Page 1

PCI-/cPCI-/LPCI-/

LPCIe-725X Series

8-CH Relay Output &

8-CH Isolated Digital Input Cards

User’s Manual

Manual Rev. 2.03

Revision Date: June 24, 2008

Part No: 50-11038-1000

Advance Technologies; Automate the World.

Page 2

Copyright 2008 ADLINK TECHNOLOGY INC.

All Rights Reserved.

The information in this document is subject to change without prior

notice in order to improve reliability , design, and function and does

not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential damages arising out of th e use or

inability to use the product or documentation, even if advised of

the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No part of this manual may be reproduced by any mechanical, elec tronic, or other means in a ny form

without prior written permission of the manufacturer.

Trademarks

Product names mentioned herein are used for identification pur-

poses only and may be trademarks and/or registered trademarks

of their respective companies.

Page 3

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK Technology Inc.

Please contact us should you require any service or assistance.

ADLINK TECHNOLOGY INC.

Web Site: http://www.adlinktech.com

Sales & Service: Service@adlinktech.com

TEL: +886-2-82265877

FAX: +886-2-82265717

Address: 9F, No. 166, Jian Yi Road, Chungho City,

Taipei, 235 Taiwan

Please email or FAX this completed service form for prompt and

satisfactory service.

Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX:

Web Site

Product Information

Product Model

OS:

Environment

M/B: CPU:

Chipset: Bios:

Please give a detailed description of the problem(s):

Page 4

Page 5

Table of Contents

Table of Contents..................................................................... i

List of Tables.......................................................................... iii

List of Figures........................................................................ iv

1 Introduction ........................................................................ 1

1.1 Features............................................................................... 2

1.2 Applications ......................................................................... 2

1.3 Specifications....................................................................... 3

Digital input ................ .......................................... ... .... ... . 3

Relay Output ........ ... .......................................... ... ... .... ....3

General Specifications ....................................................4

Power Consumption .......................................................4

1.4 Software Support................................................................. 5

Windows Drivers ..... .......................................... ... ... .... ... . 6

Linux Drivers ................................................................. 11

Third-party Software Support .................................. .... .. 12

VEE™ Interface for ADLINK DAQ Cards .....................14

Componentware/ActiveX Control ..................................15

Applications for Test and Measurement ....................... 16

2 Installation ........................................................................ 17

2.1 Unpacking Checklist ........... .... ... ... ... .... ... ... ... ..................... 17

2.2 PCB Layout........................................................................ 18

PCI-7250 PCB Layout ............ ... .... ... ... ... ... .... ... ... ... .... .. 18

cPCI-7252 PCB Layout .................................................19

LPCI-7250 PCB Layout ................................................ 20

LPCIe-7250 PCB Layout ..... ... ... .... ... ... ... ... .... ... ... ... .... .. 21

2.3 Input Signal Jumper Setting............................................... 22

2.4 Hardware Installation Outline............................................. 23

PCI Configuration ......... .... ... ... ... .... ... ... ... ... .... ... ... ... ......23

PCI Slot Selection ...... ... .... ... ......................................... 23

Installation Procedures .................................................23

2.5 Device Installation for Windows Systems.......................... 24

2.6 Connector Pin Assignments .............................................. 24

PCI-7250/51 Pin Assignment ........................................24

cPCI-7252 Pin Assignment ........................................... 26

Table of Contents i

Page 6

LPCI/LPCIe-7250 CN1 Pin Assignment .......................27

2.7 PCI-7250 and PCI-7251 Connection ................................. 28

3 Registers............................................................................ 29

3.1 PCI PnP Registers............................................................. 29

3.2 I/O Address Map................................................................ 30

3.3 Relay Output and Readback Registers.............................. 30

3.4 Isolation Input Registers ........................................... ... ... ... 31

4 Operation Theory.............................................................. 33

4.1 Using Relay Output............................................................ 33

4.2 Using Isolated Input........................................................... 35

Appendix................................................................................ 37

Relay Contact Protection Circuits...................................... 37

RC Circuit .....................................................................37

Diode Circuit ................... .......................................... ... .38

Diode & Zener diode Circuit ...................... ... ... .... ... ... ... .39

Varistor Circuit ................... .... ... ... ... .... ... ... ... ... .... ..........39

ii Table of Contents

Page 7

List of Tables

Table 1-1: Digital Input Specifications ....................................... 3

Table 1-2: Relay Output Specifications ..................................... 3

Table 1-3: General Specifications .............................................. 4

Table 1-4: Power Consumption Specifications .......................... 4

Table 2-1: Jumpers and DI Channels ...................................... 22

Table 2-2: Input Signal Selection Jumper Settings .................. 22

Table 2-3: CN1 - PCI-7250/51 Pin Assignment ....................... 25

Table 2-4: CN1 - cPCI-7252 Pin Assignment .......................... 26

Table 2-5: LPCI/LPCIe-7250 CN1 Pin Assignment ................. 27

Table 3-1: PCI-7250 Address Map with PCI-7251 Installed .... 30

Table 3-2: cPCI-7252 Address Map ........................................ 30

Table 3-3: LPCI/LPCIe-7250 Address Map ............................. 30

Table 3-4: Data Format of Relay Output and Readback Status Reg-

isters ....................................................................... 31

Table 3-5: Relay Output ........................................................... 31

List of Tables iii

Page 8

List of Figures

Figure 2-1: PCI-7250 Layout...................................................... 18

Figure 2-2: cPCI-7252 Layout.................................................... 19

Figure 2-3: LPCI-7250 PCB Layout ........................................... 20

Figure 2-4: LPCIe-7250 PCB Layout ................................... ... ... 21

Figure 2-5: CN1 - D Type Connector......................................... 24

Figure 2-6: Connection between PCI-7250 and PCI-7251......... 28

Figure 4-1: Form C Relay........................................................... 33

Figure 4-2: Form A Relay........................................................... 34

Figure 4-3: PCI-7250 Differential Input Circuit ........................... 35

Figure 4-4: cPCI-7252 Isolated Input Circuit.............................. 35

Figure 4-5: LPCI/LPCIe-7250 Differential Input Circuit .............. 36

iv List of Figures

Page 9

1 Introduction

The PCI-7250/7251, cPCI-7252, LPCI-7250 and LPCIe-7250 8CH Relay Output & 8-CH Isolated Digital Input Cards are basic

Digital I/O cards for PCI bus compliant computers used in industrial applications.

This PCI-7250/7251 provide 8 relay actuators and 8 opto-isolated

digital inputs. Of the eight relays, four are Form C (R0~R3) and

four are Form A (R4~R7). The cPCI-7252 provides 8 relay actuators and 16 opto-isolated digital inputs; all relays are Form C. The

LPCI-7250 and LPCIe-7250 provide 8 relay actuators and 8 optoisolated digital inputs; all relays are Form C. They are very suited

for constant ON/OFF control devices. For convenience the above

models will be referred to as PCI-725X in this manual.

All digital input channels are isolated and suitable applications in

noisy environment. For identical non-polarized opto-isolated digita l

input channels, switching can be carried out using AC-filtered or

non-AC-filtered channels.

PCI-7250 is equipped with LEDs to reflect the status of each relay

output. When a relay is energized, its corresponding LED will turn

ON, otherwise it is OFF.

The relay outputs and digital inputs are controlled by two bytes of

I/O addresses. When a bit is read or written, its output status will

be controlled, or its input status will be monitored. The I/O signals

are routed through to a 37-pin D -type or a 50-p in SCSI-II connec tor.

Introduction 1

Page 10

1.1 Features

The PCI-725X Relay Actuator and D/I cards provide the following

advanced features:

X 32-bit PCI-Bus, Plug and Play (PCI-7250, LPCI-7250)

X 32-bit CompactPCI® Bus, Plug and Play (cPCI-7252)

X 8 relay actuator outputs

X 8 opto-isolated digital inputs (PCI-7250, LPCI-7250,

LPCIe-7250)

X x1 lane PCI Express Interface (LPCIe-7250)

X 16 opto-isolated digital inputs (cPCI-7252)

X Onboard LED indicators to show energized relays

X Jumper selectable AC-filter/non-AC-filter input signals

X On-board relay driving circuits

X On-board digital input signal conditioning circuits

Note: PCI-7251 is the extens io n mod u le of th e PCI- 72 5 0. Each

PCI-7251 card provides an additional 8 relay outputs and 8

photo isolated inputs. Up to three PCI-7251 cards can be attached to one PCI-7250 card to provide 32 rela y outputs and

32 photo isolated inputs.

1.2 Applications

X Industrial ON/OFF control

X External high power relay driving signal switching

X Laboratory automation

X Industrial automation

X Switch contact status sensing, limit switch monitoring,

X Useful with A/D and D/A cards to implement a data acquisi-

tion & control system

2 Introduction

Page 11

1.3 Specifications

Digital input

Input channels

Photo-coupler

Input current

Input Voltage

Input impedance

Input mode Isolation AC-filter/ Non-AC-filter

Isolated voltage

8 for PCI-7250, PCI-7251, LPCI-7250 and LPCIe-7250

16 for cPCI-7252

PC-814 (for PCI-7250, PCI-7251 and cPCI-7252)

PC3H4 (for LPCI-7250 and LPCIe-7250)

10 mA rated

60 mA max for isolated input

Up-to 24 VDC or 24 VAC 50-1,000 Hz

Logic Low: 0-1.5 V

Logic High 5-24 V

Ω

2.2 K

5000 Vrms channel-to-system (PCI-7250,PCI-7251 and

cPCI-7252)

2500 Vrms channel-to-system (LPCI-7250, LPCIe-7250)

Table 1-1: Digital Input Specifications

Relay Output

Output channels 8

Relay type

Contact rating

Breakdown voltage 1000 V AC/DC min..

Release time 8msec typical

Operate time 8msec typical

Contact resistance

Insulation resistance

4 SPDT (From C) & 4 SPST (Form A) for PCI-7250 and PCI-7251

8 SPDT (From C) for cPCI-7252, LPCI-7250, and LPCIe-7250

PCI-7250/7251, cPCI-7252

X AC: 120 V @ 0.5 A

X DC: 24 V @ 1 A

LPCI-7250, LPCIe-7250

X DC: 30 V @ 2 A

100 m

Ω

1,000 MΩ min.

T able 1-2: Relay Output Specifications

Introduction 3

Page 12

PCI-7250/7251, cPCI-7252:

5

operations @ 1 A, 24 VDC

5

operations @ 0.5 A, 120 VAC

5

operations @ 2 A, 30 VDC

5

operations @ 1 A, 30 VDC

Life expectancy

X >5x10

X >2x10

LPCI-7250/LPCIe-7250:

X >10

X >5x10

LED indicators Monitor ON/OFF status of each relay

Coil Voltage +5V, 33 mA for each relay, total 0.264 A

Power supply of Relay

+5 V from the PCI-Bus (PCI-7250/7251, cPCI-7252, LPCI-7250)

+5 V from PWM switcher output (LPCIe-7250)

Table 1-2: Relay Output Specifications

General Specifications

X 162mm x 107mm for PCI-7250

X 141mm x 102mm for PCI-7251

Dimensions

Bus 32-bit PCI bus

Operating temperature 0 - 60ºC (Operating)

Storage temperature -20ºC - 80ºC (Operating)

Humidity 5 to 90% non-condensing

Table 1-3: General Specifications

X 160mm x 100mm for cPCI-7252

X 120mm x 65mm for LPCI-7250

X 120 mm x 69 mm for LPCIe-7250

Power Consumption

Power Consumption Note: No relay is energized

PCI-7250 +5V @ 140mA

PCI-7251 +5V @ 125mA

cPCI-7252 +5V @ 120mA

LPCI-7250 +5V @ 200mA

LPCIe-7250

Table 1-4: Power Consumption Specifications

4 Introduction

+3.3V @ 280 mA

+12 V @ 180 mA

Page 13

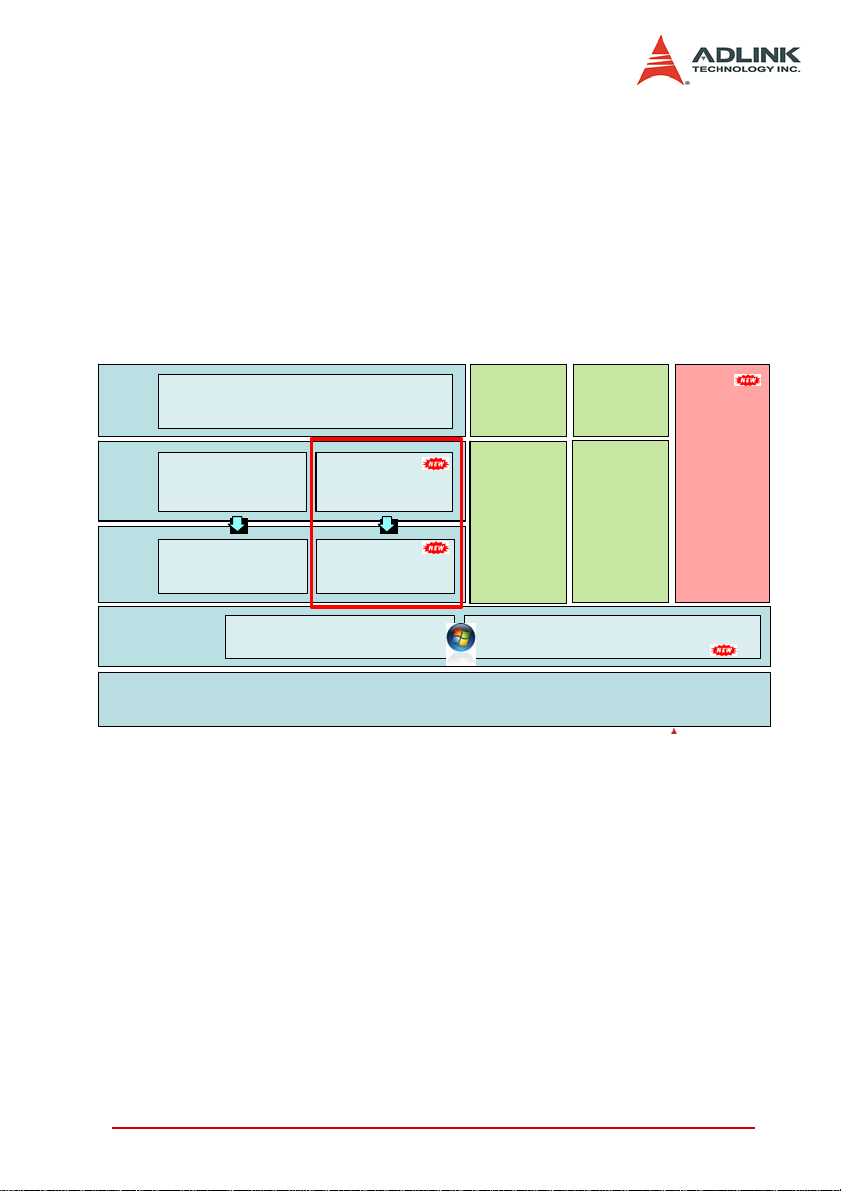

1.4 Software Support

ADLINK Technology Inc., a leading provider of high-performance,

high-quality data acquisition cards and platforms, delivers robust

software support for its comprehensive line of DAQ cards with

varying form factors including PCI Express®, PCI, CompactPCI,

and PXI. ADLINK offers support not only for mainstream Windows

and Linux OS, but also for third-party applications including LabVIEW® and MATLAB®. In addition, ADLINK also provides ActiveX

componentware for measurement and SCADA/HMI, and breakthrough proprietary softwa re applications.

ADE

Library

Driver

Operating System Windows 98/NT/2K/XP/Vista x86 Windows XP x64/Server 2003 x64/Vista x64

ADLINK DAQ Cards

(General-Purpose DAQ, Digital I/O, Analog Output, Performance DAQ, PXI, High-Speed Digital I/O, Digitizer)

VB.NET/C#.NET/VC++/VB/Delphi/BCB etc.

DAQBench

PCIS-/D2K-/WD-OCX

ActiveX Control

D2K-/PCIS-/WD-DASK

DAQPilot

ActiveX Control

.NET Assembly

DAQPilot Drivers

(Task-oriented)

LabVIEW MATLAB

ADLINK

DAQ-VI EWPnP

VI Library

ADLINK

DAQ-MTLB

DAQ Toolbox

DAQMaster

Configuration

based

System Manager

For ADLINK

DAQ Devices

2

Introduction 5

Page 14

Windows Drivers

ADLINK Task-oriented DAQ Driver/SDK and Wizard for Windows

DAQPilot provides one interface for all ADLINK DAQ products via

X DAQPilot API

X DAQPilot ActiveX Control

X DAQPilot .Net Assembly,

DAQPilot (Download and install from the DAQPilot product page:

http://www.adlinktech.com/TM/DAQPilot.html

X Save development time

X Shorten learning curve

DAQPilot is a driver and SDK with a graphics-driven interface for

various ADE. DAQPilot comes as ADLINK's commitment to provide full support to its comprehensive line of data acquisition products. DAQPilot is designed for the beginners as well as

experienced programmers. Moreover, because DAQPilot can finish a DAQ task in minutes, it is suitable for programmers aiming to

6 Introduction

Page 15

immediately program ADLINK DAQ modules and integrate tasks

to their own DAQ applications.

Note: ADLINK strongly recommend all users to install the new-

generation ADLINK Driver – DAQPilot instead legacy DASK

drivers. For those users who have been using the legacy

ADLINK DASK Drivers or are not able to connect to the internet, you still can get the latest update from ADLINK all-inone CD.

Introduction 7

Page 16

Configuration-Based Device Manager for ADLINK DAQ Cards

X DAQMaster (.\Utility)

The ADLINK DAQMaster is a smart device manager that enab les

access to ADLINK data acquisition and test and measurement

products. DAQMaster delivers an all-in-one configurations, user

can get a full support matrix to well configure ADLINK Test and

Measurement products.

DAQMaster enables you to:

X Manage ADLINK devices and interfaces

X Manage ADLINK installed software

X Manage ADLINK DAQPilot tasks

8 Introduction

Page 17

ADLINK Legacy DAQ Card Drivers and SDK for Windows

X PCIS-DASK (.\Software Package\PCIS-DASK)

X D2K-DASK (.\Software Package\D2K-DASK)

X WD-DASK (.\Software Package\WD-DASK)

Delphi

BCB

User Mode

PCIS-DASK

Kernel

Mode

Process

Structure

Object

Manager

DASK Kernel Driver

(.sys)

VC++

VB

VB.NET

C#

D2K-DASK

WD-DASK

Memory

Manager

System Service

Configuration

Manager

I/O Manager File System

Plug and Pay

Executive

Support

Power

Manager

Lowest-level

Driver

Hardware

Hardware Abstraction Layer

ADLINK's DASK are advanced 32-bit kernel drivers for customized DAQ application development. DASK enables users to perform detailed operations and achieve superior performance and

reliability from their data acquisition system. DASK kernel drivers

now support Windows Vista.

X PCIS-DASK for NuDAQ PCI/cPCI Series

X D2K-DASK for DAQ-2000 and PXI-2000 Series

X WD-DASK for High-speed Waveform Digitizer

DASK also supports the following:

X Supports Windows Vista 32- or 64-bit editions

X Supports AMD64 and Intel x86-64 architectures

X Digitally-signed for Windows Vista 64-bit Edition

X Utilizes WOW64 subsystem to ensure that 32-bit applica-

tions run normally on 64-bit Editions of Windows XP, Windows 2003 Server, and Windows Vista without modification.

Introduction 9

Page 18

More information about Windows Vista Support, please visit http://

www.adlinktech.com/TM/VistaSupport.html.

Note: Please use PCIS-DASK with the LPCI-7250 and LPCIe-

7250

10 Introduction

Page 19

Linux Drivers

Linux Drivers for ADLINK DAQ Cards

Drivers are available on the ADLINK website:

X PCIS-DASK/X

X D2K-DASK/X

X WD-DASK/X

ADLINK's DASK/X drivers are intended for developing customized

data acquisition applications under Linux environments. The

DASK/X drivers provide common APIs for ADLINK's extensive

family of PCI, CompactPCI, and PXI plug-in data acquisition

cards, and utilize the full capabilities of these cards under Linux

environment.

X PCIS-DASK/X for NuDAQ PCI/cPCI Series

X D2K-DASK/X for DAQ-2000 and PXI-2000 Series

X WD-DASK/X for ADLINK High-speed Waveform Digitizer

More information about Linux drivers, please visit http://

www.adlinktech.com/TM/linux_daq.html

Note: Please use PCIS-DASK/X with the LPCI-7250 and LPCIe-

7250

Introduction 11

Page 20

Third-party Software Support

MA TLAB® Data Acquisition T oolbox Adapt er for ADLINK DAQ

Cards

X DAQ-MTLB for MATLAB® (.\Software Package\DAQ-

MTLB)

The DAQ-MTLB for MATLAB® integrates ADLINK

components with MA TLAB® Dat a Acquisition Toolbox

and enables users to control a wide range of ADLINK

DAQ cards directly from the advanced MATLAB®

environment.

X Directly control scores of ADLINK DAQ cards that come in

different form factors including PCI Express®, PCI, cPCI,

and PXI

X Compliant with MATLAB DAQ Toolbox 2.2 or higher (now at

R2007a)

X Critical updates and support are available as ADLINK is

now a MathWorks Connections Program partner

X ADLINK offers the only MATLAB® adapter for high-speed

digitizers with up to 65 MHz sampling rate and 14-bit resolution

More information, please visit http://www.adlinktech.com/TM/

DAQ-MTLB.html

12 Introduction

Page 21

LabVIEW™ Data Acquisition VI Set for ADLINK DAQ Cards

X DAQ Cards DAQ-LVIEW PnP for LabVIEW™ (.\Software

Package\DAQ-LVIEW PnP)

The DAQ-LVIEW PnP is a set of LabView Virtual Instruments (Vis)

that is fully-compatible with National Instrument's DAQ VIs. Based

on the virtual instruments concept, DAQ-LVIEW PnP provides four

additional tool panels in LabView, including analog input, analog

output, digital I/O, and timer/counter.

The DAQ-LVIEW PnP is designed and verified for LabVIEW 7.0,

and is compatible with LabVIEW 6.5, 7.1, 8.0, 8.2 and 8.5.

More information, please visit http://www.adlinktech.com/TM/labview-pnp.html

Introduction 13

Page 22

VEE™ Interface for ADLINK DAQ Cards

X PCIS-VEE (.\Software Package\PCIS-VEE)

X D2K-VEE (.\Software Package\D2K-VEE)

Agilent VEE™ is a popular visual programming environment for

data acquisition that includes data analysis and control. VEE provides a visual programming interface that allows users to create

programs by connecting objects such as acquisition routines, buttons and displays in a flow diagram. For users that are familiar

with Agilent VEE, ADLINK has released the PCIS-VEE and D2KVEE for seamless integration of the following NuDAQ data acquisition cards to the VEE environment:

X PCIS-VEE.

VEE for ADLINK NuDAQ Series DAQ cards

6208, 6308, 7200, 7230, 7233, 7234, 7250, 7252, 7248, 7249,

7296, 7300, 7396, 7432, 7433, 7434, 9111, 9112, 9113, 9114,

9118, 9812

X D2K-VEE.

VEE for DAQ-2000 Series DAQ cards

2010, 2005, 2006, 2204, 2205, 2206, 2501, 2502

The ADLINK PCIS-VEE and D2K-VEE drivers are designed and

verified for Agilent VEE 4.5 environment.

14 Introduction

Page 23

Componentware/ActiveX Control

32-Bit ActiveX Controls for Measurement and SCADA/HMI

DAQBench (.\Software Package\DAQBench)

DAQBench is a specialized ActiveX control package designed for

32-bit measurement and SCADA/HMI applications. DAQBench

leverages the power of the latest Microsoft ActiveX technology the standard for code interchangeability and integration under various Windows platform. With DAQBench, programmers can take

advantage of their familiarity with development environments such

as Visual Basic, Visual C++, Delphi, and Borland C++ Builder to

build their own applications.

Introduction 15

Page 24

Applications for Test and Measurement

Smart & Easy-to-Use Data Acquisition System Creator

DAQCreator (.\Software Package\DAQCreator)

DAQCreator is an out-of-the-box data acquisition software for

acquiring, displaying, analyzing, and storing data from ADLINK

DAQ cards. Equipped with a smart wizard and intuitive panels,

users can easily configure data acquisition settings, change the

appearance of data display, perform FFT to acquired data, and

store data to a hard disk drive. Another remarkable feature of

DAQCreator is the 40 MB/s stream-to-disk data throughput made

possible through combination with advanced SCSI technology.

DAQCreator delivers a cost-effective solution for high-speed data

logging applications.

Get latest ADLINK Software Solutions from ADLINK Web site:

http://www.adlinktech.com/TM/software-product.html

Note: All company names appearing herein are trademarks or

Note: Windows Vista is either a registered trademark or trademark

16 Introduction

trade names of their respective owners.

of Microsoft Corporation in the United States and/or other

countries.

Page 25

2 Installation

This chapter describes how to install and setup the 725X cards.

Jumper settings for the digital input channel configurations (AC-filter or Non-AC-filter) and the signal definitions of the 37-pins connectors are also specified.

2.1 Unpacking Checklist

Check the shipping carton for any damage. If the shipping carton

and contents are damaged, notify the dealer for a replacement.

Retain the shipping carton and packing materials for inspection by

the dealer. Obtain authorization before returning any product to

ADLINK.

Check the following items are included in the package, if there are

any items missing, please contact your dealer:

Included Items

X PCI-7250 (or PCI-7251, cPCI-7252, LPCI-7250, LPCIe-

7250) Relay Actuator & Isolated D/I Card

X ADLINK CD (for PCI-7250, cPCI-7252, LPCI-7250, and

LPCIe-7250)

X Software Installation Guide

X This User’s Manual

Note: The packaging of OEM versions with non-standard

configuration, functionality, or package may vary

according to different configuration requests.

CAUTION: The boards must be protected from static discharge

and physical shock. Never remove any of the socketed

parts except at a static-free workstation. Use the antistatic bag shipped with the product to handle the

board. Wear a grounded wrist strap when servicing

Installation 17

Page 26

2.2 PCB Layout

PCI-7250 PCB Layout

Figure 2-1: PCI-7250 Layout

18 Installation

Page 27

cPCI-7252 PCB Layout

Figure 2-2: cPCI-7252 Layout

Installation 19

Page 28

LPCI-7250 PCB Layout

Figure 2-3: LPCI-7250 PCB Layout

20 Installation

Page 29

LPCIe-7250 PCB Layout

Figure 2-4: LPCIe-7250 PCB Layout

Installation 21

Page 30

2.3 Input Signal Jumper Setting

Note: This section is for PCI-7250, PCI-7251, LPCI-7250, and

LPCIe-7250 only.

There are 8 jumpers (JP1 to JP8) on the PCI-7250, PCI-7251,

LPCI-7250 and LPCIe-7250; each associated with one digital

input to configure that channel as either AC-Filtered or Non-ACFiltered. Digital input channels and corresponding jumpers are

listed in the table below

JUMPER INPUT SIGNAL

JP1 DI0

JP2 DI1

JP3 DI2

JP4 DI3

JP5 DI4

JP6 DI5

JP7 DI6

JP8 DI7

Table 2-1: Jumpers and DI Channels

The default setting for the input signal selection is Non-AC-Filter

(DC signal input), which is shown as below:

JP1

Input Signal Selection

Jumper JP1 - JP8 2-3 1-2

T able 2-2: Input Signal Selection Jumper Settings

22 Installation

Non-AC-Filter

(DC Signal)

AC-Filter

(AC Signal)

Page 31

2.4 Hardware Installation Outline

PCI Configuration

PCI cards (or CompactPCI cards) are equipped with plug and play

PCI controllers which can request base addresses and interrupts

according to the PCI standard. The system BIOS will assign the

system resources based on the PCI card configuration registers

and system parameters (which are set by the system BIOS). Interrupt assignment and memory usage (I/O port locations) can only

be assigned by the system BIOS. These system resource assignments are done on a board-by-board basis. It is not suggested to

assign the system resource by any other meth o ds .

PCI Slot Selection

The PCI card can be inserted into any PCI slot without any configuration of the system resources. The CompactPCI card can also

be inserted into any CompactPCI I/O slot.

Installation Procedures

1. Turn off your computer

2. Turn off all accessories (printer, modem, monitor, etc.)

connected to your computer.

3. Remove the cover from your computer.

4. Setup jumpers on the PCI or CompactPCI card.

5. Select a 32-bit PCI slot. PCI slot are shorter than ISA or

EISA slots, and are usually white or ivory.

6. Before handling the PCI cards, discharge any static

buildup on your body by touching the metal case of the

computer. Hold the edge and do not touch the components.

7. Position the board into the PCI slot you selected.

8. Secure the card in place at the rear panel of the system.

Installation 23

Page 32

2.5 Device Installation for Windows Systems

Once Windows Vista/XP/2003/2000 has sta rted, the Plug and Play

functions of the Windows system will find and locate the new

NuDAQ/NuIPC card. If this is the first time a NuDAQ/NuIPC card

is installed in your Windows system, you will be prompted to input

the device information source. Please refer to the “Software Installation Guide” for installation procedures for the device drivers.

2.6 Connector Pin Assignments

PCI-7250/51 Pin Assignment

The PCI-7250 card comes equipped with a 37-pin D type connector (CN1) accessible from the rear of the card. The pin assignment

of the D type connector is shown in below.

NO0

NO0

COM0

COM0

NC0

NC0

NO1

NO1

COM1

COM1

NC1

NC1

NO2

NO2

COM2

COM2

NC2

NC2

NO7

NO7

COM7

COM7

DI0

DI0_H

DI1

DI1_H

DI2

DI2_H

DI3

DI3_H

DI4

DI4_H

DI5

DI5_H

DI6

DI6_H

DI7

DI7_H

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

Figure 2-5: CN1 - D Type Connector

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

NO3

NO3

COM3

COM3

NC3

NC3

NO4

NO4

COM4

COM4

NO5

NO5

COM5

COM5

NO6

NO6

COM6

COM6

N/C

N/C

DI0

DI0_L

DI1

DI1_L

DI2

DI2_L

DI3

DI3_L

DI4

DI4_L

DI5

DI5_L

DI6

DI6_L

DI7

DI7_L

24 Installation

Page 33

Legend

Din:

NC n: Normal close pin of relay n

NO n: Normal open pin of relay n

COM n: Common pin of relay n

N/C: No connection

T able 2-3: CN1 - PCI-7250/51 Pin Assignment

Digital input low, channel n

(input signal Is not polarity sensitive)

Installation 25

Page 34

cPCI-7252 Pin Assignment

Signal Pin Pin Signal

IGND 1 26 IGND

DI8 2 27 DI12

DI9 3 28 DI13

DI10 4 29 DI14

DI11 5 30 DI15

DI0L 6 31 DI4H

DI0H 7 32 DI4L

DI1L 8 33 DI5H

DI1H 9 34 DI5L

D2IL 10 35 DI6H

DI2H 11 36 DI6L

DI3L 12 37 DI7H

DI3H 13 38 DI7L

NO01439NO5

NO11540NO4

COM0 16 41 COM5

COM1 17 42 COM4

NC0 18 43 NC5

NC1 19 44 NC4

NO22045NO7

NO32146NO6

COM2 22 47 COM7

COM3 23 48 COM6

NC2 24 49 NC7

NC3 25 50 NC6

Table 2-4: CN1 - cPCI-7252 Pin Assignment

Legend

Din: Digital input channel n

IGND: Ground of DIn signals

DinH: Digital input channel n with positive polarity

DinL: Digital input channel n with negative polarity

NC n: Normal close pin of relay n

NO n: Normal open pin of relay n

COM n: Common pin of relay n

26 Installation

Page 35

LPCI/LPCIe-7250 CN1 Pin Assignment

Signal Pin Pin Signal

NO0 1 26 NO4

COM0 2 27 COM4

NC0 3 28 NC4

NO1 4 29 NO5

COM1 5 30 COM5

NC1 6 31 NC5

NO2 7 32 NO6

COM2 8 33 COM6

NC2 9 34 NC6

NO3 10 35 NO7

COM3 11 36 COM7

NC3 12 37 NC7

N/C 13 38 N/C

N/C 14 39 N/C

N/C 15 40 N/C

N/C 16 41 N/C

N/C 17 42 N/C

IDI_0H 18 43 IDI_0L

IDI_1H 19 44 IDI_1L

IDI_2H 20 45 IDI_2L

IDI_3H 21 46 IDI_3L

IDI_4H 22 47 IDI_4L

IDI_5H 23 48 IDI_5L

IDI_6H 24 49 IDI_6L

IDI_7H 25 50 IDI_7L

T able 2-5: LPCI/LPCIe-7250 CN1 Pin Assignment

Legend

Din: Digital input channel n

IGND: Ground of DIn signals

DinH: Digital input channel n with positive polarity

DinL: Digital input channel n with negative polarity

NC n: Normal close pin of relay n

NO n: Normal open pin of relay n

COM n: Common pin of relay n

Installation 27

Page 36

2.7 PCI-7250 and PCI-7251 Connection

There are 8-relay outputs and 8-isolation inputs on both the PCI7250 and PCI-7251. The PCI-7251 is used as an expansion for

the PCI-7250. The operations of the PCI-7251 are the same as

that of the PCI-7250. There can be at most 3 PCI-72 51 ex pansion

boards to one PCI-7250. Therefore, the PCI-7250 can control up

to 32 relays and detect 32 input signals.

Figure 2-6: Connection between PCI-7250 and PCI-7251

28 Installation

Page 37

3Registers

Detailed descriptions of the registers are specified in this chapter.

This information is useful for programmers who wish to control the

card with low-level programming. However, we suggest users fully

understand the PCI interface before starting any low-level programming. In addition, the contents of this chapter will also help

users understand how to use the software drivers to configure this

card.

3.1 PCI PnP Registers

This PCI card functions as a 32-b it PCI target device to any m aster on the PCI bus. There are three types of registers: PCI Configuration Registers (PCR), Local Configuration Registers (LCR) and

725X registers.

The PCR, which is PCI-bus specification compliant, is initialized

and controlled by the Plug and Play (PnP) PCI BIOS. Users may

obtain more information on the PCI BIOS specification to better

understand the operation of the PCR. Please contact PCISIG to

acquire PCI interface specifications.

The PCI bus controller PCI-9050 is provided by PLX Technology

Inc. (www.plxtech.com). For more information about the LCR,

please visit PLX Technology’s web site to download relative information. It is not necessary for users to fully understand the details

of the LCR if the software library provided is used. The PCI PnP

BIOS assigns the base address of the LCR. The assigned address

is located at an offset of 14h from the PCR.

The 725X registers are discussed in the next section. The base

address, which is also assigned by the PCI PnP BIOS, is located

at an offset of 18h from the PCR. Therefore, users can read the

address 18h from the PCR to obtain its base address by using the

BIOS function call. Do not attempt to modify the base address and

interrupt that have been assigned b y the PCI PnP BIOS, it may

cause resource conflicts with your system.

Registers 29

Page 38

3.2 I/O Address Map

All 725X registers are 8 bits long. Users can access these registers using 8-bit I/O instructions. Using these registers will allow the

relays and status of the inputs to be controlled. The following table

shows the registers address map, including descriptions and their

offset addresses relative to the base address. If the PCI-7251

expansion boards are not installed, corresponding registers have

no significance.

Offset Write Read Board

0 Relay Output Output readback

1 Not used Isolation Input

2 Relay Output Output readback

3 Not used Isolation Input

4 Relay Output Output readback

5 Not used Isolation Input

6 Relay Output Output readback

7 Not used Isolation Input

Table 3-1: PCI-7250 Address Map with PCI-7251 Installed

Offset Write Read Board

0 Relay Output Isolation Input

2 Not used Output readback

Table 3-2: cPCI-7252 Address Map

PCI-7250

PCI-7251 #1

PCI-7251 #2

PCI-7251 #3

cPCI-72521 Not used Not used

Offset Write Read Board

0 Relay Output Output readback

1 Not used Isolation Input

T able 3-3: LPCI/LPCIe-7250 Address Map

LPCI-7250/

LPCIe-7250

3.3 Relay Output and Readback Registers

There are 8 relays on each PCI-7250/7251, LPCI-7250, LPCIe7250, and cPCI-7252 board. Each relay is controlled by one bit in

the control register. Bit value ‘0’ means the relay is not energized.

30 Registers

Page 39

The normal open signal line is ‘open’. Bit value ‘1’ means the relay

is energized and the normal open signal line is now closed.

The initial bit values of the control register are all ‘0’ and the status

of the relay can be readback from the readback register. If the

relay is open, the corresponding bit value read is ‘0’. If the relay is

closed, the bit value read is ‘1’.

Bit 7 6 5 4 3 2 1 0

Relay Output DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

Output Readback R B7 RB6 RB5 RB4 RB3 RB2 RB1 RB0

Table 3-4: Data Format of Relay Output and Readback Status Registers

3.4 Isolation Input Registers

There are 8 isolated input channels on the PCI-7250 / 7251 board.

The status of the 8 channels can be read from the isolation input

register. Each bit corresponds to each channel. Bit value “1”

means input voltage is high and “0” means input voltage is low.

Bit 76543210

Iso. Input DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

Bit 15141312111098

Iso. Input DI15 DI14 DI13 DI12 DI11 DI10 DI9 DI8

Table 3-5: Relay Output

Note: Bits 8-15 are for cPCI-7252 only

Registers 31

Page 40

32 Registers

Page 41

4 Operation Theory

4.1 Using Relay Output

The PCI-7250/7251 contains two types of relays: Form C and

Form A. Relays R0 - R3 are form C relays, and R4 - R7 are plain

form A type. Note that the LPCI-7250, LPCIe-7250, and cPCI7252 contain Form C relays only. The differences between these

two types of relays are:

1. Form C Relay: (R0 - R3)

NO

COM

NC

Control Bit = High (1)

Figure 4-1: Form C Relay

Form C type relays have three contacts: NC (Normal Close), NO

(Normal Open), and COM (Common). The COM post, located at

the middle, must make contact with either the NO post or NC post.

When the control bit is high (1), there is contact between the COM

post and NO post. If the control bit is low (0), there is contact

between the COM post and NC post.

In normal power-up and reset, the relay is in low status.

NO

COM

NC

Control Bit = Low (0)

Operation Theory 33

Page 42

2. Form A Relay: (R4 - R7)

NO

NO

COM

Control Bit = High(1)

COM

Control Bit = Low(0)

Figure 4-2: Form A Relay

Form A relay only has two contacts: NO (Normal Open) and COM

(Common). The COM post can make contact either with the NO

post or not. When the control bit is high (1), the COM post and NO

post are contacted. If the control bit is low (0), the COM post and

NO post does not make contact.

In normal power-up and reset, the relay is in low status.

The relay output contacts are rated at a maximum of 0.5 at

120 VAC (resistive), 1 A 24 VDC, or 0.3 A 60 VDC. You should

reduce these ratings for inductive loads. For more information on

relay contact, please refer to the Appendix.

34 Operation Theory

Page 43

4.2 Using Isolated Input

Ω

Ω

The PCI-7250 (or PCI-7251) contains 8 identical opto-isolated

control input channels. The circuit diagram of the differential input

channel is shown below.

DInH

V IN

2.2k

F

I

Ri

DInL

Figure 4-3: PCI-7250 Differential Input Circuit

The digital input is first routed through a photo-coupler (PC-814),

which is shown in the following diagram.

The cPCI-7252 contains 16 identical opto-isolated control input

channels. The circuit diagram of the differential input signals of

channel number 0-7 are the same as of the PCI-7250. While the

input signals for channel numbers 8-15 are isolated inputs, the

connection is not polarity sensitive whether AC or DC voltage is

used.

DInH

V IN

1.2k

Ri

F

I

IGND

PC-814

(opto-isolator)

PC-814

(opto-isolator)

Figure 4-4: cPCI-7252 Isolated Input Circuit

Operation Theory 35

Page 44

The LPCI-7250 and LPCIe-7250 contain 8 identical opto-isolated

Ω

control input channels through PC3H4 photo-coupler. The circuit is

shown as the following diagram:

DInH

V IN

2.2k

F

I

Ri

DInL

Figure 4-5: LPCI/LPCIe-7250 Differential Input Circuit

In addition, a single-pole filter with a time constant of about 5ms is

used to filter AC inputs passing through.

The normal input voltage range for an active high state is 3 to

24 VAC or DC. The normal in put range can be extended by changing the resister (Ri) to limit the current (IF) through the PC-814

(opto-isolator to about 10 mA). The exact re sister valu e to repla ce

the original resister Ri (1.2 K

formula.

Vin = IF x Ri

Pw = Vin x IF

For example, if the input voltage is 110V, then the Ri should be

replace by

Ri = 110 (V) / 0.01 (A) = 11 KΩ

Pw = 110 (V) X 0.01 (A) = 1.1 W

PC3H4

(opto-isolator)

Ω) can be calculated by the following

36 Operation Theory

Page 45

Appendix

Relay Contact Protection Circuits

The contacts are the most important elements of a relay construction, Contact performance conspicuously influenced by contact

material, and voltage and current values applied to the contacts.

Another important issue is contact p rotection; the rig ht contact pr otection circuit can suppress the counter EMF to a low level. However, note that incorrect use will result in an adverse effect. Typical

contact protection circuits are given below:

RC Circuit

This circuit is suitable for DC applications. If the load is a timer,

leakage current flow through the RC circuit may cause fa ulty operation.

Contact

R C

Inductive

Load

The circuit below is suitable for both DC and AC applications. If

the load is a relay or solenoid, the release time is lengthened.

Effective when connected to both contact s if the power supply voltage is 24V or 48V and the voltage cross the load is 100 to 200V.

Contact

R

C

Inductive

Load

Appendix 37

Page 46

Device Selection:

As a guide in selecting R and C,

X R: 0.5 to 1Ω per 1V contact voltage

X C: 0.5 to 1μF per 1A contact current

Values vary depending on the properties of the capacitor C acting

to suppress the discharge the moment the cont act s open. Resistor

R acts to limit the current when the power is turned on. Test to

confirm. Use a capacitor with a breakdown voltage of 200 to 300V.

Use AC type capacitors (non-polarized) for AC circuits.

Diode Circuit

This circuit is suitable for DC applications. The diode connected in

parallel causes the energy stored in the coil to flow to the coil in

the form of current and dissipates it as joule heat at the resistive

component of the inductive load. This circuit further delays the

release time compared to the RC circuit.

Contact

Diode

Inductive

Load

Device Selection:

Use a diode with a reverse breakdown voltage of at least 10 times

the circuit voltage and a forward current at least as large as the

load current.

38 Appendix

Page 47

Diode & Zener diode Circuit

This circuit is also suitable for DC application. Effective when the

release time i in the diode circuit is too long.

Contact

Diode

Inductive

Load

Device Selection:

Use a zener diode with a zener voltage about the same as the

power supply voltage.

Varistor Circuit

This circuit is also suitable for both AC & DC applications. Using

the stable voltage characteristics of the varistor, this circuit prevents excessively high voltages from being applied across the

contacts. This circuit also slightly delays the release time. Effective

when connected to both contacts if the power supply voltage is

24V or 48V and the voltage cross the load is 100 to 200V.

Contact

Diode

Inductive

Load

Appendix 39

Page 48

40 Appendix

Loading...

Loading...