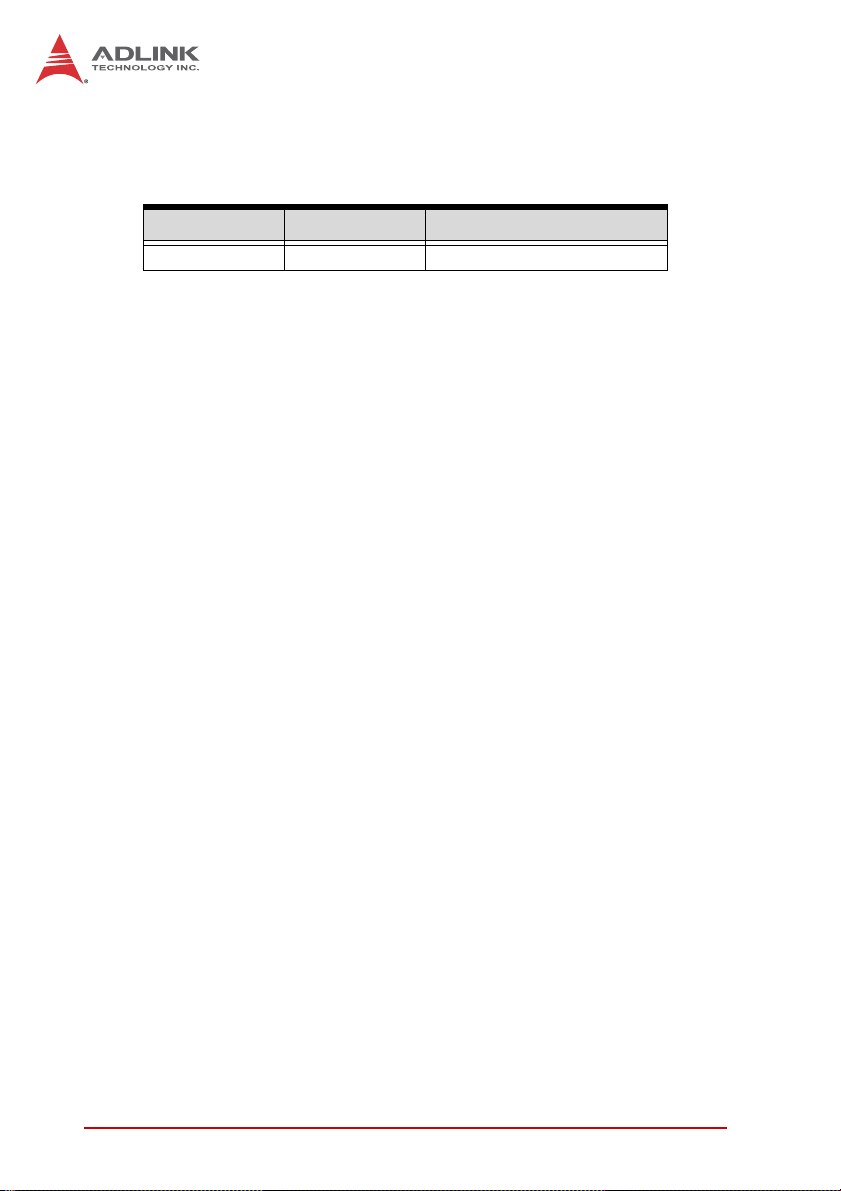

Revision Release Date Description of Change(s)

2.00 June 13, 2014 Initial release

ii

Page 3

NEON 1020/1040

Preface

Copyright 2014 ADLINK Technology, Inc.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

Disclaimer

The information in this document is subject to change without prior

notice in order to improve reliability, design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of the use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

Environmental Responsibility

ADLINK is committed to fulfill its social responsibility to global

environmental preservation through compliance with the European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE)

directive. Environmental protection is a top priority for ADLINK.

We have enforced measures to ensure that our products, manufacturing processes, components, and raw materials have as little

impact on the environment as possible. When products are at their

end of life, our customers are encouraged to dispose of them in

accordance with the product disposal and/or recovery programs

prescribed by their nation or company.

Trademarks

Product names mentioned herein are used for identification purposes only and may be trademarks and/or registered trademarks

of their respective companies.

Preface iii

Page 4

Conventions

Take note of the following conventions used throughout this

manual to make sure that users perform certain tasks and

instructions properly.

Additional information, aids, and tips that help users perform

tasks.

NOTE:

NOTE:

Information to prevent minor physical injury, component dam-

age, data loss, and/or program corruption when trying to com-

CAUTION:

WARNING:

plete a task.

Information to prevent serious physical injury, component

damage, data loss, and/or program corruption when trying to

complete a specific task.

iv Preface

Page 5

NEON 1020/1040

Table of Contents

Preface.................................................................................... iii

List of Figures....................................................................... vii

List of Tables.......................................................................... ix

1 Introduction ........................................................................ 1

1.1 Overview.............................................................................. 1

1.2 Features............................................................................... 1

1.3 Specifications....................................................................... 2

1.4 Schematics .......................................................................... 4

1.5 Indicators ............................................................................. 7

1.6 I/O Connectors..................................................................... 8

1.6.1 Digital I/O and Power.................................................. 9

1.6.2 100/GbE ................................................................... 11

1.6.3 VGA/USB.................................................................. 12

1.7 General Purpose Digital Signals ........................................ 13

1.7.1 General Purpose Digital Output (EDO) .................... 13

1.7.2 General Purpose Digital Input (EDI) ......................... 14

1.7.3 Hardware Trigger Input............................................. 14

1.7.4 PWM Light Control Output........................................ 14

2 Getting Started ................................................................. 17

2.1 Unpacking Checklist .......................................................... 17

2.2 Connecting a VGA/USB cable ........................................... 17

2.3 Connecting an Ethernet cable ........................................... 17

2.4 Connecting a power cable ................................................. 19

2.5 Operating System Installation............................................ 19

2.6 Driver Installation ............................................................... 19

Important Safety Instructions.............................................. 27

Table of Contents v

Page 6

Getting Service...................................................................... 29

vi Table of Contents

Page 7

NEON 1020/1040

List of Figures

Figure 1-1: NEON-1040 Front View ................................................... 4

Figure 1-2: NEON-1020/1040 Rear View........................................... 5

Figure 1-3: NEON-1020/1040 Side View ........................................... 6

Figure 1-4: NEON-1020/1040 LED Array........................................... 7

Figure 1-5: NEON-1020/1040 I/O Array............................................. 8

Figure 1-6: Digital I/O and Power Connector ..................................... 9

Figure 1-7: 100/GbE Connector ....................................................... 11

Figure 1-8: VGA/USB Connector ..................................................... 12

Figure 1-9: General Purpose Digital Output (EDO) Circuit .............. 13

Figure 1-10: General Purpose Digital Input (EDI) Circuit ................... 14

Figure 1-11: Hardware Trigger Input Circuit....................................... 14

Figure 1-12: PWM Light Control Output Circuit.................................. 15

Figure 2-1: VGA/USB Alignment Pin (device side) .......................... 17

Figure 2-2: Ethernet Alignment Channel (device side) .................... 18

Figure 2-3: Power Alignment Pin (device side) ................................ 19

List of Figures vii

Page 8

This page intentionally left blank.

viii List of Figures

Page 9

NEON 1020/1040

List of Tables

Table 1-1: NEON-1020/1040 LED Function ..................................... 7

Table 1-2: NEON-1020/1040 I/O Array Legend................................ 8

Table 1-3: Digital I/O and Power Pin Assignment........................... 10

Table 1-4: 100/GbE Pin Assignment............................................... 11

Table 1-5: VGA/USB Pin Assignment............................................. 13

List of Tables ix

Page 10

This page intentionally left blank.

xList of Tables

Page 11

1 Introduction

1.1 Overview

NEON-1020/1040

The NEON-1040 is a powerful new generation x86 smart camera

that features the Intel

®

Atom™ Processor E3845 1.9 GHz, 4 MP at

60 fps, global shutter image sensor, and PWM lighting control support. The NEON-1040 stands out with its minimal footprint and

superior computing power, and rugged IP67-rated construction

and M12 connectors enable the NEON-1040 to withstand the

harshest industrial environments.

High-end quad-core processor with FPGA coprocessors, GPU

and up to 32GB storage for image processing, programs, and

archiving, all provide advanced image processing ability ideally

suited to high speed high resolution industrial imaging. Optimal I/O

connectivity includes one additional slave GigE Vision camera

connection, 4x digital inputs, 4x digital outputs, and VGA output,

all maximizing integration with external devices.

Flexible software development support, including GenTL support

for image acquisition and Open CV and Open CL programming,

further significantly benefits developers by easing migration from

x86 platforms.

1.2 Features

X Intel

X 4MP, 60fps, monochrome global shutter CMOS sensor

X IP67-rated housing and M12 connectors

X Advanced image processing support

X Additional GigE Vision slave camera support

X Built-in PWN lighting control

X 4x digital inputs, 4x digital outputs, USB 2.0 port, RS-232

X VGA output, max. 2560x1600 @60 Hz

X Flexible software support with STEMMER Common Vision

X GeniCam , GenTL, Open CV and Open CL compatible with

®

Atom™ Quad-Core Processor E3845 1.91GHz

ports

Blox, MVTec HALCON, and many others

image acquisition

Introduction 1

Page 12

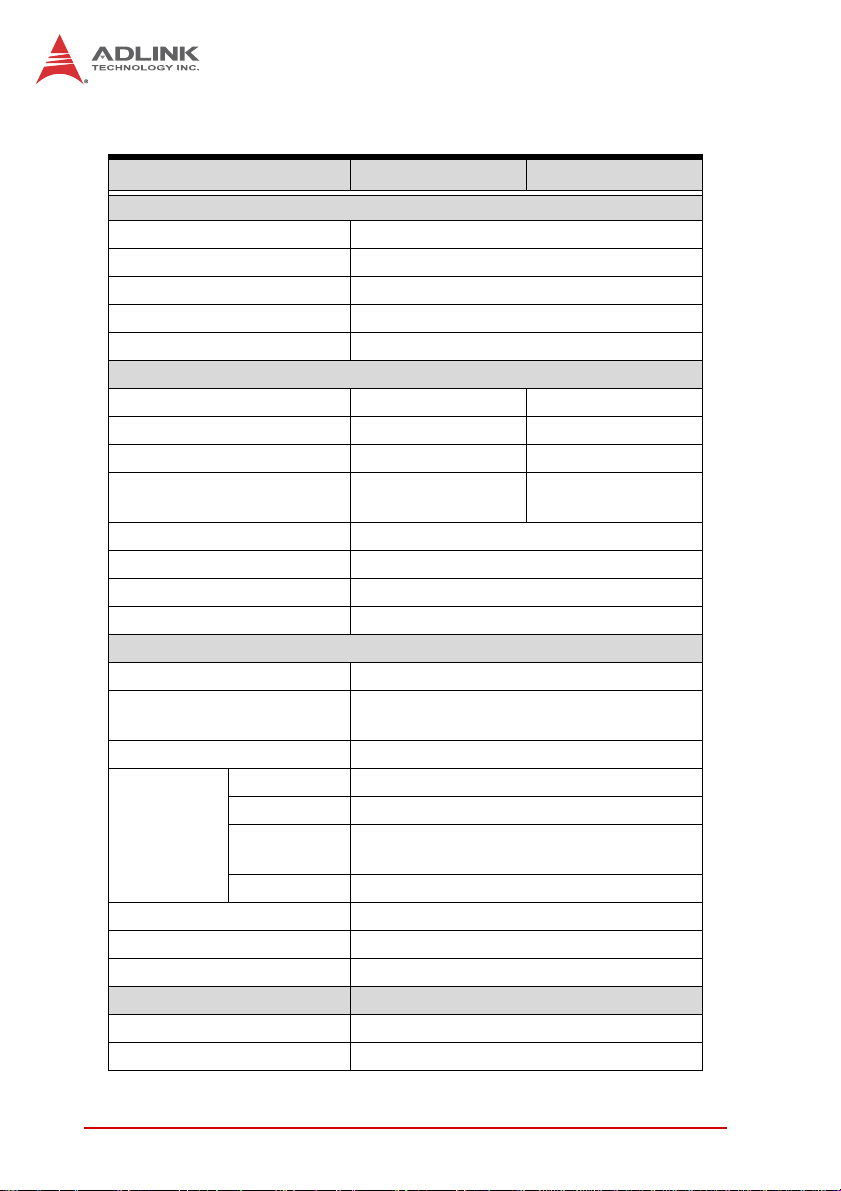

1.3 Specifications

NEON-1020 NEON-1040

Processing & Memory

Processor Quad core Intel Atom E3845 @ 1.91GHz

Display VGA output, max 2560x1600 at 60 Hz.

RAM 2GB DDR3L

Storage 8 to 32 GB solid state drive

Advanced Processing ROI, LUT, Shading Correction

Sensor

Image Sensor CMV2000 CMV4000

Resolution 2048 x 1088 2048 x 2048

Sensor Size 2/3” 1”

Frame Rate

Format Monochrome

Pixel Size (μm) 5.5

Shutter Global

Trigger Mode External trigger, software trigger, free run

I/O

Trigger Input 1x Opto-isolated trigger input

Digital Output

Digital Input 4x TTL level input

Drive Method Constant current 500 mA

PWM

Lighting

Control

Ethernet 1 x GbE

Serial Communication 1 x RS-232 (TX and RX only)

USB 1 x USB 2.0

Physical

Dimensions 68.5W x 110D x 52.7H mm

Lens mount C mount

Intensity PWM control, max. 125 KHz

Applicable

Light Units

20KHz 1000 steps

120fps (8bit)

60fps (12bit)

4x sink type output, max sink 100mA

sink voltage max 30VDC

12 VDC to 24 VDC illuminators

60fps (8bit)

30fps (12bit)

2Introduction

Page 13

NEON-1020/1040

NEON-1020 NEON-1040

Connectors

Software

OS

Environmental & Electrical

Power Consumption 12 to 24 VDC +/-10%, 13W (typical)

Operating Temperature 0 to 50°C

Vibration Operating, 5 Grms, 5-500 Hz, 3 axes

Certification IP67, CE, FCC Class A

1xM12 8-pin female, 1xM12 17-pin male,

1x M12 12-pin male

Windows 7, Windows Embedded Standard

7

Introduction 3

Page 14

1.4 Schematics

X All units are in millimeters (mm)

X External dimensions for the NEON-1020 and

NOTE:

NOTE:

71.5

30

NEON-1040 are identical

68.5

35.5

110

127.3

36

Figure 1-1: NEON-1040 Front View

4Introduction

Page 15

5.95

NEON-1020/1040

98.1

50

Figure 1-2: NEON-1020/1040 Rear View

Introduction 5

Page 16

65.2

1.50

Figure 1-3: NEON-1020/1040 Side View

6Introduction

52.7

Page 17

NEON-1020/1040

1.5 Indicators

Figure 1-4: NEON-1020/1040 LED Array

The NEON 1020/1040 provides five labeled LED indicators on the

top side, with function as follows.

Indicator Color Status Description

POWER Blue

STATUS Red

LAN ACT Green

USER1 Orange On/Off/ Flashing User defined LED1

USER2 Green On/Off/ Flashing User defined LED2

Table 1-1: NEON-1020/1040 LED Function

On System power on

Off System power off

On Image capture in progress

Off Image capture idle

On

Off Ethernet port disconnected.

Flashing

Ethernet port connected and

inactive

Ethernet port connected and

active

Introduction 7

Page 18

1.6 I/O Connectors

A

B C

Figure 1-5: NEON-1020/1040 I/O Array

A Power/IO/UART

B Ethernet

C VGA/USB

Table 1-2: NEON-1020/1040 I/O Array Legend

8Introduction

Page 19

1.6.1 Digital I/O and Power

Figure 1-6: Digital I/O and Power Connector

NEON-1020/1040

Pin Signal Type Description

1 RS232 RXD Input RS-232 receive. Brown

DO3/

2

Strobe out 3

DO1/

3

Strobe out 1

Hardware

4

trigger input

(+)

Hardware

5

trigger input

(-)

PWM light

6

control out (+)

Introduction 9

Output

Output

Input

Input

Output

Open-collector output 3

or strobe out 3

Open-collector output 1

or strobe out 1

Hardware Trigger input

positive

Hardware Trigger input

negative

PWM LED control out

positive, for

connection to LED

lighting device; Power

source of LED current

control is shared

System PWR

17-Pin M12

Pigtail

Blue

White

Green

Pink

Yell ow

Page 20

Pin Signal Type Description

17-Pin M12

Pigtail

PWM LED control out

negative, for

connection to LED

lighting device; Power

source of LED current

Black

7

PWM light

control out (-)

Output

control is shared

System PWR

Power input w/ input

8 System PWR Input

range +12V ~ +24V

Gray

+/-10%

Power input w/ input

9 System PWR Input

range +12V ~ +24V

Red

+/-10%

10 RS232 TXD Output RS-232 transmit Violet

DO2/

11

12

Strobe out 2

DO0/

Strobe out 0

Output

Output

13 DI3 Input

14 DI0 Input

15 DI2 Input

16 DI1 Input

Open-collector output 2

or strobe out 2

Open-collector output 0

or strobe out 0

Digital input signal

source 3

Digital input signal

source 0

Digital input signal

source 2

Digital input signal

source 1

Gray/Pink

Red/Blue

White/Green

Brown/Green

White/Yellow

Yellow/Brown

Ground, reserved for

17 GND GND

use with ground from

White/Gray

power supply

Table 1-3: Digital I/O and Power Pin Assignment

The negative pin of Digital OUT and Digital IN is GND.

NOTE:

NOTE:

10 Introduction

Page 21

NEON-1020/1040

1.6.2 100/GbE

M12 8-pin (female) connector that provides communication capabilities at 10 Mbit/sec, 100 Mbit/sec, or 1 Gbit/sec(1000 Mbit/sec).

Figure 1-7: 100/GbE Connector

Pin Signal Description

1 MDI_3- Data C-

2 MDI_4+ Data D+

3 MDI_4- Data D-

4 MDI_1- Data A-

5 MDI_2+ Data B+

6 MDI_1+ Data A+

7 MDI_3+ Data C+

8 MDI_2- Data B-

T able 1-4: 100/GbE Pin Assignment

Introduction 11

Page 22

1.6.3 VGA/USB

M12 12-pin (male) connector that transmits output video and USB

2.0 signals. The output video signal is a standard RGB analog

video output transferring the OS desktop to connected independent display devices. The video output can display an extended

Windows and/or an exclusive display.

Figure 1-8: VGA/USB Connector

Pin Signal Type Description

1 USB Power Output

2 USB DATA (+) Bidirectional USB data +

3 USB_DATA (-) Bidirectional USB data -

4 GND GND Ground

5 VGA RED Output Red of RGB video signal

6 VGA BLUE Output Blue of RGB video signal

7 VGA VSYNC Output

12 Introduction

5 V supplied to USB

peripherals

Vertical sync of RGB

video signal

Page 23

NEON-1020/1040

Pin Signal Type Description

8 VGA HSYNC Output

9 VGA GREEN Output

Horizontal synch of RBG

video signal

Green of RGB video

signal

10 GND GND Ground

11 VGA DDC SCL Bidirectional DDC serial clock line

12 VGA DDC SDA Bidirectional DDC serial data line

Table 1-5: VGA/USB Pin Assignment

1.7 General Purpose Digital Signals

1.7.1 General Purpose Digital Output (EDO)

Four digital output channels are provided, such that, in the common ground connection of digital output, as shown, when a 1

(logic high) is written by FPGA to a DO channel, sink current

passes through the transistors and the DO channel goes low, and

when a 0 (logic low) is written by FPGA to a DO channel, no current passes through the transistors and the DO channel goes high.

Max 100 mA

DOn

Max. 30VDC

GND

Figure 1-9: General Purpose Digital Output (EDO) Circuit

Introduction 13

Page 24

1.7.2 General Purpose Digital Input (EDI)

Four digital input channels are provided.

DIn

Max 6VDC

GND

1k

Figure 1-10: General Purpose Digital Input (EDI) Circuit

1.7.3 Hardware Trigger Input

Four digital input channels are provided.

Hardware Trigger input (+)

Max. 6VDC

Hardware Trigger input (-)

Figure 1-11: Hardware Trigger Input Circuit

1k

NEON-1020/1040

1.7.4 PWM Light Control Output

One channel constant-current sink LED driver, constant 500mA

output current with 1000 level light control controls brightness of

LED lighting devices, sharing the NEON-1020/1040 System PWR

input, requiring that System PWR voltage matches the LED lighting device's operating voltage.

14 Introduction

Page 25

NEON-1020/1040

System PWR

PWM LED control out (+)

Max. 500 mA

Neon-1020/1040

PWM controller

PWM LED control out (-)

Figure 1-12: PWM Light Control Output Circuit

LED Light

Introduction 15

Page 26

This page intentionally left blank.

16 Introduction

Page 27

NEON-1020/1040

2 Getting Started

This chapter describes connection and configuration of the

NEON-1020/1040.

2.1 Unpacking Checklist

Before unpacking, check the shipping carton for any damage. If

the shipping carton and/or contents are damaged, inform your

dealer immediately. Retain the shipping carton and packing

materials for inspection. Obtain authorization from your dealer

before returning any product to ADLINK. Ensure that the following items are included in the package.

X NEON-1020/1040

X Quick Start Guide

2.2 Connecting a VGA/USB cable

1. Align the alignment pin (device side) with the alignment

channel (cable side)

Figure 2-1: VGA/USB Alignment Pin (device side)

2. Fully insert the cable connector.

3. Tighten the threaded collar (cable side) to fix the connection.

Getting Started 17

Page 28

2.3 Connecting an Ethernet cable

1. Align the alignment pin (cable side) with the alignment

channel (device side)

Figure 2-2: Ethernet Alignment Channel (device side)

2. Fully insert the cable connector.

3. Tighten the threaded collar (cable side) to fix the connection.

18 Getting Started

Page 29

NEON-1020/1040

2.4 Connecting a power cable

1. Align the alignment pin (device side) with the alignment

channel (cable side)

Figure 2-3: Power Alignment Pin (device side)

2. Fully insert the cable connector.

3. Tighten the threaded collar (cable side) to fix the connec-

tion.

2.5 Operating System Installation

The NEON-1020/1040 is compatible with Windows Embedded

Standard 7 (WES7E),and supports File-Based Write Filter

(FBWF), providing a stable, secure, and high performance

software operating environment. The device OS is pre-installed.

For other OS support, please contact ADLINK directly.

2.6 Driver Installation

While the following describes NEON-1020/1040 driver installation

for WES 7 and Windows 7, with other Windows systems following

similar procedures.

1. Run Setup, installation begins.

Getting Started 19

Page 30

2. Select Next when prompted until installation is complete.

20 Getting Started

Page 31

NEON-1020/1040

Getting Started 21

Page 32

3. If a Security Warning window appears, select “Install this

driver anyway”.

22 Getting Started

Page 33

NEON-1020/1040

4. If a “Found New Hardware Wizard” window appears,

ignore and the window automatically closes after installation is complete.

5. When installation is complete, select Finish.

Getting Started 23

Page 34

The device should appear in the Device Manager, as shown

24 Getting Started

Page 35

NOTE:

NOTE:

NEON-1020/1040

If an error occurs and installation is rolled back, e-mail

the file setupapi.log in the Windows folder to ADLINK.

Log files on Vista systems are moved to %windir%\inf

and renamed to setupapi.app.log and setupapi.dev.log

where windir is the Windows folder.

Getting Started 25

Page 36

This page intentionally left blank.

26 Getting Started

Page 37

NEON-1020/1040

Important Safety Instructions

For user safety, please read and follow all instructions,

WARNINGS, CAUTIONS, and NOTES marked in this manual

and on the associated equipment before handling/operating the

equipment.

X Read these safety instructions carefully.

X Keep this user’s manual for future reference.

X Read the specifications section of this manual for detailed

information on the operating environment of this equipment.

X When installing/mounting or uninstalling/removing

equipment:

Z Turn off power and unplug any power cords/cables.

X To avoid electrical shock and/or damage to equipment:

Z Keep equipment away from water or liquid sources;

Z Keep equipment away from high heat or high humidity;

Z Keep equipment properly ventilated (do not block or

cover ventilation openings);

Z Make sure to use recommended voltage and power

source settings;

Z Always install and operate equipment near an easily

accessible electrical socket-outlet;

Z Secure the power cord (do not place any object on/over

the power cord);

Z Only install/attach and operate equipment on stable

surfaces and/or recommended mountings; and,

Z If the equipment will not be used for long periods of time,

turn off and unplug the equipment from its power source.

Important Safety Instructions 27

Page 38

X Never attempt to fix the equipment. Equipment should only

be serviced by qualified personnel.

A Lithium-type battery may be provided for uninterrupted, backup

or emergency power.

Risk of explosion if battery is replaced with one of an incorrect

type. Dispose of used batteries appropriately.

WARNING:

X Equipment must be serviced by authorized technicians

when:

Z The power cord or plug is damaged;

Z Liquid has penetrated the equipment;

Z It has been exposed to high humidity/moisture;

Z It is not functioning or does not function according to the

user’s manual;

Z It has been dropped and/or damaged; and/or,

Z It has an obvious sign of breakage.

28 Important Safety Instructions

Page 39

Getting Service

Contact us should you require any service or assistance.

ADLINK Technology, Inc.

Address: 9F, No.166 Jian Yi Road, Zhonghe District

New Taipei City 235, Taiwan

ᄅקؑխࡉ৬ԫሁ 166 ᇆ 9 ᑔ

Tel: +886-2-8226-5877

Fax: +886-2-8226-5717

Email: service@adlinktech.com

Ampro ADLINK Technology, Inc.

Address: 5215 Hellyer Avenue, #110

San Jose, CA 95138, USA

Tel: +1-408-360-0200

Toll Free: +1-800-966-5200 (USA only)

Fax: +1-408-360-0222

Email: info@adlinktech.com

ADLINK Technology (China) Co., Ltd.

Address: Ϟ⍋Ꮦ⌺ϰᮄᓴ∳催⾥ᡔು㢇䏃 300 ো(201203)

300 Fang Chun Rd., Zhangjiang Hi-Tech Park

Pudong New Area, Shanghai, 201203 China

Tel: +86-21-5132-8988

Fax: +86-21-5132-3588

Email: market@adlinktech.com

NEON-1020/1040

ADLINK Technology Beijing

Address: ࣫ҀᏖ⍋⎔Ϟഄϰ䏃 1 োⲜ߯ࡼ E ᑻ 801 ᅸ(100085)

Beijing, 100085 China

Tel: +86-10-5885-8666

Fax: +86-10-5885-8626

Email: market@adlinktech.com

ADLINK Technology Shenzhen

Address: ⏅ഇᏖቅ⾥ᡔು催ᮄϗ䘧᭄ᄫᡔᴃು

Tel: +86-755-2643-4858

Fax: +86-755-2664-6353

Email: market@adlinktech.com

LiPPERT ADLINK Technology GmbH

Address: Hans-Thoma-Strasse 11, D-68163

Mannheim, Germany

Tel: +49-621-43214-0

Fax: +49-621 43214-30

Email: emea@adlinktech.com

Rm. 801, Power Creative E, No. 1 Shang Di East Rd.

A1 2 ὐ C (518057)

2F, C Block, Bldg. A1, Cyber-Tech Zone, Gao Xin Ave. Sec. 7

High-Tech Industrial Park S., Shenzhen, 518054 China

Getting Service 29

Page 40

ADLINK Technology, Inc. (French Liaison Office)

Address: 6 allée de Londres, Immeuble Ceylan

91940 Les Ulis, France

Tel: +33 (0) 1 60 12 35 66

Fax: +33 (0) 1 60 12 35 66

Email: france@adlinktech.com

ADLINK Technology Japan Corporation

Address: ͱ101-0045 ᵅҀ䛑ҷ⬄⼲⬄䤯ފ⬎ 3-7-4

Tel: +81-3-4455-3722

Fax: +81-3-5209-6013

Email: japan@adlinktech.com

ADLINK Technology, Inc. (Korean Liaison Office)

Address: 137-881 昢殾柢 昢爎割 昢爎堆嵢 326, 802 (昢爎壟, 微汾瘶捒娯)

Tel: +82-2-2057-0565

Fax: +82-2-2057-0563

Email: korea@adlinktech.com

ADLINK Technology Singapore Pte. Ltd.

Address: 84 Genting Lane #07-02A, Cityneon Design Centre

Tel: +65-6844-2261

Fax: +65-6844-2263

Email: singapore@adlinktech.com

ADLINK Technology Singapore Pte. Ltd. (Indian Liaison Office)

Address: #50-56, First Floor, Spearhead Towers

Malleswaram, Bangalore - 560 055, India

Tel: +91-80-65605817, +91-80-42246107

Fax: +91-80-23464606

Email: india@adlinktech.com

⼲⬄ 374 ɛɳ 4F

KANDA374 Bldg. 4F, 3-7-4 Kanda Kajicho,

Chiyoda-ku, Tokyo 101-0045, Japan

802, Mointer B/D, 326 Seocho-daero, Seocho-Gu,

Seoul 137-881, Korea

Singapore 349584

Margosa Main Road (between 16th/17th Cross)

ADLINK Technology, Inc. (Israeli Liaison Office)

Address: 27 Maskit St., Corex Building

PO Box 12777

Herzliya 4673300, Israel

Tel: +972-77-208-0230

Fax: +972-77-208-0230

Email: israel@adlinktech.com

ADLINK Technology, Inc. (UK Liaison Office)

Tel: +44 774 010 59 65

Email: UK@adlinktech.com

30 Getting Service

Loading...

Loading...