Page 1

ND-6021 & ND-6024

Analog Input Modules

User’s Guide

Page 2

Page 3

©Copyright 1996~2001 ADLINK Technology Inc.

All Rights Reserved.

Manual Rev. 4.00: June 5,2001

The information in this document is subject to change without prior notice in

order to improve reliability, design and function and does not represent a

commitment on the part of the manufacturer.

In no event will the manufacturer be liable to direct, indirect, special, incidental,

or consequential damages arising out of the use or inability to use the product

or documentation, even if advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

NuDAM

Other product names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their respective

companies.

is registered trademarks of ADLINK Technology Inc.,

Page 4

Page 5

Table of Contents

Chapter 1 Introduction .......................................................1

1.1 About the NuDAM Analog Output Modules ............................. 1

1.2 Overview of NuDAM-6021 ....................................................... 2

1.3 Overview of NuDAM-6024 ....................................................... 7

Chapter 2 Initialization & Installation ..............................12

2.1 Software Installation............................................................... 12

2.2 Initializing a Brand-New Module............................................. 13

2.3 Install a New NuDAM to a Existing Network .......................... 15

2.4 Application Wiring for NuDAM-6021 ......................................16

2.5 Application Wiring for NuDAM-6024 ......................................17

Chapter 3 Command Set .................................................. 18

3.1 Command and Response ...................................................... 18

3.2 Summary of Command Set.................................................... 21

3.2. Set Configuration.................................................................... 23

3.3 Read Configuration ................................................................26

3.4 Read Module Name ...............................................................27

3.5 Read Firmware Version.......................................................... 28

3.6 Reset Status........................................................................... 29

3.7 Synchronized Sampling (6024 only) ......................................30

3.8 Read Synchronized Data (6024 only) .................................... 31

3.9 Digital Input (6024 only) .........................................................32

3.10 Analog Data Output................................................................ 33

3.11 4mA Offset Calibration ........................................................... 35

3.12 20mA Calibration.................................................................... 36

3.13 Trim Calibration ...................................................................... 37

3.14 Save Power On Analog Output Value.................................... 38

3.15 Last Value Readback ............................................................. 39

3.16 Current Readback .................................................................. 40

3.17 Read....................................................................................... 41

3.18 Change Leading Code Setting ............................................... 43

3.19 Set Host Watchdog Timer & Safety Value ............................. 45

3.20 Read Host Watchdog Timer & Safety Value.......................... 48

3.21 Host is OK .............................................................................. 50

Table of Contents • i

Page 6

Chapter 4 Data Format .....................................................51

4.1 Unit Conversion...................................................................... 51

4.2 Engineering Units................................................................... 52

4.3 Percent of FSR....................................................................... 53

4.4 Hexdecimal Format ................................................................ 54

4.5 Summary of Data Format....................................................... 55

Chapter 5 Analog Output Calibration.............................. 56

5.1 Calibration .............................................................................. 56

5.2 Analog Output Module Calibration ......................................... 56

Product Warranty/Service ...... Error! Bookmark not defined.

ii • Table of Contents

Page 7

1

Introduction

1.1 About the NuDAM Analog Output Modules

The NuDAM provides an analog output modules which can convert the digital

command to analog. The basic features of each module are shown here.

• NuDAM-6021 : analog signal output module with safety functions

• NuDAM-6024 : 4 channel analog output module

Introduction • 1

Page 8

1.2 Overview of NuDAM-6021

What is NuDAM-6021 ?

ND-6021 is an analog signal output module. It receives the digital command

from host computer through RS-485 network. The format of the digital value

can be engineering units, hexdecimal format or percentage of full-scale

range(FSR). A microprocessor is used to convert the digital command to

digital value to send to DAC. The DAC converts the digital value into analog

form. The analog output can be either voltage or current output.

The ND-6021 is designed for safety. It provides many safety functions such as

isolation, watchdog, and power on safe value. The opto-isolators provide

5000Vrms isolation voltage to isolate the digital section and the remote

controlled analog equipments. The damage of power surges is avoided.

Another safety fucntion is the watchdog. Whenever the host is loss contact with

the remoted NuDAM module, or the micro-processor is down, the module will

reset itself and send the safety value to the analog output therefore the industry

safety is guarantee. The safety value / power-up value can be set by

configuration software.

The analog output can be readback through the module‘s ADC. which can

monitor the ’real‘ output of the device. The host can check the digital command

and the real output to avoid short circuits. The slew rate of the output signal is

also controllable by software.

Features of NuDAM-6021

• One uni-polar analog output channel

• Two sets of differential current and voltage output terminals

• Versatile digital signal format

• Programmable host watchdog timer for host failure protection

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

2 • Introduction

Page 9

Specifications of NuDAM-6021

Interface

♦

• Interface : RS-485, 2 wires

• Speed (bps) : 1200, 2400, 4800, 9600, 19.2K, 38.4K

Analog Output

♦

• Singal Output type: Differential type

• Resolution: 12 bits

• Accuracy: ±0.1% of FSR for current output

±0.2% of FSR for voltage output

• Unit Convertion: V or mA

• Output range: Voltage output: 0 to 10 V (uni-polar)

Current output: 0 to 20 mA,4 to 20 mA

• Maximum Sampling Rate: 100 samples /sec

• Slew rate: Voltage output: 0.0625 to 64 V/sec

Current output: 0.125 to 128 mA/sec

• Internal Current Load Resistor: 500Ω (%1)

Readback Analog Input

♦

• Accuracy: ±0.2% of FSR

Isolation

♦

• Isolation voltage: 5000 Vrms

Watchdog Function

♦

• Module internal watchdog timer : 150 ms

• Power failure threshold : 4.65 V

• Host programmable watchdog : 100 ms ~ 25.500 sec

Introduction • 3

Page 10

Power

♦

• Power supply : +10V to +30V

• Power consumption : 1.0W

Pin Definitions of ND-6021

Pin # Signal Name Description

1 +IOUT Positive Current Output Terminal

2 -IOUT Negative Current OutputTerminal

3 +VOUT Positive Voltage Output Terminal

4 -VOUT Negative Voltage Output Terminal

6 Default* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

4 • Introduction

Page 11

A Look at ND-6021 & Pin Assignment

20

Analog Output

ND-6021

Code Output R ange

30

31

32

(Current/Voltage)

0 ~20 mA

4 ~ 20 mA

0 ~ 10V

1

+VOUT

-IOUT

+IOUT

-VOUT

DEFAULT*

(Y)DATA+

(G)DATA-

11

10

(R)+Vs

(B)GND

Introduction • 5

Page 12

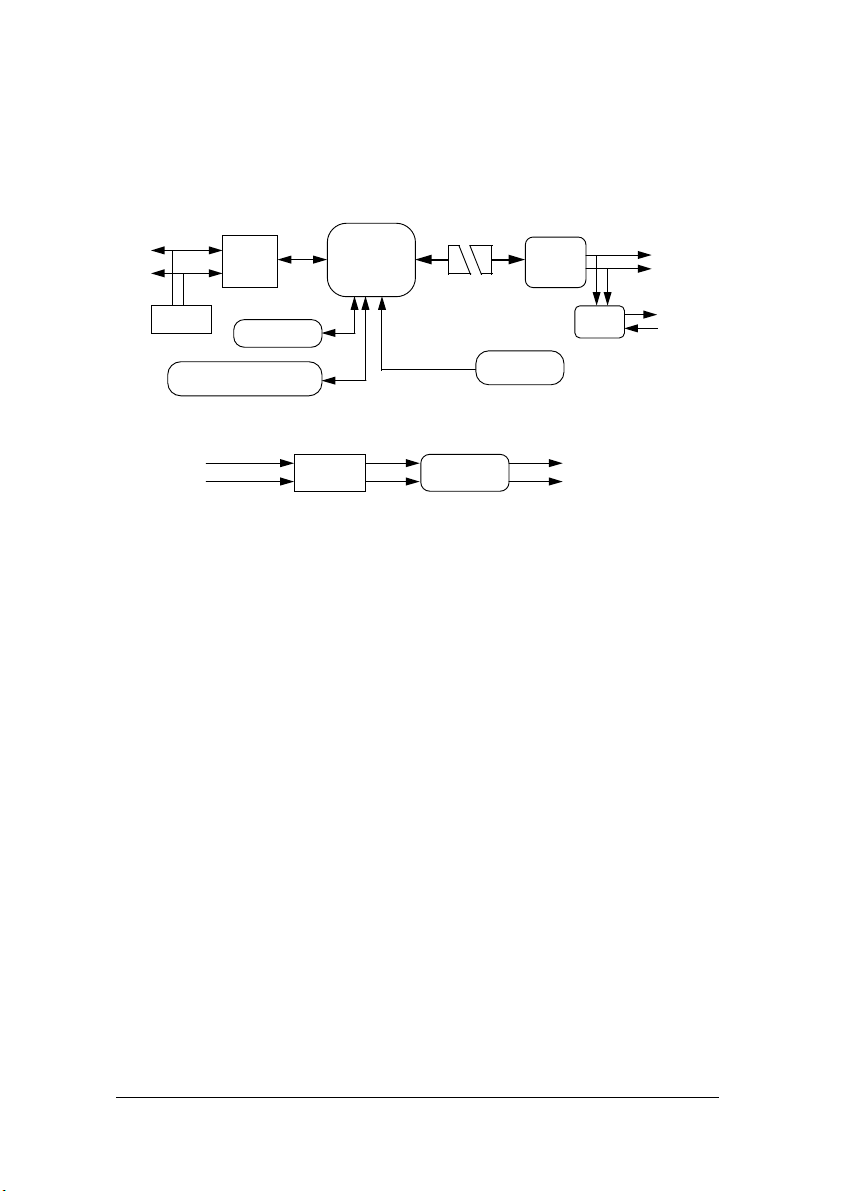

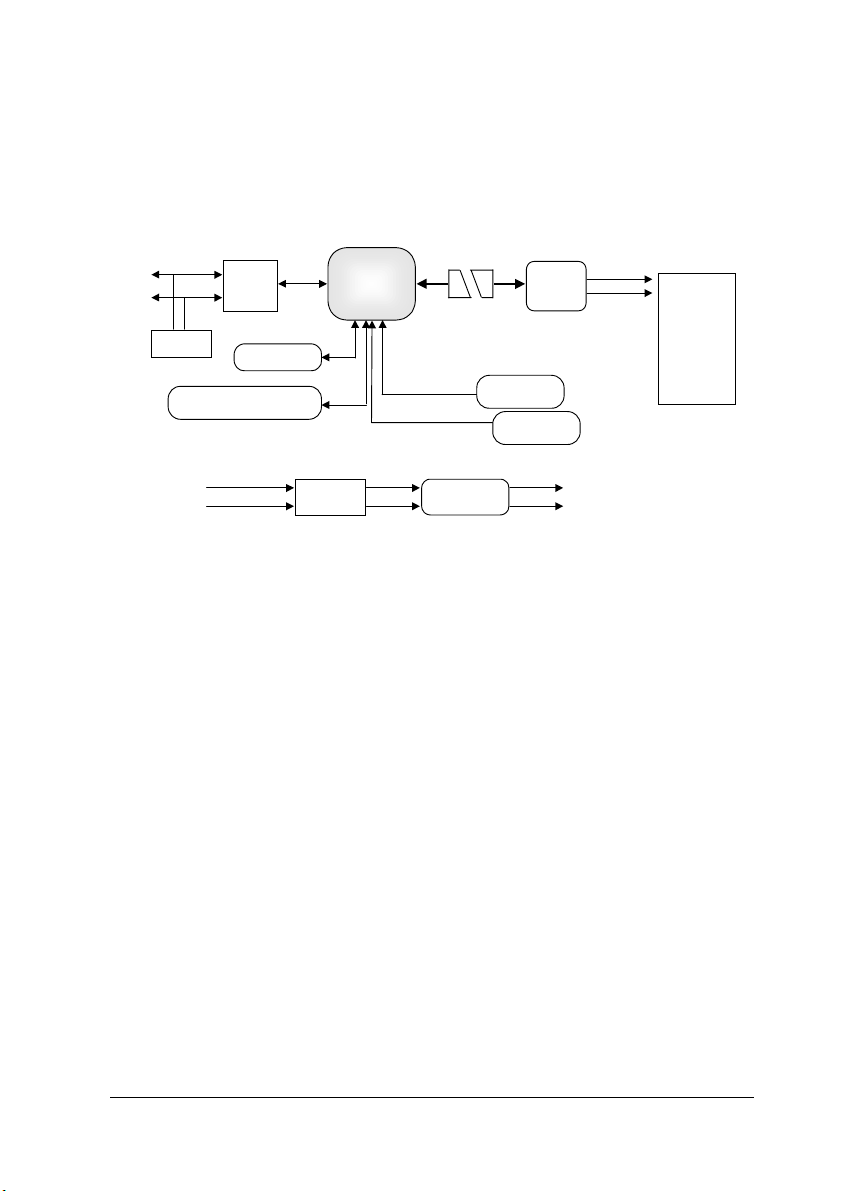

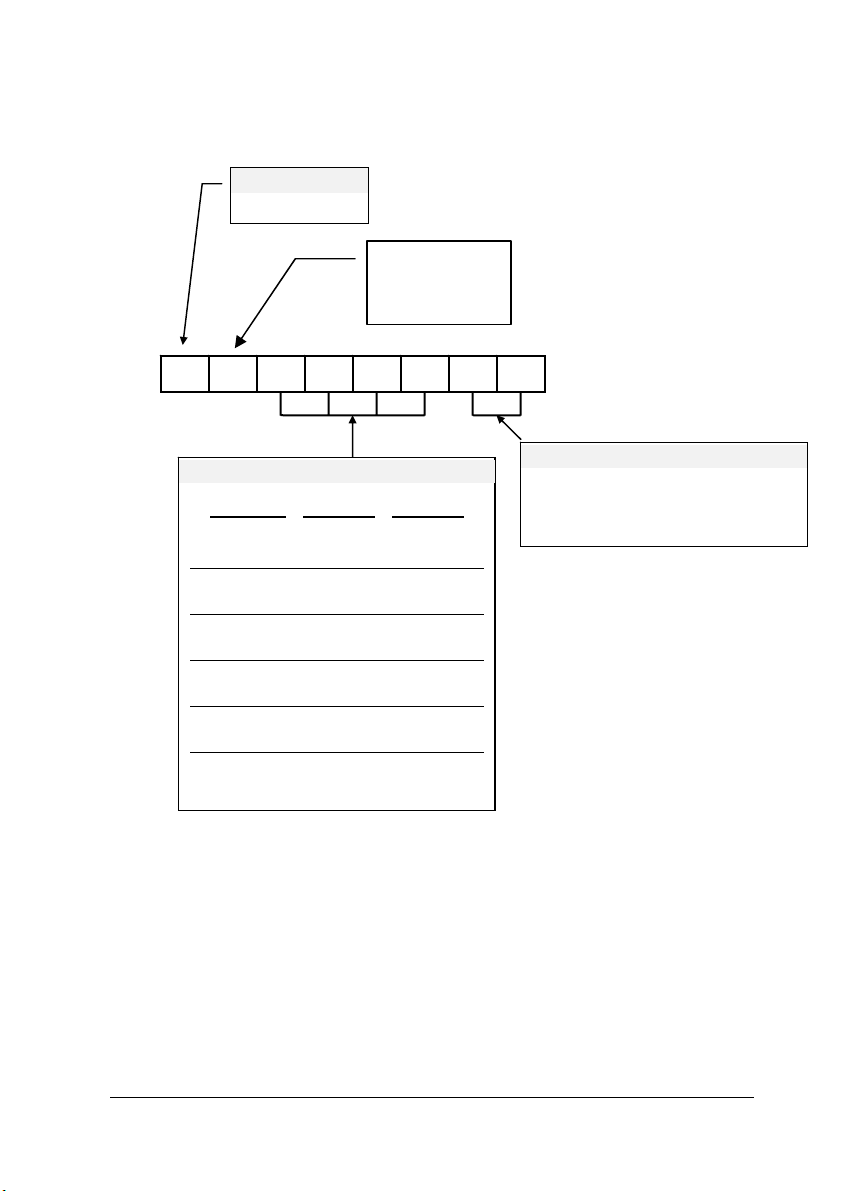

Functional Block Diagram of ND-6021

Data+

RS-485

Rec/DRv

Data-

RS-485

Terminator

Watchdog / Power Failure

Supervisor

+10V ~ +30 V

GND

EEPROM

Power

Regulator

Micro

Processor

+5V

GND

DC to DC

Convertor

Photo

Isolators

*Defalut Setting

(1 bit Digital In)

DAC

(12 bits)

Voltage Output

V to I

Current Output

Isolated Power

Isolated Ground

VOUT +

VOUT -

IOUT +

IOUT -

6 • Introduction

Page 13

1.3 Overview of NuDAM-6024

What is NuDAM-6024 ?

ND-6024 is a 4 channel bipolar analog signal output module. It receives the

digital command from host computer through RS-485 network. A

microprocessor is used to convert the digital command to digital value to send

to DAC. The DAC converts the digital value into analog form.

The ND-6024 is designed for safety. It provides many safety functions such as

isolation, watchdog, and power on safe value. The opto-isolators provide

5000Vrms isolation voltage to isolate the digital section and the remote

controlled analog equipments. The damage of power surges is avoided.

Another safety fucntion is the watchdog. Whenever the host is loss contact

with the remoted NuDAM module, or the micro-processor is down, the module

will reset itself and send the safety value to the analog output therefore the

industry safety is guarantee. The safety value / power-up value can be set by

configuration software.

Features of NuDAM-6024

• 4 channel bipolar analog output

• Programmable host watchdog timer for host failure protection

• Internal watchdog timer for device failure protection

• Easy programming by software

• Easy installation and wiring

Specifications of NuDAM-6024

Interface

♦

• Interface : RS-485, 2 wires

• Speed (bps) : 1200, 2400, 4800, 9600, 19.2K, 38.4K

Analog Output

♦

• Channel numbers : 4

• Singal Output type: Differential output

Introduction • 7

Page 14

Voltage Output: ±10V

♦

• Resolution: 12-bit resolution

• Accuracy: ±1/2 LSB

• Gain Drift: ±5ppm/°C

Digital Input

♦

• Channel numbers : 7

• Logical level 0: +2V max.

Logical Level 1: +3.5V ~ +30V

Isolation

♦

• Isolation voltage: 5000 Vrms

Watchdog Function

♦

• Module internal watchdog timer : 150 ms

• Power failure threshold : 4.65 V

• Host programmable watchdog : 100 ms ~ 25.500 sec

Power

♦

• Power supply : +10V to +30V

• Power consumption : 2.5W

8 • Introduction

Page 15

Pin Definitions of ND-6024

Pin # Signal Name Description

1 DI4 Digital input channel 4

2 DI3 Digital input channel 3

3 DI2 Digital input channel 2

4 DI1 Digital input channel 1

5 DI0 Digital input channel 0

6 Default* Initial state setting

7 (Y) DATA+ RS-485 series signal, positive

8 (G) DATA- RS-485 series signal, negative

9 (R) +Vs Power supply, +10V~+30V

10 (B) GND Ground

11 VOUTA+ Positive Voltage Output A Terminal

12 AGND Negative Voltage Output A Terminal

13 VOUTB+ Positive Voltage Output B Terminal

14 BGND Negative Voltage Output B Terminal

15 VOUTC+ Positive Voltage Output C Terminal

16 CGND Negative Voltage Output C Terminal

17 VOUTD+ Positive Voltage Output D Terminal

18 DGND Negative Voltage Output D Terminal

19 DI6 Digital input channel 6

20 DI5 Digital input channel 5

Introduction • 9

Page 16

A Look at ND-6024 & Pin Assignment

DI5

DI6

DGND

VOU TD+

ND-6024 4-CH

Code Signal

33

CGND

VOU TC+

BGND

VOU TB +

Analog Output

10V

±

AGND

VOU TA+

10 • Introduction

DI4

DI3

DI2

DI1

DI0

DEFAULT*

(Y)DATA+

(G)DATA-

(R)+Vs

(B)GND

Page 17

Functional Block Diagram of ND-6024

Data+

RS-485

Rec/DRv

Data-

RS-485

Terminator

Watchdog / Power Failure

Supervisor

+10V ~ +30 V

GND

EEPROM

Power

Regulator

Micro

Processor

+5V

GND

DC to DC

Convertor

Photo

Isolators

*Defalut Setting

(1 bit Digital In)

DAC

(12 bits)

DIØ…… DI6

Voltage Outpu t

Isolated Pow er

Isolated Grou nd

•VOUTA+

AGND

•VOUTB+

BGND

•VOUTC+

CGND

•VOUTD+

DGND

Introduction • 11

Page 18

2

Initialization & Installation

2.1 Software Installation

1. If you have already installed “NuDAM Administration” then skip other

steps.

2. Backup your software diskette.

3. Insert “NuDAM Administration” diskette into floppy drive A:

4. Change drive to A:

5. Installation command syntax

INSTALL drive:

drive name is C to Z.

Example 1 : install to drive C:

A:\>

Example 2 : install to drive F:

A:\>

6. NuDAM Administration Utility will be installed in the directory C:\NUDAM

12 • Initialization & Installation

INSTALL C:

INSTALL F:

Page 19

2.2 Initializing a Brand-New Module

Objective of Initializing a Brand-New NuDAM

All NuDAM modules, except NuDAM-6520 and NuDAM-6510, in a RS-485

network must have an unique address ID. Every brand-new NuDAM has a

factory default setting as following:

• Address ID is 01

• Baud rate is 9600 bps

• Check-sum disable

• Host Watchdog timer is disable

Therefore, to configure the brand-new NuDAM before using is necessary to

avoid conflicting address. The baud rate may also be changed according to

user‘s requirements.

The initialization procedures of a brand-new NuDAM are shown in the following

sections.

Default State

The NuDAM modules must be set at Default State when you want to change the

default settings, including the ID address, baud rate, check-sum status etc. All

NuDAM modules have an special pin labeled as

be in Default State if the

Under this state, the default configuration is set as following:

DEFAULT*

pin is shorted to ground when power ON.

DEFAULT*

. The module will

• Address ID is 00

• Baud rate is 9600 bps

• Check-sum disable

• Watchdog timer is disable

Therefore, the configuration of the host and the module can be easily set

identically and initializing a module will be possible no matter what configuration

is set under operating state.

Initialization Equipments

• Host computer with an RS-232 port

• An installed RS-485 module (NuDAM-6520) with 9600 baud rate

• The brand new NuDAM module

Initialization & Installation • 13

Page 20

• Power supply (+10 to +30 VDC) for NuDAM modules

• Administrating utility software

Initialization Procedure

1. Power off the host computer and the installed NuDAM-6520. Be sure of

the baud rate of the NuDAM-6520 is 9600 bps.

2. Connect a brand new NuDAM module with the RS-485. Set the module

in Default State by shorting the

detailed wiring.

3. Power on the host computer.

4. Power on the power supply for NuDAM modules.

5. Use the NuDAM Administrating utility to configure the address ID, Baud

rate and check-sum status of the module.

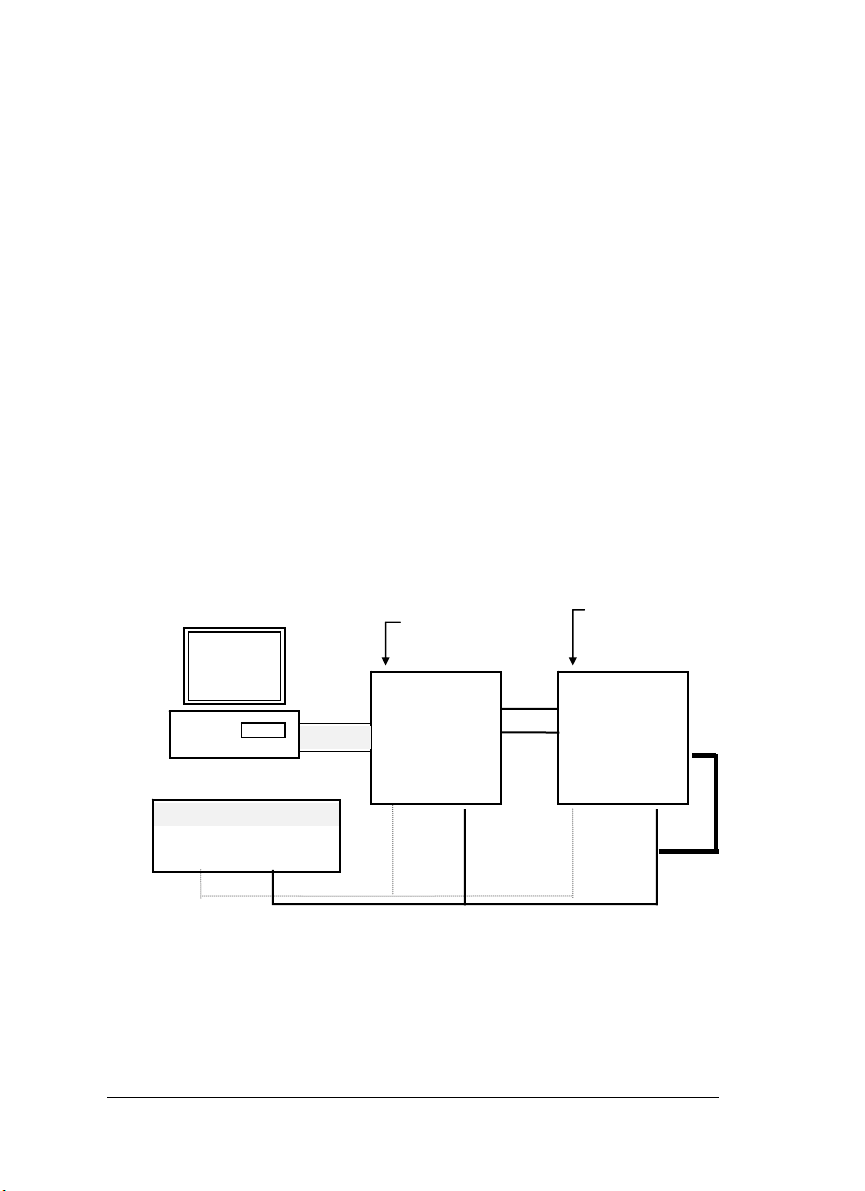

Initialization Wiring

DEFAULT*

pin. Refer to Figure 2.1 for

Host

Computer

RS-232

Local Power Supply

+10 V to +30 V

+Vs GND

Figure 2-1 Layout for Initialization the NuDAM module

14 • Initialization & Installation

NuDAM-6520

RS-232/RS-485

Converter

DATA +

DATA -

+Vs GND

New

NuDAM

module

DATA+

DATA Default*

+Vs GND

Page 21

2.3 Install a New NuDAM to a Existing Network

Equipments for Install a New Module

• A existing NuDAM network

• New NuDAM modules

• Power supply (+10 to +30 V

Installing Procedures

1. Configure the new NuDAM module according to the initialization

procedure in section 2.2.

2. The baud rate and check-sum status of the new module must be identity

with the existing RS-485 network. The address ID must not be conflict

with other NuDAM modules on the network.

3. Power off the NuDAM power supply of the existing RS-485 network.

4. Power off the host computer.

5. Wire the power lines for the new NuDAM with the existing network. Be

careful about the signal polarity as wiring.

6. Wire the RS-485 data lines for the new NuDAM with the existing

network. Be careful about the signal polarity as wiring.

7. Wire to the input or output devices. Refer to section 2.4 for illustrations.

8. Power on the host computer.

9. Power on the NuDAM local power supply.

DC

)

10. Use the NuDAM administration utility to check entire network.

Initialization & Installation • 15

Page 22

2.4 Application Wiring for NuDAM-6021

Differential Current Output

Differential Current Output Channel of NuDAM 6021

DAC

Differential Voltage Output

Differential Voltage Output Channel of NuDAM 6021

DAC

+IOUT

Current Loading

-IOUT

+VOUT

Voltage Loading

-VOUT

16 • Initialization & Installation

Page 23

2.5 Application Wiring for NuDAM-6024

Differential Voltage Output

Differential Voltage Output Channel of NuDAM 6021

DAC

+VOUT

Voltage Loading

-VOUT

Initialization & Installation • 17

Page 24

3

Command Set

3.1 Command and Response

Introduction

The NuDAM command is composed by numbers of characteristics, including

the leading code, address ID, the variables, the optional check-sum bytes, and

a carriage return to indicate the end of a command. The host computer can

only command only one NuDAM module except those synchronized

commands with wildcard address “**”. The NuDAM may or may not give

response to the command. The host should check the response to handshake

with the modules.

Document Conventions

The following syntax conventions describes the NuDAM commands in this

manual.

Leading Code is the first characteristic of the NuDAM

(Leading Code)

(Addr)

(Command

Variable)

[Data]

[Checksum]

command. All NuDAM commands need a command

leading code, such as %,$,#,@,...etc.

1- character

Module’s address ID, the value is in the range of 00 - FF

(Hex).

2- character

Command codes or value of variables.

Variable length

Some commands need additional data.

Variable length

Checksum in brackets indicate optional parameter,

only checksum is enable then this field is required.

18 • Command Set

Page 25

2- character

< >

Format of NuDAM Commands

(Leading Code)(Addr)(Command)[Data][Checksum]<CR>

When checksum is enable then [Checksum] is needed, it is 2-character. Both

command and response must append the checksum characters.

How to calculate checksum value ?

Identifies a control code character, such as <CR> for

carriage return, its value is 0x0D. 1- character

[Checksum] =

Example 1: checksum is disable

Example 2: checksum is enable

‘$’ = 0x24 ‘0’ = 0x30 ‘1’ = 0x31 ‘2’ = 0x32

((LeadingCode)+(Addr)+(Command)+[Data])

User Command : $012<CR>

Response : !01400600<CR>

$

01

2

<CR>

User Command :

Response :

$

01

2

B7

<CR>

: LeadingCode

: Address

: Command (Read Configuration)

: Carriage return 0x0D

$012B7<CR>

!01400600AC<CR>

: LeadingCode

: Address

: Command (Read Configuration)

: Checksum value

: Carriage return 0x0D

MOD 0x100

Command Set • 19

Page 26

B7 = (

0x24 + 0x30 + 0x31 + 0x32

‘!’ = 0x24 ‘0’ = 0x30 ‘1’ = 0x31 ‘4’ = 0x34

‘6’ = 0x36

AC

= ( 0x24 + 0x30 + 0x31 + 0x34 + 0x30 + 0x30 + 0x36 + 0x30

MOD 0x100

Note : 1. There is no spacing between the command words and the

2. Every command follows a <CR> carriage return for ending.

3. The checksum characters are optional.

Response of NuDAM Commands

The response message depends on versatile NuDAM command. The

response is composed with a few characteristics, including leading code,

variables, and carriage return for ending. There are two categories of leading

code for response message, ”!“ or ”>“ means valid command and ”?“ means

invalid. By checking the response message, user can monitor the command is

valid or not.

Note : Under the following conditions, there will have no response message.

1. The specified address ID is not exist.

2. Syntax error.

3. Communication error.

4. Some special commands does not have response message .

checksum characters.

) MOD 0x100

)

20 • Command Set

Page 27

3.2 Summary of Command Set

There are three categories of NuDAM commands. The first is the general

commands, including set configuration command, read configuration, reset,

read module‘s name or firmware version, etc. Every NuDAM can response to

the general commands. The second is the functional commands, which

depends on functions of each module. Not every module can execute all

function commands. The third is the special commands including functions

about the programmable watchdog timer, safe values, and the programmable

leading code. All the commands used in the NuDAM analog output module are

list in the following table.

Command Set of Analog Output Modules

Command Syntax Module

s

General Commands

Set Configuration

Read Configuration

Read Module Name

Read Firmware Version

Reset Status

Functional Commands

Synchronized Sampling

Read Synchronized Data

Digital Input

Analog Data Out

4 mA Offset Calibration

20 mA Offset Calibration

Trim Calibration

Save Power On Analog

Value

Last Value Readback

Current Readback

Special Commands

Read Command Leading

Code Setting

Change Command

%(OldAddr)(NewAddr)

All 23

(OutputRange)(BaudRate)

(DataFormat)

$(Addr)2

$(Addr)M

$(Addr)F

$(Addr)5

#**

$(Addr)9

$(Addr)8

#(Addr)(OutData)

#(Addr)(Port)(OutData)

All 26

All 27

All 28

All 29

6024

6024

6024

6021 30

6024

$(Addr)0 6021(1)

$(Addr)1 6021(1)

$(Addr)3(Counts) All(1)

$(Addr)4

$(Addr)6

$(Addr)6(Port)

$(Addr)8

~(Addr)0

~(Addr)10(C1)(C2)(C3)

All 38

6021 39

6024

6021 40

All

All 43

Error!

Bookmark

not

defined.

Page

35

36

37

Command Set • 21

Page 28

Leading Code Setting

Set Host Watchdog /

Safety Value

Read Host WatchDog /

Safe Value

Host is OK

Note: “ALL” means for ND-6021, ND-6024

(1) For Firmware Reversion E1.00,the command must beprocessed in

*Default mode.

(C4)(C5)(C6)

~(Addr)2(Flag)(TimeOut)

(SafeValue)

~(Addr)2(Flag)(TimeOut)

(SafeA)(SafeB)(SafeC)

(SafeD)

~(Addr)3

~**

6021 45

6024

All 48

All 50

22 • Command Set

Page 29

3.2. Set Configuration

@Description

Configure the basic setting of NuDAM, including the address ID, output

signal range, baud rate, and data format. The new configuration will be

available after executing the command.

@Syntax

%(OldAddr)(NewAddr)(OutputRange)(BaudRate)(DataFormat)<CR>

% Command leading code. (1-character)

NuDAM module original address ID. The

(OldAddr)

(NewAddr)

(OutputRange)

(BaudRate)

(DataFormat)

default address ID of a brand new module is

01. The value range of address ID is 00 to FF

in hexadecimal. (2-character)

New address ID, if you don’t want to change

address ID, let new address ID equals to the

old one. (2-character)

Define analog output range, refers to Table

3-1 for details. (2-character)

Define communication baud rate, refers to

Table 3-2 for details. (2-character)

Define checksum, integration time and

output data format, refers to Figure 3-1 for

details. (2-character)

@Response

!(Addr)<CR>

or

?(Addr)<CR>

(Addr)

!

?

Note : When you want to change the checksum or baud rate, the DEFAULT*

pin must be grounded at first.

@Example

Address ID.

Command is valid.

Command is invalid, parameter values are invalid,

or change the setting without grounding the

DEFAULT* pin.

Command Set • 23

Page 30

User command: %0118310610<CR>

Response: !18<CR>

Item Meaning Description

% (Leading Code) Command leading code.

01 (OldAddr) Original address ID is 01(Hex).

18 (NewAddr) New address ID is 18(Hex).

31 (OutputRange) Analog output range is 4 to 20 mA

06 (BaudRate) Baud rate is 9600.

10 (DataFormat) 10 means a slew rate is 1.000 mA/sec

and checksum is disable.

<CR> Carriage return 0x0D.

Code

(Hex)

30 0 to 20 mA 6021

31 4 to 20 mA 6021

32 0 to 10 V 6021

33 -10 to 10 V 6024

Signal Range of Output Range Modules

Table 0-1 Analog Output Range Setting

Code Baudrate

03 1200 bps

04 2400 bps

05 4800 bps

06 9600 bps

07 19200 bps

08 38400 bps

24 • Command Set

Table 3-2 Baud rate setting code

Page 31

Reserved

Must to be 0

Checksum

0 : disable

1 : enable

7

6 5

BitCode

0000 immediate change

0001 0.0625

4

3

2 1 0

Slew Rate

Voltage Current

V/sec 0.125 mA/sec

Analog Output Data Unit

00 : Engineering units

01 : % of Full Scale Range

10 : Hexadecimal

0010 0.125 V/sec 0.250 mA/sec

0011 0.250

V/sec 0.500 mA/sec

0100 0.500 V/sec 1.000 mA/sec

0101 1.000 V/sec 2.000 mA/sec

0110 2.000

V/sec 4.000 mA/sec

0111 4.000 V/sec 8.000 mA/sec

1000 8.000 V/sec 16.00 mA/sec

1001 16.00

V/sec 32.00 mA/sec

1010 32.00 V/sec 64.00 mA/sec

1011 64.00 V/sec 128.0 mA/sec

Figure 3-1 Data format of Analog Output Setting

*6024 only supports immediate change and engineering units.

Command Set • 25

Page 32

3.3 Read Configuration

@Description

Read the configuration of module on a specified address ID.

@Syntax

$(Addr)2<CR>

$

(Addr)

2

@Response

!(Addr)(OutputRange)(BaudRate)(DataFormat)<CR>

or

?(Addr)<CR>

!

?

(Addr)

(OutputRange)

(BaudRate)

(DataFormat)

@Example

User command: $182<CR>

Response: !18320610<CR>

!

18

32

06

10

Command leading code

Address ID.

Command code for reading configuration

Command is valid.

Command is invalid.

Address ID.

Current setting of analog voltage output, refers

to Table 3-1 for details.

Current setting of communication baud rate,

refers to Table 3-2 for details.

Current settings of checksum, integration time

and output data format, refers to Figure 3-1 for

details.

Command is valid.

Address ID.

Analog output range is 0 to 10V

Baud rate is 9600 bps.

The output data is in engineering units, slew rate is

1mA/sec, checksum is disable.

26 • Command Set

Page 33

3.4 Read Module Name

@Description

Read module name of NuDAM at specified address.

@Syntax

$(Addr)M<CR>

$

(Addr)

M

@Response

!(Addr)(ModuleName) <CR>

or

?(Addr)<CR>

!

?

(Addr)

(ModuleName)

@Example

User command: $18M<CR>

Response: !186021<CR>

!

18

6021

Command leading code.

Address ID.

Read module name.

Command is valid.

Command is invalid.

Address ID.

NuDAM module‘s name would be ’6021‘.

4 characters

Command is valid.

Address ID is 18 (Hex).

ND-6021 (It is a analog output module)

Command Set • 27

Page 34

3.5 Read Firmware Version

@Description

Read firmware version of NuDAM at specified address.

@Syntax

$(Addr)F<CR>

$

(Addr)

F

@Response

!(Addr)(FirmRev) <CR>

or

?(Addr)<CR>

!

?

(Addr)

(FirmRev)

@Example

User command: $18F<CR>

Response: !18A2.30<CR>

!

18

A2.30

Command leading code.

Address ID

Read module firmware version.

Command is valid.

Command is invalid.

Address ID.

NuDAM module‘s firmware version.

Command is valid.

Address ID is 18 (Hex).

Firmware Version

28 • Command Set

Page 35

3.6 Reset Status

@Description

Read the reset status of module at specified address to check whether if it

has been reset since the last reset status command was issued to the

module.

@Syntax

$(Addr)5<CR>

$

(Addr)

5

@Response

!(Addr)(Status)<CR>

or

?(Addr)<CR>

!

?

(Addr)

(Status)

@Example

User command: $185<CR>

Response: !180<CR>

Status is 0 means this digital I/O module has not been reset,

since the last reset status command was issued.

Command leading code.

Address ID.

Reset Status Command.

Command is valid.

Command is invalid.

Address ID.

0 : It has not been reset since the last reset

status command was issued.

1 : It has been reset since the last reset

status command was issued.

Command Set • 29

Page 36

3.7 Synchronized Sampling (6024 only)

@Description

Synchronized all modules to sample input values and stored the values in

the module’s register at the same time and use “Read Synchronized Data”

command to read the data and process it one by one.

For analog output module, this command is only available to modules

involving the digital input function, such as NuDAM-6024.

@Syntax

#**<CR>

#

**

@Response

Note : Synchronized sampling command has NO response.

@Example

Command leading code.

Synchronized sampling command

User command:

Synchronized sampling command

30 • Command Set

#**<CR>

has no response

.

Page 37

3.8 Read Synchronized Data (6024 only)

@Description

After a synchronized sampling command

input value that was stored in the addressed module’s register and use

same method to process other module‘s data one by one.

@Syntax

$(Addr)9<CR>

$

(Addr)

9

@Response

!(Status)(DataIn)<CR>

or

?(Addr)<CR>

>

?

(Status)

(DataIn) Value of digital input channel. (2-character).

@Examples

User command: $309<CR>

Response: >17F<CR>

>

1

7F

Command leading code.

Address ID.

Read synchronized data.

Command is valid.

Command is invalid.

0 : Data has been sent at least once before.

1 : Data has been sent for the first time since a

synchronized sampling command was

issued.(1-character)

Command is valid.

Data has not been sent before.

7F(01111111) means digital input channel

0,1,2,3,4,5,6 are HIGH.

#**

was issued, you can read the

Command Set • 31

Page 38

3.9 Digital Input (6024 only)

@Description

Read the digital input channel value.

@Syntax

$(Addr)8<CR>

$

(Addr)

8

@Response

!(DataIn)0000<CR>

or

?(Addr)<CR>

!

?

(DataIn) Value of digital input. (2-character)

@Example

User command: $308<CR>

Response: !320000<CR>

!

32

0000

Command leading code.

Address ID

Digital data input command.

Command is valid.

Command is invalid.

Command is valid.

32 (00110010) means digital output channel 1, 4, 5

are ON, channel 0, 2, 3, 6 are OFF.

No used

32 • Command Set

Page 39

3.10 Analog Data Output

@Description

Send a value to analog output module at specified address. The data

format of the value can be engineering unit, percent, or hexdecimal value,

which is set by configuration setting command.

(ND-6024 only supports engineering format.)

@Syntax

#(Addr)(OutData)<CR> (6021 Only)

#(Addr)(Port)(OutData)<CR> (6024 Only)

# Command leading code. (1-character)

(Addr) Address ID. (2-character)

(Port)

(OutData)

@Response

<CR>

or

?(Addr)<CR>

>

?

(Addr)

@Examples

User command: #0616.000<CR>

Response: ><CR>

A, B, C or D

Value of the analog output signal,. The unit of the

value can be engineering units, % of FSR, or

hexadecimal value. Refers to chapter 4 for details of

the data format.

Command is valid.

Command is invalid or no synchronized sampling

command was issued.

Address ID.

The command sets the analog output to be 16 mA at address 06H, if the

data format is configured as engineering units and 0~20mA output range.

User command: #08+020.00<CR>

Response: ><CR>

Command Set • 33

Page 40

The command sets the analog output to be 4 mA at address 08H, if the

data format is configured as % of FSR and 0~20mA output range.

4mA = 20mA x 20.00%

User command: #097FF<CR>

Response: ><CR>

The command sets the analog output to be 5 V at address 09H, if the data

format is configured as hexdecimal format and output range of 0~10V.

5 V = 7FF / FFF x 10V

User command: #08A-05.000<CR>

Response: ><CR>

The command sets the analog output port A to be –5 V at address 08H.

34 • Command Set

Page 41

3.11 4mA Offset Calibration

@Description

Stores the current output value as 4 mA reference at the specified analog

output module.(only 6021)

@Syntax

$(Addr)0<CR>

$

(Addr)

0

@Response

!(Addr)<CR>

or

?(Addr)<CR>

!

?

(Addr)

@Example

User command: $060<CR>

Response: !06<CR>

Command leading code

Address ID

Command Code

Command is valid.

Command is invalid or no synchronized sampling

command was issued.

Address ID.

To perform the 4 mA calibartion for analog output module at address 06H.

Note : Analog output module should be trimmed to the correct value by “Trim

Calibration” command before to execute “4 mA Calibration”. Refers

to Chapter 5 “Analog Output Calibration” for details.

Command Set • 35

Page 42

3.12 20mA Calibration

@Description

Stores the current output value as 20 mA reference at the specified analog

output module. (only 6021)

@Syntax

$(Addr)1<CR>

$

(Addr)

1

@Response

!(Addr)<CR>

or

?(Addr)<CR>

!

?

(Addr)

@Example

User command: $061<CR>

Response: !06<CR>

To perform the 20 mA calibration for analog input module at address ID

06H.

Note : Analog output module should be trimmed to the correct value by “Trim

Calibration” command before to execute “20 mA Calibration”. Refers

to Chapter 5 “Analog Output Calibration” for details .

Command leading code (1 character)

Address ID (2 characters)

Function Code, 20 mA calibration (1 character)

Command is valid.

Command is invalid.

Address ID.

36 • Command Set

Page 43

3.13 Trim Calibration

@Description

Trims the specified analog output module a specified number of units up or

down.

@Syntax

$(Addr)3(Counts)<CR>

$

(Addr)

3

(Counts)

@Response

!(Addr)<CR>

or

?(Addr)<CR>

!

?

(Addr)

@Example

User command: $06314<CR>

Response: !06<CR>

Increase analog output value about 97.6µA (14H * 4.88µA = 97.6µA) at

address 06H.

Command leading code

Address ID

Function Code

Number of counts to increase or decrease the output

current.

Range 00 - 5F : 0 to +95 counts (increase)

Range A1 - FF : -95 to -1 counts (decrease)

1 count equals approximately 4.88µA or 2.44mV

(4.88mV for ND-6024)

Command is valid.

Command is invalid.

Address ID.

Note : Analog output module trim calibration should have a corrent calibration

wiring. Refers to Chapter 5 “Analog Output Calibration” for details.

Command Set • 37

Page 44

3.14 Save Power On Analog Output Value

@Description

Save the current output value to the non-volatile register for NuDAM

analog output module. The power on value be put on the output channel

when system power ON.

@Syntax

$(Addr)4<CR>

$ Command leading code. (1-character)

(Addr) Address ID. (2-character)

4

@Response

!(Addr)<CR>

or

?(Addr)<CR>

!

?

(Addr)

@Example

User command: $064<CR>

Response: !06<CR>

Save the current analog output value as the default value when the analog

output module start-up.

Function code of saving power on analog value.

(1-character)

Command is valid.

Command is invalid.

Address ID.

38 • Command Set

Page 45

3.15 Last Value Readback

@Description

Return the latest analog output value which is set by “Analog Data Out”

command. If the analog output module never execute the “Analog Data

Out” command then it return the start-up output value. (only 6021)

@Syntax

$(Addr)6<CR>

$(Addr)6(Port)<CR> (6024 Only)

$ Command leading code. (1-character)

(Addr) Address ID. (2-character)

6

(Port)

@Response

!(Addr)(Data)<CR>

or

Function code of last value readback.

(1-character)

Port A, B, C or D.

?(Addr)<CR>

!

?

(Addr)

(Data)

@Example

User command: $086<CR>

Response: !0802.000<CR>

This analog output module return the latest output value is 2.000 mA at

address 08H, if data format is engineering units and the signal range is

0~20mA.

Command is valid.

Command is invalid.

Address ID.

The current analog output value, the data format

depends on module configuration.

Command Set • 39

Page 46

3.16 Current Readback

@Description

Read the estimated current output value at the specified analog output

module.

@Syntax

$(Addr)8<CR>

$ Command leading code. (1-character)

(Addr) Address ID. (2-character)

6

@Response

!(Addr)(Data)<CR>

or

?(Addr)<CR>

!

?

(Addr)

(Data)

@Example

User command: $088<CR>

Response: !0802.000<CR>

This analog output module return the latest output value is 2.000 mA at

address 08H, if data format is engineering units and the signal range is

0~20mA.

Function code of last value readback.

(1-character)

Command is valid.

Command is invalid.

Address ID.

The current analog output value, the data format

depends on module configuration.

40 • Command Set

Page 47

3.17 Read

@Description

Read command leading code setting and host watchdog status.

@Syntax

~(Addr)0<CR>

~

(Addr)

0

@Response

!(Addr)(Status)(C1)(C2)(C3)(C4)(C5)(C6)<CR>

or

?(Addr)<CR>

!

?

(Addr)

(Status)

(C1)

(C2)

(C3)

(C4)

(C5)

(C6)

Command leading code.

Address ID

Read command leading code setting.

Command is valid.

Command is invalid.

Address ID.

(2-character)

Bit 0 : Reserved

Bit 1 : Power failure or watchdog failure

Bit 2 : Host watchdog is enable

Bit 3 : Host failure

Leading code 1, for read configuration status,

firmware version, etc. default is $. (1-character)

Leading code 2, for read synchronize sampling,

digital output ,default is #. (1-character)

Leading code 3, for change configuration.

default is %. (1-character)

Leading code 4, for read alarm status, enable alarm,

etc. default is @. (1-character)

Leading code 5, for read command leading code,

change command leading code, etc. default is ~.

(1-character)

Leading code 6, this leading code is reserved. default

is *. (1-character)

Command Set • 41

Page 48

@Example

User command: ~060<CR>

Response: !0600$#%@~*<CR>

Command leading code setting is $#%@~* for module address ID is 06,

current status is factory default setting.

42 • Command Set

Page 49

3.18 Change Leading Code Setting

@Description

User can use this command to change command leading code setting as

he desired.

@Syntax

~(Addr)10(C1)(C2)(C3)(C4)(C5)(C6)<CR>

~

(Addr)

10

(C1)

(C2)

(C3)

(C4)

(C5)

(C6)

@Response

!(Addr)< CR>

or

?(Addr)<CR>

!

?

(Addr)

Command leading code.

Address ID, range (00 - FF).

Change command leading code setting.

Leading code 1, for read configuration status,

firmware version, etc. default is $.

(1-character)

Leading code 2, for read synchronize sampling,

digital output ,default is #. (1-character)

Leading code 3, for change configuration.

default is %. (1-character)

Leading code 4, for read alarm status, enable alarm,

etc. default is @. (1-character)

Leading code 5, for read command leading code,

change leading code, etc. default is ~.

(1-character)

Leading code 6, this leading code is reserved. default

is *. (1-character)

Command is valid.

Command is invalid.

Address ID.

Command Set • 43

Page 50

@Examples

User command: ~060<CR>

Response:

User command:

Response: !06<CR>

User command:

Response: !06A1.8<CR>

Read leading code setting is $#%@~* for module address 06 and change

leading code $ to A, then use A06F to read firmware version of module on

address 06.

*** WARNING ***

• We do not recommend users to change the default setting of leading

code, because it will confuse yourself.

• The leading code change only use the command conflicts other

devices of other brand on the network.

• The changing of leading code is not necessay if all modules in a

network are NuDAMs‘.

!0600$#%@~*<CR>

~0610A#%@~*<CR>

A06F

44 • Command Set

Page 51

3.19 Set Host Watchdog Timer & Safety Value

@Description

Set host watchdog timer, module will change to safety state when host is

failure. Define the output value in this command.

@Syntax

~(Addr)2(Flag)(TimeOut)(SafeValue)<CR>

~(Addr)2(Flag)(TimeOut)(SafeA)(SafeB)(SafeC)(SafeD) (6024 Only)

~

(Addr)

2

(Flag)

(TimeOut)

Command leading code.

Address ID, range (00 - FF).

Set host watchdog timer and safe state value.

0 : Disable host watchdog timer

1 : Enable host watchdog timer (1-character)

Host timeout value, between this time period host

must send (Host is OK) command to module,

otherwise module will change to safety state.

Range 01 - FF. (2-character)

One unit is 53.3 ms (Firmware version 1.x)

01 = 1 * 53.3 = 53.3 ms

FF = 255 * 53.3 = 13.6 sec

One unit is 100 ms (Firmware version 2.x)

01 = 1 * 100 = 100 ms

FF = 255 * 100 = 25.5 sec

(SafeValue)

(SafeA)

(SafeB)

(SafeC)

(SafeD)

Safety value of analog output when host is failure.

(3-character)

000: analog output is 0mA or 0 V

7FF: analog output is 10 mA or 5V

FFF: analog output is 20 mA or 10V

Safety value of analog output for port A, B, C and D

when host is failure. (3-character)

000: analog output is –10 V

800: analog output is 0 V

FFF: analog output is 10 V

Command Set • 45

Page 52

@Response

!(Addr)<CR>

or

?(Addr)<CR>

!

?

(Addr)

@Example

User command: ~0621123F0<CR>

Response: !06<CR>

06

2

1

12

3F0

Command is valid.

Command is invalid.

Address ID

Address ID

Set host watchdog timer and safe state value.

Enable host watchdog timer.

Timeout value. 0x12 = 18

18 * 53.3 = 959 ms (Firmware Version 1.x)

18 * 100 = 1800 ms (Firmware Version 2.x)

0x3F0 is hexadecimal

Analog output value is 4.923 mA for 0-20mA

Analog output value is 4.923 mA for 4-20mA

Analog output value is 2.462 V for 0-10 V

Analog output safety value are as following :

For type is 0 ~20 mA or 4~20 mA (Output Range is 0x30, 0x31)

value = (0x3F0 / 0xFFF) * 20 mA = 4.923 mA

For type is 0 ~10V (Output Range is 0x32)

value = (0x3F0 / 0xFFF) * 10 V = 2.462 V

User command: ~062112800800800800<CR>

Response: !06<CR>

46 • Command Set

Page 53

06

2

1

12

800

800

800

800

Address ID

Set host watchdog timer and safe state value.

Enable host watchdog timer.

Timeout value. 0x12 = 18

18 * 53.3 = 959 ms (Firmware Version 1.x)

18 * 100 = 1800 ms (Firmware Version 2.x)

0x800 is hexadecimal

Analog output value is 0V for port A

Analog output value is 0V for port B

Analog output value is 0V for port C

Analog output value is 0V for port D

Command Set • 47

Page 54

3.20 Read Host Watchdog Timer & Safety Value

@Description

Read host watchdog timer setting and the safety value.

@Syntax

~(Addr)3<CR>

~

(Addr)

3

@Response

!(Addr)(Flag)(TimeOut)(SafeValue)<CR>

!(Addr)(Flag)(TimeOut)(SafeA)(SafeB)(SafeC)(SafeD)<CR>(6024Only)

or

?(Addr)<CR>

!

?

(Addr)

(Flag)

(TimeOut)

Command leading code.

Address ID

Read host watchdog setting and module safety state

value.

Command is valid.

Command is invalid.

Address ID, range (00 - FF).

0 : Host watchdog timer is disable

1 : Host watchdog timer is enable(1-character)

Host timeout value.

Range 01 - FF. (2-character)

One unit is 53.3 ms (Firmware version 1.x)

01 = 1 * 53.3 = 53.3 ms

FF = 255 * 53.3 = 13.6 sec

One unit is 100 ms (Firmware version 2.x)

01 = 1 * 100 = 100 ms

FF = 255 * 100 = 25.5 sec

(SafeValue)

(SafeA)

(SafeB)

(SafeC)

48 • Command Set

Safety value of analog output when host is failure.

(3-character)

Safety value of analog output for port A, B, C and D

when host is failure. (3-character)

Page 55

@Example

User command: ~063<CR>

Response: !061123F0<CR>

06

1

12

3F0

User command: ~063<CR>

Response: !06112800800800800<CR>

06

1

12

Address ID

Host watchdog timer is enable.

Timeout value. 0x12 = 18

18 * 53.3 = 959 ms (Firmware Version 1.x)

18 * 100 = 1800 ms (Firmware Version 2.x)

0x3F0 is hexadecimal

Analog output value is 4.923 mA for 0-20mA

Analog output value is 4.923 mA for 4-20mA

Analog output value is 2.462 V for 0-10 V

Address ID

Host watchdog timer is enable.

Timeout value. 0x12 = 18

18 * 53.3 = 959 ms (Firmware Version 1.x)

18 * 100 = 1800 ms (Firmware Version 2.x)

800

800

800

800

0x800 is hexadecimal

Analog output value is 0V for port A

Analog output value is 0V for port B

Analog output value is 0V for port C

Analog output value is 0V for port D

Command Set • 49

Page 56

3.21 Host is OK

@Description

When host watchdog timer is enable, host computer must send this

command to every module before timeout otherwise

timer enable”

Timeout value and safety state output value is defined in 3.14. “Set Host

Watchdog Timer & Safety Value”

@Syntax

module‘s output value will go to safety state output value.

“host watchdog

~**<CR>

@Response

Note : Host is OK command has NO response.

@Example

~

**

User command: ~**<CR>

Command leading code.

Host is OK.

50 • Command Set

Page 57

4

Data Format

4.1 Unit Conversion

The data value in the command of the analog output module is corresponding

to the amplitude of the physical analog signal. The user should understand the

data format to represent a analog signal by an ASCII string. The physical

meaning of a data depends on both the unit conversion and the value. The unit

conversion of the digits value can be configured by the setting configuration

command. Three types of unit conversion are used in analog output modules.

1. Engineering units.

2. Percent of FSR (Full Scale Range).

3. Hexdecimal.

Data Format • 51

Page 58

4.2 Engineering Units

The date is in engineering unit when the bit 1 and 0 of the configuration register

are ‘00’. The data string is composited by 6 characters. Because the output of

ND-6021 is unipolar, the value is always positive.

The meaning of the value depends on the output range setting too. When the

output range is set to 0~10V, the unit of the value is in ‘Volts’. When the output

range is set to 0~20mA or 4~20mA, the unit of the value is in ‘mA’.

• Set bit 1 and bit 0 of data format variable to “00” means the data is

represented in engineering units

• Data string is fixed length of 6 characters. The value is composed of

five decimal digits with a decimal fixed point

• Two digits present the integer part and three present the fraction

Example 4.2.1:

• If the output range is set as 0 to 20 mA

• The desired analog output value is +5.678 mA

The data value should be :

Example 4.2.2:

• If the output range is set as 0 to 10 V

• The desired analog output value is +2.345 V

The data value should be :

52 • Data Format

05.678<CR>

02.345<CR>

Page 59

4.3 Percent of FSR

The date is in percent of FSR(Full Scale Range) when the bit 1 and 0 of the

configuration register are ‘01’. The data string is composited by 6 characters.

Because the output of ND-6021 is unipolar, the value is always positive.

The value is unit-less and depends on the output range setting too.

• Set bit 1 and bit 0 of data format variable to “01” means the data is

represented in percent of FSR.

• Data string is fixed length of 6 characters. The value is composed of

five decimal digits with a decimal fixed point.

• Three digits present the integer part and two digits present the fraction

• Maximum resolution is 0.2%.

Example 4.3.1 :

• If the output range is set as 0 to 20 mA

• The desired analog output current is 10 mA

The data value should be :

10 mA / 20 mA = 50.00 %

Example 4.3.2 :

• If the output range is set as 4 to 20 mA

• The desired analog output current is 10 mA

The data value should be :

(10 mA - 4 mA ) / (20 mA - 4mA) = 37.50 %

050.00<CR>

037.50<CR>

Data Format • 53

Page 60

4.4 Hexdecimal Format

The data is in hexdecimal format as the bit 1 and 0 are set as ‘10’. The data

string length is 3 characters. It is equivilant to 12 binary bits. Because the

output of ND-6021 is unipolar, the maximum value of the digits is FFF(H) and

the minimum value of the digits is 000(H).

As the output range is set to 0~20mA, the value ‘FFF(H)’ represents 20mA and

‘000(H)’ represents 0mA. Similarily, as the output range is set to 4~20mA, the

value ‘FFF(H)’ represents 20mA and ‘000(H)’ represents 4mA.

Example 4.3.1 :

• If the output range is set as 0 to 20 mA

• The desired analog output current is 10 mA

Two’s complement hexdecimal :

7FF<CR>

54 • Data Format

Page 61

4.5 Summary of Data Format

The following table shows the relation between the output range setting with

the data format and the resolution.

Code

30 0 to 20 mA Eng. Units 20.000 00.000

31 4 to 20 mA Eng. Units 20.000 04.000

32 0 to 10 V Eng. Units 10.000 00.000 2.442 mV

Code

30 0 to 20 mA % of FSR 100.00 000.00

31 4 to 20 mA % of FSR 100.00 000.00

32 0 to 10 V % of FSR 100.00 000.00 2.442 mV

Code

30 0 to 20 mA Hexdecimal FFF 000

31 4 to 20 mA Hexdecimal FFF 000

32 0 to 10 V Hexdecimal FFF 000 2.442 mV

Output

Range

Output

Range

Output

Range

Data

Format

Data

Format

Data

Format

Maximum

Value

Maximum

Value

Maximum

Value

Minimum

Value

Minimum

Value

Minimum

Value

Output

Resolutio

n

4.88µA

4.88µA

Output

Resolution

4.88µA

4.88µA

Output

Resolution

4.88µA

4.88µA

Data Format • 55

Page 62

5

Analog Output Calibration

5.1 Calibration

The NuDAM analog output module needs to be calibrated. It has a factory

default calibration . User can use NuDAM Adminstration utility to do any type of

calibration.

5.2 Analog Output Module Calibration

What do you need to do calibration ?

1. One 5 1/2 digit multimeter.

2. A resistor 250 Ω (Accurary is 0.01 %).

3. NuDAM Aministration Utility.

Calibration Procedure

1. Select output range to 0 ~20 mA or 4~20 mA.

2. Put the resistor 250 Ω to the NuDAM-6021 (+ IOUT (Pin.1) and -IOUT

(Pin.2)).

3. Put 5 1/2 digit multimeter to measure + IOUT (Pin.1) and -IOUT (Pin.2)

.

56 • Analog Output Calibration

Page 63

4. Send the “

output value is

command is

5. Use “

output value to

6. Send “

module to complete the 4 mA calibration.

7. Send the “

output value is

command is

8. Use “

output value to

9. Send “

module to complete the 20 mA calibration.

Analog Data Output

4 mA

. For example if the address is 0x03 then the

#0304.000.

Trim calibration

4mA Calibration

Analog Data Output

$(Addr)3(Counts)” command to adjust until the

1 V (4 mA)

$(Addr)0” command to the analog output

20 mA

. For example if the address is 0x03 then the

#0320.000

Trim calibration

5 V (20 mA)

20mA Calibration

Calibration wiring of NuDAM-6021

-IOUT

+IOUT

$(Addr)3(Counts)” command to adjust until the

#(Addr)(OutData)” command with

.

#(Addr)(OutData)” command with

.

$(Addr)1” command to the analog output

250 Ohms

+

-

5 1/2 Digital Meter

Analog Output Calibration • 57

Page 64

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all the

after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and follow

the instructions exactly. When sending in damaged products for repair,

please attach an RMA application form which can be downloaded from:

http://rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for

products bought in China.

• The warranty period starts on the day the product is shipped from

ADLINK’s factory.

• Peripherals and third-party products not manufactured by ADLINK

will be covered by the original manufacturers' warranty.

• For products containing storage devices (hard drives, flash cards,

etc.), please back up your data before sending them for repair.

ADLINK is not responsible for any loss of data.

• Please ensure the use of properly licensed software with our

systems. ADLINK does not condone the use of pirated software and

will not service systems using such software. ADLINK will not be

held legally responsible for products shipped with unlicensed

software installed by the user.

• For general repairs, please do not include peripheral accessories. If

peripherals need to be included, be certain to specify which items

you sent on the RMA Request & Confirmation Form. ADLINK is not

responsible for items not listed on the RMA Request & Confirmation

Form.

3. Our repair service is not covered by ADLINK's guarantee in the following

situations:

• Damage caused by not following instructions in the User's Manual.

• Damage caused by carelessness on the user's part during product

transportation.

• Damage caused by fire, earthquakes, floods, lightening, pollution,

other acts of God, and/or incorrect usage of voltage transformers.

58 • Product Warranty/Service

Page 65

• Damage caused by inappropriate storage environments such as

with high temperatures, high humidity, or volatile chemicals.

• Damage caused by leakage of battery fluid during or after change of

batteries by customer/user.

• Damage from improper repair by unauthorized ADLINK technicians.

• Products with altered and/or damaged serial numbers are not

entitled to our service.

• This warranty is not transferable or extendible.

• Other categories not protected under our warranty.

4. Customers are responsible for all fees necessary to transport damaged

products to ADLINK.

For further questions, please e-mail our FAE staff: service@adlinktech.com

Product Warranty/Service • 59

Loading...

Loading...