Contents Page:

Home

Part 4: Short Description-Microcontrol Cl. 975 - 1 - 5

1. General ................................................. 3

2. Description of the Controls ..................................... 4

2.1 KeysontheFrontPanel........................................ 4

2.2 InternalSwitches............................................ 5

2.3 Display ................................................. 6

3. Description of the Function Keys ................................. 7

3.1 “STOP”Keyand“O”Key...................................... 7

3.2 “START”Keyand“CLEAR”Key .................................. 7

3.3 “ Σ ”Key ................................................ 7

3.4 “SEAMBEGINNING”Key ...................................... 7

3.5 “+”and“-”Keys ........................................... 8

3.6 “SEWINGSUPPRESSION”Key................................... 8

3.7 “DRYRUN/TERMINATE”Key.................................... 8

3.8 “THREADING”Key.......................................... 8

4. Selecting the Sewing and Testing Programs ........................... 9

4.1 DisplayoftheProgramVersion.................................... 9

4.2 SewingProgram ............................................ 10

4.3 SewinginIntervalOperation ..................................... 10

4.4 SewingatLowRpminIntervaloperation .............................. 10

4.5 SewingatHouse-shapedSeamRpm ................................ 11

4.6 SewingatMaximumRpm....................................... 11

4.7 RaisingandLoweringtheSewingHead............................... 11

4.8 DisplayoftheSynchronizerPosition................................. 11

4.9 TimerTestandMemoryTest ..................................... 12

4.10 ContinuityTest ............................................. 12

4.11 TestoftheFrontPanelElements................................... 12

4.12 TestoftheInputElements....................................... 14

4.13 SelectingInputElements ....................................... 14

4.14 SelectingOutputElements ...................................... 16

4.15 Positioninginthe2ndPosition .................................... 17

4.16 Positioninginthe1stPosition .................................... 17

4.17 Positioninginthe1stand2ndPosition ............................... 17

5. Function Displays and Error Messages .............................. 18

5.1 DisplayofOperatingAids....................................... 18

5.2 ErrorMessagesoftheSewingPrograms .............................. 18

5.3 ErrorMessagesoftheControls.................................... 20

1. General

The MICROCONTROL controls of the DÜRKOPP ADLER 975 - 1 - 5

have as an integral part the comprehensive MULTITEST testing and

monitoring system.

A microcomputer assumes the control tasks, monitors the sewing

procedure and displays operator errors and malfunct ions.

Special programs aid in making mechanical settings and make

possible a quick inspe ction of the input and output elements without

additional me asuring equipment.

Errors and testing results are shown in a 2 x 16-digit display.

During fault-free operation the display shows information to the

operating a nd the sewing sequences.

For program testing and error diagnosis it is possible to blank out the

summation counter and to alternatively receive a cycle display of the

parallel-operating PROM components for the left and right clamping

tables as well as for t he sewing process.

With an operator error or a malfunction the function sequence is

interrupted. The cause is shown in the display by the appropriate error

symbol. In most case s the error symbol disappears after the cause of

the error is re medied and the CLEAR key pressed.

In some cases the main switch must be turned off when the error is

corrected for safety reasons.

A number of err or messages are meant only for th e maintenance staff.

All functions can be called up and changed by pressing the

appropriate key. The sewing unit must be in its base position for this.

When the sewing unit is turned on the con trols conduct a number of

self-tests. At this time the program and data memory and the display,

among other things, are checked as to fault-free functioning.

After the sewing unit is turned off the set values fo r the individual

functions ar e stored in the progra m and data memory ( battery

buffered) and automatically activated when next t urned on again.

ATTENTION !

This short description of the Microcontrol 975 - 1 - 5 is valid for the

Program Version 975A03 !

3

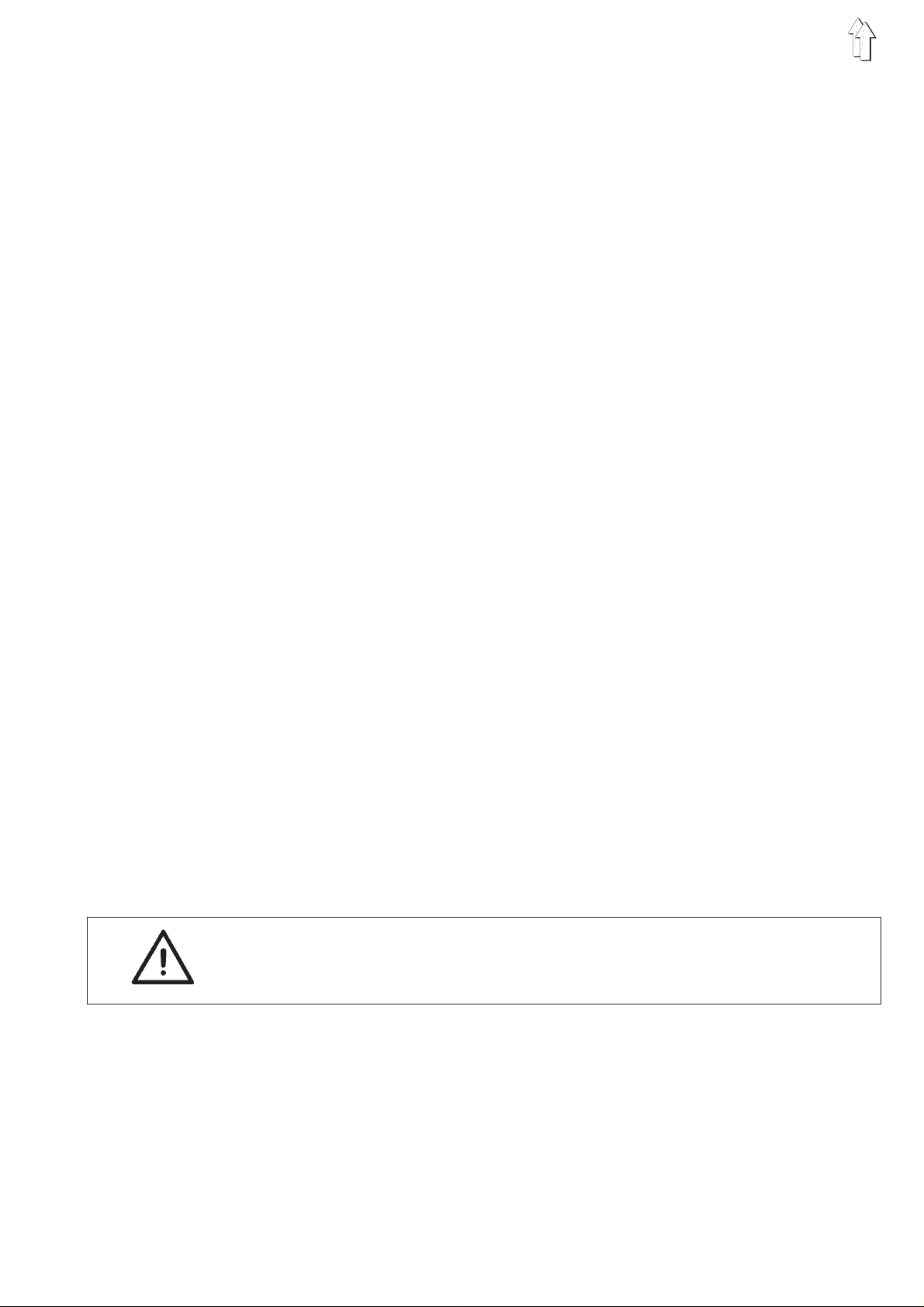

2. Description of the Controls

2.1 Keys on the Front Panel

CI

Key Function Key Function

Selecting sewing and testing programs

Stopping the current program Activating the function

Activating the selected program

Threading - Reserve -

auto

- Reserve - - Reserve -

Start Increasing the parameter value

Clear Decreasing the parameter value

( Cancelling an error message )

Reset counter Sewing suppression

Activating the function

Seam beginning Dry run / Terminate

4

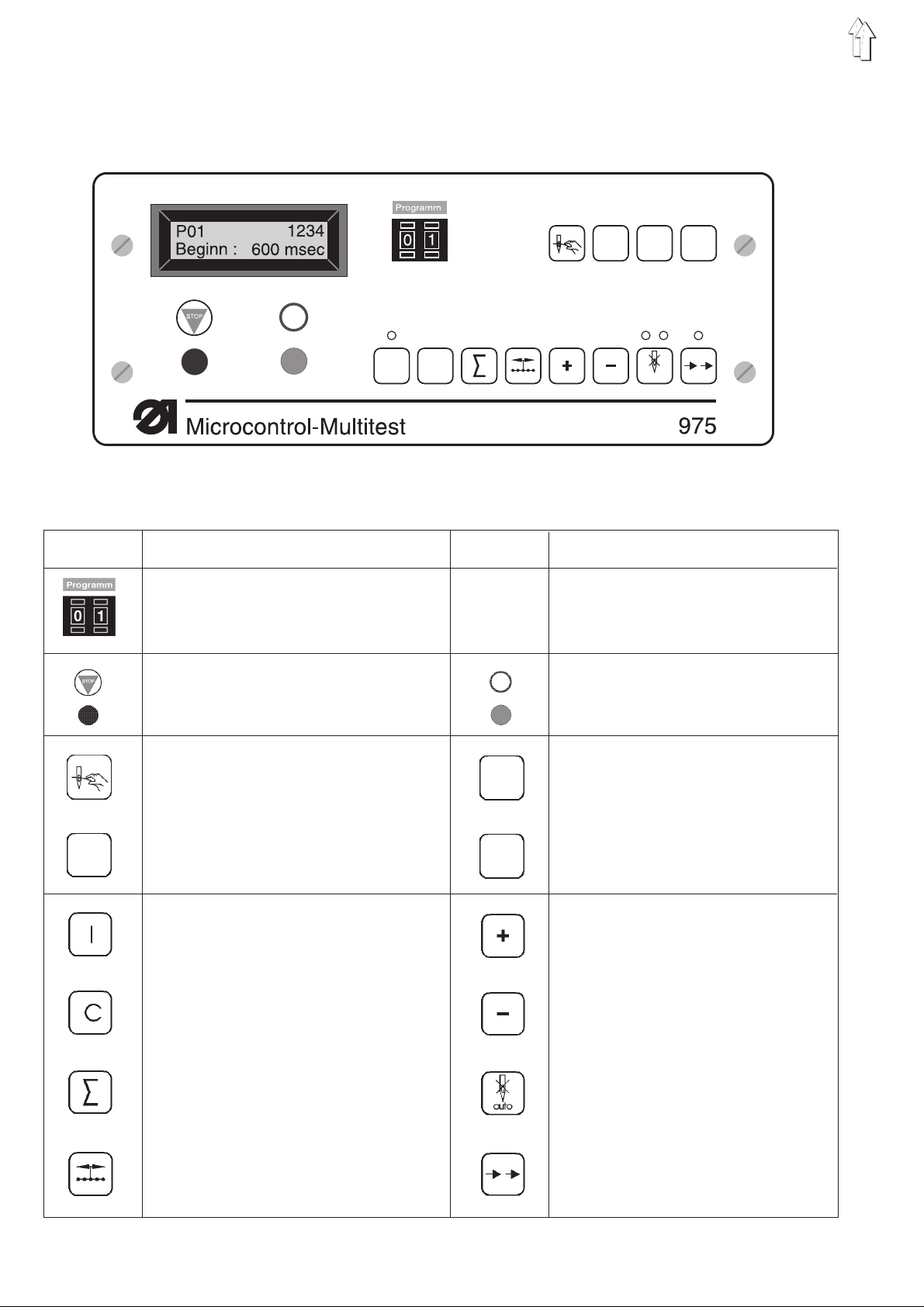

2.2 Internal Switches

DIP-switch b417 b401 b402

CI

auto

On the controls behind the display there are 3 pre-selector switches

for setting various machine parameter s.

ATTENTION !

The switches are e valuated only once after the sewing unit is turned

on.

After changing a switch position turn the main switch off and on again

or press the “ STOP ”key.

DIP-switch b417

b417 Function OFF ON

1 Display Piece counter Program cycle

2 Sewing Norm al Continuous test

sequence

3...8 - Reserve - ————— —————

Dials b40 1 and b402

With these switches the sewing rpms for the sewing of the

house-shaped seam ( b401 ) and for sewing at maximum rpm

( b402 ) are set.

Switch position Sewing rpm

0960min

11280min

21700min

32260min

4-9 3000min

-1

-1

-1

-1

-1

5

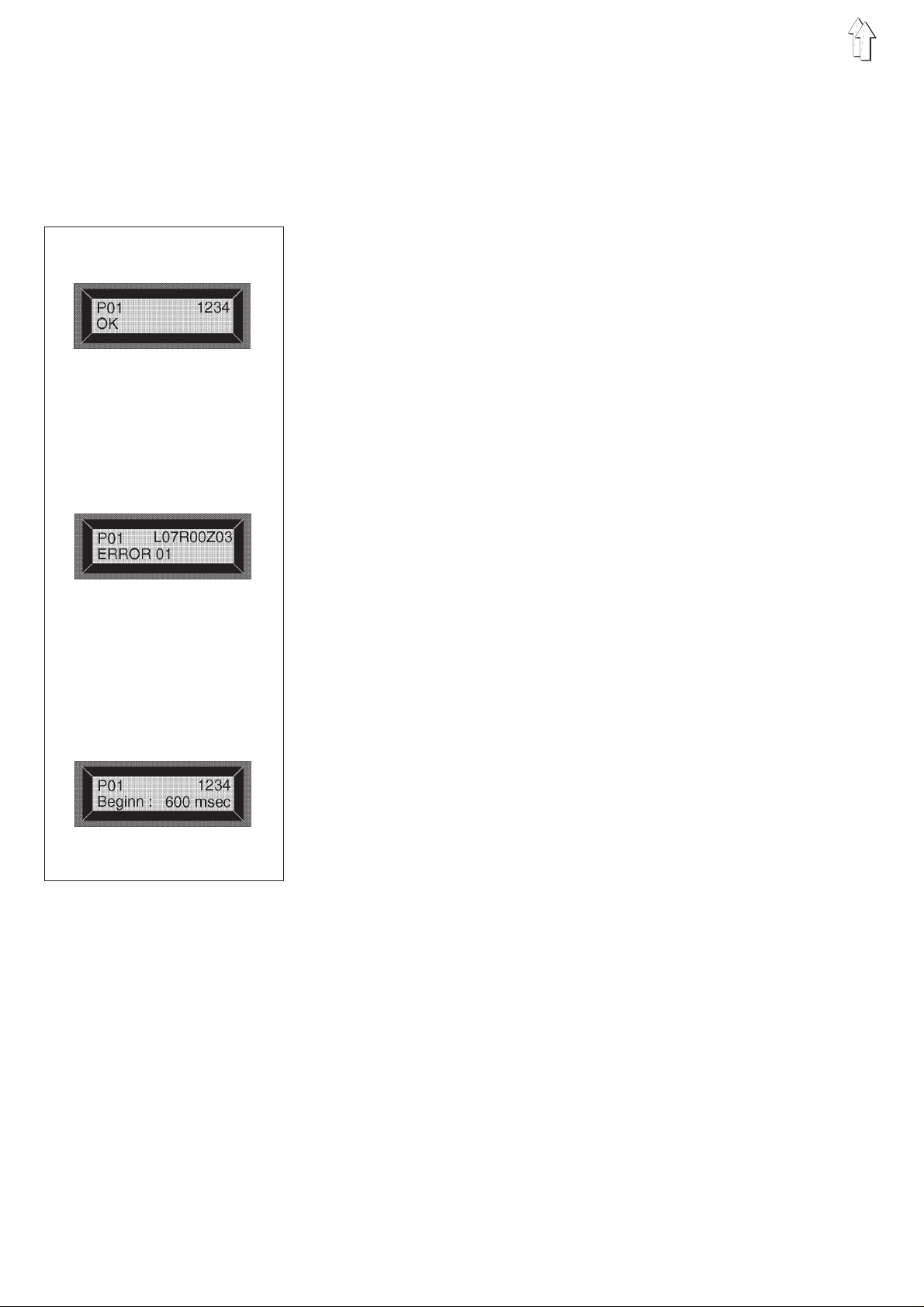

2.3 Display

The Microcont rol controls are equipped with a 2 x 16-digit display.

It shows program numbers, piece counts, status reports, error

messages, seam beginning delay, among other items.

The sewing unit is ready for operation when the prompt to press the

“ START ” key appears in the display.

Example 1:

P01 = Program number

1234 = Piece count

OK = Status report

Example 2:

P01 = Program number

L07R00Z03 = Program cycle

ERROR 01 = Error message

Example 3:

P01 = Program number

1234 = Piece counter

Begin: 600 msec = Seam beginning delay

6

3. Description of the Keys

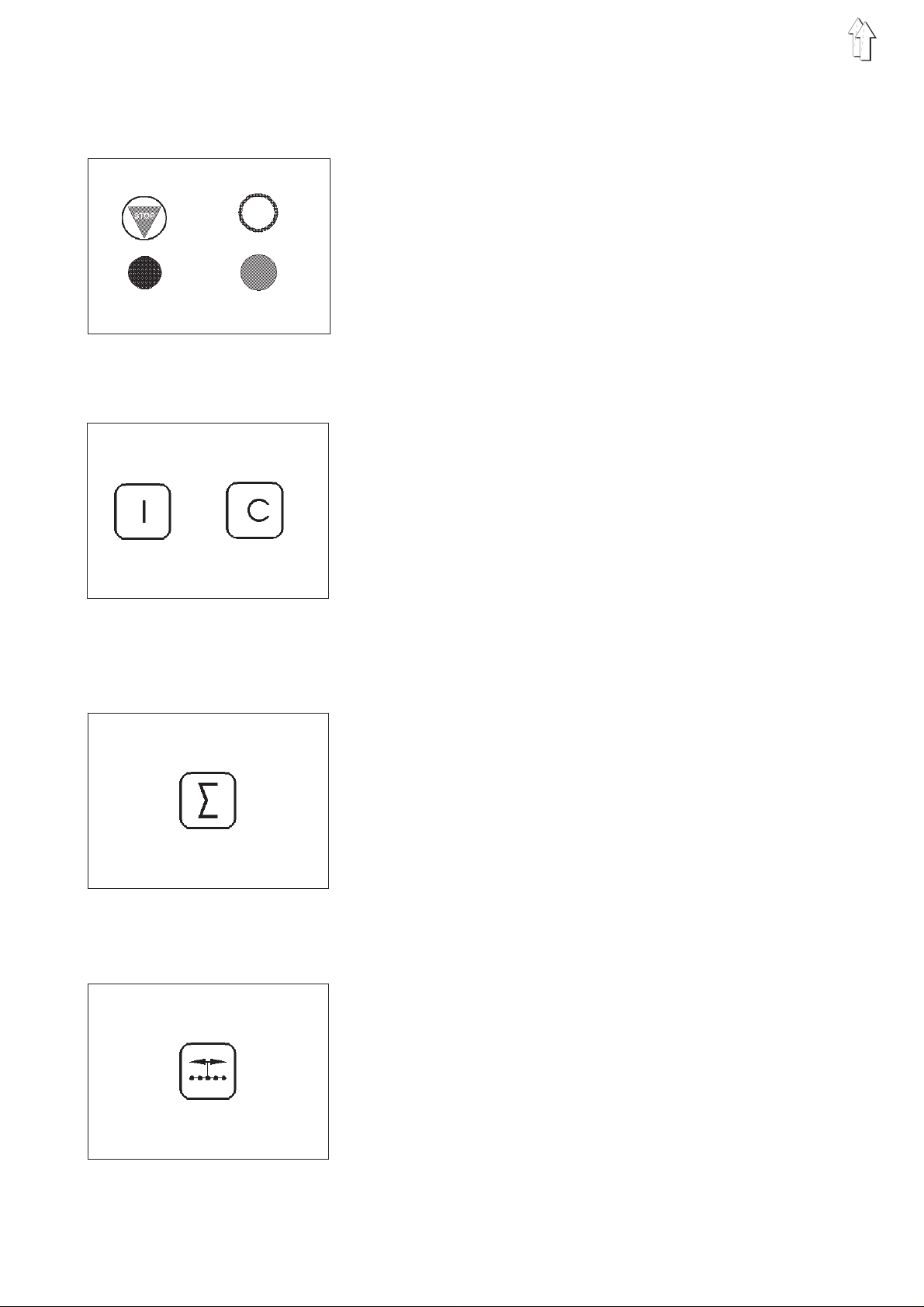

3.1 “ STOP ” Key and “ O ” Key

By pressing the “ STOP ” key all current procedures of the sewing unit

and the clamping tables are immediately interrupted.

By pressing the “ STOP ” key the sewing, aid and testing programs set

with the “ PROGRAM ” switch are activated.

By pressing the “ O ” key the selected output and input elements or the

front panel elements in the various testing programs are activated.

3.2 “ START ” Key and “ CLEAR ” Key

By pressing the “ START ” key the command for the initial run of the

clamping tables is issued after the sewing unit is turned on.

By pressing the “ START ” key a STOP command is cancelled.

By pressing the “ CLEAR ” key slight errors are cancelled after the

malfunction ha s been corrected.

If, after pressing the “ CLEAR ” key, the error message does not

disappear, then the service technician must be notified.

3.3 “ Σ ” Key

3.4 “ SEAM BEGINNING ” Key

By pressing the “ Σ ” key the piece count ( in the up per right of the

display ) is reset to 00 00.

The piece count sho ws the number of pieces finished since the last

reset.

In program 40 the sewing process is activated by pressing the “ Σ ”

key, if one of the two clamping tables is in sewing position.

By pressing the “ SEAM BEGINNING ” key t he set delay is show n in

the display.

With the “ SEAM BEGINNING ” key held down, the delay can be set

with the “ + ”and“- ” keys.

Setting range: 0....600 msec

The set value re mains in the memory e ven after the sewing u nit is

turned off.

7

Loading...

Loading...